Method for measuring inner wall water film thickness of microwave humidity sensor on basis of linear fitting

A technology of humidity sensor and water film thickness, which is applied in the direction of using microwaves to measure moisture content, measuring devices, instruments, etc., can solve the problems of high cost and complicated equipment of the optical fiber method, and achieve the effect of convenient use, elimination of measurement errors, and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

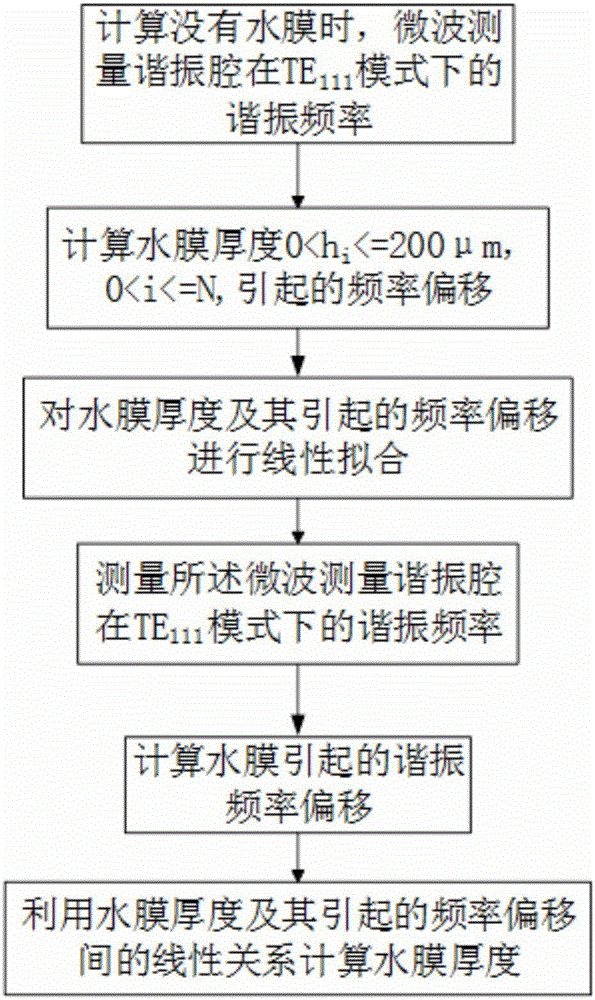

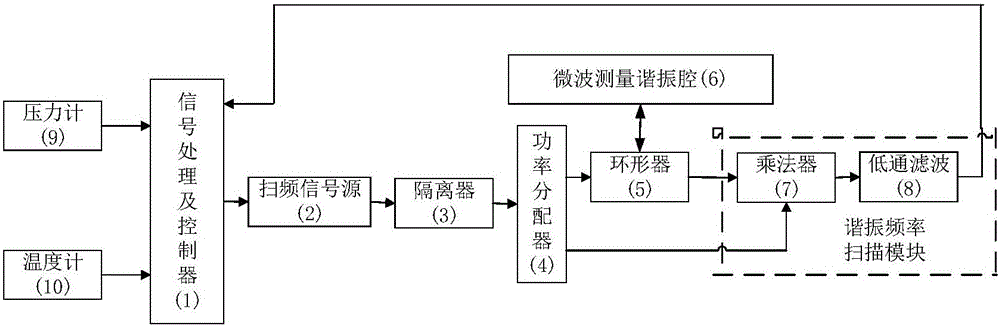

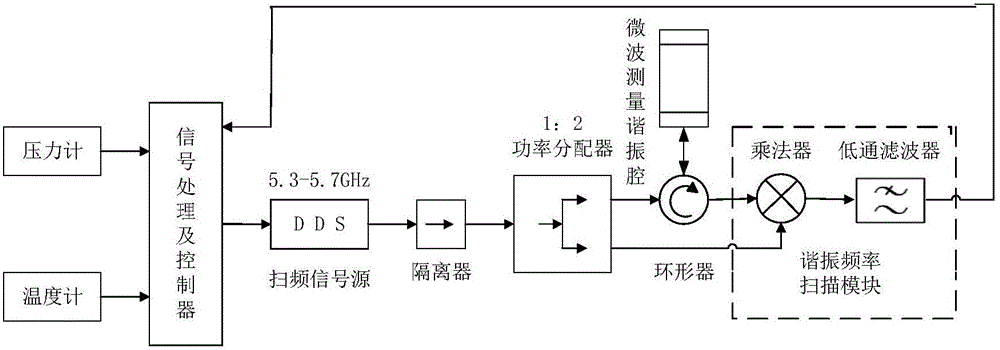

[0033] like figure 1 As shown, a method for measuring the thickness of water film on the inner wall of a microwave humidity sensor based on linear fitting includes the following steps:

[0034] Step 1: Calculate the microwave measurement cavity 6 at TE when there is no water film 111 The resonant frequency f in the mode 02 :

[0035] f 02 = c 2 π ϵ r m - ( 1.841 a ) 2 + ( π l ) 2 - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com