Patents

Literature

260 results about "Exposure treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exposure Treatment. Definition. Exposure treatment is a technique that is widely used in cognitive-behavioral therapy (CBT) to help patients systematically confront a feared stimulus in a live or virtual environment or in the imagination. Through repeated exposure to the stimulus, patients are helped to nullify fears and increase self-efficacy.

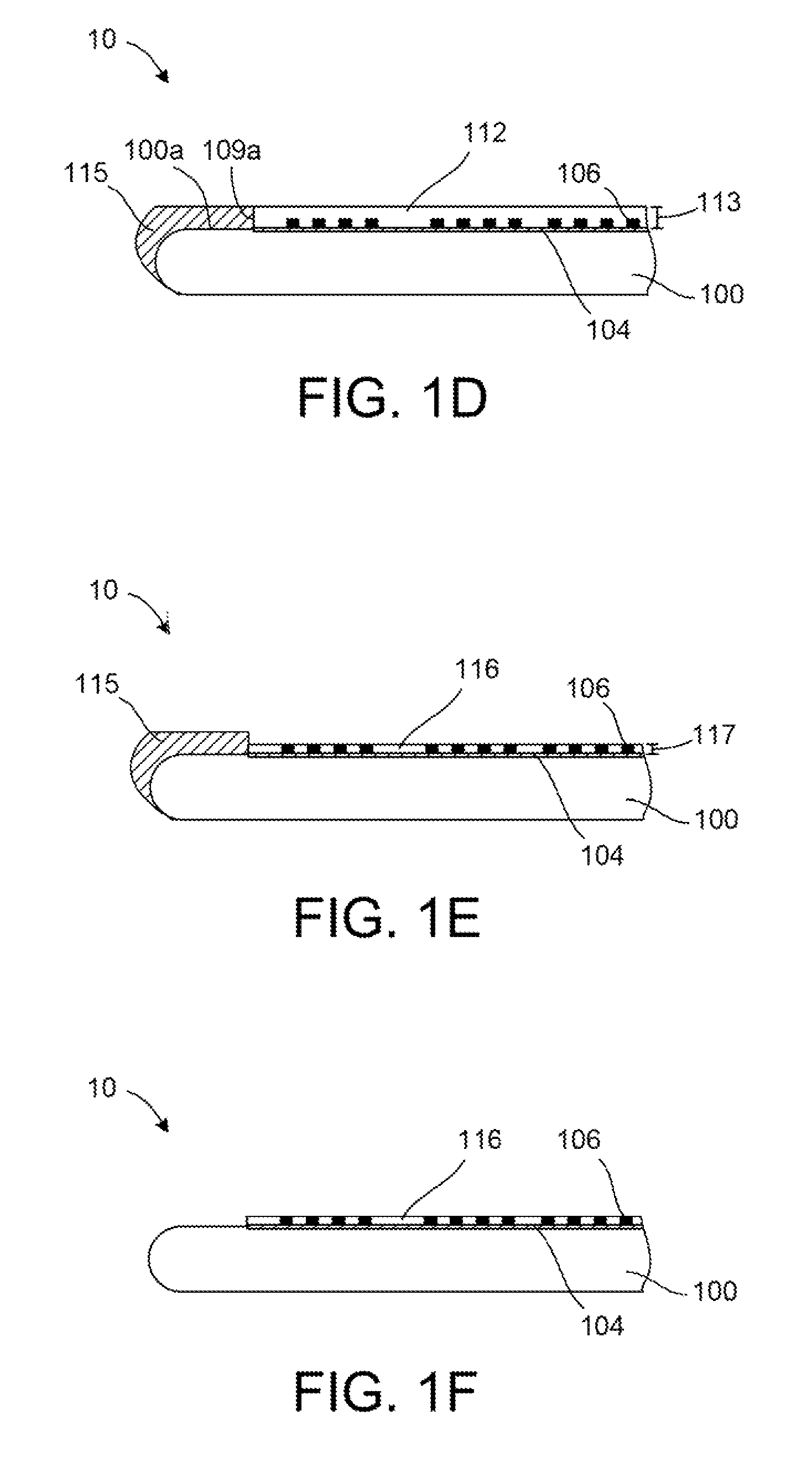

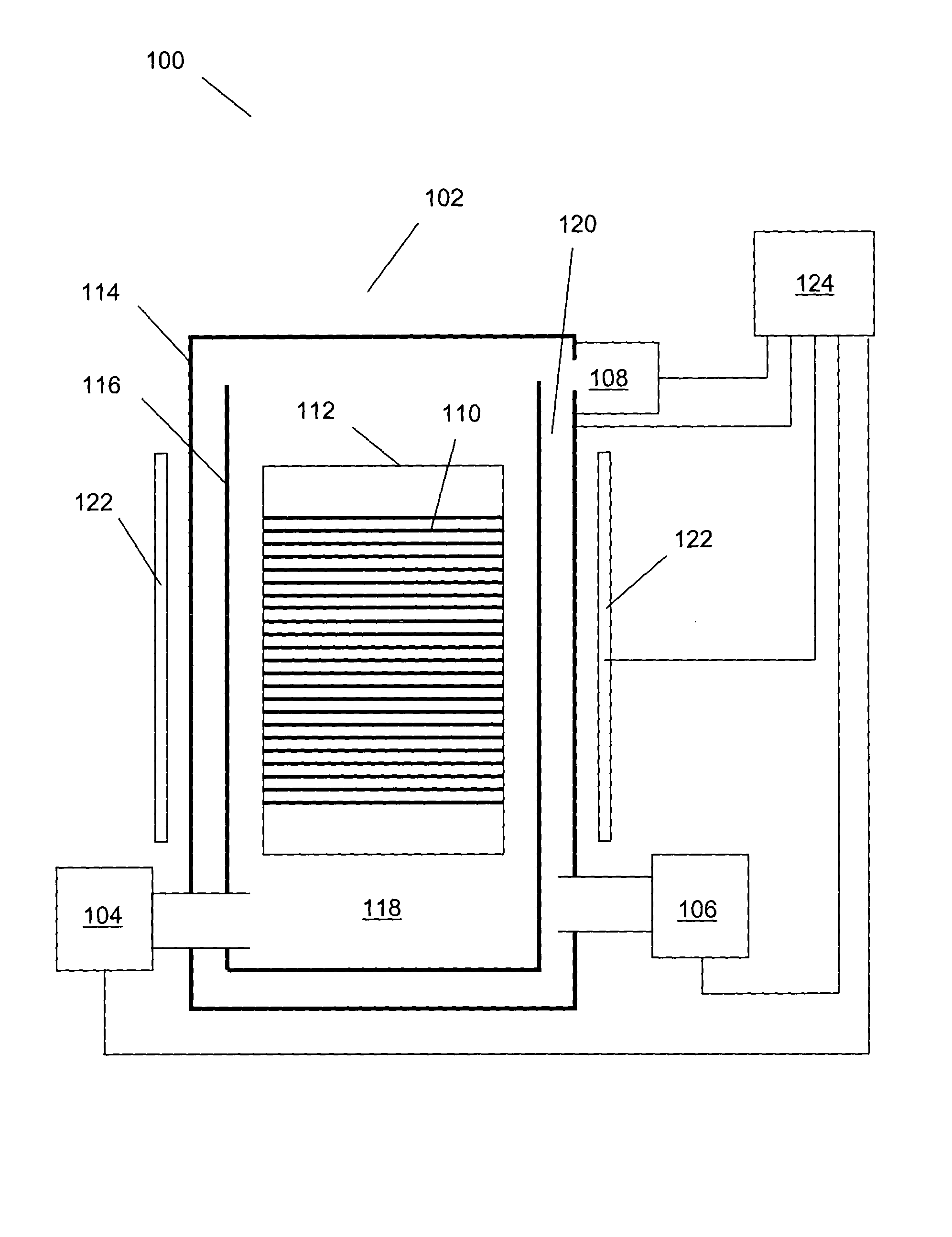

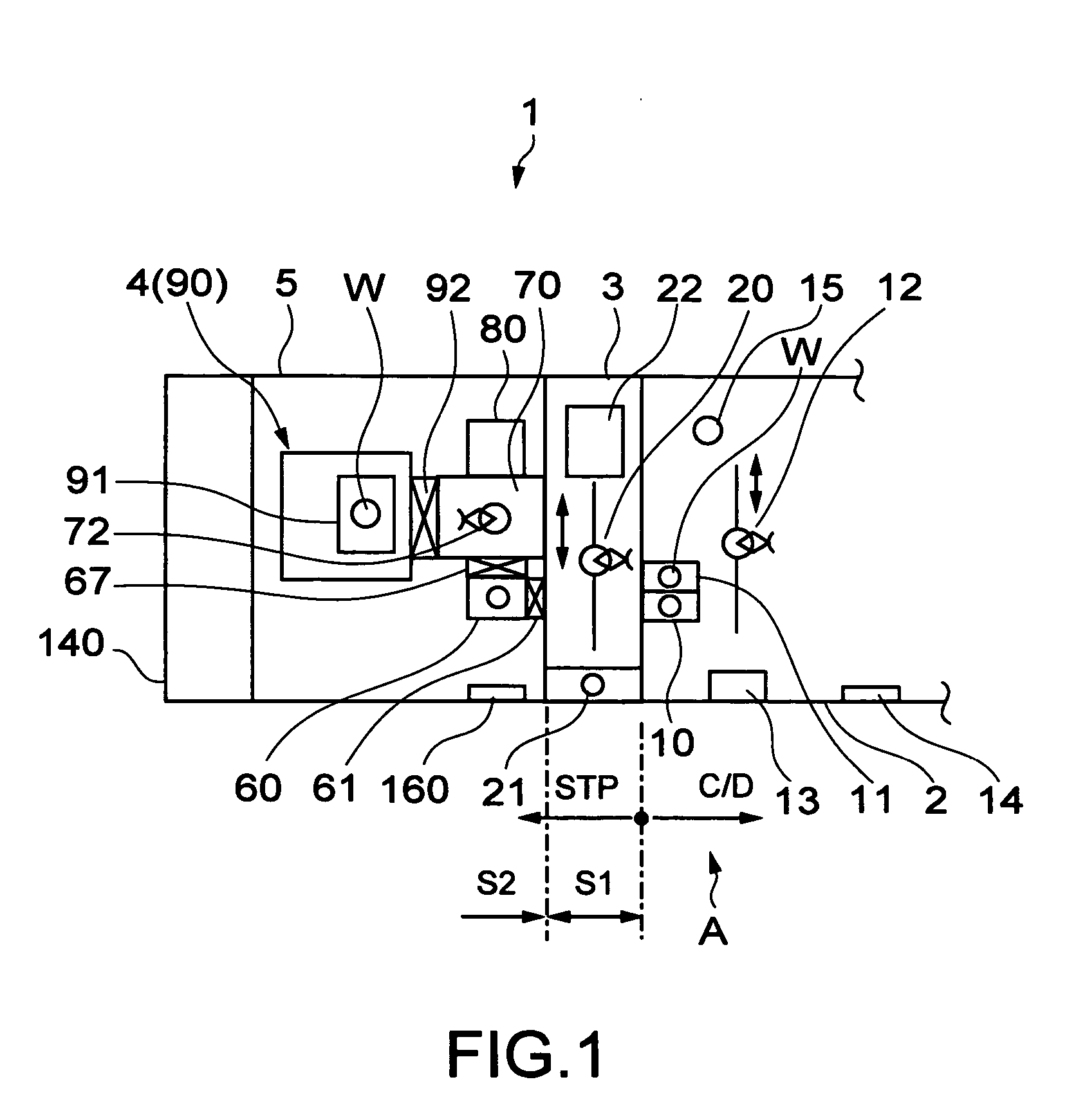

Supporting plate, stage device, exposure apparatus, and exposure method

ActiveUS20050094125A1Reduce the impactSuppression problemSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusBiomedical engineeringSupport surface

Owner:NIKON CORP

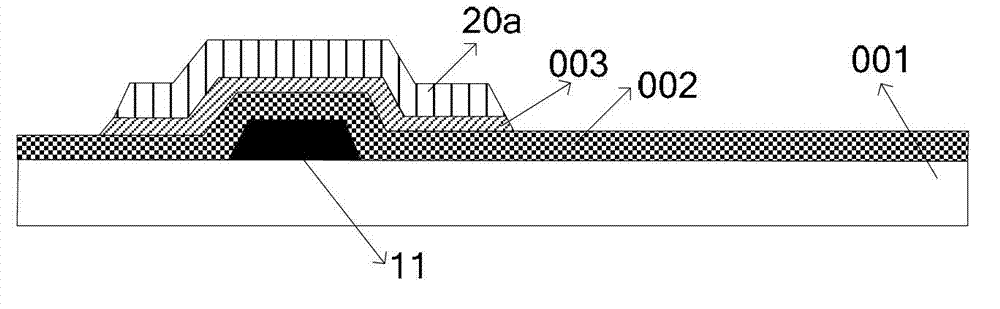

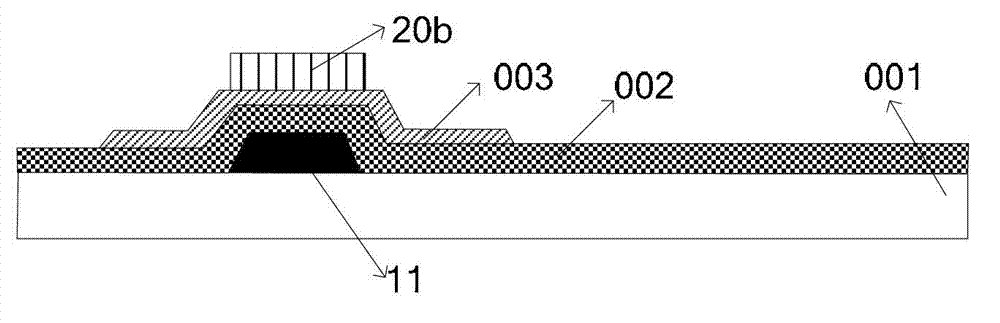

Light-modulating element, display element, and exposure element

InactiveUS7050219B2Shorten the light pathImprove efficiencyNon-linear opticsOptical elementsCatoptricsCoupling

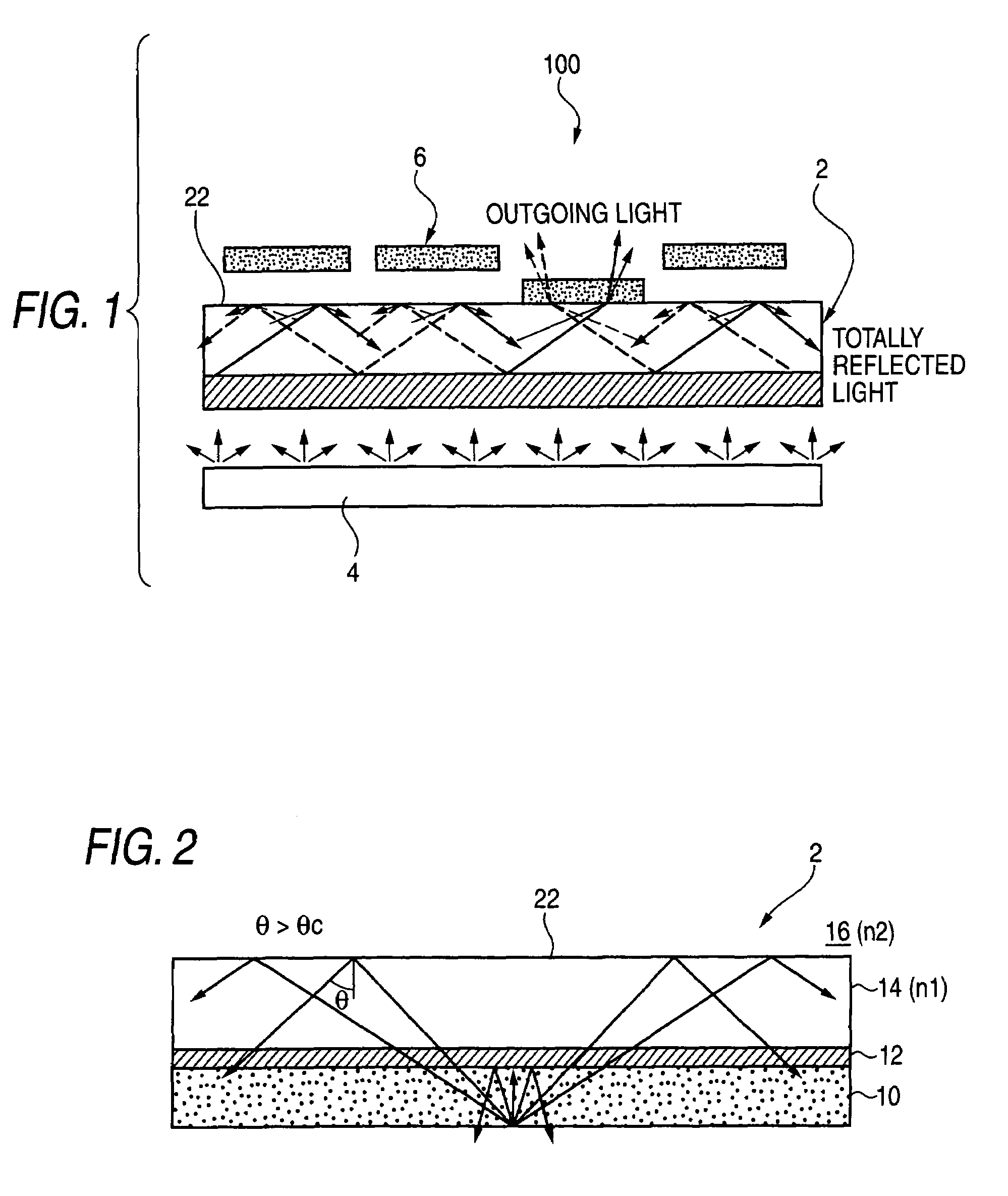

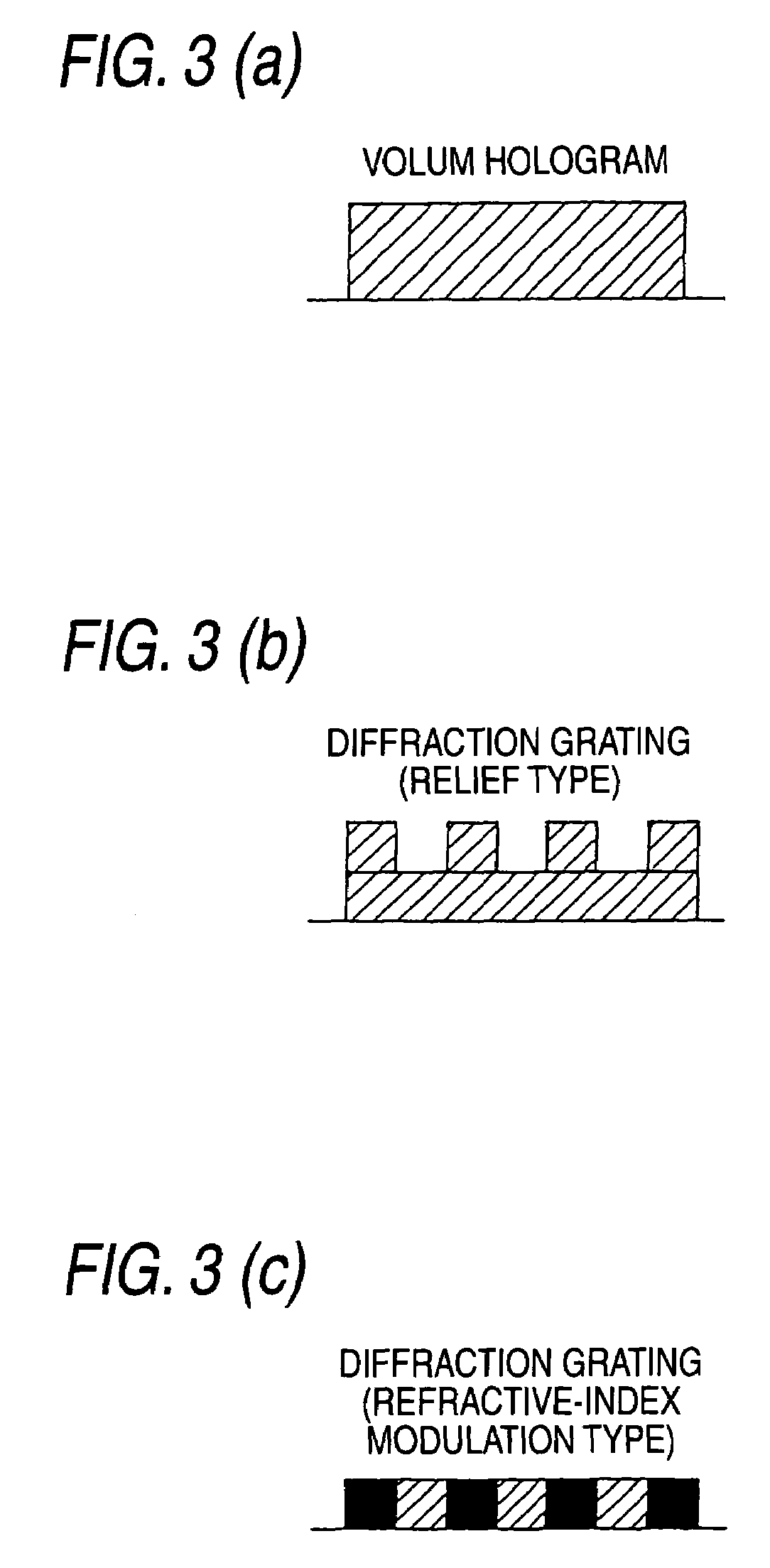

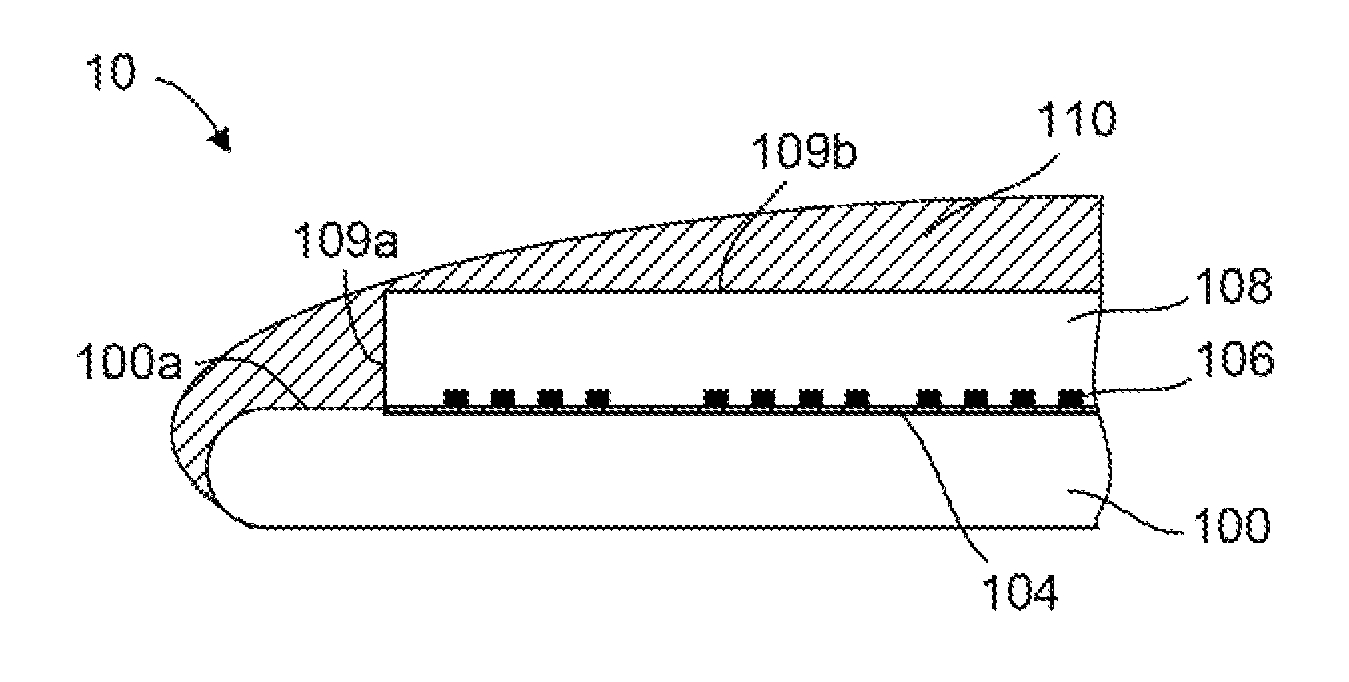

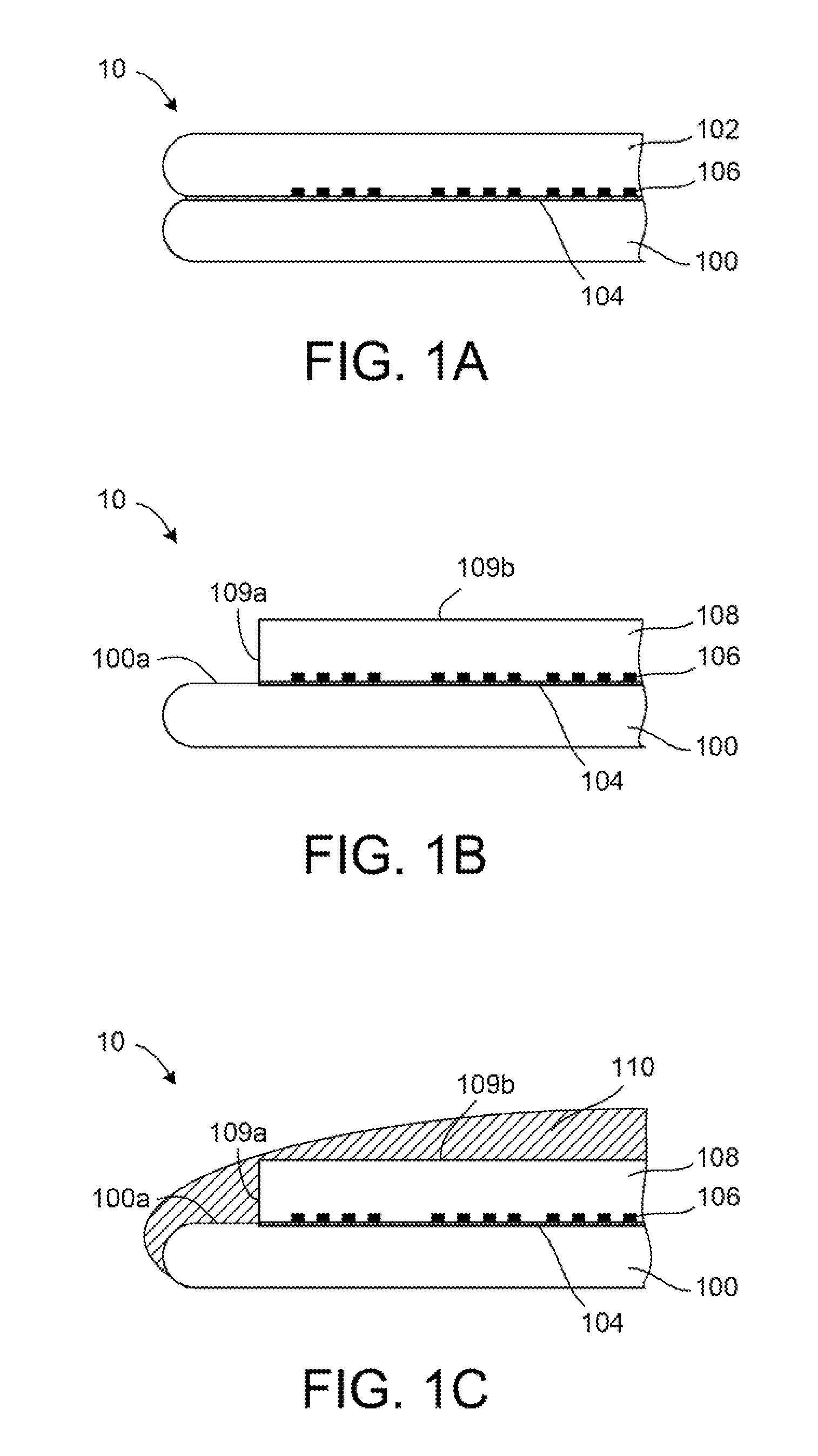

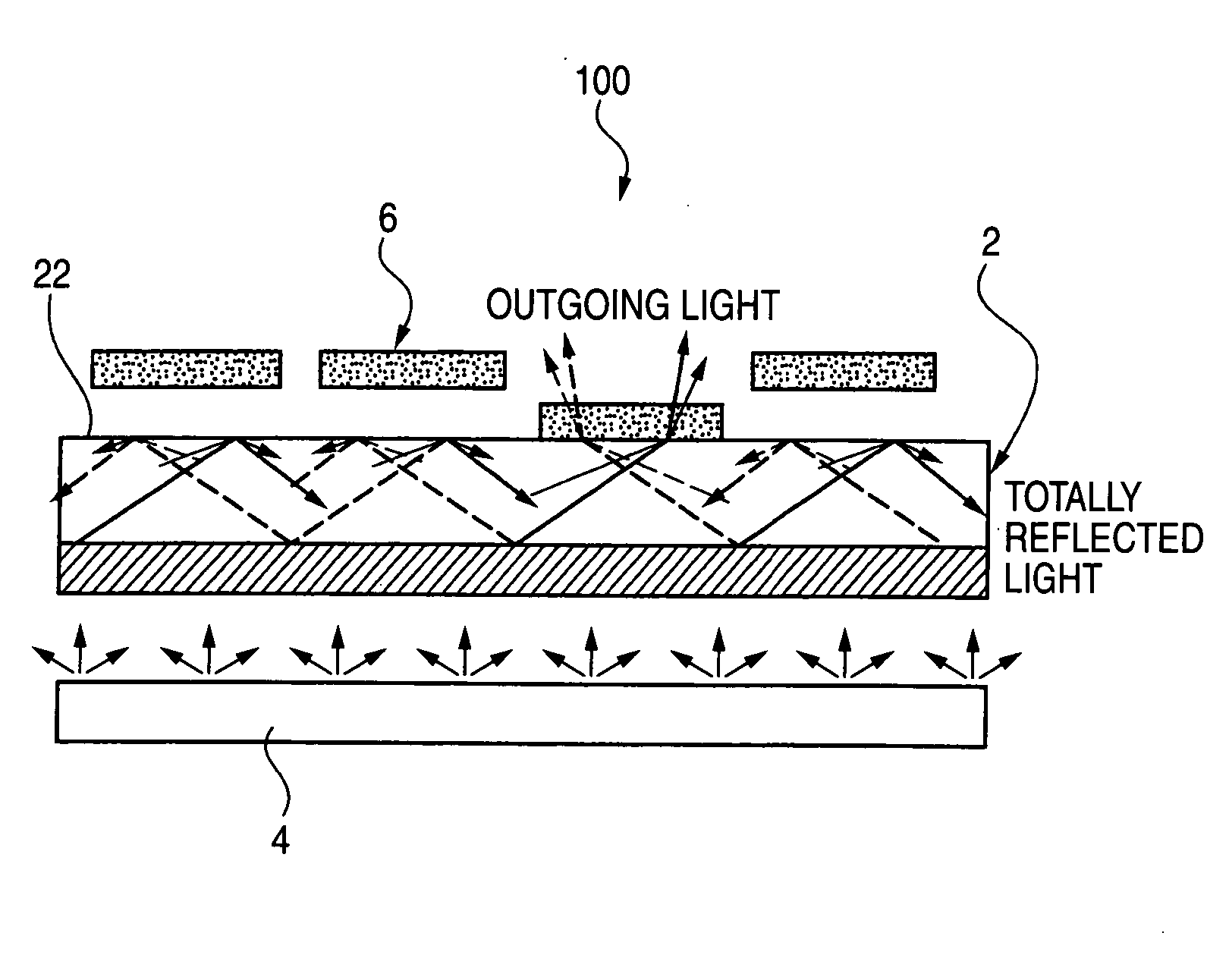

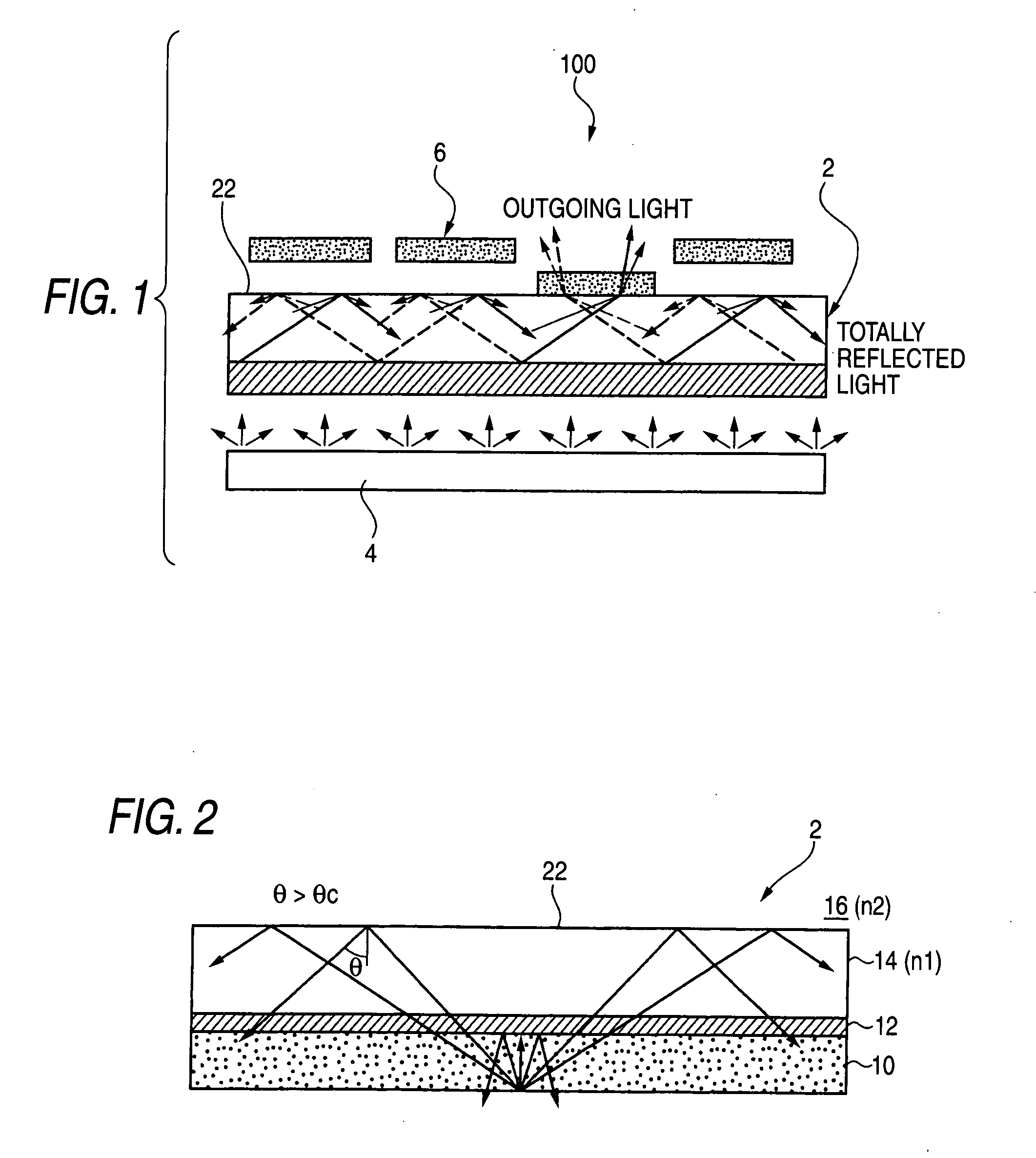

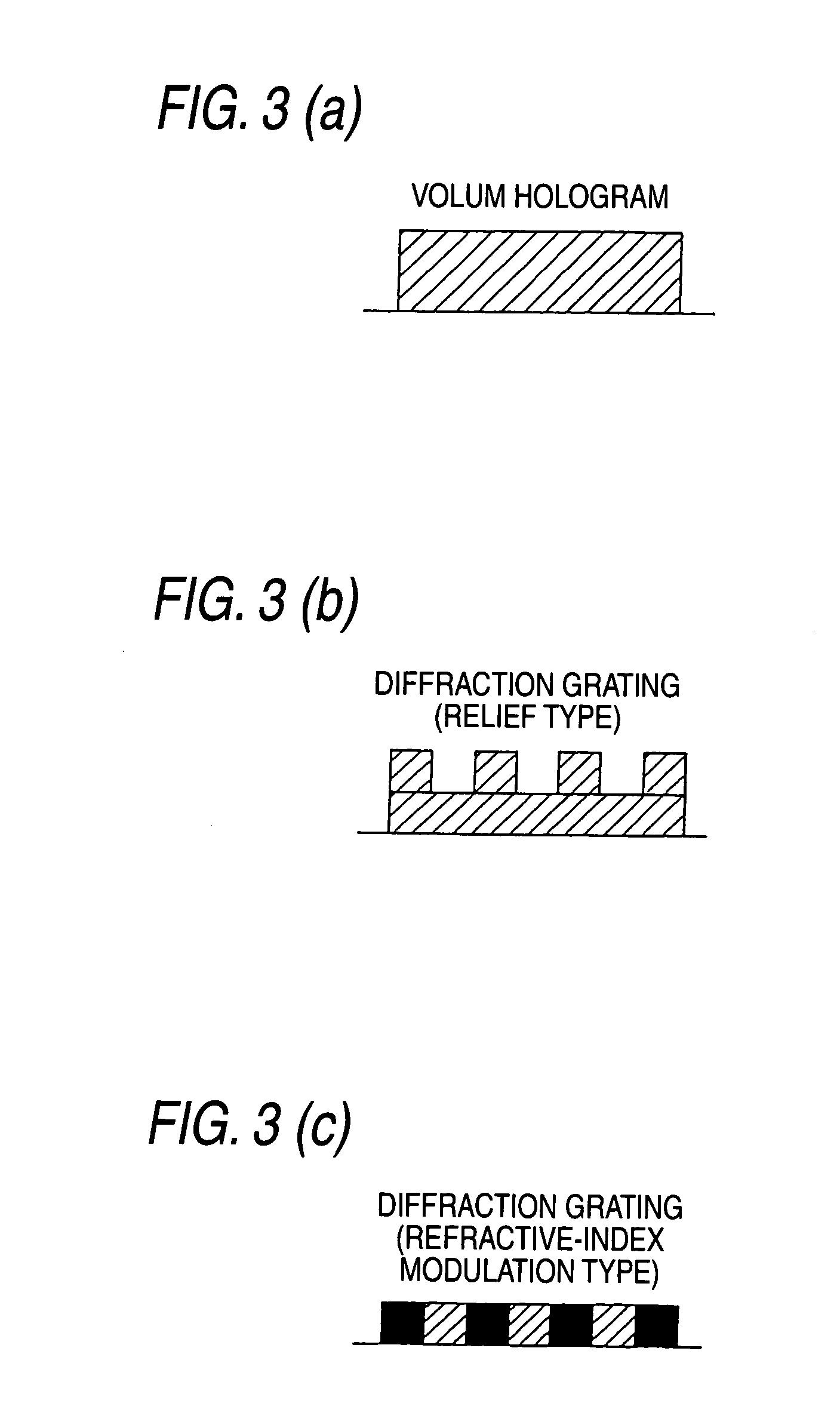

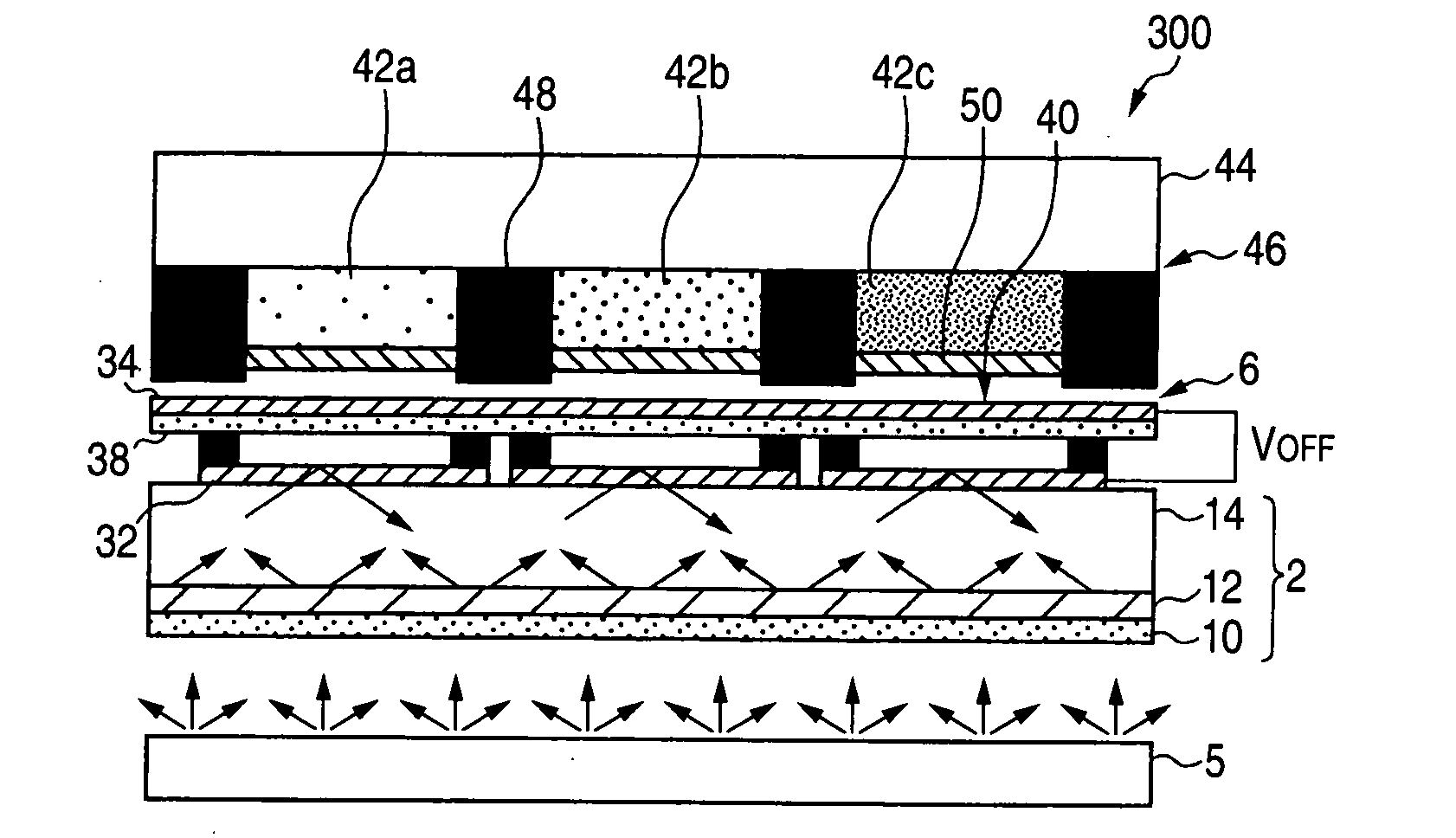

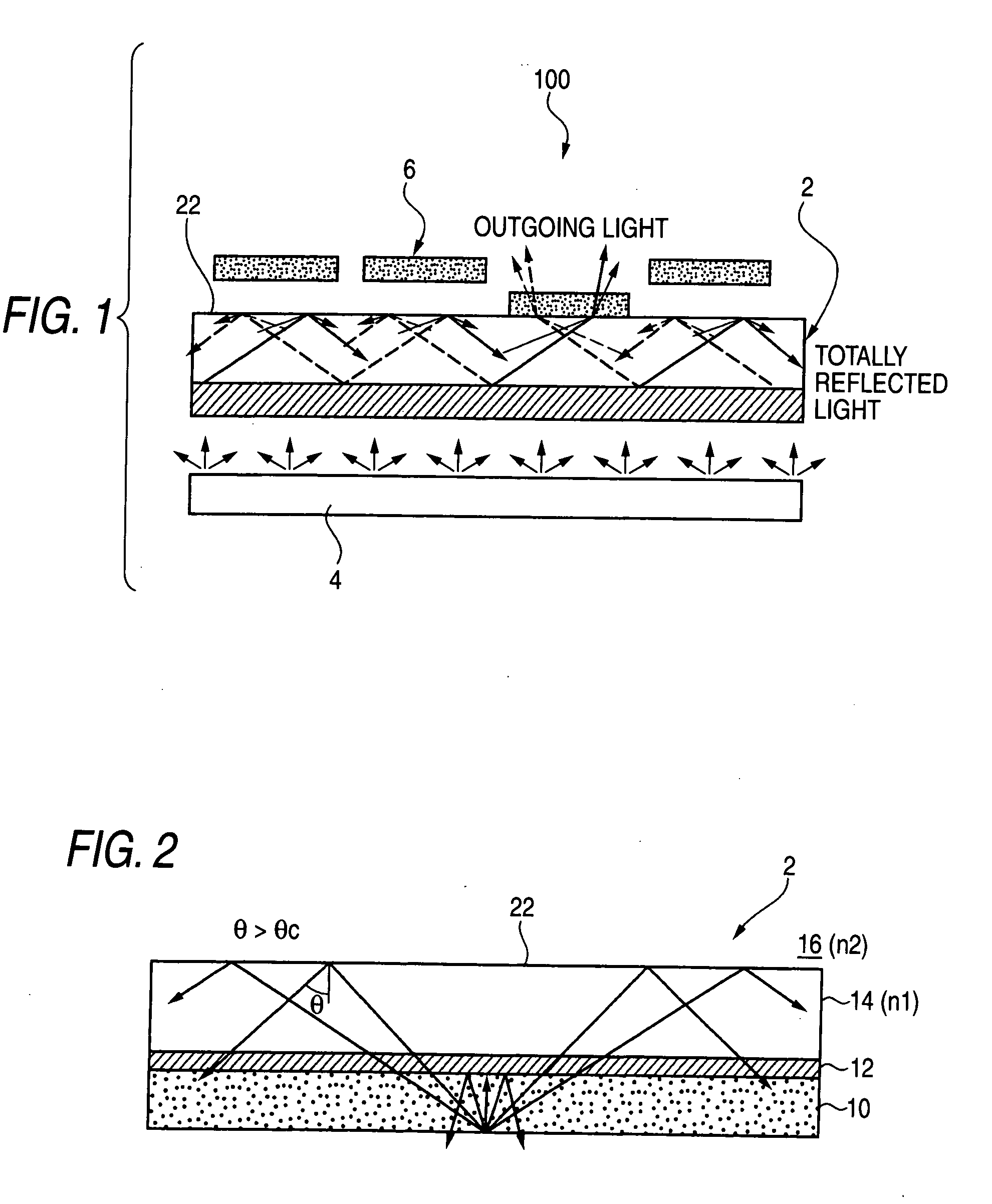

Subjects for the invention are to provide a light-modulating element having an elevated energy efficiency while preventing a decrease in contrast at low cost without using a display technique employing a waveguide or lightguide plate, and to provide a display element capable of producing high-quality display images and an exposure element capable of exposure treatment.In the invention, the light-modulating element comprises: a total-reflection optical member 2 having such a property that at least part of planar incident light introduced into the light-modulating element is totally reflected at an interface (total reflection plane) 22 of a layer constituted by the light-modulating element and the incident light does not substantially go out through the side opposite to the incident-light introduction side; and light-coupling elements 6 which are disposed on the total reflection plane 22 side of the total-reflection optical member 2 and serve to selectively couple with the incident light and take out the same from the total reflection plane 22.

Owner:FUJIFILM HLDG CORP +1

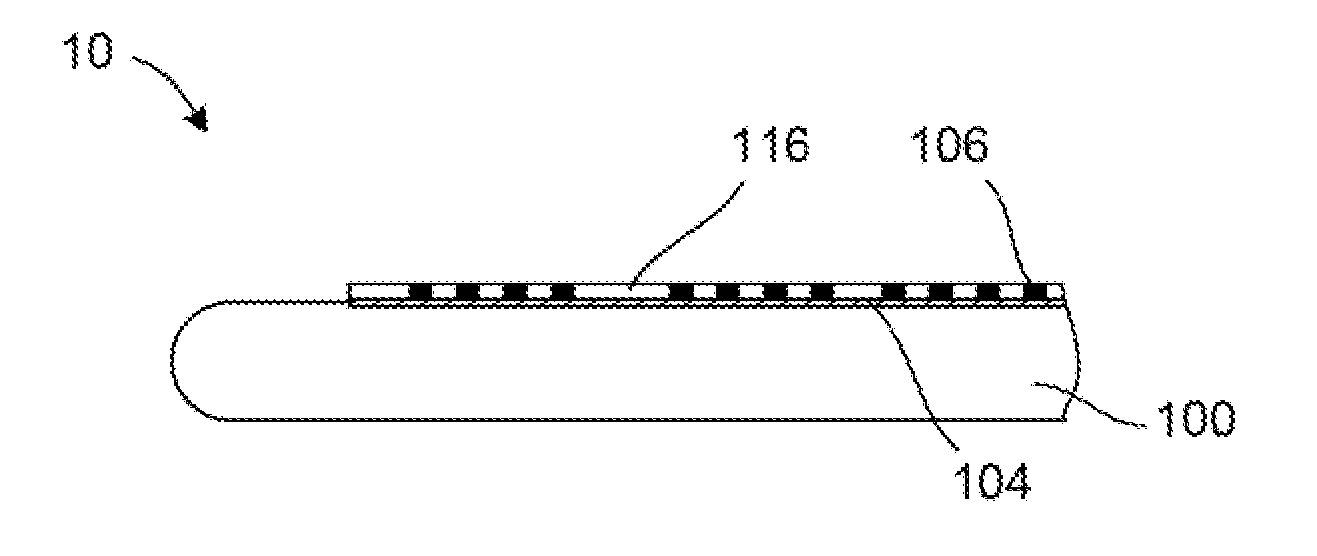

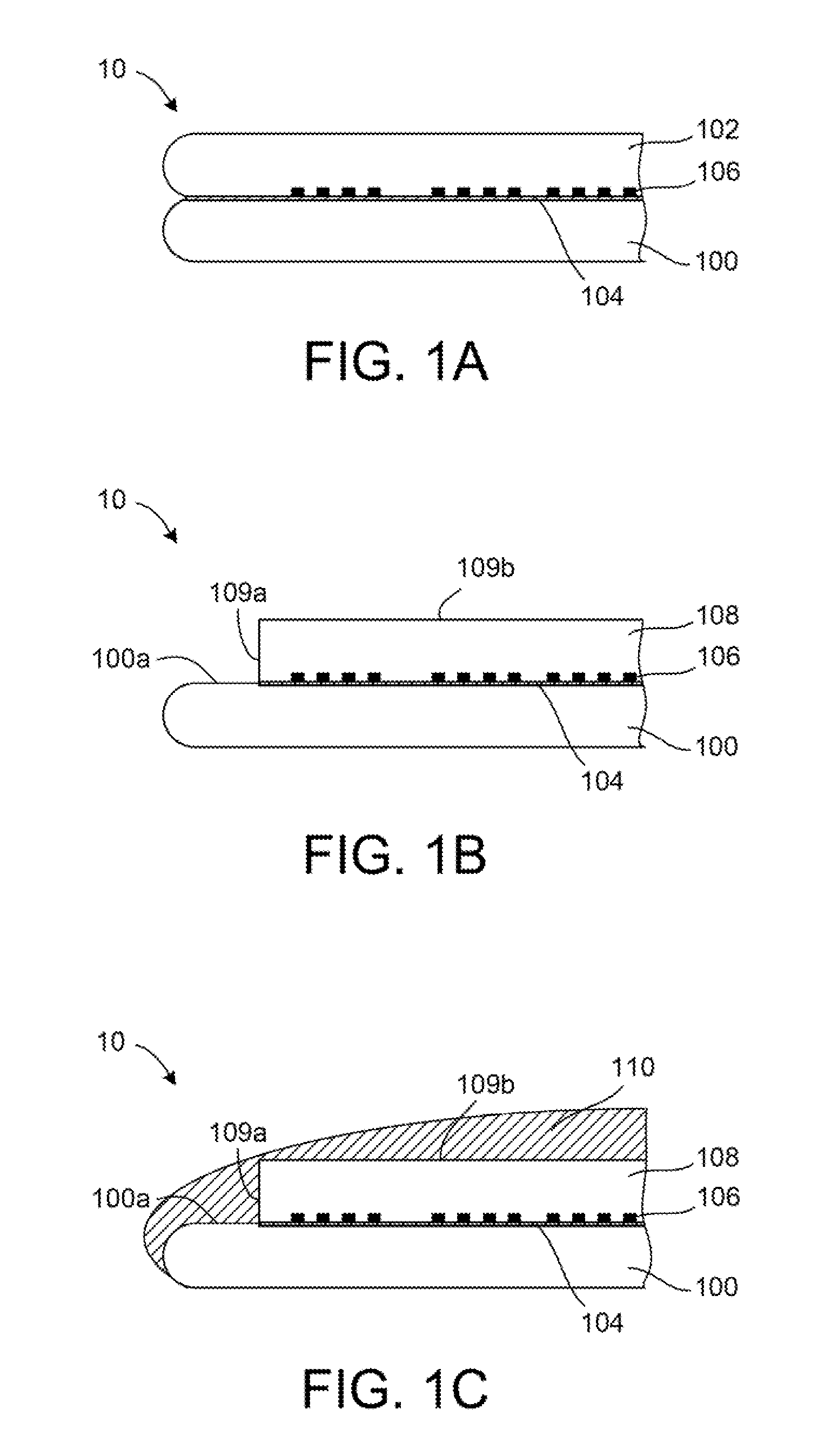

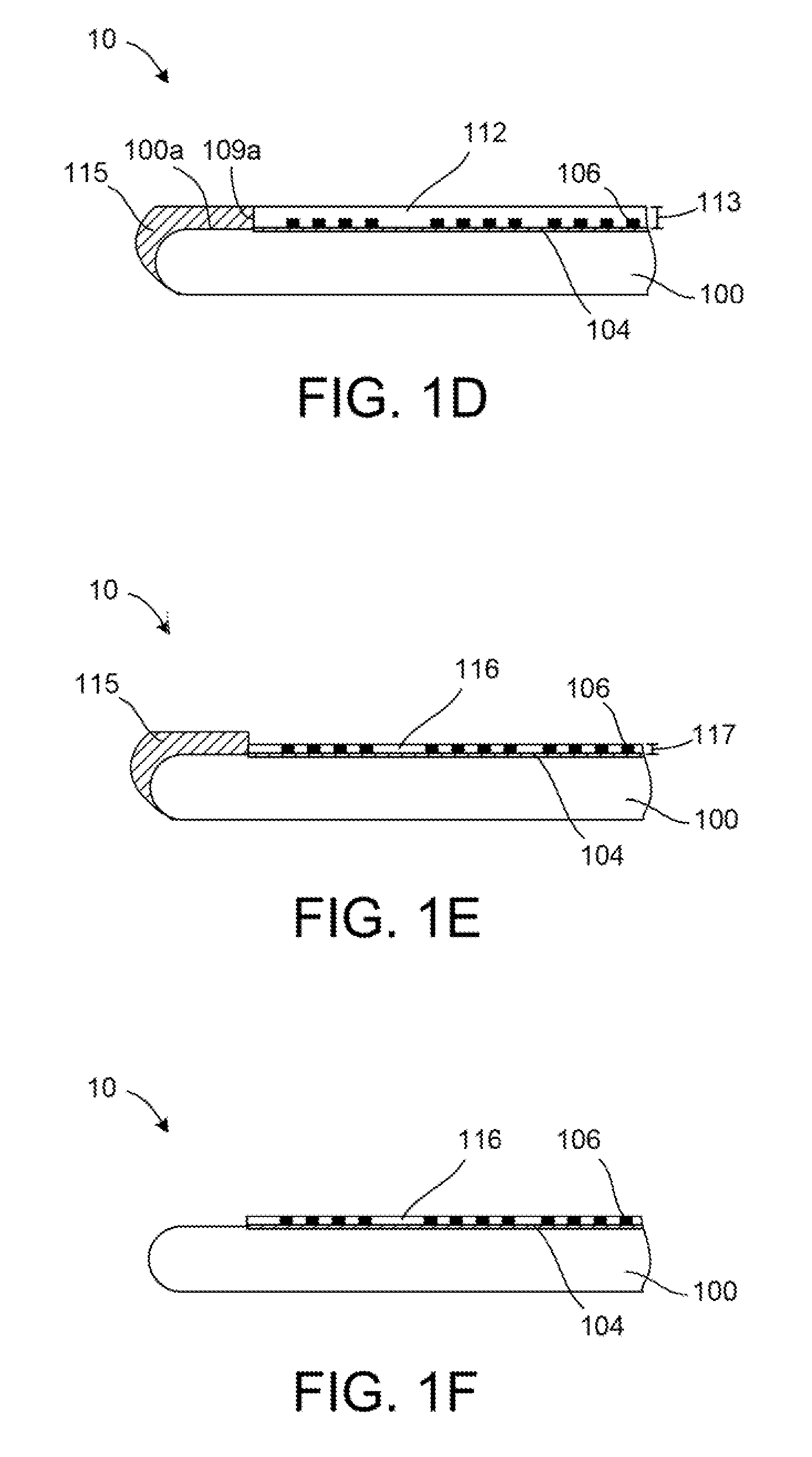

Method for thinning a bonding wafer

A method is provided for thinning a wafer, for example a wafer containing Through Silicon Vias (TSV). The method includes providing a bonding wafer coupled to a handling wafer, and performing a wafer edge trimming process that forms a trimmed bonding wafer, where the wafer edge trimming process removes an edge portion of the bonding wafer and exposes an upper surface of the handling wafer. The method further includes forming a protective mask on the trimmed bonding wafer and on the exposed upper surface of the handling wafer, planarizing the protective mask and the trimmed bonding wafer, and selectively removing the planarized protective mask by an etching process. In one embodiment, the removing includes performing a first wet etching process that selectively removes a portion of the planarized trimmed bonding wafer relative to the planarized protective mask, and performing a second wet etching process that selectively removes the planarized protective mask.

Owner:TOKYO ELECTRON LTD

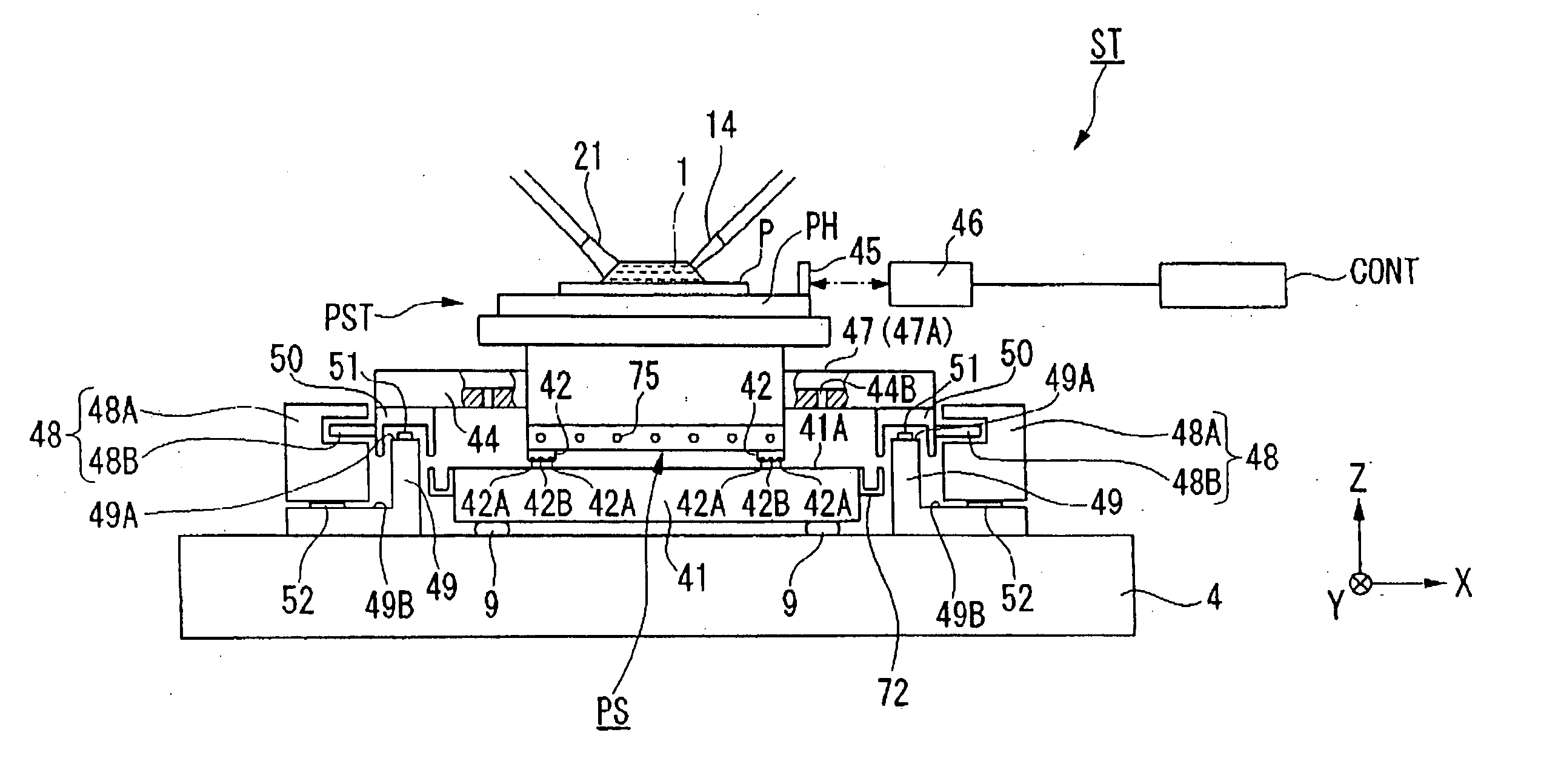

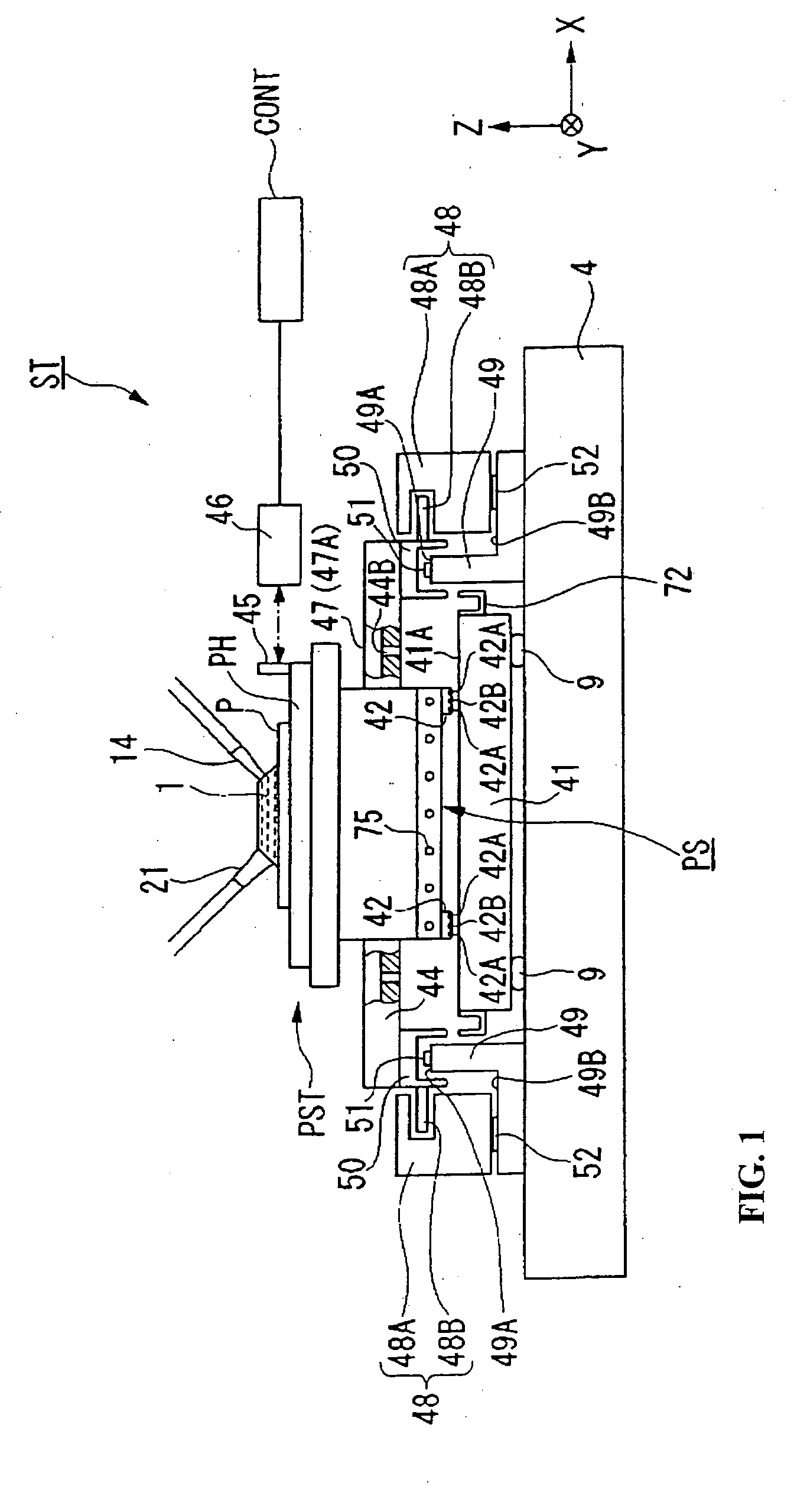

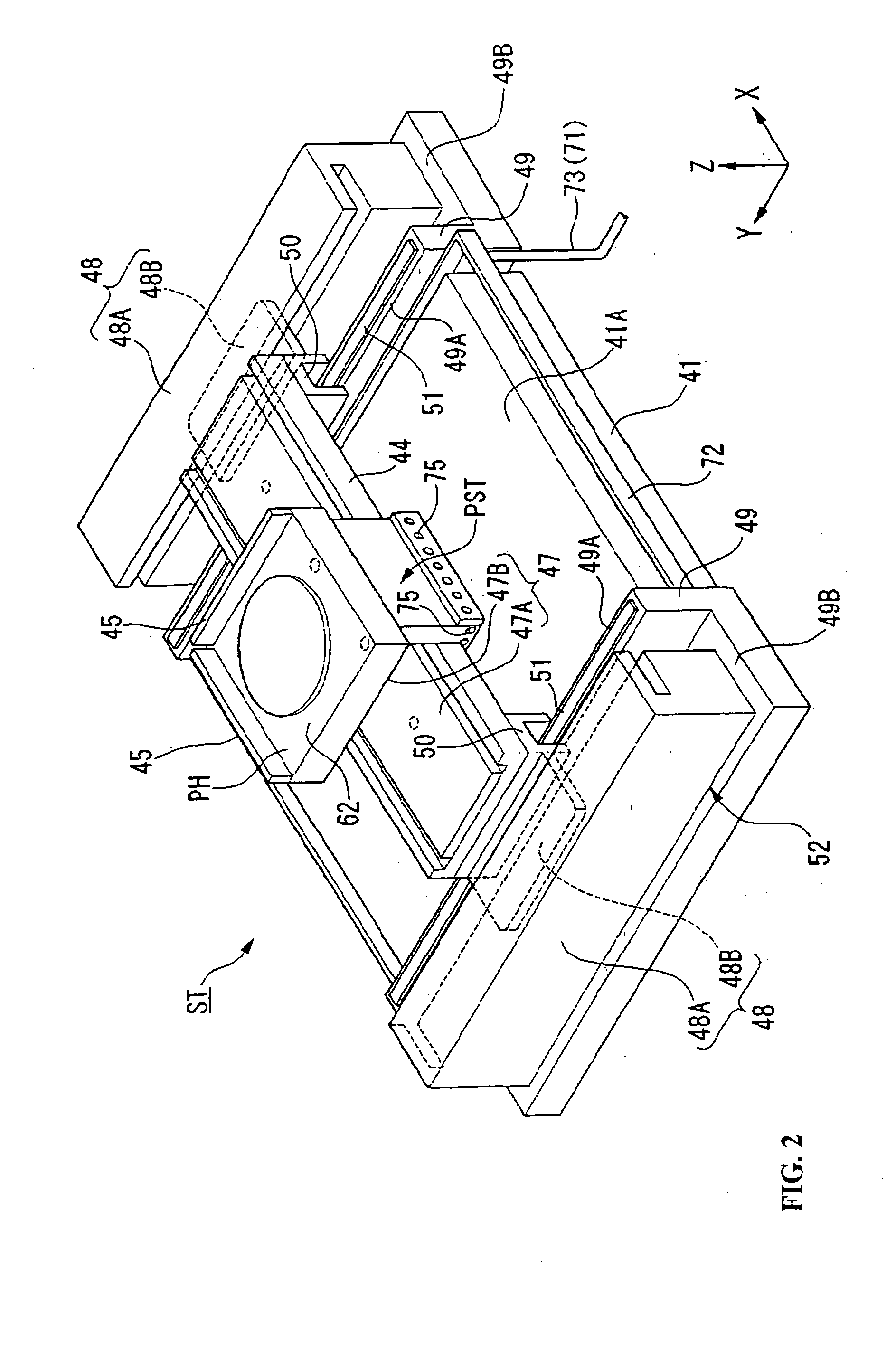

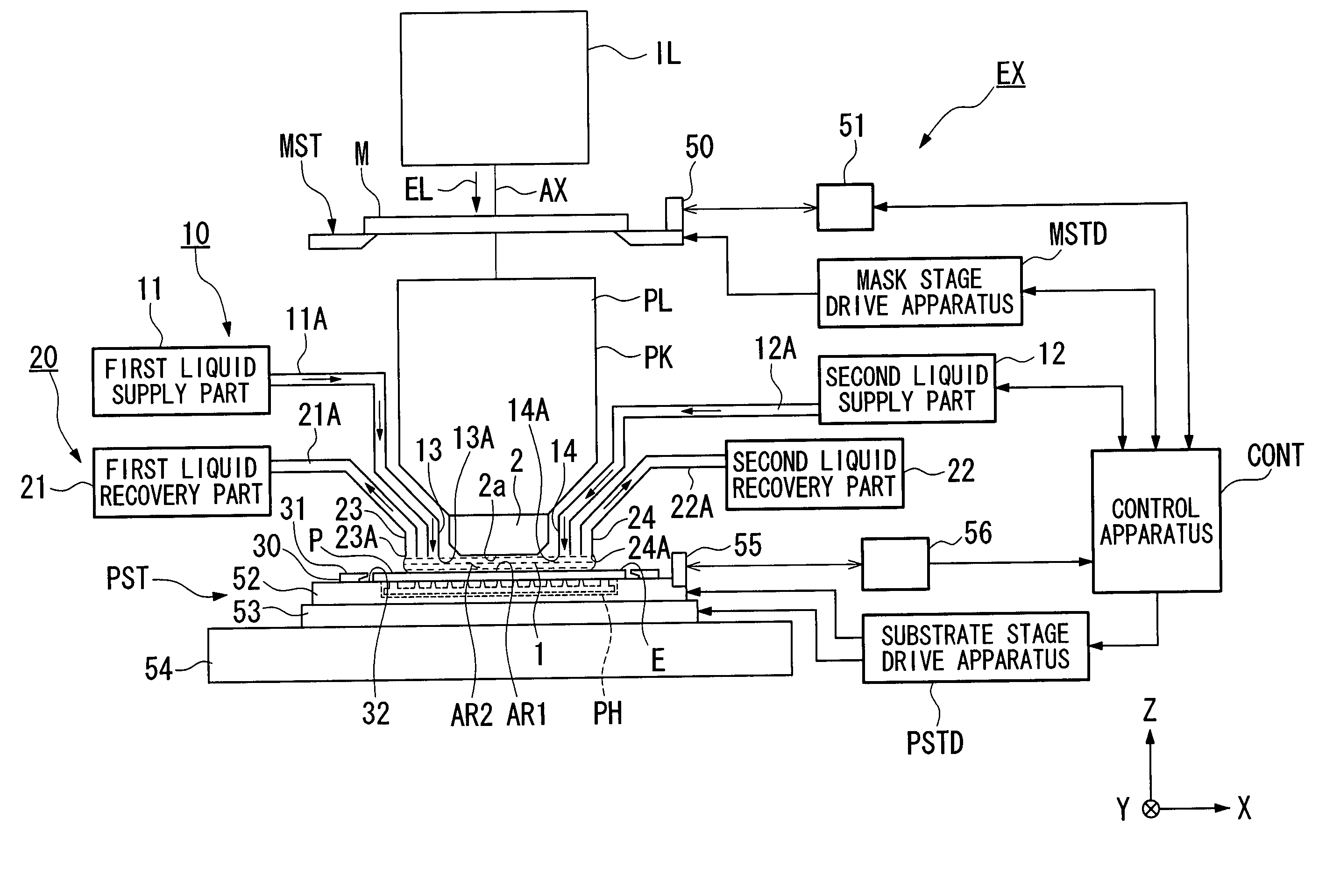

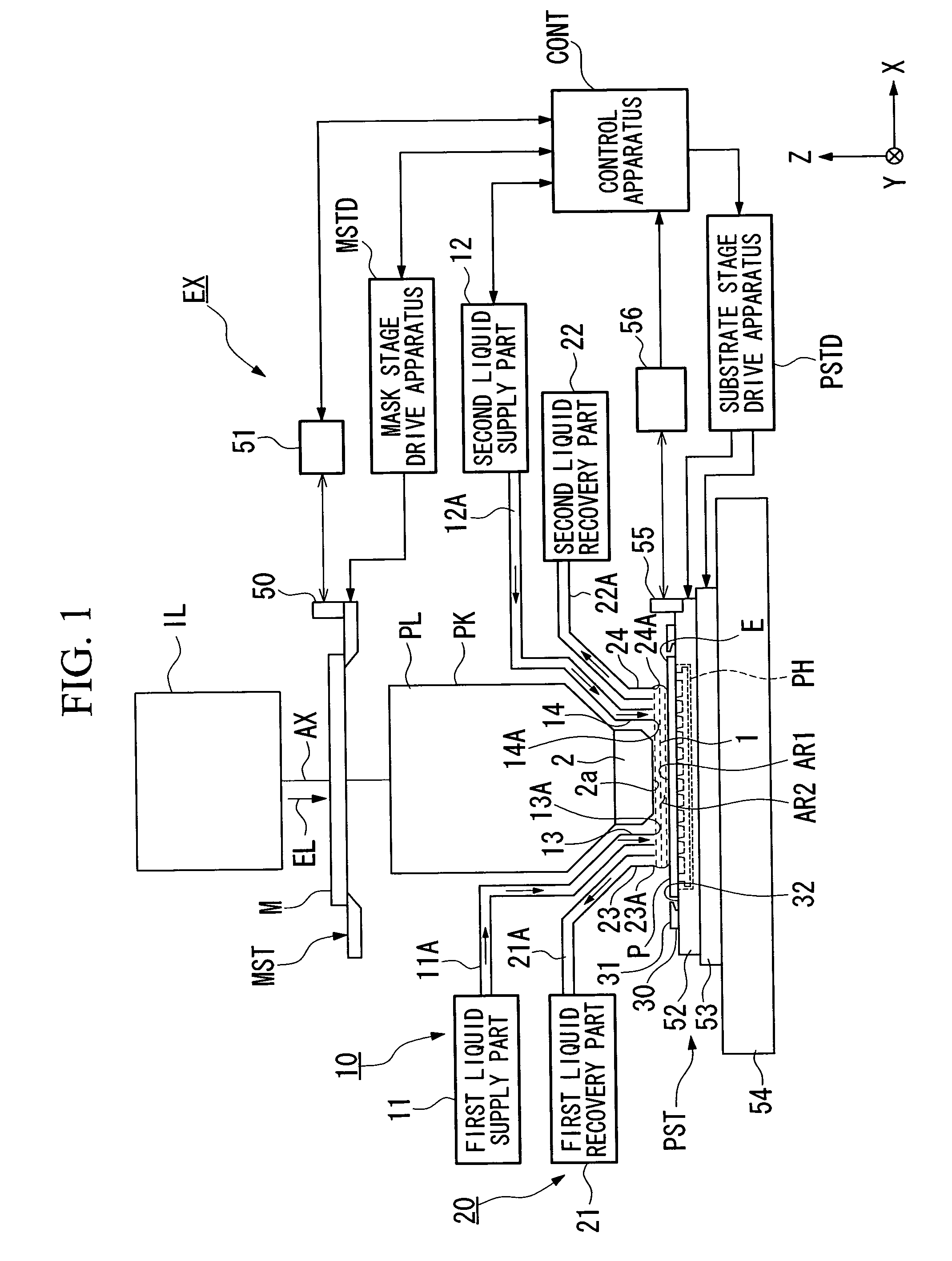

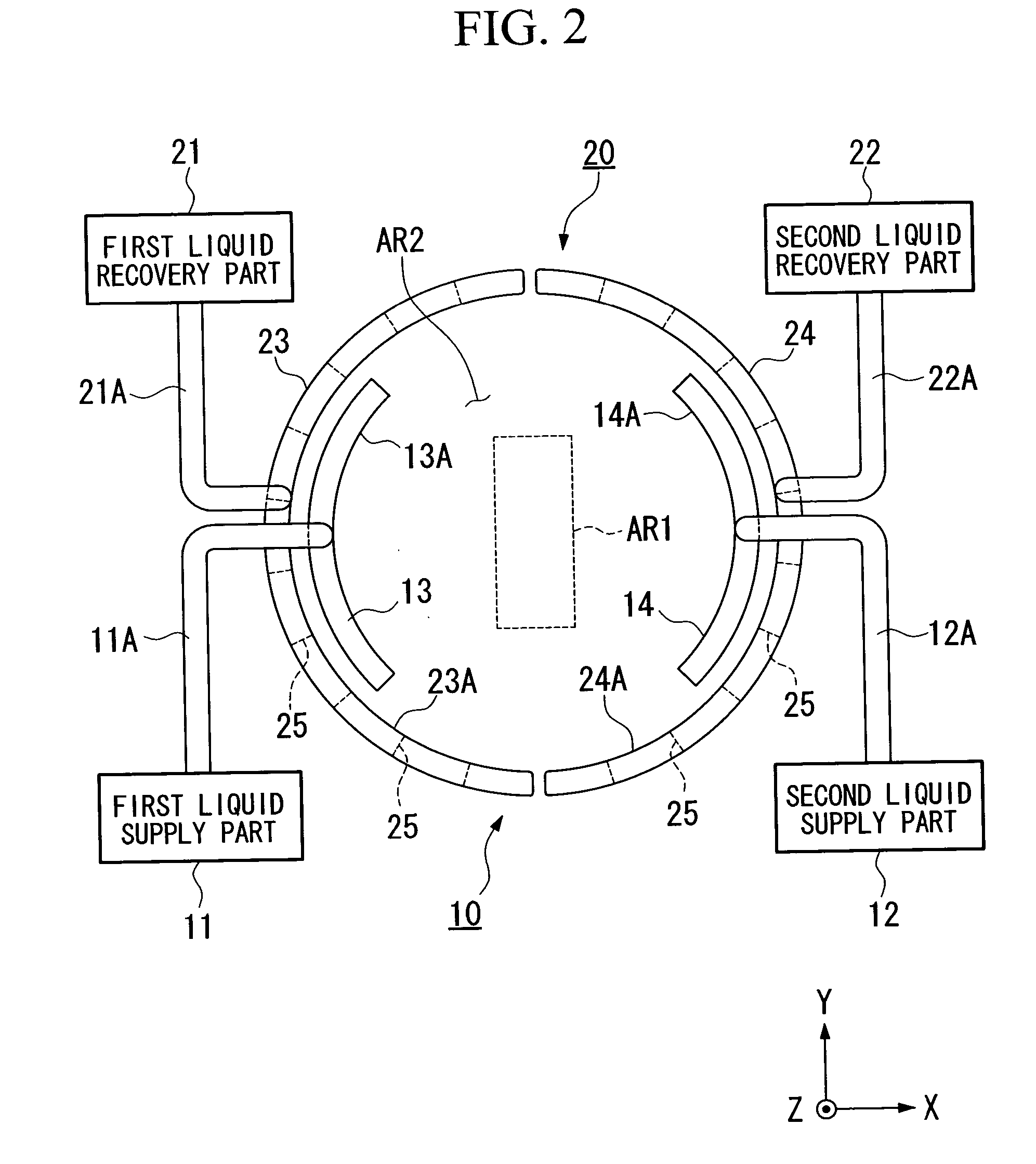

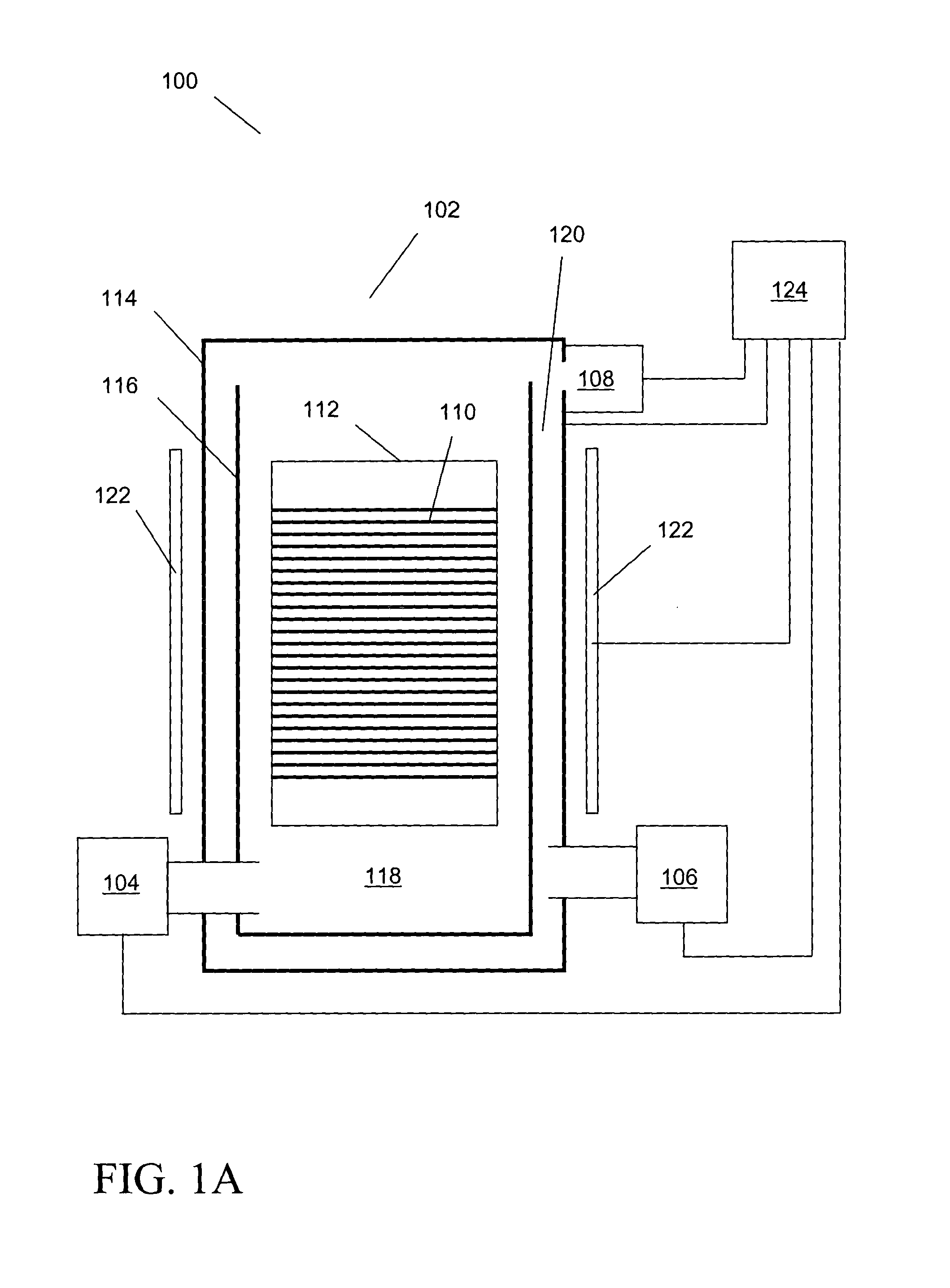

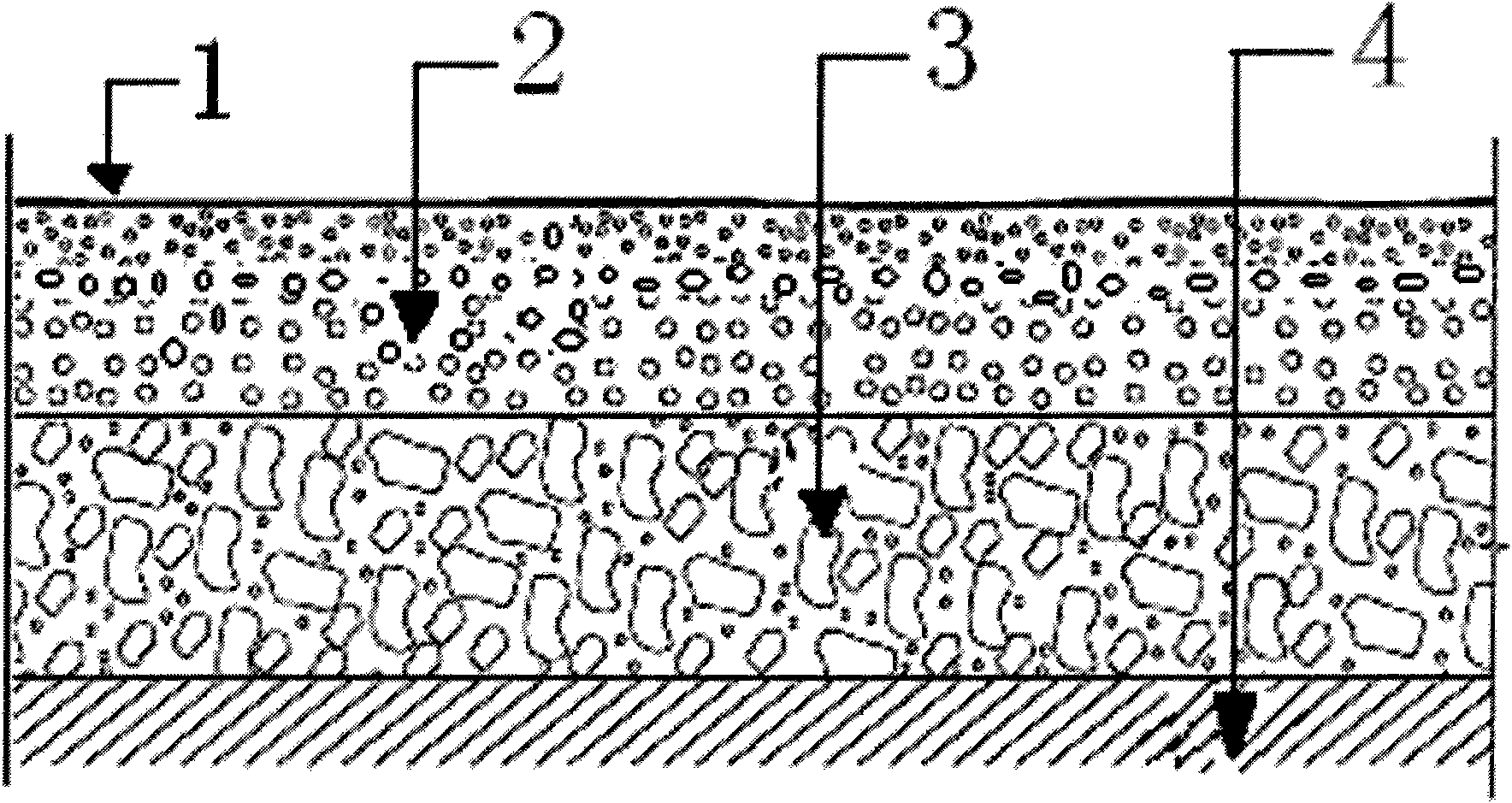

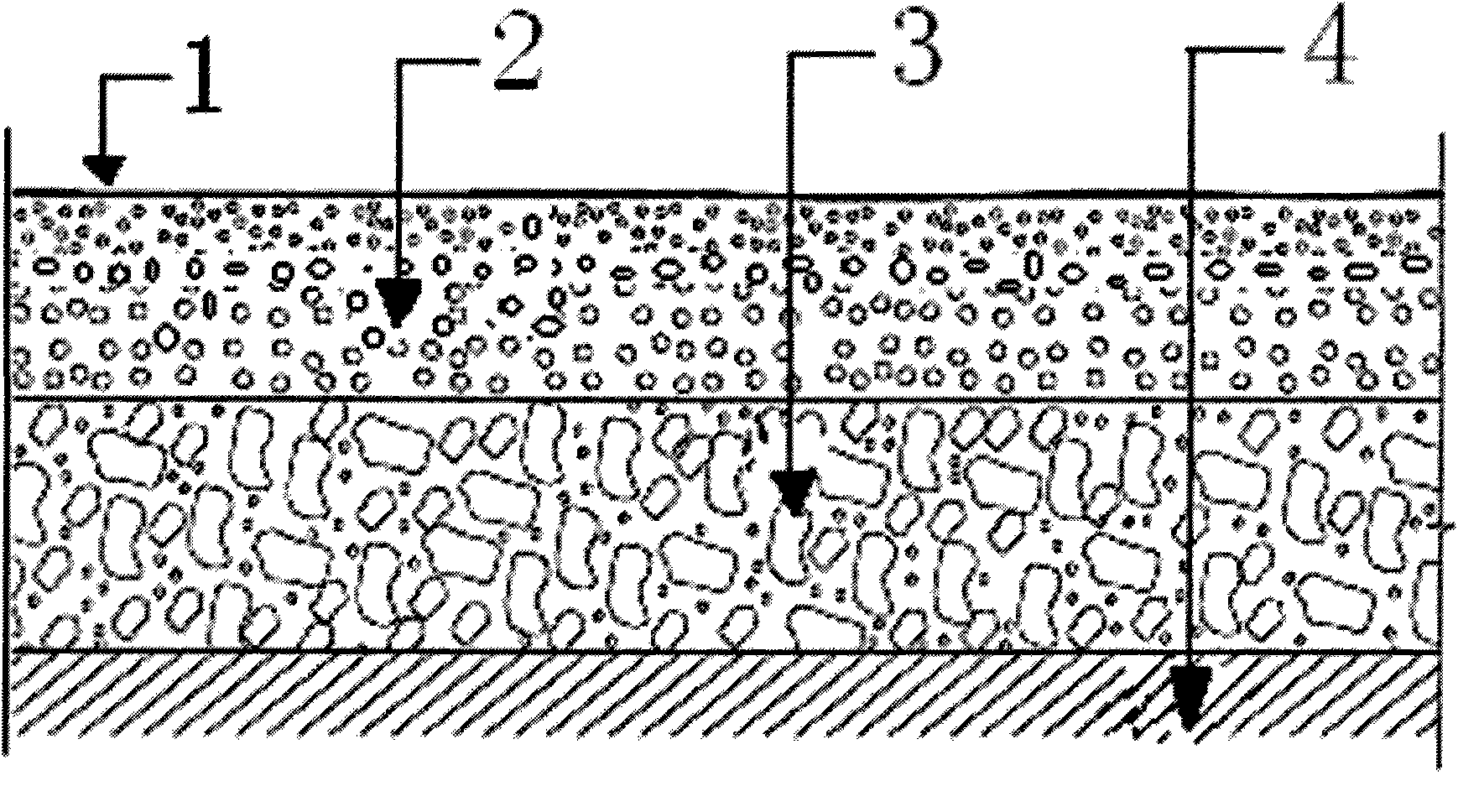

Stage apparatus, exposure apparatus, and exposure method

InactiveUS20070109521A1Prevent penetrationFormed satisfactorilySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringMechanical engineering

A stage apparatus PST is provided with a holder PH, which has a substrate holding surface 33A that holds a substrate P; a stage 52, which supports and moves the holder PH; and a recovery apparatus 60, which is disposed in the vicinity of the holder PH and has lyophilic parts 3, 5 of which at least a part of each is lyophilic, that uses the lyophilic parts 3, 5 to recover a liquid 1. As a result, the infiltration of liquid into the space between the substrate and the holder is prevented, even if performing an exposure treatment by filling the space between a projection optical system and the substrate with the liquid.

Owner:NIKON CORP

Formation of a metal-containing film by sequential gas exposure in a batch type processing system

InactiveUS20050056219A1Integrated cost-effectivelyElectrical apparatusChemical vapor deposition coatingNitrogenSilicon

A method is provided for forming a metal-containing film on a substrate by a sequential gas exposure process in a batch type processing system. A metal-containing film can be formed on a substrate by providing a substrate in a process chamber of a batch type processing system, heating the substrate, sequentially flowing a pulse of a metal-containing precursor gas and a pulse of a reactant gas in the process chamber, and repeating the flowing processes until a metal-containing film with desired film properties is formed on the substrate. The method can form a metal-oxide film, for example HfO2 and ZrO2, a metal-oxynitride film, for example HfxOzNw, and HfxOzNw, a metal-silicate film, for example HfxSiyOz and ZrxSiyOz, and a nitrogen-containing metal-silicate film, for example HfxSiyOzNw and ZrxSiyOzNw. A processing tool containing a batch type processing system for forming a metal-containing film by a sequential gas exposure process is provided.

Owner:TOKYO ELECTRON LTD

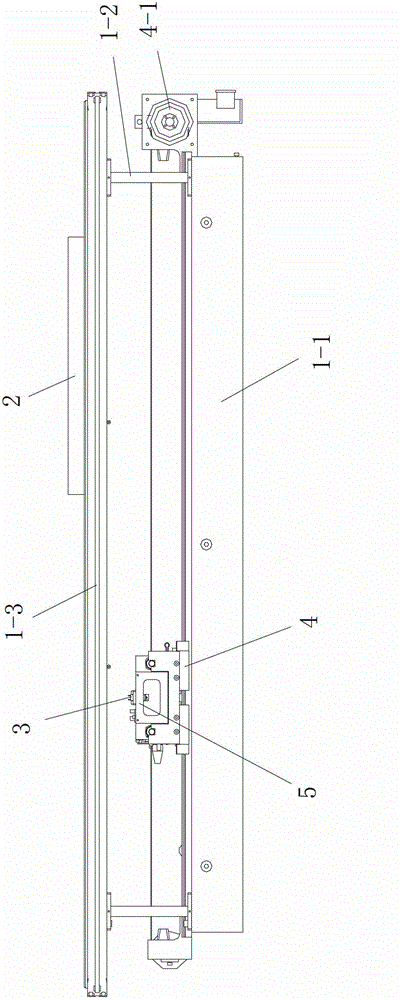

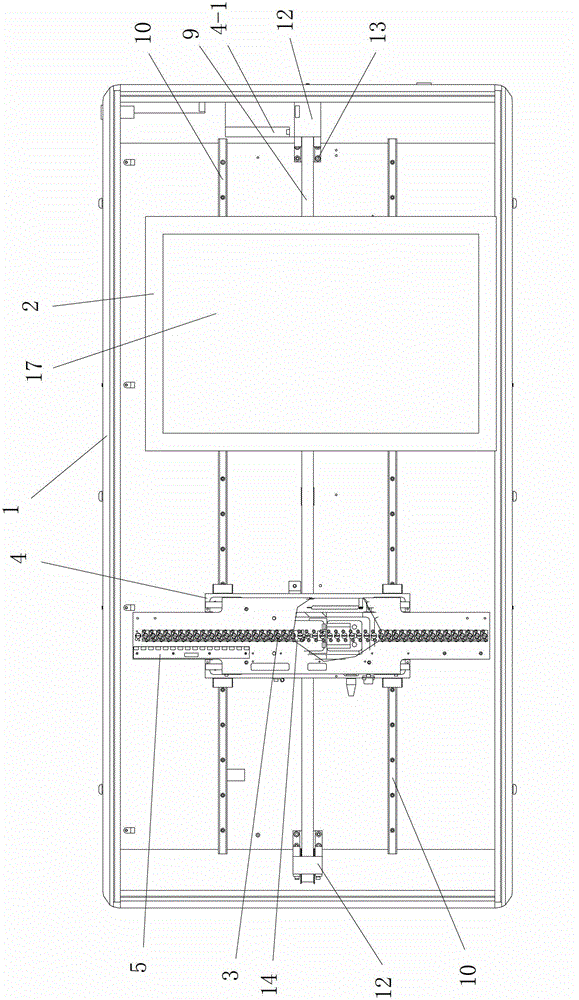

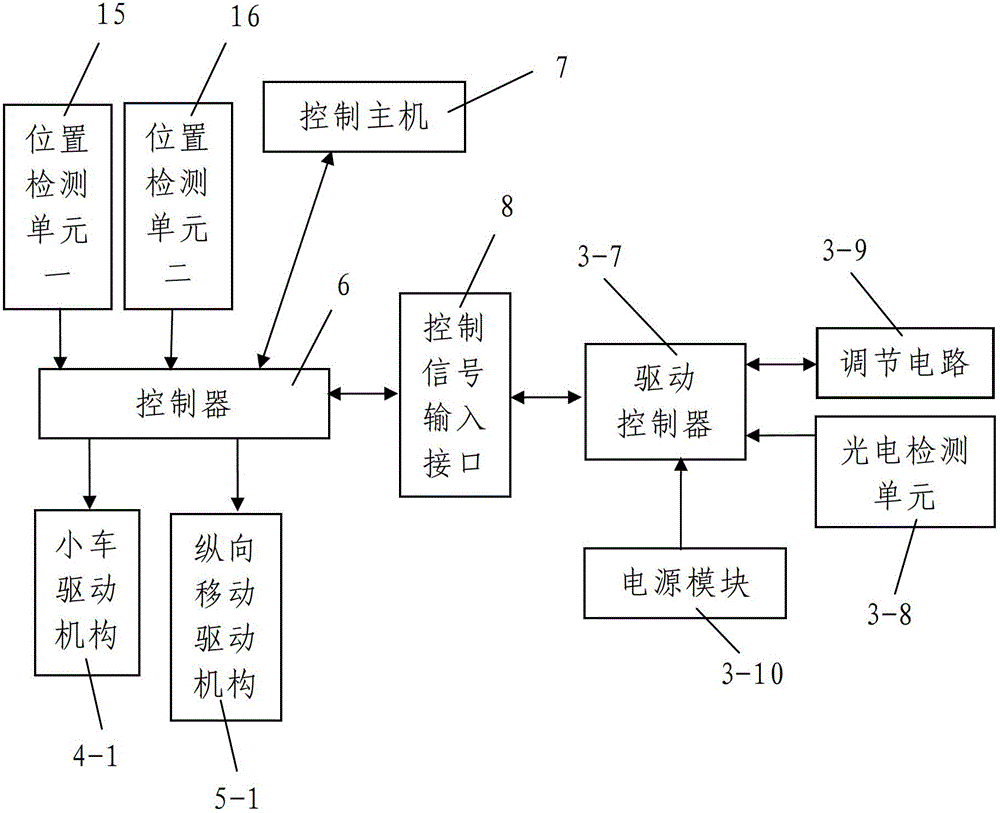

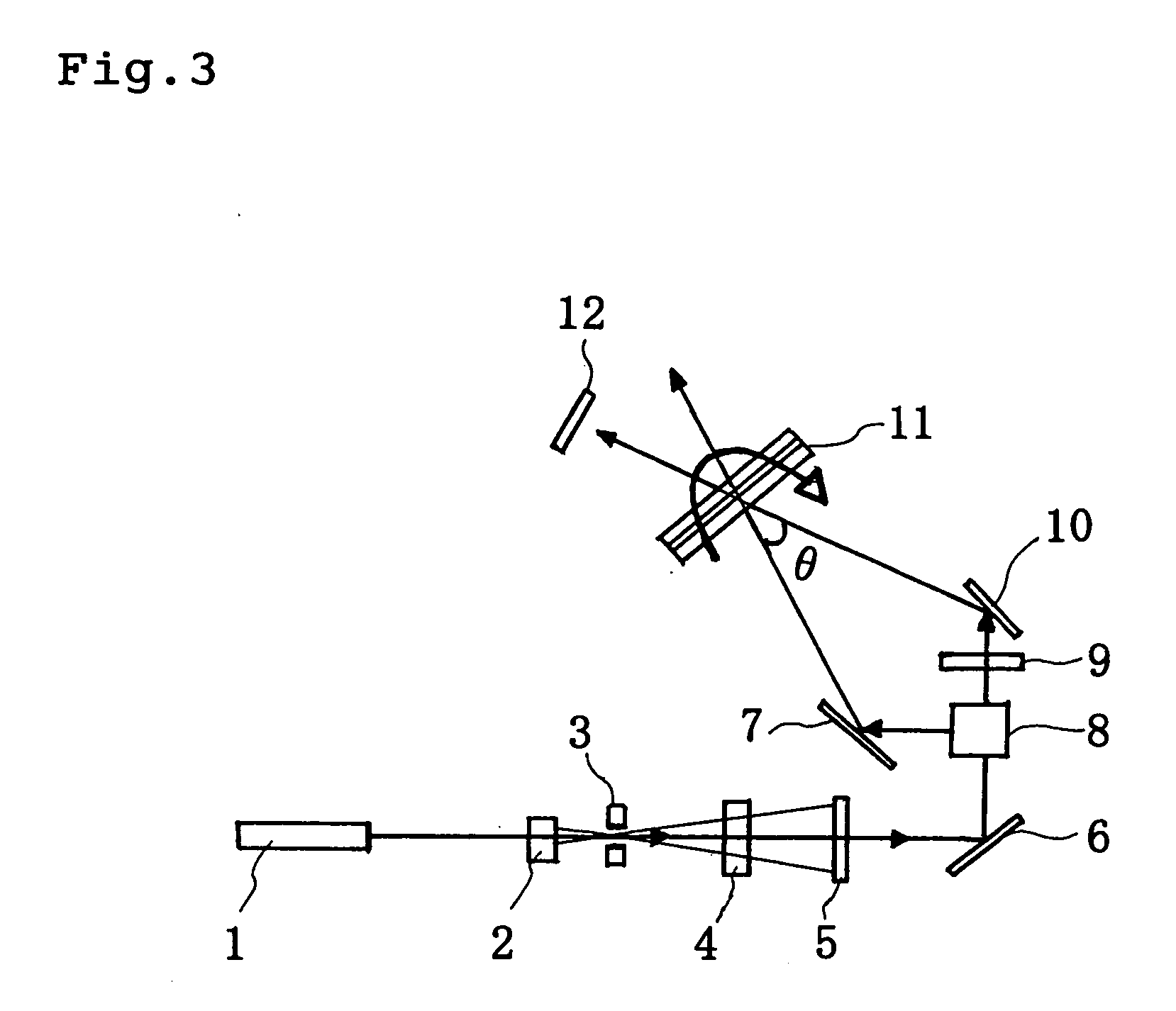

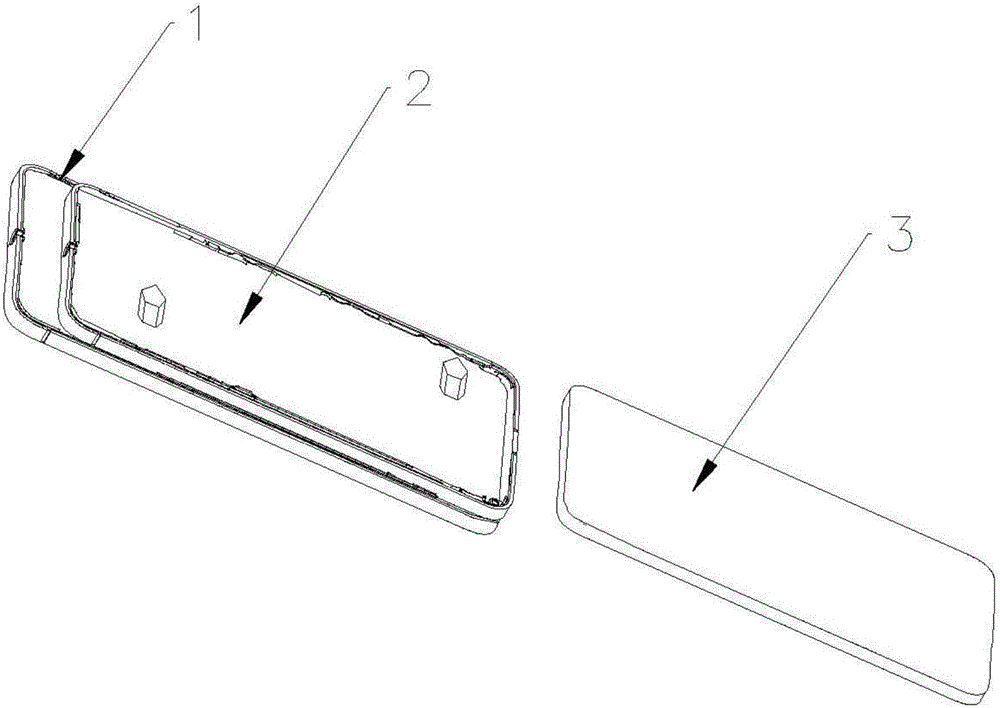

Laser direct plate marking device for plane screen print plate and device

ActiveCN103149801ASimple structureReasonable designPhotomechanical exposure apparatusMicrolithography exposure apparatusScreen printingEngineering

The invention discloses a laser direct plate marking device for a plane screen print plate and device. The device comprises a screen frame for screen printing, a screen mesh stretched on the screen frame for screen printing, wherein the bottom of the screen mesh is coated with a photosensitive material coating, an optical component arranged below the screen frame for screen printing and used for performing exposure treatment on the photosensitive material coating, a scanning trolley for driving the optical component to reciprocate on the horizontal surface, and a longitudinal moving member for driving the optical component to shuttle on the horizontal surface; and the optical component comprises a plurality of lasers arranged on the same horizontal surfaces, the plurality of lasers are arranged on the same straight line parallel to a longitudinal central line of a rectangular screen frame from front to the back. The method comprises the following steps of confirming a control parameter of a mechanical structure, confirming a control parameter of a laser, and exposure imaging. The device disclosed by the invention is reasonable in design, low in investment cost, simple for use and operation, good in use effect, and wide in application range, and can be used for finishing the print plate manufacturing process of a screen frame in different sizes.

Owner:深圳市先地图像科技有限公司 +2

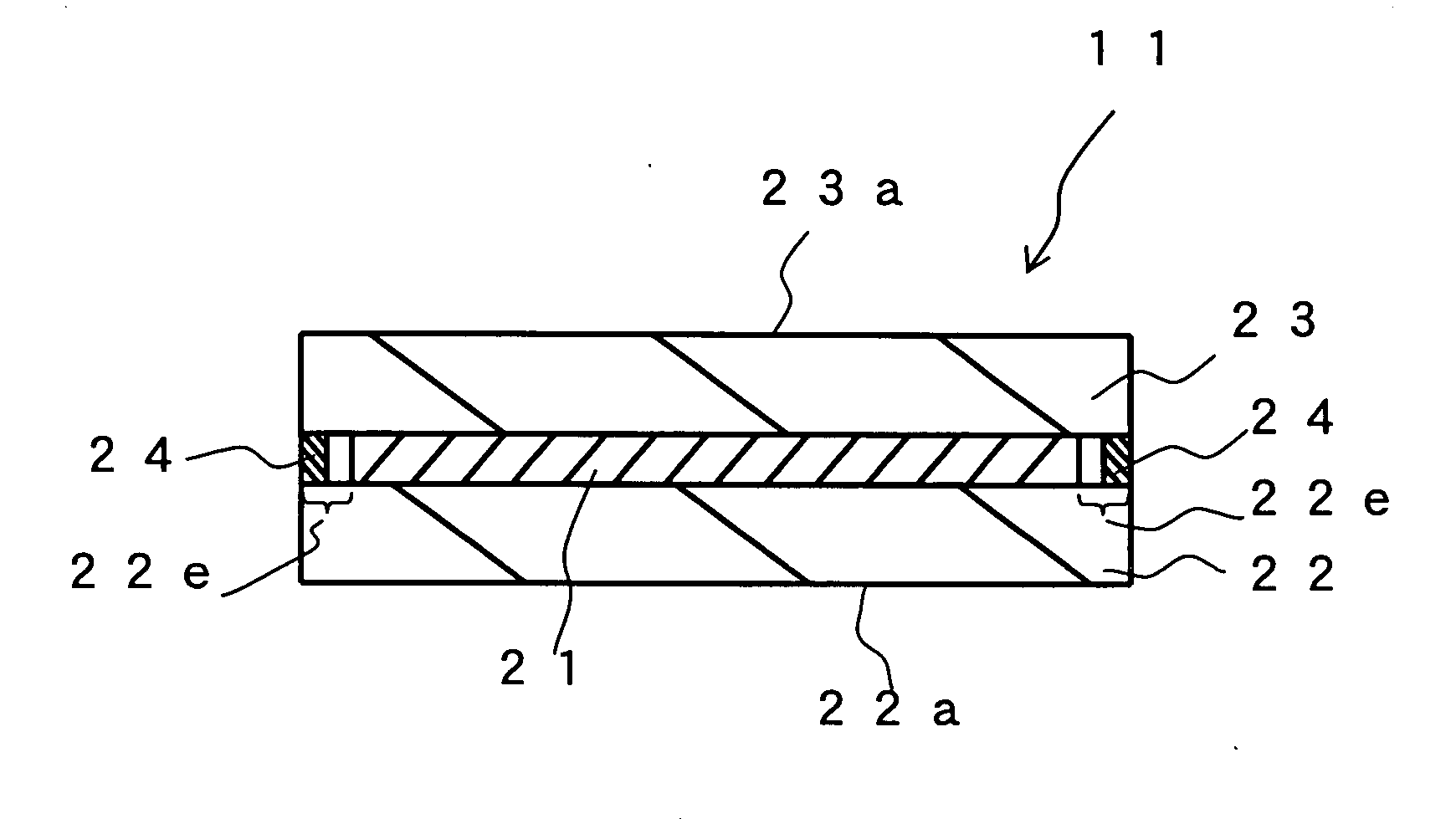

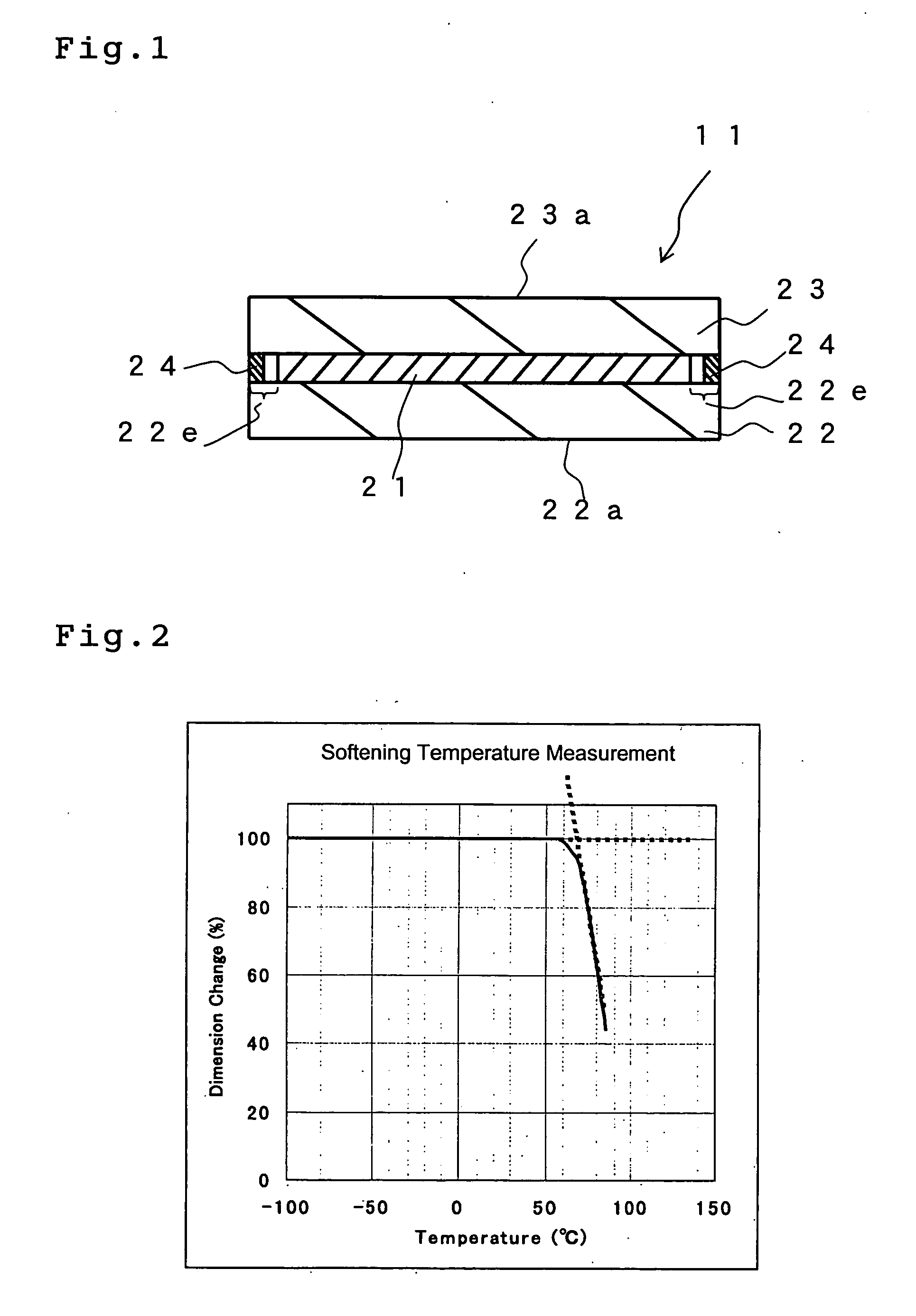

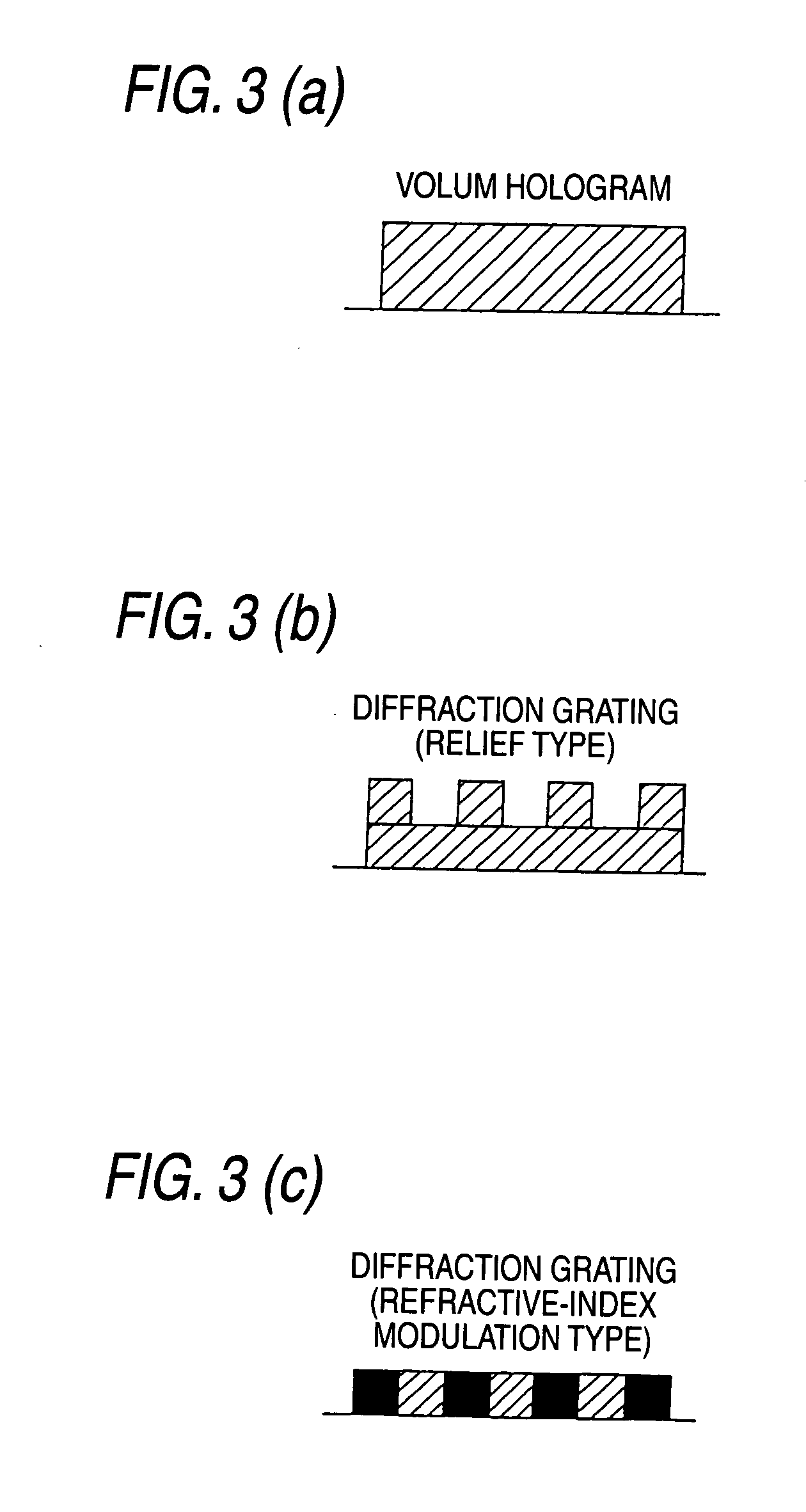

Hologram Recording Material and Hologram Recording Medium

InactiveUS20070243473A1Polymerization reactionPhotosensitive materialsRecord information storageRefractive indexHigh multiplicity

The present invention provides a hologram recording material which is not required to be subjected to pre-exposure treatment at the time of recording, attains high refractive index change, high sensitivity, low scattering, environment resistance, durability, low dimensional change, and high multiplicity, and is suitable for volume hologram recording. Also, the present invention provides a hologram recording medium. A hologram recording material comprising a matrix material having a softening temperature of 50° C. or higher, and a photopolymerizable monomer which is in a liquid phase state at room temperature. The matrix material is preferably contained in an amount of 50% by weight or more and 90% by weight or less of the whole of the hologram recording material. A softening temperature of the hologram recording material is preferably 0° C. or higher.

Owner:TDK CORPARATION

Method for thinning a bonding wafer

A method is provided for thinning a wafer, for example a wafer containing Through Silicon Vias (TSV). The method includes providing a bonding wafer coupled to a handling wafer, and performing a wafer edge trimming process that forms a trimmed bonding wafer, where the wafer edge trimming process removes an edge portion of the bonding wafer and exposes an upper surface of the handling wafer. The method further includes forming a protective mask on the trimmed bonding wafer and on the exposed upper surface of the handling wafer, planarizing the protective mask and the trimmed bonding wafer, and selectively removing the planarized protective mask by an etching process. In one embodiment, the removing includes performing a first wet etching process that selectively removes a portion of the planarized trimmed bonding wafer relative to the planarized protective mask, and performing a second wet etching process that selectively removes the planarized protective mask.

Owner:TOKYO ELECTRON LTD

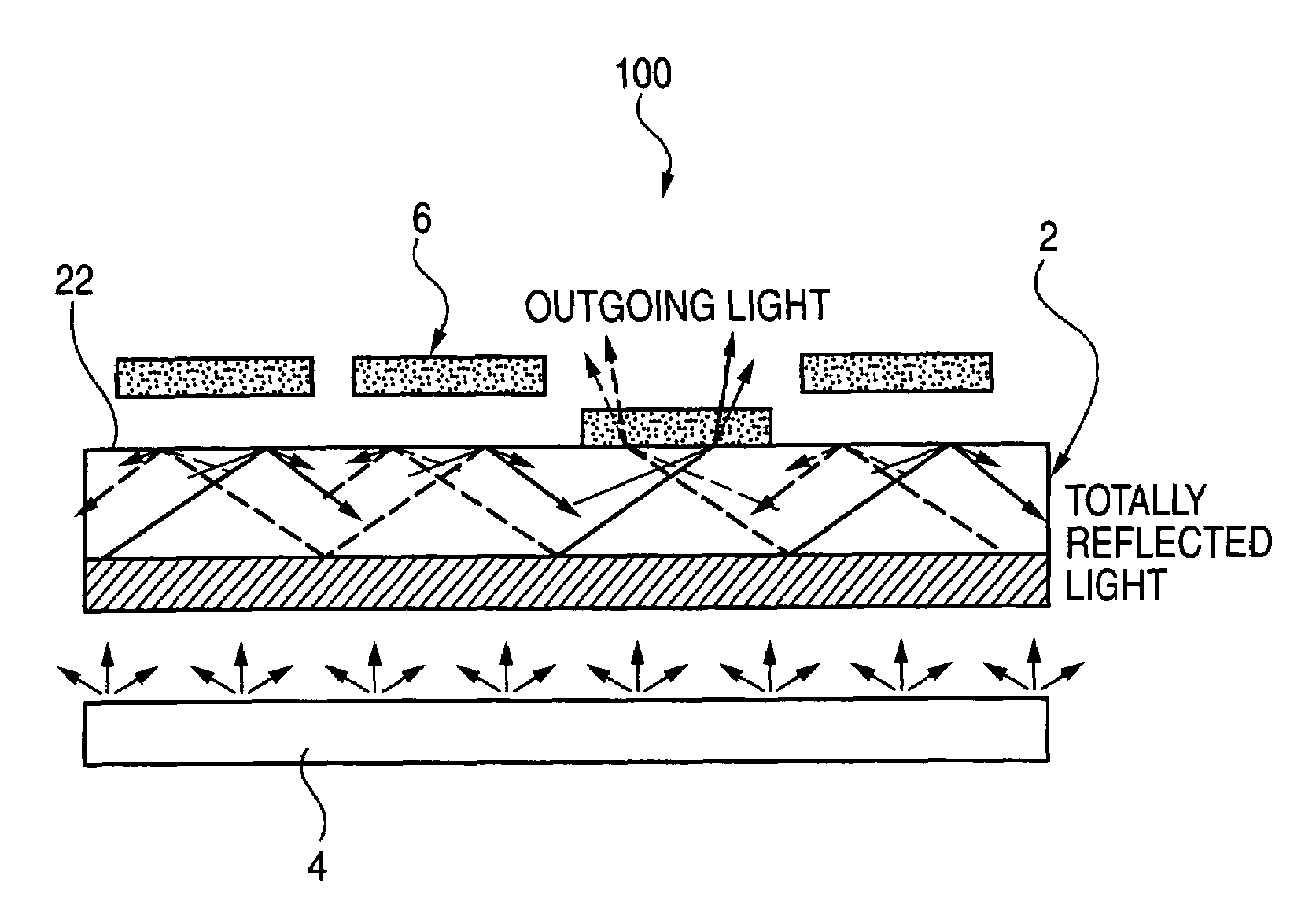

Optical modulating device, display, and exposure device

InactiveUS20050018272A1Shorten the light pathImprove efficiencyNon-linear opticsOptical elementsCatoptricsCoupling

Subjects for the invention are to provide a light-modulating element having an elevated energy efficiency while preventing a decrease in contrast at low cost without using a display technique employing a waveguide or lightguide plate, and to provide a display element capable of producing high-quality display images and an exposure element capable of exposure treatment. In the invention, the light-modulating element comprises: a total-reflection optical member 2 having such a property that at least part of planar incident light introduced into the light-modulating element is totally reflected at an interface (total reflection plane) 22 of a layer constituted by the light-modulating element and the incident light does not substantially go out through the side opposite to the incident-light introduction side; and light-coupling elements 6 which are disposed on the total reflection plane 22 side of the total-reflection optical member 2 and serve to selectively couple with the incident light and take out the same from the total reflection plane 22.

Owner:FUJIFILM HLDG CORP +1

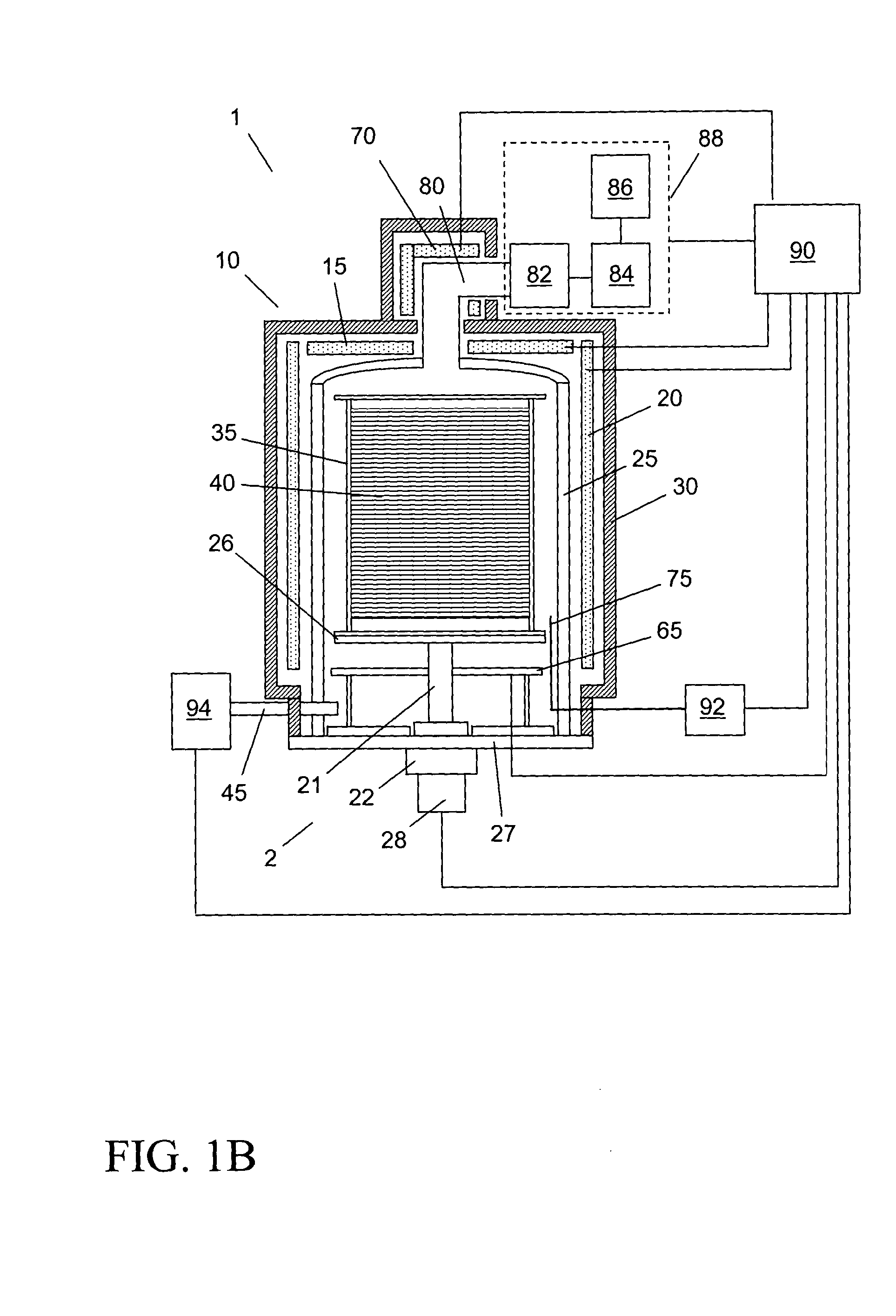

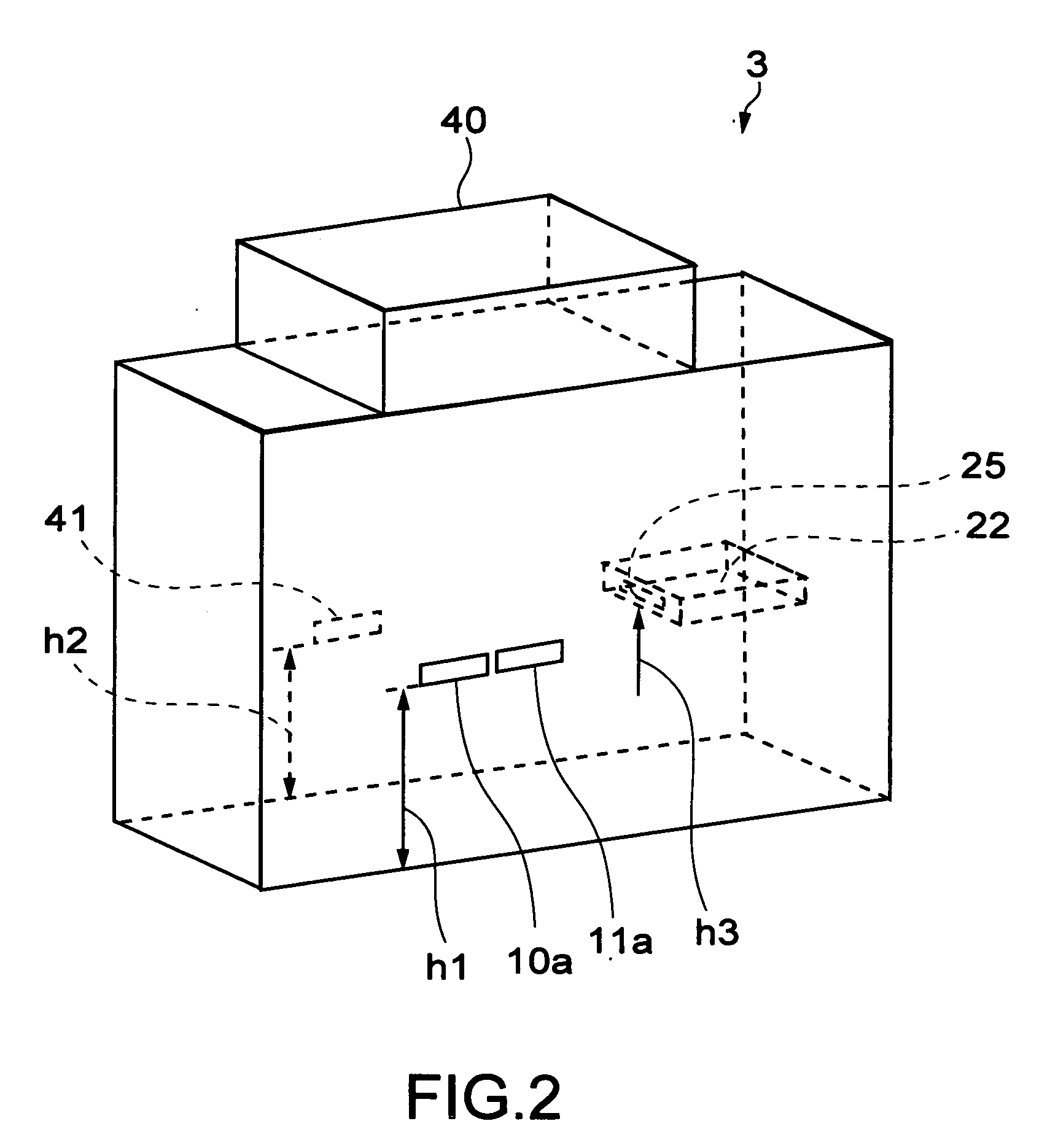

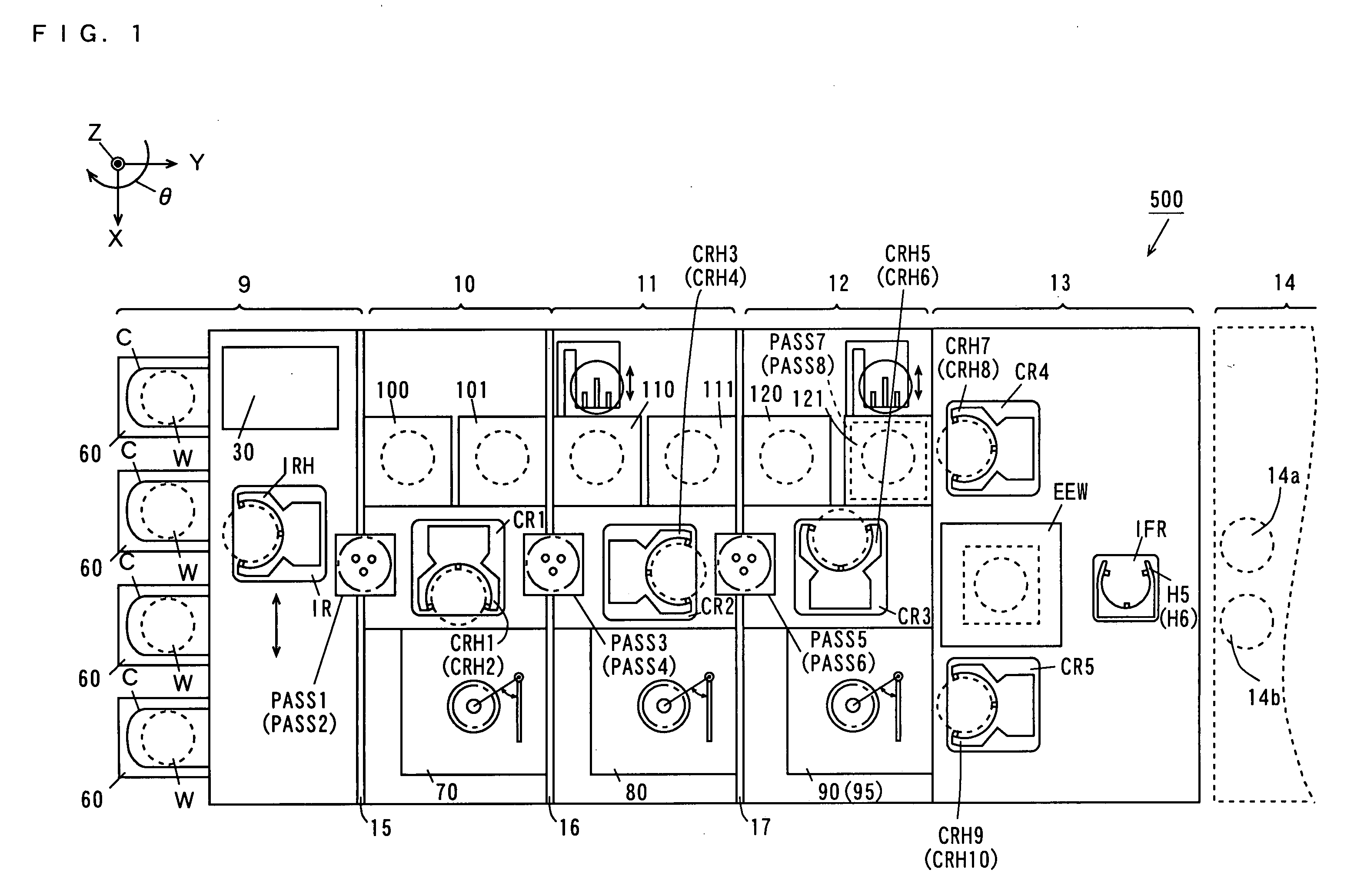

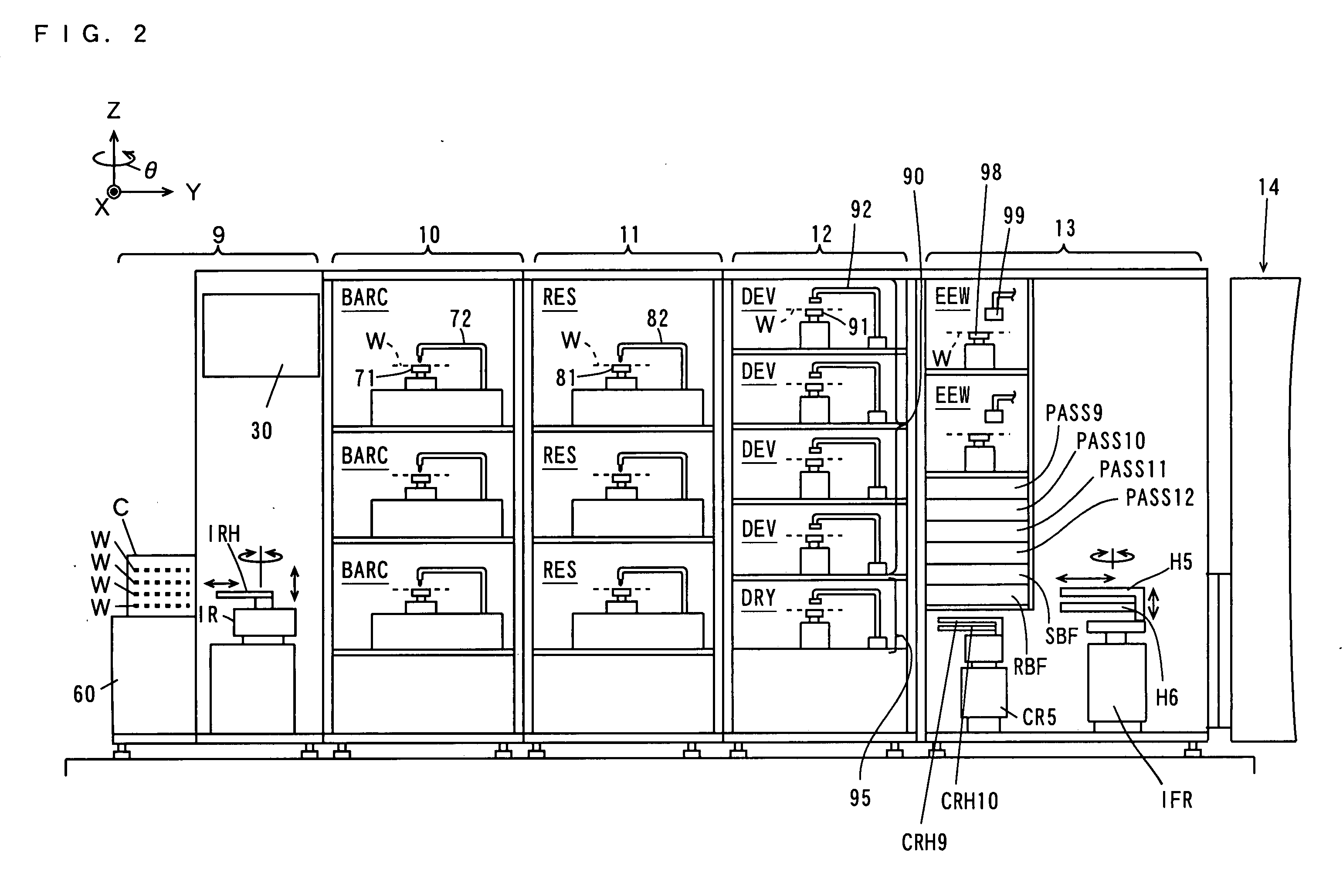

Substrate processing apparatus and substrate processing method

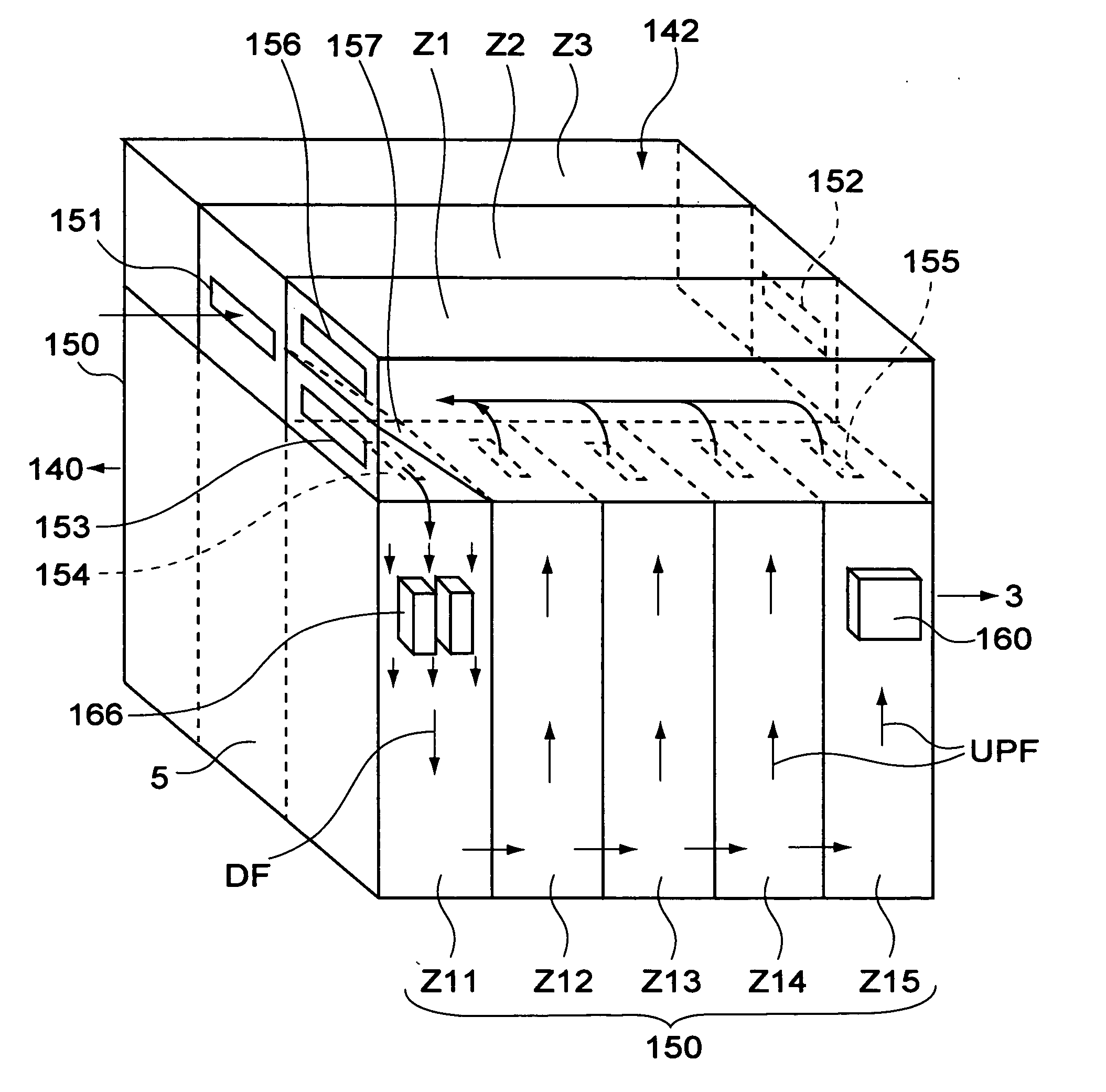

InactiveUS20060169208A1Reduce device sizeImprove throughputPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringPressure Atmosphere

A substrate treatment apparatus that treats a substrate under treatment has an interface section, a substrate loading / unloading section, a reduced pressure atmosphere conveyance chamber, and an exposure treatment chamber. The interface section has a conveyance mechanism that can freely load and unload the substrate under treatment from another device into the apparatus or vice versa. The substrate under treatment can be loaded and unloaded into and from the substrate loading / unloading section in one direction by the conveyance mechanism of the interface section. The reduced pressure atmosphere conveyance chamber is disposed adjacent to and perpendicular to the direction of the substrate loading / unloading section and has a conveyance mechanism that conveys the substrate under treatment under a reduced pressure atmosphere. The exposure treatment chamber is disposed adjacent to and in parallel with the direction of the reduced pressure atmosphere conveyance chamber and performs an exposure treatment for the substrate under treatment.

Owner:TOKYO ELECTRON LTD

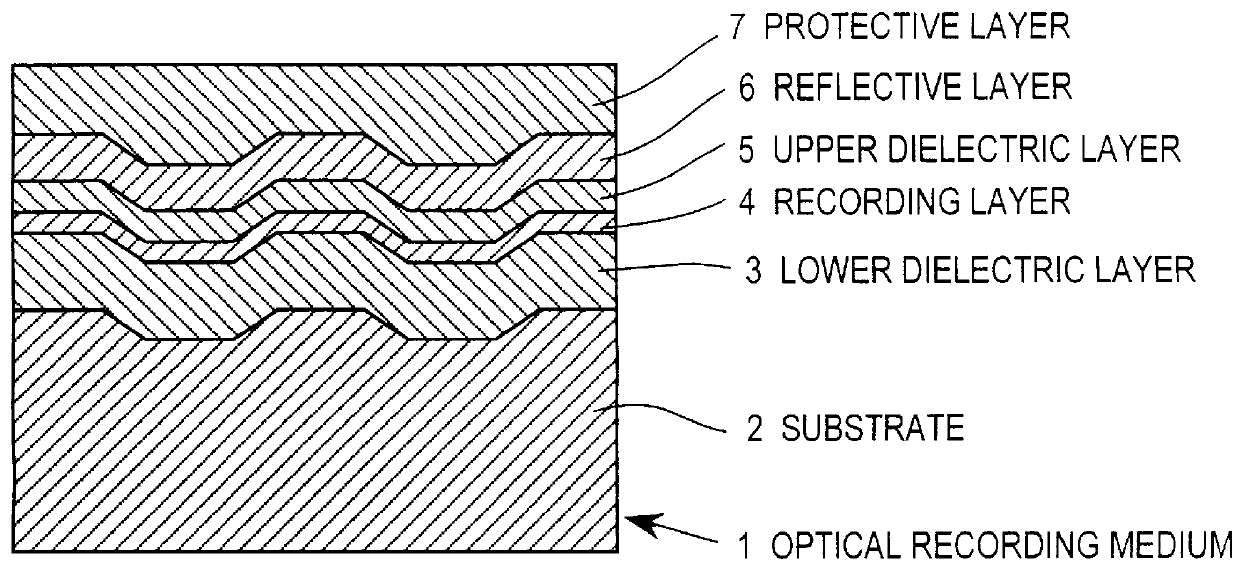

Method for making an optical recording medium

InactiveUS6051363APrevent oxidationShorten the overall cyclePhotosensitive materialsRadiation applicationsOptical recordingPhase change

A method for preparing an optical recording medium of phase change type is provided. This recording medium comprises a substrate, a recording layer, and a lower and an upper dielectric layers provided in direct contact with the recording layer. In this method, a step of an exposure treatment wherein the surface of the lower dielectric layer is exposed to an oxidative atmosphere is conducted after forming the lower dielectric layer on the substrate and before forming the recording layer on the lower dielectric layer. A step of a heat treatment wherein said lower dielectric layer is heat treated may be carried out in addition to the exposure treatment.

Owner:TDK CORPARATION

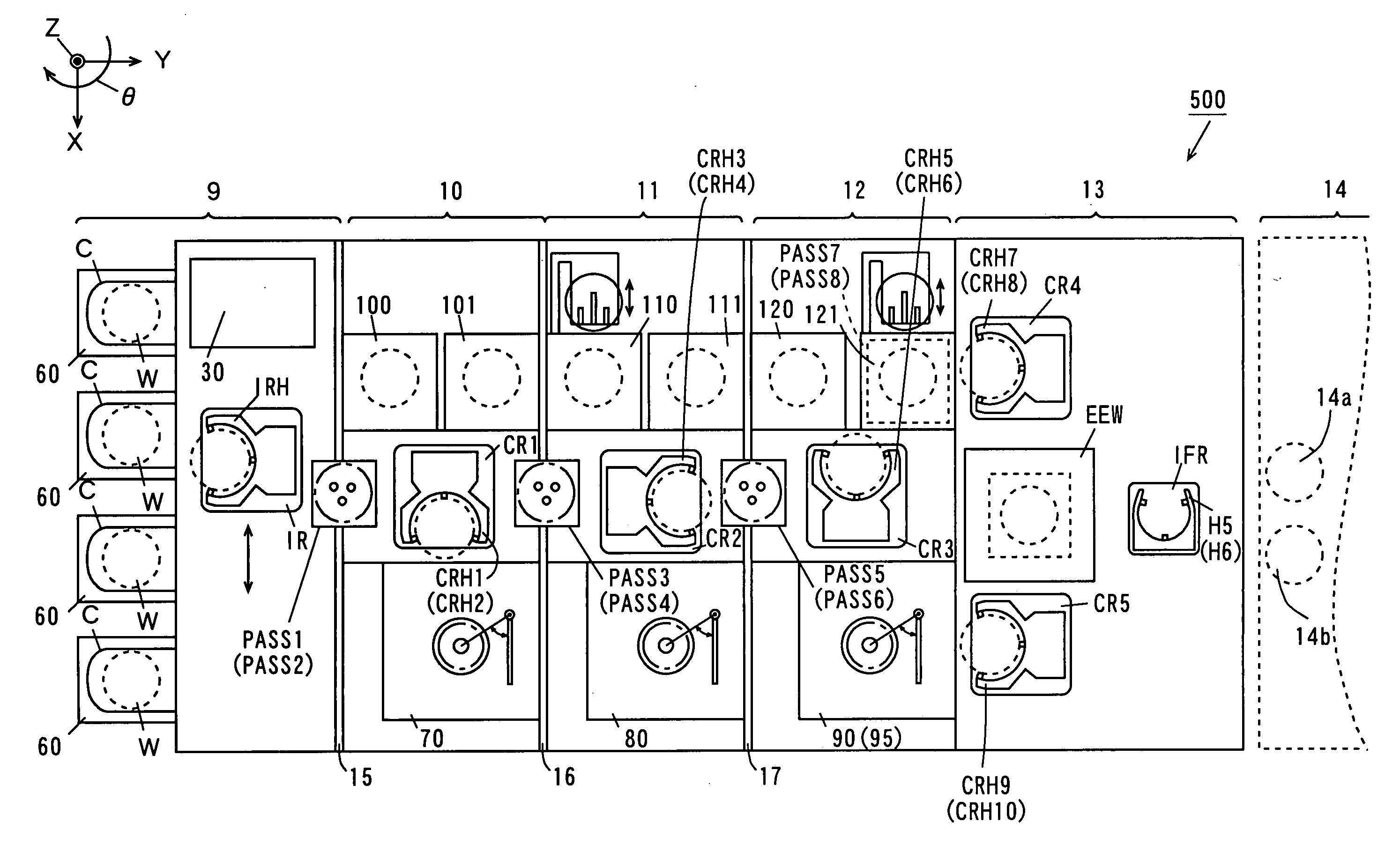

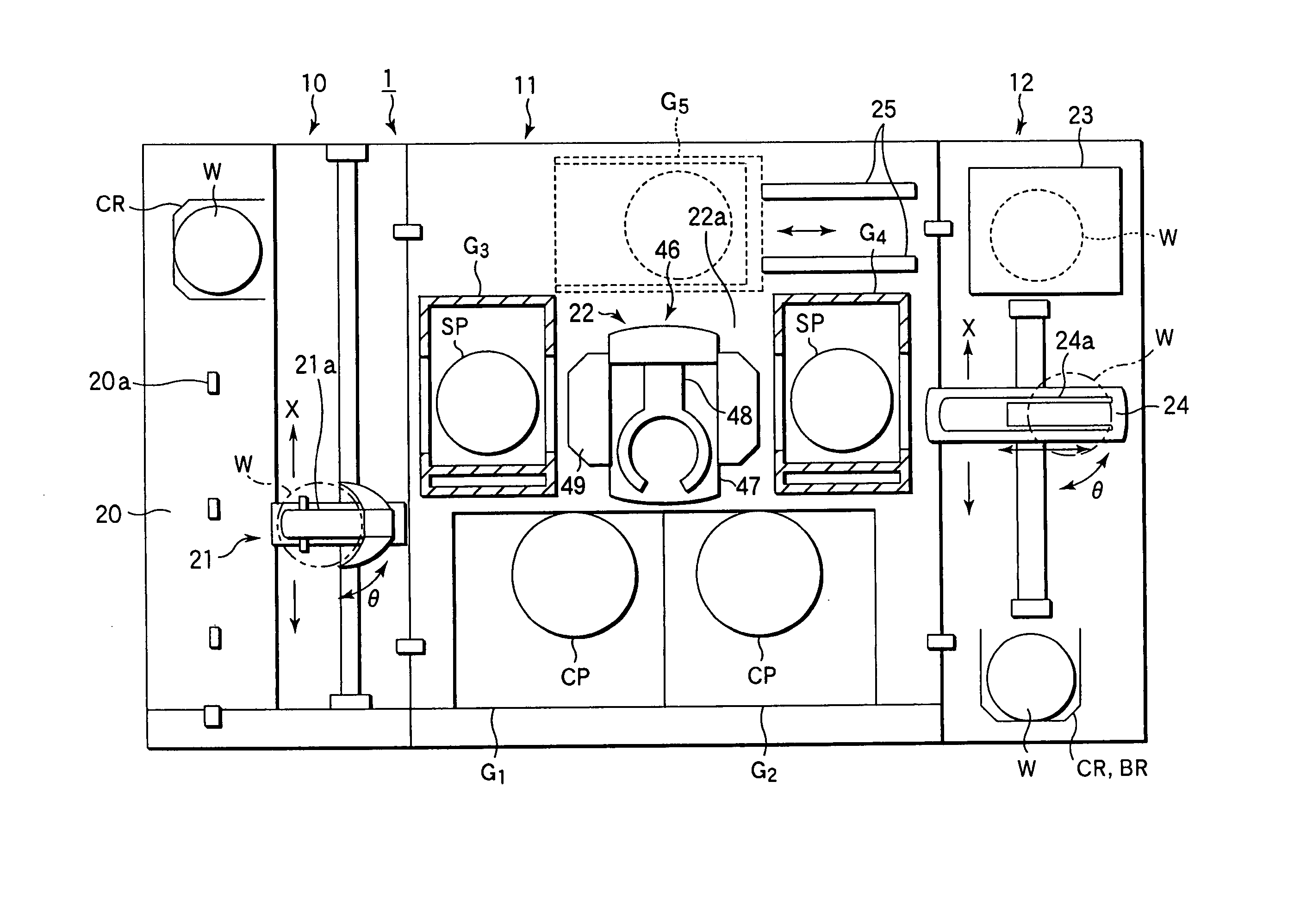

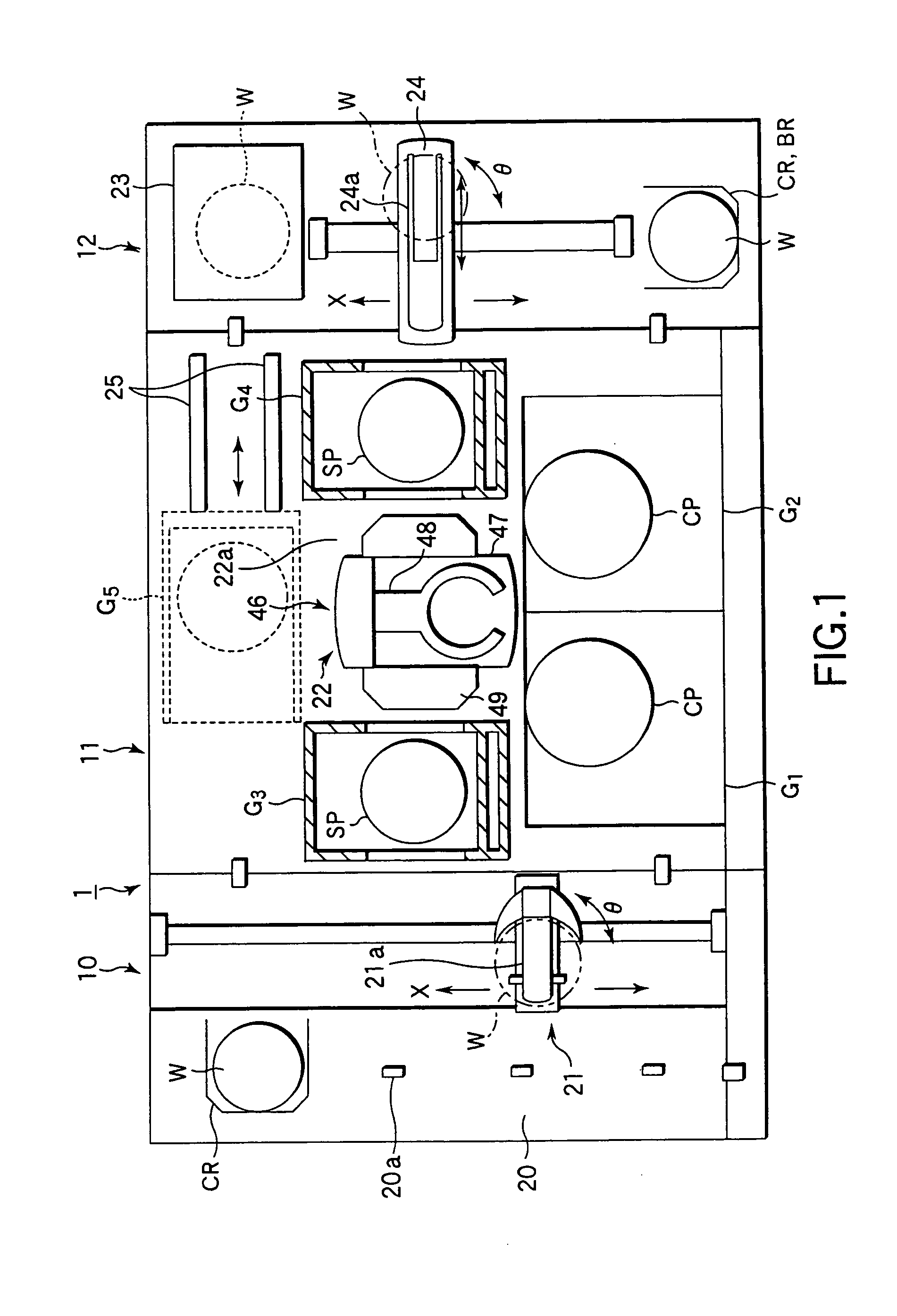

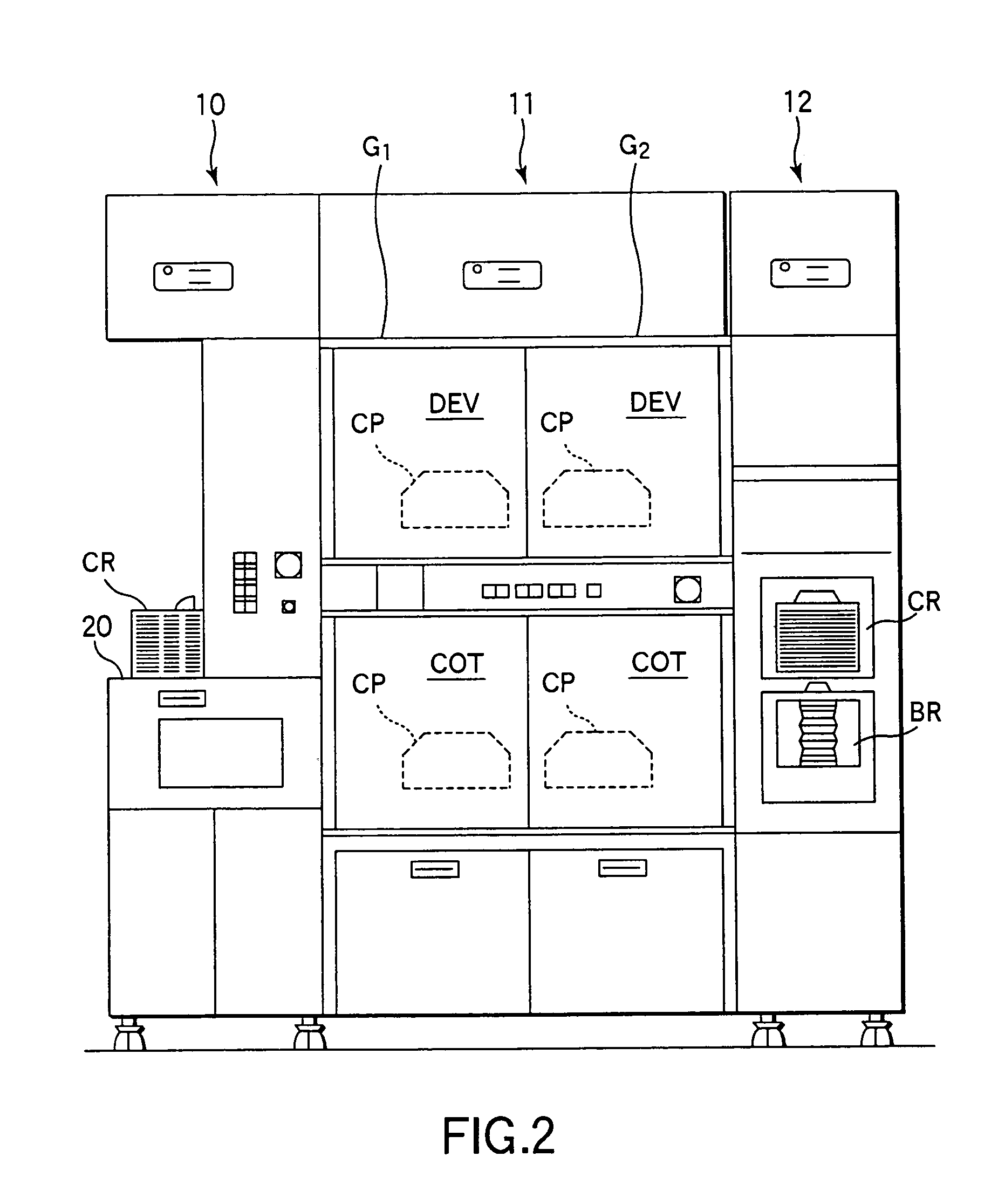

Substrate processing apparatus and substrate processing method

InactiveUS20060147201A1Back contamination can be preventedAvoid pollutionLiquid processingPhotomechanical apparatusEngineeringRobot

An interface transport mechanism employs an upper hand during the transport of a substrate to an exposure device, and employs a lower hand during the transport of the substrate that has been carried out of the exposure device. A fifth central robot employs a lower hand during the transport of a substrate after the exposure processing by an exposure device, and employs an upper hand during the transport of a substrate after the drying processing that has been carried out of a drying processing group. That is, the upper hand is employed to transport a substrate to which no liquid is attached, and the lower hand is employed to transport a substrate to which a liquid is attached after the exposure processing.

Owner:SOKUDO CO LTD

Light-modulating element, display element, and exposure element

InactiveUS20060066939A1Shorten the light pathImprove efficiencyNon-linear opticsOptical elementsWaveguideContrast ratio

Subjects for the invention are to provide a light-modulating element having an elevated energy efficiency while preventing a decrease in contrast at low cost without using a display technique employing a waveguide or lightguide plate, and to provide a display element capable of producing high-quality display images and an exposure element capable of exposure treatment.

Owner:FUJIFILM CORP

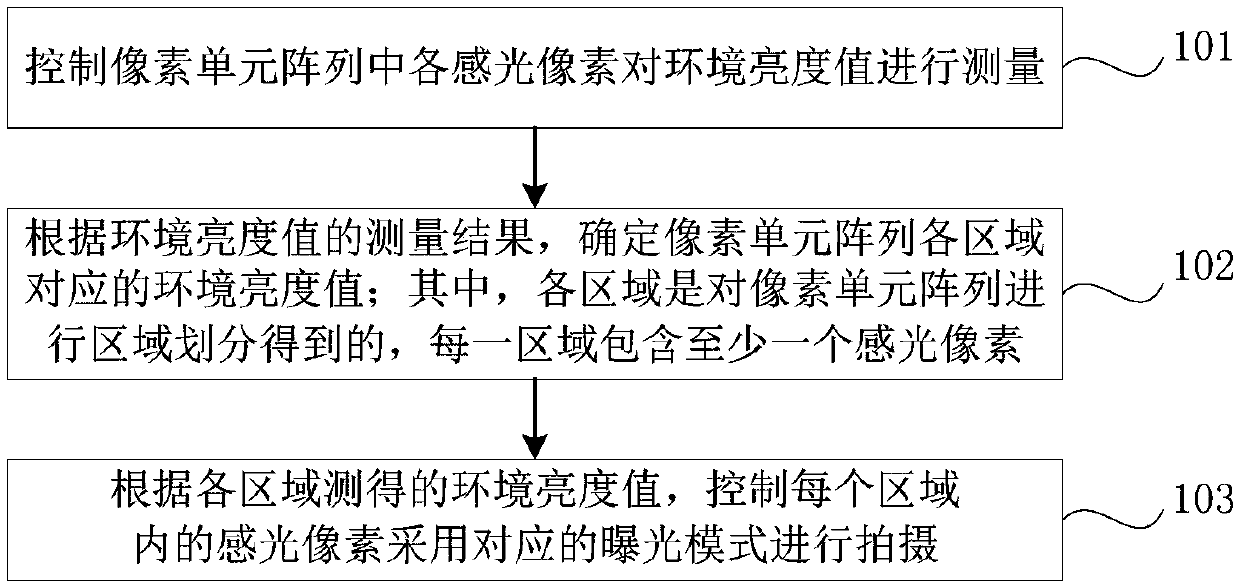

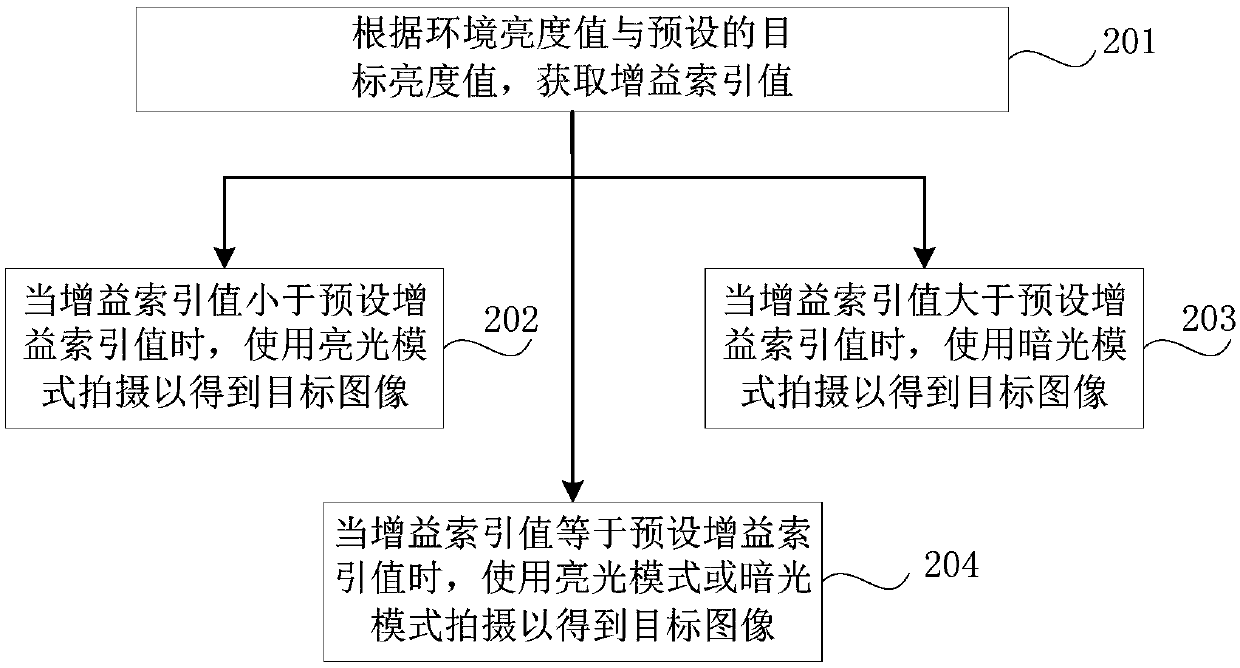

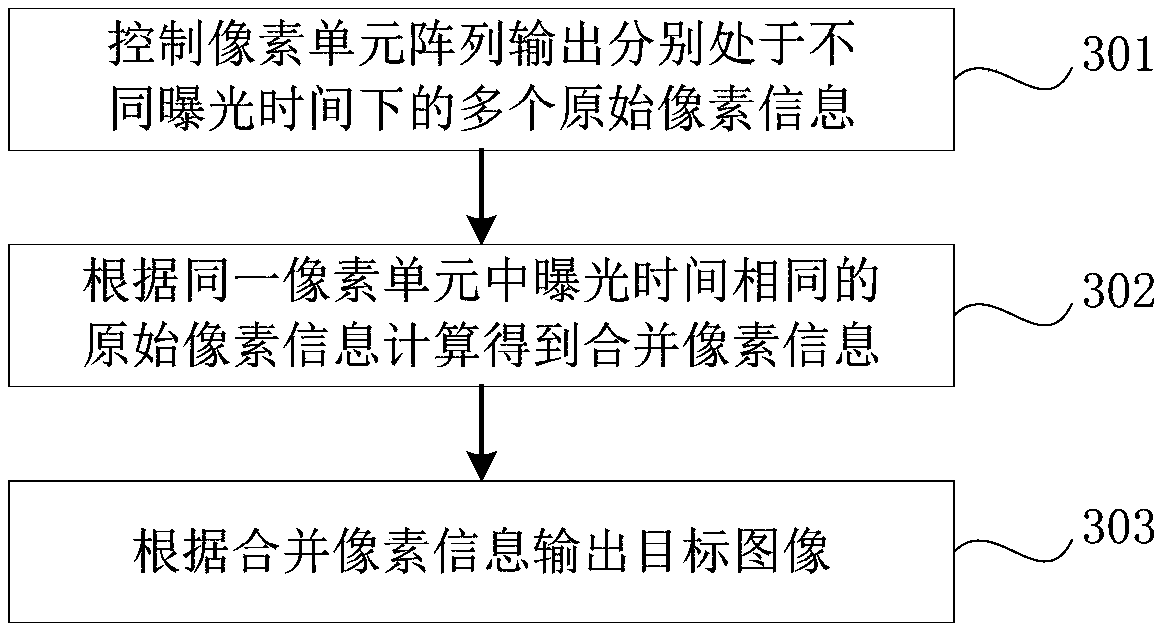

Photographing exposure control method and device, imaging equipment and electronic equipment

InactiveCN108683861AImprove shooting experienceImprove clarityTelevision system detailsColor television detailsSignal-to-noise ratio (imaging)Exposure control

The invention provides a photographing exposure control method, a photographing exposure control device, imaging equipment and electronic equipment. The method is applied to the imaging equipment thatcomprises a pixel unit array composed of multiple light-sensitive pixels. The method comprises the steps of controlling each light-sensitive pixel in a pixel unit array to measure an environment brightness value; determining the environment brightness value corresponding to each area of the pixel unit array according to a measurement result of the environment brightness value; and controlling thelight-sensitive pixels in each area to adopt a corresponding exposure mode for photographing according to the measured environment brightness value of each area. According to the method, the pixel unit arrays are subjected to partitioned exposure treatment, that is to say the light-sensitive pixels in each area are controlled to adopt the proper exposure mode for photographing according to the measured environment brightness value of each area, so that the signal to noise ratio of the relatively dark area in the image can be improved, the good target image with relatively good definition is acquired, and the photographing experience of the user is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

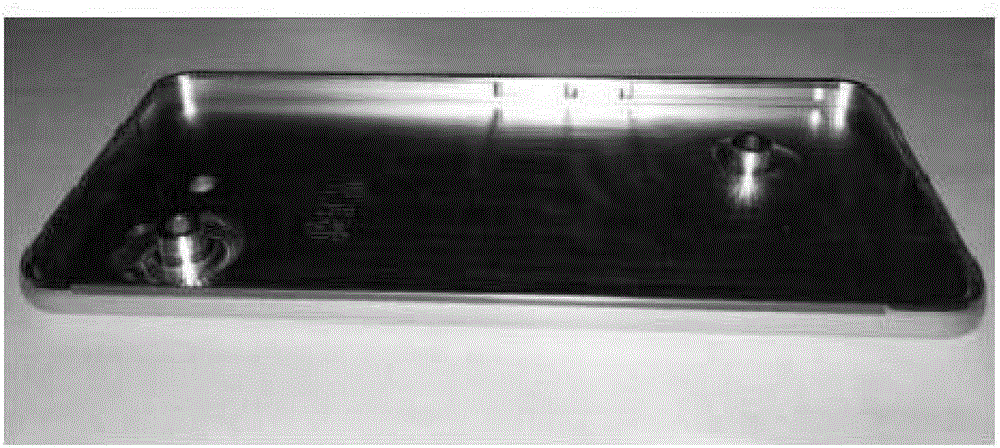

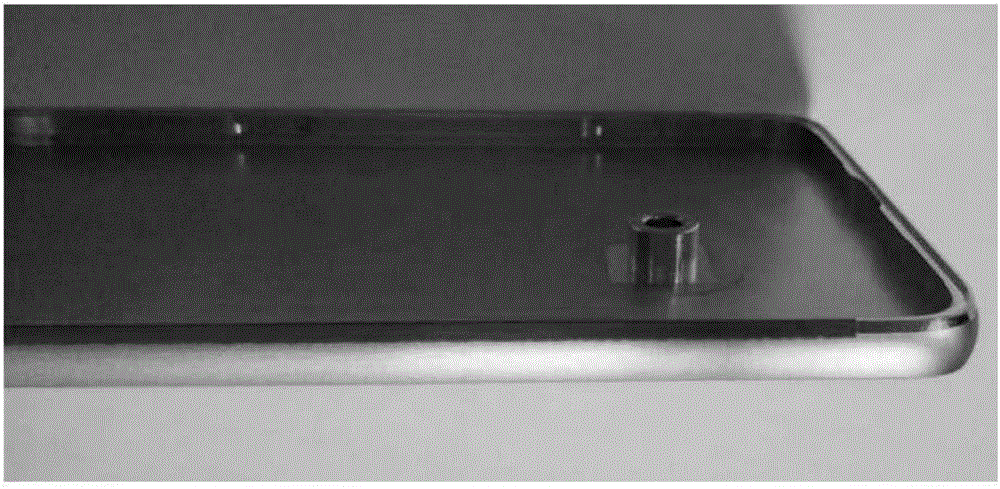

Surface treatment method for highlight edge of aluminum alloy mobile phone shell

ActiveCN106400083ANot easy to fadeImprove yieldSurface reaction electrolytic coatingInksSand blastingPrinting ink

The invention belongs to the technical field of aluminum alloy surface treatment, and particularly relates to a surface treatment method for the highlight edge of an aluminum alloy mobile phone shell. The surface treatment method comprises the following steps of machining of the counter and an inner cavity of the aluminum alloy mobile phone shell, CNC highlight treatment carried out on a frame after surface polishing, surface alkaline washing, surface sand blasting and first-time anodic oxidation, oil removal and cleaning, spraying of printing ink after shielding of the mobile phone shell, printing ink baking, ultraviolet exposure treatment, developing treatment, baking, UV radiation for curing printing ink, second-time anodic oxidation treatment, printing ink removal and third-time anodic oxidation treatment. After the highlight edge of the aluminum alloy mobile phone shell is subjected to three times of anodic oxidation treatment, the portion, close to a display screen, of a longitudinal frame of the mobile phone shell has the same color as the display screen, a frame-free visual sense is formed, the straightness of a color junction edge in second-time anodic oxidation and third-time anodic oxidation is ensured by the adoption of a three-dimensional exposure mode, the production yield reaches up to 90% or above, the cost is low, and production efficiency is high.

Owner:淮北暴风工业设计有限公司

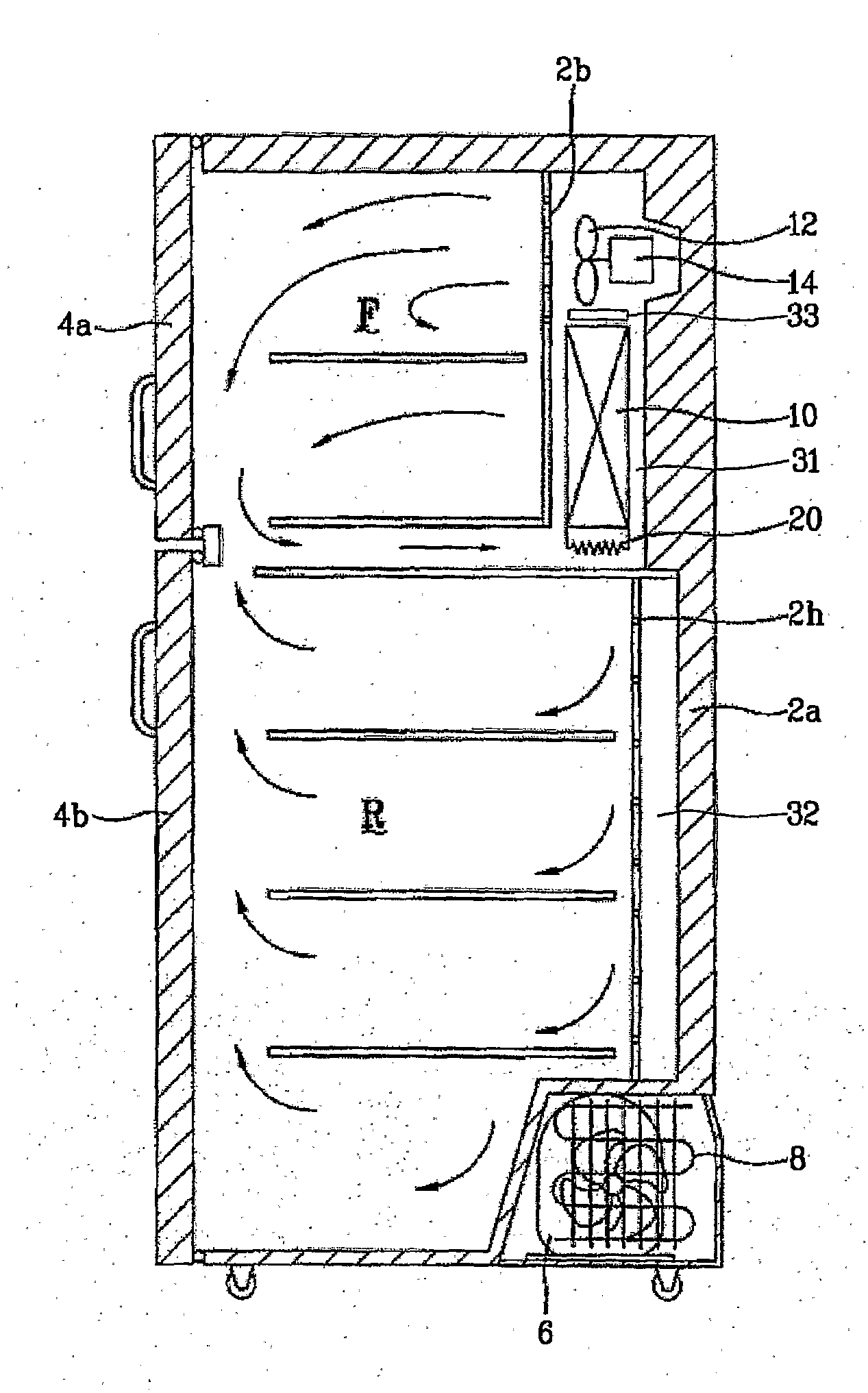

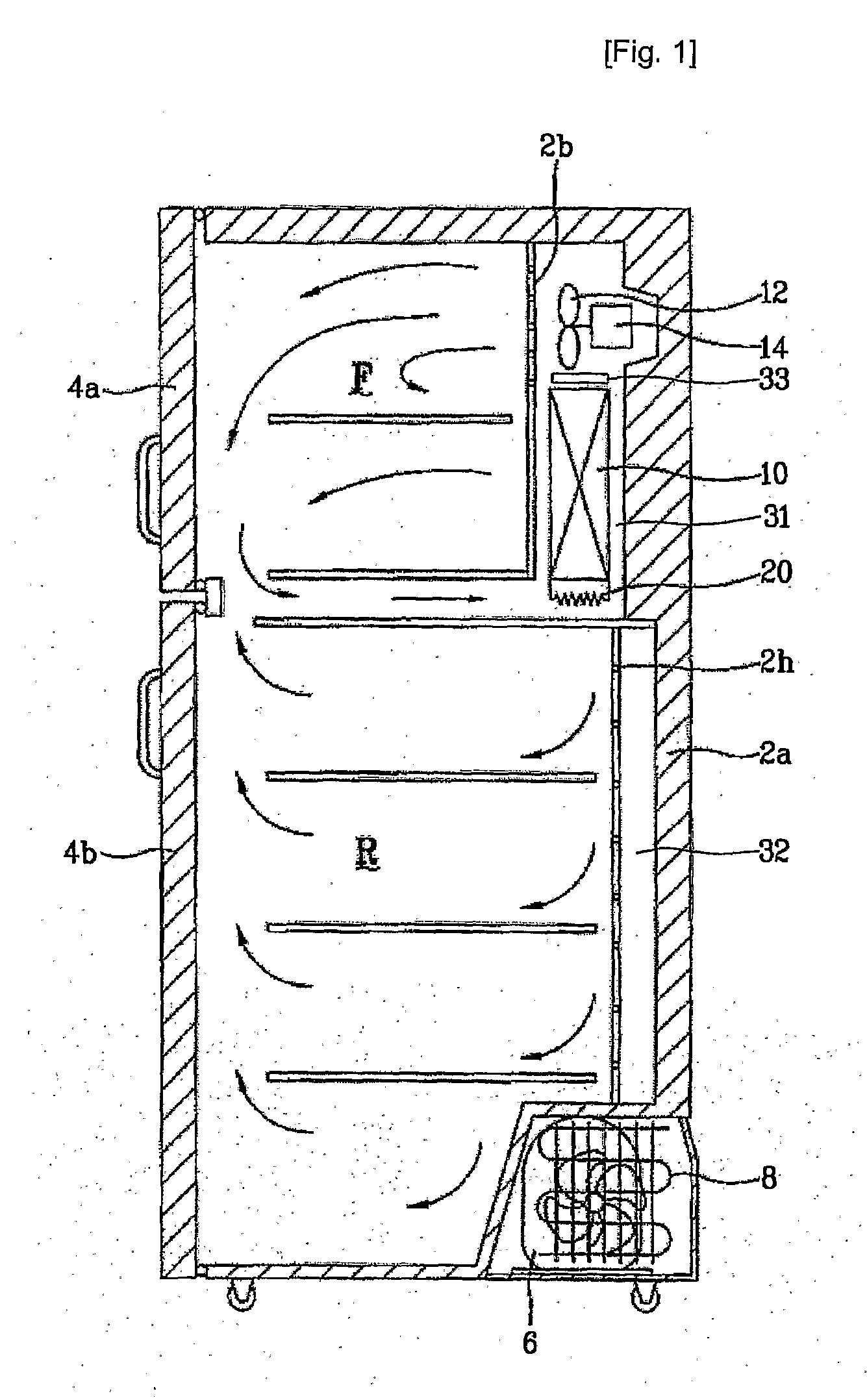

Refrigerator

ActiveUS20090217694A1Improve antibacterial propertiesHigh activityEvaporators/condensersRefrigeration devicesRefrigerated temperatureHolding room

The present invention relates to a refrigerator, including: a refrigerating cycle having an evaporator (1a); a space for exchanging heat with the evaporator; a region for exchanging heat between the evaporator and the space; and a storage chamber and a door for defining the space, wherein at least one of the region, the storage chamber and the door has undergone at least one of a Kimchi lactic acid bacteria culture treatment and a Kimchi lactic acid bacteria culture exposure treatment.

Owner:LG ELECTRONICS INC

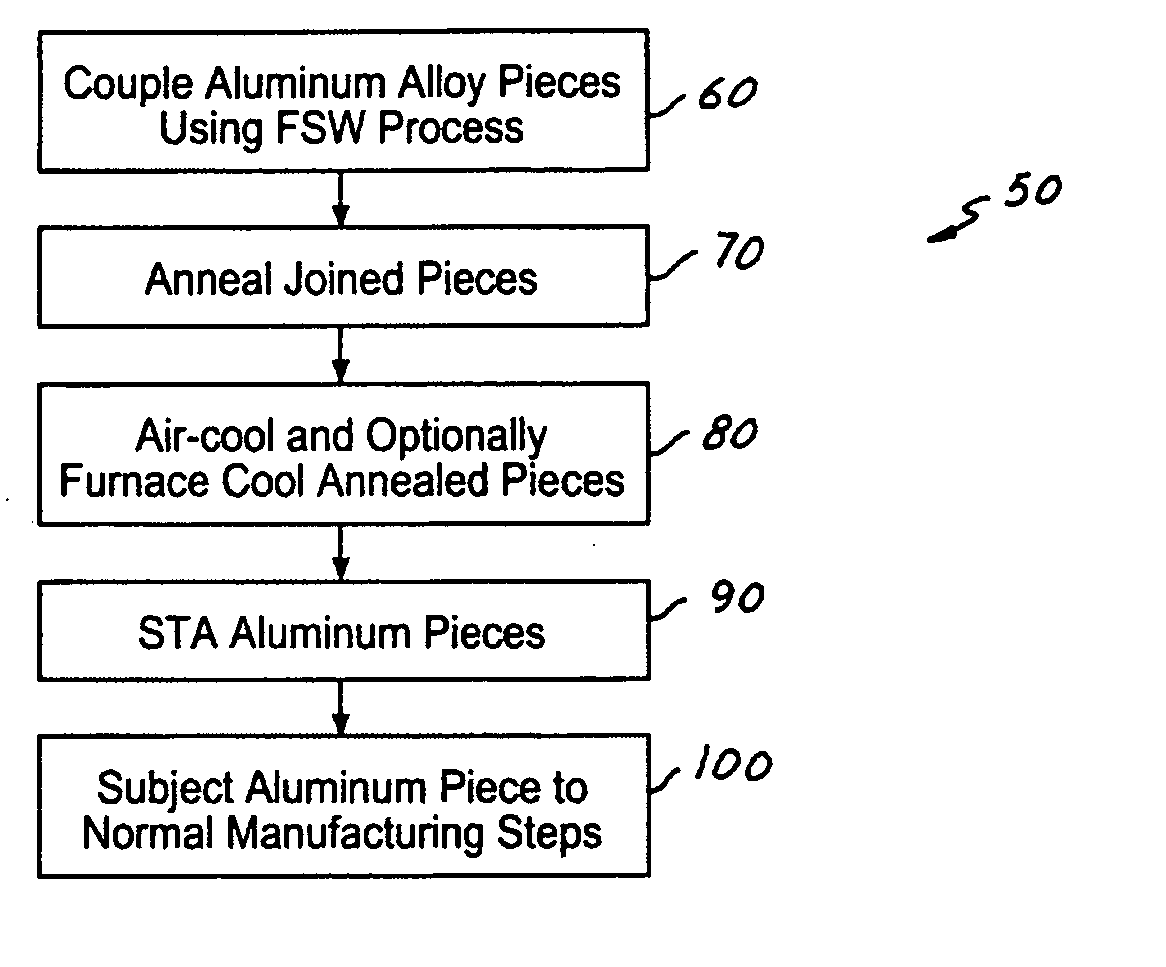

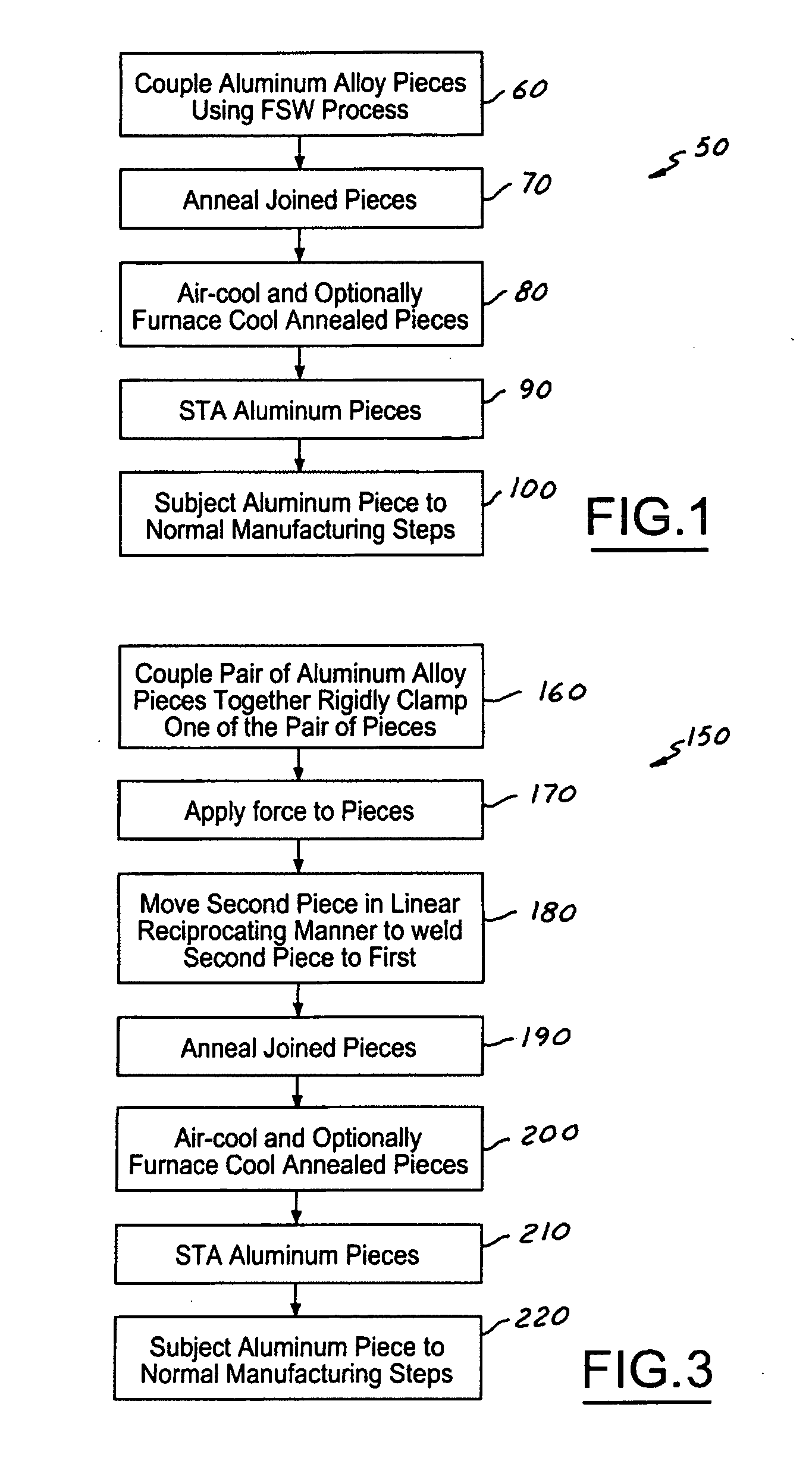

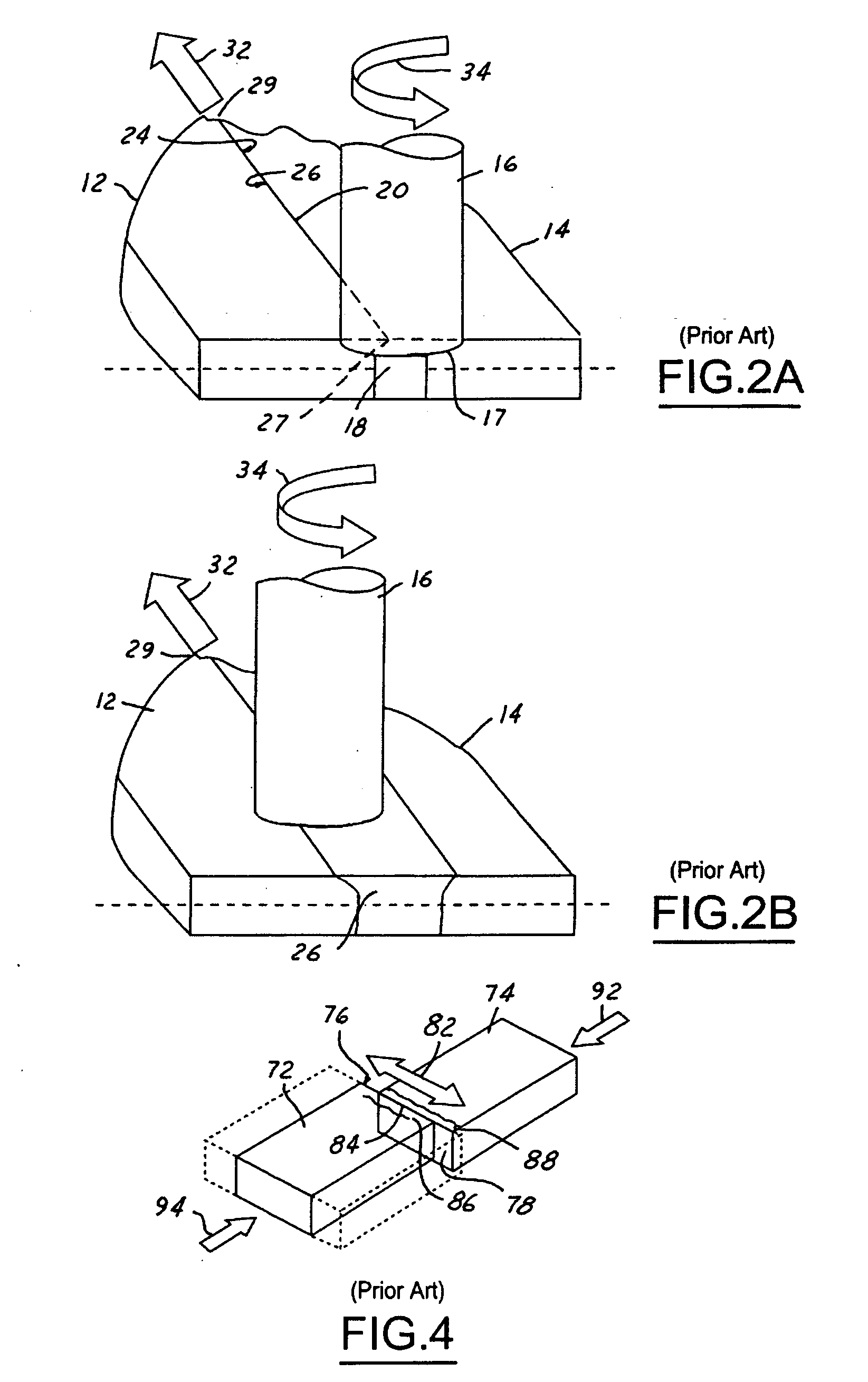

Method to improve properties of aluminum alloys processed by solid state joining

ActiveUS20060054252A1Restored mechanical strengthDecrease in original ductilityNon-electric welding apparatusAbnormal grain growthStored energy

A method for forming an aluminum alloy article having improved mechanical properties using a solid-state joining process in which the problem of ductility reduction is minimized by conducting a thermal exposure treatment prior to solution heat treatment. This thermal exposure treatment, done at a temperature below the solution heat treatment temperature, releases stored energy in the aluminum-alloy material. The aluminum-alloy material then does not have sufficient energy to cause recrystallization and abnormal grain growth during the subsequent solution heat treatment process. The resultant aluminum-alloy material has a restored mechanical strength with only a minor, but acceptable, decrease in original ductility.

Owner:THE BOEING CO

Method for removing resist pattern and method for manufacturing semiconductor device

InactiveUS20040091820A1Easy to disassembleResistance of the resist pattern is reducedTransistorSolid-state devicesResistPhotosensitizer

It is an object to provide a technique for removing a resist favorably without leaving residue in the case of using a nonaqueous resist stripper. According to the present invention, in order to achieve the object, when a resist pattern is removed by using the nonaqueous resist stripper, it becomes easier to remove the resist pattern after dry etching or ion doping, by performing exposure treatment on the resist pattern. After a resist pattern is formed from a DNQ-novolac resin type of positive resist composition, the resist pattern is irradiated with light within the range of photosensitive wavelength of the DNQ photosensitizer, thereby removing the resist pattern with the nonaqueous resist stripper.

Owner:SEMICON ENERGY LAB CO LTD

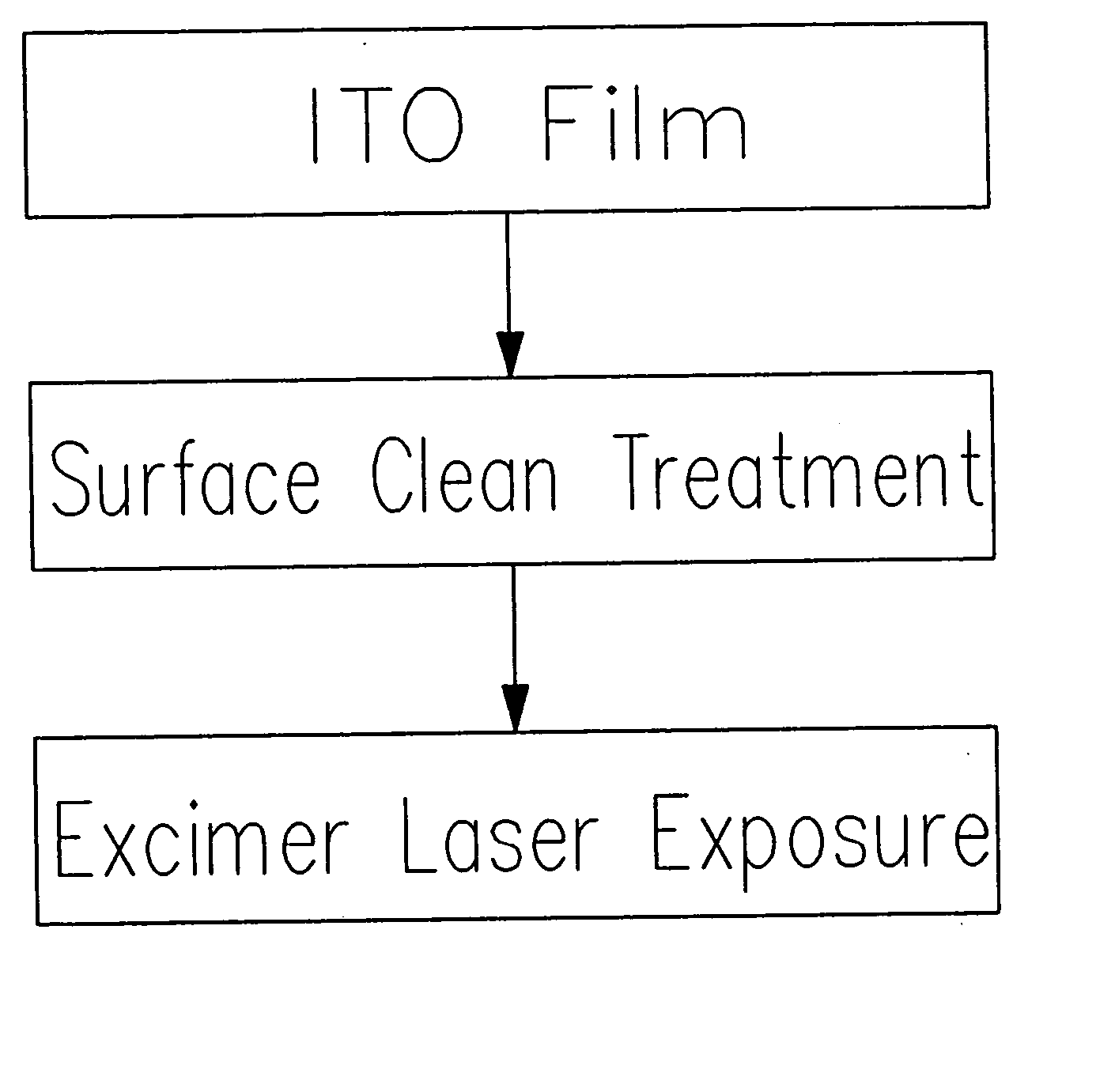

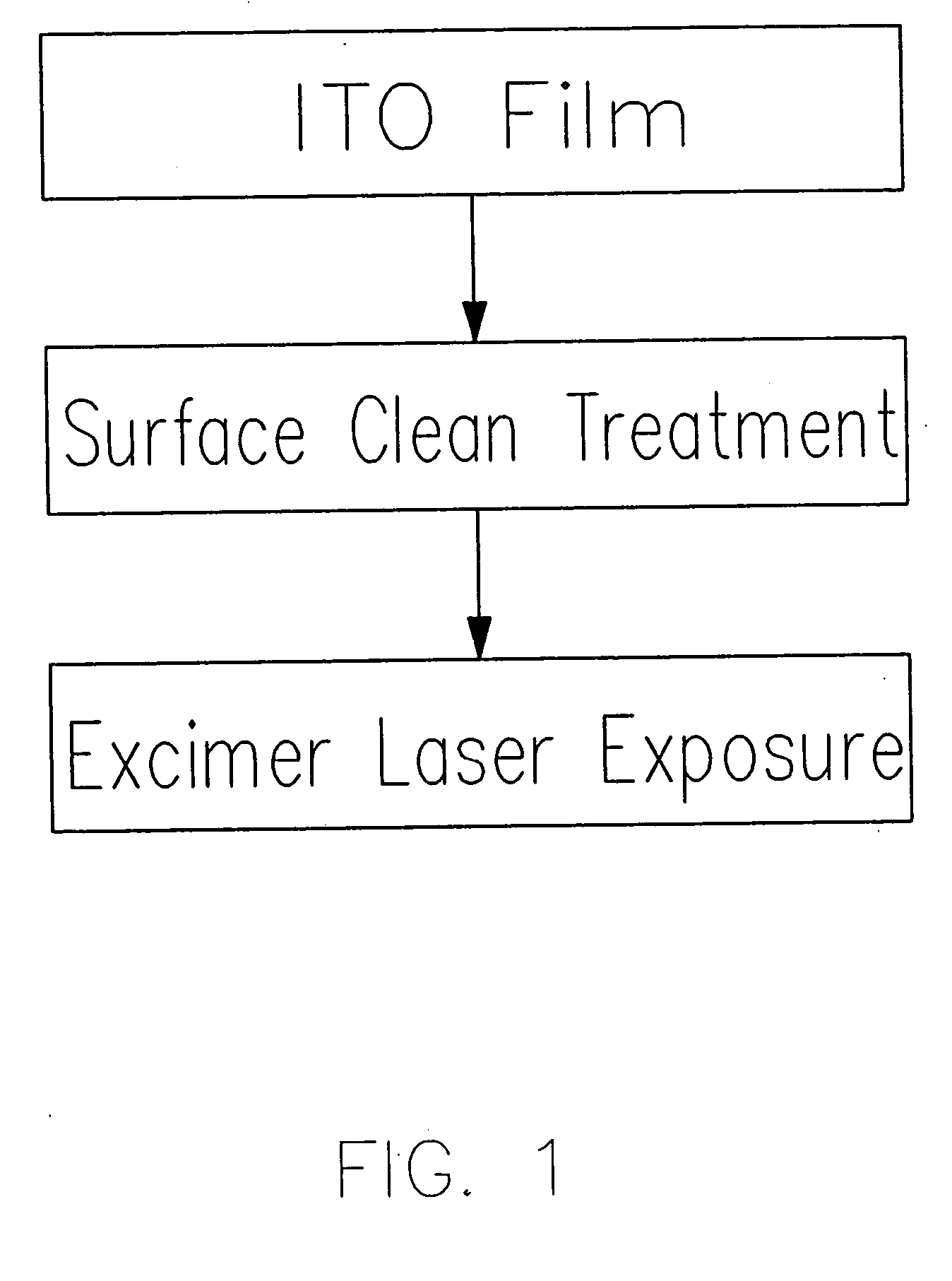

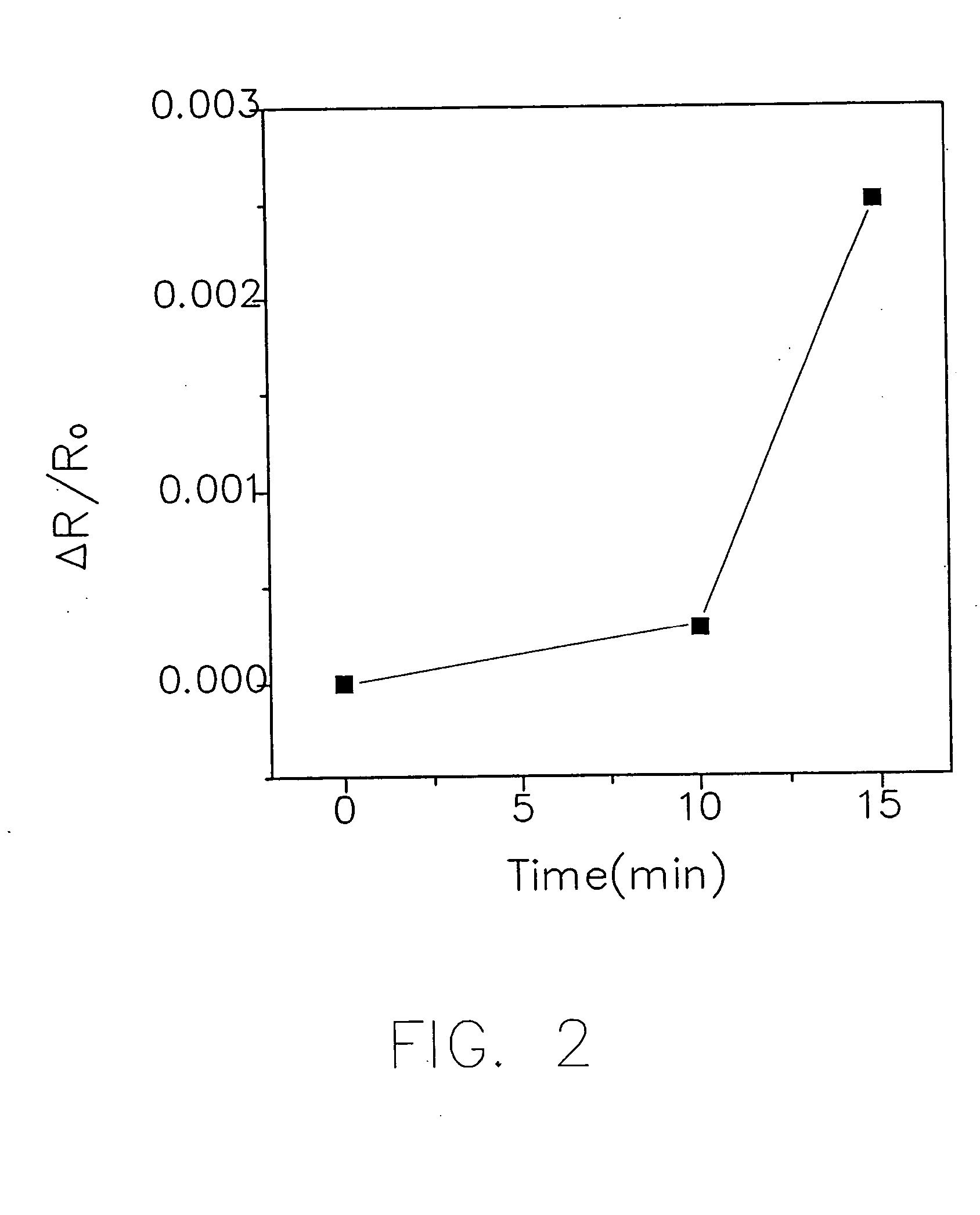

Method for increasing the work function of ITO film under an excimer laser exposure treatment

InactiveUS20060024450A1Convenience to workFunction increaseRadiation applicationsSolid-state devicesWork functionIndium tin oxide

The present invention relates to a method for increasing the work function of the indium-tin-oxide (ITO) film under an excimer laser exposure treatment. The range of the excimer laser energy is between tens and hundreds mJ / cm2, the frequency range is between zero and one hundred Hz, and exposure time is between five minutes to tens hours. It, therefore, can increase the work function of the indium-tin-oxide (ITO) film.

Owner:FENG CHIA UNIVERSITY

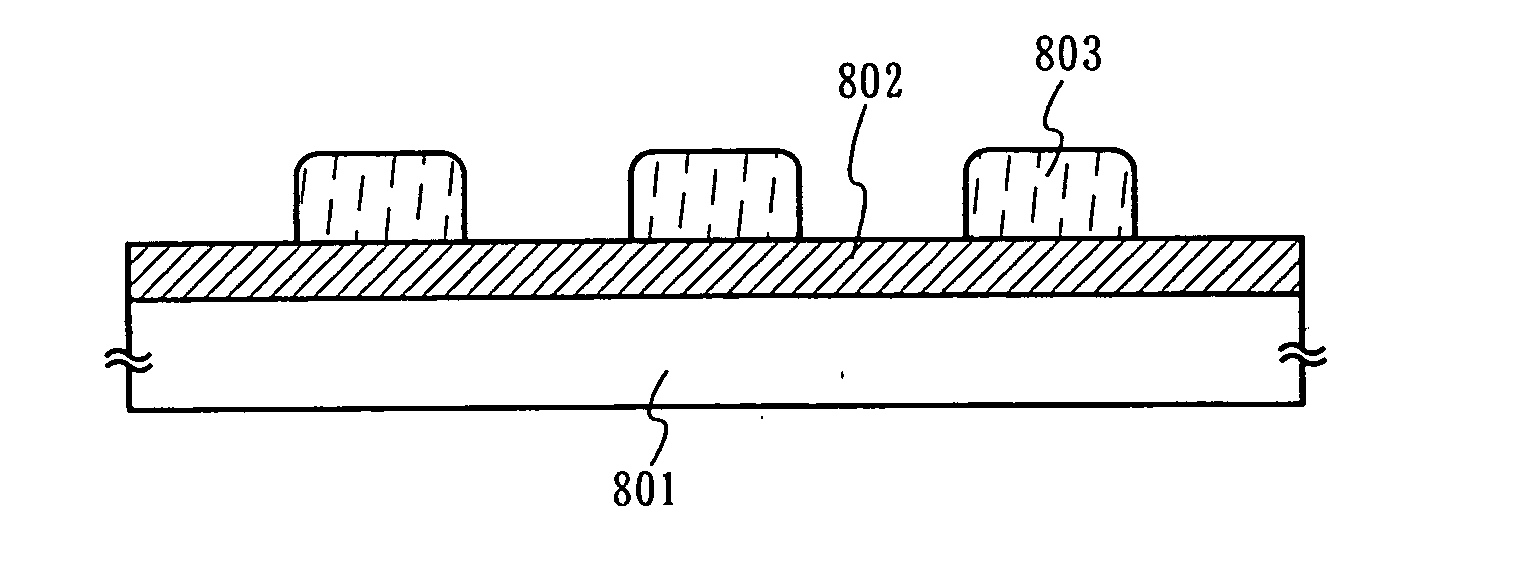

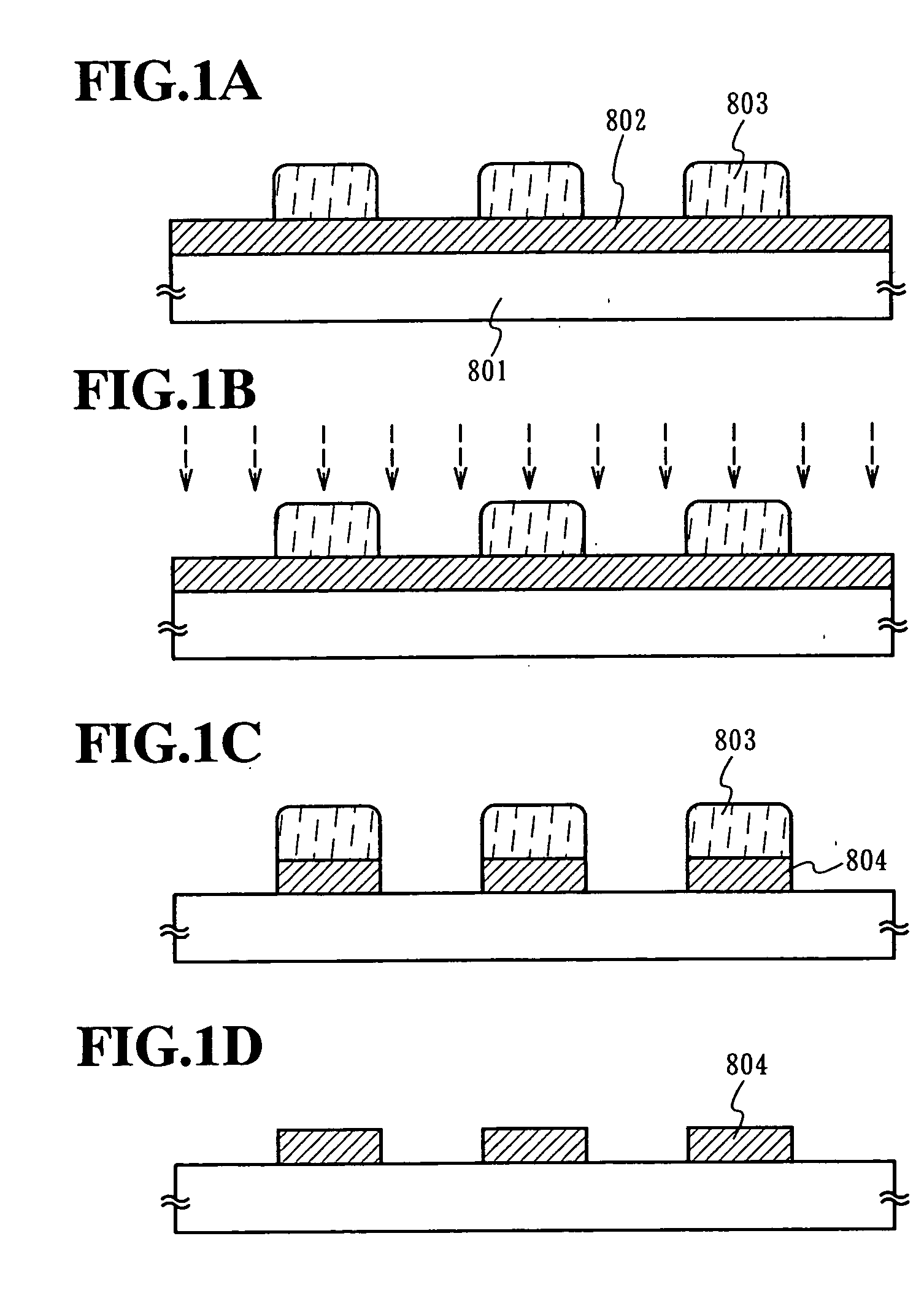

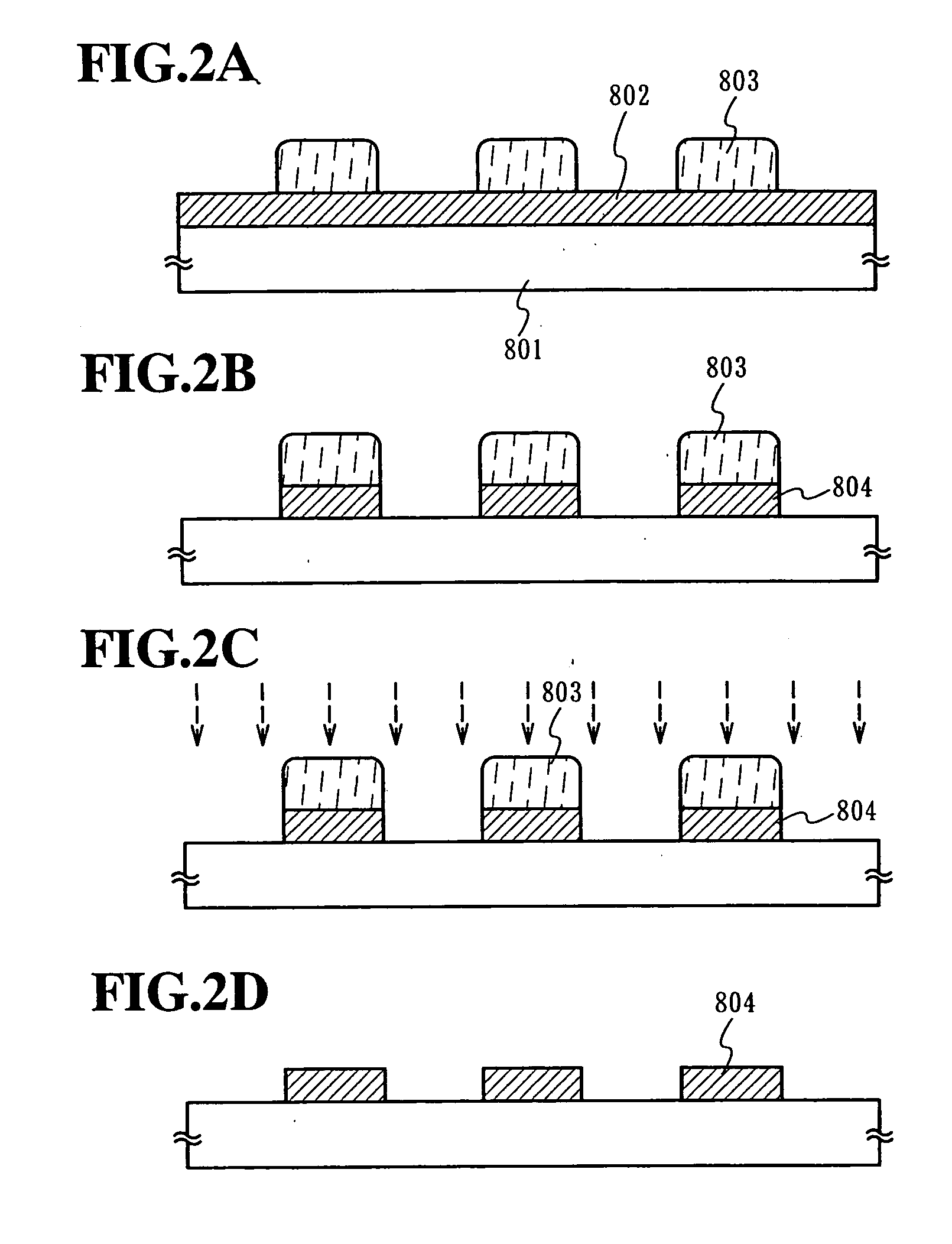

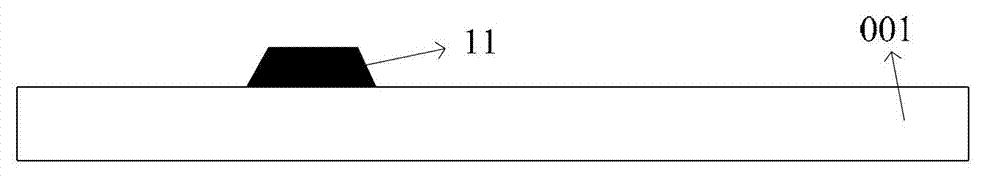

Manufacturing method of thin film transistor and manufacturing method of array base plate

ActiveCN102738007AAccurateImprove product qualitySolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistSemiconductor

The embodiment of the invention provides a manufacturing method of a thin film transistor and a manufacturing method of an array base plate, relates to the filed of liquid crystal panel manufacturing and enables a source / drain and a grid to be exactly aligned. The manufacturing method of the thin film transistor comprises the following steps of: forming a grid on a transparent base plate; forming a grid insulating layer on the base plate with the grid; manufacturing a transparent semiconductor thin film on the grid insulating layer, forming a semiconductor layer through using a picture composition technique, and reserving a photoresist above the semiconductor layer; carrying out exposure treatment on the reserved photoresist by taking the grid as a mask from one side of the transparent base plate, and forming a channel photoresist corresponding to the grid after developing; and manufacturing a source-drain metal thin film on the base plate with the channel photoresist, peeling off the channel photoresist and the source-drain metal thin film on the channel photoresist, and forming the source and the drain by using the picture composition technique. The two methods are applied to manufacturing products or devices including thin film transistors.

Owner:BOE TECH GRP CO LTD

Imprinted water-permeable cement concrete ground structure with aggregate exposed on surface, and manufacturing method thereof

InactiveCN102400429AWear-resistantPermeableIn situ pavingsPaving detailsStructure of the EarthMaterials science

The invention discloses an imprinted water-permeable cement concrete ground structure with aggregate exposed on the surface. The structure comprises components of, from top to bottom: a cement water-permeable concrete layer, a bedding layer and a base layer. The layers are orderly arranged from top to bottom. Patterns and textures are formed through an imprinting technology on the upper surface of the cement water-permeable concrete layer with an aggregate exposure effect, wherein the cement water-permeable concrete layer is the top layer. The manufacturing method of the ground structure comprises steps that: (1) the base layer is paved; (2) the bedding layer is paved on the base layer; (3) at least one cement water-permeable concrete layer is paved on the bedding layer; (4) the patterns and textures are formed through imprinting on the surface of the top cement water-permeable concrete layer; (5) an aggregate exposure treatment is carried out upon the surface of the imprinted top cement water-permeable concrete layer. The aggregate exposure treatment comprises specific steps that: a surface-setting-retarding material is sprayed on the surface of the imprinted top cement water-permeable concrete layer, or a cement-setting-retarding film is coated on the surface of the imprinted top cement water-permeable concrete layer, then the surface of the imprinted top cement water-permeable concrete layer is washed; or the surface of the imprinted top cement water-permeable concrete layer is directly washed, such that the aggregate exposure effect is realized. The method also comprises a step (6), which is a maintenance step. The imprinted water-permeable cement concrete ground structure with the aggregate exposed on the surface is both an environment-friendly ground structure and a decorative ground structure.

Owner:北京中景橙石科技股份有限公司

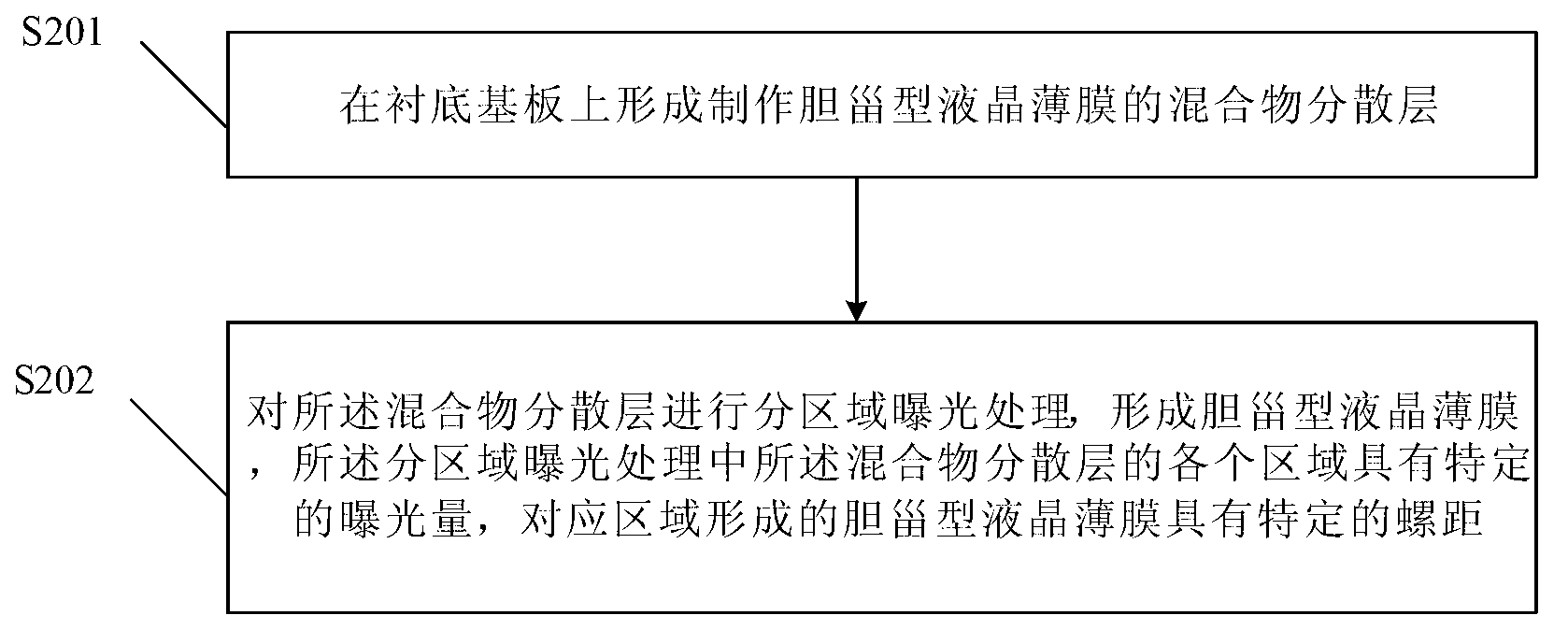

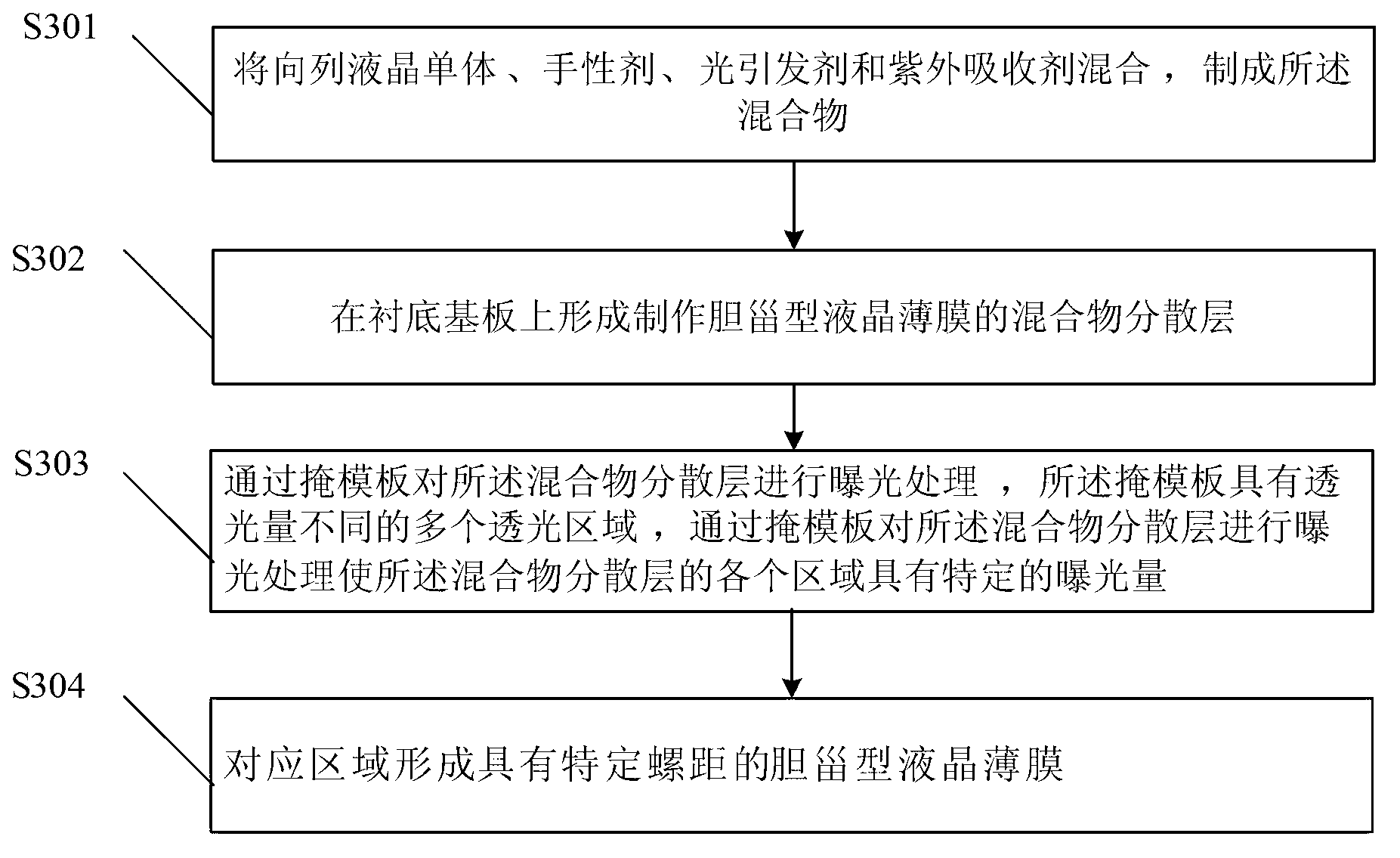

Manufacturing method of cholesteric liquid crystal film, cholesteric liquid crystal film and optical filter

InactiveCN103309073AImprove production efficiencyLiquid crystal compositionsNon-linear opticsLight filterCholesteric liquid crystal

The invention provides a manufacturing method of a cholesteric liquid crystal film, a cholesteric liquid crystal film and an optical filter. The manufacturing method comprises the steps as follows: a mixture dispersion layer for manufacturing the cholesteric liquid crystal film is formed in a substrate base plate; the mixture dispersion layer is subjected to regional exposure treatment, so that the cholesteric liquid crystal film is formed; and during the regional exposure treatment, each region of the mixture dispersion layer has specific exposure, and the cholesteric liquid crystal film formed in the corresponding region has a specific screw pitch. With the adoption of the technical scheme, the cholesteric liquid crystal film with various colors can be manufactured and formed simultaneously, so that the manufacturing efficiency is improved.

Owner:BOE TECH GRP CO LTD

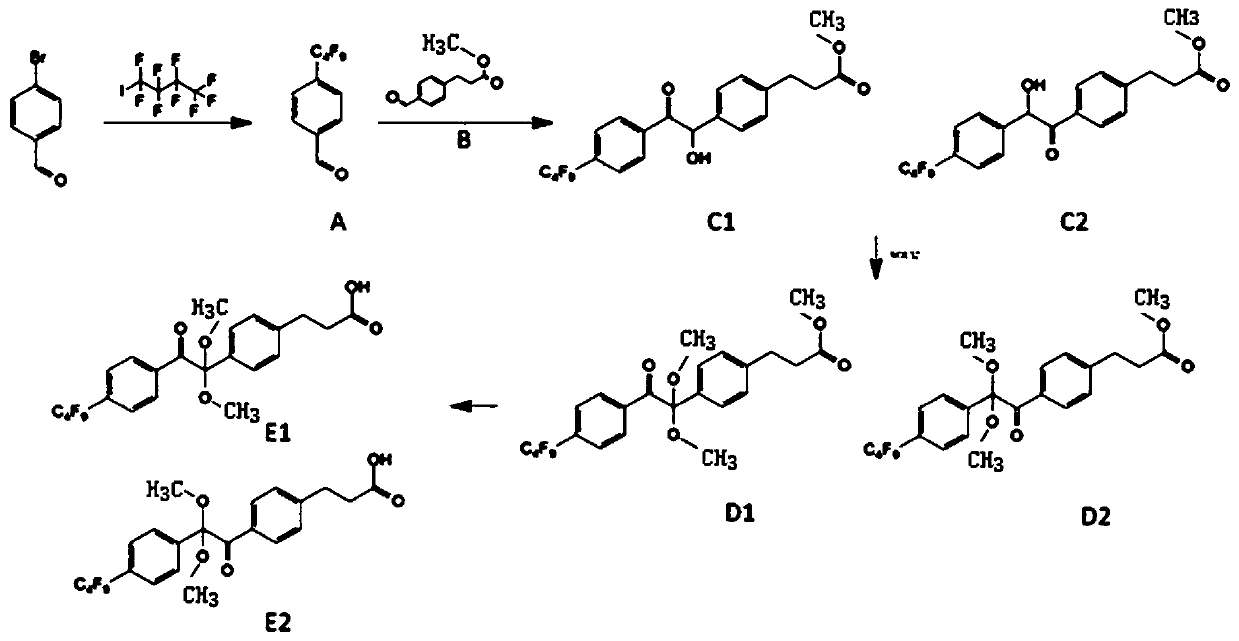

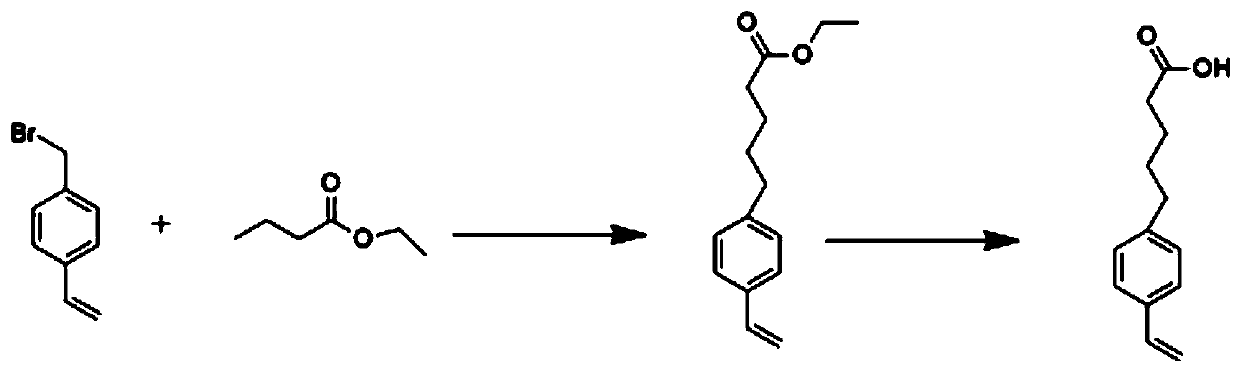

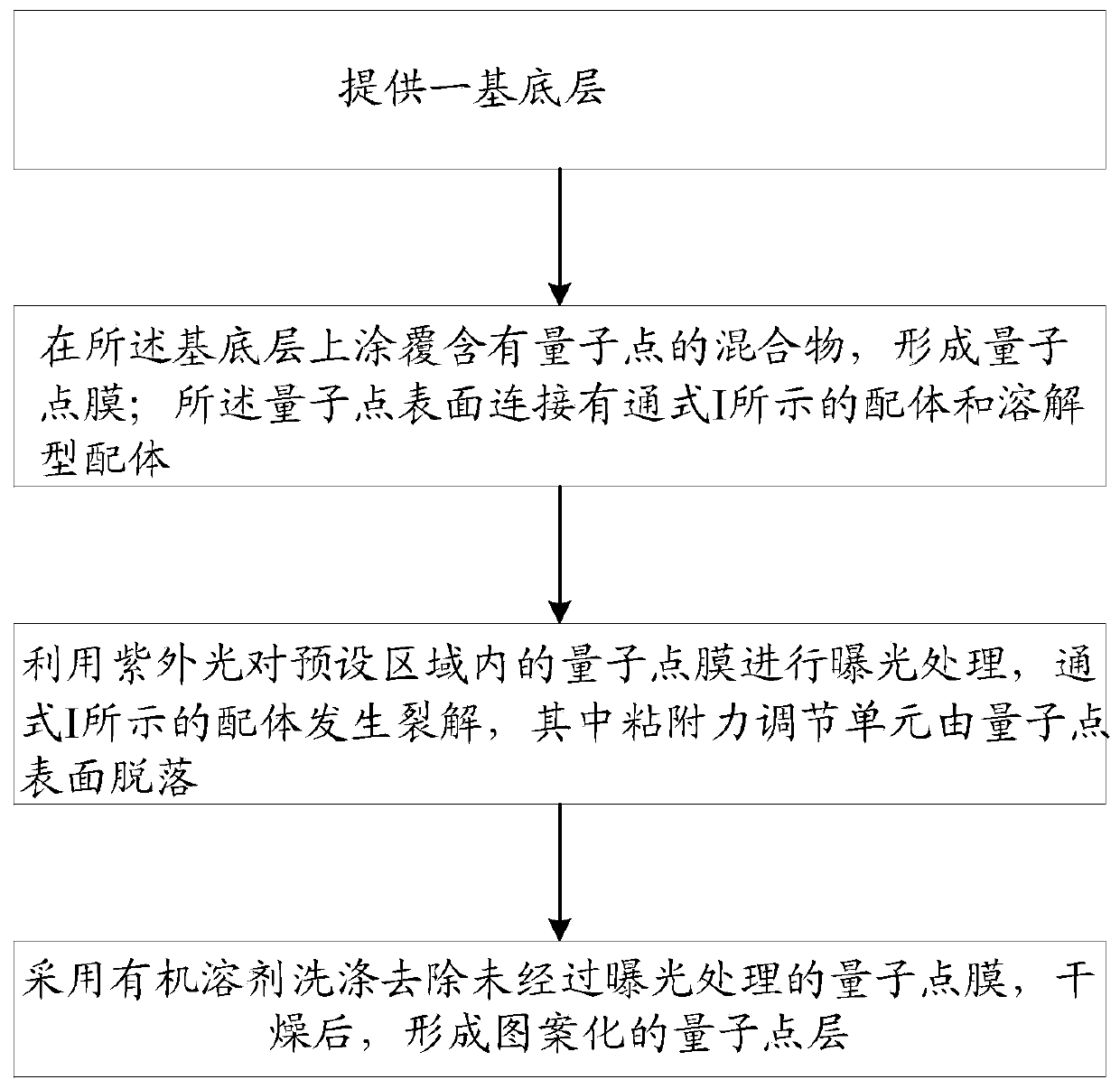

Ligand, quantum dot and patterning method of quantum dot layer

PendingCN110590549AReduce solubilityEasy to keepOrganic chemistrySolid-state devicesAdhesion forceOrganic solvent

The invention relates to the field of display, and in particular to a ligand, a quantum dot and a patterning method of a quantum dot layer. The invention provides the ligand, and the ligand comprisesa coordination unit, a cracking unit, and an adhesion force adjustment unit. The surface of the provided quantum dot is connected with the ligand. The provided patterning method is as follows: providing a base layer; coating the base layer with a mixture containing the quantum dot to form a quantum dot film; exposing the quantum dot film in a preset area by using ultraviolet light, wherein a photolysis reaction of the cracking unit in the ligand is carried out, and molecular segments containing the adhesion force adjustment unit fall off from the surface of the quantum dot after decomposing; and washing and removing the quantum dot film without exposure treatment by using an organic solvent, and performing drying to form a patterned quantum dot layer. The formed quantum dot layer has relatively high resolution.

Owner:BOE TECH GRP CO LTD

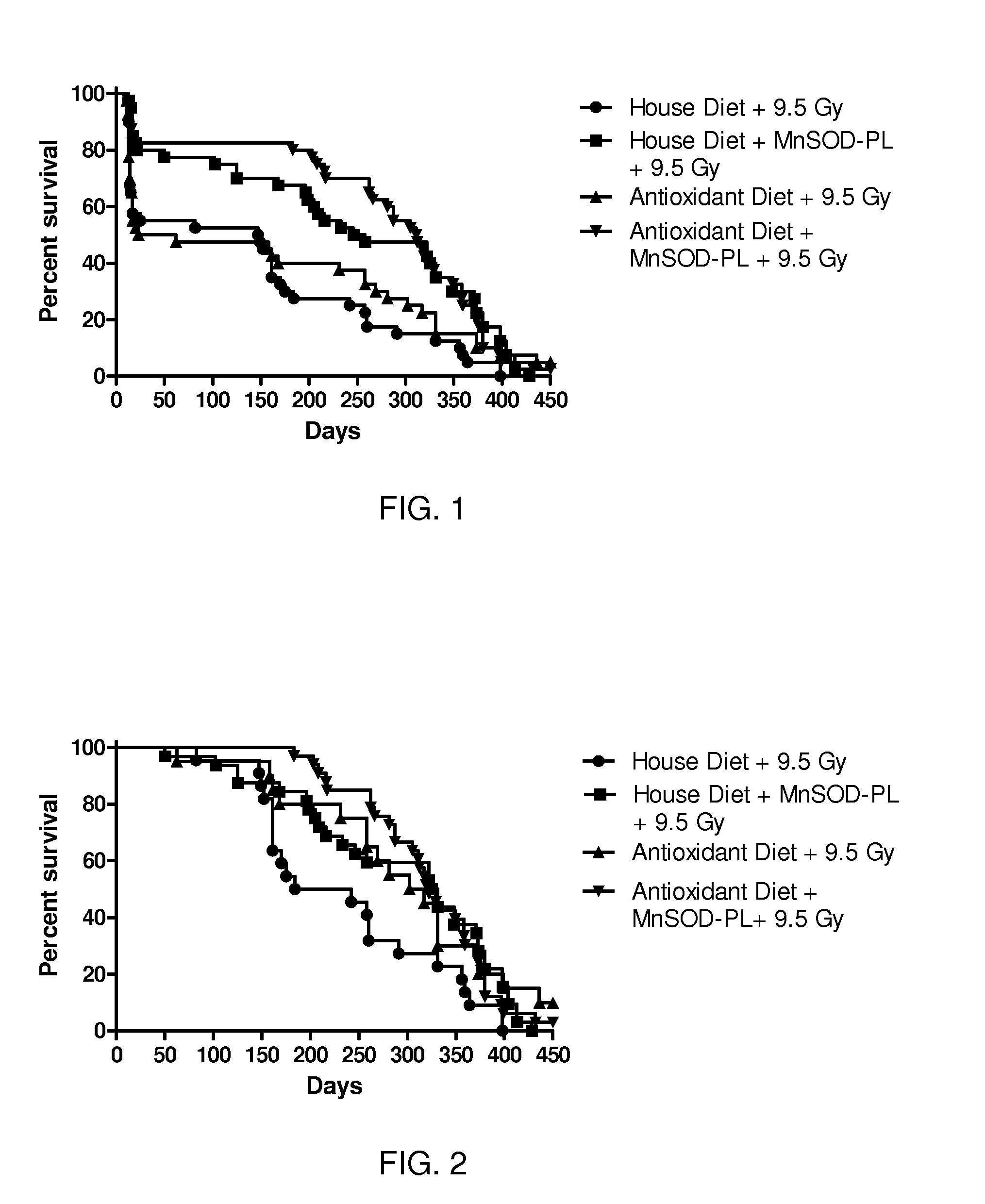

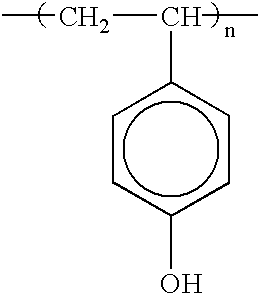

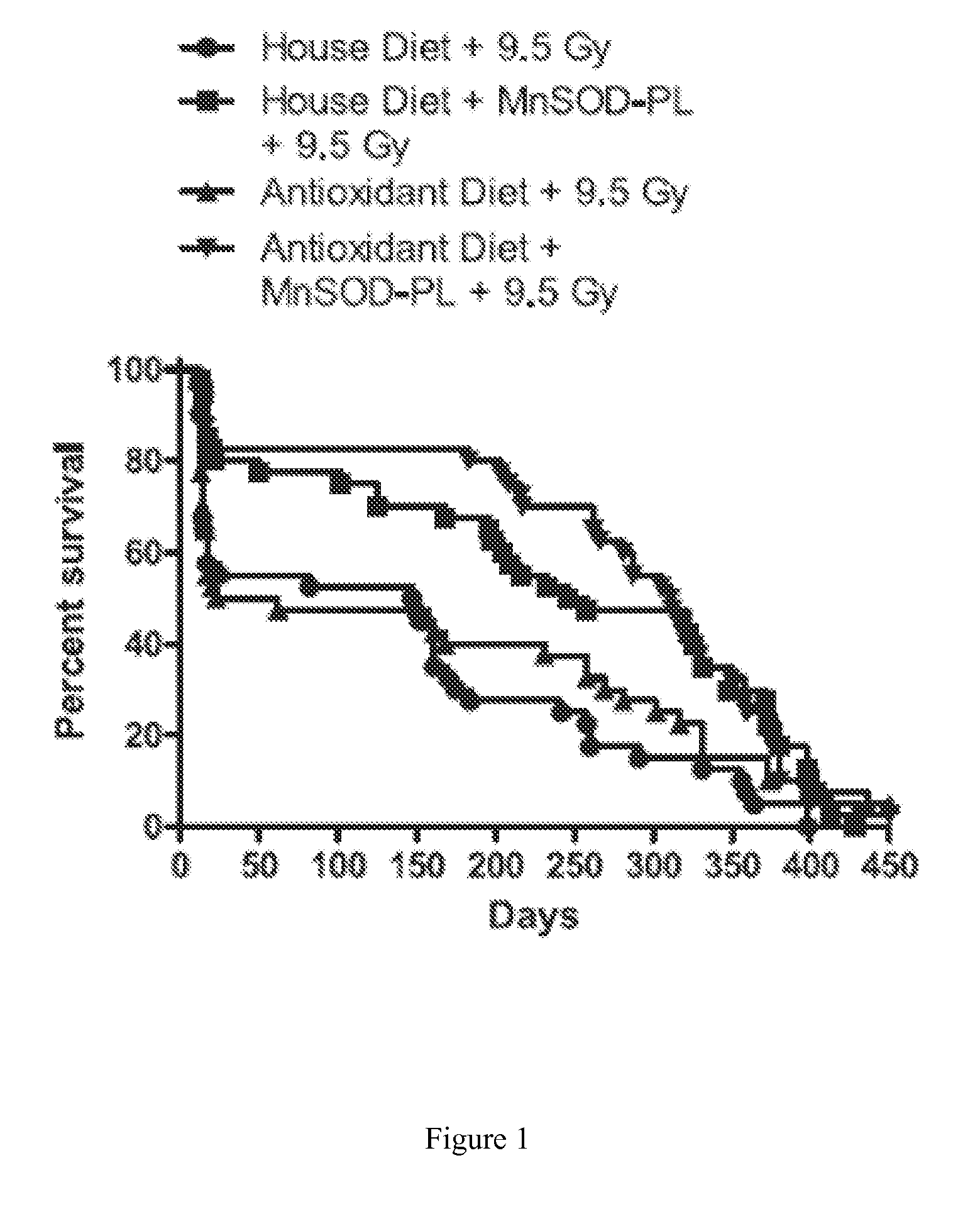

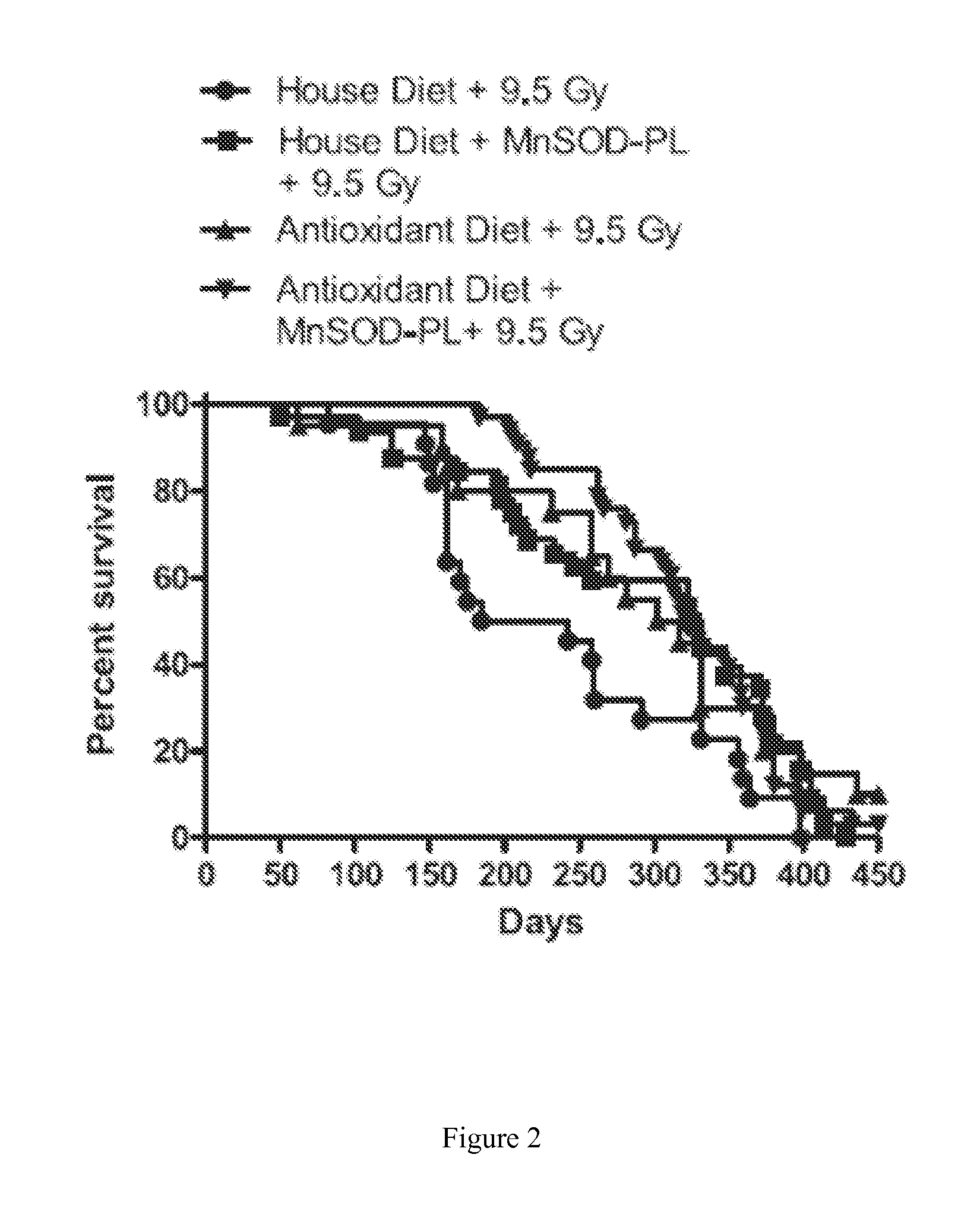

Method and Composition for Ameliorating the Effects tor a Subject Exposed to Radiation or Other Sources of Oxidative Stress

InactiveUS20140023701A1Reduce the impactBiocideHydrocarbon active ingredientsAlpha-Lipoic AcidIsoflavones

Radiation-oxidative exposure treatment compositions comprise a mixture of micronutrient multivitamin and trace elements, a mixture of antioxidants and chemopreventative agents, and optionally a mixture of fatty acids. Micronutrient multivitamin and trace elements mixtures include vitamins A, Bp, B1, B2, B3, B5, B6, B7, B9, B12, C, D, E and K; inositol; calcium, iodine, magnesium, zinc, selenium, copper, manganese, chromium, molybdenum, potassium, boron and vanadium. Mixtures of non-essential antioxidants and chemopreventative agents include bioflavins, alpha lipoic acid, N-acetyl-L-cysteine (optionally) lutein, lycopene, astaxanthin, plant sterols, isoflavones, garlic extract, which provides allicin; green tea extract, cruciferous vegetable extract, fruit extracts, coenzyme Q-10, and resveratrol. Fatty acid mixtures include eicosapentaenoic acid and docosahexaenoic acid.Methods of treatment of a subject exposed to a radiation source or an oxidative stress with the radiation-oxidative exposure treatment composition include the step of administering to the subject a daily dose of the radiation-oxidative exposure treatment composition such that the life shortening effects induced by the radiation source or the oxidative stress are ameliorated.

Owner:NUGEVITY +1

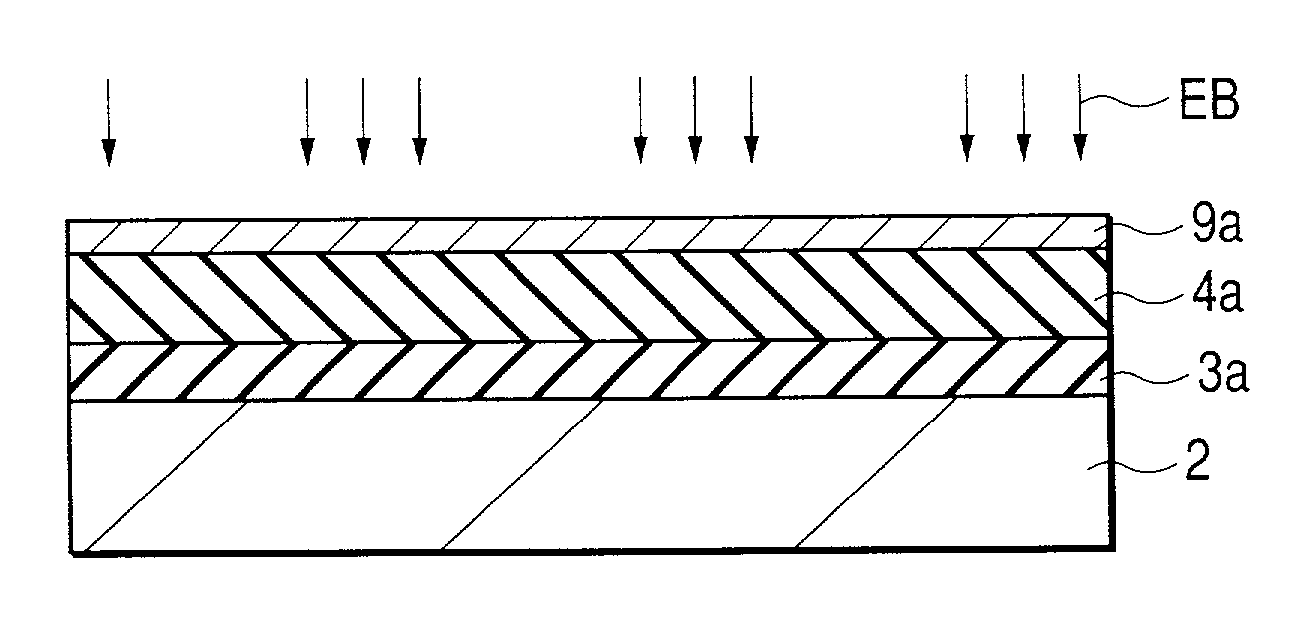

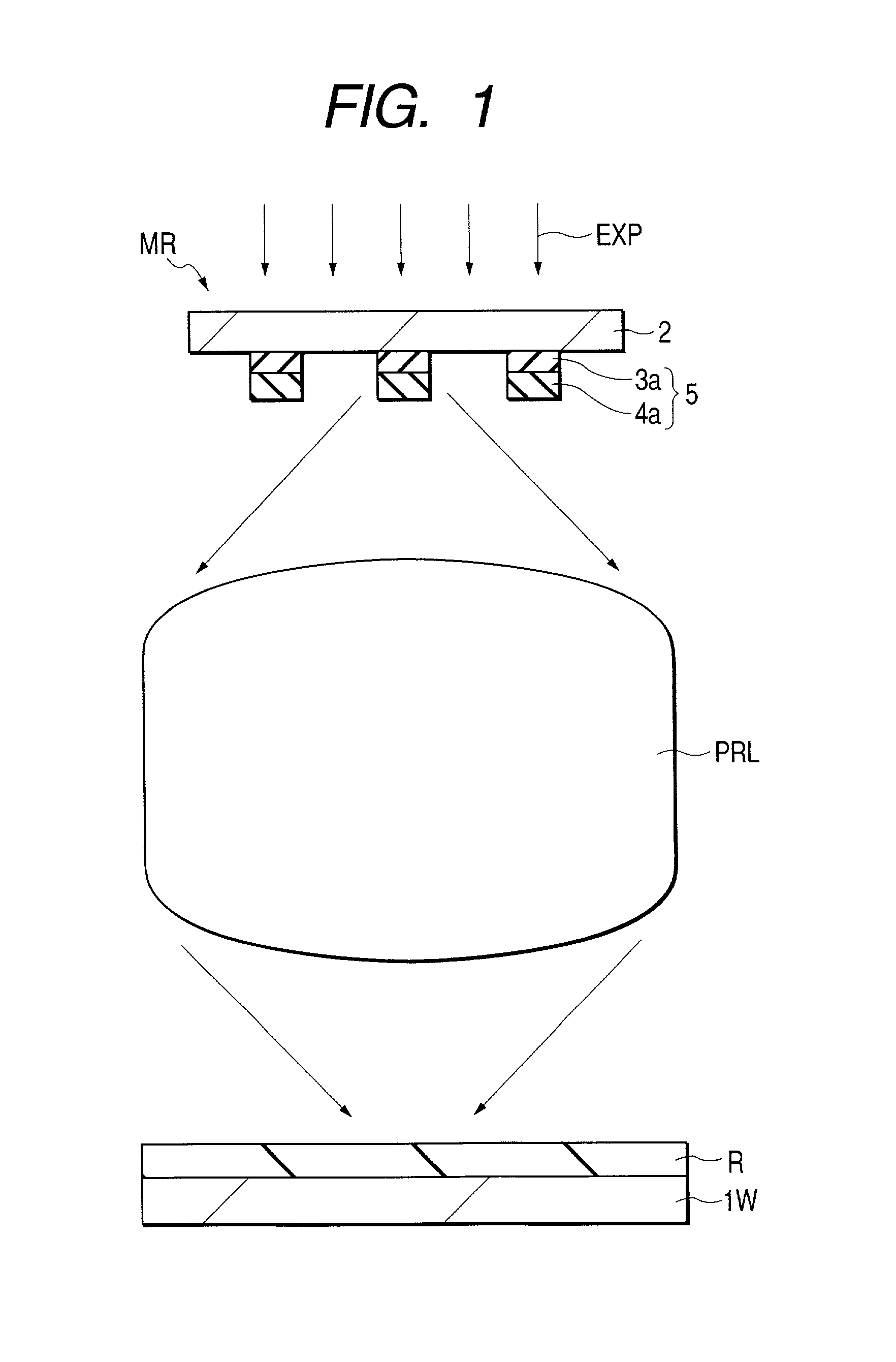

Method of manufacturing a semiconductor device

InactiveUS20020052122A1Shorten the overall cycleLow costElectric discharge tubesSemiconductor/solid-state device manufacturingResistOrganic layer

Well printing a specified pattern even when exposure treatment using a resist mask uses exposure light with a wavelength over 200 nm. When exposure treatment is applied to a semiconductor wafer 1W by using exposure light EXP with a wavelength over 200 nm, a photomask MR is used. The photomask MR is provided with an opaque pattern 5 comprising a resist layer 4a on a photoabsorptive organic layer 3a in reaction to exposure light EXP.

Owner:HITACHI LTD

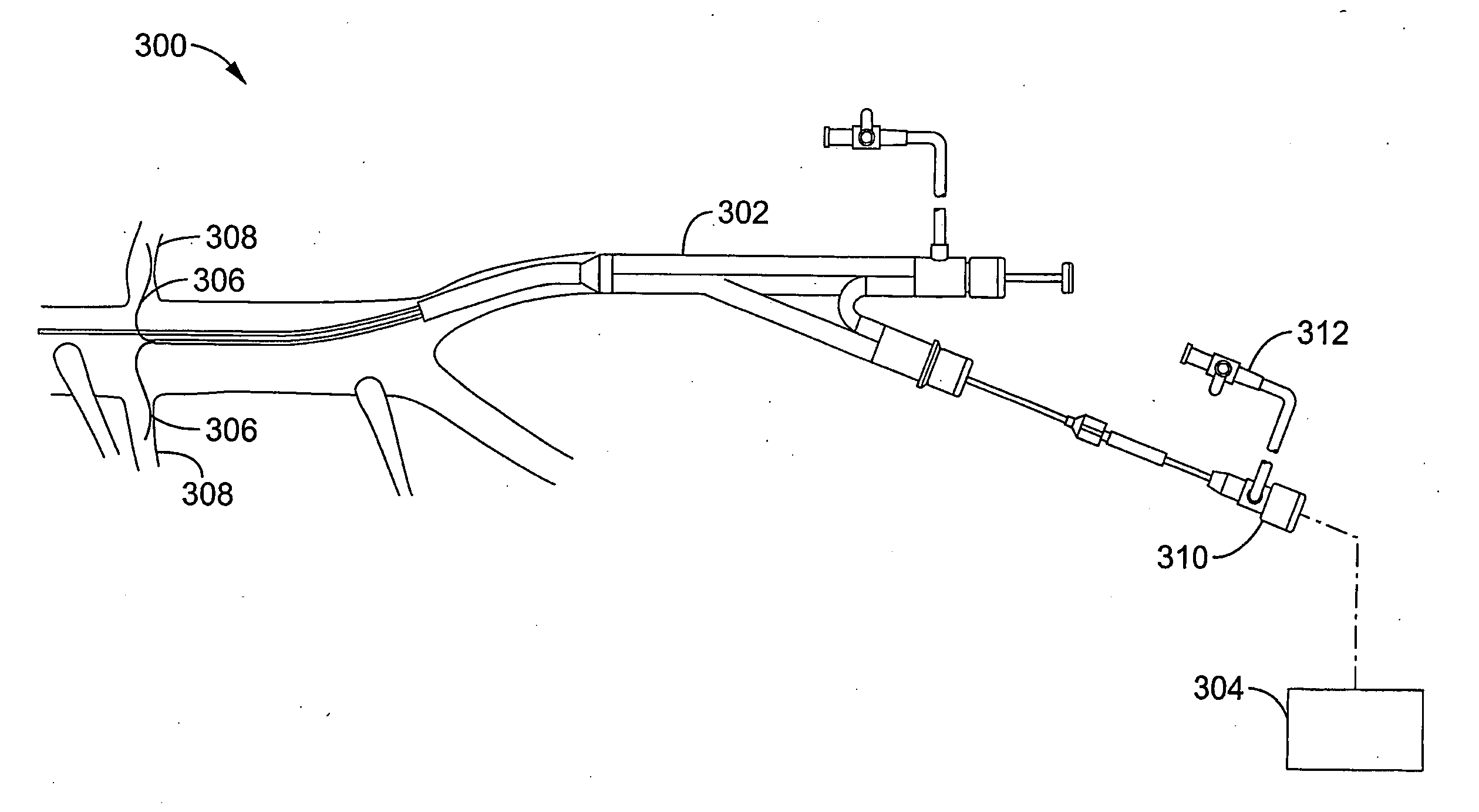

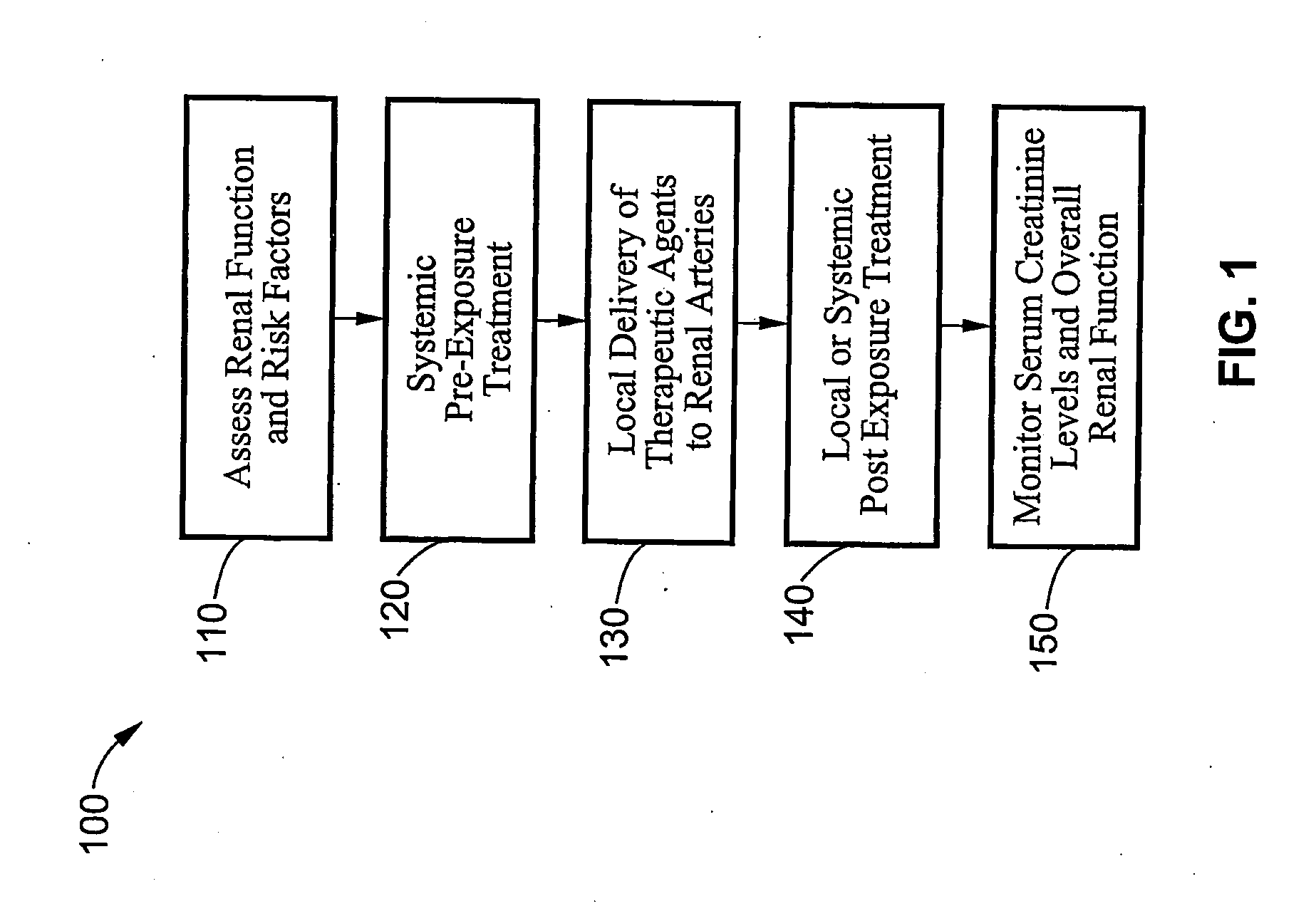

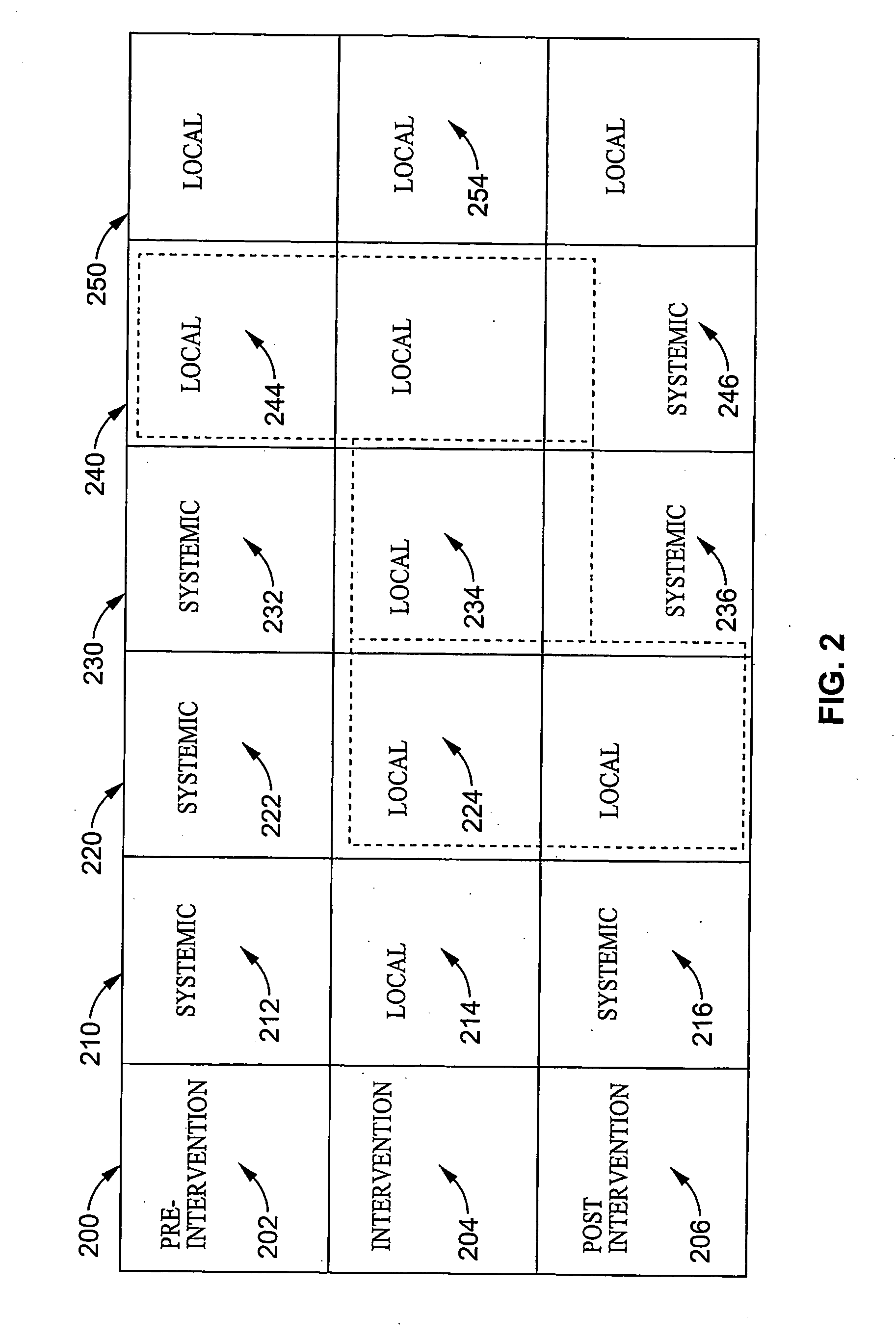

System and method for prevention of radiocontrast induced nephropathy

InactiveUS20070213686A1Reduce riskIncrease blood flowBalloon catheterMulti-lumen catheterLower riskVascular dilatation

An apparatus and method particularly useful in treatments and therapies directed at the kidneys such as the prevention of radiocontrast nephropathy (RCN) arising from diagnostic procedures using iodinated contrast materials. A series of treatment schemes are provided based upon local therapeutic agent delivery to the kidneys that can be used as a prophylactic treatment for patients undergoing interventional procedures that have been identified as being at an elevated risk for developing RCN as well as for low risk patients. The methods may include pre-exposure and post contrast exposure treatments alone or in combination with the local delivery of therapeutic agents to the kidneys. Among the agents identified for such treatments are normal saline and the vasodilators papaverine and fenoldopam mesylate and appropriate dosing is provided.

Owner:ANGIODYNAMICS INC

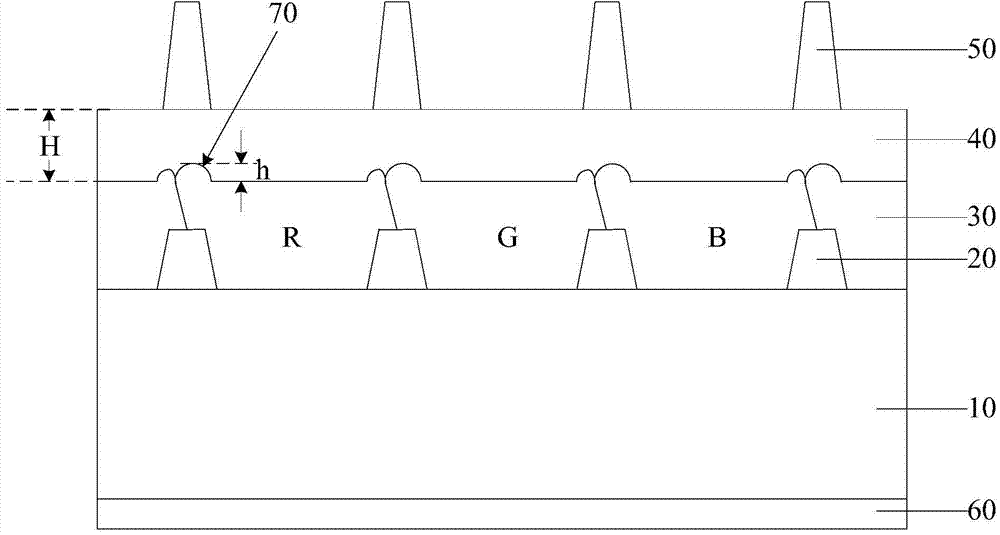

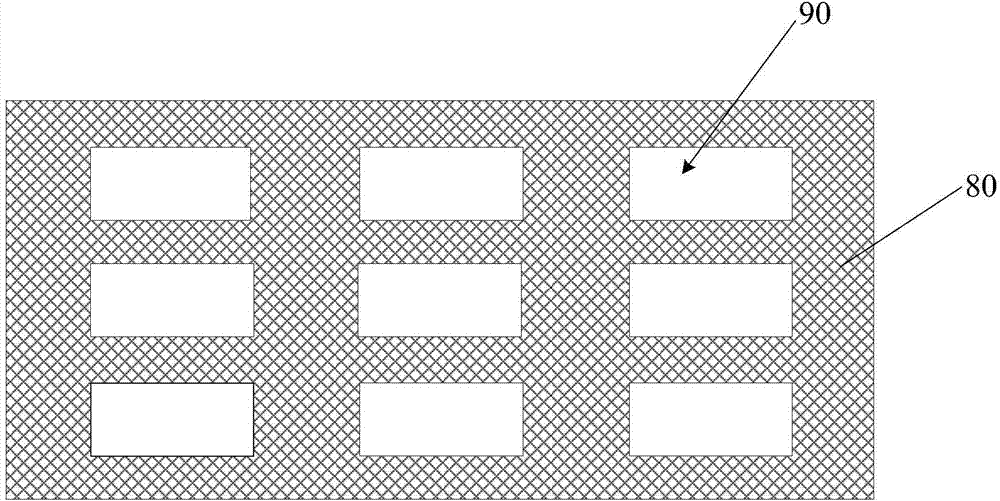

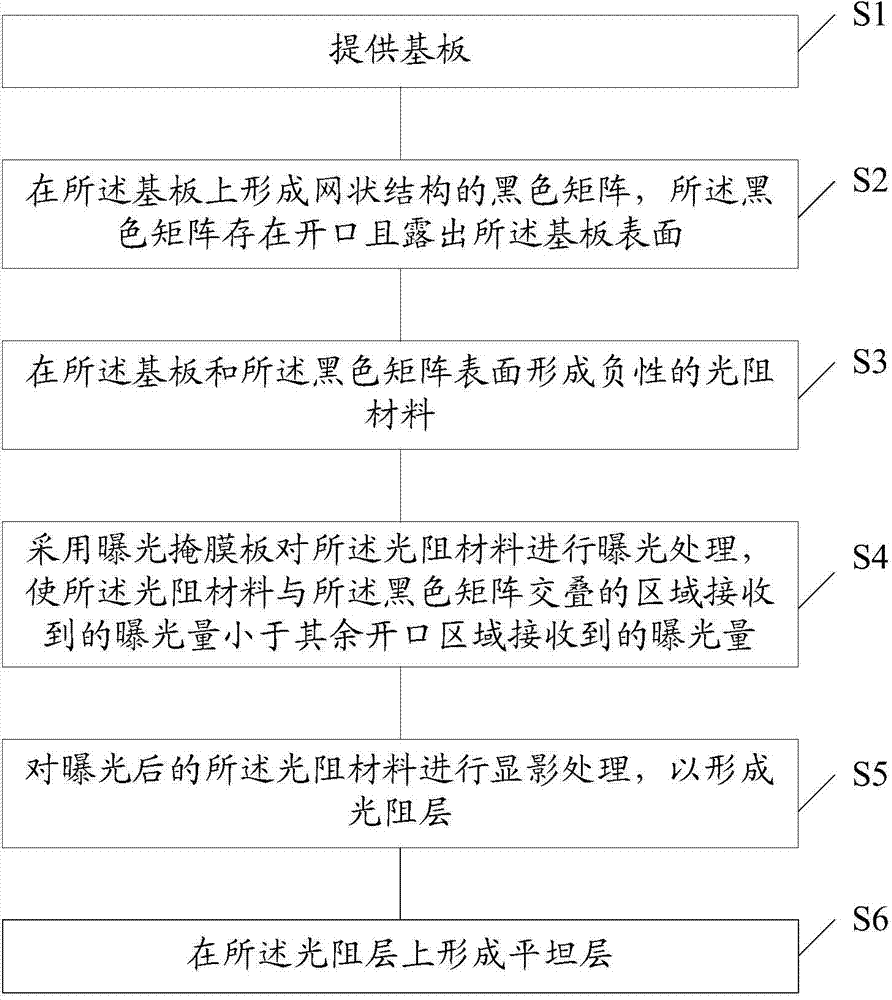

Light filter manufacturing method and exposure mask plate

InactiveCN104749674ALow costImprove the display effectOptical filtersPhotomechanical exposure apparatusLiquid-crystal displayEngineering

Provided are a light filter manufacturing method and an exposure mask plate. The light filter manufacturing method comprises the step of providing a substrate; forming a black matrix with a net structure on the substrate, wherein the black matrix is provided with an opening and exposed out of the surface of the substrate; forming a negative photoresist material on the surfaces of the substrate and the black matrix; adopting the exposure mask plate to conduct exposure treatment on the photoresist material and enabling the exposure amount received by a overlapped region of the photoresist material and the black matrix to be smaller than the exposure amount received by the residual open region; conducting developing treatment on the exposed photoresist material to form a light resistance layer. The exposure mask plate is used for the light filter manufacturing method. The exposure mask plate comprises a shading region and an exposure region, wherein multiple protrusion structures are arranged at the edge position in contact with the exposure region in the shading region. The horned portions of the light resistance layer can be decreased or eliminated, the phenomenon that poor liquid crystal deflection caused by too thick horns influences a light filer and the display performance of a liquid crystal display is prevented, and further the cost of light filter can be reduced.

Owner:INESA DISPLAY MATERIALS

Method for developing processing and apparatus for supplying developing solution

InactiveUS20050053874A1Improved CD uniformityInhibition of defect generationPhotoprinting processesSemiconductor/solid-state device manufacturingResistEngineering

In a developing processing of a wafer having a resist film low in the dissolving rate in a developing solution formed thereon and subjected to an exposure treatment, a developing solution of a low concentration is supplied first onto a wafer and the wafer is left to stand for a prescribed time to permit a developing reaction to proceed, followed by further supplying a developing solution having a concentration higher than that of the developing solution supplied first onto the wafer, leaving the substrate to stand and subsequently rinsing the wafer, thereby improving the uniformity of the line width in the central portion and the peripheral portion of the wafer.

Owner:TOKYO ELECTRON LTD

Production technology of double-sided PCB

ActiveCN105555046AThe mass concentration is reasonableImprove air tightnessConductive material chemical/electrolytical removalCircuit precursor manufactureResistMetallurgy

The invention relates to the technical field of PCBs, in particular to a production technology of a double-sided PCB. The technology sequentially comprises the following steps: double-sided copper foil substrate pretreatment, line coating and exposure treatment, line development, etching, de-inking treatment, solder resist pretreatment, solder resist development, lettering treatment, molding treatment, testing and antioxidant treatment. A copper foil substrate is subjected to surface polish-brush treatment through a polish-brush; a photosensitive ink layer and a solder resist ink layer coat the surface of the copper foil substrate; relatively high adsorption force is provided among the photosensitive ink layer, the solder resist ink layer and the copper foil substrate; the photosensitive ink layer and the solder resist ink layer are good in quality; and the produced PCB is good in quality. Cutting treatment is carried out on the copper foil substrate by a V-Cut technology; and the minimum thickness of the formed substrate corresponding to a V-shaped plate-dividing groove is controlled at 0.4-0.5mm, so that subsequent plate division is facilitated; and no burr is left.

Owner:湖北碧辰科技股份有限公司 +1

Method and composition for ameliorating the effects for a subject exposed to radiation or other sources of oxidative stress

Radiation-oxidative exposure treatment compositions may include a mixture of micronutrient multivitamin and trace elements, a mixture of antioxidants and chemopreventative agents, and optionally a mixture of fatty acids. Methods of treatment of a subject exposed to a radiation source or an oxidative stress with the radiation-oxidative exposure treatment composition may include the step of administering to the subject a daily dose of the radiation-oxidative exposure treatment composition such that the life shortening effects induced by the radiation source or the oxidative stress are ameliorated.

Owner:NUGEVITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com