Patents

Literature

122 results about "Solid state detector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

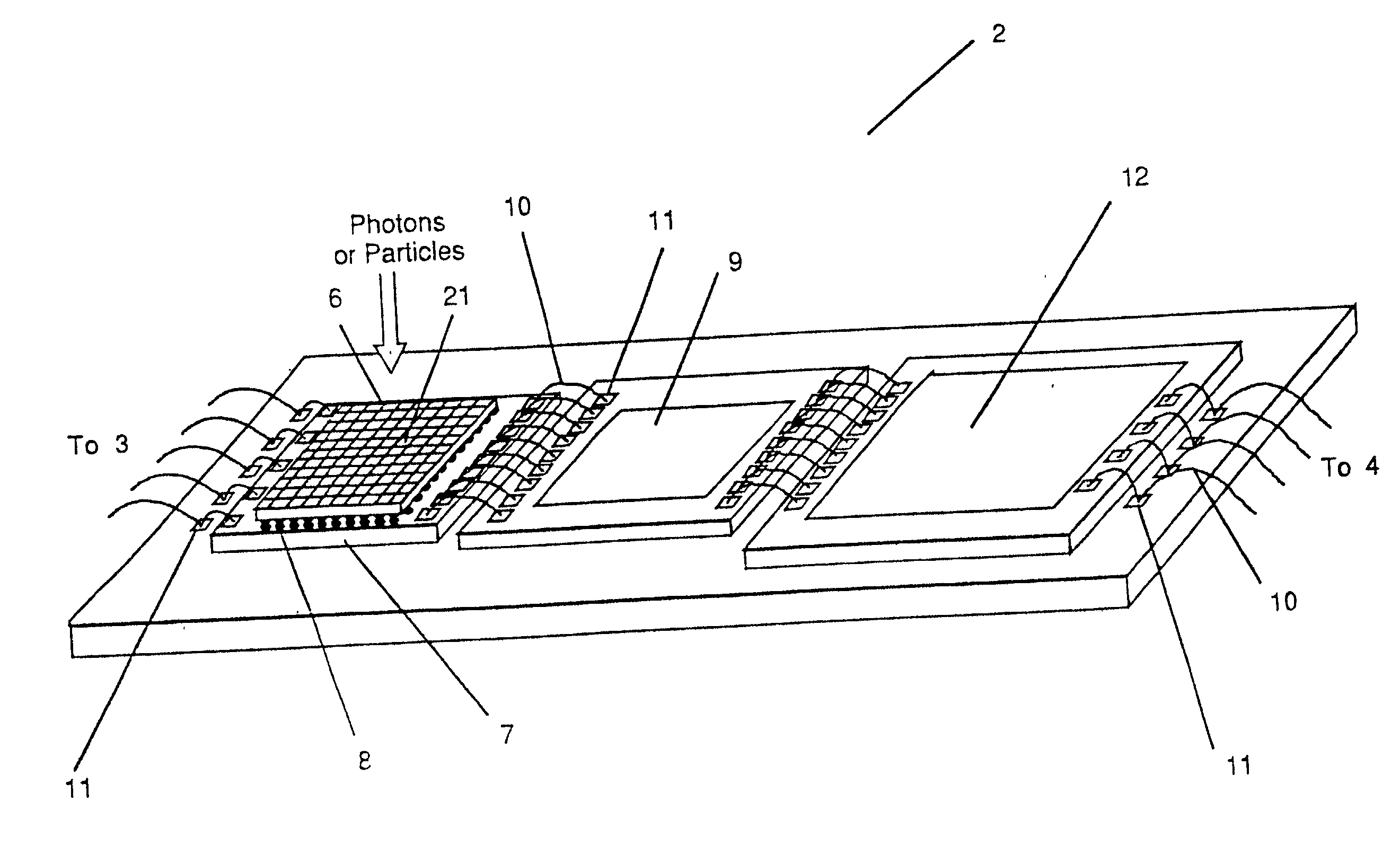

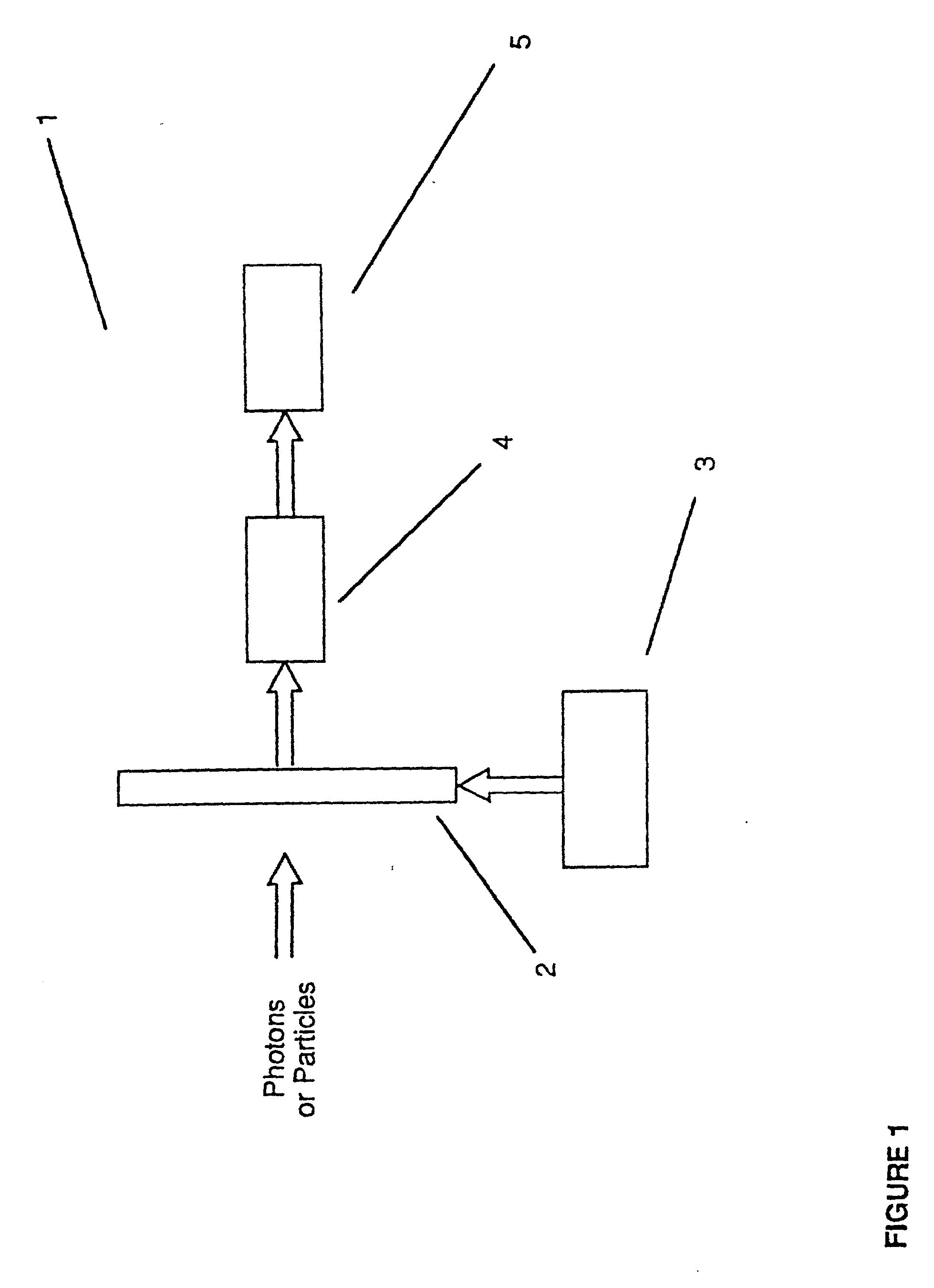

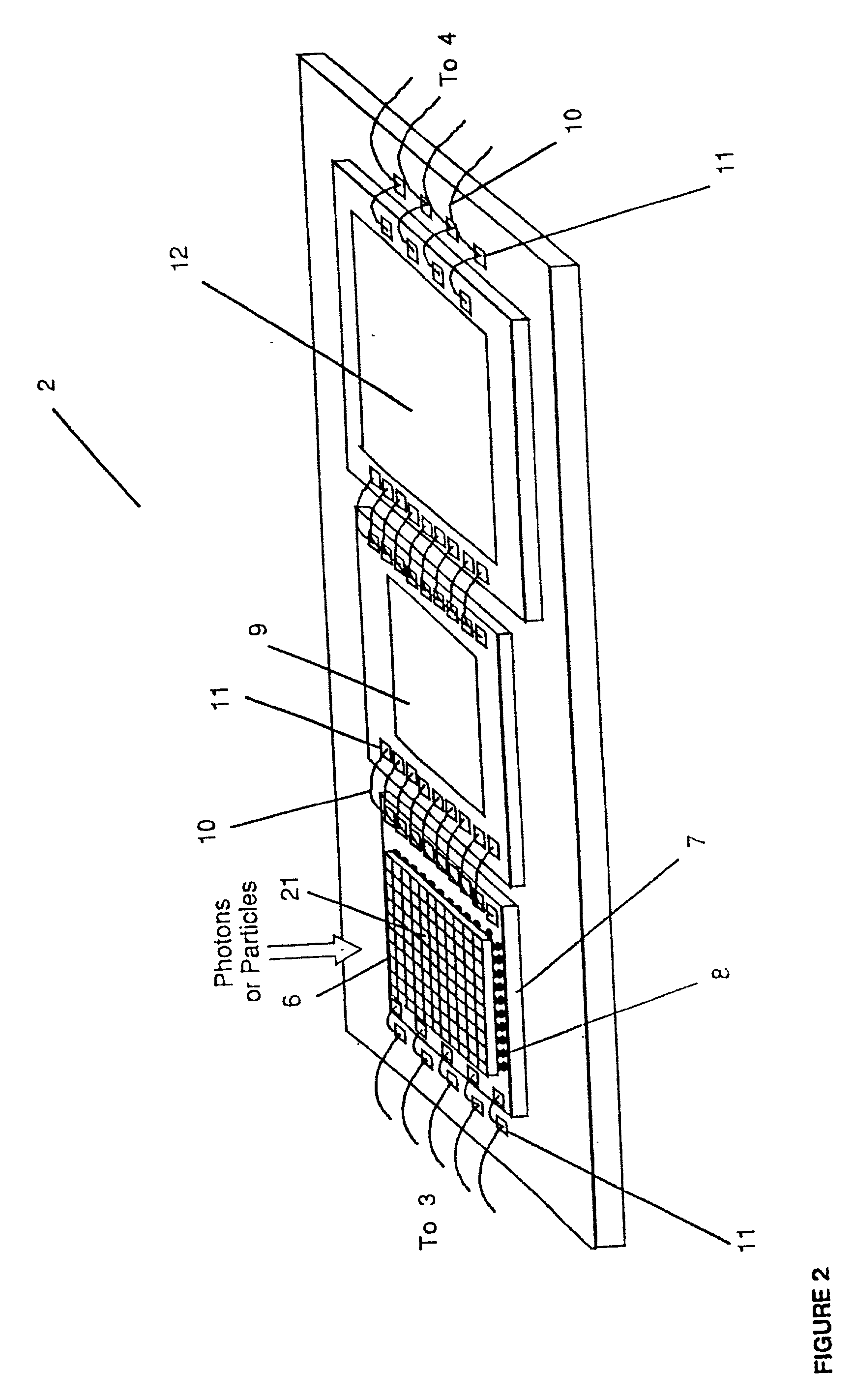

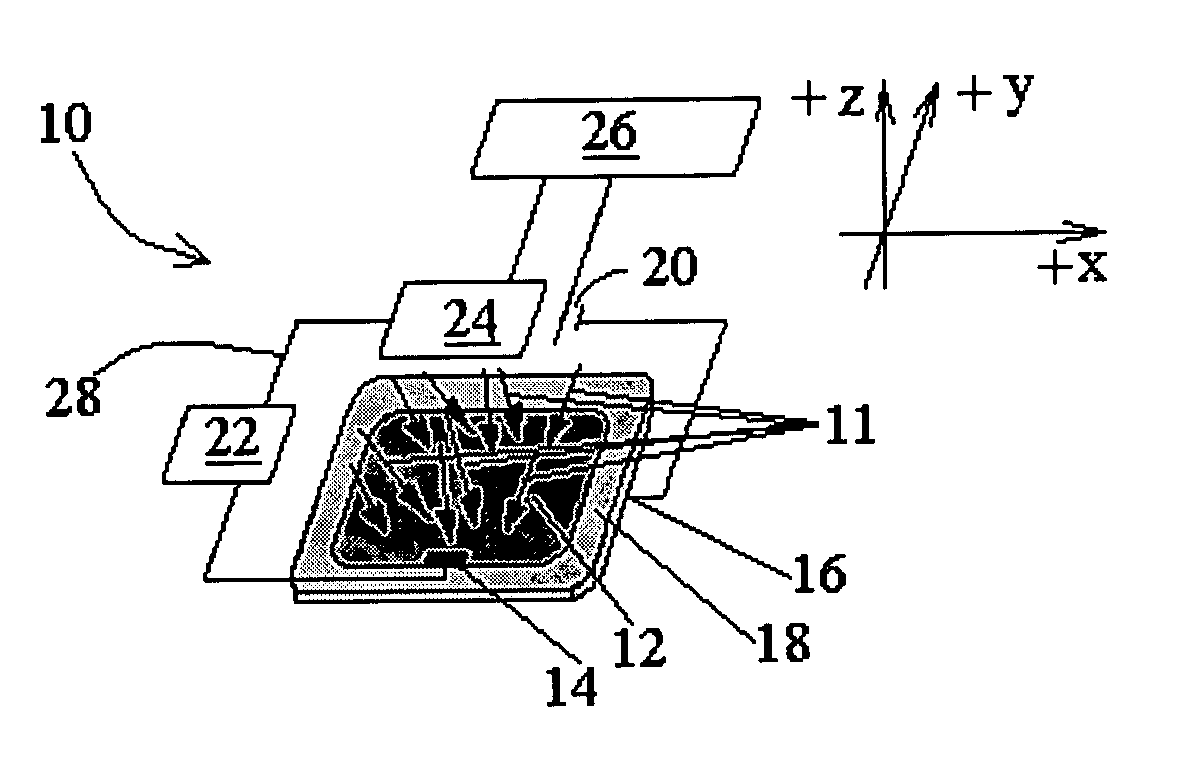

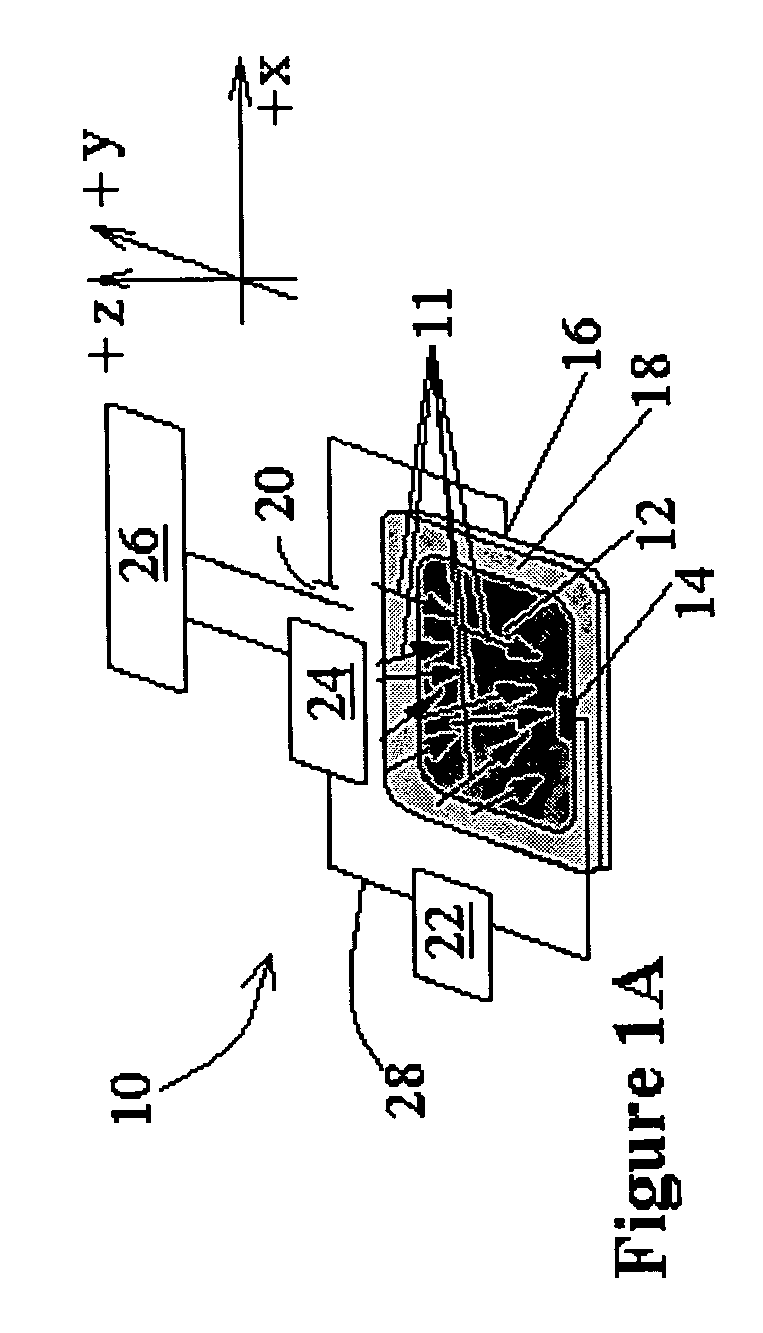

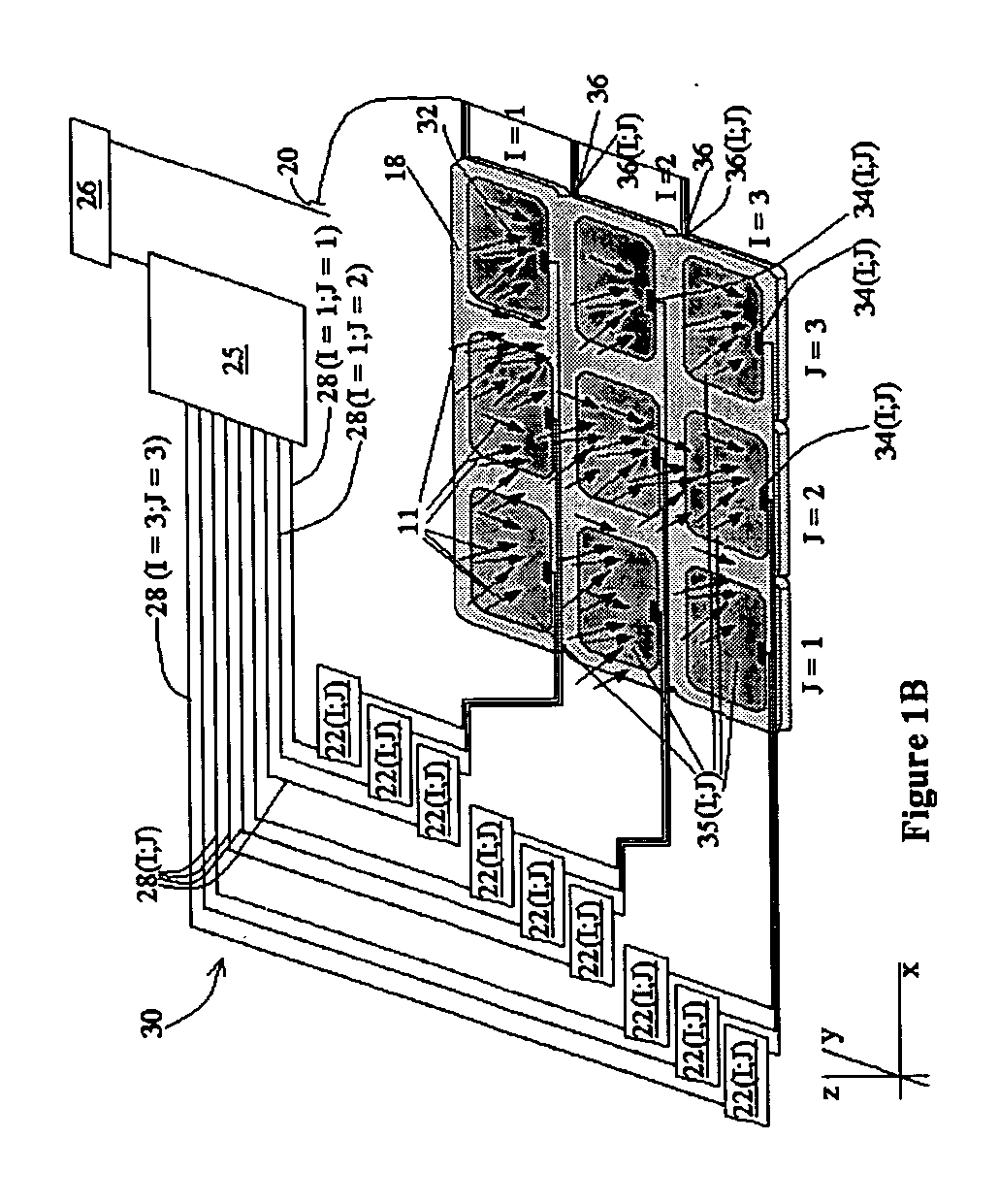

High data rate smart sensor technology

InactiveUS6362482B1Overcome problemsCathode ray tubes/electron beam tubesSolid-state devicesAnalog image processingSignal on

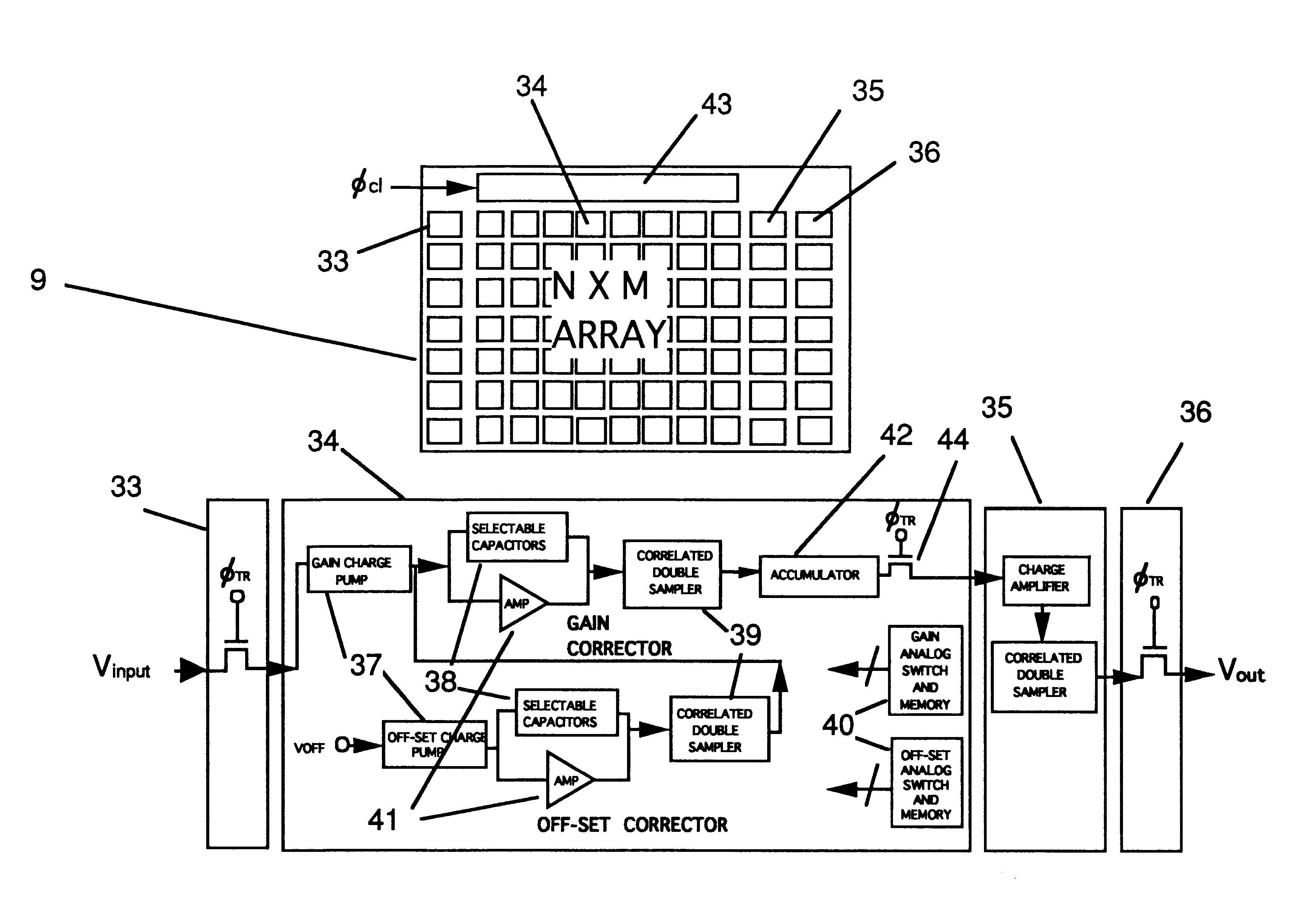

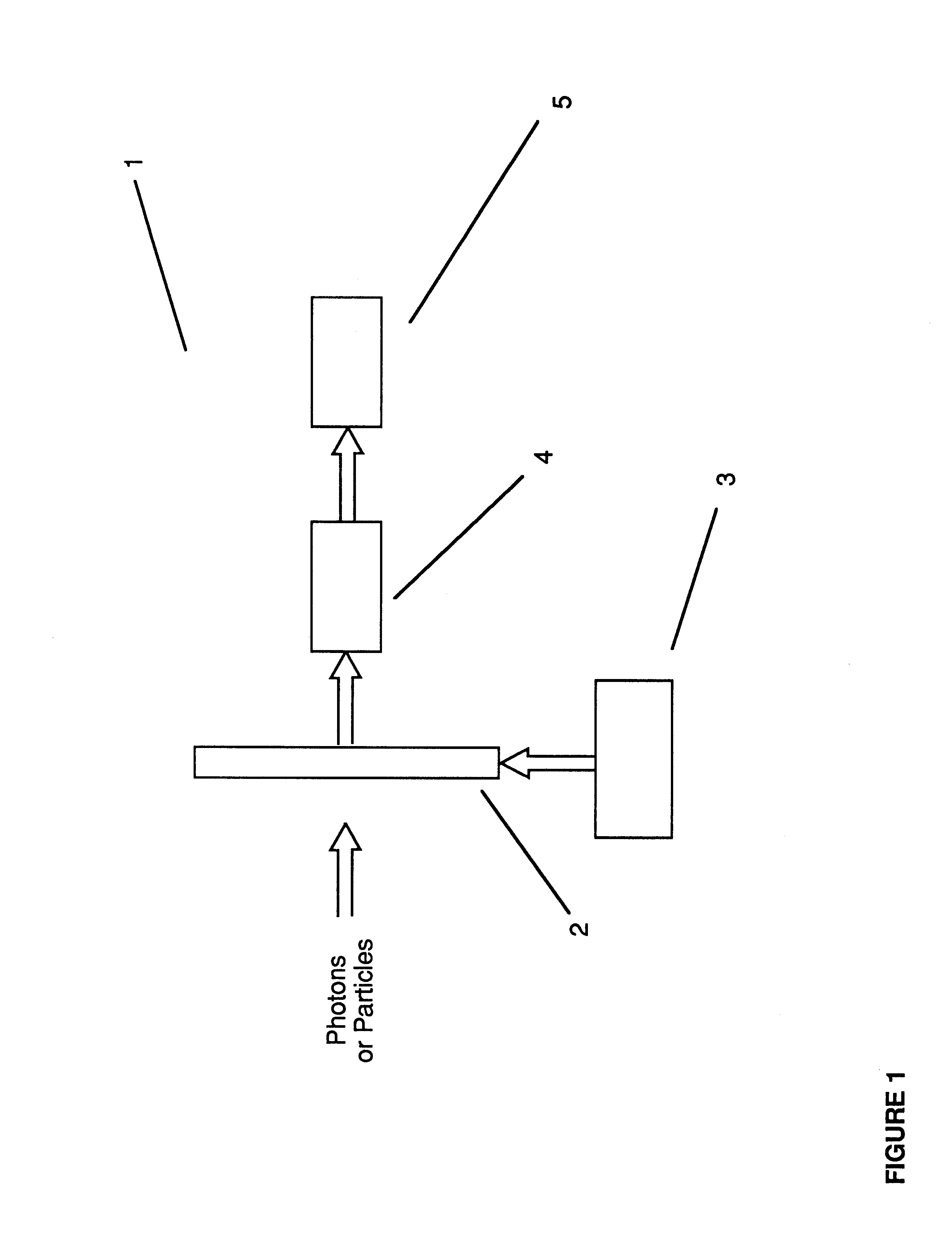

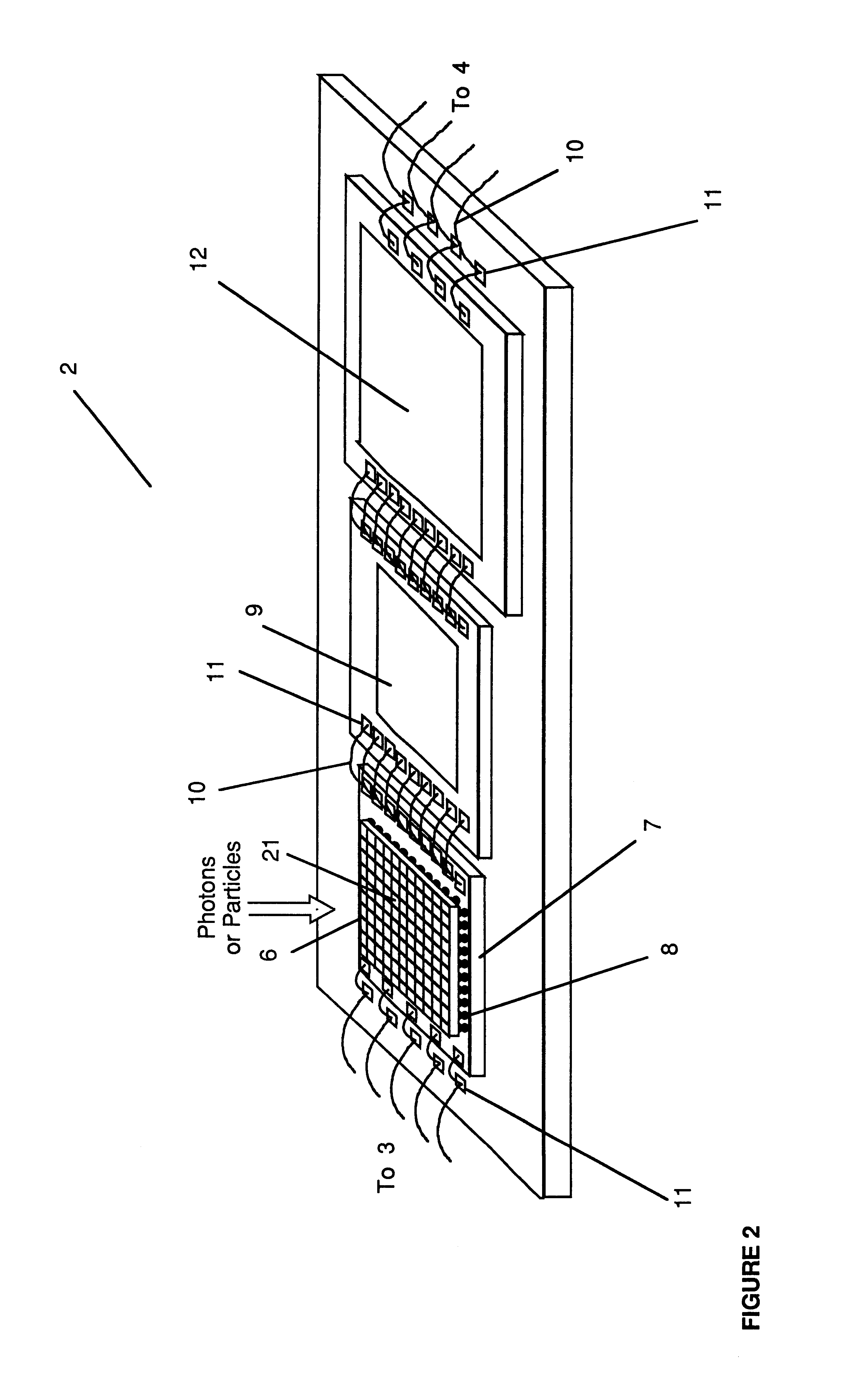

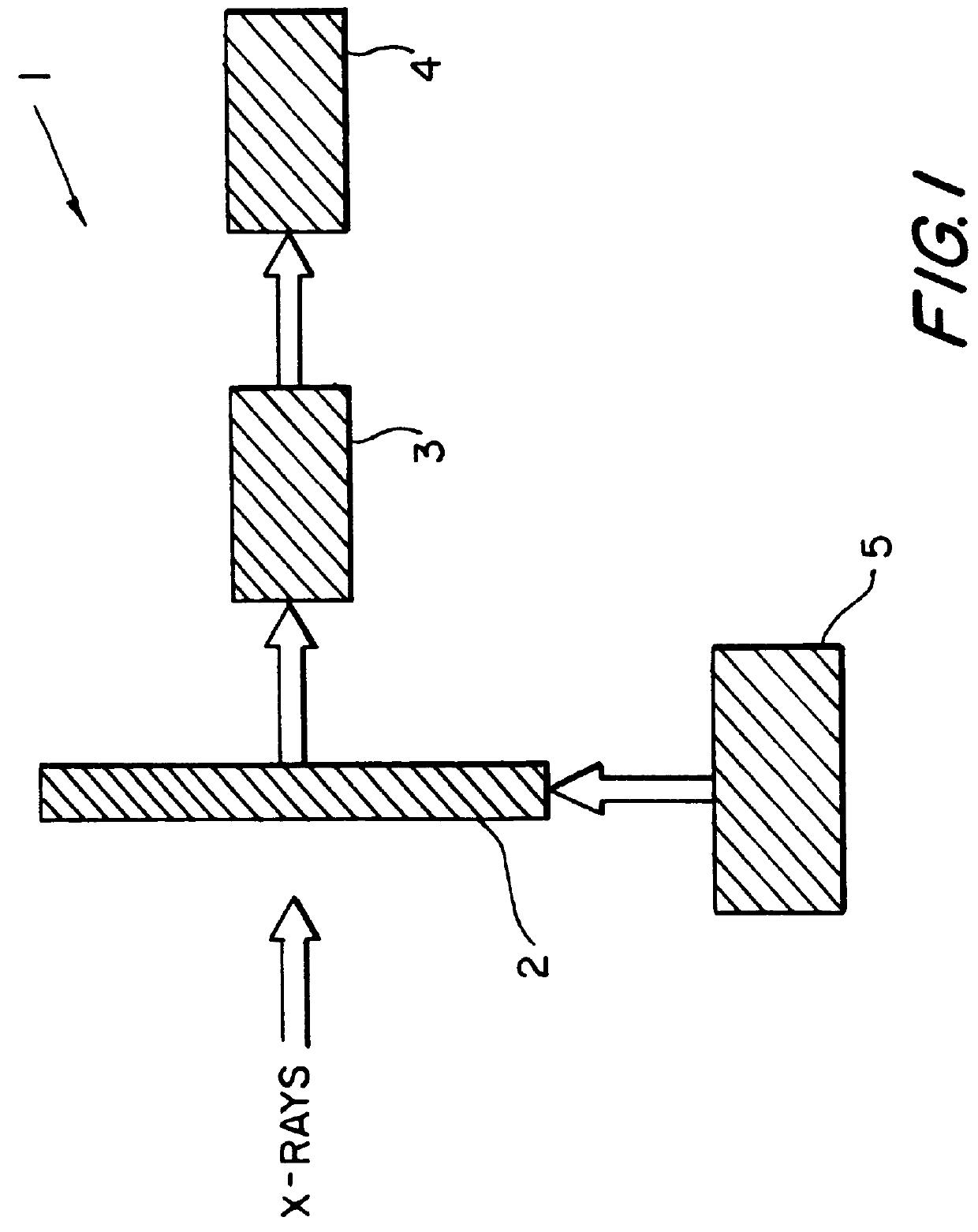

A device for the high-speed analysis of photon- or particle-generated image data or for the high-speed energy-discrimination analysis of photon- or particle-counting data. The device uses a sensor that collects the photons or particles on an array of solid state detectors, as electrical analog signals, and stores the analog-signal information on capacitors of readout arrays associated with the detector arrays. Integration of the photon or particle flux signals on the readout arrays proceeds for a given time frame and then image-related signals are transferred to an analog correction processor. The analog correction processor is comprised of one or more integrated circuit chips where each chip contains an array of correction processor unit cells. In these unit cells signals are corrected, in parallel, for gain and offset nonuniformities in the detection and processing chain. Corrections to all the signals are made in a time frame or less and the information is then transferred to an analog image processor. Particle-counting data is transferred directly from the readout array chips to the analog image processor. The analog image processor is comprised of one or more integrated circuit chips where each chip is made up of an array of image processor unit cells. Each unit cell contains circuitry for implementing an image processing or energy discrimination algorithm, and circuitry for outputting the signals and / or the position of only those unit cells for which the algorithm is satisfied. The analog image processor chip may also contain circuitry that counts the number of cells for which the algorithms have been satisfied. The analog image processor implements the algorithm and outputs the data in a time frame or less.

Owner:CONTINENTAL ADVANCED LIDAR SOLUTIONS US LLC

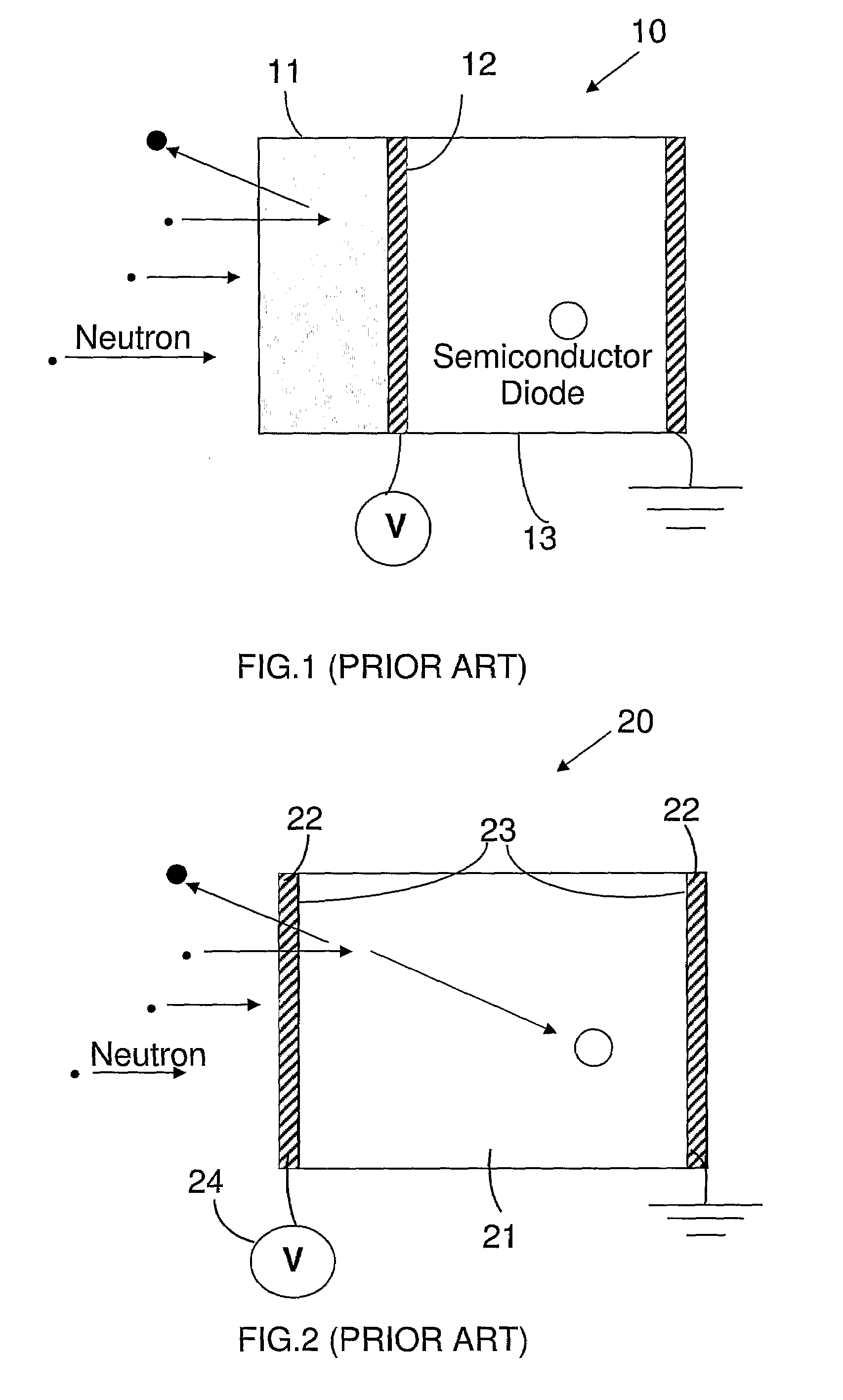

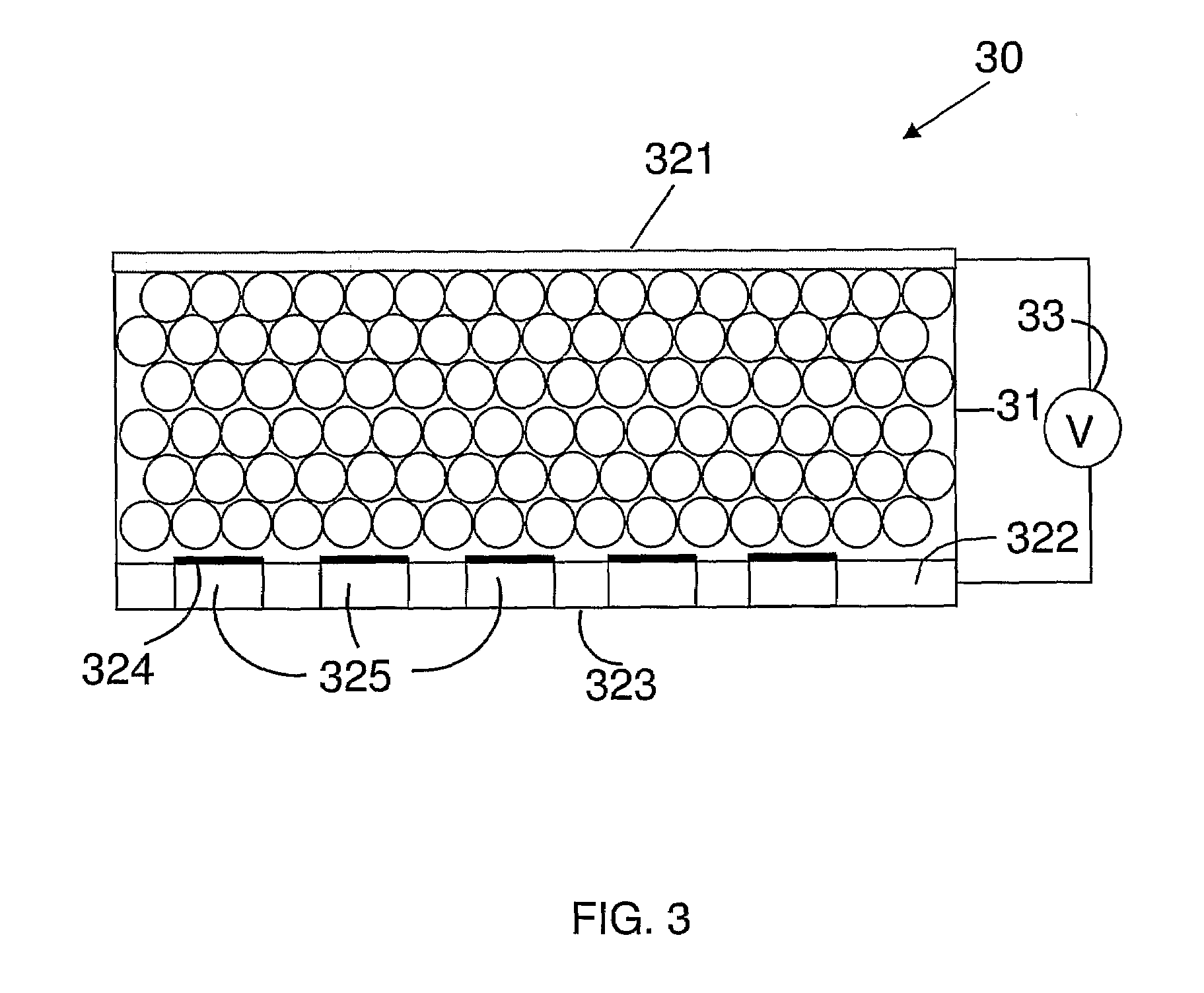

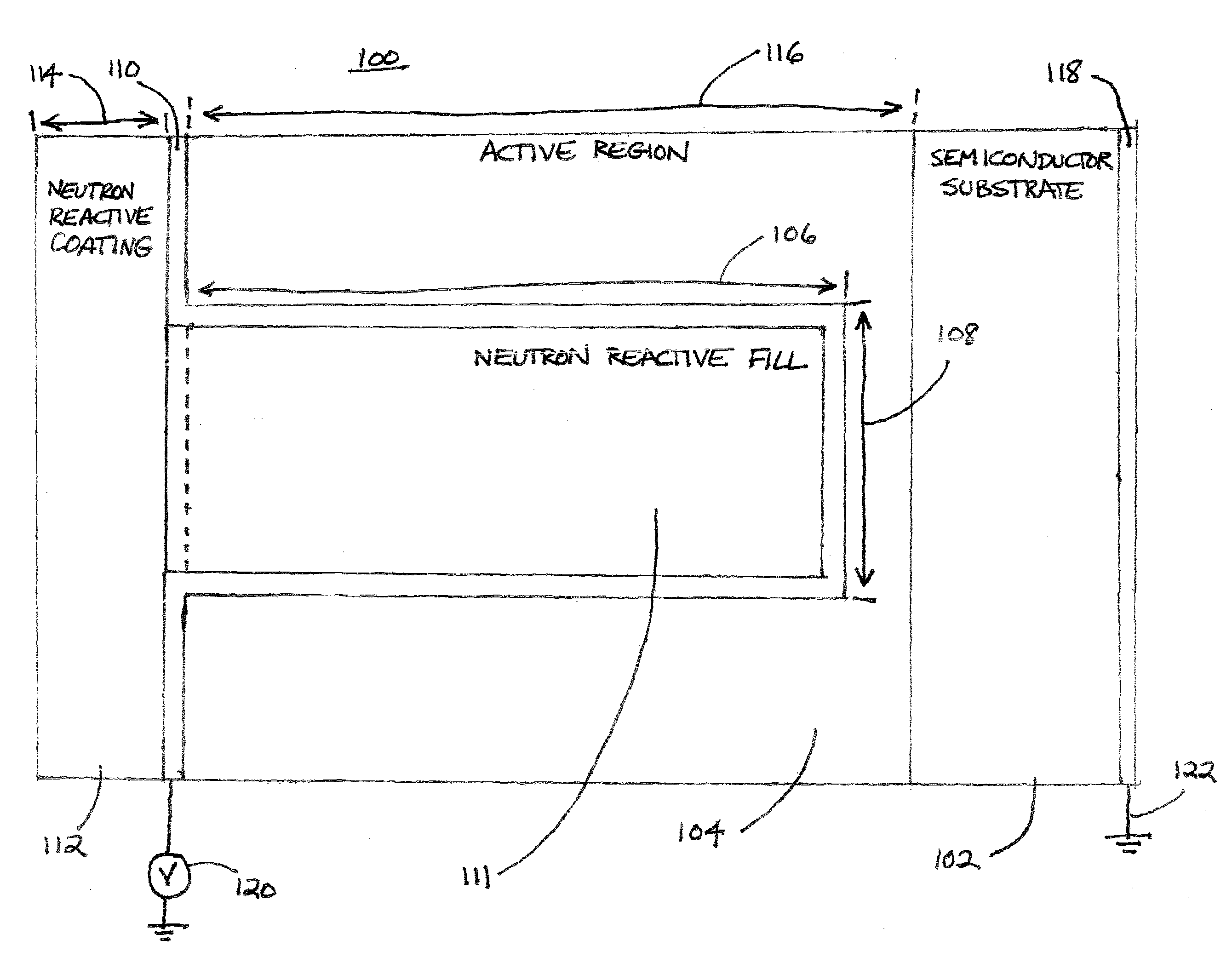

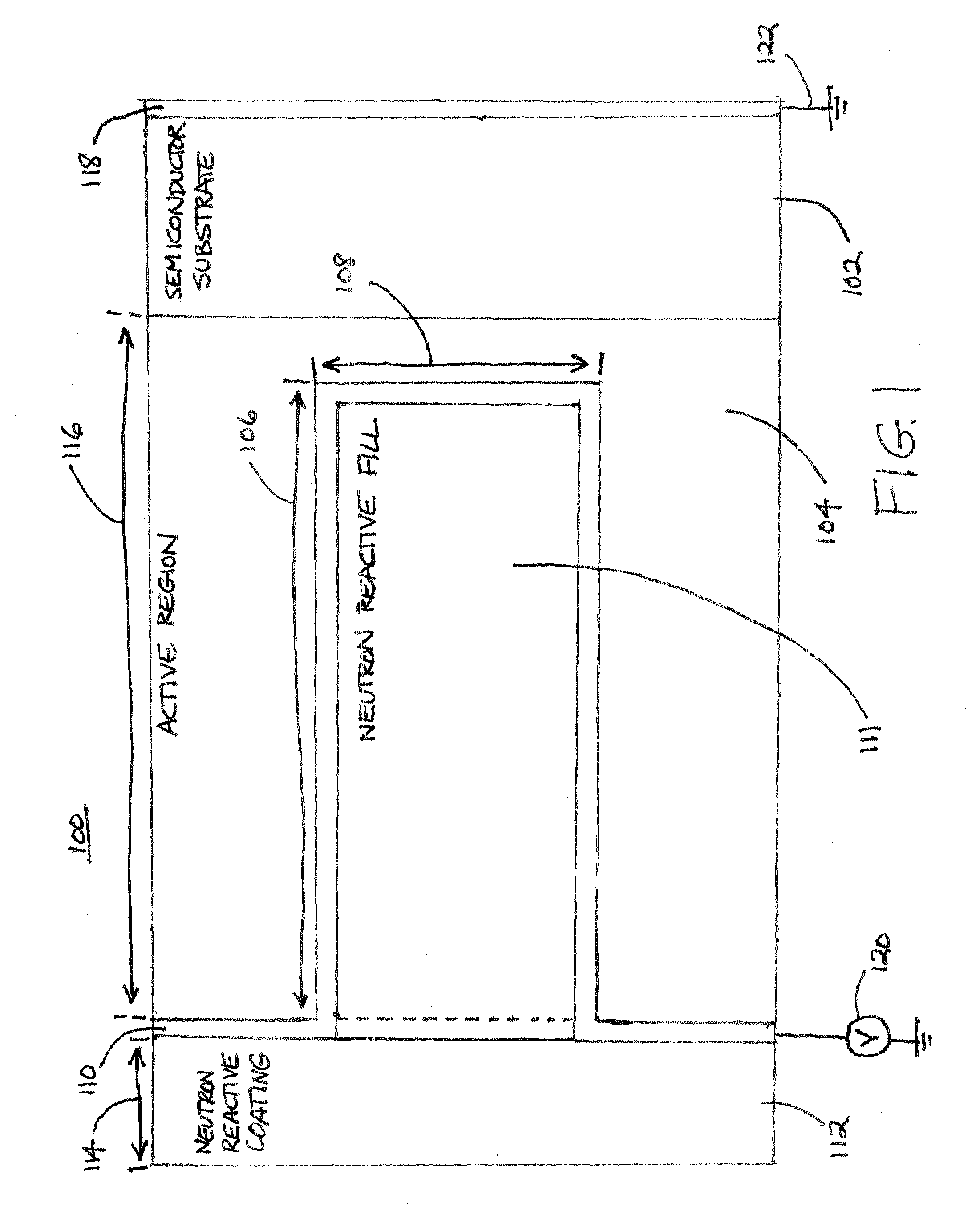

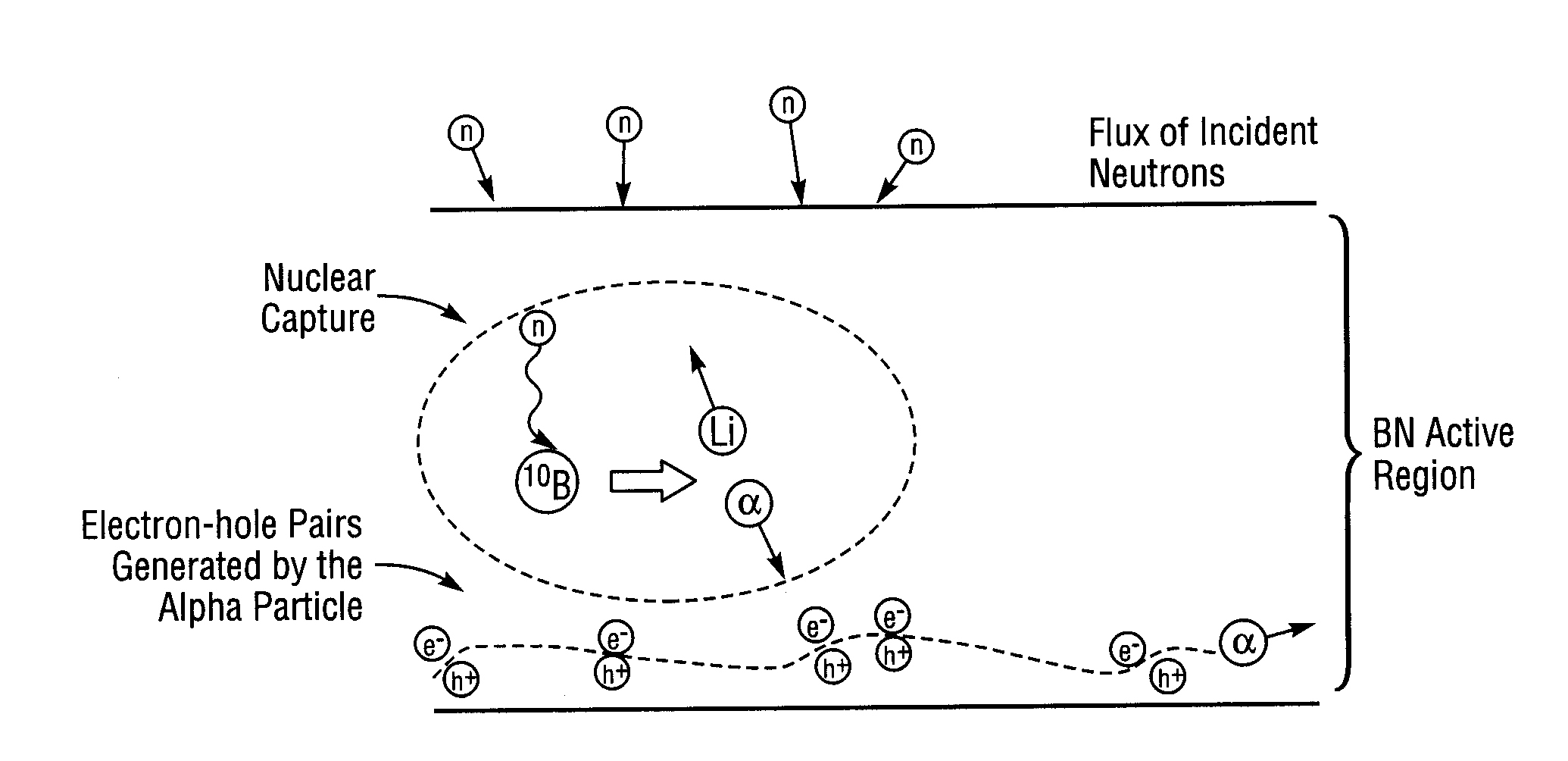

Solid-state neutron and alpha particles detector and methods for manufacturing and use thereof

InactiveUS20090302226A1Optimize detection resultsMeasurement with semiconductor devicesSolid-state devicesParticulatesSemiconductor materials

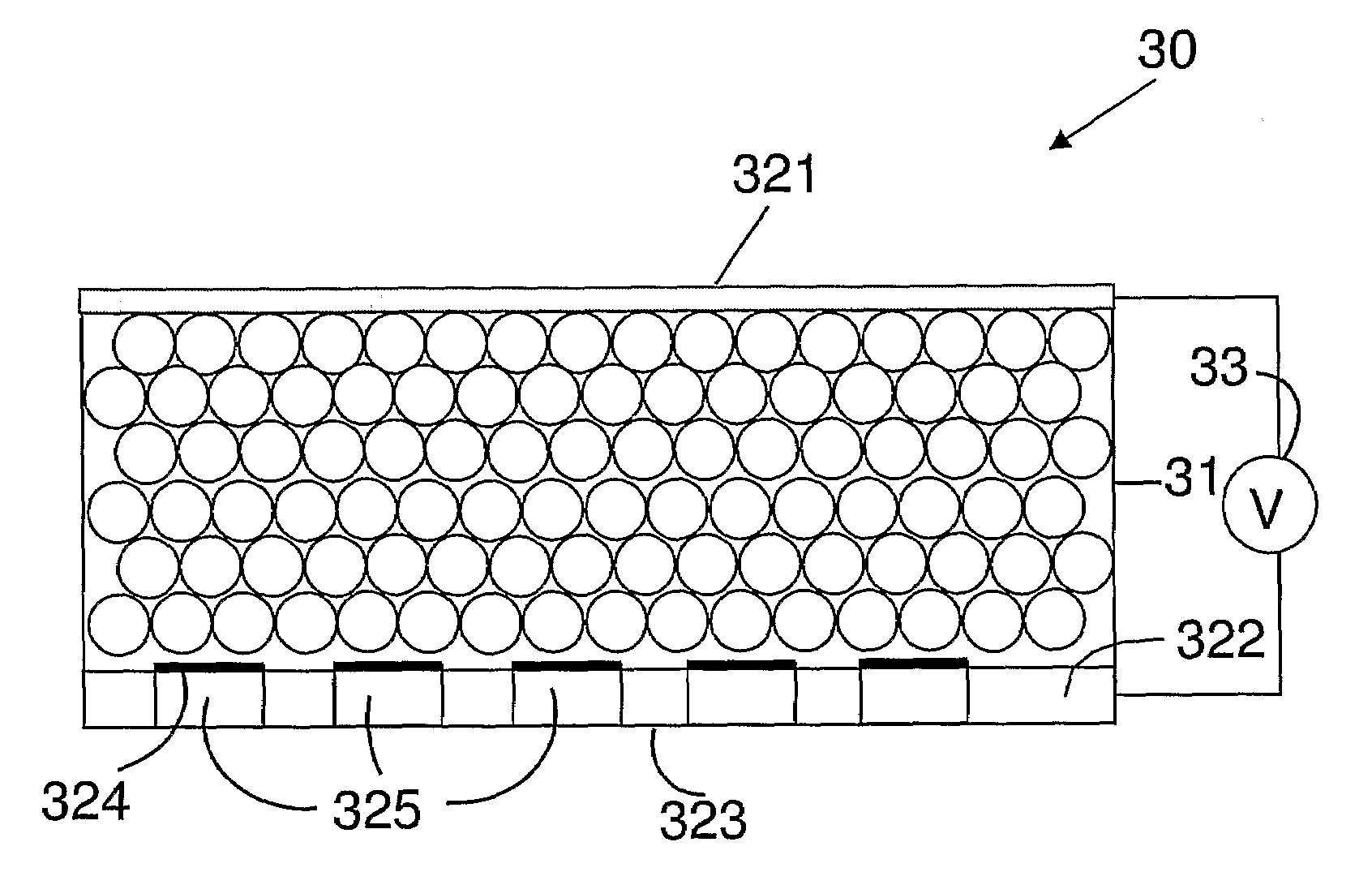

A solid-state detector for detection of neutron and alpha particles detector and methods for manufacturing and use thereof are described. The detector has an active region formed of a polycrystalline semiconductor compound comprising a particulate semiconductor material sensitive to neutron and alpha particles radiation imbedded in a binder. The particulate semiconductor material contains at least one element sensitive to neutron and alpha particles radiation, selected from a group including 10Boron, 6Lithium, 113Cadmium, 157Gadolinium and 199Mercury. The semiconductor compound is sandwiched between an electrode assembly configured to detect the neutron and alpha particles interacting with the bulk of the active region. The binder can be either an organic polymer binder or inorganic binder. The organic polymer binder comprises at least one polymer that can be selected from the group comprising polystyrene, polypropylene, Humiseal™ and Nylon-6. The inorganic binder can be selected from B2O3, PbO / B2O3 / , Bi2O3 / PbO, Borax glass, Bismuth Borate glass and Boron Oxide based glass.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

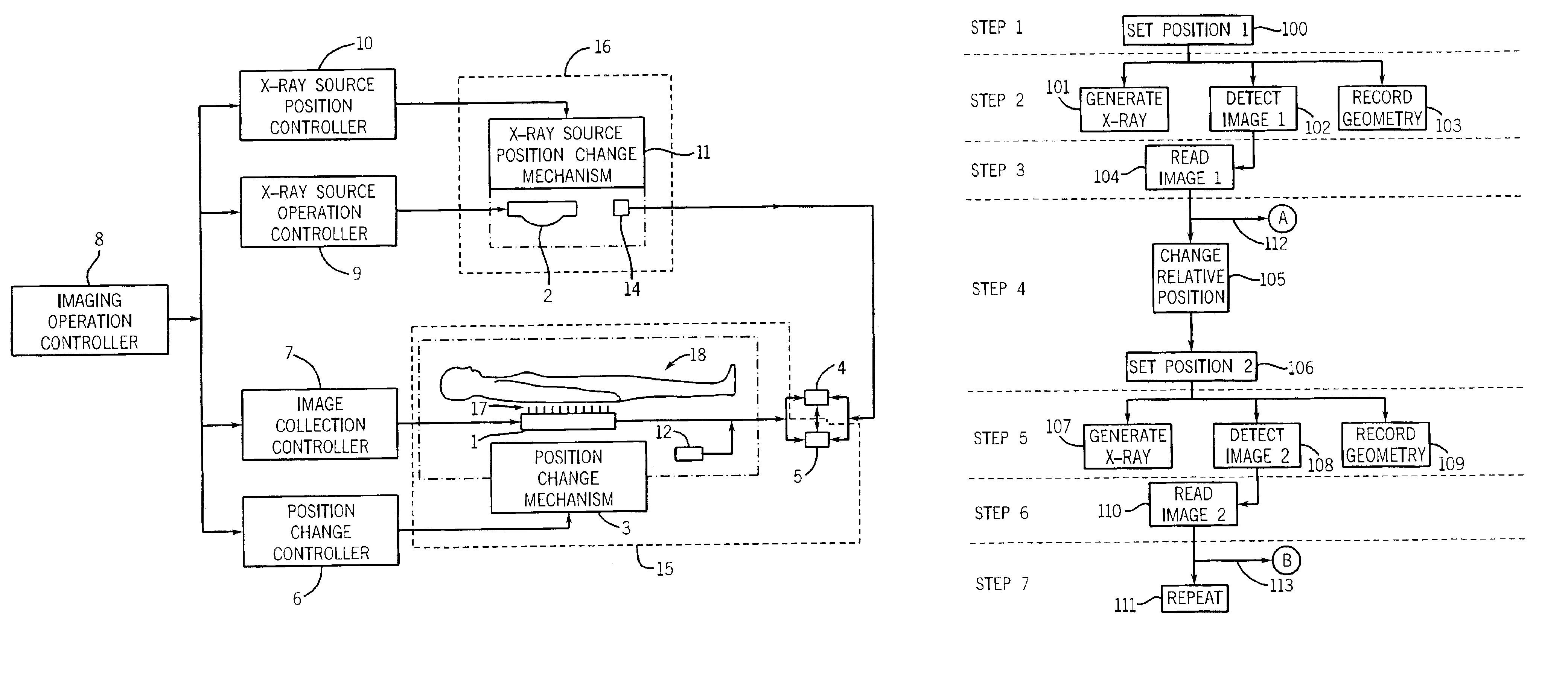

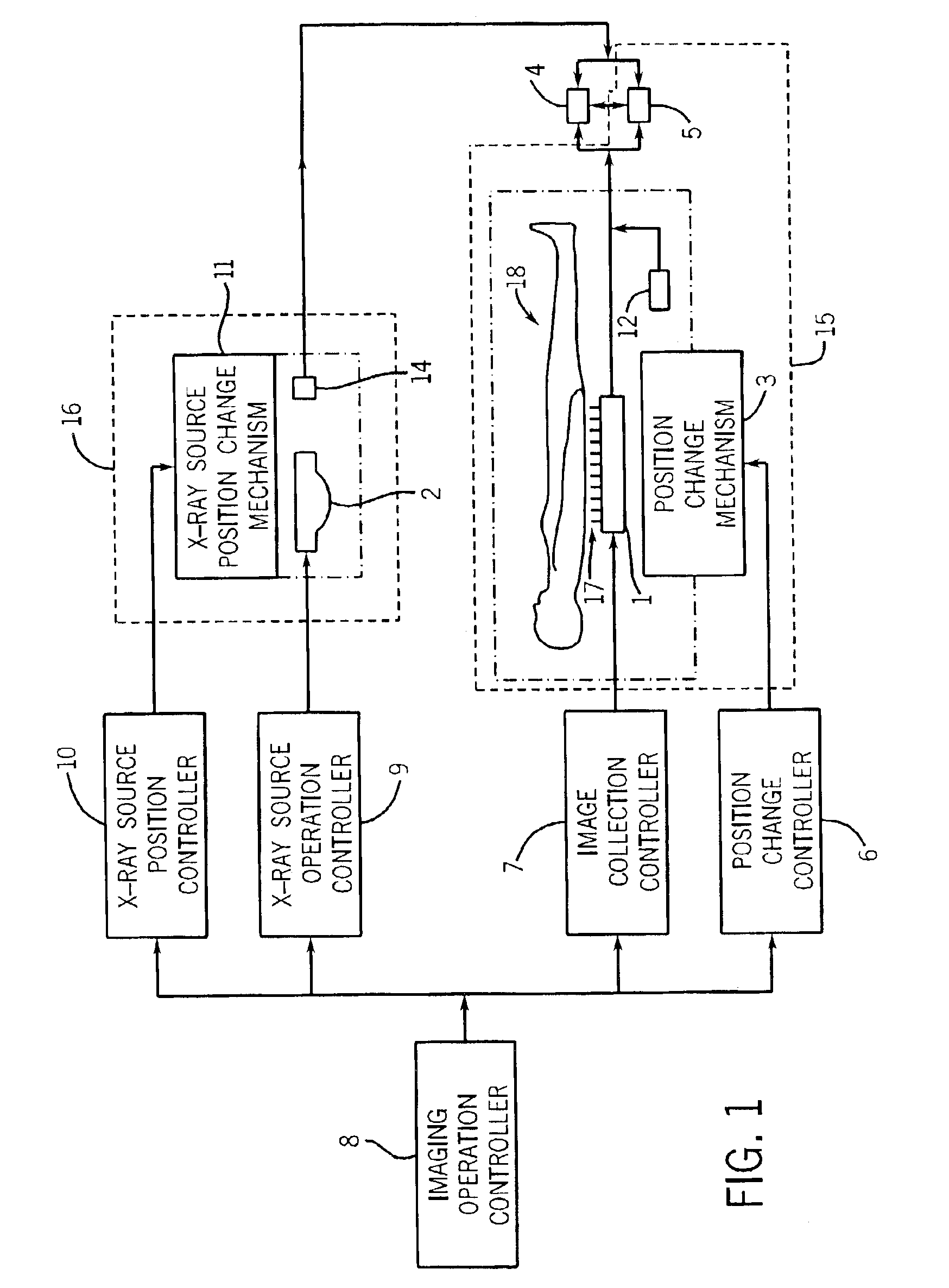

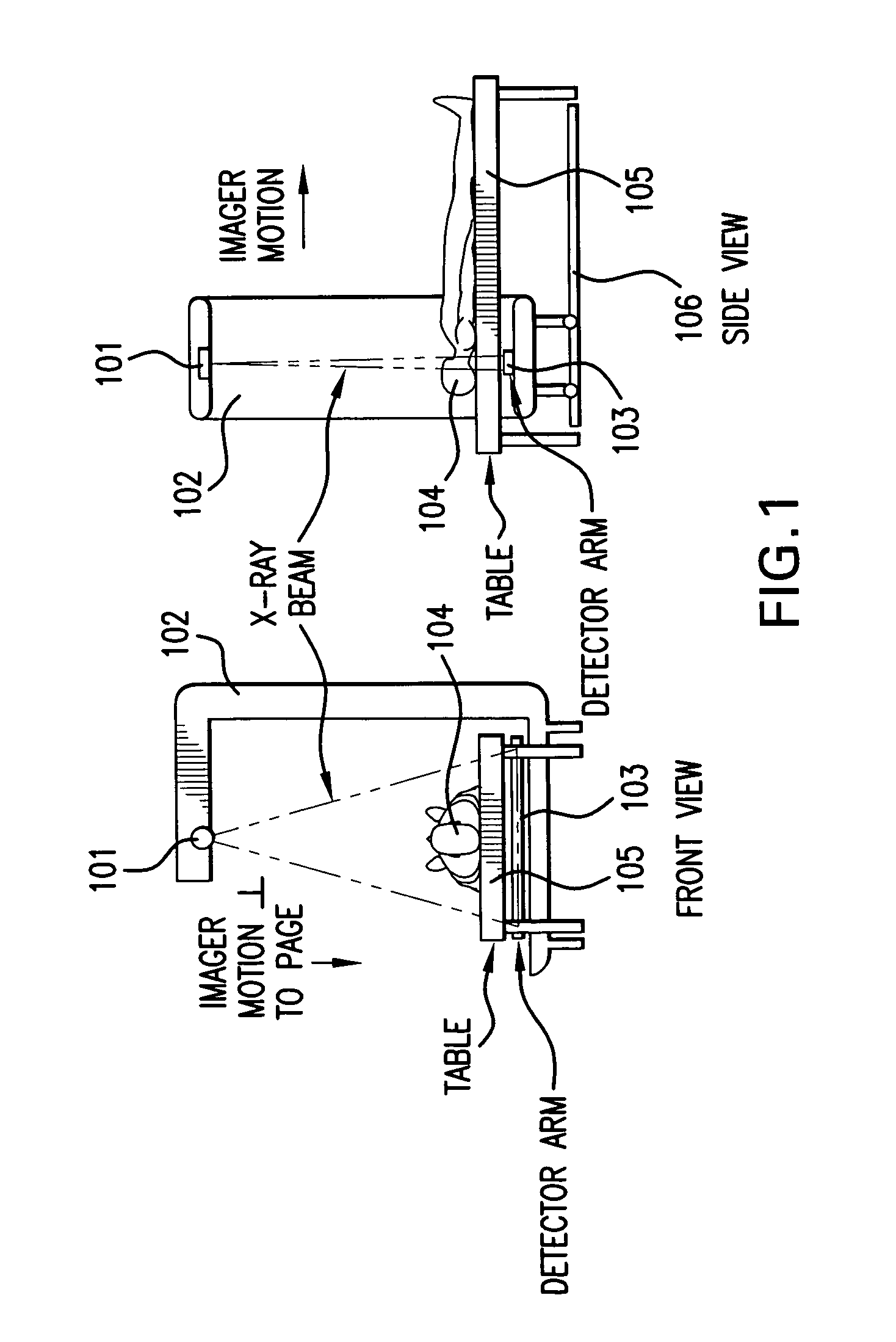

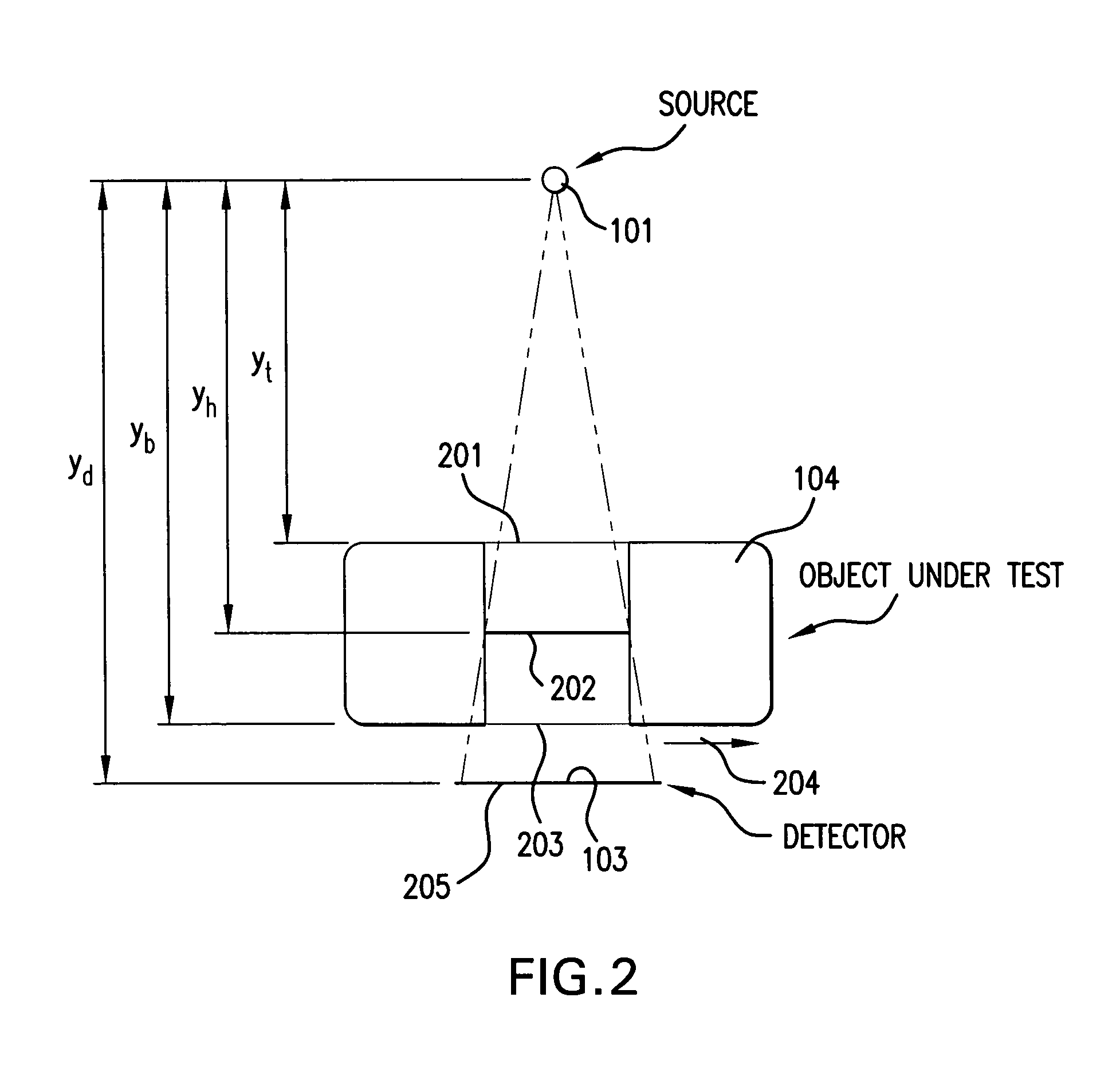

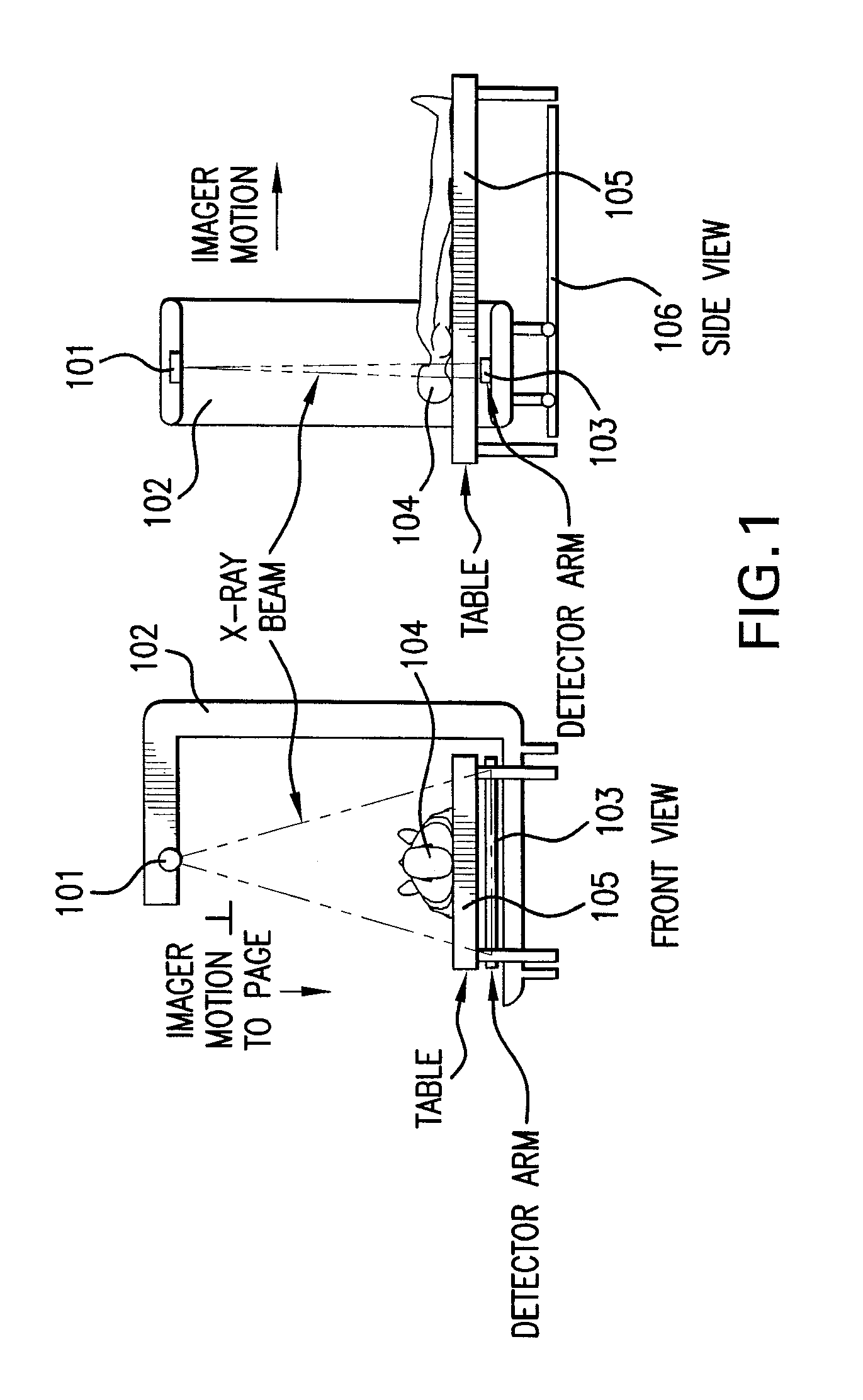

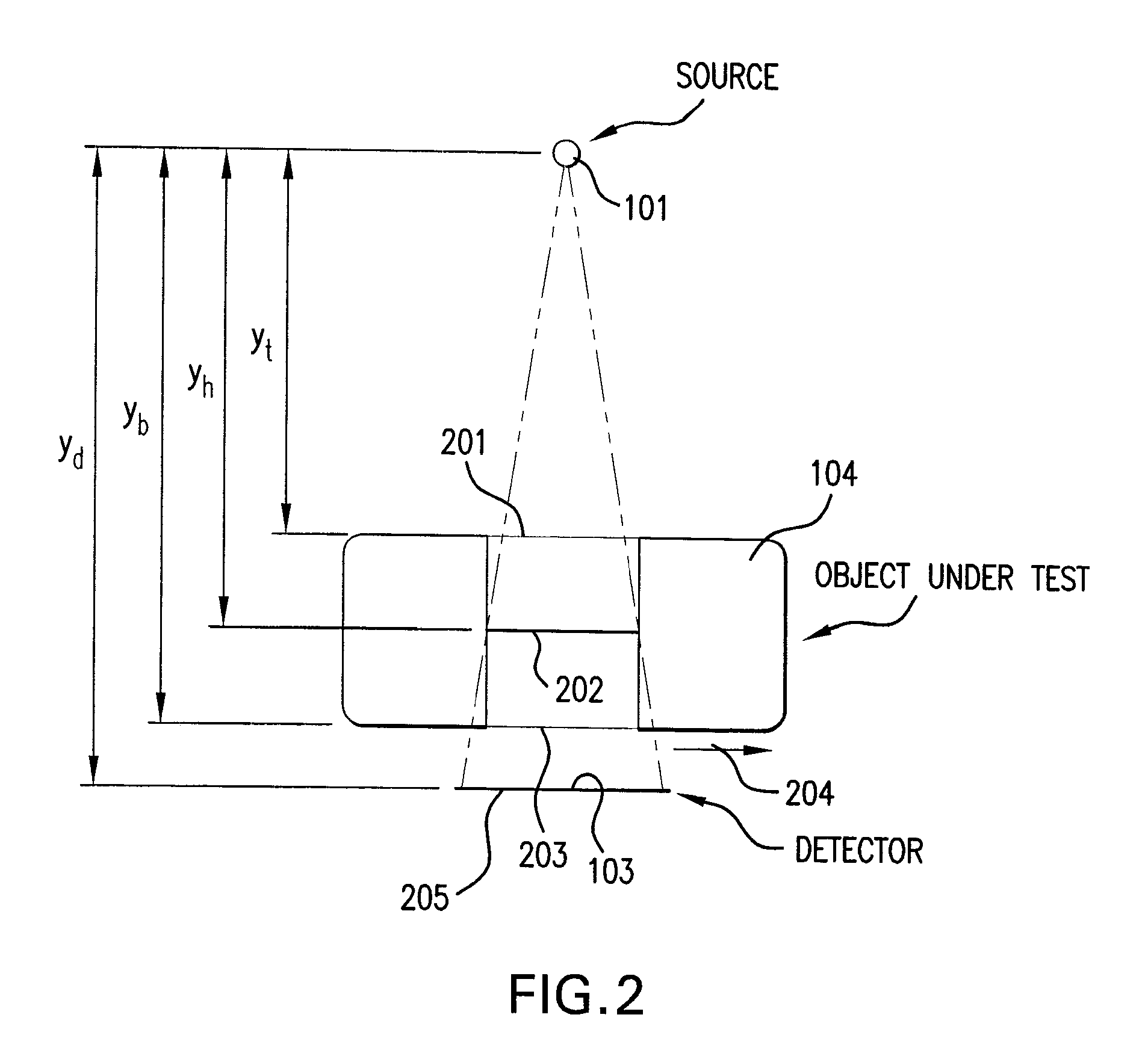

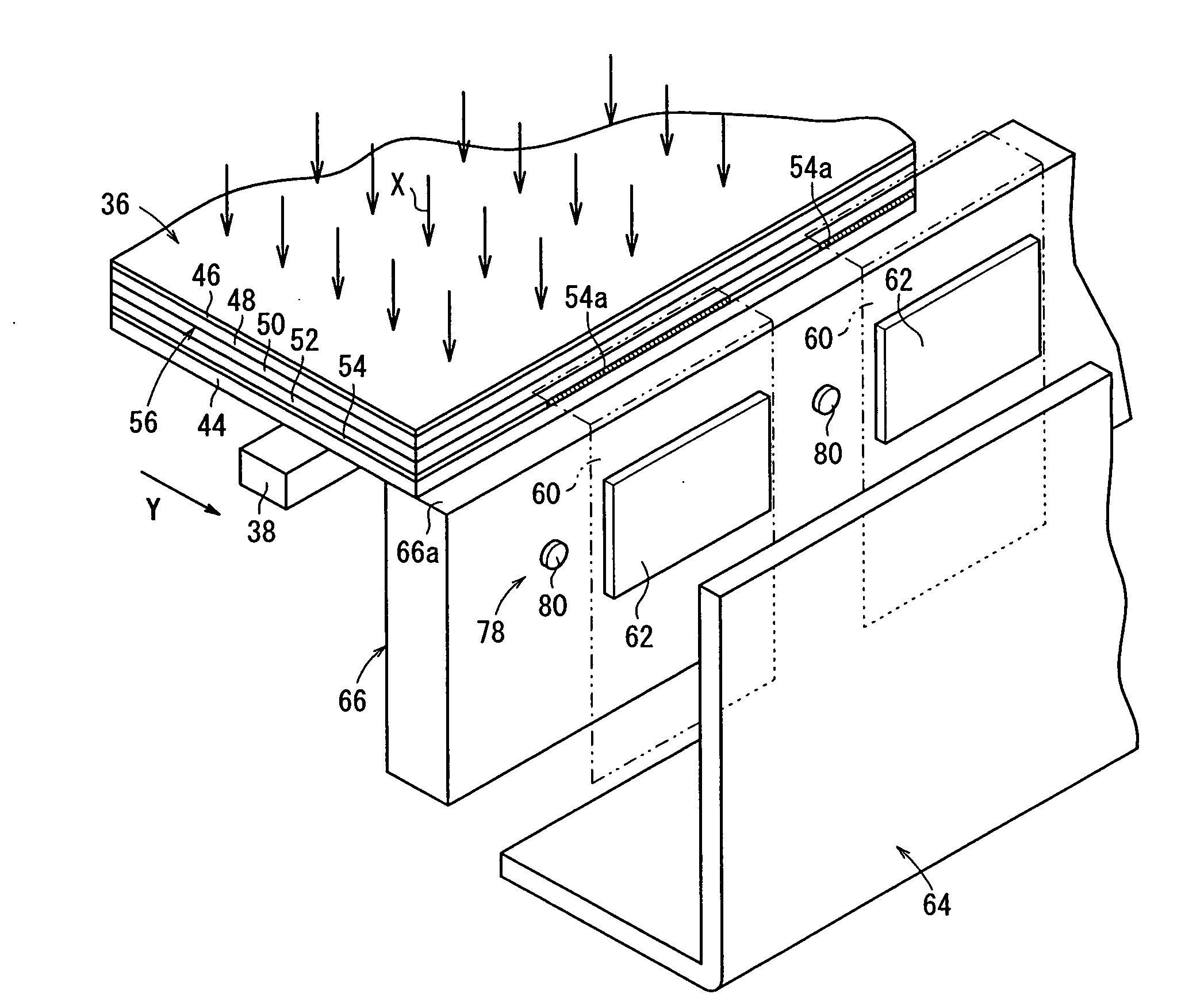

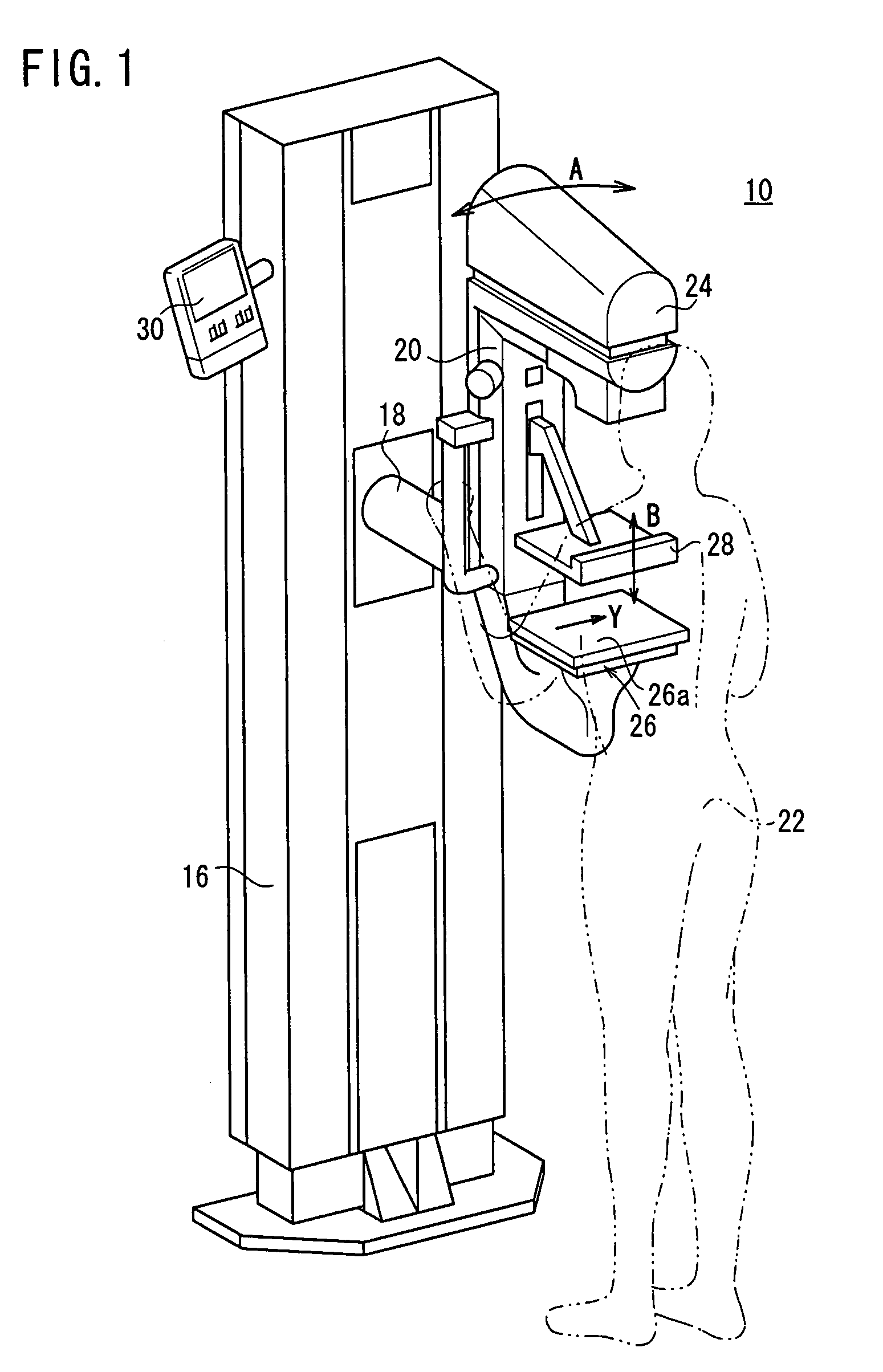

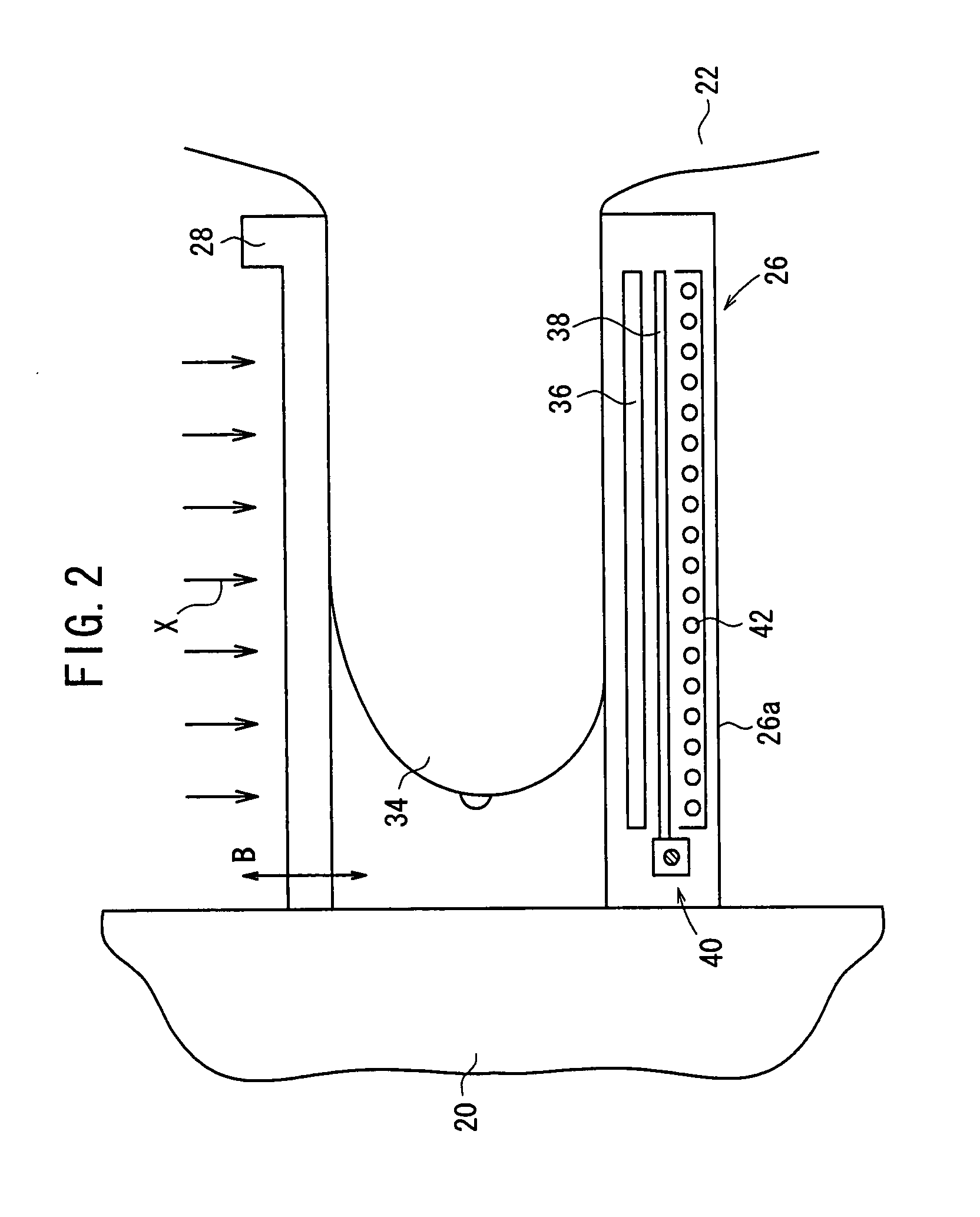

Image pasting using geometry measurement and a flat-panel detector

InactiveUS6944265B2Promote sportsX-ray apparatusMaterial analysis by transmitting radiationFlat panel detectorMeasurement device

A device for use in image pasting is described. The device includes a digital x-ray detector capable of automatic digital imaging without the use of an image intensifier; the detector preferably being a flat-panel detector. Additionally, an image pasting system using a solid-state detector is described. The system can connect the detected images to a display via a network (such as a WAN, a LAN, or the internet). Further, an image geometry measurement device for use in pasting x-ray images is disclosed. The geometry measurement device helps determine the relative position of two images to be used in image pasting. This information can be used alone, or in connection with an image pasting algorithm. Still further, methods of forming composite images are disclosed using a flat-panel detector and using the geometry of the images. The disclosed devices and systems can be integrated with other digital image pasting technology.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

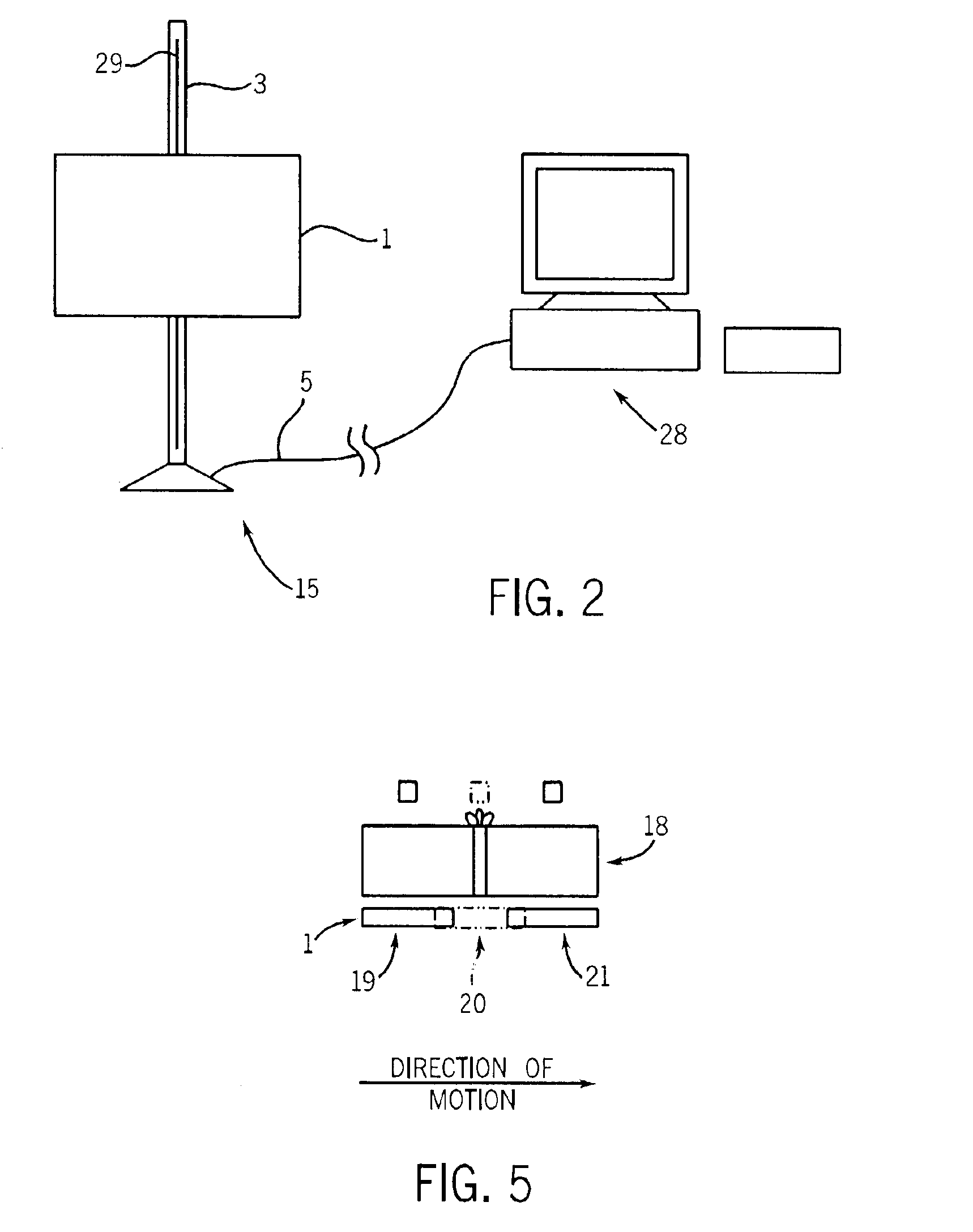

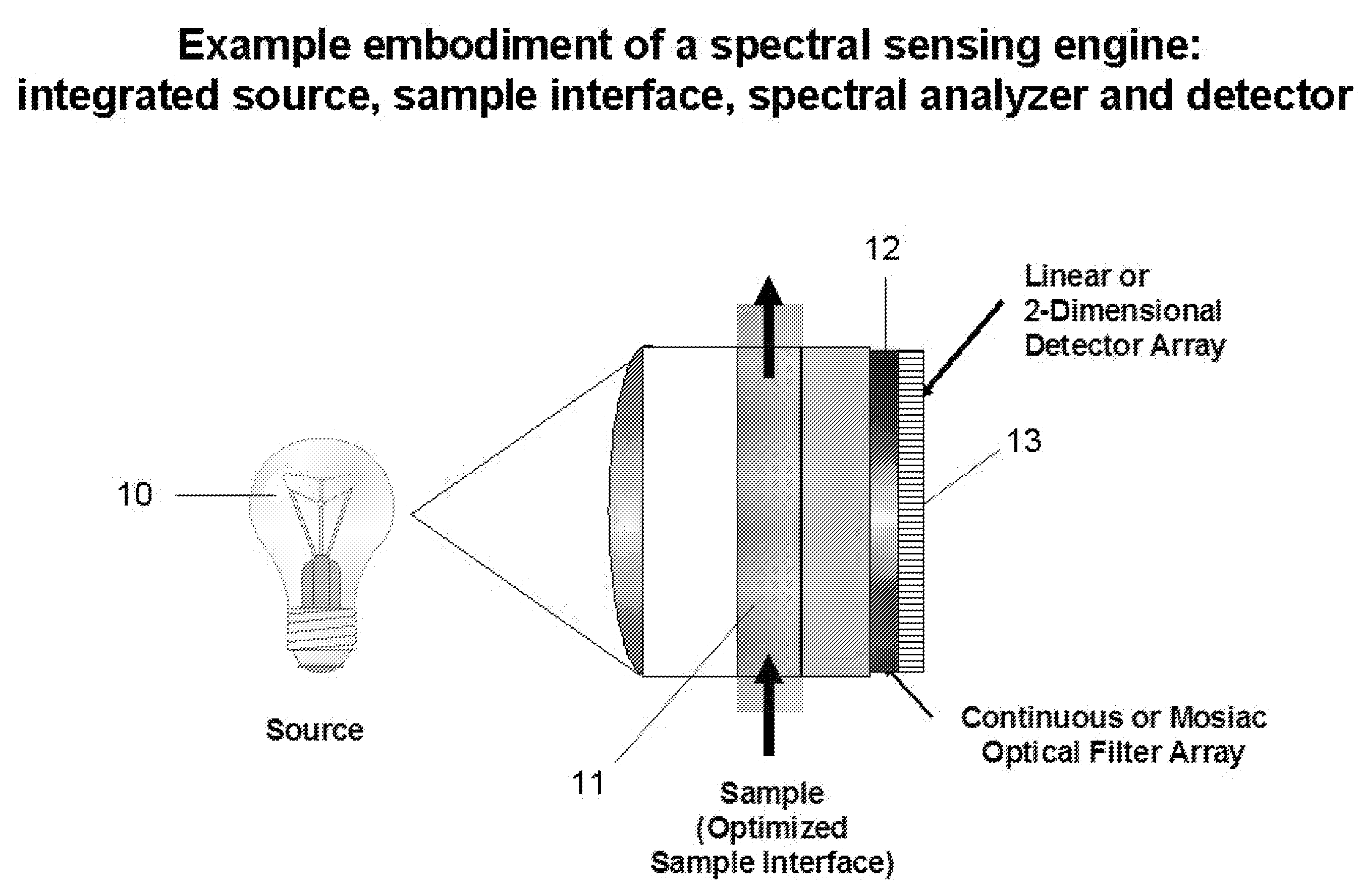

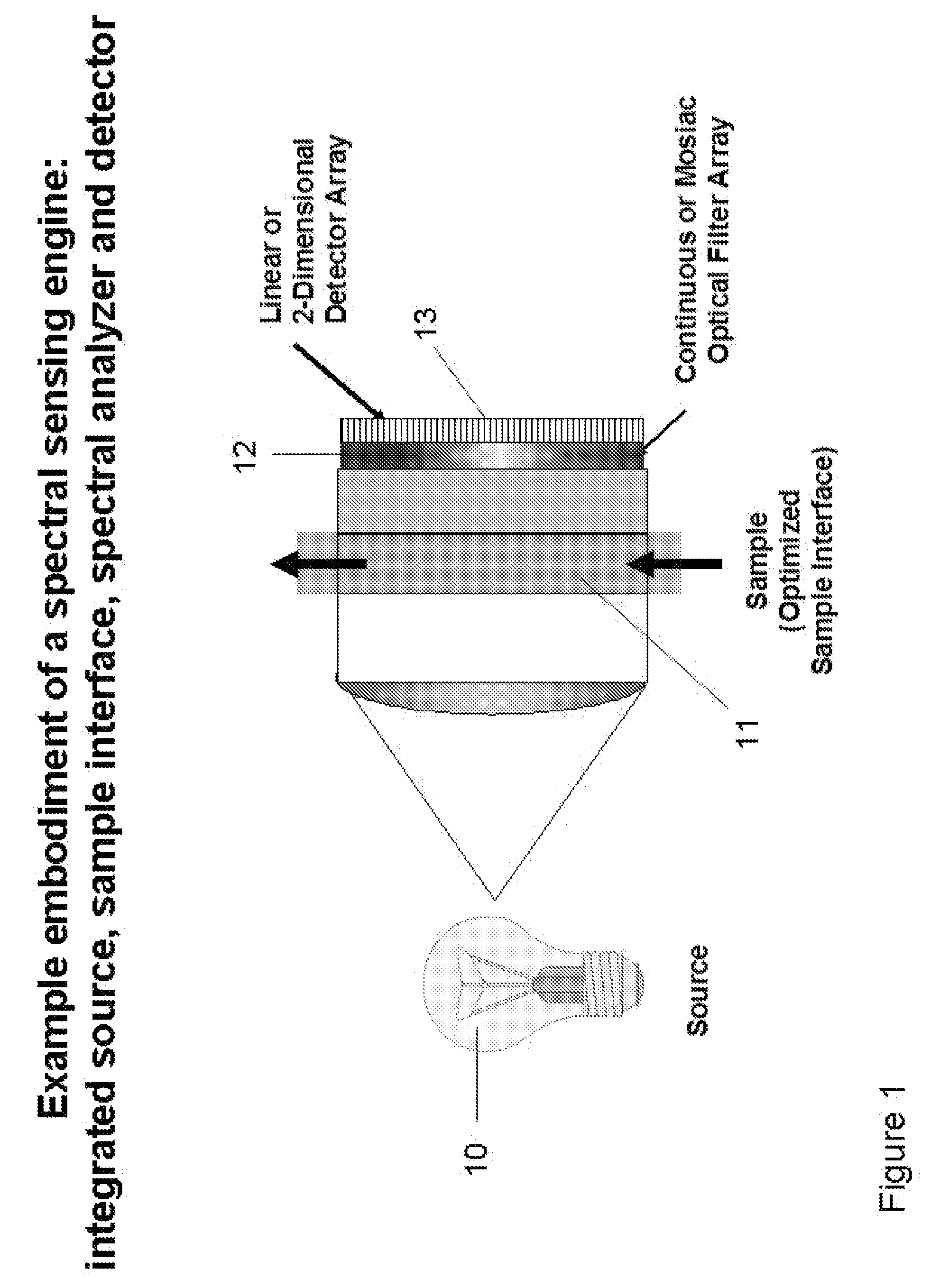

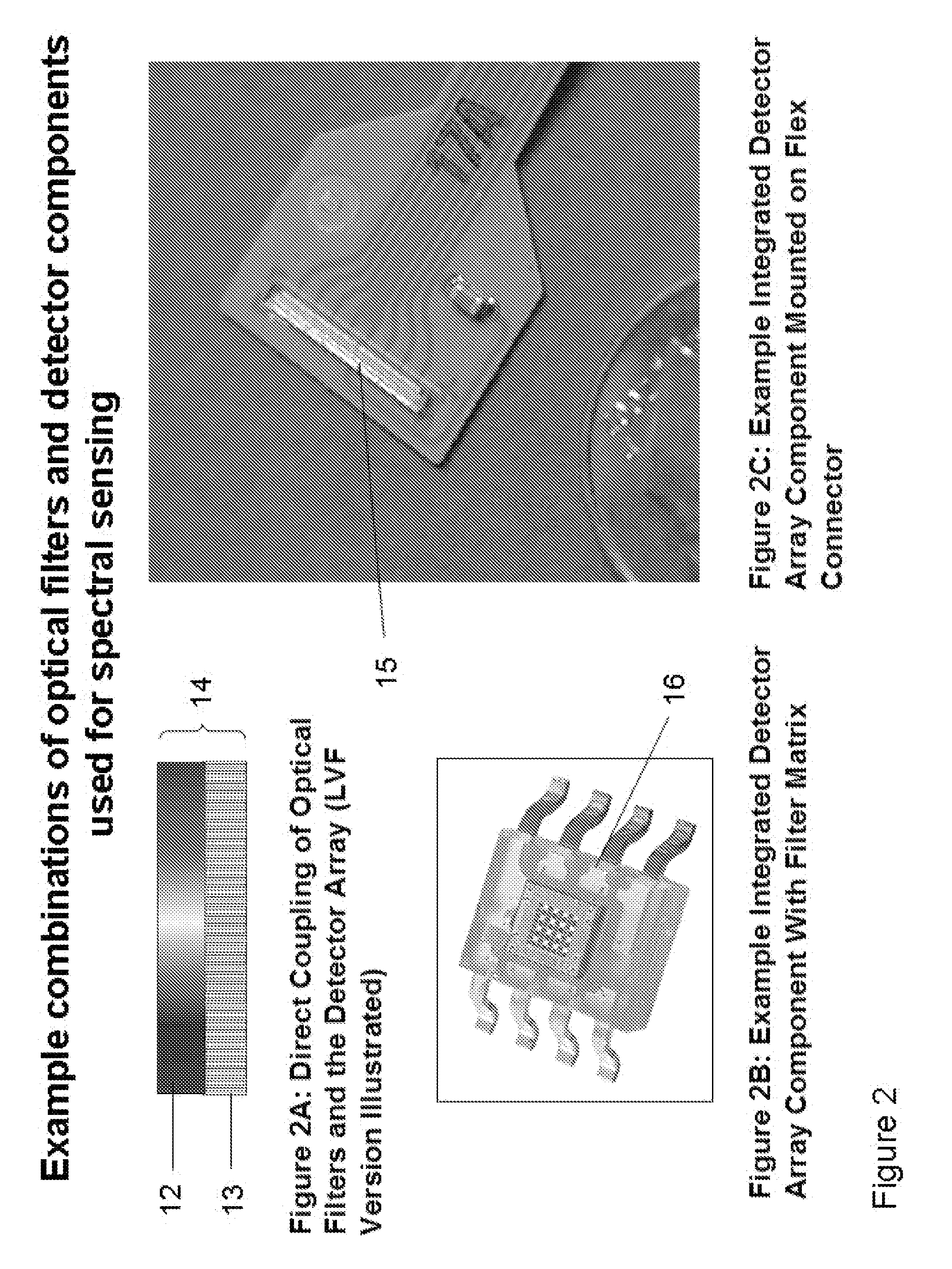

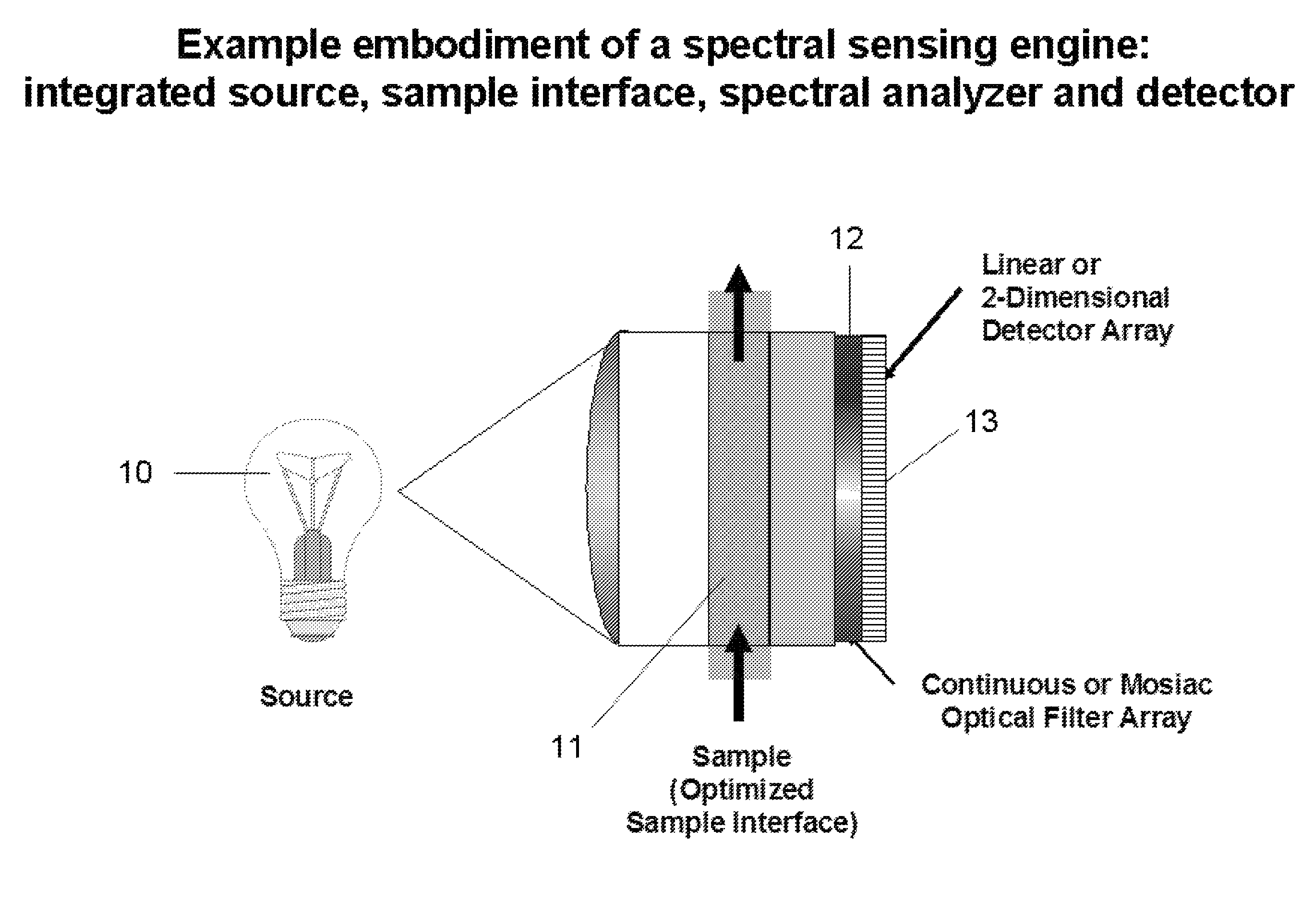

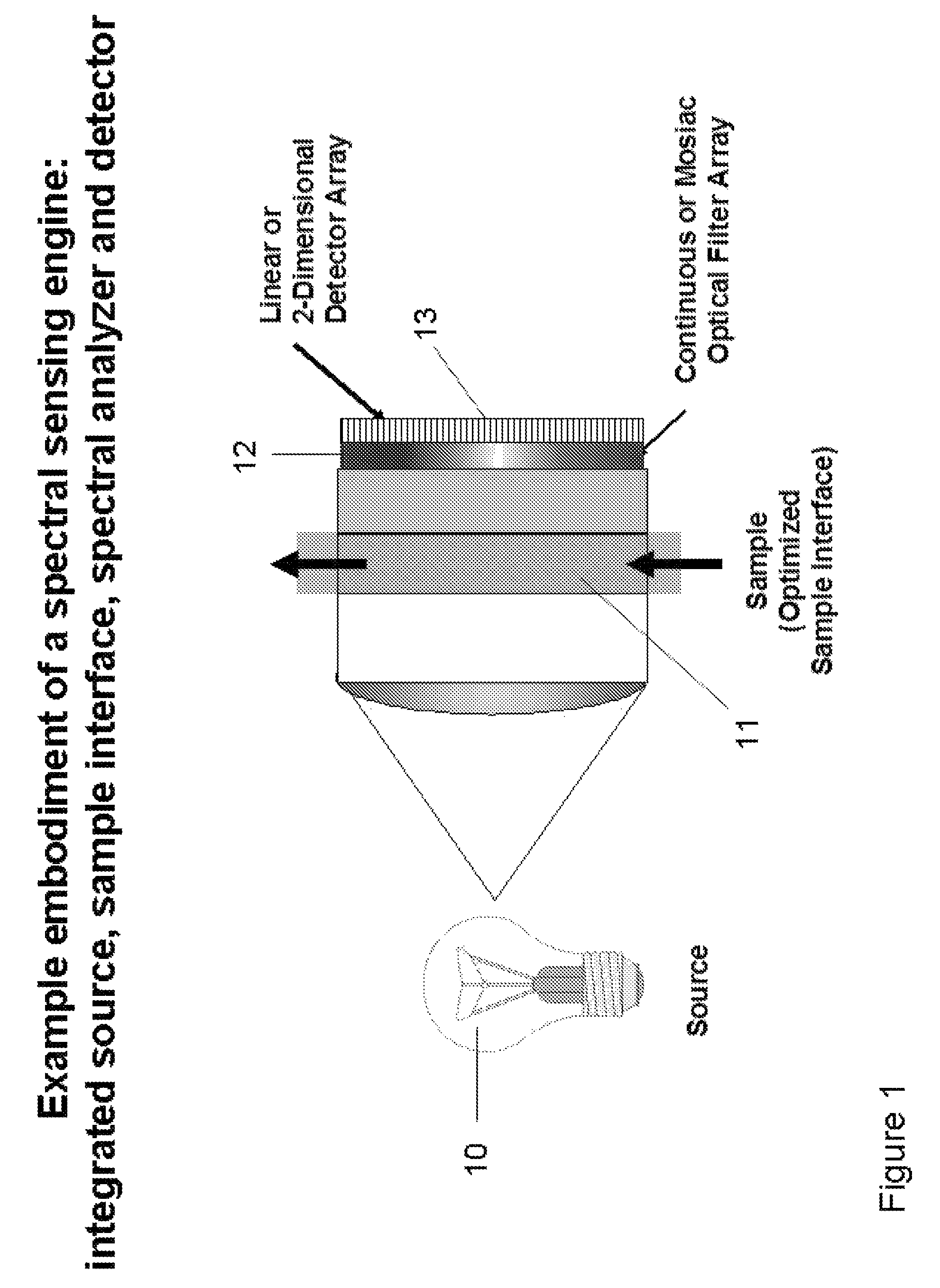

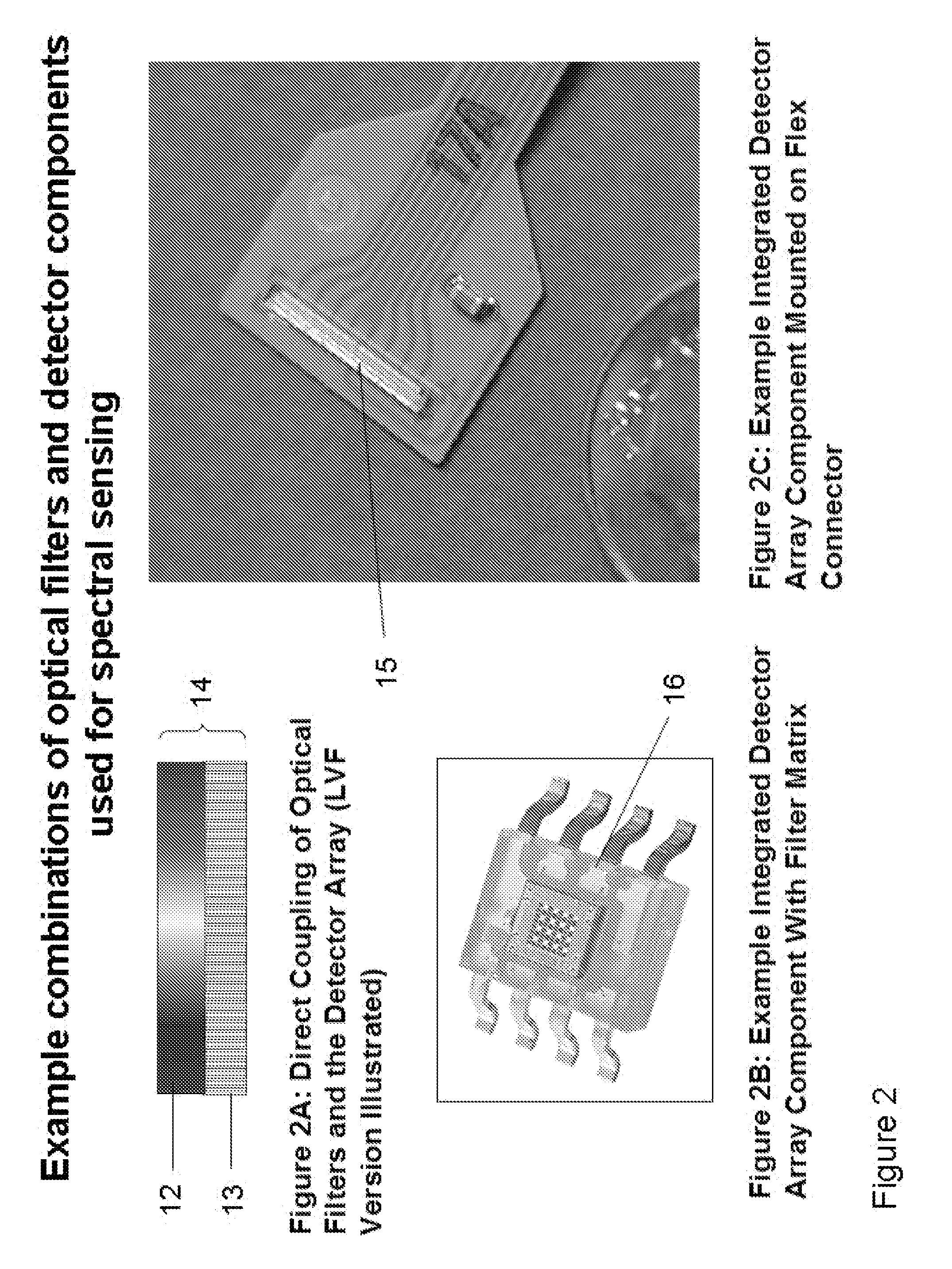

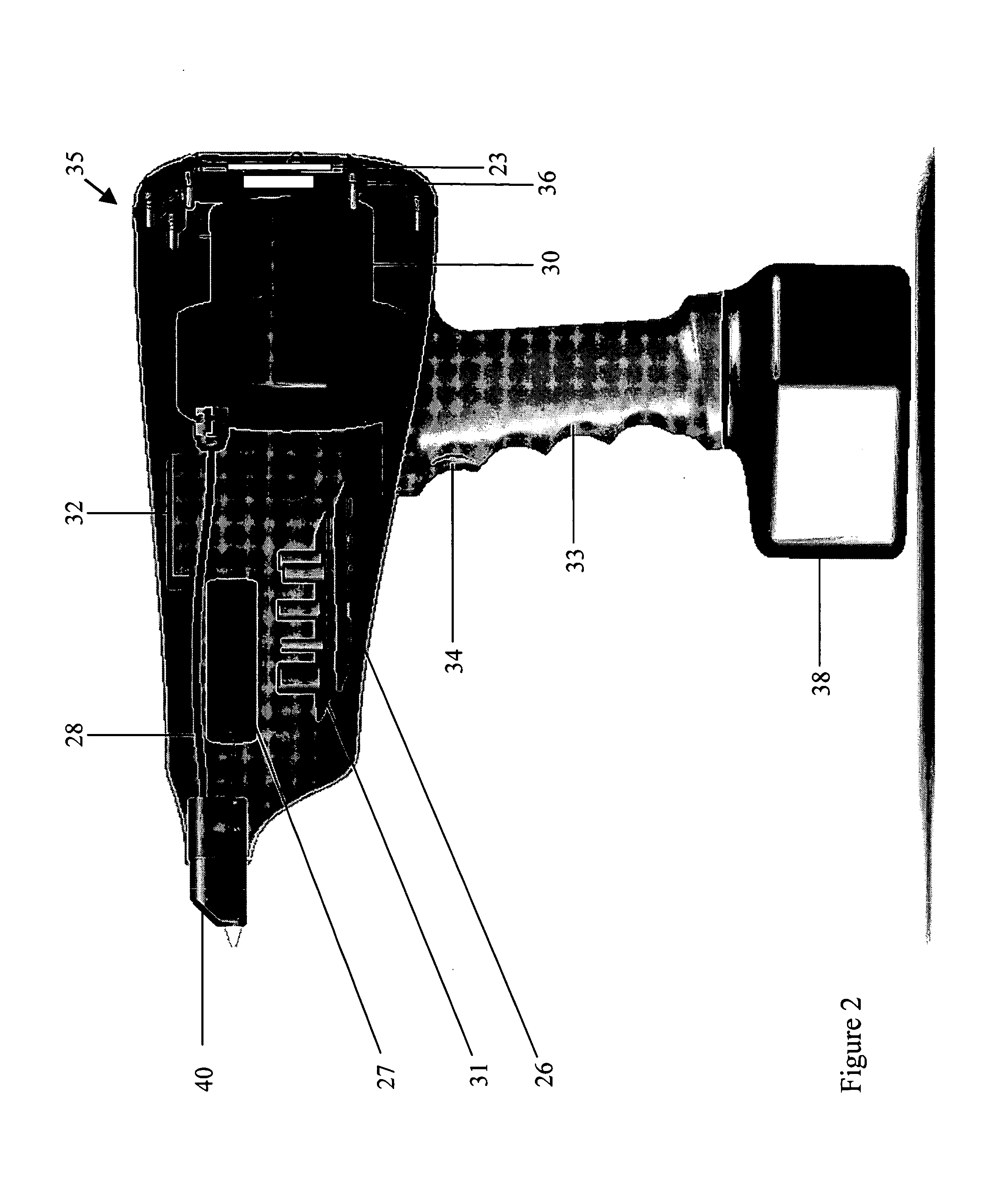

Integrated sensing module for handheld spectral measurements

InactiveUS20080265146A1Low costSmall sizeRadiation pyrometryInvestigating moving fluids/granular solidsFluorescenceOn board

An integrated spectral sensing engine featuring energy sources and detectors within a single package includes sample interfacing optics and acquisition and processing electronics. The miniaturized sensor is optimized for specific laboratory and field-based measurements by integration into a handheld format. Design and fabrication components support high volume manufacturing. Spectral selectivity is provided by either continuous variable optical filters or filter matrix devices. The sensor's response covers the range from 200 nm to 25 μm based on various solid-state detectors. The wavelength range can be extended by the use of filter-matrix devices. Measurement modes include transmittance / absorbance, turbidity (light scattering) and fluorescence (emission). On board data processing includes raw data acquisition, data massaging and the output of computed results. Sensor applications include water and environmental, food and beverage, chemical and petroleum, and medical analyses. These can be expanded into various field and consumer-based applications.

Owner:APPELL GEORGE N +1

High resolution imaging system

ActiveUS7634061B1Reduce doseIncrease contrastSolid-state devicesMaterial analysis by optical meansLow noiseHigh resolution imaging

New sensors, pixel detectors and different embodiments of multi-channel integrated circuit are disclosed. The new high energy and spatial resolution sensors use solid state detectors. Each channel or pixel of the readout chip employs low noise preamplifier at its input followed by other circuitry. The different embodiments of the sensors, detectors and the integrated circuit are designed to produce high energy and / or spatial resolution two-dimensional and three-dimensional imaging for different applications. Some of these applications may require fast data acquisition, some others may need ultra high energy resolution, and a separate portion may require very high contrast. The embodiments described herein addresses these issues and also other issues that may be useful in two and three dimensional medical and industrial imaging. The applications of the new sensors, detectors and integrated circuits addresses a broad range of applications such as medical and industrial imaging, NDE and NDI, security, baggage scanning, astrophysics, nuclear physics and medicine.

Owner:NOVA R&D

Integrated sensing module for handheld spectral measurements

InactiveUS7907282B2Low costSmall sizeRadiation pyrometryInvestigating moving fluids/granular solidsFluorescenceOn board

An integrated spectral sensing engine featuring energy sources and detectors within a single package includes sample interfacing optics and acquisition and processing electronics. The miniaturized sensor is optimized for specific laboratory and field-based measurements by integration into a handheld format. Design and fabrication components support high volume manufacturing. Spectral selectivity is provided by either continuous variable optical filters or filter matrix devices. The sensor's response covers the range from 200 nm to 25 μm based on various solid-state detectors. The wavelength range can be extended by the use of filter-matrix devices. Measurement modes include transmittance / absorbance, turbidity (light scattering) and fluorescence (emission). On board data processing includes raw data acquisition, data massaging and the output of computed results. Sensor applications include water and environmental, food and beverage, chemical and petroleum, and medical analyses. These can be expanded into various field and consumer-based applications.

Owner:APPELL GEORGE N +1

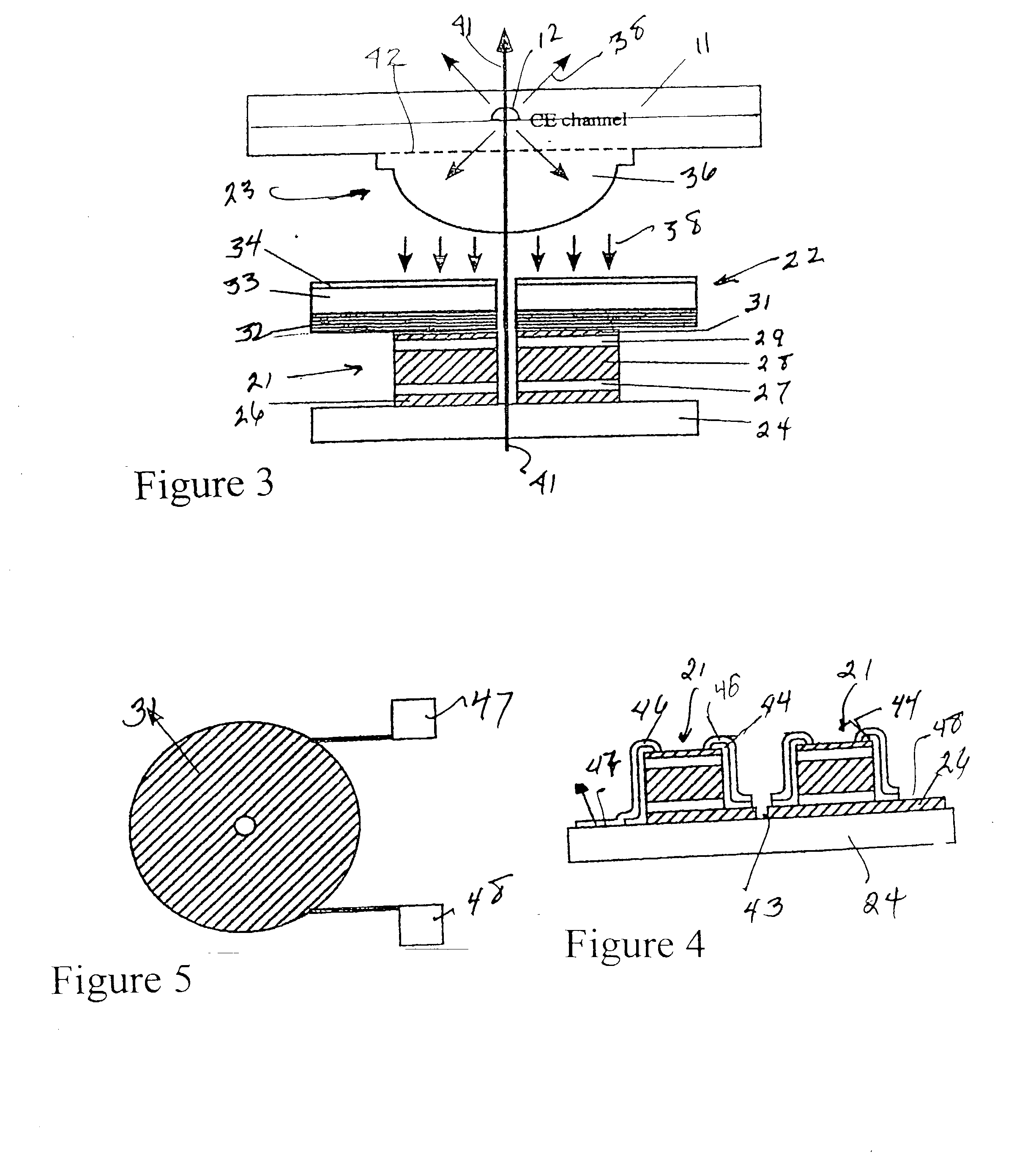

Solid-state detector and optical system for microchip analyzers

InactiveUS20030222223A1Easy to makeMaterial analysis by electric/magnetic meansSemiconductor/solid-state device manufacturingAnalyteSolid state detector

A miniaturized optical excitation and detector system is described for detecting fluorescently labeled analytes in electrophoretic microchips and microarrays. The system uses miniature integrated components, light collection, optical fluorescence filtering, and an amorphous a-Si:H detector for detection. The collection of light is accomplished with proximity gathering and / or a micro-lens system. Optical filtering is accomplished by integrated optical filters. Detection is accomplished utilizing a-Si:H detectors.

Owner:PALO ALTO RES CENT INC +1

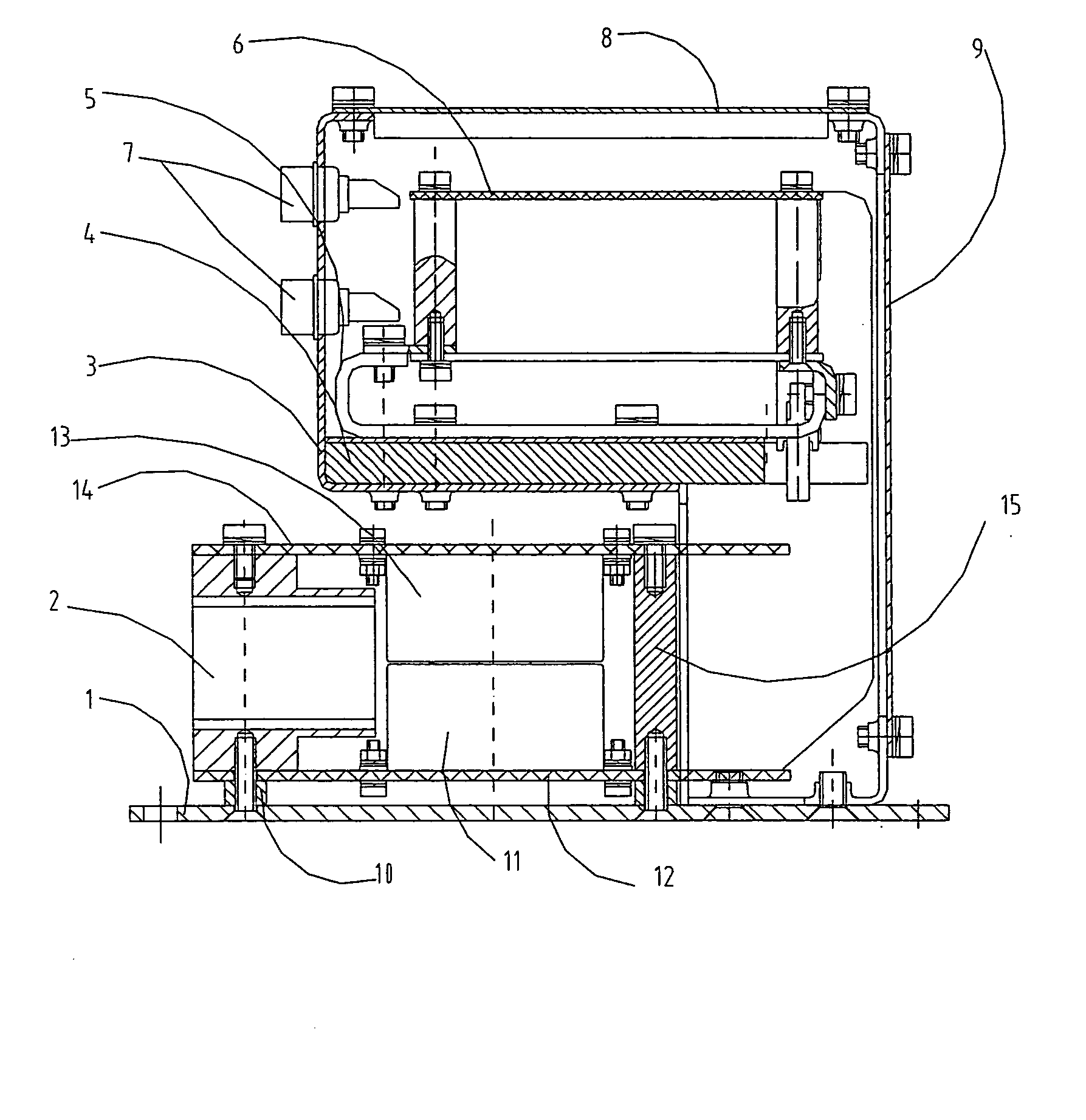

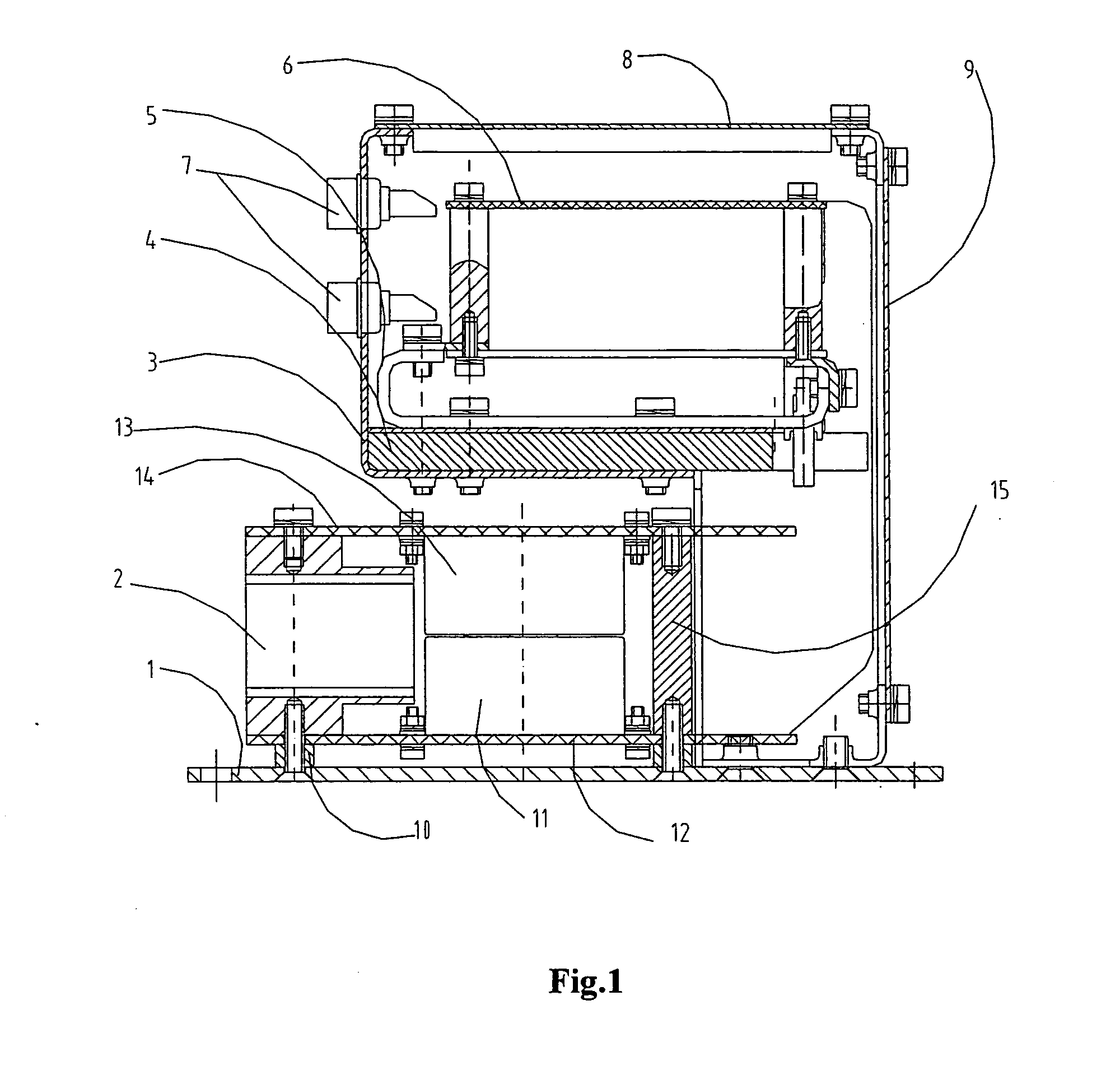

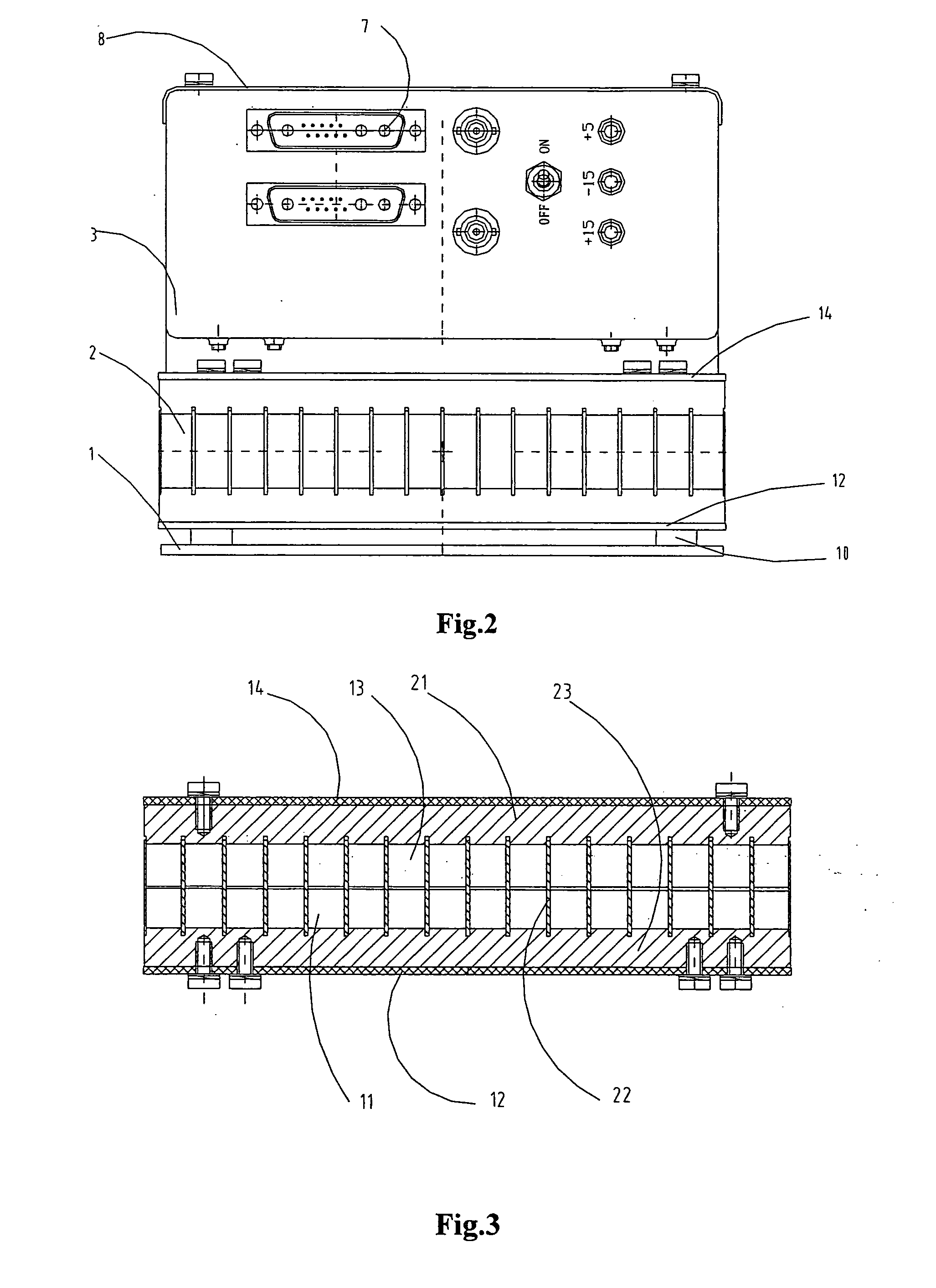

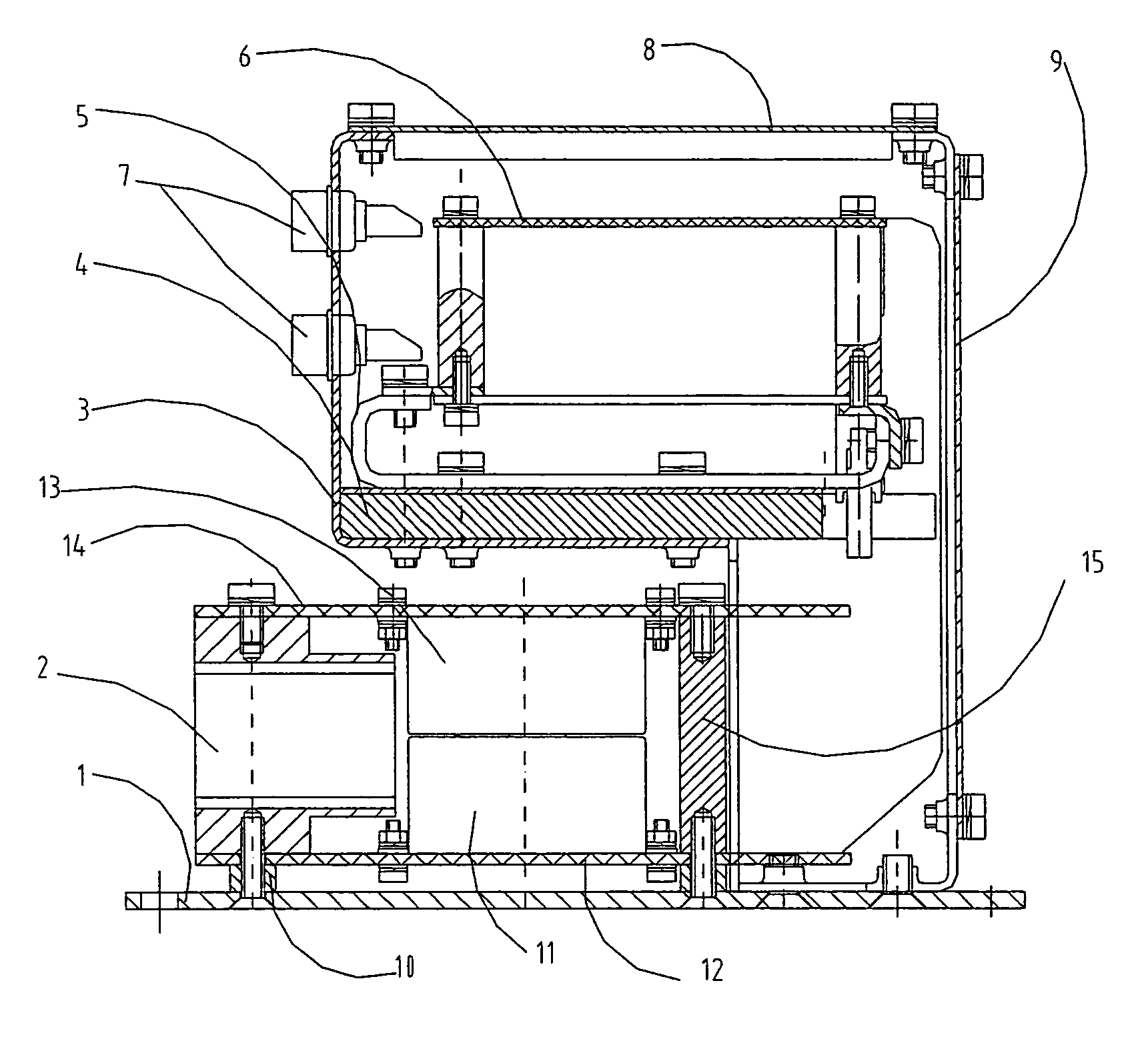

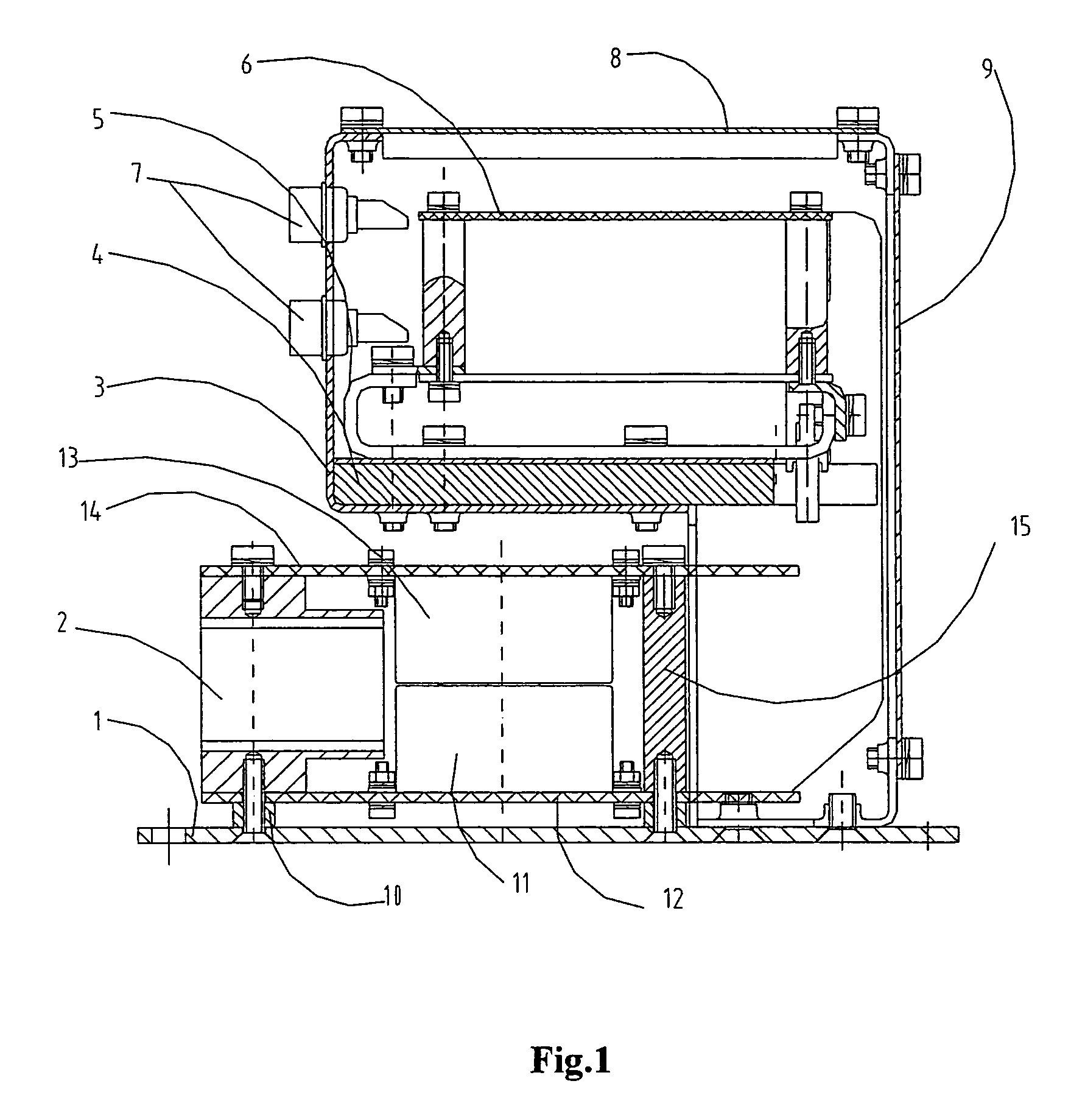

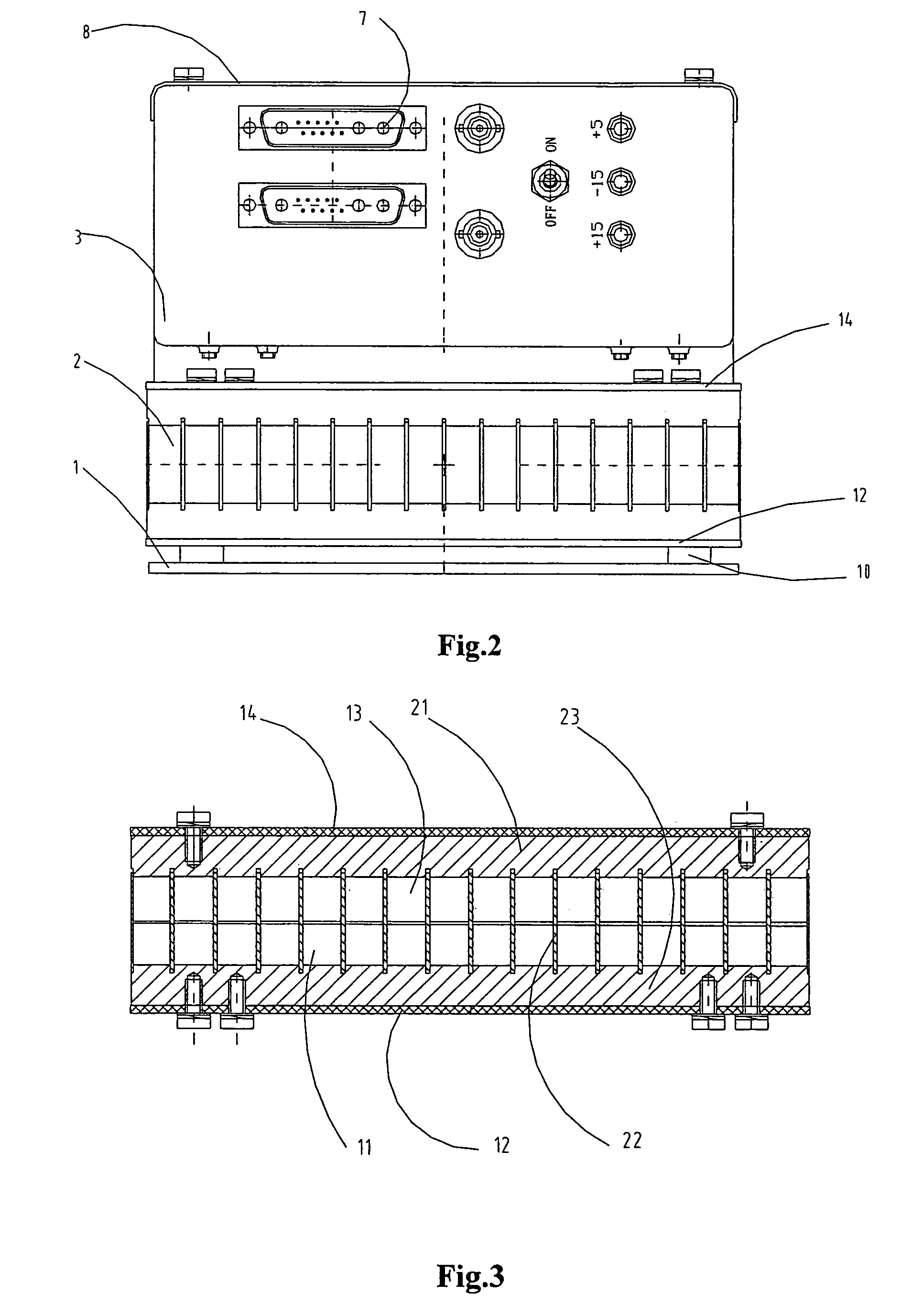

Solid state detector module structure and radiation imaging system

ActiveUS20070096030A1Convenient disassemblingExtend your lifeSolid-state devicesHandling using diaphragms/collimetersSolid state detectorRadiation imaging

The present invention discloses a solid state detector module structure, comprising: an upper support plate and a lower support plate provided opposing to each other, a collimator provided between the upper support plate and the lower support plate for collimating the incident rays; and solid state detector arrays provided between the upper support plate and the lower support plate at the rear side of the collimator in the transmitting direction of the rays, wherein the solid state detector arrays comprises an upper and lower rows, with the upper row of the solid state detector array fixed under the upper support plate, and the lower row thereof fixed on the lower support plate. The present invention further discloses a radiation imaging system having the same. The solid state detector module structure of present invention decreases the scattering of ray beams, increases the capabilities of scattering resistance and the definition of image and enhances inspection speed compared with prior art.

Owner:TSINGHUA UNIV +1

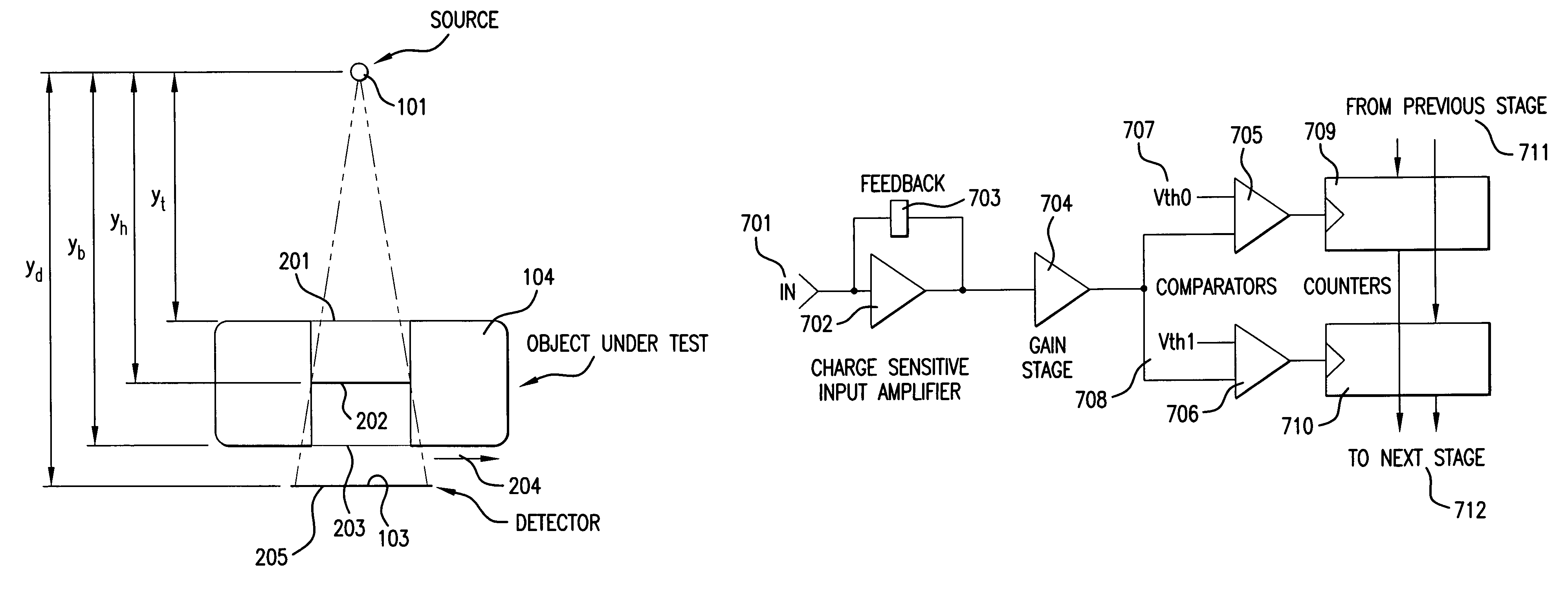

High Resolution Imaging System

InactiveUS20100116999A1Reduce doseIncrease contrastPrinted circuit assemblingSolid-state devicesLow noiseHigh resolution imaging

New sensors, pixel detectors and different embodiments of multi-channel integrated circuit are disclosed. The new high energy and spatial resolution sensors use solid state detectors. Each channel or pixel of the readout chip employs low noise preamplifier at its input followed by other circuitry. The different embodiments of the sensors, detectors and the integrated circuit are designed to produce high energy and / or spatial resolution two-dimensional and three-dimensional imaging for different applications. Some of these applications may require fast data acquisition, some others may need ultra high energy resolution, and a separate portion may require very high contrast. The embodiments described herein addresses these issues and also other issues that may be useful in two and three dimensional medical and industrial imaging. The applications of the new sensors, detectors and integrated circuits addresses a broad range of applications such as medical and industrial imaging, NDE and NDI, security, baggage scanning, astrophysics, nuclear physics and medicine.

Owner:NOVA R&D

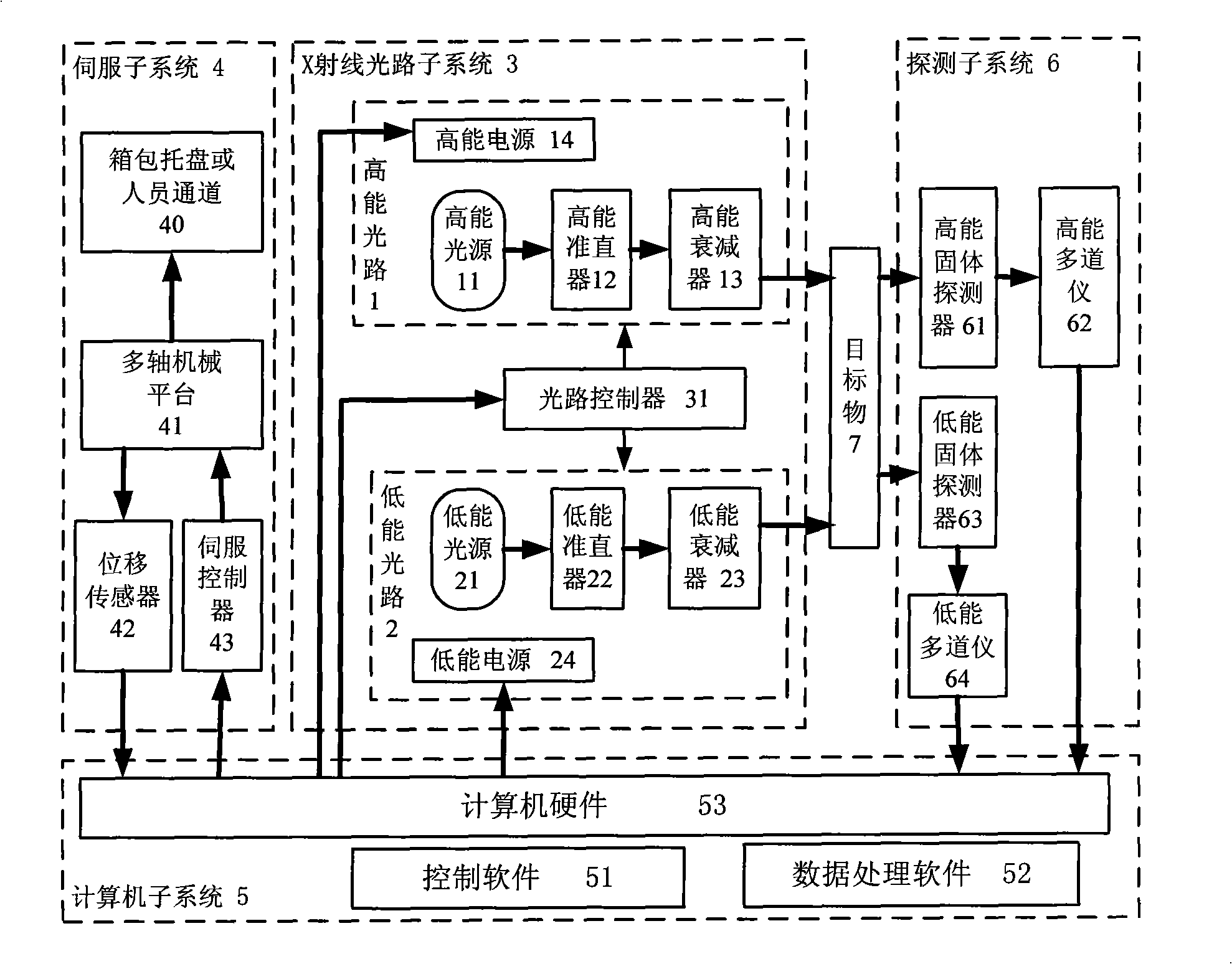

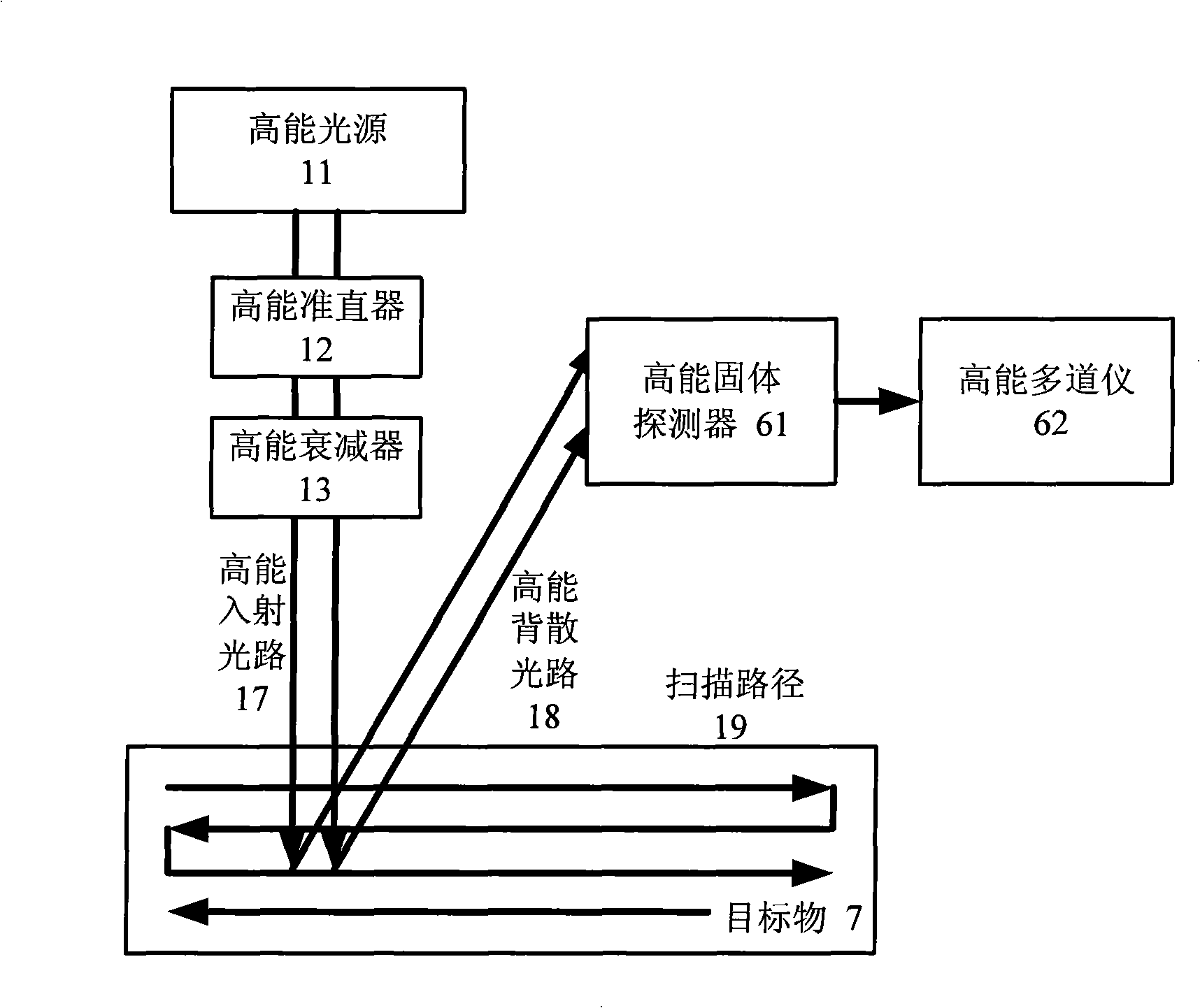

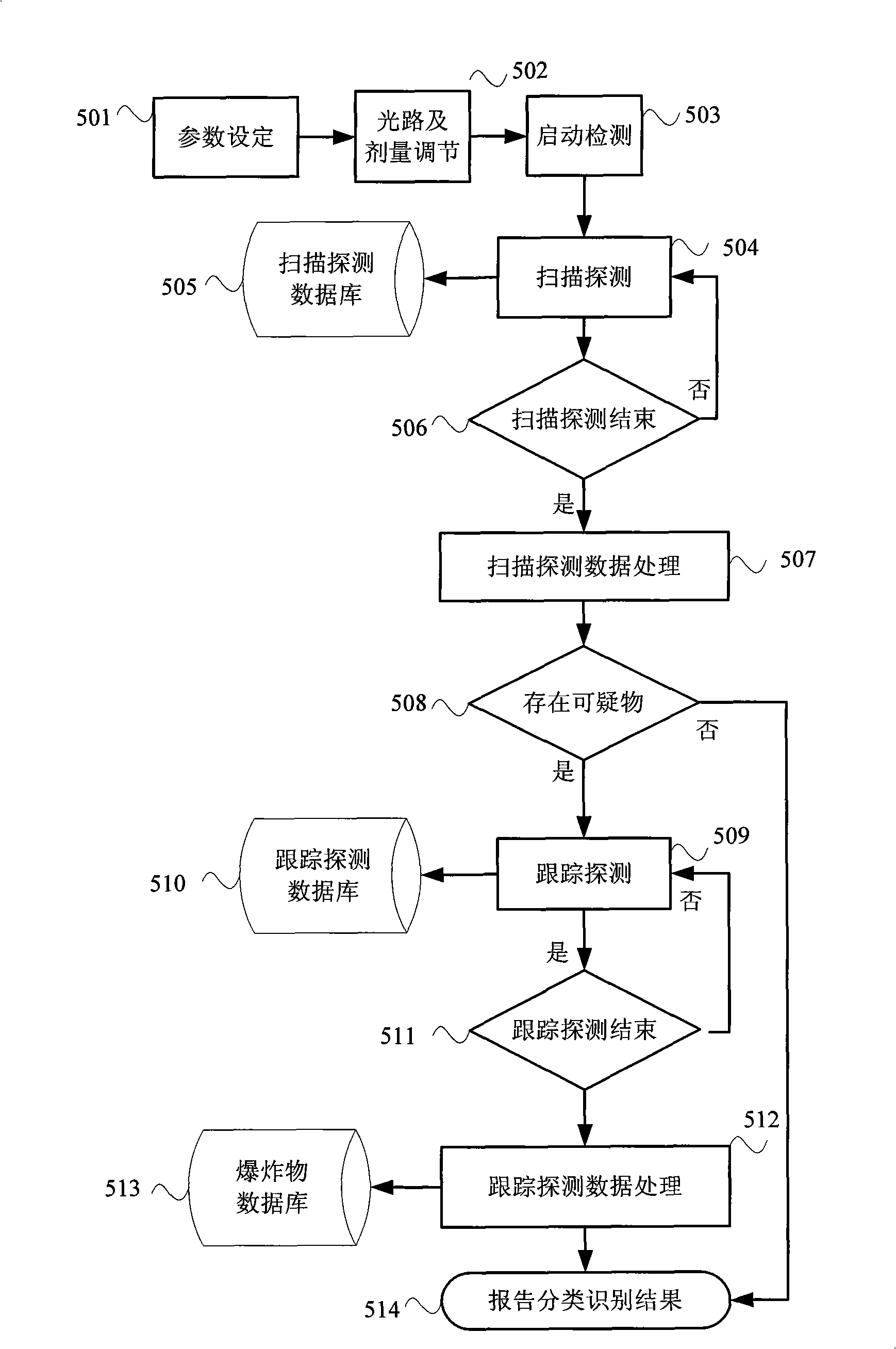

Explosive substance testing system apparatus and testing method thereof

InactiveCN101303317AHigh precisionImprove reliabilityMaterial analysis using wave/particle radiationSpecial data processing applicationsHuman bodyX-ray

The invention discloses an explosive substance testing system apparatus and testing method thereof. The apparatus includes an X-ray light path subsystem, a detecting subsystem, a servo subsystem and a computer subsystem, wherein the light path subsystem includes a 75Kev and a 150Kev energy segment white light sources; the light path subsystem and the detecting subsystem are totally mounted on a multiple shaft mechanical platform, at different angle positions at the same side relative to the object, so as to configure a Compton backscattering geometric light path. The testing method includes a computer software control method and a data processing method, including: adopting a control method integrating the scanning detecting and tracking detecting, acquiring the density information and Compton scattering energy difference pair information data of the object by a solid state detector to execute data-handling and characteristic matching, obtaining the density and effective atomic number information of the object, and determining whether the object is the explosive substance and the affiliated species by the pattern recognition, thereby implementing the quick, safe and nondestructive testing, which is suitable for flow ability test of case or human body carrying explosive substance.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

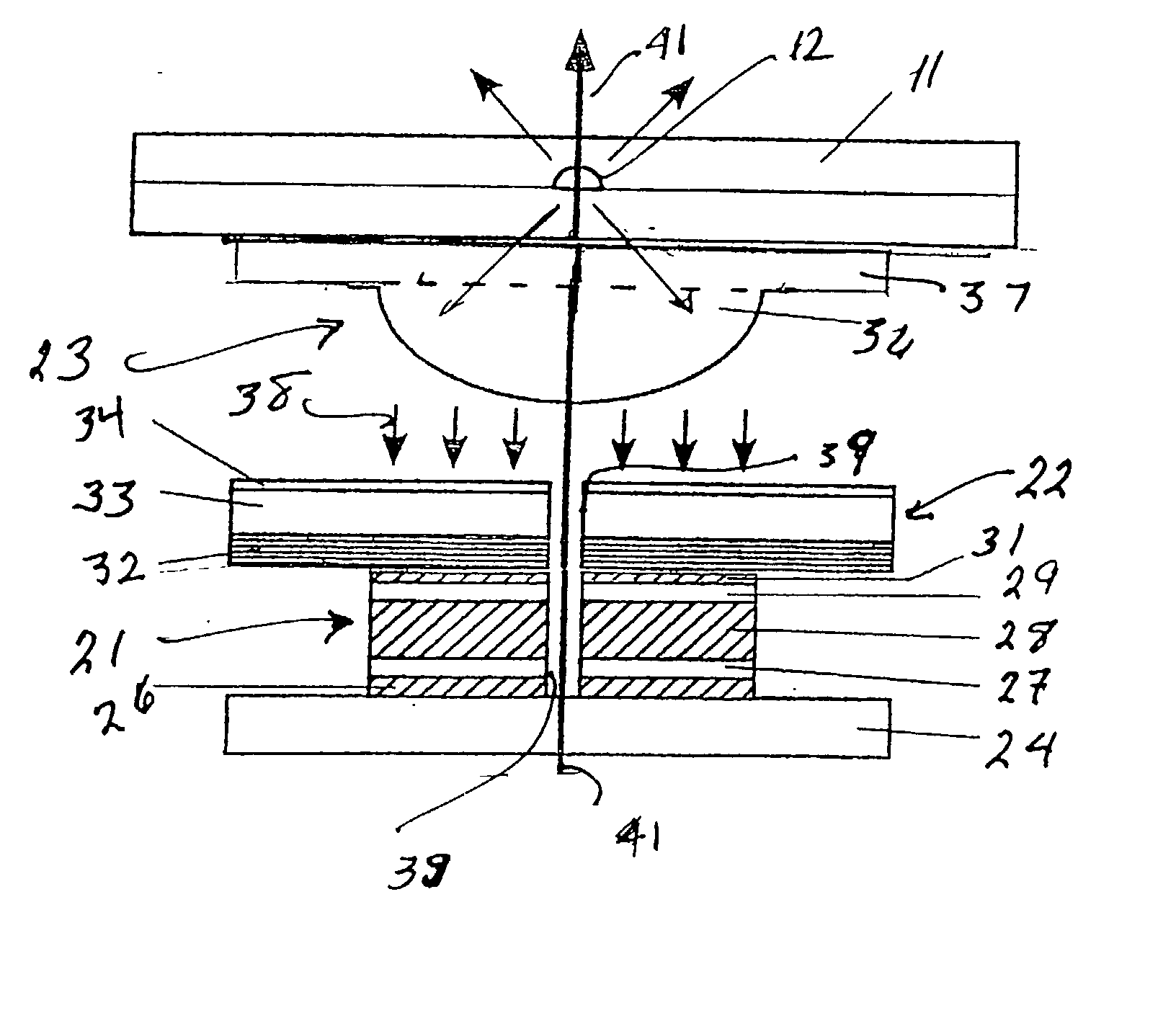

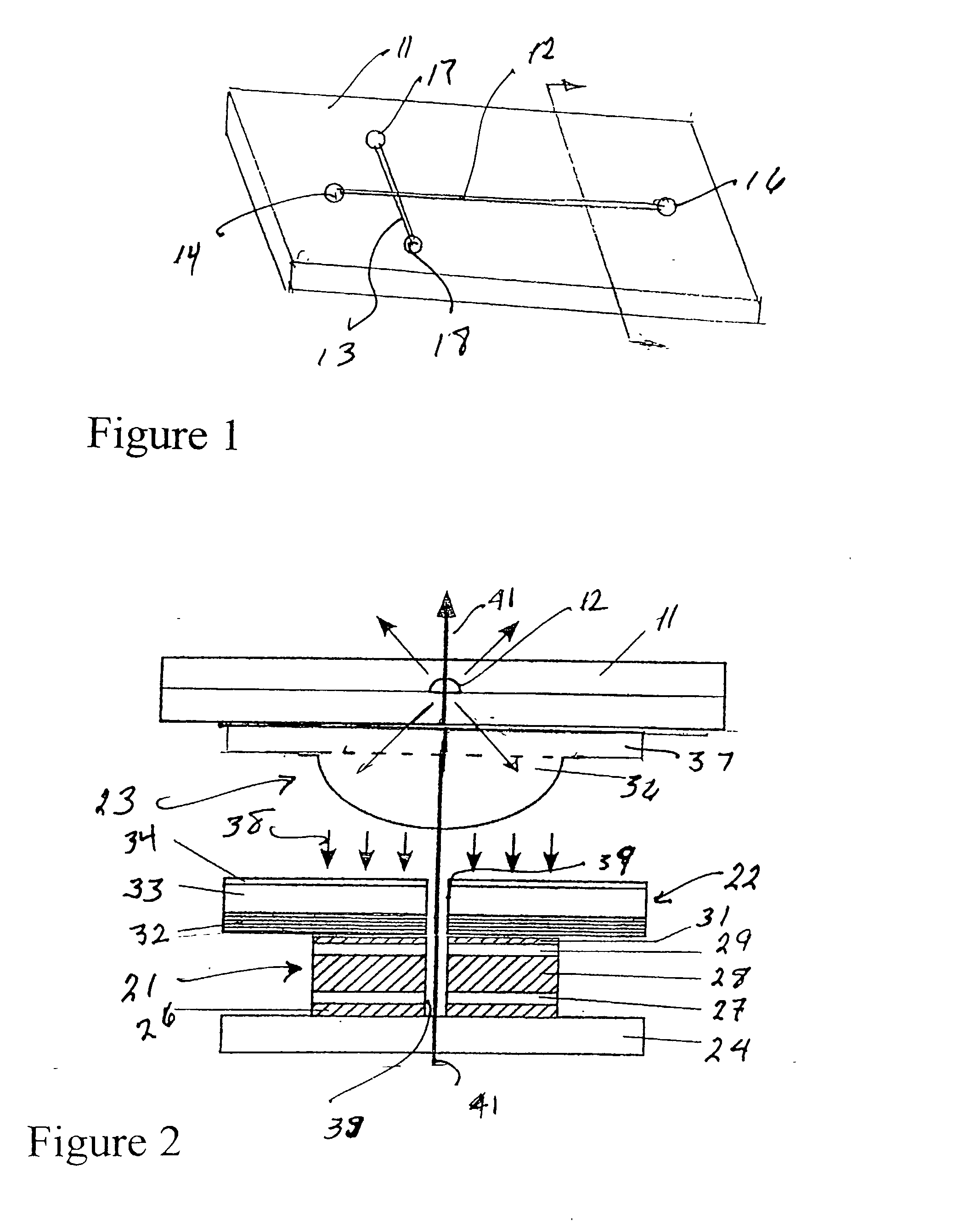

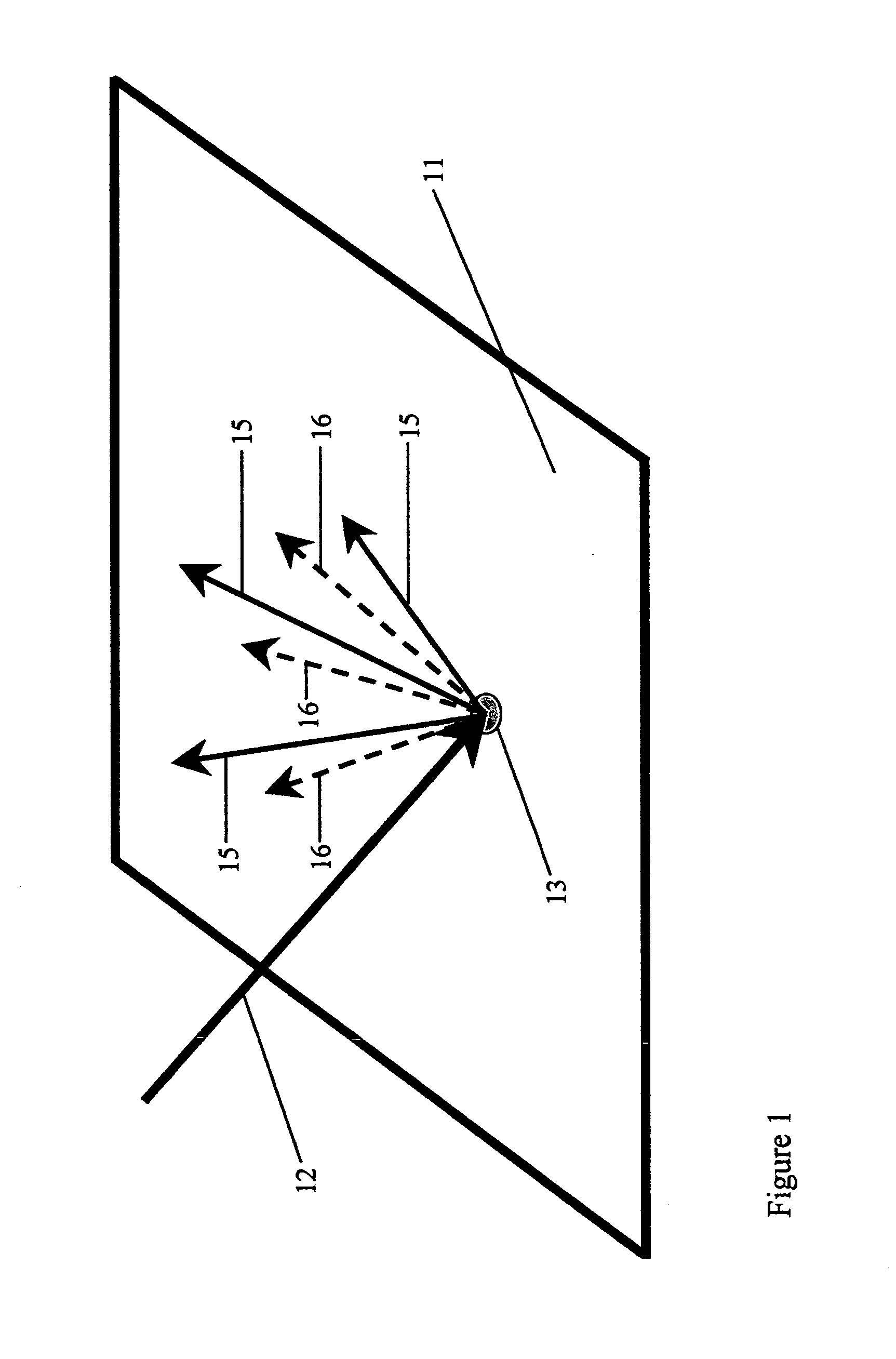

Position sensitive solid state detector with internal gain

Owner:SCI WARES +1

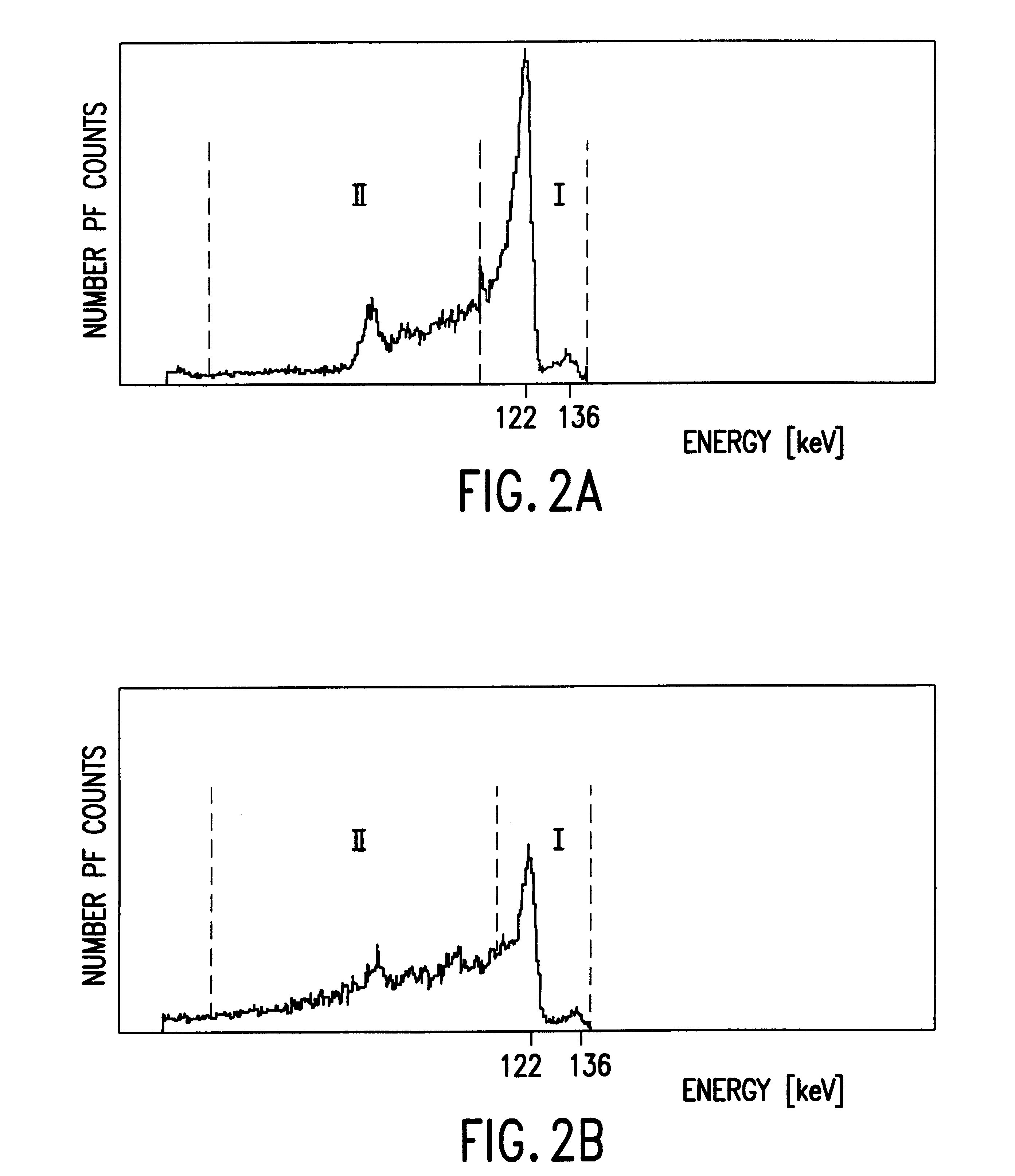

Room temperature solid state gamma or X-ray detectors

InactiveUS6331705B1Reduce in quantityWeaken energySolid-state devicesMaterial analysis by optical meansSolid state detectorX-ray

The invention provides a method for detecting gamma or X-ray radiation with a room temperature solid state detector, which comprises the selection of the detector's electron trapping parameter (muτ)e and / or the detector voltage V so as to tune the electron trapping to optimally compensate for the incomplete charge collection.

Owner:STATE OF ISRAEL ATOMIC ENERGY COMMISSION SOREQ NUCLEAR RES CENT THE

High data rate smart sensor

InactiveUS20030029989A1Overcome problemsCathode ray tubes/electron beam tubesSolid-state devicesAnalog image processingImaging data

Owner:CONTINENTAL AUTONOMOUS MOBILITY US LLC

Radiation image information capturing apparatus and method of detecting temperature of amplifier thereof

ActiveUS20070221859A1Effective controlInhibit transferVolume/mass flow measurementSolid-state devicesAudio power amplifierSolid state detector

Amplifiers are mounted on flexible boards connected to a solid-state detector. A first temperature adjustment member is disposed near one of the surfaces of the amplifiers and the flexible boards, and a second temperature adjustment member is disposed near the other surface of the flexible boards. The first temperature adjustment member adjusts the temperature of the amplifiers themselves, and prevents heat from being transferred from the one of the surfaces of the flexible boards to the solid-state detector. The second temperature adjustment member prevents heat from being transferred from the other surface of the flexible boards to the solid-state detector.

Owner:FUJIFILM CORP

Raman instrumentation

InactiveUS20070279627A1Reduce power consumptionEasy to handleRadiation pyrometryRaman scatteringSolid state detectorNear infrared laser

A portable Raman spectroscopy instrument capable of discriminating between chemicals in the solid, liquid and vapor states is described. The instrument is in the shape of a gun and uses a solid state detector and an NIR laser. It relies on gating techniques to minimize weight and lower energy needs.

Owner:INTEVAC

Apparatus and method for fluorescent imaging

InactiveUS20090266999A1Economical and easy to operateSimple electronic meansOptical radiation measurementRadiation measurementExcitation beamSolid state detector

An apparatus and method for fluorescent imaging. The apparatus includes a light-generating means for generating at least one modulated fluorescence excitation beam, a light retransmitting means for retransmitting the fluorescence excitation beam onto an area that is to be examined, a light-imaging means for imaging a fluorescent beam from the area to be examined onto a first image sensor, a control and evaluation means for controlling the light-generating means to power the first image sensor and for evaluating the data supplied by the first image sensor to generate a fluorescent image, where the fluorescent excitation beam may be continuously modulated, the first image sensor is a solid state detector that may be powered phase-sensitively, and the data supplied by the first image sensor contain pixel by pixel phase information on the fluorescent beam.

Owner:STORZ ENDOSKOP PROD GMBH

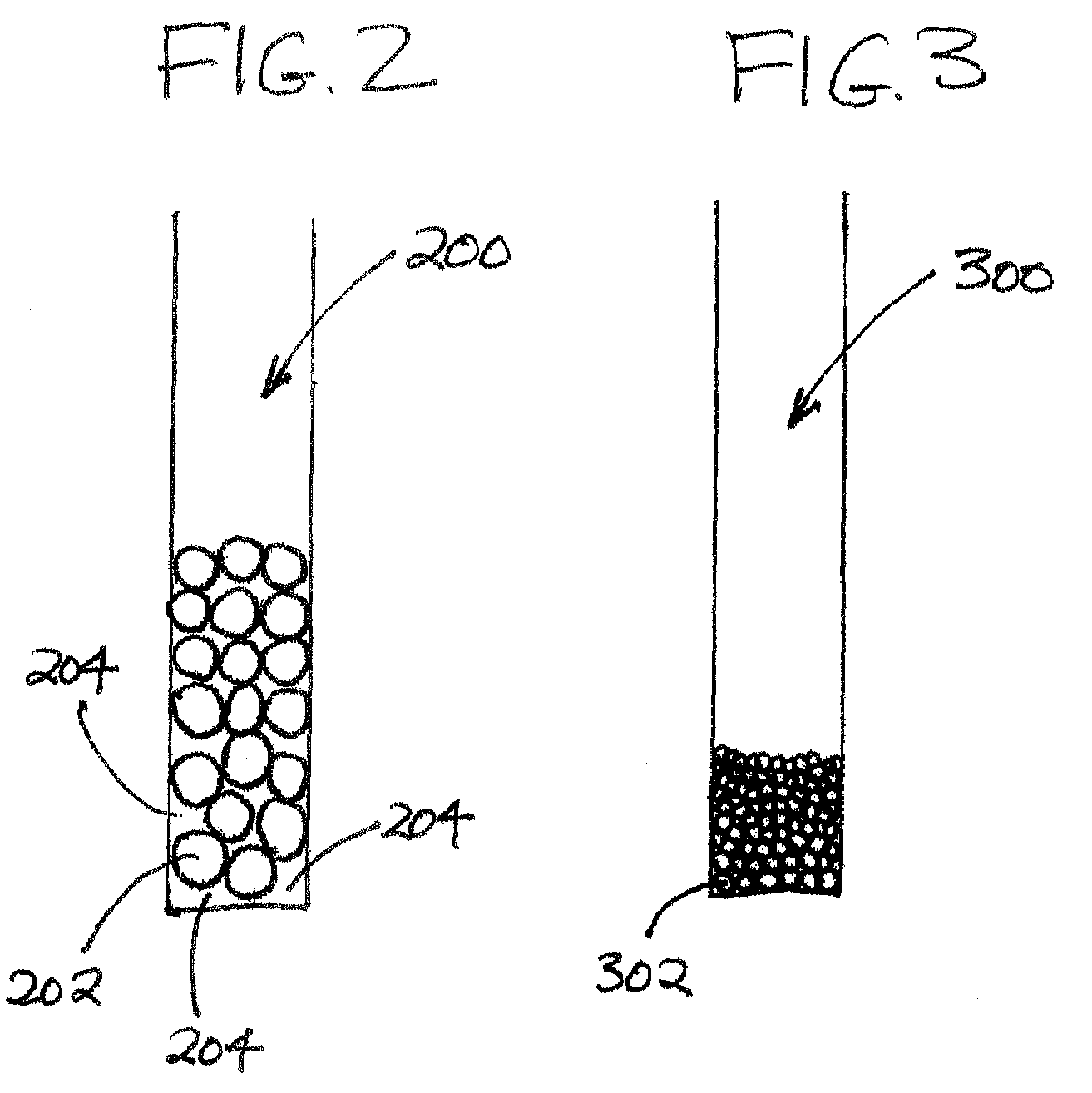

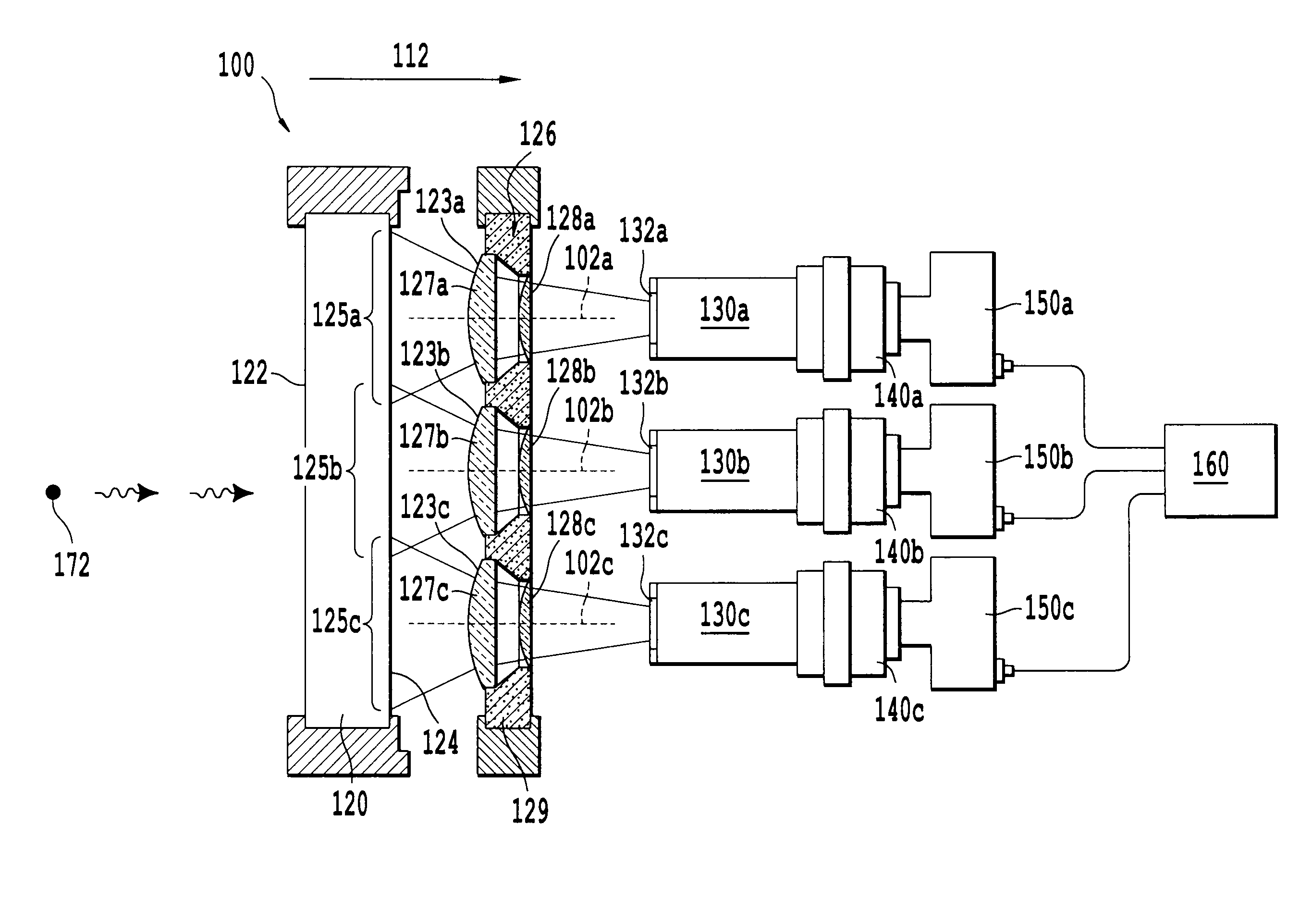

Radiation detection system using solid-state detector devices

InactiveUS7592601B2Easy to detectImprove viabilityMeasurement with semiconductor devicesMeasurement with scintillation detectorsSolid state detectorEngineering

A neutron detection device (100) includes a semiconductor substrate including a gallium arsenide substrate region (102) having a back surface, and a high purity gallium arsenide active region (104) having a front surface. A back contact layer (118) is disposed on the back surface for providing a first voltage potential at the back surface. A plurality of elongated tube cavities extend from a plurality of respective openings in the front surface into the high purity gallium arsenide active region (104) and almost through, but not totally through, the high purity gallium arsenide active region (104). A front contact layer is disposed on the front surface for providing a second voltage potential at the front surface. Neutron reactive material, e.g., pulverized Boron-10 powder, fills the plurality of elongated tube cavities to a high packing density. A radiation detection system and a method of fabricating the neutron detection device are also disclosed.

Owner:INNOVATIVE AMERICAN TECH

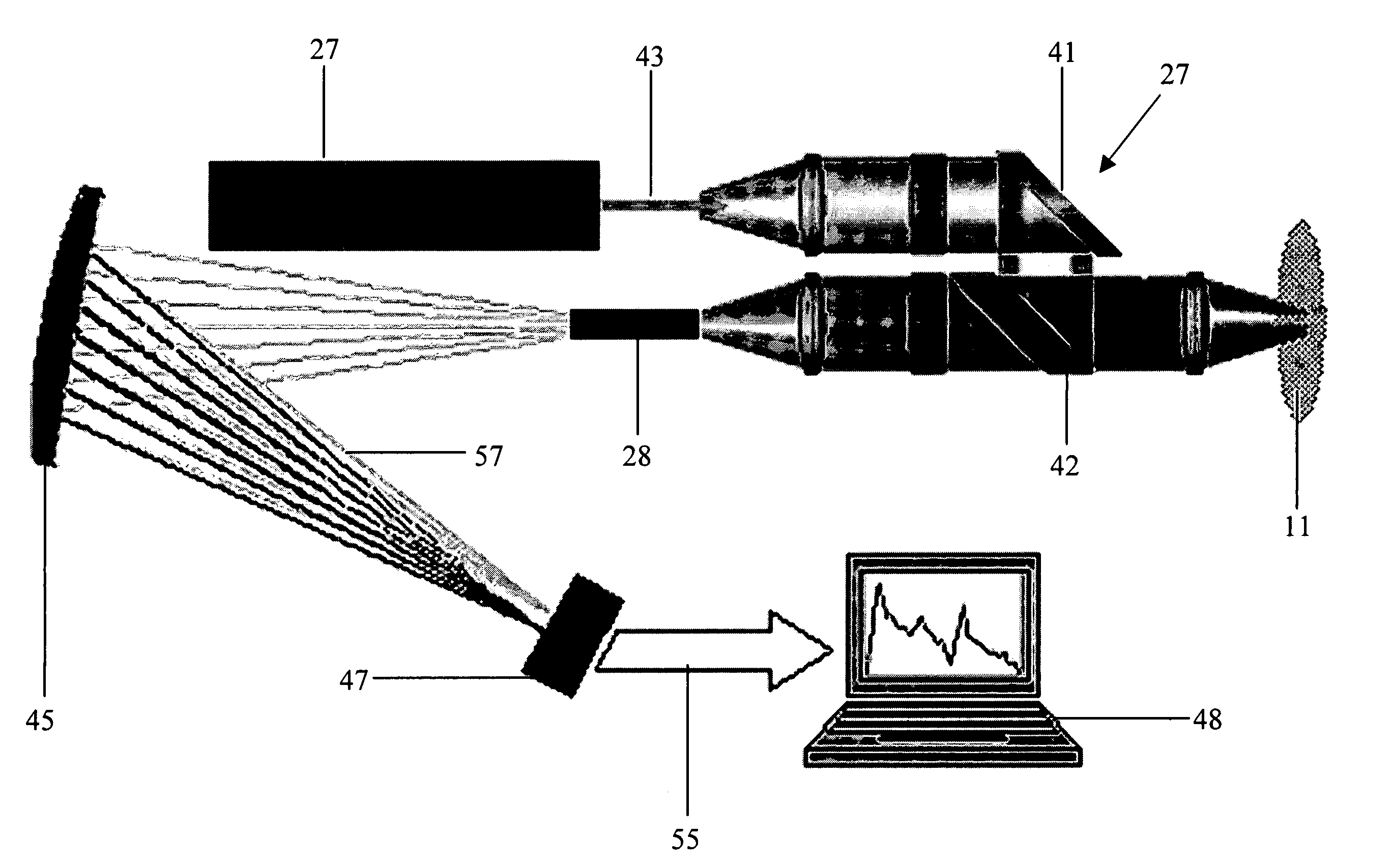

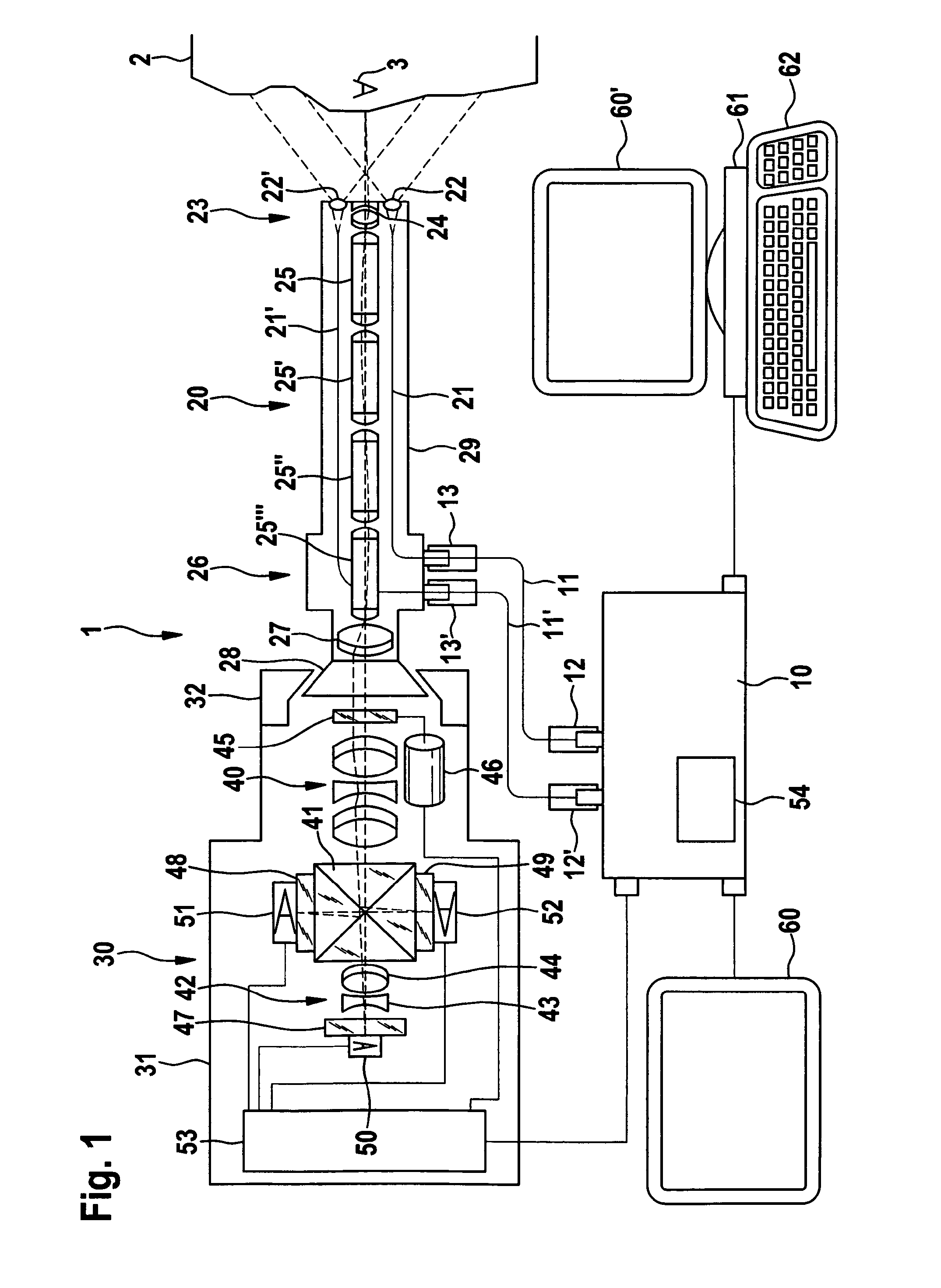

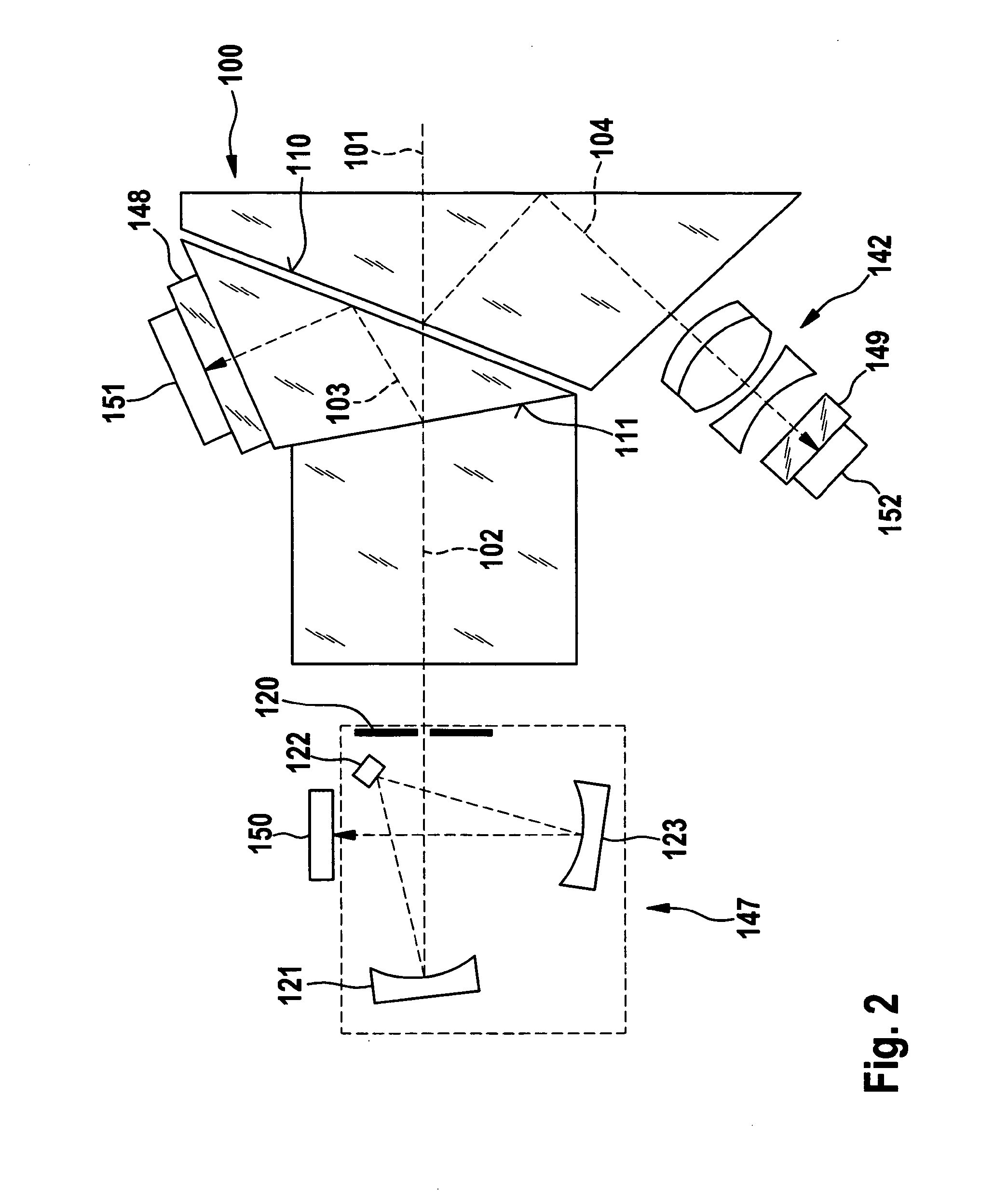

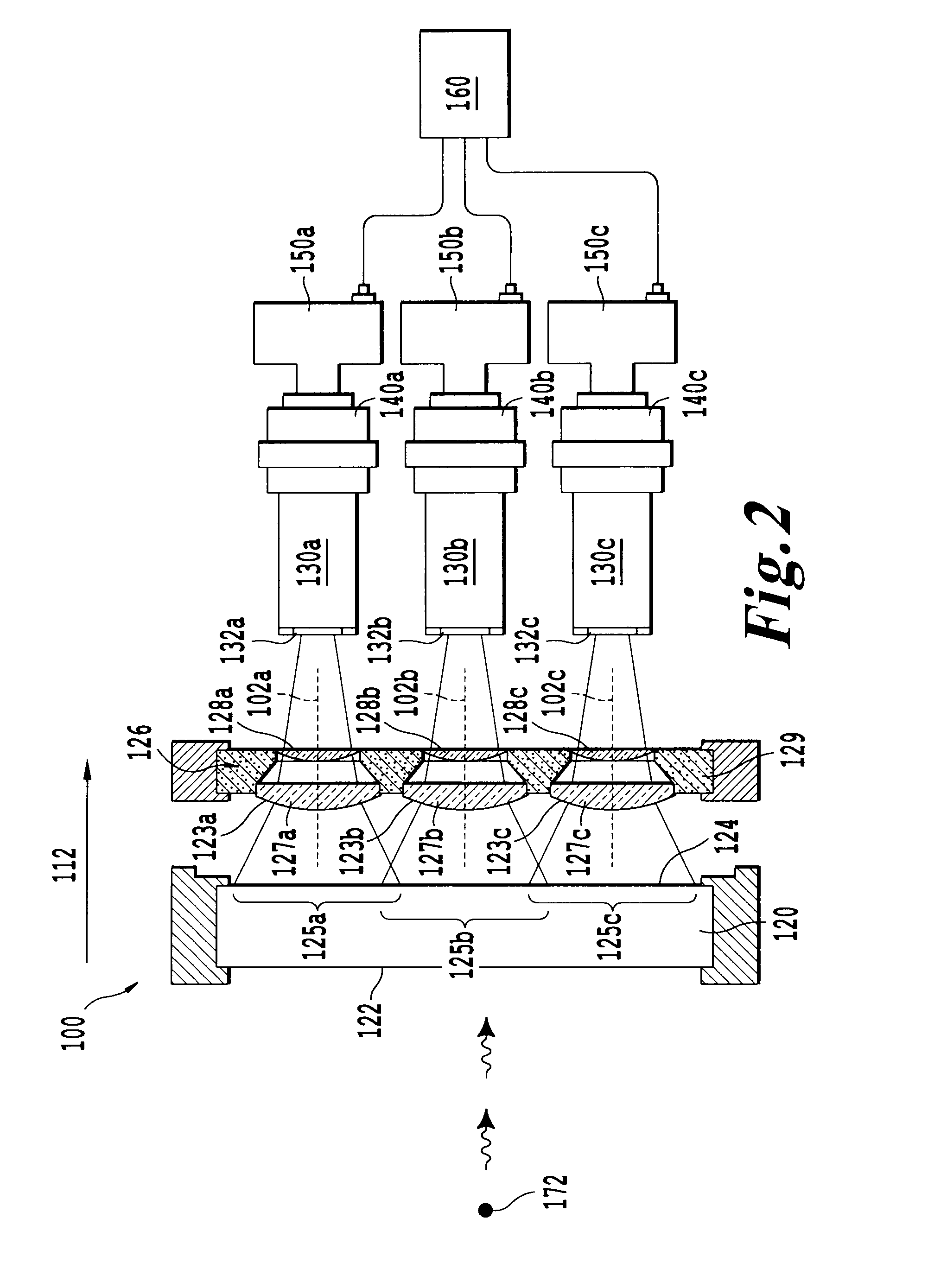

X-ray detector including scintillator, a lens array, and an image intensifier

ActiveUS20100140487A1Material analysis by optical meansTomographyOptical radiationSolid state detector

An X-ray detection device including a scintillator configured to convert gamma rays or X-rays into optical radiation, an optical image intensifier configured to intensify the optical radiation to generate intensified optical radiation, an optical coupling system configured to guide the intensified optical radiation, and a solid state detector configured to detect the intensified optical radiation to generate an interaction image representing an X-ray energy emission and to perform photon counting based on data of the interaction image.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

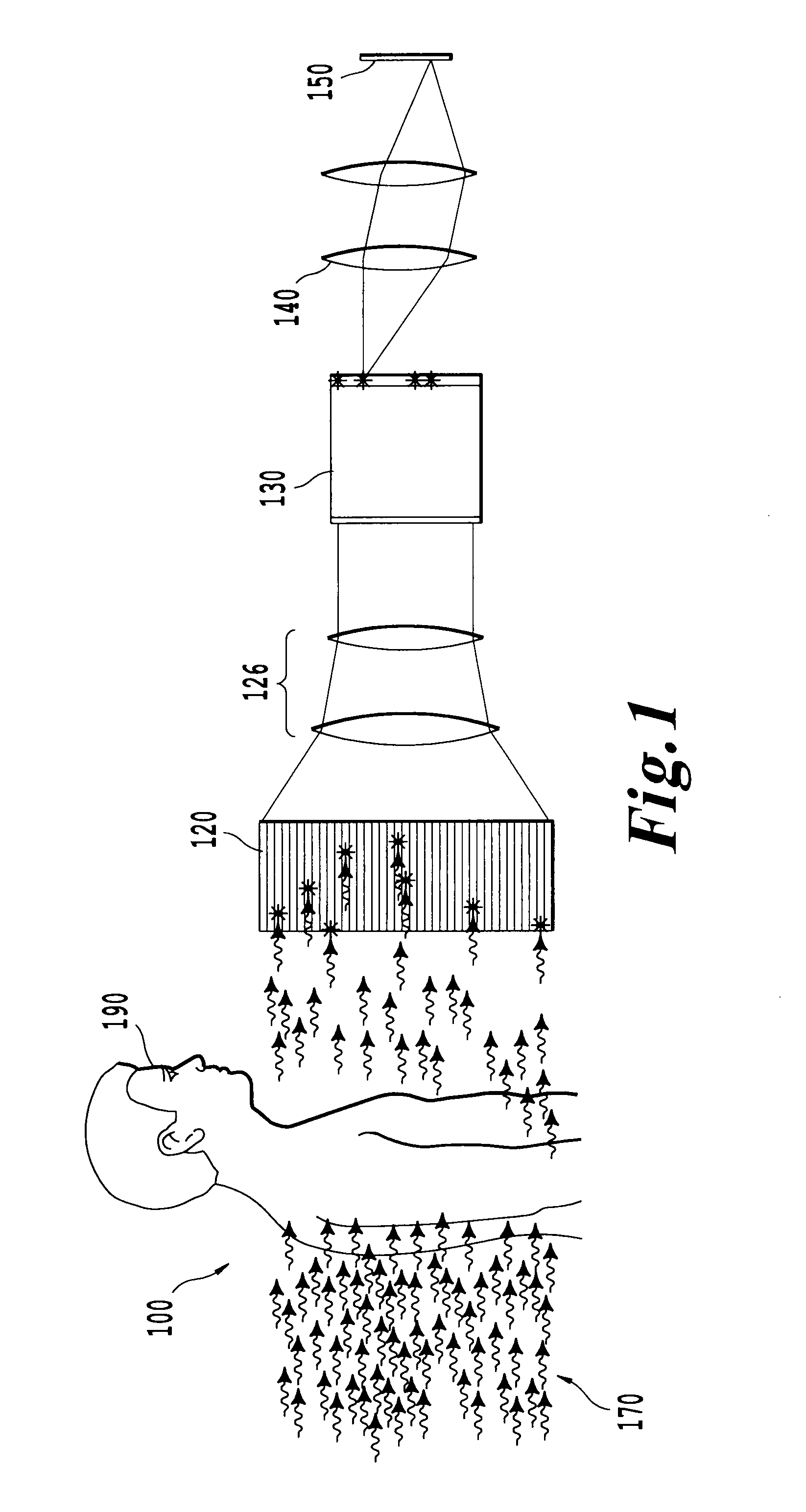

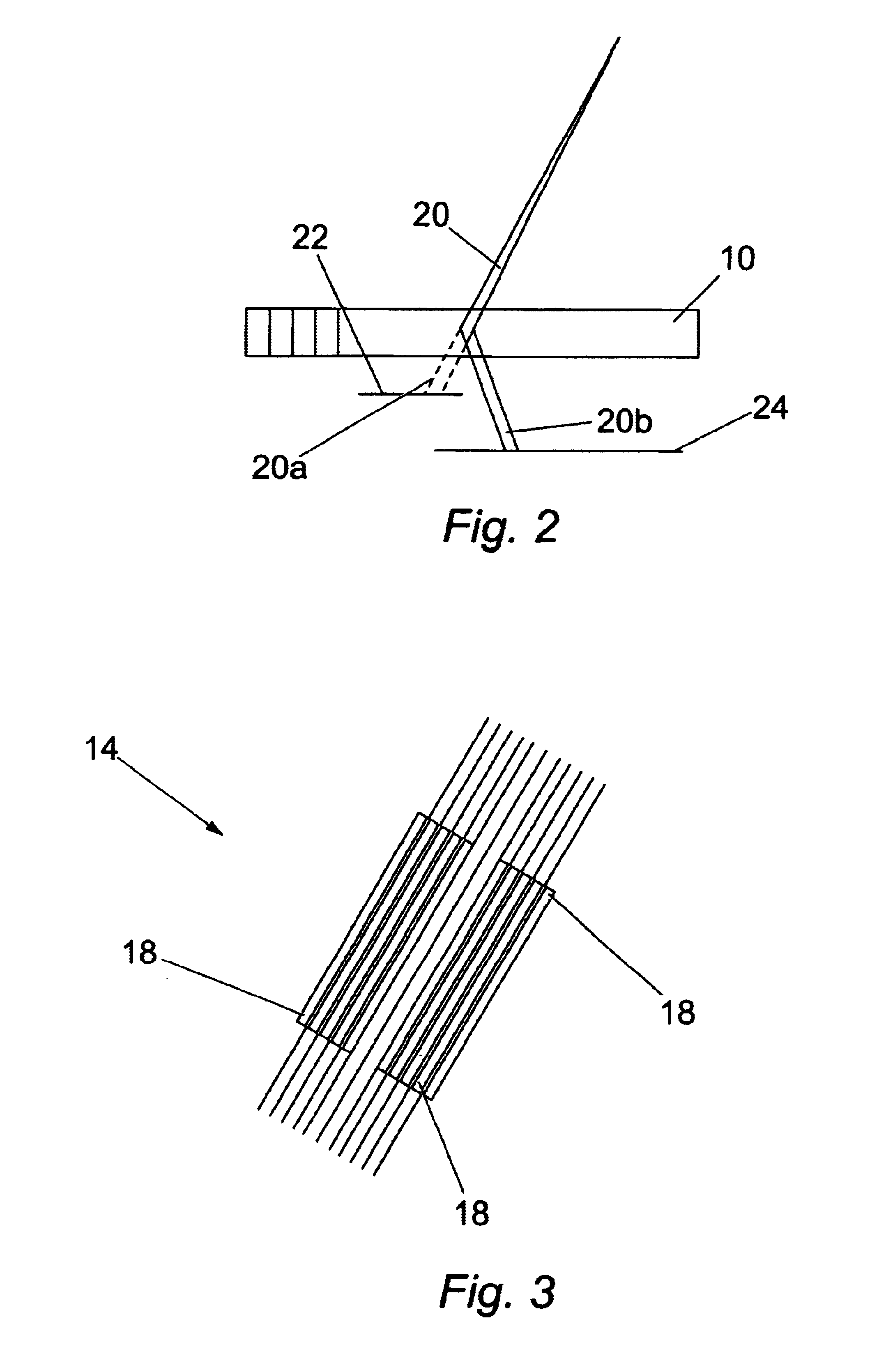

Gamma camera including a scintillator and an image intensifier

InactiveUS20090050811A1Material analysis using wave/particle radiationRadiation/particle handlingOptical radiationSoft x ray

A gamma-ray or X-ray detection device including a scintillator configured to convert gamma rays or X-rays into optical radiation, an optical image intensifier configured to intensify the optical radiation to generate intensified optical radiation, an optical coupling system configured to guide the intensified optical radiation, and a solid state detector configured to detect the intensified optical radiation to generate an interaction image representing a gamma-ray or X-ray energy emission.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

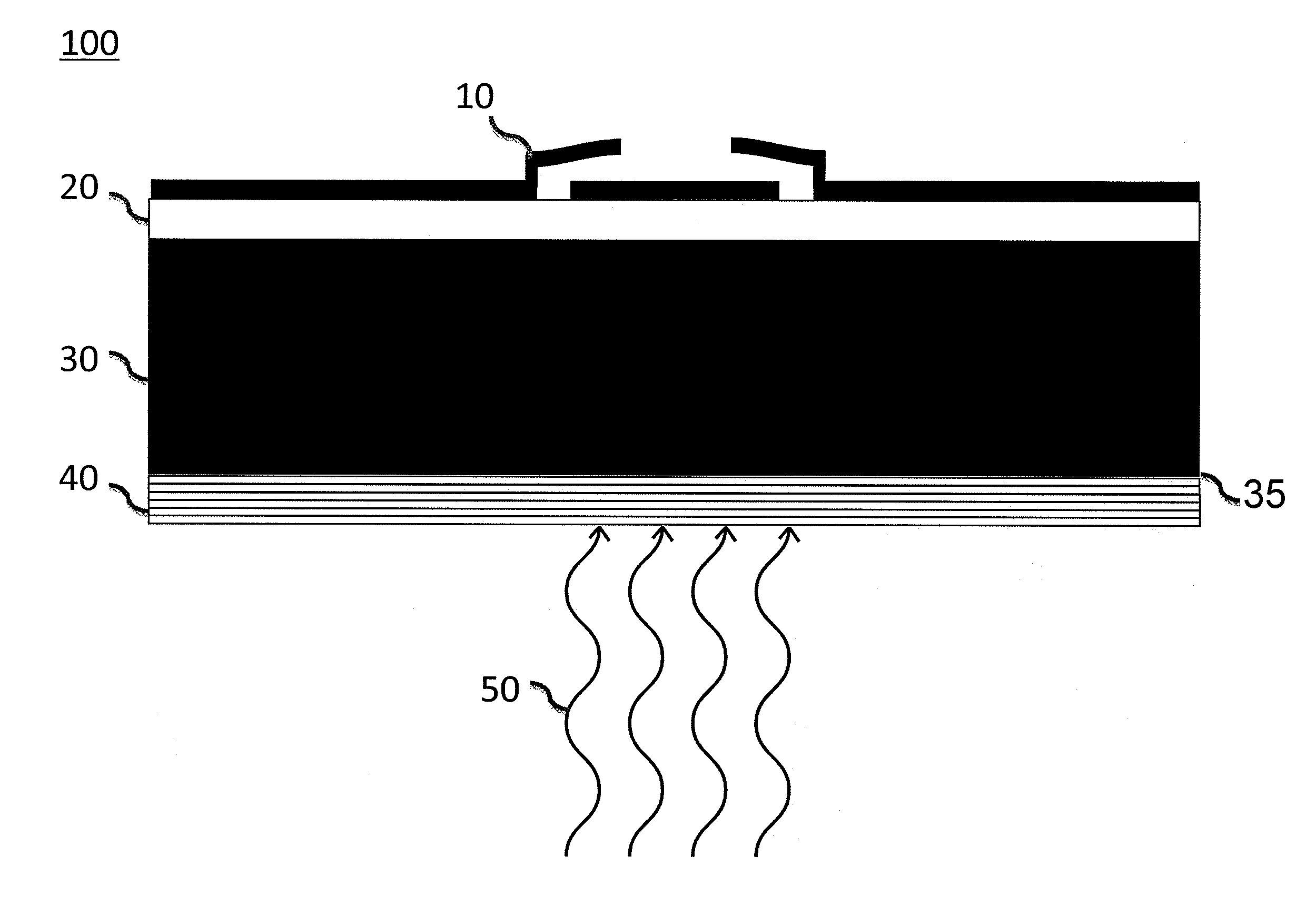

Low-voltage, solid-state, ionizing-radiation detector

InactiveUS20060033029A1Low working voltageIncreased manufacturing flexibilitySolid-state devicesMaterial analysis by optical meansLow voltageHigh pressure

A stratified, solid-state detector for ionizing radiation, is provided, wherein an operating bias is applied in parallel to all the strata. Since the bias required for accelerating electrons away from holes in a solid-state material is generally a function of material thickness, a stack of thin solid-state-material layers, connected in parallel, will operate at only a fraction of the bias required for a single, thick layer of solid-state-material of an equivalent thickness. Thus, stratification allows for reduced operating voltage and improved manufacturing flexibility. Additionally, a high-voltage power supply need not be used, thus increasing the safety of the detector. Stratification may further provide information on incident-radiation energy, based on depth penetration into the detector, wherein the layers may operate as “depth pixels.” Generally, the higher the incident radiation energy, the greater the probability for deep penetration into the solid state material. The stratified, solid-state detector may be designed as a stack of relatively thin solid-state-material layers, each with dedicated electrical contacts, and electrical insulation between layers. Alternatively, the stratified detector may be designed as a stack of relatively thin solid-state-material layers, with thin electrode layers, alternating between positive and negative senses, between them. Alternatively, the stratified detector may be designed as a stack of relatively thin solid-state-material layers, with thin electrode strips between them, wherein the electrode strips form a weave: at one layer the electrode strips are positive, running in a first direction, and at another, the electrode strips are negative, and running in a direction orthogonal to the positive strips. In effect, the weave electrode structure forms a pixel-like structure from single-pixel solid-state-material layers. The incident radiation may be orthogonal to or parallel with the stack of solid-state-material layers.

Owner:V TARGET TECH

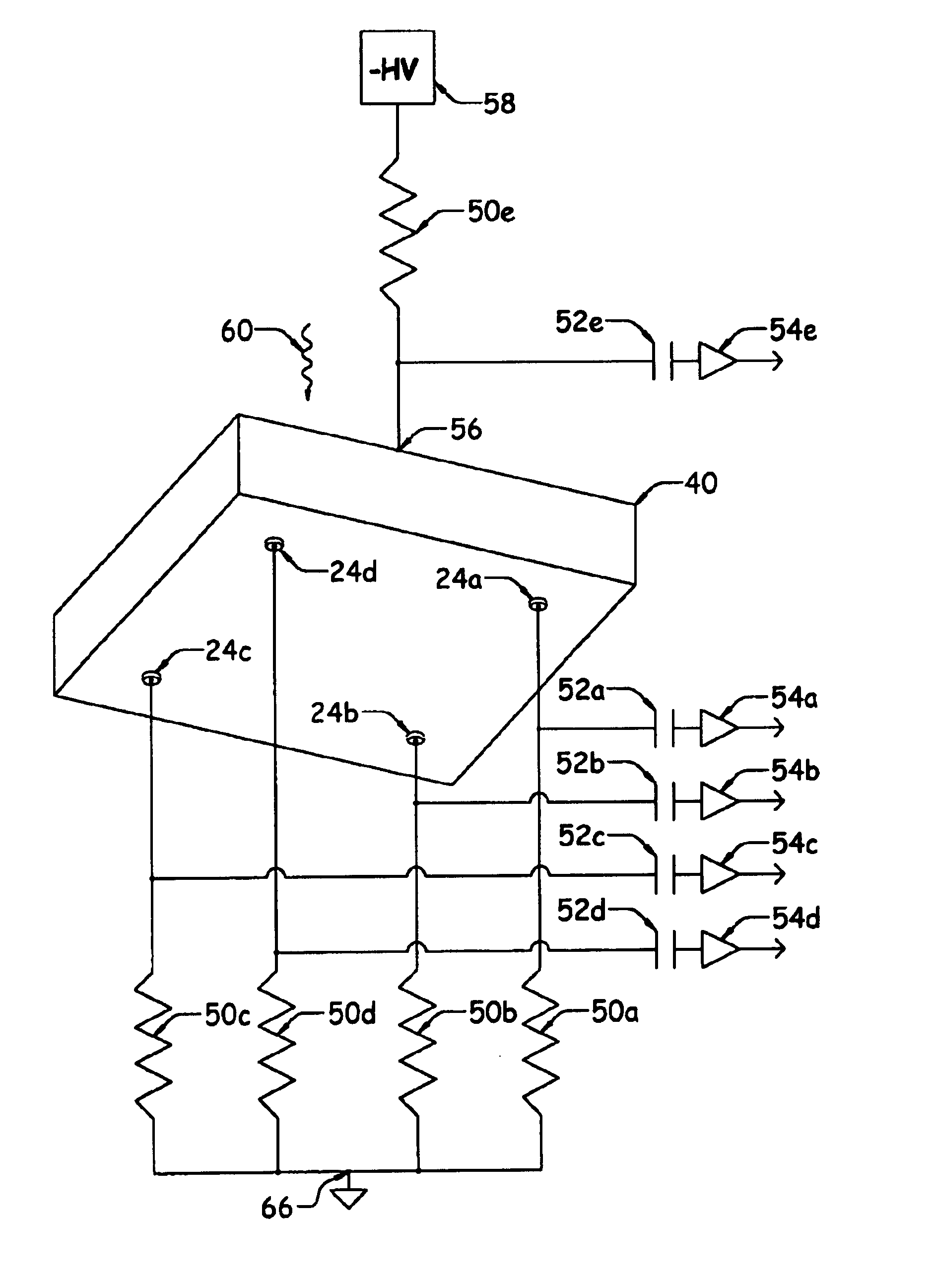

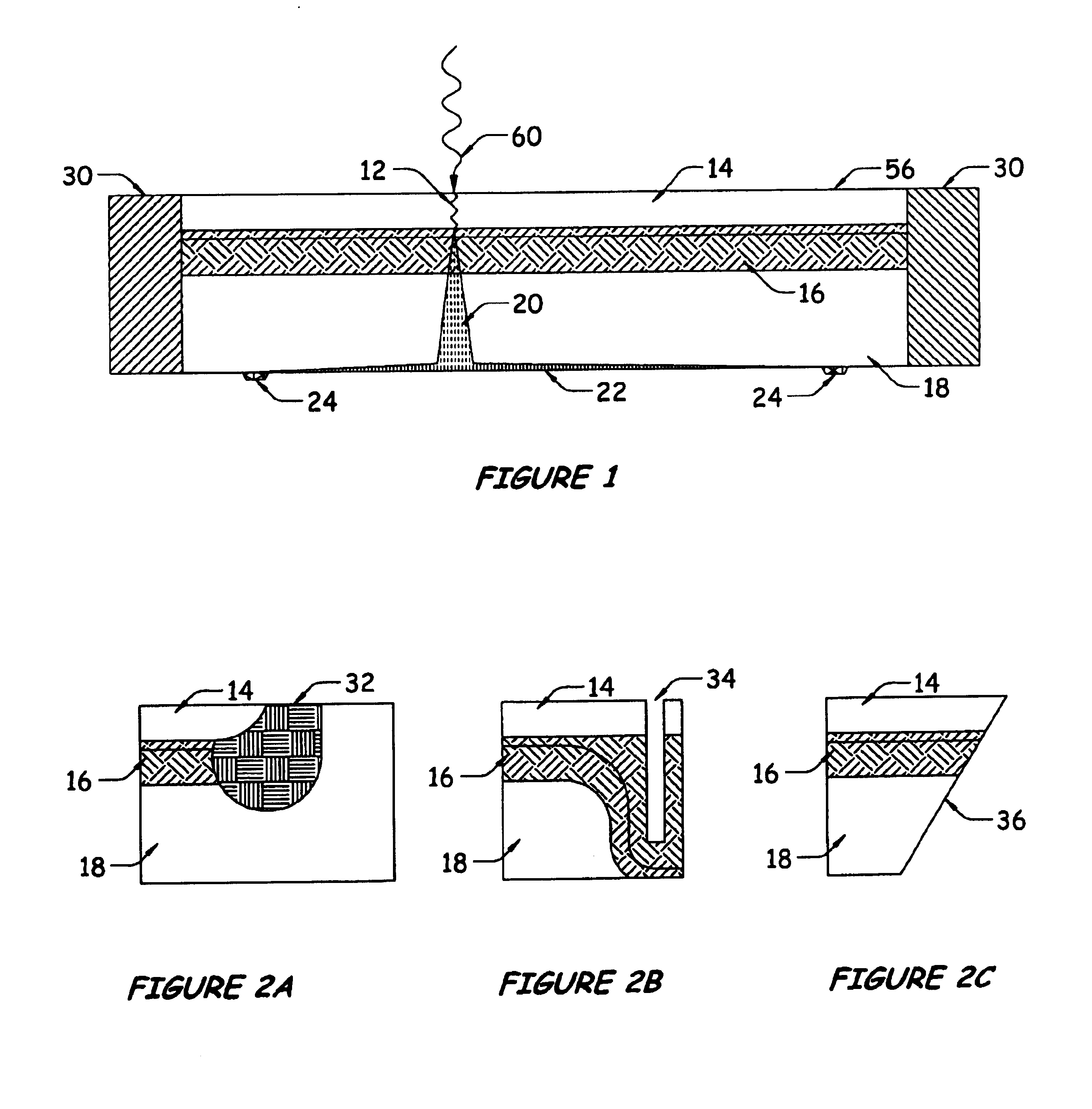

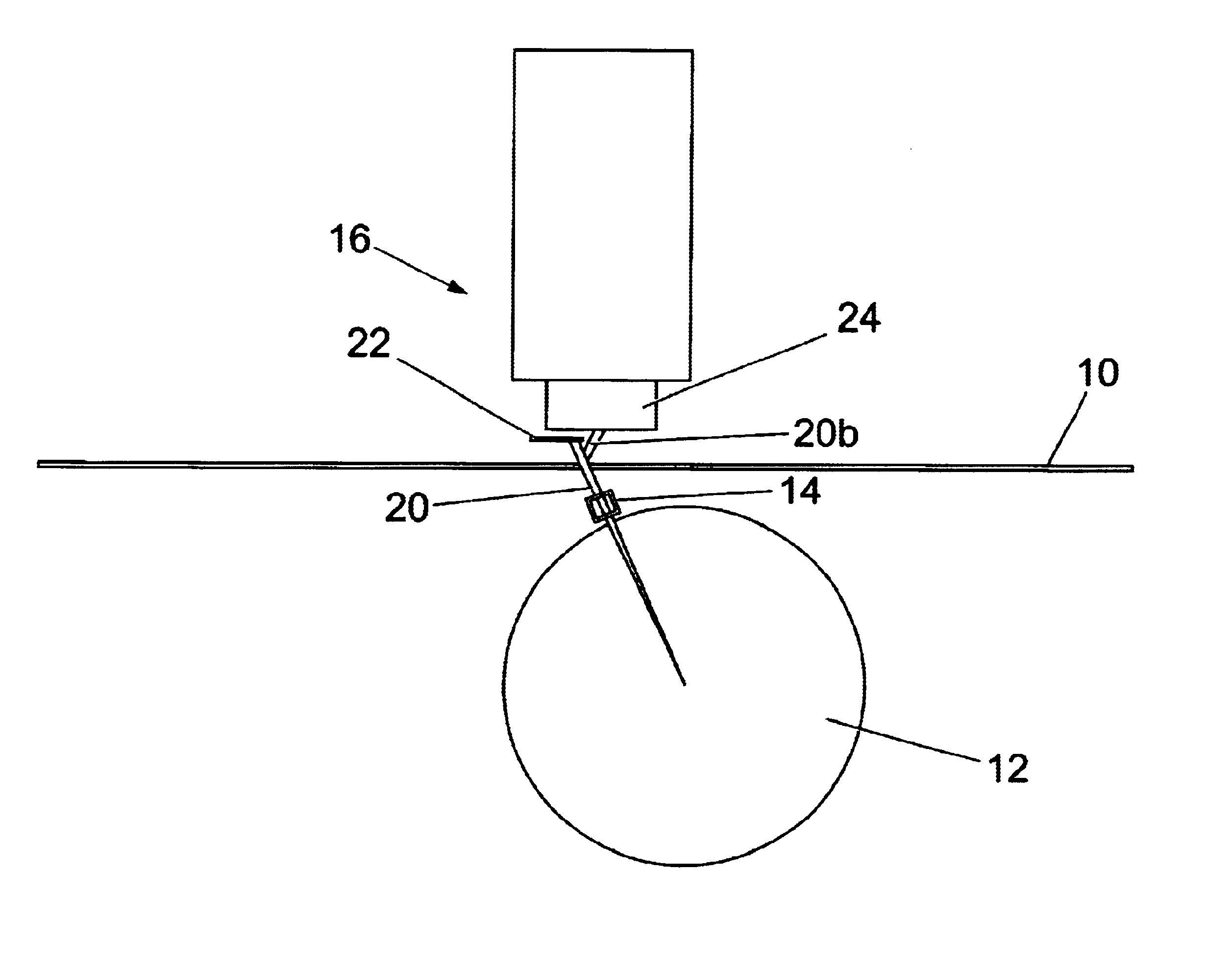

Position sensitive solid state detector with internal gain

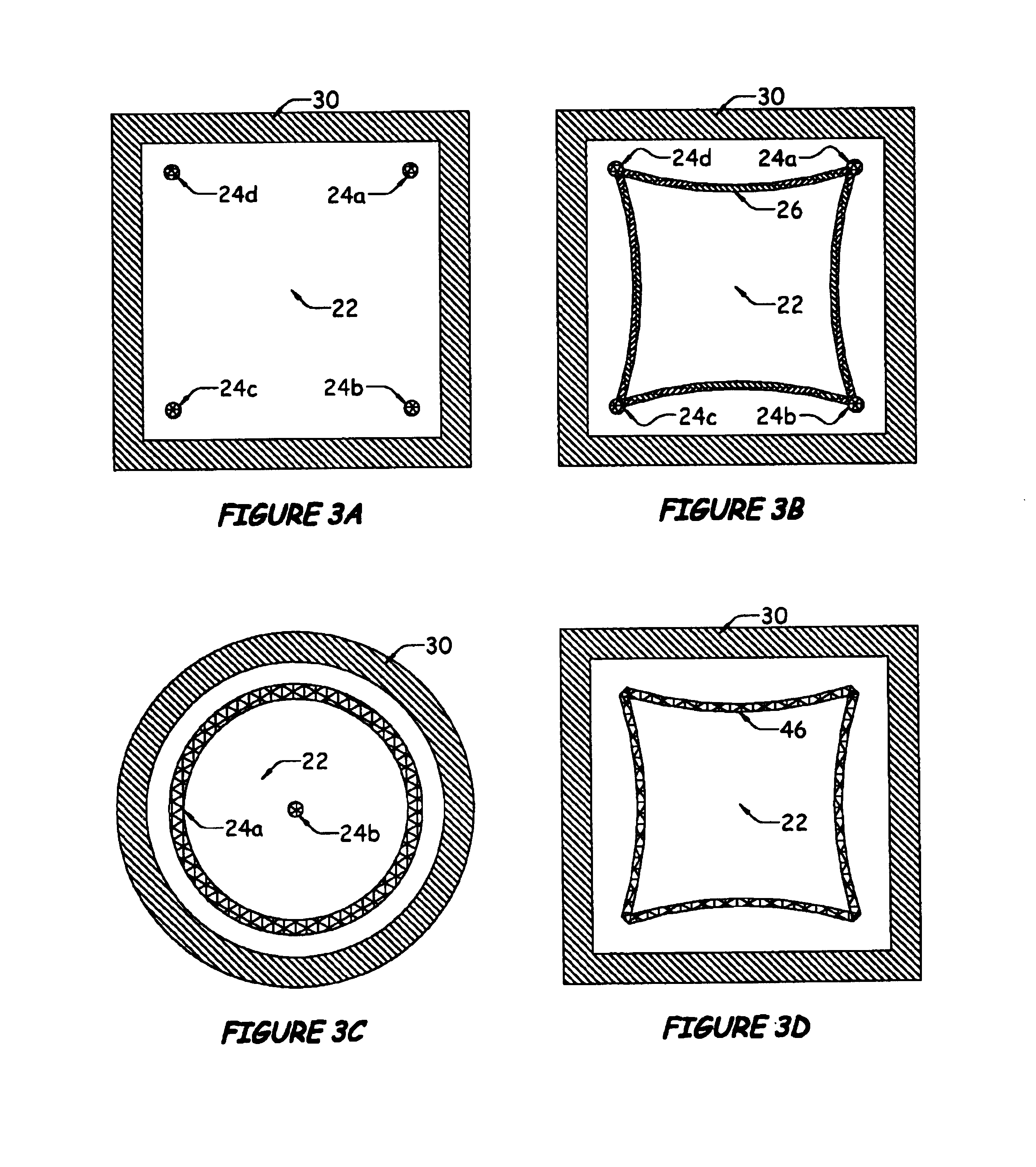

InactiveUS20030080298A1Solid-state devicesMaterial analysis by optical meansSolid state detectorDeadband

The present invention is a solid state detector that has internal gain and incorporates a special readout technique to determine the input position at which a detected signal originated without introducing any dead space to the active area of the device. In a preferred embodiment of the invention, the detector is a silicon avalanche photodiode that provides a two dimensional position sensitive readout for each event that is detected.

Owner:SCI WARES +1

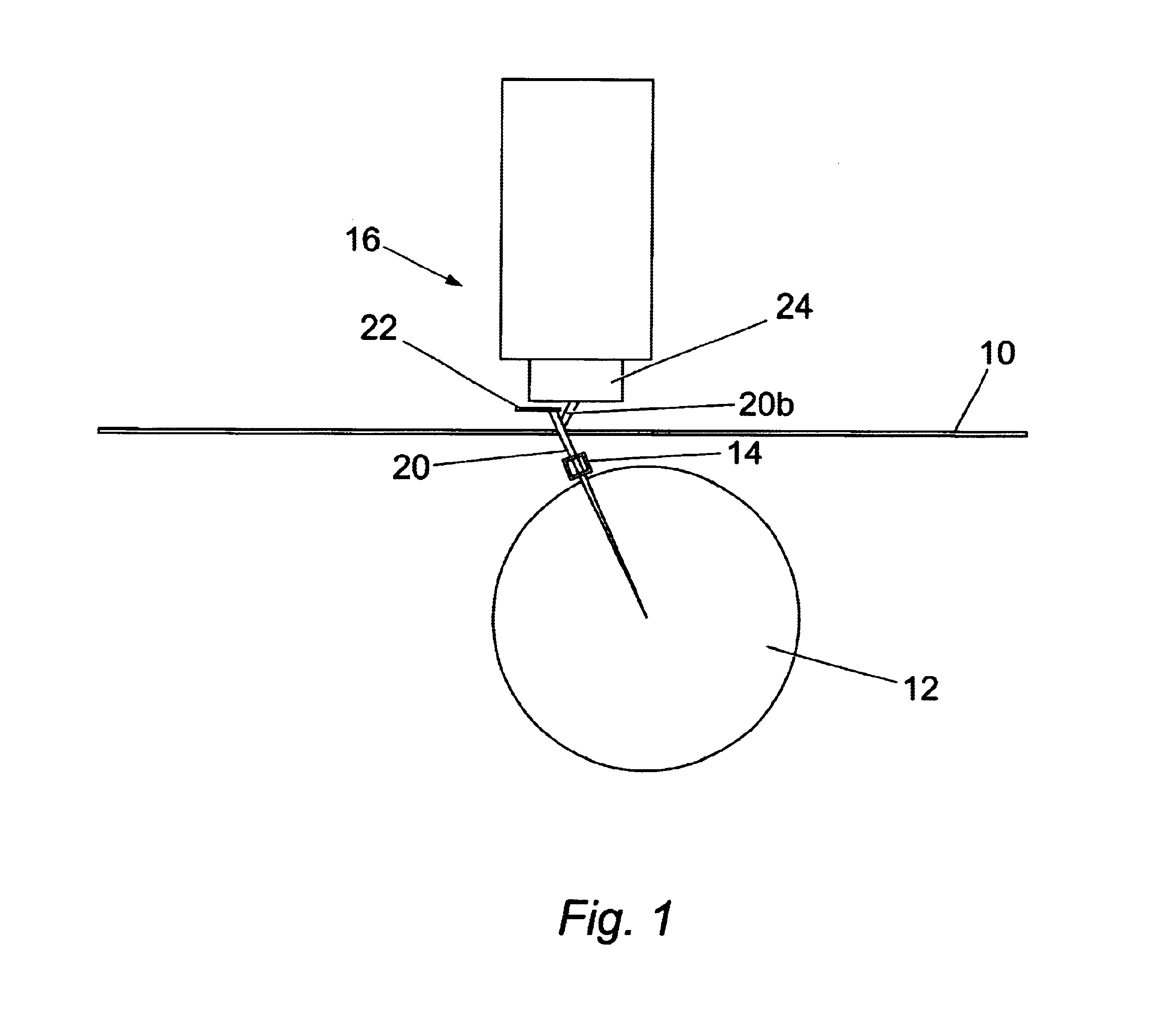

X-ray topographic system

InactiveUS6782076B2Semiconductor/solid-state device testing/measurementCharacter and pattern recognitionSolid state detectorLight beam

Owner:BRUKER TECH LTD

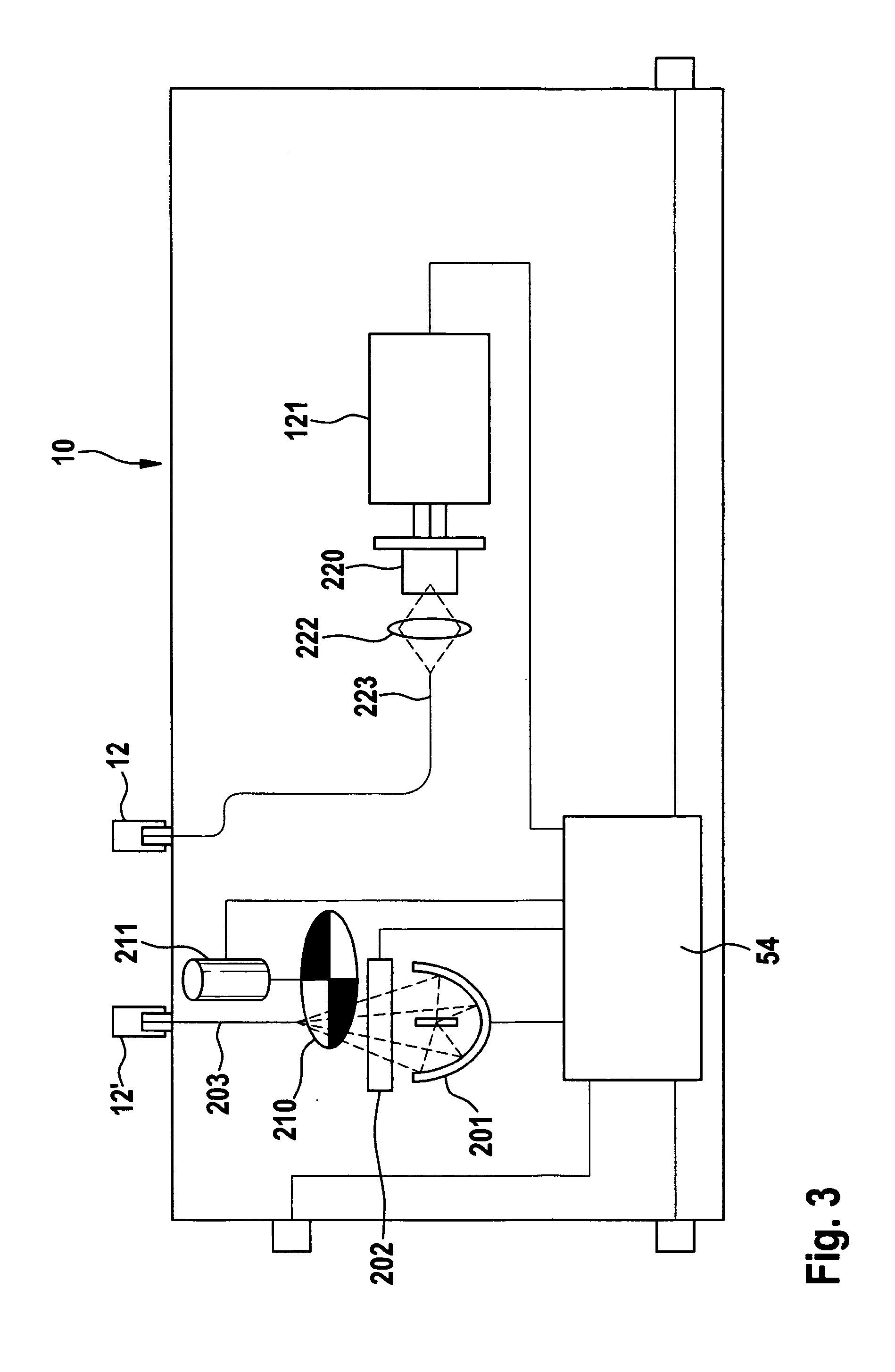

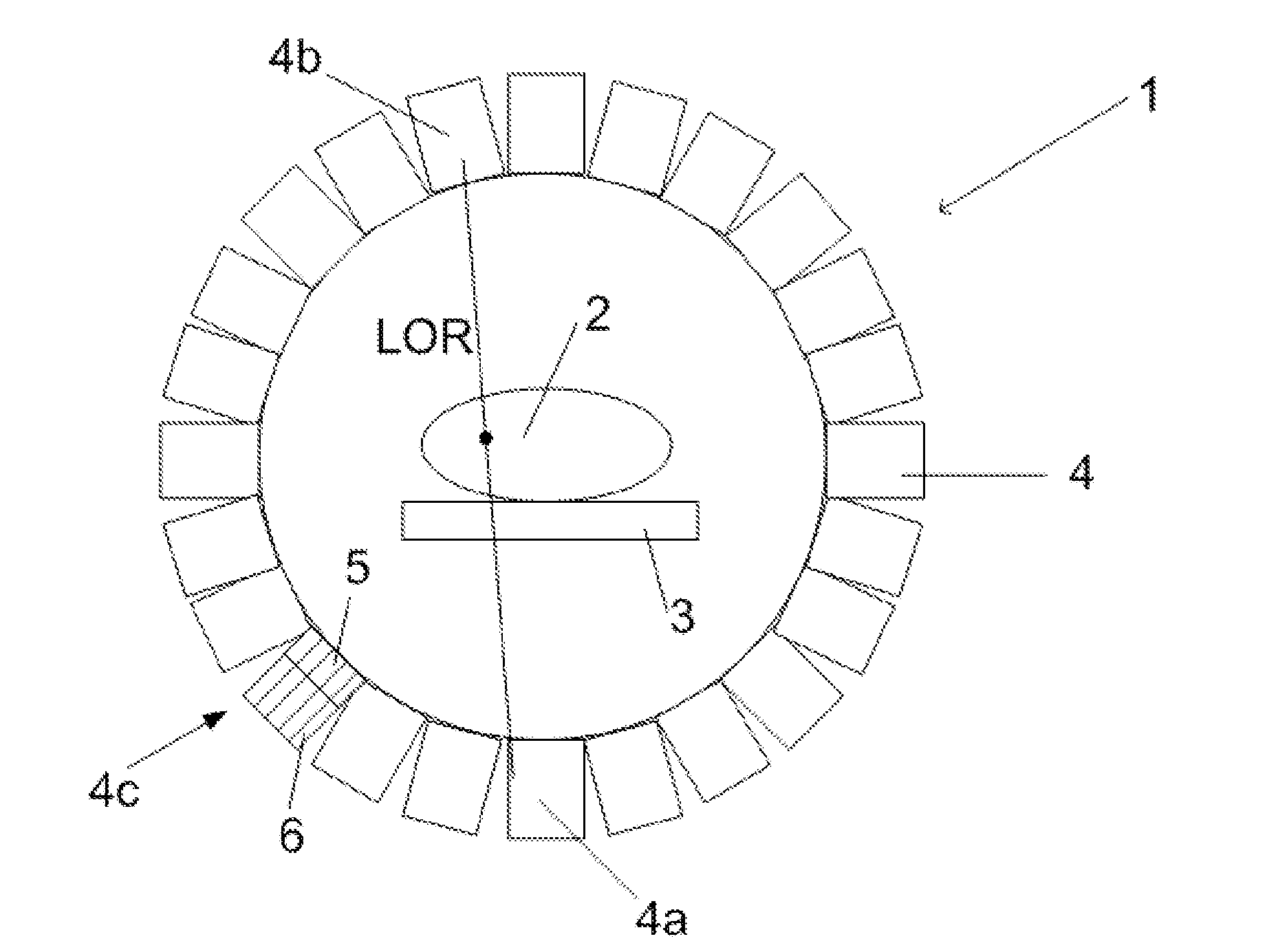

Device for detecting highly energetic photons

ActiveUS20110253901A1Improve spatial resolutionSolve the low detection efficiencySolid-state devicesMaterial analysis by optical meansSolid state detectorEngineering

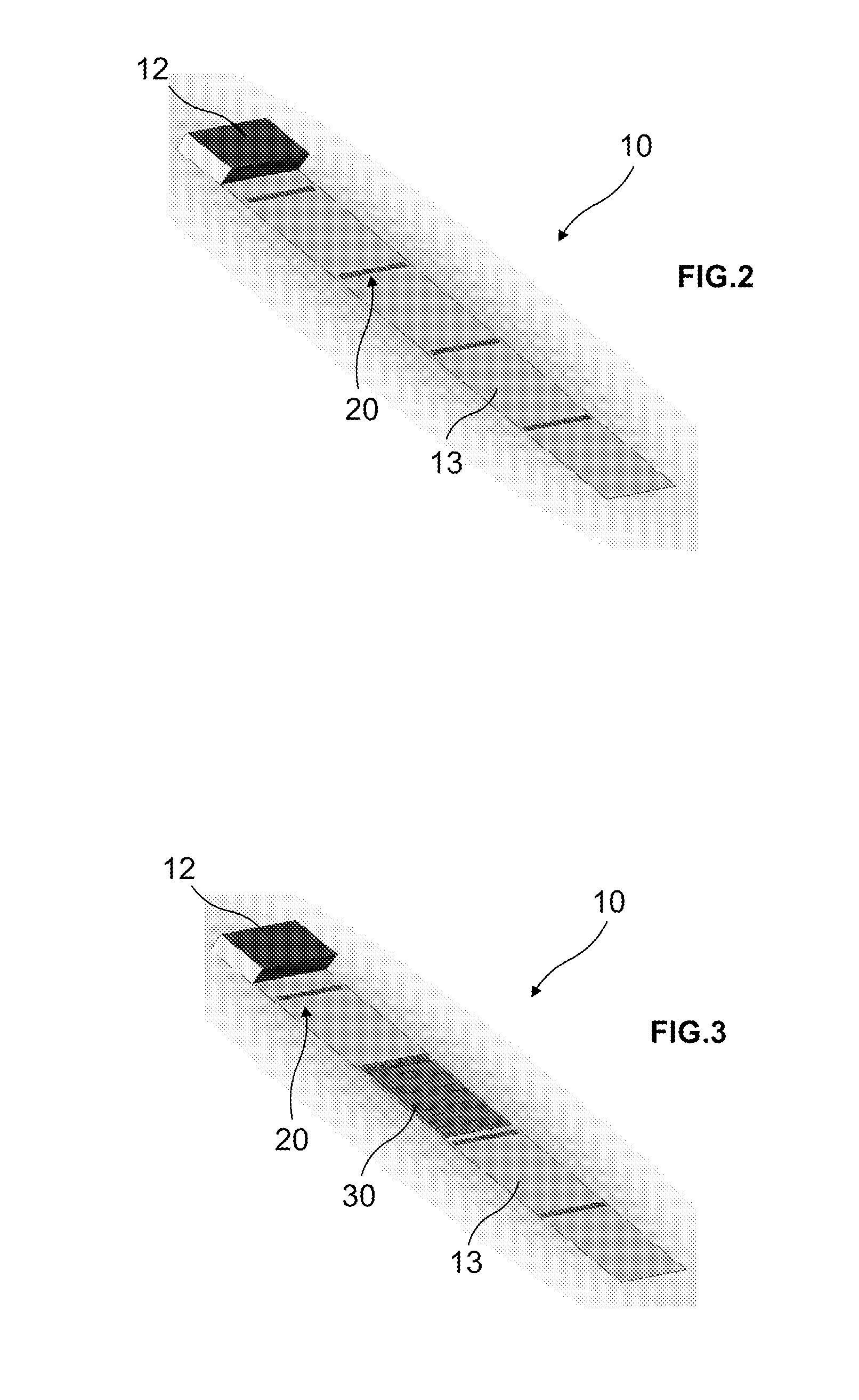

A device (10) for detecting highly energetic photons, comprising one or more pixelated solid-state detectors (11) for detecting the highly energetic photons; means for providing a high voltage for polarizing said solid-state detectors; one or more pixelated readout elements (30), a readout element being connected to each of said one or more pixelated solid-state detectors (11); an input / output element (12) connected to said readout elements (30) for data input and output; and a base layer (13) for mounting the pixelated solid-state detectors (11), the readout elements (30) and the input / output element (12).

Owner:INST DE FISICA D ALTES ENERTIES (IFAE)

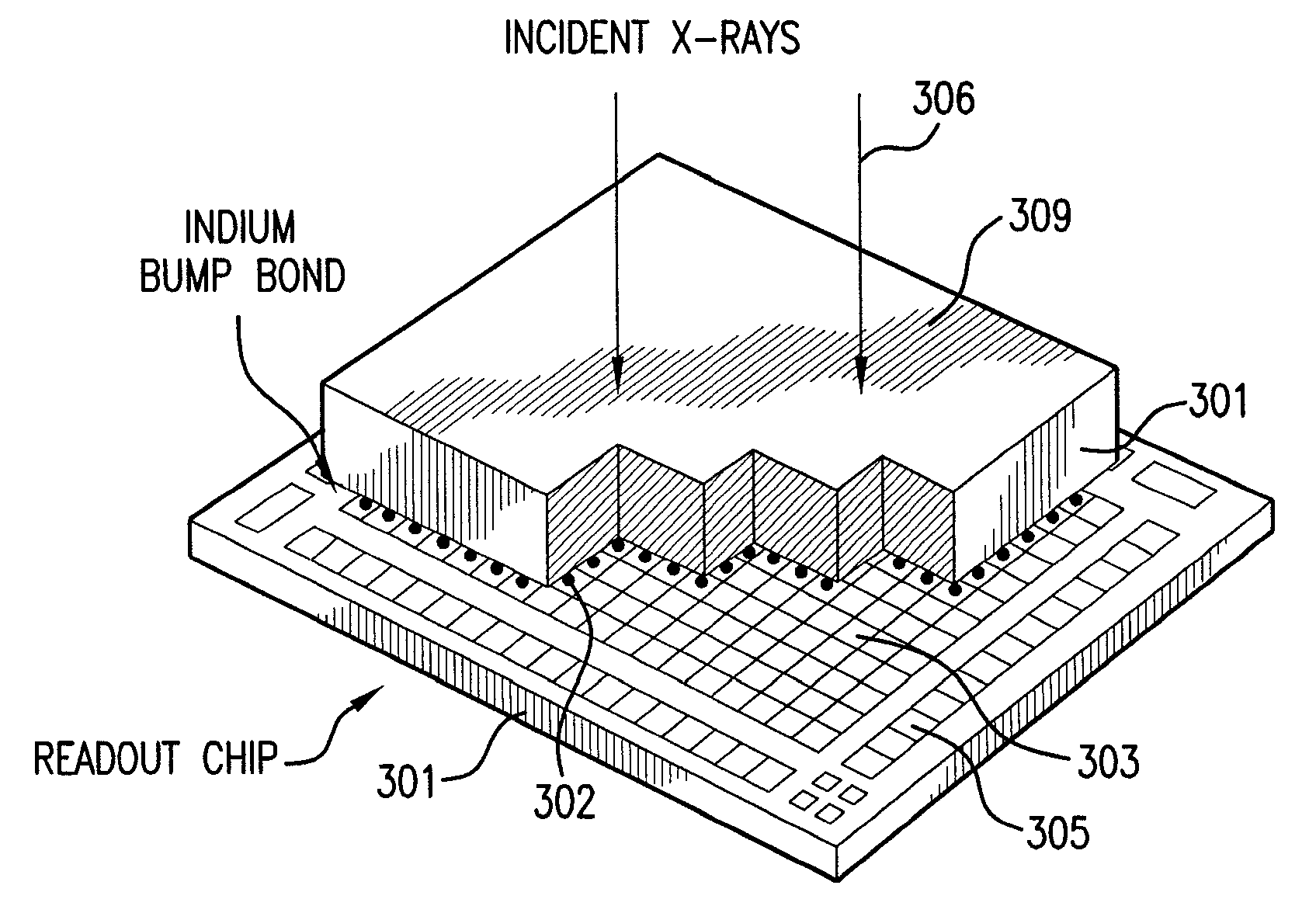

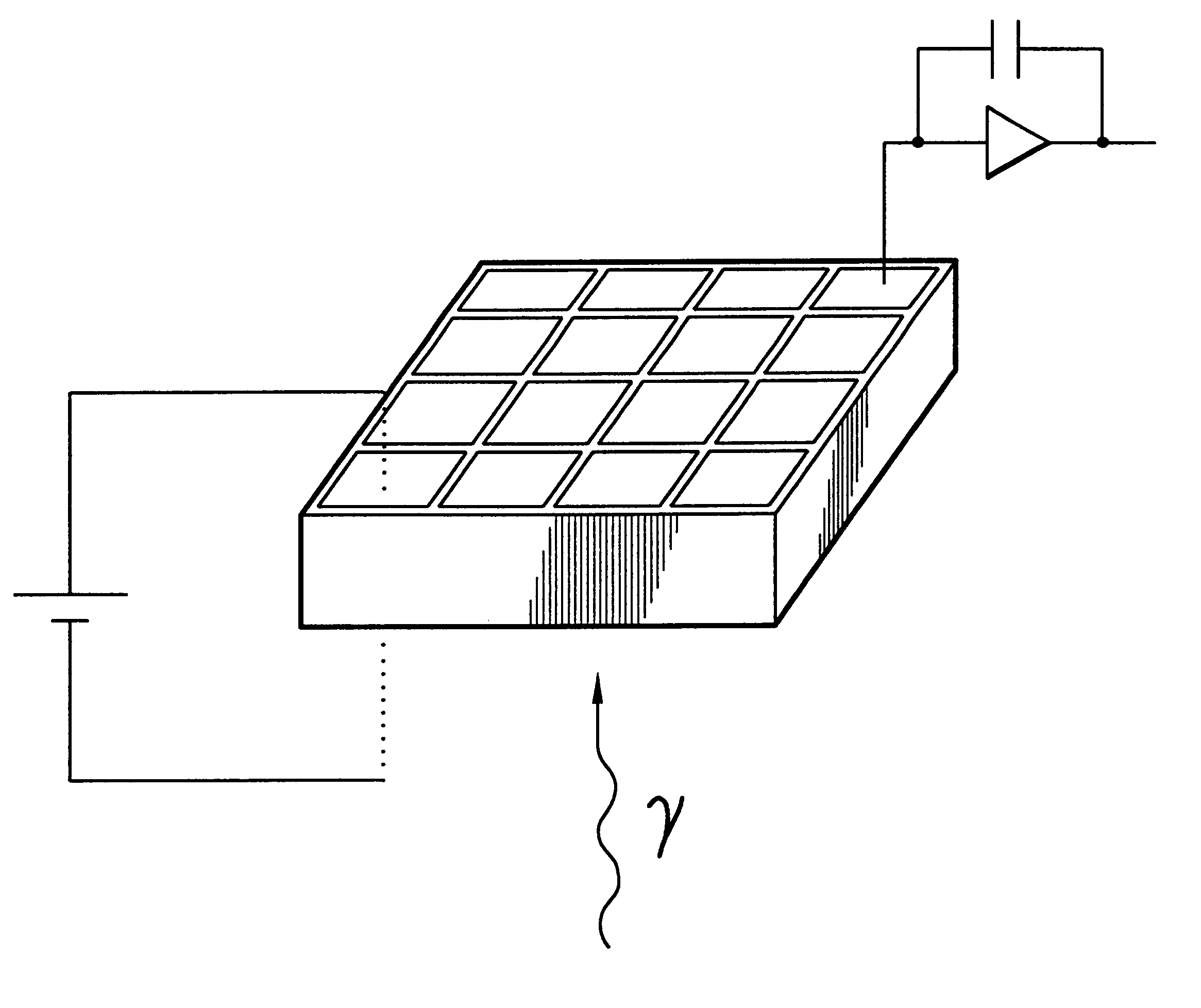

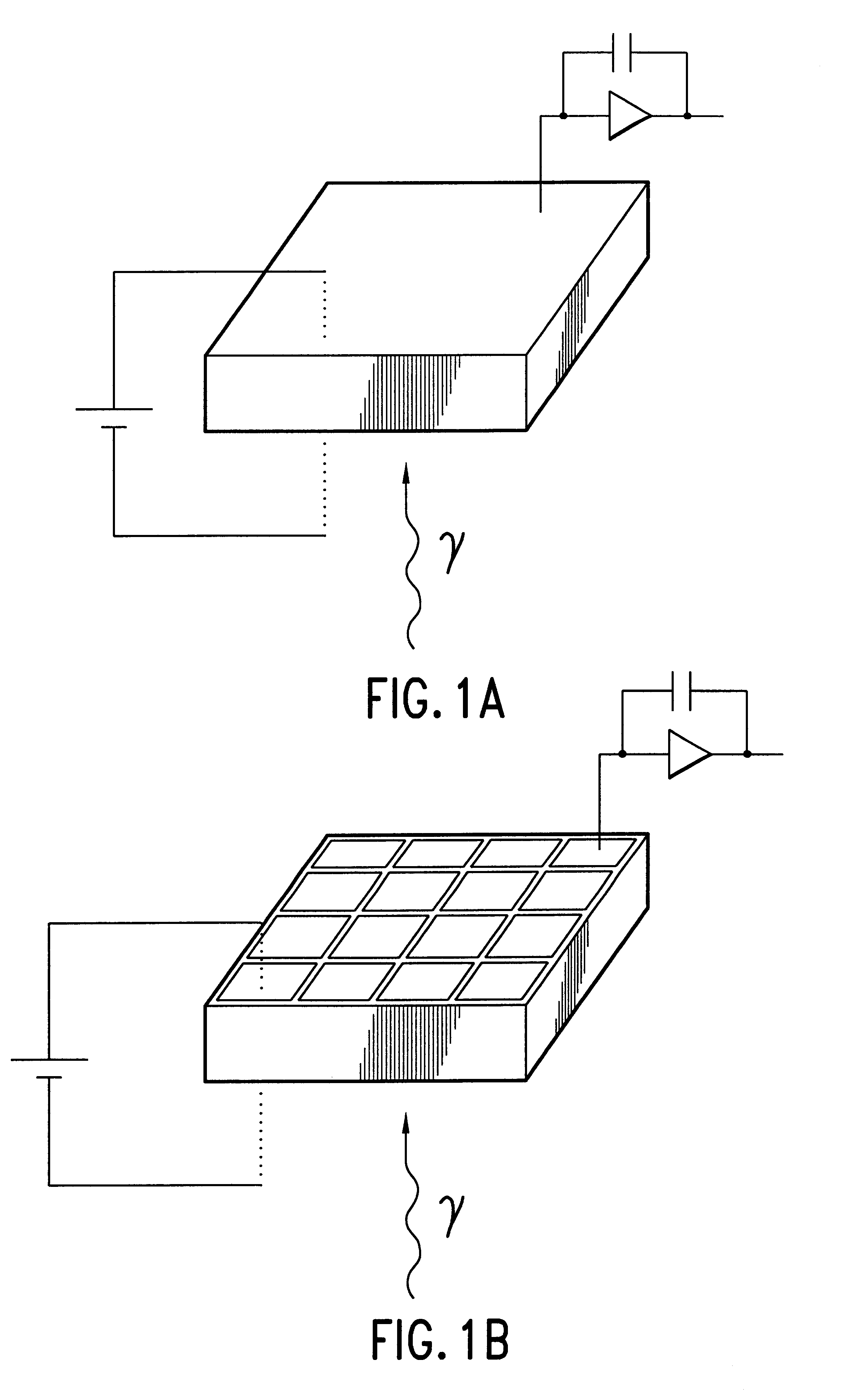

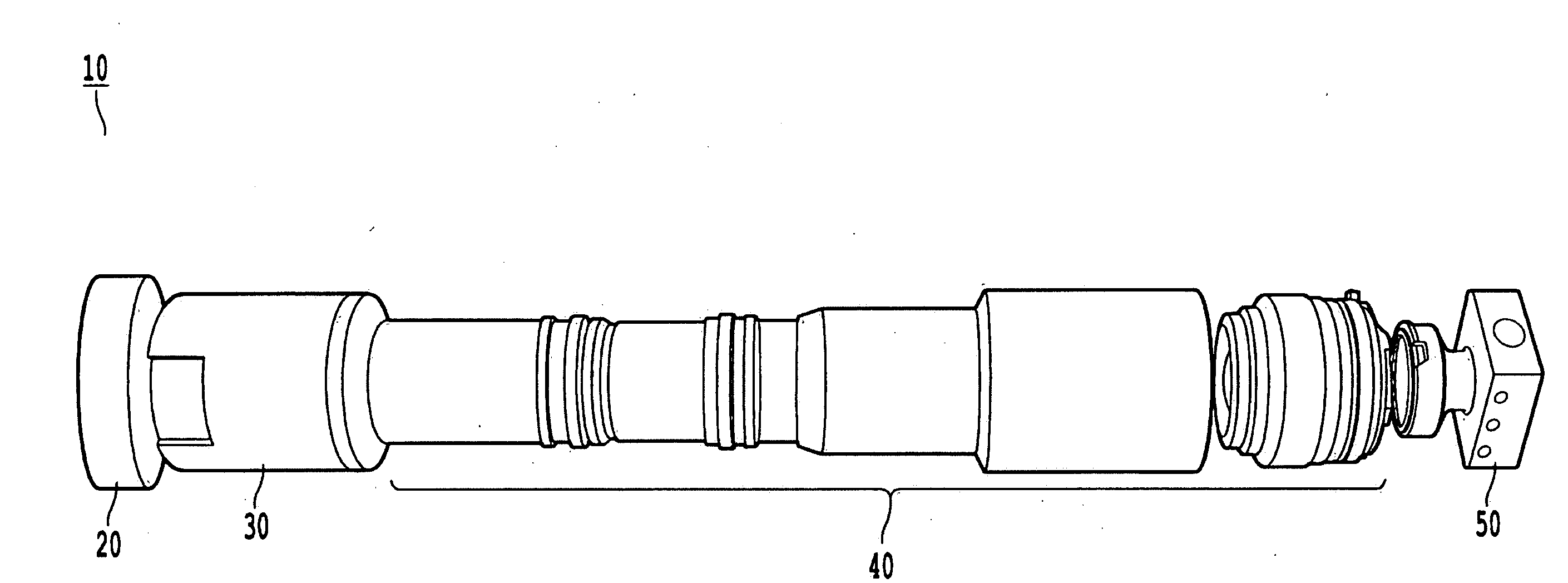

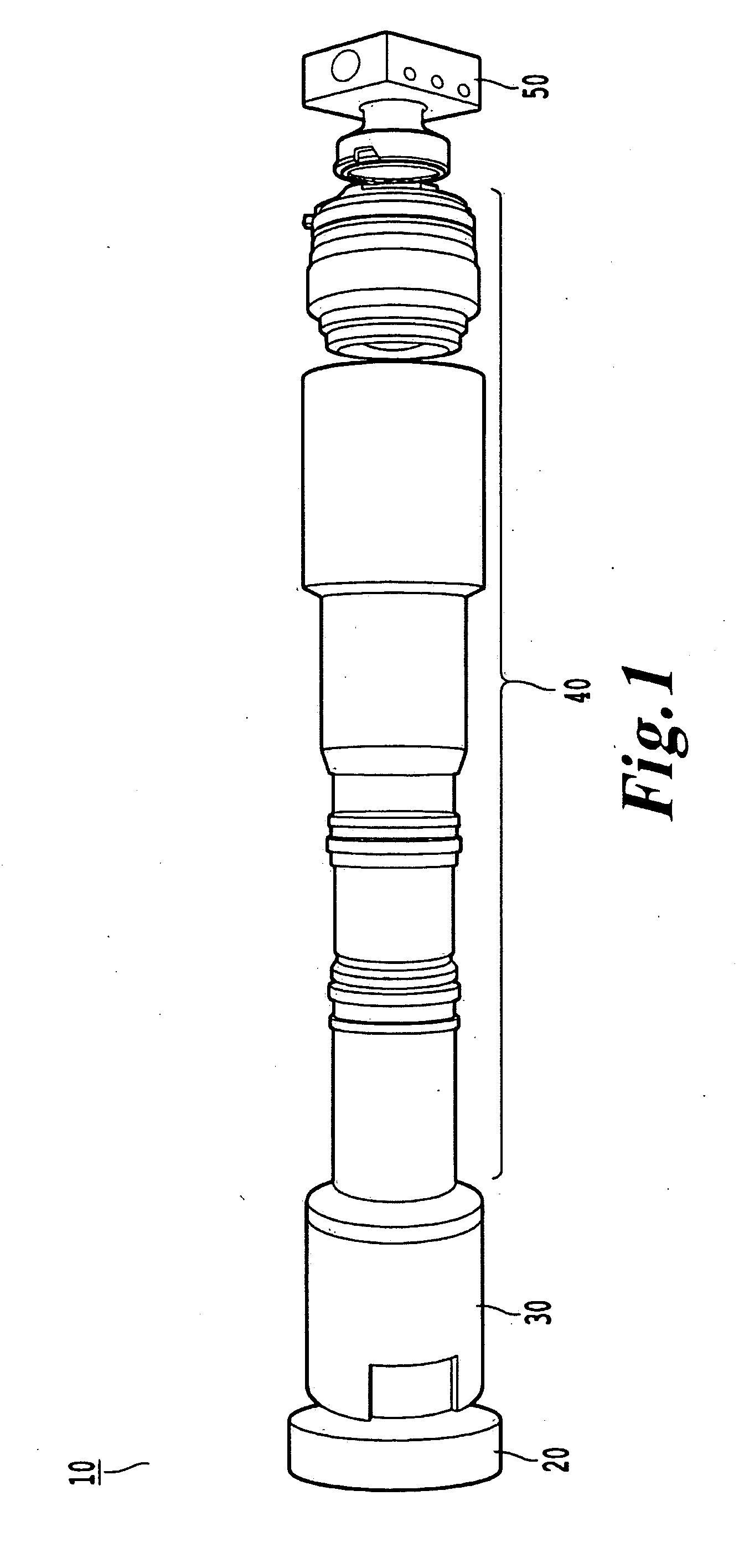

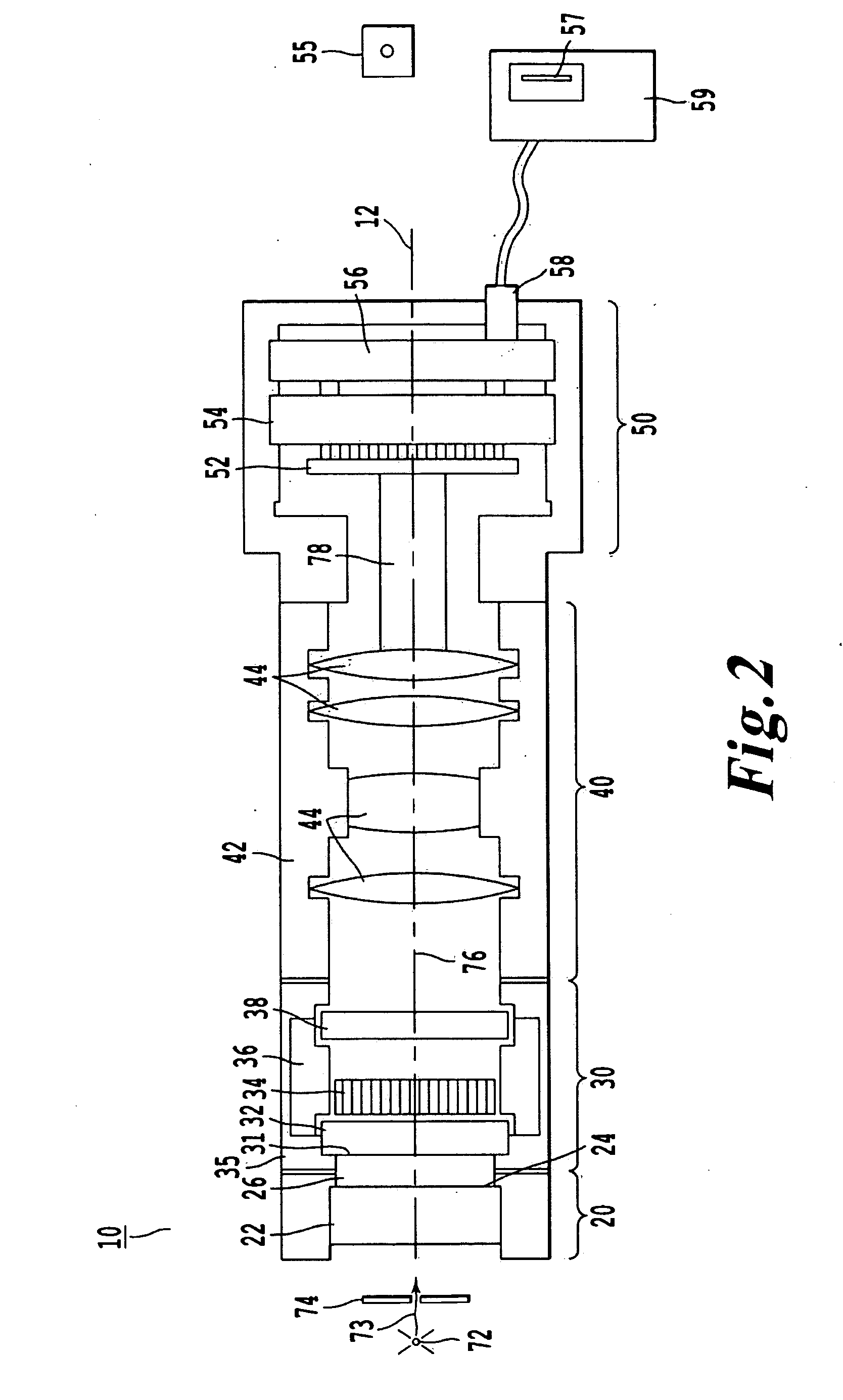

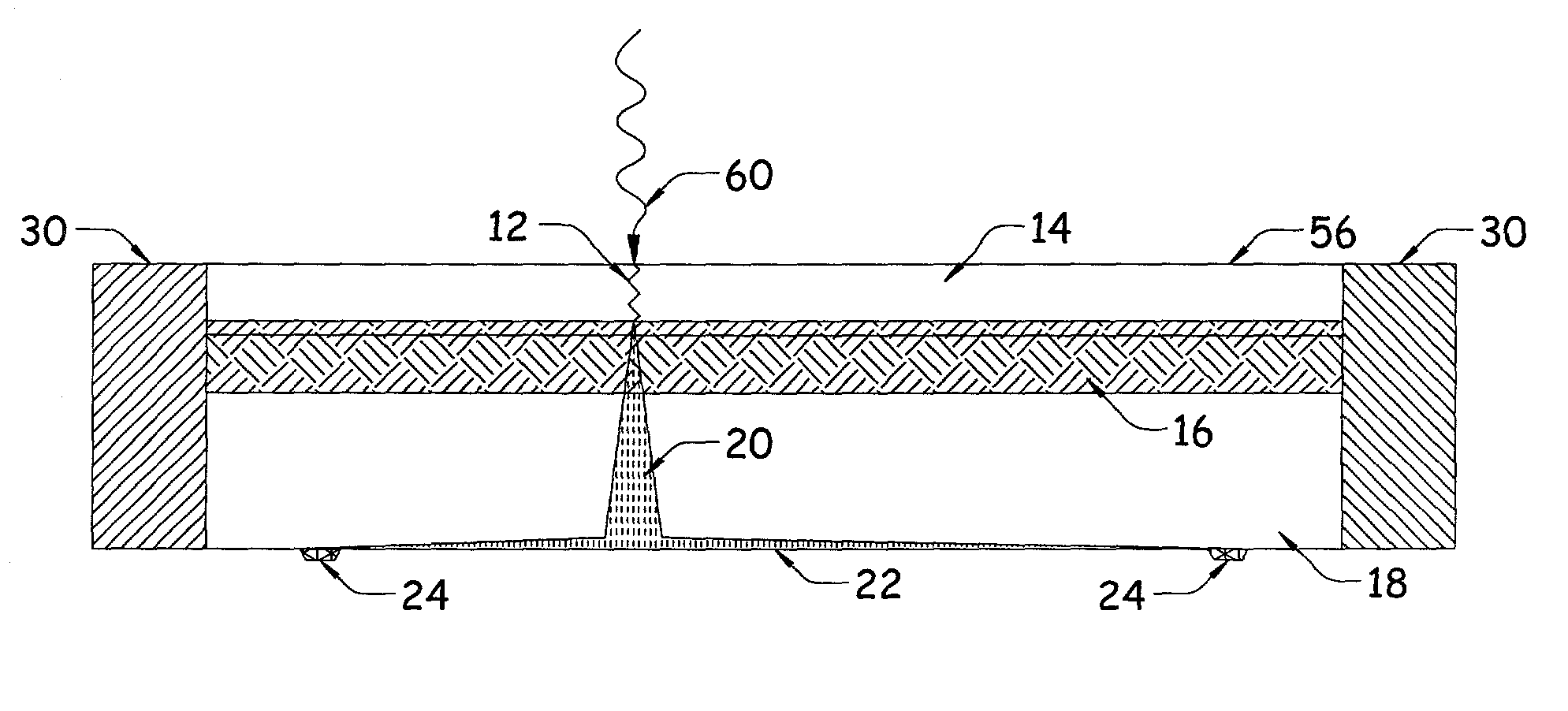

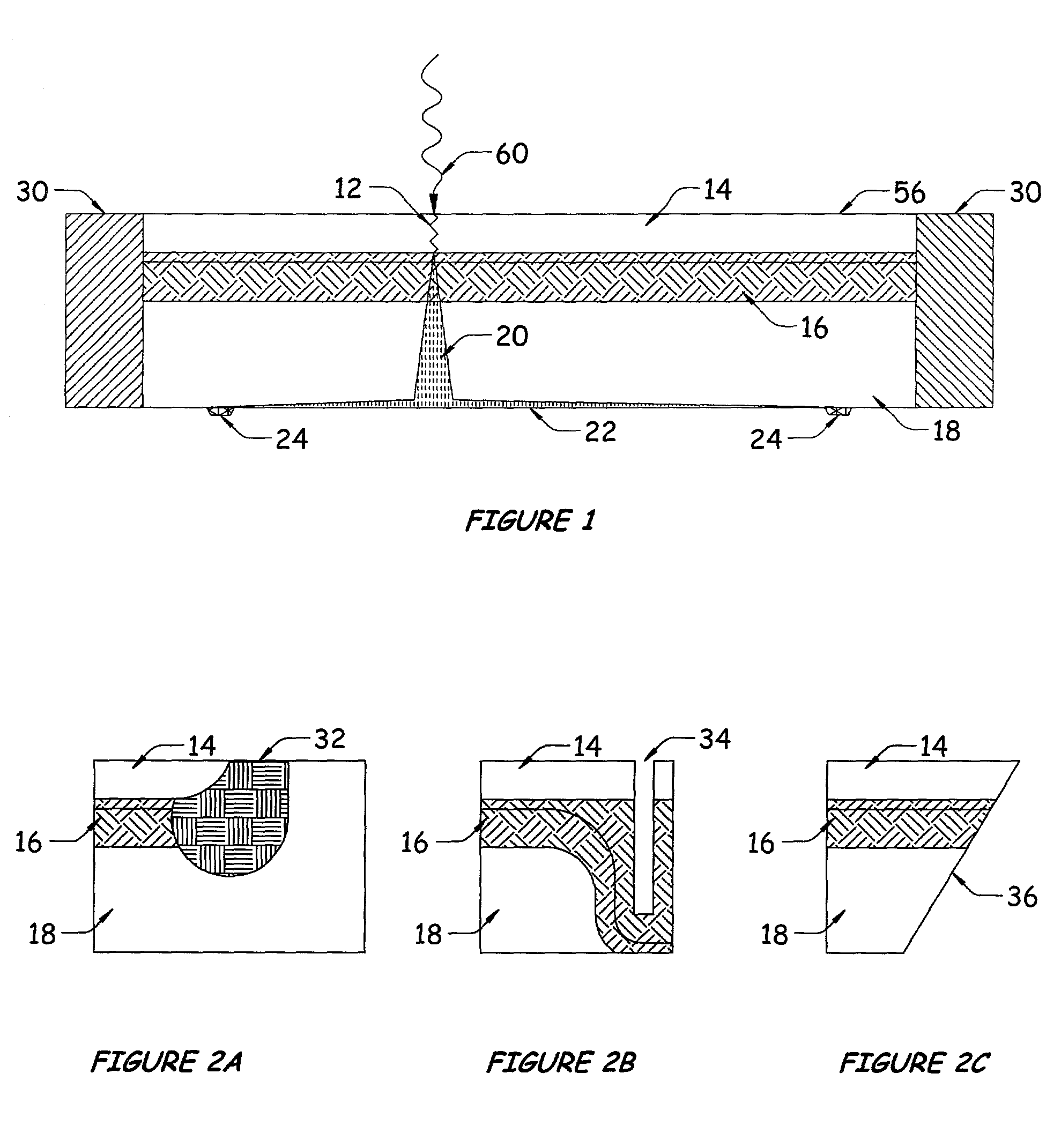

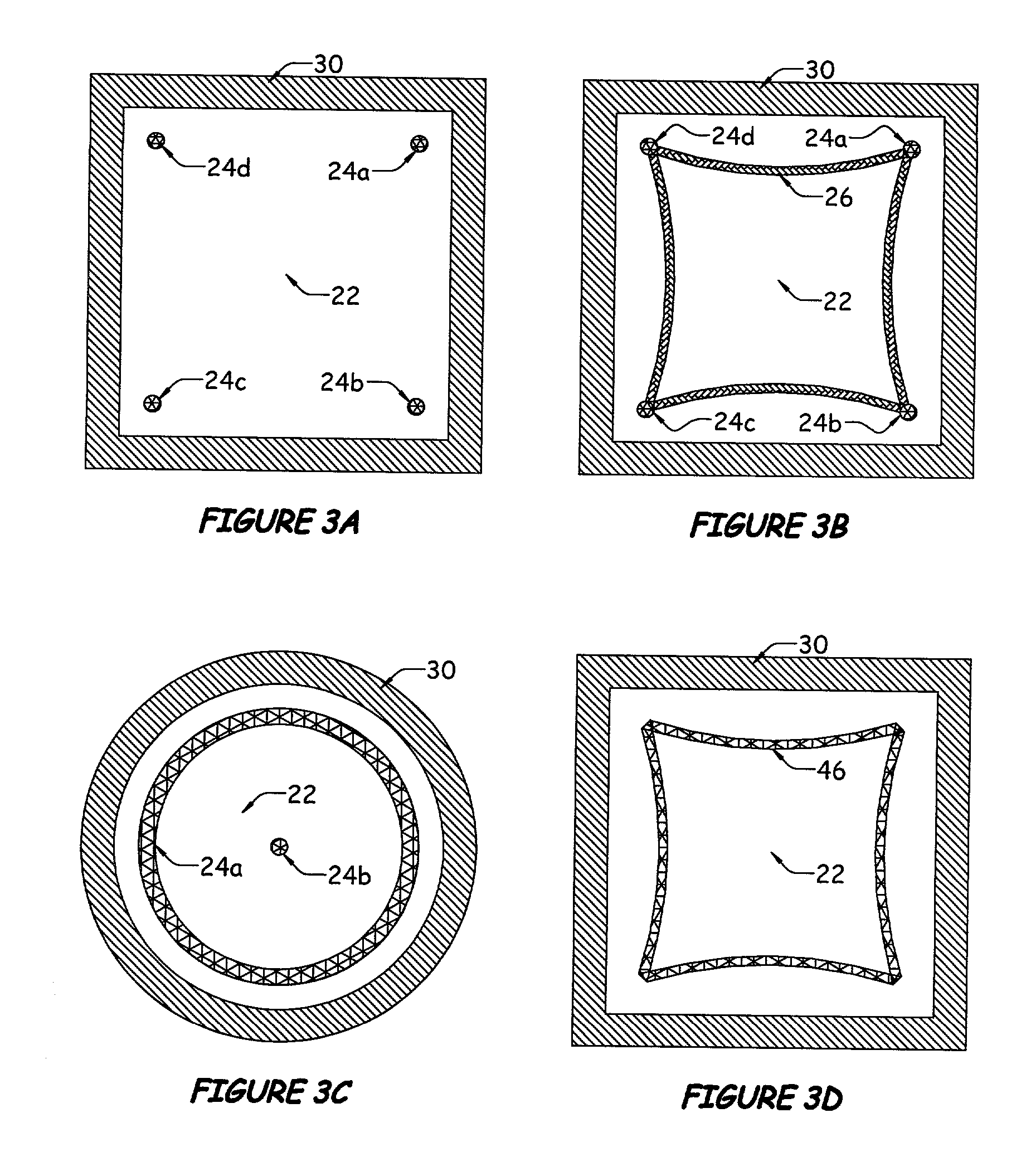

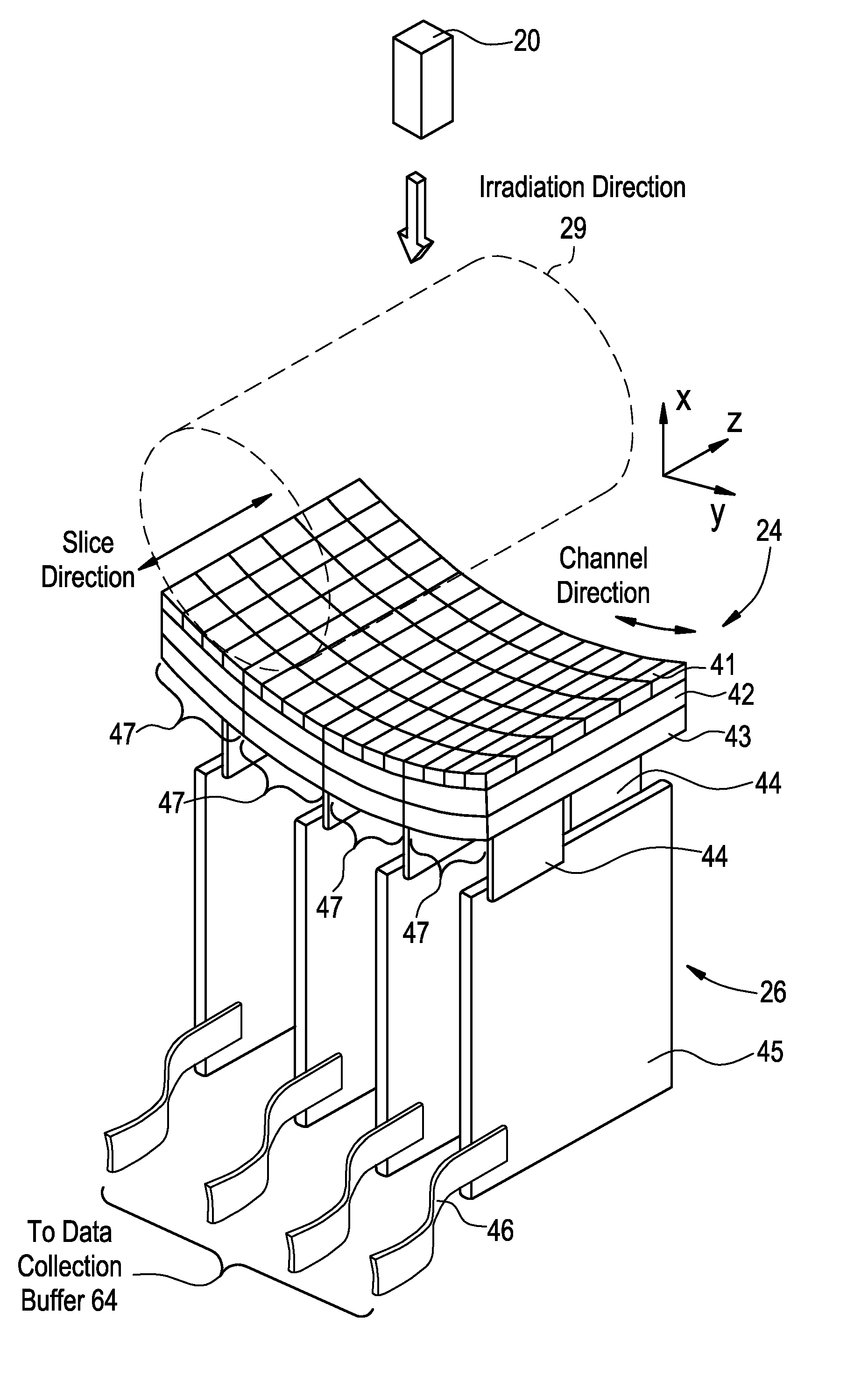

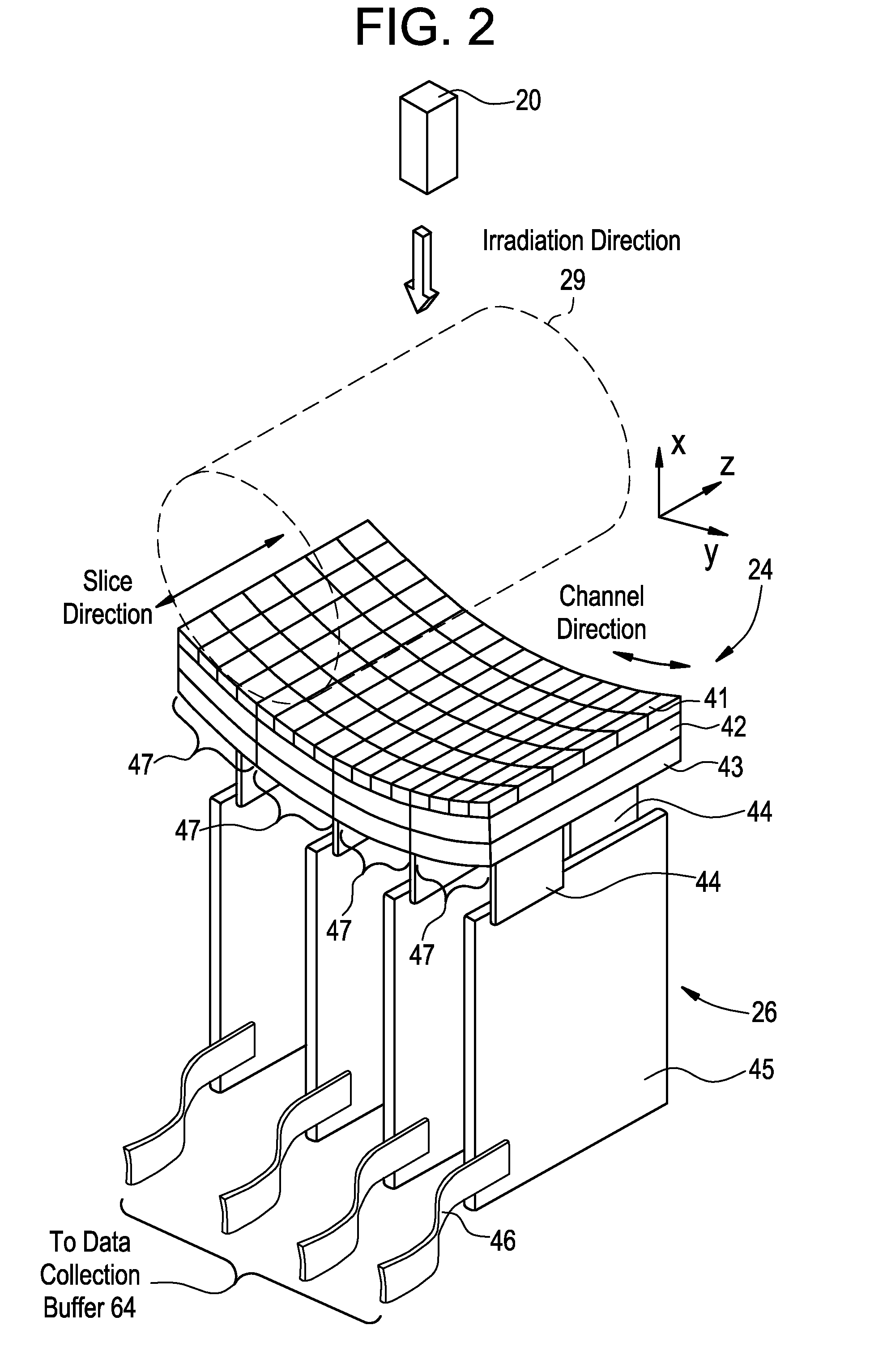

High speed crystallography detector

InactiveUS6057552AReduce signal to noise ratioSlow readoutSolid-state devicesMaterial analysis by optical meansX-rayDetector array

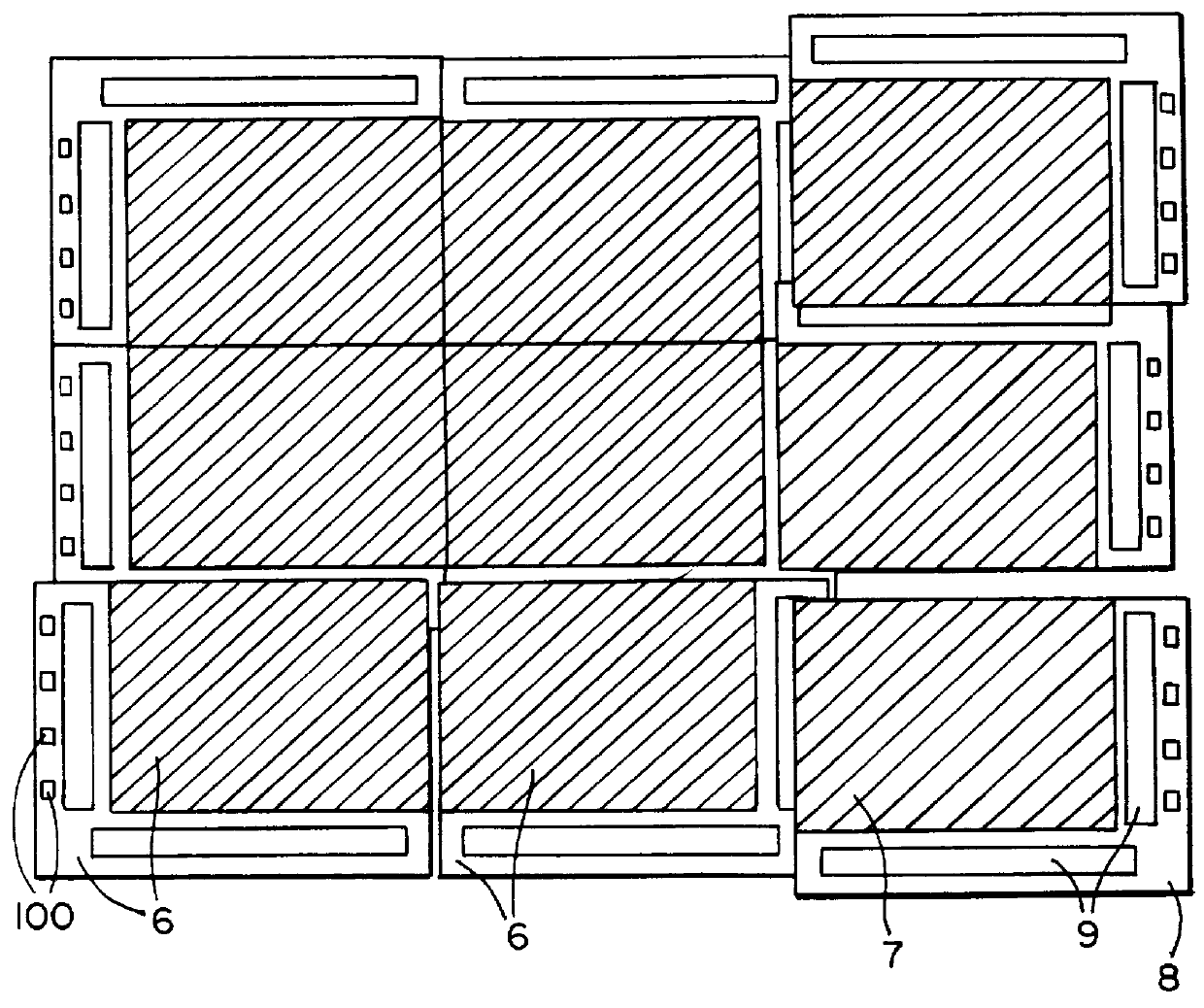

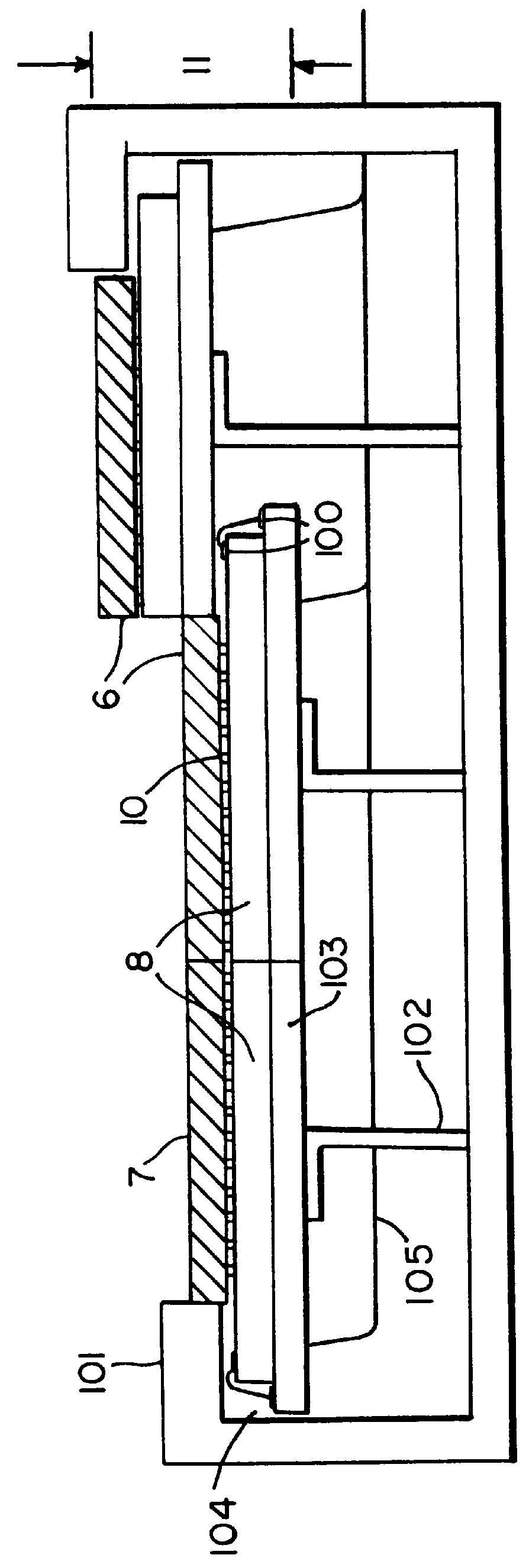

A device for the collection, digitization and analysis of synchrotron x-ray crystallographic data using an area detector which detects x-ray photons directly on arrays of solid state detectors and stores the information on capacitors located on readout unit cell array chips. The device consists of a two dimensional area detector, for amplification, collection and conversion of the diffracted x-rays to electrical signals, drive electronics for providing the timing pulses and biases to the area sensor, output electronics for converting the x-ray signals to digital signals and storing the signals, and a data processor to analyze the digital signal form the output electronics. The solid-state detector array is made up of a variable-area three-dimensional array of detector array chips where each chip is in turn made up of an array of solid-state detectors. Each detector on the detector array chip is electrically connected to a readout unit cell on a readout array chip directly beneath the detector array chip. The readout unit cell contains the circuitry for storage, switching and readout of the x-ray signals.

Owner:CONTINENTAL AUTONOMOUS MOBILITY US LLC

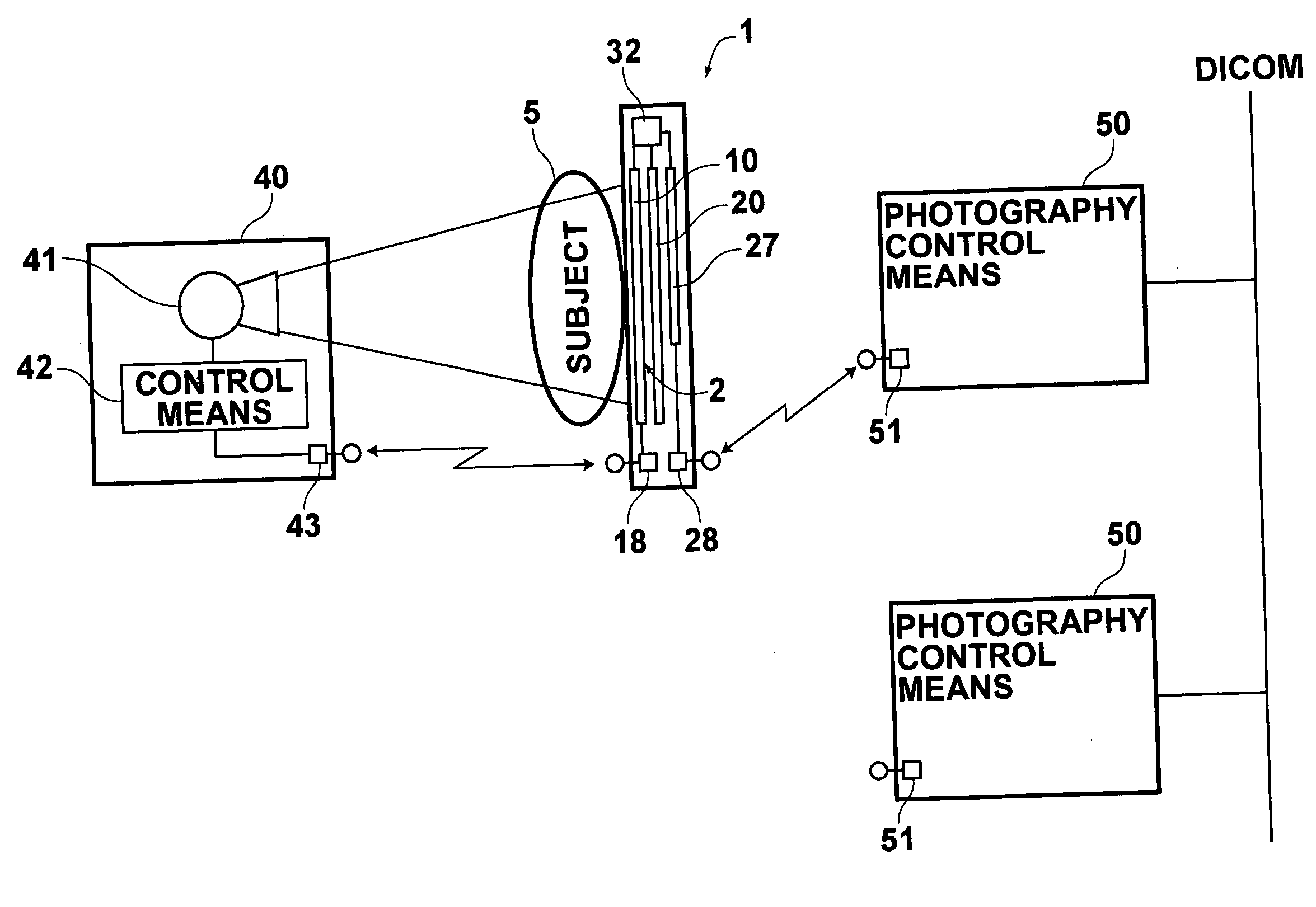

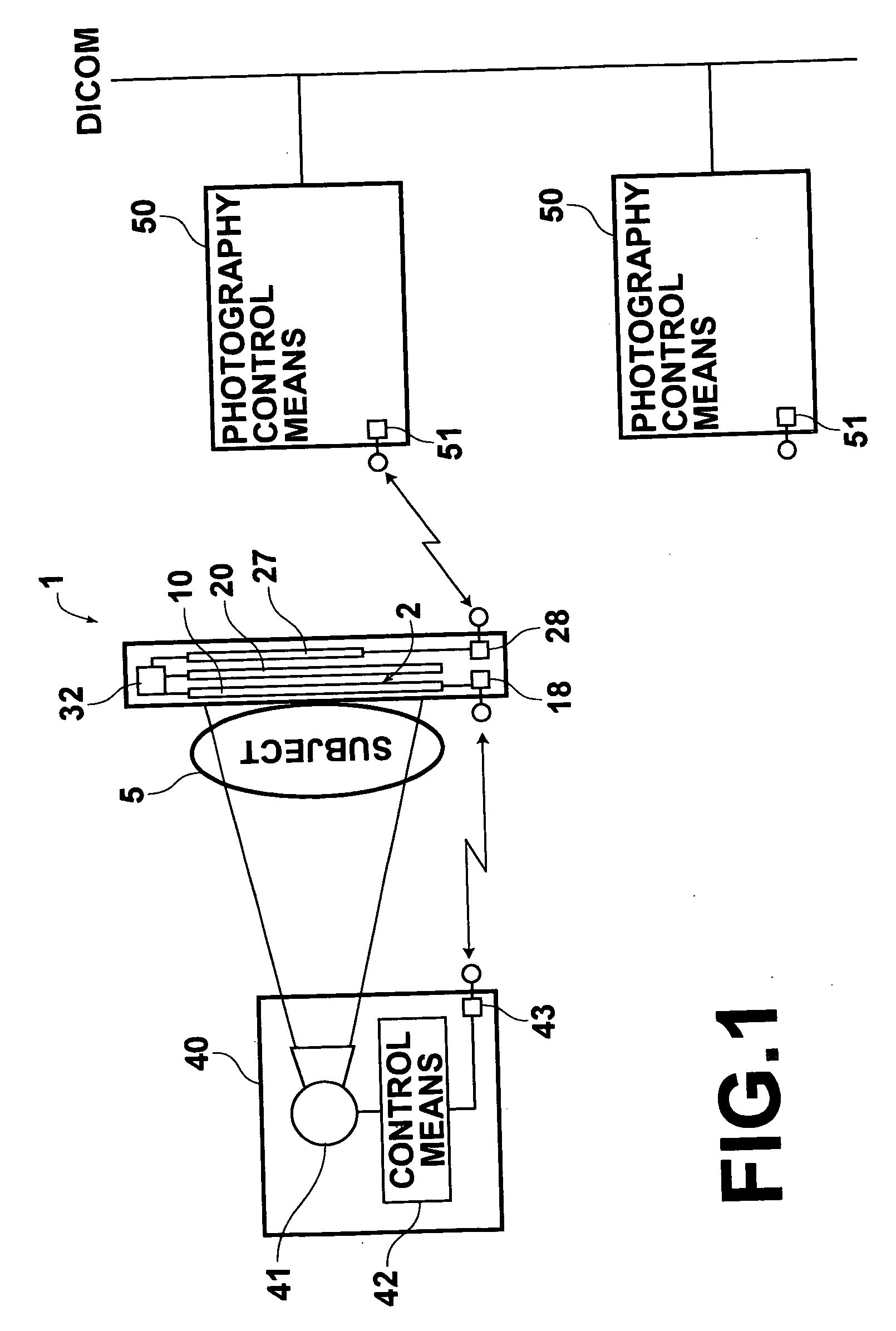

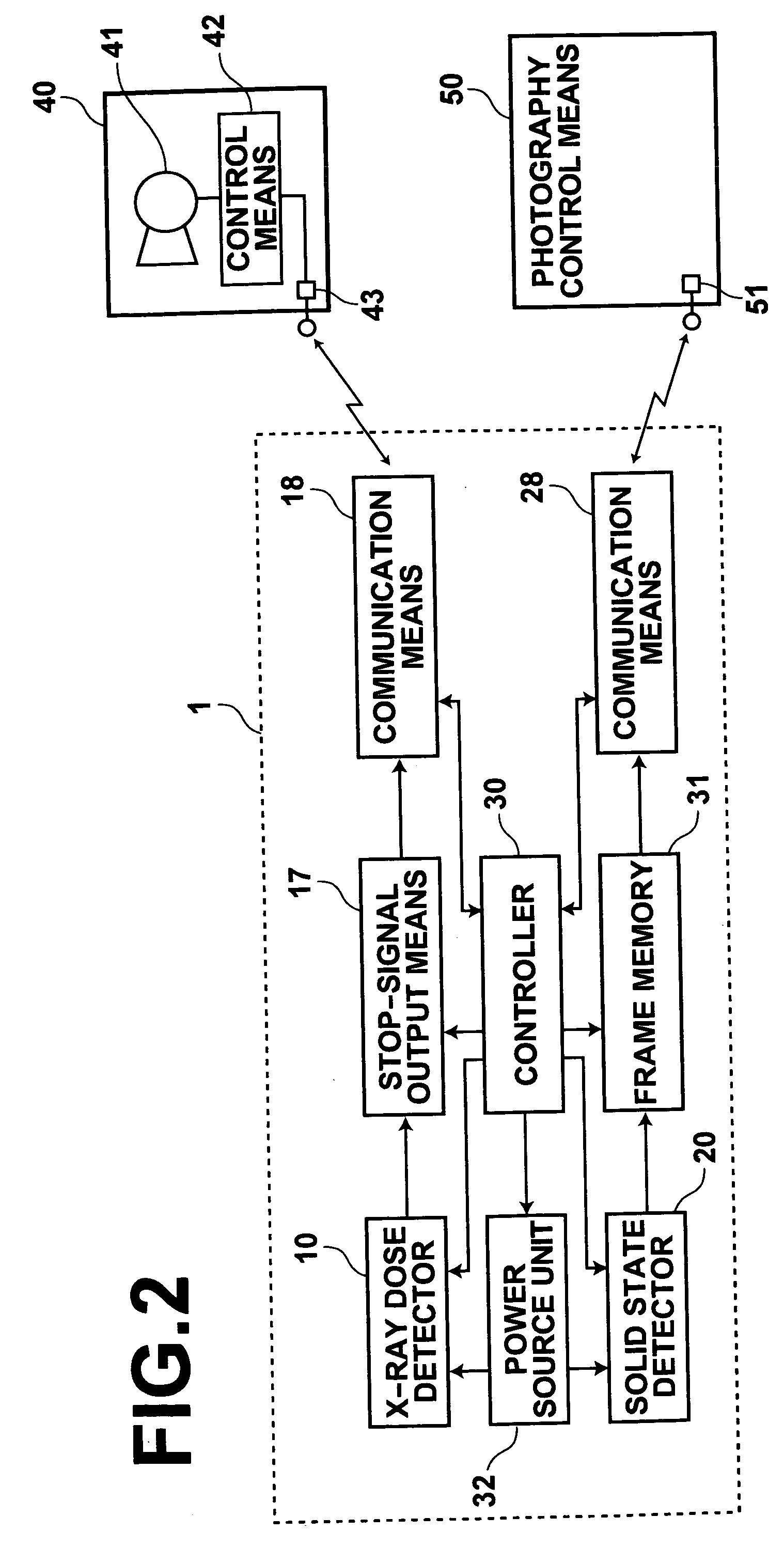

Photo timer and radiographic apparatus

InactiveUS20060023839A1Flexibility is not limitedImprove convenienceX-ray apparatusSolid state detectorX-ray

A photo timer includes an X-ray dose detector for detecting the dose of X-rays irradiated from an X-ray irradiation apparatus, a stop-signal output means for outputting a stop signal to stop irradiation of the X-rays from the X-ray irradiation apparatus when the detected X-ray dose exceeds a predetermined value, and a communication means for sending the stop signal to the X-ray irradiation apparatus by wireless means. A radiographic apparatus includes the photo timer, a solid state detector for recording image information by irradiation of X-rays which carry the image information and outputting an image signal representing the image information, and a communication means for sending the image signal to a photography control means by wireless means. Further, cables are not required to connect the X-radiographic apparatus (photo timer) and the X-ray irradiation apparatus, or the X-radiographic apparatus and the photography control means.

Owner:FUJIFILM CORP +1

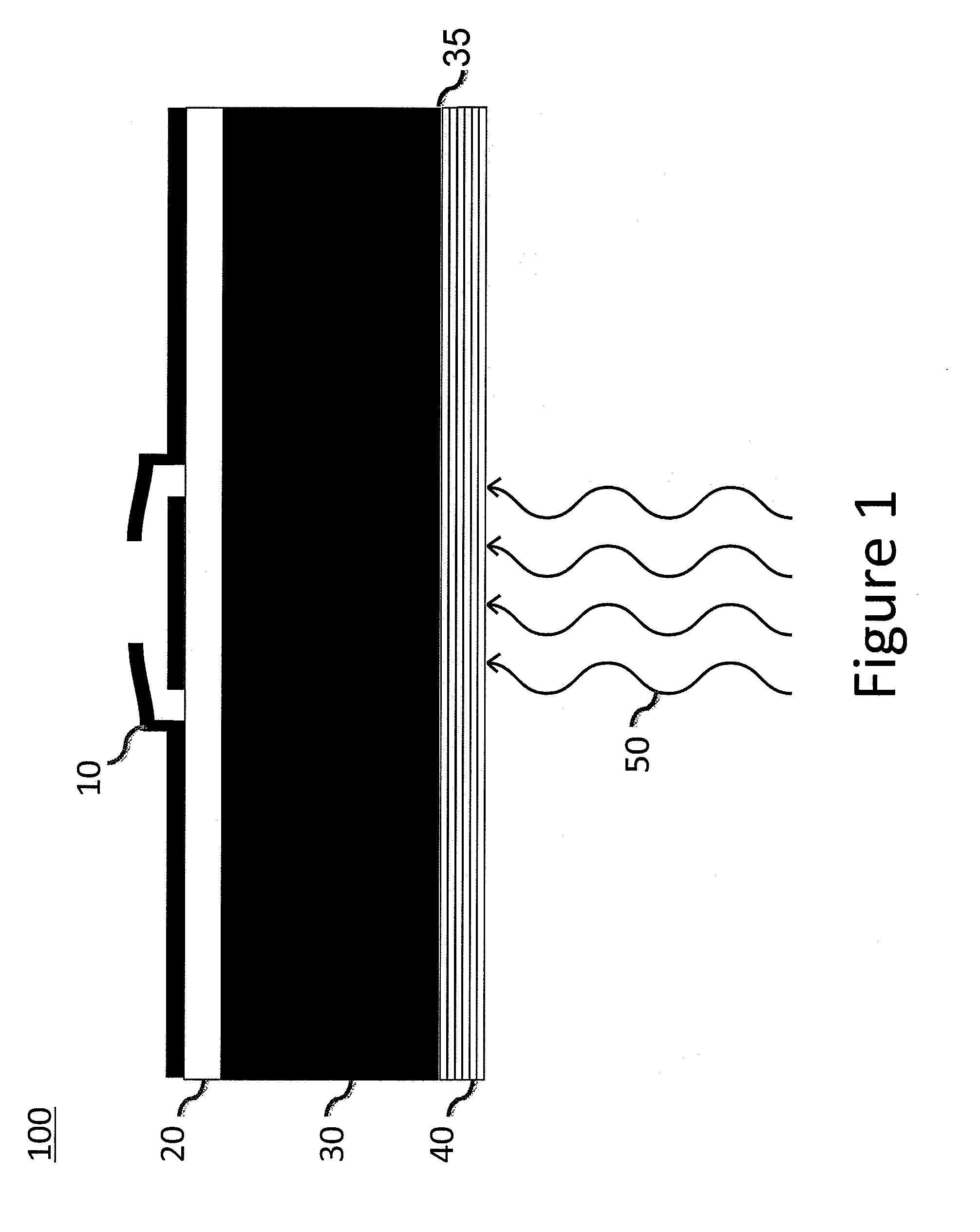

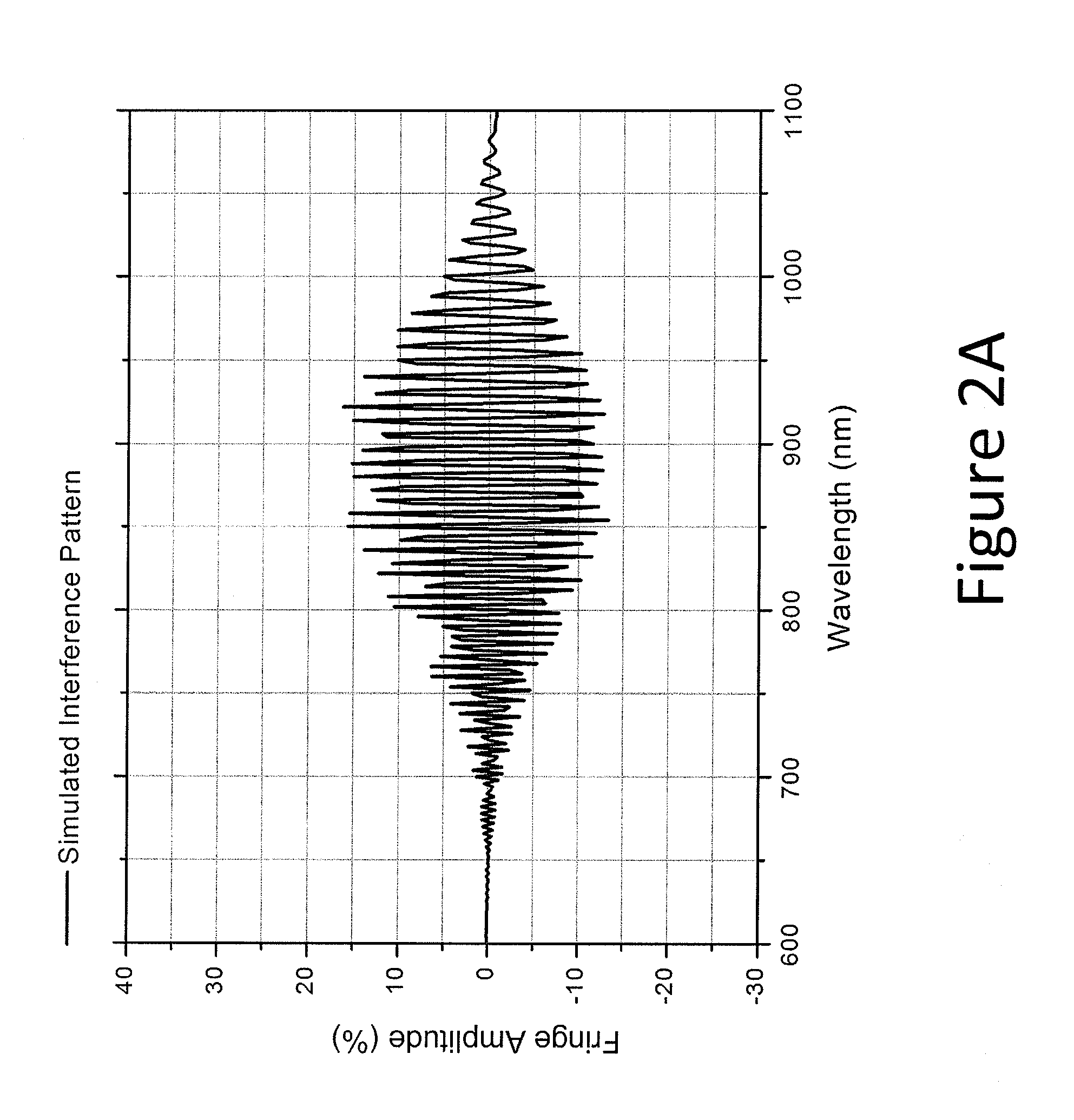

Solid state back-illuminated photon sensor

ActiveUS20110175185A1Minimizing etaloning spanning the NIRImprove quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron multiplicationPhotonic sensor

A backside-illuminated image sensor is disclosed having improved quantum efficiency (QE) in the near infrared wavelengths (NIR: 750-1100 nm) with minimal optical interference fringes produced by multiple reflected rays within the photosensitive Si region of the sensor, which may be a charge-coupled device, a complementary metal oxide sensor or an electron-multiplication sensor. The invention comprises a fringe suppression layer applied to the backside surface of the photosensitive Si region of a detector (Si substrate) whereby the fringe suppression layer functions in concert with the Si substrate to reduce the occurrence of interference fringes in the NIR while maintaining a high QE over a broad range of wavelengths (300-1100 nm). The combination of a fringe suppression layer applied to a Si substrate provides a new class of back illuminated solid state detectors for imaging.

Owner:TELEDYNE DIGITAL IMAGING US INC

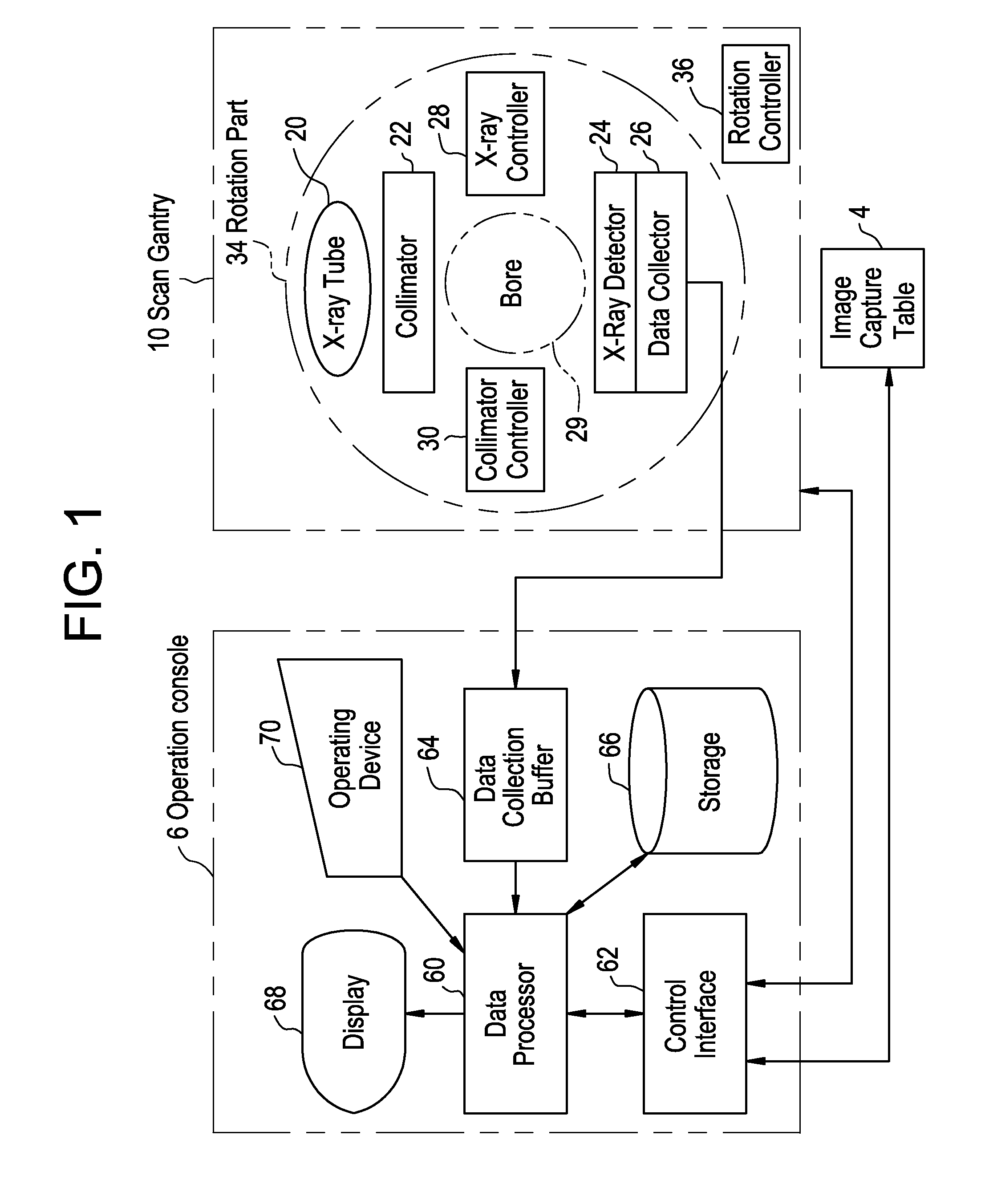

X-ray detector and x-ray ct apparatus

InactiveUS20070098138A1Valid conversionMaterial analysis using wave/particle radiationRadiation/particle handlingSolid state detectorX-ray

To realize an X-ray detector and an X-ray CT apparatus with improved efficiency for X-ray utilization while leaving gaps existing among solid state detectors which are arranged two-dimensionally. A scintillator has a parallelepiped structure in which a top face and an under face are deviated from each other in a channel direction only by an amount d1 exceeding width of a gap, thereby eliminating an X-ray insensitive area when viewed from the X-ray incidence direction. Therefore, efficiency for X-ray utilization improves and, moreover, improvement in X-ray detectivity and picture quality of a slice image to be captured is realized.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Solid state detector module structure and radiation imaging system

ActiveUS7429738B2Increase capacityInspection speed is fastSolid-state devicesMaterial analysis by optical meansState of artSolid state detector

The present invention discloses a solid state detector module structure, comprising: an upper support plate and a lower support plate provided opposing to each other, a collimator provided between the upper support plate and the lower support plate for collimating the incident rays; and solid state detector arrays provided between the upper support plate and the lower support plate at the rear side of the collimator in the transmitting direction of the rays, wherein the solid state detector arrays comprises an upper and lower rows, with the upper row of the solid state detector array fixed under the upper support plate, and the lower row thereof fixed on the lower support plate. The present invention further discloses a radiation imaging system having the same. The solid state detector module structure of present invention decreases the scattering of ray beams, increases the capabilities of scattering resistance and the definition of image and enhances inspection speed compared with prior art.

Owner:TSINGHUA UNIV +1

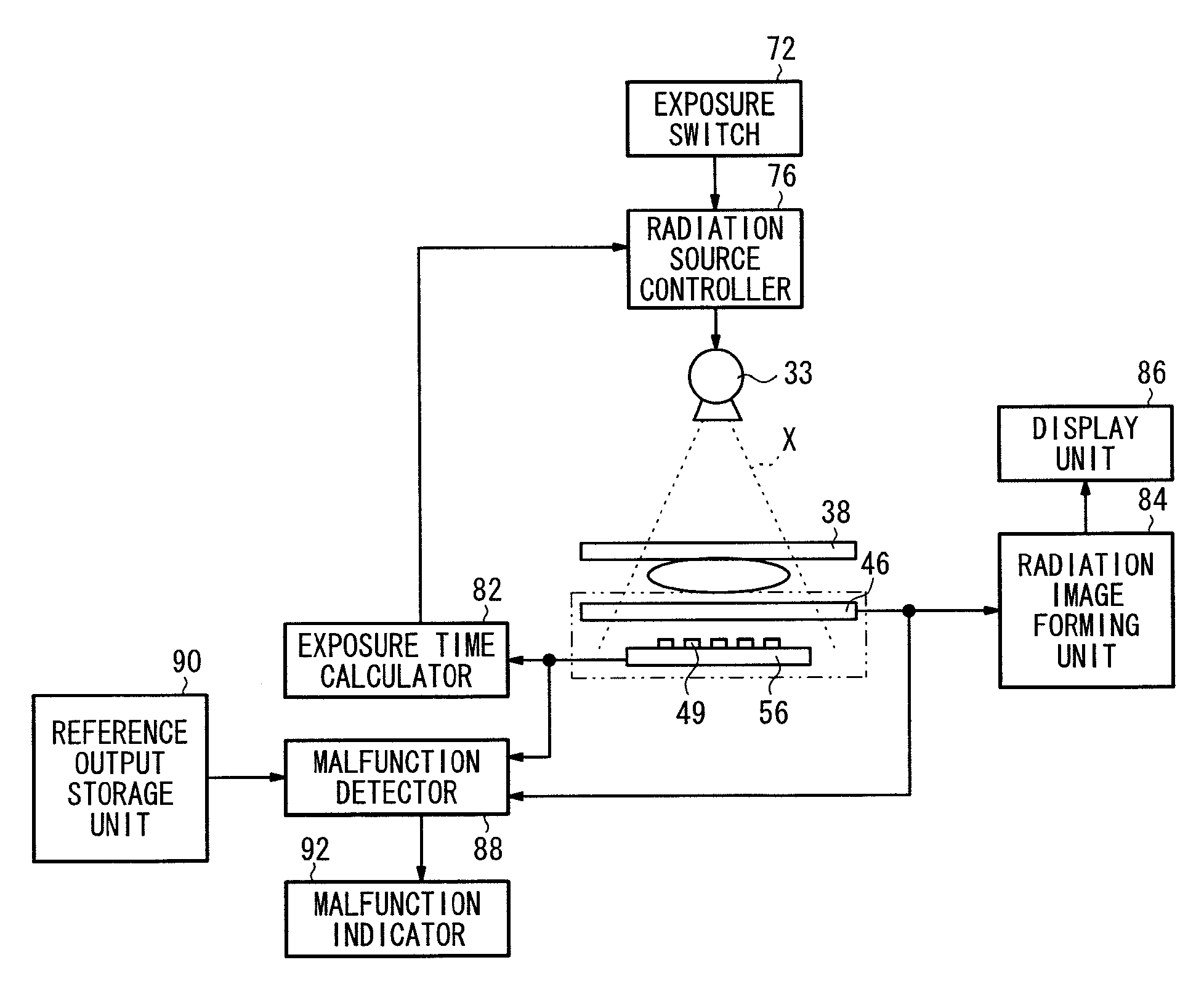

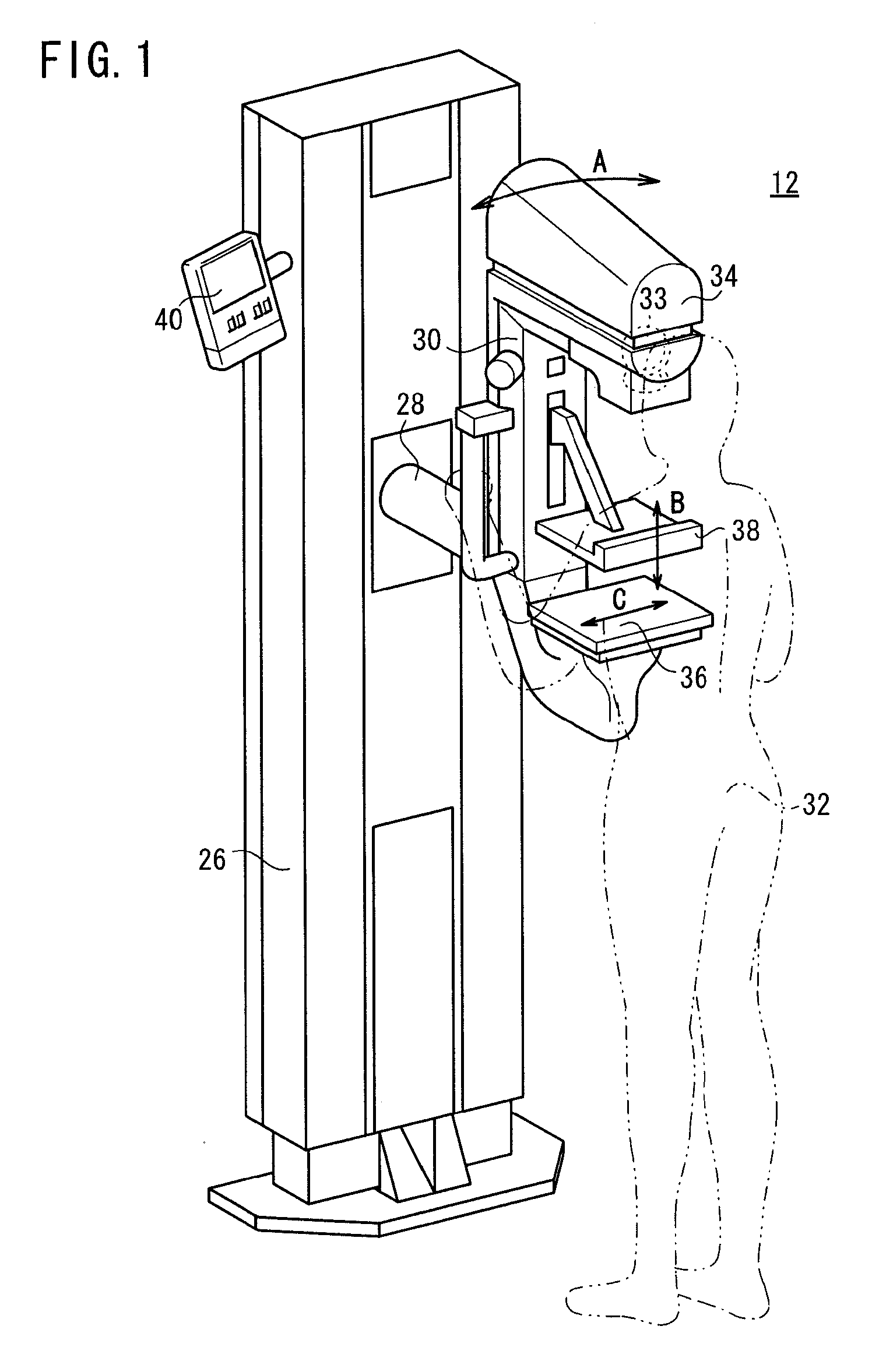

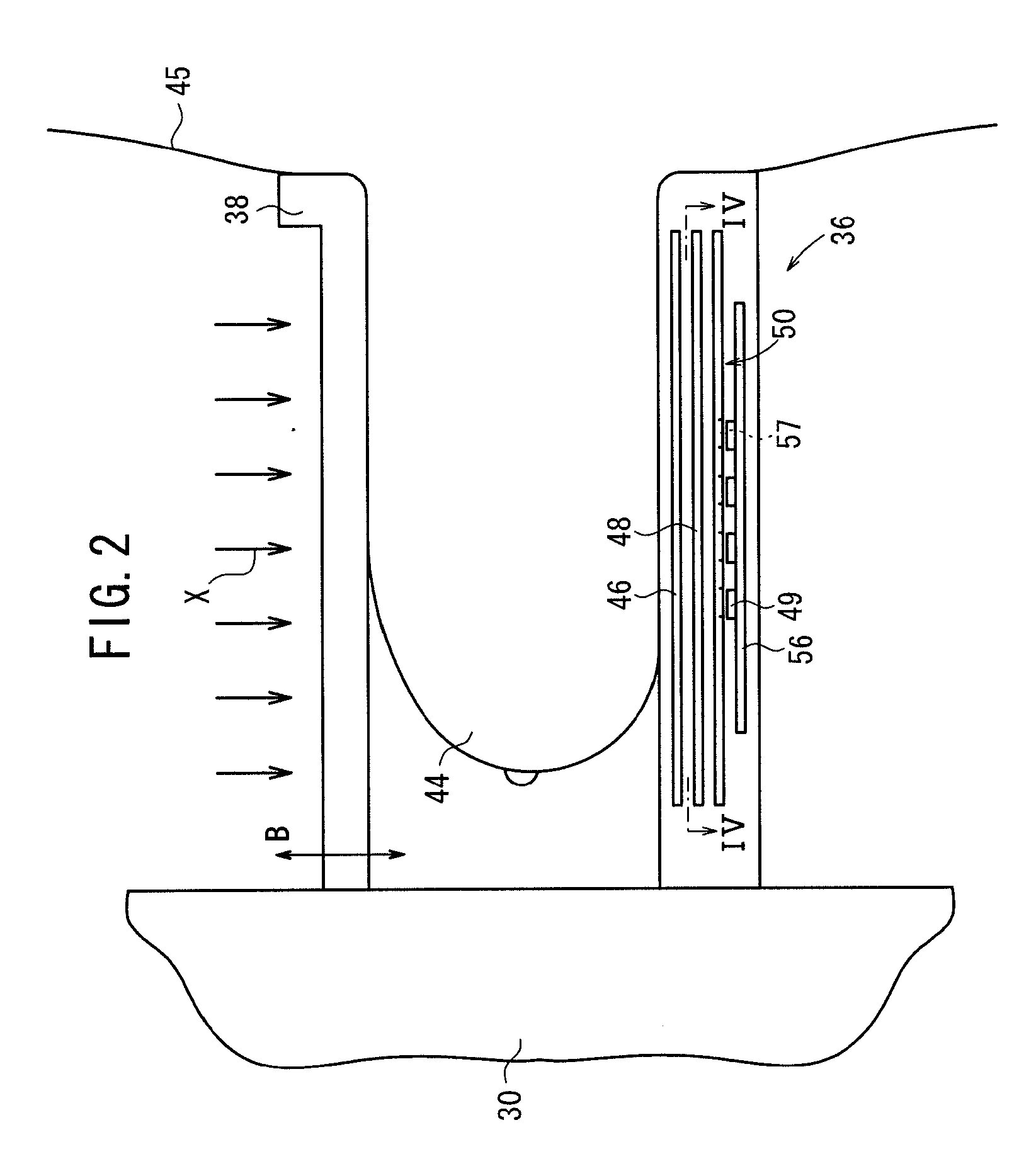

Radiation image capturing apparatus and method of detecting malfunction of radiation image capturing apparatus

InactiveUS20080224047A1Easy and inexpensiveMaterial analysis by optical meansPhotometry using electric radiation detectorsSolid state detectorImage capture

A mammographic system as a radiation image capturing apparatus includes a radiation source for emitting radiation, a solid-state detector for detecting radiation emitted from the radiation source and generating a radiation image based on such radiation, AEC sensors for detecting a radiation dose emitted from the radiation source, a radiation source controller for controlling the dose emitted from the radiation source based on output signals from the AEC sensors, a reference output storage unit for storing reference output ranges defining respective ranges of reference output signals for the solid-state detector and the AEC sensors, and a malfunction detector for comparing output signals generated by the solid-state detector and the AEC sensors with the respective reference output ranges to detect a malfunction of the solid-state detector, the AEC sensors, or the radiation source.

Owner:FUJIFILM CORP

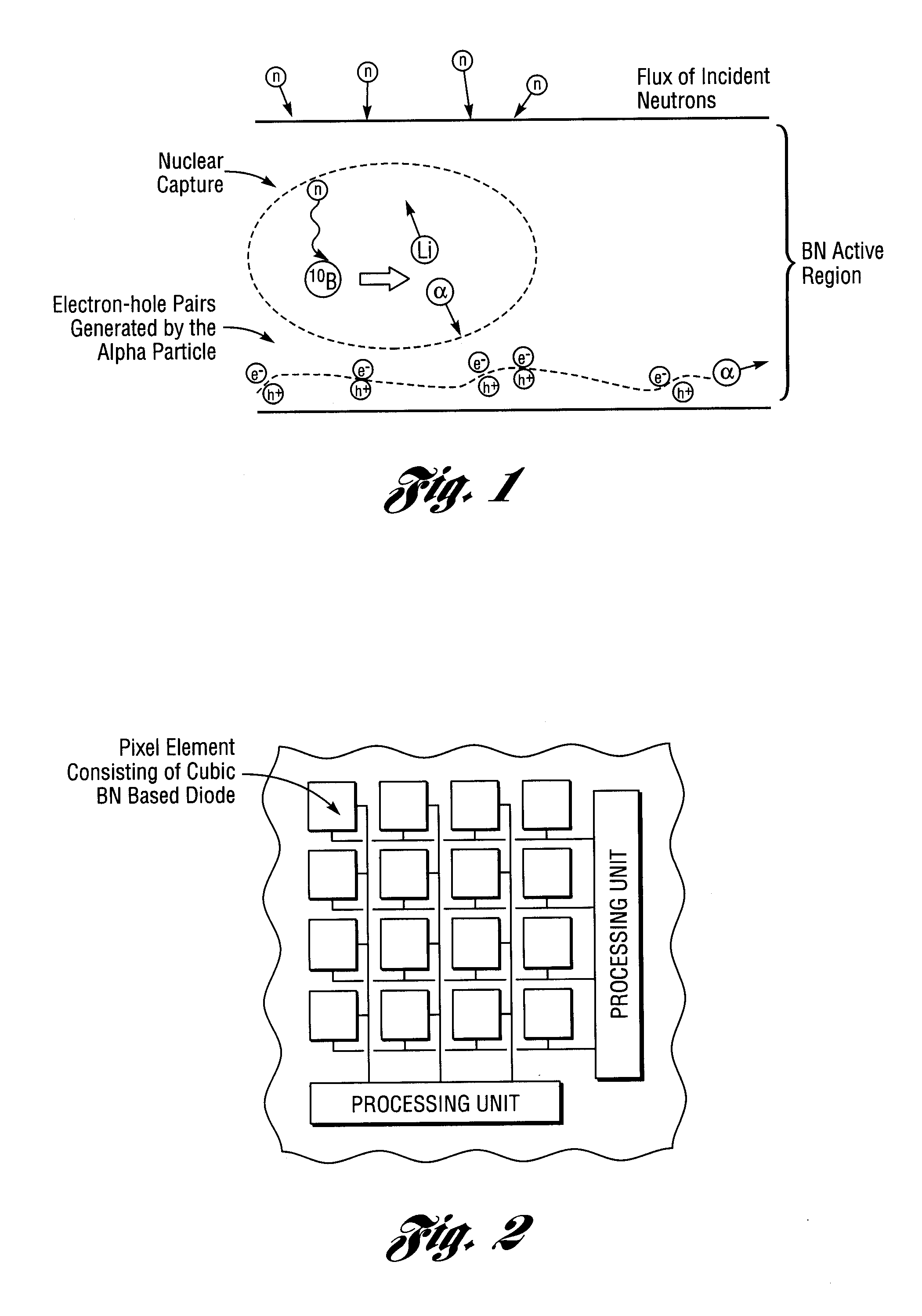

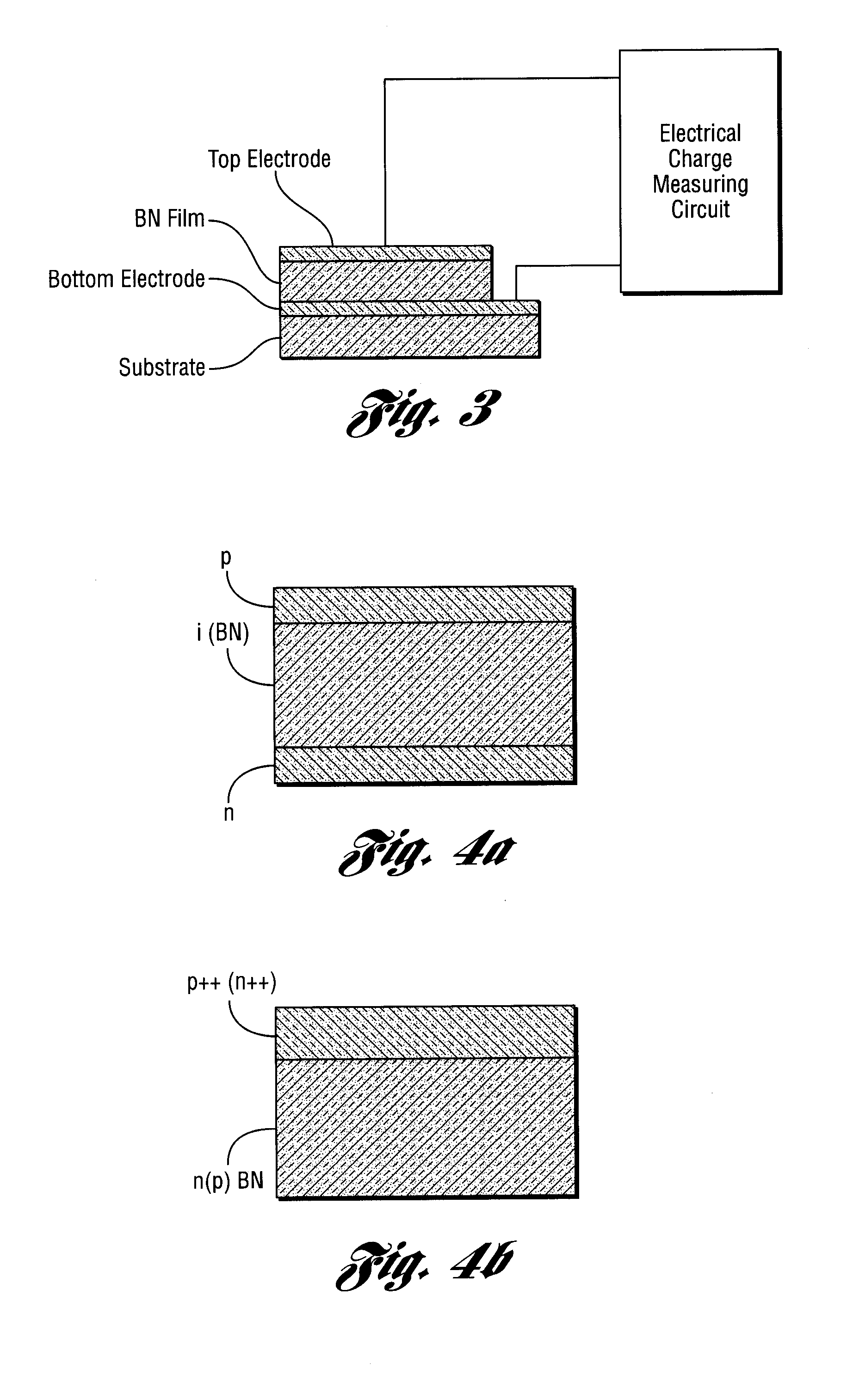

Detector Having A Thin Film Of Boron Nitride (BN) Such As Cubic BN And Method, Systems And Array Utilizing Same

InactiveUS20080296506A1Measurement with semiconductor devicesMaterial analysis by optical meansSolid state detectorBoron nitride

A detector having a thin film of boron nitride (BN) such as cubic BN, and method, system and array utilizing same are provided. Solid-state p-i-n, deep depletion p-n and Schottky diode detector devices based on a thin film of semiconducting cubic BN are provided. Miniaturized solid-state detectors based on cubic boron nitride have a broad range of applications, both civilian and military.

Owner:RGT UNIV OF MICHIGAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com