Patents

Literature

205results about How to "Wide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

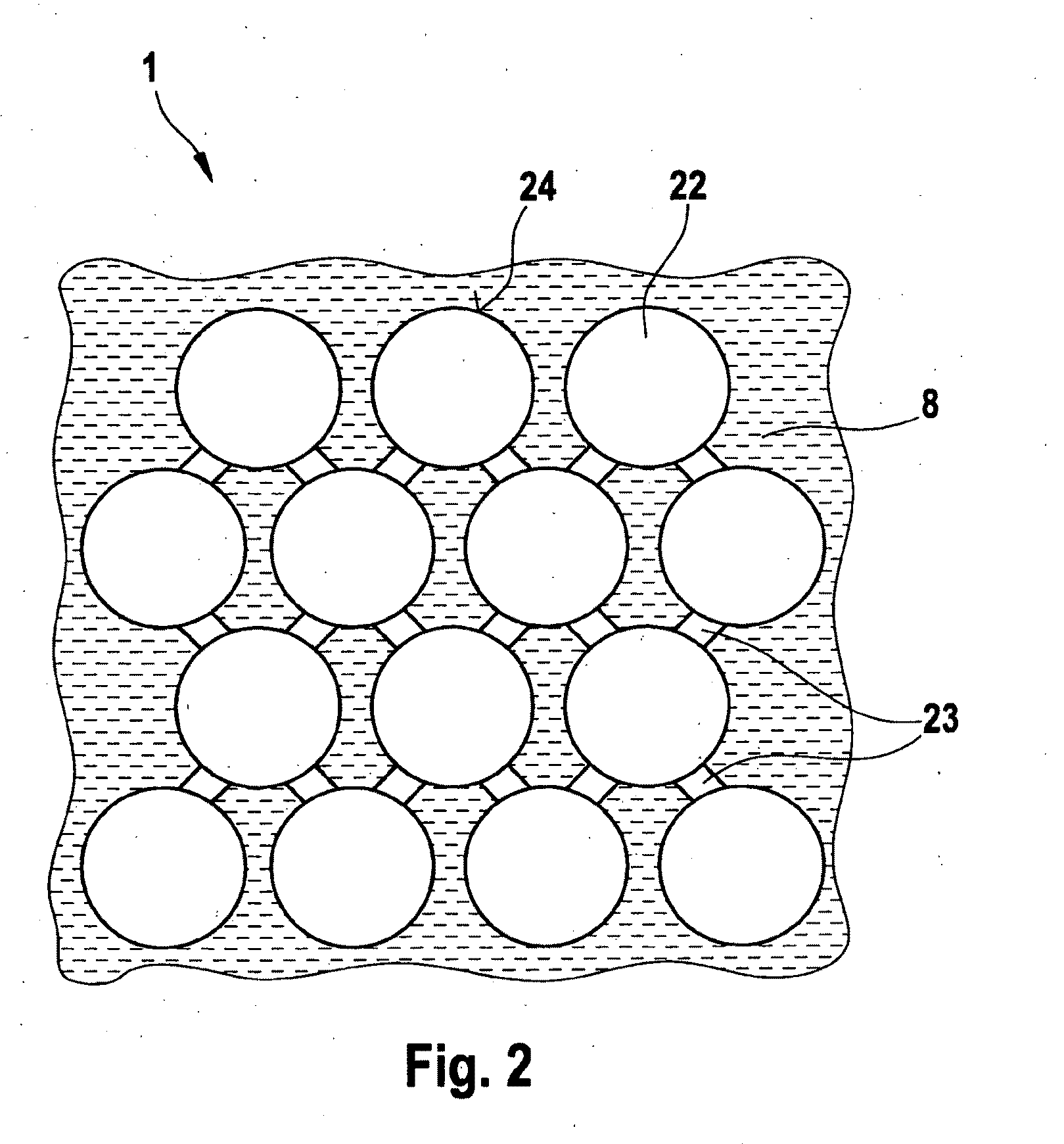

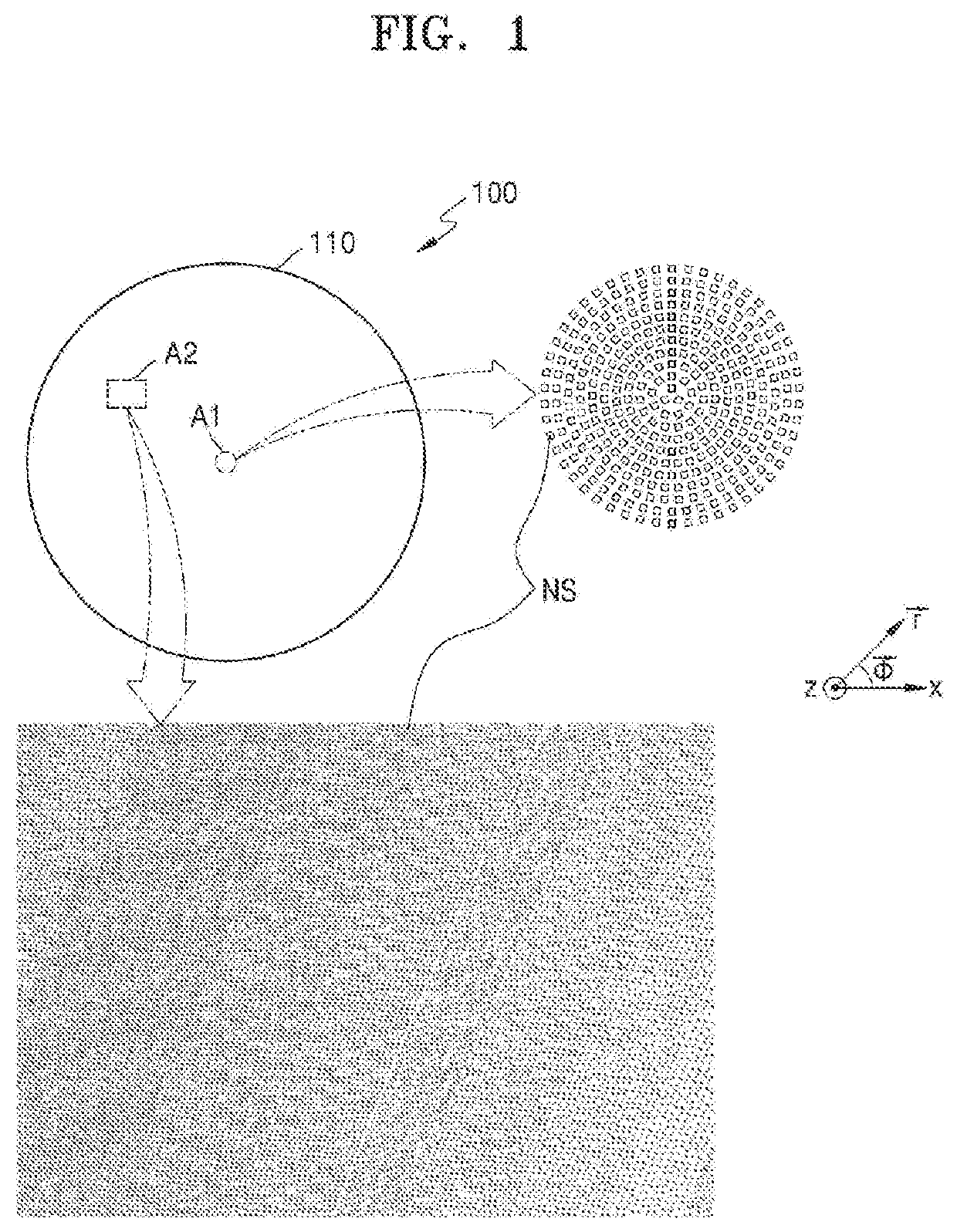

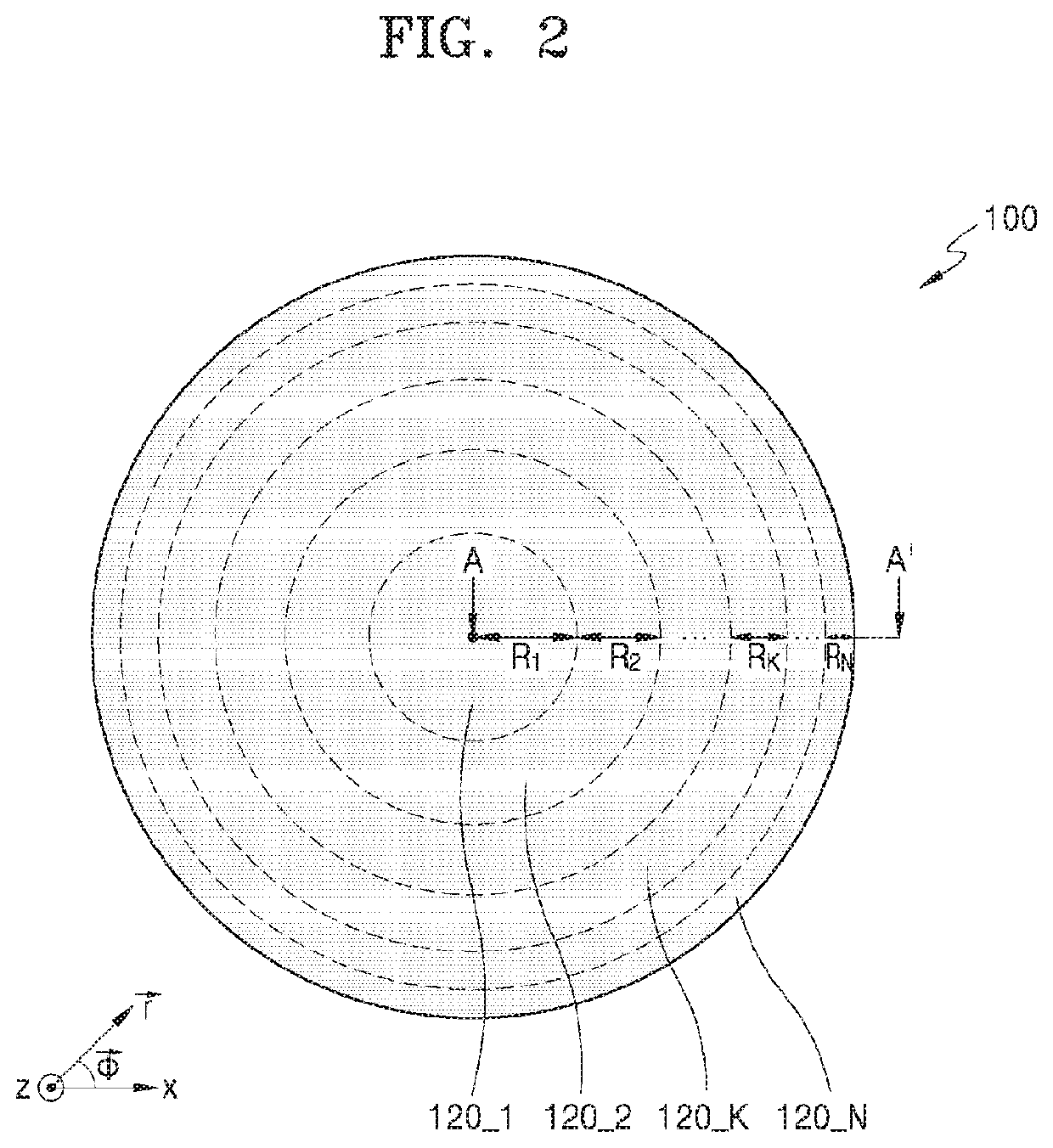

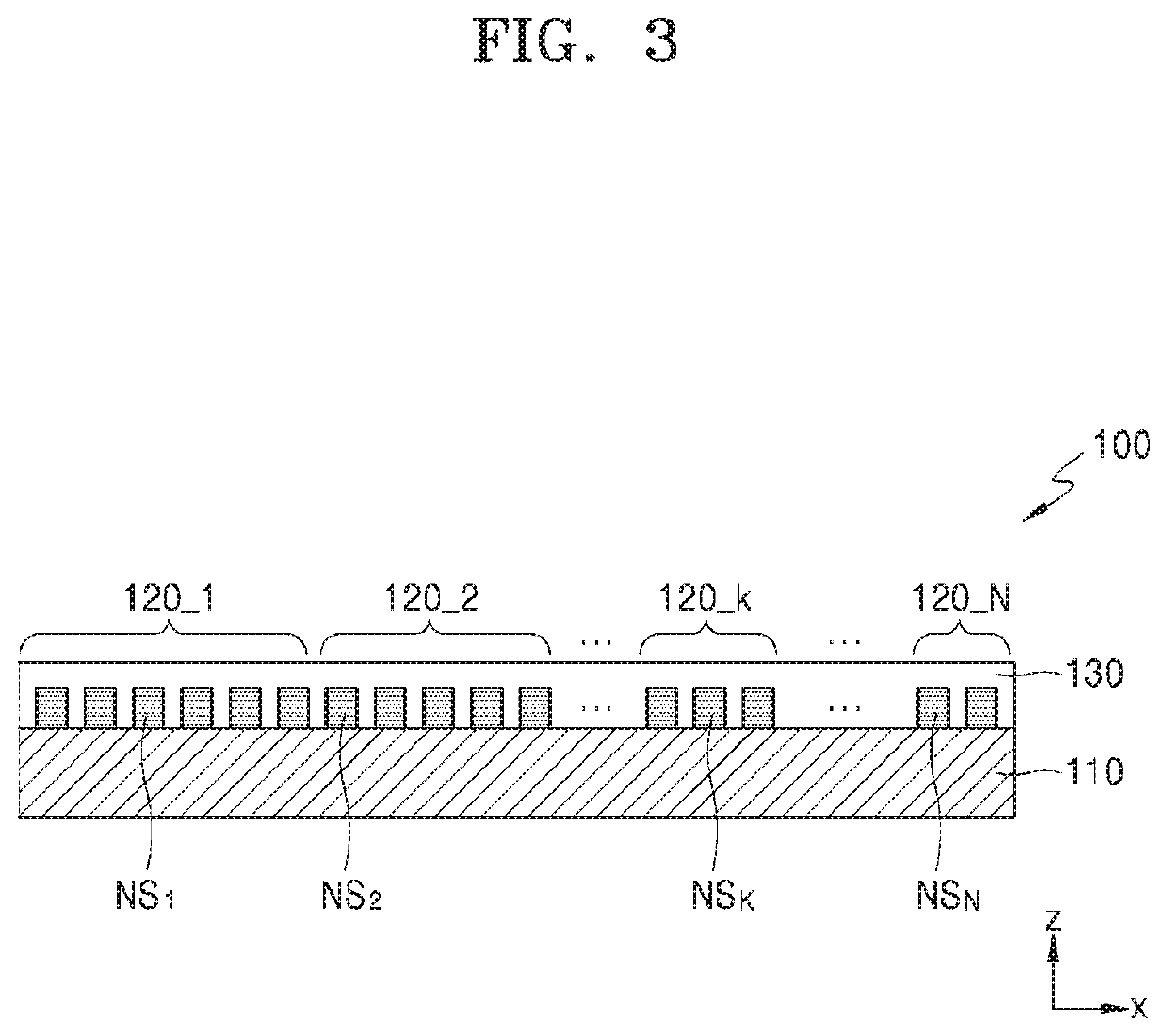

Micro concentrators elastically coupled with spherical photovoltaic cells

InactiveUS20090014056A1Reduce componentsLow costPV power plantsPhotovoltaic energy generationHigh concentrationEngineering

With small dimensional optics, small photovoltaic cells have heat distribution surfaces, very high concentrations and subsequently high utilization of the semiconductors can be achieved. Discrete photodiodes can be formed as spherical and other geometric shaped, cells with high performance characteristics, precision dimensions, and low cost. This invention positions discrete photovoltaic cells by using their geometric shape, elastic electrical mounts, couples them to small optical concentrator systems of refractory and or reflective optics and makes electrical network connections to those photodiodes, reliably, adjusting for thermal expansion, and at low cost to form low cost and reliable electrical power arrays. The electrical connectors and network can form part of the reflective optics and heat removal system. The electrical interconnection system can also form a reliable network that is self-correcting and tolerant of point failures.

Owner:ENERGY RELATED DEVICES +1

Computer-aided diagnosis system and method

InactiveUS6434262B2Useful diagnostic informationGood presence and meaning and significanceImage enhancementImage analysisX-rayLow contrast

An x-ray system acquires an initial low-contrast, wide latitude (G=2.5, or G=2 or less) x-ray image of a breast. A processing system automatically finds suspected abnormalities in the breast by processing the low contrast initial image, and then automatically converts the initial x-ray image to a high-contrast, narrow latitude image at the locations of the found abnormalities to thereby facilitate diagnosis and patient care. The technology includes effective ways to produce, process and display the various images, and can be extended to other types of images.

Owner:WANG SHIH PING

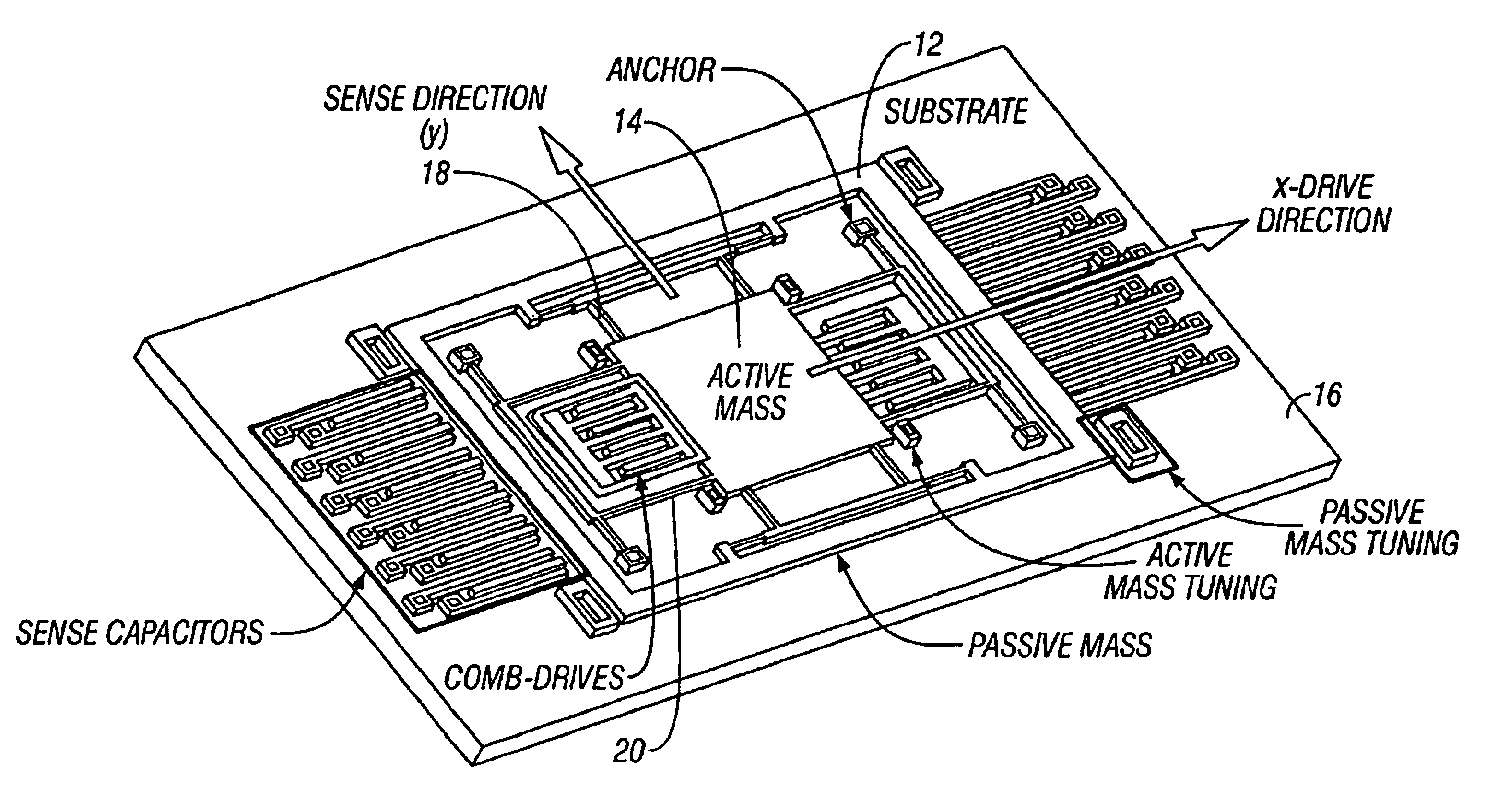

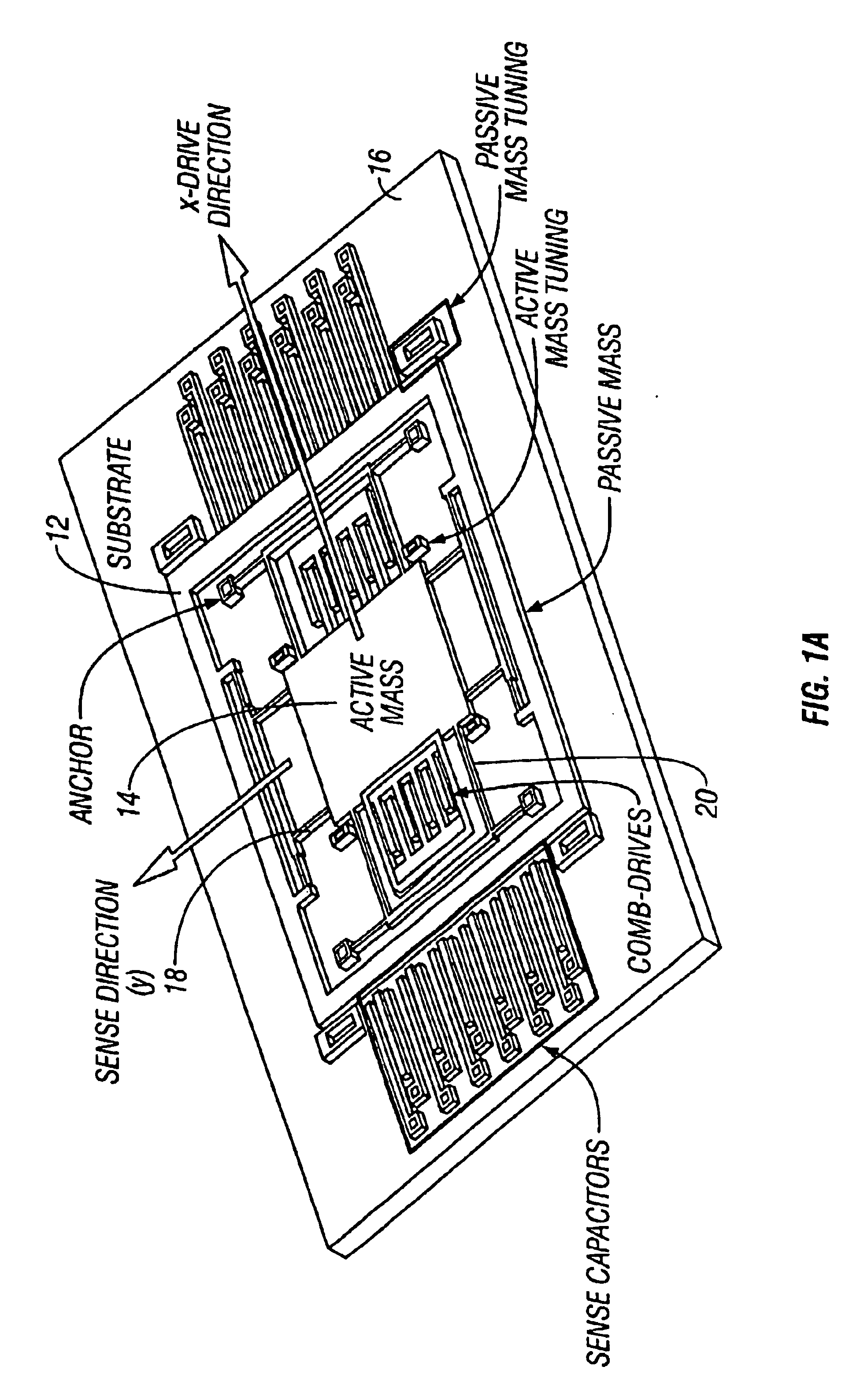

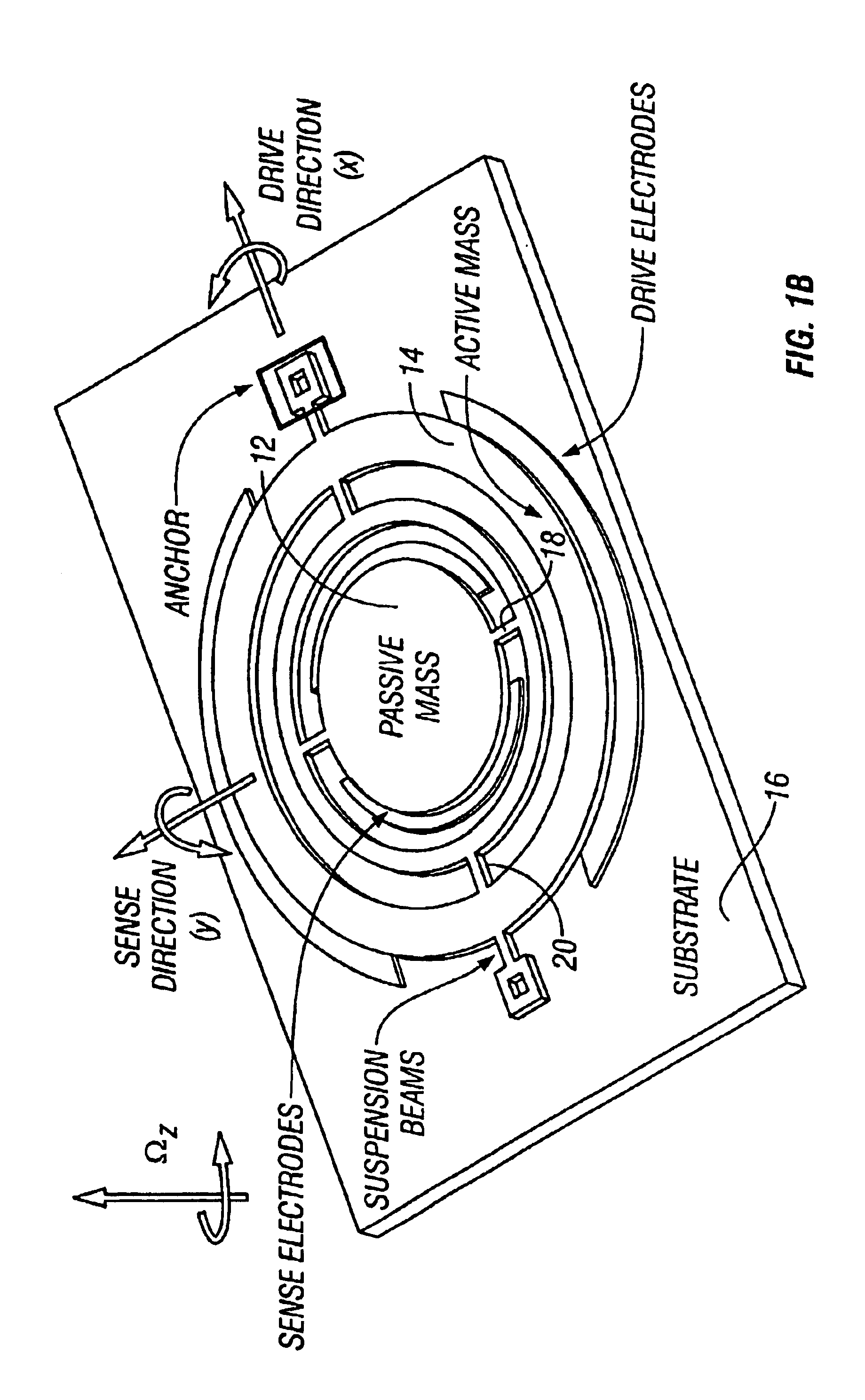

Non-resonant four degrees-of-freedom micromachined gyroscope

InactiveUS6845669B2WideOscillation amplitude is largeMechanical apparatusAcceleration measurement using interia forcesGyroscopeEngineering

A micromachined design and method with inherent disturbance-rejection capabilities is based on increasing the degrees-of-freedom (DOF) of the oscillatory system by the use of two independently oscillating proof masses. Utilizing dynamical amplification in the 4-degrees-of-freedom system, inherent disturbance rejection is achieved, providing reduced sensitivity to structural and thermal parameter fluctuations and damping changes over the operating time of the device. In the proposed system, the first mass is forced to oscillate in the drive direction, and the response of the second mass in the orthogonal direction is sensed. The response has two resonant peaks and a flat region between peaks. Operation is in the flat region, where the gain is insensitive to frequency fluctuations. An over 15 times increase in the bandwidth of the system is achieved due to the use of the proposed architecture. In addition, the gain in the operation region has low sensitivity to damping changes. Consequently, by utilizing the disturbance-rejection capability of the dynamical system, improved robustness is achieved, which can relax tight fabrication tolerances and packaging requirements and thus result in reducing production cost of micromachined methods.

Owner:RGT UNIV OF CALIFORNIA

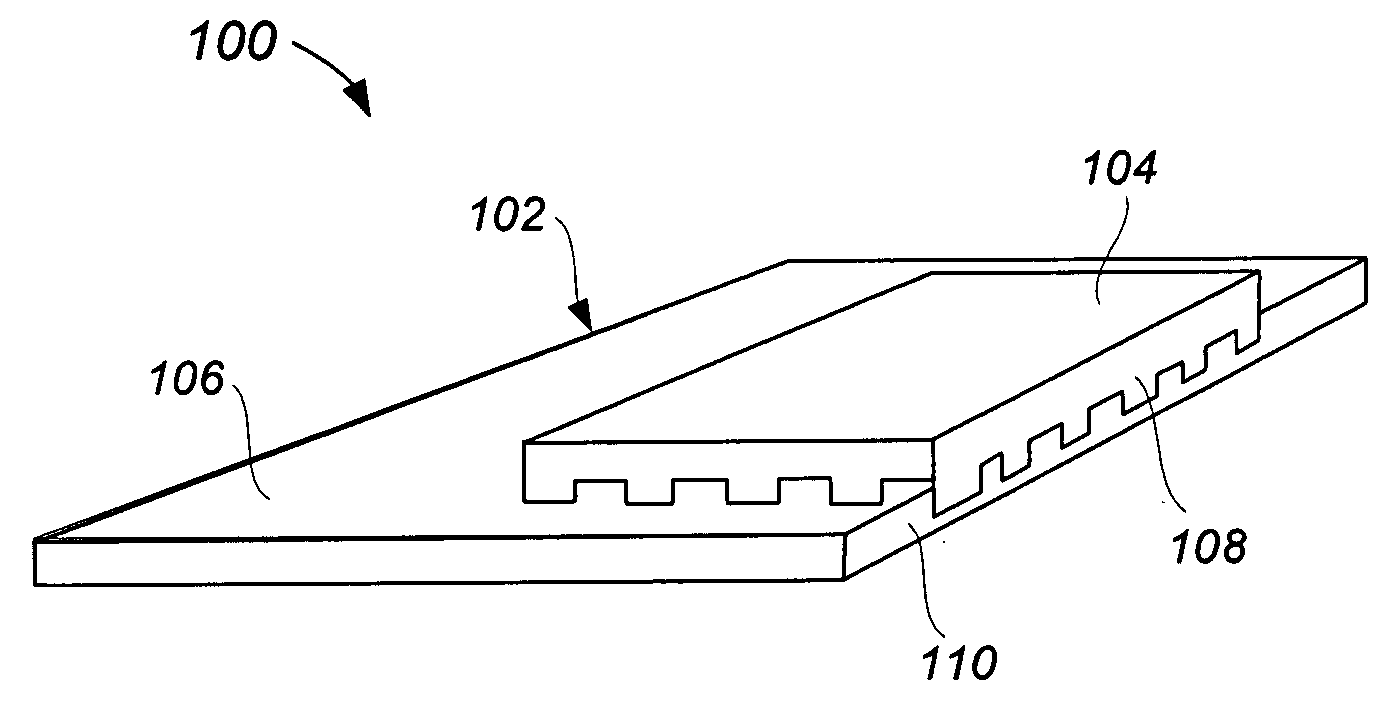

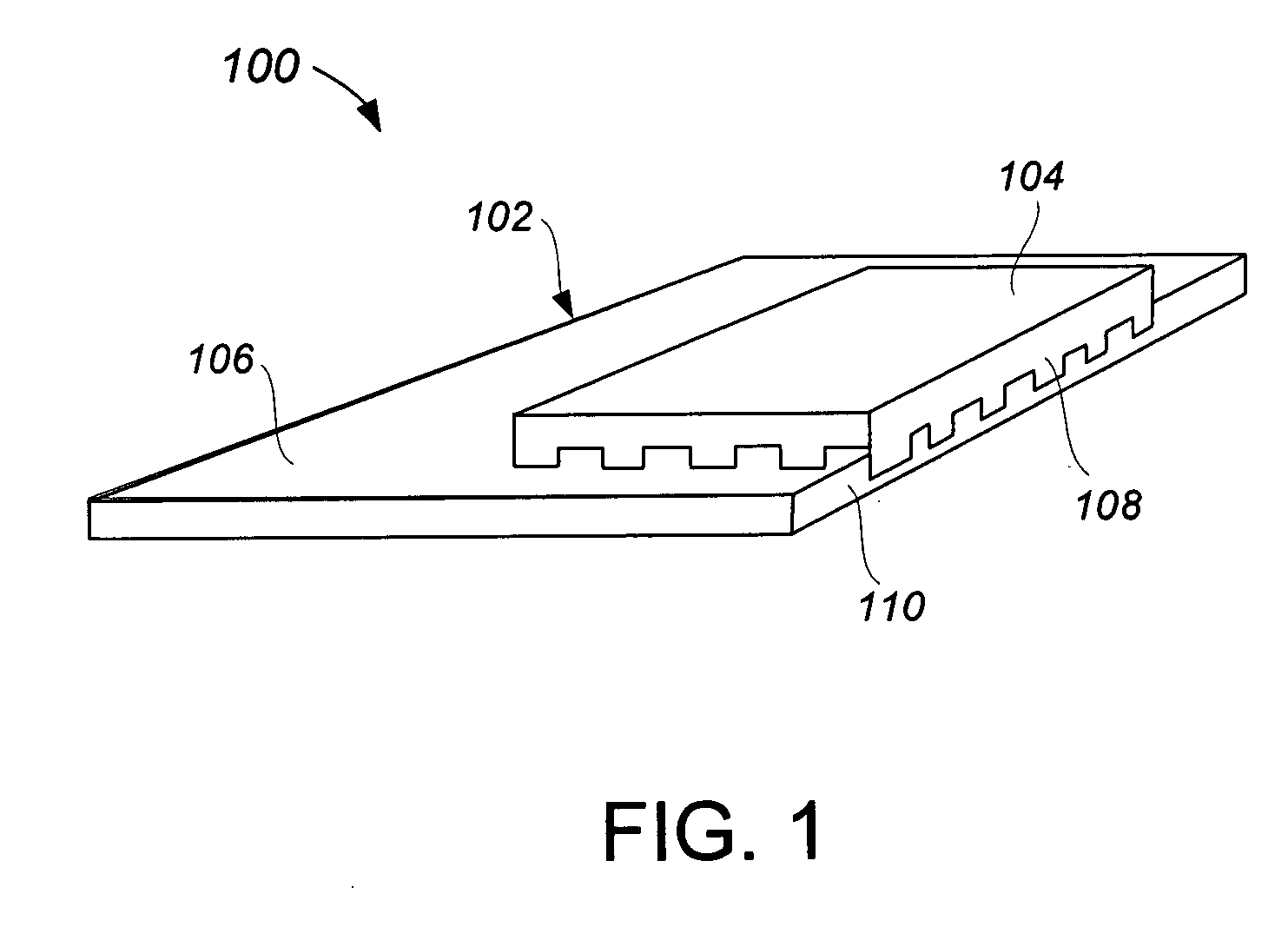

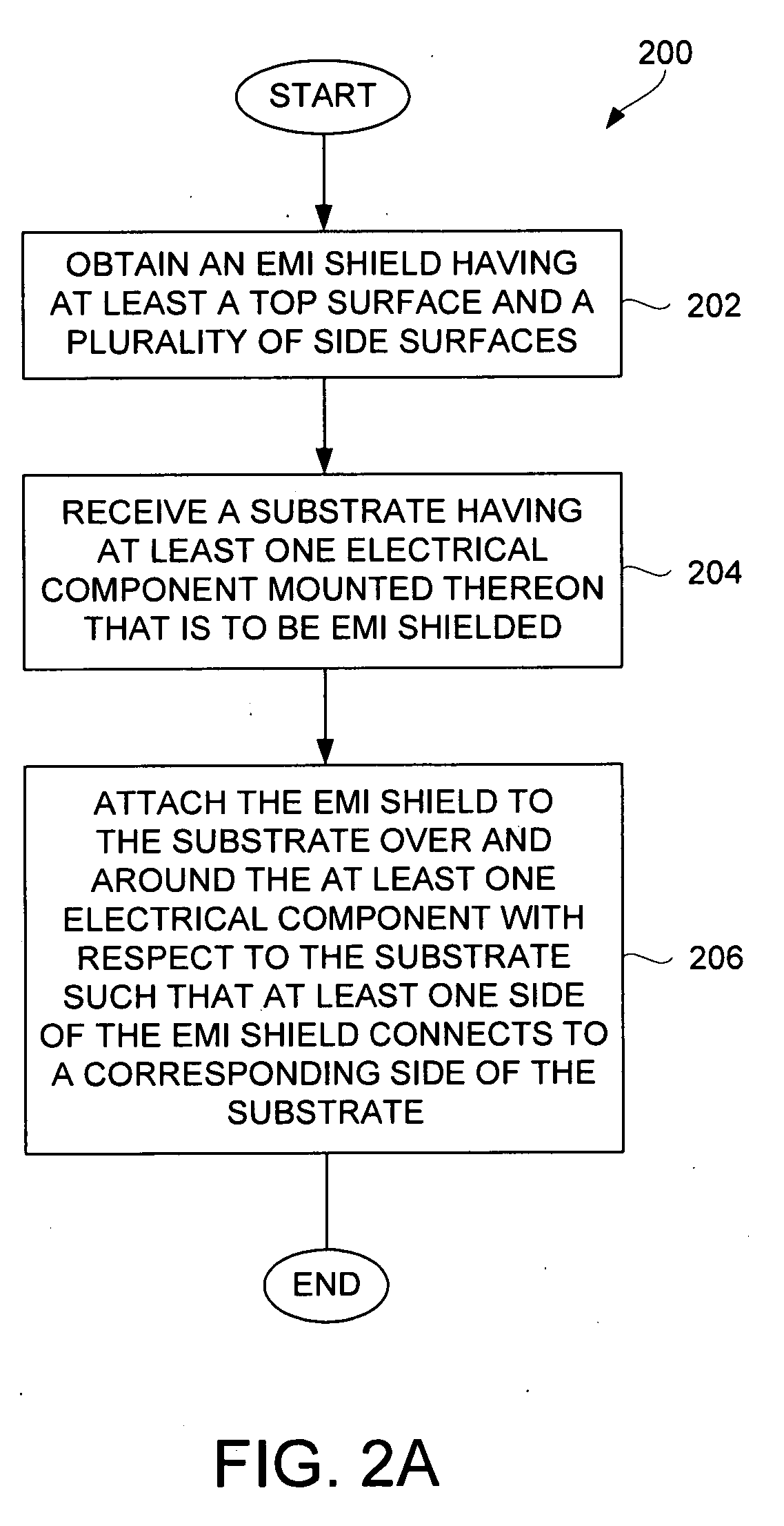

Electromagnetic Interference Shielding for Compact Electronic Devices

InactiveUS20100246143A1Efficient use ofWideMagnetic/electric field screeningElectrical apparatus contructional detailsElectromagnetic interferenceElectromagnetic shielding

Improved approaches for providing electromagnetic interference shielding to one or more electrical components within a housing of a portable electronic device are disclosed. According to one aspect of certain embodiments, an electromagnetic shield can be attached to one or more edges of a substrate (e.g., printed circuit board) provided within a housing of a portable electronic device. Advantageously, this allows the substrate space to be efficiently utilized such that relatively wide electrical components can be provided on the substrate without having to further increase the width of the substrate to provide space for an EMI shielding structure and its attachment to the substrate. The housing of the portable electronic device can be compact, such as a low profile housing.

Owner:APPLE INC

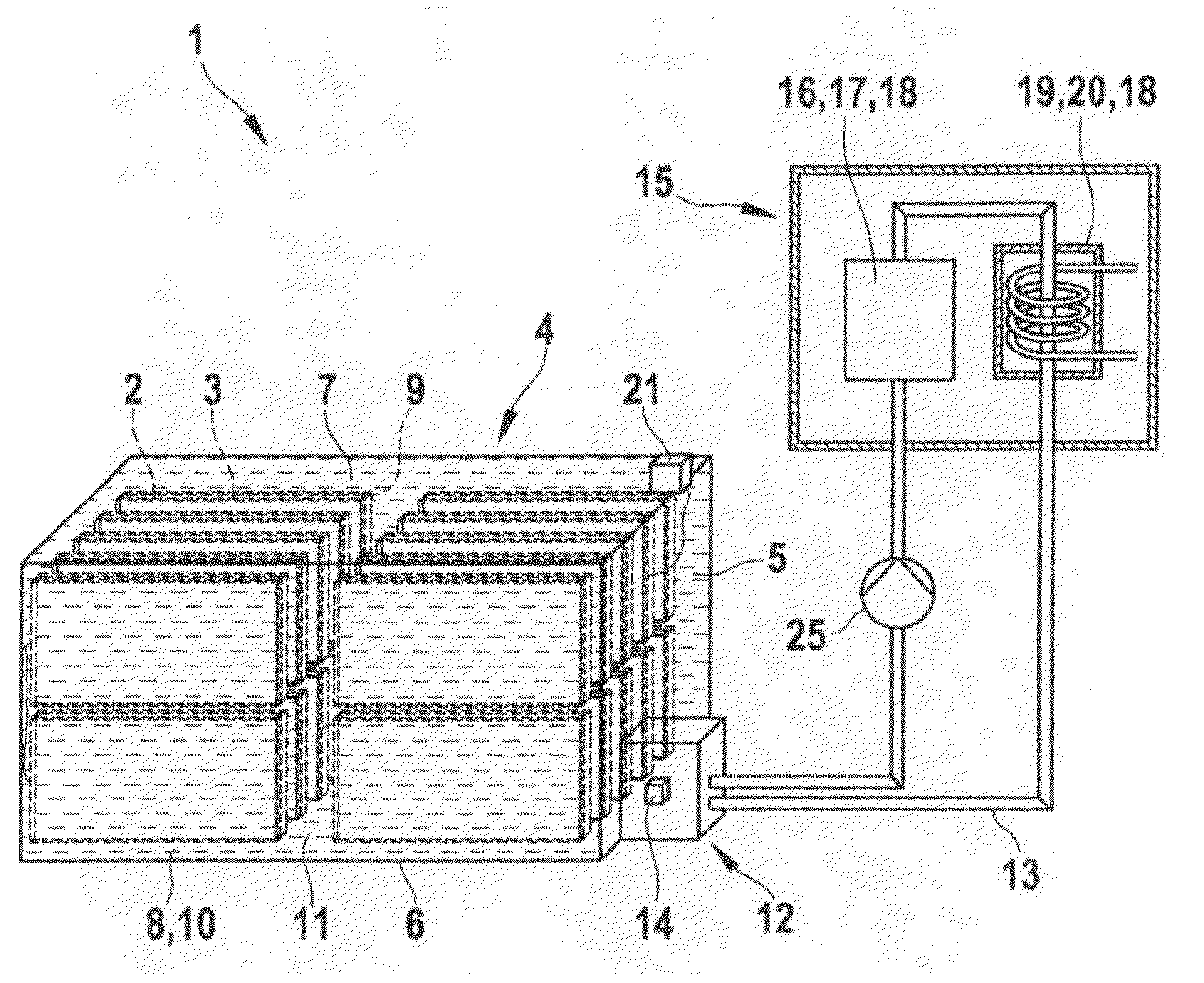

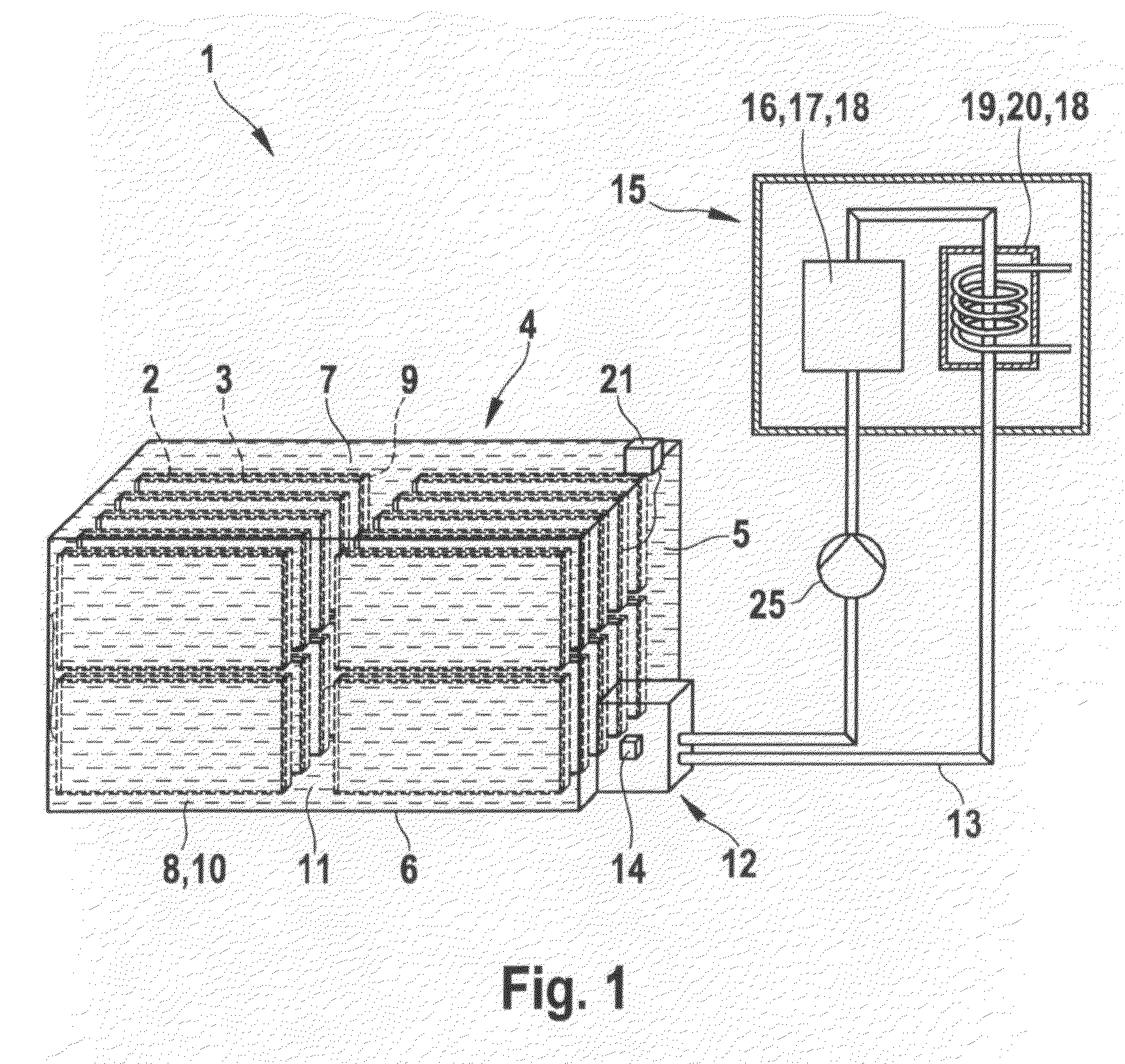

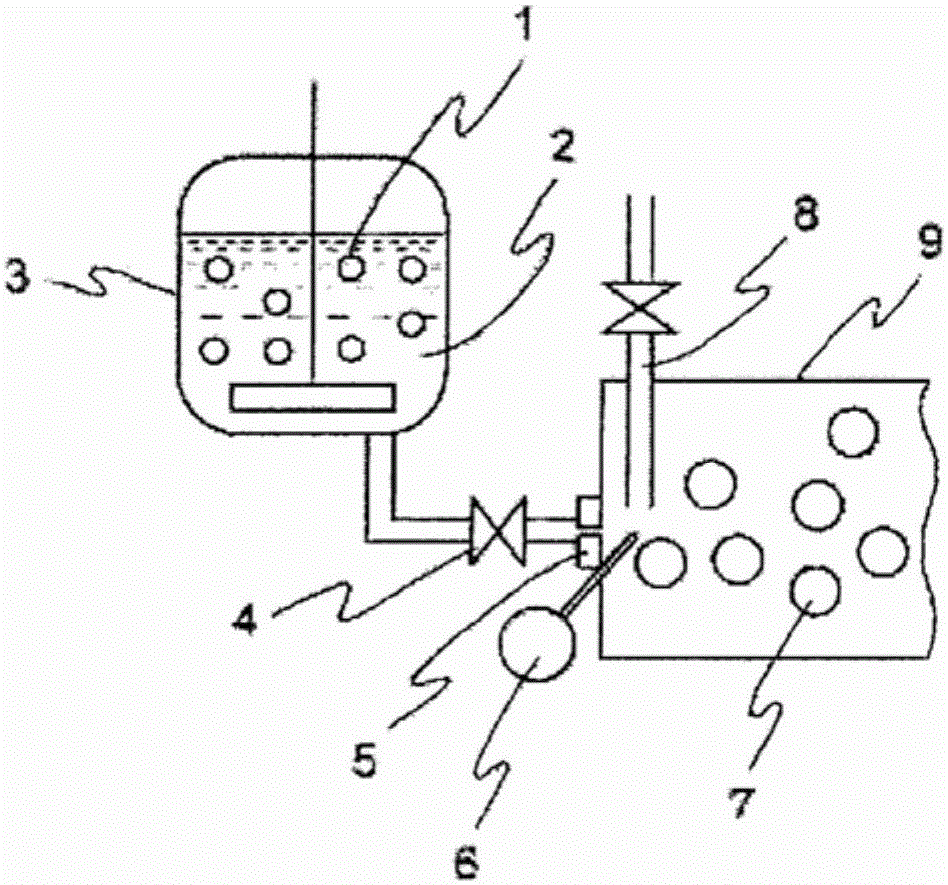

Temperature-controlled battery device and method for it

InactiveUS20110027631A1WideAvoid disadvantagesCell temperature controlBattery isolationTemperature controlElectrical battery

A battery device having at least one battery and having at least one heating and / or cooling device temperature-controlling the battery. It is provided that the battery, submerged in an heating and / or cooling medium, is situated in a housing that accommodates the heating and / or cooling medium. The present invention also relates to a corresponding method.

Owner:ROBERT BOSCH GMBH

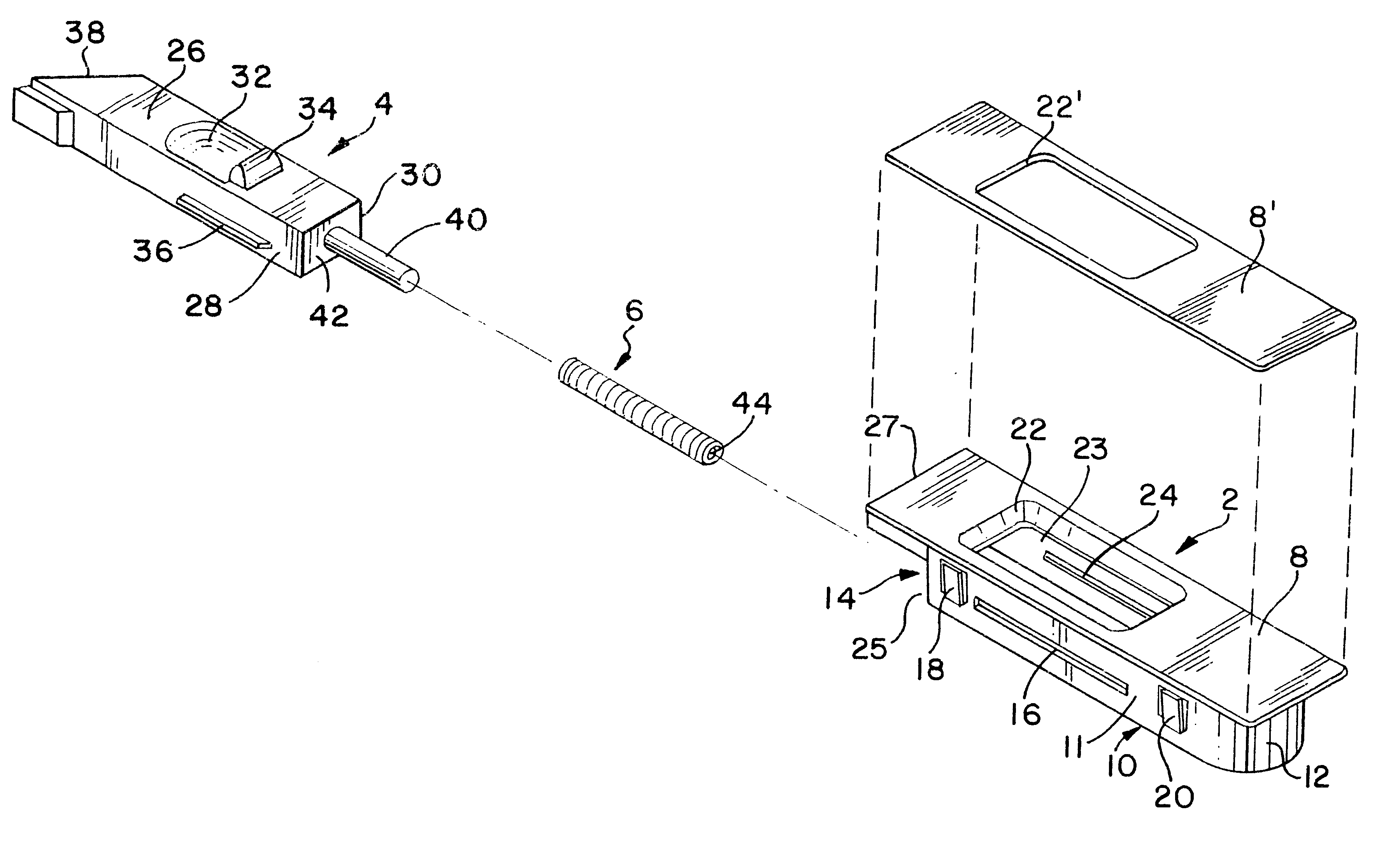

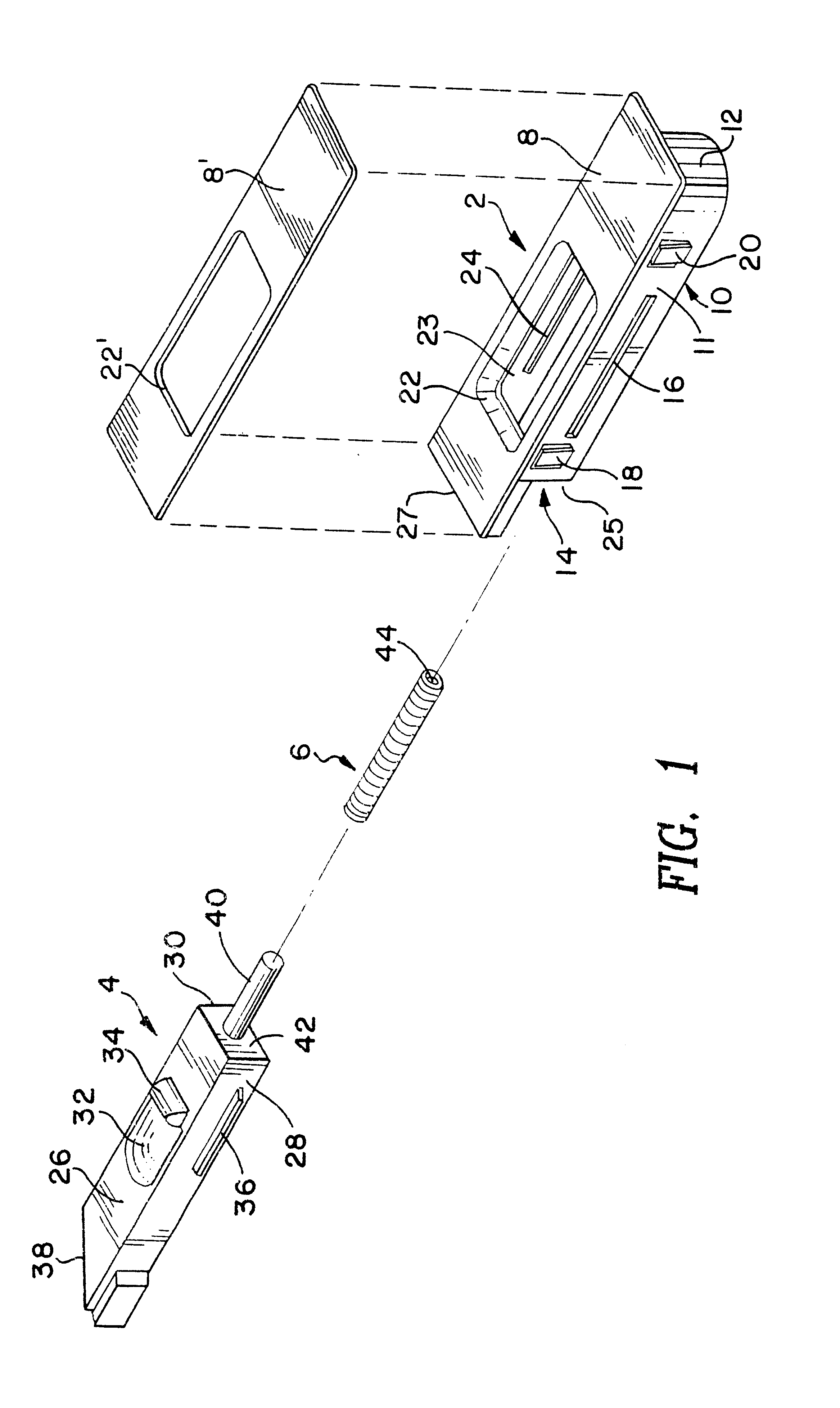

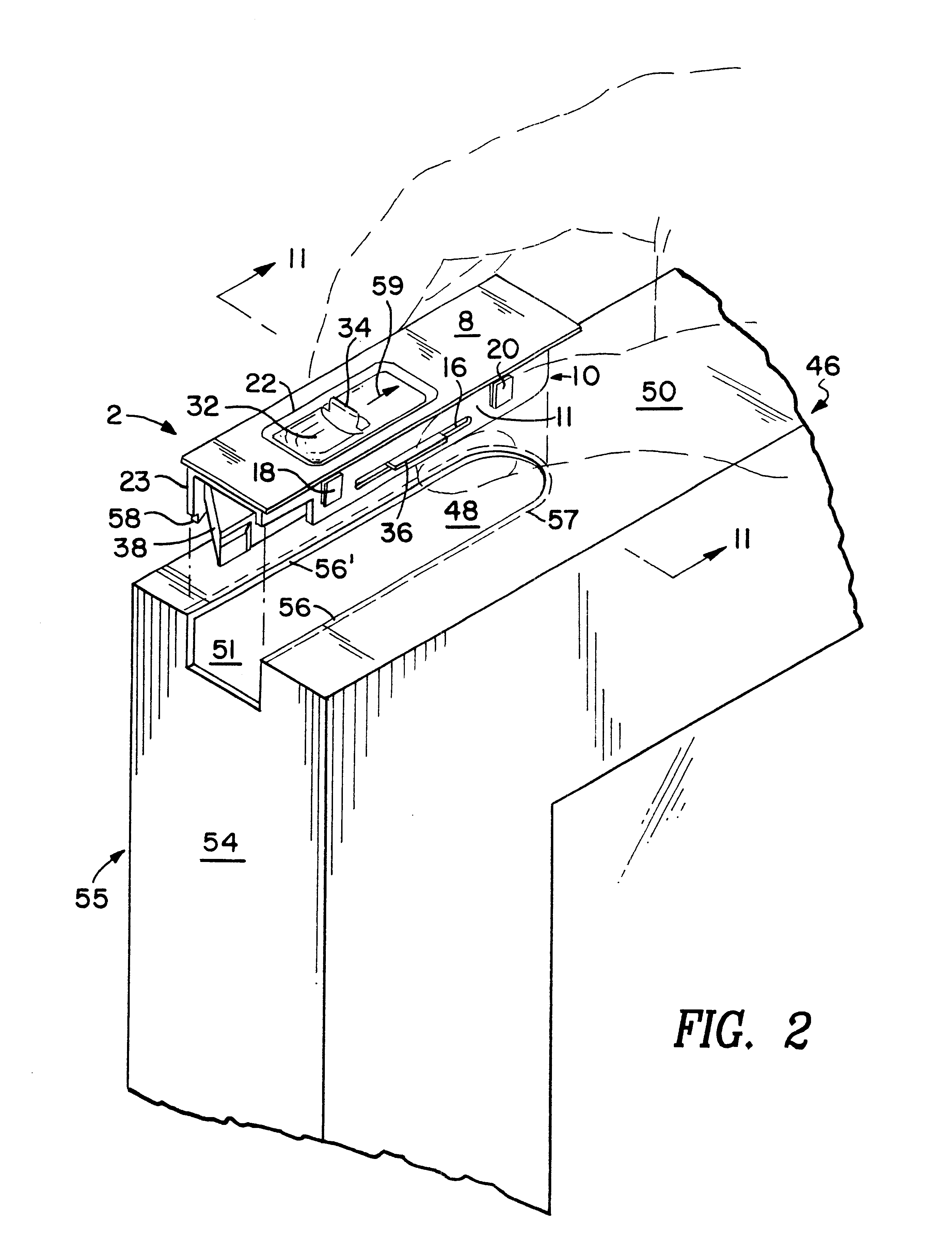

Snap on latch mechanism for a sash window

InactiveUSRE37916E1WideEasy to assembleConstruction fastening devicesLock casingsSlab windowSash window

Owner:NOVA WILDCAT ASHLAND LLC

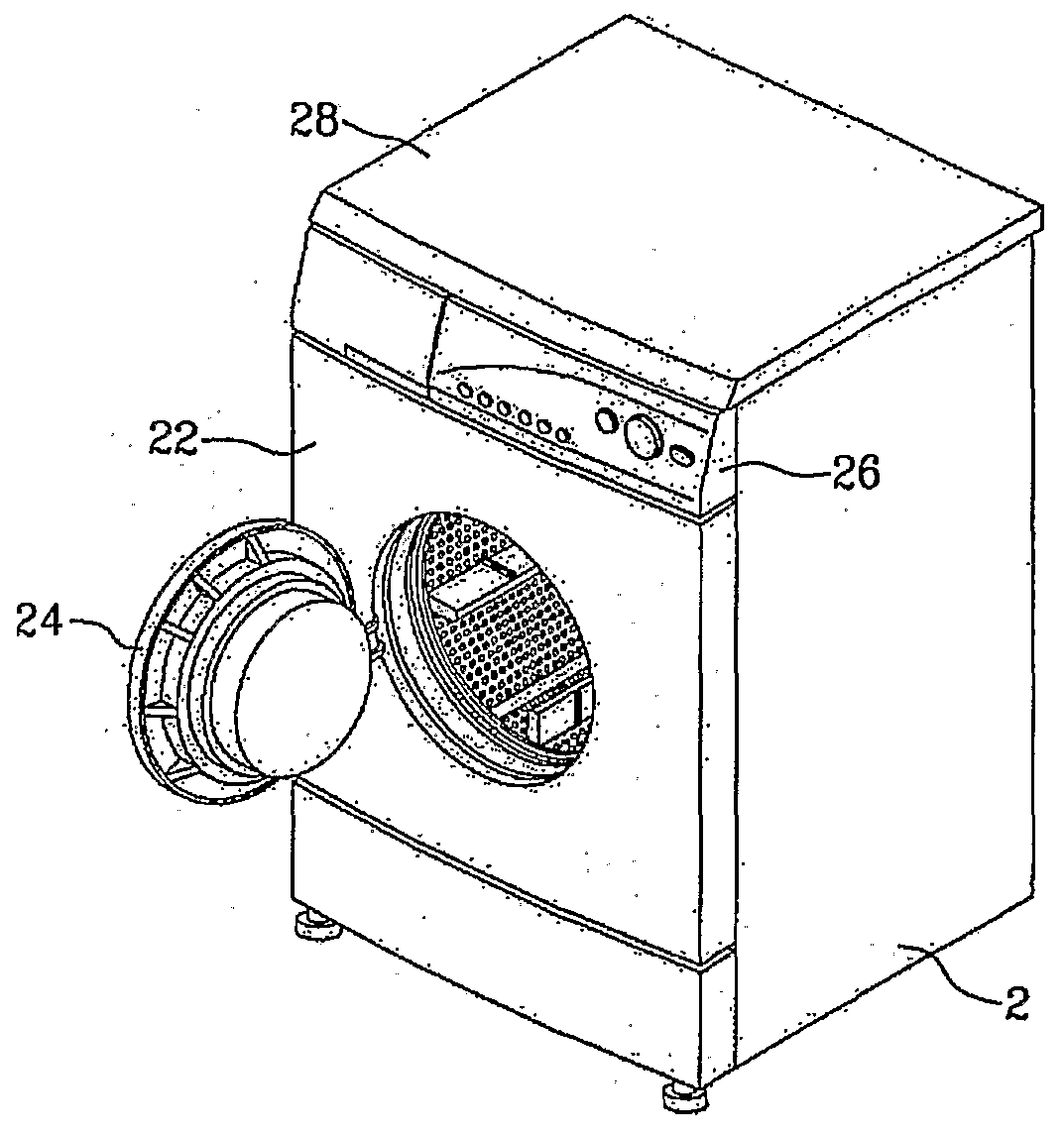

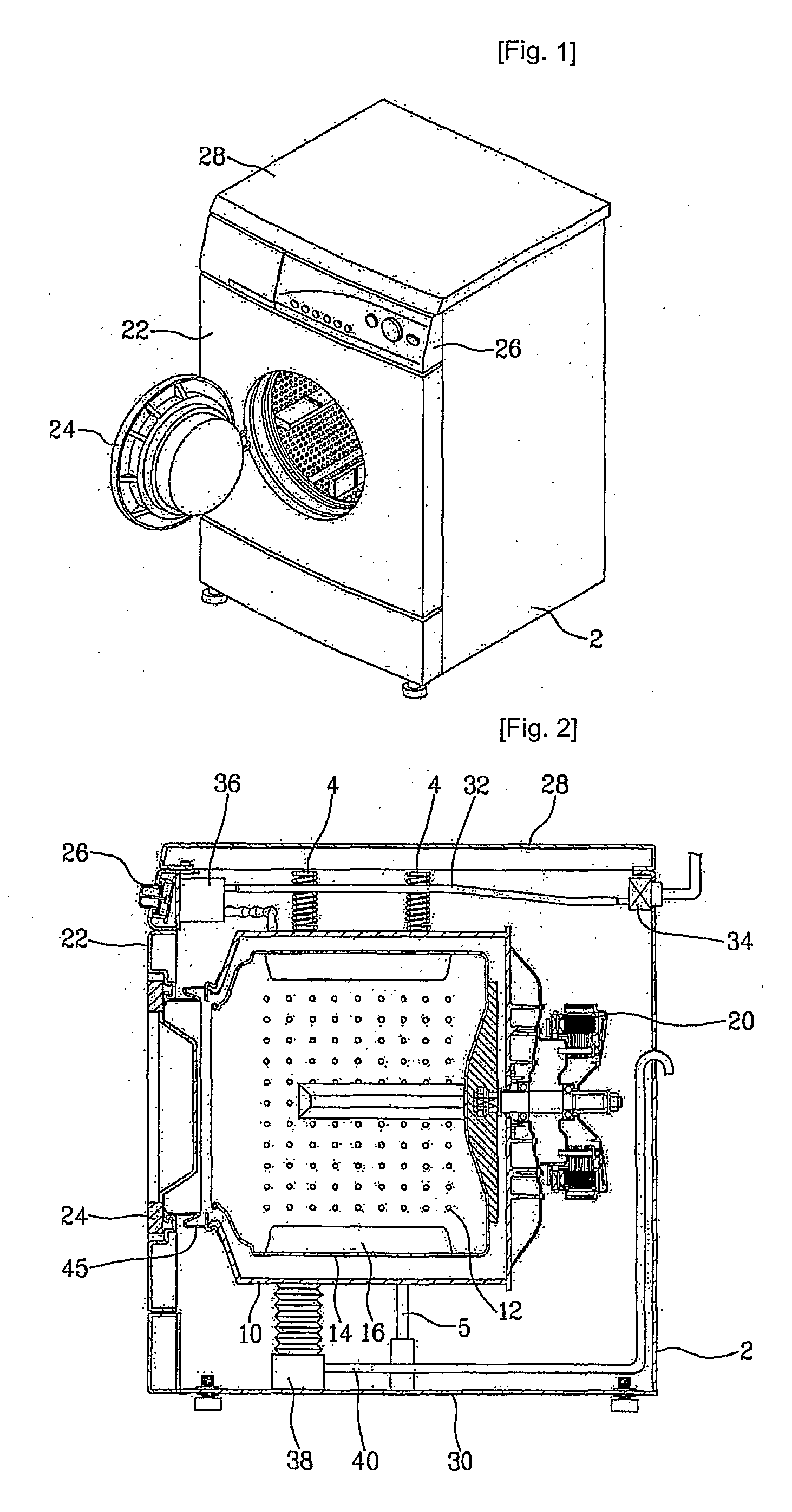

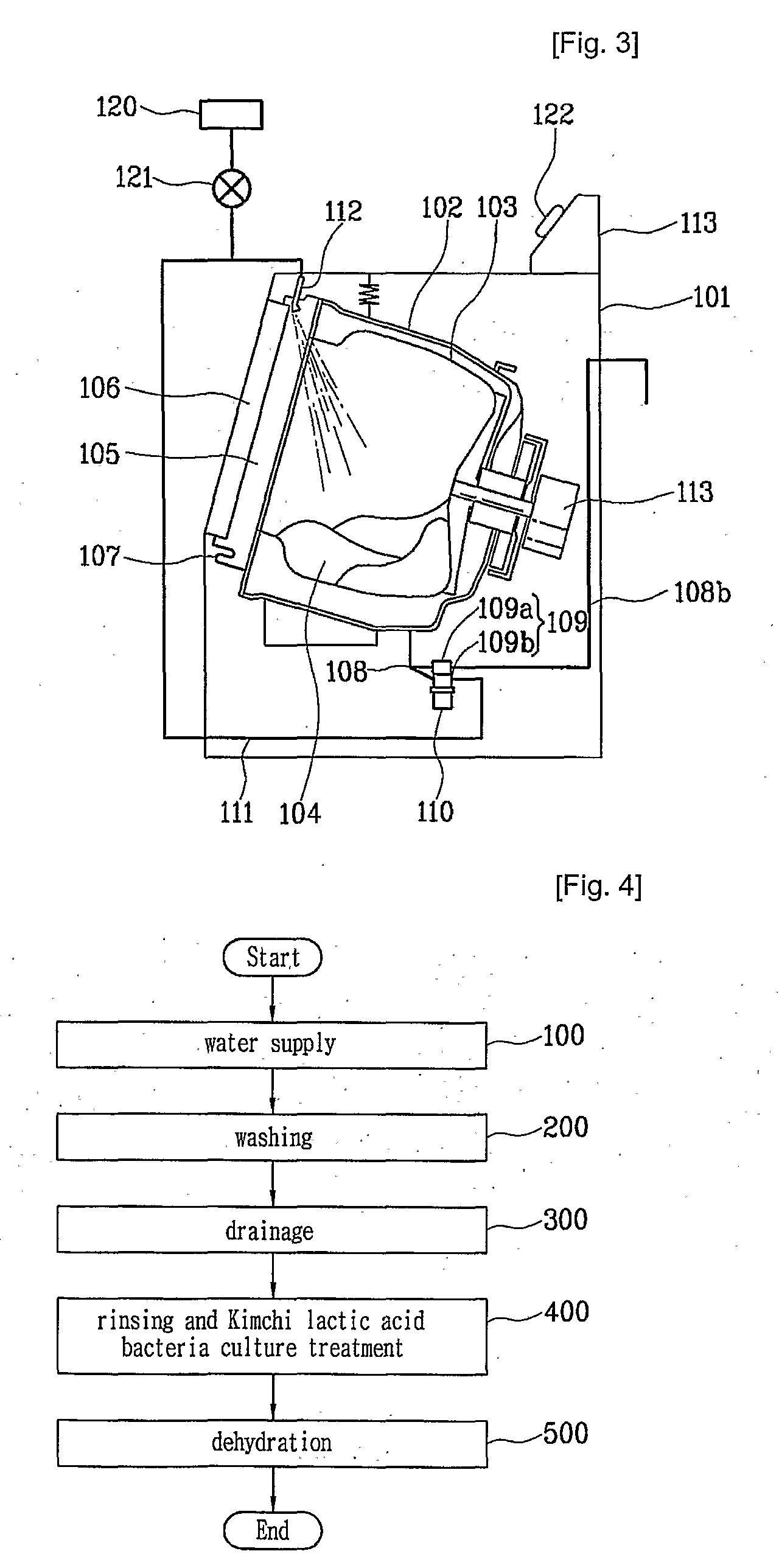

Apparatus of Supplying and Discharging Fluid and Method of Operating the Same

ActiveUS20090320213A1Improve antimicrobial property of compositionWideTableware washing/rinsing machine detailsTextile treatment machine partsChemistryExposure treatment

The present invention relates to n apparatus of supplying and discharging a fluid, comprising: an inner tub; a fluid inflow passage connected to the inner tub; and a fluid outflow passage connected to the inner tub, wherein at least one of the inner tub, the inflow passage and the outflow passage has undergone at least one of the Kimchi lactic acid bacteria culture treatment and the Kimchi lactic acid bacteria culture exposure treatment.

Owner:LG ELECTRONICS INC

Micro concentrators elastically coupled with spherical photovoltaic cells

InactiveUS8013238B2Make arrays expensive, inefficient, and sometimes unreliableBetter utilize the expensive semiconductorPV power plantsPhotovoltaic energy generationHigh concentrationElectricity

Owner:ENERGY RELATED DEVICES +1

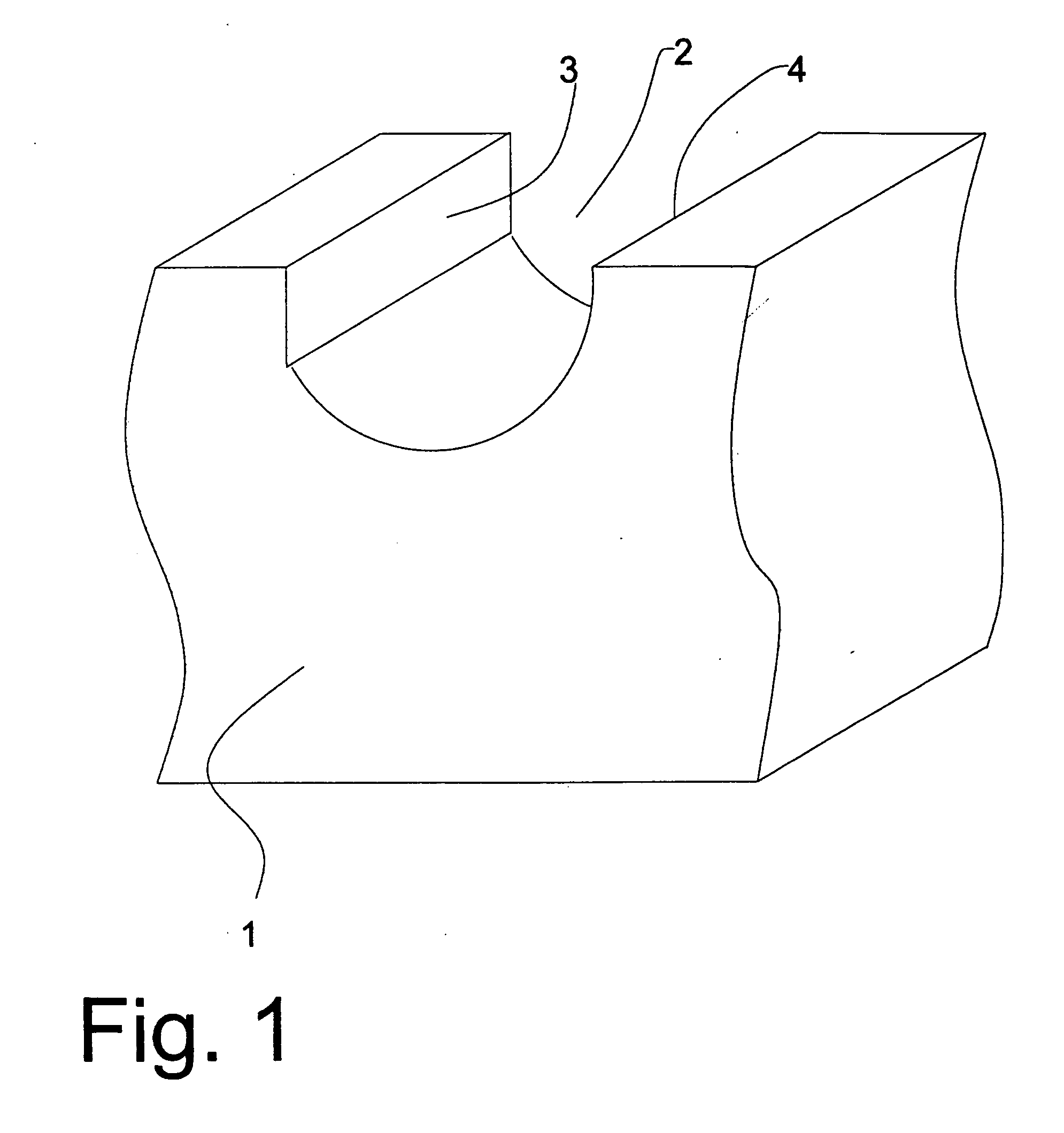

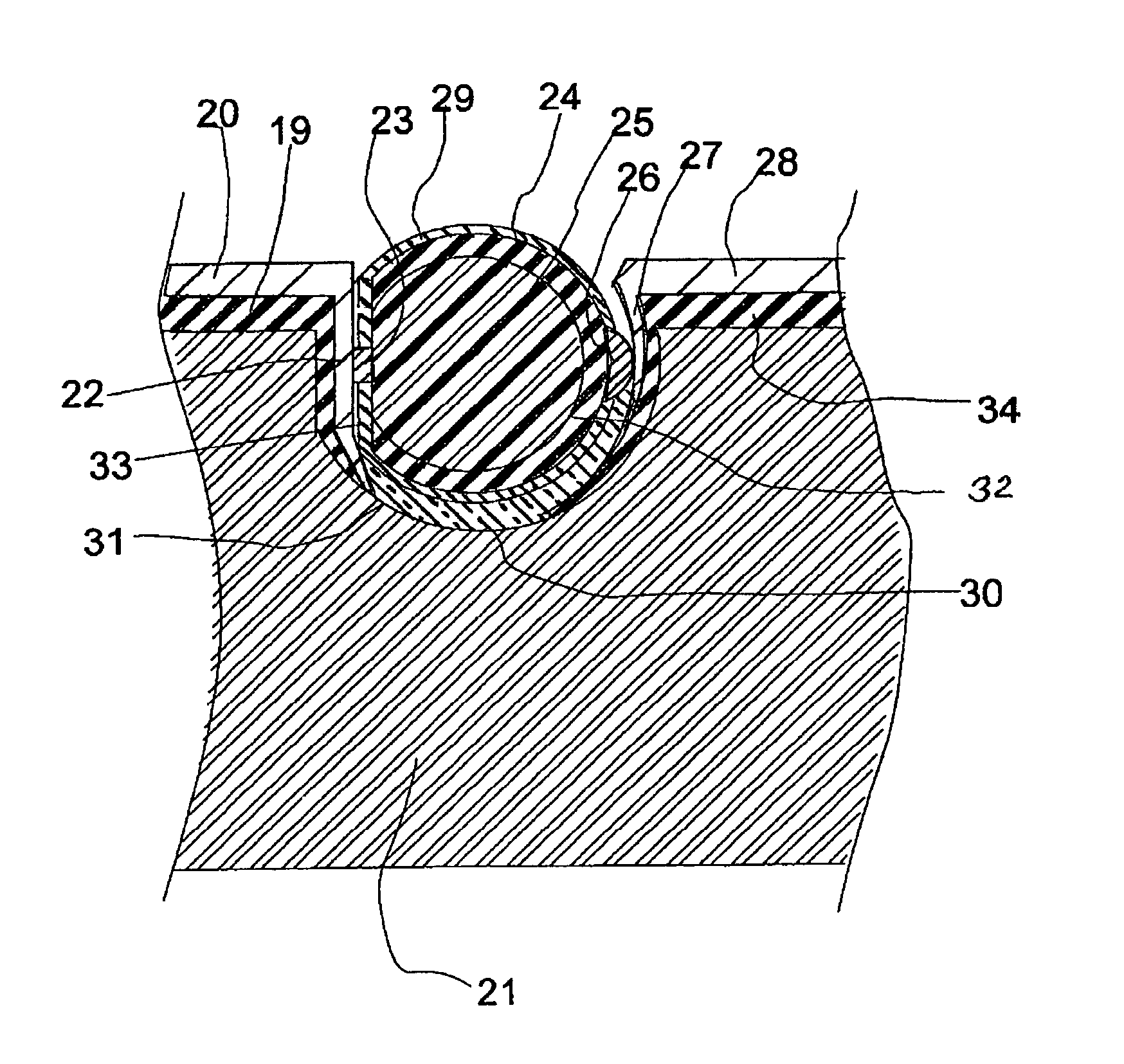

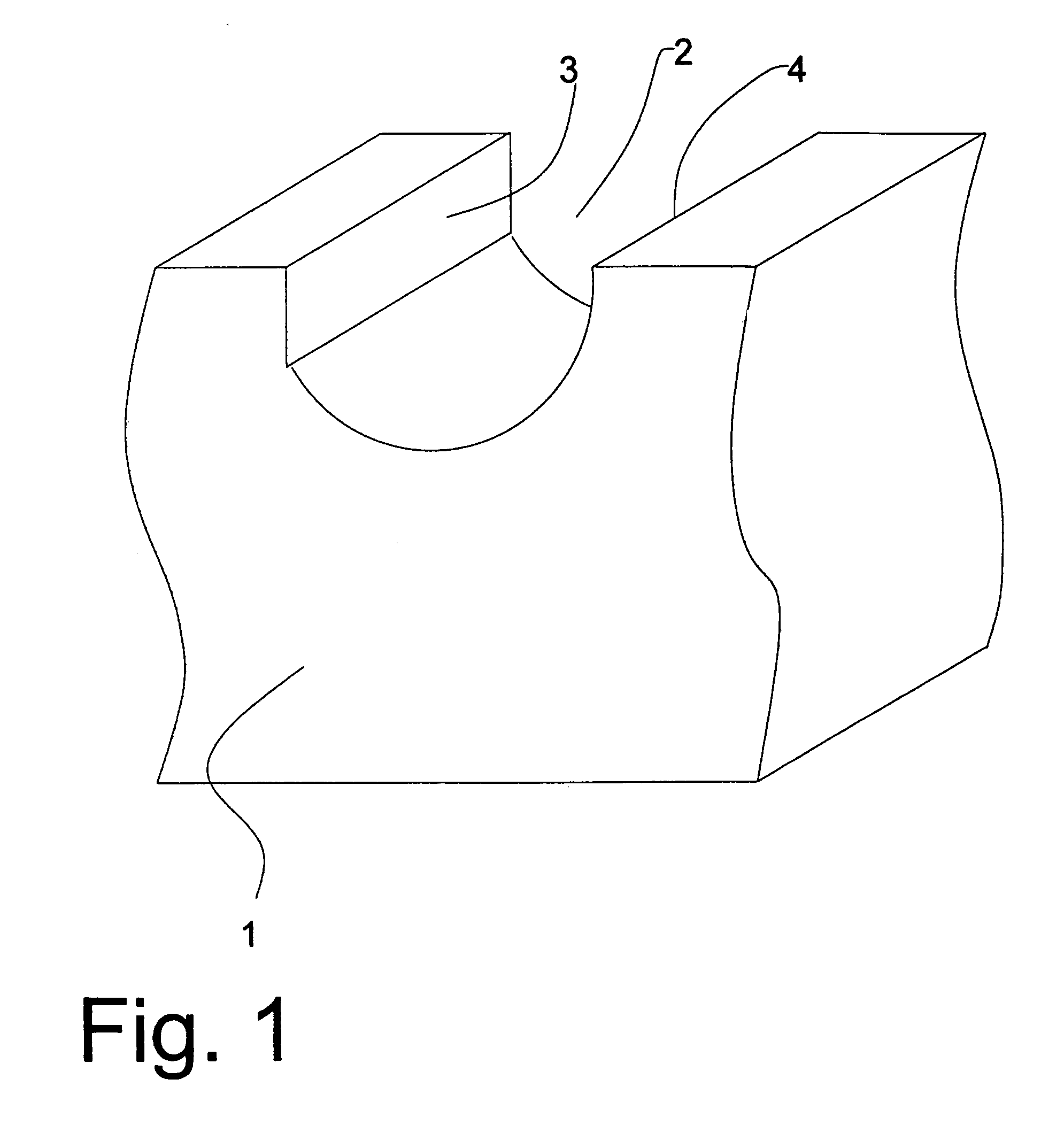

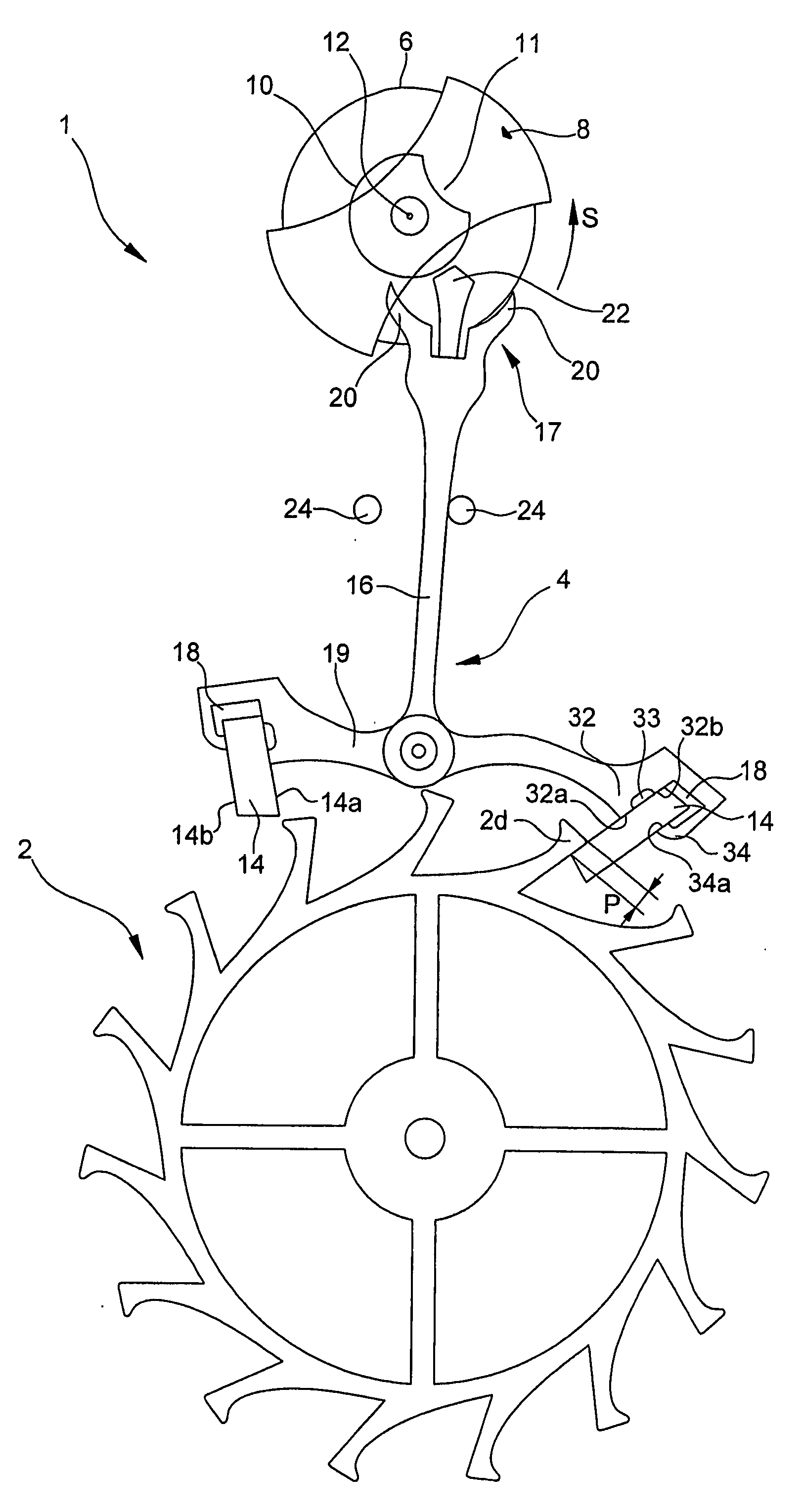

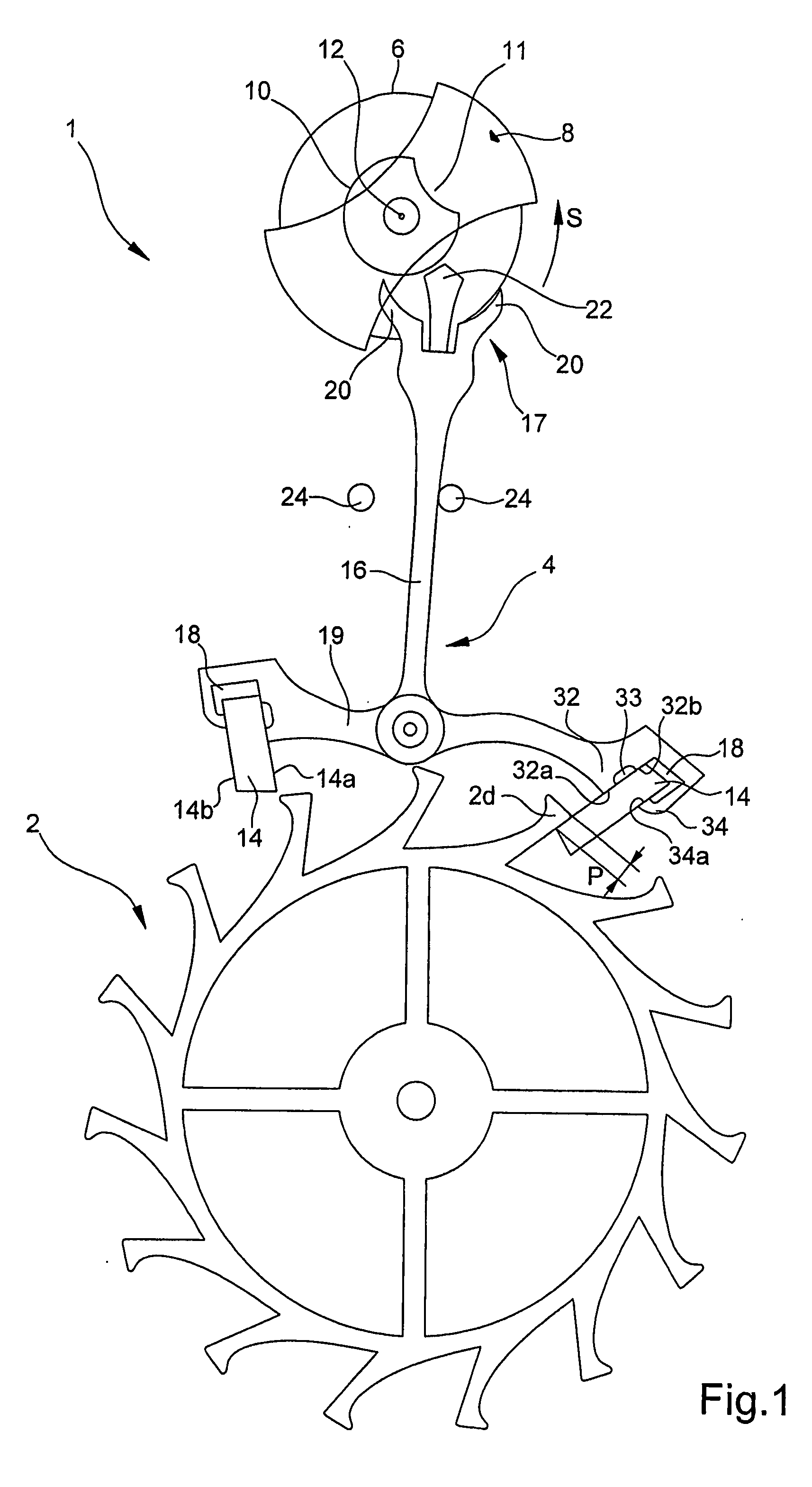

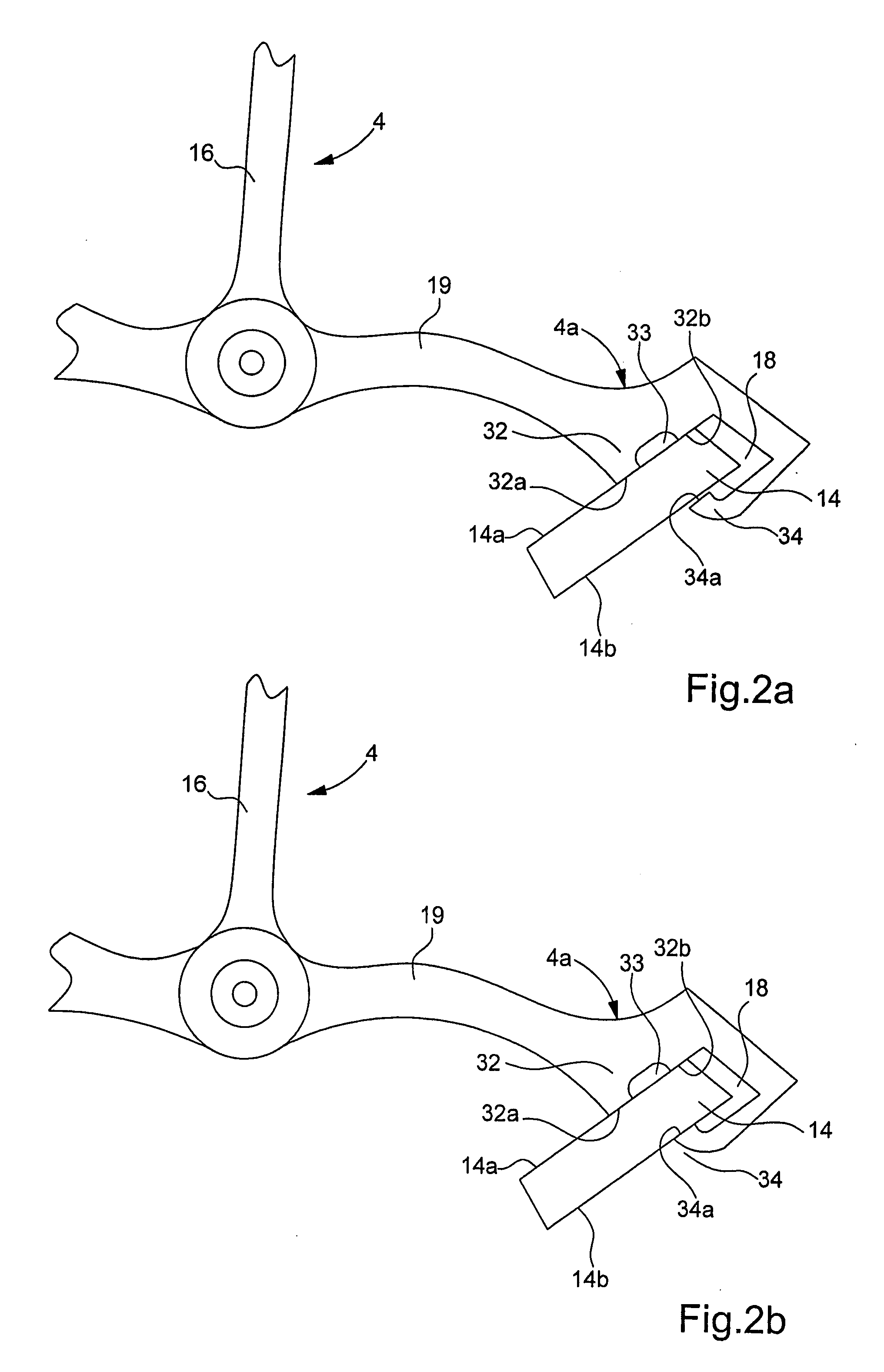

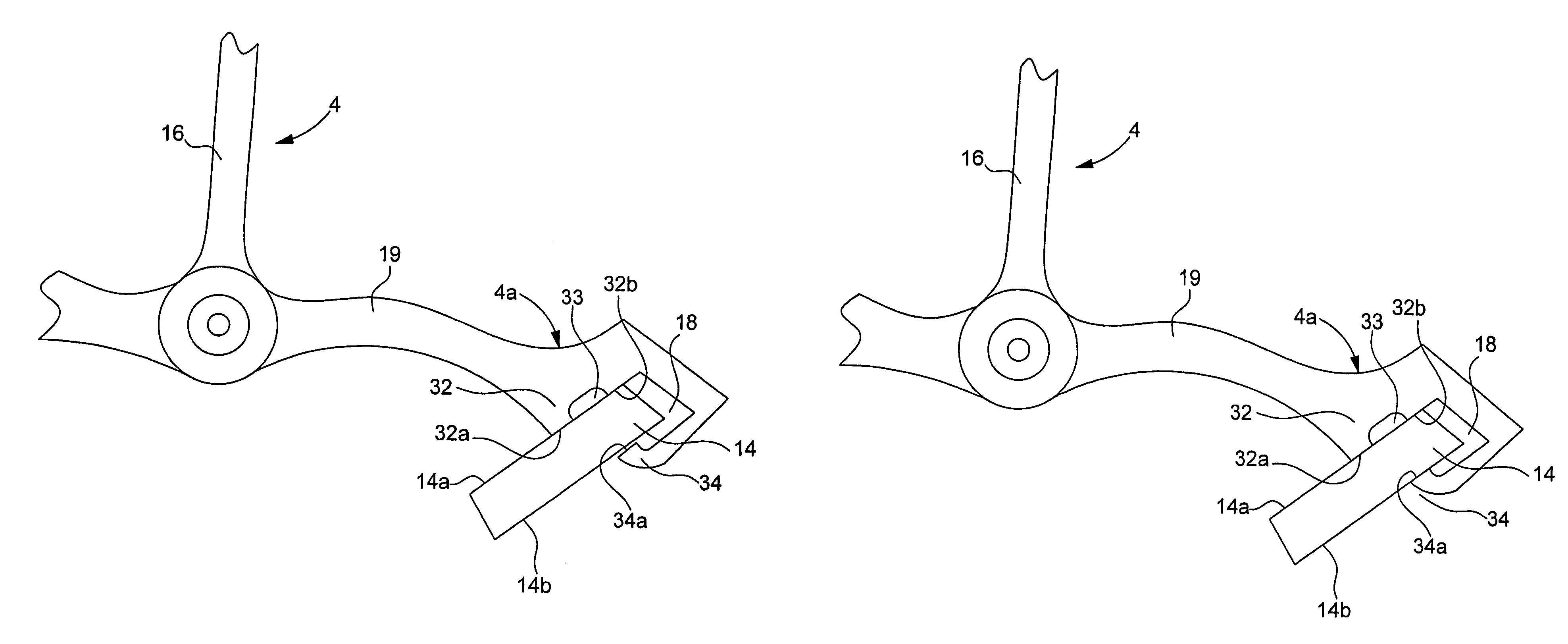

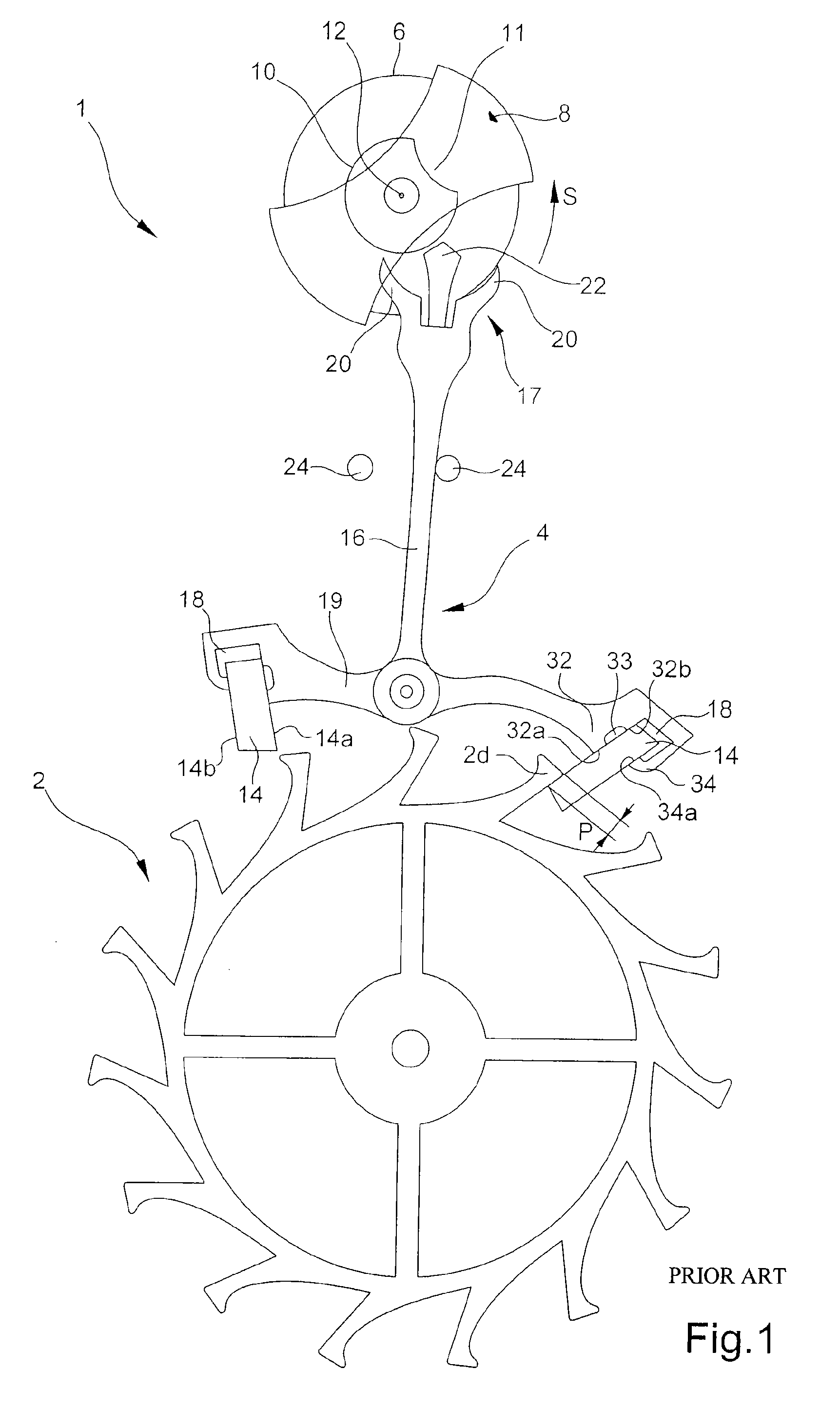

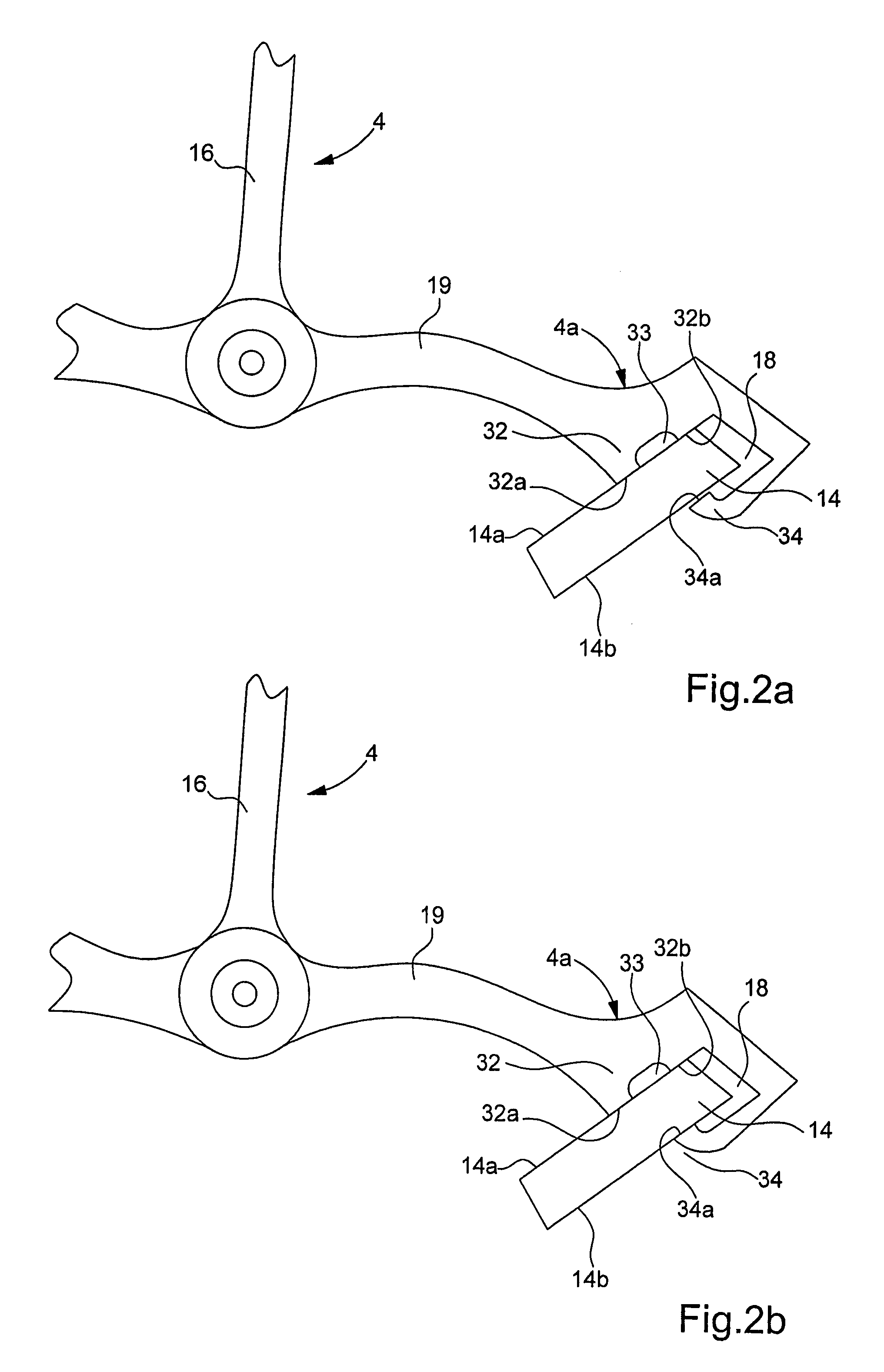

Device and Method for Securing a Pallet-Stone to an Escapement Pallet of a Timepiece Movement

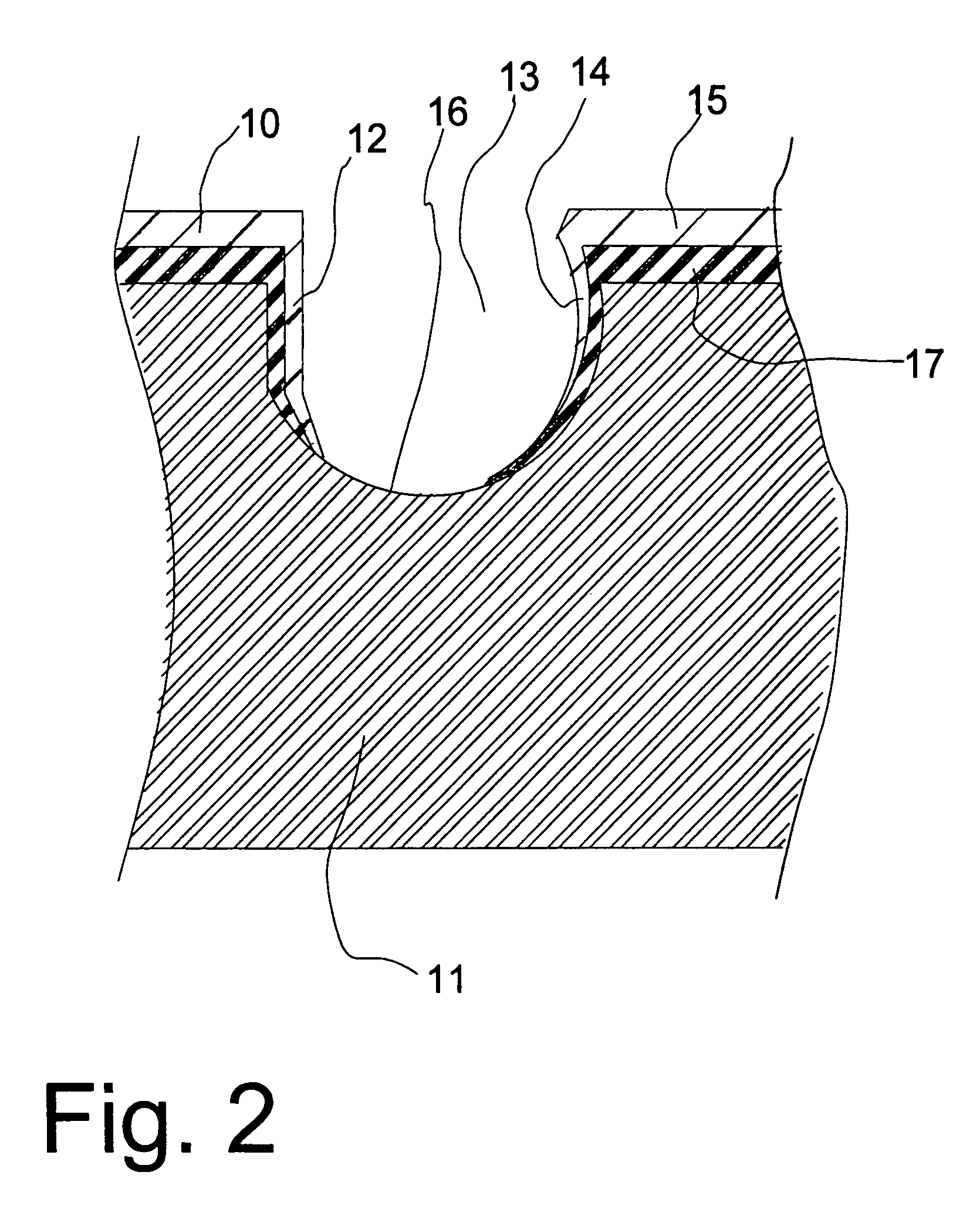

The invention concerns a device for securing a pallet stone to an escapement pallet including at least one housing for receiving said pallet stone, characterized in that the portion of the pallet including said housing is made of a shape memory alloy able to undergo a reversible transformation from an austenitic crystallographic phase to a martensitic crystallographic phase.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Meta-lens and optical apparatus including the same

Owner:SAMSUNG ELECTRONICS CO LTD

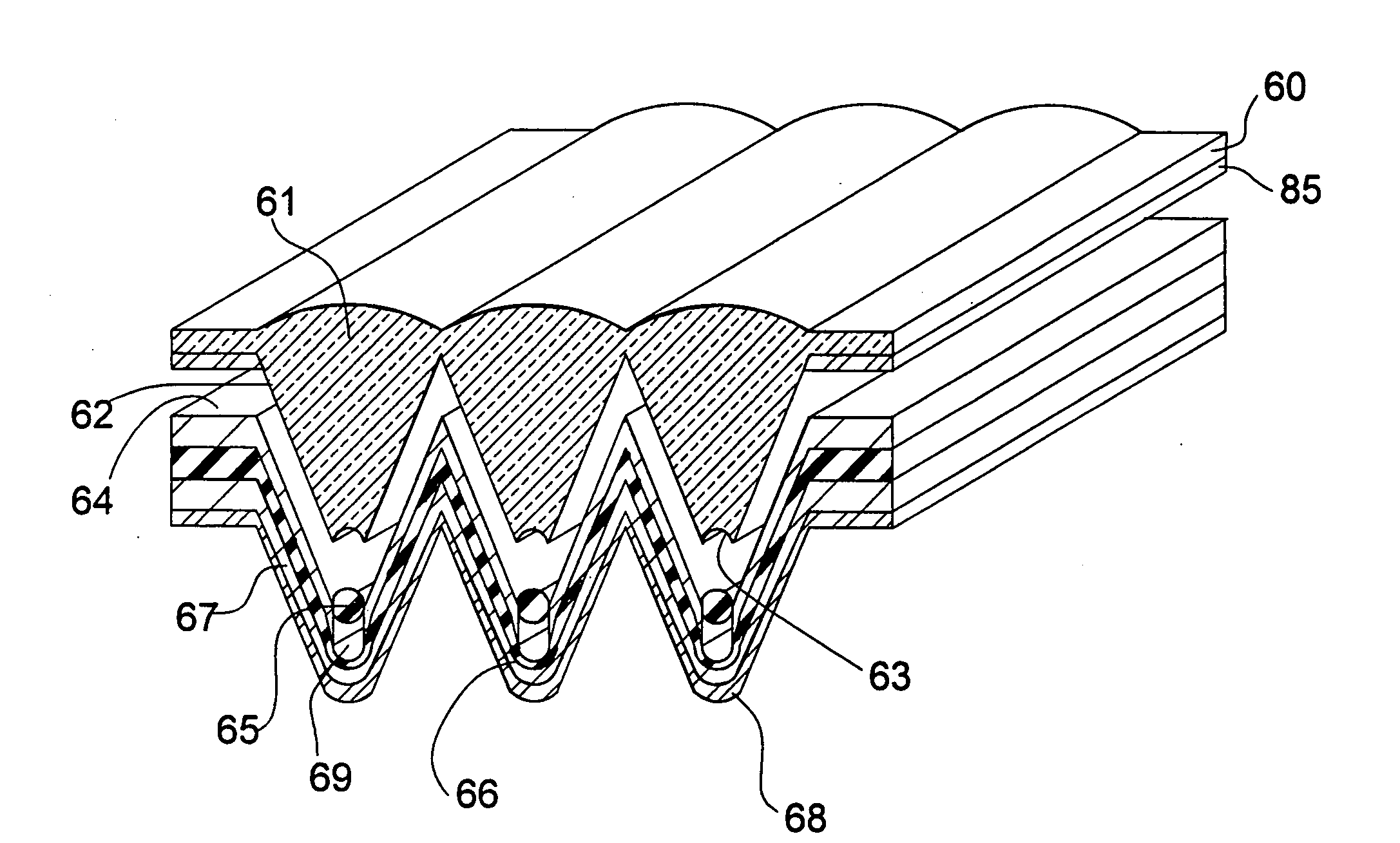

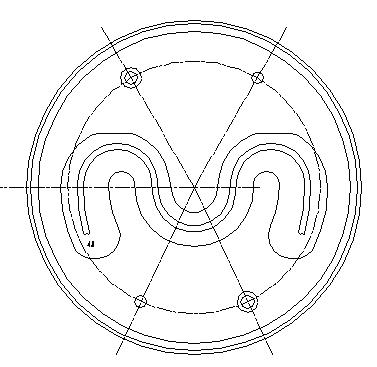

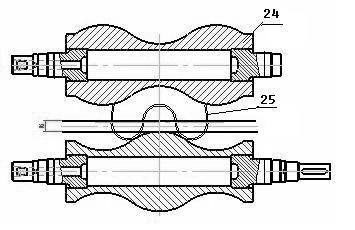

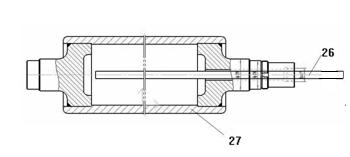

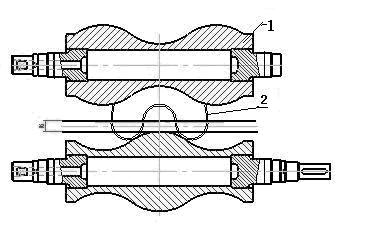

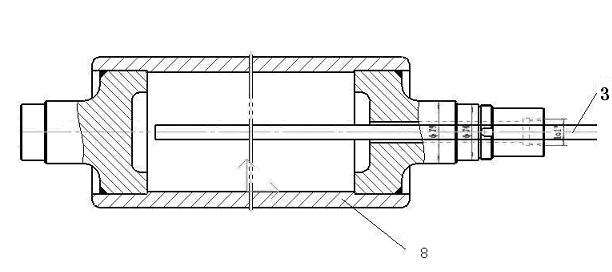

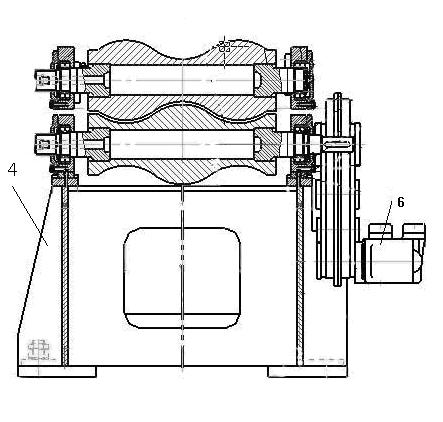

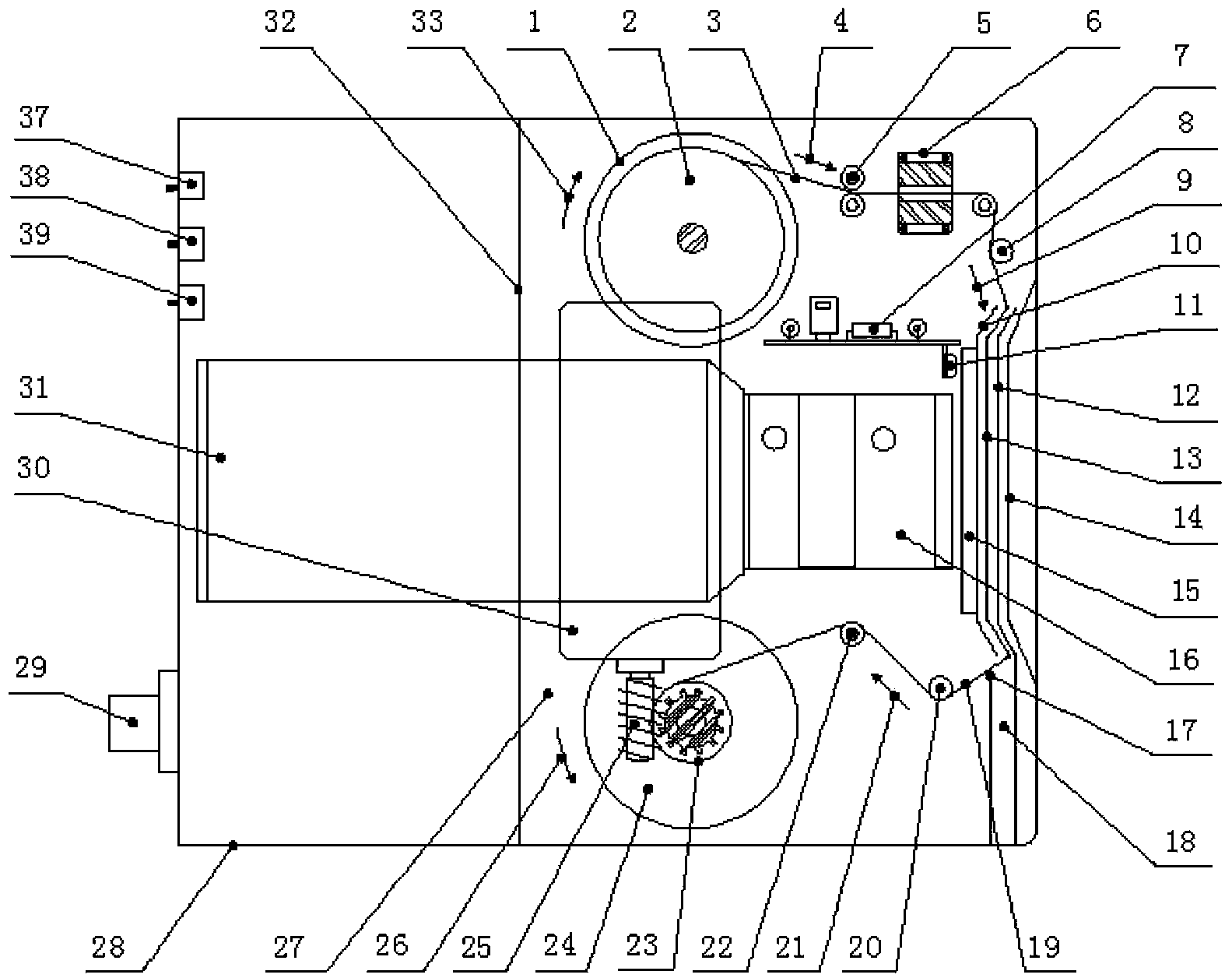

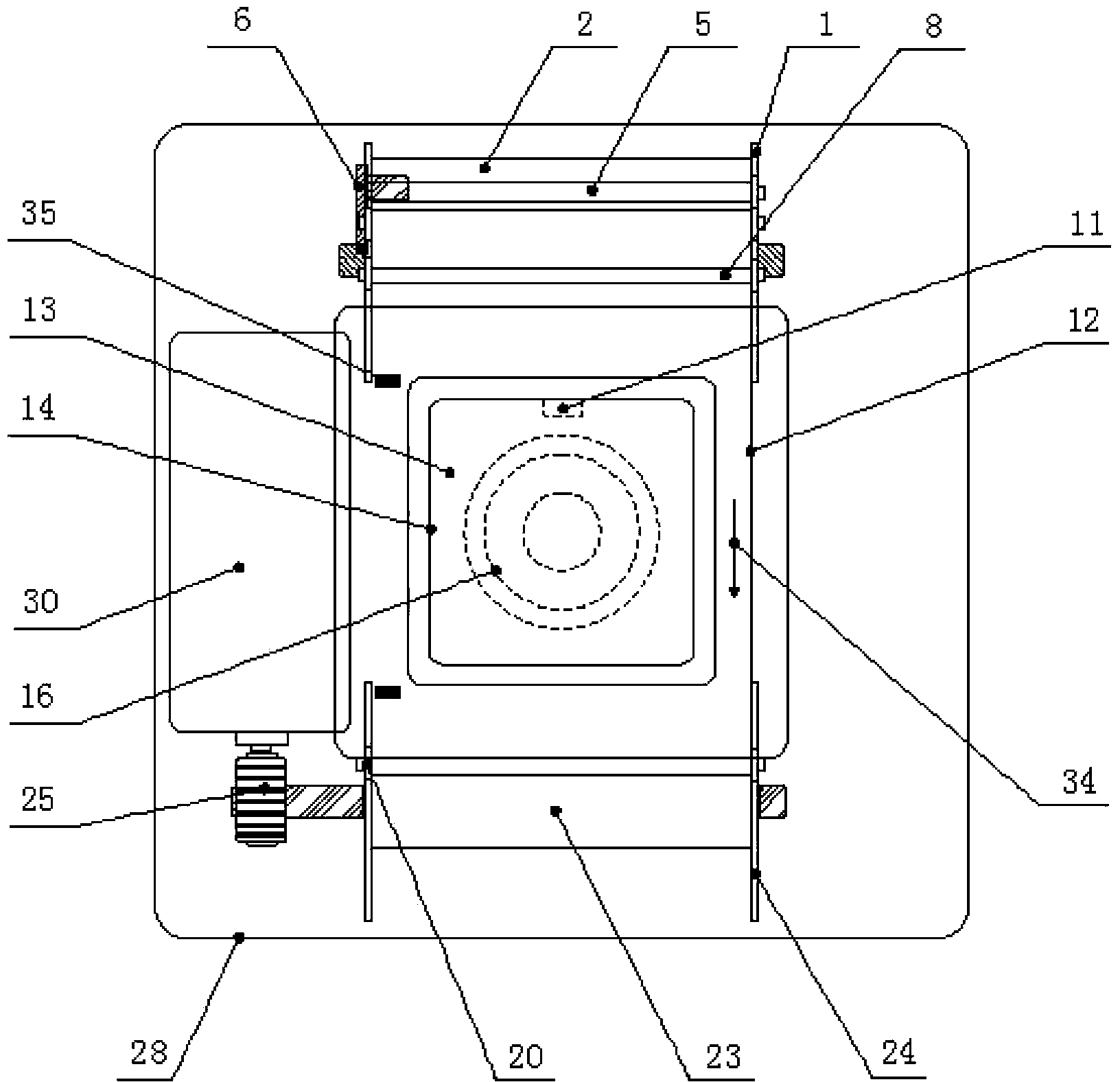

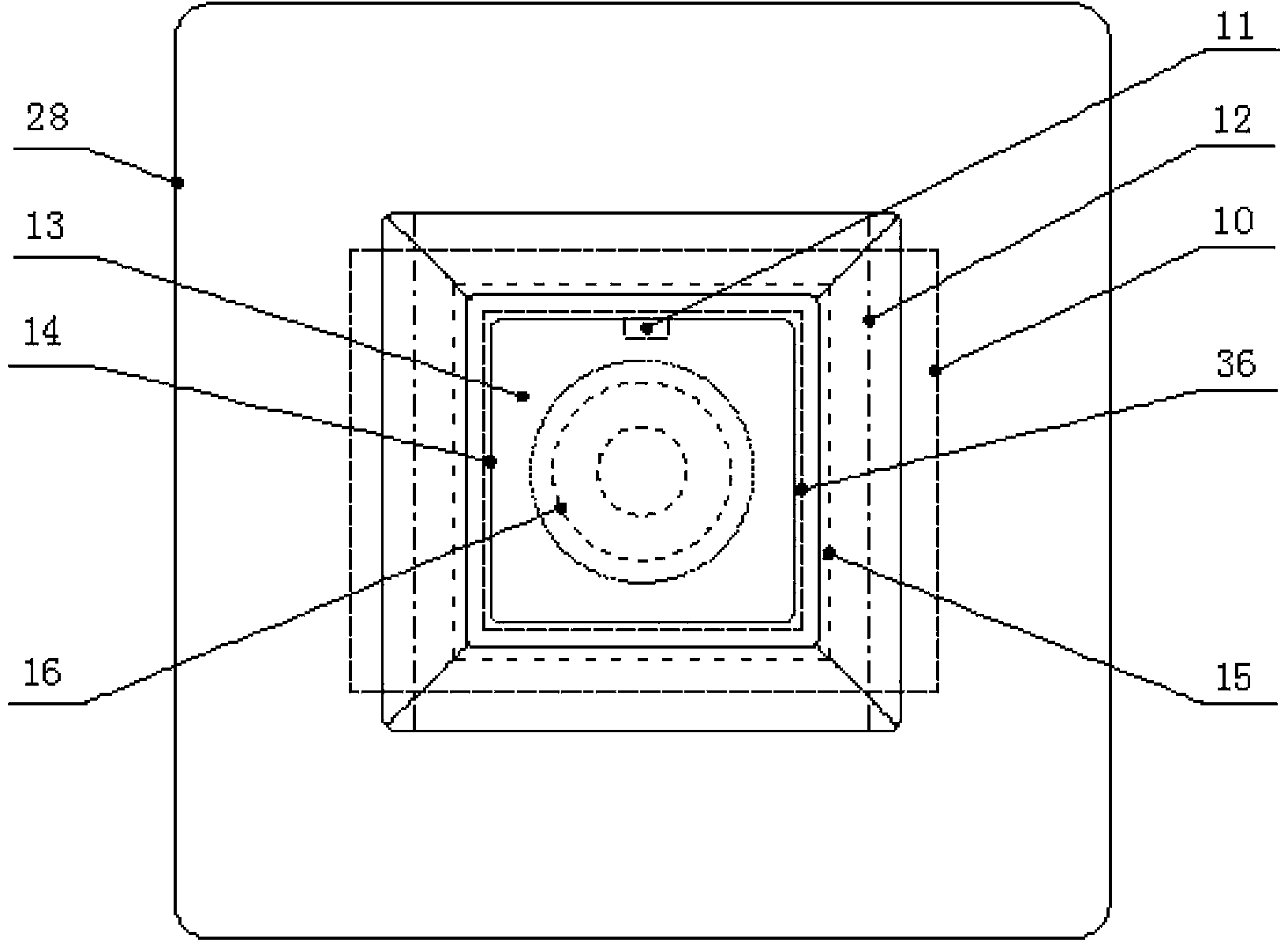

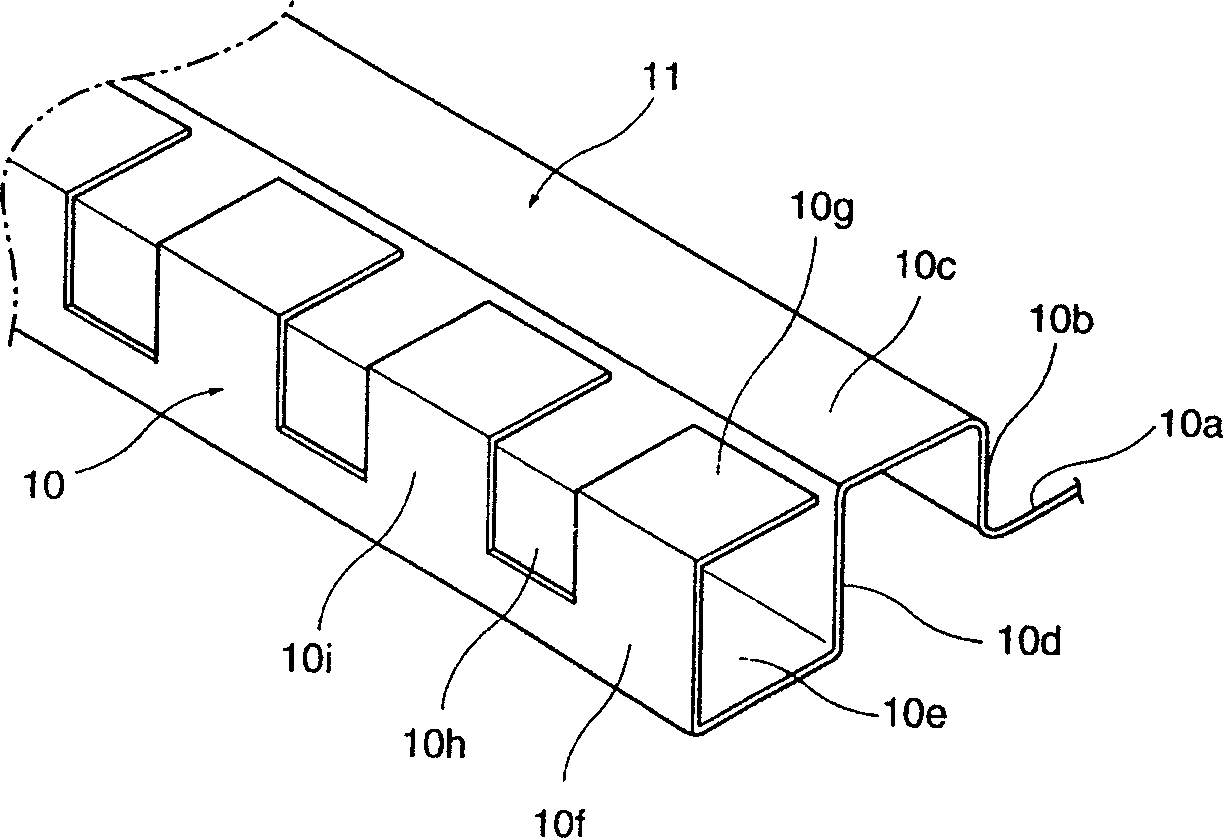

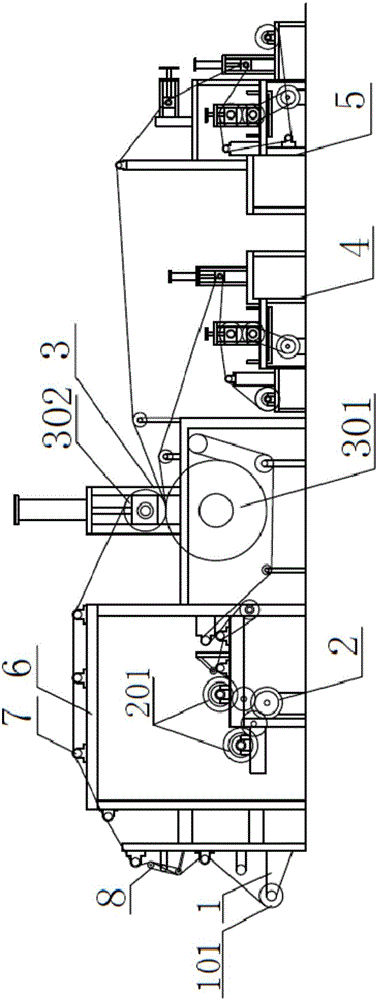

Process and equipment for manufacturing wide-width magnesium alloy plate in coils

The invention relates to the technical field of process and equipment for a new non-ferrous metal material and discloses a process and equipment for manufacturing a wide-width magnesium alloy plate. In the process, an as-cast rod material is subjected to milling face scaling, multi-axis forging, machining, high-temperature ageing, heating, extruding, flattening and coiling to finish the coiling production of the wide-width magnesium alloy plate. The equipment comprises a multi-axis forging machine, an extruding machine, a flattening machine and a coiling machine; the extruding machine, the flattening machine and the coiling machine are arrayed along a discharging axis of the magnesium alloy plate and are controlled by a synchronous control system, wherein the extruding machine is internally provided with a semi-circular or wavy arc-shaped extruding and distributing module; and a rod material heater is arranged at the inlet end of the extruding and distributing module. According to the invention, by utilization of the small-tonnage extruding machine and a mould in which an arc line between two points is longer than a straight line between the two points, the wide-width magnesium alloy plate which is larger than the size of the outlet of the extruding machine is produced in coils through an arc surface rolling and flattening machine for flattening an arc surface. The coiling production of the wide-width magnesium alloy plate can be finished with smaller investment.

Owner:李跃华

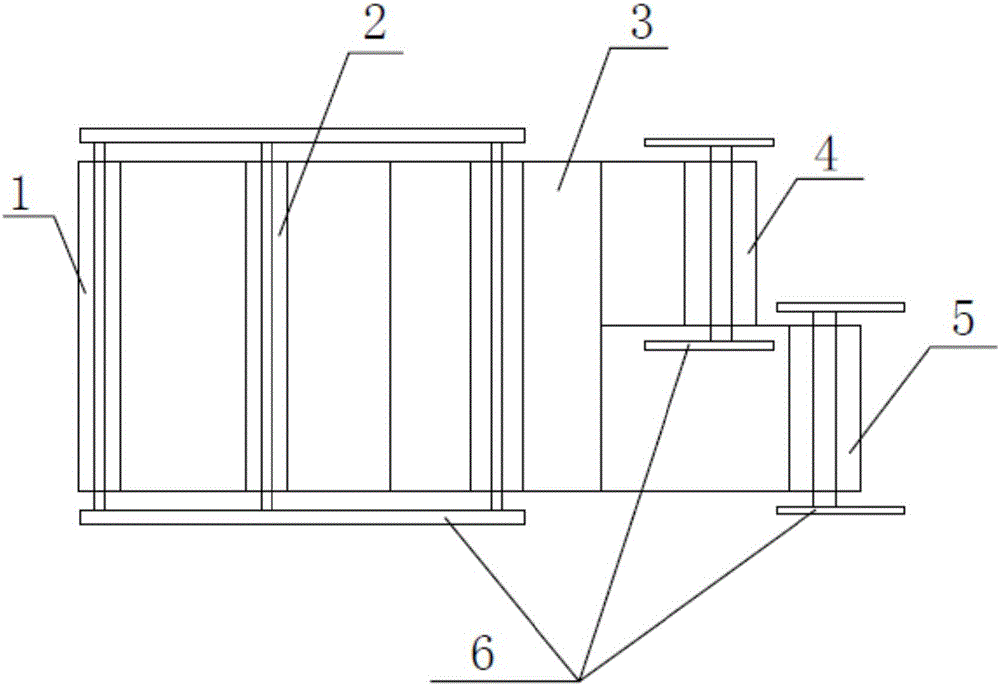

Process and device for flattening W-like arc-shaped magnesium alloy blank plate

InactiveCN102430575AFlattened implementationLess investmentRollsMetal rolling arrangementsSlip lineNonferrous metal

The invention relates to the technical field of processing of novel nonferrous metal materials and discloses a process and device for flattening a W-like arc-shaped magnesium alloy blank plate. The process comprises the following step of: successively flattening the W-like arc-shaped plate for three times: (1) carrying out broadening by adopting a W-like gap constituted by two corresponding concave and convex arc-shaped rollers of an arc roller flattening machine; (2) obtaining a smooth magnesium alloy plate by adopting a five-roller flattening machine; and (3) carrying out smoothing and warm rolling with 5% of rolling reduction by adopting a finishing flattening machine to eliminate an extrusion slip line and obtaining a magnesium alloy plate surface with the thickness of 2mm-4mm and the broad width of 620mm by flattening. The device comprises a preliminary flattening machine, a flat plate flattening machine, the finishing flattening machine and a synchronous control system which are arranged along a discharge axial line of the magnesium alloy plate at an outlet of an extruding machine. According to the process and the device disclosed by the invention, a semi-finished product, namely the W-like arc-shaped magnesium alloy blank plate which is produced by a small-tonnage extruding machine, can be flattened, the purpose of increasing the breadth can be achieved by flattening the curved surface, and the flattening of the W-like arc-shaped magnesium alloy blank plate is realized. The process and the device disclosed by the invention have the characteristics of optimized process, reasonable equipment and low investment.

Owner:李跃华

Automatic dust and pollution prevention device of optical window

ActiveCN103411637AOvercoming cleanlinessOvercoming the need for a water supply for its installationCamera filtersMeasurement apparatus housingsCamera lensLaser ranging

The invention discloses an automatic dust and pollution prevention device of an optical device. A device (such as a camera shooting instrument, a laser distance measuring machine, an infrared detector, an optical sensor and other light receiving and emitting devices) provided with the optical window is placed in a sealed protection shell, a thin film optical window is arranged on the wall face, opposite to the optical window, of the sealed protection shell, and thin film paper arranged in the thin film optical window has the automatic updating function. Therefore, the automatic dust and pollution prevention device can effectively overcome the technical defects that in the prior art, the optical window of a lens, an optic and the like can not be automatically cleaned and maintained and air and water need to be supplied to devices of the optical window of the lens, the optic and the like, and solves the technical problem that the optical window of the lens and the optic and the like can not be cleaned and maintained when the device provided with the optical window is installed in field high air, special fields and dangerous environments. Besides, the automatic dust and pollution prevention device of the optical device has the advantages of being reasonable in design, high in universality, wide in application range, small in size, compact in structure, high in automation degree, convenient to use and maintain and the like.

Owner:江苏盈丰电子科技有限公司

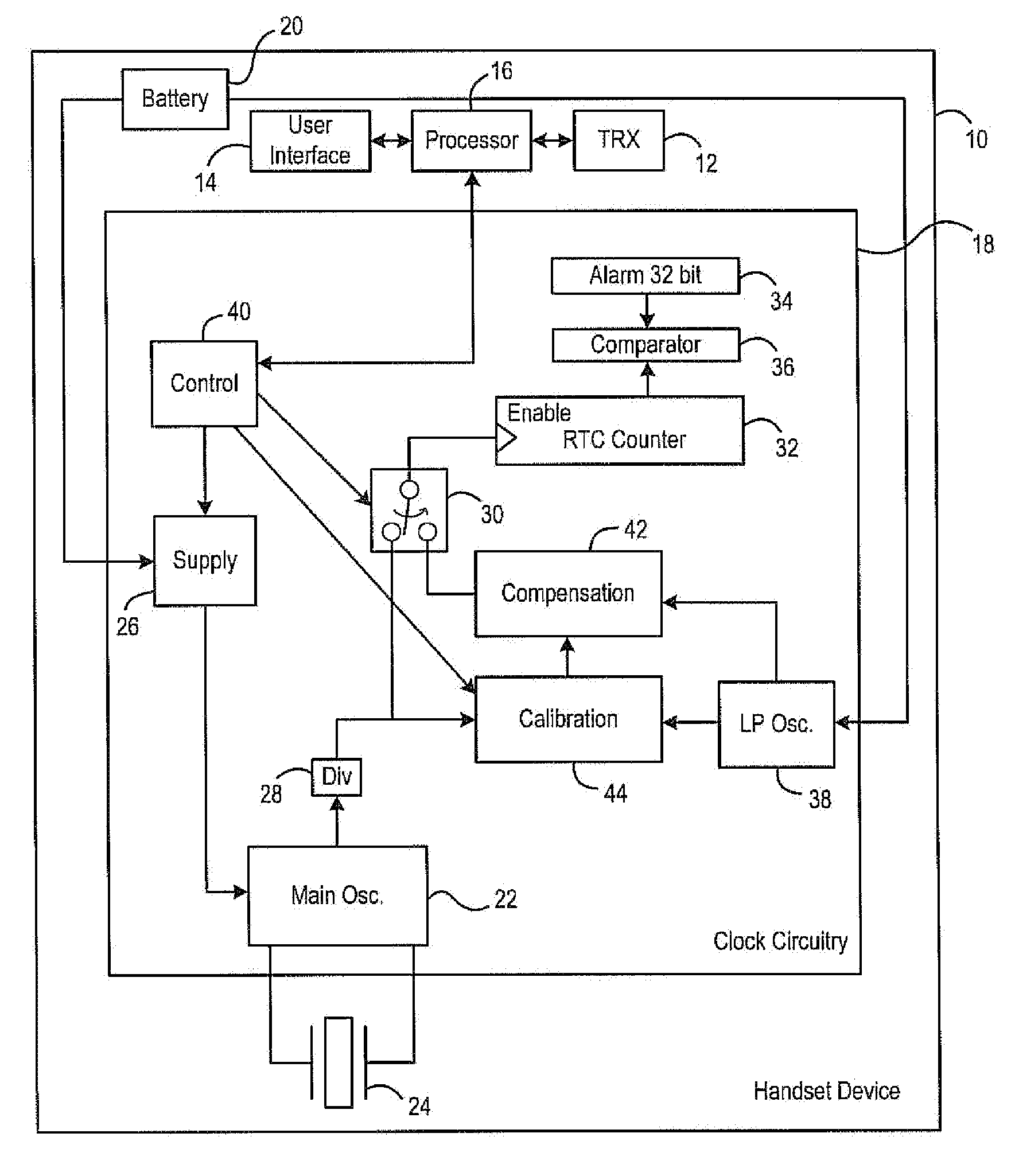

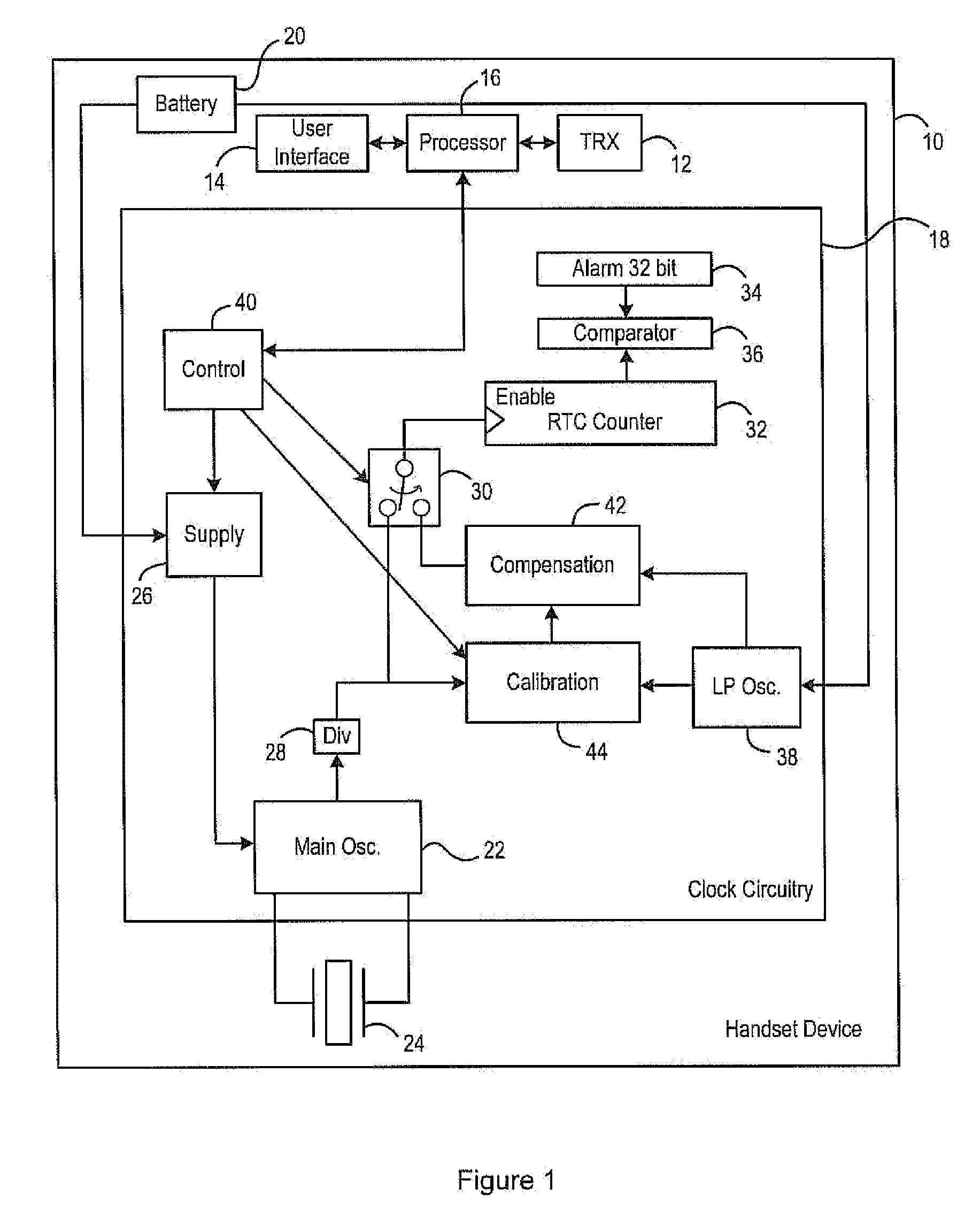

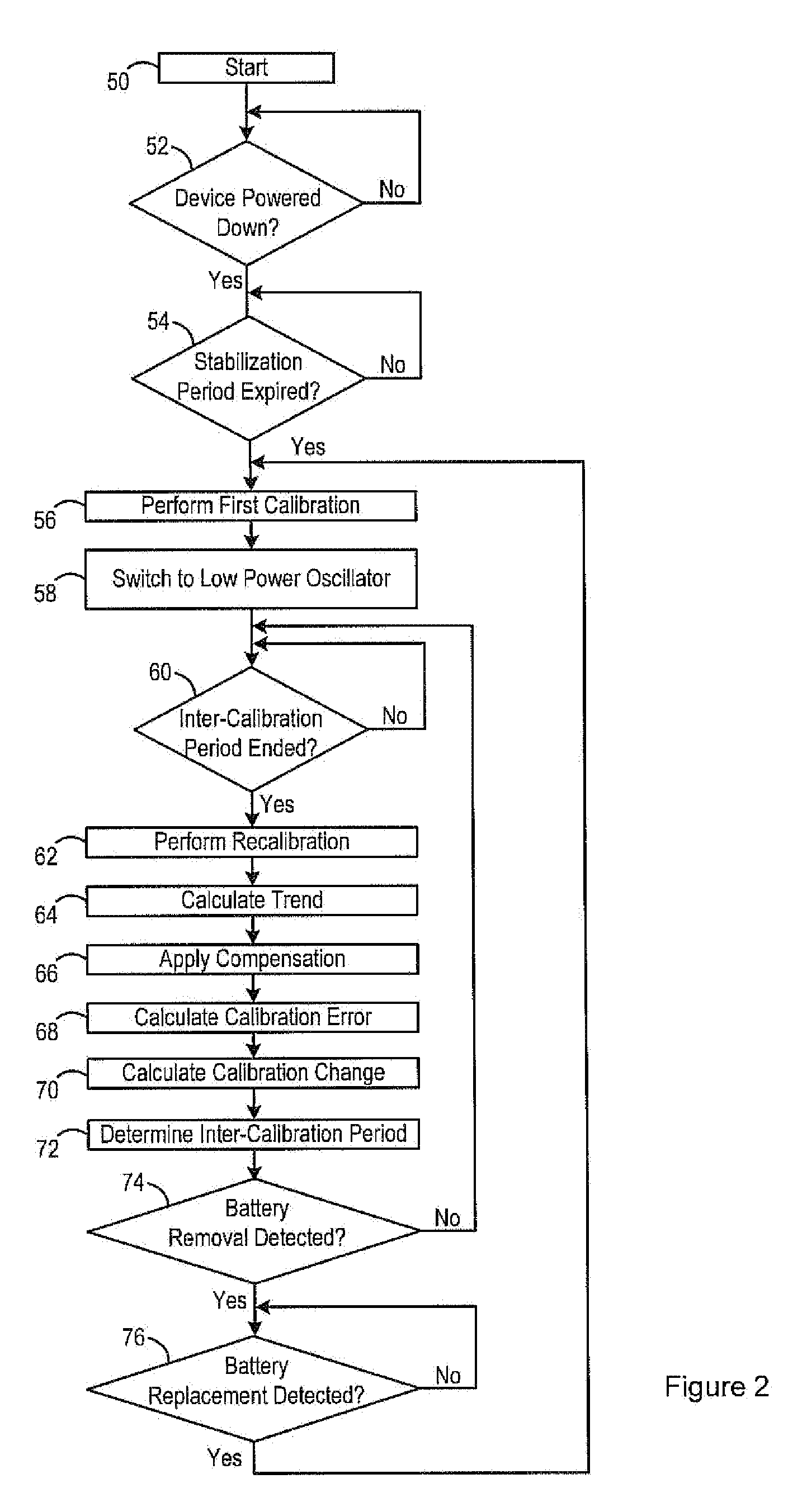

Correction of Low Accuracy Clock

ActiveUS20120306580A1CorrectlyEasy to calculatePulse automatic controlTime pulsesPower modeNormal mode

An electronic device has two oscillators, for example a first highly accurate crystal oscillator and a second less accurate low power oscillator. In a normal mode of operation, time is counted based on an output from the crystal oscillator, but in a low power mode of operation, time is counted based on an output from the less accurate oscillator. During the low power mode of operation, a calibration process is performed repeatedly. During a first calibration time period the second oscillator is calibrated against the first oscillator to obtain a first calibration result, and a recalibration is performed during a second calibration time period to obtain a second calibration result. A correction factor is determined from the first and second calibration results, and the correction factor is applied when subsequently counting time based on the output from the second oscillator.

Owner:TELEFON AB LM ERICSSON (PUBL)

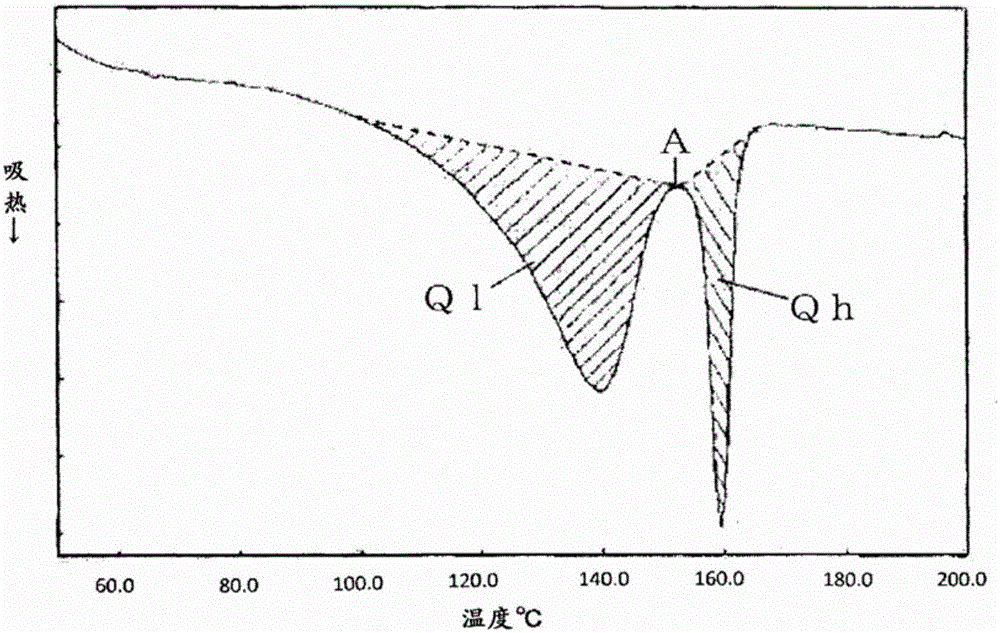

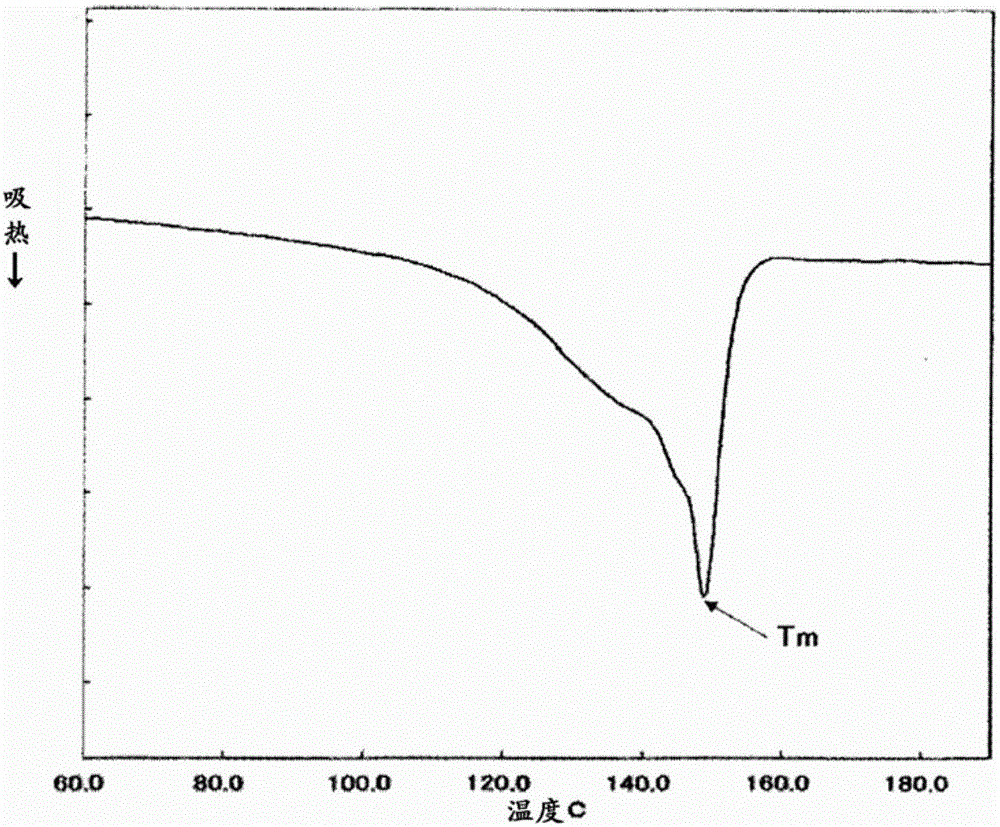

Method for manufacturing foamed polypropylene-resin particles

Owner:KANEKA CORP

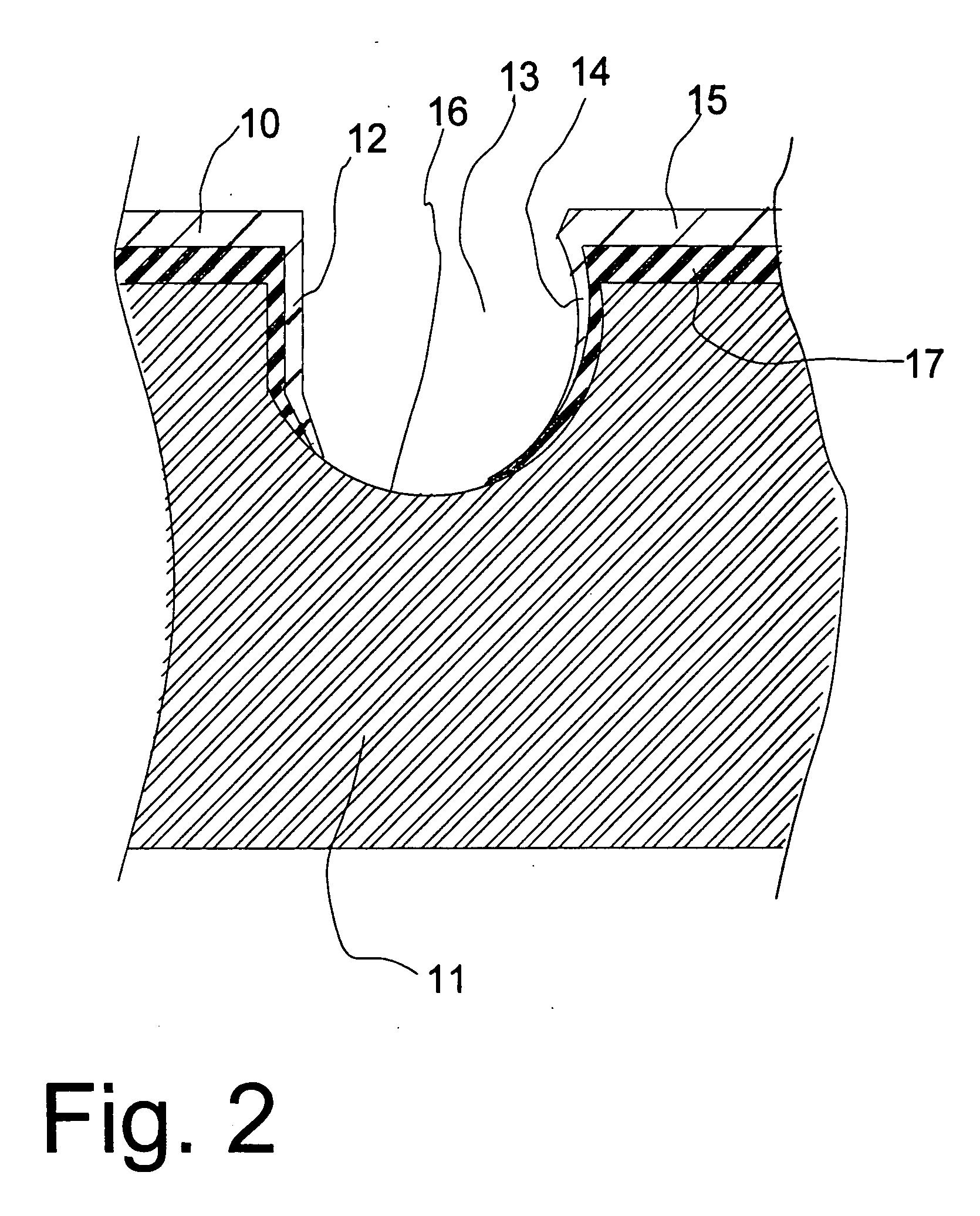

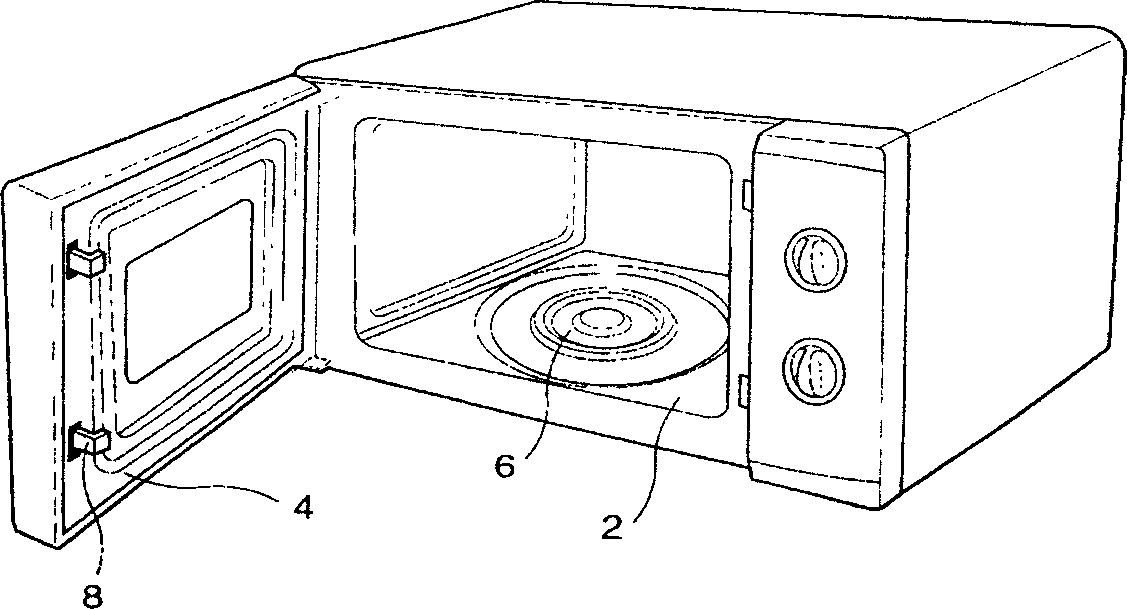

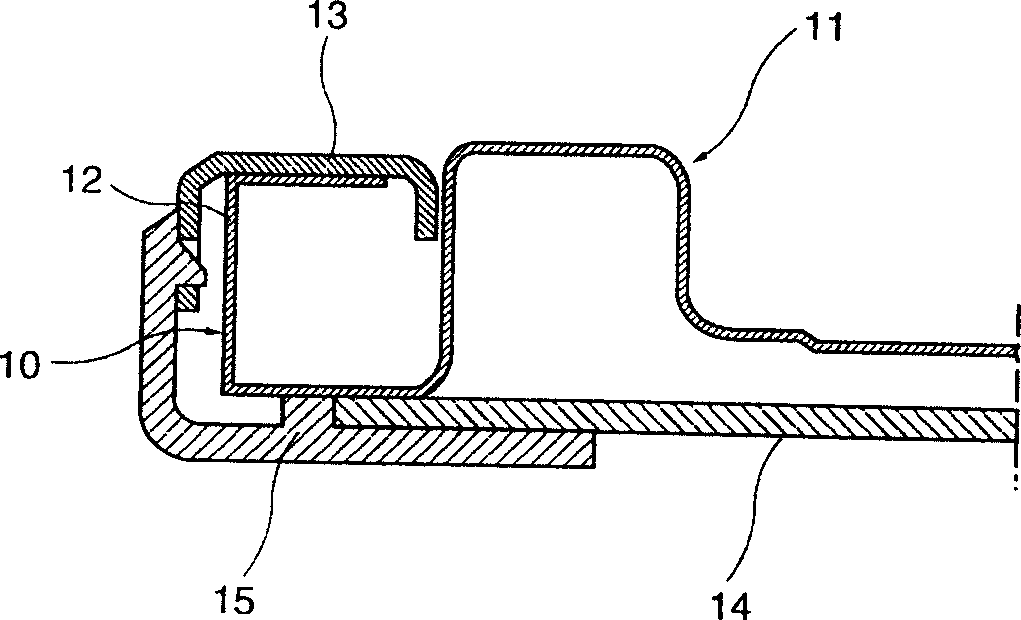

Electromagnetic wave screening structure for microwave oven door

InactiveCN1752571AEffective shieldingPrevent leakageDoors for stoves/rangesDomestic stoves or rangesMicrowave ovenWave shape

The present invention discloses an electromagnetic wave shielding structure for microwave oven door. It includes door frame, edge-sealing face, door blocking component and door hook placed on one side end of door frame. The door frame is a frame of door combination body for closing front face of cooking cavity, the edge-sealing face is zigzag-formed on the edge of door frame for shielding electromagnetic wave outwards-leaked from door edge, and the blocking component also is combined in the edge of door frame. Said invention can effectively shield electromagnetic wave with different angles and various waveforms.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Device and method for securing a pallet-stone to an escapement pallet of a timepiece movement

The invention concerns a device for securing a pallet stone to an escapement pallet including at least one housing for receiving said pallet stone, characterized in that the portion of the pallet including said housing is made of a shape memory alloy able to undergo a reversible transformation from an austenitic crystallographic phase to a martensitic crystallographic phase.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

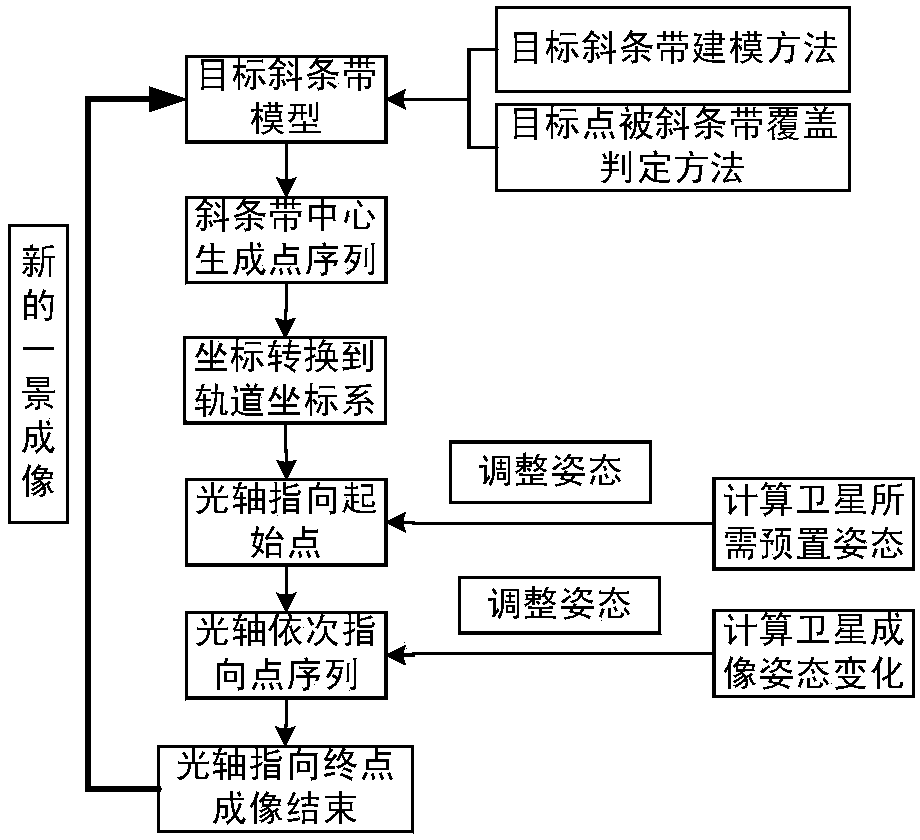

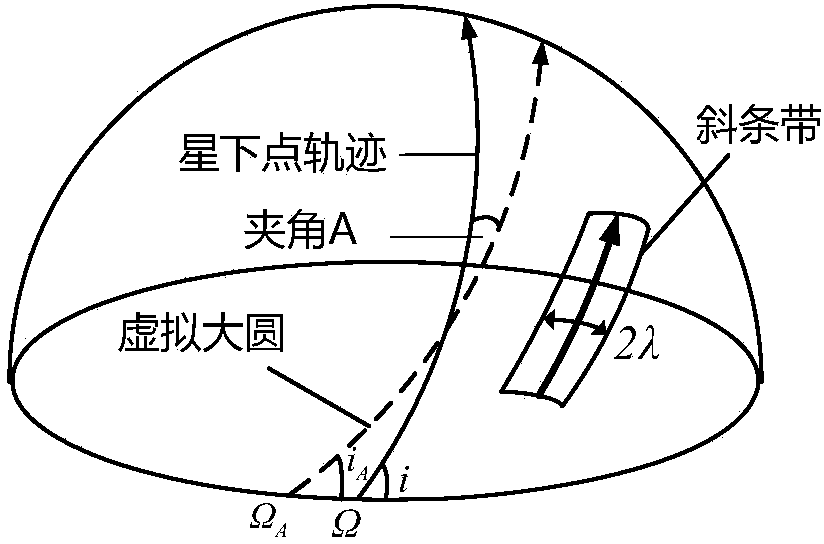

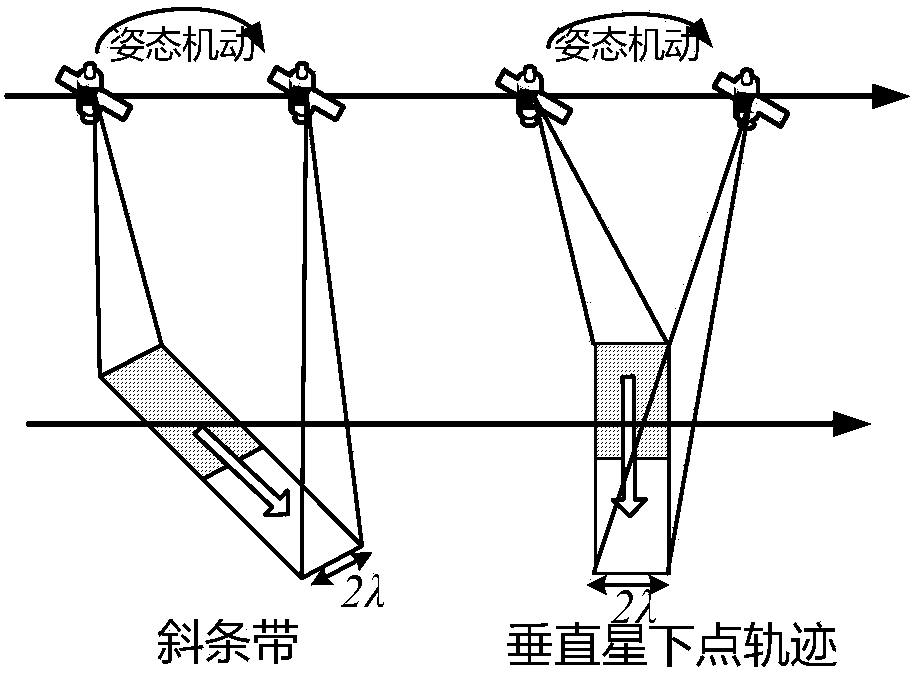

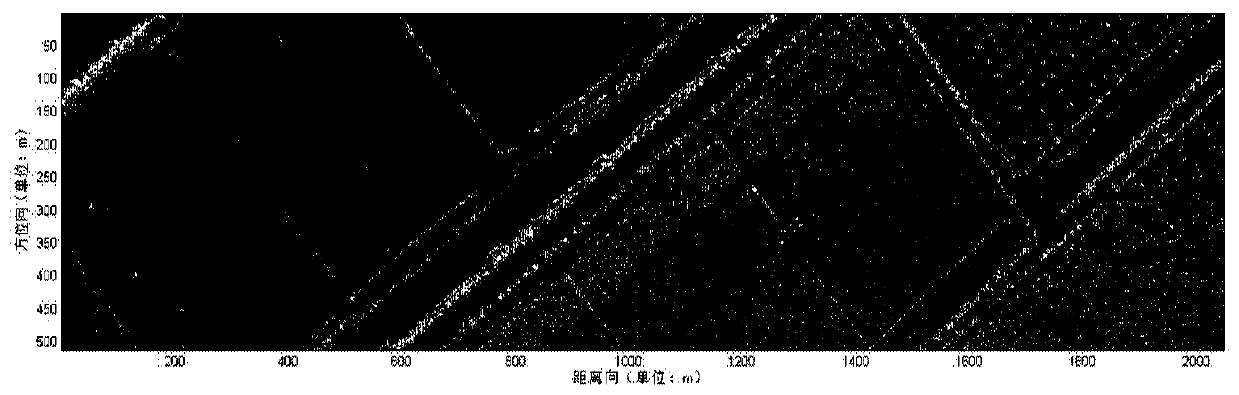

Method for carrying out inclined stripe imaging on targets in agile satellite maneuvering

ActiveCN104217123AWideImprove performanceSpecial data processing applicationsImaging modalitiesPerformed Imaging

The invention provides a method for carrying out inclined stripe imaging on targets in agile satellite maneuvering. The method overcomes the defect that an imaging track in a traditional imaging mode has to be parallel to a sub-satellite point track. An imaging mode of a target region adopting inclined stripe coverage and sub-satellite point track forming a certain angle is provided, a judging principle that any one target point on the earth is covered by an inclined stripe is built, and a method for imaging the target inclined stripe is provided on the basis, so that the imaging of a satellite on a narrow region forming a certain included angle with the sub-satellite point track is realized. The method provided by the invention has the advantages that the problems of modeling on the inclined stripe imaging region in the satellite maneuvering process imaging and the imaging on the inclined stripe target are solved, so that the satellite imaging region is more flexible, and the imaging efficiency is improved.

Owner:AEROSPACE DONGFANGHONG SATELLITE

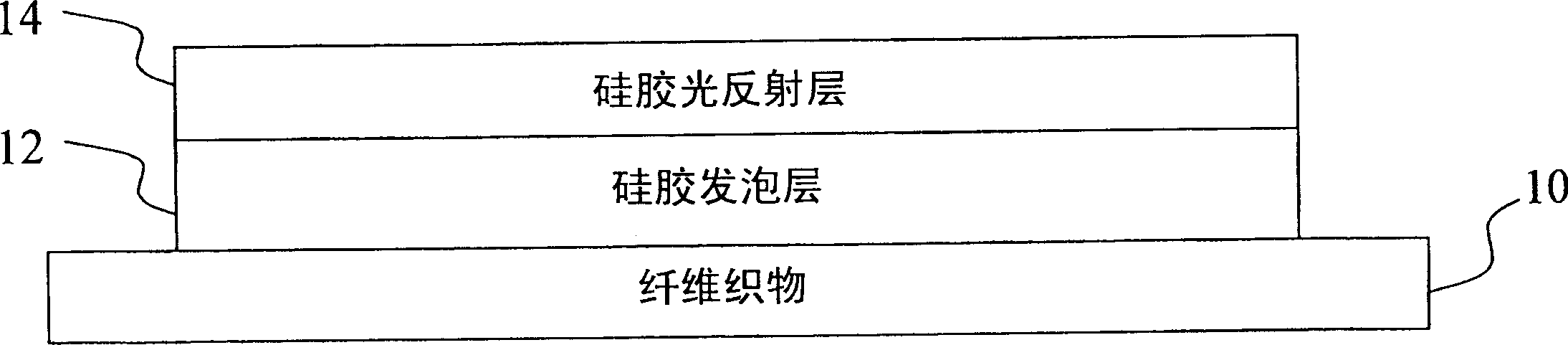

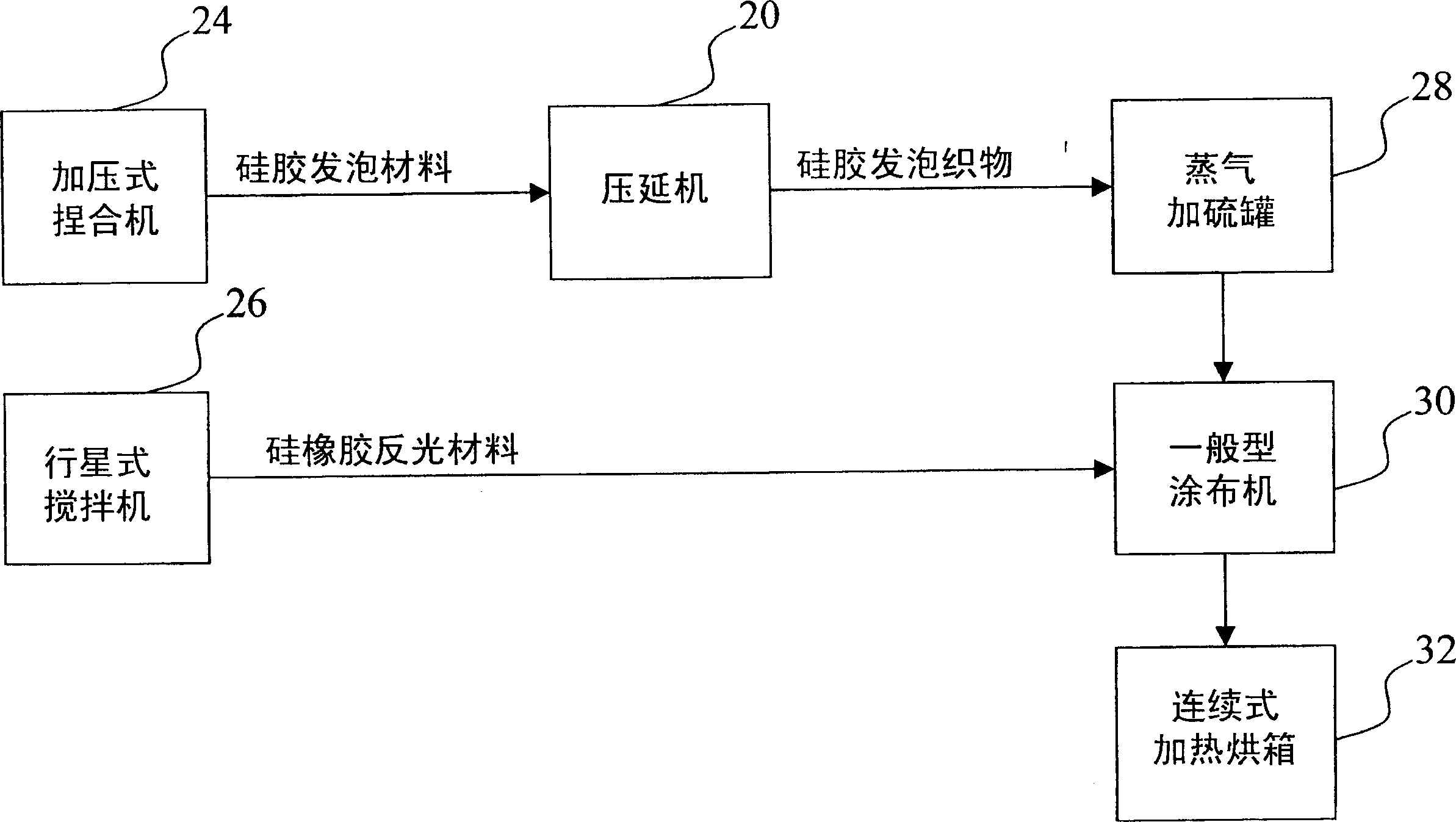

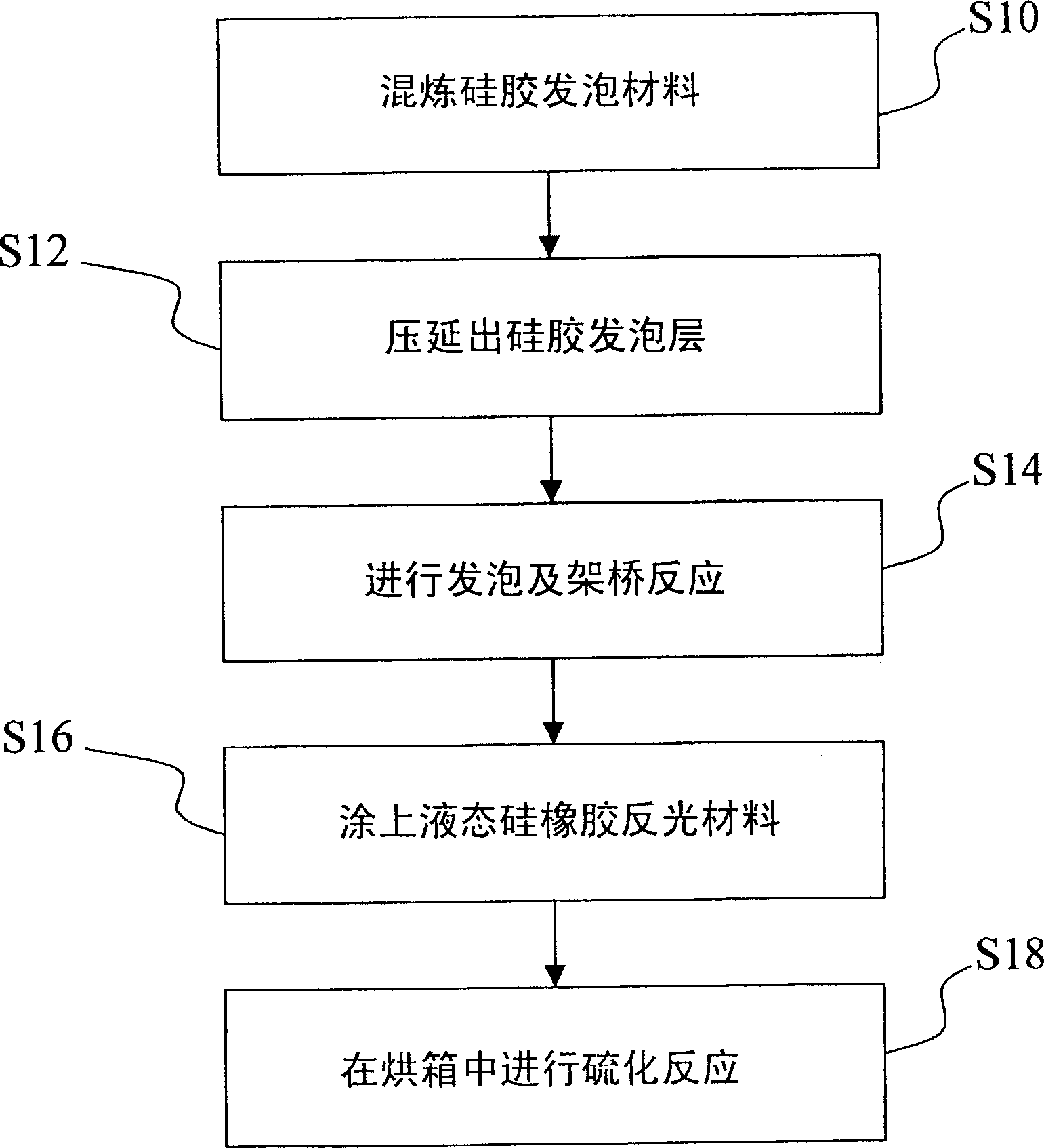

Materials composition and processing method for composite fiber

InactiveCN1880570AUniform thicknessWith thermal insulation effectFibre treatmentLaminationFiberLiquid state

The invention discloses a material composting and manufacturing method of composite fiber, which consists of silica gel foaming layer with insulating effect and silica gel reflecting layer, wherein the silica gel foaming material is attached on the fiber cloth to extend silica gel foaming layer, which proceeds foaming and bridging reaction in the steam sulphur tank; the silica gel foaming material is fetched out coated by liquid silica gel, which forms flexible composite fiber at lower temperature after cooling.

Owner:FORMOSAN RUBBER GRP

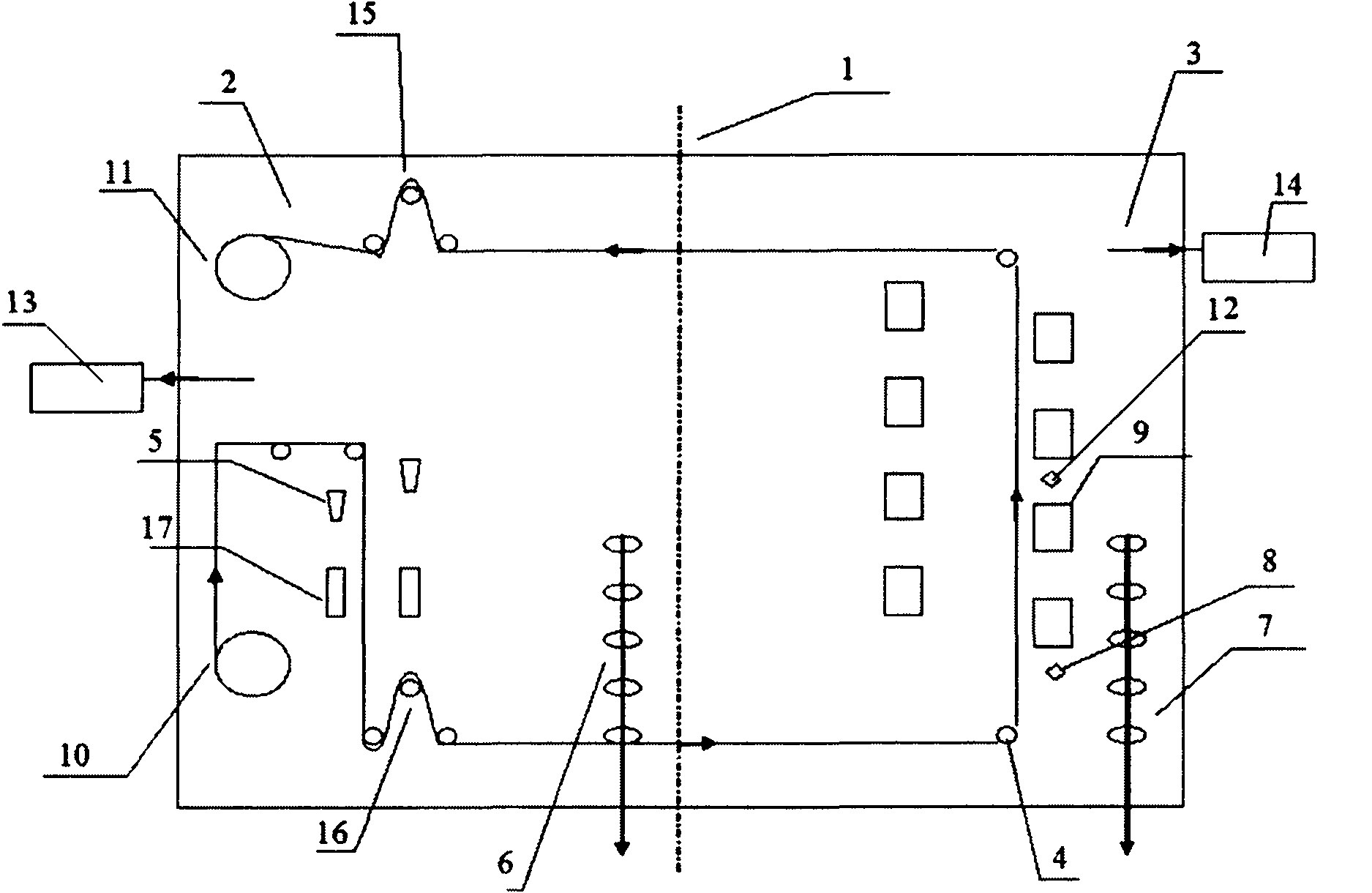

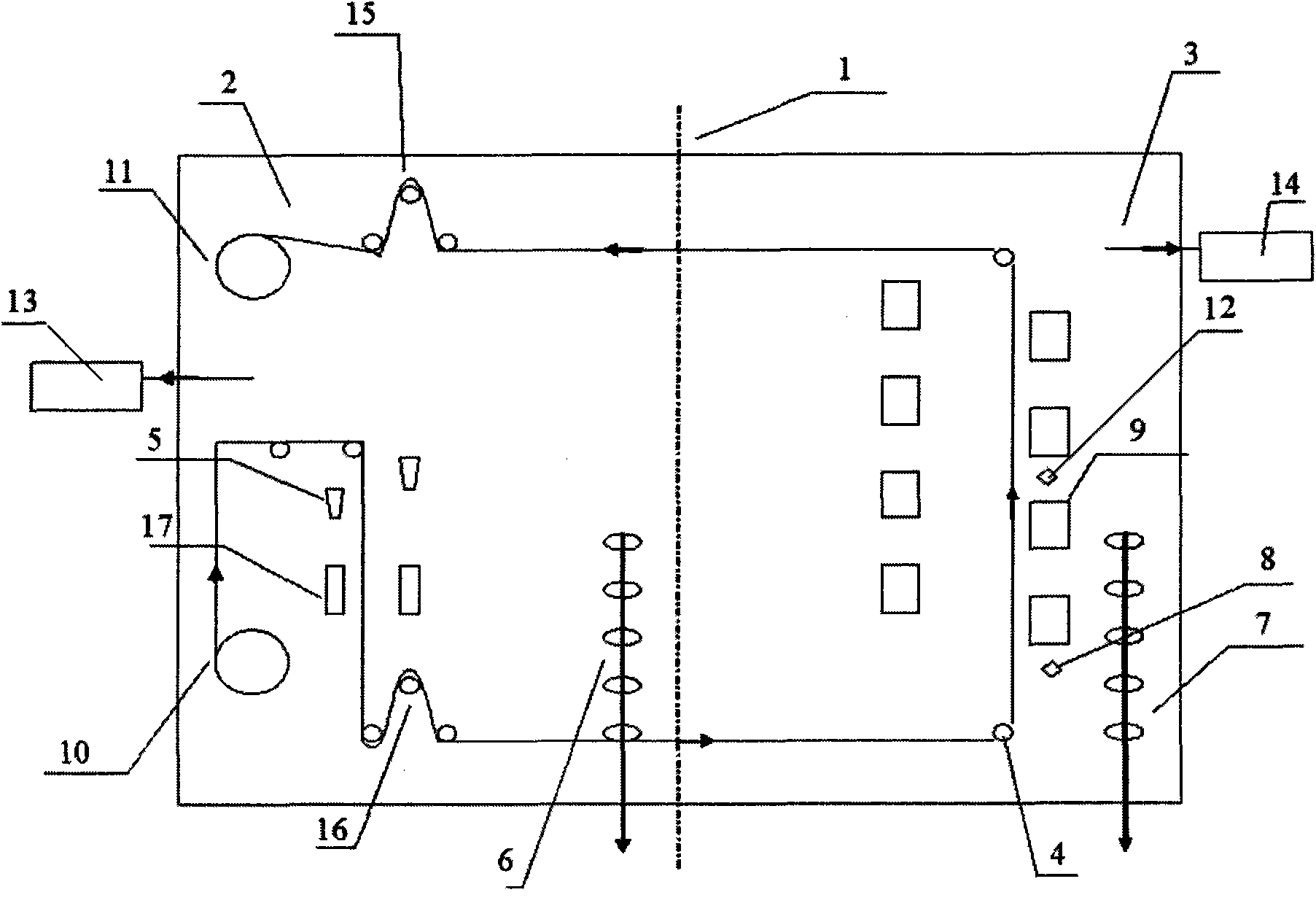

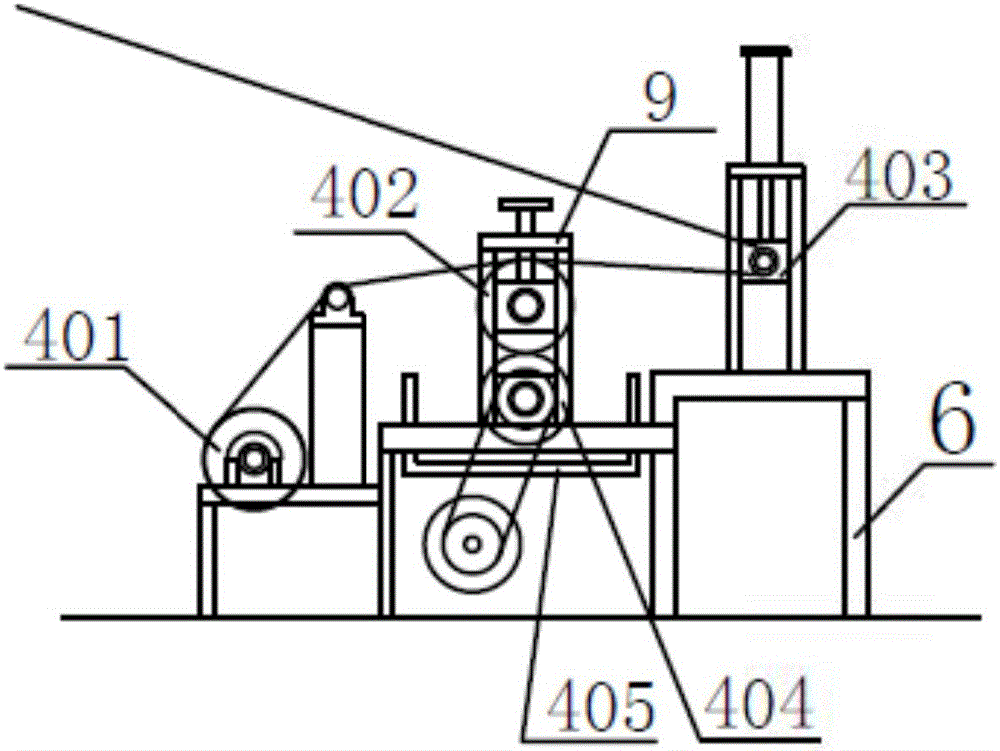

Manufacturing method and device of winding banded ITO conductive film

ActiveCN101914755AWideQuality improvementVacuum evaporation coatingSputtering coatingMaterials preparationIndium tin oxide

The invention discloses a manufacturing method of a winding banded ITO conductive film, a substrate is placed in a material preparation chamber and the surface is processed through an infrared heater and an ion source in a vacuum condition; the substrate enters a sputtering chamber, and a sputtering target and a silica dispenser are used for sputtering a silica film on the substrate; an indium tin oxide film is sputtered on the silica film; a transmission rack (4) is arranged in the material preparation chamber (2) and the sputtering chamber (3), the front and tail ends of the transmission rack (4) are both arranged in the material preparation chamber (2), a discharging roller (10) and a receiving roller (11) are respectively arranged at the front and tail ends of the transmission rack (4), the infrared heater (17) and the ion source (5) are respectively arranged at two sides of the transmission rack (4) in the material preparation chamber (2), the sputtering target (9) is arranged at two sides of the transmission rack (4) in the sputtering chamber (3), and the silica dispenser (8) and an indium tin oxide dispenser (12) are respectively arranged in the front and middle of the sputtering target (9) in the sputtering chamber (3). The method and the device sputter coatings on the substrate and can realize continuous production, increase the product width and length and enlarge the product use.

Owner:HUAIAN FUYANG ELECTRONICS MATERIALS

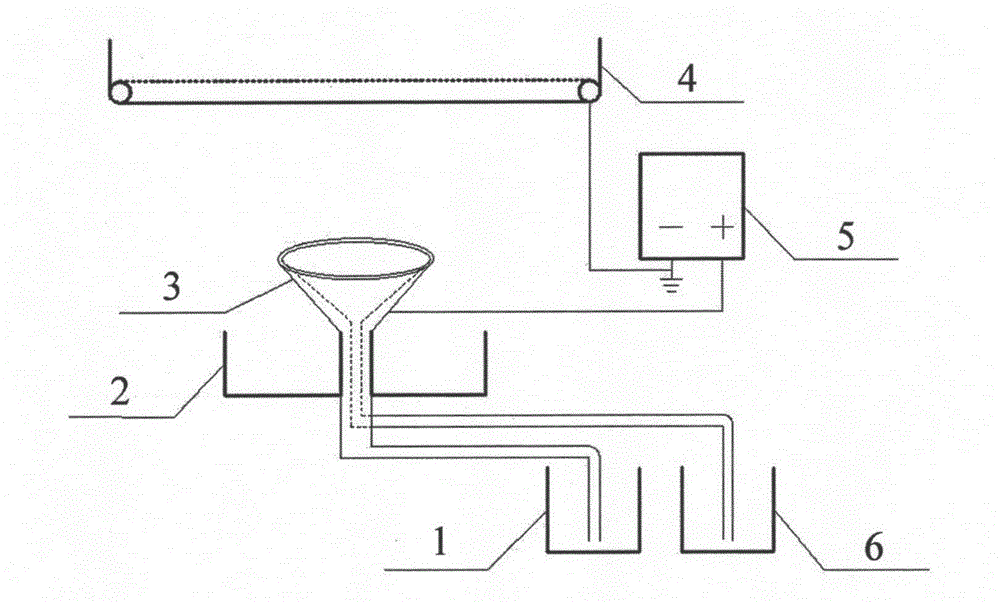

Electrostatic spinning device for preparing coaxial nanofiber in batches

InactiveCN104611772AAvoid easy cloggingRealize large-scale productionFilament/thread formingNeedle freeFiber

The invention provides an electrostatic spinning device for preparing coaxial nanofiber in batches. The electrostatic spinning device for preparing the coaxial nanofiber in batches is characterized by comprising a first liquid supplying device, a second liquid supplying device, a needle-free coaxial electrostatic spinning spraying head, a fiber collecting device and a high pressure generator, the needle-free coaxial electrostatic spinning spraying head comprises an outer solution spinneret and an inner solution spinneret arranged on the inner side of the outer solution spinneret, the outer solution spinneret and the inner solution spinneret are connected with the first liquid supplying device and the second liquid supplying device respectively, an outer solution and an inner solution are placed in the first liquid supplying device and the second liquid supplying device respectively, the outer solution is covered with the inner solution on the edge of the needle-free coaxial electrostatic spinning spraying head in the axial direction, so that a coaxial composite solution is formed, and multiple coaxial spinning jet flows are formed in the axial direction along the edge of the needle-free coaxial electrostatic spinning spraying head under the action of a high pressure static electric field generated by the high pressure generator. By the adoption of the electrostatic spinning device, nanofiber felt of skin core structures can be manufactured in batches.

Owner:DONGHUA UNIV

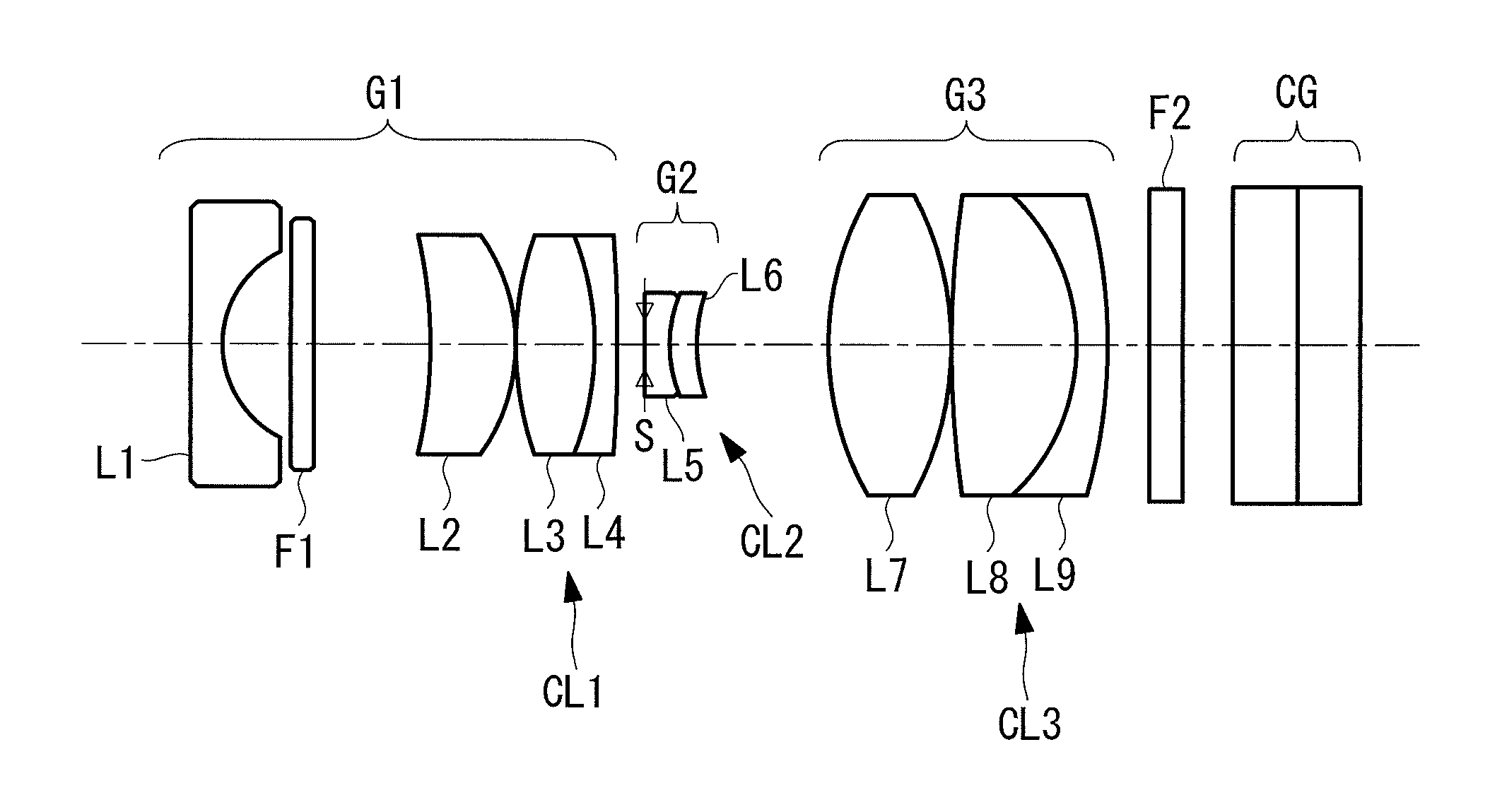

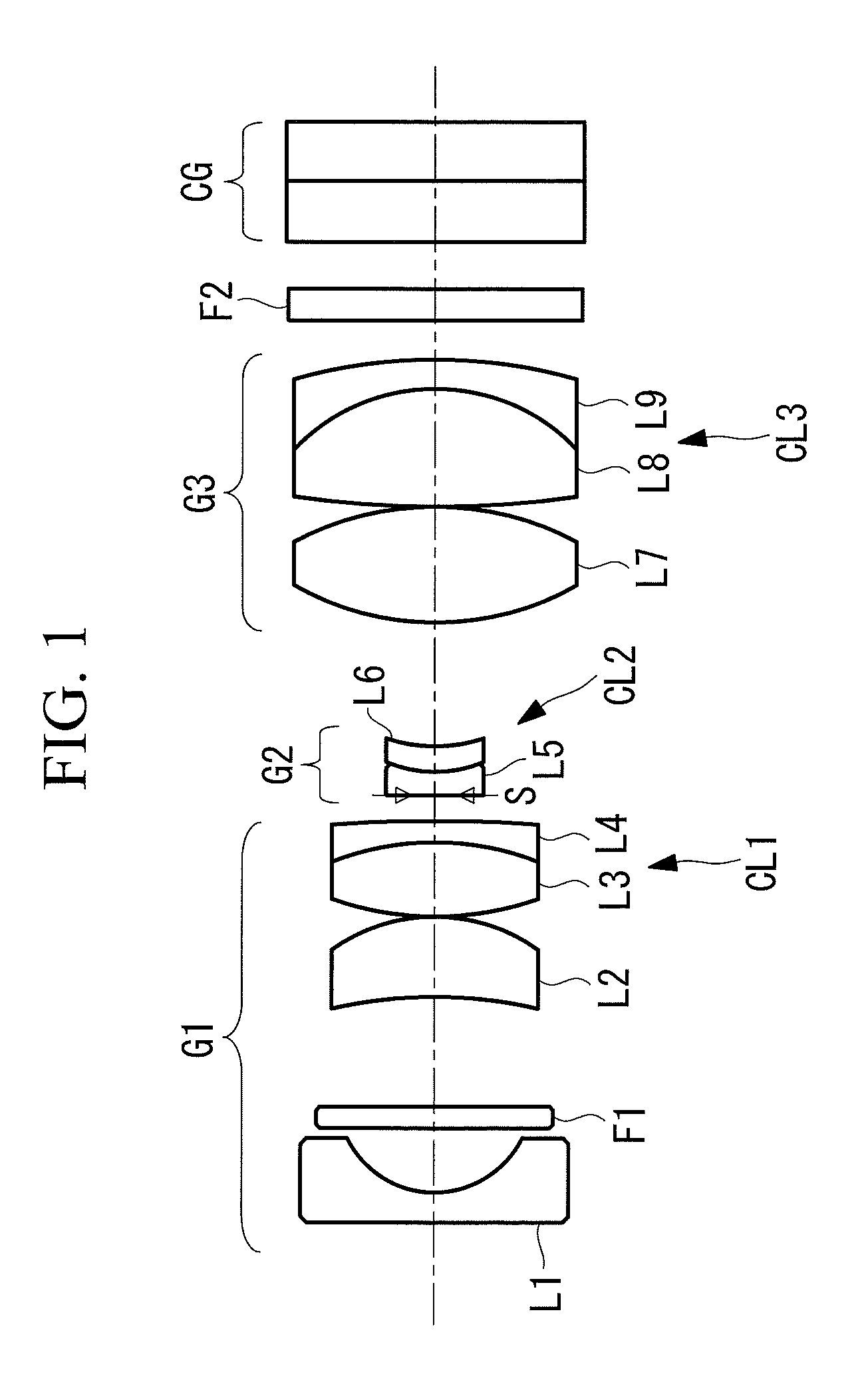

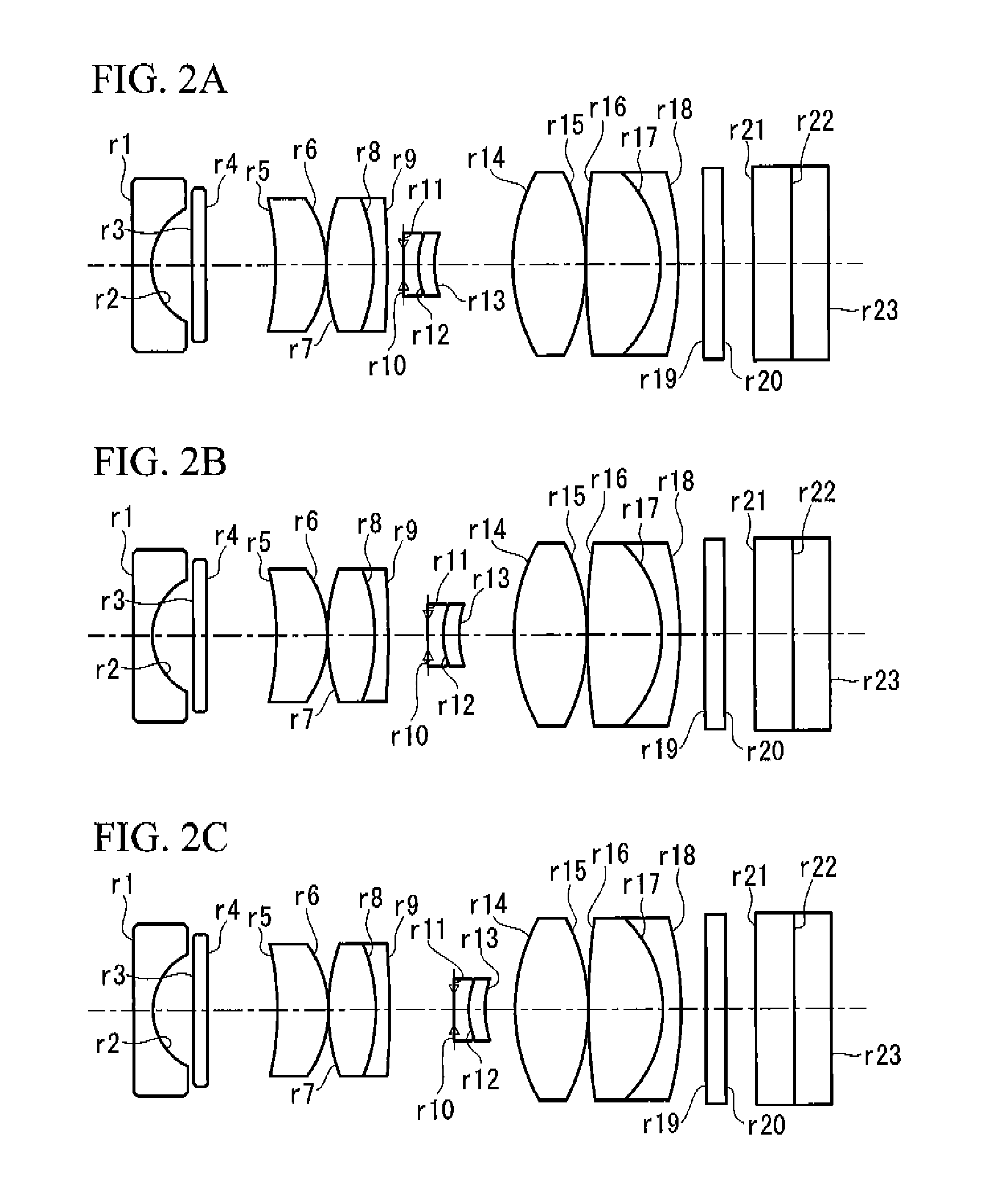

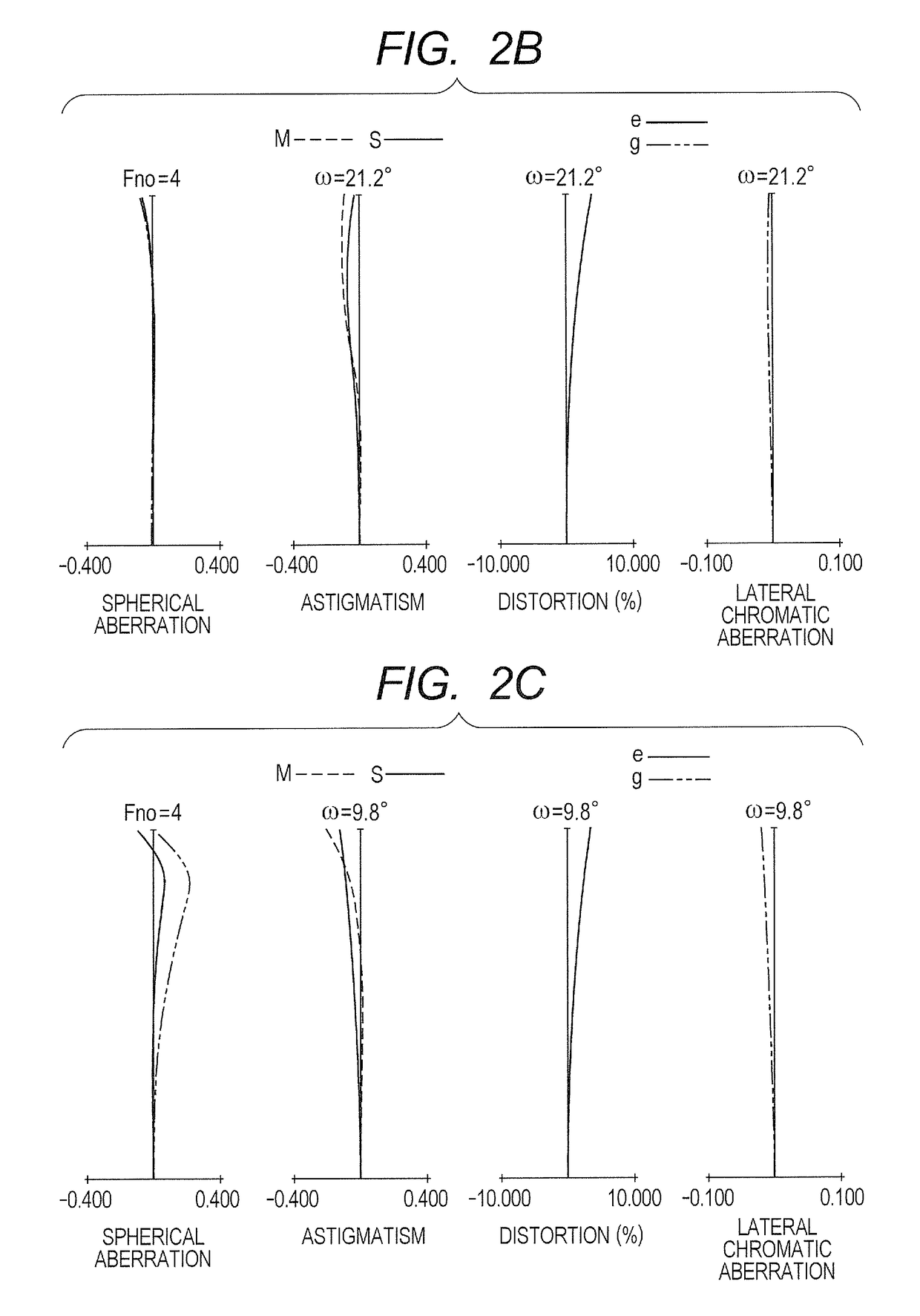

Objective Optical System

An objective optical system consists of, from an object side to an image side: a first lens group having positive optical power; a second lens group having negative optical power; and a third lens group having positive optical power, wherein the first lens group includes, from the object side to the image side, a first lens having negative optical power and a second lens having positive optical power, and the second lens group is moved according to a change in an object distance to perform focusing, and the following conditional expressions are satisfied:−19<f2 / f1<−3.50.5<v / f<1.1where f2 is a focal length of the second lens, f1 is a focal length of the first lens, v is an amount of movement of the second lens group, and f is a focal length of an entire system during the most distant view observation.

Owner:OLYMPUS CORP

Magnesium silicate fiber blanket and production method thereof

ActiveCN101706030AWith insulationWith sound-absorbing functionMagnesium silicatesThermal insulationFiberThermal insulation

The invention relates to a magnesium silicate fiber blanket belonging to the technical field of fire-proof heat preservation and insulation materials. The magnesium silicate fiber blanket is characterized by comprising the following materials with oxides in percentage by weight: 40%-85% of SiO2, 3%-40% of MgO, 2%-30% of CaO, and the balance of one or the any combination of B2O3, Al2O3, Fe2O3, Na2O and K2O, wherein the total amount of the SiO2, the MgO and the CaO is more than or equal to 85%. The magnesium silicate fiber blanket is processed through the procedures of material melt, centrifugal thread throwing or blowing fiber forming, cotton collection, pinprick, heat treatment, cutting, and the like. The magnesium silicate fiber blanket has functions of non-inflammation, heat insulation, sound absorption and fire prevention and is a fire-resistant heat-preserving heat-insulating fire-proof material which is widely suitable for various heat engineering equipment and pipelines.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

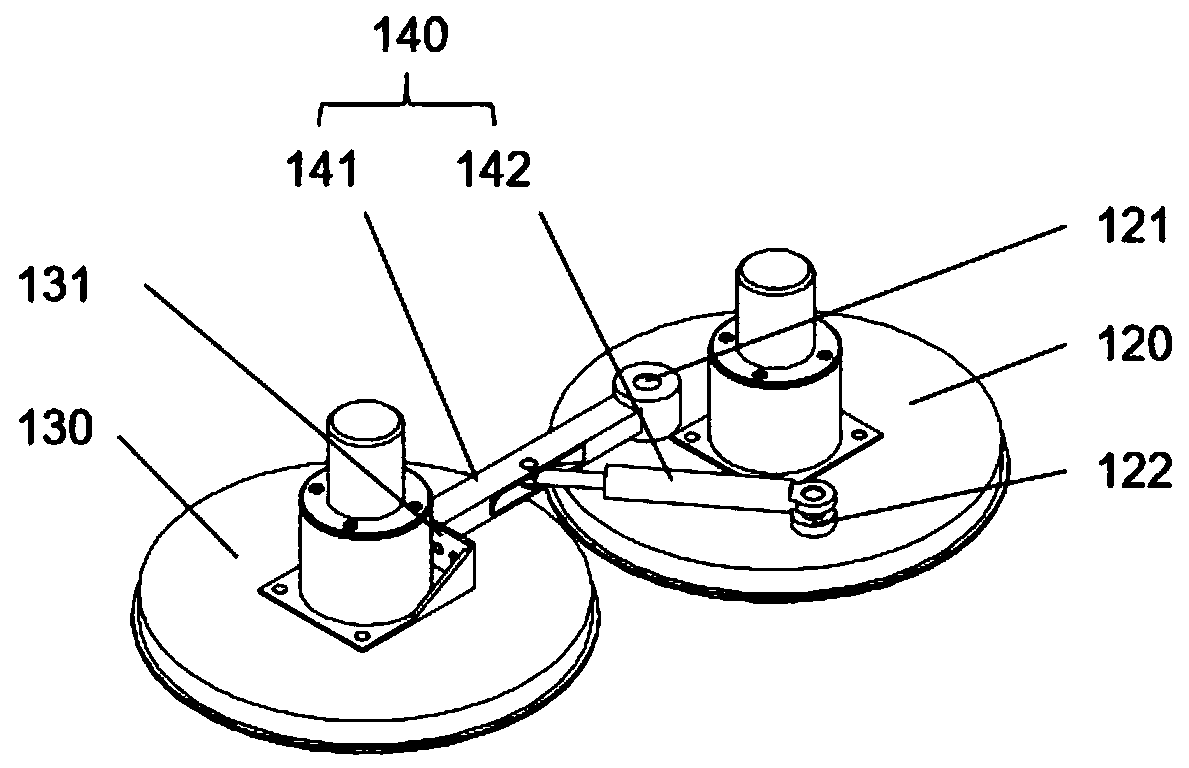

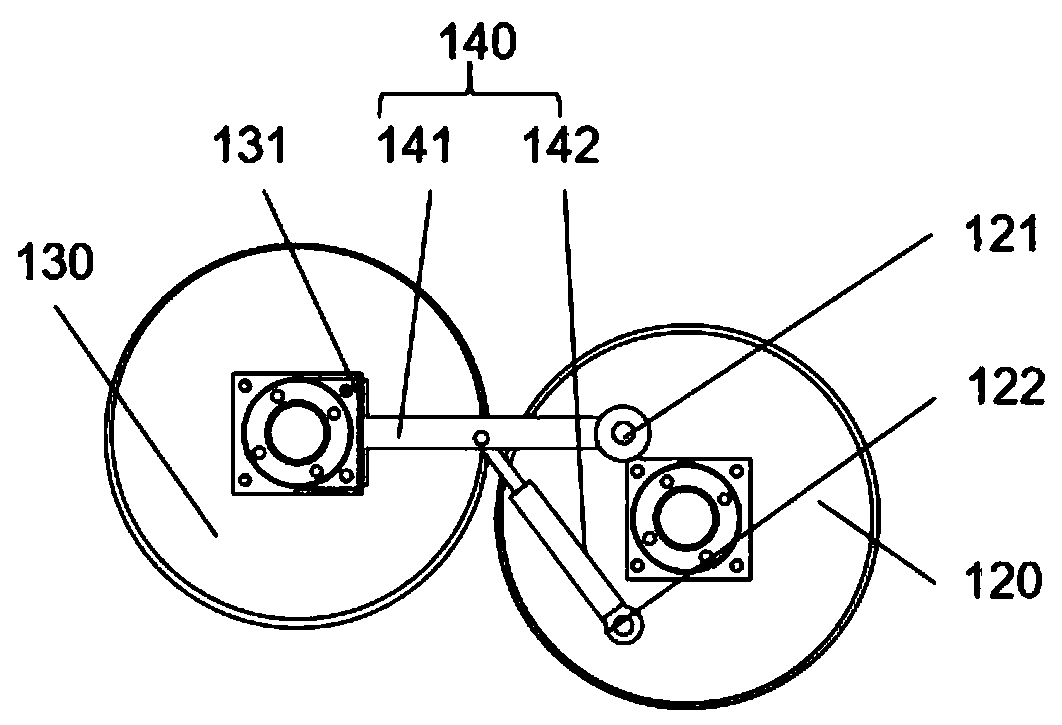

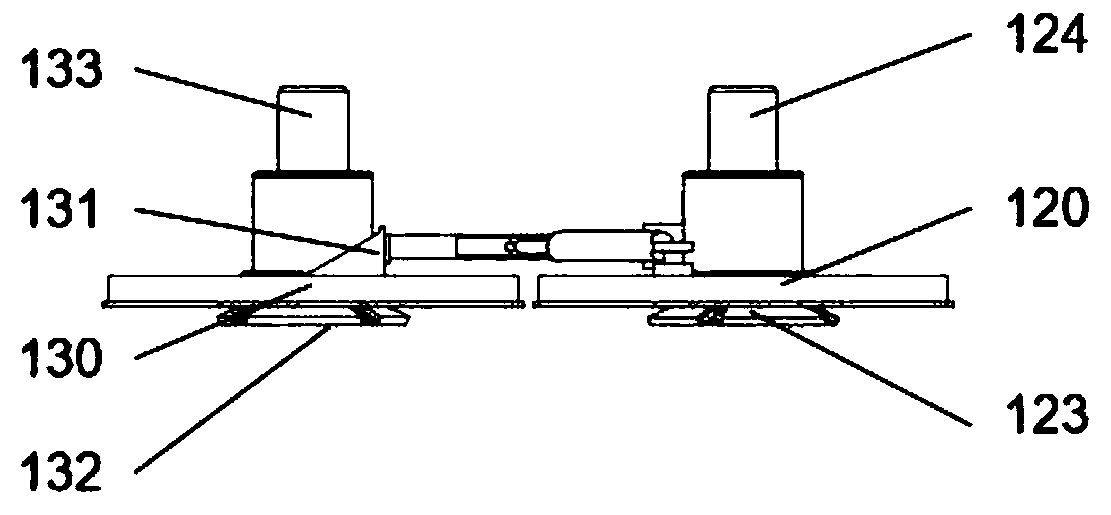

Weeding and obstacle avoiding mechanism and weeding and obstacle avoiding robot

InactiveCN111201899AWidth adjustmentAvoid harmProgramme-controlled manipulatorMowersFruit treeControl engineering

The invention relates to a weeding and obstacle avoiding mechanism and a weeding and obstacle avoiding robot. The weeding and obstacle avoiding mechanism comprises a weeding structure and an obstacleavoiding structure, wherein the weeding structure comprises a fixed cutter disc cover and a rotating cutter disc cover; the rotating cutter disc cover is connected with the fixed cutter disc cover through the obstacle avoiding structure; the obstacle avoiding structure comprises a connecting rod and a linear driving part; the first end of the connecting rod is rotatably connected with the fixed cutter disc cover, and the second end of the connecting rod is connected with the rotating cutter disc cover; and the first end of the linear driving part is rotatably connected with the fixed cutter disc cover, and the second end of the linear driving part is rotatably connected with the connecting rod. According to the weeding and obstacle avoiding mechanism and the weeding and obstacle avoiding robot, the obstacle avoiding structure is adopted to drive the rotating cutter disc cover to rotate relative to the fixed cutter disc cover, obstacle avoiding and mowing between plants can be achieved,damage to fruit trees is prevented, and weeds around the fruit trees at different intervals can be removed thoroughly; the weeding width can be changed; and the mowing operation efficiency is improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

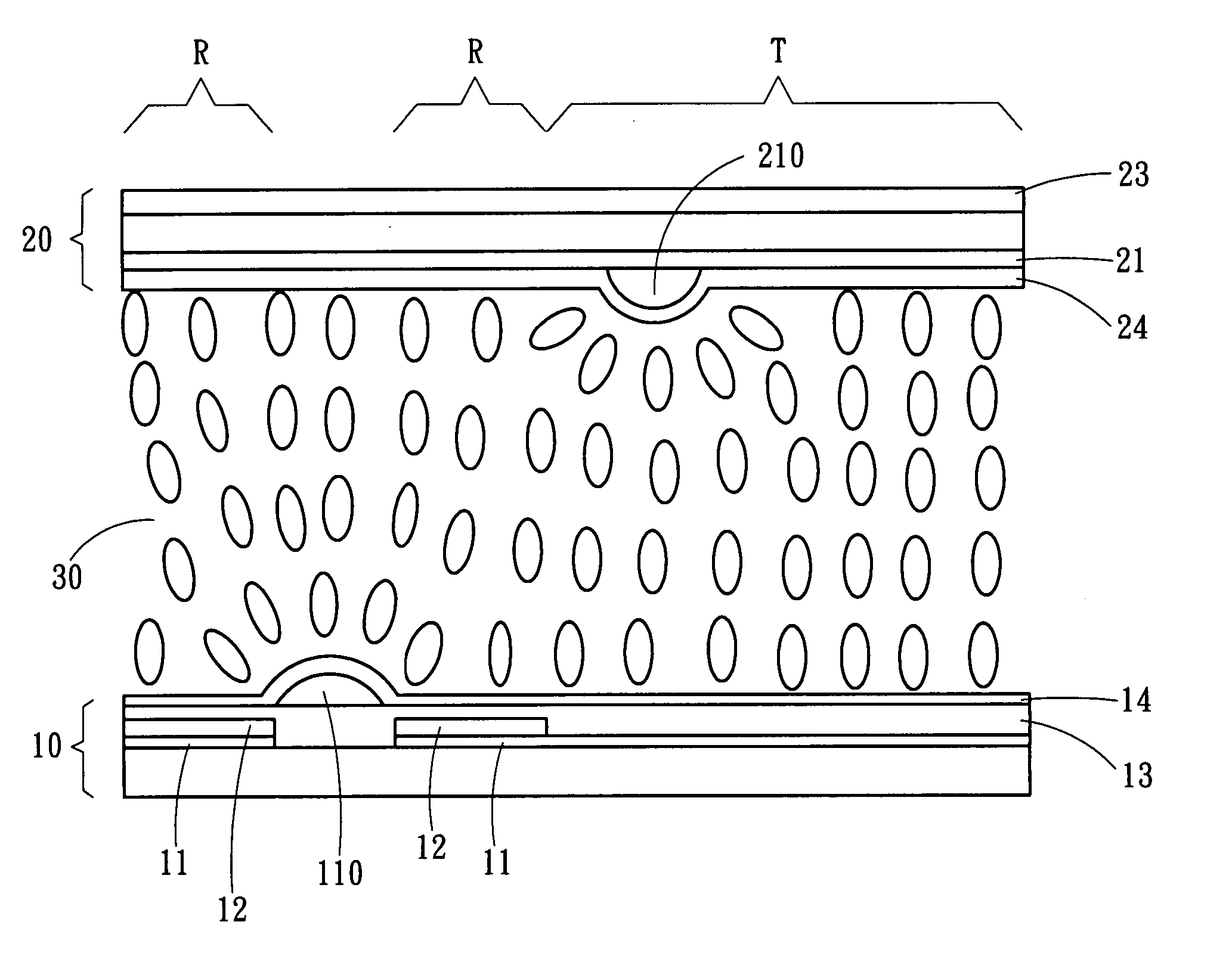

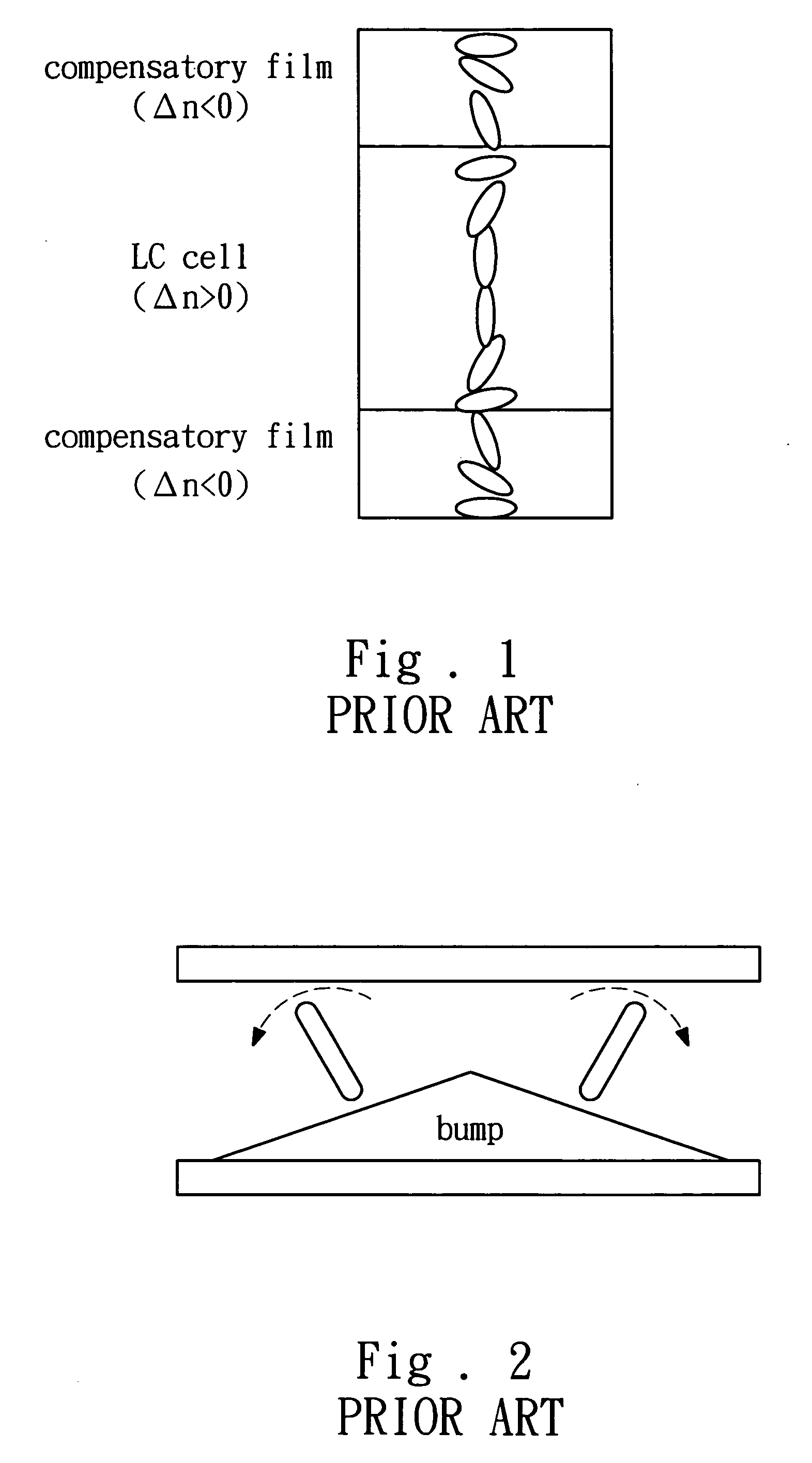

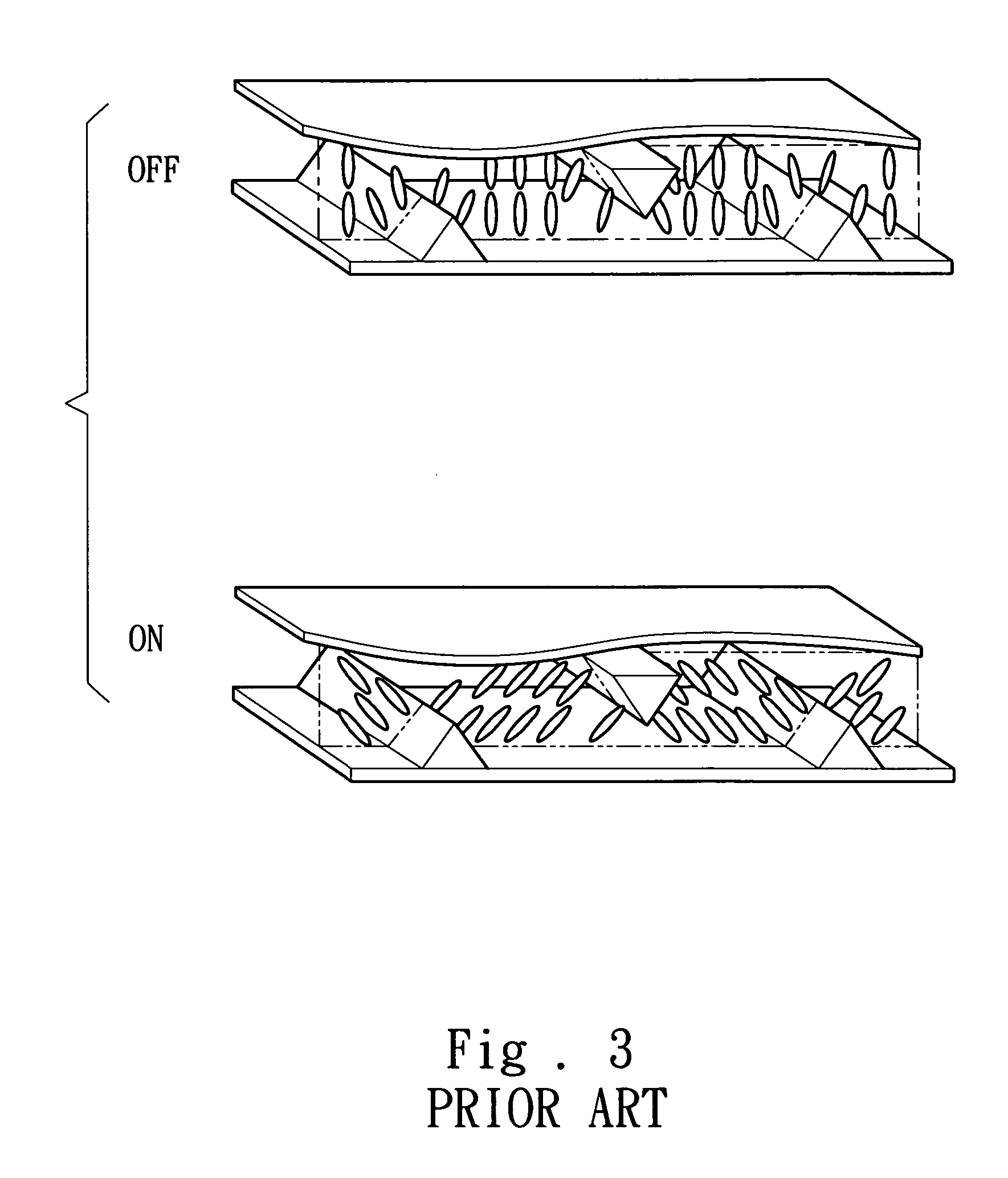

Reflective and transflective liquid crystal display

A reflective and transflective liquid crystal display, a figure of bump structure is defined at a pixel electrode, and a reflective layer is formed around the peripheral at the top or bottom of the figure of bump structure to define the reflective zone and the transmissive zone of each single pixel. The upper electrode can contain the figure of slit or bump structure. By adjusting the relative positions of the figures of slit or bump structure between electrodes, the pre-tilt angles and tilting directions of liquid crystal molecules can be controlled, and a multi-domain division alignment is formed, and thus a multi-domain division, semi-transmissive, and wide view angle liquid crystal panel can be formed.

Owner:WINTEK CORP

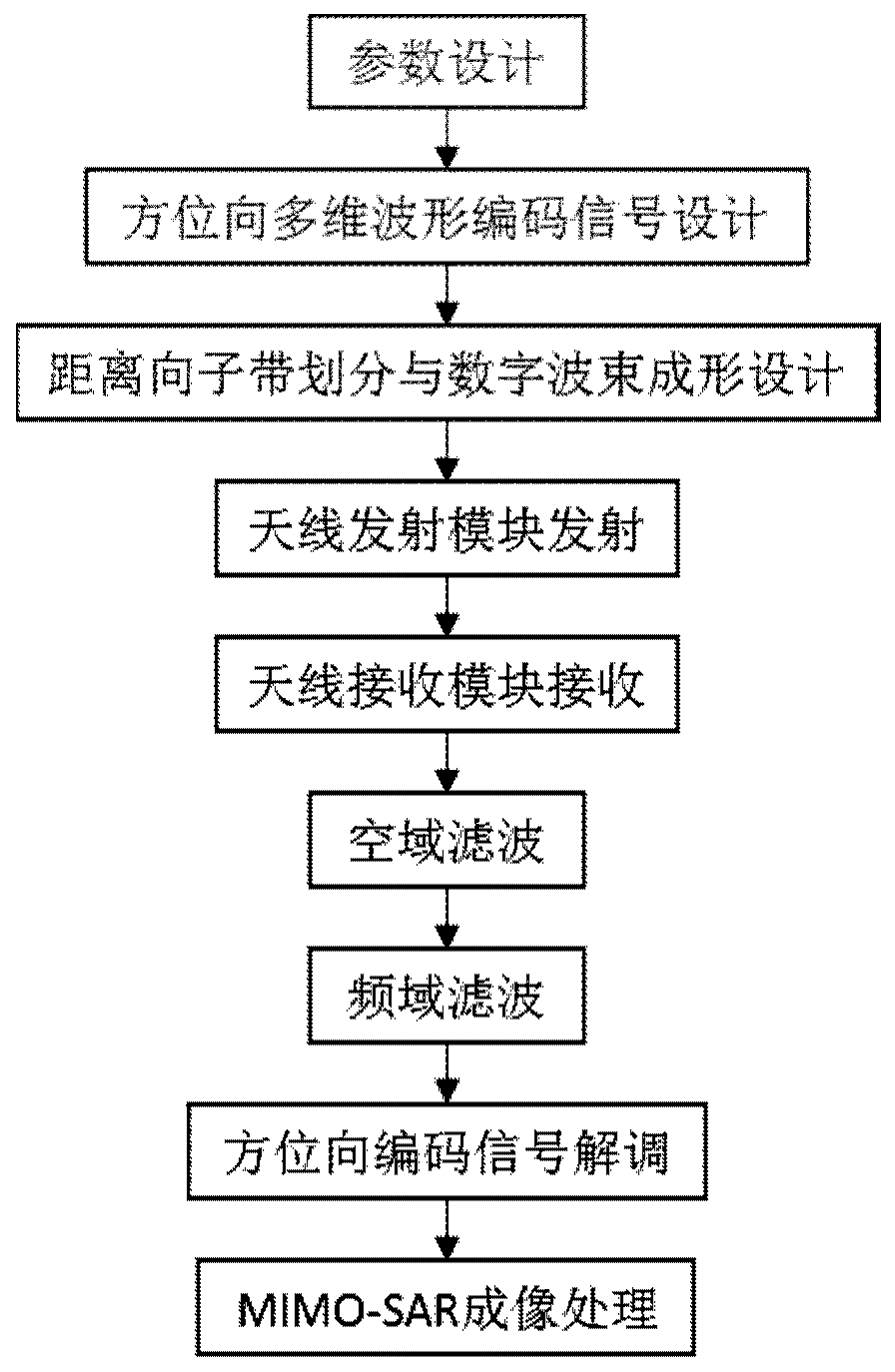

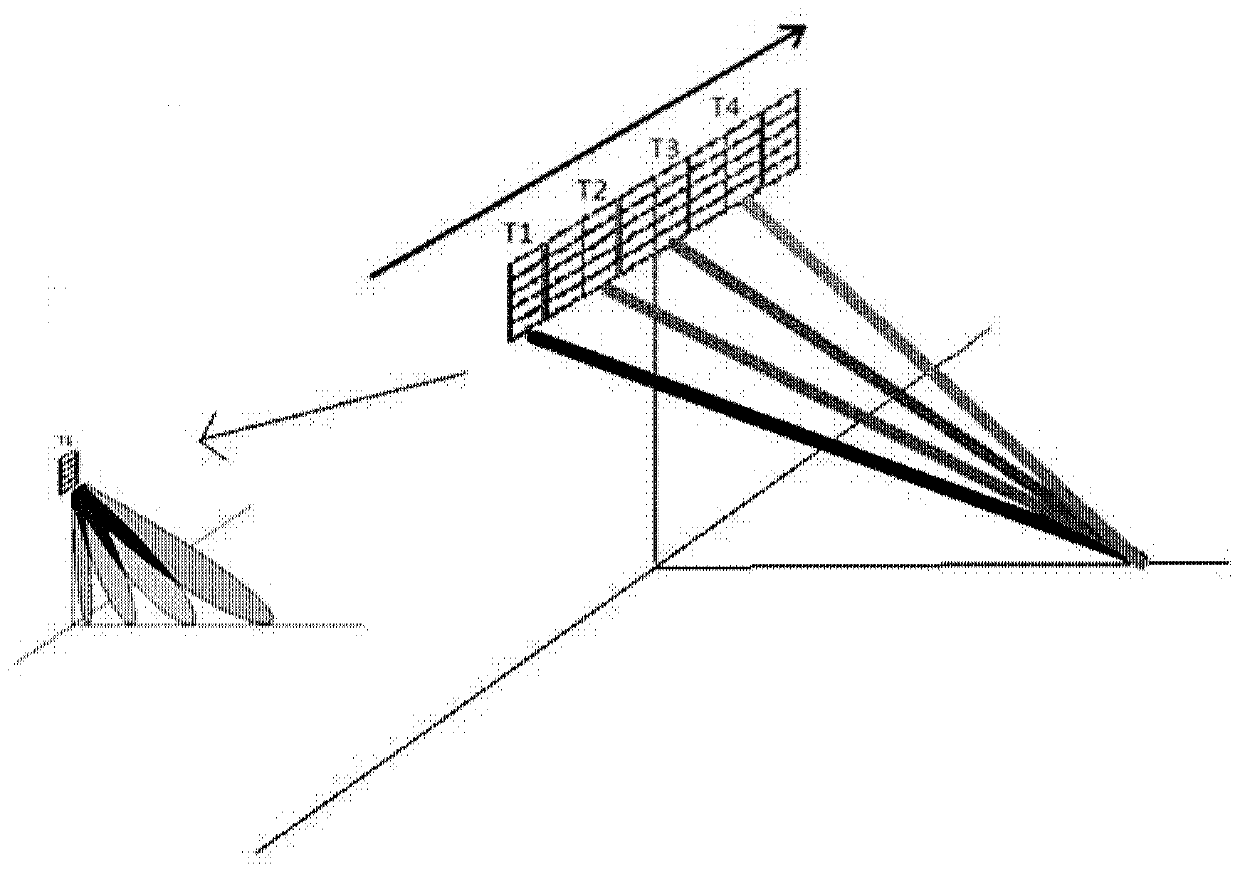

Multi-input multi-output synthetic aperture radar imaging method

InactiveCN110333507AImprove detection efficiencyIncreased mapping bandwidthRadio wave reradiation/reflectionMulti inputWaveform coding

A multi-input multi-output synthetic aperture radar imaging method comprises the steps that parameters are set; according to the number of azimuth transmitting antennas, a corresponding quantity of orthogonal multidimensional waveform coding signals are determined; according to the number of distance sub-bands, a transmitting waveform of distance array elements is determined; the signals are transmitted to a to-be-imaged scene; after the signals are reflected by a to-be-imaged object, a receiving module receives the signals and forwards the signals to a processing system for sampling; based onthe sampled signals, reflected echoes of the multiple distance sub-bands are separated through space domain filtering; the reflected echoes of the multiple distance sub-bands are further separated through frequency domain filtering, and the isolation degree among the distance sub-band signals is increased; the separated reflected echoes of the distance sub-bands are demodulated, so that a received echo corresponding to each azimuth transmitting antenna is obtained; and the received echoes are imaged through the multi-input multi-output synthetic aperture radar imaging method.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Pure copper ammonia fiber high-density imitated silk jacquard plus material and preparing method of pure copper ammonia fiber high-density imitated silk jacquard plus material

InactiveCN104047093AWideConsistent qualitySwivel-woven fabricsLappet-woven fabricsFiberCuprammonium rayon

The invention provides a pure copper ammonia fiber high-density imitated silk jacquard plus material and a preparing method of the pure copper ammonia fiber high-density imitated silk jacquard plus material. Warp yarns of the plus materials are copper ammonia 75D / 45F, weft yarns are copper ammonia 75D / 54F, the warp yarn density is 750 to 787 / 10cm, the weft yarn density is 630 to 709 / 10cm, the breadth is 250 to 340cm, the plus material is jacquard fabrics, the pattern width is 60 to 64cm, and the length is 90 to 100cm. The plus material is woven by a single weaving shaft of a rapier loom, the luster, the drapability, the ventilation performance and the hand feeling of the plus material are very similar to those of real silk, the breadth of the plus material is greater, in addition, the quality of the plus material on the whole breadth is identical, and front and back side defect spots do not exist.

Owner:JIANGSU YUEDA HOME TEXTILE

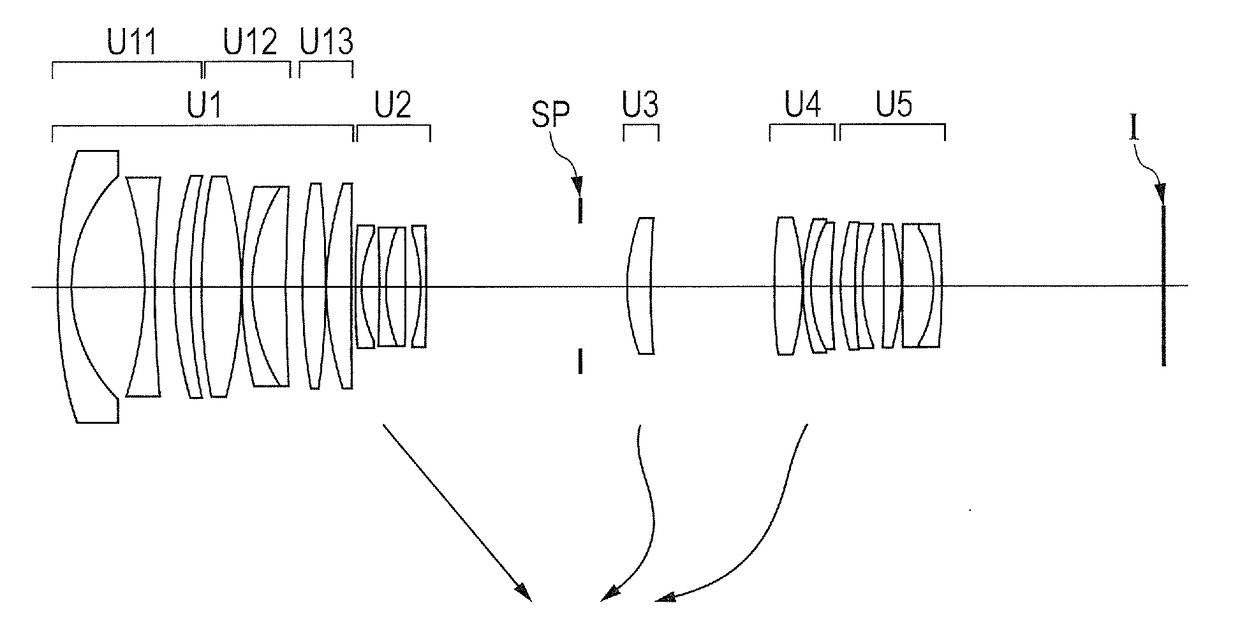

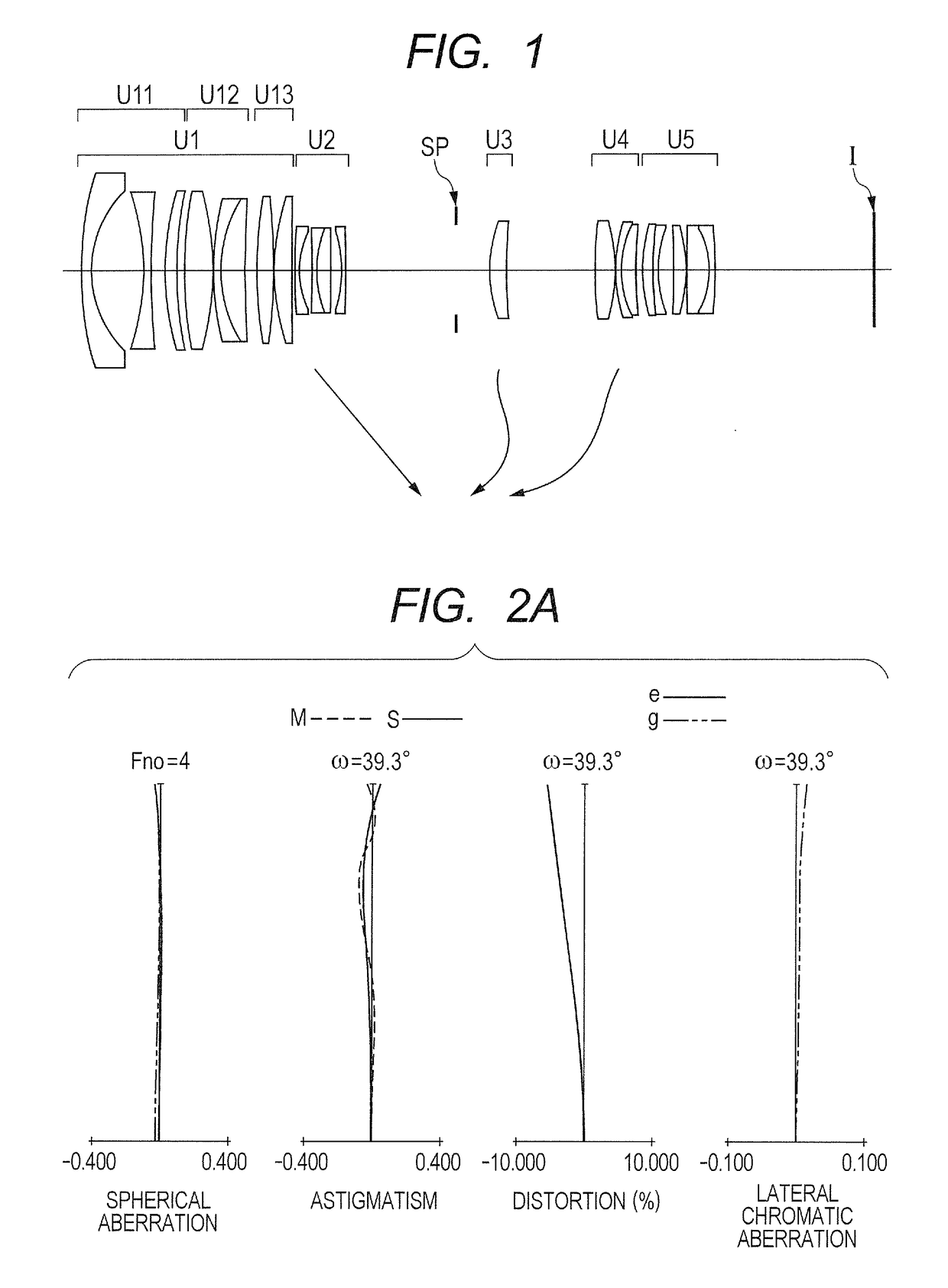

Zoom lens and image pickup apparatus including the same

A zoom lens includes, in order from object side: a positive first unit not moving for zooming; a second unit moving during zooming; a positive third unit; a positive fourth unit; and a rear unit including at least one unit, the second unit including one or more lens sub-units and having a negative refractive power as a whole, the fourth unit moving during zooming, the zoom lens including a stop between the second and third units or between the third and fourth units. Lateral magnifications of the second unit at a wide angle end and a telephoto end when beam enters from infinity, focal lengths at the wide angle end and the telephoto end, a focal length of the first unit, and a focal length of the second unit at the wide angle end are appropriately set.

Owner:CANON KK

Aluminum foil sticking compound machine

The invention provides an aluminum foil sticking compound machine. The aluminum foil sticking compound machine comprises an uncoiling device, a first gluing device, a second gluing device, a compressing device and a coiling device, wherein the uncoiling device is positioned at the front end of a frame; a cloth uncoiling roller is rotationally connected to the frame; the first gluing device is positioned at the tail end of the frame, and comprises a first glue slot for accommodating glue and a first rubber roller positioned above the first glue slot; the second gluing device is positioned beside the first gluing device, and comprises a second glue slot for accommodating glue and a second rubber roller positioned above the second glue slot; the compressing device is positioned on the middle part of the frame, and comprises an upper compressing roller and a lower compressing roller; the coiling device is positioned beside the compressing device, and is used for coiling compound fireproof cloth through a coiling roller. By adopting the aluminum foil sticking compound machine provided by the invention, larger-width compound fireproof cloth can be produced under the condition that a used aluminum foil raw material is constant in width.

Owner:天津市善文玻璃纤维制品有限公司

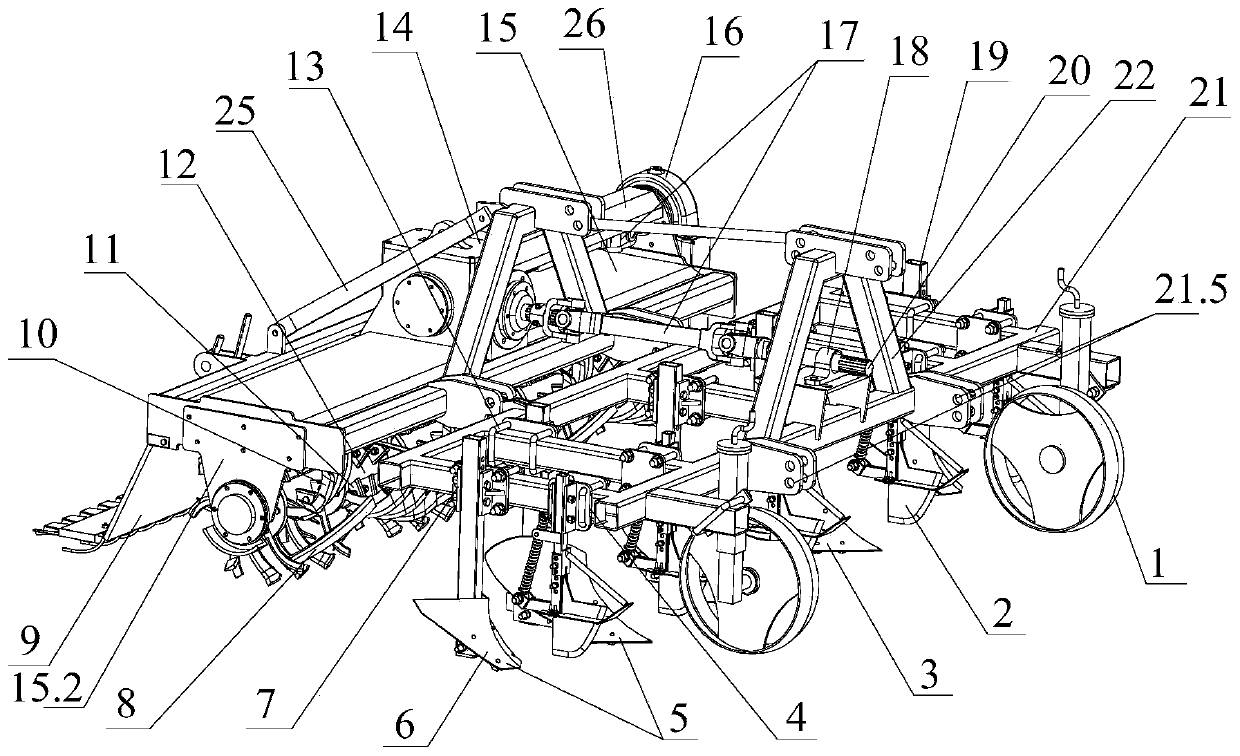

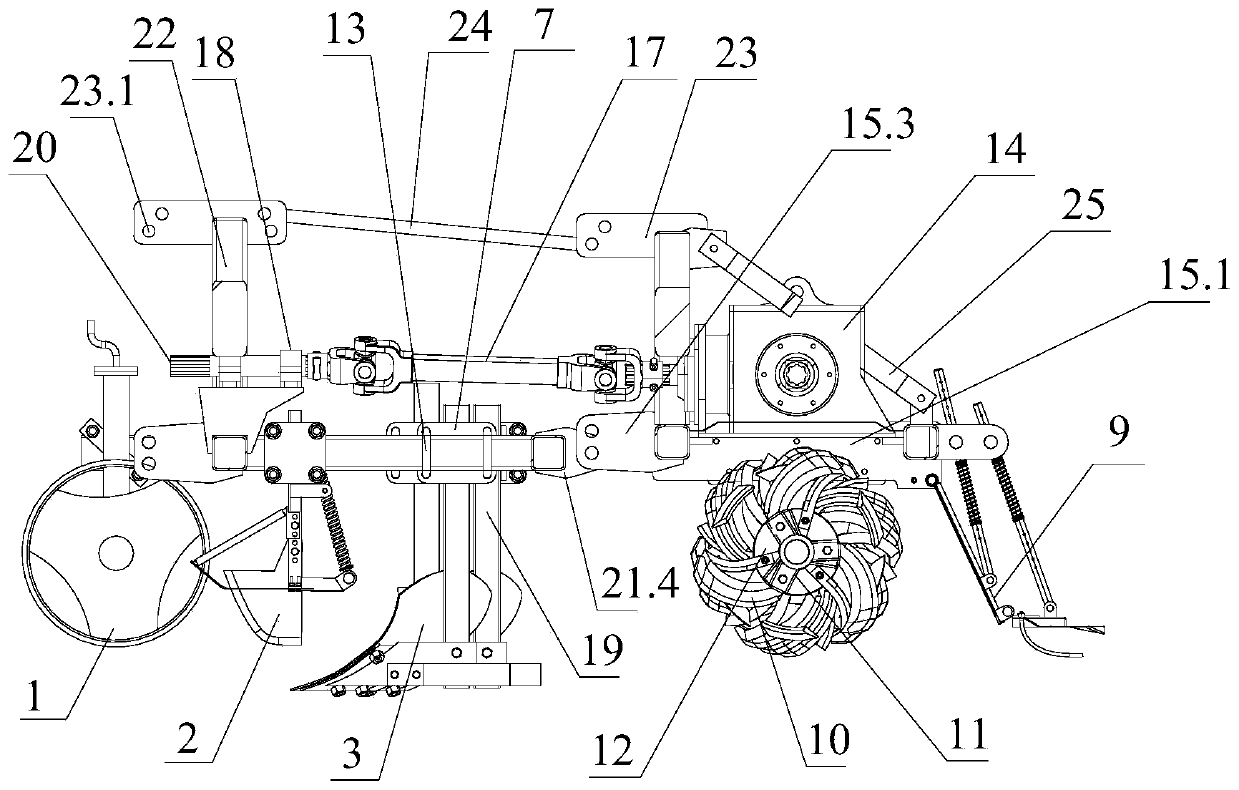

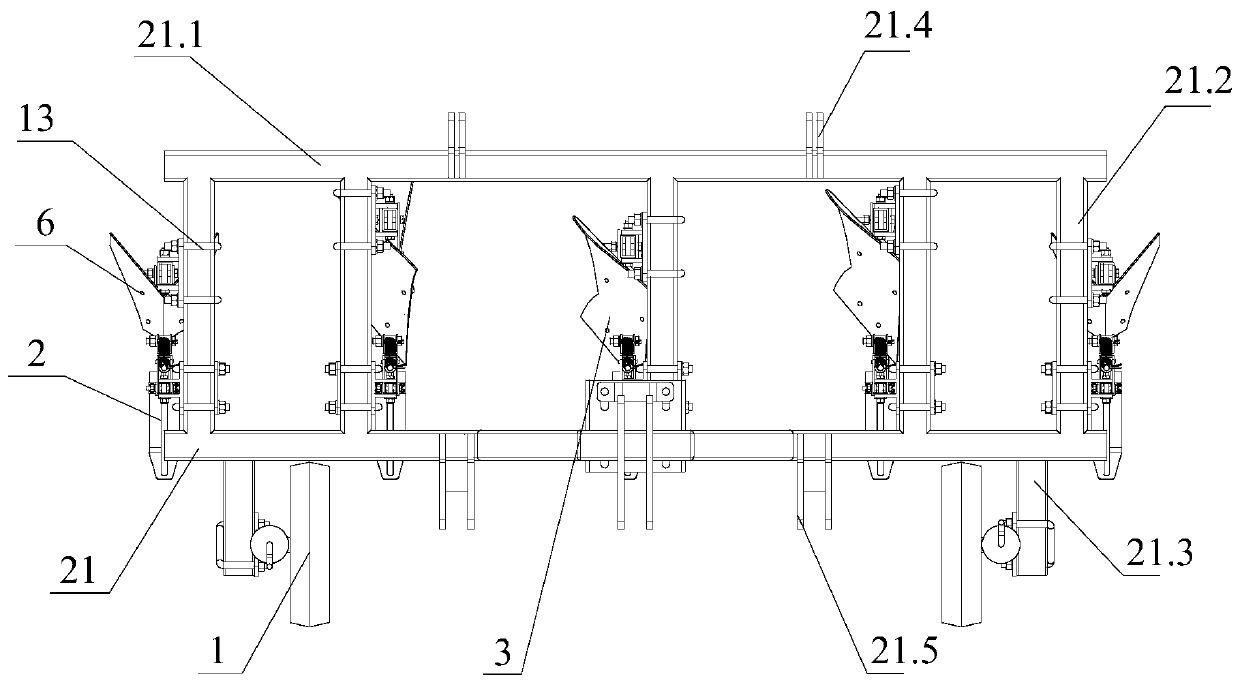

Combined tillage machine for returning dry-land straw to field by ploughing and rotary burying

InactiveCN110366883AProne to entanglementProne to cloggingSpadesAgricultural machinesUniversal jointAgricultural engineering

The invention discloses a combined tillage machine for returning dry-land straw to the field by ploughing and rotary burying. The combined tillage machine comprises a ploughing device which comprisesa frame, the frame comprises length rods at two ends, a plurality of width rods are arranged at intervals between the two length rods, and one end of each width rod is provided with a grass twining prevention device. Furrow ploughs are arranged at the other ends of the width rods on two sides of the frame, a soil breaking plough is arranged at the other end of the width rod in the middle of the frame, supporting frames are symmetrically arranged on the length rod at one end of the frame, depth-limiting wheel mechanisms are mounted on the supporting frames, and the length rod at the other end of the frame is connected with one end of a rotary burying platform of a rotary burying device. A rotary burying cutter roller is arranged between bearing fixing frames and spirally provided with rotary blades, and an intermediate gearbox is arranged in the center of the rotary burying platform and provided with a universal joint. Compared with separate operations, the combined tillage machine hasadvantages that power consumption can be reduced, field operation can be completed in one time by a tractor, soil compaction is reduced, and labor efficiency improvement and labor cost reduction are realized.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com