Optical switch and fabrication method thereof

An optical switch and manufacturing method technology, applied in optics, optical components, manufacturing tools, etc., can solve the problems of reducing the accuracy of etching patterns, rough sidewalls of micro mirrors, increasing etching masks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

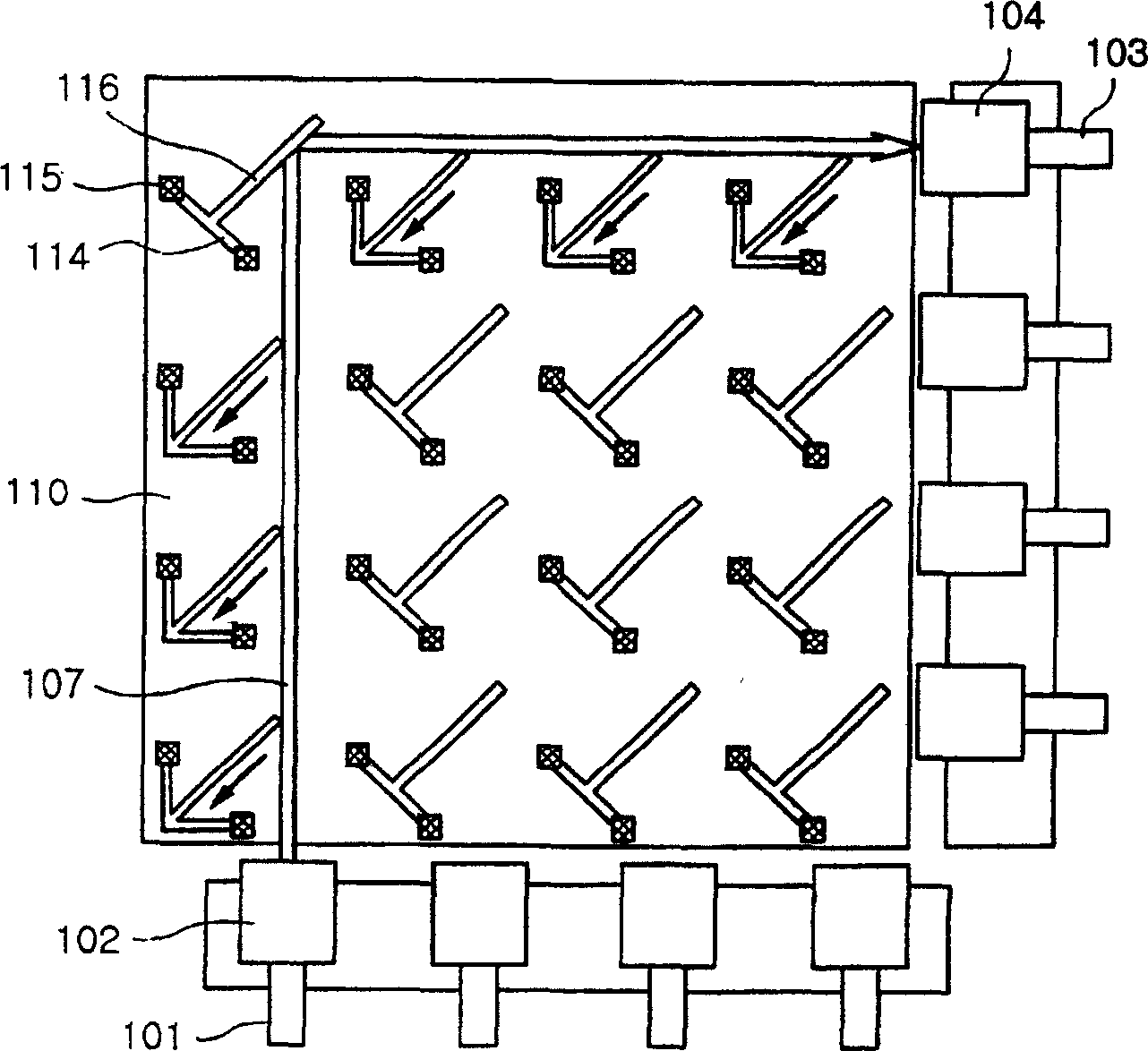

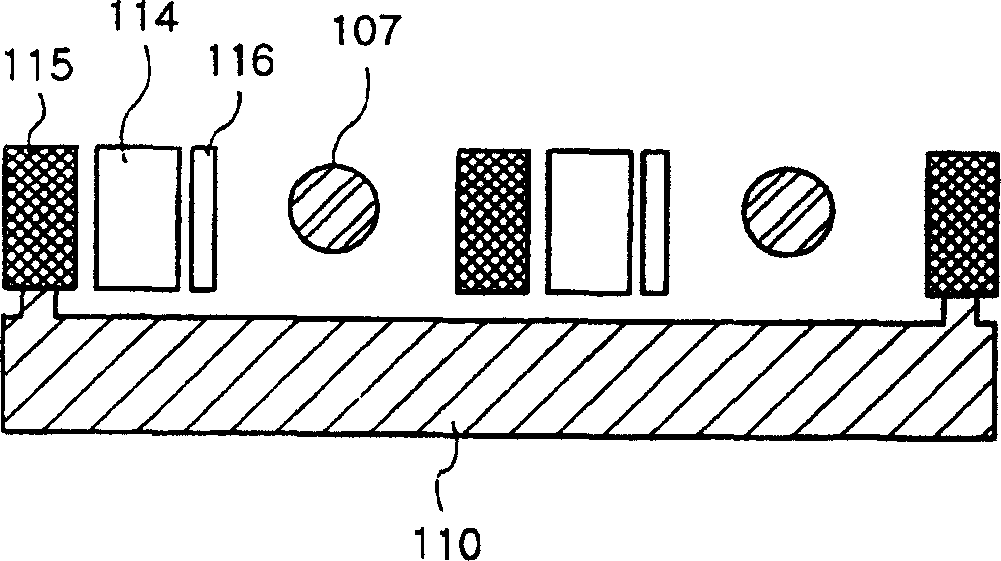

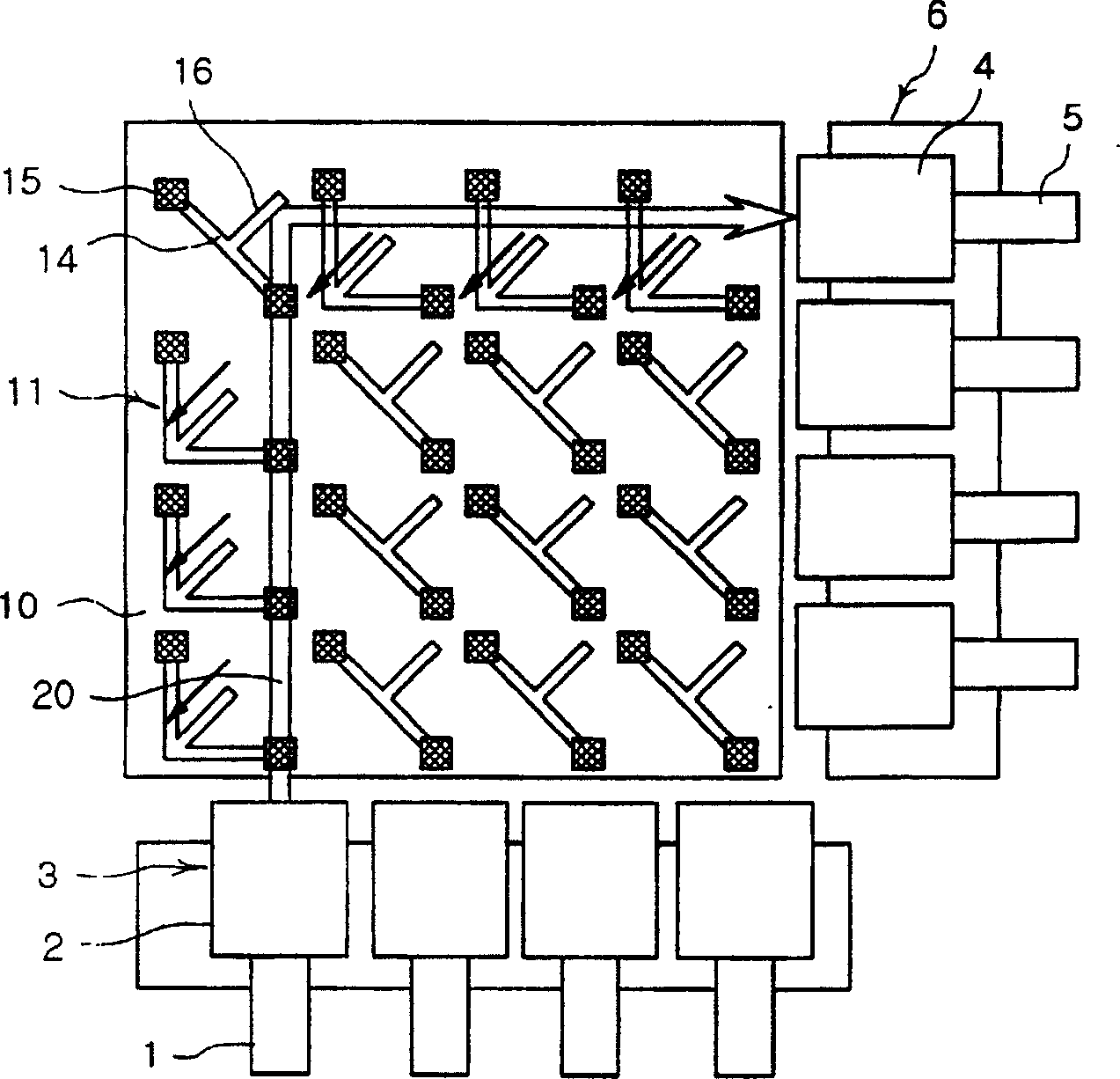

[0040] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, in which image 3 is a plan view of the optical switch of the present invention, Figure 4 It is a sectional view of the optical switch of the present invention.

[0041] The optical switch of the present invention is designed such that, in the direction crossing the optical signal, the micro mirror on the optical path can be moved by the actuating element, and the actuating element is located on a layer different from the optical path, so as to improve integration.

[0042] exist image 3Among them, the optical switch includes an optical signal input terminal 3 and an optical signal output terminal 6 located on the base layer. The optical signal input end 3 includes N optical fibers 1 arranged at predetermined intervals, and a lens 2 for preventing optical signal scattering is connected to the end of the optical fibers 1 . Likewise, the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com