Light-modulating element, display element, and exposure element

a technology of display elements and exposure elements, applied in the field of light-modulating elements, display elements, exposure elements, can solve the problems of low light utilization efficiency, deterioration of image quality, and existing flat display elements described above, and achieve the effect of improving light utilization efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0229] the invention constituted by two-dimensionally arranging display elements described above will be explained below by means of FIG. 12 and FIG. 13.

[0230]FIG. 12 is a plan view of a flat display element comprising two-dimensionally arranged display elements employing a flexible this film. FIG. 13 is sectional views taken on C-C of FIG. 12; (a) is a view illustrating the OFF state and (b) is a view illustrating the ON state.

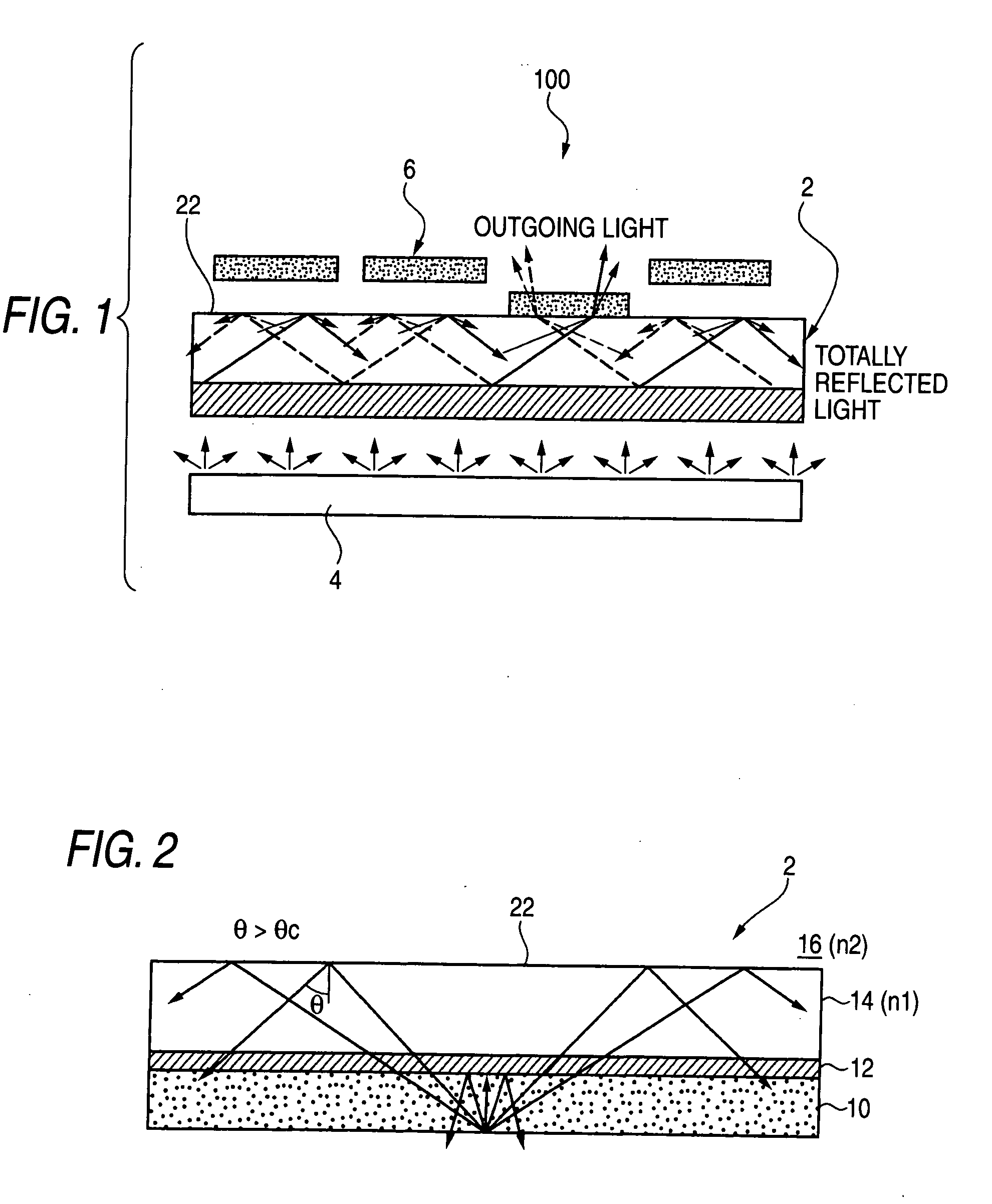

[0231] As shown in FIG. 12 and FIG. 13, the flat display element 200 according to this embodiment comprises a total-reflection optical member 2 and light-coupling elements 6 disposed over the total reflection plane 22 of the optical member 2 in two-dimensional arrangement with m lines and n rows (m and n are integers). Specifically, signal electrodes 32 transparent to incident light have been arranged in parallel in the row direction so as to constitute n rows over the total reflection plane 22, and scanning electrodes 34 likewise transparent to incident lig...

third embodiment

[0236] Next, the invention in which ultraviolet is modulated with the display element of the invention to cause phosphors to show excitation luminescence will be explained.

[0237]FIG. 14 is a plan view of an excitation luminescence type flat display element comprising the flat display element described above and phosphors disposed on the viewing side thereof. FIG. 15 is sectional views taken on D-D of FIG. 14; (a) is a view illustrating the OFF state and (b) is a view illustrating the ON state.

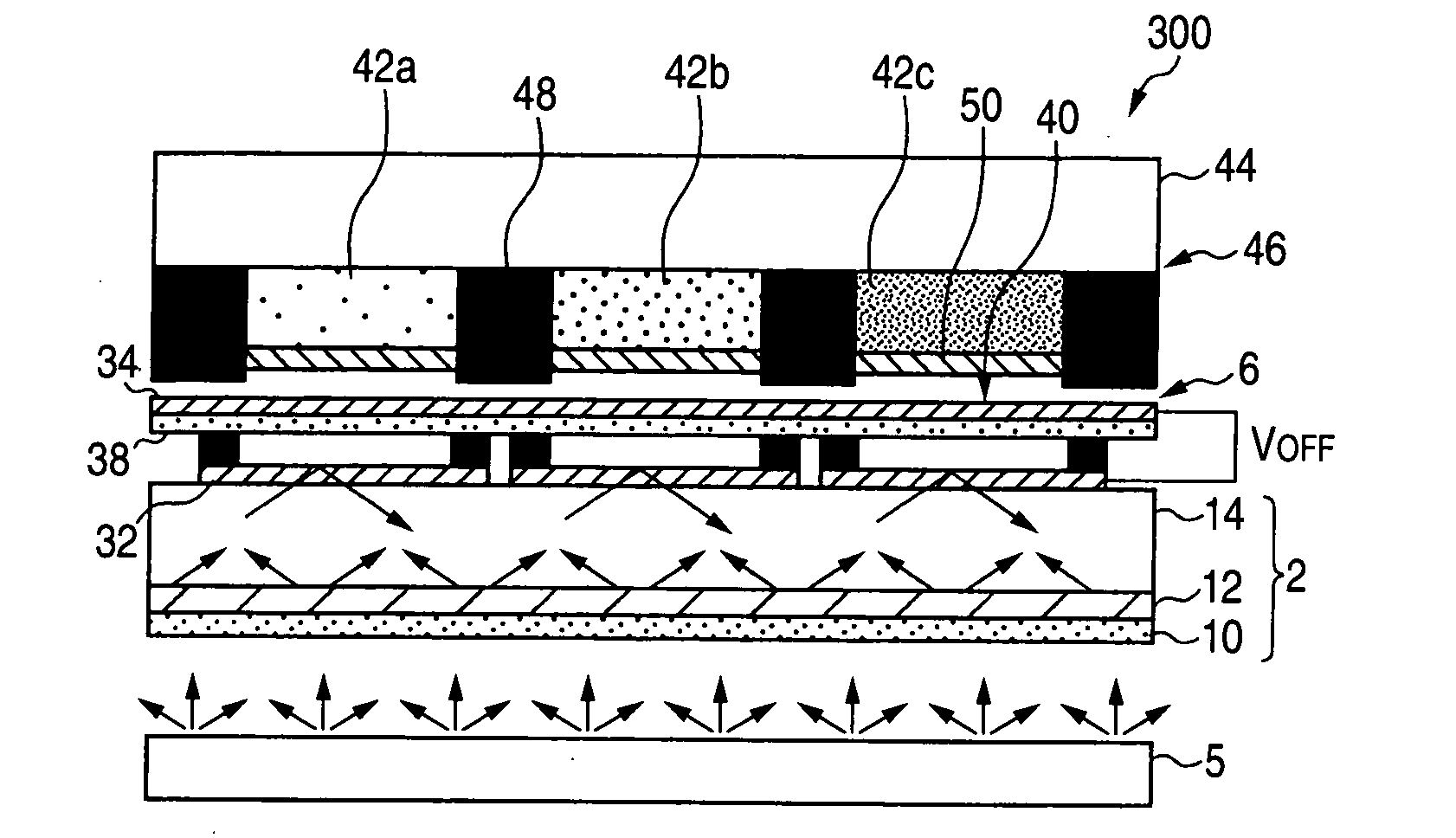

[0238] As shown in FIG. 14 and FIG. 15, the excitation luminescence type flat display element 300 according to this embodiment has the same constitution as the flat display element 200 described above, except that the flat light source 4 has been replaced with a UV flat light source 5 which emits planar UV light and that a front-side plate 46 comprising a transparent substrate 44 and phosphors formed thereon has been disposed so as to face the flexible thin film 40 of the total-reflection opti...

fourth embodiment

[0248] the invention in which ultraviolet is modulated with the display element of the invention to cause phosphors to show excitation luminescence will be explained below.

[0249]FIG. 16 is sectional views illustrating part of an excitation luminescence type flat display element according to this embodiment which includes a flexible thin film and formed thereon the phosphors of the excitation luminescence type flat display element described above; (a) is a view illustrating the OFF state and (b) is a view illustrating the ON state.

[0250] As shown in FIG. 16(a), the excitation luminescence type flat display element 400 according to this embodiment has no front-side plate and has phosphors 52a, 52b, and 52c directly formed on the flexible thin film 40. Thus, the constitution and molding step have been simplified, and a further reduction in thickness and a cost reduction are attained. The phosphors 52a, 52b, and 52c are partitioned by a black matrix to thereby enhance the contrast of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com