Laser direct plate marking device for plane screen print plate and device

A technology of screen printing and laser directing, applied in the exposure device of photoplate making process, photoplate making process of pattern surface, printing, etc., can solve the problems of high cost of consumables, high cost of consumables, loss of image details, etc., and achieve mechanical structure Reasonable design, convenient installation and layout, convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

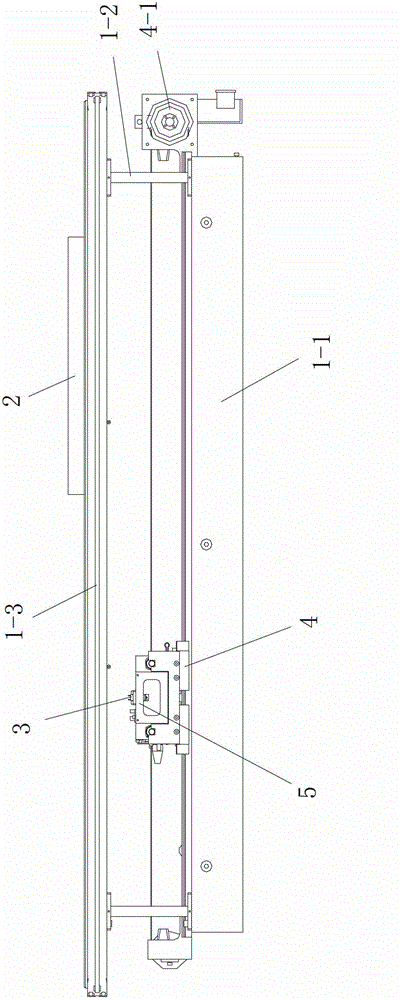

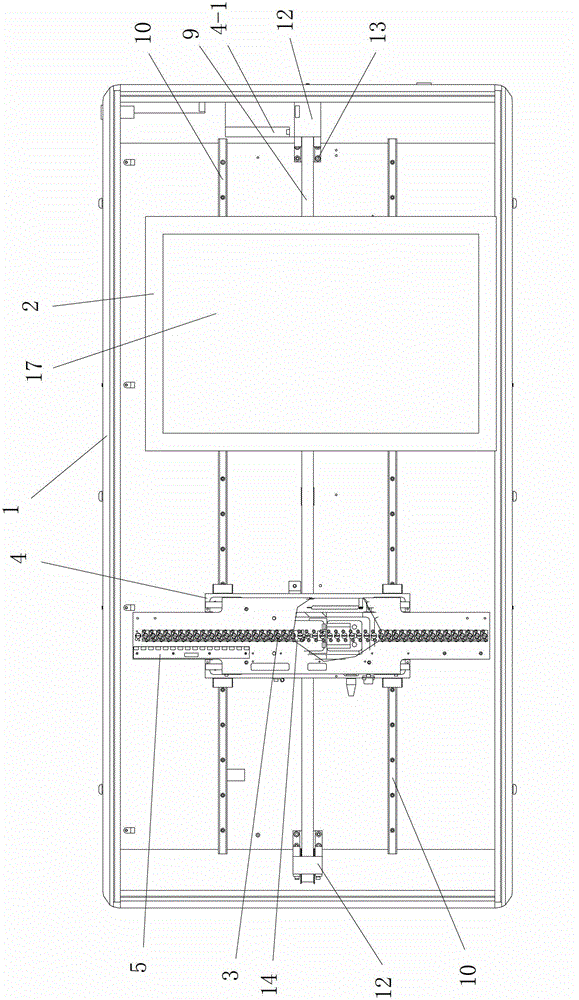

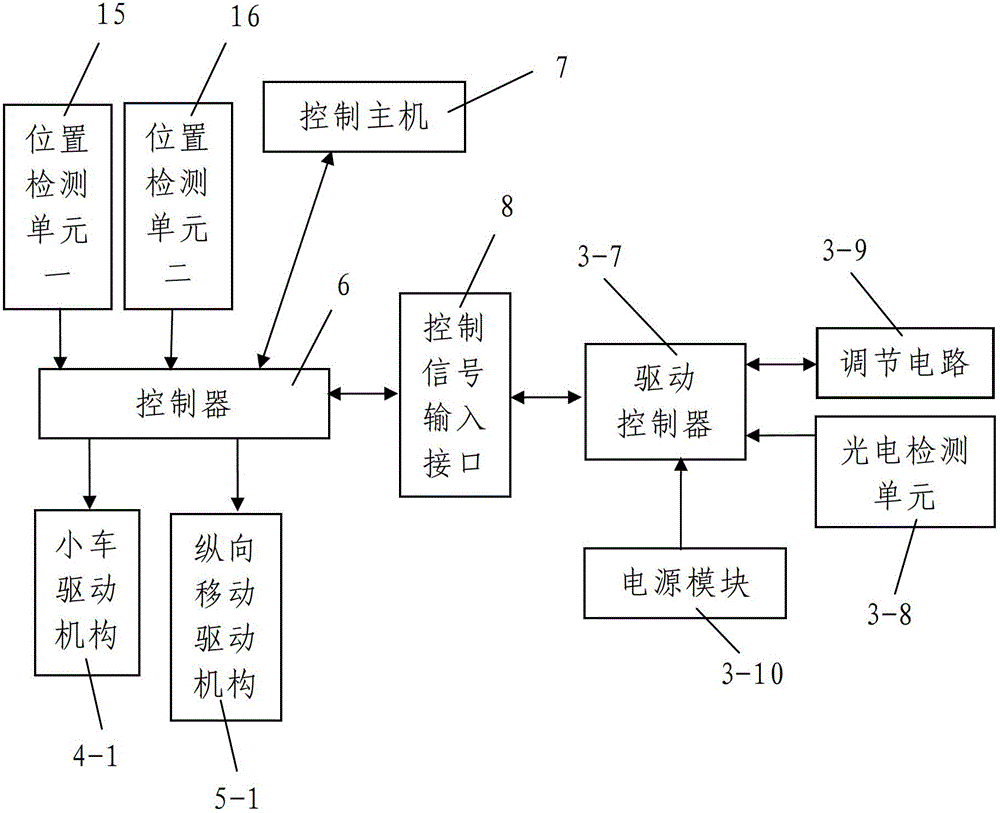

[0059] Such as figure 1 , figure 2 and image 3A laser direct plate-making device for planar screen printing is shown, including a screen frame 2 for screen printing installed on an exposure platform 1, stretched on the screen frame 2 for screen printing, and coated with a photosensitive material at the bottom The coated screen 17, the optical assembly located under the screen frame 2 for screen printing, which exposes the photosensitive material coating and obtains the exposed imaging pattern, and drives the optical assembly to reciprocate left and right on the horizontal plane The scanning trolley 4 and the longitudinal moving part that drives the optical assembly to move back and forth on the horizontal plane. The screen frame 2 for screen printing is a rectangular screen frame arranged horizontally. The optical assembly includes a plurality of lasers 3 arranged on the same horizontal plane, and the plurality of lasers 3 are arranged on the same straight line L from fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com