Method and system for detecting and screening end defects in circular parts

A technology of ring-shaped parts and screening method, applied in the field of image processing, can solve the problems of low efficiency, poor stability and reliability, and high missed detection rate, and achieve the effects of solving detection difficulties, broad application prospects and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention provides a method for detection and screening of end face defects of ring parts, comprising the following steps:

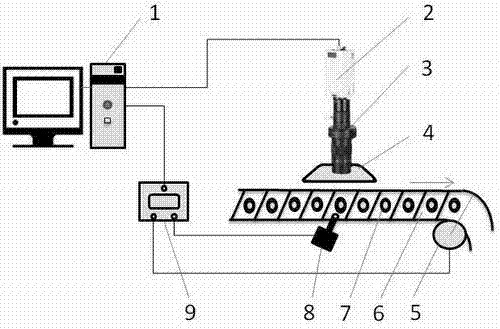

[0047] (1) Shooting the ring part to be inspected by an optical magnifying device to obtain an optically enlarged image of the end face of the ring part to be inspected;

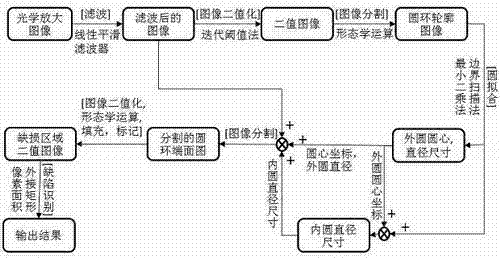

[0048](2) Reading the optically magnified image through a control computer, performing image processing and defect recognition on the optically magnified image, including image filtering, threshold iteration, image binarization, morphological operations, image segmentation, defect recognition, etc. , and then determine whether the ring part is qualified according to the defect situation, and send the determination result to the communication port of the control computer in the form of an order;

[0049] (3) Receive commands from the communication port of the control computer through a controller. If the ring part is unqualified, the controller controls the air pressure nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com