Patents

Literature

42results about How to "High polishing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

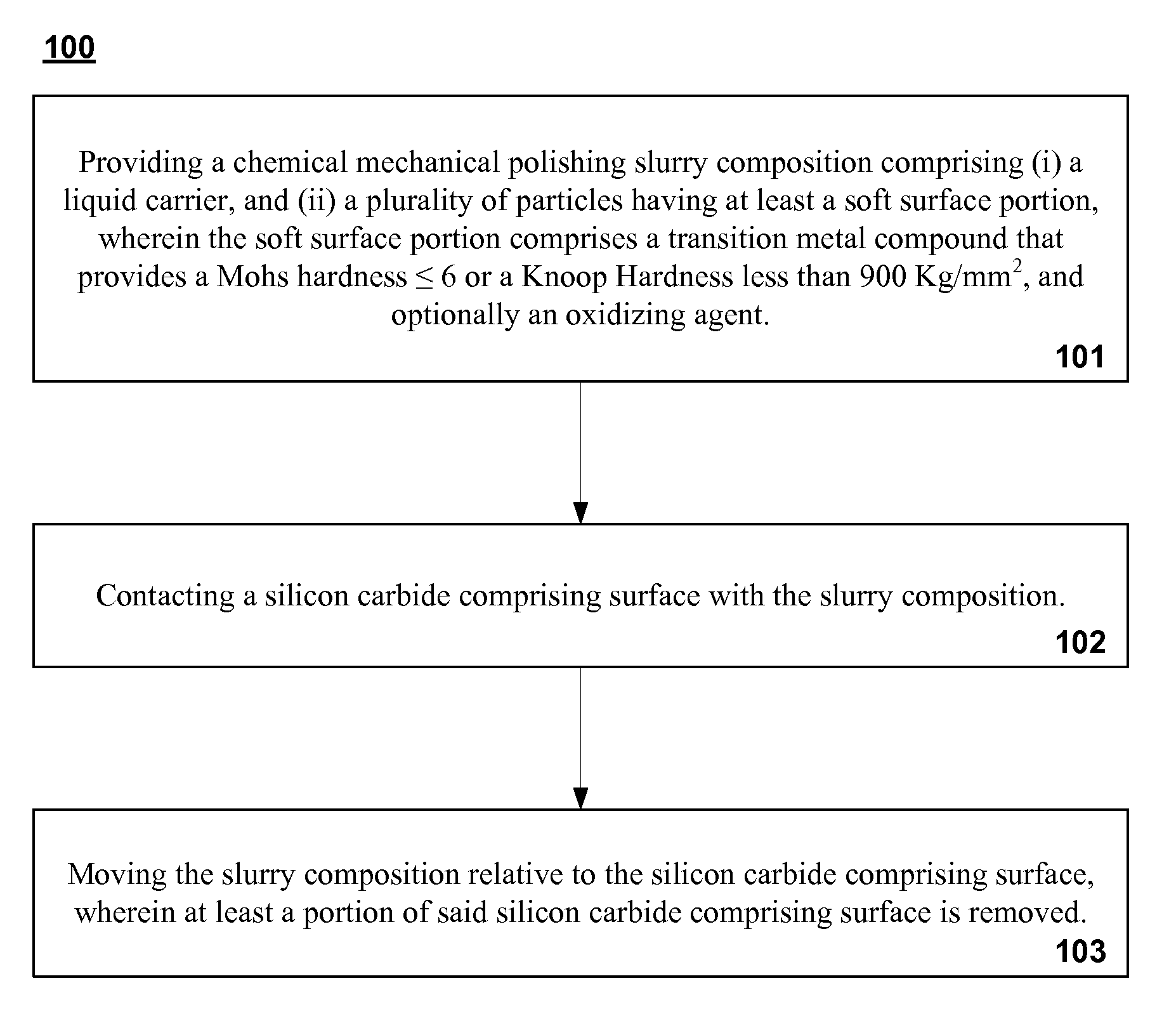

Chemical mechanical polishing of silicon carbide comprising surfaces

ActiveUS20100258528A1High polishing rateReduce sub-surface damageOther chemical processesDecorative surface effectsMohs scale of mineral hardnessSlurry

Slurry compositions and chemically activated CMP methods for polishing a substrate having a silicon carbide surface using such slurries. In such methods, the silicon carbide surface is contacted with a CMP slurry composition that comprises i) a liquid carrier and ii) a plurality of particles having at least a soft surface portion, wherein the soft surface portion includes a transition metal compound that provides a Mohs hardness ≦6, and optionally iii) an oxidizing agent. The oxidizing agent can include a transition metal. The slurry is moved relative to the silicon carbide comprising surface, wherein at least a portion of eth silicon carbide surface is removed.

Owner:ENTEGRIS INC +1

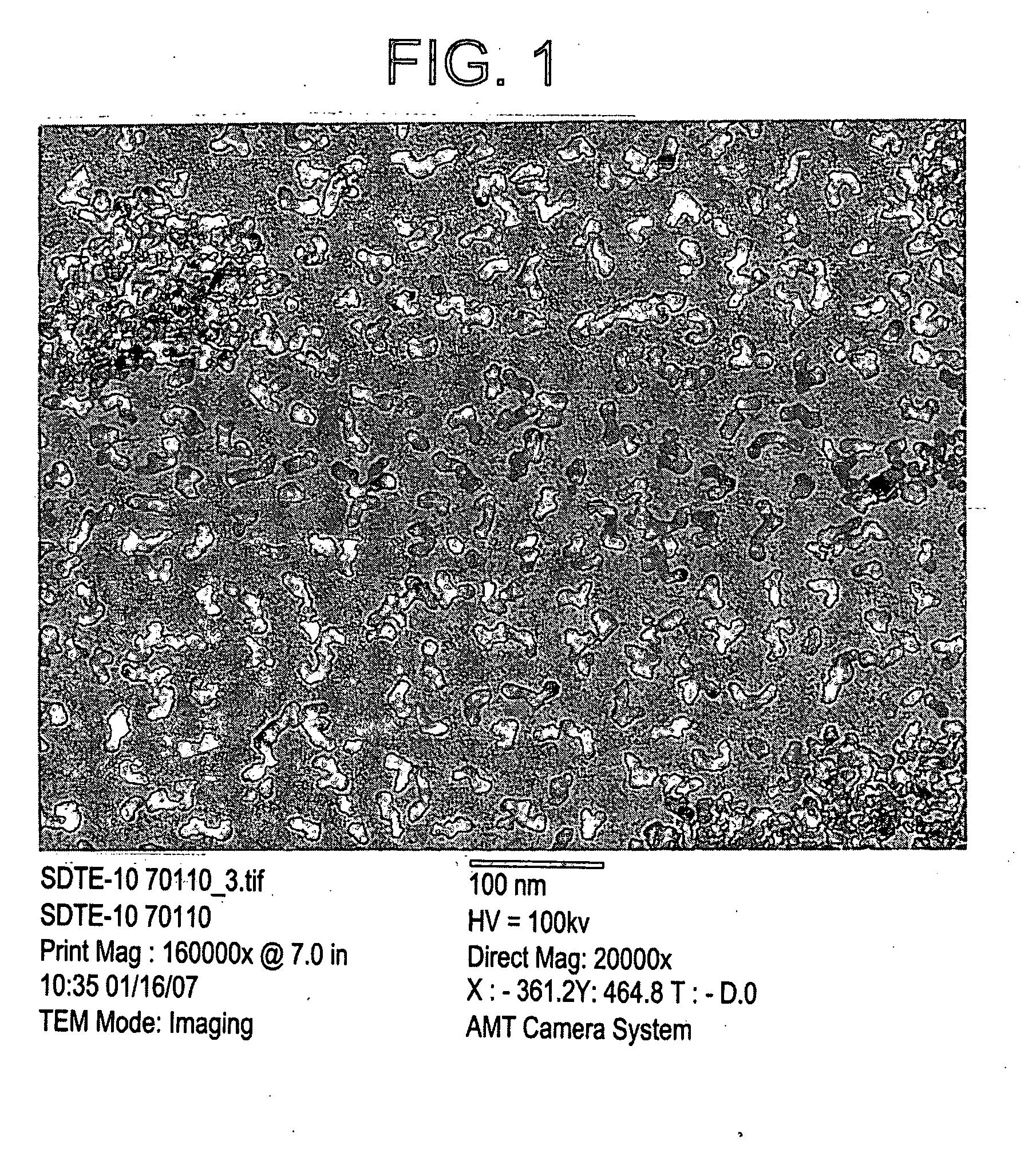

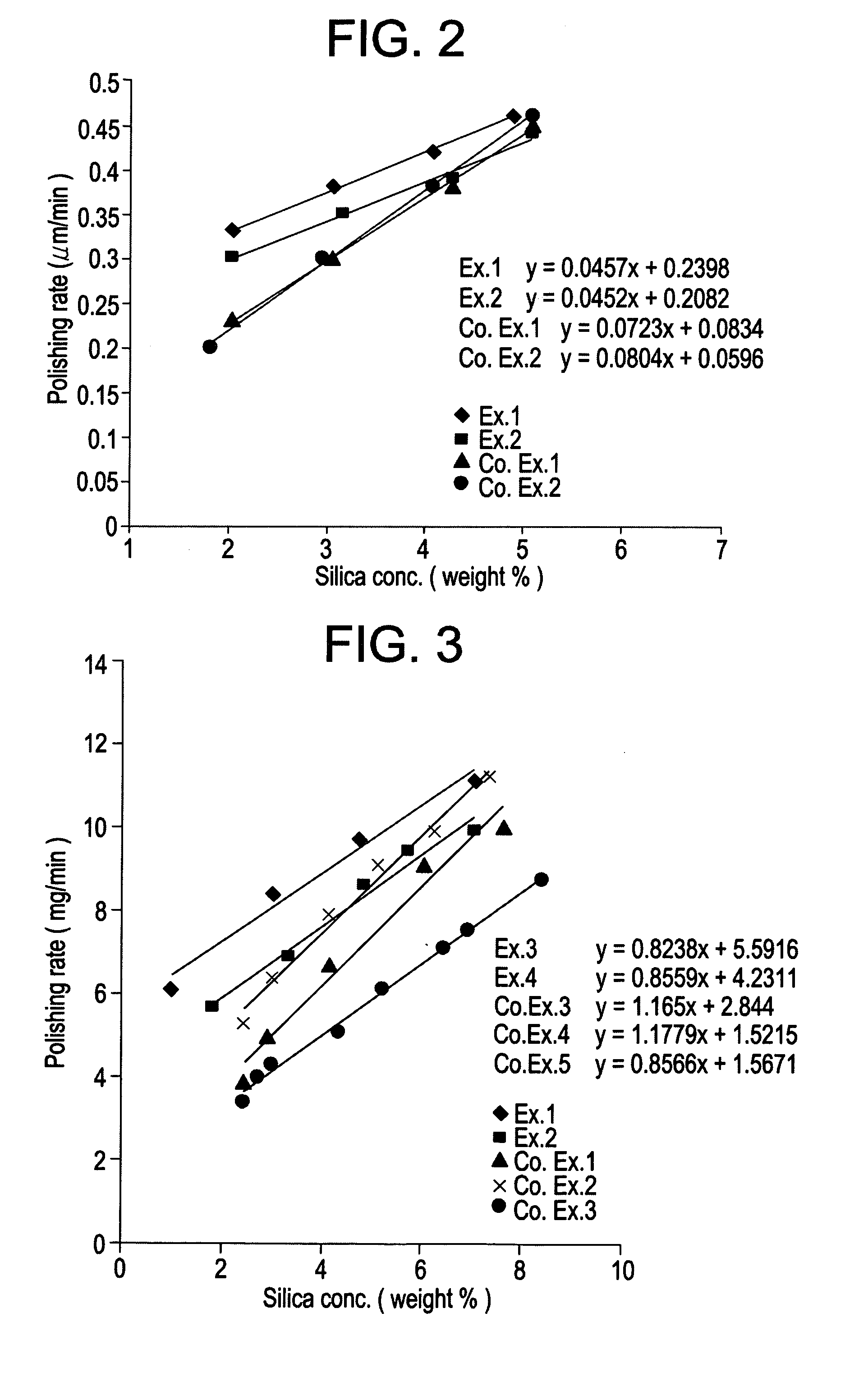

Polishing compound for semiconductor wafer polishing and polishing method

InactiveUS20090223136A1High polishing rateLittle changePigmenting treatmentOther chemical processesColloidal silicaSilica particle

The polishing compound for semiconductor wafer of the present invention contains colloidal silica composed of silica particles to which tetraethylammonium is fixed, and concentration of silica particles dispersed in water is between 0.5 to 50 weight %. Concentration of tetraethylammonium contained in silica particles to which tetraethylammonium is fixed is desirable to be in the range from 5x10-4 to 2.5x10-2 as indicated by molar ratio of tetraethylammonium / silica.

Owner:NIPPON CHECMICAL IND CO LTD +1

Polishing liquid and polishing method using the same

InactiveUS20090004863A1Excellent polishing rateHigh polishing rateOther chemical processesSemiconductor/solid-state device manufacturingMohs scale of mineral hardnessParticulates

The present invention provides a polishing liquid for polishing a ruthenium-containing barrier layer, the polishing liquid being used in chemical mechanical polishing for a semi-conductor device having a ruthenium-containing barrier layer and conductive metal wiring lines on a surface thereof, the polishing liquid comprising an oxidizing agent; and a polishing particulate having hardness of 5 or higher on the Mohs scale and having a composition in which a main component is other than silicon dioxide (SiO2). The present invention also provides a polishing method for chemical mechanical polishing of a semi-conductor device, the method contacting the polishing liquid with the surface of a substrate to be polished, and polishing the surface to be polished such that contacting pressure from a polishing pad to the surface to be polished is from 0.69 kPa to 20.68 kPa.

Owner:FUJIFILM CORP

Polishing composition for semiconductor wafer, method for production thereof and polishing method

InactiveUS20080287038A1Good dispersionImprove surface roughnessPigmenting treatmentOther chemical processesSilica particleSilicon dioxide

The present invention relates to a polishing composition for a substrate including a metal such as wiring, etc., formed on a semiconductor wafer, which can provide a high polishing rate without causing scratches on the wiring metal, a method of producing the polishing composition, and a polishing method. The polishing composition for a semiconductor wafer comprises an acid and an aqueous medium dispersion containing positively-charged silica particles having an amino group-containing silane coupling agent bonded on a surface thereof, the polishing composition having a pH of 2 to 6.

Owner:NIPPON CHECMICAL IND CO LTD

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20110081780A1Reduce polishing rateHigh polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidSilica particle

A chemical mechanical polishing aqueous dispersion includes (A) silica particles, and (B1) an organic acid, the number of silanol groups included in the silica particles (A) calculated from a signal area of a 29Si-NMR spectrum being 2.0 to 3.0×1021 / g.

Owner:JSR CORPORATIOON

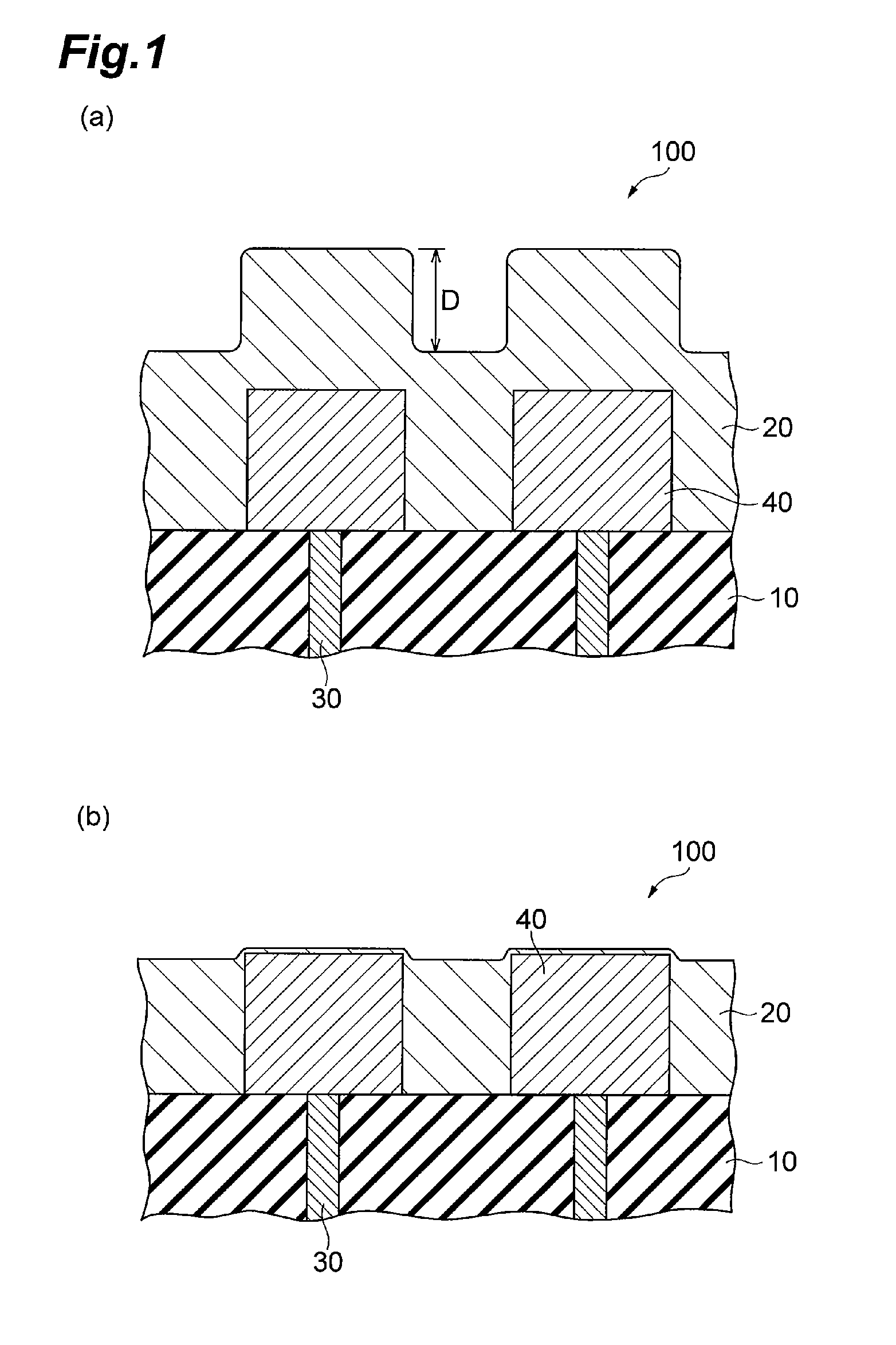

Chemical mechanical polishing pad and chemical mechanical polishing method

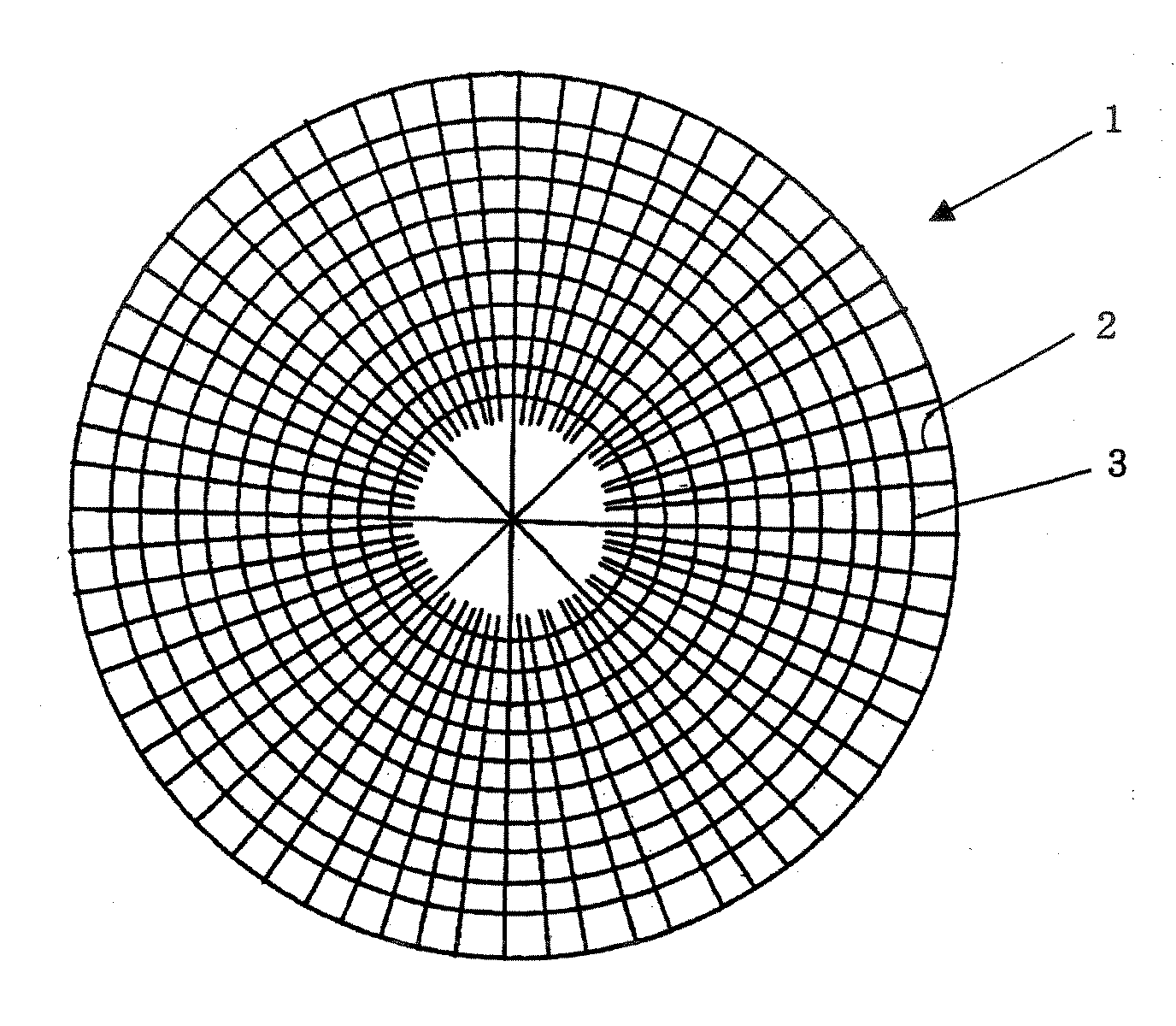

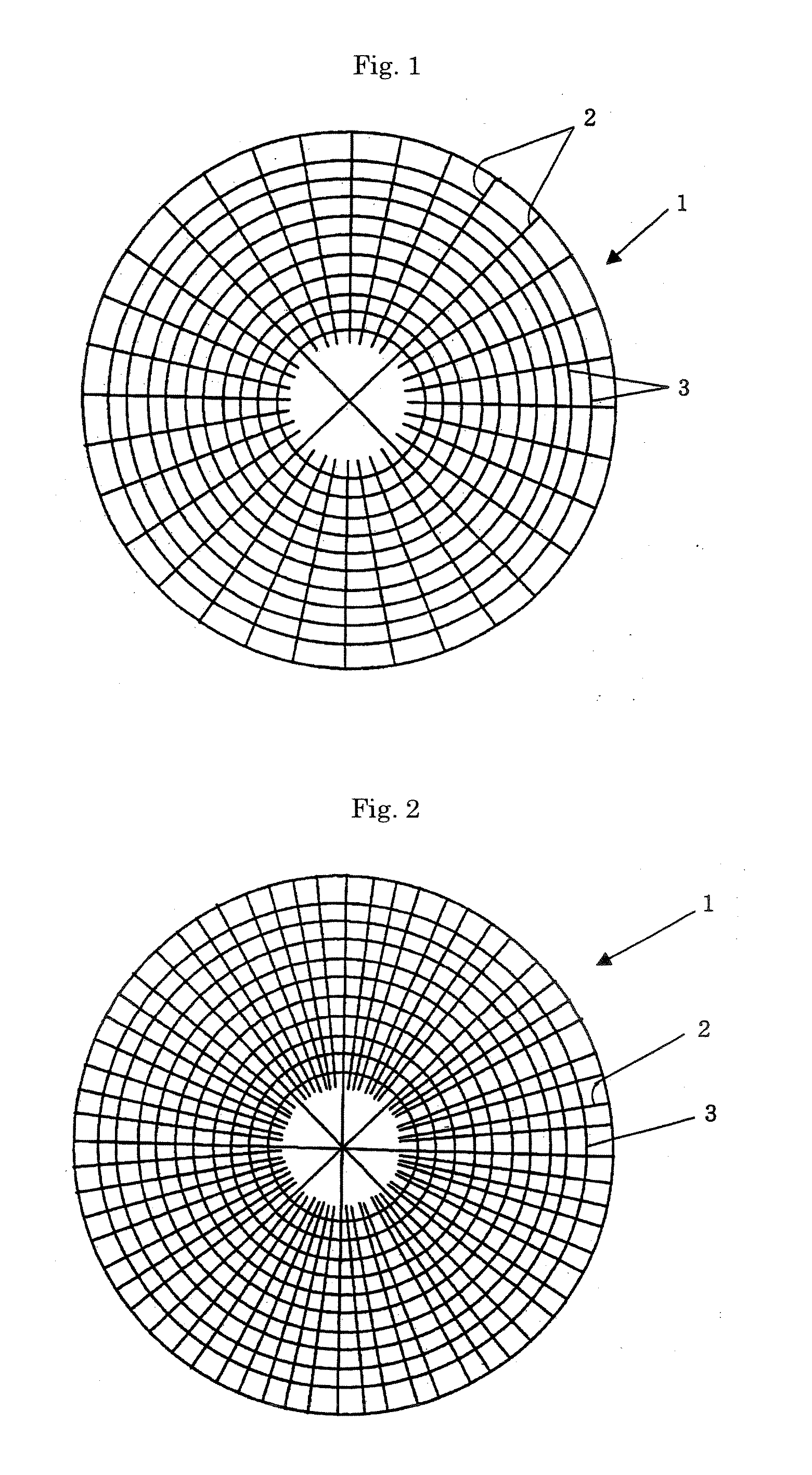

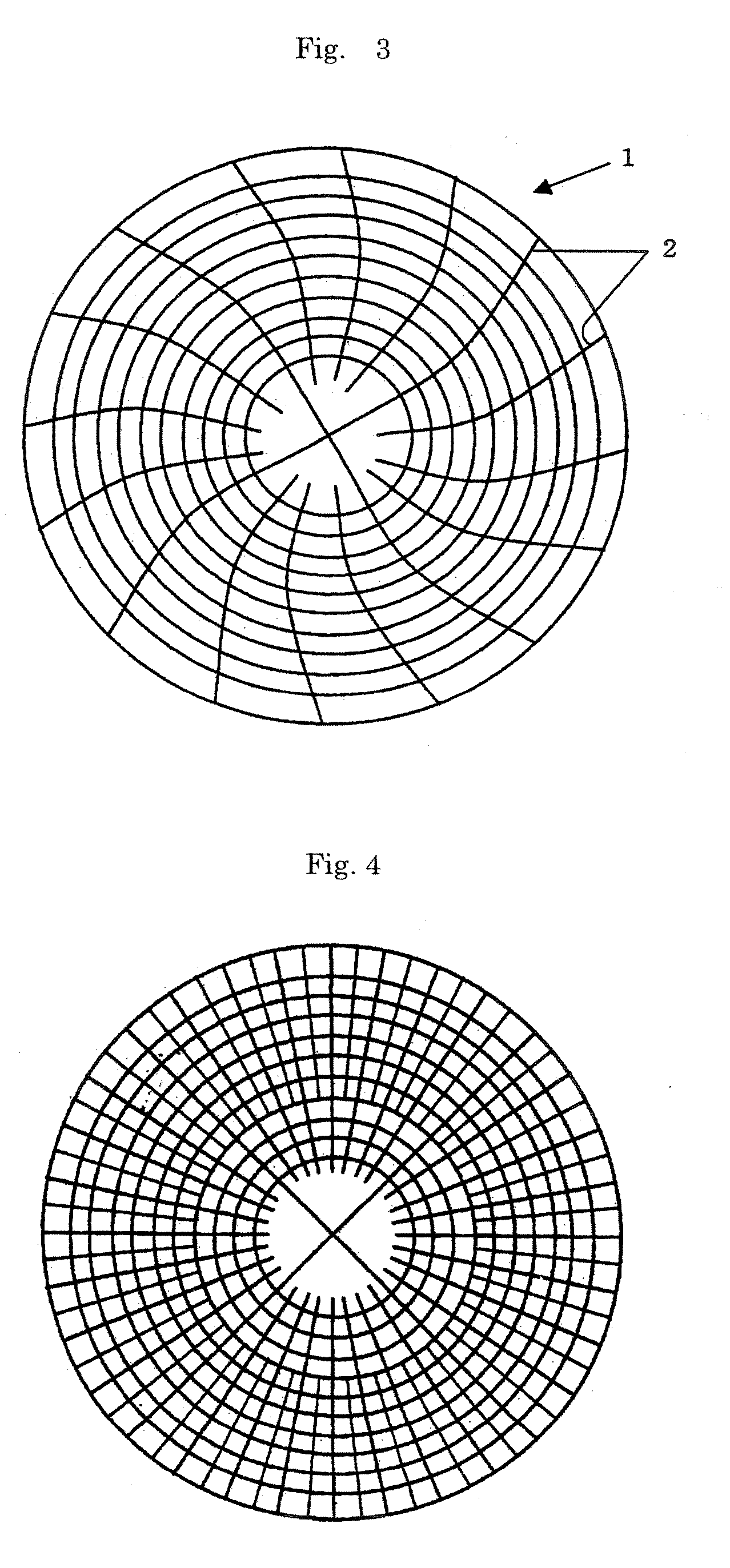

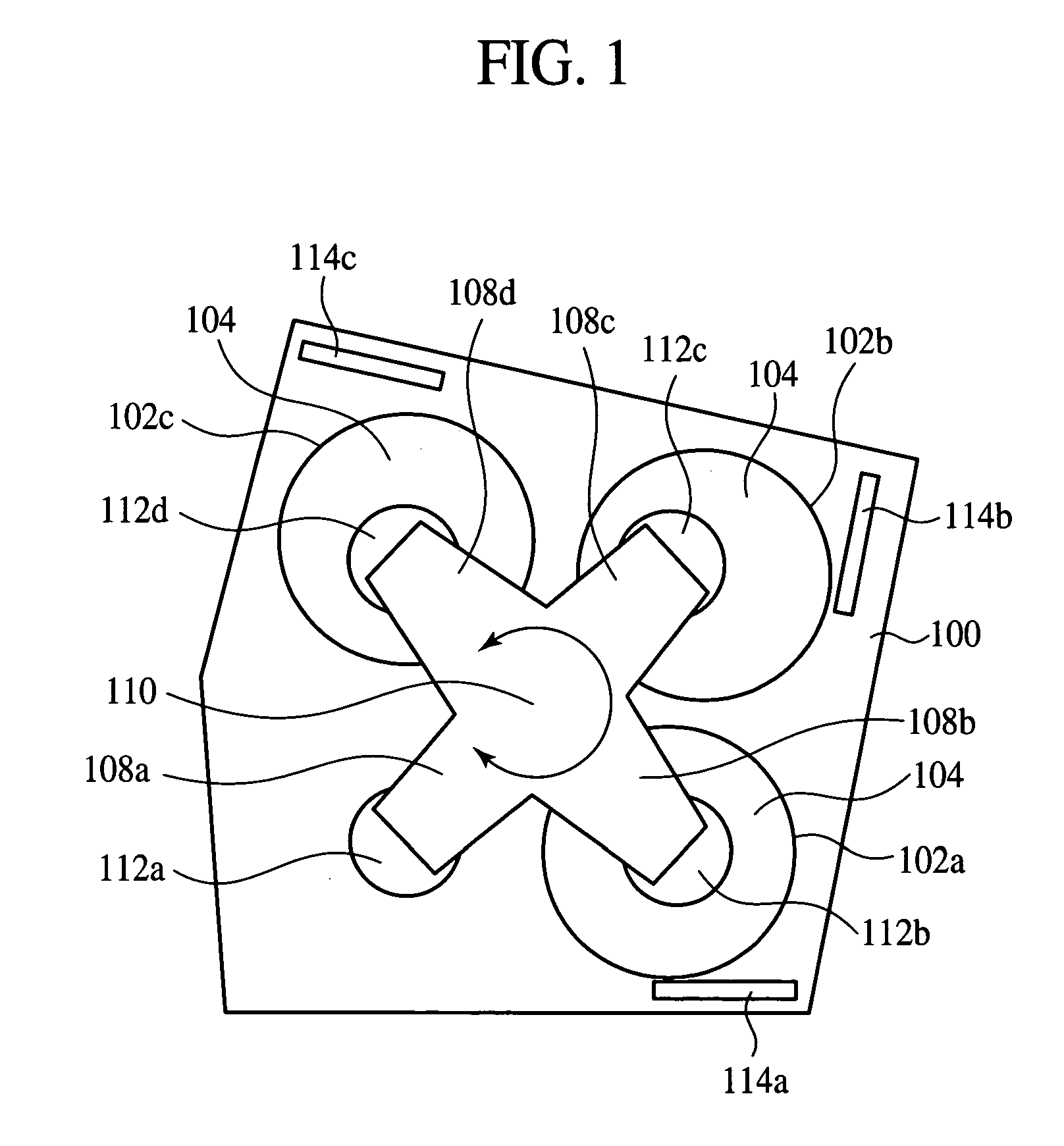

ActiveUS20070149096A1High polishing rateImprove in-plane uniformityAbrasion apparatusLapping machinesCompound (substance)Engineering

A chemical mechanical polishing pad of the present invention has the following two groups of grooves on the polishing surface: (i) a group of first grooves intersect a single virtual straight light extending from the center toward the periphery of the polishing surface and have a land ratio represented by the following equation of 6 to 30: Land ratio=(P−W)÷W (P is the distance between adjacent intersections between the virtual straight line and the first grooves, and W is the width of the first grooves); and (ii) a group of second grooves extend from the center portion toward the peripheral portion of the polishing surface and consist of second grooves which are in contact with one another in the area of the center portion and second grooves which are not in contact with any other second grooves in the area of the center portion. The chemical mechanical polishing pad of the present invention has a high polishing rate and excellent in-plane uniformity in the amount of polishing of the surface to be polished even when the amount of an aqueous dispersion for chemical mechanical polishing is made small.

Owner:JSR CORPORATIOON

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20110053462A1Reduce polishing rateHigh polishing rateOther chemical processesDecorative surface effectsIon contentIon chromatography

A chemical mechanical polishing aqueous dispersion including (A) silica particles, and (B1) an organic acid, the sodium content, the potassium content, and the ammonium ion content of the silica particles (A) determined by ICP atomic emission spectrometry, ICP mass spectrometry, or ammonium ion quantitative analysis using ion chromatography having a relationship in which the sodium content is 5 to 500 ppm and at least one of the potassium content and the ammonium ion content is 100 to 20,000 ppm.

Owner:JSR CORPORATIOON

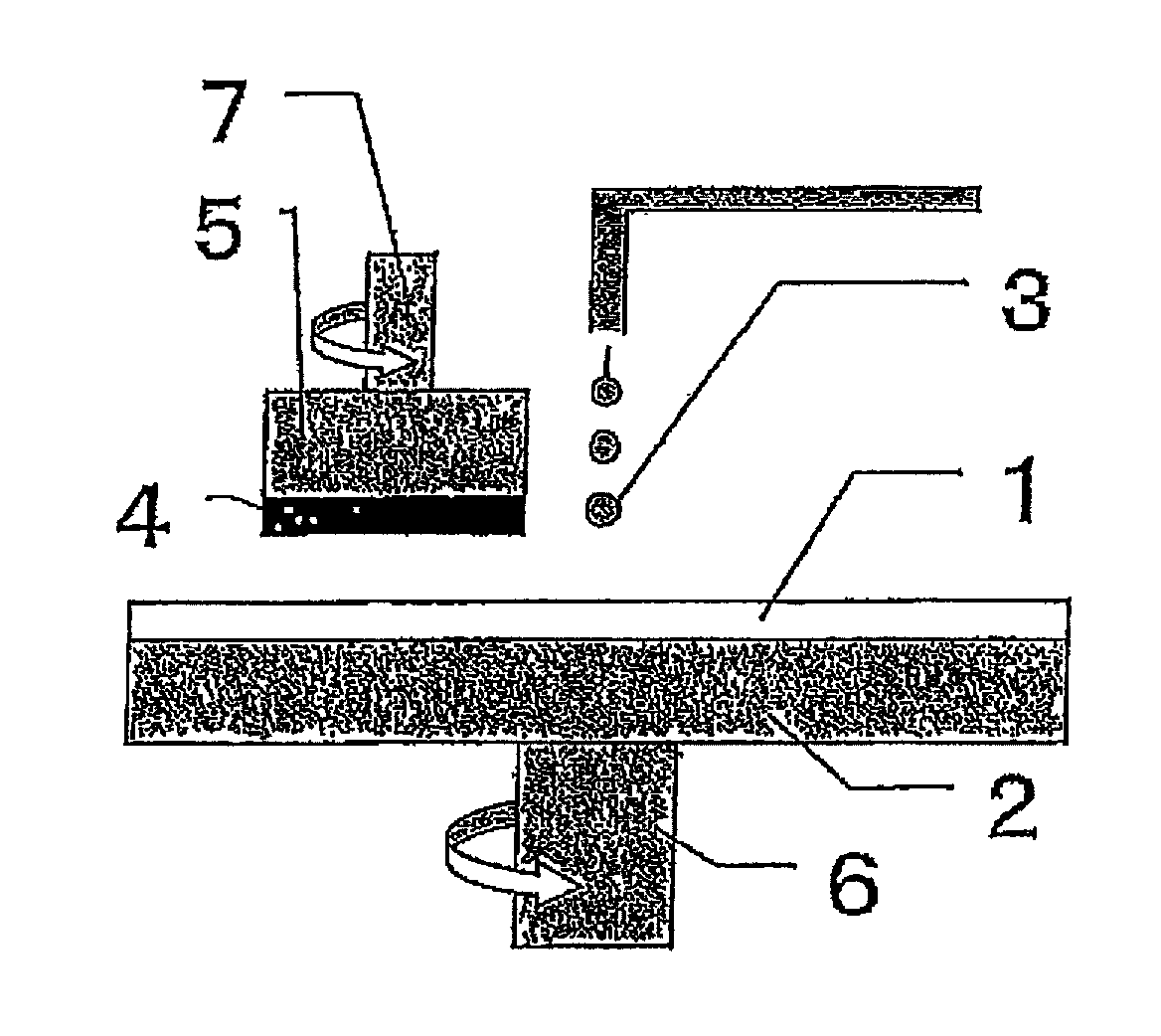

Polishing method, polishing apparatus and polishing tool

ActiveUS20120244649A1Improve flatnessHigh polishing rateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAcid waterElectrolysis

A polishing method and a polishing apparatus particularly suitable for finishing a surface of a substrate of a compound semiconductor containing an element such as Ga or the like to a desired level of flatness, so that a surface of a substrate of a compound semiconductor containing an element of Ga can be flattened with high surface accuracy within a practical processing time. In the presence of water (232) such as weak acid water, water with air dissolved therein, or electrolytic ion water, a surface of a substrate (142) made of a compound semiconductor containing either one of Ga, Al, and In and the surface of a polishing pad (242) having an electrically conductive member (264) in an area of the surface which is held in contact with the substrate (142) are relatively moved while being held in contact with each other, thereby polishing the surface of the substrate (142).

Owner:OSAKA UNIV +1

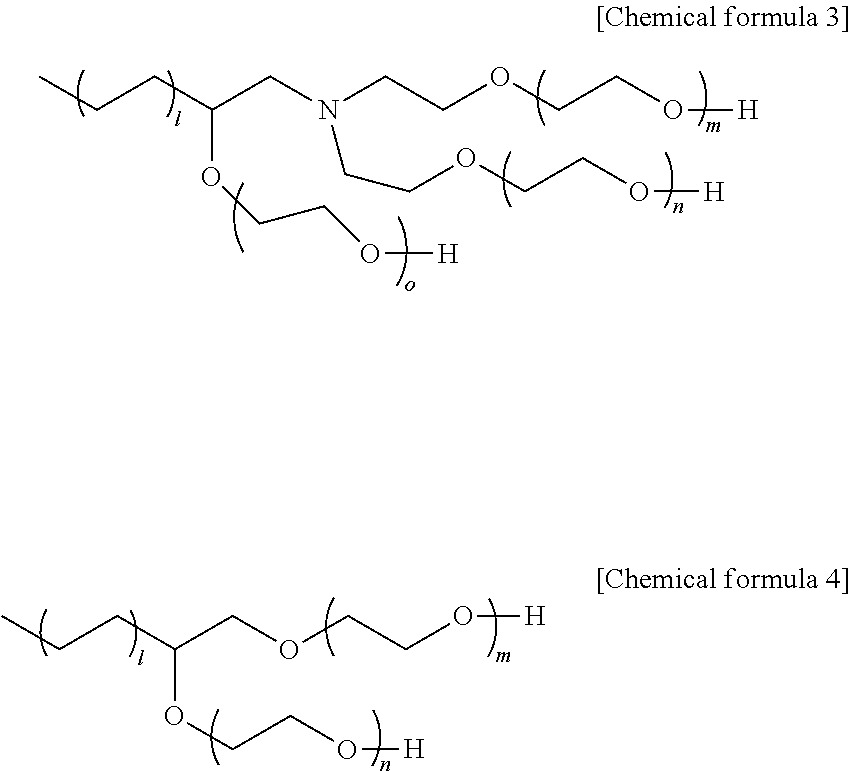

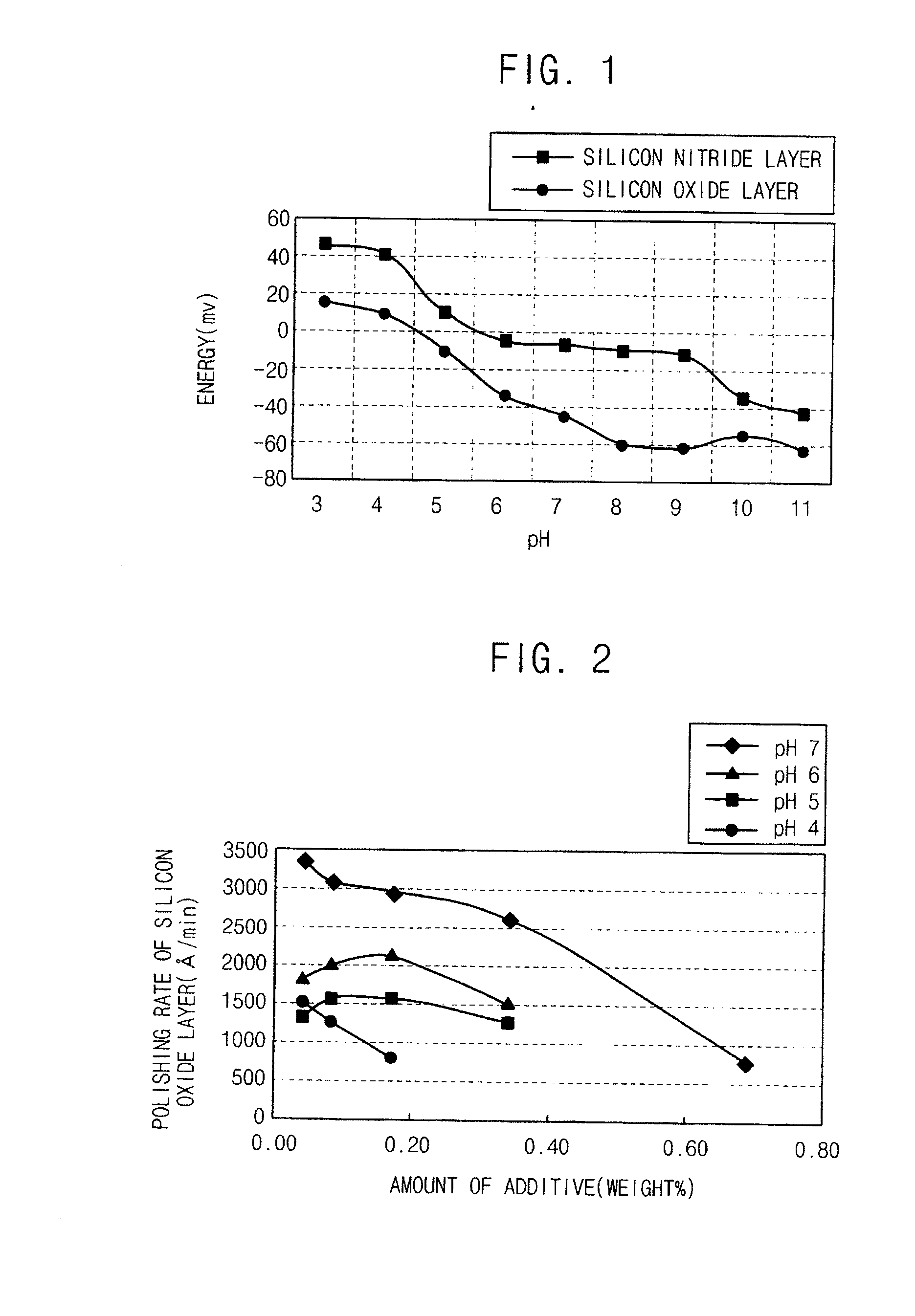

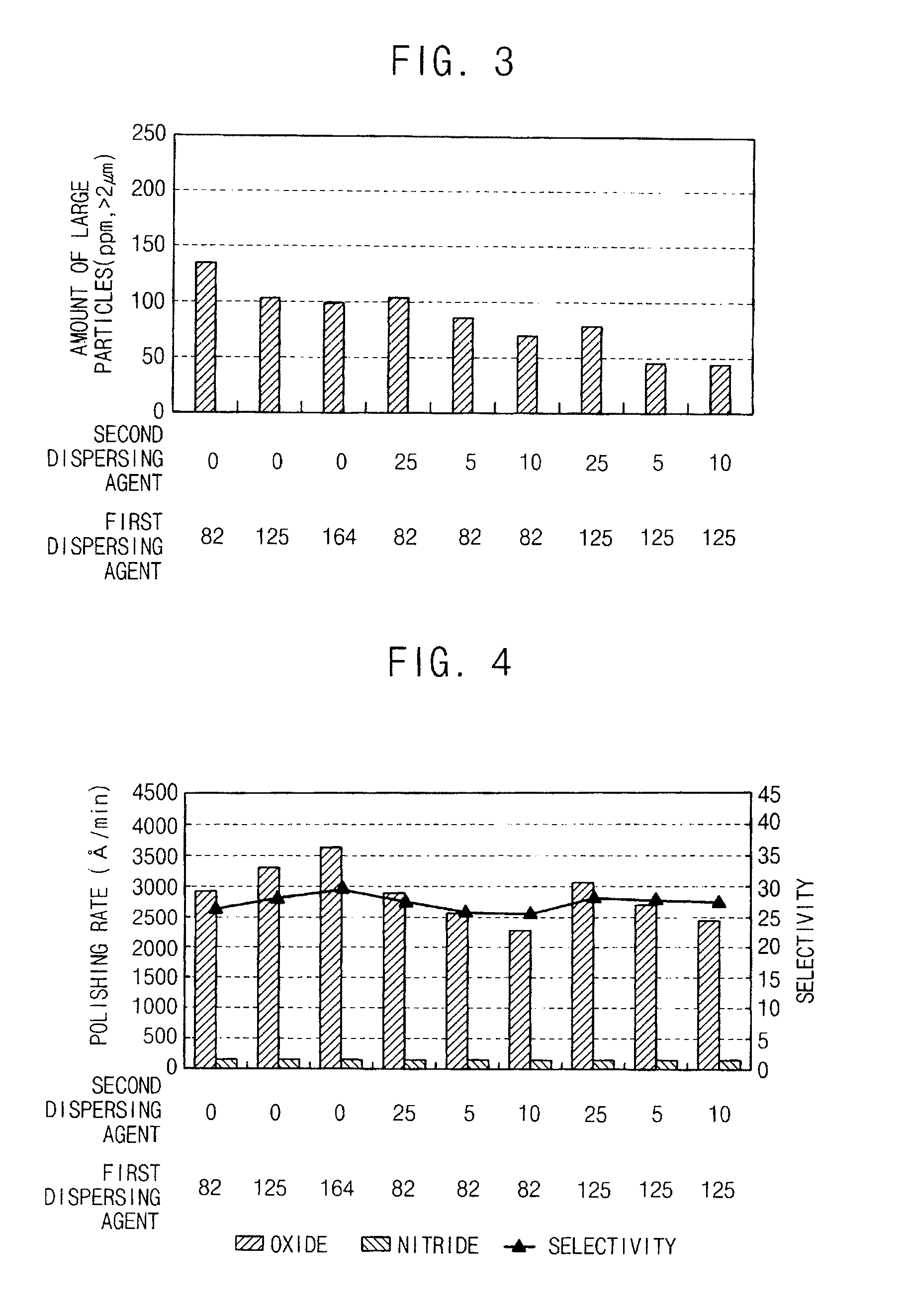

Slurry composition for cmp, and polishing method

ActiveUS20120270399A1Improve polishing selectivityHigh polishing rateMaterial nanotechnologyOther chemical processesPolymer sciencePolyolefin

The present invention relates to a CMP slurry composition comprising an abrasive particle; a dispersant; an ionic polymer additive; and a non-ionic polymer additive including a polyolefin-polyethylene glycol copolymer including at least two polyethylene glycol repeat unit as a backbone and at least a polyethylene glycol repeating unit as a side chain, and a polishing method with using the slurry composition. The CMP slurry composition shows a low polishing rate to a single-crystalline silicon layer or a polysilicon layer and a high polishing rate to a silicon oxide layer, resulting in having an excellent polishing selectivity.

Owner:LG CHEM LTD

Metal polishing solution and polishing method

InactiveUS20060214133A1High polishing rateImprove performanceOther chemical processesSemiconductor/solid-state device manufacturingReaction rateRates reactions

A metal polishing solution comprising an oxidizing agent, wherein assuming that an oxidation reaction rate immediately after an oxidation of a metal to be polished starts at its surface is E1 and an oxidation reaction rate when an oxidation reaction reaches a stationary state is E2, E1 / E2 is 1.5 or more and a time required for reaching an oxidation reaction rate of (E1+E2) / 2 is from 1 to 50 seconds.

Owner:FUJIFILM HLDG CORP +1

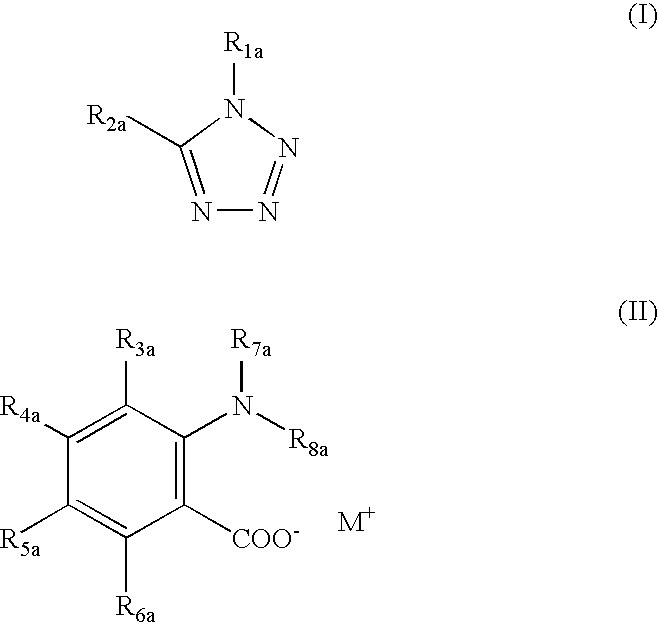

CMP Slurry Composition for Barrier Polishing for Manufacturing Copper Interconnects, Polishing Method Using the Composition, and Semiconductor Device Manufactured by the Method

InactiveUS20100164106A1High polishing rateMinimizing surface defectOther chemical processesSemiconductor/solid-state device detailsColloidal silicaCopper interconnect

Provided is a CMP slurry composition for barrier polishing for manufacturing copper interconnects, the composition including abrasive particles, a copper surface protective agent, a copper corrosion inhibitor, an oxidizing agent, and a pH adjustor, wherein the abrasive particles are non-spherical colloidal silica having a ratio of an average primary particle size to an average secondary particle size of about 0.6 or less and the copper surface protective agent is a carboxyl-functionalized water-soluble polymer.

Owner:CHEIL IND INC

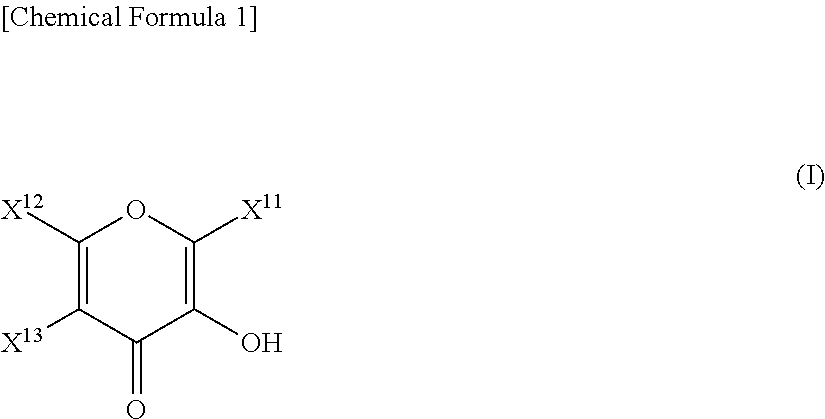

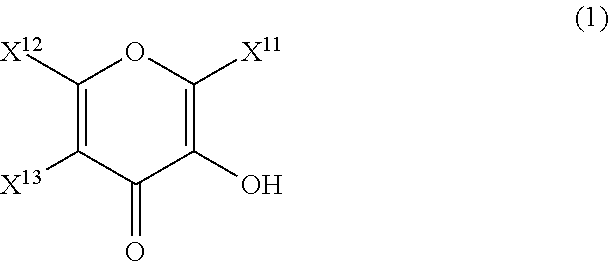

Polishing liquid for cmp, and polishing method

ActiveUS20160137881A1High polishing rateHigh propertyOther chemical processesSemiconductor/solid-state device manufacturingPyroneCerium

Owner:RESONAC CORP

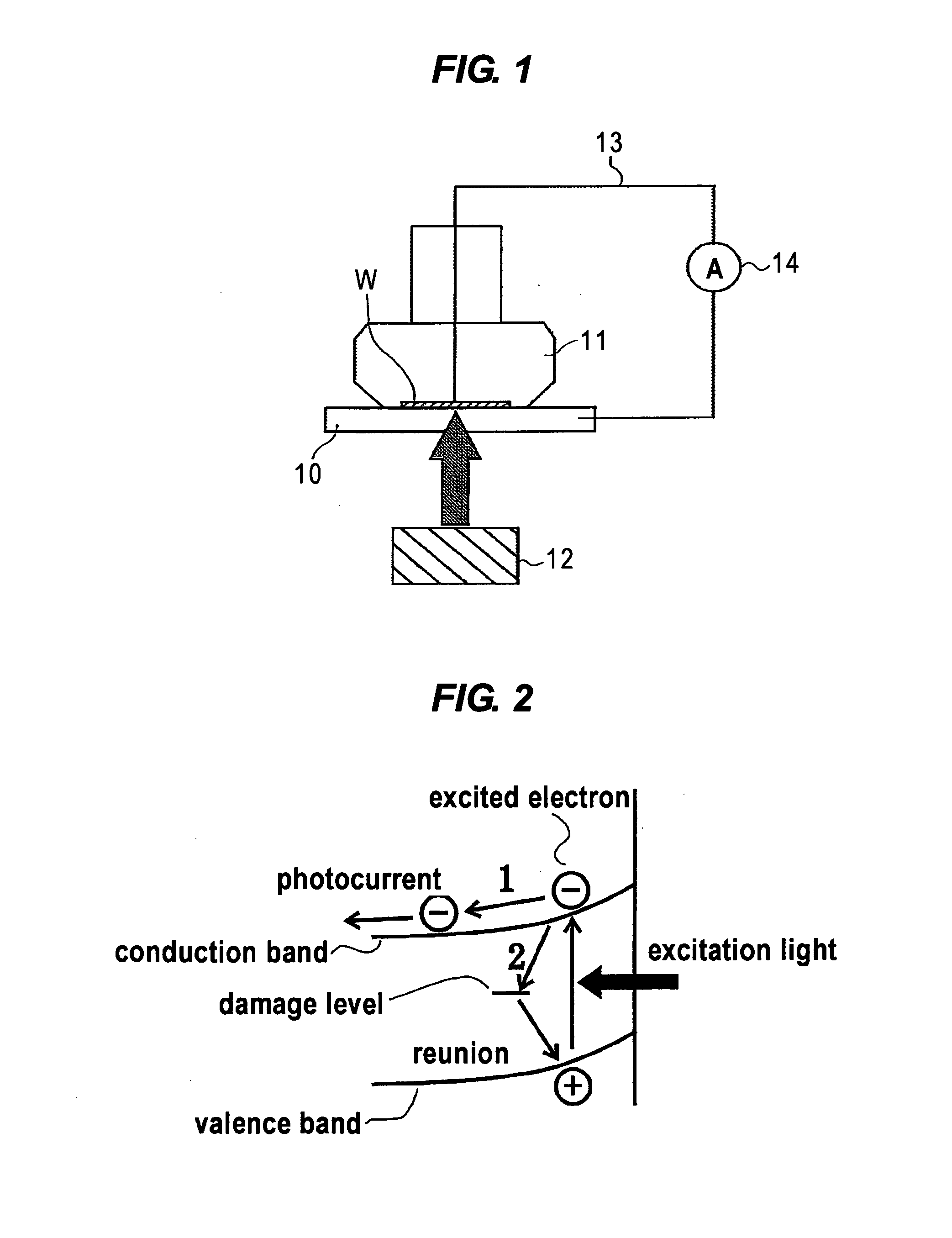

Polishing method of non-oxide single-crystal substrate

ActiveUS20140057438A1Stable and high-speed polishingHigh polishing rateSemiconductor/solid-state device manufacturingAqueous dispersionsOxidation-Reduction AgentSingle crystal substrate

There is provided a polishing method for polishing a non-oxide single-crystal substrate such as a silicon carbide single-crystal substrate at a high polishing rate to obtain a high-quality surface that is smooth and excellent in surface properties. This polishing method is a method of supplying a polishing liquid to a polishing pad not including abrasive grains to bring a surface to be polished of the non-oxide single-crystal substrate and the polishing pad into contact with each other and polishing the surface to be polished by a relative movement between them, the method characterized in that the polishing liquid comprises: an oxidant whose redox potential is 0.5 V or more and which contains a transition metal; and water, and does not contain abrasive grains.

Owner:ASAHI GLASS CO LTD

Polishing liquid for metal film and polishing method

InactiveUS20100323584A1Increase speedHigh molecular weightPigmenting treatmentOther chemical processesHigh rateWater soluble

The invention relates to a polishing liquid for metal film comprising 7.0% by weight or more of an oxidizer for metal, a water-soluble polymer, an oxidized metal dissolving agent, a metal anticorrosive agent and water, provided that the total amount of the polishing liquid for metal film is 100% by weight,wherein the water-soluble polymer has a weight average molecular weight of 150,000 or more and is at least one member selected from among a polycarboxylic acid, a salt of a polycarboxylic acid, and a polycarboxylic acid ester. According to the invention, provided is a polishing liquid for metal film, by which polishing can be performed at a high rate even under a polishing pressure as low as 1 psi or lower, and such that a polished film after polishing is excellent in planarity, furthermore, with which a high polishing rate can be obtained even in an initial stage of polishing, and provided is a polishing method using the polishing liquid.

Owner:HITACHI CHEM CO LTD

Polishing agent, polishing method and additive liquid for polishing

ActiveUS20160024351A1High selectivityLow polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidPolyamide

Owner:ASAHI GLASS CO LTD

Slurry Composition For a Chemical Mechanical Polishing Process, Method of Polishing an Object Layer and Method of Manufacturing a Semiconductor Memory Device Using the Slurry Composition

InactiveUS20080045020A1High polishing rateLow polishing rateOther chemical processesAnionic surface-active compoundsDevice materialSlurry

A slurry composition for a chemical mechanical processing process includes about 0.05 to about 0.3 percent by weight of a ceria abrasive, about 0.005 to about 0.04 percent by weight of an anionic surfactant, about 0.0005 to about 0.003 percent by weight of a polyoxyethylene-based nonionic surfactant, about 0.2 to about 1.0 percent by weight of a salt of polyacrylic acid having an average molecular weight substantially greater than a molecular weight of the anionic surfactant, and a remainder of water. In addition, a method of polishing an object layer and a method of manufacturing a semiconductor device using the slurry composition are also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

Polishing liquid for cmp and polishing method using the same

ActiveUS20120315763A1High polishing rateHigh flatnessOther chemical processesSemiconductor/solid-state device manufacturingNonionic surfactantCerium

Owner:RESONAC CORP

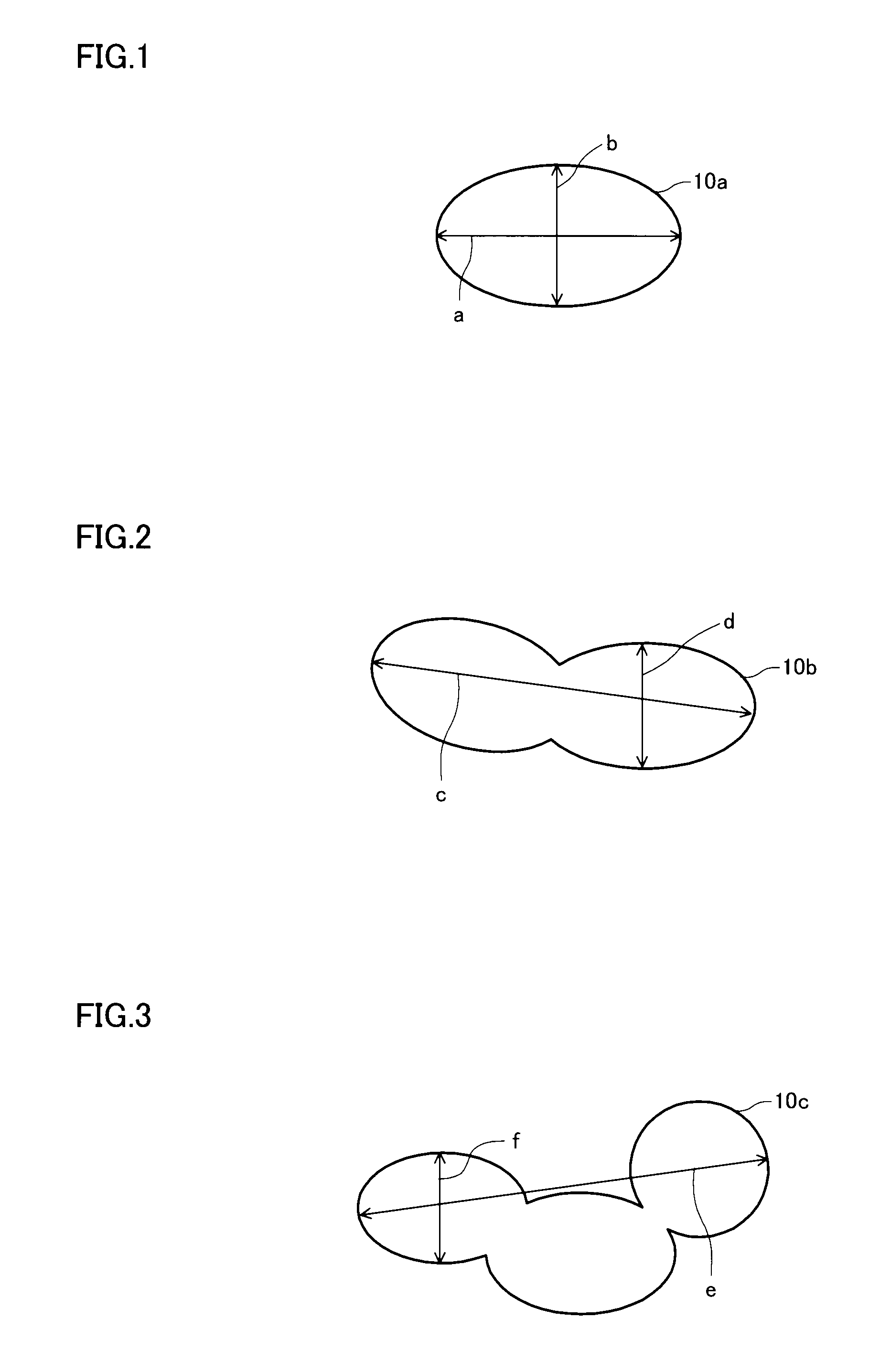

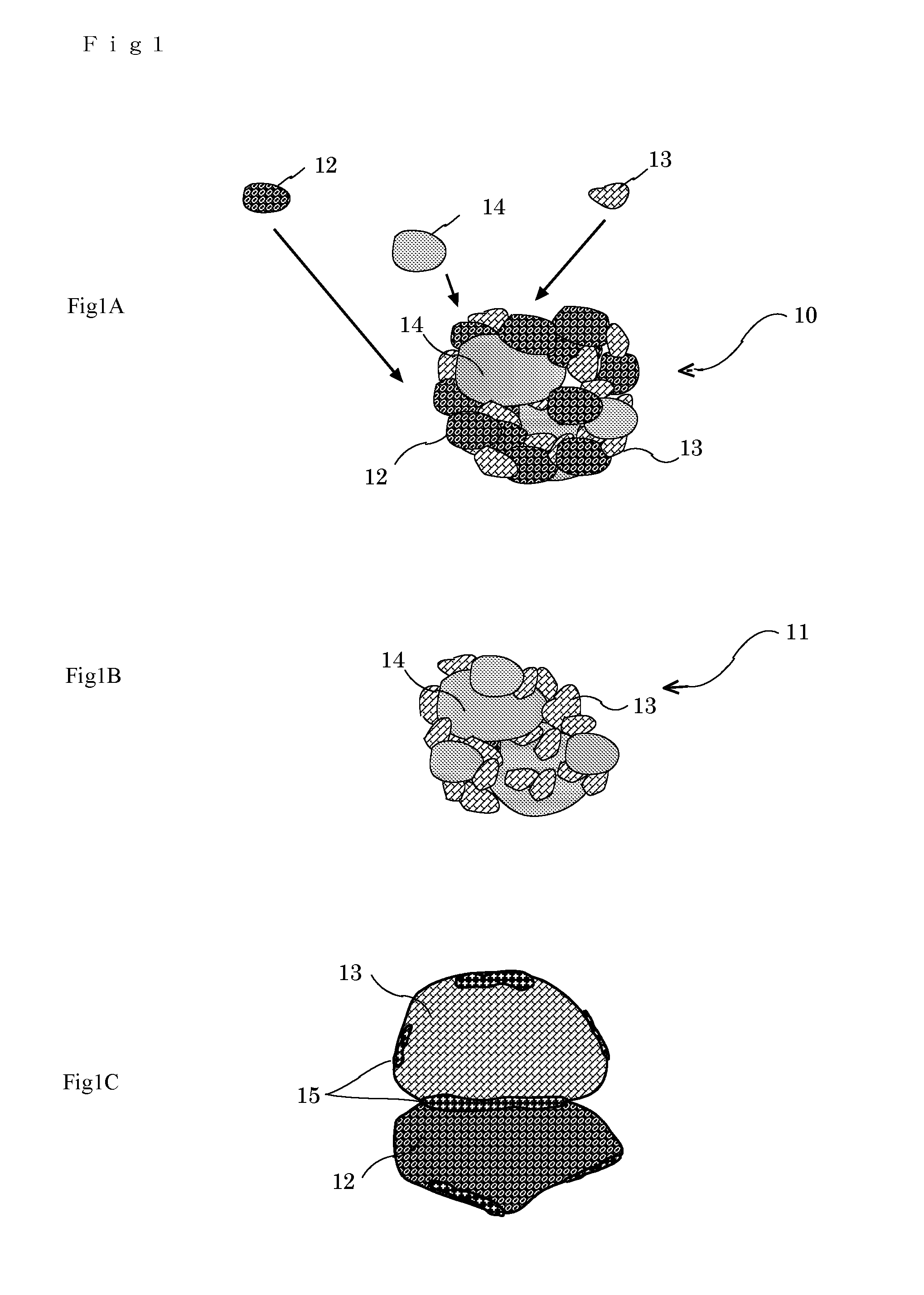

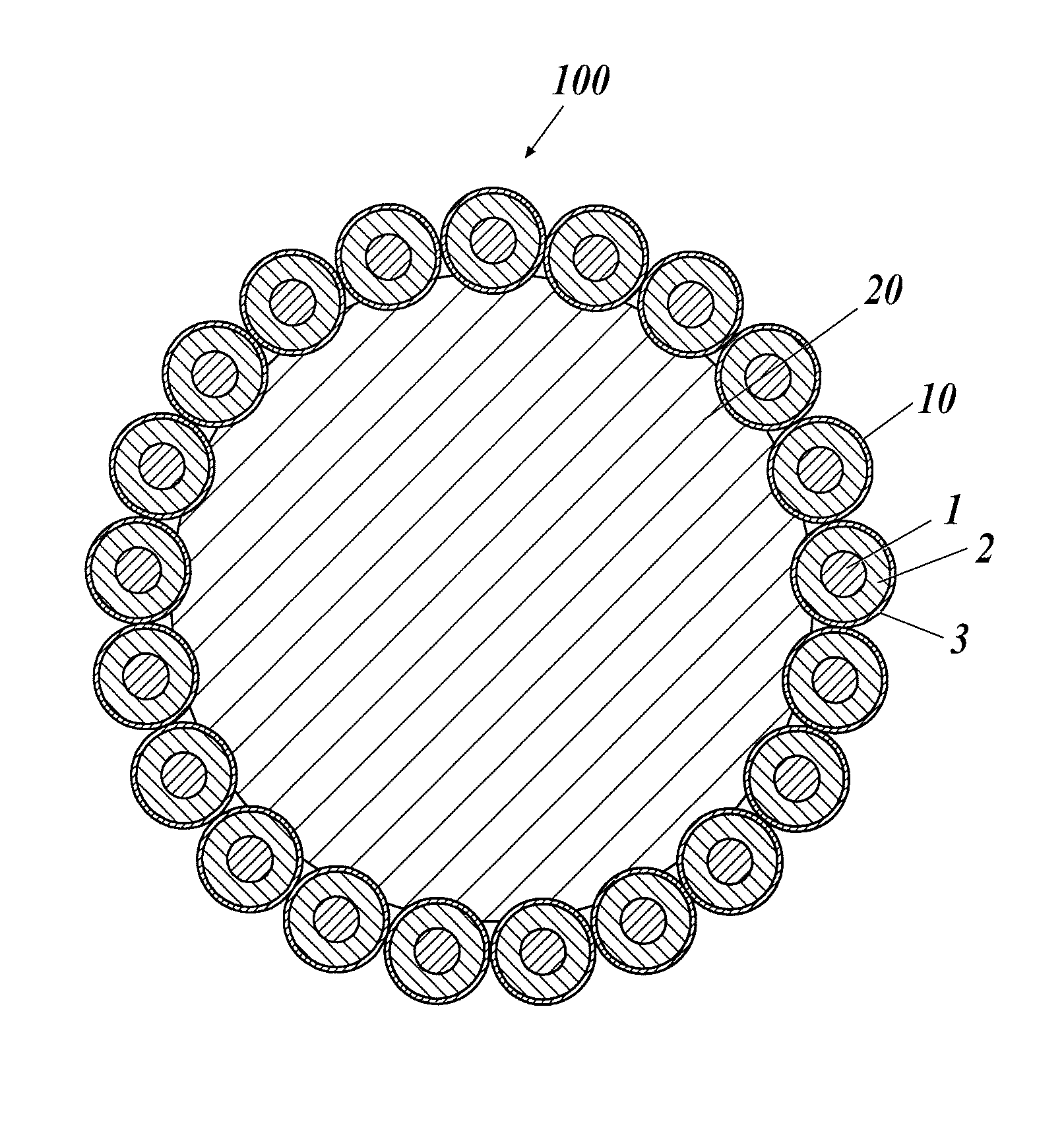

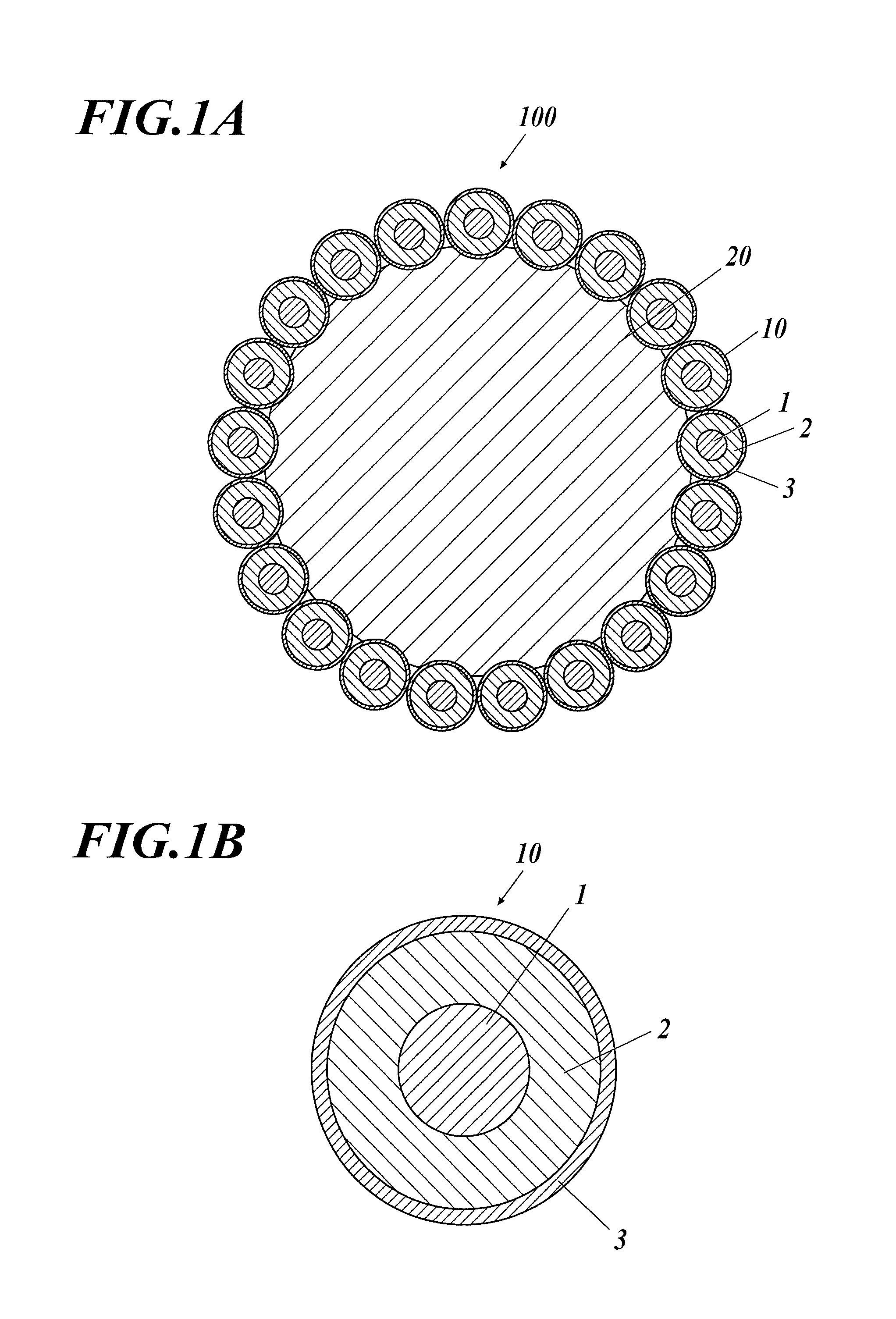

Polishing Material Particles, Method For Producing Polishing Material, And Polishing Processing Method

ActiveUS20160194538A1High polishing rateGood monodispersityPigmenting treatmentOther chemical processesRare-earth elementCerium

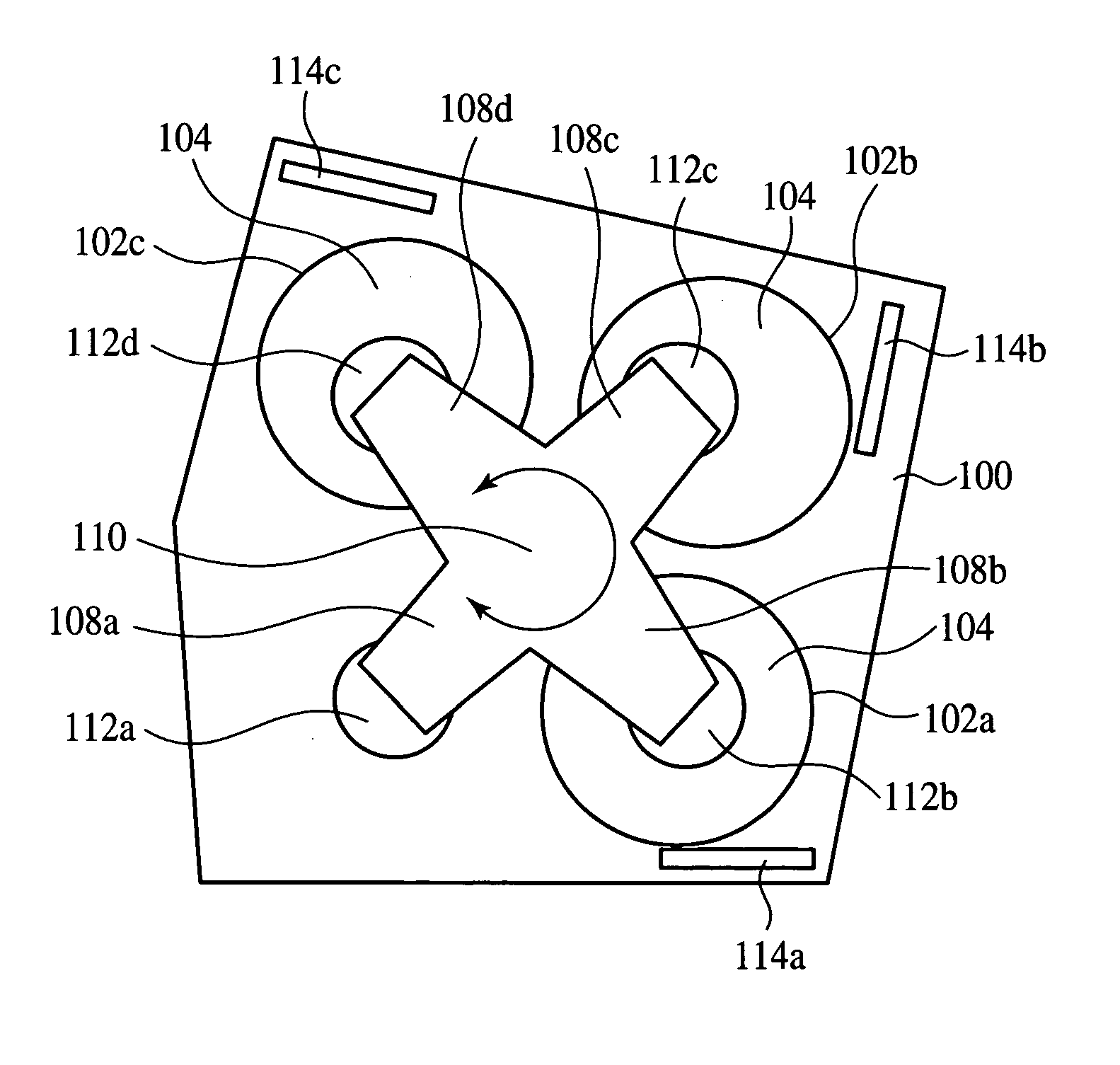

Disclosed are polishing material particles which have polishing performance suitable for precision polishing and also have a high polishing speed and high monodispersibility; a polishing material containing the polishing material particles; and a polishing processing method using the polishing material. The polishing material particles are spherical particles having an average aspect ratio of 1.00 to 1.15, wherein the particle diameter (D50 (nm)) of the polishing material particles as determined from a particle diameter cumulative distribution curve falls within the range from 50 to 1500 nm. The average content of cerium or the total content of cerium and at least one element selected from lanthanum (La), praseodymium (Pr), neodymium (Nd), samarium (Sm) and europium (Eu) in the polishing material particles is 81 mol % or more relative to the total content of all of rare earth elements that constitute the polishing material particles.

Owner:KONICA MINOLTA INC

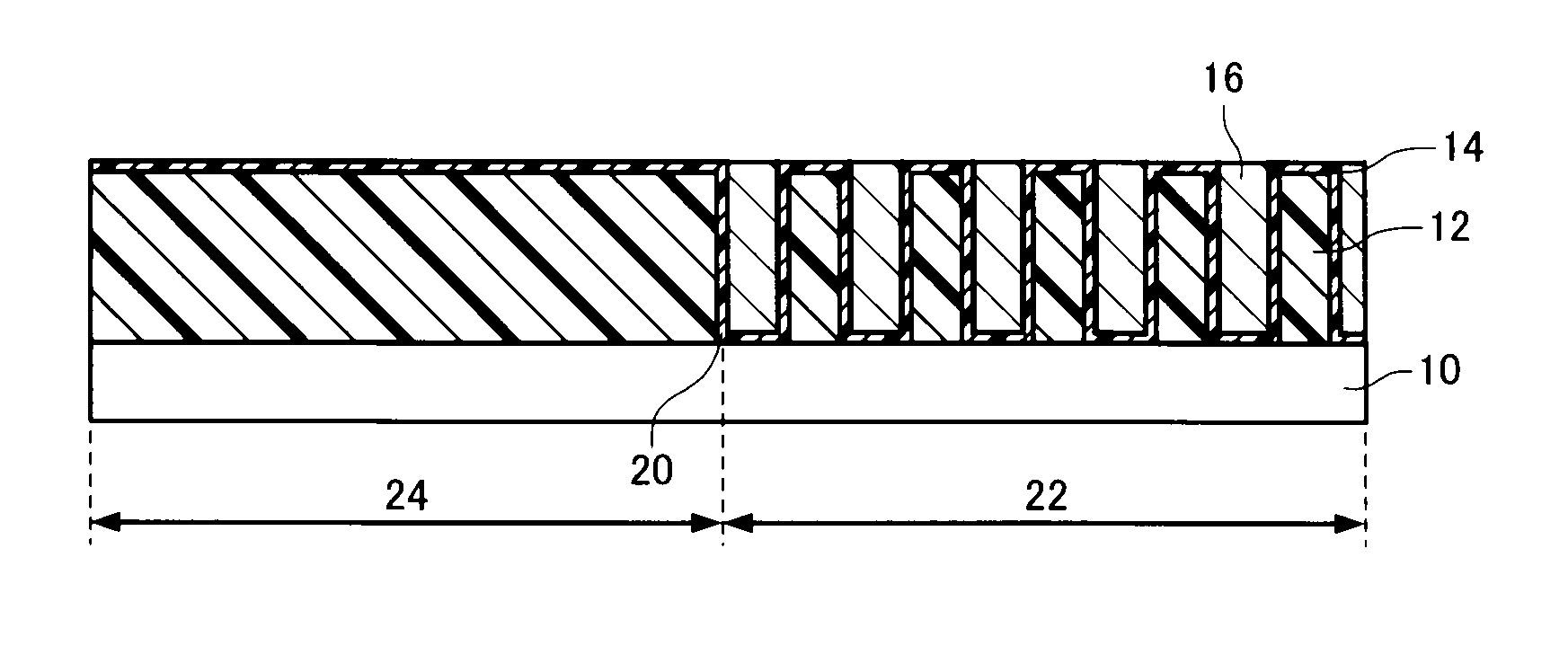

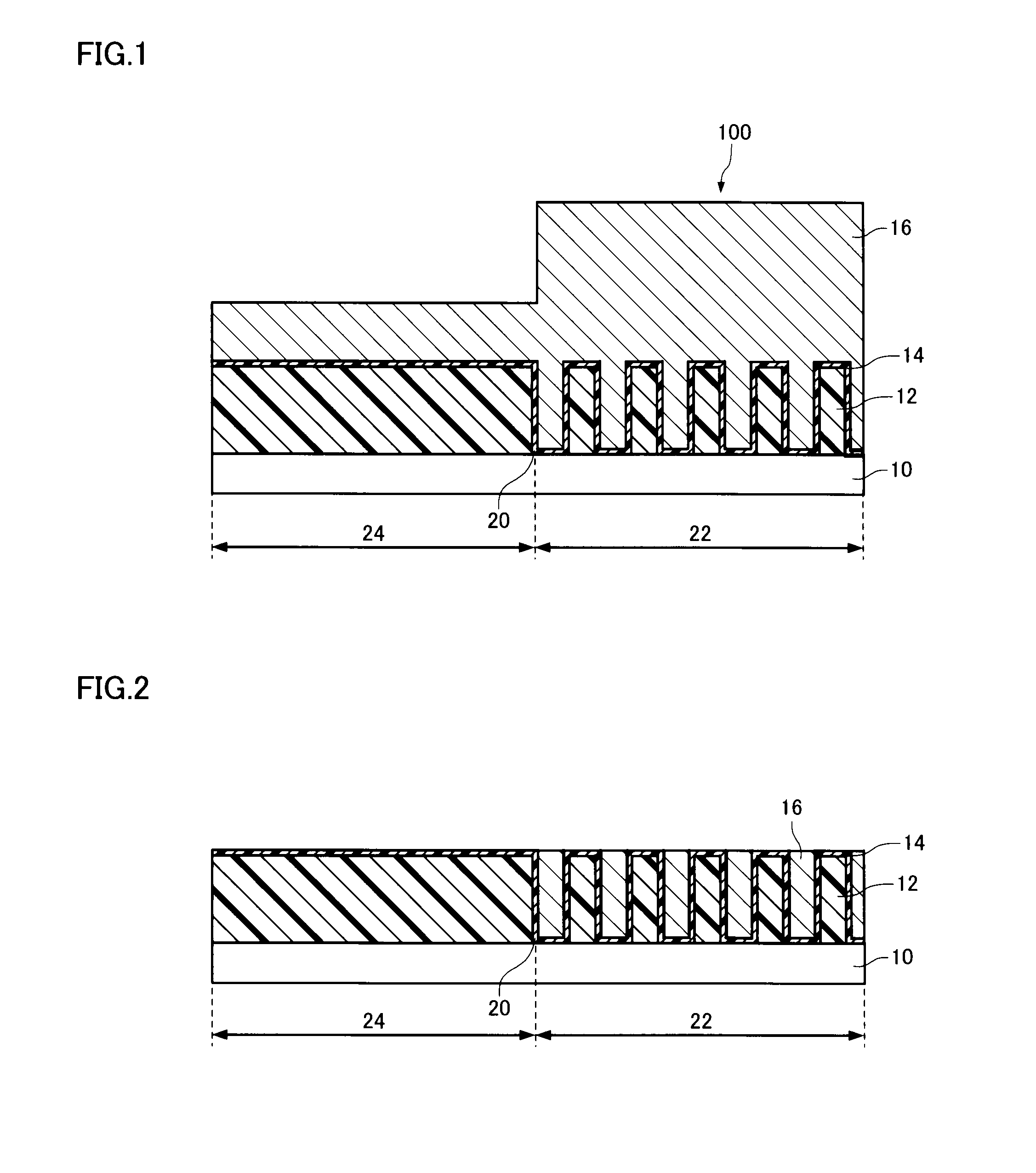

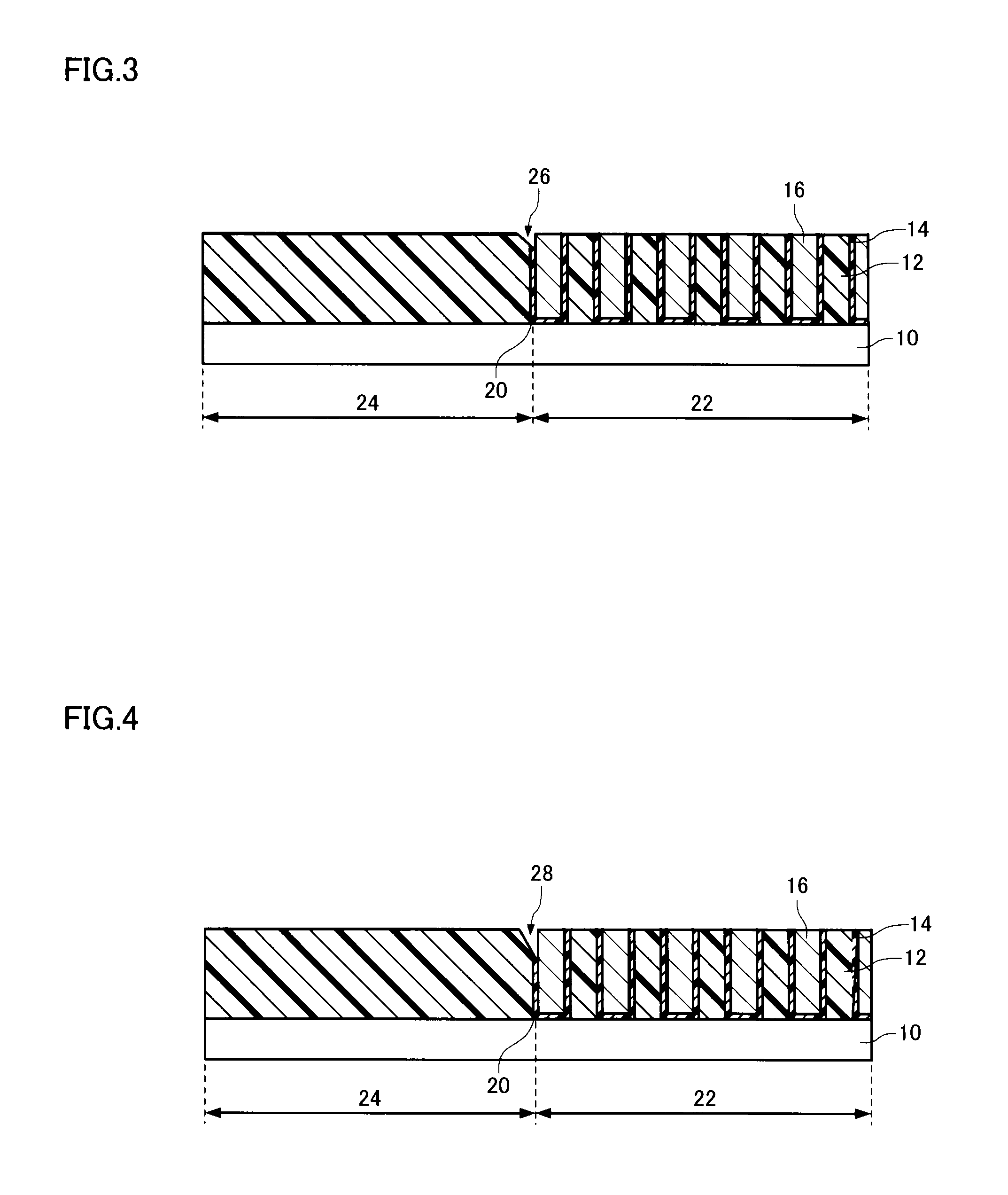

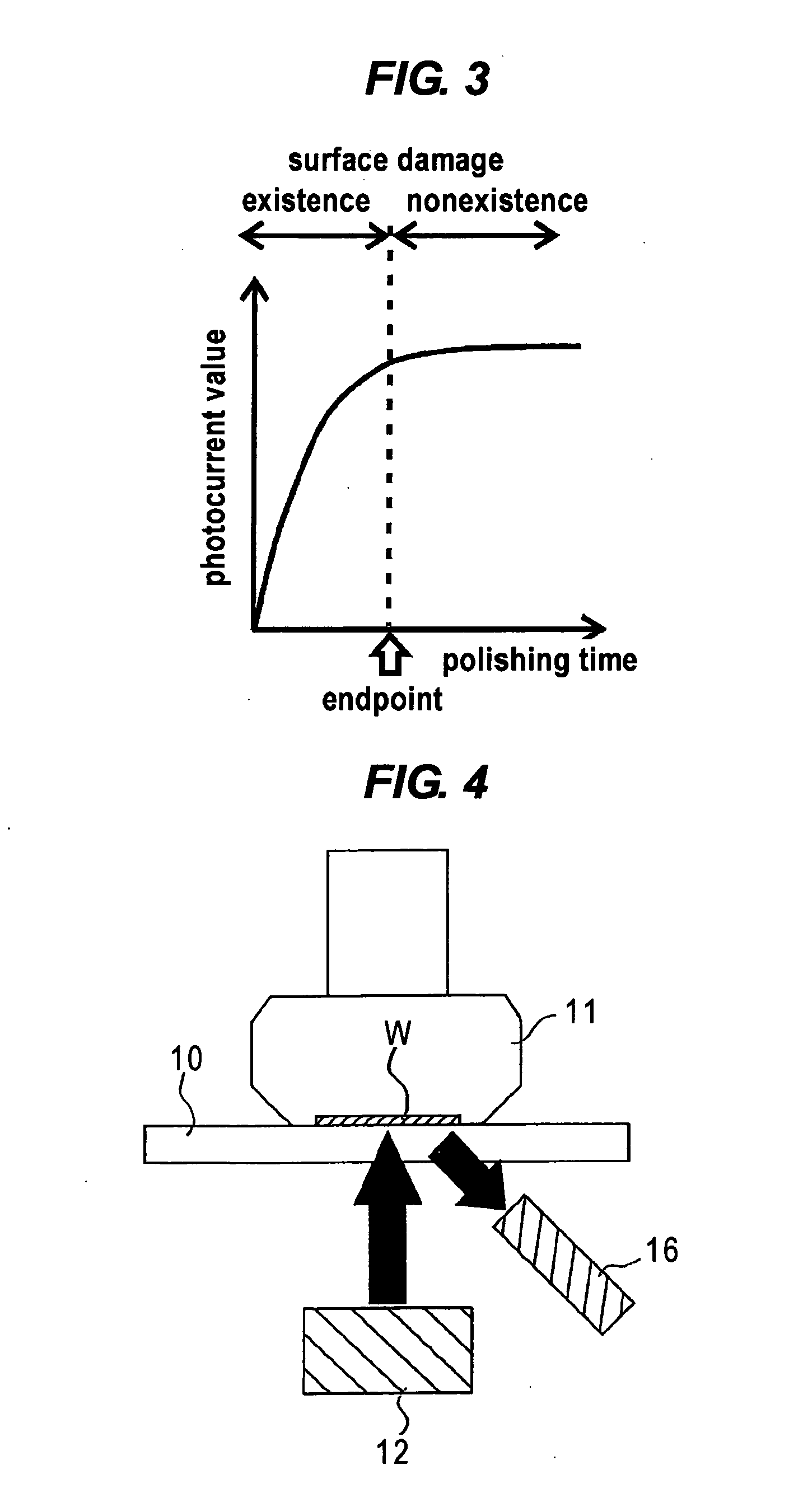

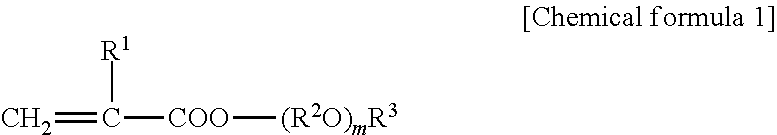

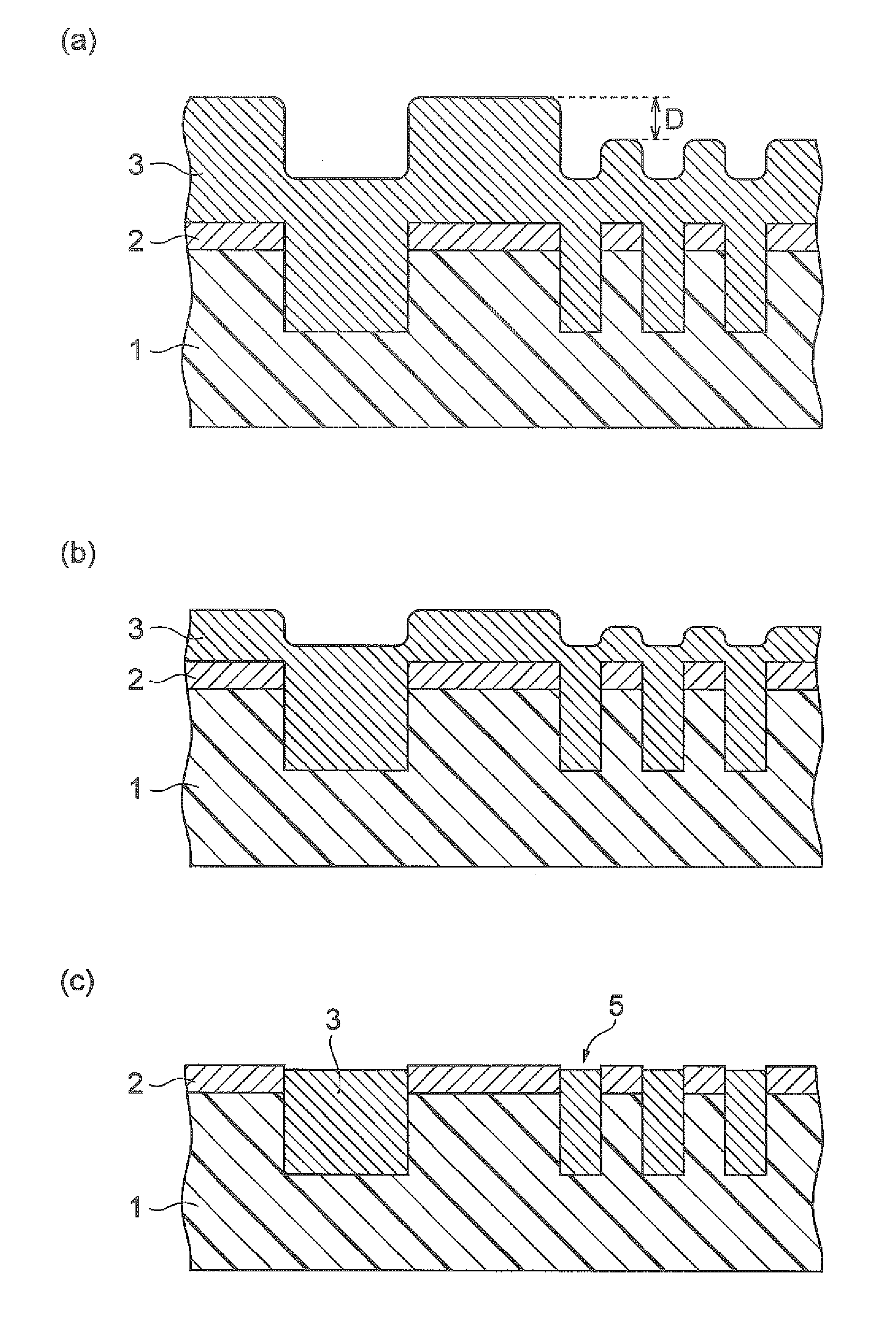

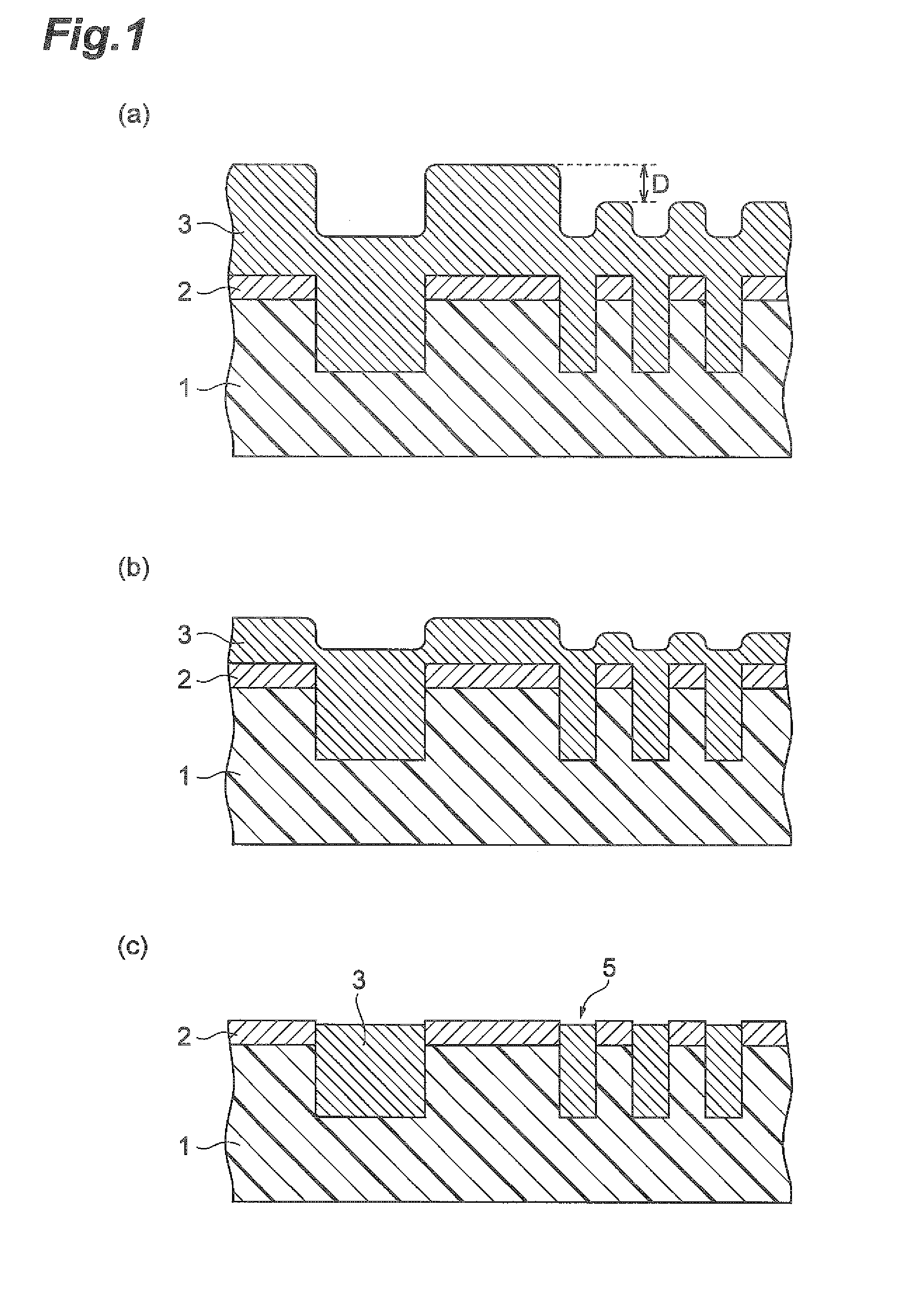

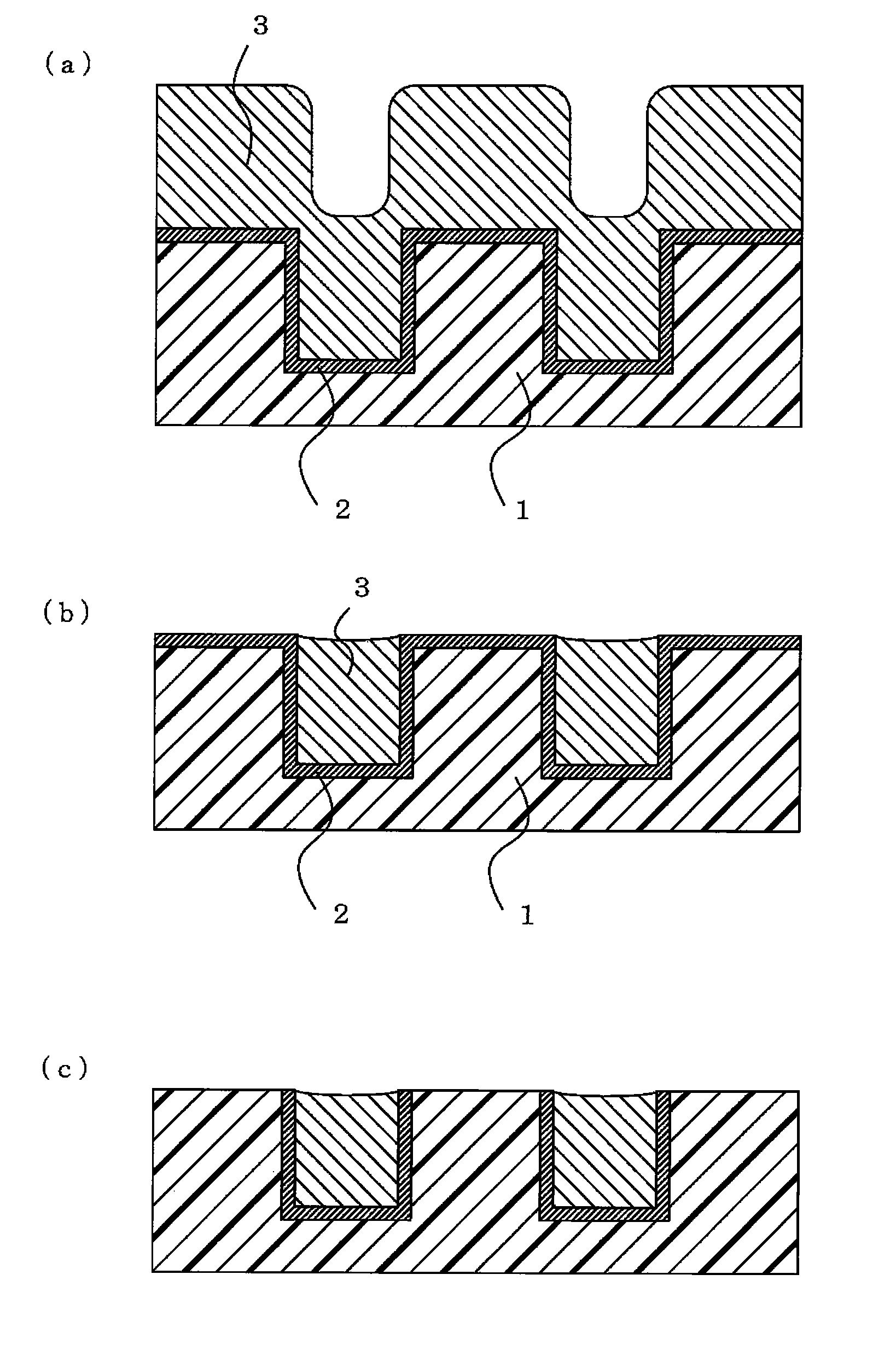

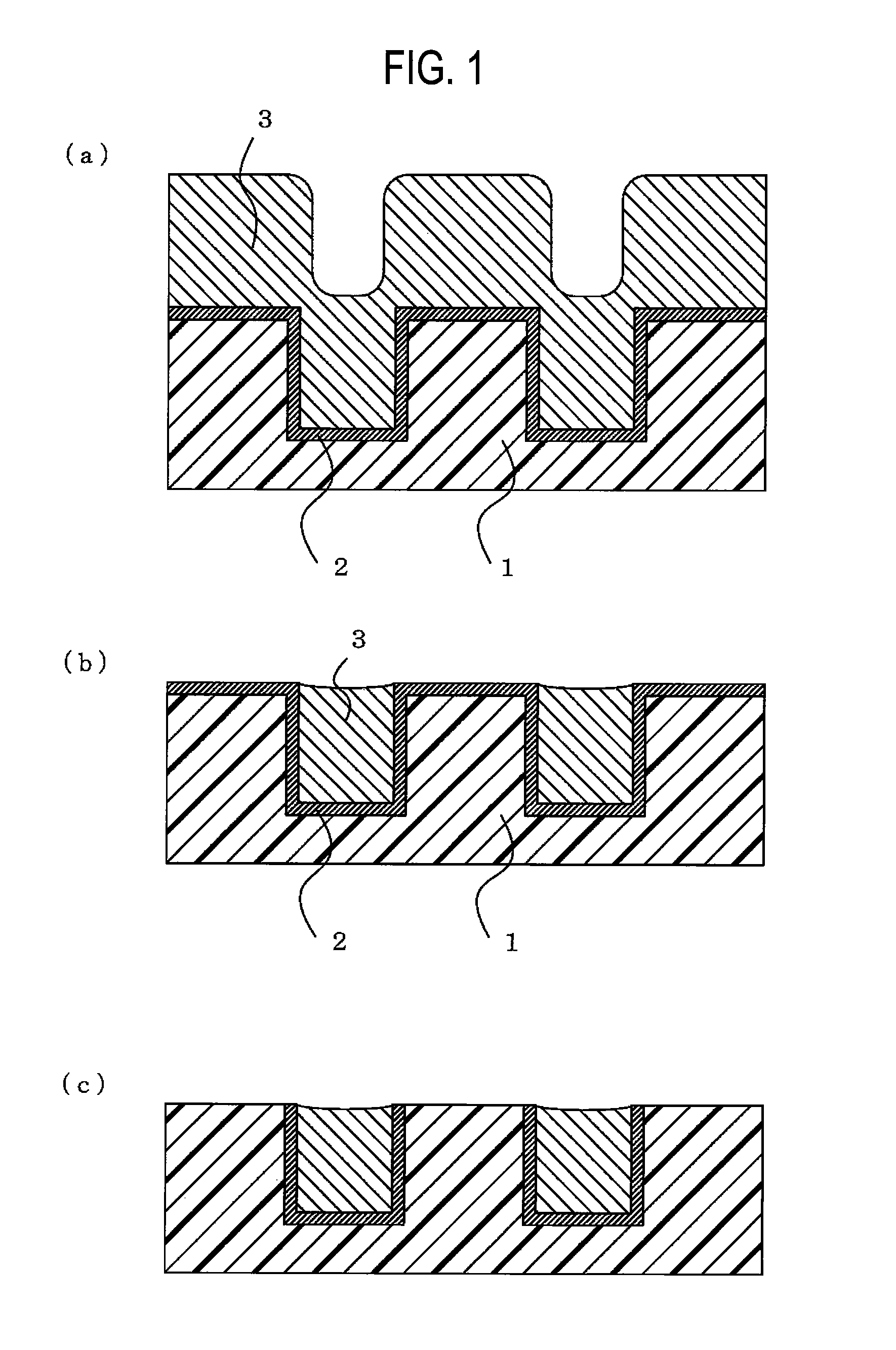

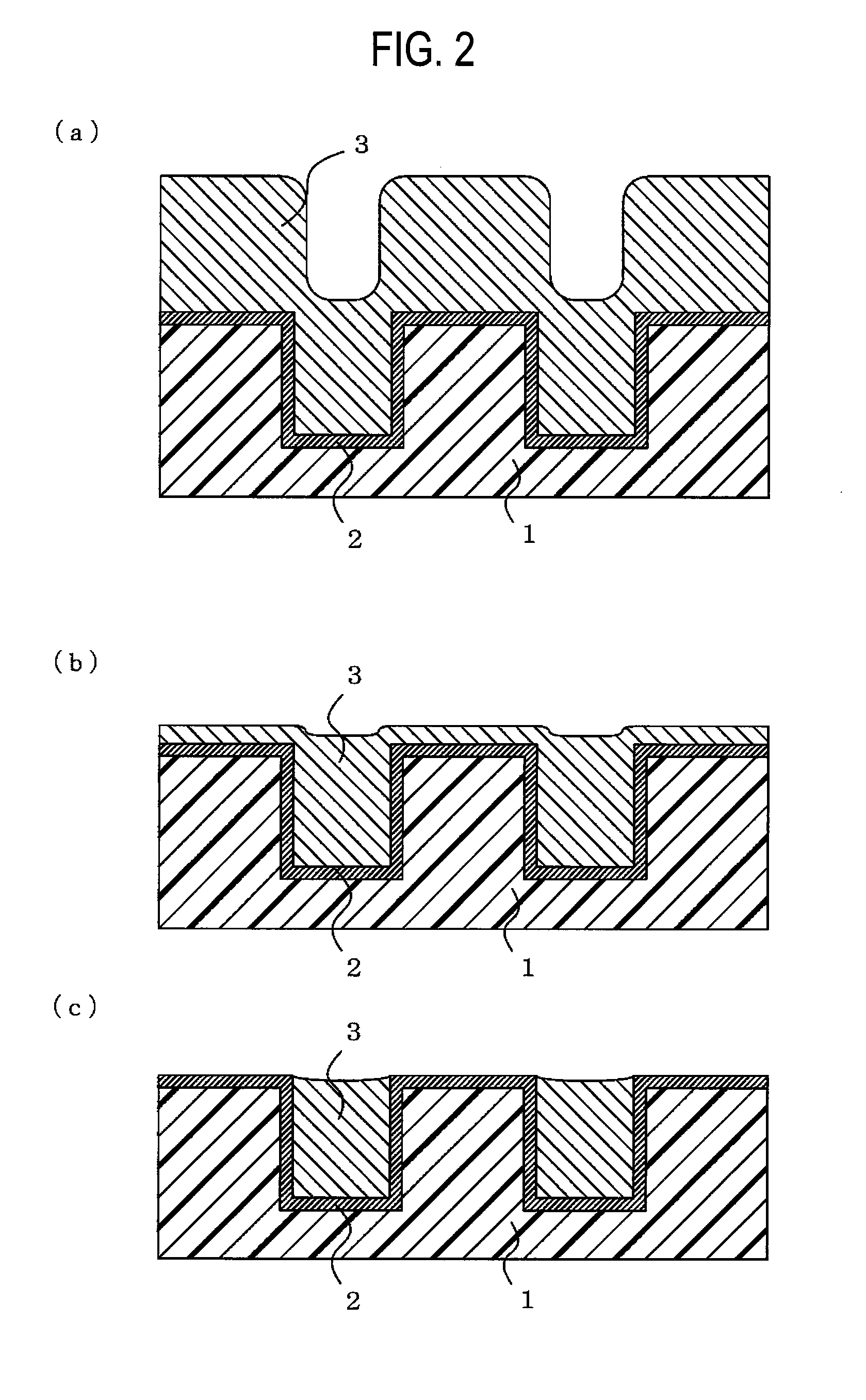

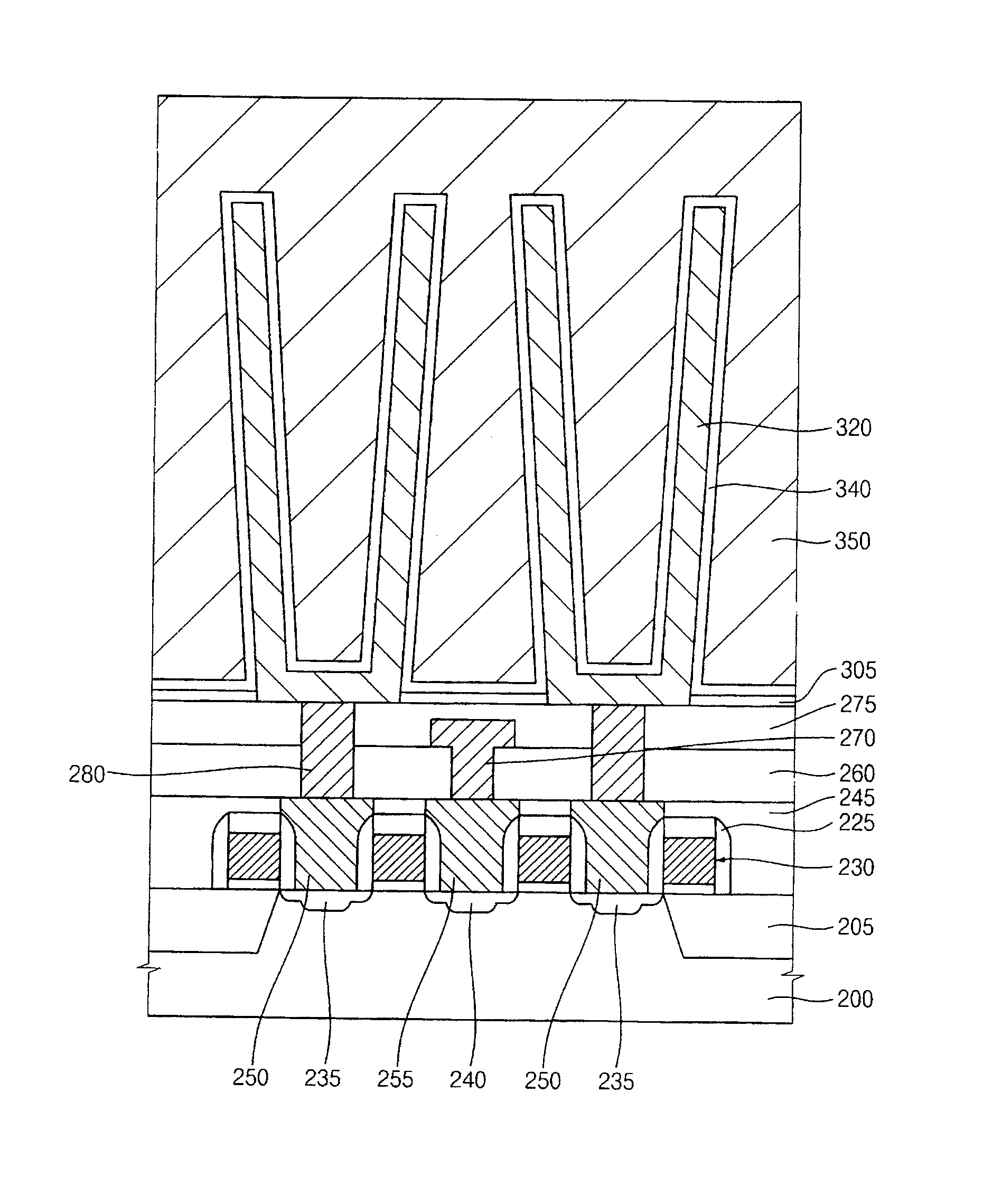

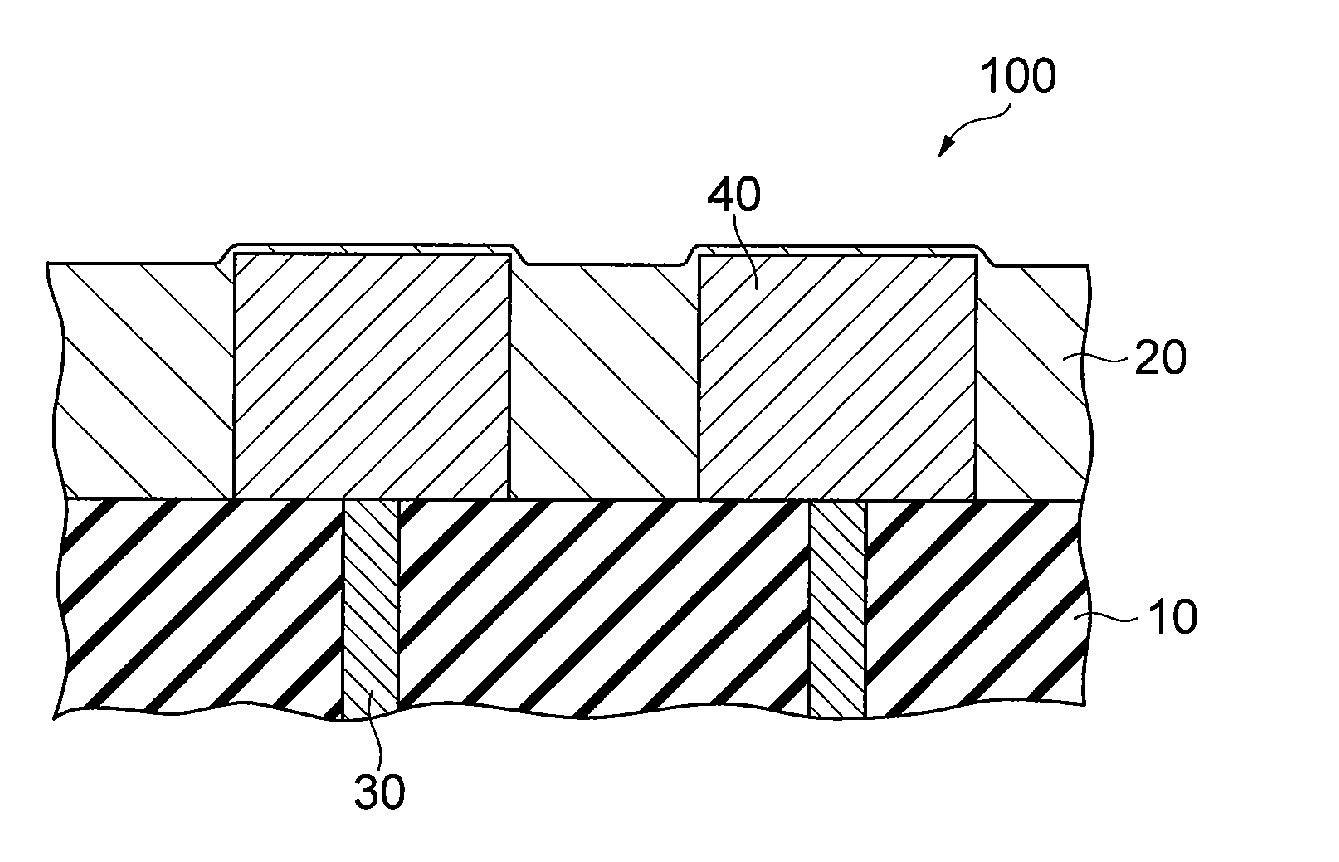

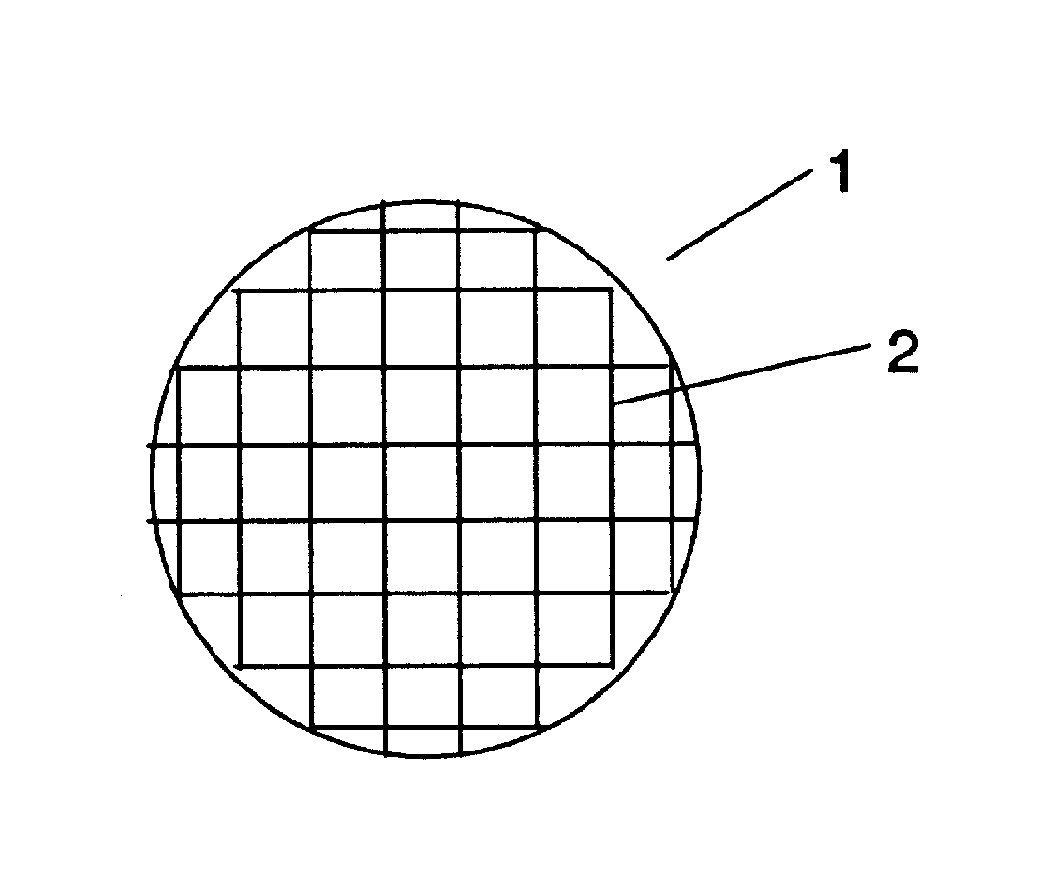

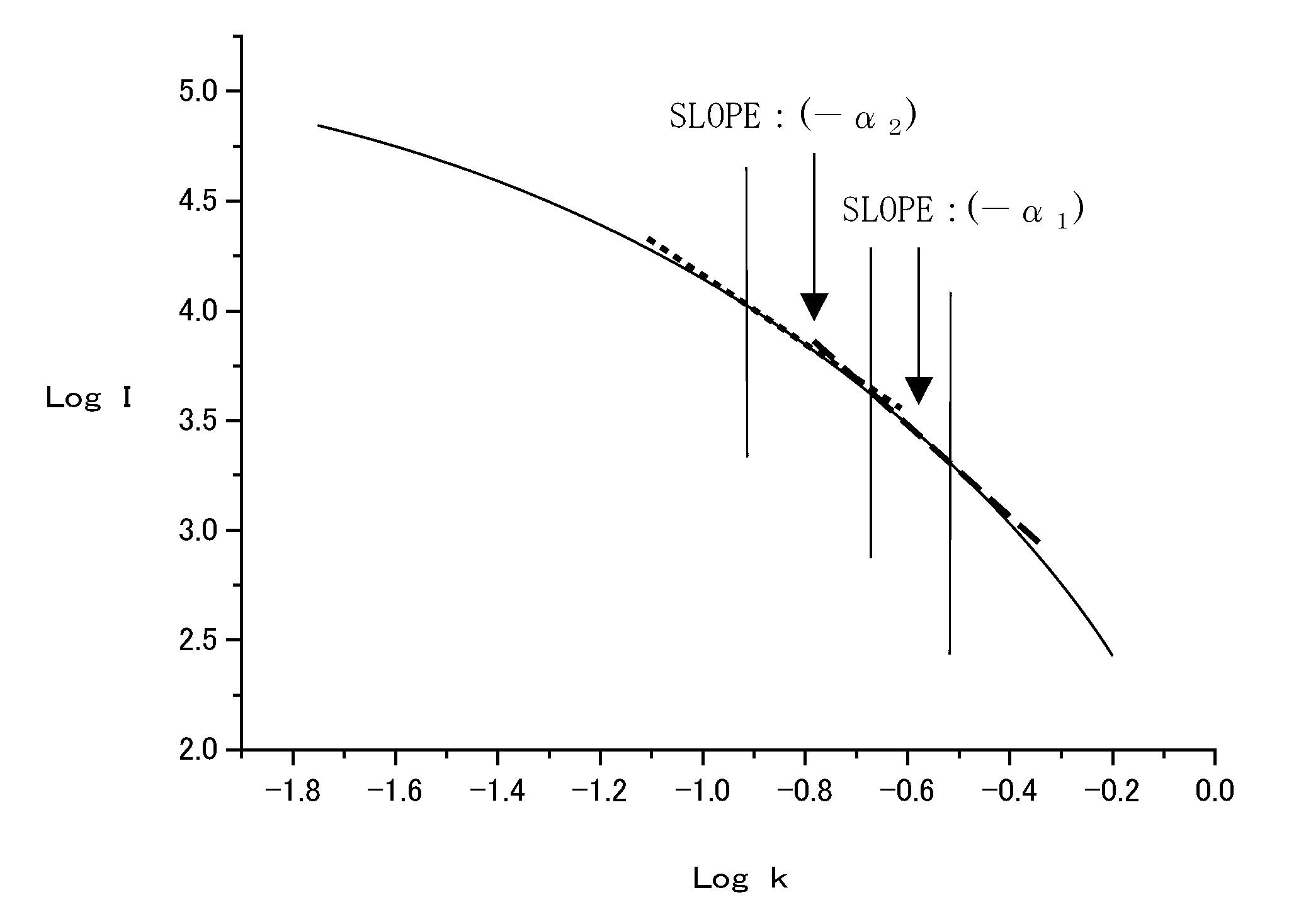

Semiconductor device fabrication method

InactiveUS20050026439A1Uniform film thicknessAccurate detectionSemiconductor/solid-state device manufacturingLapping machinesEngineeringSlurry

The method comprises the step polishing the surface of a film-to-be-polished formed over a semiconductor substrate 10 with a polishing pad while a polishing slurry containing abrasive grains, and an additive of a surfactant is being supplied onto the polishing pad 104 to thereby planarize the surface of the film-to-be-polished, and the step of further polishing the surface of the film-to-be-polished with the polishing pad while the polishing slurry and water are being supplied onto the polishing pad, after the surface of the film-to-be-polished has been planarized. In the finishing polish, not only deionized water but also the polishing slurry are supplied on to the polishing pad, a position for the polishing slurry to be supplied to and a position for the deionized water to be supplied to are suitably set, and a ratio of a supply amount of the polishing slurry and a supply amount of the deionized water is suitably set, whereby the intra-plane film thickness of the film-to-be-polished as finish-polished can be uniform.

Owner:FUJITSU SEMICON LTD

Polishing composition

InactiveUS20140251950A1Improve polishing rateEasy to disassembleElectrical apparatusOther chemical processesColloidal silicaColloid

Owner:FUJIMI INCORPORATED

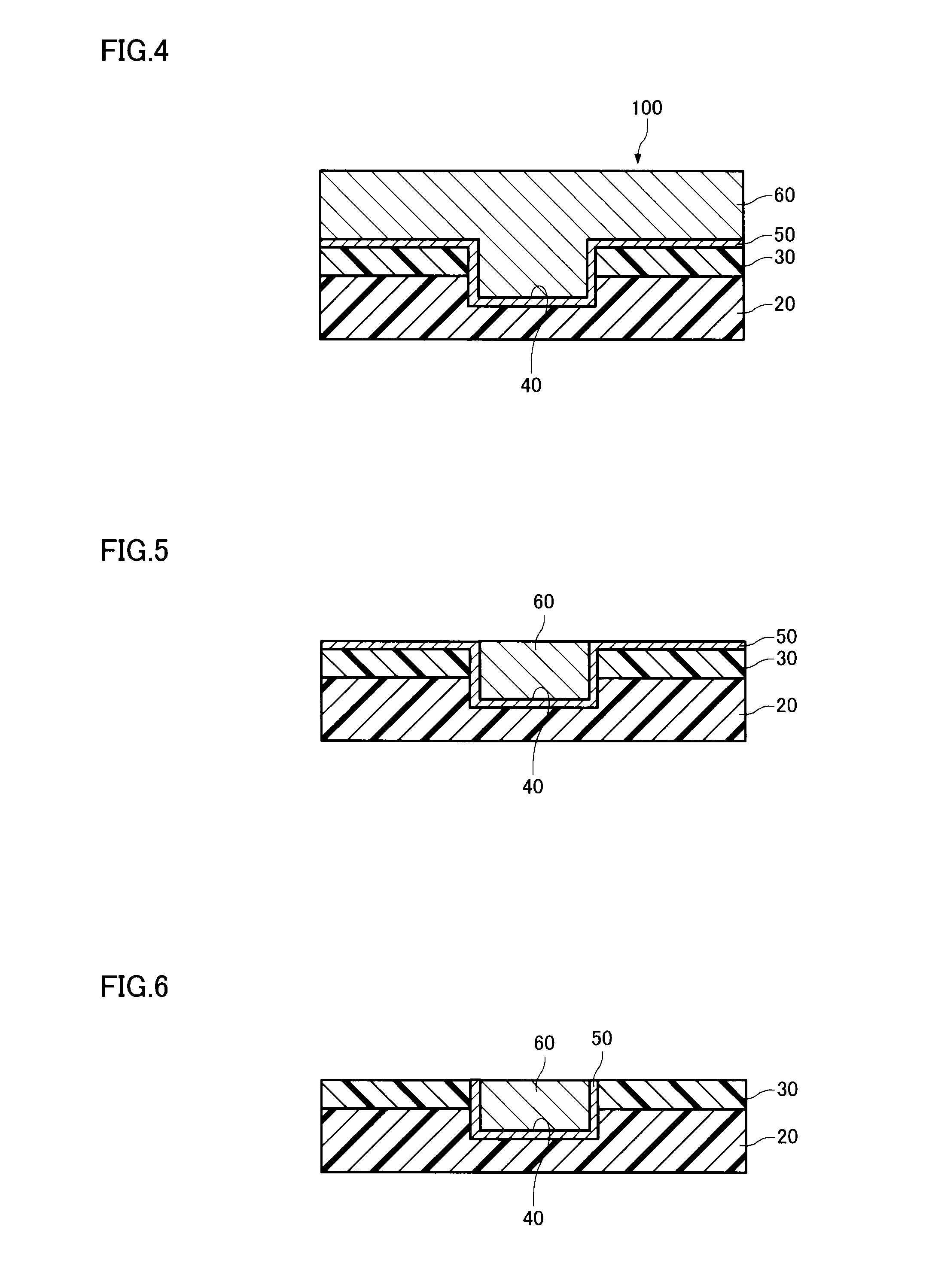

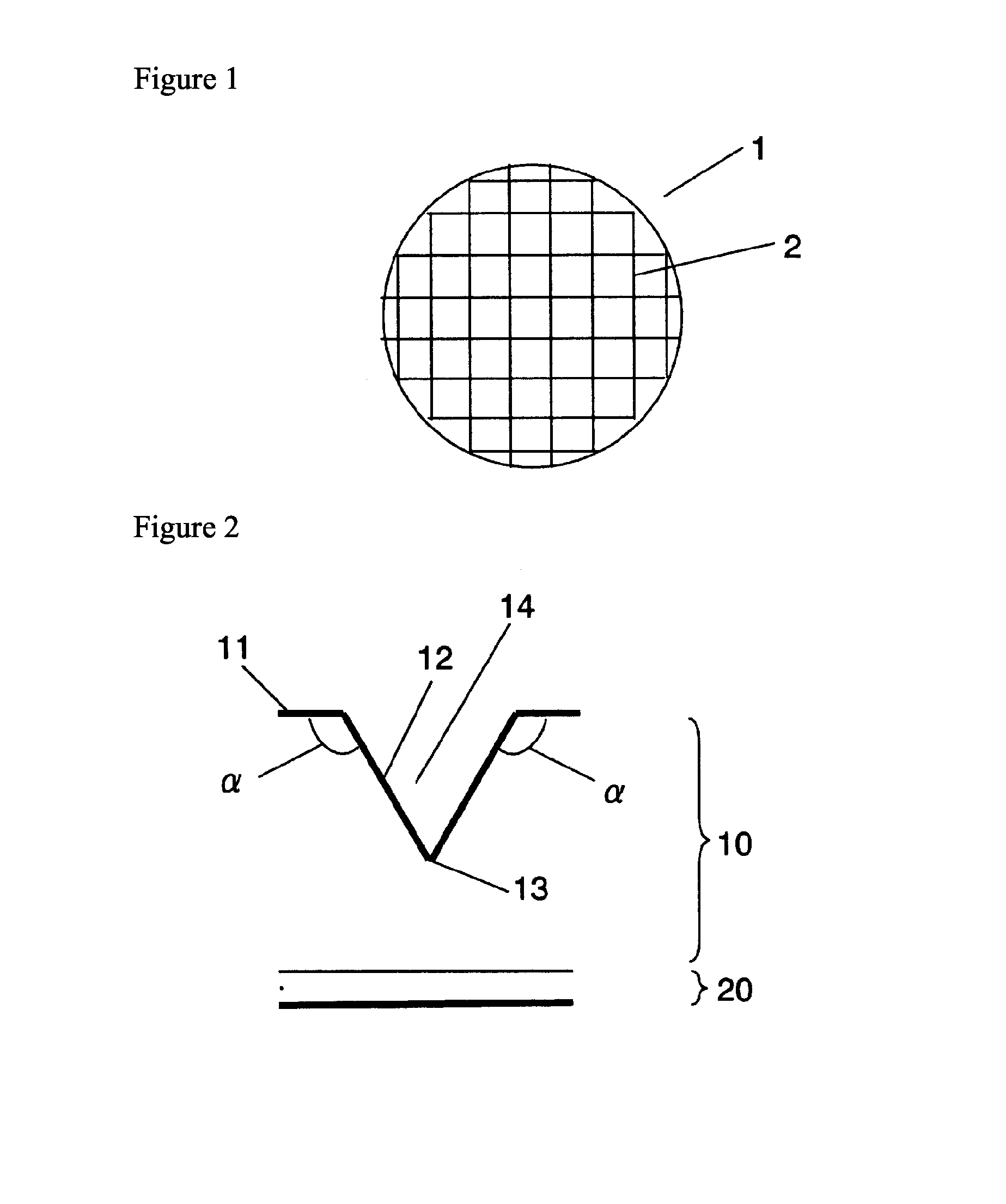

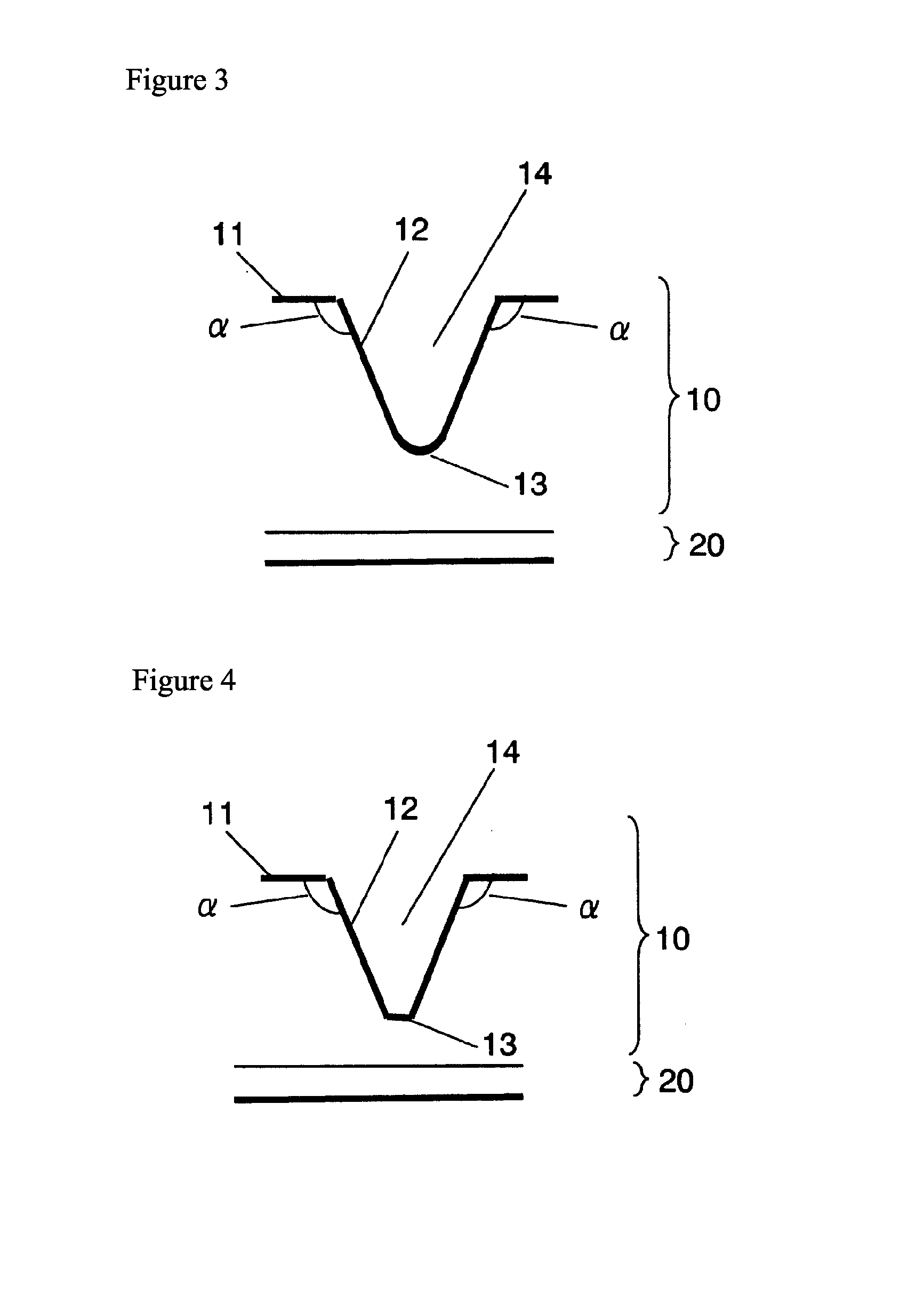

Polishing pad

InactiveUS20140170943A1High polishing rateSuppress fluctuation in polishing rateAbrasion apparatusLapping toolsCushionEngineering

A polishing pad comprising at least a polishing layer and a cushion layer, wherein a groove is formed on a polishing surface of the polishing pad, at least one of angles formed by the polishing surface and a side surface of the groove which continues to the polishing surface is 105-150° inclusive, and the cushion layer has a strain constant of 7.3×10−6 to 4.4×10−4 μm / Pa inclusive. The use of the polishing pad can achieve a purpose of preventing the fluctuation in a polishing rate while keeping the polishing rate at a high level.

Owner:TORAY IND INC

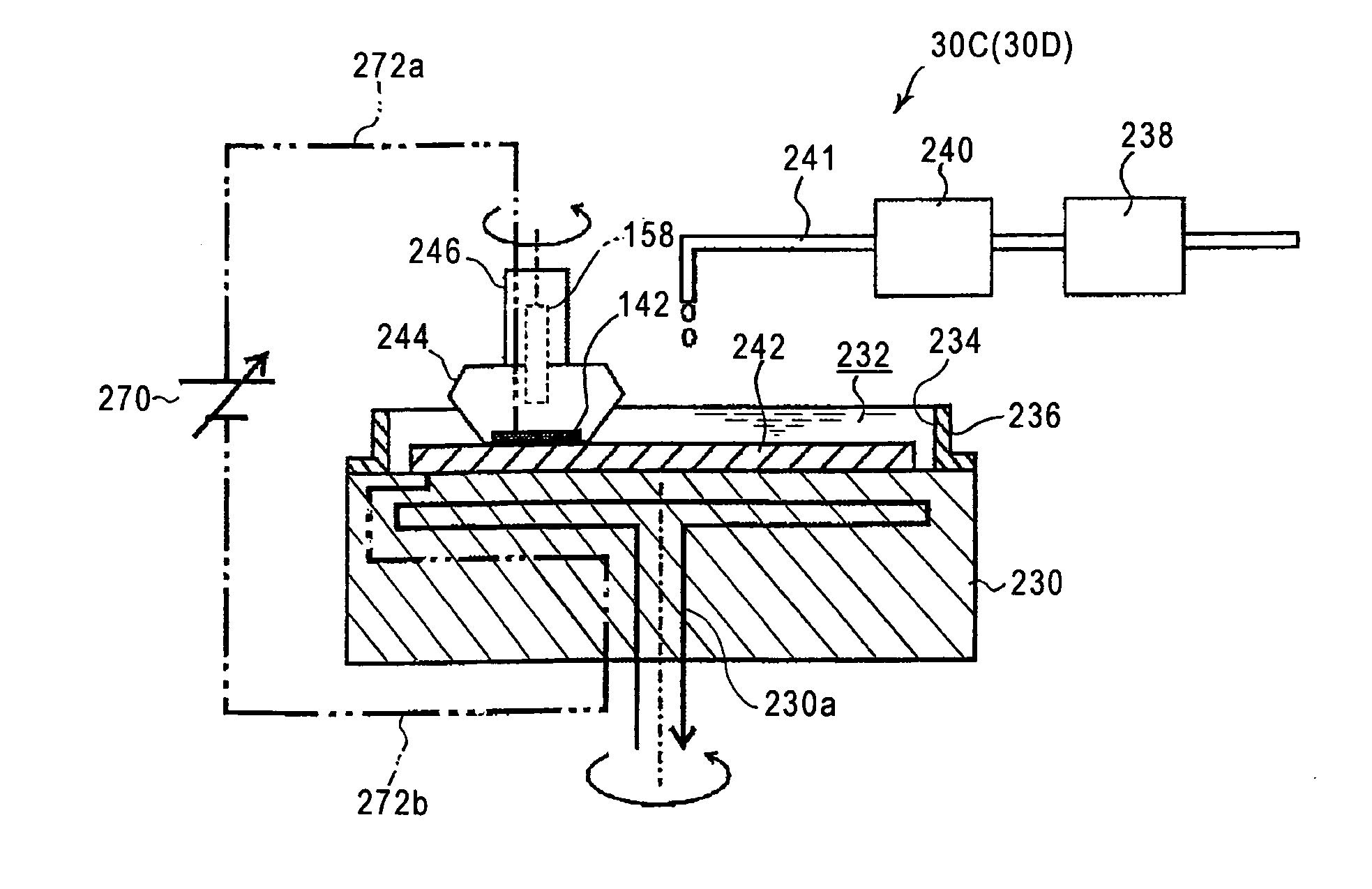

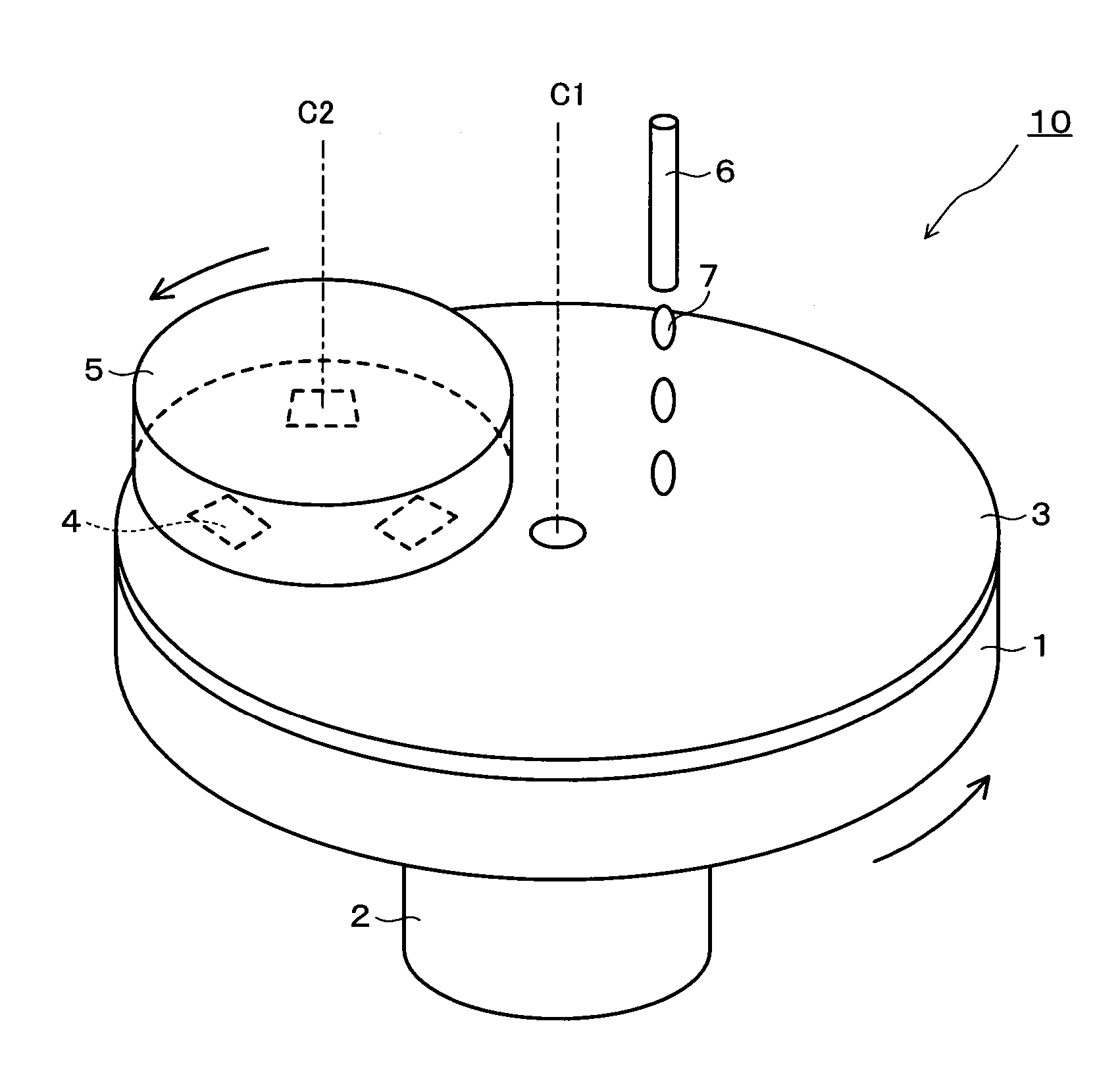

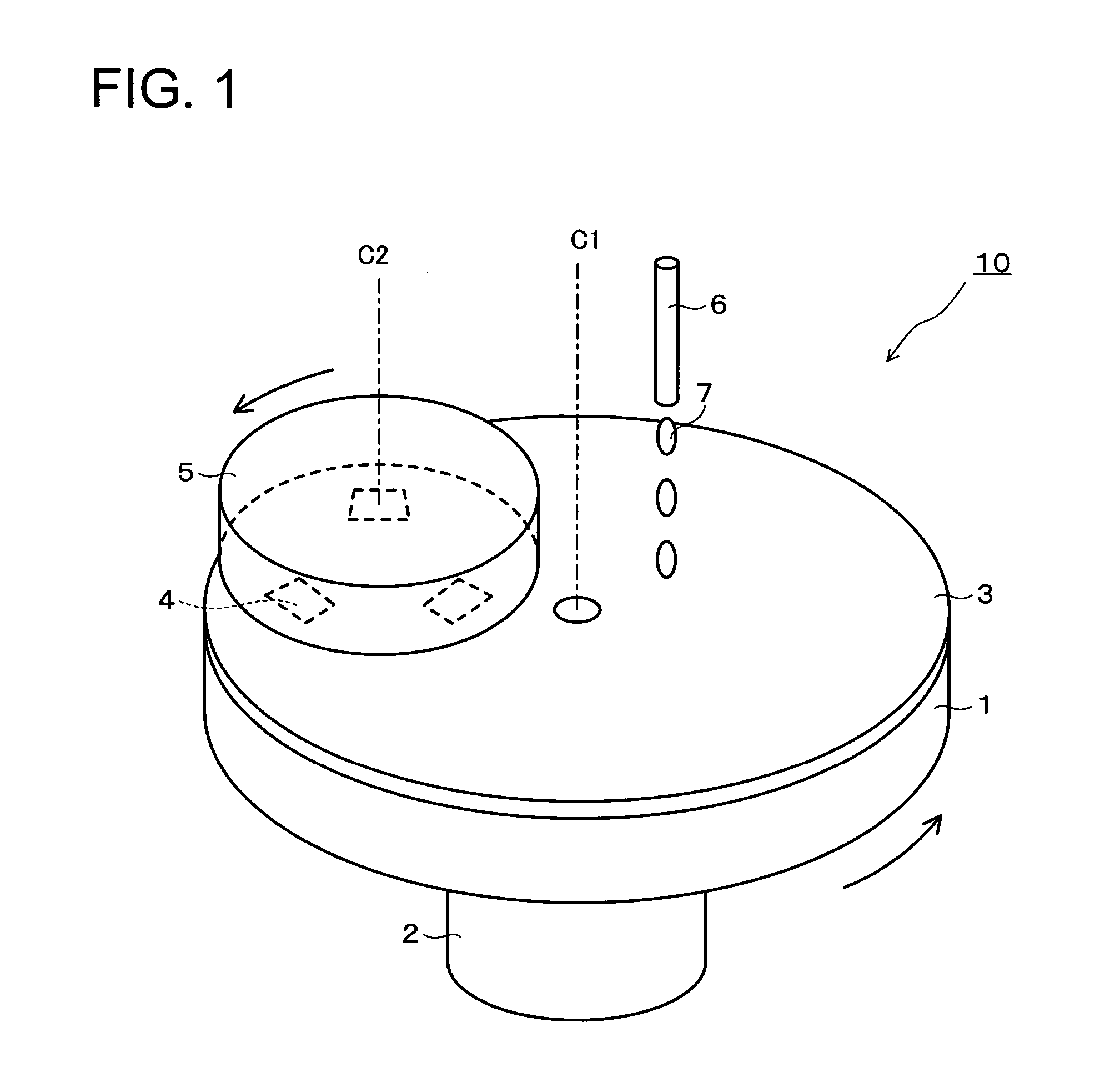

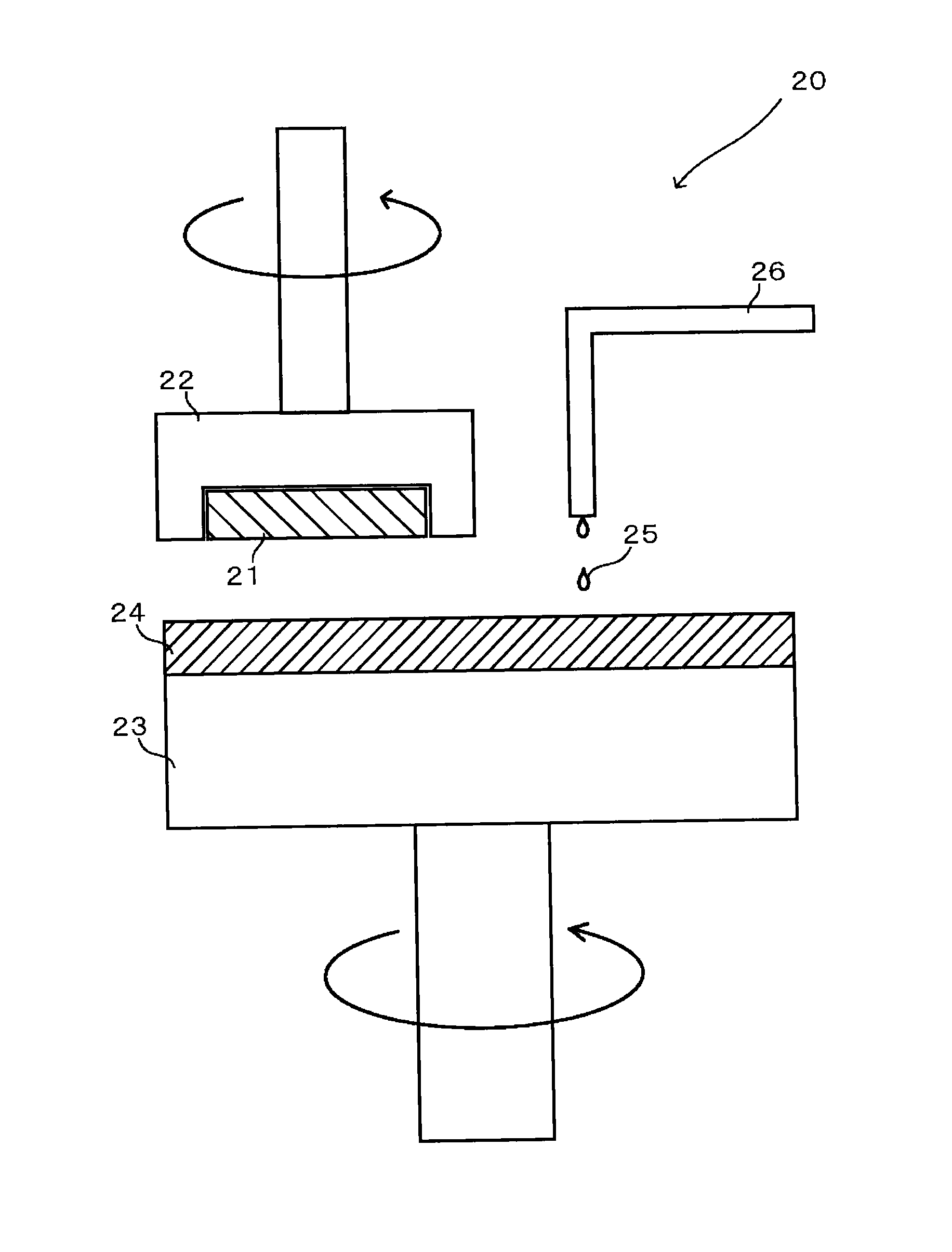

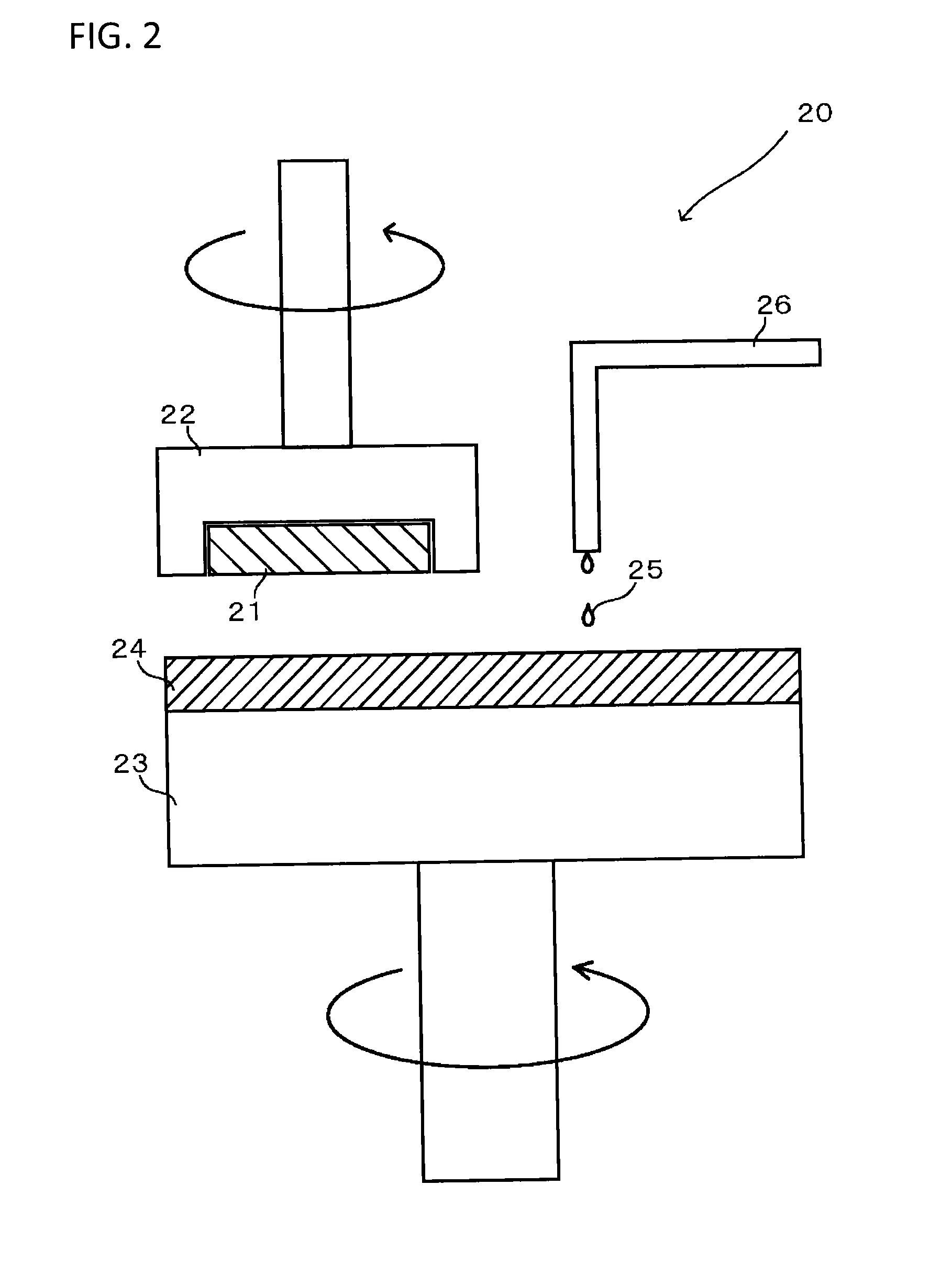

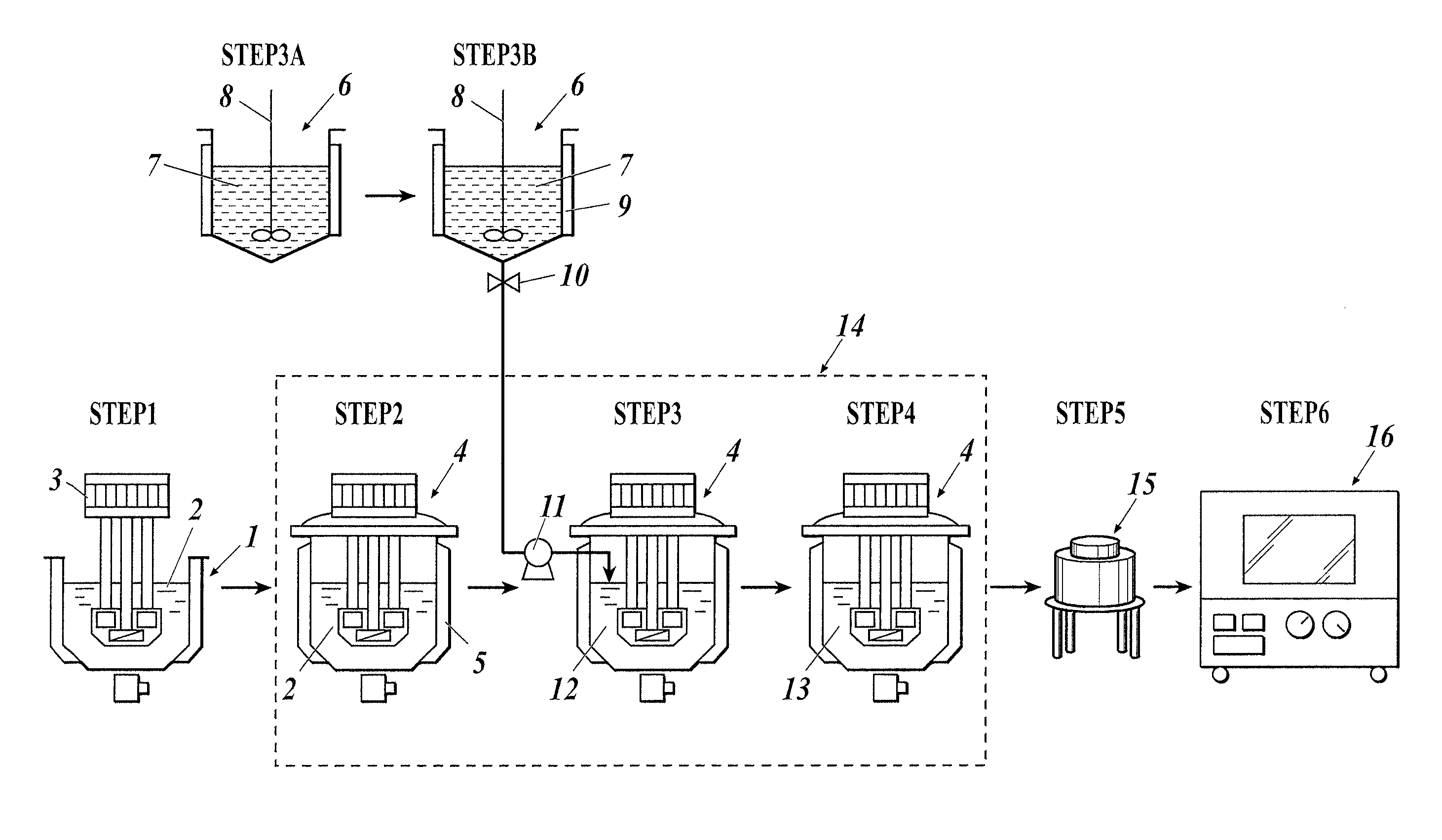

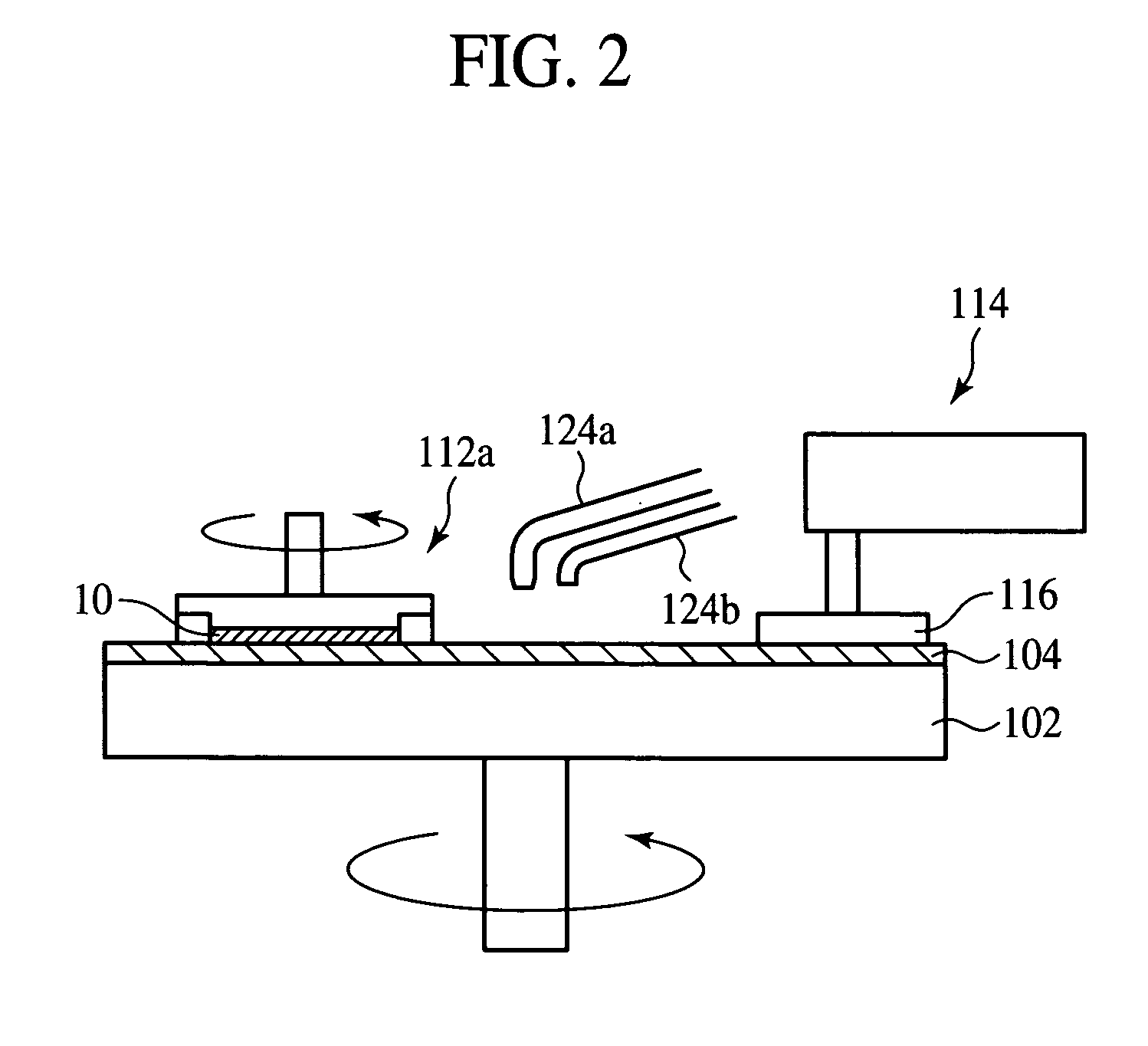

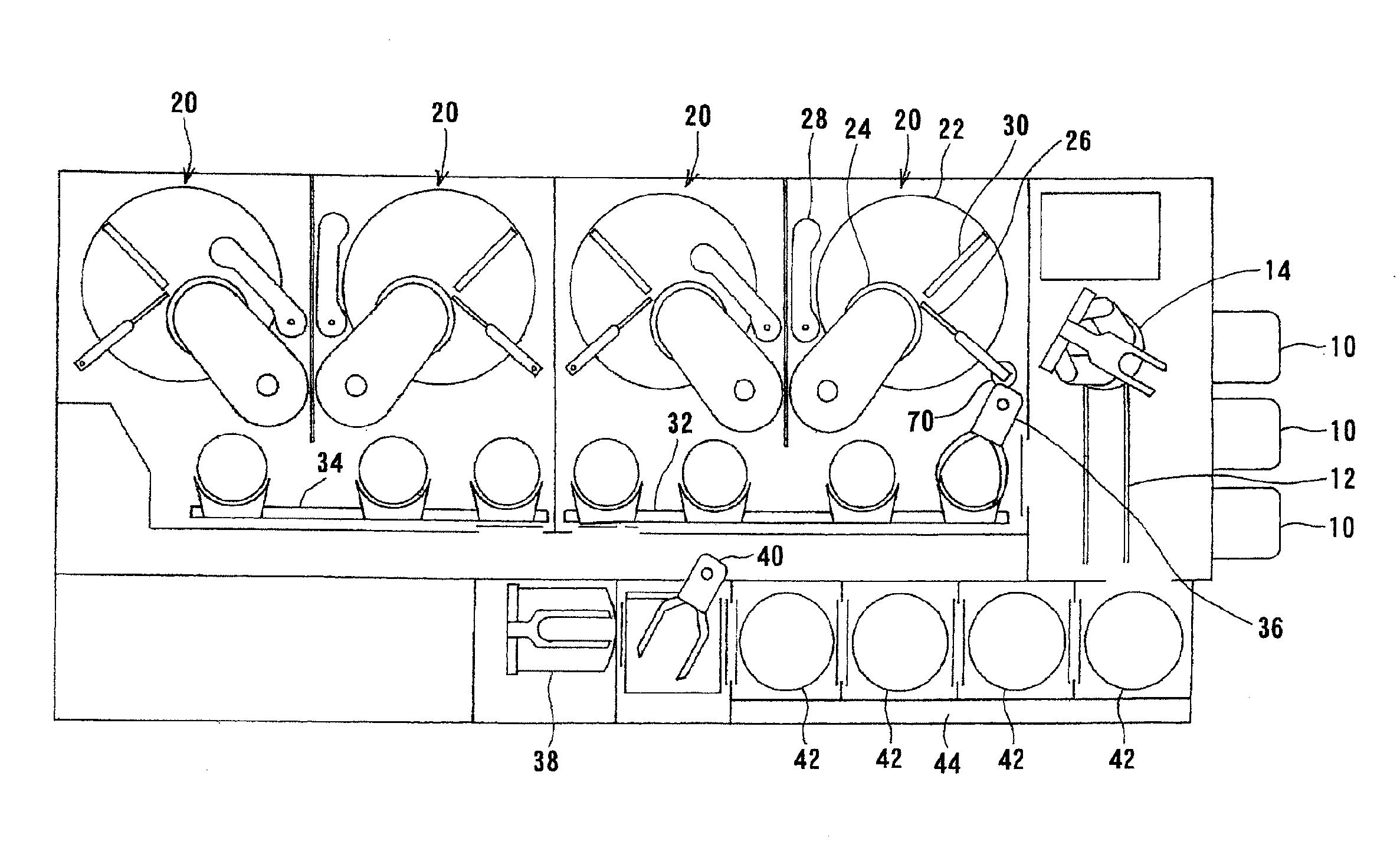

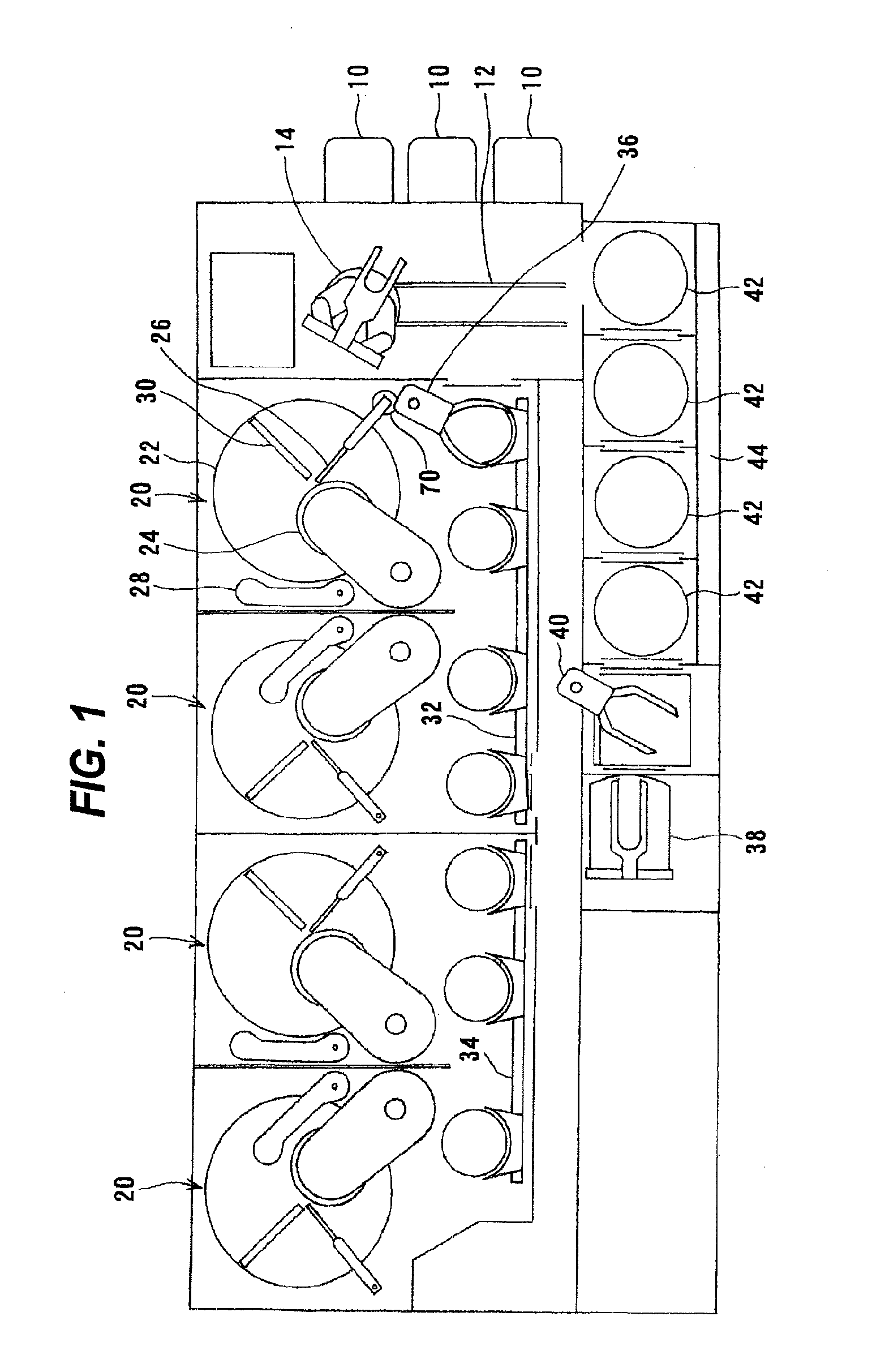

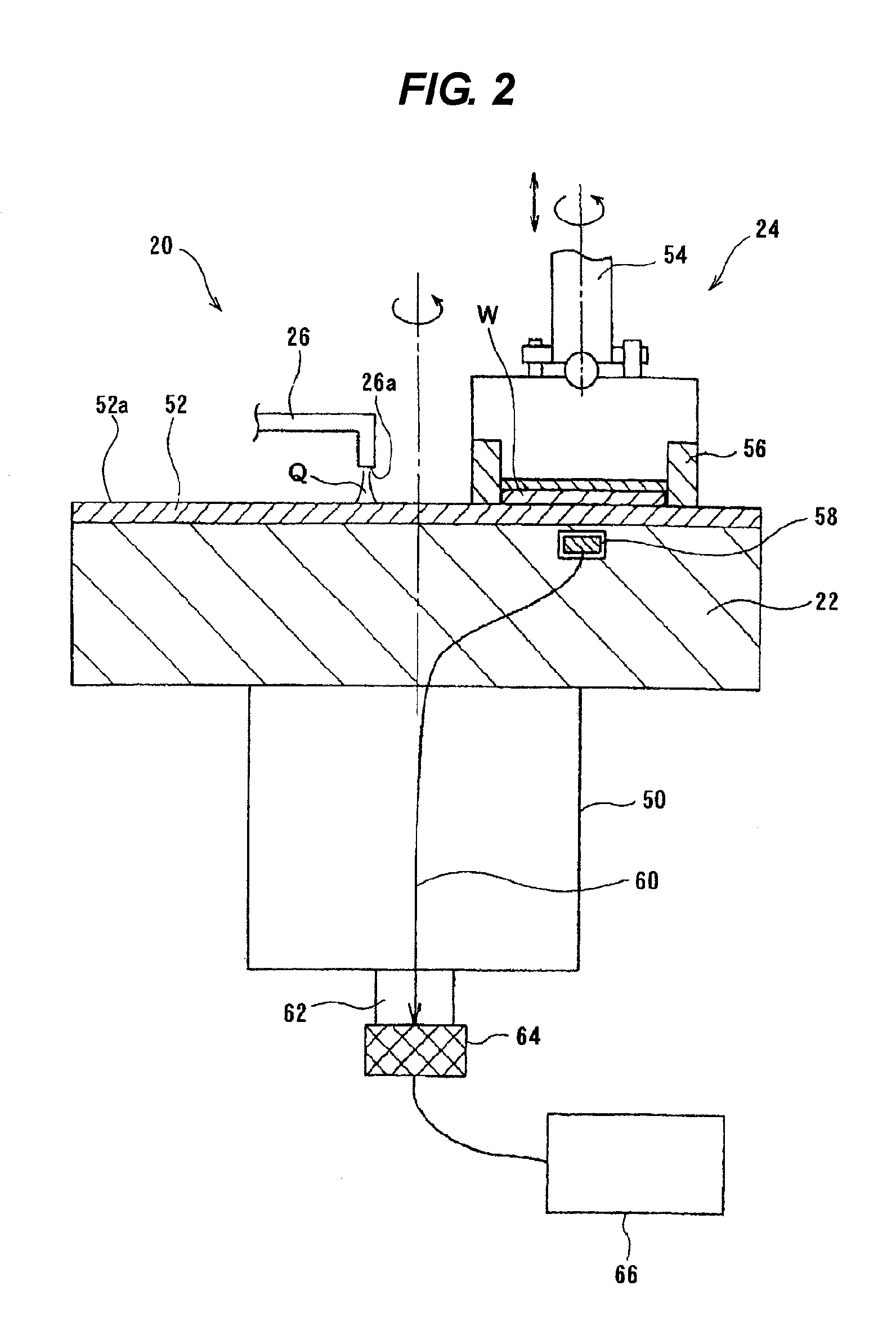

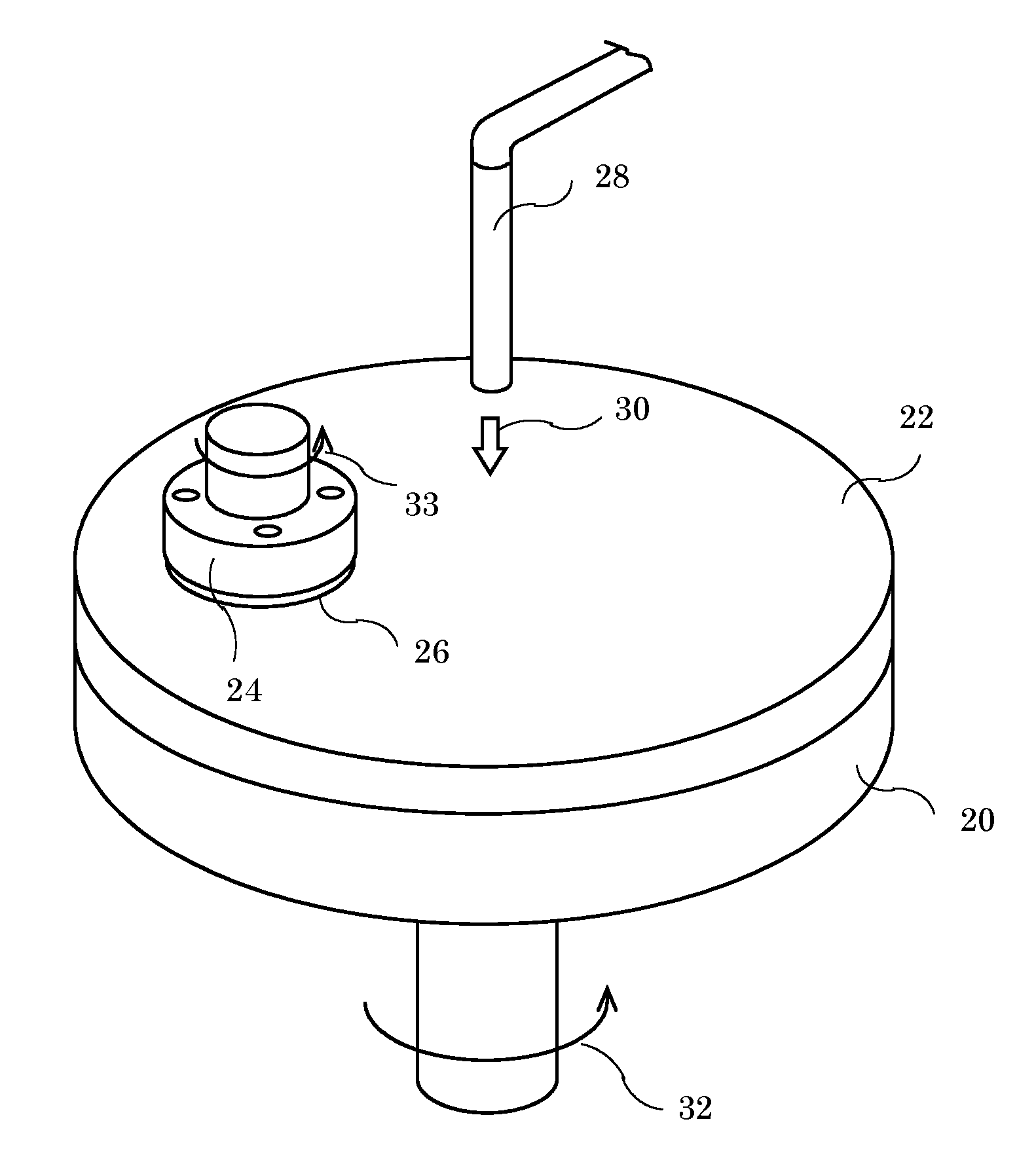

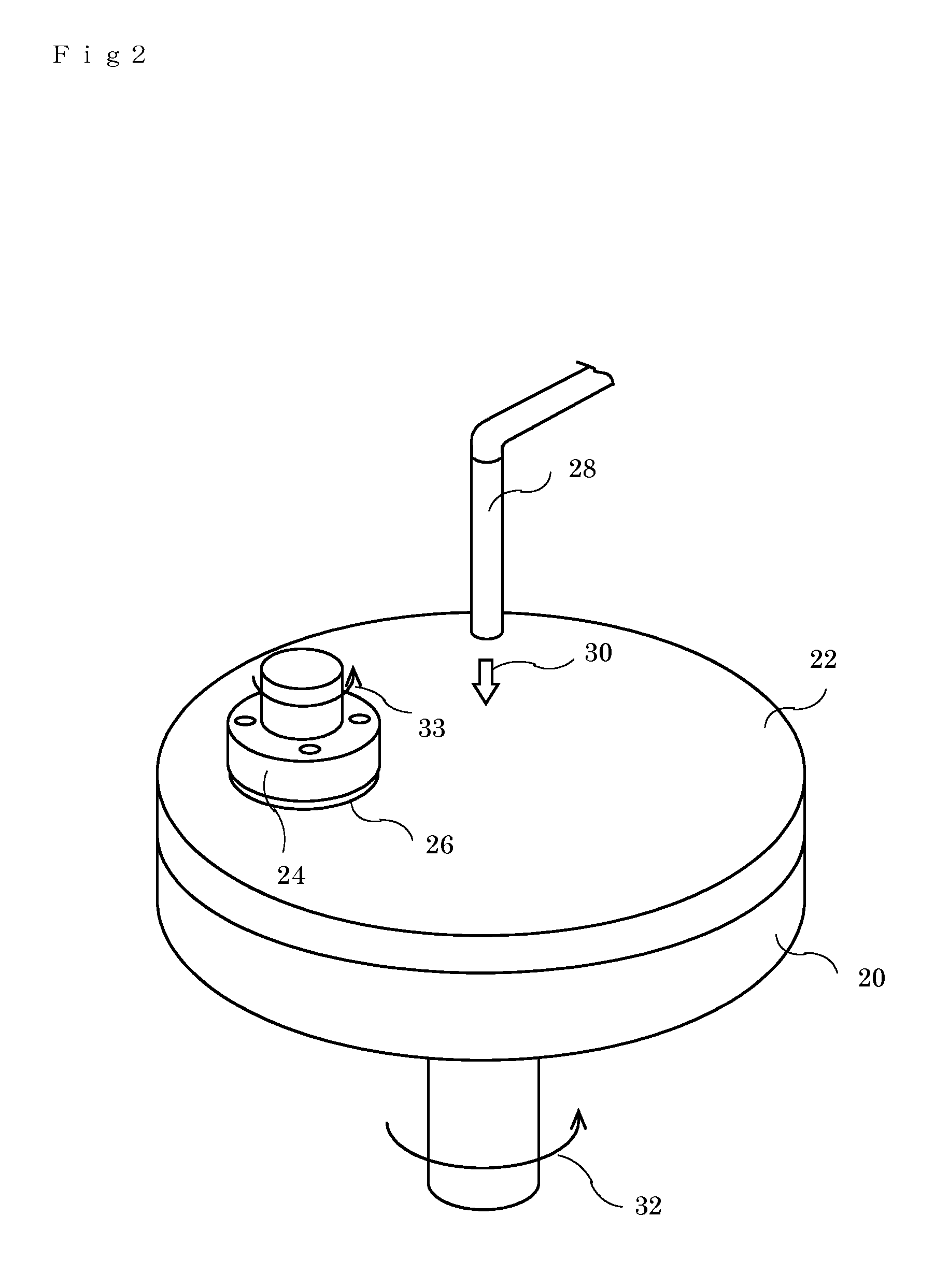

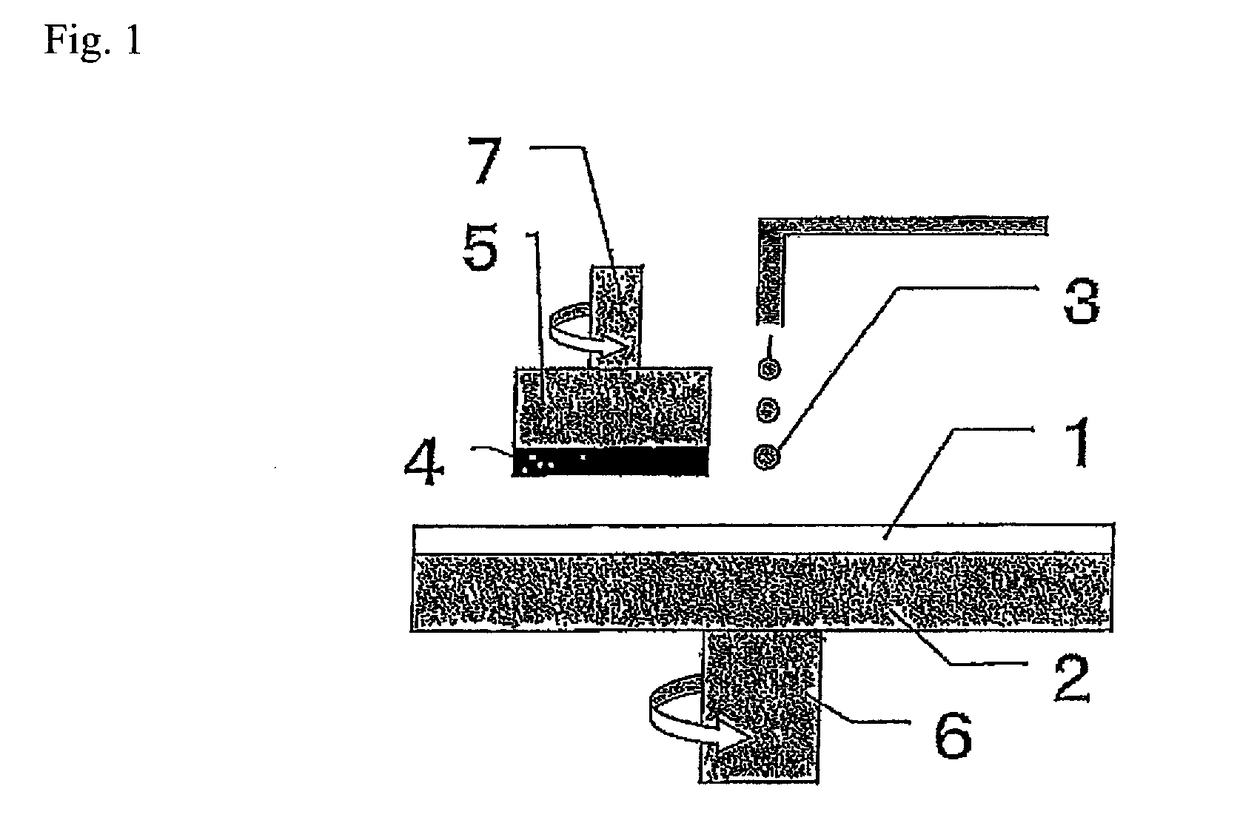

Polishing apparatus and polishing method

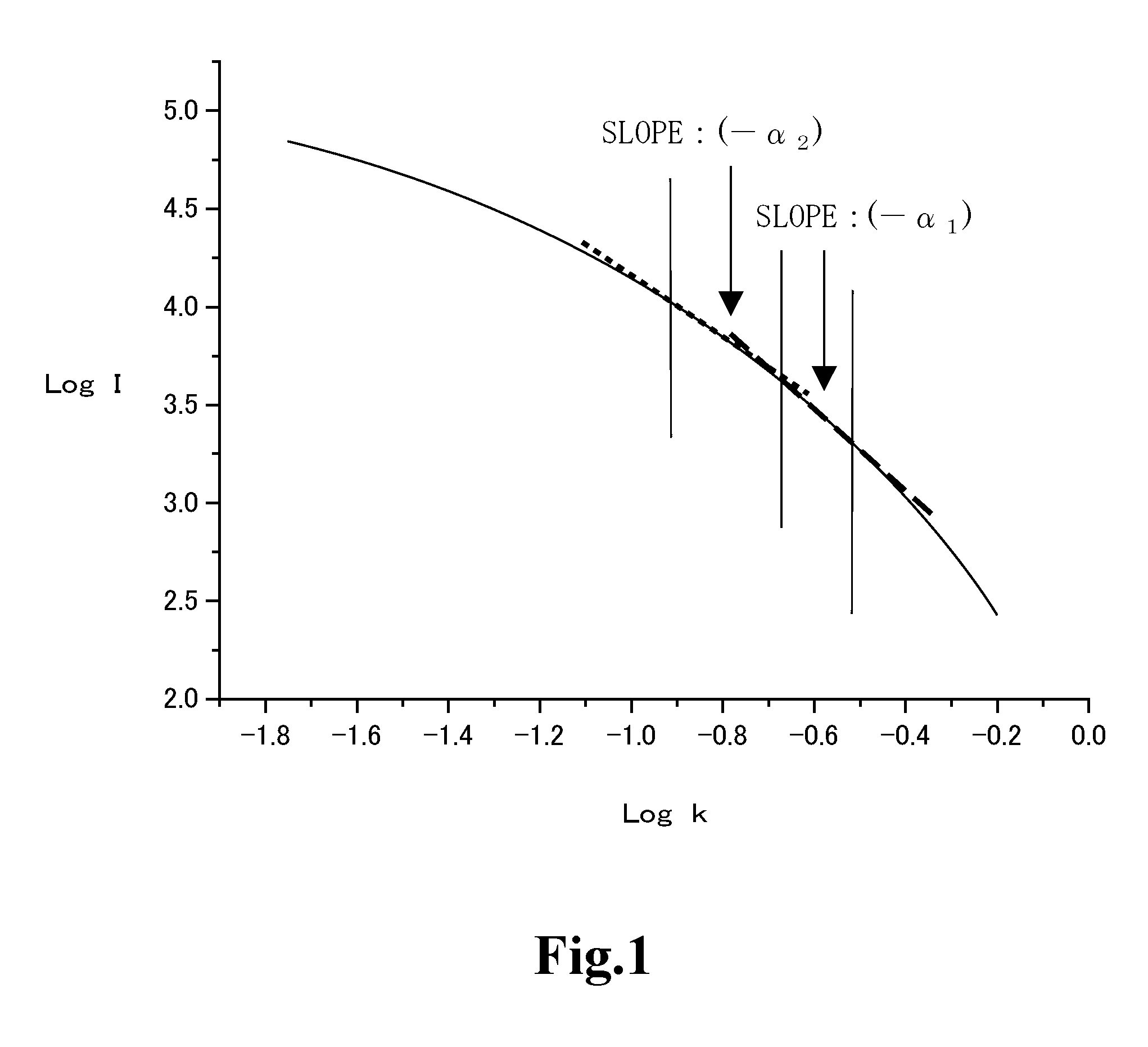

ActiveUS20100255756A1Reduce usageHigh polishing ratePolishing machinesRevolution surface grinding machinesEngineeringNozzle

A polishing apparatus can perform more precise control of a polishing profile without carrying out many polishing tests in advance. The polishing apparatus includes: a polishing table 22 having a polishing surface 52a; a top ring 24 for holding a polishing object W and pressing the polishing object W against the polishing surface 52a; a polishing liquid supply nozzle 26 for supplying a polishing liquid to the polishing surface 52a; a movement mechanism 70 for moving a polishing liquid supply position 26a of the polishing liquid supply nozzle 26 approximately along the radial direction of the polishing surface 52a; a controller 66 for controlling the movement mechanism 70; and a simulator 72 for predicting the relationship between the polishing liquid supply position 26a of the polishing liquid supply nozzle 26 and a polishing profile, performing a simulation and outputting data to the controller 66.

Owner:EBARA CORP

Silica for cmp, aqueous dispersion, and process for producing silica for cmp

ActiveUS20160177155A1High polishing rateReducing scratches during polishingSilicaOther chemical processesChemistryParticle density

To reduce scratches during polishing while ensuring an appropriately high polishing rate, provided are a silica for CMP satisfying the following (A) to (C), an aqueous dispersion using a silica for CMP, and a method of producing a silica for CMP: (A) a BET specific surface area of 40 m2 / g or more and 180 m2 / g or less; (B) a particle density measured by a He-gas pycnometer method of 2.24 g / cm3 or more; and (C) a coefficient of variation in primary particle diameter calculated by TEM / image analysis of 0.40 or less.

Owner:TOKUYAMA CORP

Polishing abrasive particle, production method therefore, polishing method, polishing device, and slurry

ActiveUS20160325398A1High polishing rateAccelerates chemical abrasive actionOther chemical processesSemiconductor/solid-state device manufacturingLiquid wasteWorking environment

[Object] The present invention is objected to polish the surface of the object material with a high quality at a high polishing rate.[Solution] The object surface is polished using a wet polishing method. Slurry is produced by scattering abrasive particles into pure water. In the abrasive particle, where components which has a mechanochemical effect and which reacts to the friction heat generated in polishing the object material are joined with each other and integrated to a particle. There, respective component is joined with each other using a mechanical alloying process, while maintaining the inherent material properties. When the slurry is used in a lapping process of sapphire, silicon carbide, gallium nitride and the like, the polishing process can be substantially shortened and the processing cost is drastically reduced. Further, it secures a high quality of the polishing surface. The abrasive particle can be used repeatedly in the polishing process. Since the pH value of the slurry is around 3 to 9, it does not deteriorate working environment and the liquid-waste treatment is easy.

Owner:ASAHI KASEI KK

Polishing composition and polishing method

ActiveUS20170298253A1Limiting polishing rateHigh polishing rateOther chemical processesSemiconductor/solid-state device manufacturingPolycrystalline siliconSilicon nitride

There are provided a polishing composition and a method for polishing capable of, when a substrate including polysilicon is polished, limiting the polishing rate of the polysilicon, and selectively polishing a silicon compound other than the polysilicon, such as silicon nitride. The polishing composition used includes abrasives, an organic acid and a conjugate base of the organic acid.

Owner:FUJIMI INCORPORATED

Cmp polishing solution and polishing method using same

InactiveUS20160086819A1High polishing rateImprove polishing rateOther chemical processesSemiconductor/solid-state device detailsChemistryBase metal

A CMP polishing liquid for polishing a ruthenium-based metal, comprising polishing particles, an acid component, an oxidizing agent, and water, wherein the acid component contains at least one selected from the group consisting of inorganic acids, monocarboxylic acids, carboxylic acids having a plurality of carboxyl groups and having no hydroxyl group, and salts thereof, the polishing particles have a negative zeta potential in the CMP polishing liquid, and the pH of the CMP polishing liquid is less than 7.0.

Owner:HITACHI CHEM CO LTD

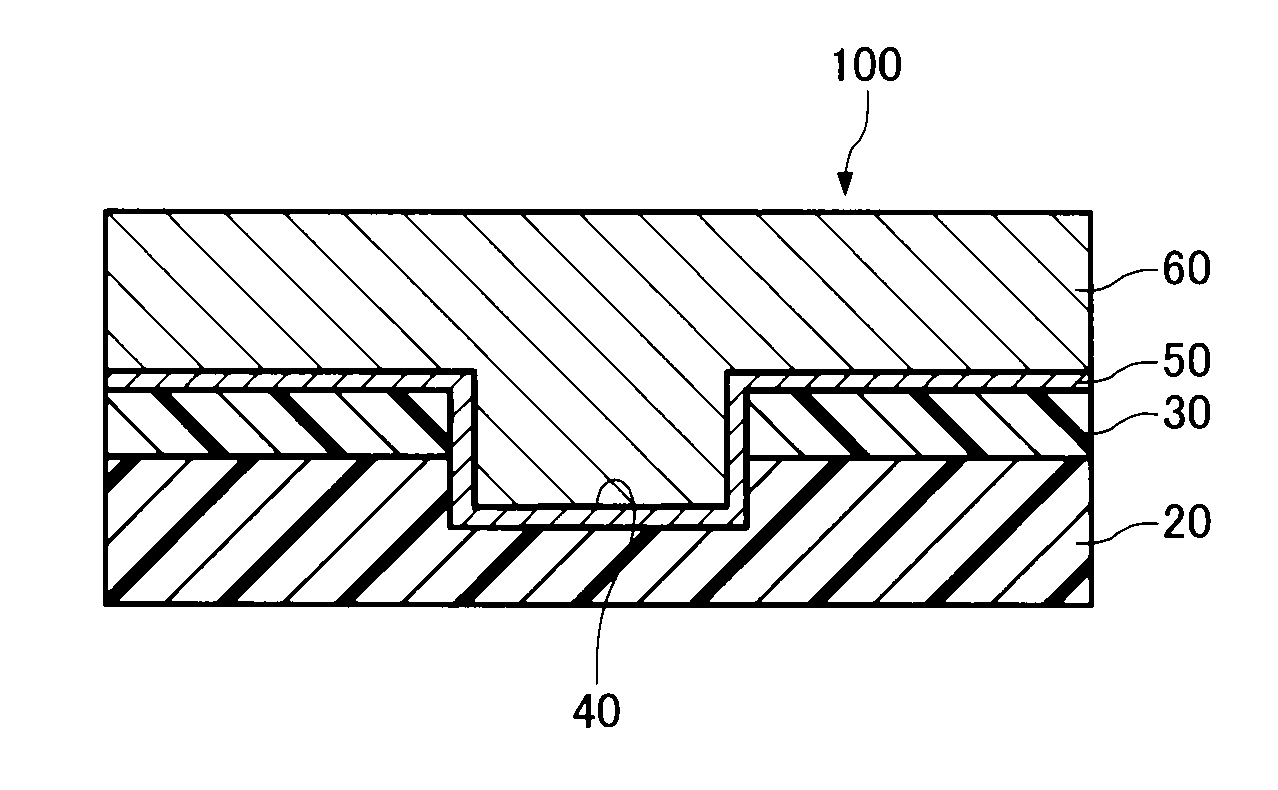

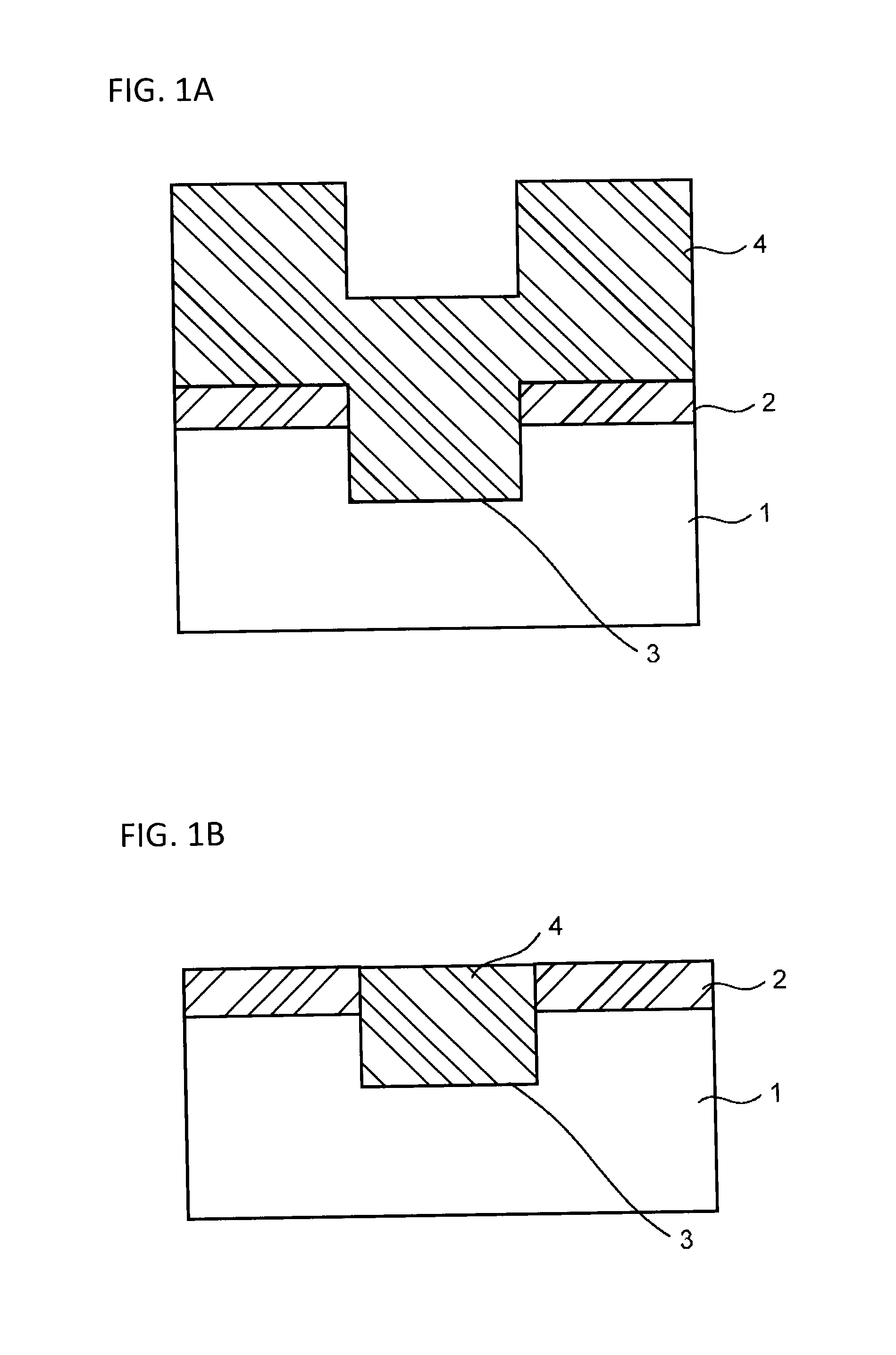

Chemical mechanical polishing pad, production method thereof, and chemical mechanical polishing process

InactiveUS20050222336A1High polishing rateSatisfactory useful lifeFlexible-parts wheelsGrinding devicesCompound (substance)Polymer chemistry

A chemical mechanical polishing pad comprising a water-insoluble matrix which comprises (A) a styrene polymer and (B) a diene polymer. A method for producing the above chemical mechanical polishing pad, the method comprising the steps of preparing a composition comprising (A) a styrene polymer, (B) a diene polymer and (C) a crosslinking agent, shaping the above composition into a predetermined shape, and heating the composition during or after shaping to cure it. A chemical mechanical polishing process which comprises polishing a surface to be polished of an object to be polished by use of the chemical mechanical polishing pad. According to the present invention, it is possible to provide a chemical mechanical polishing pad which can be suitably applied to polishing of metal film and insulation film, particularly to an STI technique, provides a flat polished surface, can provide a high polishing rate and has a satisfactory useful life.

Owner:JSR CORPORATIOON

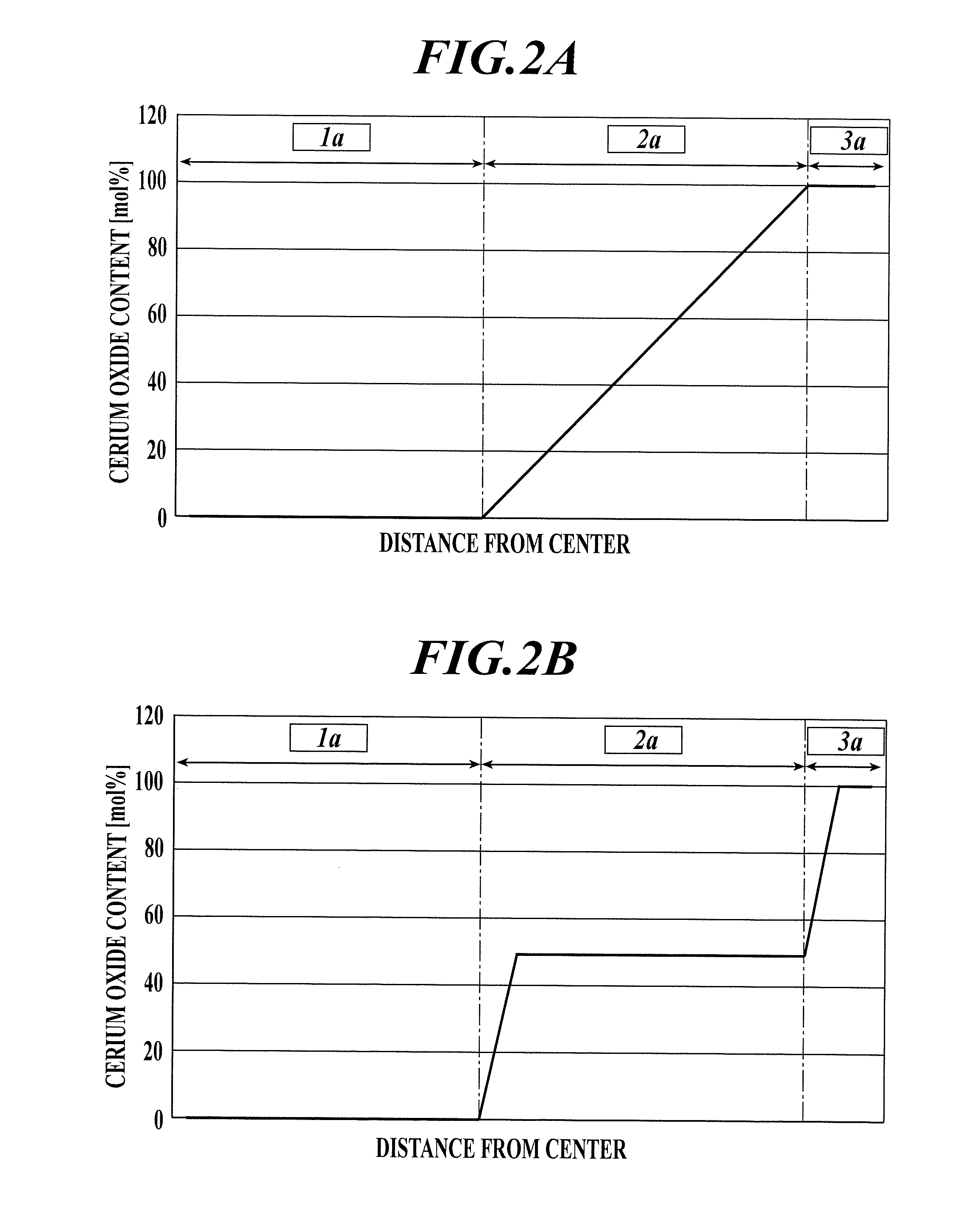

Polishing Material Composition And Production Method Therefor

InactiveUS20150174734A1High polishing rateIncreased durabilityOther chemical processesAbrasion apparatusAlkaline earth metalOrganic base

An abrasive composition to be used in an abrasive material, including an inorganic abrasive particle. The particle comprises a shell layer being an outermost layer and mainly composed of cerium oxide; and an intermediate layer comprising cerium oxide and an oxide of at least one element selected from the group consisting of Al, Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, Zr, In, Sn, Y, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, W, Bi, Th, and alkali earth metals and formed on an inner side of the shell layer. The abrasive composition also includes an organic base member comprising a polymerizable compound, wherein an outer surface of the organic base member is covered with the inorganic abrasive particle.

Owner:KONICA MINOLTA INC

Chemical mechanical polishing method for cobalt

ActiveUS20190085206A1High polishing rateHigh rateOther chemical processesSolid-state devicesColloidal silicaCompound (substance)

A process for chemical mechanical polishing a substrate containing cobalt and TiN to planarize the surface and at least improve surface topography of the substrate. The process includes providing a substrate containing cobalt and TiN; providing a polishing composition, containing, as initial components: water; an oxidizing agent; aspartic acid or salts thereof; and, colloidal silica abrasives with diameters of ≤25 nm; and, providing a chemical mechanical polishing pad, having a polishing surface; creating dynamic contact at an interface between the polishing pad and the substrate; and dispensing the polishing composition onto the polishing surface at or near the interface between the polishing pad and the substrate; wherein some of the cobalt is polished away to planarize the substrate to provide improved cobalt:TiN removal rate selectivity.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

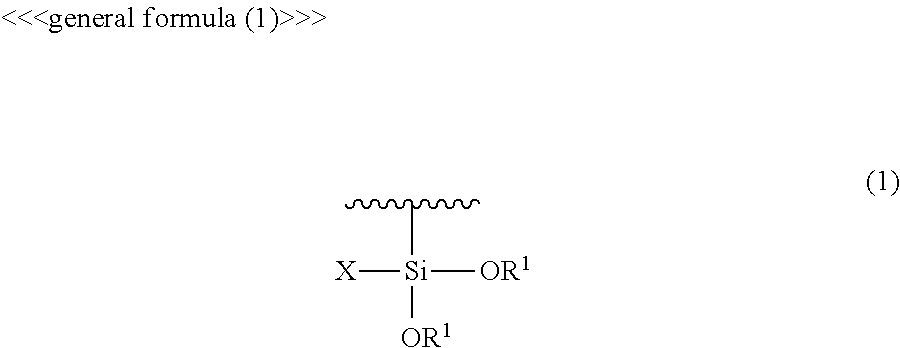

Polishing pad and method for producing same

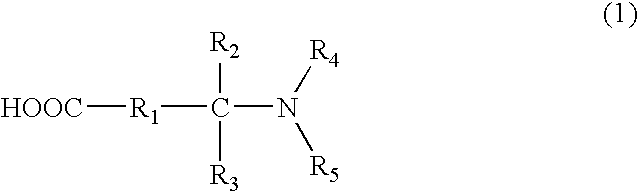

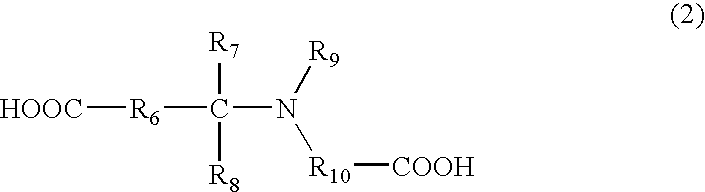

InactiveUS20170073456A1High polishing rateExcellent in planarization propertySemiconductor/solid-state device manufacturingLapping toolsSide chainPolymer chemistry

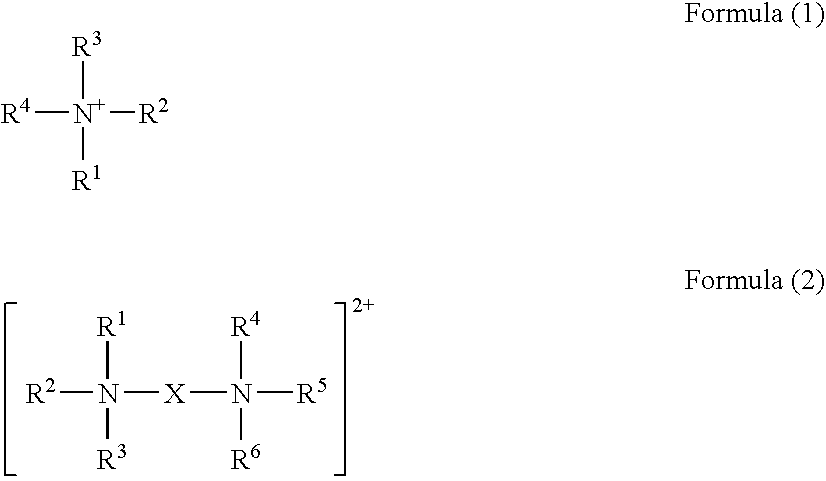

The purpose of the present invention is to provide: a polishing pad having a high polishing rate and excellent planarizing properties; and a method for producing the polishing pad. A polishing pad which has a polishing layer comprising a polyurethane resin foam, said polishing pad being characterized in that a polyurethane resin, which is a material used for forming the polyurethane resin foam, has an alkoxysilyl group represented by general formula (1) in a side chain thereof. (In the formula, X represents OR1 or OH; and R1's independently represent an alkyl group having 1 to 4 carbon atoms.)

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com