Interwell parallel resistivity CT (computed tomography) testing method

A testing method and resistivity technology, which is applied in the field of parallel resistivity CT testing between wells, can solve the problems of low data acquisition efficiency, difficult testing of kilometer-deep wells, and limited resolution, so as to achieve large data volume and improve overall well testing. Efficiency and precision, the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

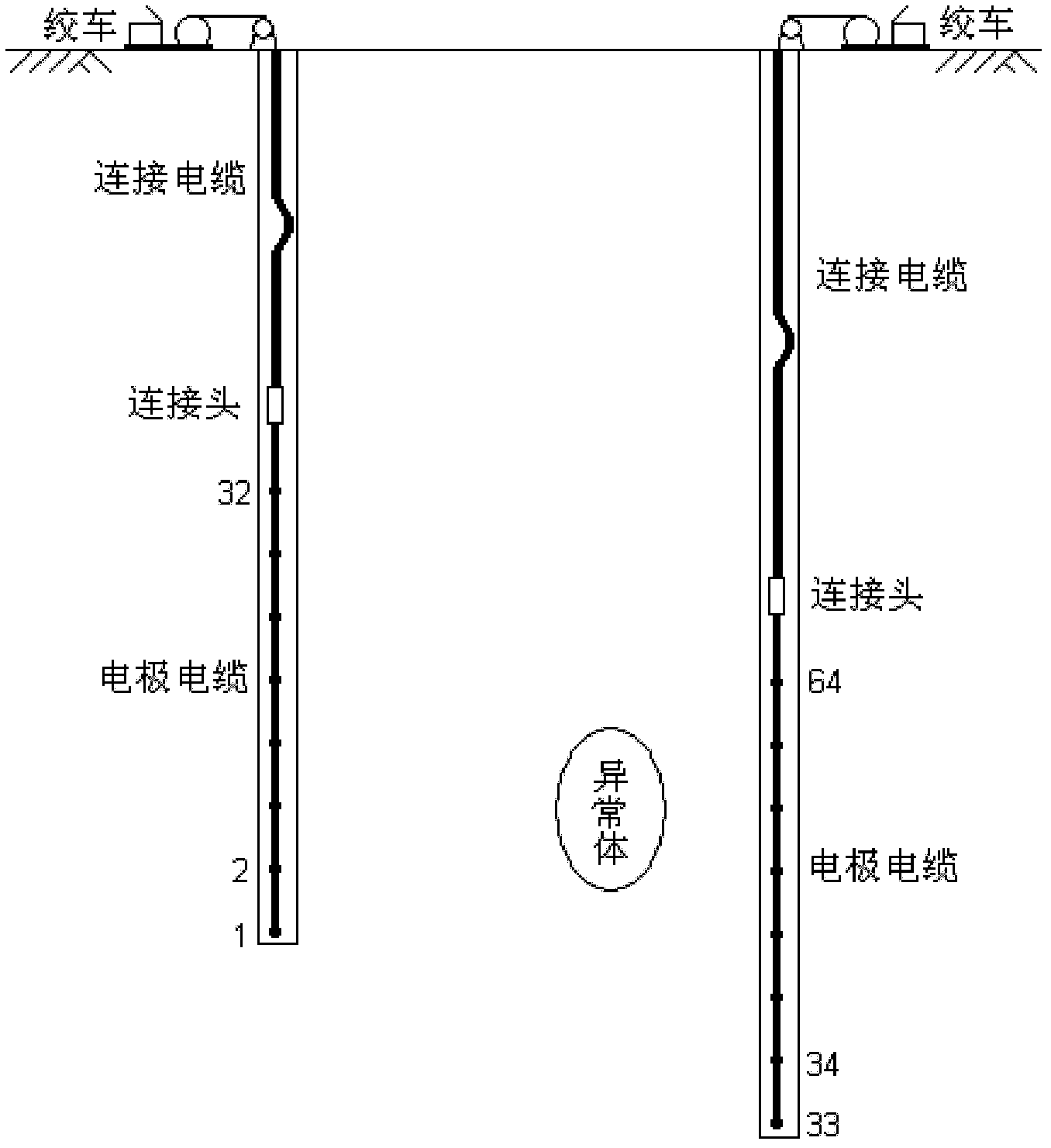

[0029] (1) After the borehole drilling reaches the exploration depth, two boreholes are used to arrange the resistivity CT testing system. Electrodes are arranged at different depths of the wellbore on site according to the needs, and the test section is automatically adjusted and changed by the winch.

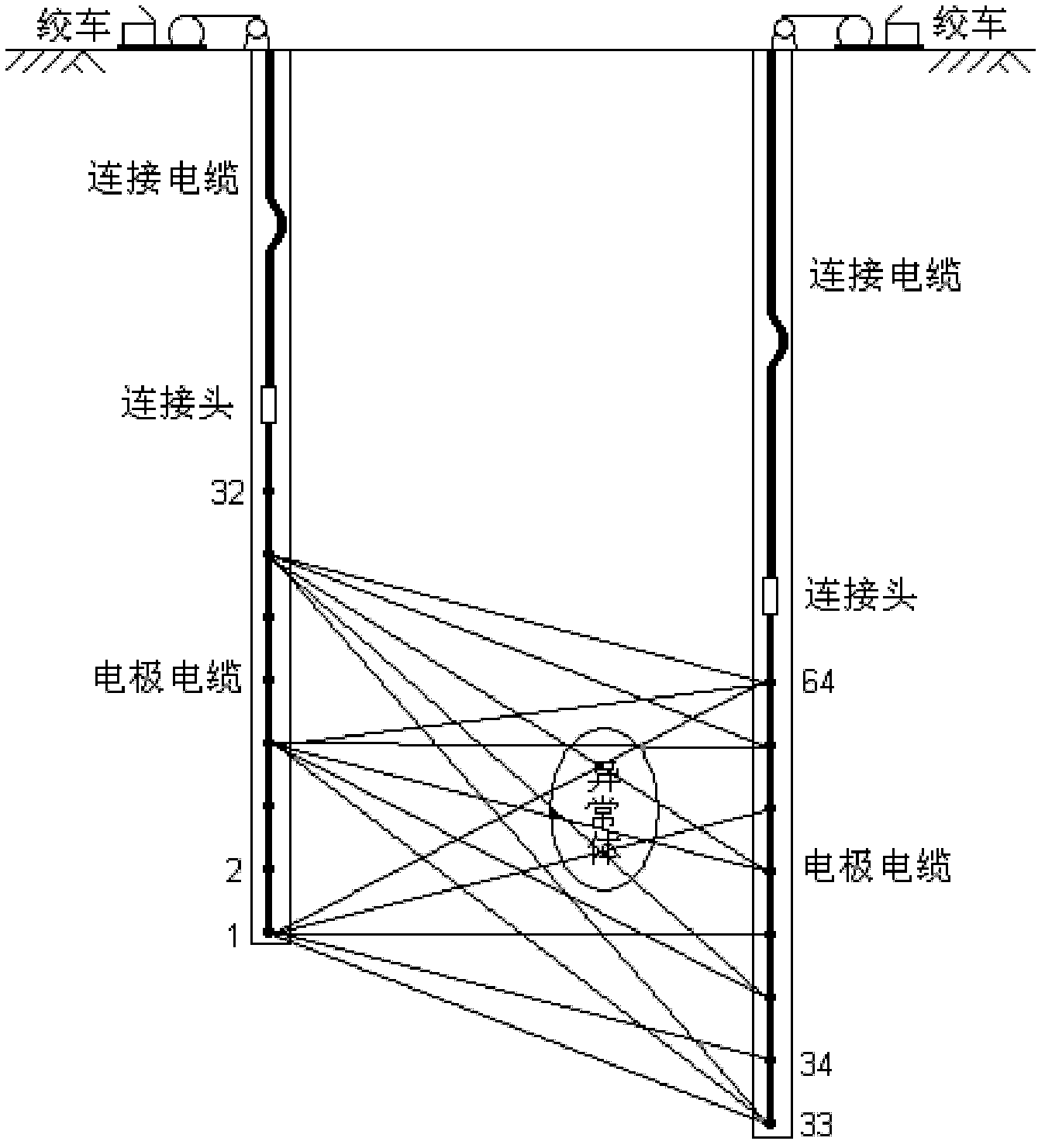

[0030] (2) Conduct cross-well parallel resistivity CT data acquisition for the selected detection area, unify 64 electrodes in two holes into one measurement line, use high-power parallel electrical instrument for data acquisition, and obtain various measurements under different electrode power supply conditions simultaneously The electric field parameters of the electrodes.

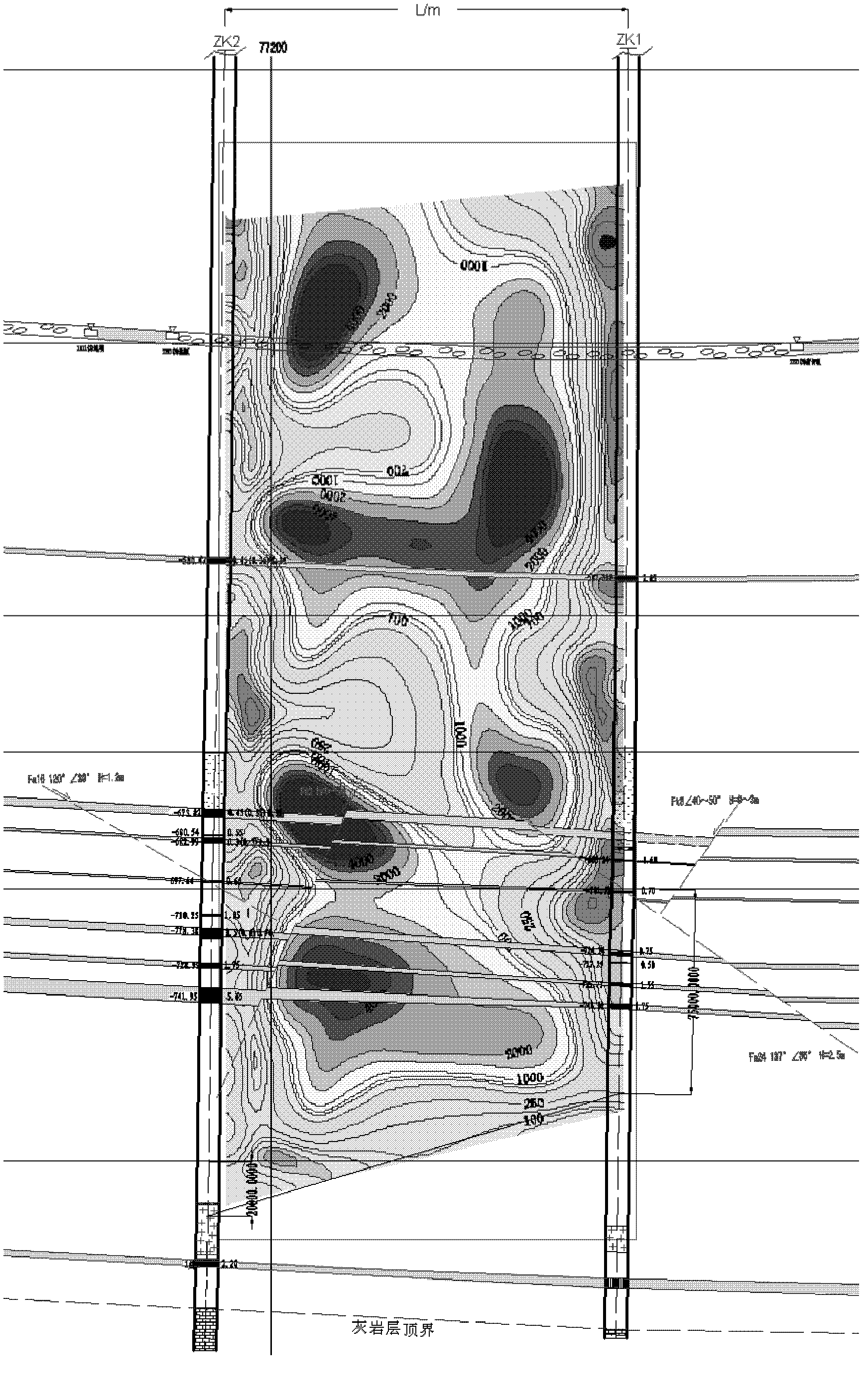

[0031](3) Adjust the detection area according to the test needs, and carry out parallel electrical method data acquisition in different test sections. Usually, the data of the two stations need to be overlapped. Calculated based on the electrode distance of 5.0m, each station can control the length of t...

example

[0035] In order to explore the characteristics of geological anomalies between two boreholes, parallel resistivity CT testing research was carried out on the ground above the working face of a mine in Huainan Mining Group. The maximum depth of the two boreholes is 1160m. The layout of interwell resistivity CT test is as follows: figure 1 As shown, the transmitted ray at the measuring point of station 1 is as follows figure 2 shown. Such as image 3 Shown is the CT inversion calculation section of the entire wellbore resistivity, from which it can be seen that the rock-coal seam combination at the coal seam position is characterized by high resistance, and the layering is more obvious. Coal seams have strong response and poor convergence on interwell resistivity profiles, but single-layer or multi-layer coal seams can be effectively distinguished based on this. The resistivity distribution characteristics between the coal measures and the coal measures, between the Taihui ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com