Patents

Literature

191results about How to "Inhibition of defect generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

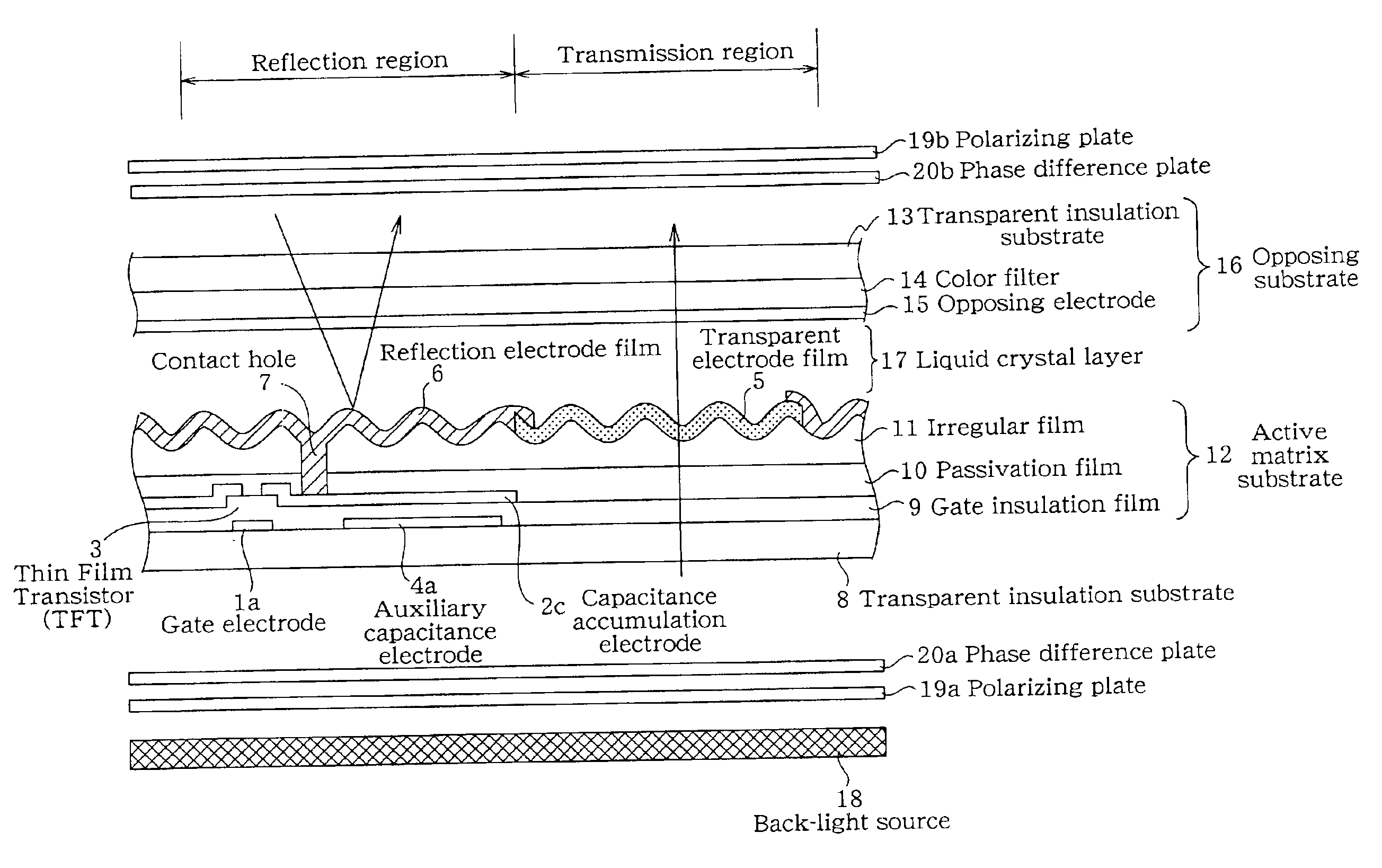

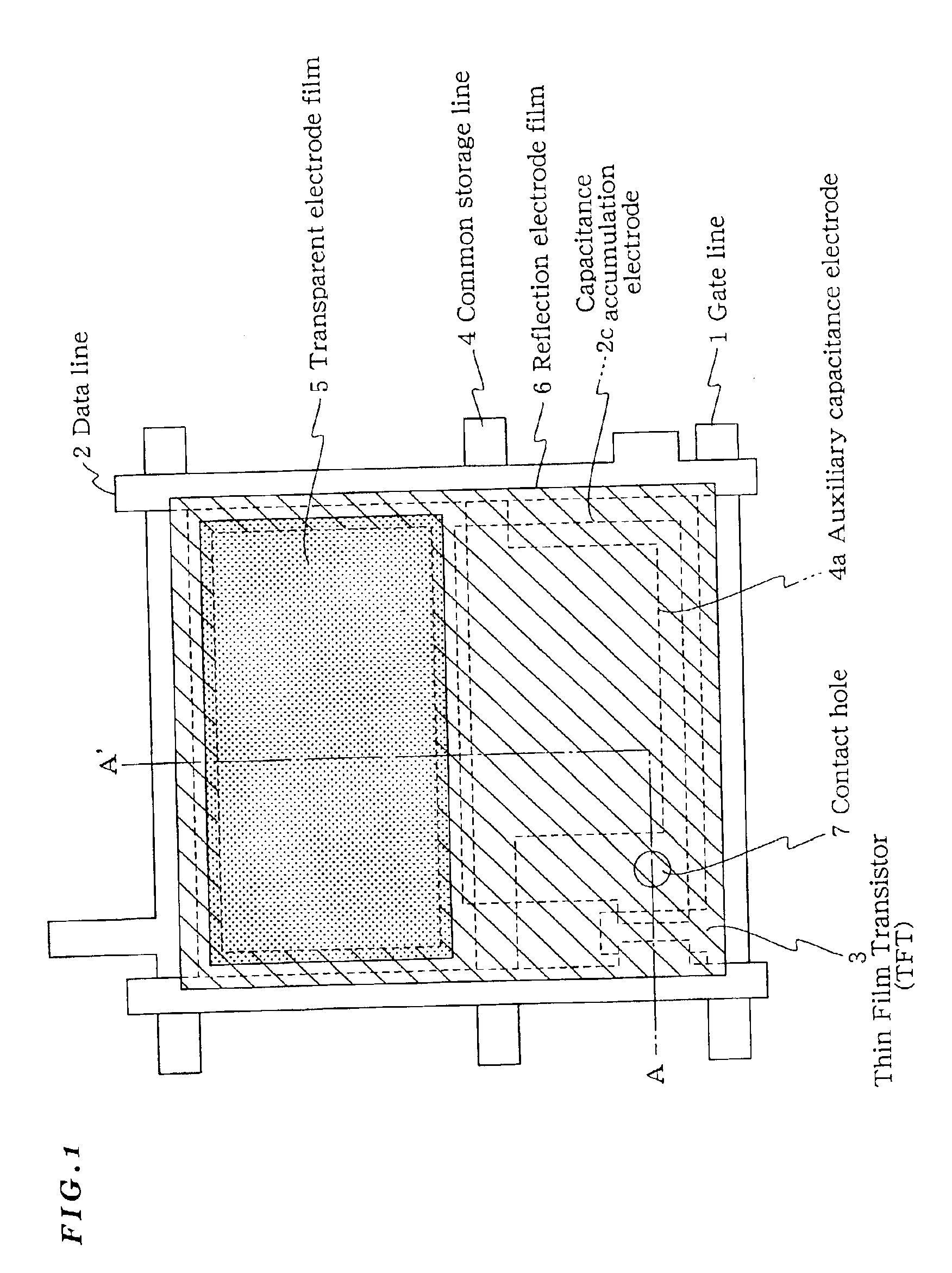

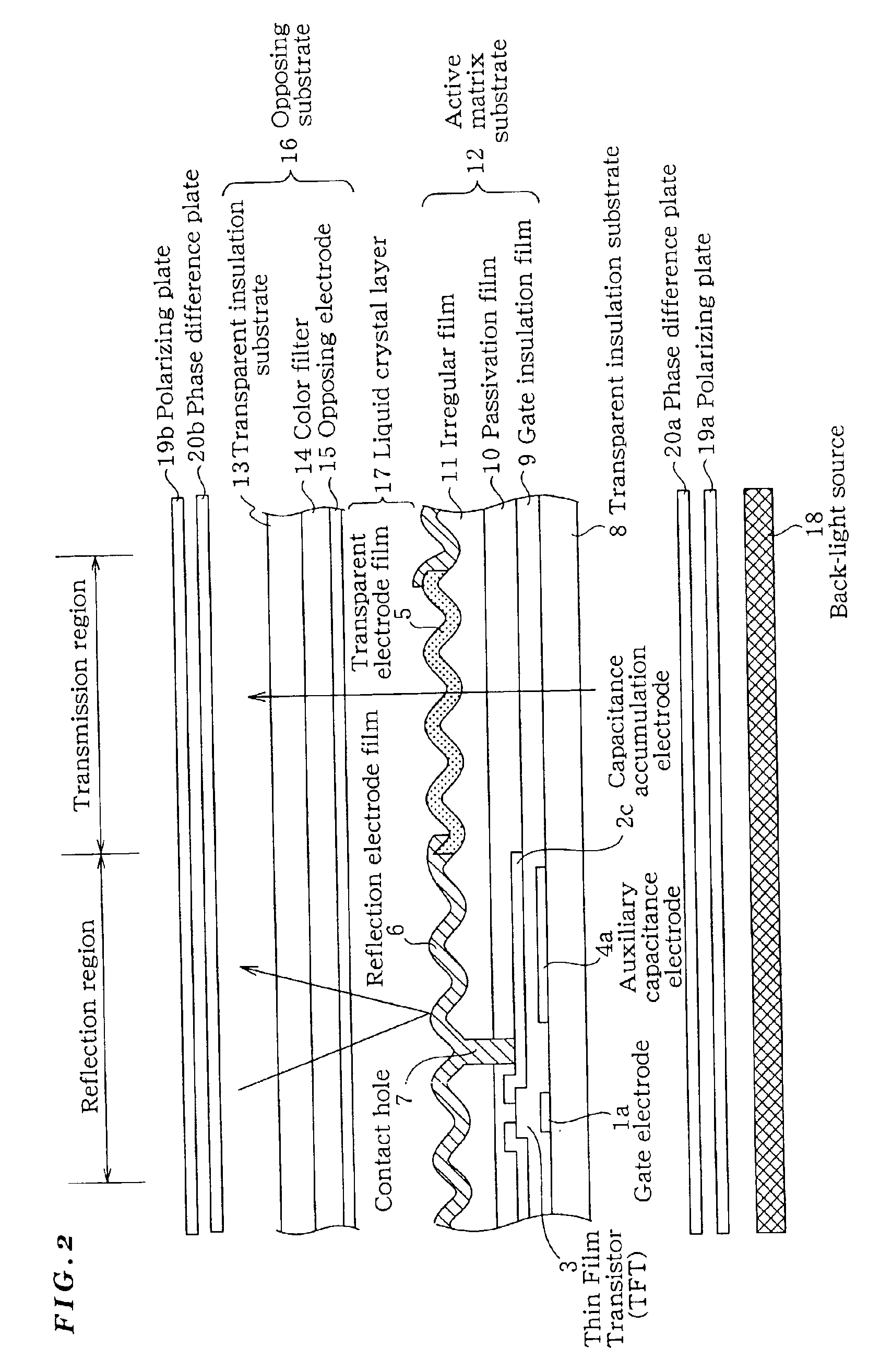

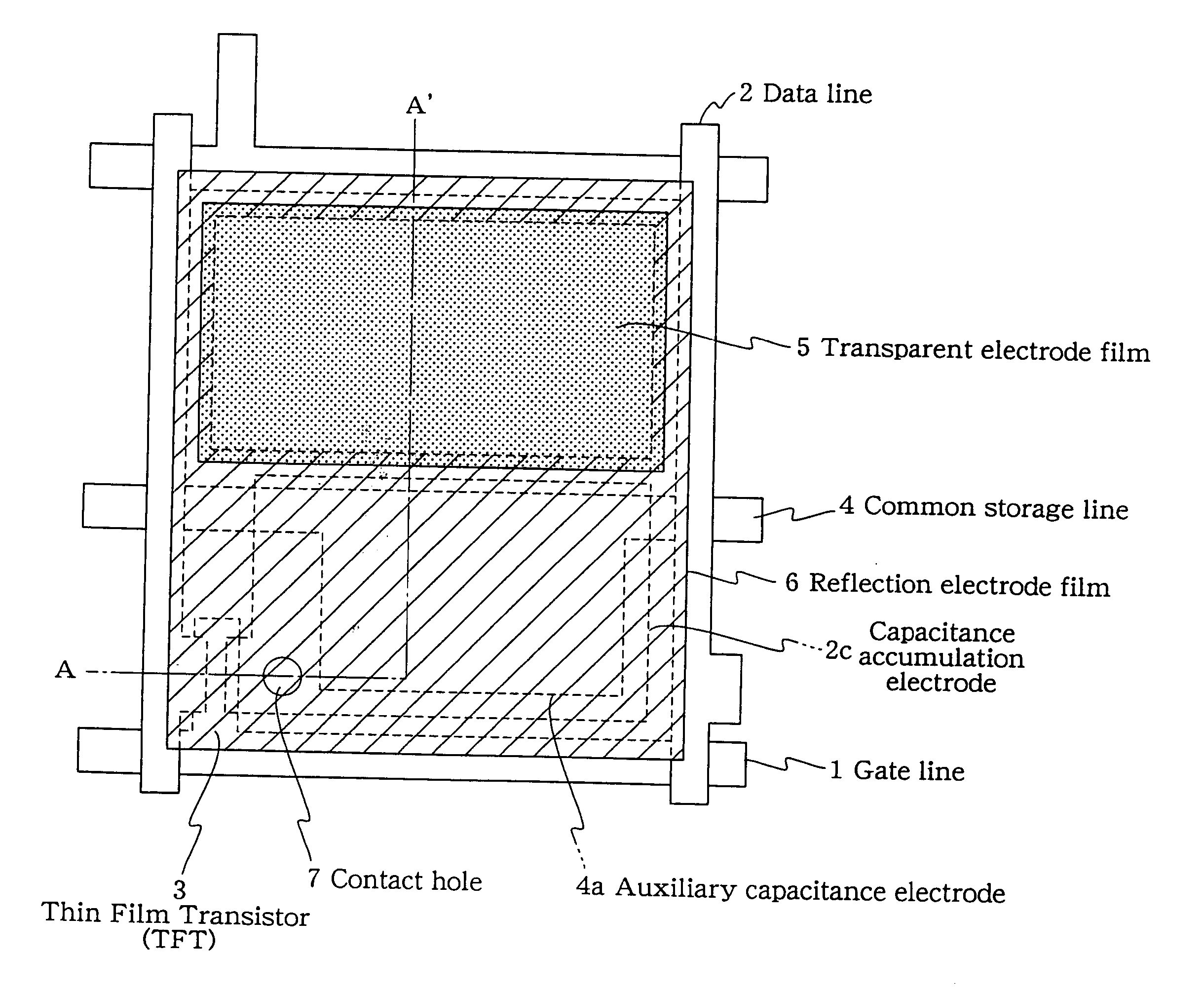

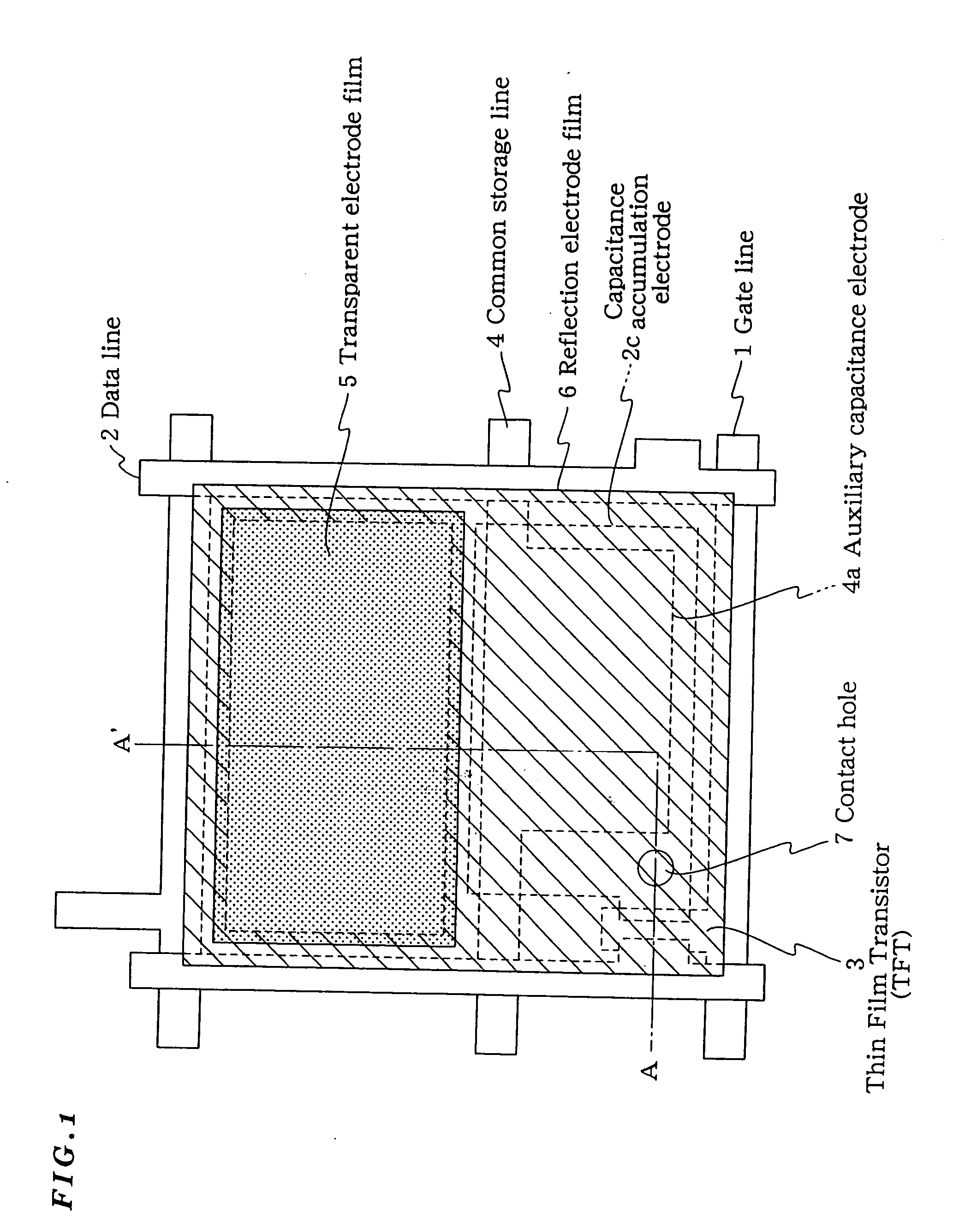

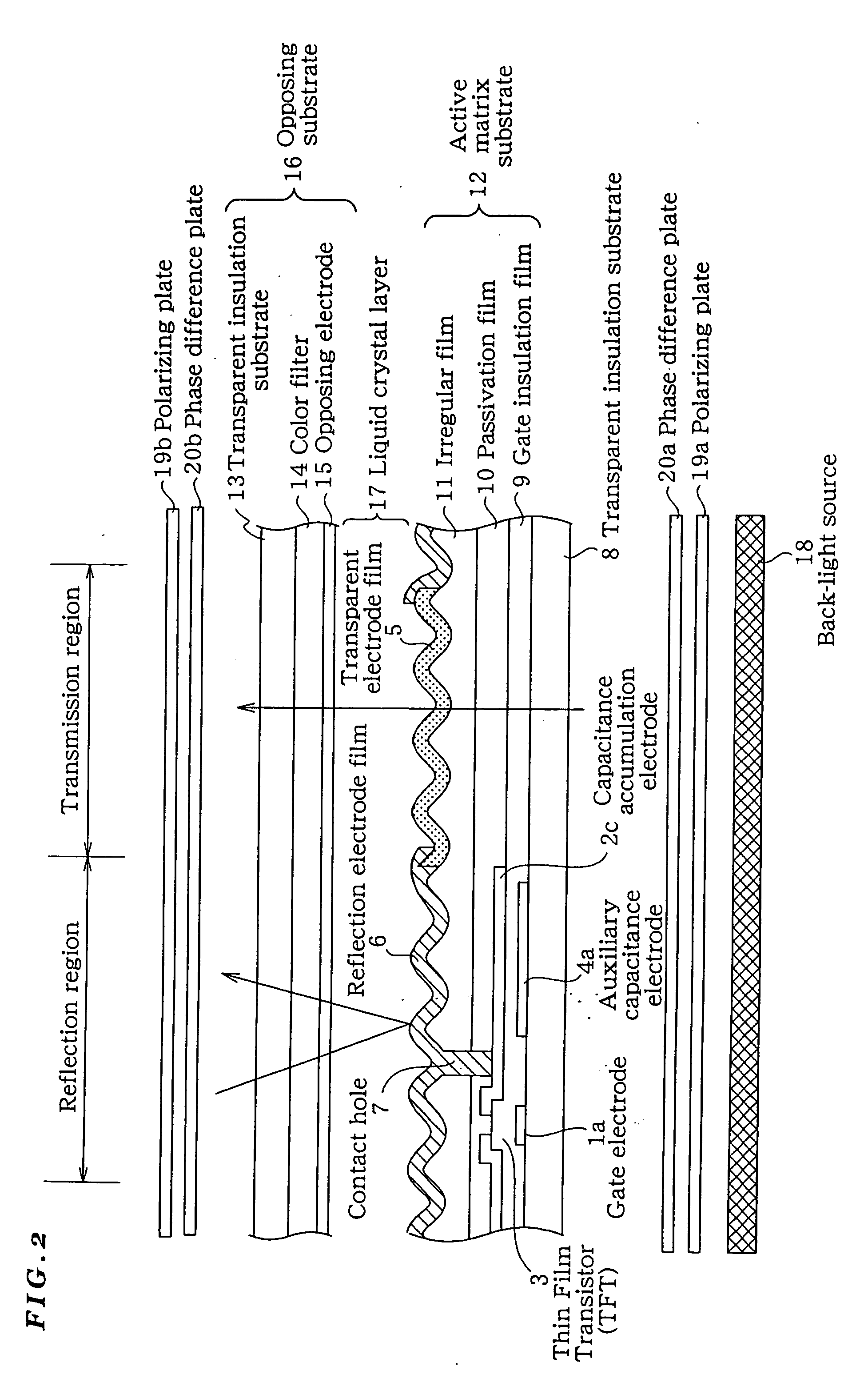

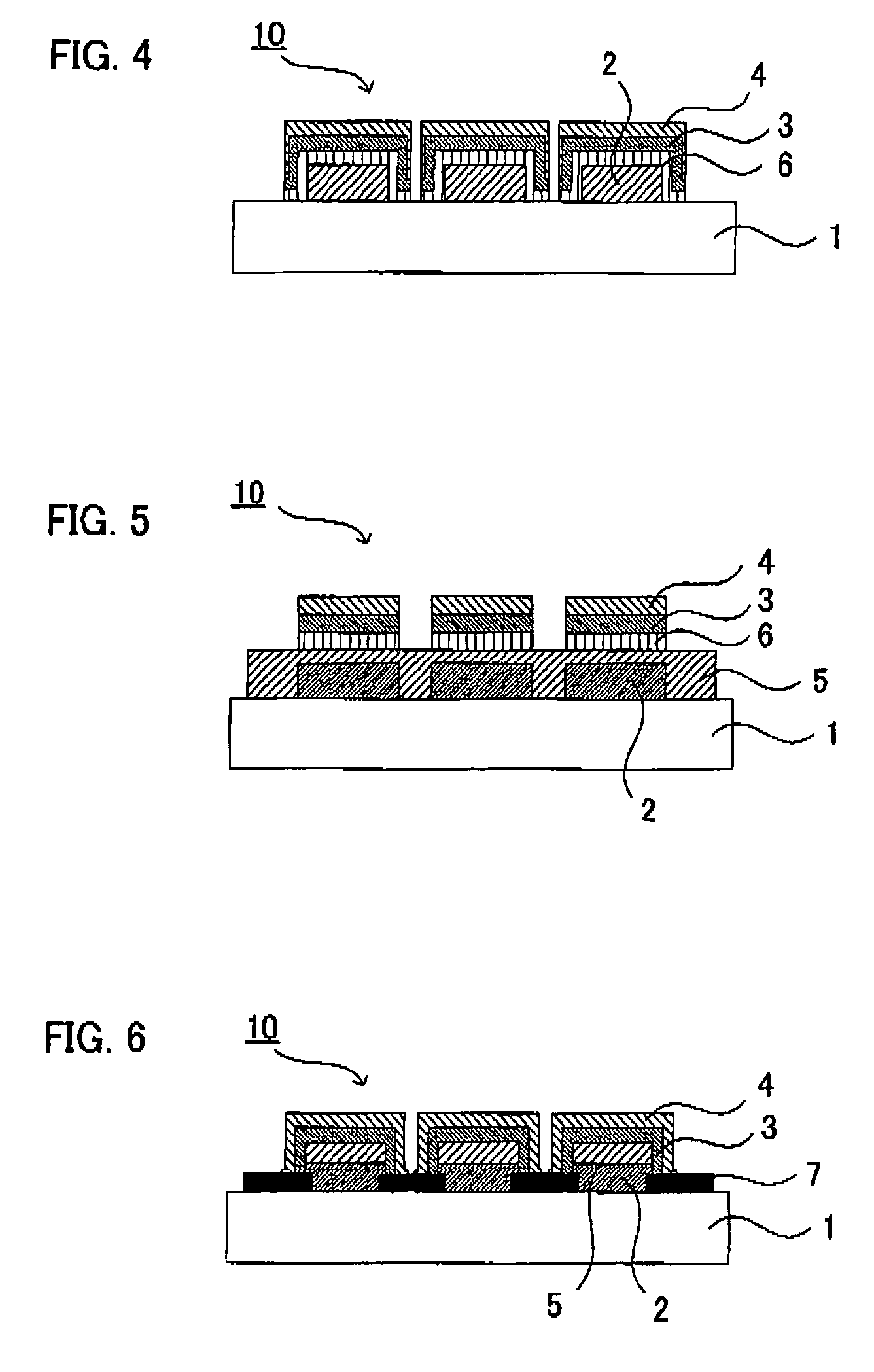

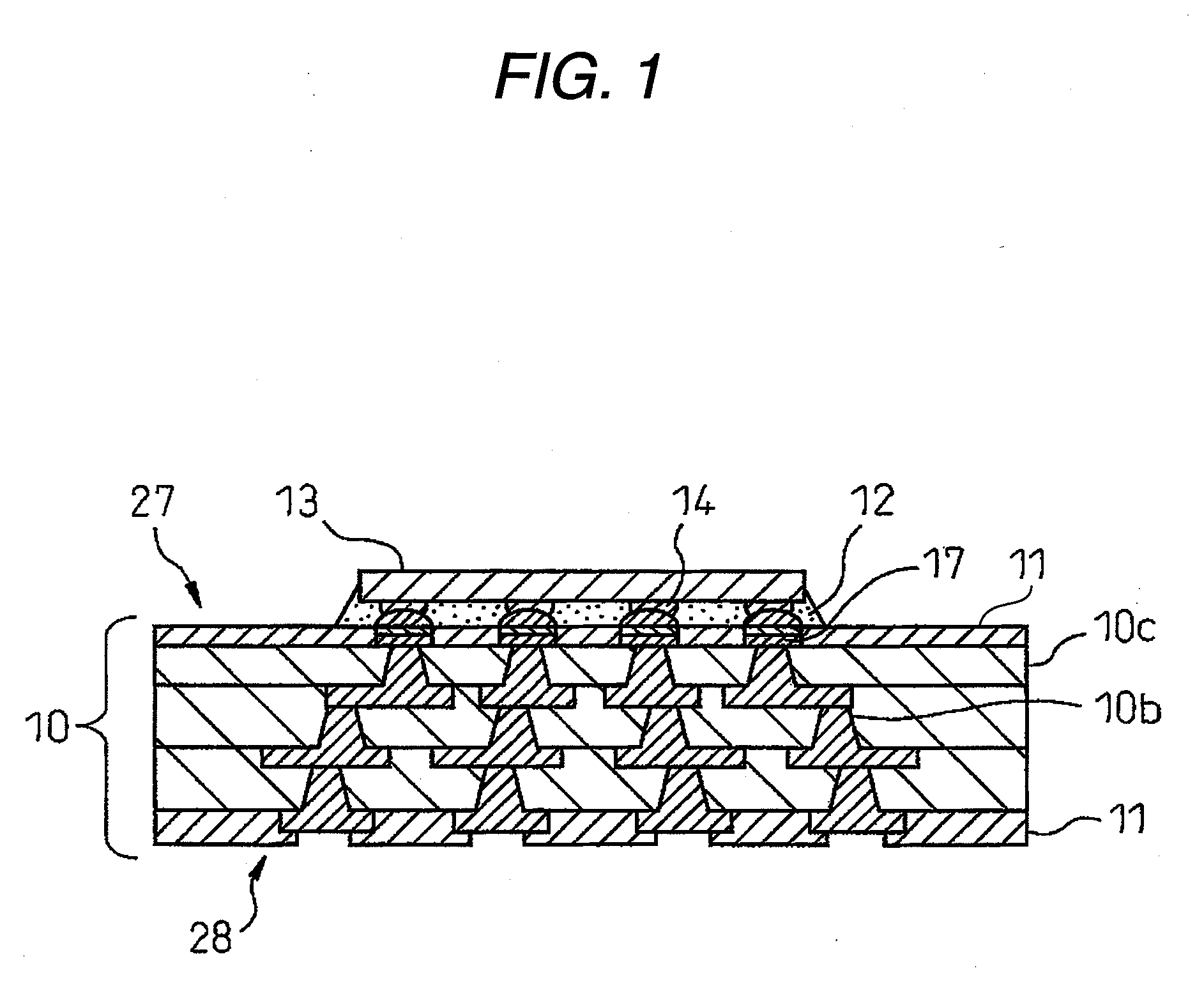

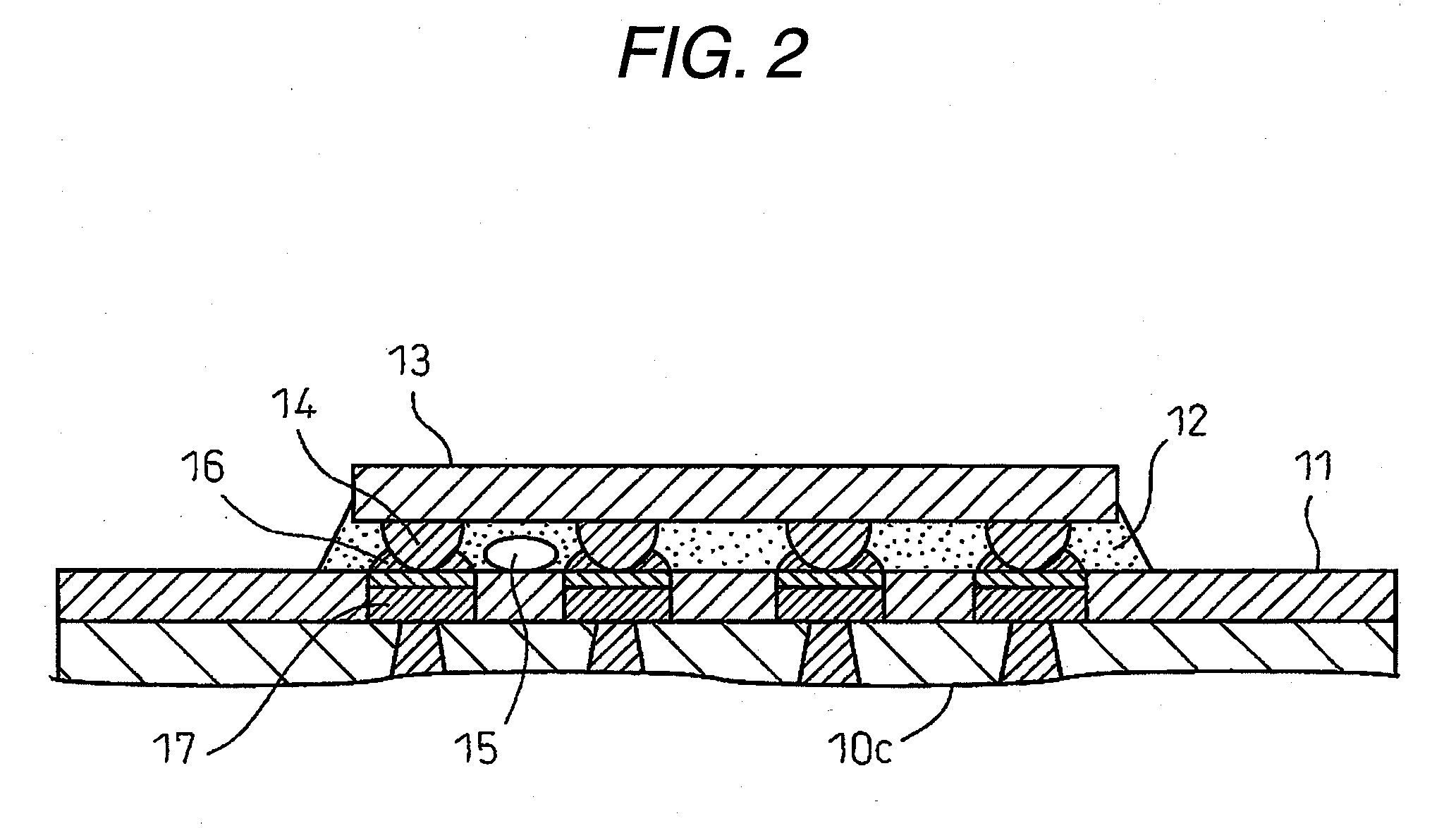

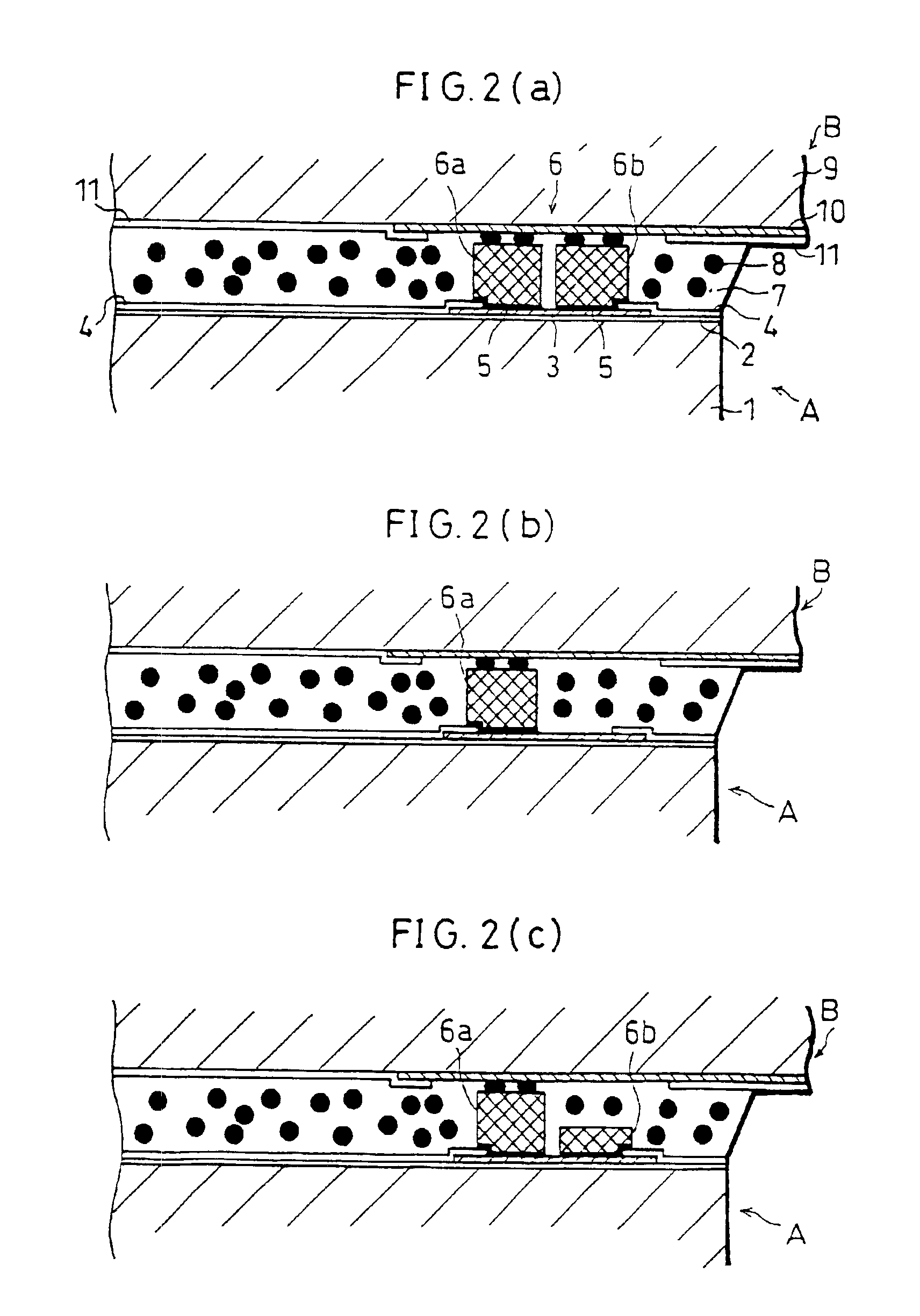

Transflective type LCD and method for manufacturing the same

In a transflective type LCD provided with a transparent region and a reflection region in each pixel, when an irregular film 11 is formed on an active matrix substrate 12 to form irregularities of a reflection electrode film 6, the irregular film 11 is specifically formed to almost the same film thickness in both the transparent region and the reflection region to provide substantially the same inter-substrate gap in these two regions so that they may have almost the same V-T characteristics and also the reflection electrode film 6 made of Al / Mo is formed so as to overlap with a transmission electrode film 5 made of ITO all around an outer periphery of the transmission electrode film 5 by a width of at least 2 μm, thus suppressing electric erosion from occurring between the ITO and Al substances at the edge of the transmission electrode film 5.

Owner:NEC LCD TECH CORP

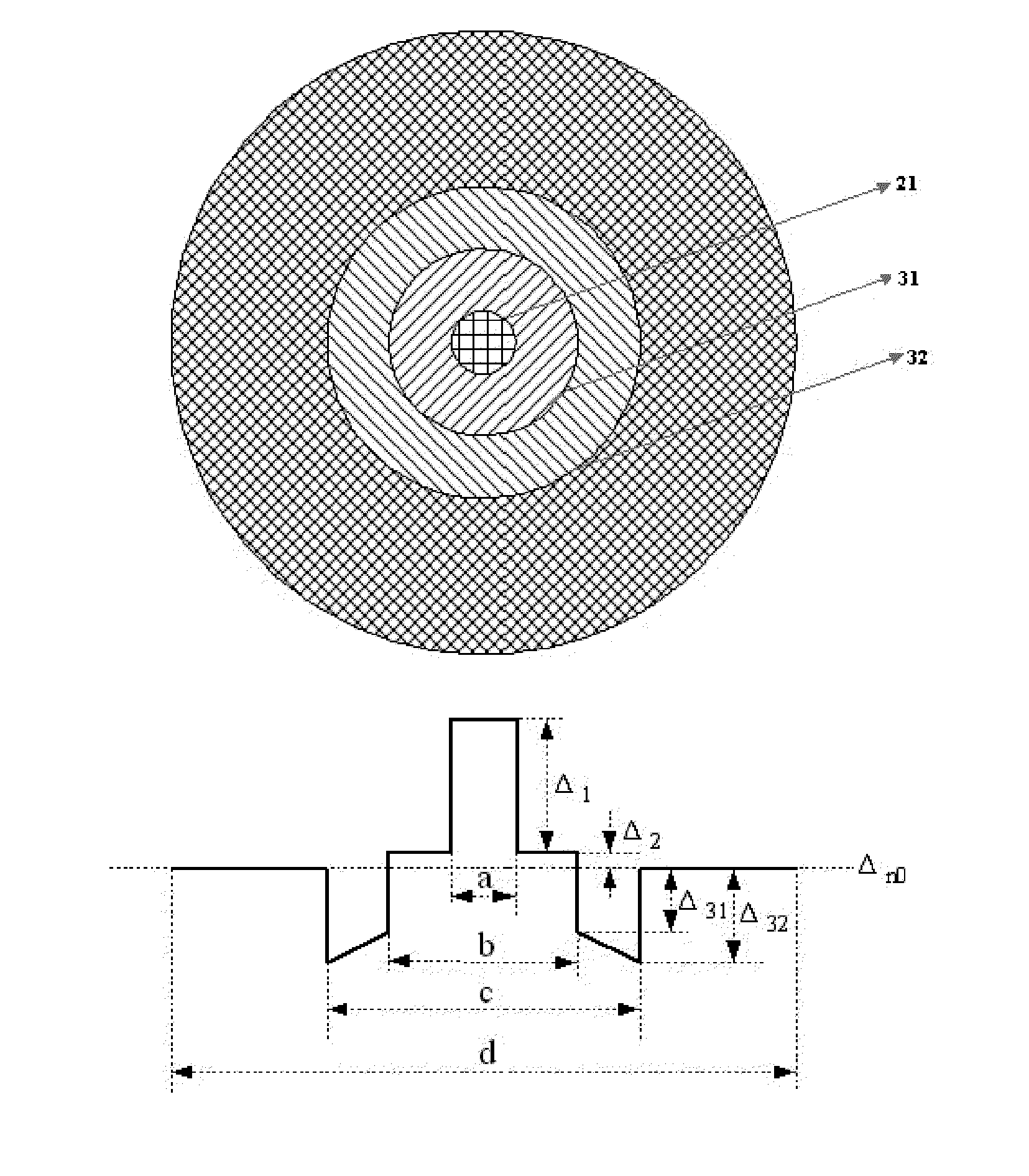

Single-mode fiber and production method thereof

ActiveUS20110058780A1Prevent viscosity being lowIncrease refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingSingle-mode optical fiberUltrasound attenuation

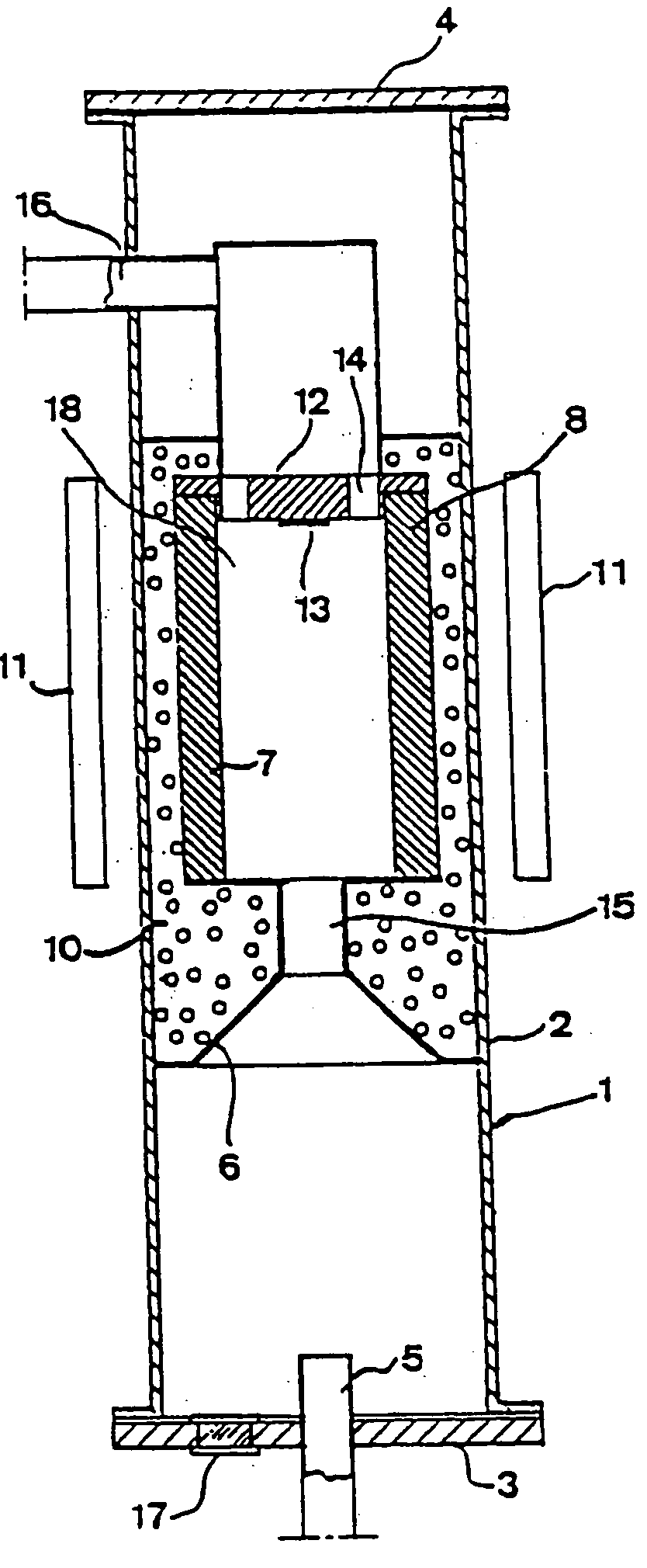

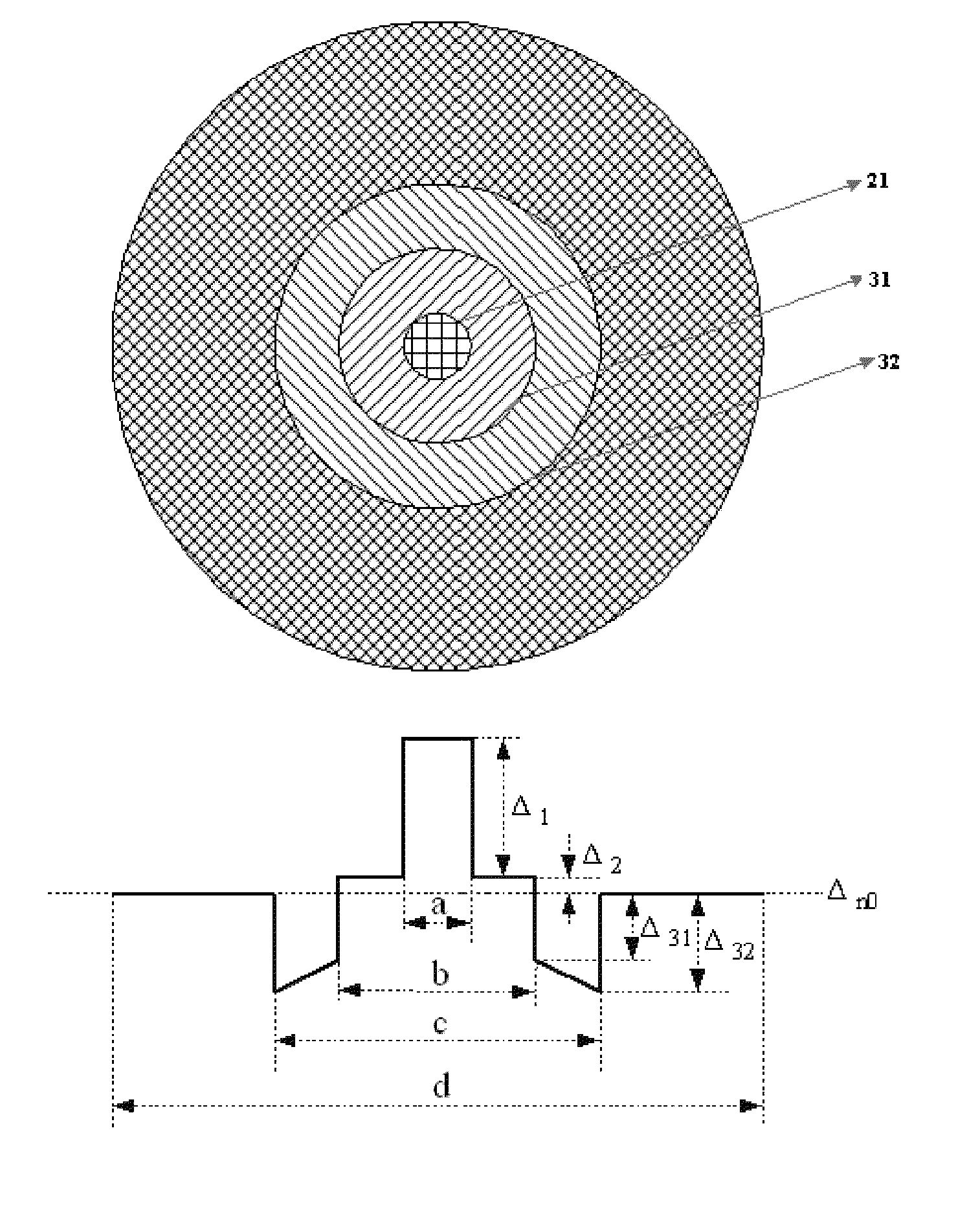

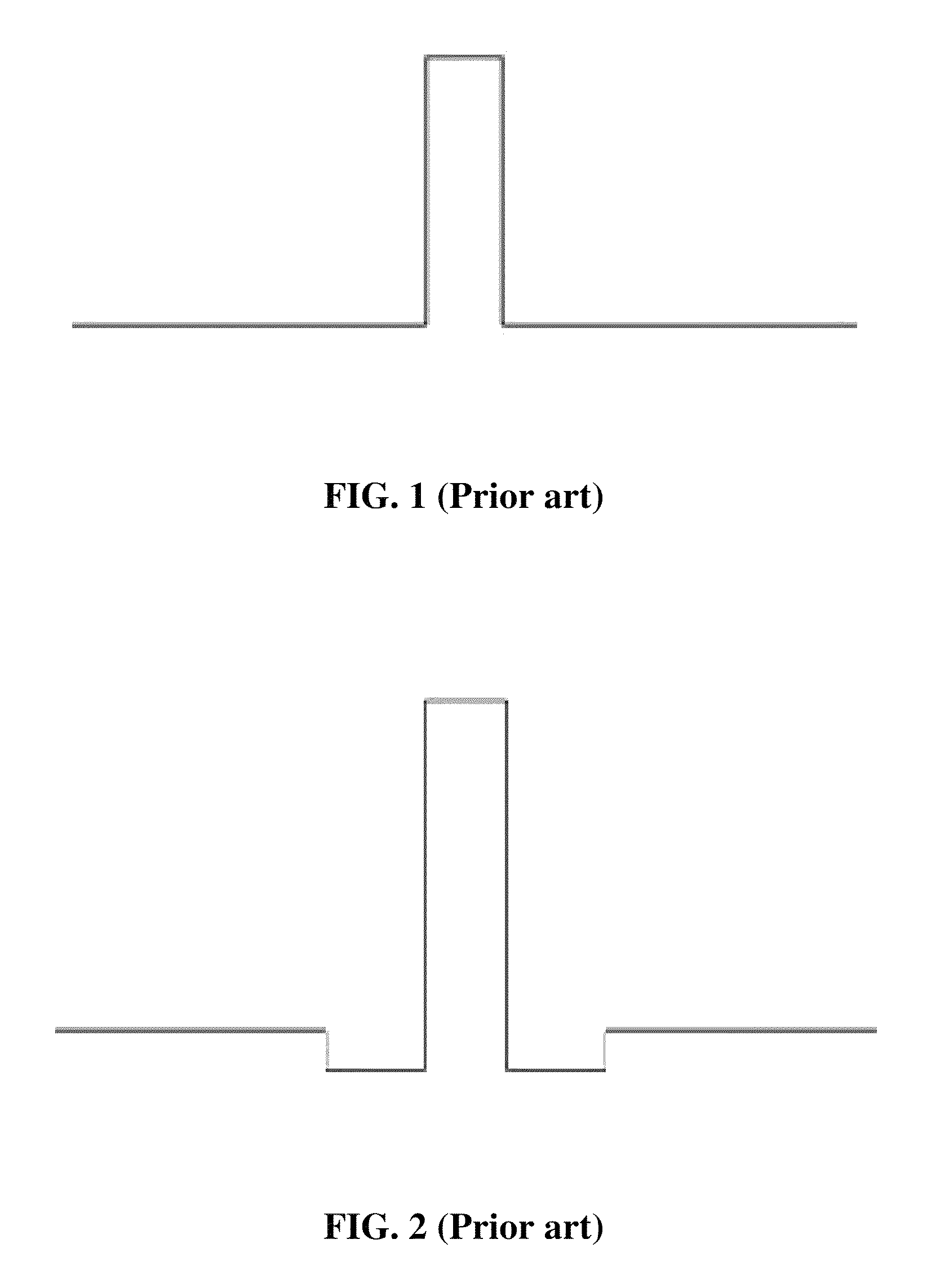

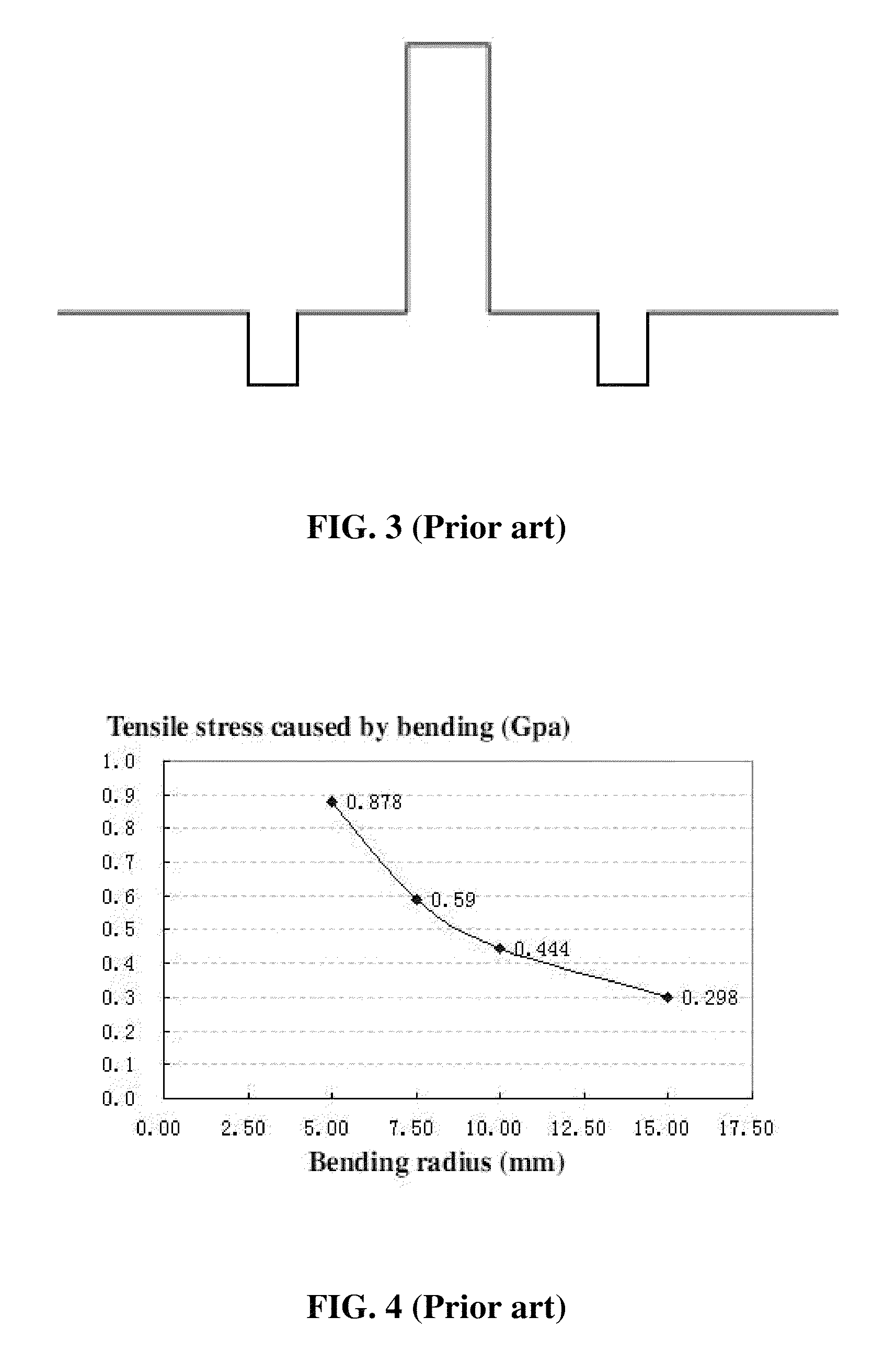

A single mode fiber having a core, an inner cladding, a depressed cladding, and an outer cladding composed of pure silica glass. The core is surrounded in sequence with the inner cladding and the depressed cladding. The core has silica glass doped with germanium and fluorine, with a diameter (a) of 8.0-8.8 μm, a relative refractive index difference (Δ1) of 0.35-0.38%, and the contribution of fluoride (ΔF) is −0.09±0.02%. The inner cladding has silica glass doped with germanium and fluorine, with a diameter (b) of 18-21 μm and a relative refractive index difference (Δ2) of 0±0.02%. The depressed cladding has silica glass doped with fluorine, with a diameter (c) of 26-36 μm and a relative refractive index difference (Δ32) at the external interface thereof is between −0.22 and −0.35%, and a relative refractive index difference (Δ31) at the internal interface thereof is between −0.20 and −0.35%, and Δ32≦Δ31. The fiber has a good bending resistance, good mechanical properties, and extended service lifetime, and prevents the additional stresses generated by bending from passing on to the core, thereby reducing attenuation.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

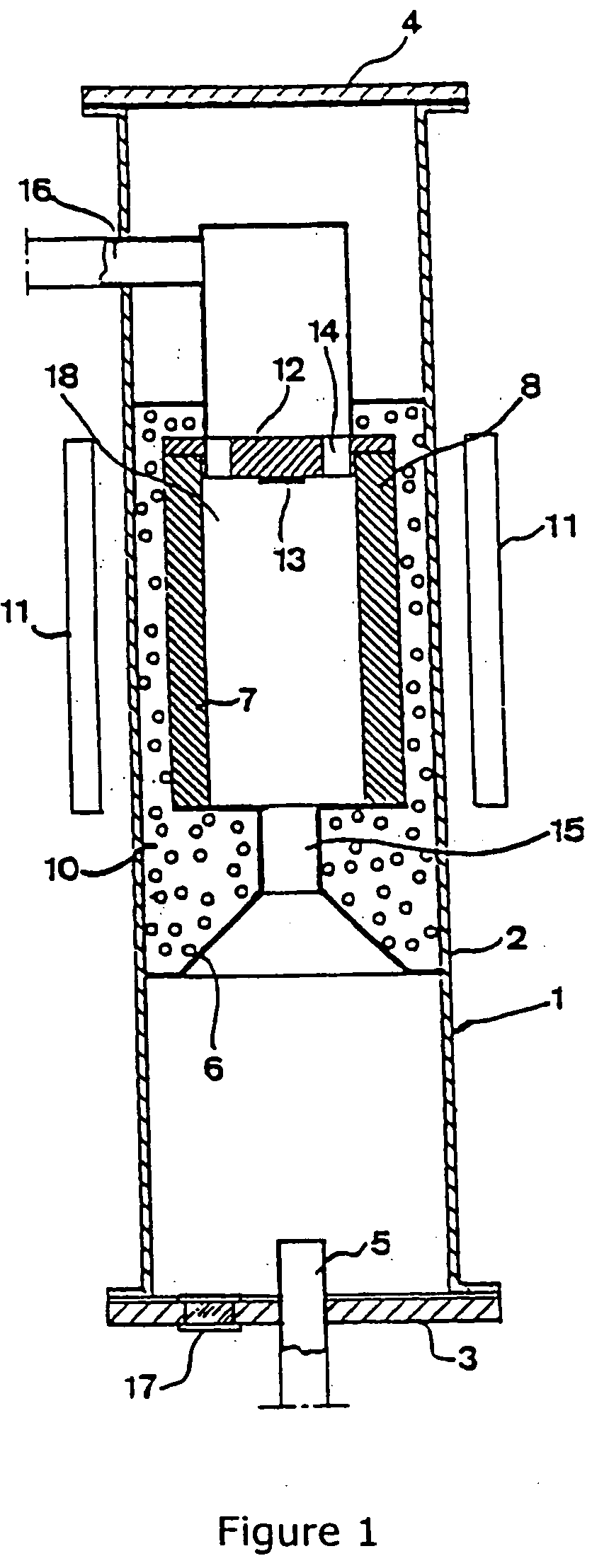

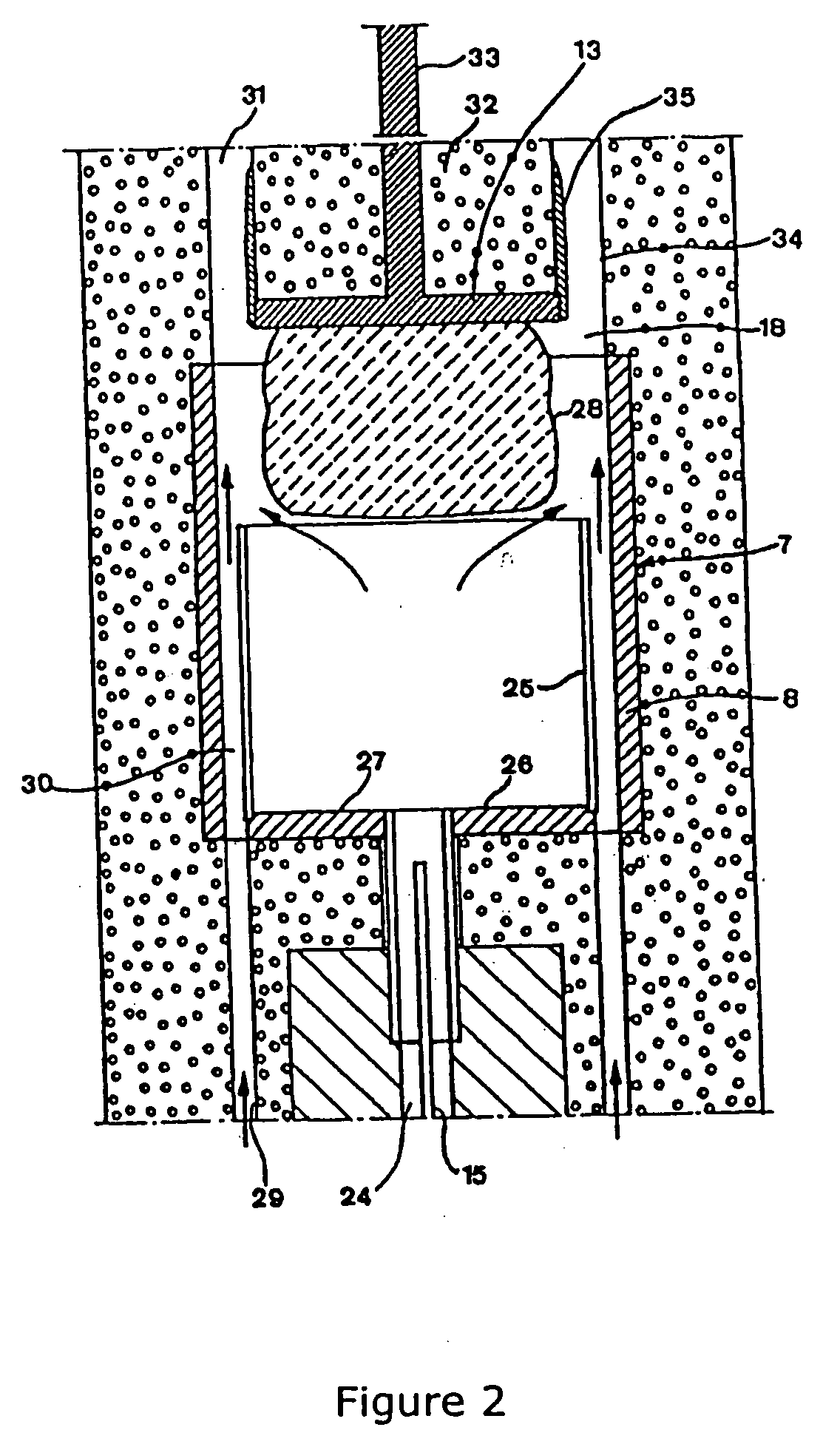

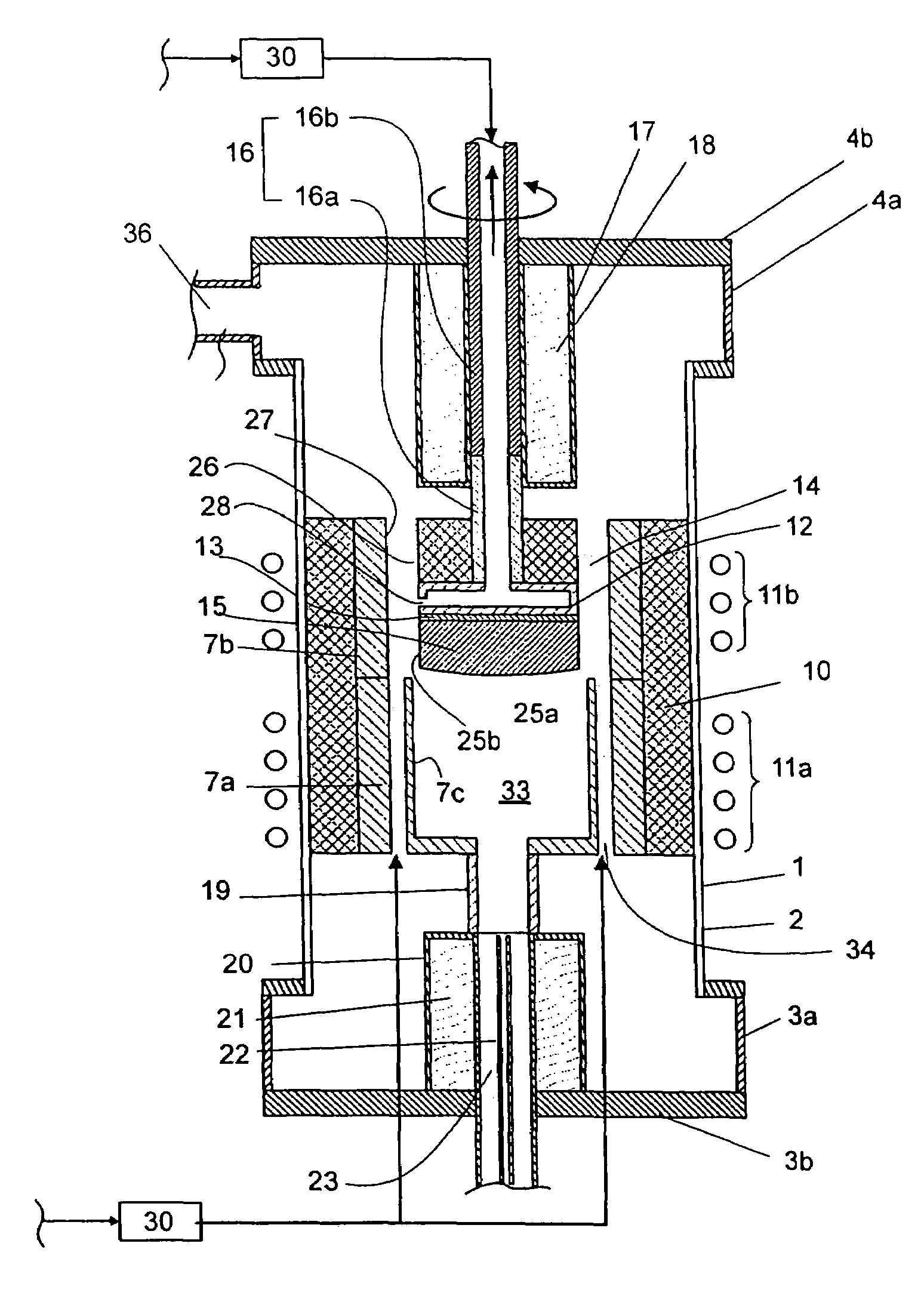

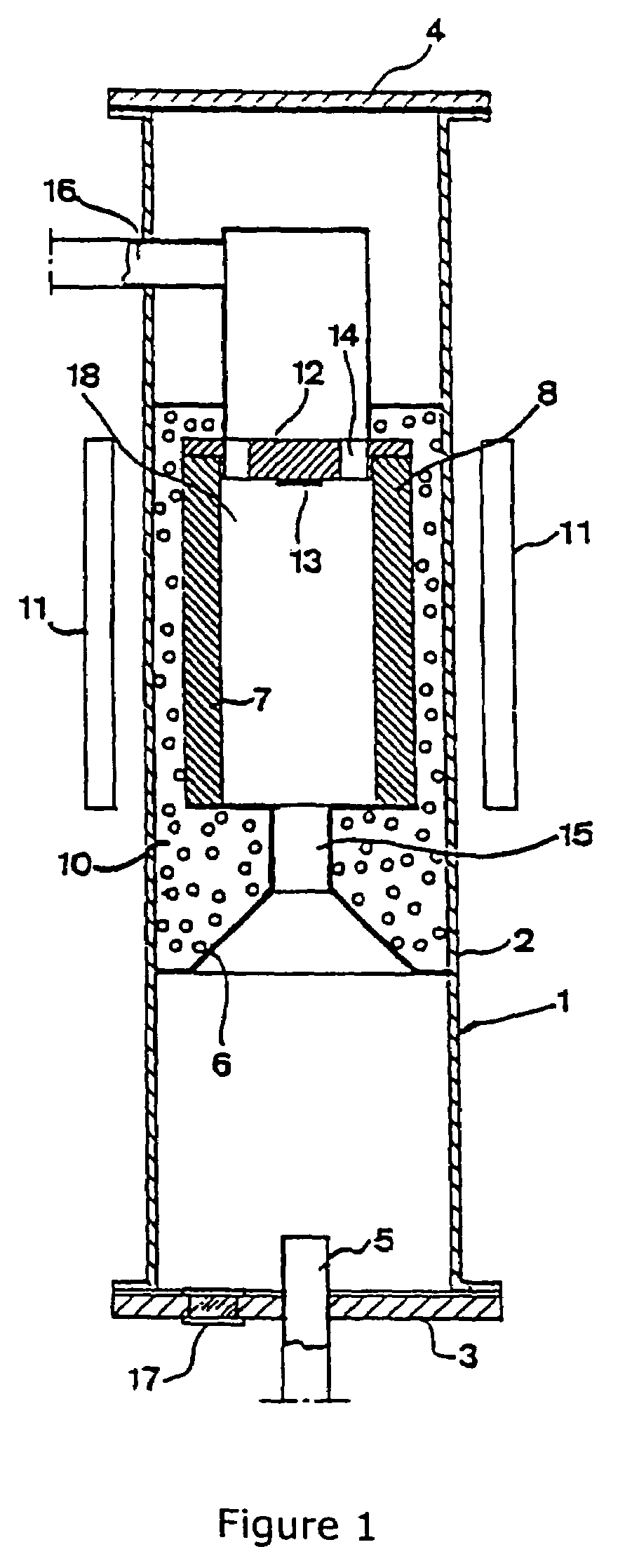

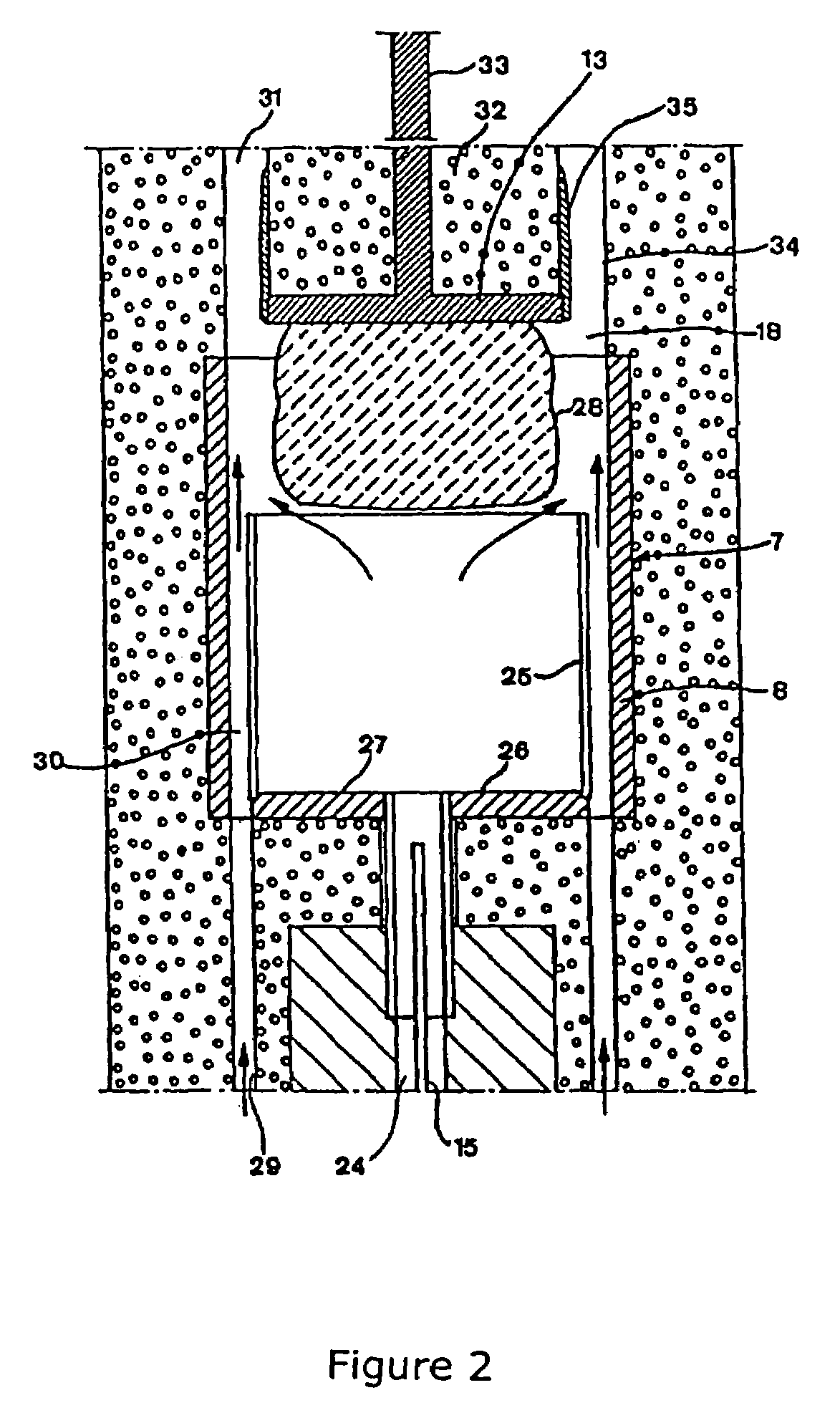

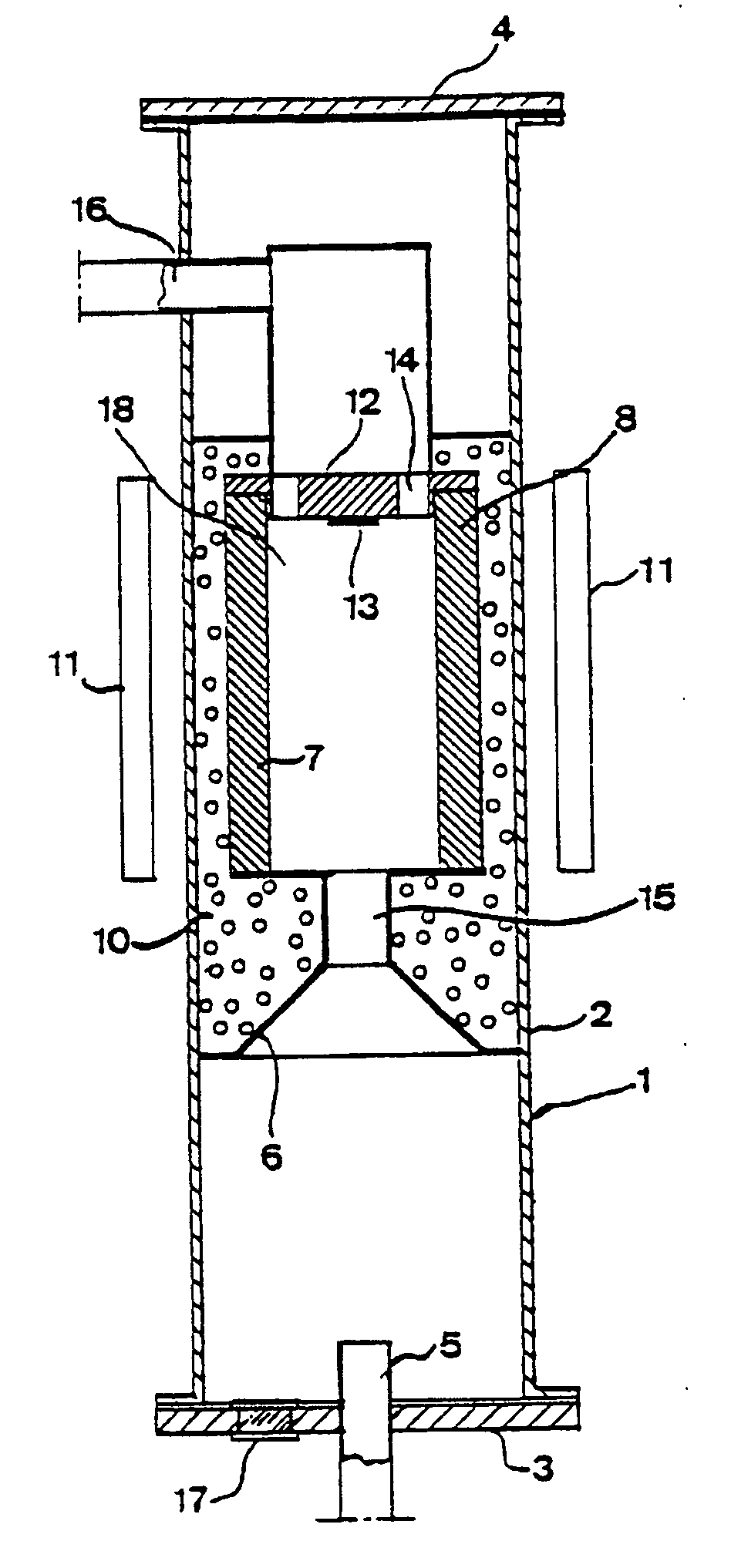

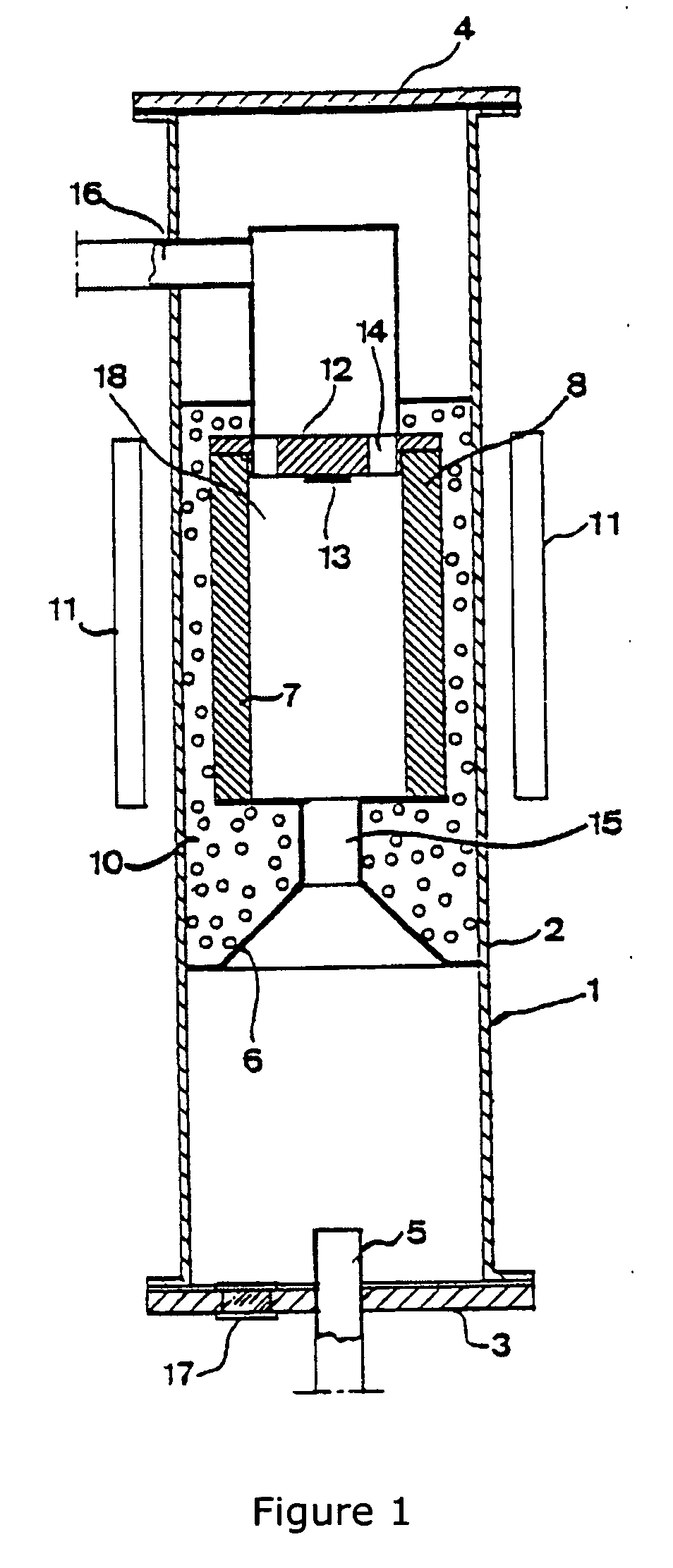

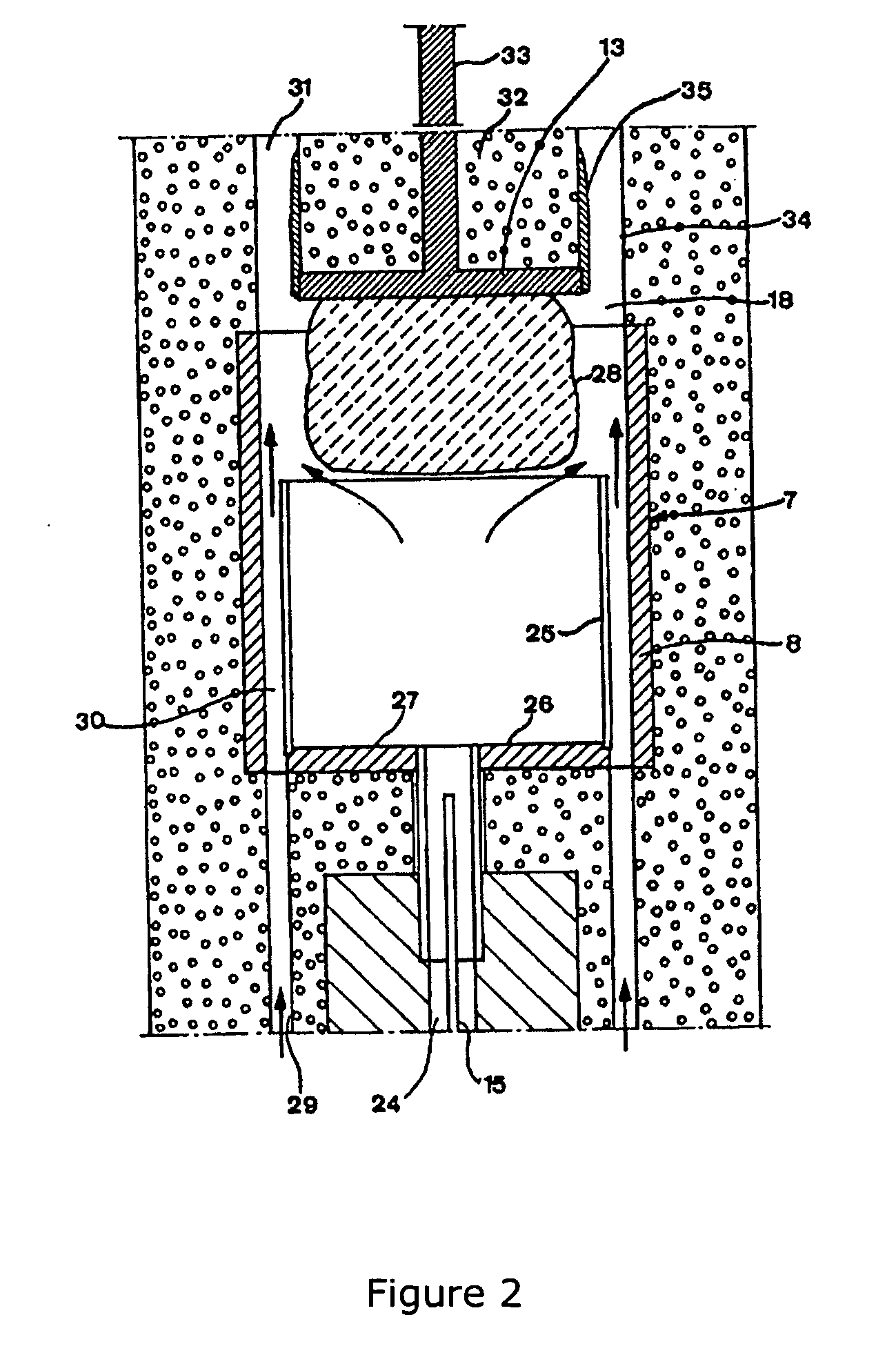

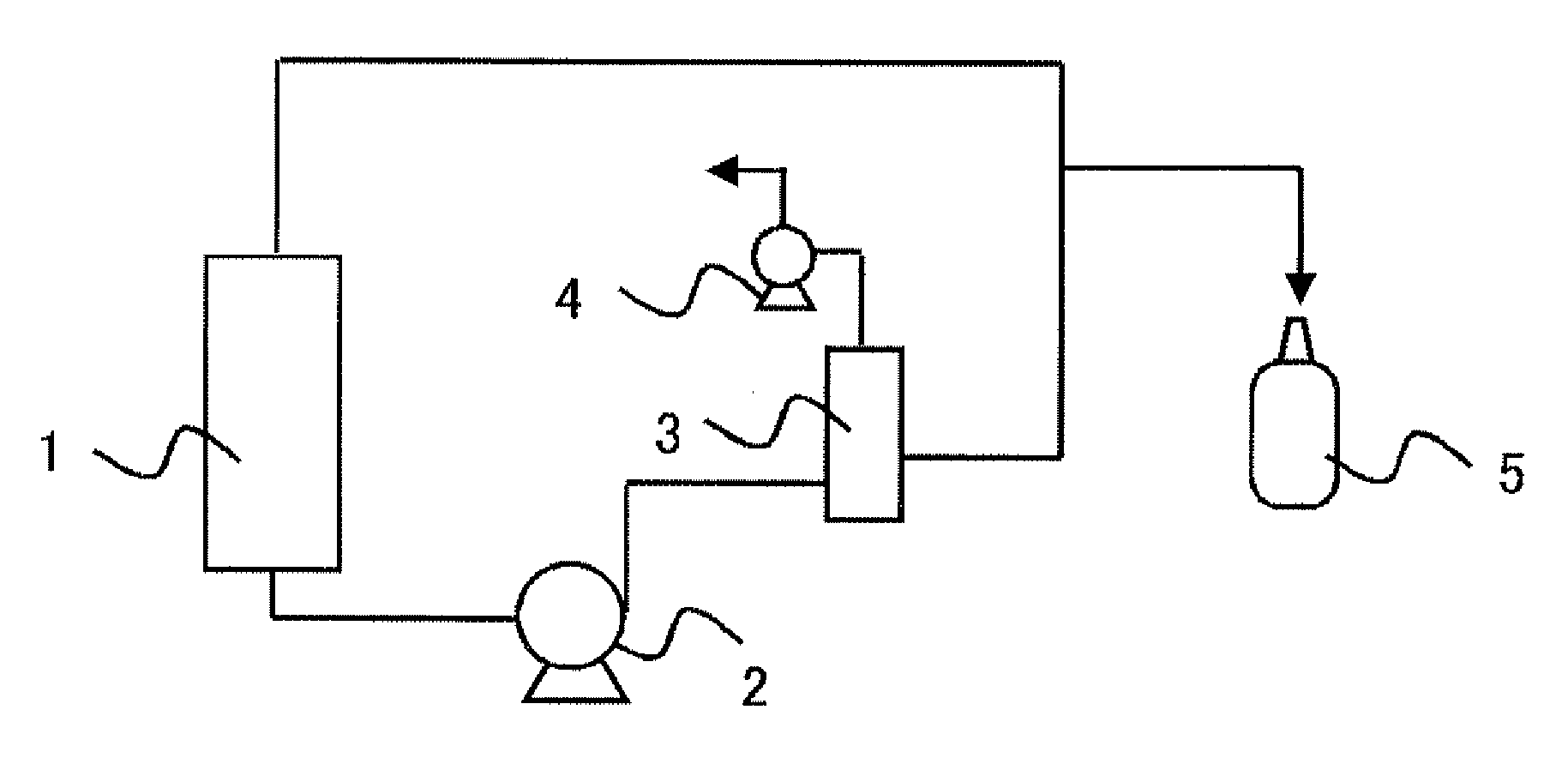

Device and method for producing single crystals by vapor deposition

ActiveUS20050000406A1Down and eliminate formationPreventing structural defect generationFrom gel statePolycrystalline material growthGas phaseSingle crystal

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL

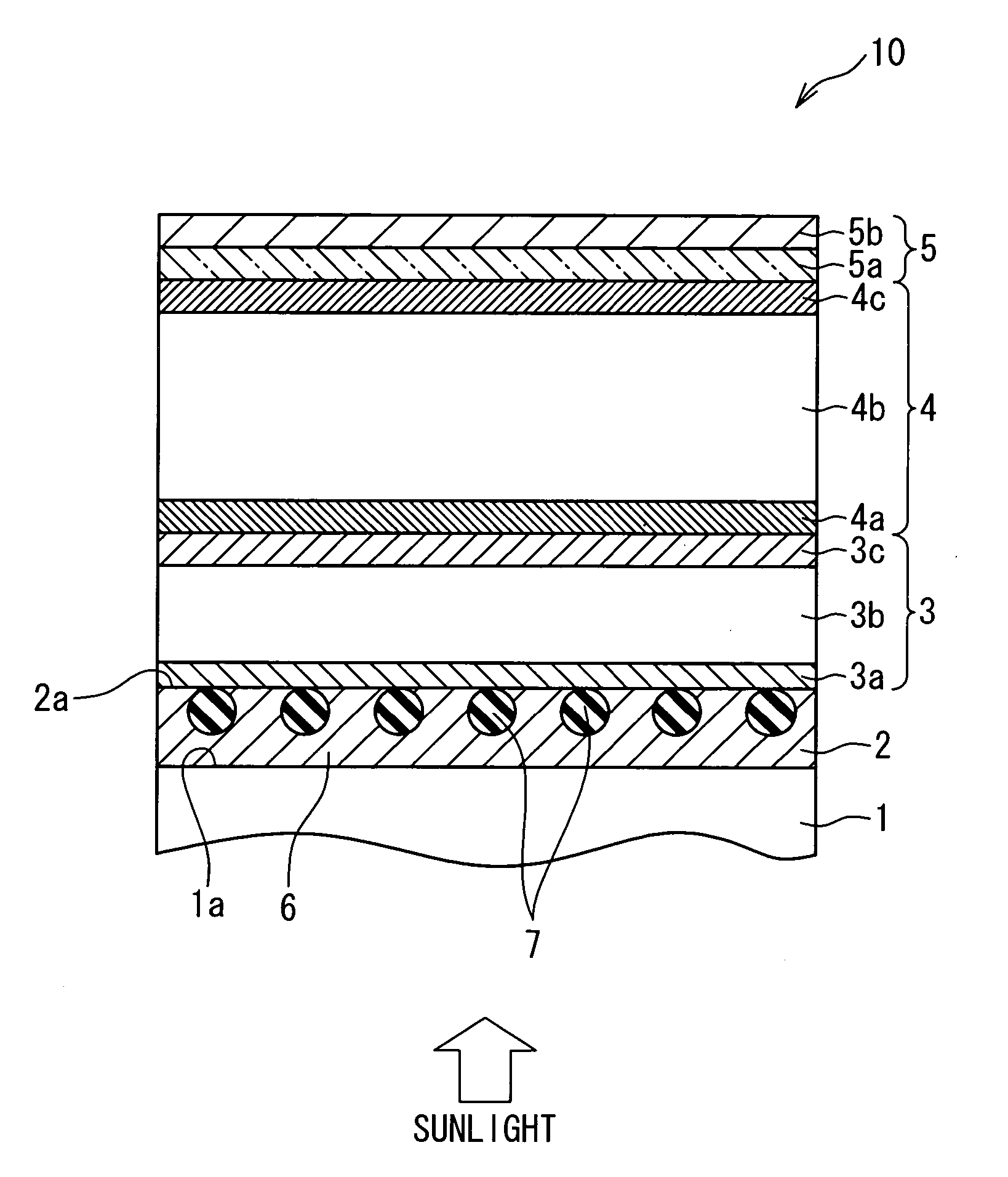

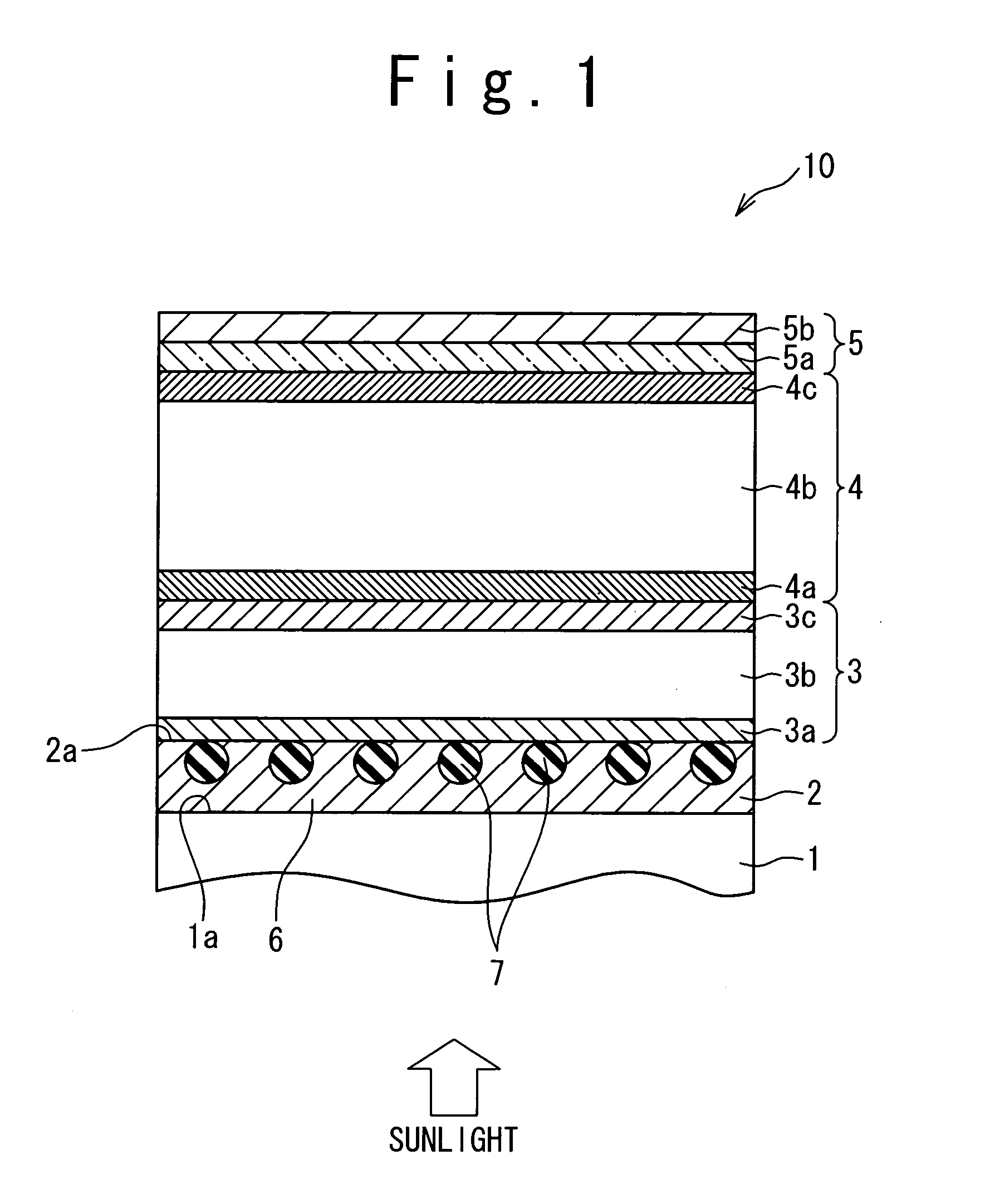

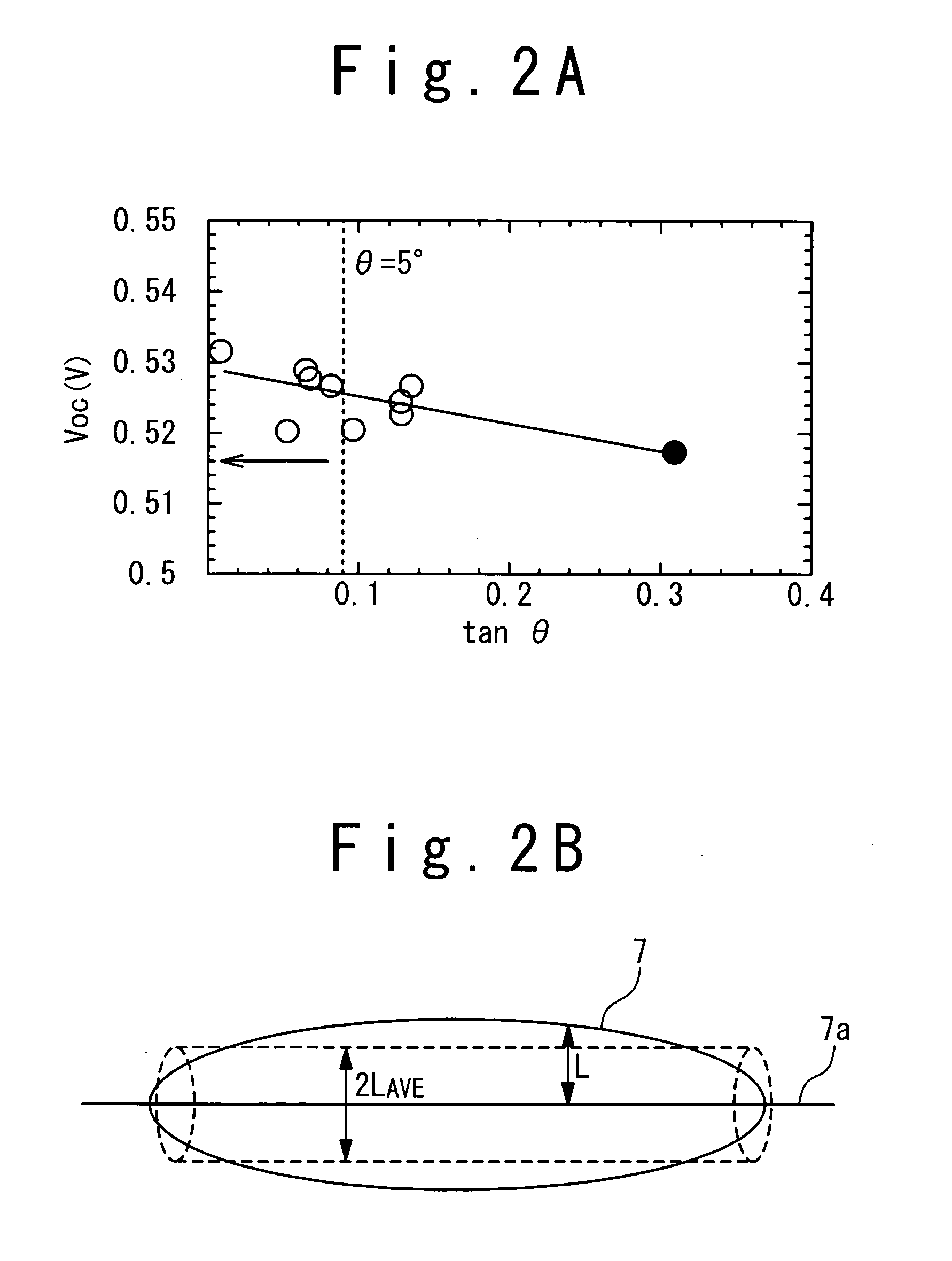

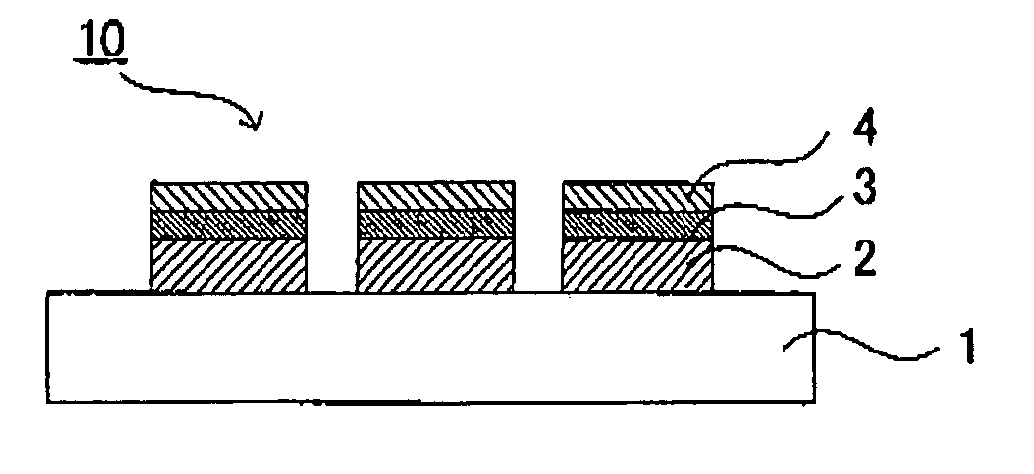

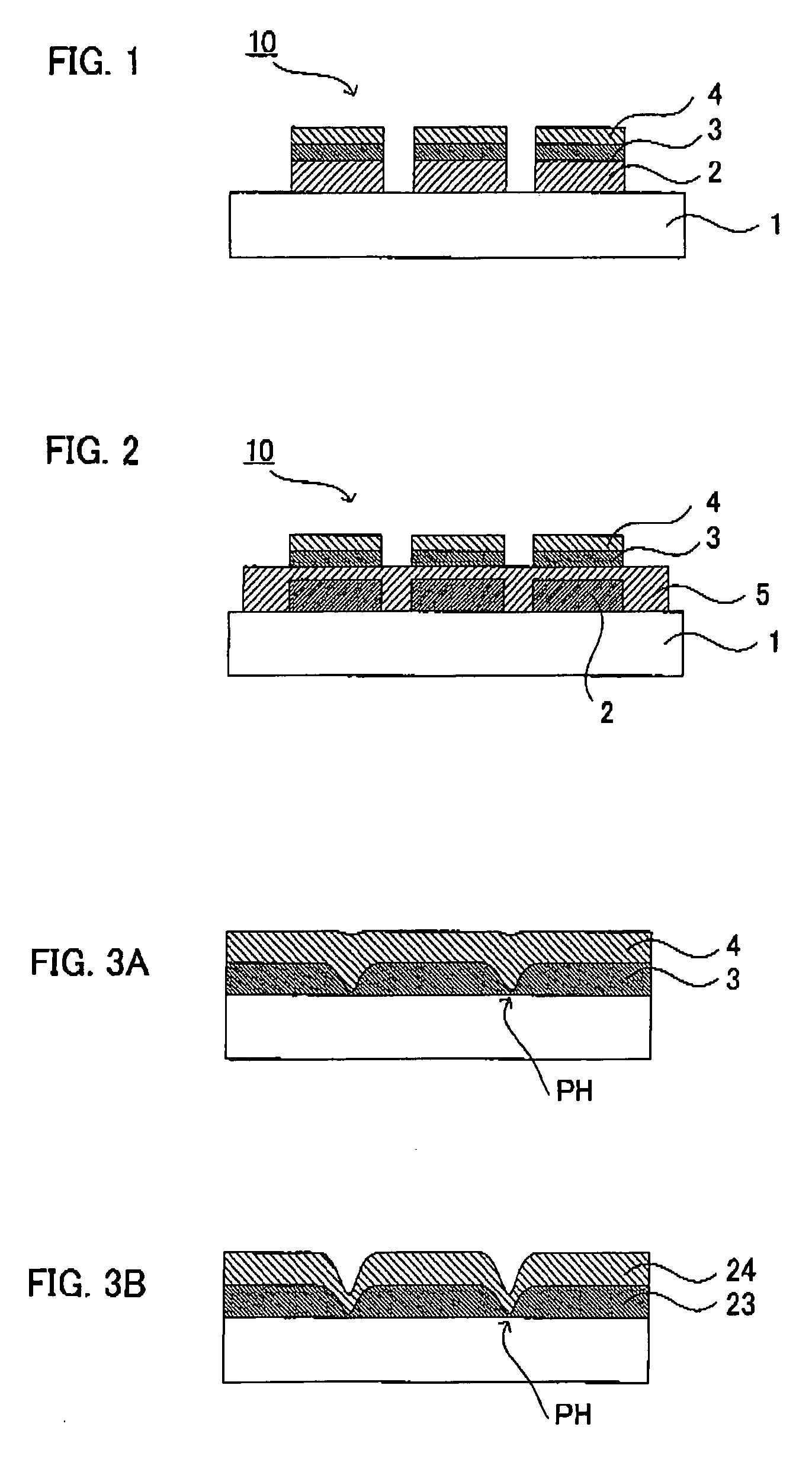

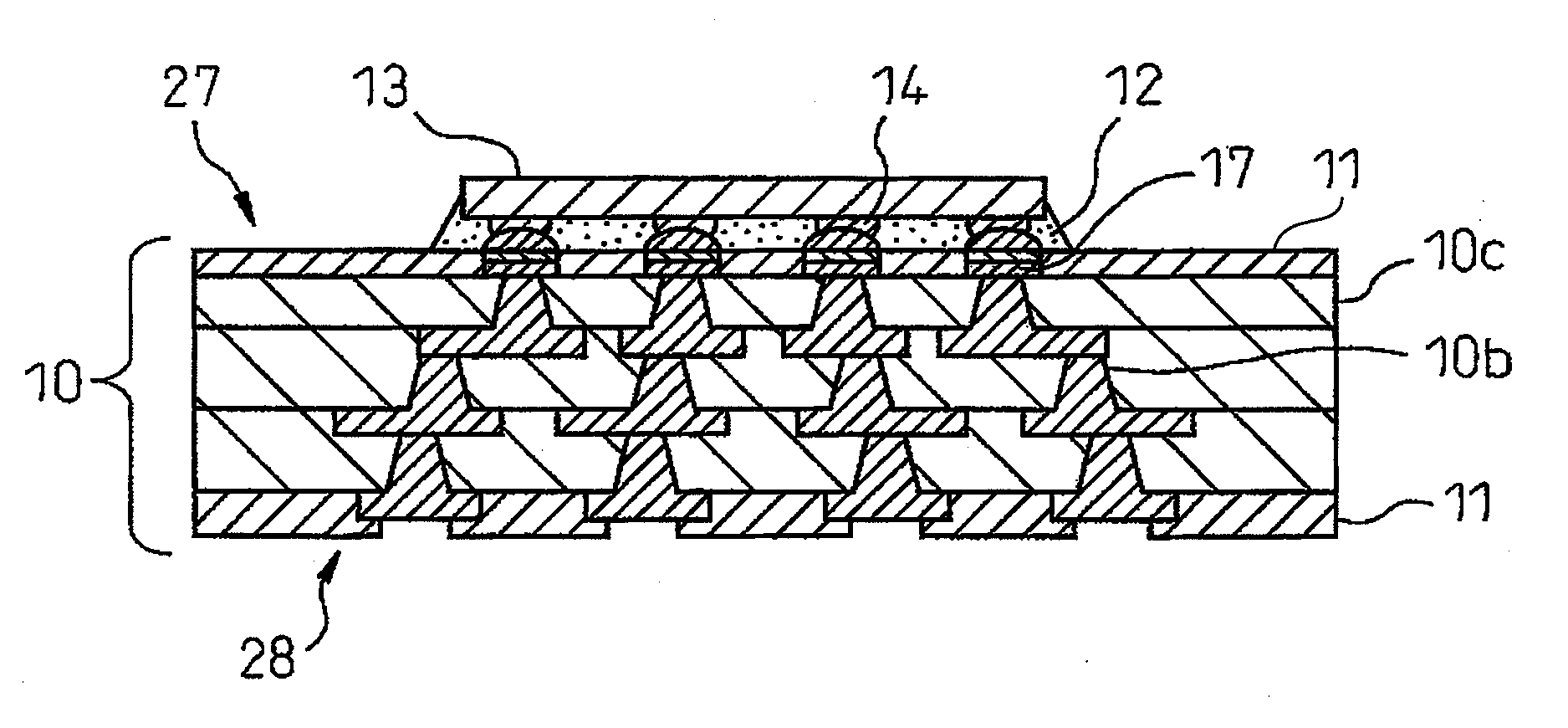

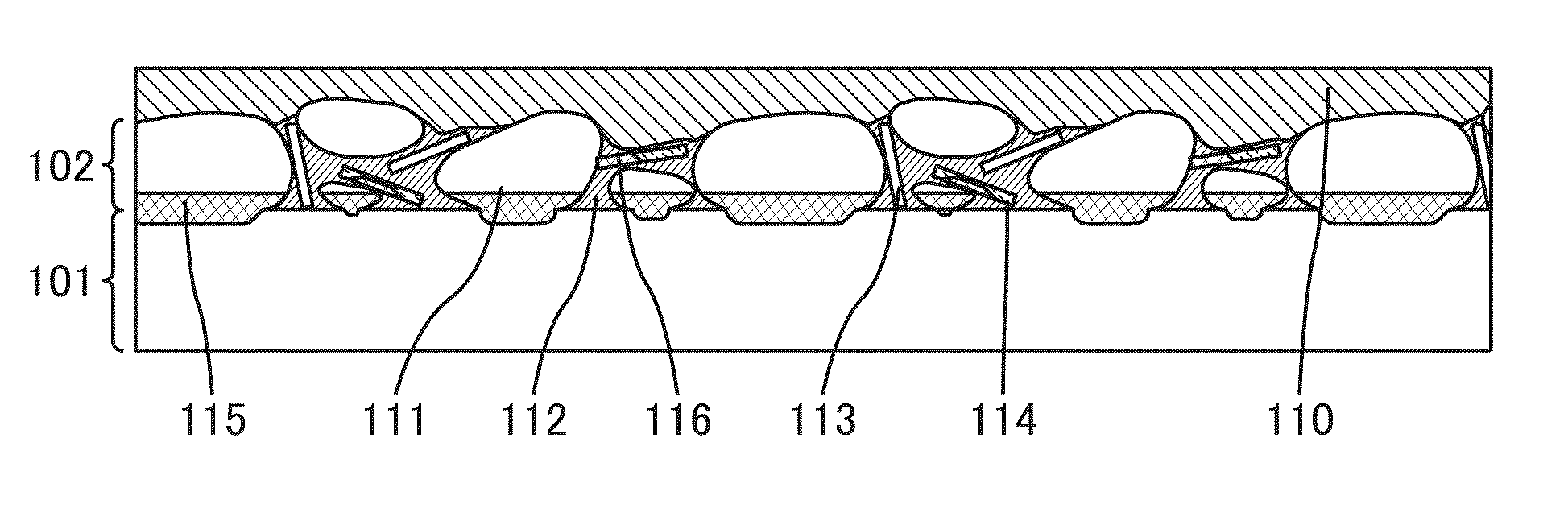

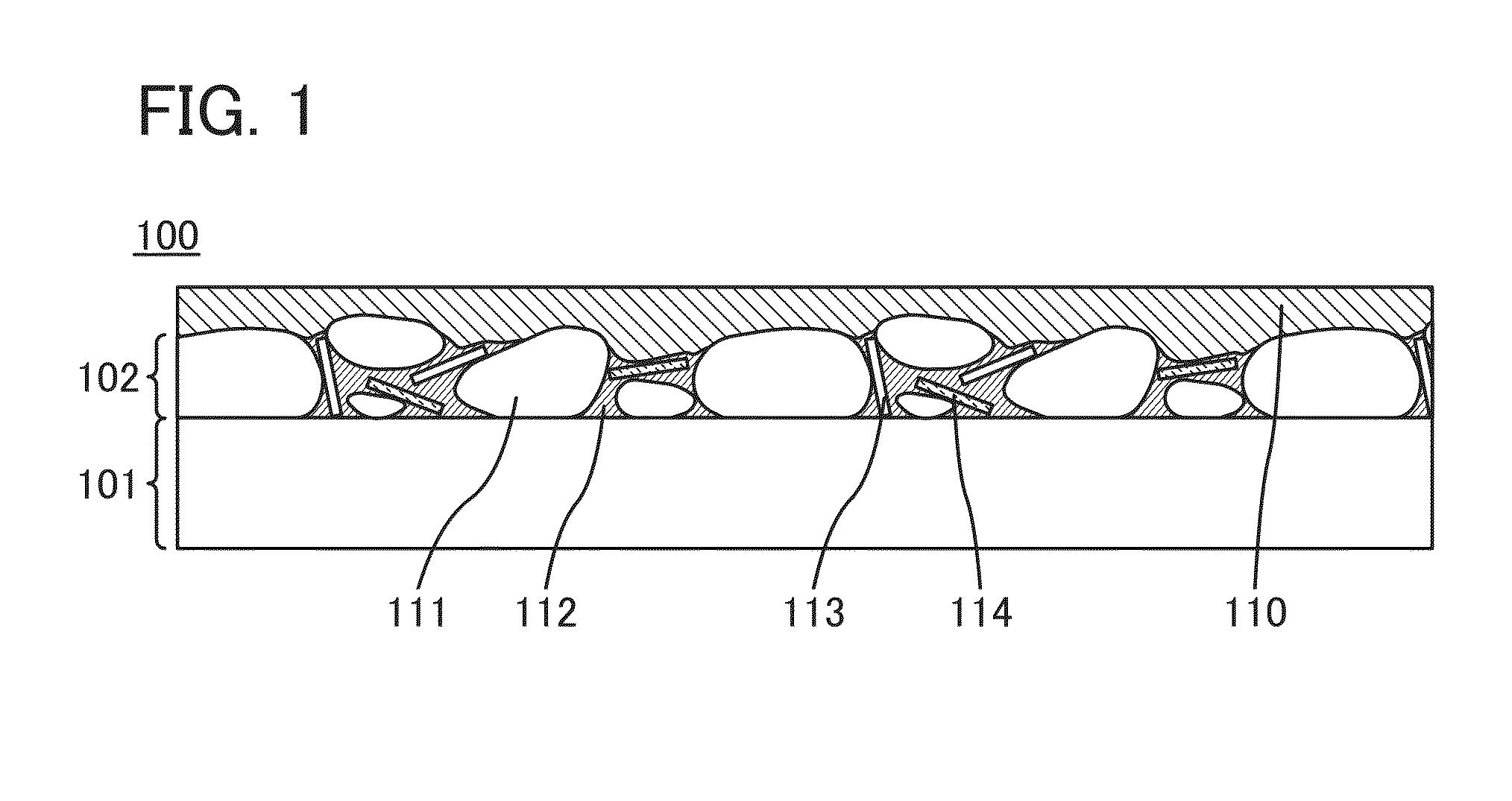

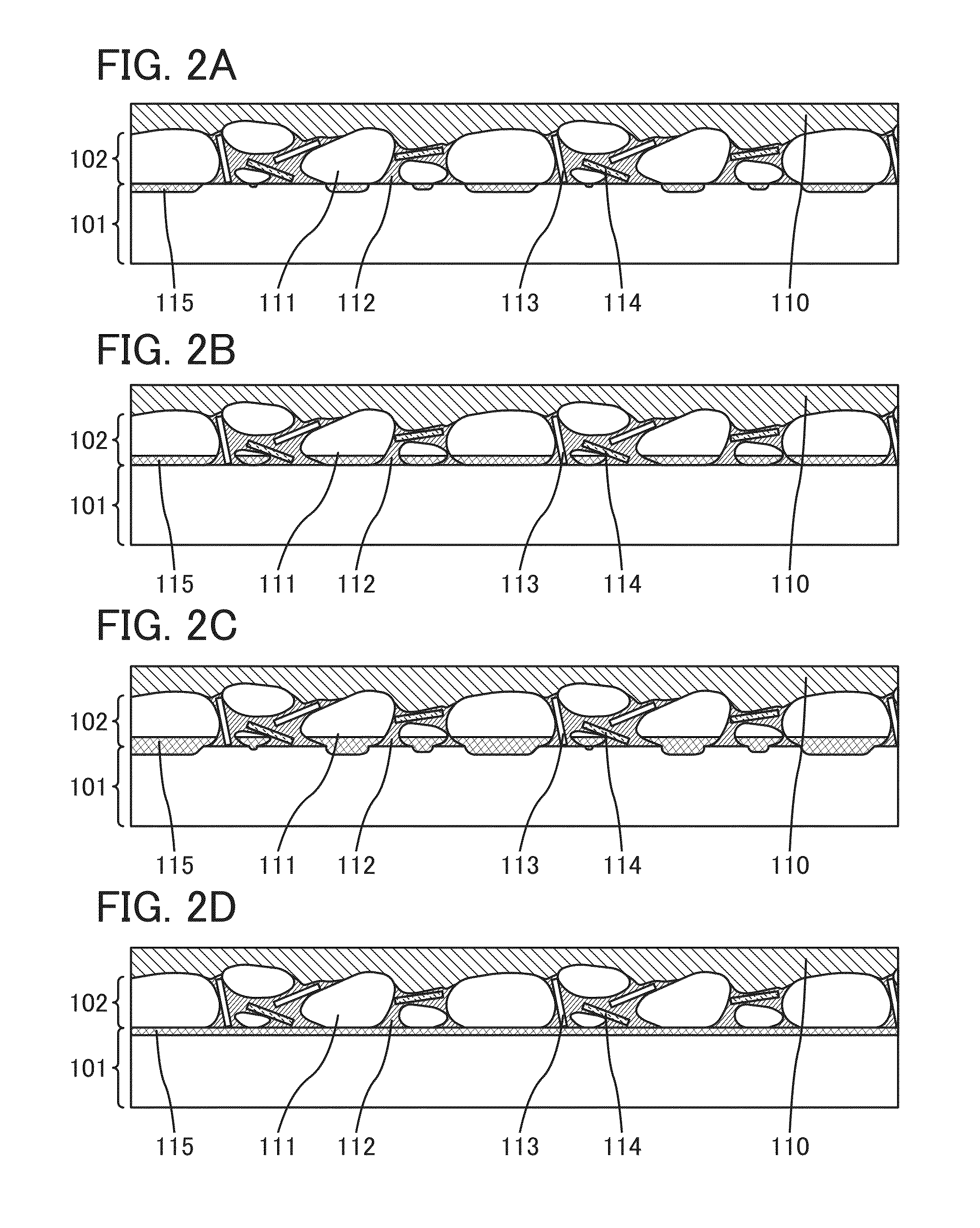

Photoelectric conversion device

InactiveUS20060090790A1Improve conversion efficiencyIncrease the lengthSemiconductor/solid-state device manufacturingPhotovoltaic energy generationConductive materialsPhotoelectric conversion

A photoelectric conversion device is composed of a substrate, a lower electrode layer formed to cover the substrate, and a first semiconductor layer formed on the lower electrode. The lower electrode layer includes a first matrix formed of transparent conductive material, and light scattering granules embedded within the first matrix.

Owner:MITSUBISHI HEAVY IND LTD

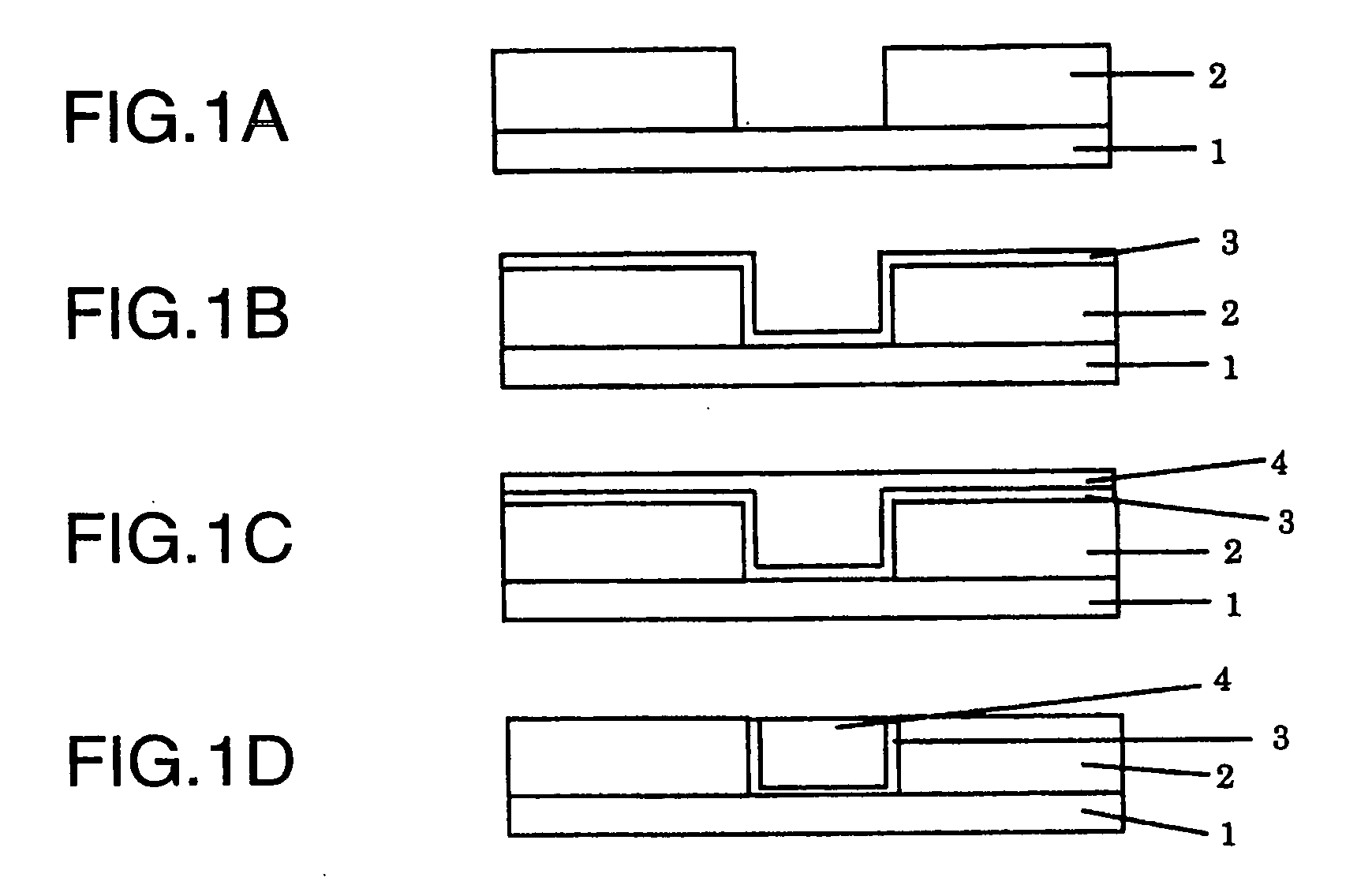

Flexible display and method for manufacturing the same

InactiveUS20110052836A1Inhibition of defect generationImprove the bonding force between layersLiquid crystal compositionsFinal product manufacturePlastic materialsMetallic materials

A flexible display comprises a flexible substrate made of plastic material, a display element on a first surface of the flexible substrate, and a surface residual film containing at least one of a metal material or a metal oxide material. The surface residual film is bonded to at least a part of a second surface of the flexible substrate. The second surface is opposed to the first surface. A method for manufacturing a flexible display comprises preparing a glass substrate, forming adhesive material film on the glass substrate, the adhesive material film being made of at least one of a metal material or a metal oxide material, and forming a flexible substrate from plastic material on the adhesive material film.

Owner:SAMSUNG DISPLAY CO LTD

Transflective type LCD and method for manufacturing the same

In a transflective type LCD provided with a transparent region and a reflection region in each pixel, when an irregular film 11 is formed on an active matrix substrate 12 to form irregularities of a reflection electrode film 6, the irregular film 11 is specifically formed to almost the same film thickness in both the transparent region and the reflection region to provide substantially the same inter-substrate gap in these two regions so that they may have almost the same V-T characteristics and also the reflection electrode film 6 made of Al / Mo is formed so as to overlap with a transmission electrode film 5 made of ITO all around an outer periphery of the transmission electrode film 5 by a width of at least 2 μm, thus suppressing electric erosion from occurring between the ITO and Al substances at the edge of the transmission electrode film 5.

Owner:NEC LCD TECH CORP

Color filter substrate for organic EL element

InactiveUS20070003743A1Good image displayInhibition of defect generationMaterial nanotechnologySolid-state devicesDisplay deviceDark spot

The main object of the present invention is to provide an inexpensive color filter substrate for an organic EL element and an organic EL display device which are capable of displaying good images having no defects such as dark spots. To attain the object, the invention provides a color filter substrate for an organic EL element having a substrate, a colored layer formed in a pattern form on / over the substrate, and a transparent electrode layer and a conductive layer laminated, in any order, on / over the colored layer, wherein the conductive layer is a coated film.

Owner:DAI NIPPON PRINTING CO LTD

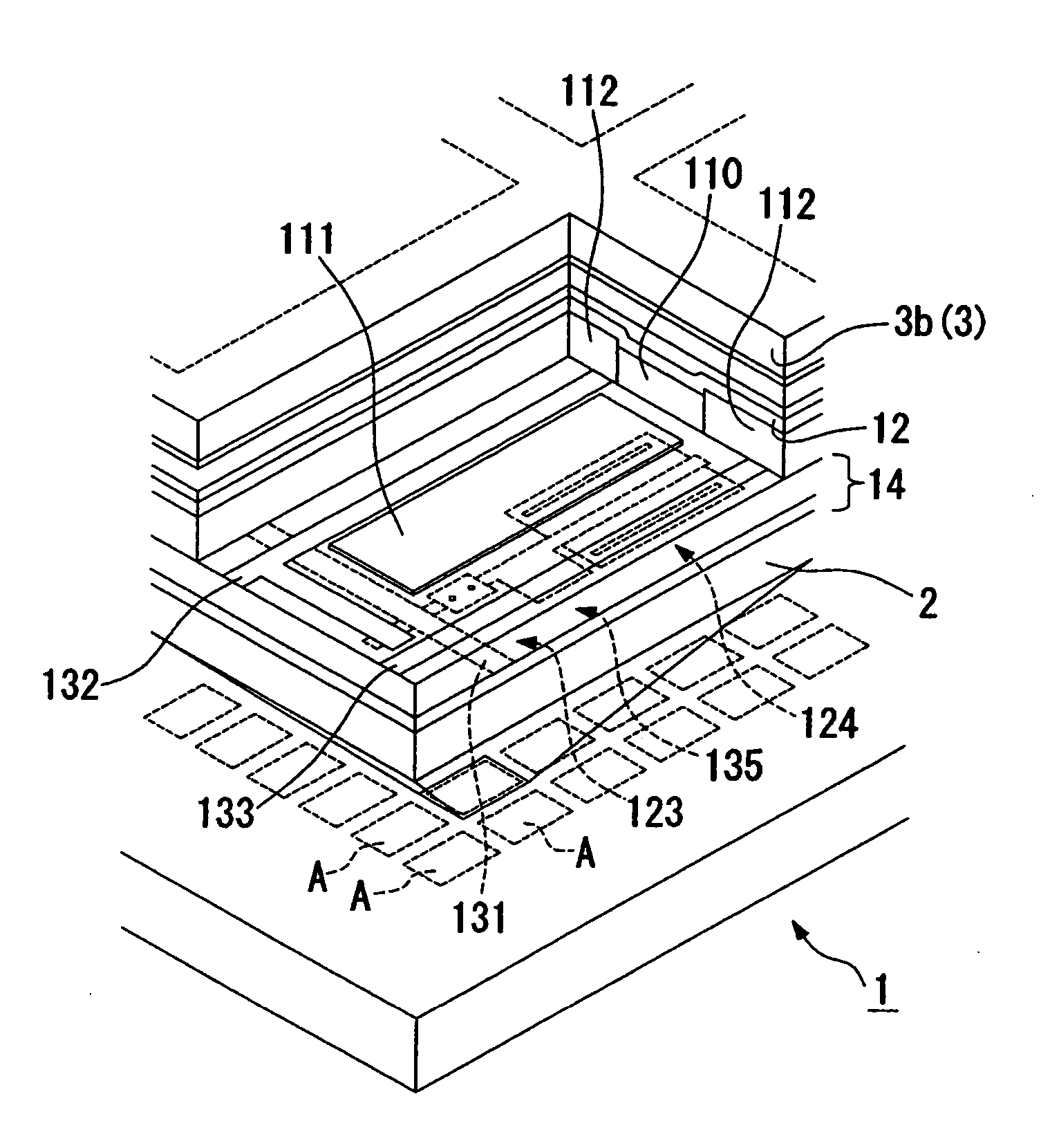

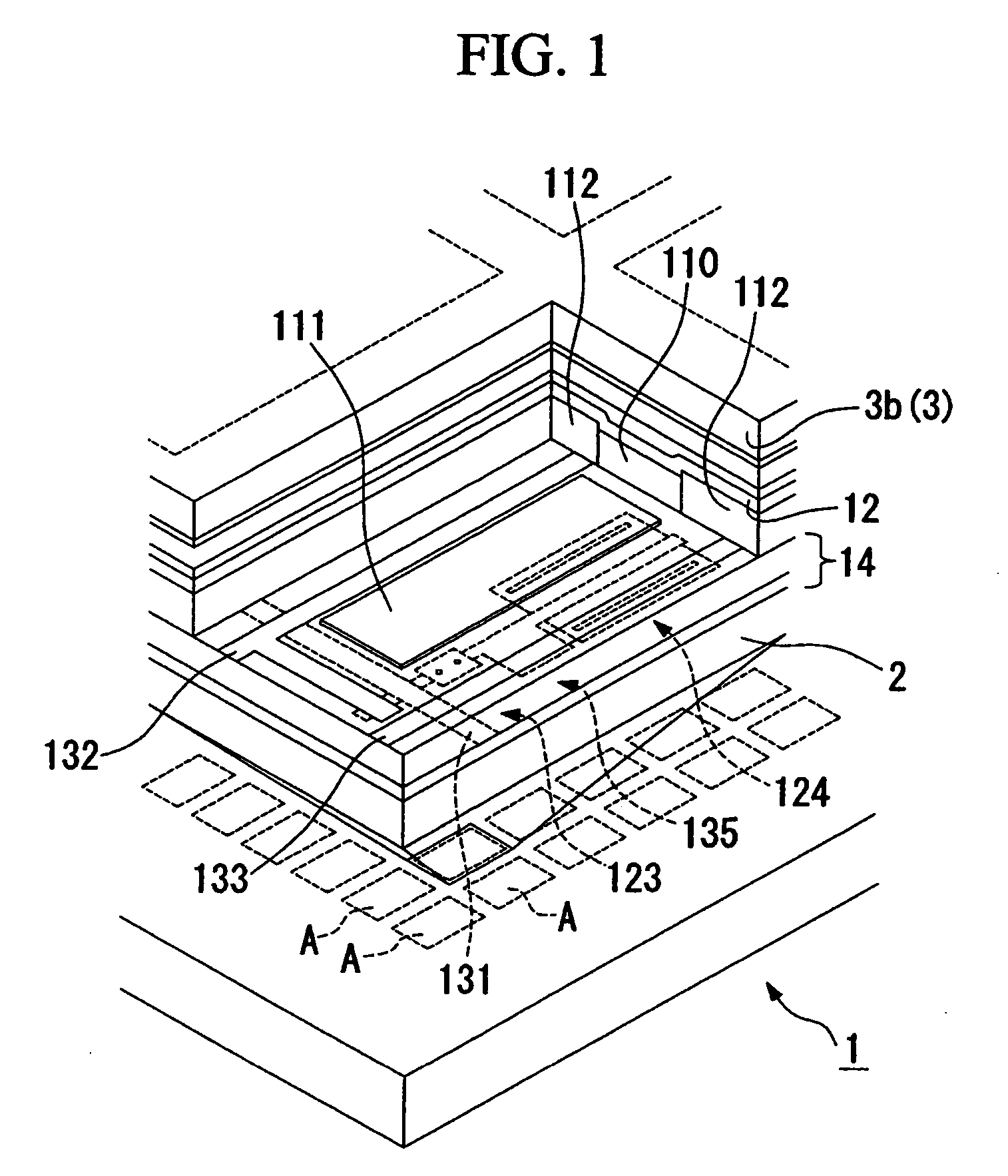

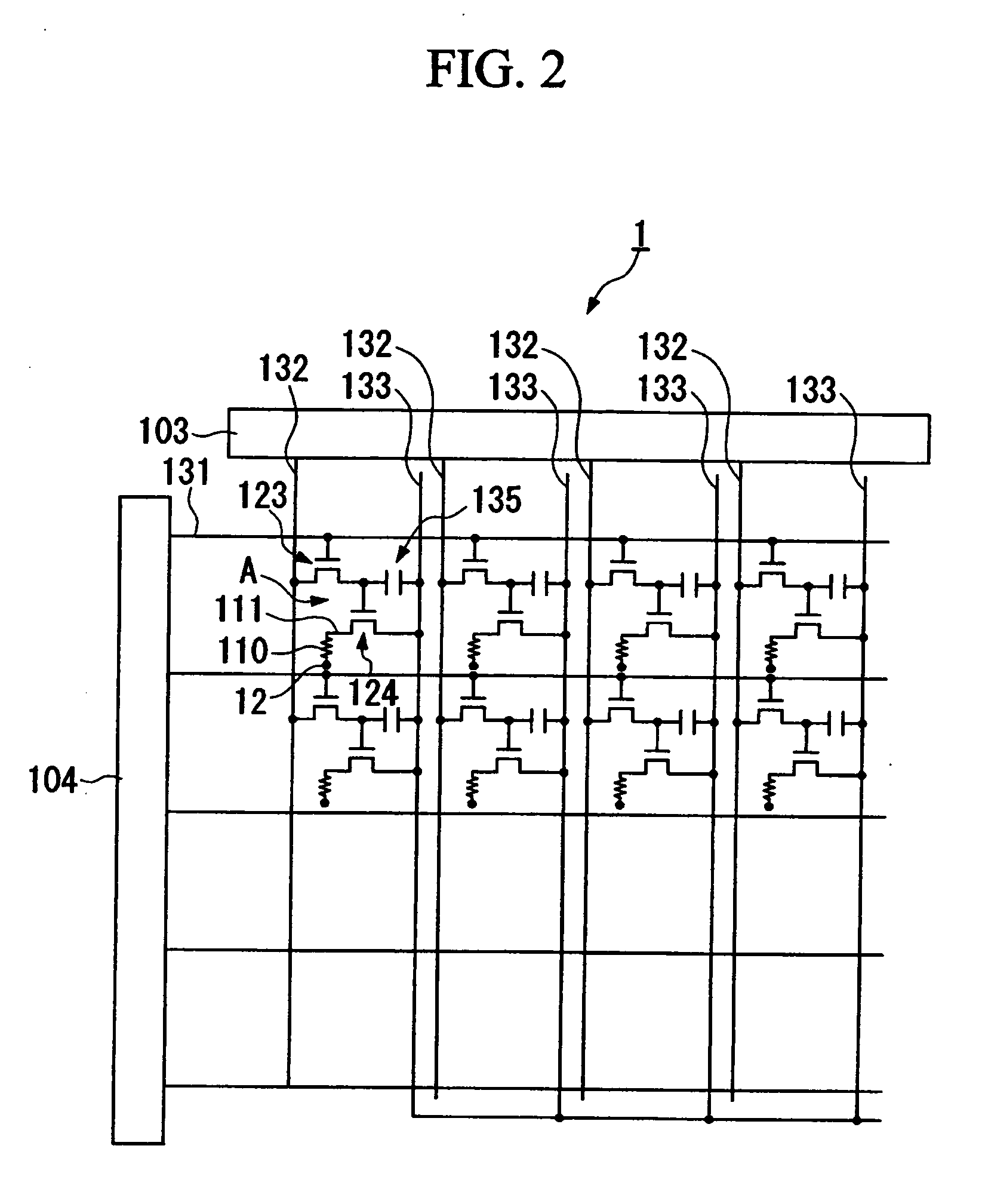

Organic EL device and electronic apparatus

ActiveUS20050269947A1High color purityIncrease the driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsTransmitted light

An organic EL device includes light-reflective electrodes; light-transmissive electrodes; organic EL layers that are respectively provided between the light-reflective electrodes and the light-transmissive electrodes to emit a plurality of color light components, the organic EL layer emitting a different color light component in each pixel; and transflective layers that are selectively provide in predetermined color pixels to reflect or transmit light emitted from the organic EL layers, respectively, each transflective layer being opposite to the light-reflective electrode with the organic EL layer interposed therebetween.

Owner:INTELLECTUAL KEYSTONE TECH LLC

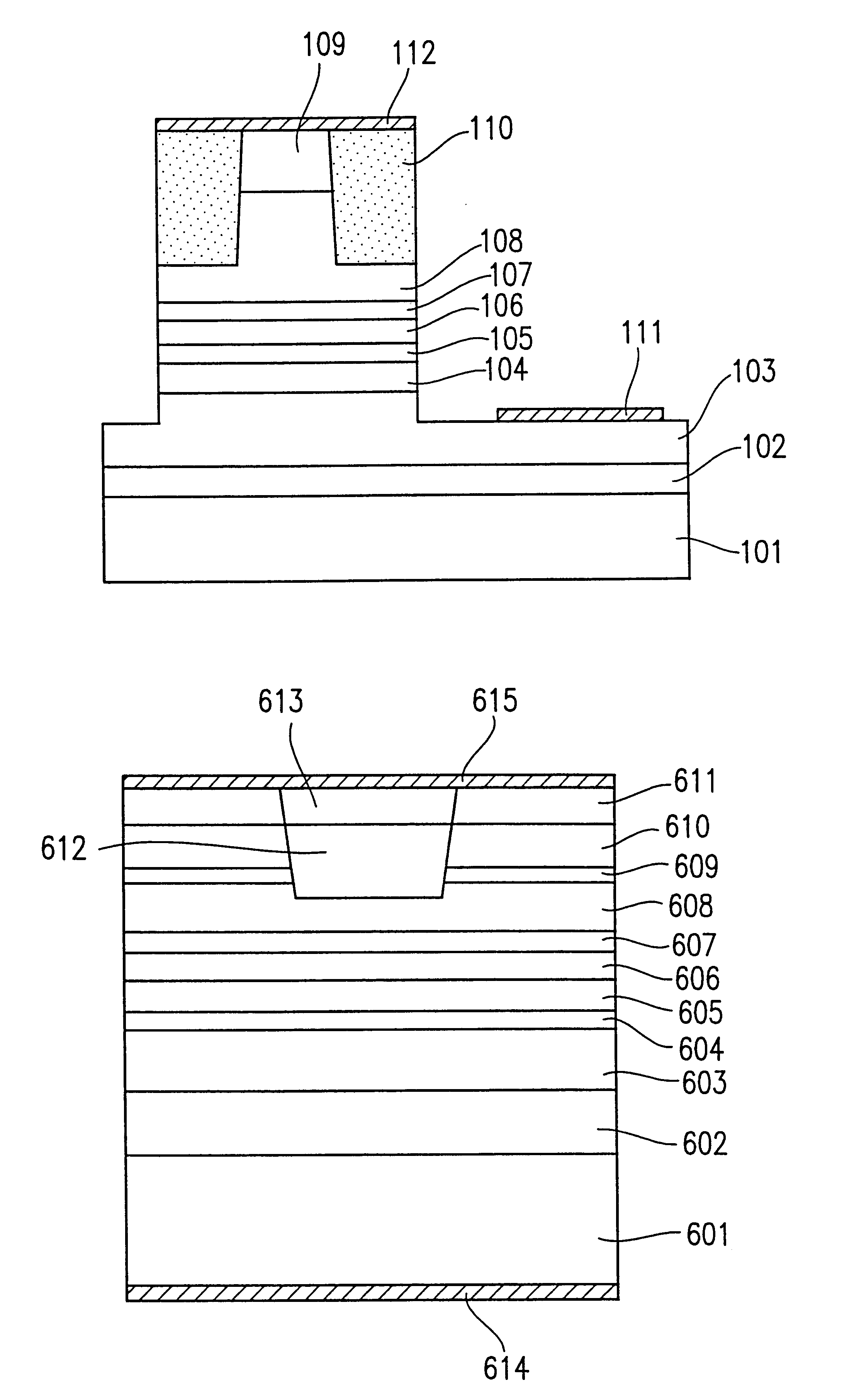

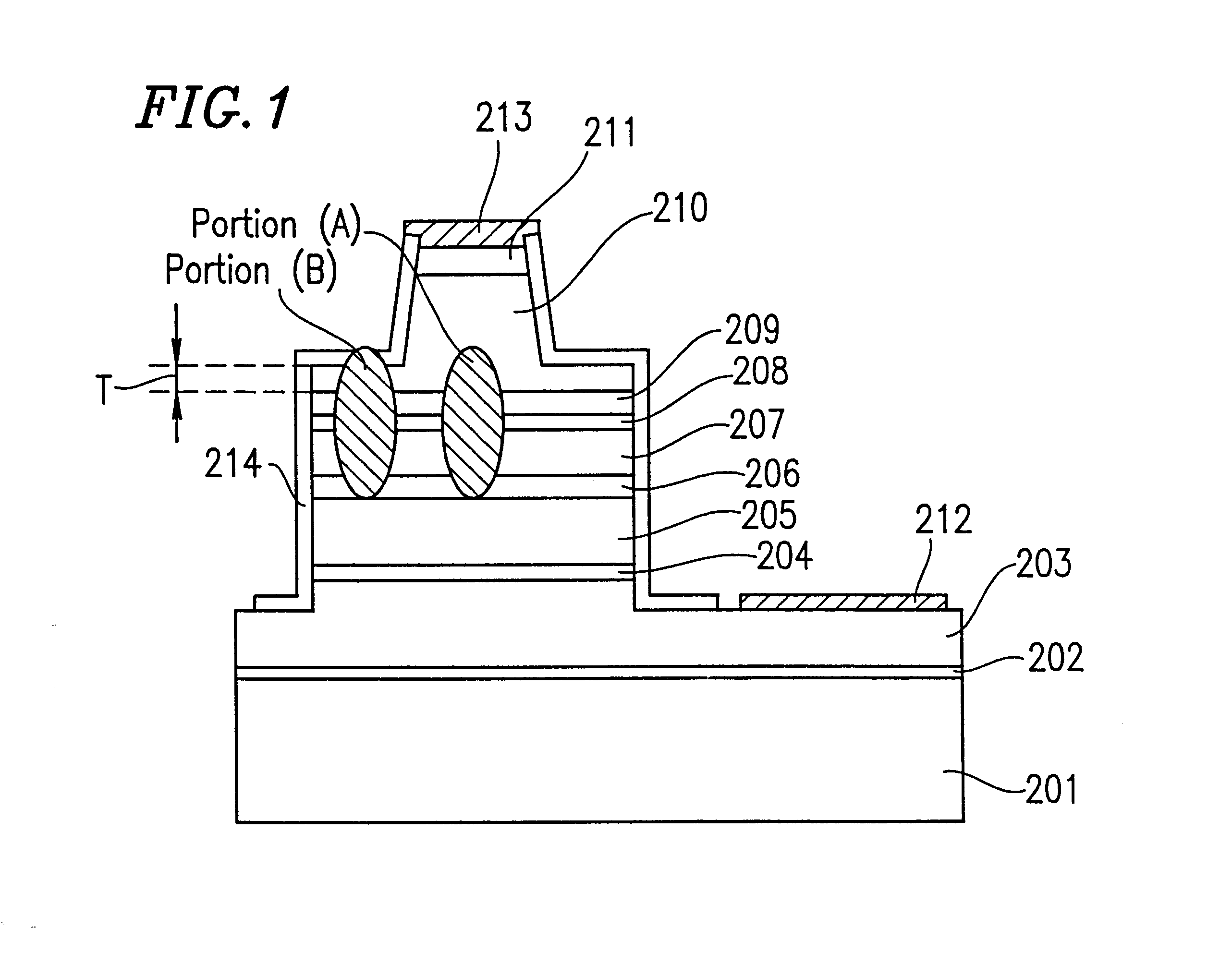

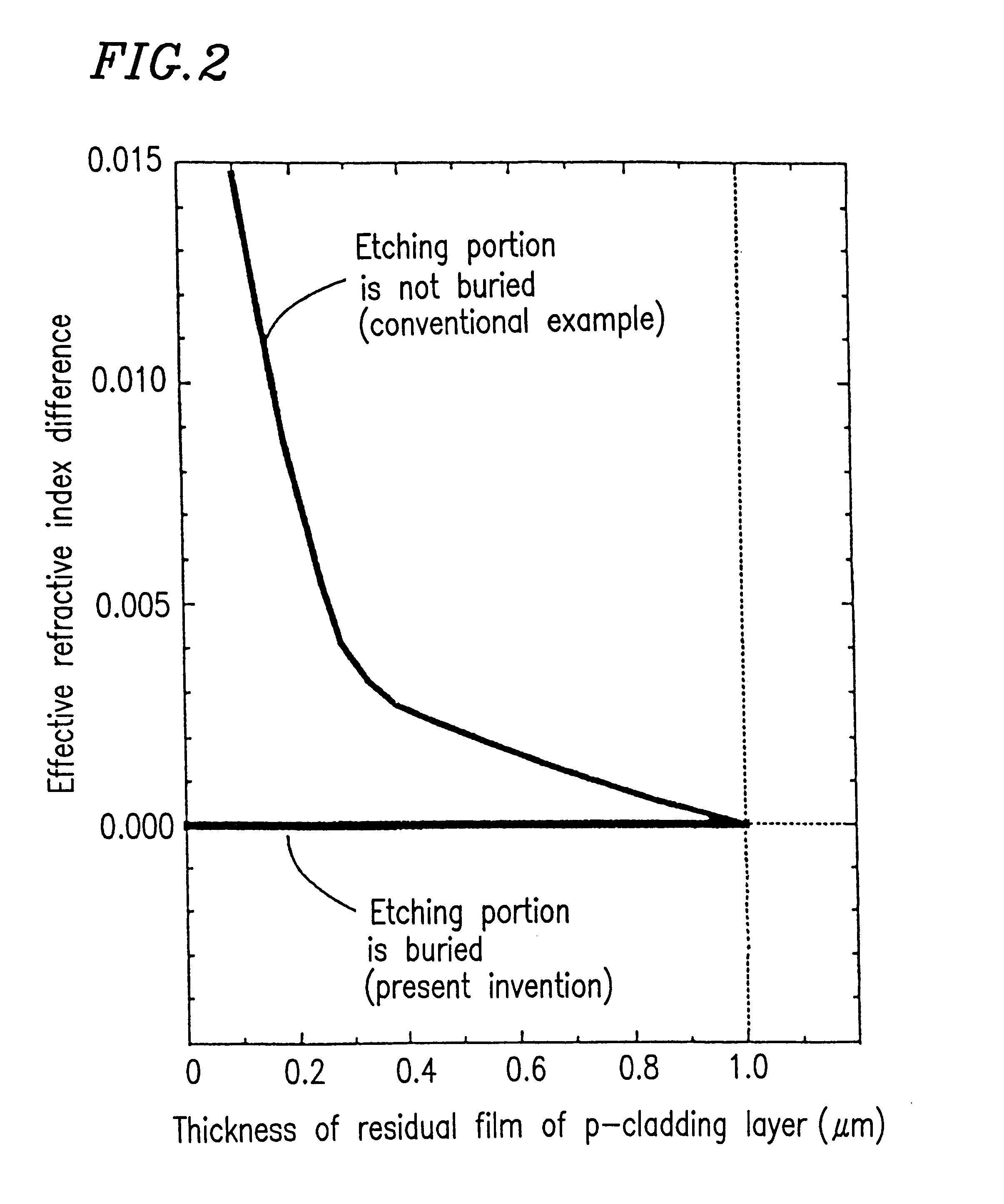

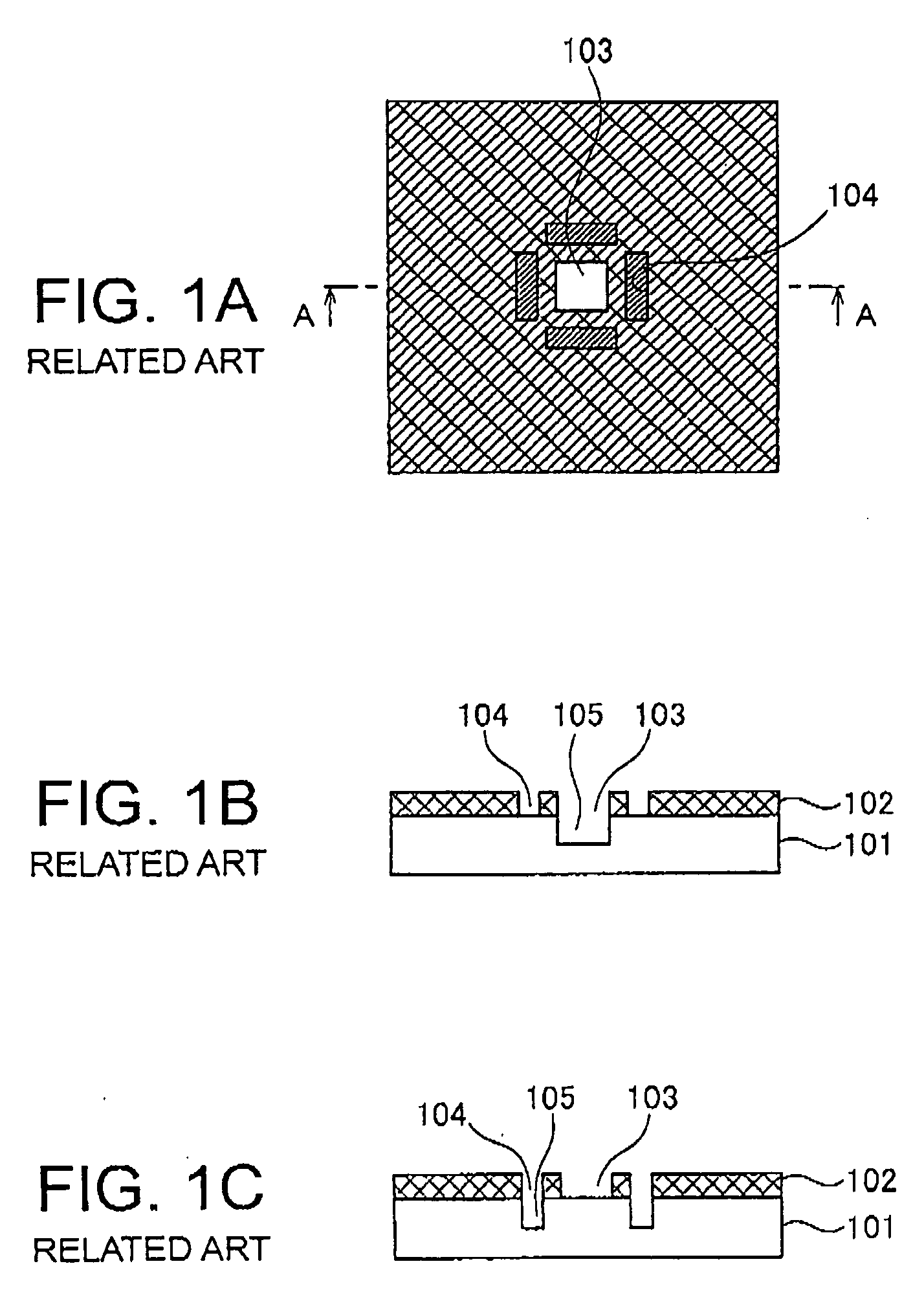

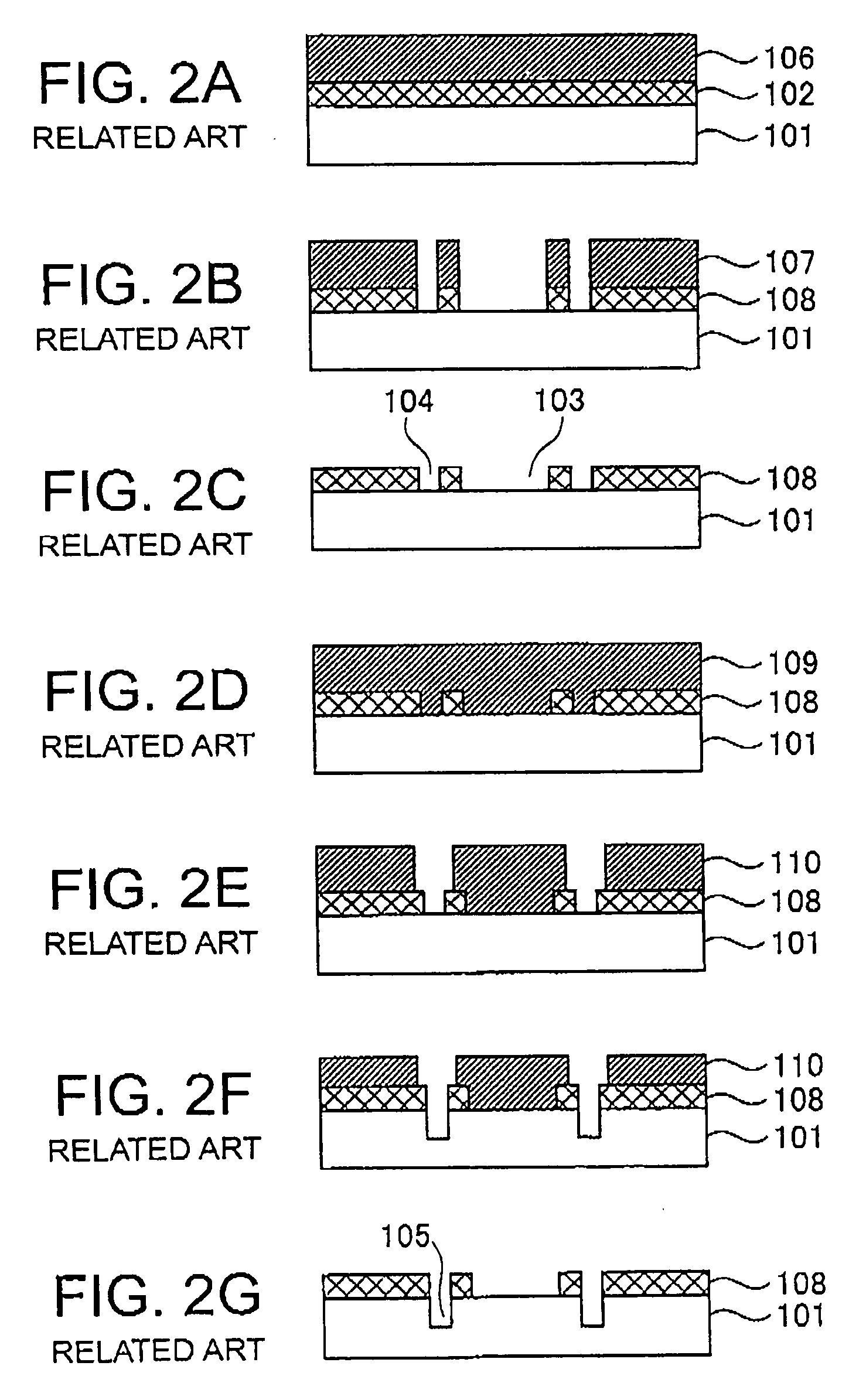

Compound semiconductor laser

InactiveUS6597716B1Efficient manufacturingUniform characteristicsOptical wave guidanceLaser detailsRefractive indexActive layer

A compound semiconductor laser of a III group nitride semiconductor of the present invention includes a first cladding layer 104 of a first conduction type formed on a substrate 101, an active layer 106 formed on the first cladding layer, a second cladding layer 108 of a second conduction type formed on the active layer 106, and a buried layer 110 formed on the second cladding layer 108, the buried layer having an opening portion for constricting a current in a selected region of the active layer, wherein an upper portion of the second cladding layer 108 has a ridge portion, the ridge portion residing in the opening portion of the buried layer 110, and the buried layer 110 does not substantially absorb light output from the active layer 106, and the buried layer has a refractive index which is approximately identical with that of the second cladding layer 108.

Owner:SHARP KK

Photoelectric conversion device and manufacturing process thereof

InactiveUS20040007753A1Improve reliabilityAvoid it happening againFinal product manufactureSemiconductor/solid-state device detailsSemiconductor packagePhotoelectric conversion

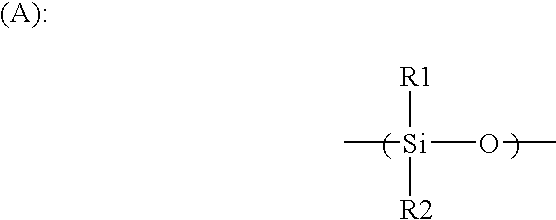

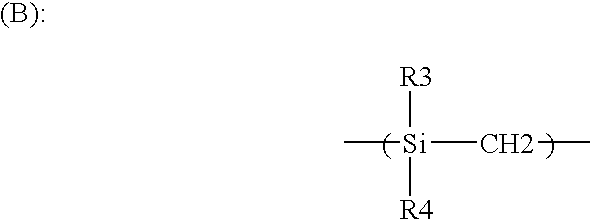

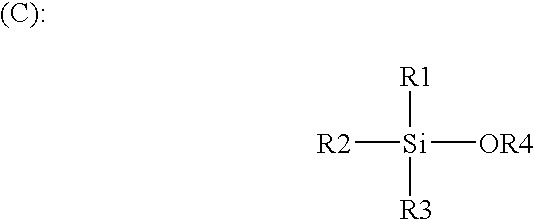

There is disclosed a photoelectric conversion device which is manufactured by depositing numerous crystalline semiconductor particles of one conductivity type on a substrate having an electrode of one side to join the crystalline semiconductor particles to the substrate, interposing an insulator among the crystalline semiconductor particles, forming a semiconductor layer of the opposite conductivity type over the crystalline semiconductor particles, and connecting an electrode to the semiconductor layer of the opposite conductivity type, in which the insulator comprises a mixture or reaction product of polysiloxane and polycarbosilane. The insulator interposed among the crystalline semiconductor particles is free from defects such as cracking and peeling, so that a low cost photoelectric conversion device with high reliability can be provided.

Owner:KYOCERA CORP

Device and method for producing single crystals by vapor deposition

ActiveUS7361222B2Down and eliminate formationInhibition of defect generationPolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsHalogenPhysical chemistry

Owner:NORSTEL

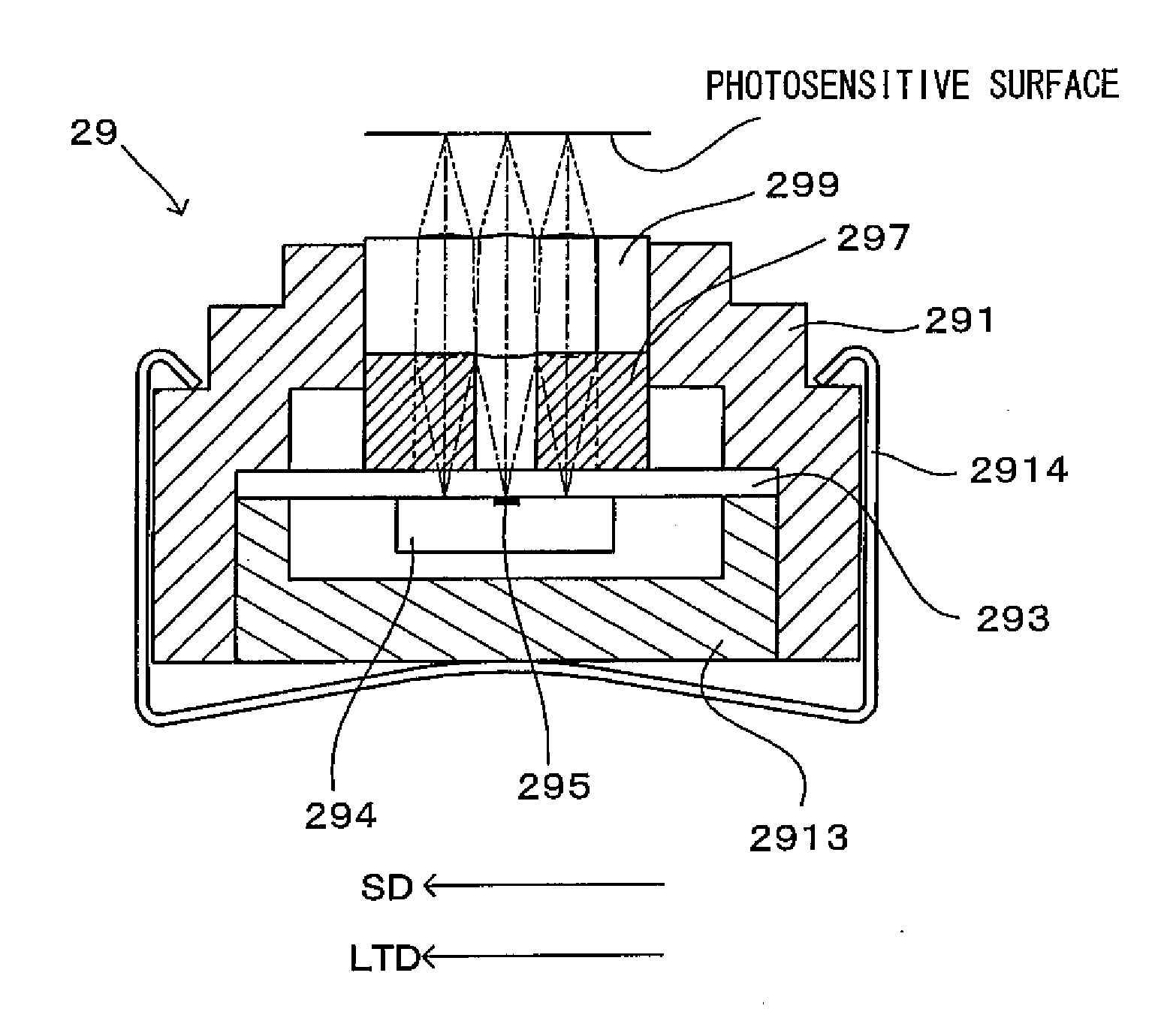

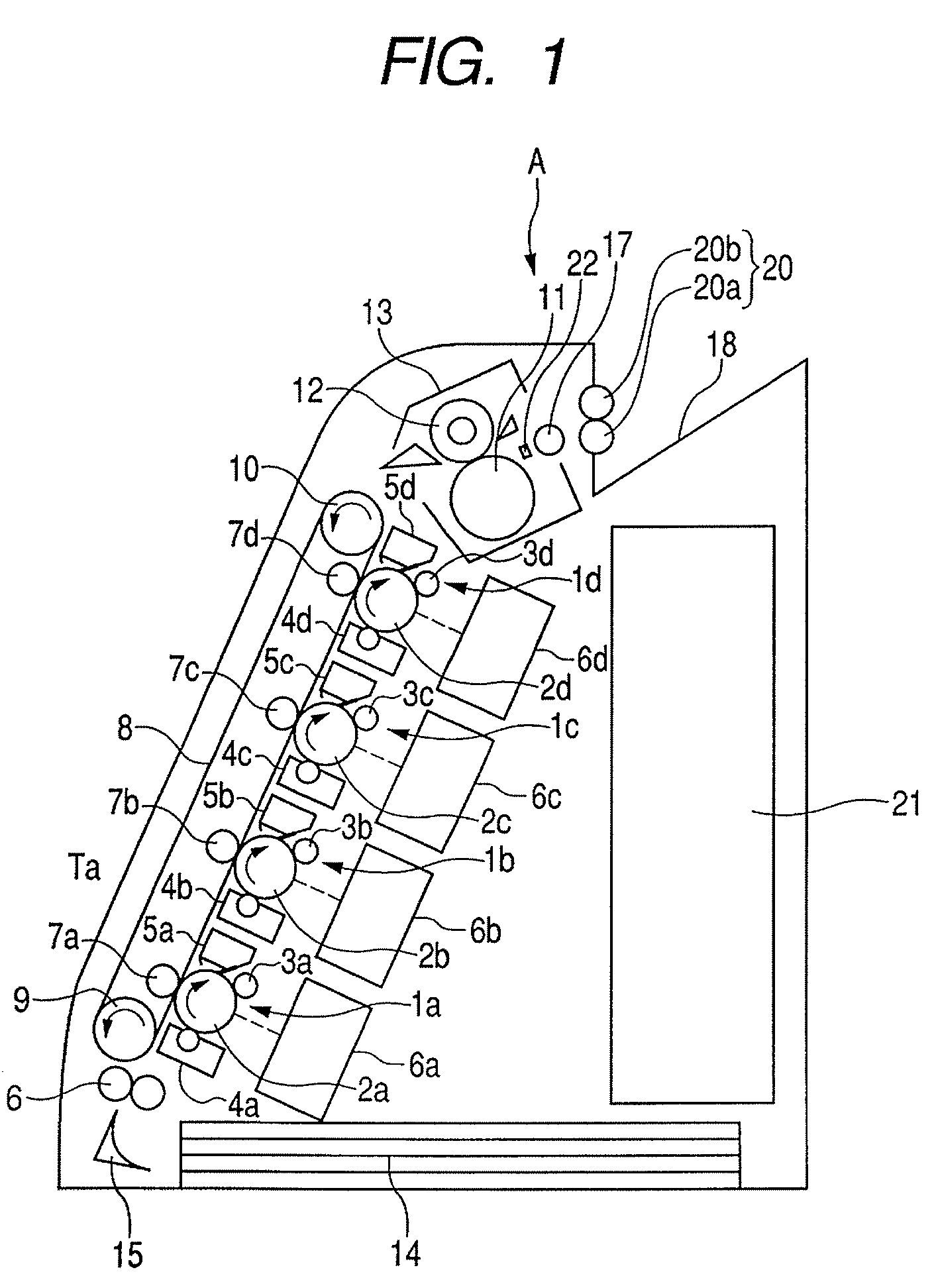

Line Head and Image Forming Apparatus Using the Same

InactiveUS20080030566A1Avoid it happening againIncrease the number ofInking apparatusElectrographic process apparatusImage formationOptoelectronics

Owner:SEIKO EPSON CORP

Wiring board, semiconductor apparatus and method of manufacturing them

ActiveUS20090095514A1Avoid it happening againInhibition of defect generationPrinted circuit assemblingSemiconductor/solid-state device detailsSemiconductorDielectric layer

There are provided steps of providing a dielectric layer and a wiring layer on a surface of a support to form an intermediate body, removing the support from the intermediate body to obtain a wiring board, and carrying out a roughening treatment over a surface of the support before the intermediate body forming step.

Owner:SHINKO ELECTRIC IND CO LTD

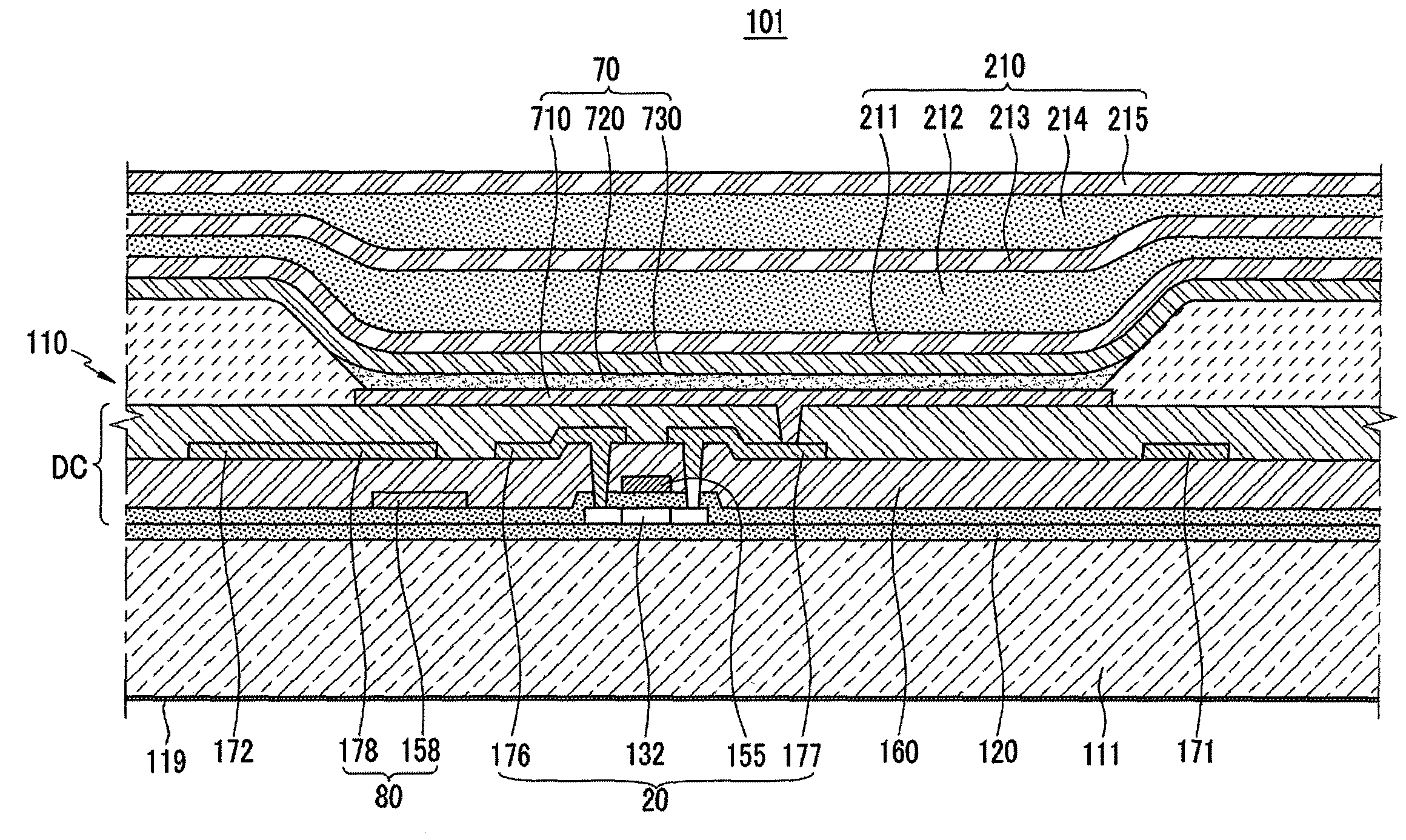

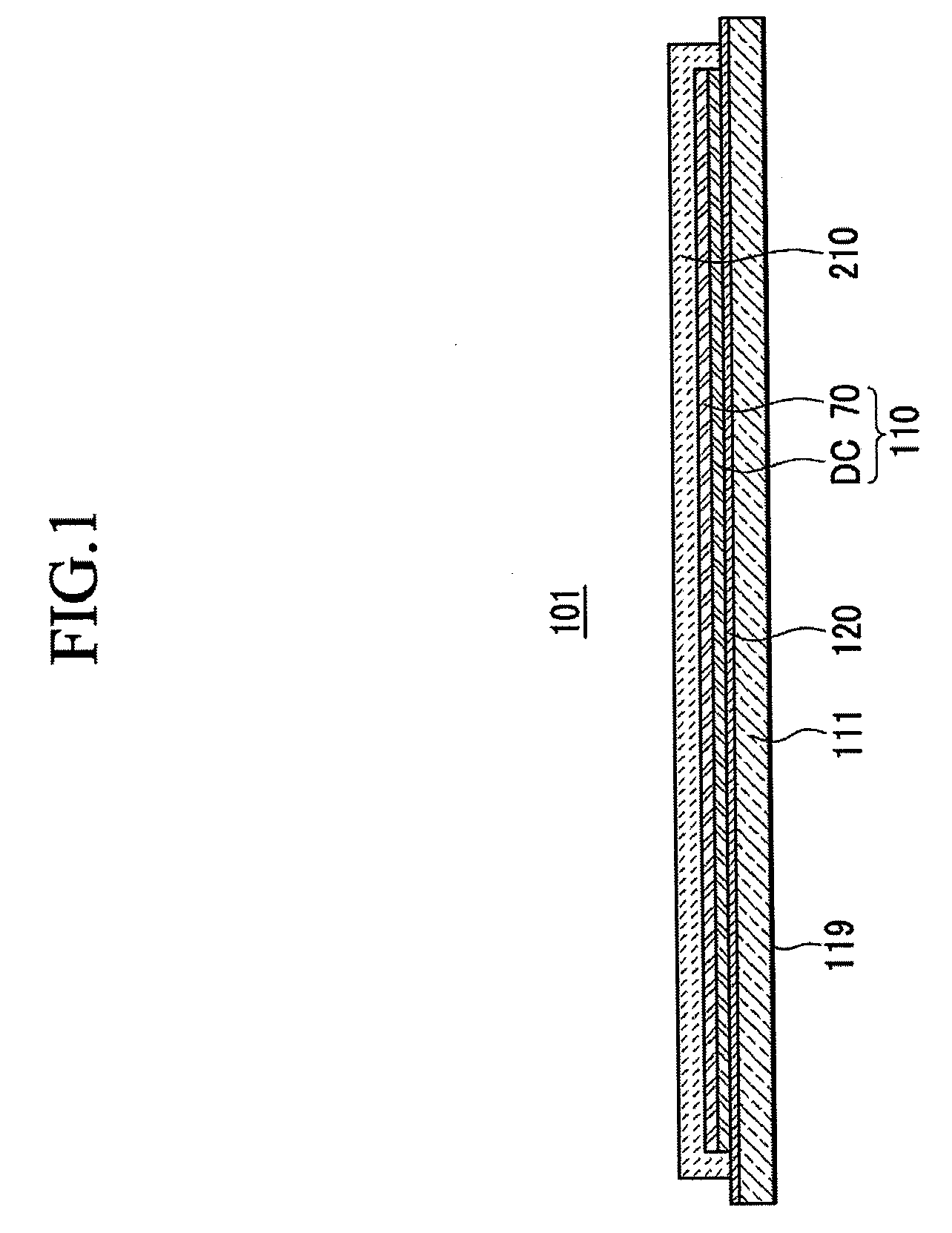

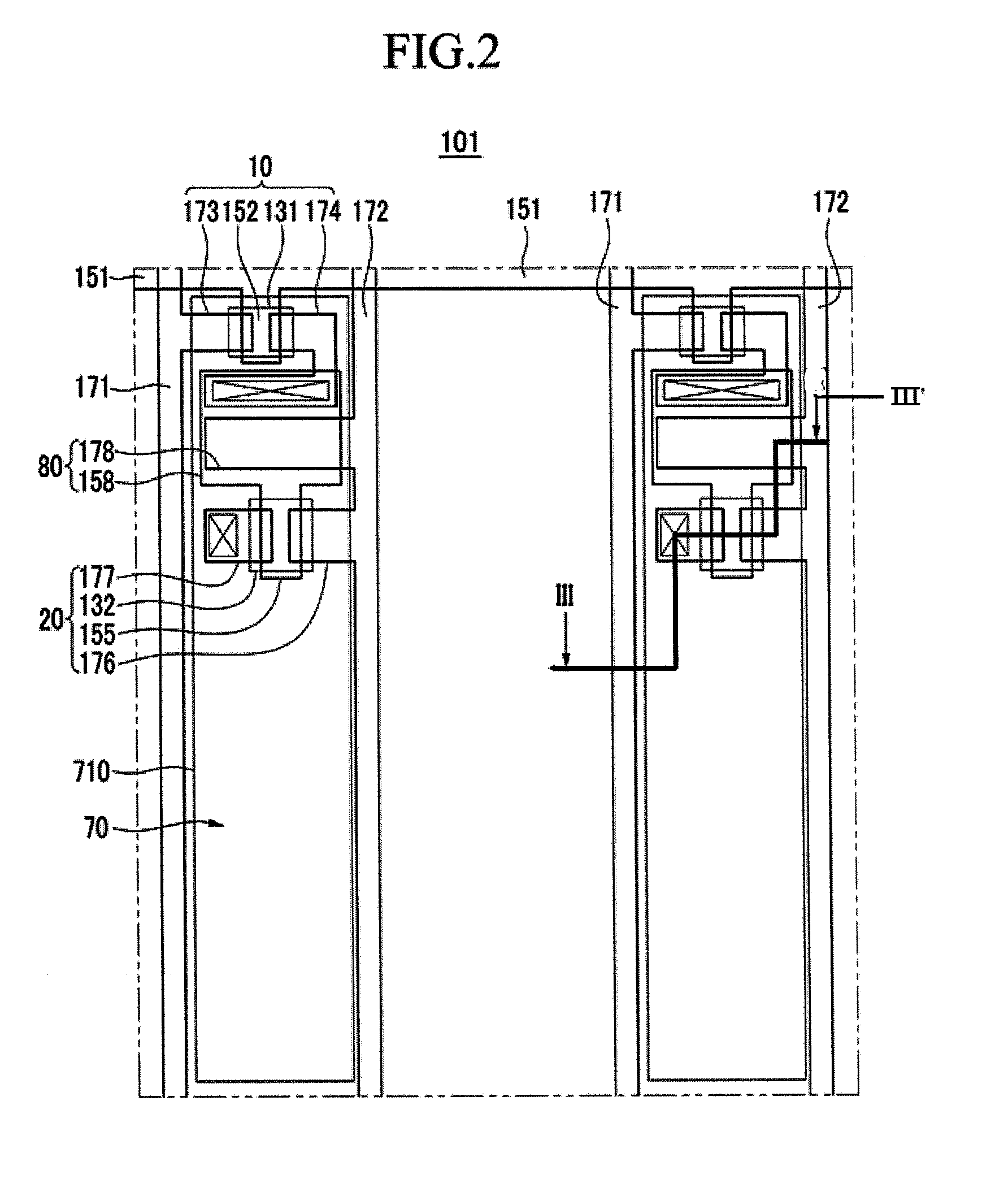

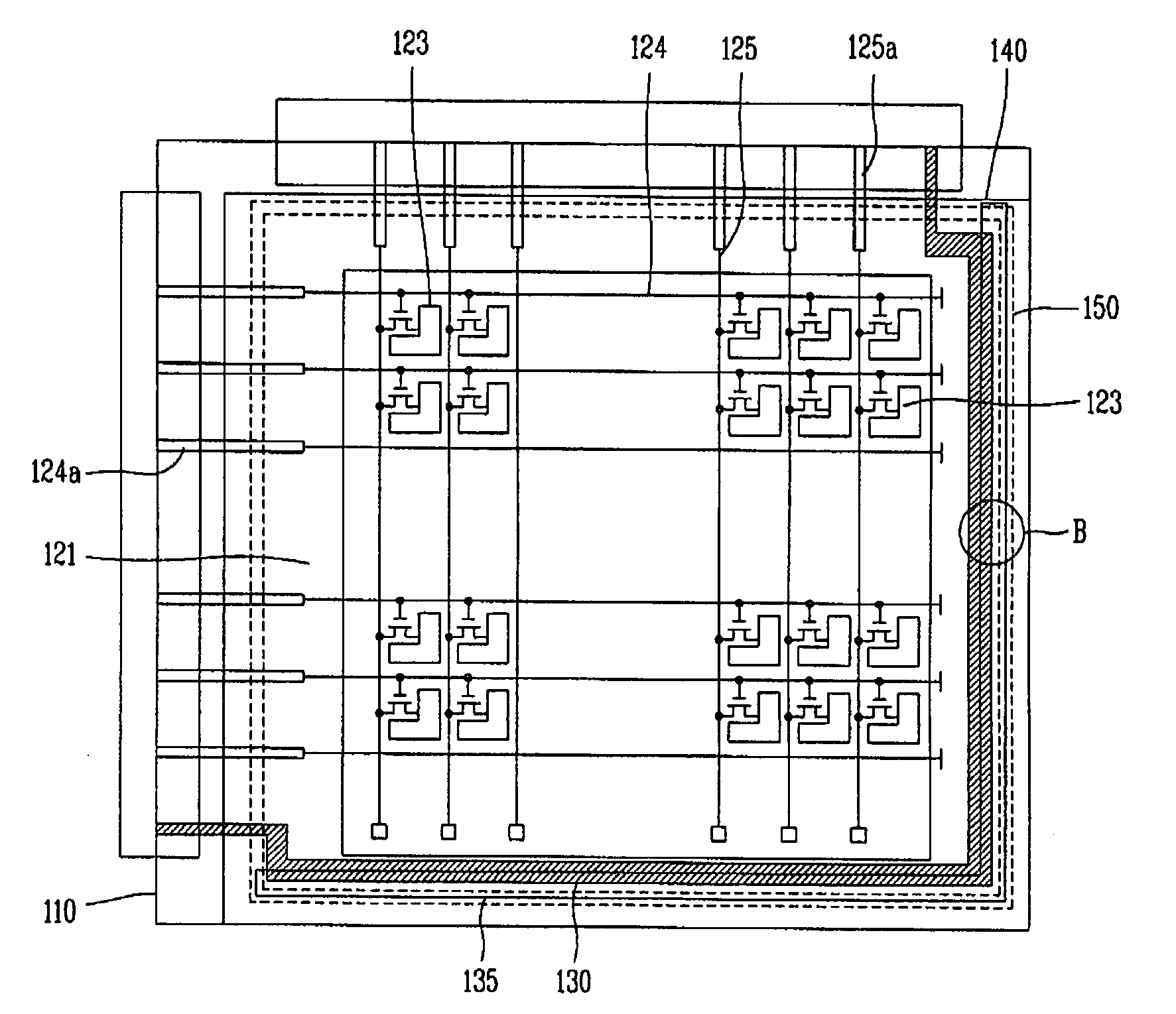

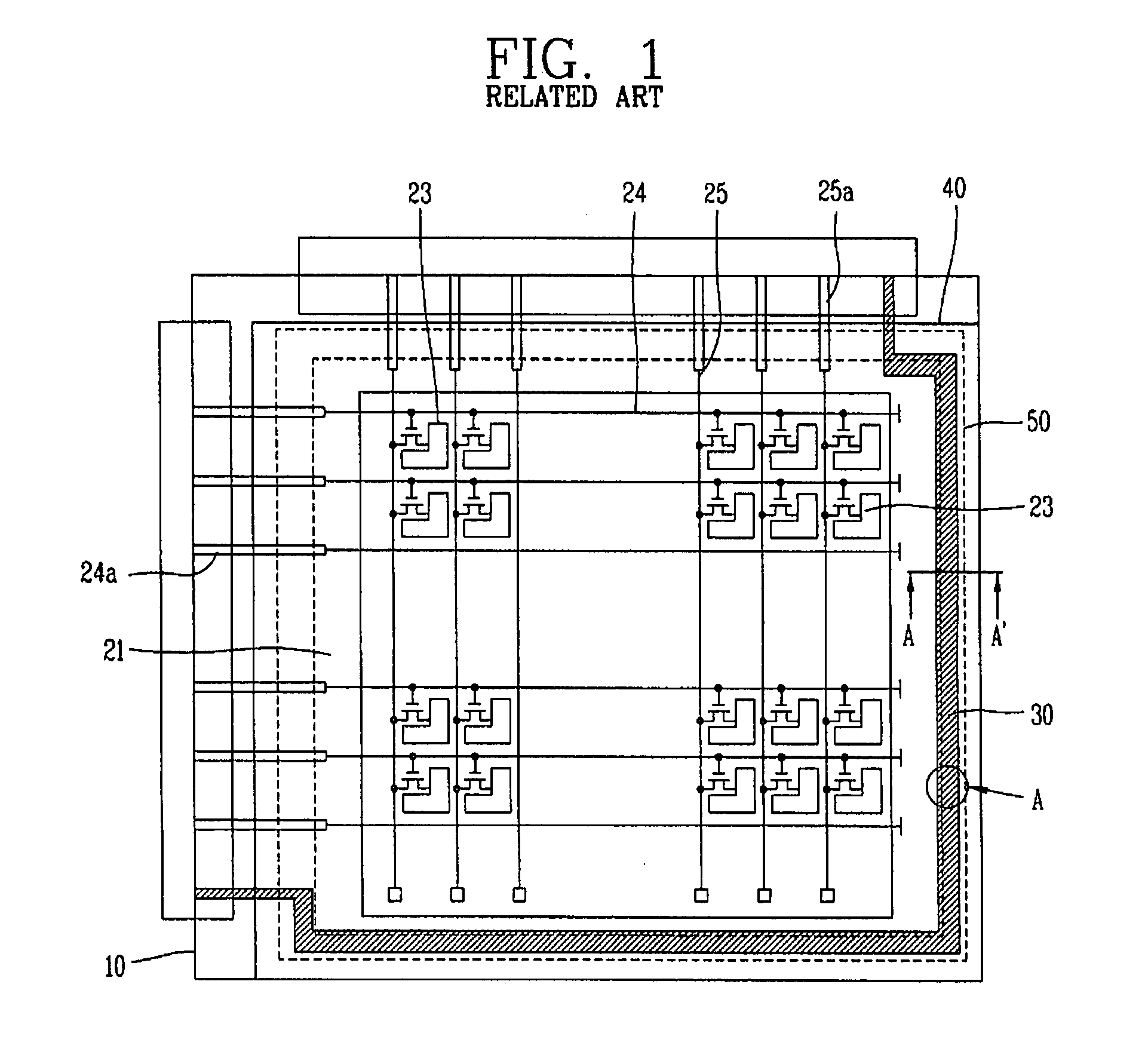

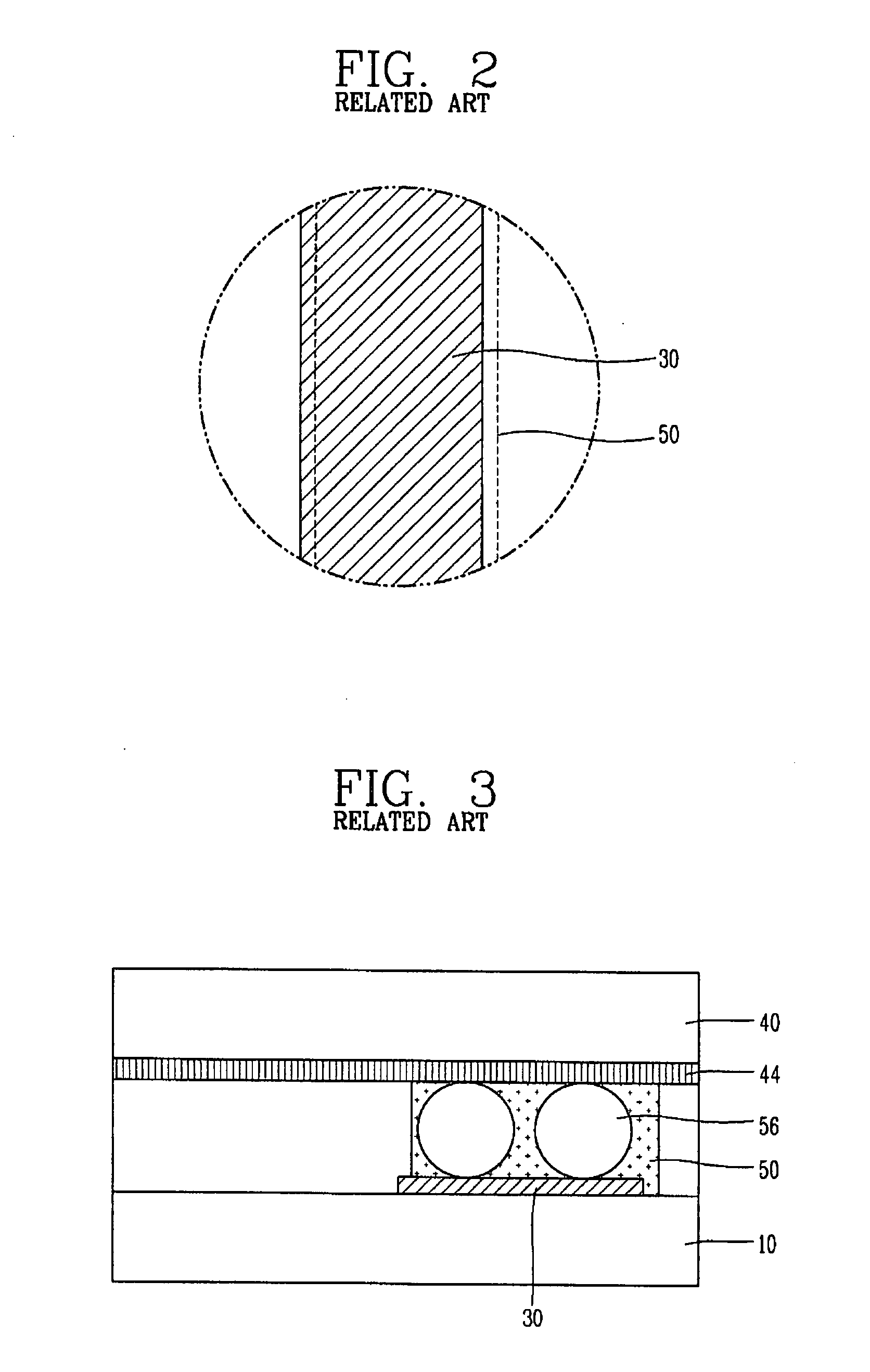

Liquid crystal display device

ActiveUS20080002134A1Efficient detectionInhibition of defect generationNon-linear opticsLiquid-crystal displayVisual inspection

A liquid crystal display module includes an observation region to allow a visual inspection be performed after bonding of the substrates for inspecting the sealant that may be otherwise blocked by the common voltage line. An embodiment of a liquid crystal display device includes a first electrode on a first substrate, a second electrode and a third electrode on a second substrate, the second electrode electrically contacting the first electrode at a first portion and the third electrode at a second portion, and including a transparent conductive material, a sealant attaching the first and second substrates together in a sealant region, the sealant between the first and second electrodes and the sealant including a plurality of conductive balls for electrically connecting the first and second electrodes, and a liquid crystal layer between the attached first and second substrates and within the sealant.

Owner:LG DISPLAY CO LTD

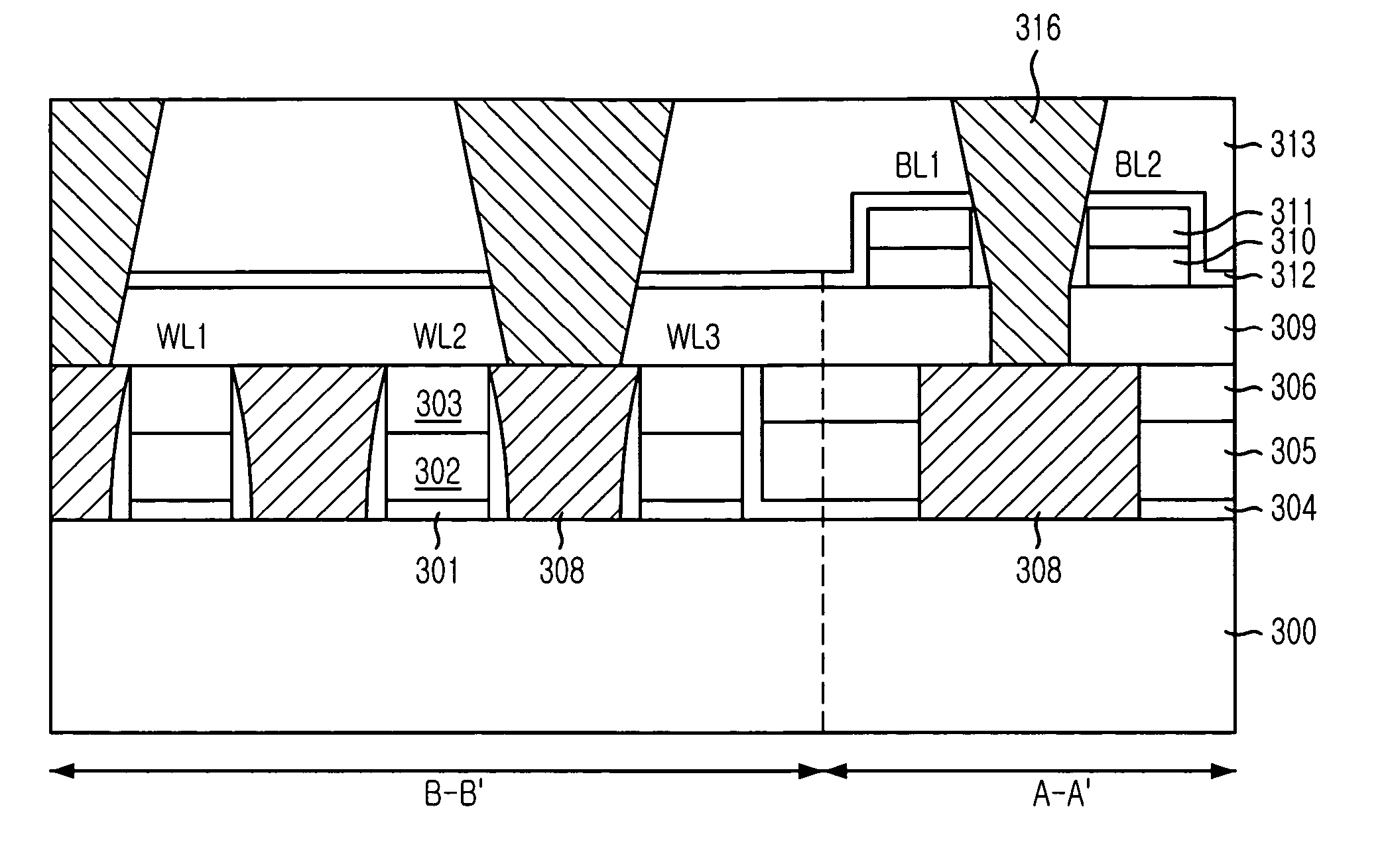

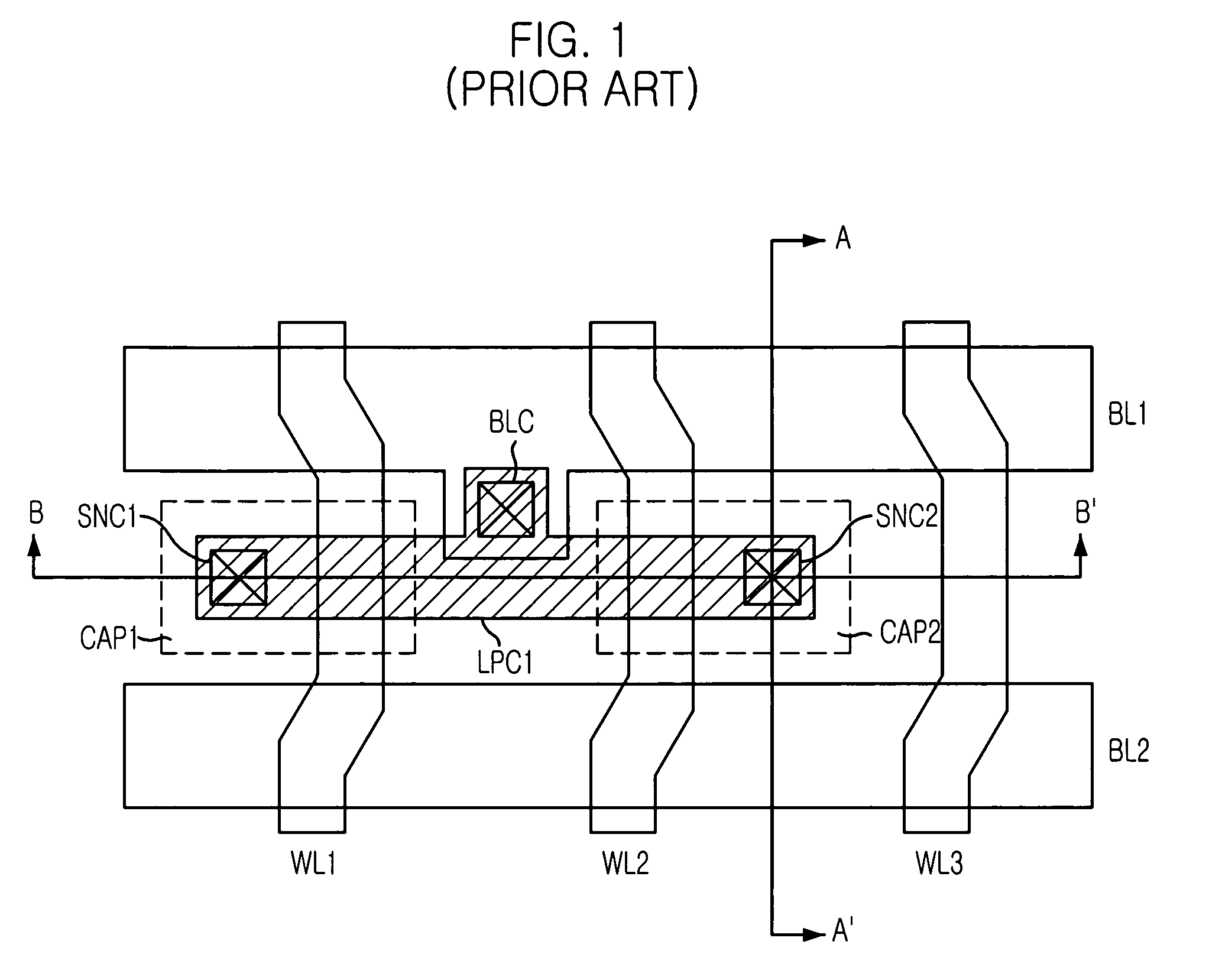

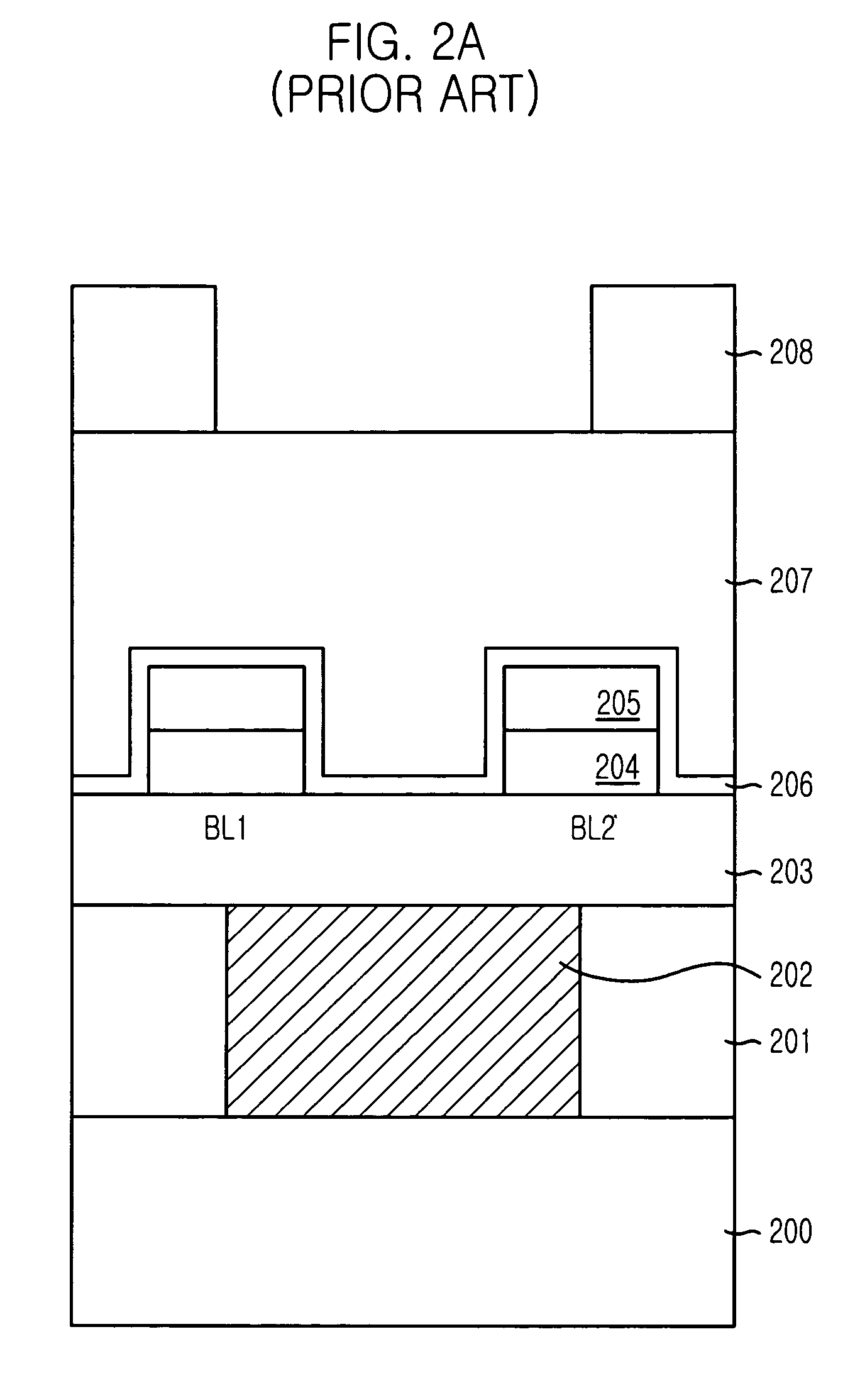

Method for fabricating semiconductor device

InactiveUS7122467B2Inhibition of defect generationSemiconductor/solid-state device manufacturingSemiconductor devicesInter layerInsulation layer

Disclosed is a method for fabricating a semiconductor device with an improved process margin obtained by preventing damage to an inter-layer insulation layer during a wet cleaning process. Particularly, the method includes the steps of: forming a plurality of a first conductive pattern having a stack pattern of a first conductive and a first hard mask; forming a first inter-layer insulation layer of a good gap-fill property with a height between the first conductive material and the first hard mask on the first conductive layer; forming a second inter-layer insulation layer; forming a second conductive layer contacted the first conductive layer between the plurality of the first conductive patterns as passing through the first and the second inter-layer insulation layers; forming a third inter-layer insulation layer; forming a plurality of second conductive patterns; forming a fourth inter-layer insulation layer; and forming a third conductive layer contacted to the second conductive layer.

Owner:SK HYNIX INC

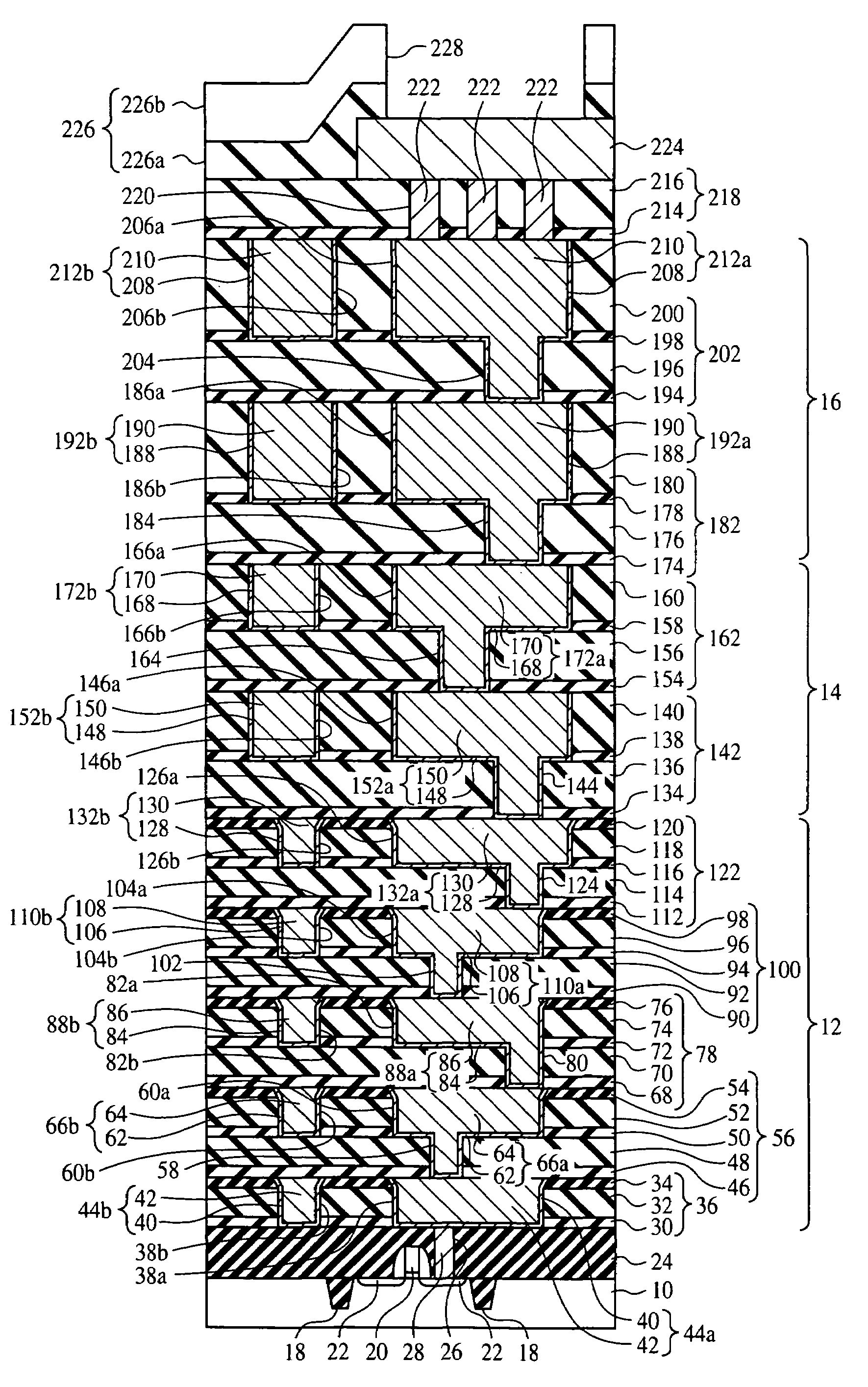

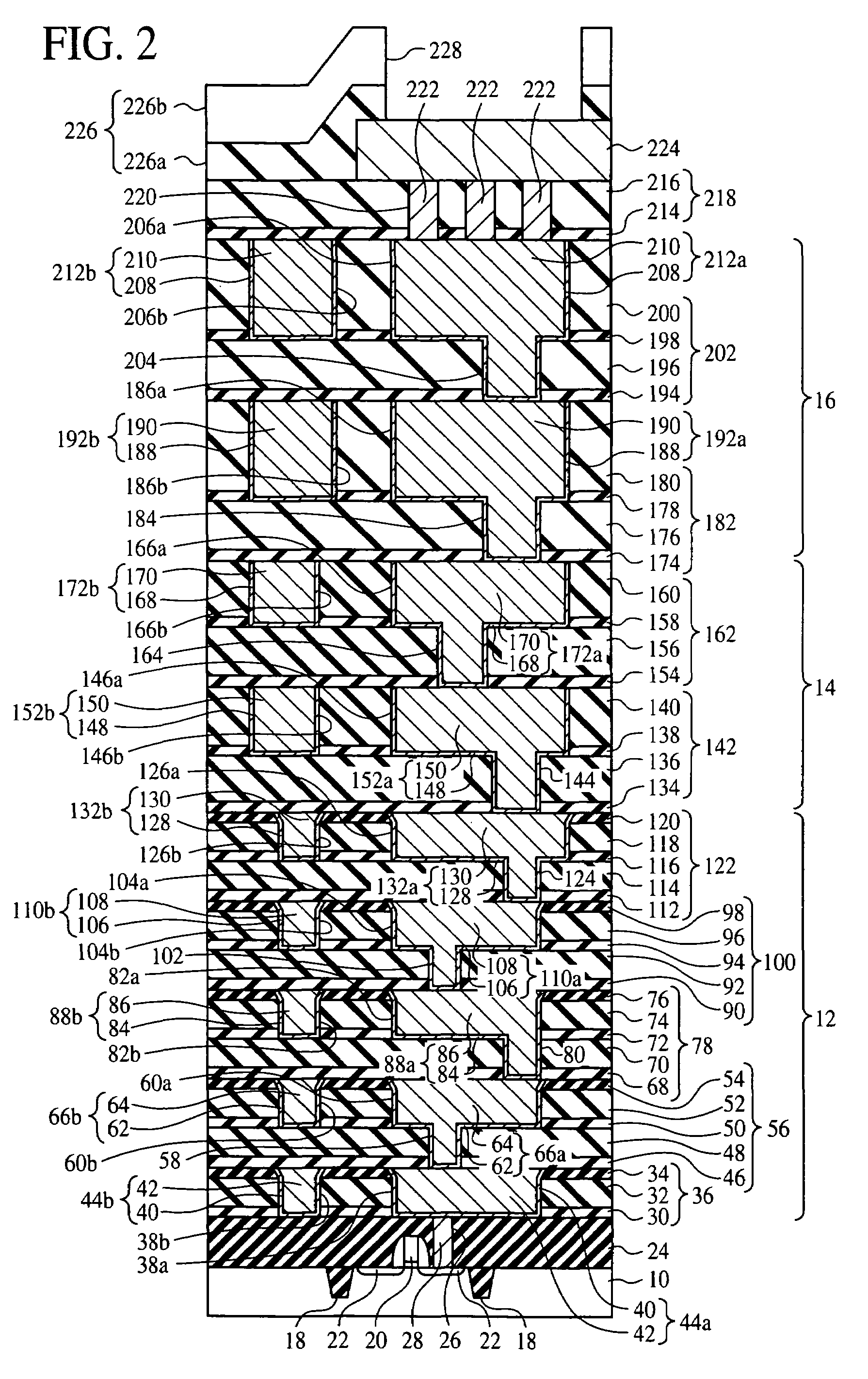

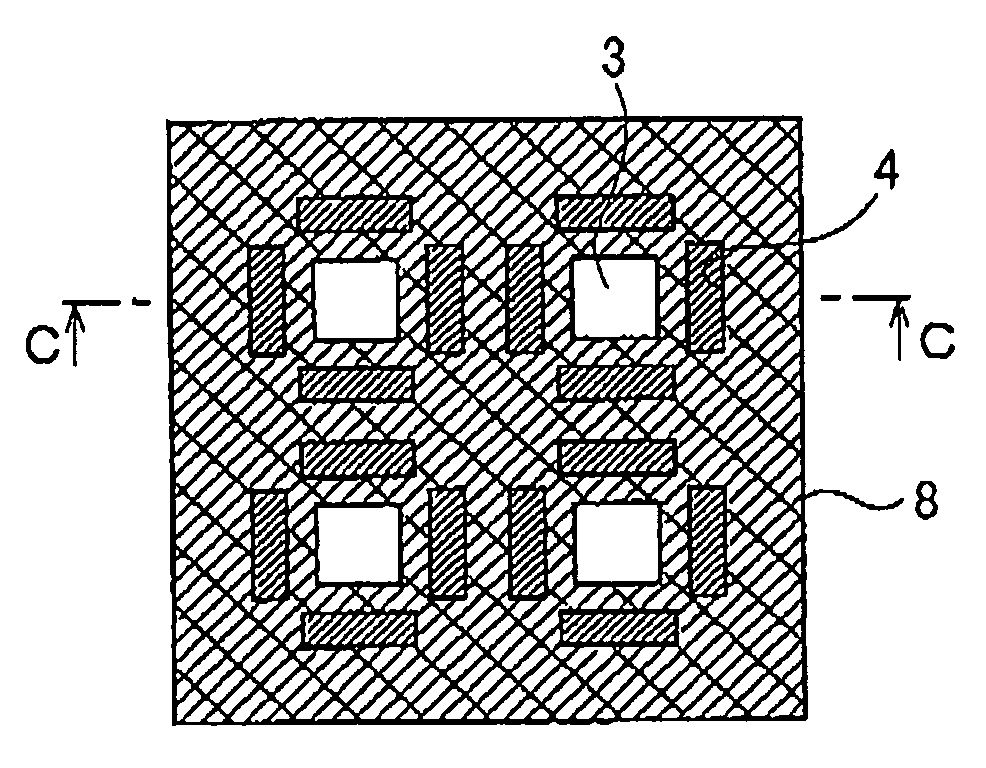

Semiconductor device and method for fabricating the same

InactiveUS7250679B2Inhibition of defect generationReduce interconnectionSemiconductor/solid-state device detailsSolid-state devicesInter layerEngineering

The semiconductor device comprises a lower interconnection part 12 which is formed on a silicon substrate 10 and includes an inter-layer insulation film 36 formed of a low-k film 32 and a hydrophilic insulation film 34 formed on the low-k film 32, and an interconnection layer 44a, 44b buried in interconnection trenches 38a, 38b formed in the inter-layer insulation film 36 and having an interconnection pitch which is a first pitch; and an intermediate interconnection part 14 which is formed on the lower interconnection part 12 and includes an inter-layer insulation film 142 formed of low-k films 136, 140, an interconnection layer 152a, 152b buried in interconnection trenches 146a, 146b formed in the inter-layer insulation film 142 and having an interconnection pitch which is a second pitch larger than the first pitch, and an SiC film 154 formed directly on the low-k film 140 and the interconnection layer 152a, 152b.

Owner:FUJITSU SEMICON LTD

Device and method to producing single crystals by vapour deposition

InactiveUS20080149020A1Down and eliminate formationInhibition of defect generationAfter-treatment apparatusPolycrystalline material growthHalogenHydrogen

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL +1

Polishig fluid for metallic films and method for producing semiconductor substrate using the same

InactiveUS20050176250A1High polishing rateHigh rateSemiconductor/solid-state device manufacturingLapping machinesMetallurgySemiconductor

A polishing fluid for metallic films, wherein the etching rate is 10 nm / min. or less, the polishing rate under a load of 10 KPa is 200 nm / min. or more, and the contrast, a ratio of the above-mentioned polishing rate to the etching rate, is 20 or more; and a method for producing a semiconductor substrate using the same.

Owner:TAKAHASHI HIDEAKI +3

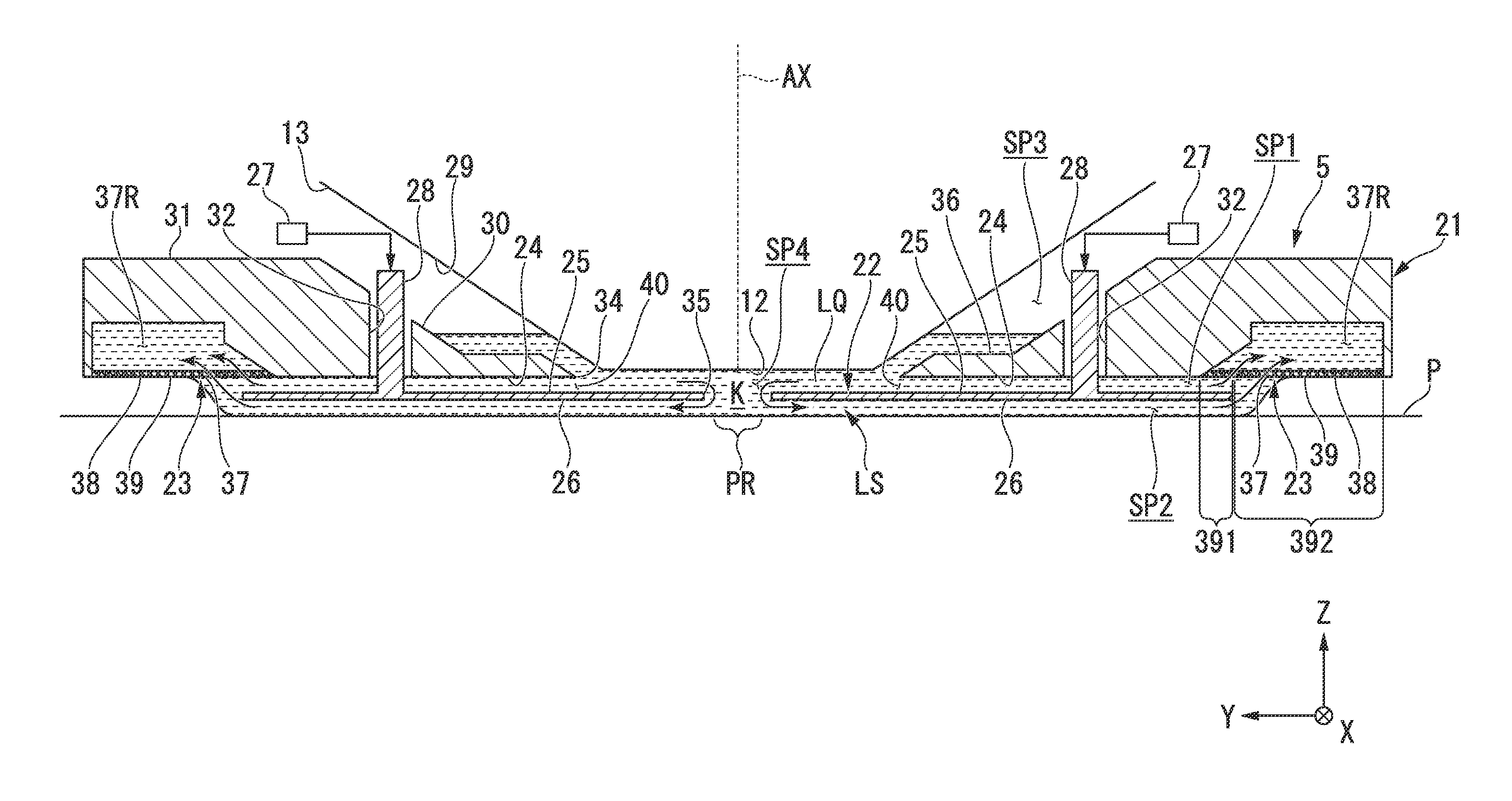

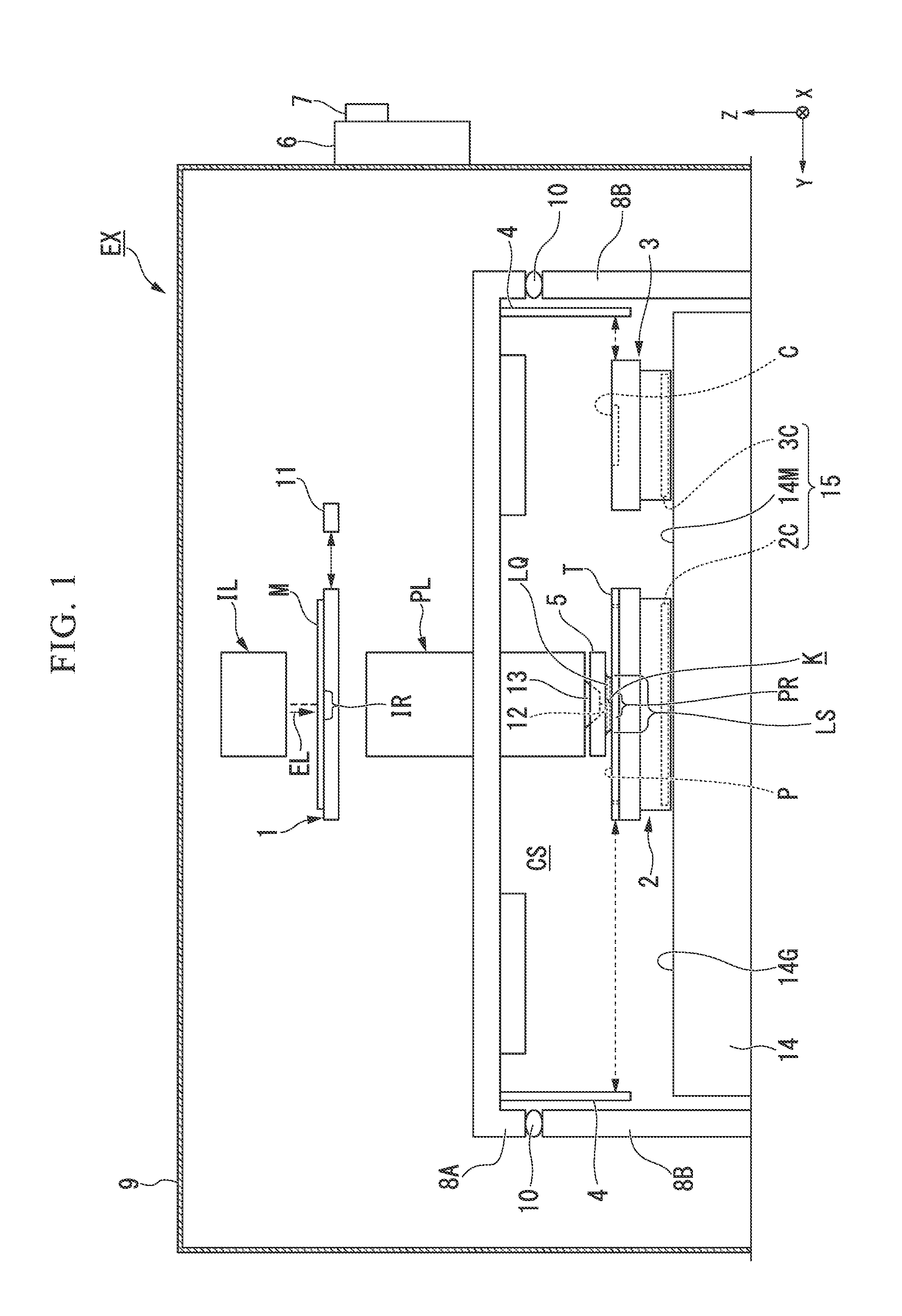

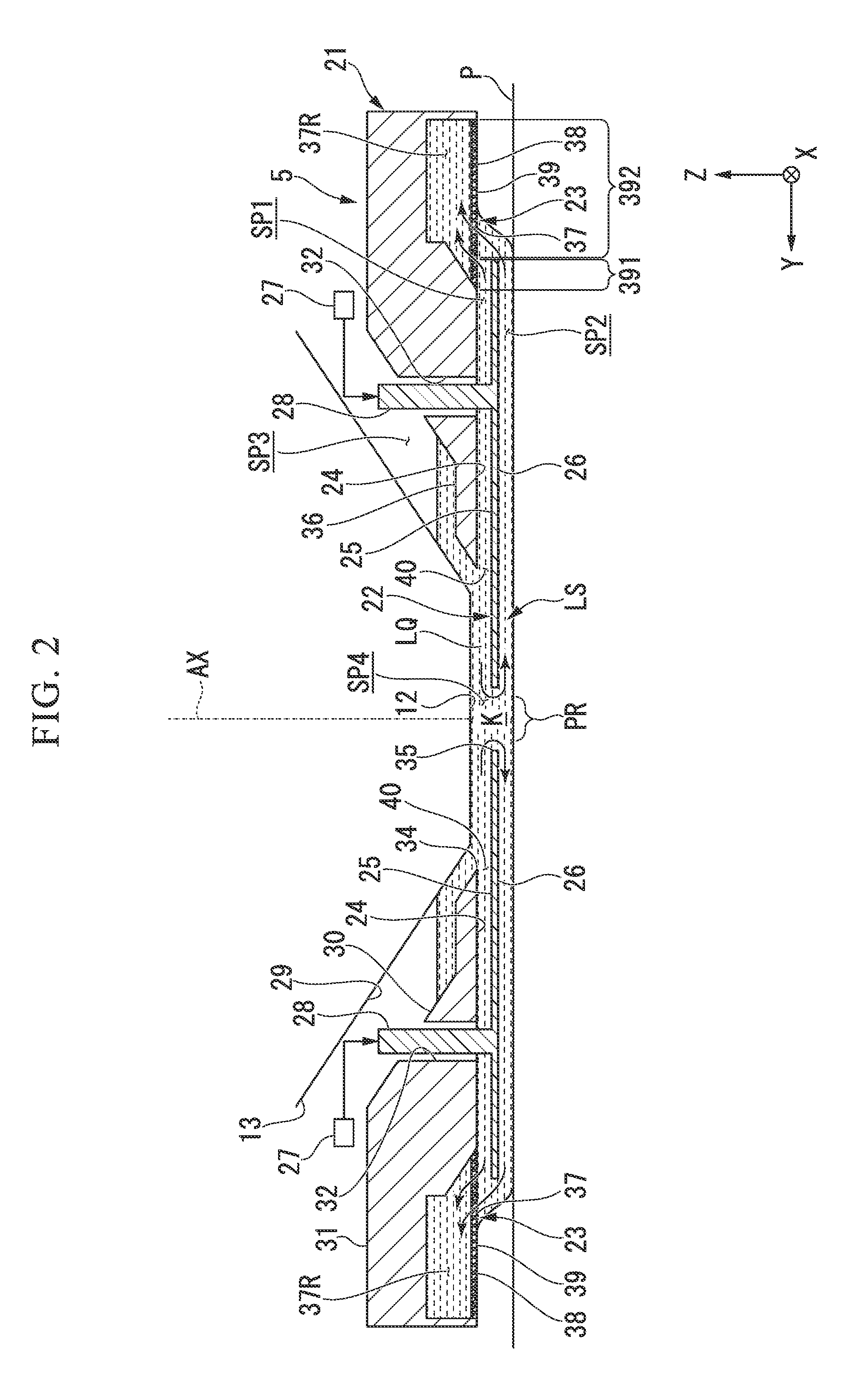

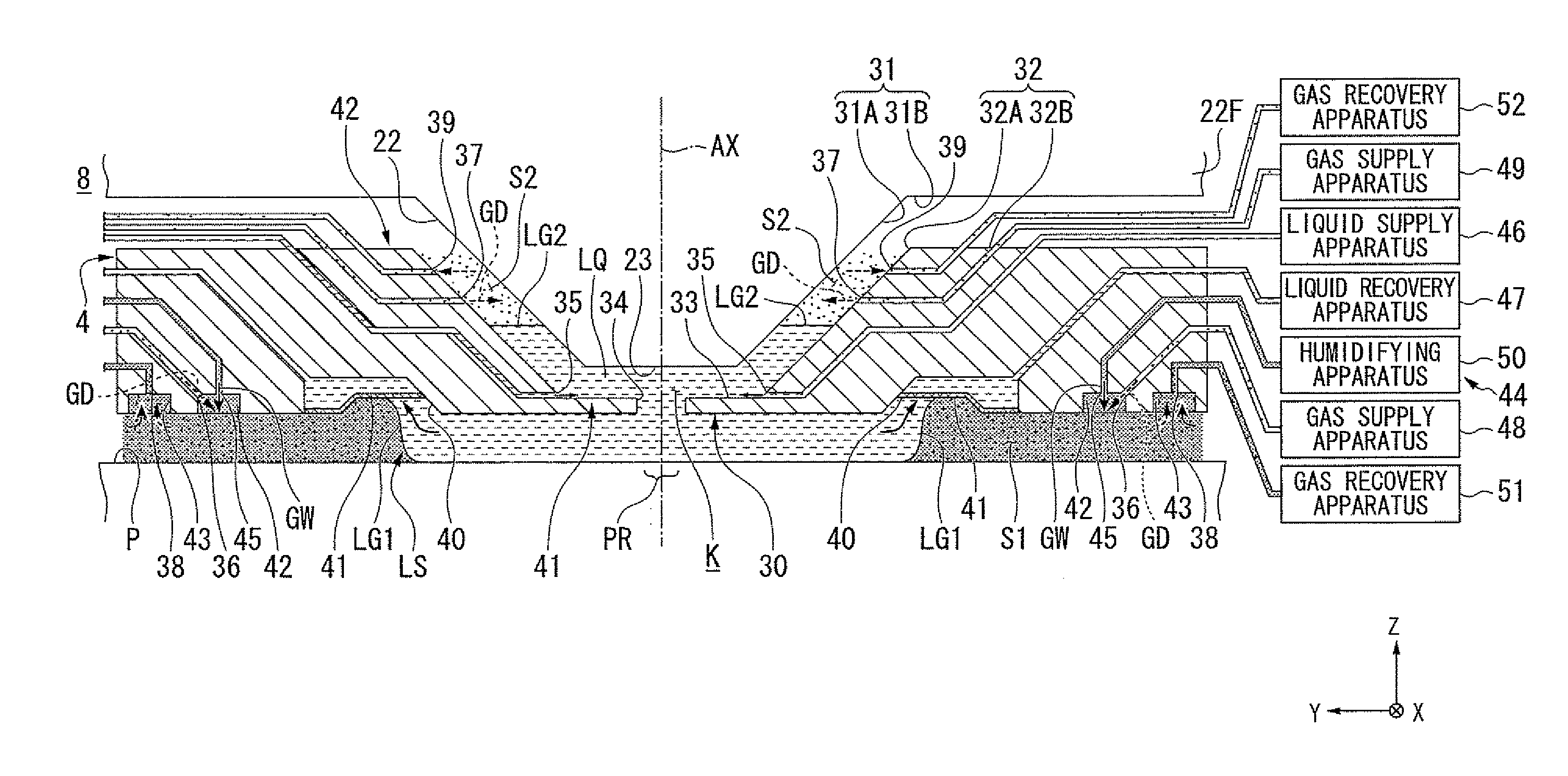

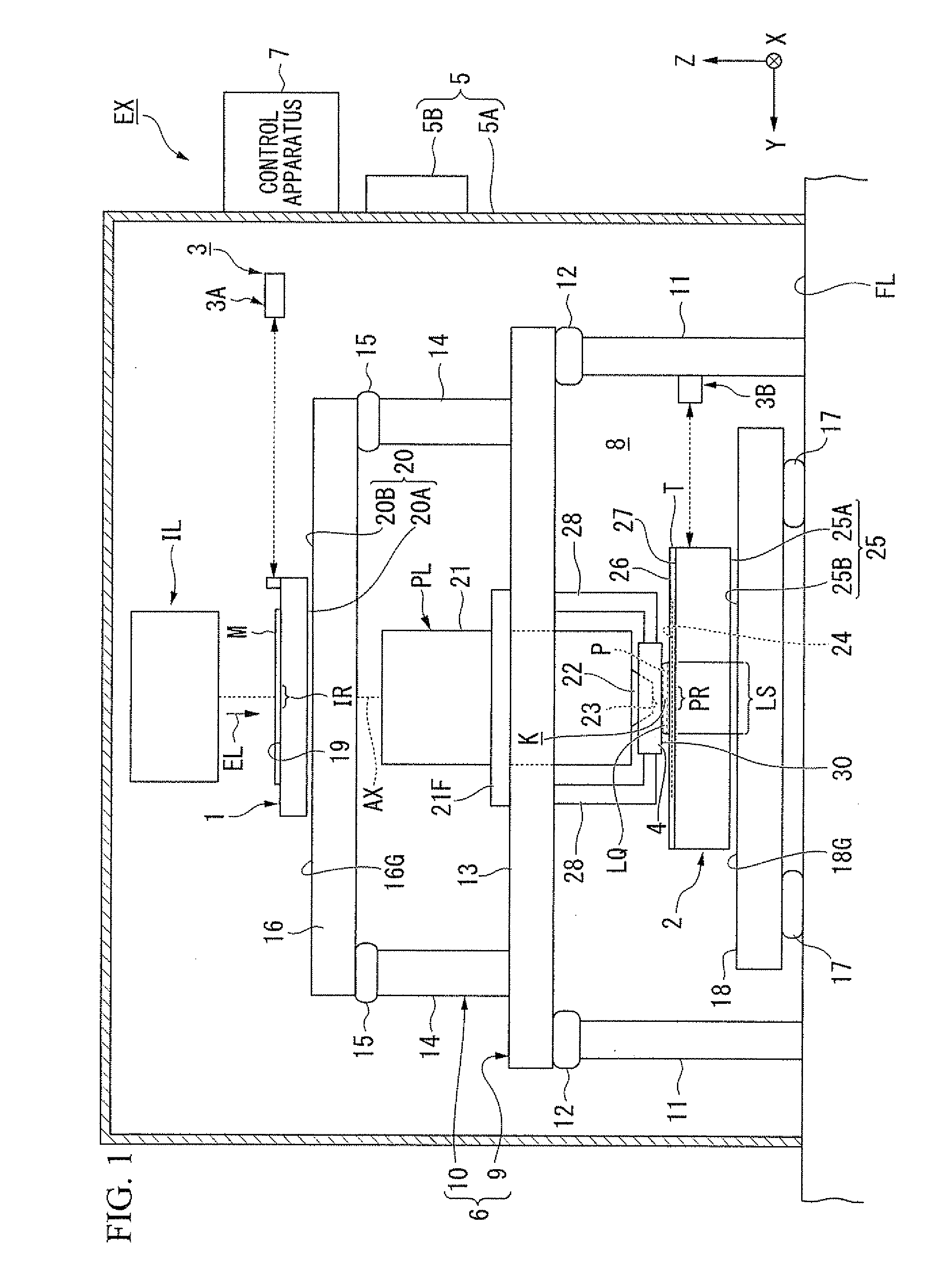

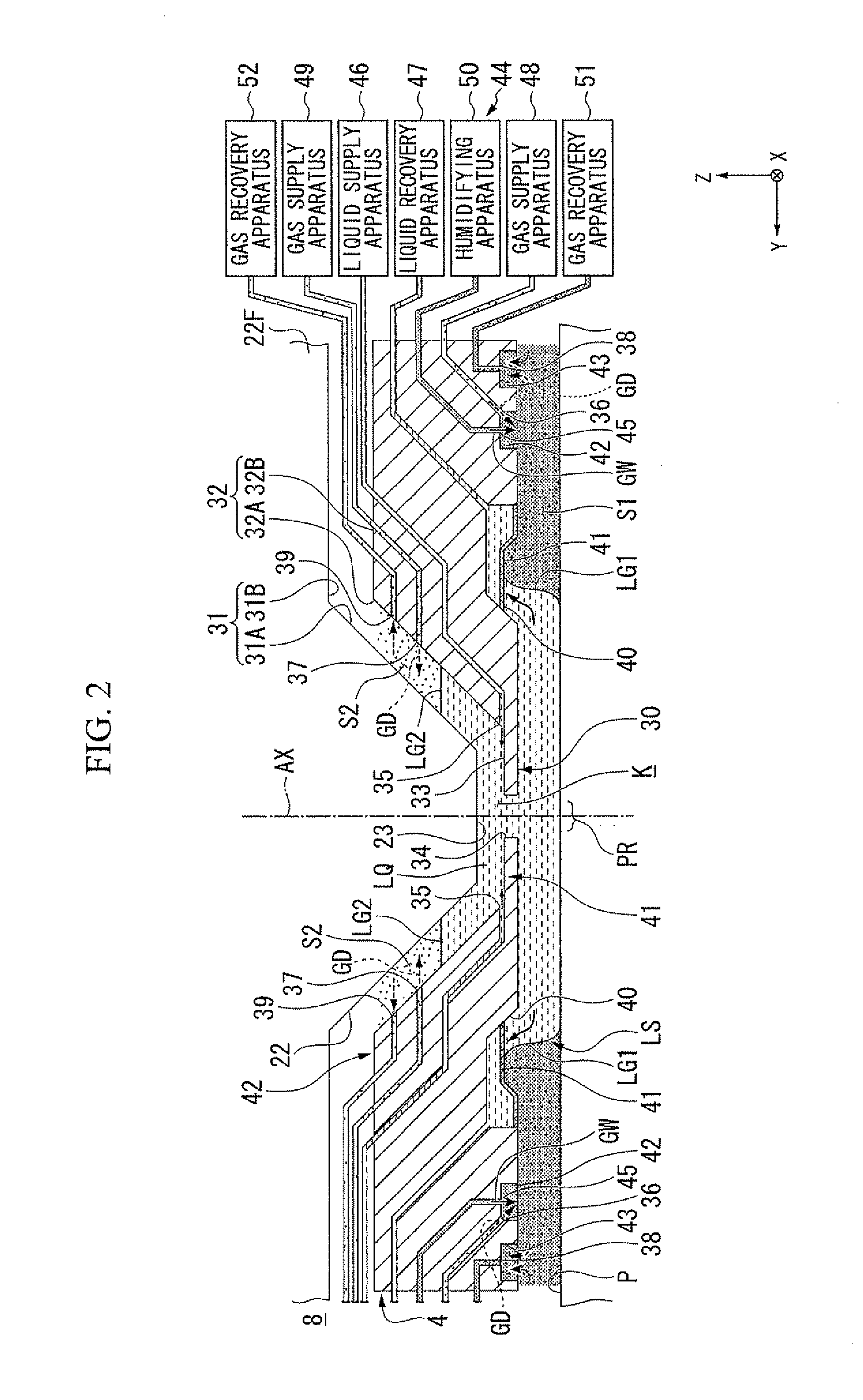

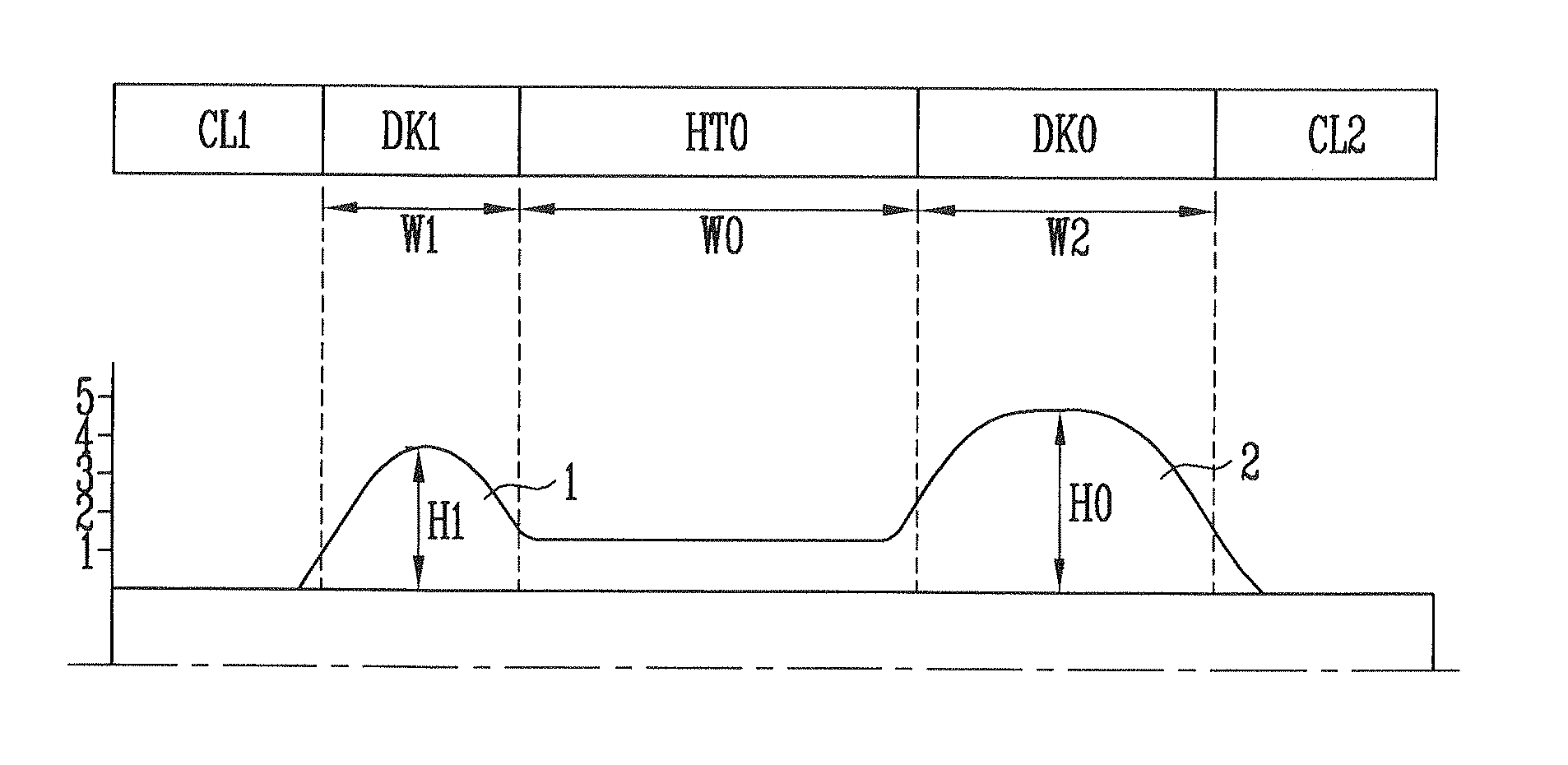

Liquid immersion member, exposure apparatus, exposing method, method for manufacturing device, program, and recording medium

ActiveUS20130265556A1Suppress occurrenceInhibitionPhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsOptical path

A liquid immersion member forms a liquid immersion space on an object which is movable below an optical member so that an optical path of exposure light emitted from an emitting surface of the optical member is filled with liquid. The liquid immersion member includes a first member that has a first lower surface, a second member that has a second upper surface which faces the first lower surface via a gap and a second lower surface which the object is able to face, and that is movable with respect to the first member, and a recovery part that recovers at least a portion of a liquid from a second space, which is between the second lower surface and the object, at an outside of the second lower surface with respect to the optical path.

Owner:NIKON CORP

Secondary battery

ActiveUS20150086868A1Deterioration of characteristicSuppress generationBatteries circuit arrangementsBattery isolationLithiumCharge discharge

An object of one embodiment of the present invention is to provide a secondary battery in which deterioration of charge-discharge cycle characteristics is suppressed, to suppress generation of defects caused by expansion and contraction of an active material in a negative electrode, or to prevent deterioration caused by deformation of a secondary battery. To prevent deterioration, a material that can be alloyed with lithium and fluidified easily is used for a negative electrode. To hold a negative electrode active material over a surface of a current collector, a covering layer that covers the negative electrode active material is provided. Furthermore, a portion where the current collector and the negative electrode active material are in contact with each other is alloyed. In other words, an alloy that is in contact with both the current collector and the negative electrode active material is provided in the negative electrode.

Owner:SEMICON ENERGY LAB CO LTD

Single-mode fiber and production method thereof

ActiveUS8200057B2High mechanical reliabilityEasy to useGlass making apparatusOptical fibre with graded refractive index core/claddingRelative refractive indexOptoelectronics

A single mode fiber having a core, an inner cladding, a depressed cladding, and an outer cladding composed of pure silica glass. The core is surrounded in sequence with the inner cladding and the depressed cladding. The core has silica glass doped with germanium and fluorine, with a diameter (a) of 8.0-8.8 μm, a relative refractive index difference (Δ1) of 0.35-0.38%, and the contribution of fluoride (ΔF) is −0.09±0.02%. The inner cladding has silica glass doped with germanium and fluorine, with a diameter (b) of 18-21 μm and a relative refractive index difference (Δ2) of 0±0.02%. The depressed cladding has silica glass doped with fluorine, with a diameter (c) of 26-36 μm and a relative refractive index difference (Δ32) at the external interface thereof is between −0.22 and −0.35%, and a relative refractive index difference (Δ31) at the internal interface thereof is between −0.20 and −0.35%, and Δ32≦Δ31. The fiber has a good bending resistance, good mechanical properties, and extended service lifetime, and prevents the additional stresses generated by bending from passing on to the core, thereby reducing attenuation.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

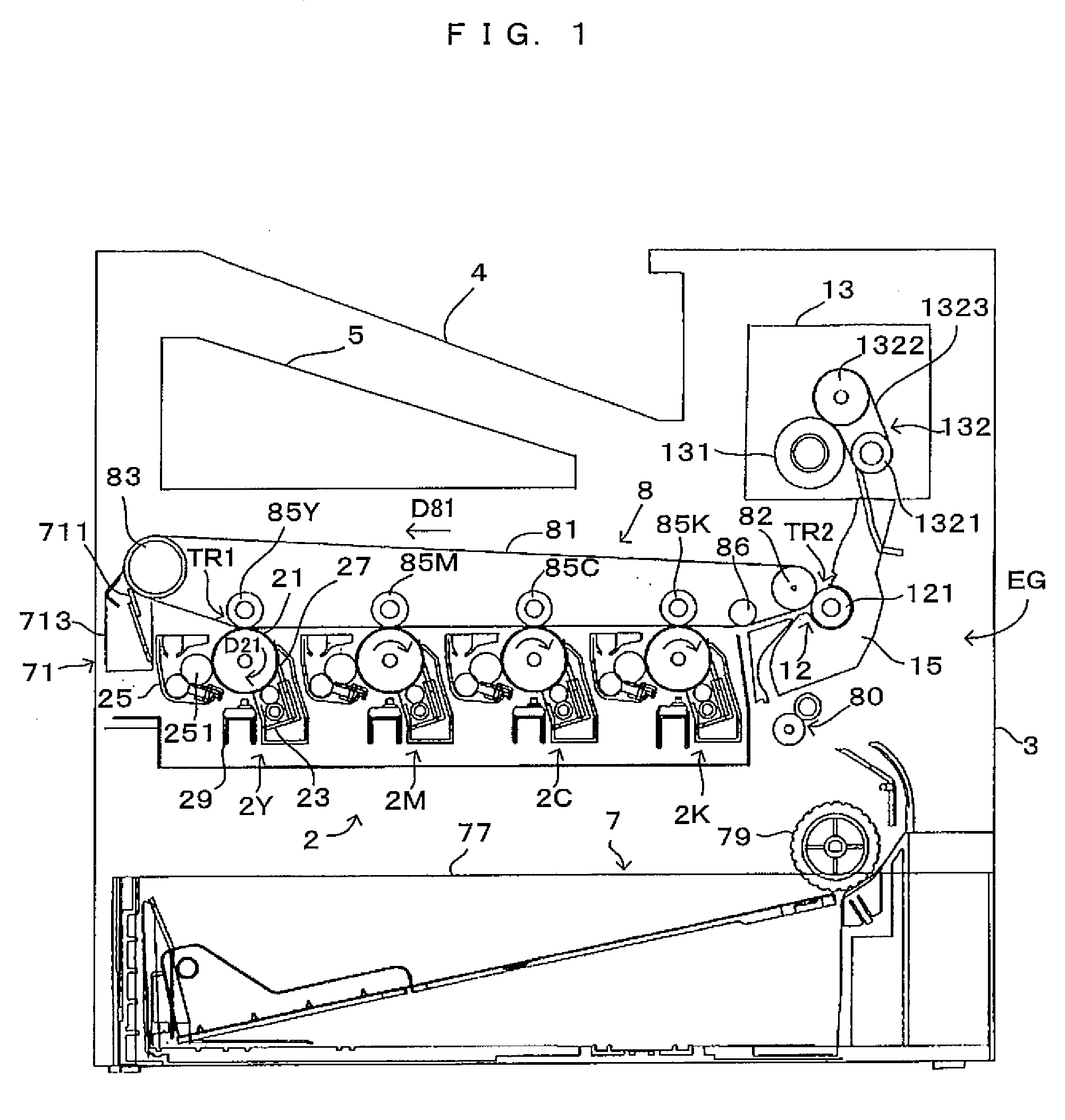

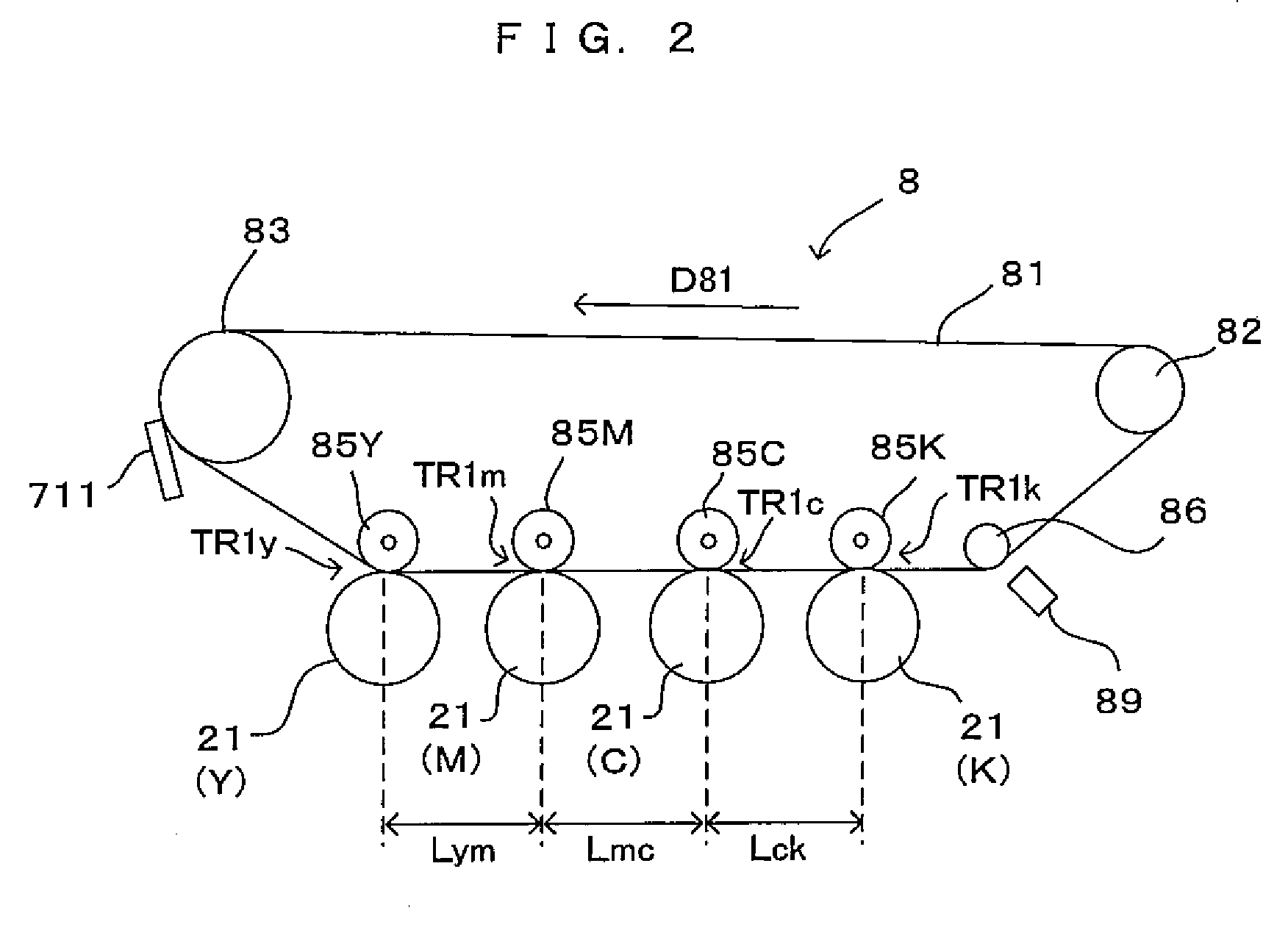

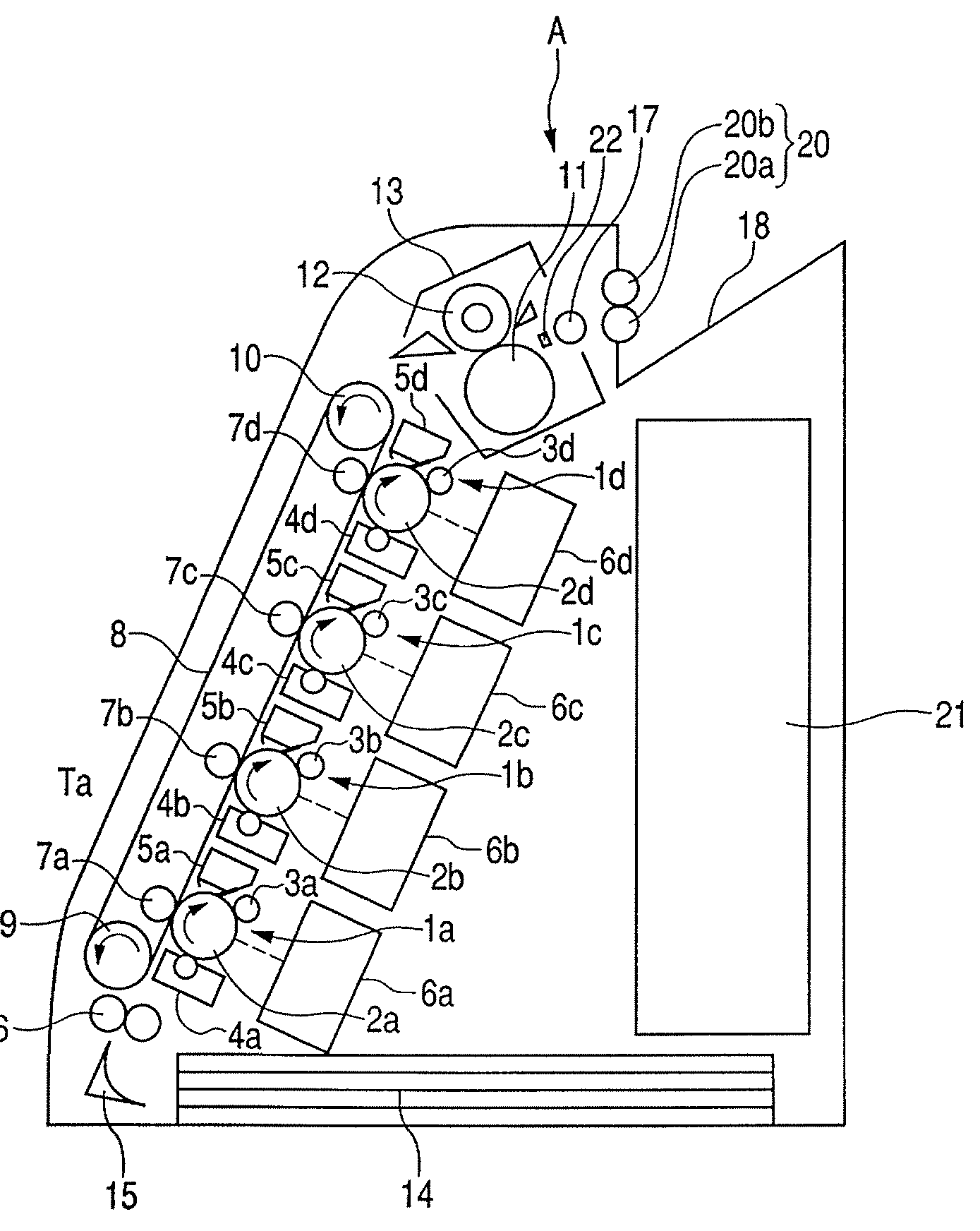

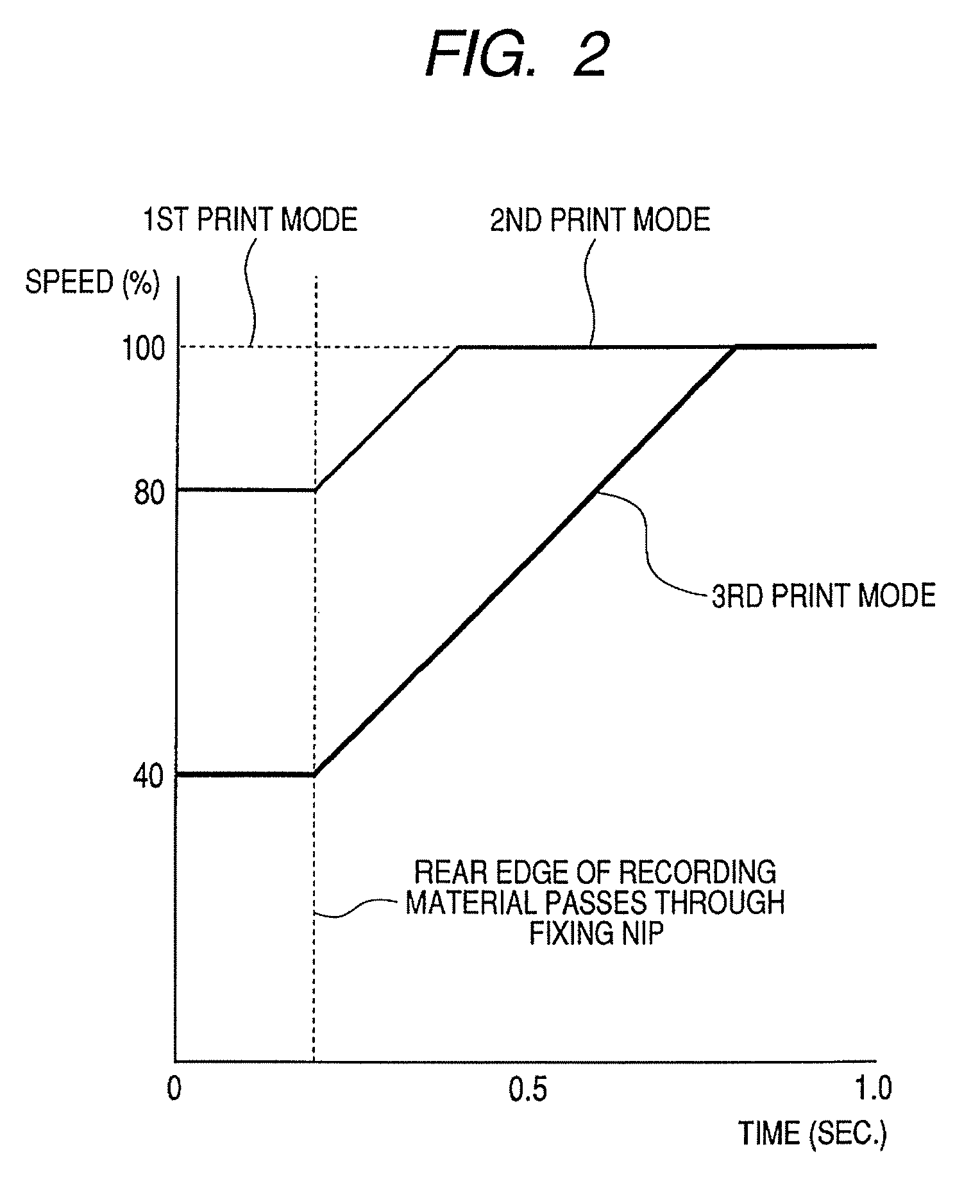

Image forming apparatus having heat-fixing unit

InactiveUS7570895B2Guaranteed discharge performanceInhibition of defect generationElectrographic process apparatusImage formationEngineering

An image forming apparatus includes an image forming portion; a fixing portion having a fixing nip portion which heats and fixes the unfixed image and an discharge roller which discharges the recording material, wherein in the case where the recording material is the plain paper which is equal to or larger than the predetermined size, the discharge roller conveys the plain paper in a range from a front edge to a rear edge at a predetermined speed, in the case where the recording material is the plain paper smaller than the predetermined size, the discharge roller conveys the plain paper at a first speed until the rear edge passes through the fixing nip portion, and the discharge roller conveys the plain paper at a second speed higher than the first speed after the rear edge passed through the fixing nip portion.

Owner:CANON KK

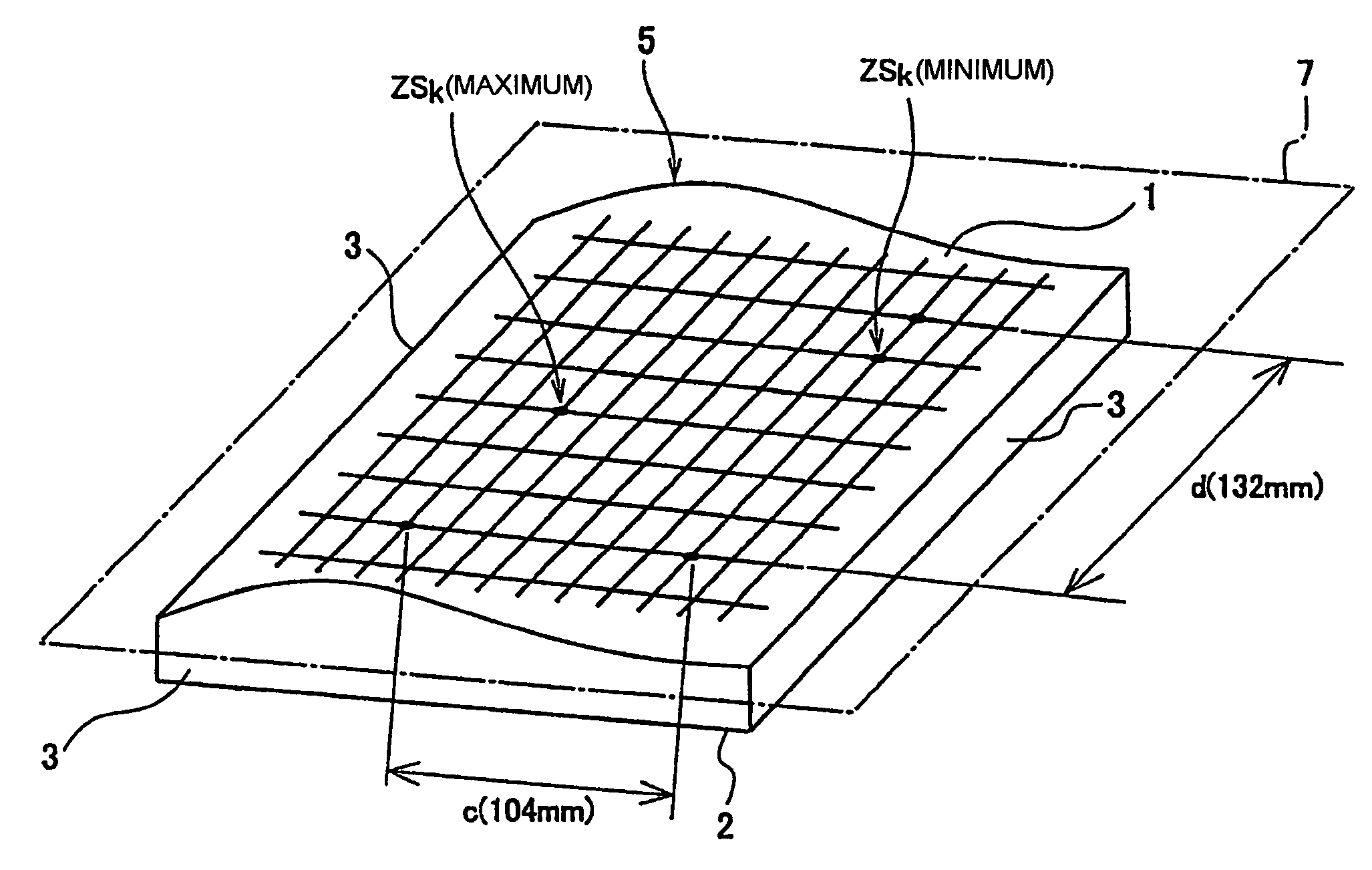

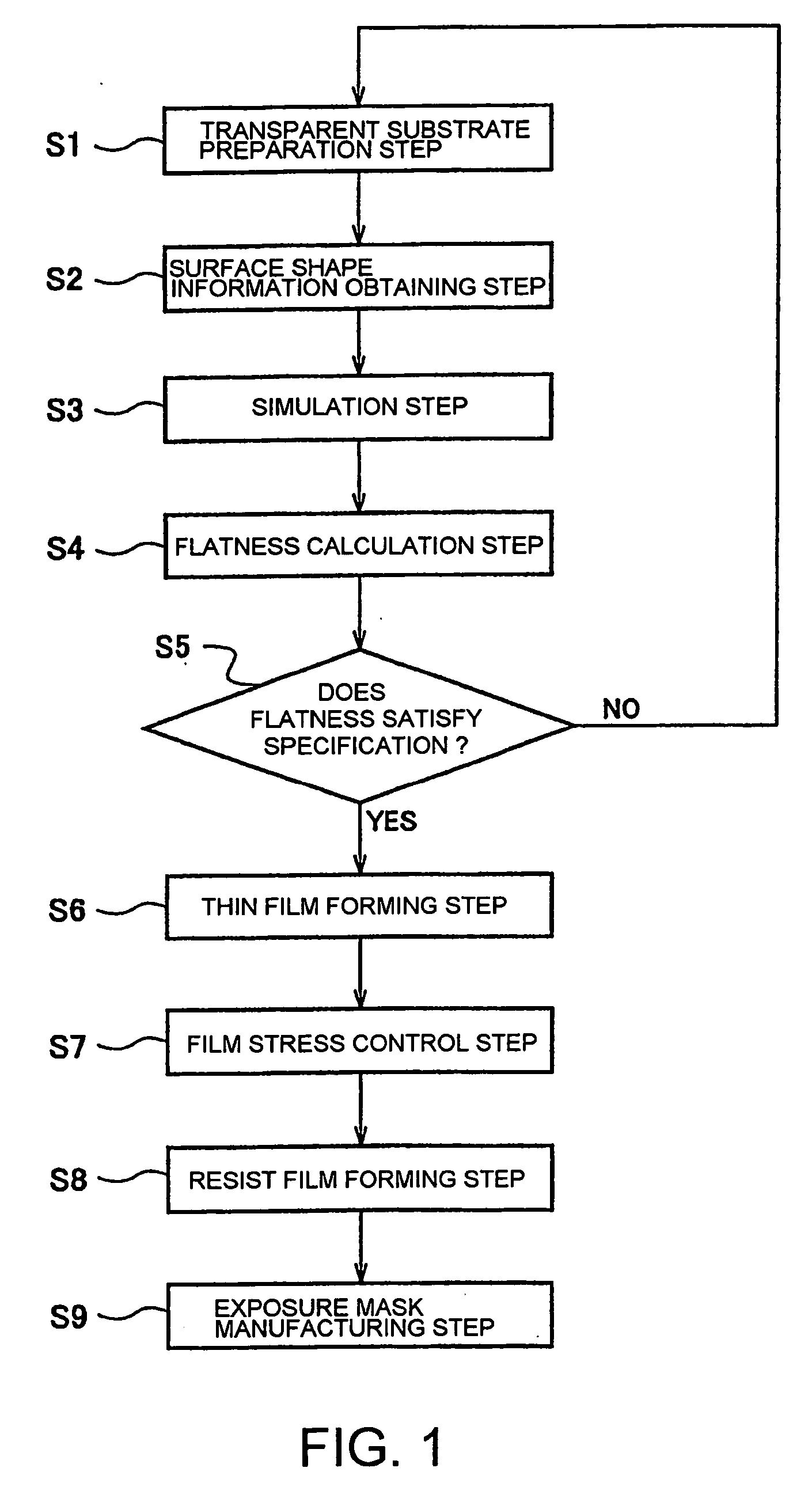

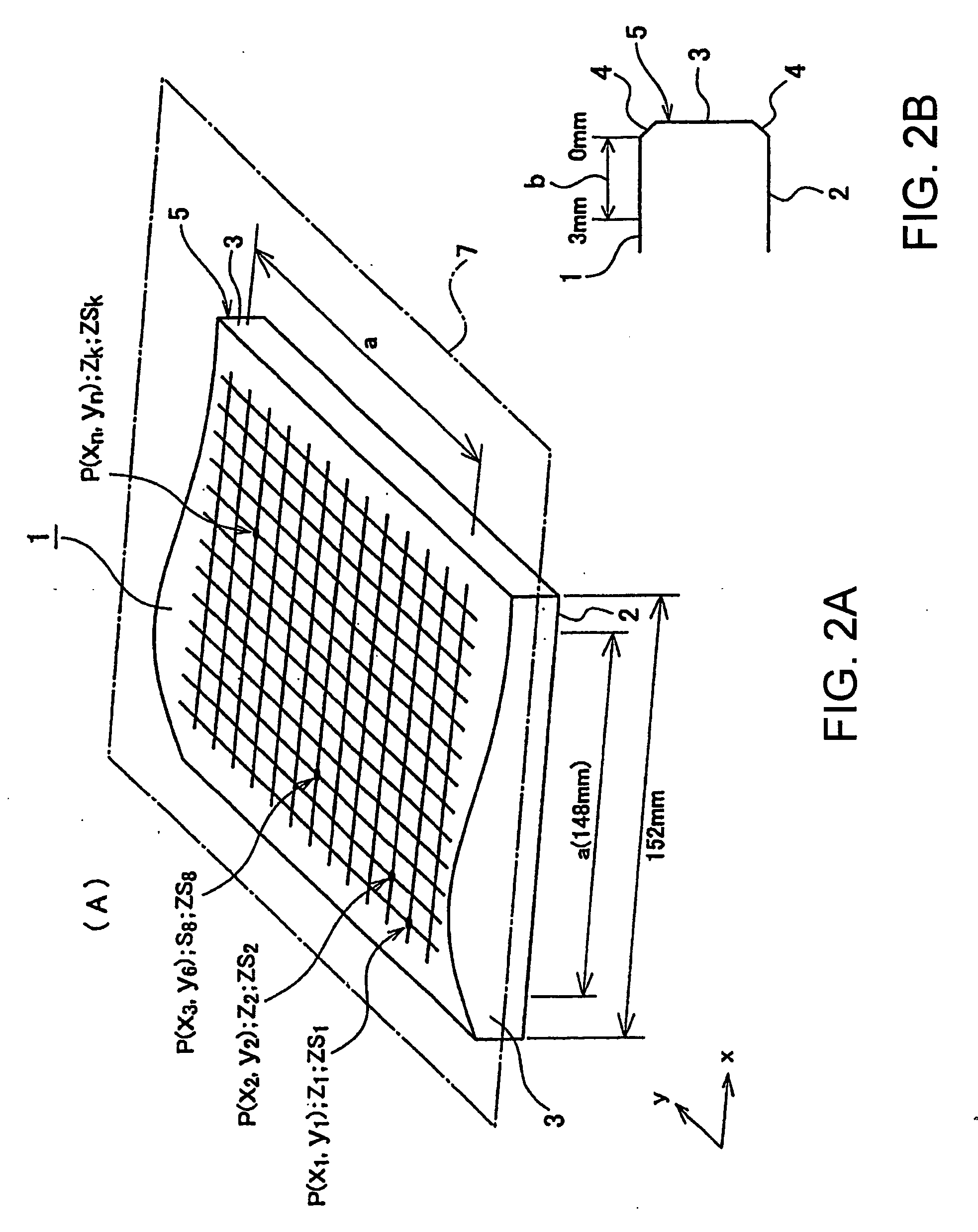

Mask blank transparent substrate manufacturing method, mask blank manufacturing method, and exposure mask manufacturing method

ActiveUS20060194126A1Inhibition of defect generationImprove accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingMeasurement pointEngineering

A method includes a preparation step of preparing a transparent substrate having a precision-polished main surface, a surface shape information obtaining step of obtaining, as surface shape information, height information at a plurality of measurement points on the main surface of the transparent substrate that contacts a mask stage of an exposure apparatus, a simulation step of obtaining, based on the surface shape information and shape information of the mask stage, height information at the plurality of measurement points by simulating the state where the transparent substrate is set in the exposure apparatus, a flatness calculation step of calculating, based on the height information obtained through the simulation, a flatness of the transparent substrate when it is set in the exposure apparatus, a judging step of judging whether or not the calculated flatness satisfies a specification, and a thin film forming step of forming a thin film as serving as a mask pattern, on the main surface of the transparent substrate whose flatness satisfies the specification.

Owner:HOYA CORP

Method of forming fine patterns

InactiveUS20040121615A1Easy to adjustImprove efficiencySemiconductor/solid-state device manufacturingPhotosensitive material processingPhotoresistMaterials science

It is disclosed a method of forming fine patterns comprising: covering a substrate having photoresist patterns with an over-coating agent for forming fine patterns, applying heat treatment to cause thermal shrinkage of the over-coating agent so that the spacing between adjacent photoresist patterns is lessened by the resulting thermal shrinking action, and removing the over-coating agent substantially completely by way of bringing thusly treated substrate into contact with a remover solution for over 60 seconds.

Owner:TOKYO OHKA KOGYO CO LTD

Exposure apparatus, exposure method, and device manufacturing method

ActiveUS20120062860A1InhibitionInhibition of defect generationPhotomechanical apparatusPhotographic printingEngineeringFluid supply

An exposure apparatus exposes a substrate with exposure light via a liquid. The exposure apparatus includes an optical system including an emission surface from which the exposure light is emitted; a liquid supply port that supplies the liquid in order to fill an optical path of the exposure light emitted from the emission surface with the liquid; and a fluid supply port that supplies a fluid including a material capable of changing the specific resistance of the liquid to at least a part of a space around a liquid immersion space that is formed by the liquid.

Owner:NIKON CORP

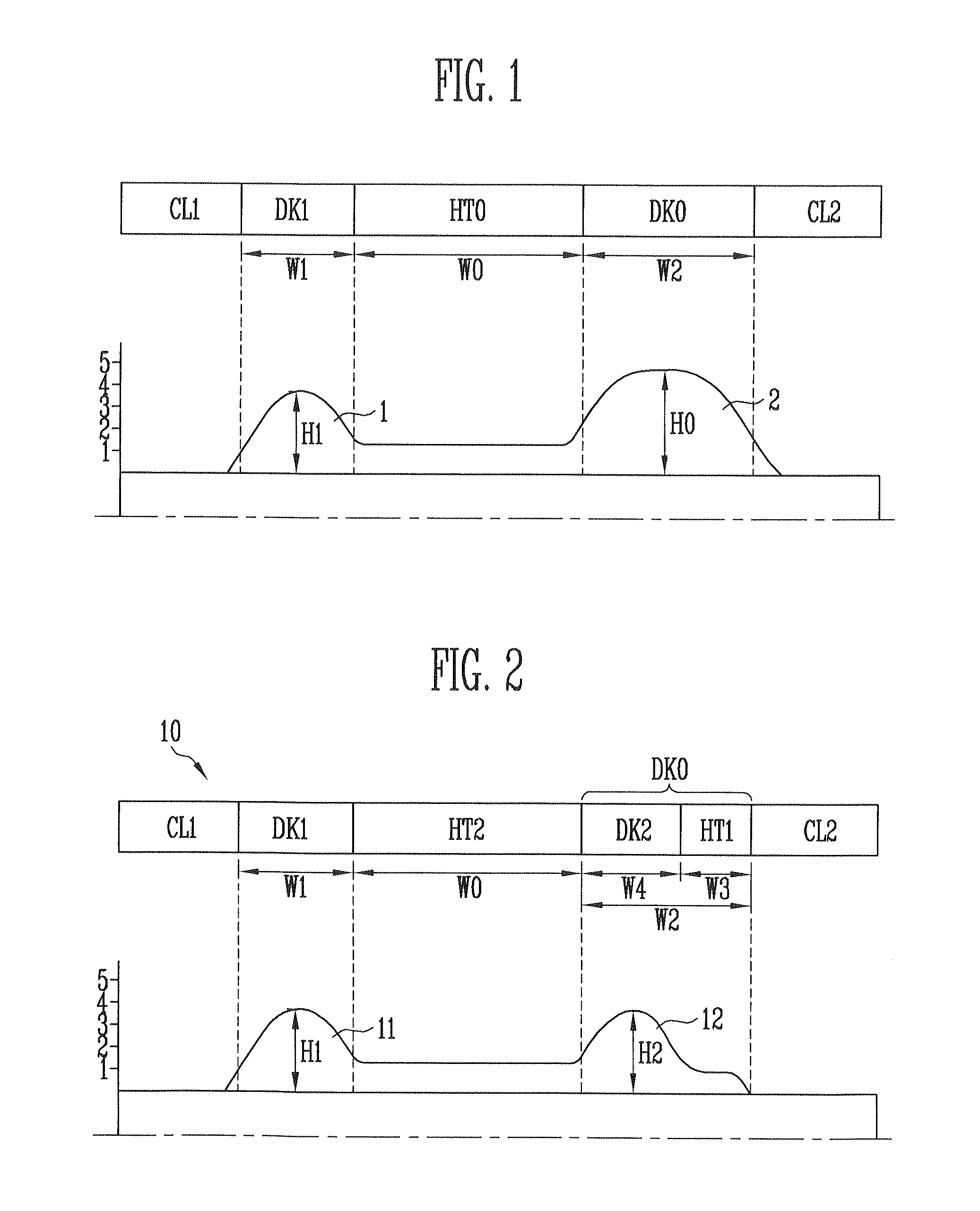

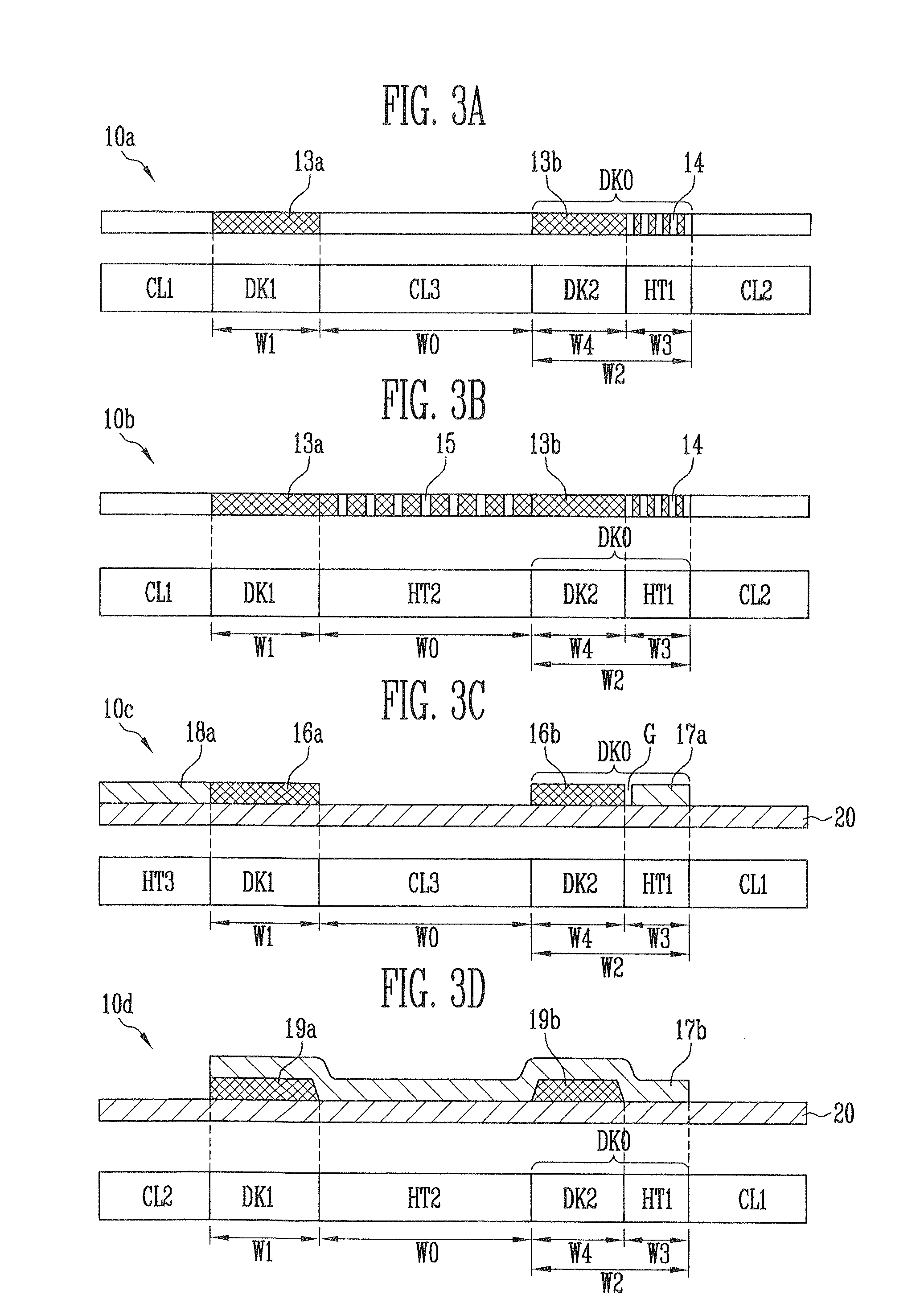

Halftone mask and manufacturing method thereof and method for forming film using the same

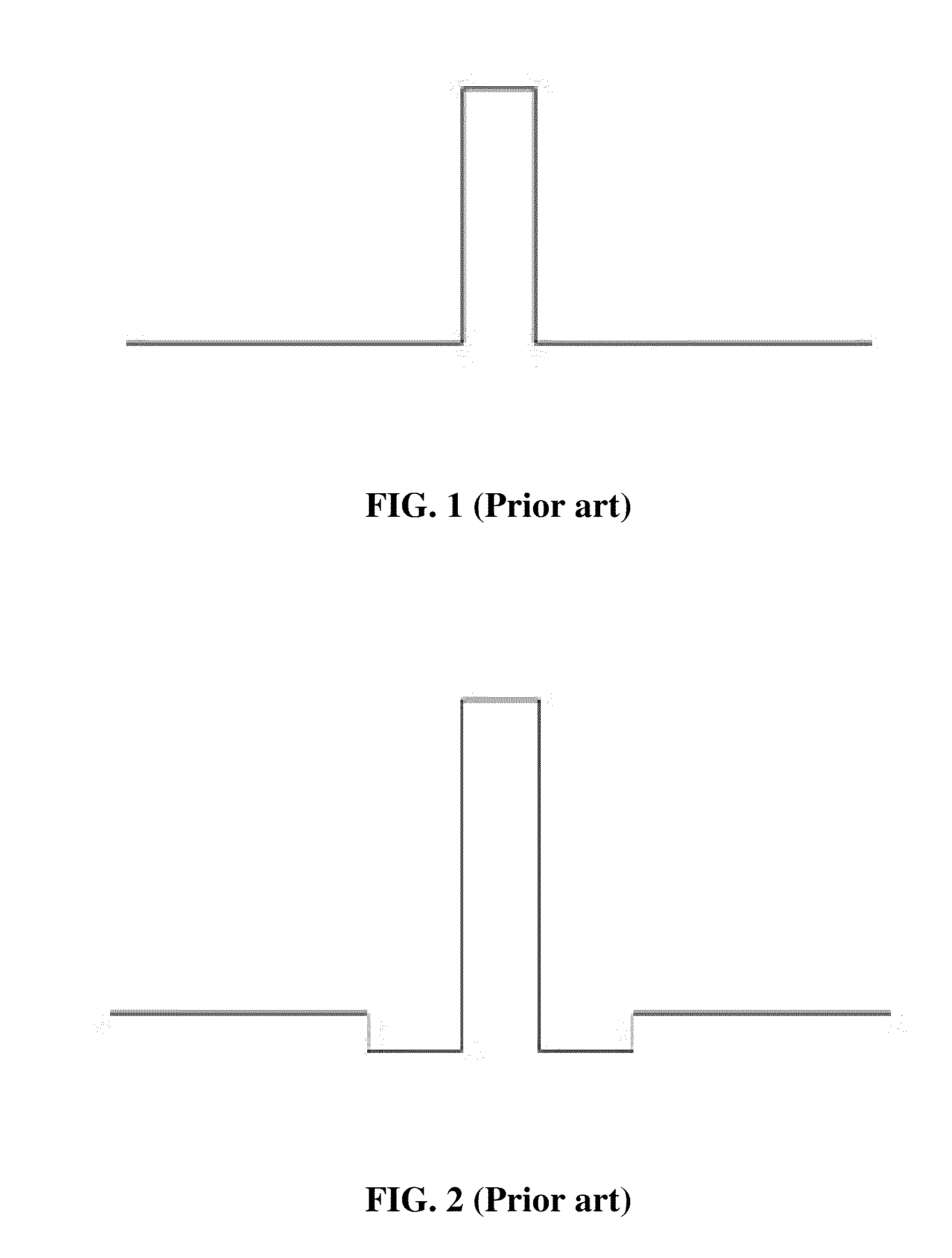

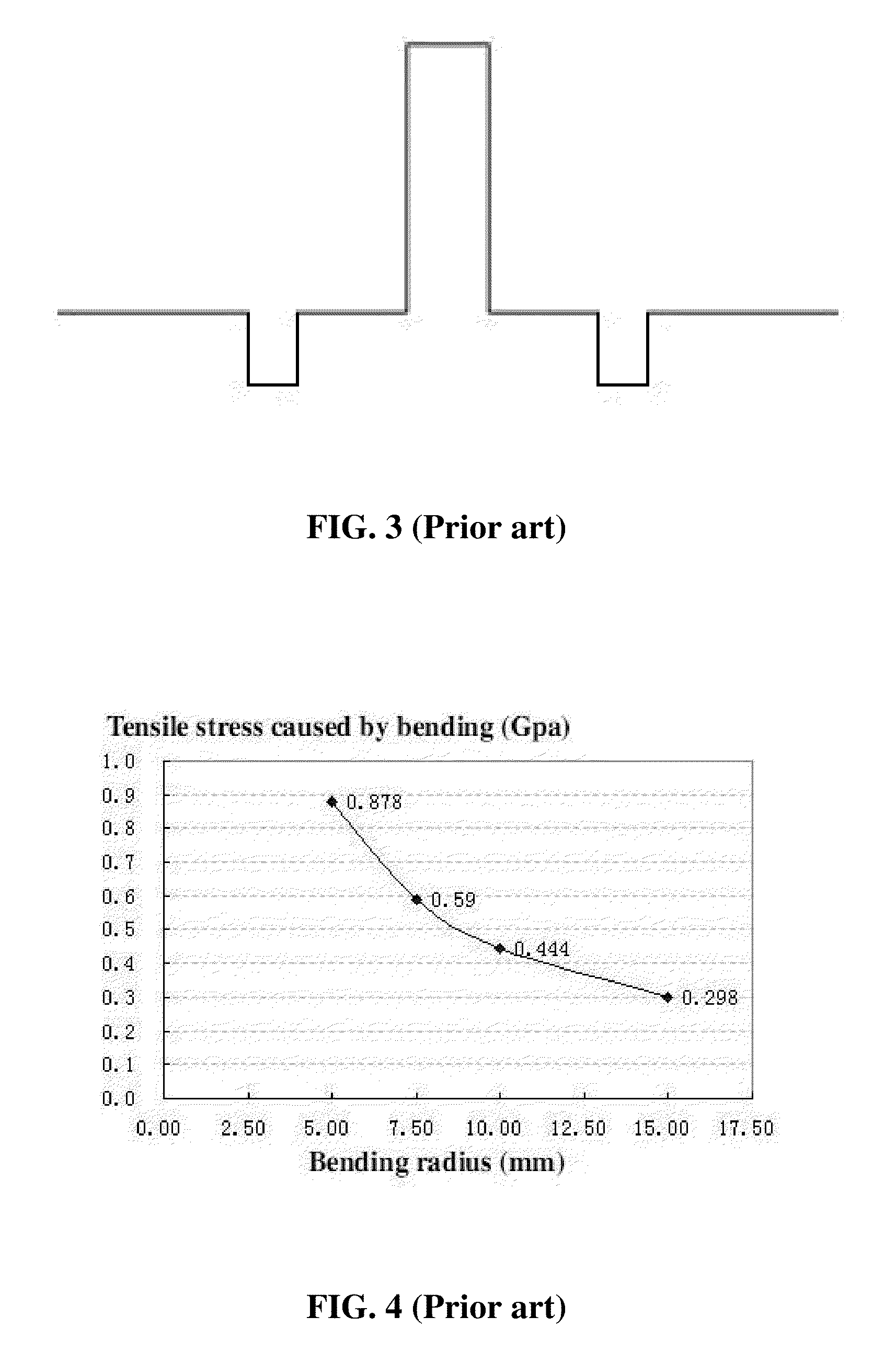

ActiveUS20100330468A1Reduce in quantityImprove productivitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringLight intensity

Embodiments relate to halftone masks that can uniformly form the height of an underlying layer in two regions that are spaced apart from each other, a manufacturing method thereof, and a method for forming a film using the same. The halftone mask includes a first light blocking unit and a second light blocking unit, and a semi-transmitting unit that is disposed adjacent to the side of the second light blocking unit. The first and second light blocking units block light and are spaced apart from each other at a predetermined interval. The semi-transmitting unit is positioned at a side far from the first light blocking unit and reduces intensity of light. Sum of the second length of the second light blocking unit and the third length of the semi-transmitting unit is larger than the first length of the first blocking unit.

Owner:SAMSUNG DISPLAY CO LTD

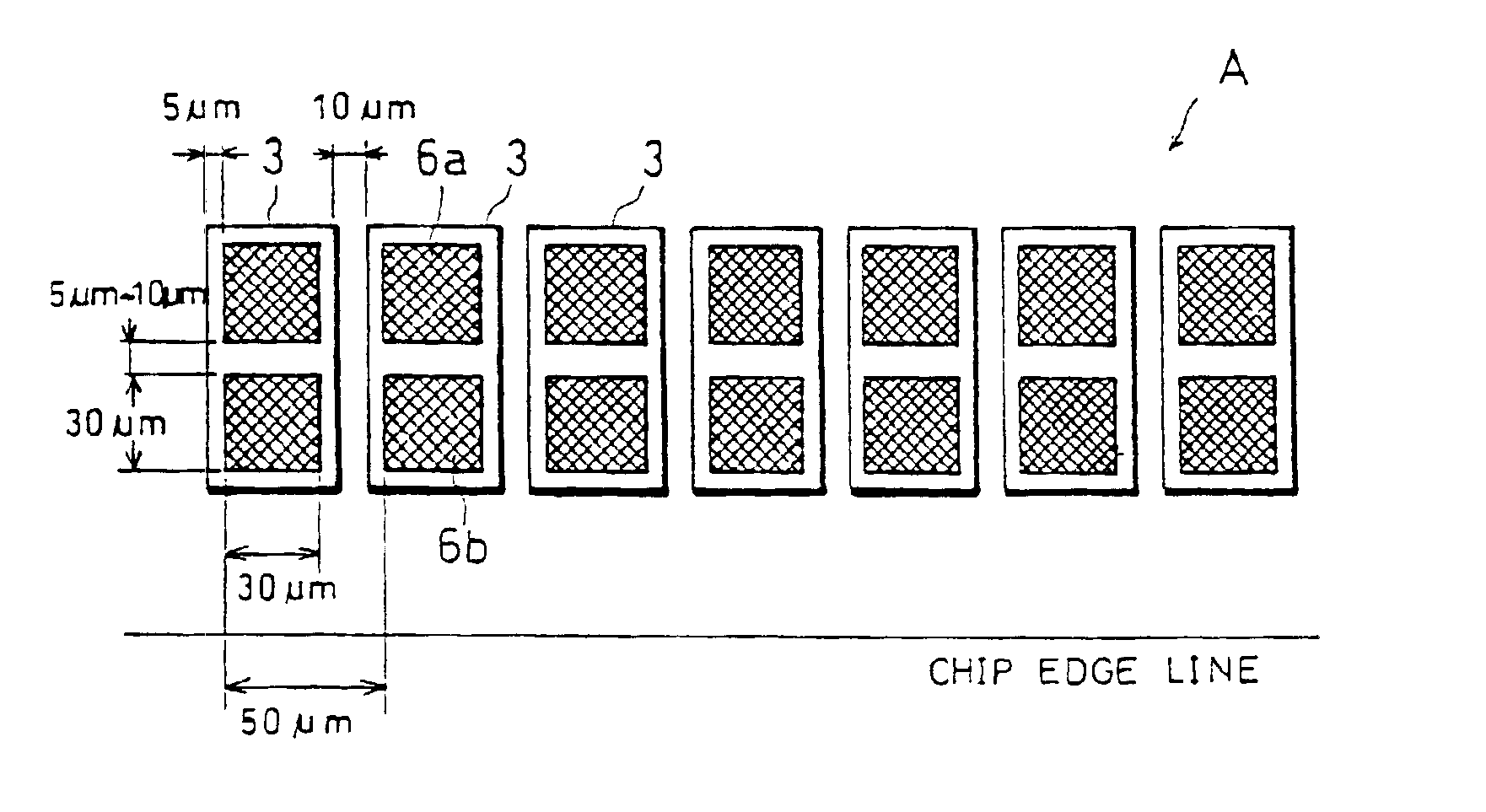

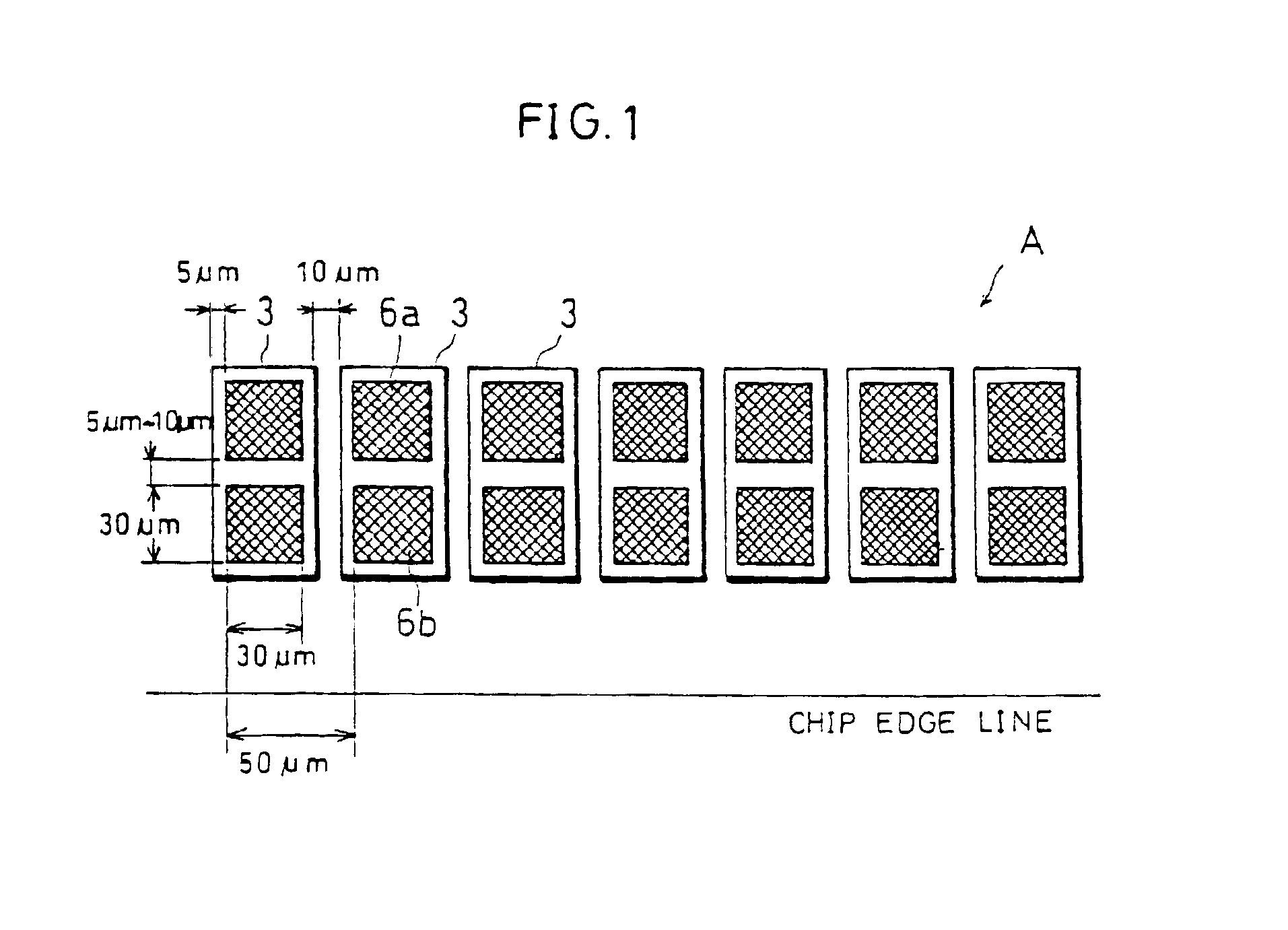

Semiconductor device with bumps on electrode pads oriented in given direction

InactiveUS6933607B2Narrow pitchSuppress occurrence of defectSemiconductor/solid-state device detailsSolid-state devicesPhotoresistEngineering

A semiconductor device includes a semiconductor substrate, a plurality of electrode pads aligned on the semiconductor substrate, and a plurality of bump electrodes placed on each electrode pad, wherein the plurality of bump electrodes on the electrode pad are aligned in a direction orthogonal to a direction where the electrode pads are aligned. A manufacturing method of the semiconductor device includes the steps of patterning a photoresist which serves as a bump electrode forming use mask on the semiconductor substrate having formed thereon the electrode pads and forming a bump electrode in a perpendicular straight wall shape to be thinner than the photoresist by plating the bump electrode forming use metal to the electrode pad.

Owner:SHARP KK

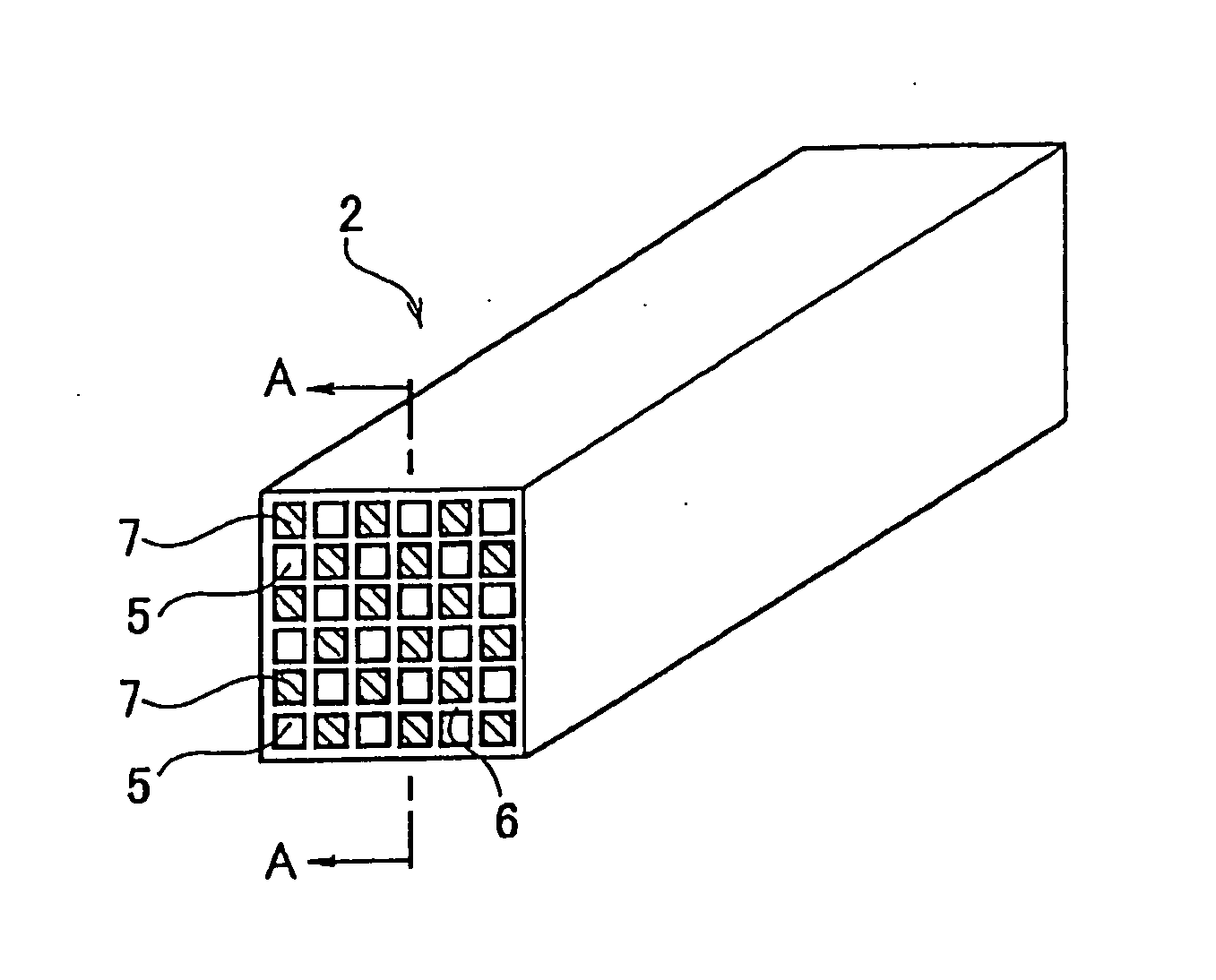

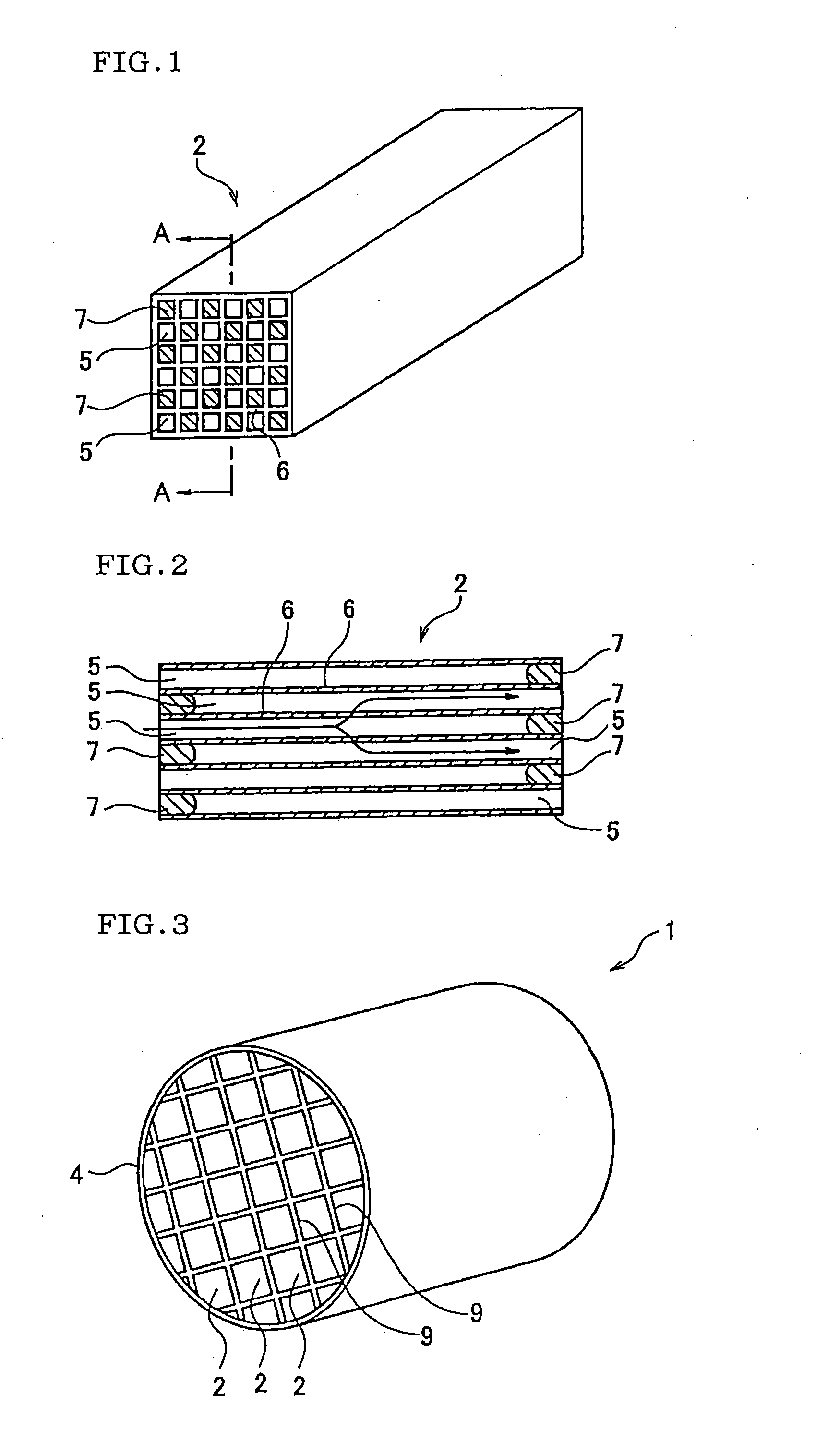

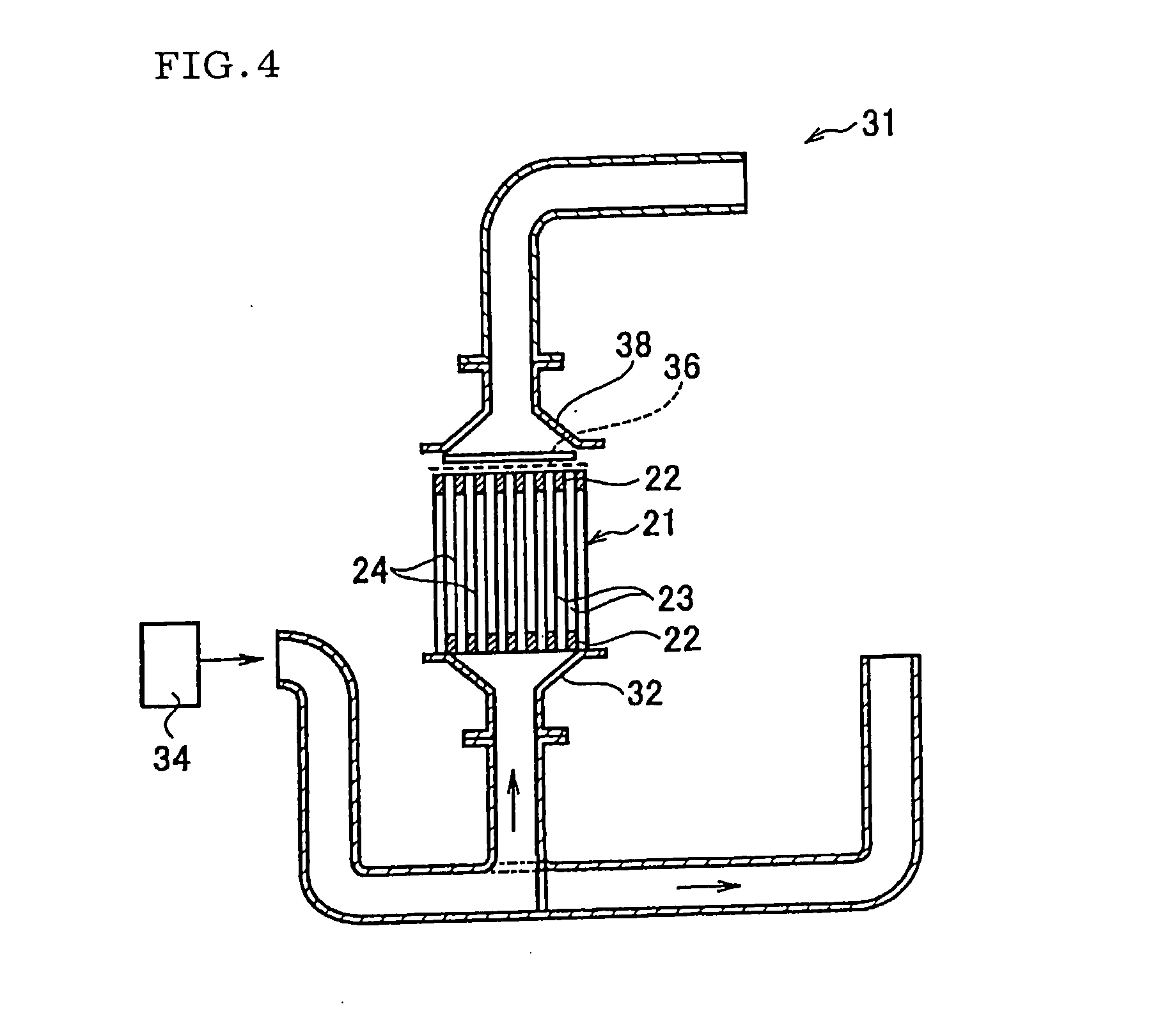

Method of producing honeycomb structure body

InactiveUS20060192324A1Avoid distractionHigh mechanical strengthDispersed particle filtrationCeramic shaping apparatusPorosityMetallurgy

There is provided a method for producing a honeycomb structure, including: a first step of mixing and kneading a ceramic raw material, an organic binder, a water-absorbing resin, and water to obtain clay, a second step of forming the clay into a honeycomb-structured shape and drying the clay to obtain a honeycomb dried body, and a third step of firing the honeycomb dried body to obtain a honeycomb structure having a porosity of 40% or more after firing. The method can suppress defects or deformation upon forming and improve a yield.

Owner:NGK INSULATORS LTD

Pattern forming method and phase shift mask manufacturing method

ActiveUS20070190434A1InhibitionReduce data volumePhotomechanical apparatusSemiconductor/solid-state device manufacturingResistPhase shifted

A phase shift mask manufacturing method comprises the steps of processing a light-shielding layer over a transparent substrate into a predetermined light-shielding pattern, forming a resist film on the predetermined light-shielding pattern, performing writing on the resist film based on writing data and developing the resist film, thereby forming a resist pattern, and etching an underlying layer using the predetermined light-shielding pattern and the resist pattern as a mask, thereby forming recesses, that serve as phase shift portions, in the underlying layer. The writing data includes a portion where pattern data corresponding to at least the two recesses adjacent to each other through a light-shielding portion in the predetermined light-shielding pattern are combined into one pattern data.

Owner:HOYA CORP

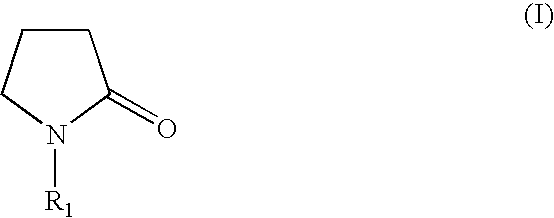

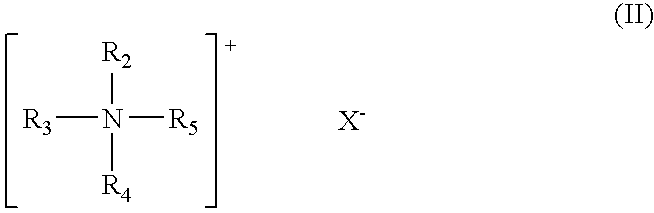

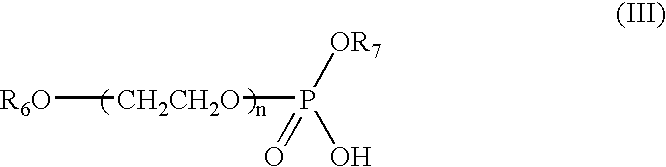

Production method of resist composition for lithography

ActiveUS20130108958A1Reduce defectsDissolution limitationPhotosensitive materialsPhotomechanical coating apparatusResistLithographic artist

A production method of a resist composition for lithography, including, at least: a filtering step for filtering a resist composition for lithography by a filter therethrough, wherein in the filtering step, the resist composition for lithography is passed through the filter after an interior of a vessel having the filter installed therein is kept under reduced pressure. There can be provided a resist composition for lithography capable of decreasing occurrences of defects such as coating defects and pattern defects.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com