Polishing pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

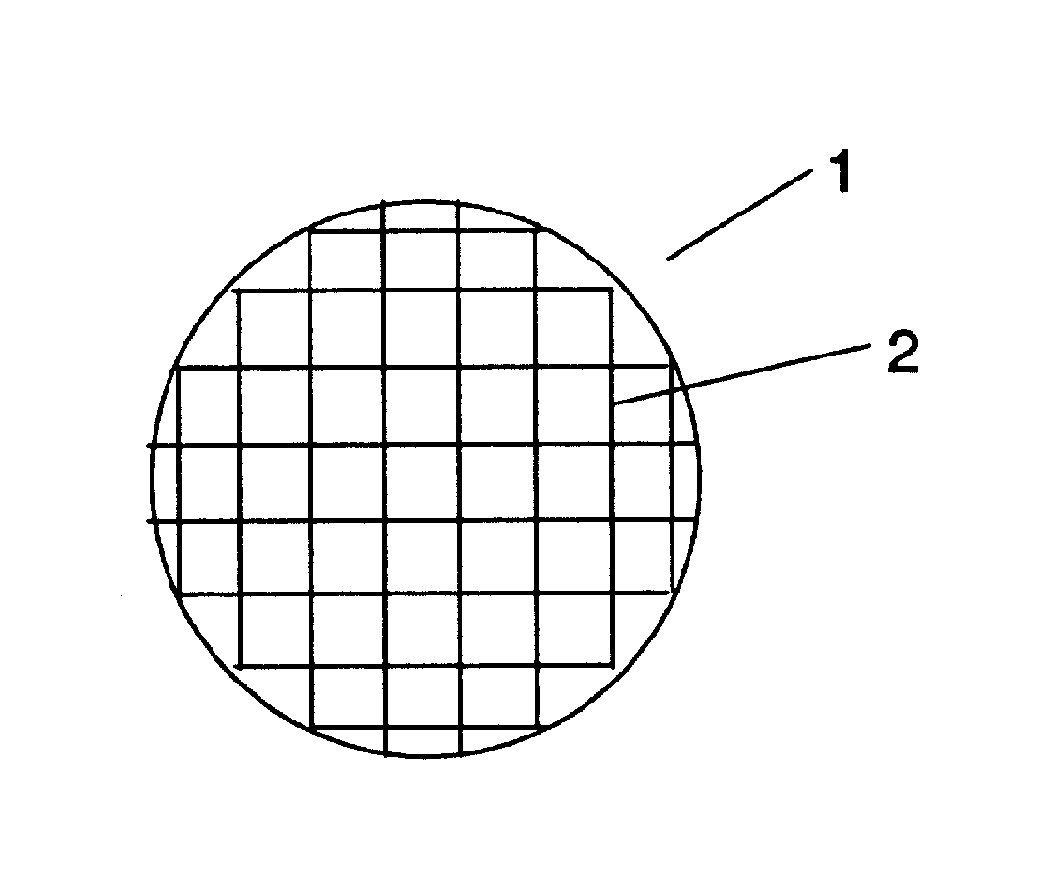

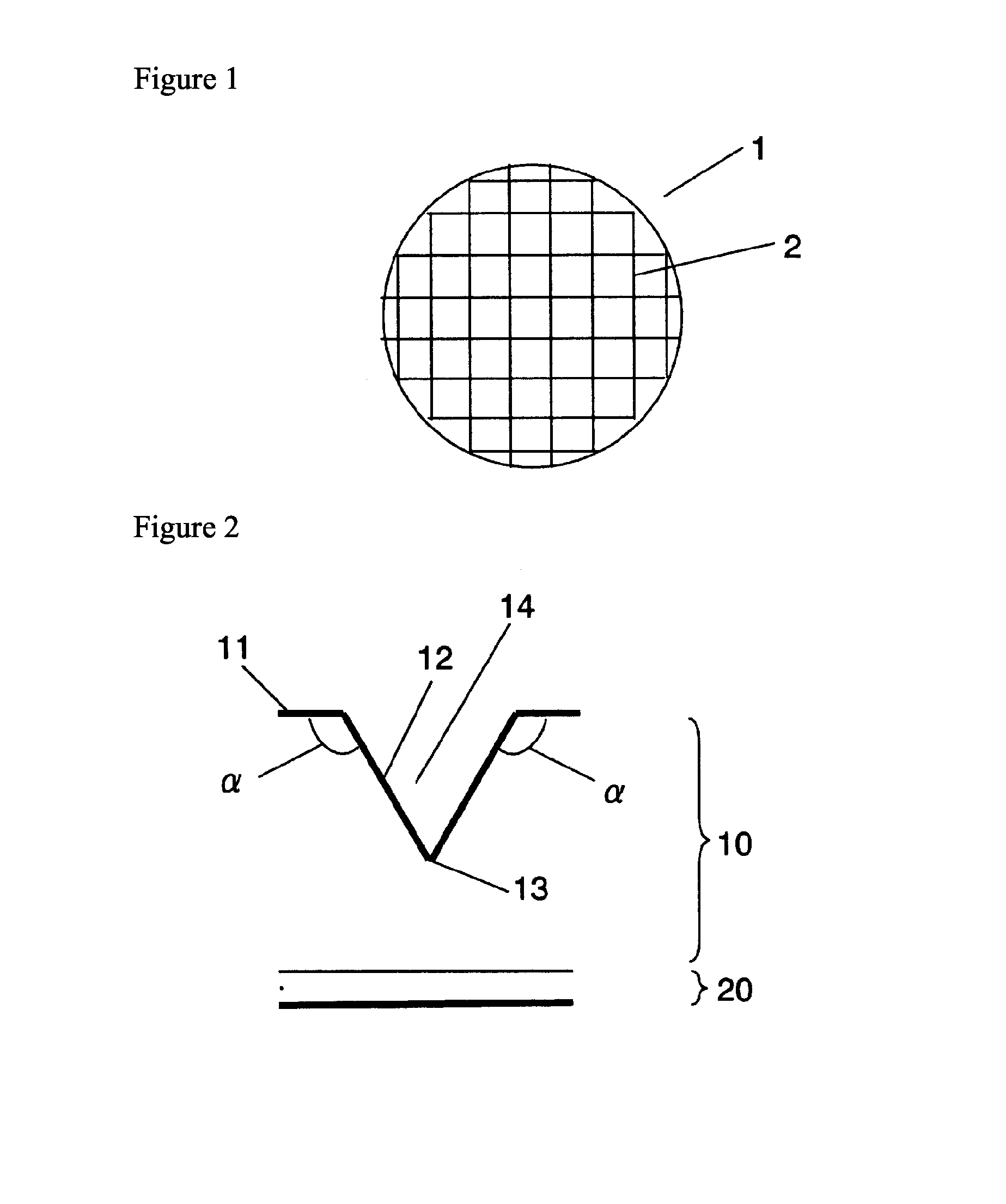

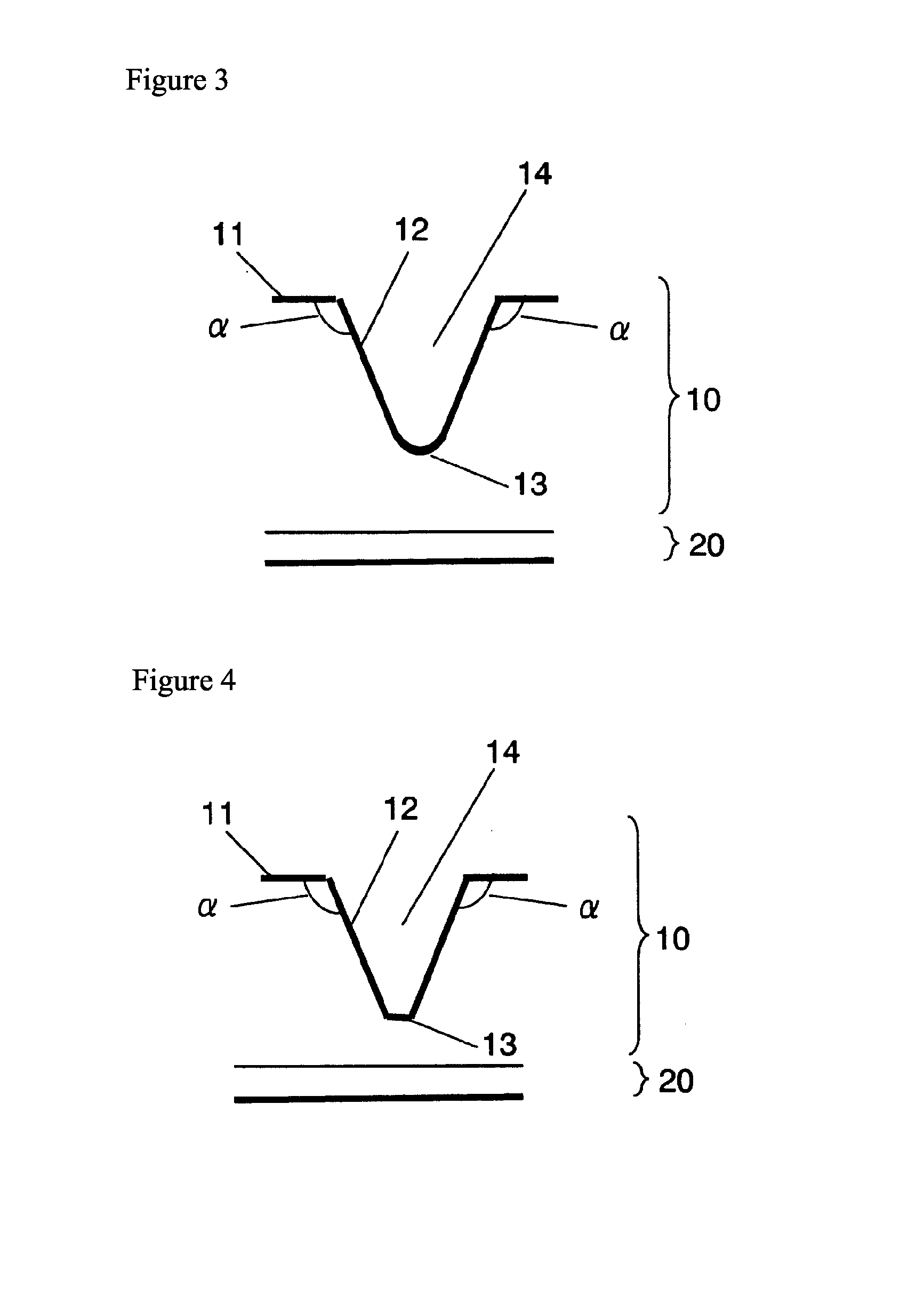

Image

Examples

example 1

[0056]In a molding machine RIM, 30 parts by weight of polypropylene glycol, 40 parts by weight of diphenylmethane diisocyanate, 0.5 part by weight of water, 0.3 part by weight of triethylamine, 1.7 parts by weight of a silicone foam stabilizer, and 0.09 part by weight of tin octylate were mixed, and the resulting mixture was discharged to a die and molded by pressure molding to prepare a foamed polyurethane sheet including independent air bubbles.

[0057]The foamed polyurethane sheet was immersed for 60 minutes in methyl methacrylate containing 0.2 part by weight of azobisisobutyronitrile. Then, the foamed polyurethane sheet was immersed in a solution composed of 15 parts by weight of polyvinyl alcohol “CP” (polymerization degree: about 500, produced by NACALAI TESQUE, INC.), 35 parts by weight of ethyl alcohol (reagent special grade, produced by KATAYAMA CHEMICAL INDUSTRIES Co., Ltd.) and 50 parts by weight of water, and dried to coat the surface layer of the foamed polyurethane shee...

example 2

[0061]A wafer of an oxide film was polished in the same manner as in Example 1 except for changing the inclination angle of the groove on the polishing layer surface to 110°. An average polishing rate was 185.0 nm / min, and the fluctuation in a polishing rate was as good as 25.4 nm / min.

example 3

[0062]A wafer of an oxide film was polished in the same manner as in Example 1 except for changing the inclination angle of the groove on the polishing layer surface to 140°. An average polishing rate was 227.3 nm / min, and the fluctuation in a polishing rate was as good as 23.8 nm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com