Patents

Literature

61results about How to "Improve polishing selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20110081780A1Reduce polishing rateHigh polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidSilica particle

A chemical mechanical polishing aqueous dispersion includes (A) silica particles, and (B1) an organic acid, the number of silanol groups included in the silica particles (A) calculated from a signal area of a 29Si-NMR spectrum being 2.0 to 3.0×1021 / g.

Owner:JSR CORPORATIOON

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20110053462A1Reduce polishing rateHigh polishing rateOther chemical processesDecorative surface effectsIon contentIon chromatography

A chemical mechanical polishing aqueous dispersion including (A) silica particles, and (B1) an organic acid, the sodium content, the potassium content, and the ammonium ion content of the silica particles (A) determined by ICP atomic emission spectrometry, ICP mass spectrometry, or ammonium ion quantitative analysis using ion chromatography having a relationship in which the sodium content is 5 to 500 ppm and at least one of the potassium content and the ammonium ion content is 100 to 20,000 ppm.

Owner:JSR CORPORATIOON

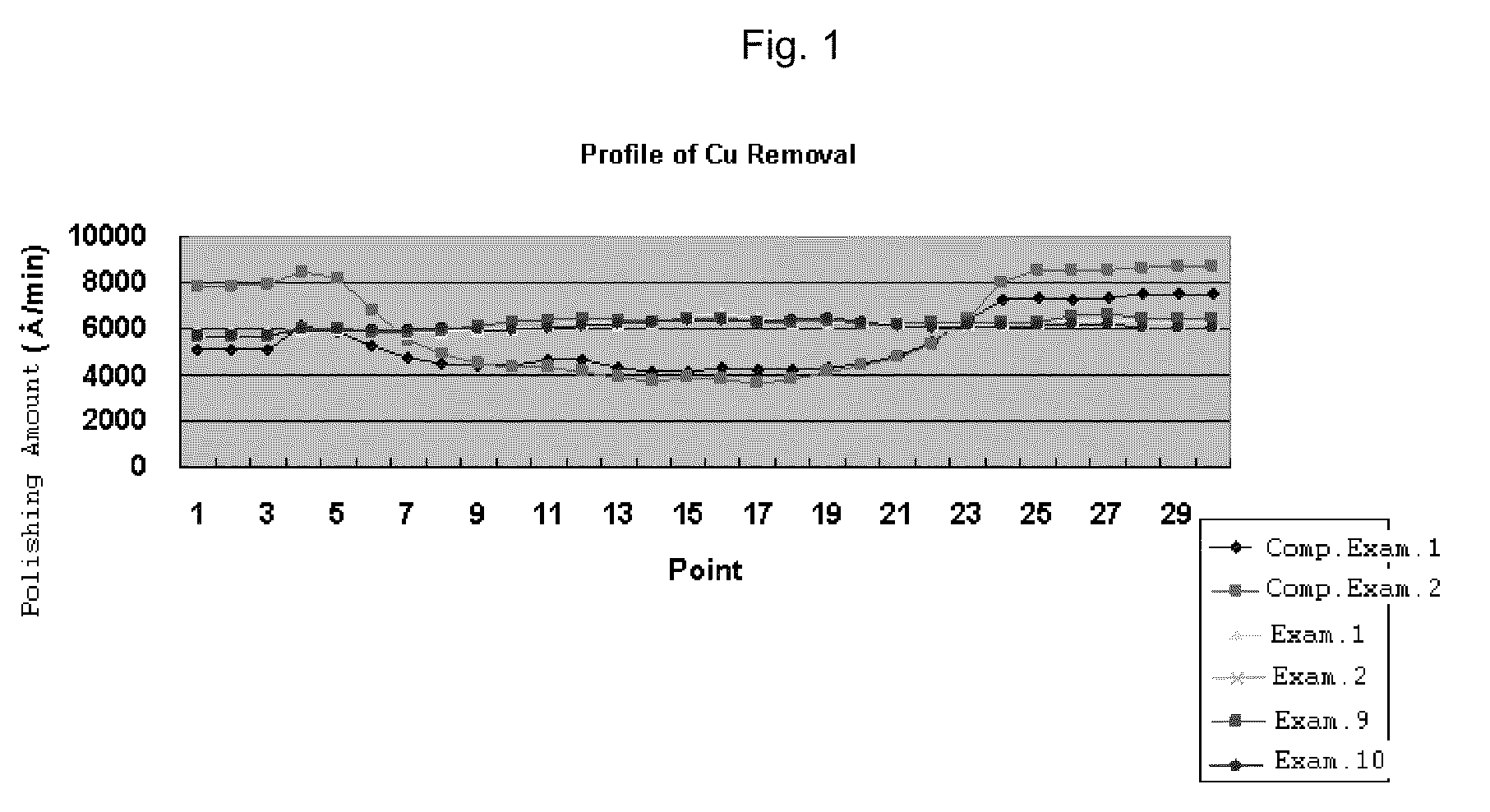

Slurry composition for primary chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20100151684A1Improved WIWNUExcellent polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidCompound (substance)

The present invention relates to a slurry composition for primary chemical mechanical polishing that can show more improved WIWNU (Within Wafer Non-Uniformity) while exhibiting excellent polishing rate and polishing selectivity, and a chemical mechanical polishing method. The slurry composition for primary chemical mechanical polishing comprises an abrasive; an oxidant, an organic acid; a specific corrosion inhibitor, and, a polymeric additive comprising polyvinylpyrrolidone having weight average molecular weight of about 3000 to 100000, and has polishing selectivity of polishing rates between a copper layer:a tantalum layer of about 30:1 or more.

Owner:LG CHEM LTD

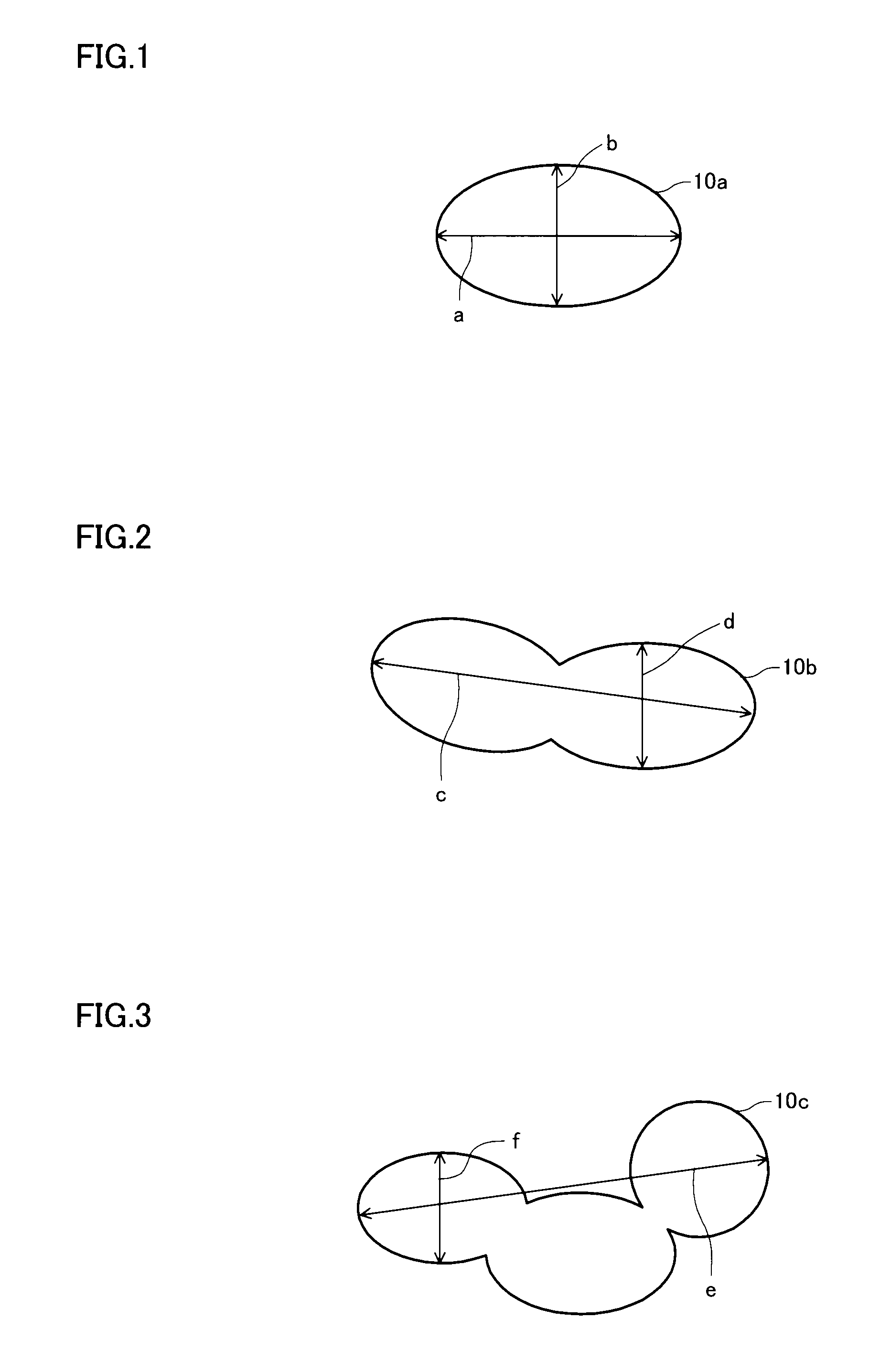

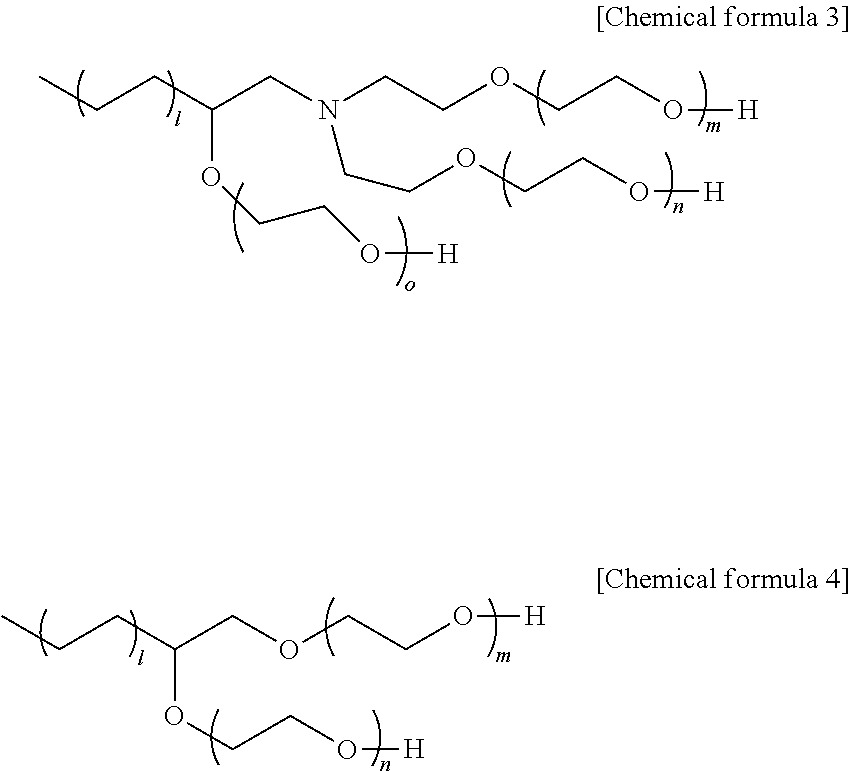

Slurry composition for cmp, and polishing method

ActiveUS20120270399A1Improve polishing selectivityHigh polishing rateMaterial nanotechnologyOther chemical processesPolymer sciencePolyolefin

The present invention relates to a CMP slurry composition comprising an abrasive particle; a dispersant; an ionic polymer additive; and a non-ionic polymer additive including a polyolefin-polyethylene glycol copolymer including at least two polyethylene glycol repeat unit as a backbone and at least a polyethylene glycol repeating unit as a side chain, and a polishing method with using the slurry composition. The CMP slurry composition shows a low polishing rate to a single-crystalline silicon layer or a polysilicon layer and a high polishing rate to a silicon oxide layer, resulting in having an excellent polishing selectivity.

Owner:LG CHEM LTD

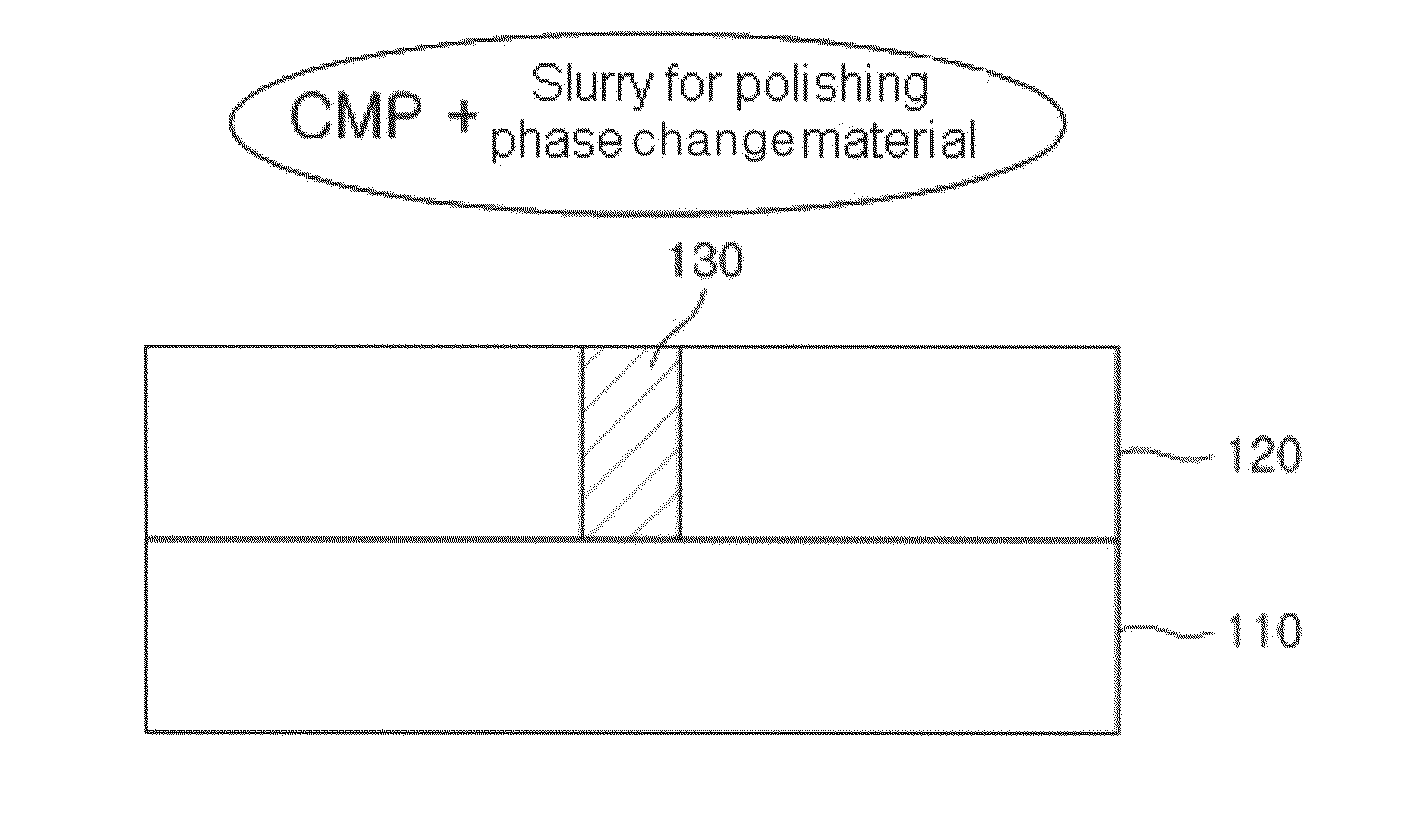

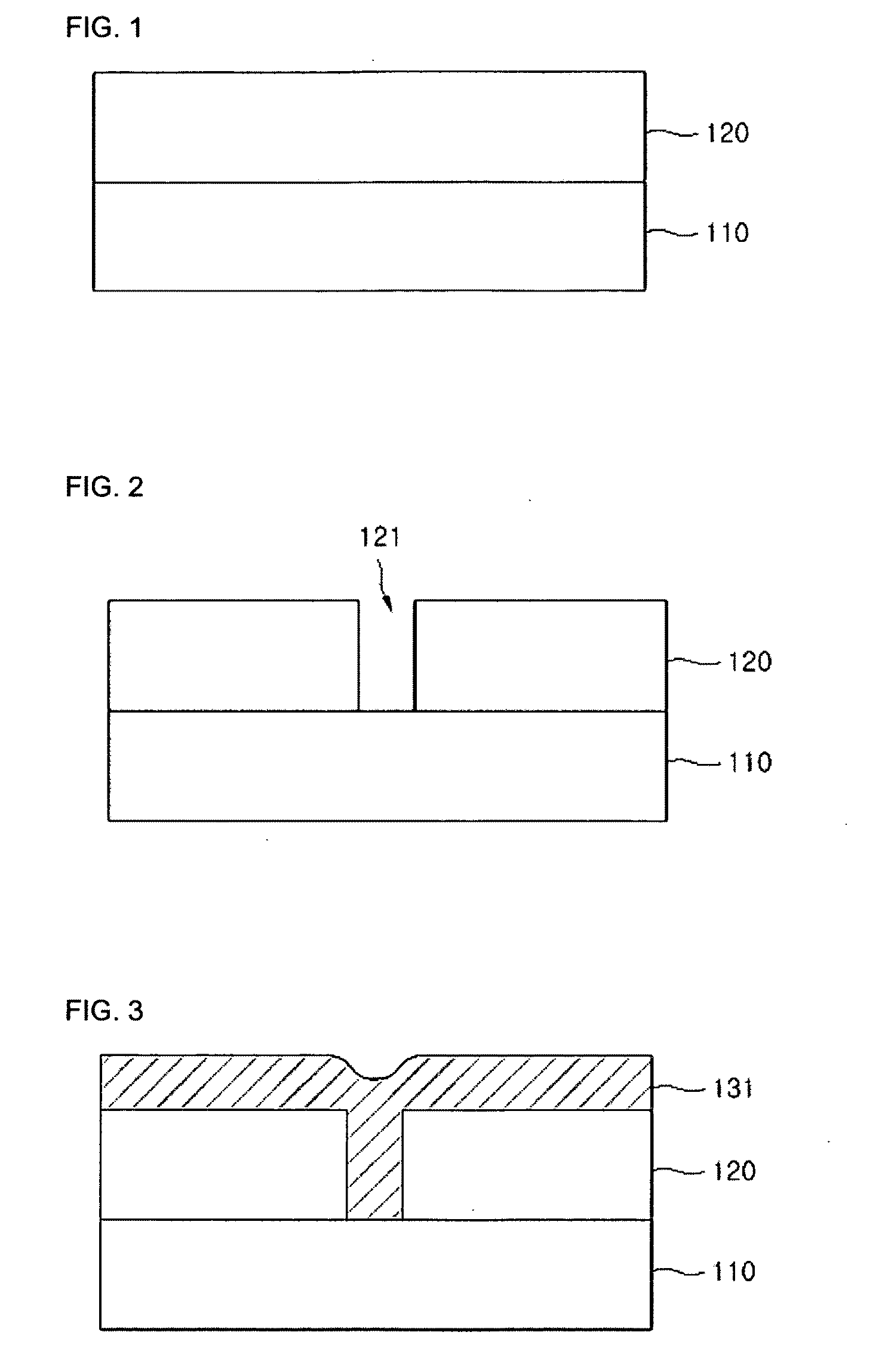

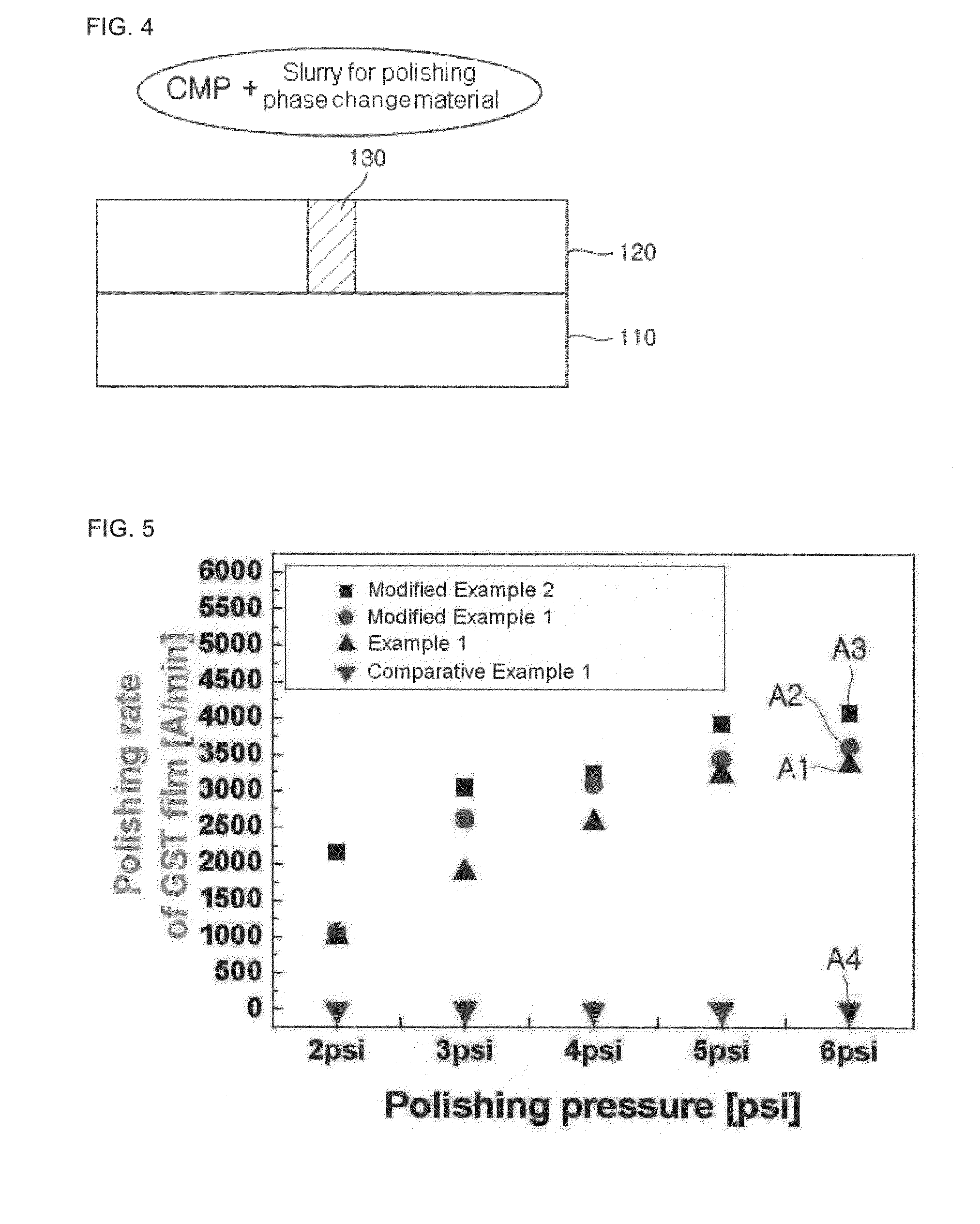

Slurry for polishing phase change material and method for patterning polishing phase change material using the same

InactiveUS20090275188A1Improve polishing selectivityReduce surface roughnessOther chemical processesSemiconductor/solid-state device manufacturingPhase-change materialSlurry

Disclosed is a slurry for polishing a phase change material. The slurry includes an abrasive, an alkaline polishing promoter and deionized water. Due to the use of the abrasive and the alkaline polishing promoter, the pH of the slurry is adjusted, the polishing rate of the phase change material is improved, and the polishing selectivity of the phase change material to an underlying insulating layer is increased. Further disclosed is a method for patterning a phase change material using the slurry.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

An aqueous slurry composition for chemical mechanical polishing and chemical mechanical polishing method

ActiveCN101679810AAids in preparationReliable wiring layerOther chemical processesSemiconductor/solid-state device manufacturingEthylene oxideCompound (substance)

Owner:LG CHEM LTD

Polishing agent, polishing agent set, and substrate polishing method

ActiveUS20150017806A1Minimizing progressionImprove polishing selectivityOther chemical processesSemiconductor/solid-state device manufacturingCationic polymerizationPropylene glycol

The polishing agent of the invention comprises water, an abrasive grain containing a hydroxide of a tetravalent metal element, polyalkylene glycol, and at least one cationic polymer selected from the group consisting of allylamine polymers, diallylamine polymers, vinylamine polymers and ethyleneimine polymers.

Owner:RESONAC CORP

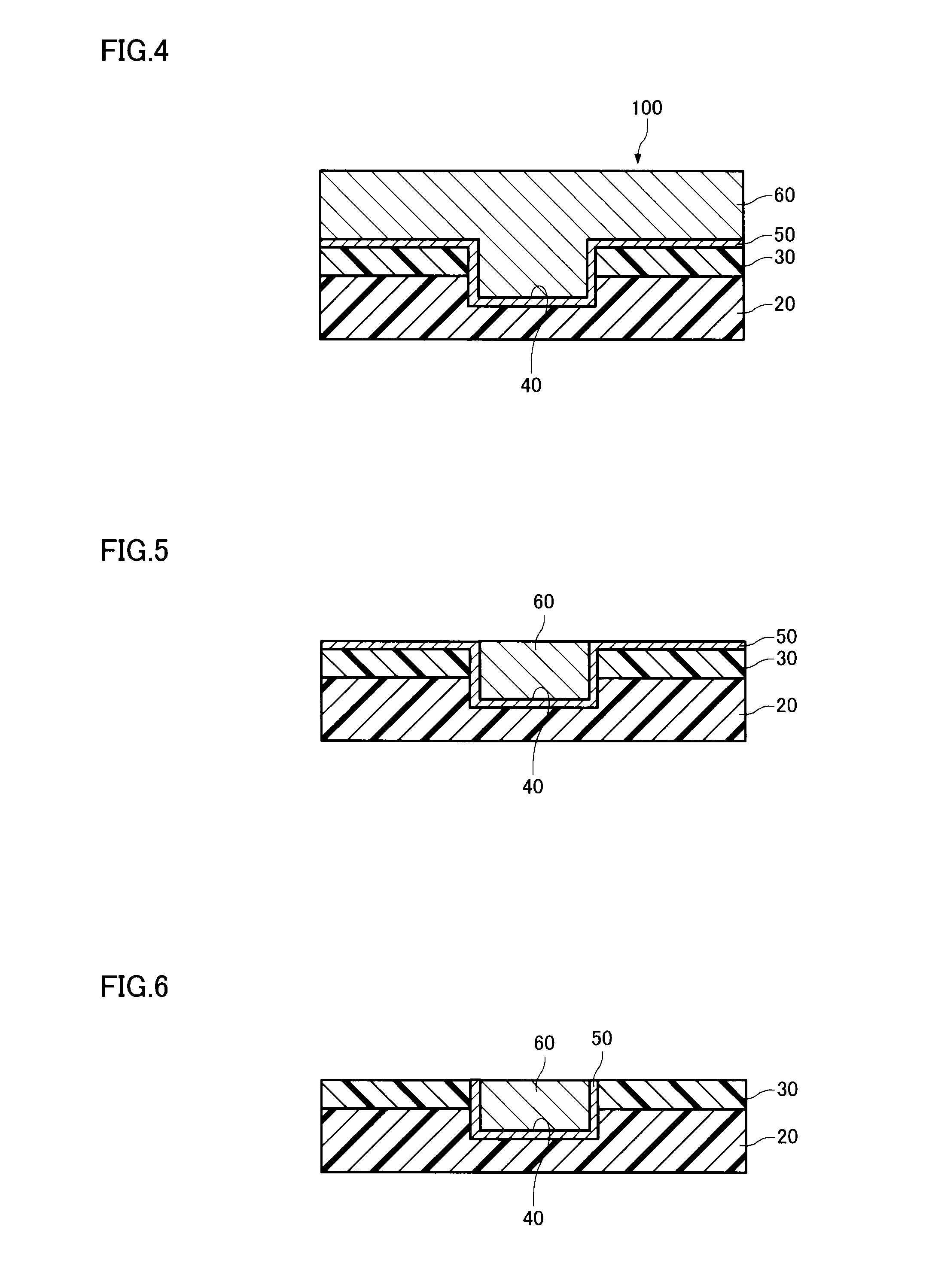

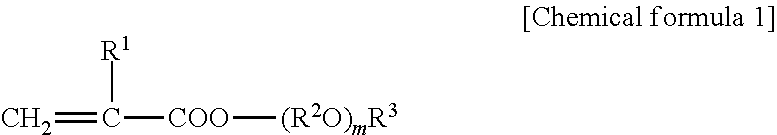

Aqueous slurry composition for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20100184291A1Superior surface condition and propertyPrevent erosionOther chemical processesSemiconductor/solid-state device manufacturingChemical-mechanical planarizationCompound (substance)

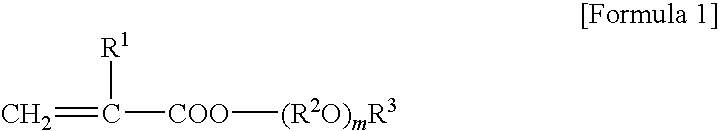

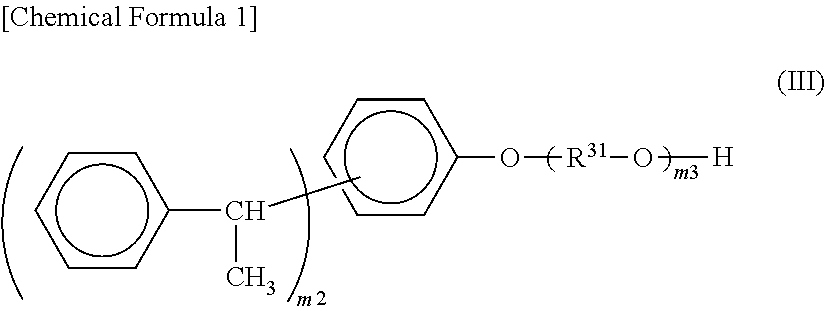

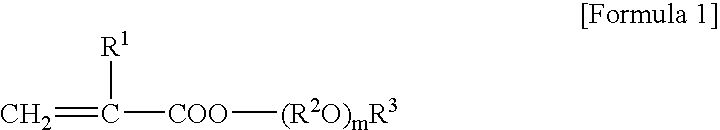

The present invention relates to an aqueous slurry composition for chemical mechanical polishing that can show good polishing rate to the target layer, and yet has a high polishing selectivity and can maintain superior surface condition of the target layer after polishing, and a chemical mechanical polishing method.The aqueous slurry composition for chemical mechanical polishing (CMP) includes abrasives; an oxidant; a complexing agent; and a polymeric additive including at least one selected from the group consisting of a polypropyleneoxide, a propyleneoxide-ethyleneoxide copolymer, and a compound represented by Chemical Formula 1.

Owner:LG CHEM LTD

Slurry composition for forming tungsten pattern and method for manufacturing semiconductor device using the same

InactiveUS20080096385A1Slow polishing selectivityFaster selectivity ratioOther chemical processesSemiconductor/solid-state device manufacturingProduction rateDevice material

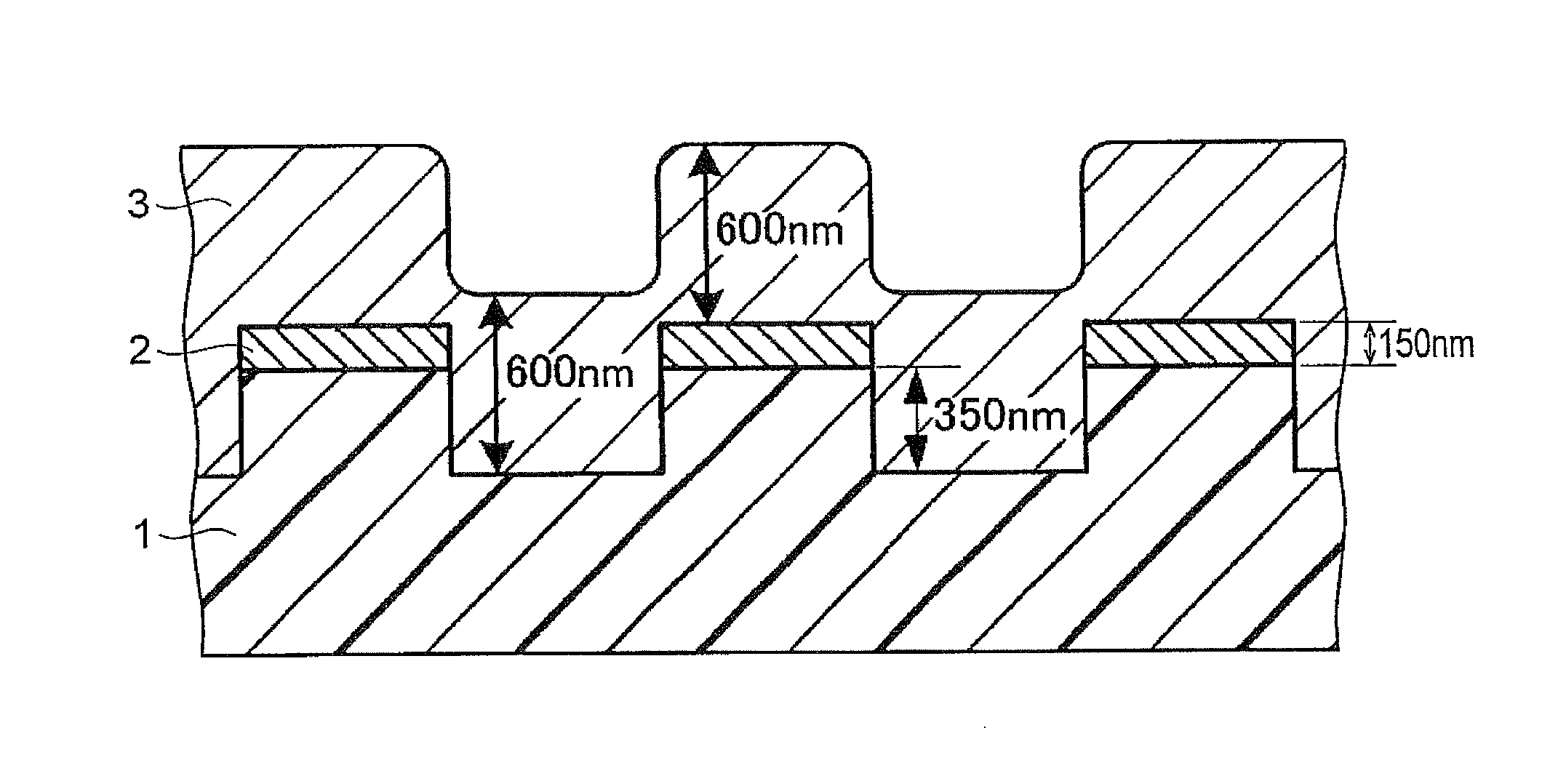

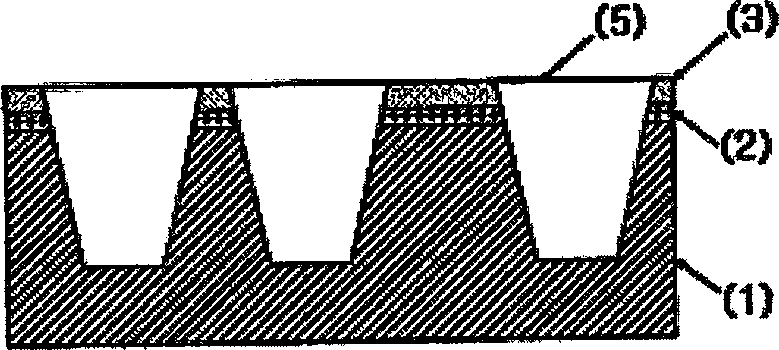

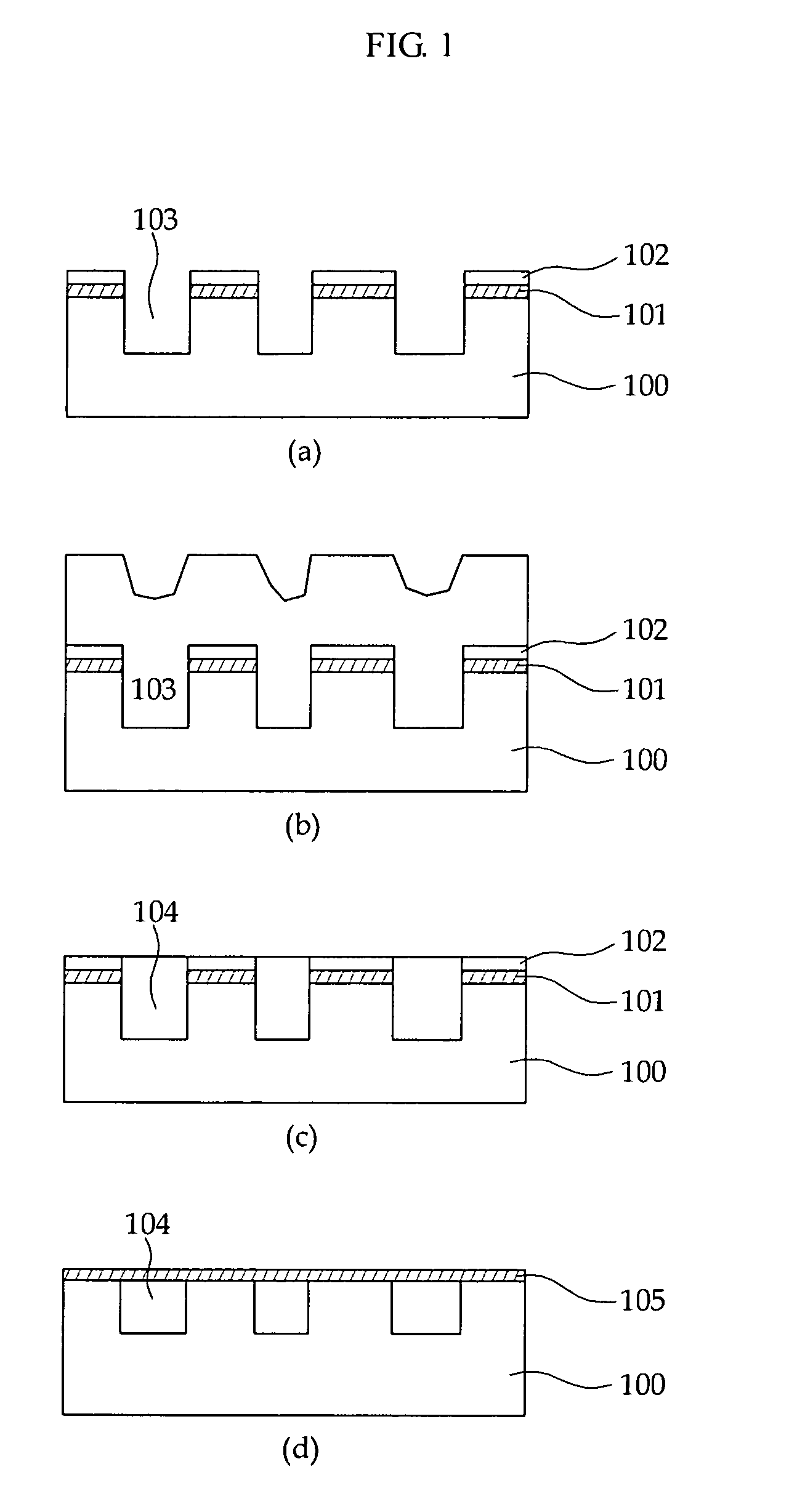

A method for manufacturing a semiconductor device with a slurry composition for forming a tungsten pattern. The method comprises: forming a trench in an insulating film formed on a substrate; depositing a tungsten film over the insulating film including the trench; first polishing a tungsten film with a first slurry for polishing metal to expose the insulating film, the polishing selectivity ratio of the first slurry onto tungsten / insulating film being range from 30 to 100; and second polishing the insulating film and the tungsten film with a second slurry, the polishing selectivity ratio of the second slurry onto insulating film / tungsten being range from 3 to 500. The method reduces a thickness difference of tungsten patterns, thereby improving a production yield of semiconductor devices.

Owner:SK HYNIX INC +1

Abrasive, abrasive set, and method for abrading substrate

ActiveUS20150024596A1Improve polishing rateImprove polishing selectivityOther chemical processesSemiconductor/solid-state device manufacturingMetalMaterials science

Owner:RESONAC CORP

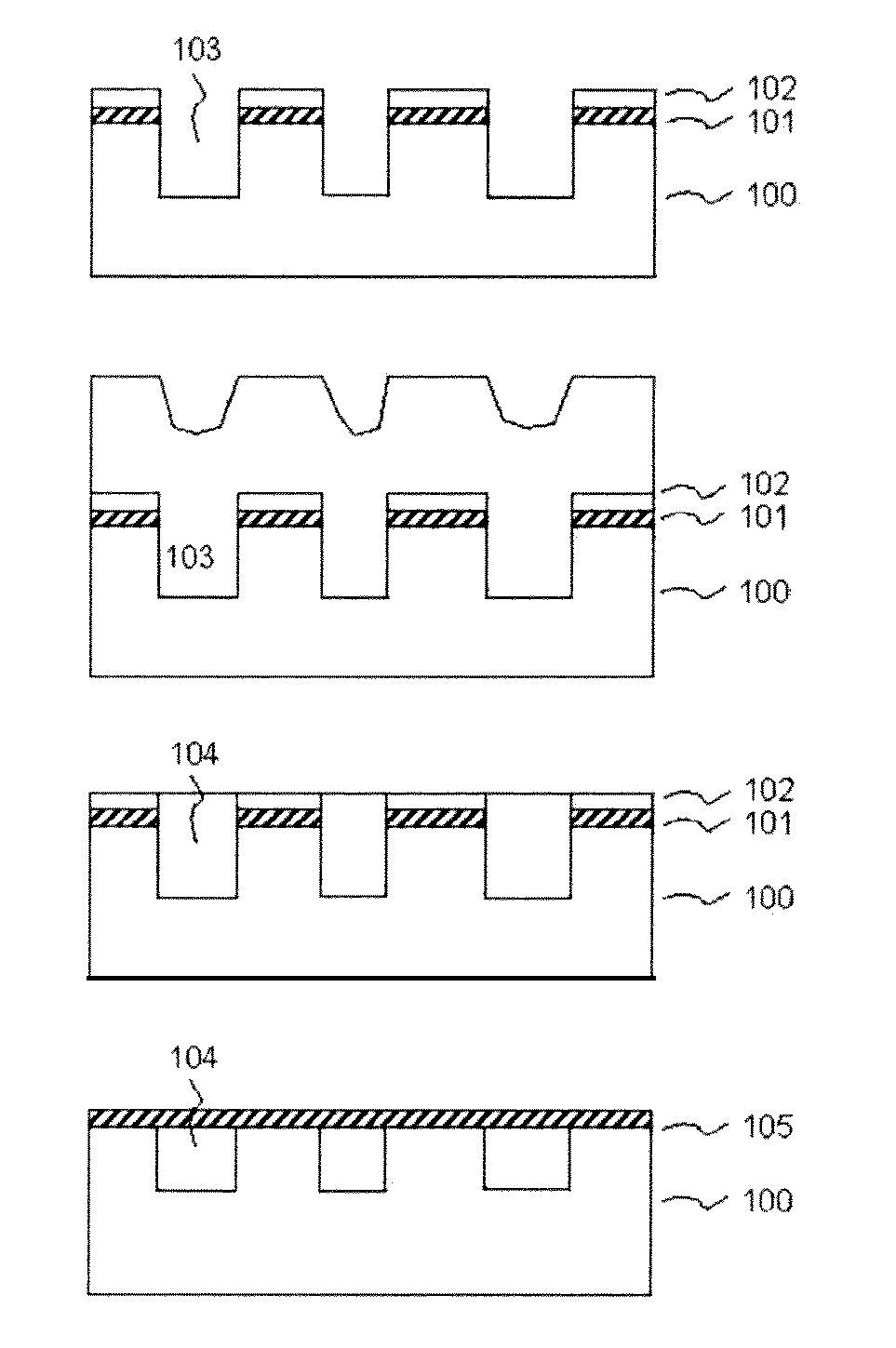

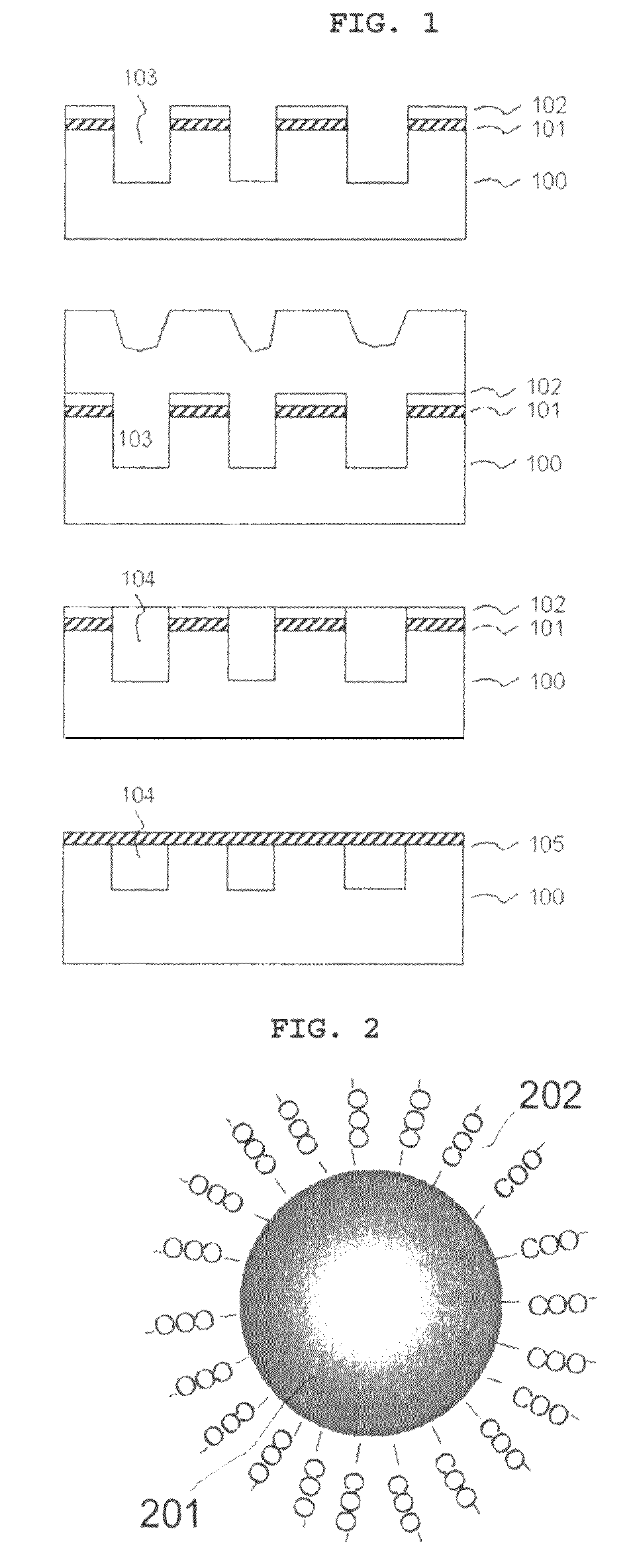

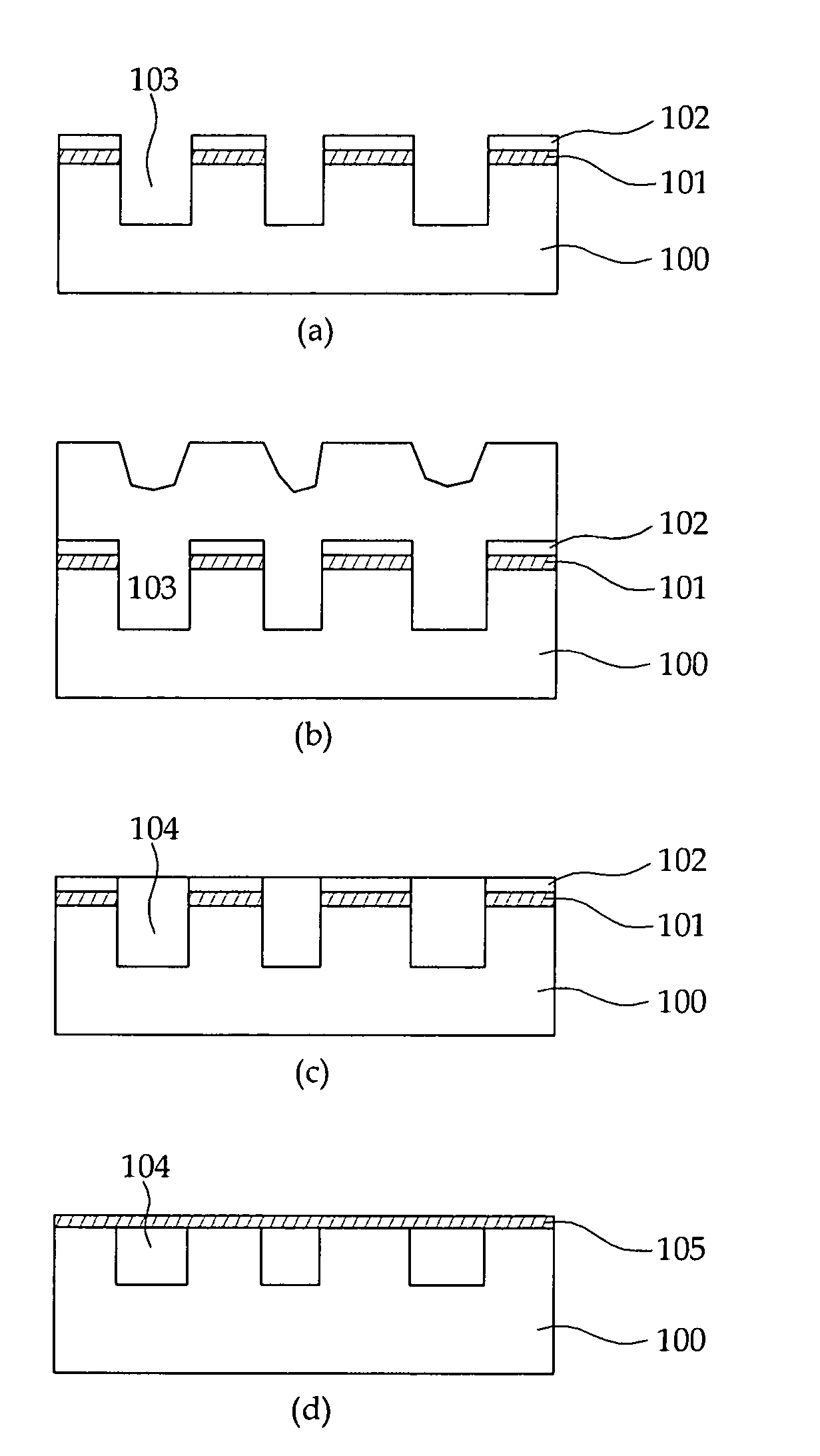

Adjuvant for Controlling Polishing Selectivity and Chemical Mechanical Polishing Slurry

ActiveUS20090267020A1High selectivityMinimize changesOther chemical processesSemiconductor/solid-state device manufacturingPolyelectrolyteAdjuvant

Disclosed is an adjuvant for controlling polishing selectivity when polishing a cationically charged material simultaneously with an anionically charged material. CMP slurry comprising the adjuvant is also disclosed. The adjuvant comprises: (a) a polyelectrolyte that forms an adsorption layer on the cationically charged material in order to increase the polishing selectivity of the anionically charged material; (b) a basic material; and (c) a fluorine-based compound. when the adjuvant for controlling polishing selectivity of CMP slurry according to the present invention is applied to a CMP process, it is possible to increase the polishing selectivity of a silicon oxide layer, to obtain a uniform particle size of CMP slurry, to stabilize variations in viscosity under an external force and to minimize generation of microscratches during a polishing process. Therefore, the adjuvant for CMP slurry according to the present invention can improve reliability and productivity during the fabrication of very large scale integrated semiconductors.

Owner:LG CHEM LTD

Polishing agent, polishing agent set and method for polishing base

ActiveUS9163162B2Polishing rate can be suppressedImprove polishing selectivityOther chemical processesCerium oxides/hydroxidesLiquid mediumPolymer science

A polishing agent according to one embodiment of the present invention contains a liquid medium, an abrasive grain including a hydroxide of a tetravalent metal element, a polymer compound having an aromatic ring and a polyoxyalkylene chain, and a cationic polymer, wherein a weight average molecular weight of the polymer compound is 1000 or more.

Owner:RESONAC CORPORATION

Chemically mechanical polishing solution

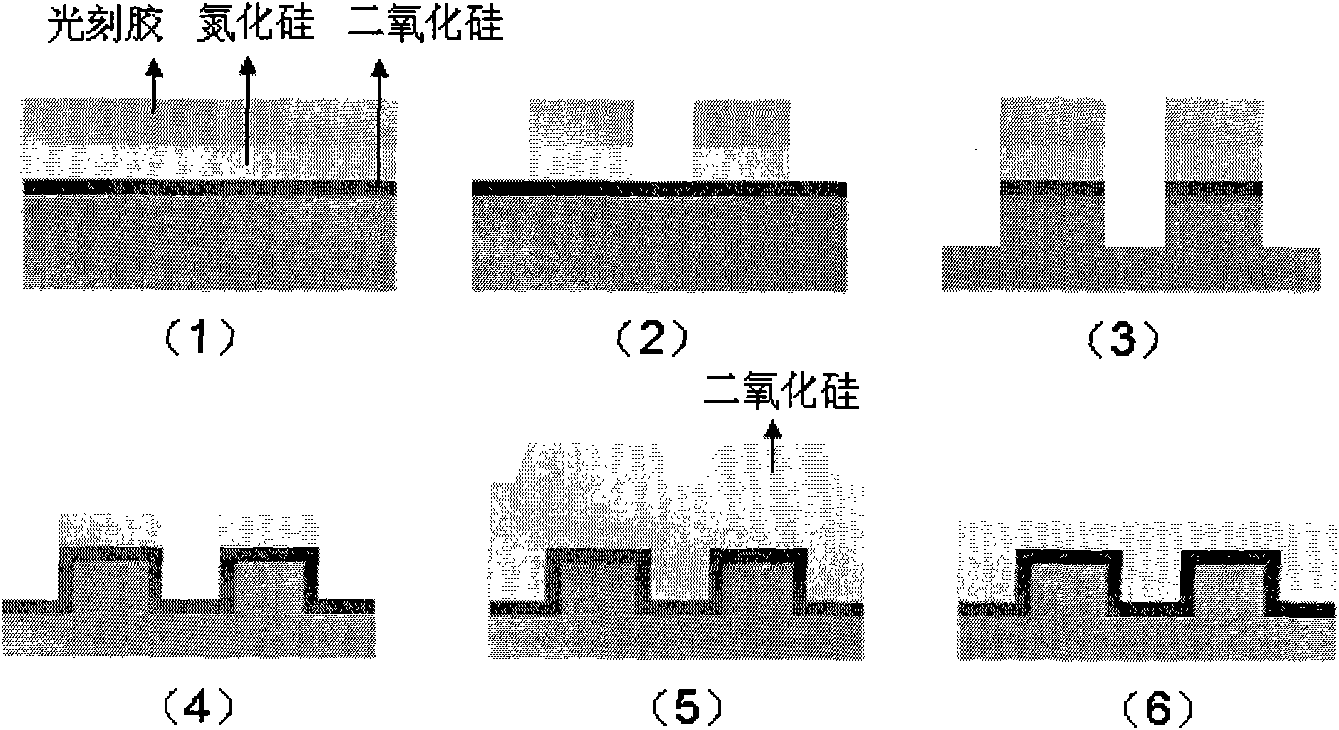

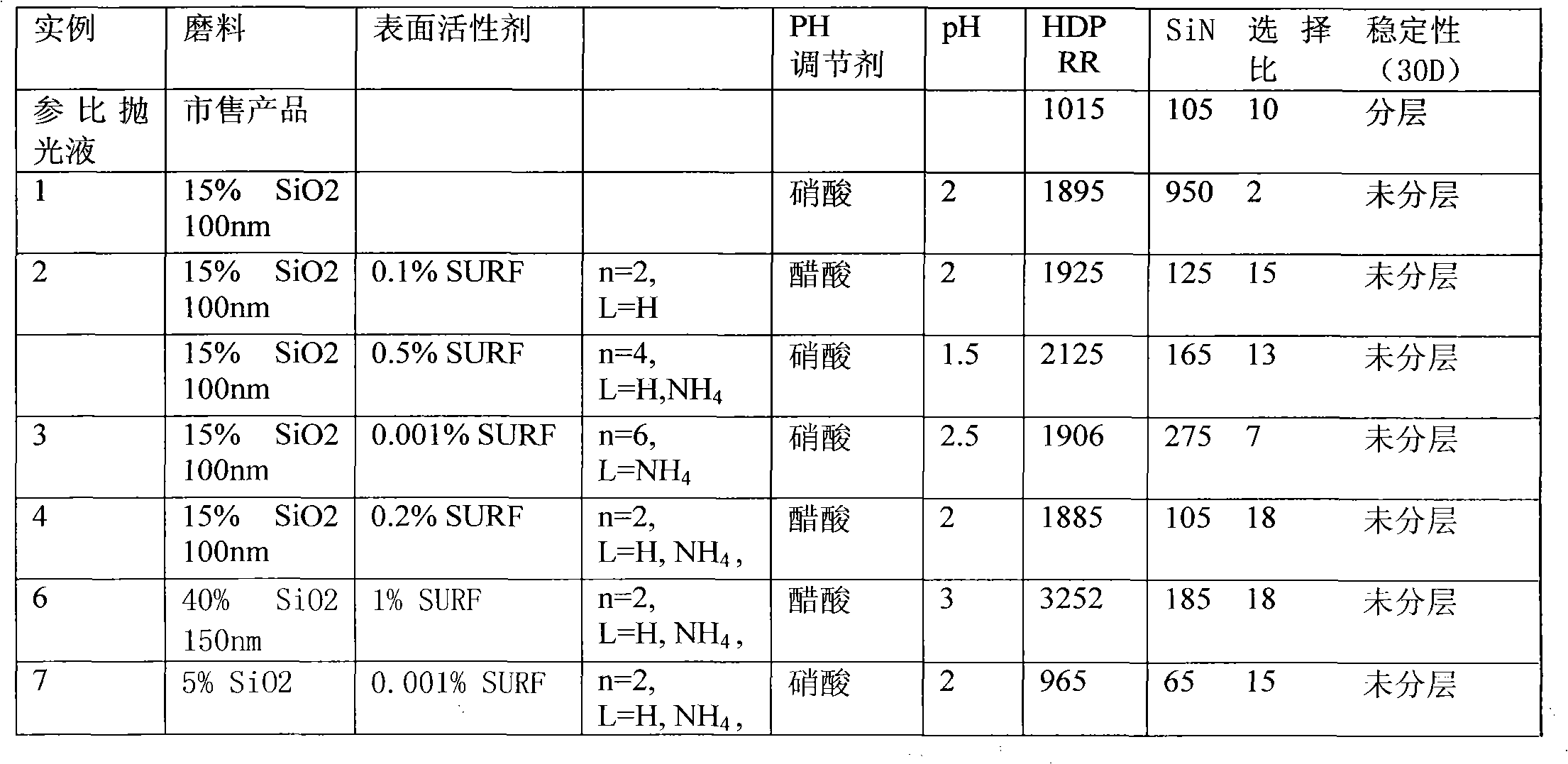

InactiveCN102464945AHigh HDP removal rateProlong settling timePolishing compositions with abrasivesWater solubleHigh silica

The invention discloses a chemically mechanical polishing solution used for shallow-trench isolation. The polishing solution at least contains one silicon-based abrasive material, one water-soluble anionic surfactant and one pH regulator, and has higher silica removal rate and lower silicon nitride removal rate, a polished surface is smooth and clean, and the chemically mechanical polishing solution has good stability and is suitable for the chemical-mechanical planarization for the shallow-trench isolation.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Acidic polishing slurry for the chemical-mechanical polishing of SiO2 isolation layers

InactiveUS20020129560A1Improve polishing selectivityShorten production timePigmenting treatmentOther chemical processesColloidal silicaPhysical chemistry

An acidic polishing slurry for chemical-mechanical polishing, containing 0.1 to 5% by weight of a colloidal silica abrasive and 0.5 to 10% by weight of a fluoride salt, is distinguished by a higher polishing selectivity with regard to the rate at which silica is removed compared to the rate at which silicon nitride is removed compared to a conventional polishing slurry containing pyrogenic silica.

Owner:BAYER AG

Polishing slurry for low dielectric material

ActiveCN101490192BImprove removal rateChange in removal rateOther chemical processesSemiconductor/solid-state device manufacturingSurface finishSlurry

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Slurry composition, method of polishing an object and method of forming a contact in a semiconductor device using the slurry composition

InactiveUS20060189152A1Efficient polishingImprove reliabilityOther chemical processesSurface-active detergent compositionsInsulation layerDevice material

In a slurry composition preventing damage to an insulation layer, and uniformly polishing a metal layer, the slurry composition includes an acidic aqueous solution having a first pH and an anionic surfactant having a second pH lower than or equal to the first pH. Irregular polishing of the metal layer relative to a pattern density may be prevented and a contact having a uniform thickness may be formed using the slurry composition.

Owner:SAMSUNG ELECTRONICS CO LTD

Adjuvant for chemical mechanical polishing slurry

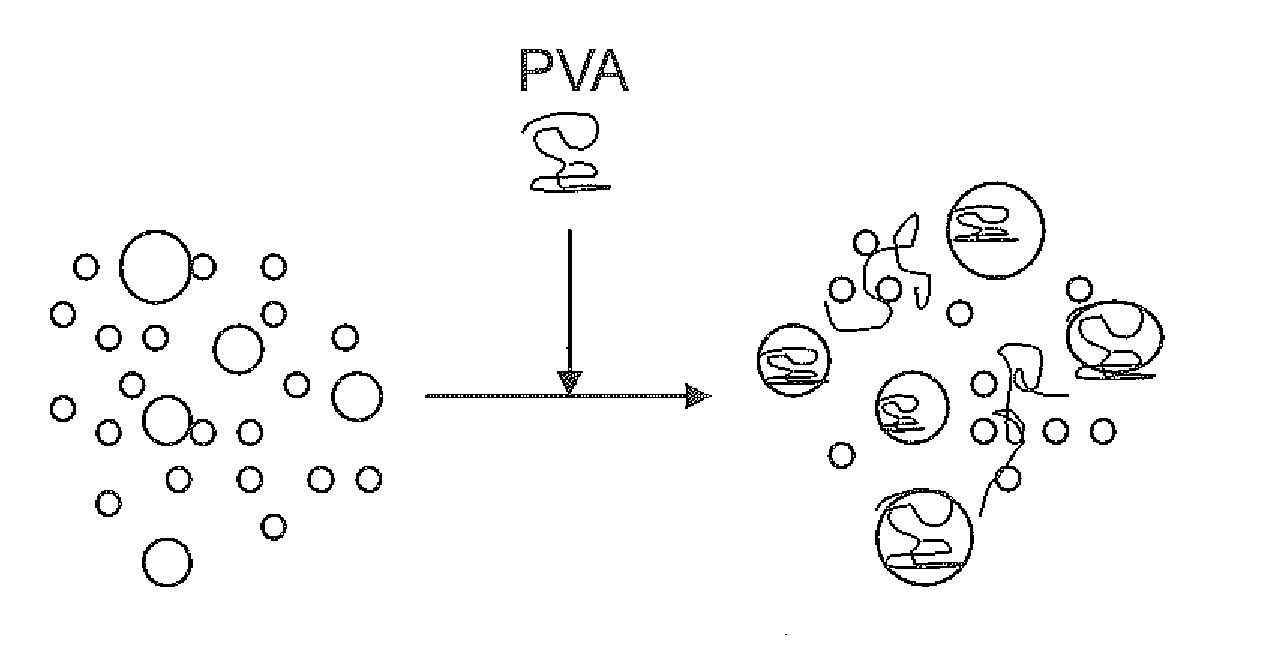

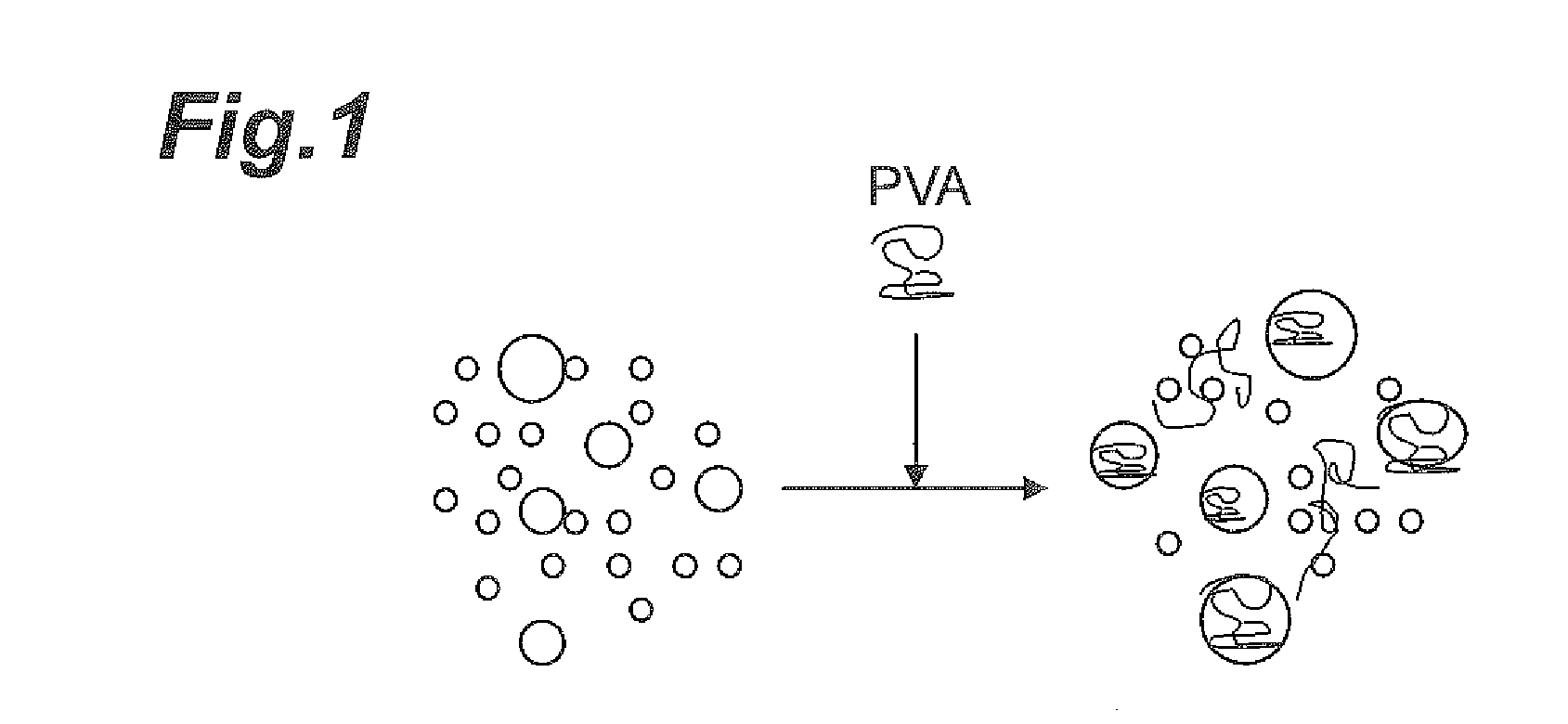

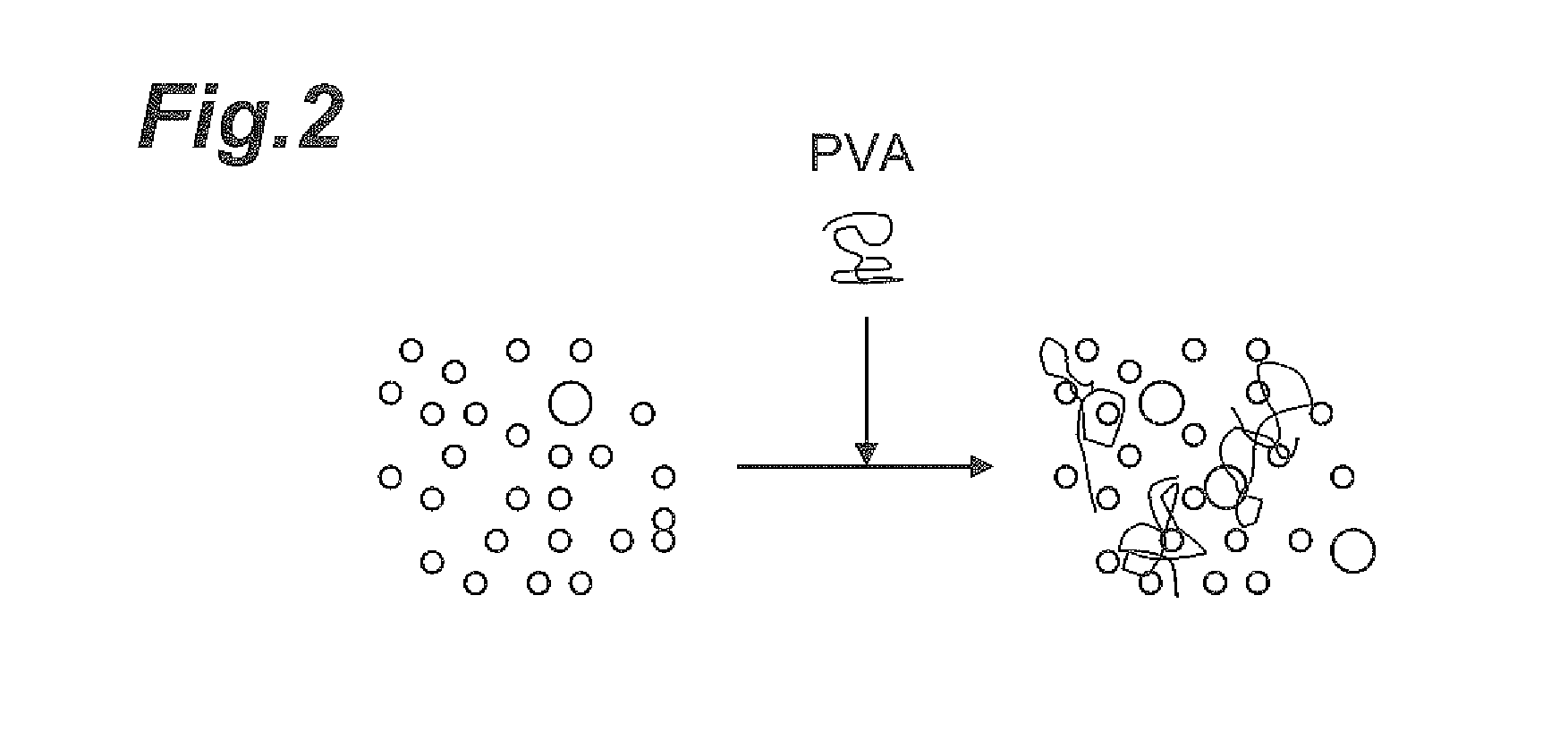

ActiveUS20060141741A1Improve polishing selectivityMinimize agglomerationOther chemical processesDecorative surface effectsPolyelectrolyteAdjuvant

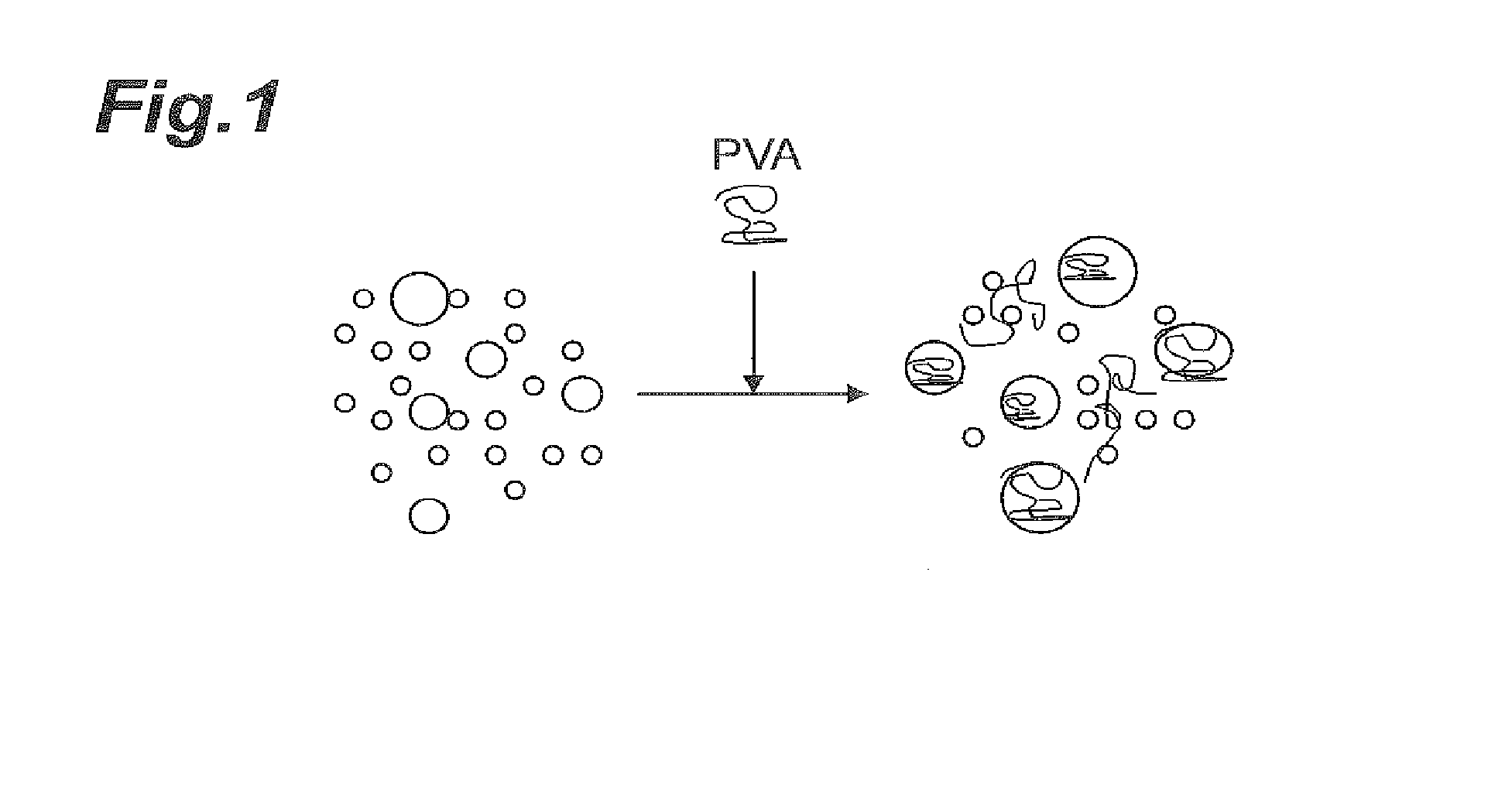

Disclosed is an adjuvant for use in simultaneous polishing of a cationically charged material and an anionically charged material, which forms a adsorption layer on the cationically charged material in order to increase the polishing selectivity of the anionically charged material to cationically charged material, wherein the adjuvant comprises a polyelectrolyte salt containing: (a) a graft type polyelectrolyte that has a weight average molecular weight of 1,000˜20,000 and comprises a backbone and a side chain; and (b) a basic material. CMP (chemical mechanical polishing) slurry comprising the above adjuvant and abrasive particles is also disclosed.

Owner:LG CHEM LTD

Ceria serosity combination with reinforced polishing uniformity

InactiveCN1872900AReduce saggingReduce erosionOther chemical processesSemiconductor/solid-state device manufacturingSlot insulationAlcohol

The invention discloses a chemical mechanical polishing slurry compound. It comprises: ceric oxide grinding agent; polycarboxylic acids or polycarboxylate with weight average molecular weight being 50,000-500,000; alcohol compound and water. The optimum proportion by weight of components in relative to total slurry compound are: ceric oxide grinding agent 0.1-20%, polycarboxylic acids or polycarboxylate 0.01-20%, alcohol compound 0.001-10%, and the pH of said slurry is 5-10. The CMP slurry compound is processed with STI (shallow slot insulation) method to form multiplayer construction and increase polishing uniformity and inhibit dent and corrosion of chip.

Owner:DONGJIN SEMICHEM CO LTD

Polishing slurry and method of polishing substrate using the same

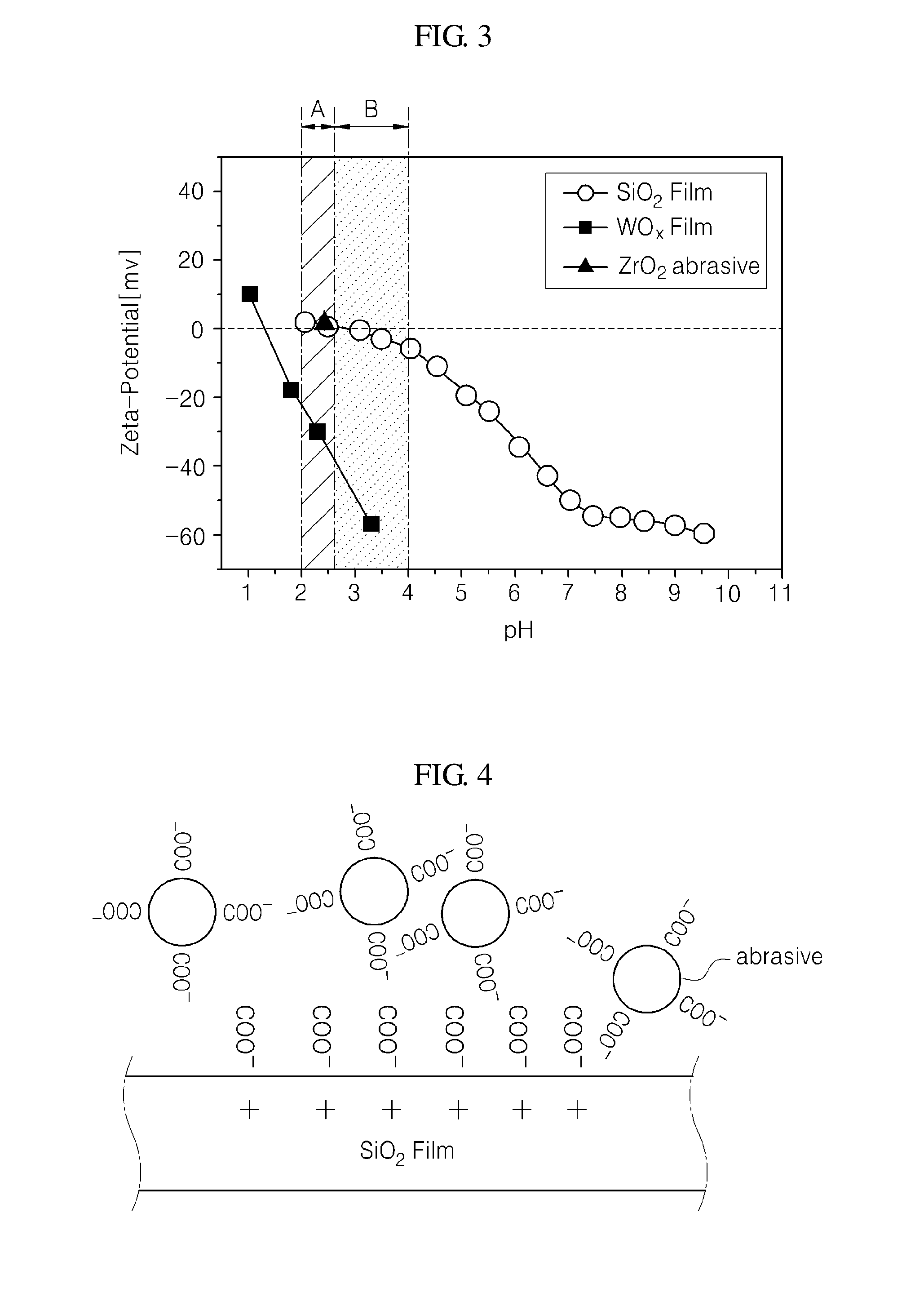

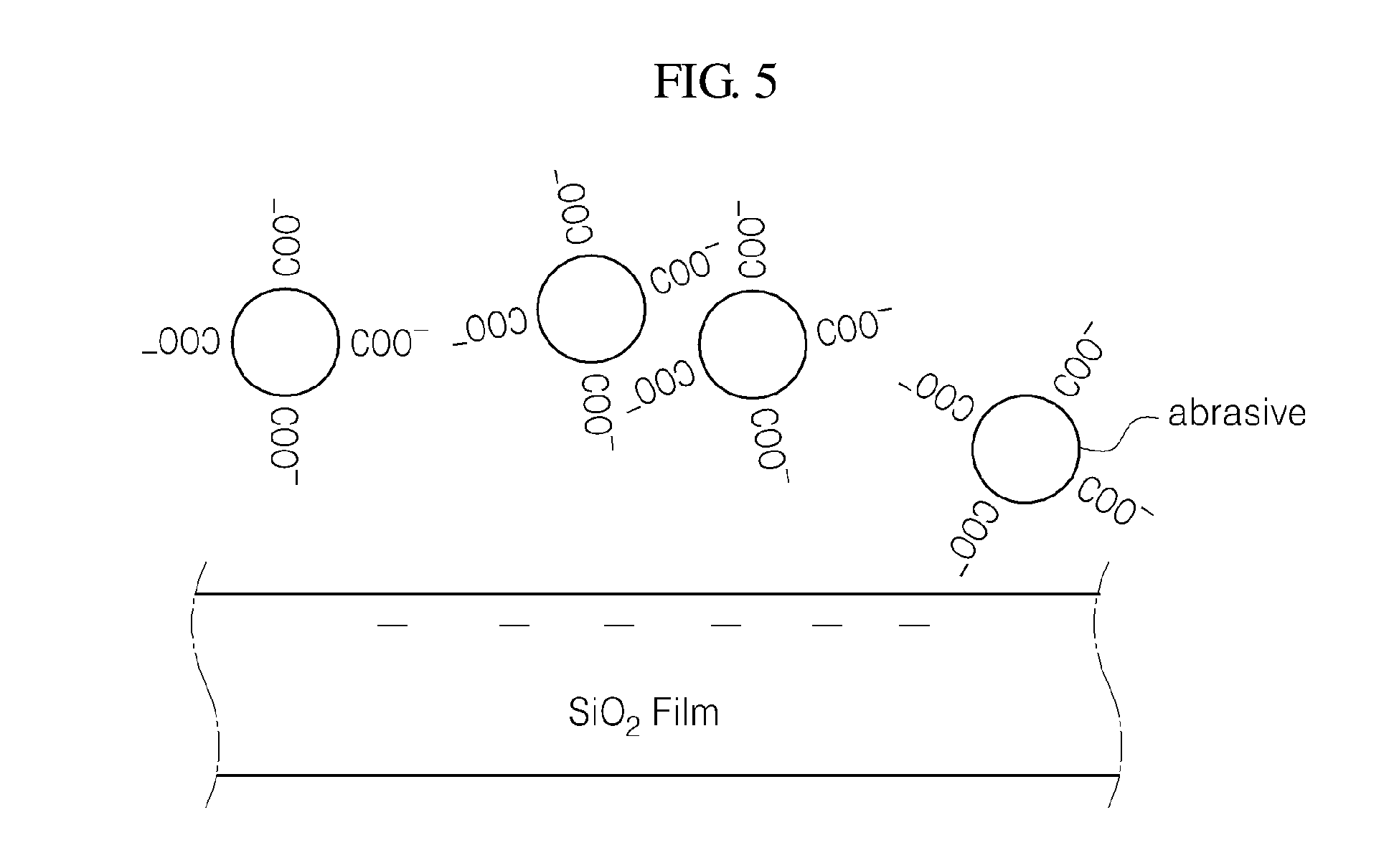

ActiveUS20160251547A1Polishing rate is suppressedPolishing selectivityOther chemical processesSemiconductor/solid-state device manufacturingZeta potentialOrganic acid

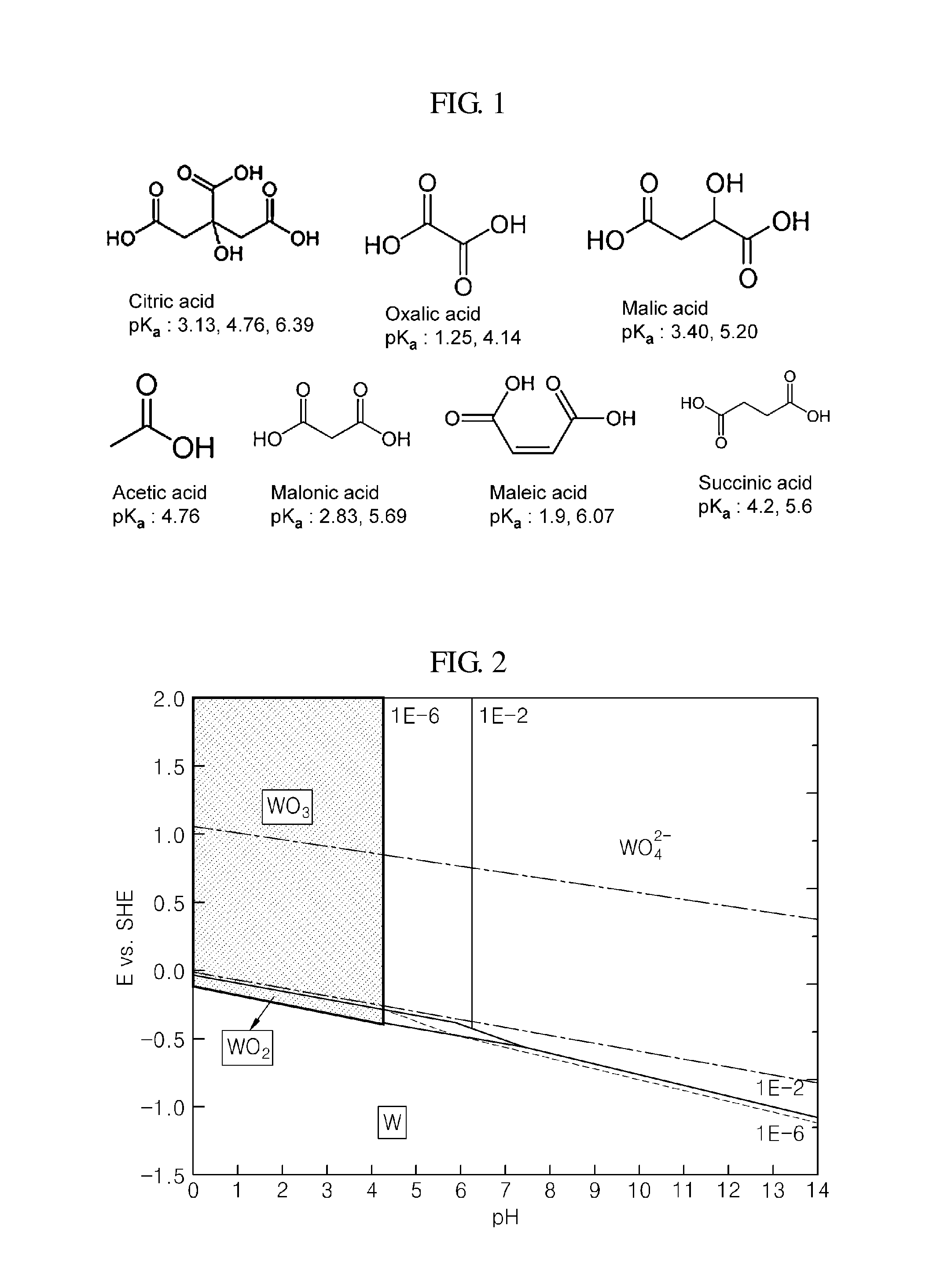

Provided are a slurry for polishing tungsten and a method of polishing a substrate. The slurry according to an exemplary embodiment includes an abrasive configured to perform polishing and include particles having a positive zeta potential, a dispersant configure to disperse the abrasive, an oxidizer configured to oxidize a surface of the tungsten, a catalyst configured to promote oxidation of the tungsten, and a selectivity control agent configured to control a polishing selectivity and include an organic acid containing a carboxyl group. According to the slurry of the exemplary embodiment, a polishing selectivity between the tungsten and the insulation layer may be improved by suppressing a polishing rate of the insulation layer.

Owner:UBMATERIALS

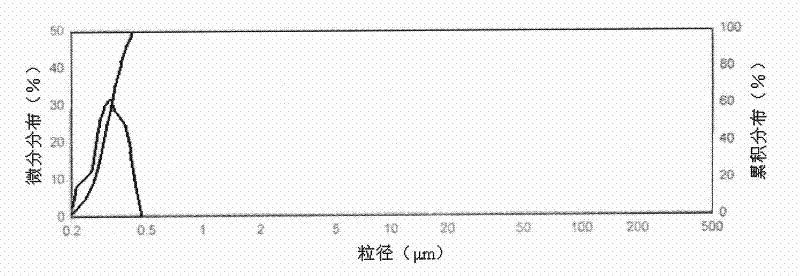

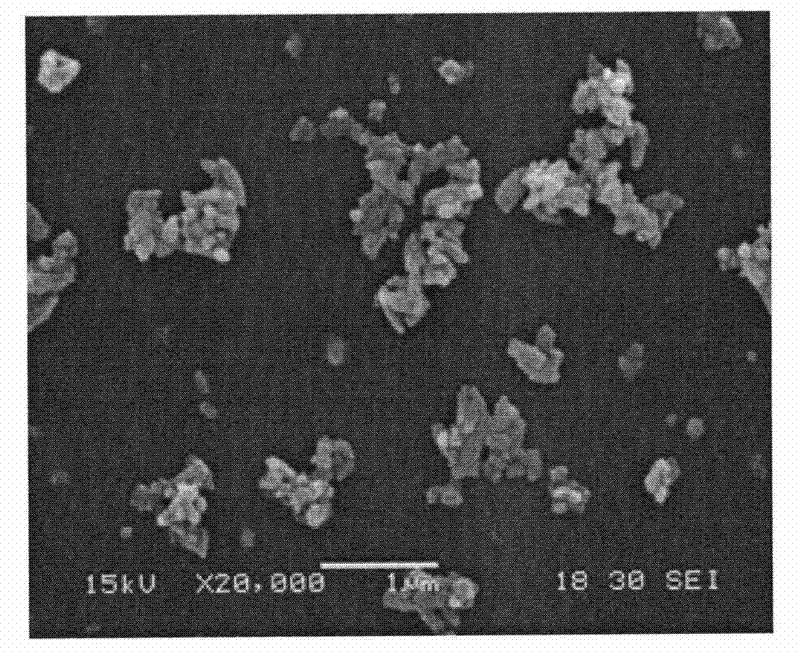

Nano cerium oxide slurry for chemical mechanical polishing and preparation method thereof

ActiveCN101608097BThe median particle size of cerium oxide is smallNarrow particle size distributionPolishing compositions with abrasivesPhysical chemistryCerium

The invention discloses a nano-cerium oxide slurry for chemical mechanical polishing and a preparation method thereof. The nano-cerium oxide slurry contains the following components in parts by weight: 10-25 parts of an acidic pH regulator, 0.1-0.8 parts of a dispersant, Nano cerium oxide powder 74.2-89.8 parts. Compared with the prior art, the nano-cerium oxide polishing solution provided by the present invention has the advantages of small cerium oxide median particle size, narrow particle size distribution range, high wear resistance, high polishing selectivity, and high product precision.

Owner:上海华明高纳稀土新材料有限公司 +1

Chemical Mechanical Polishing Slurry Composition for Polishing Phase-Change Memory Device and Method for Polishing Phase-Change Memory Device Using the Same

InactiveUS20090001340A1High polishing selectivityMinimize occurrenceOther chemical processesSemiconductor/solid-state device manufacturingEtching rateCompound (substance)

A slurry composition for chemical mechanical polishing (CMP) of a phase-change memory device is provided. The slurry composition comprises deionized water and iron or an iron compound. The slurry composition can achieve high polishing rate on a phase-change memory device and improved polishing selectivity between a phase-change memory material and a polish stop layer (e.g., a silicon oxide film), can minimize the occurrence of processing imperfections (e.g., dishing and erosion), and can lower the etch rate on a phase-change memory material to provide a high-quality polished surface. Further provided is a method for polishing a phase-change memory device using the slurry composition.

Owner:CHEIL IND INC

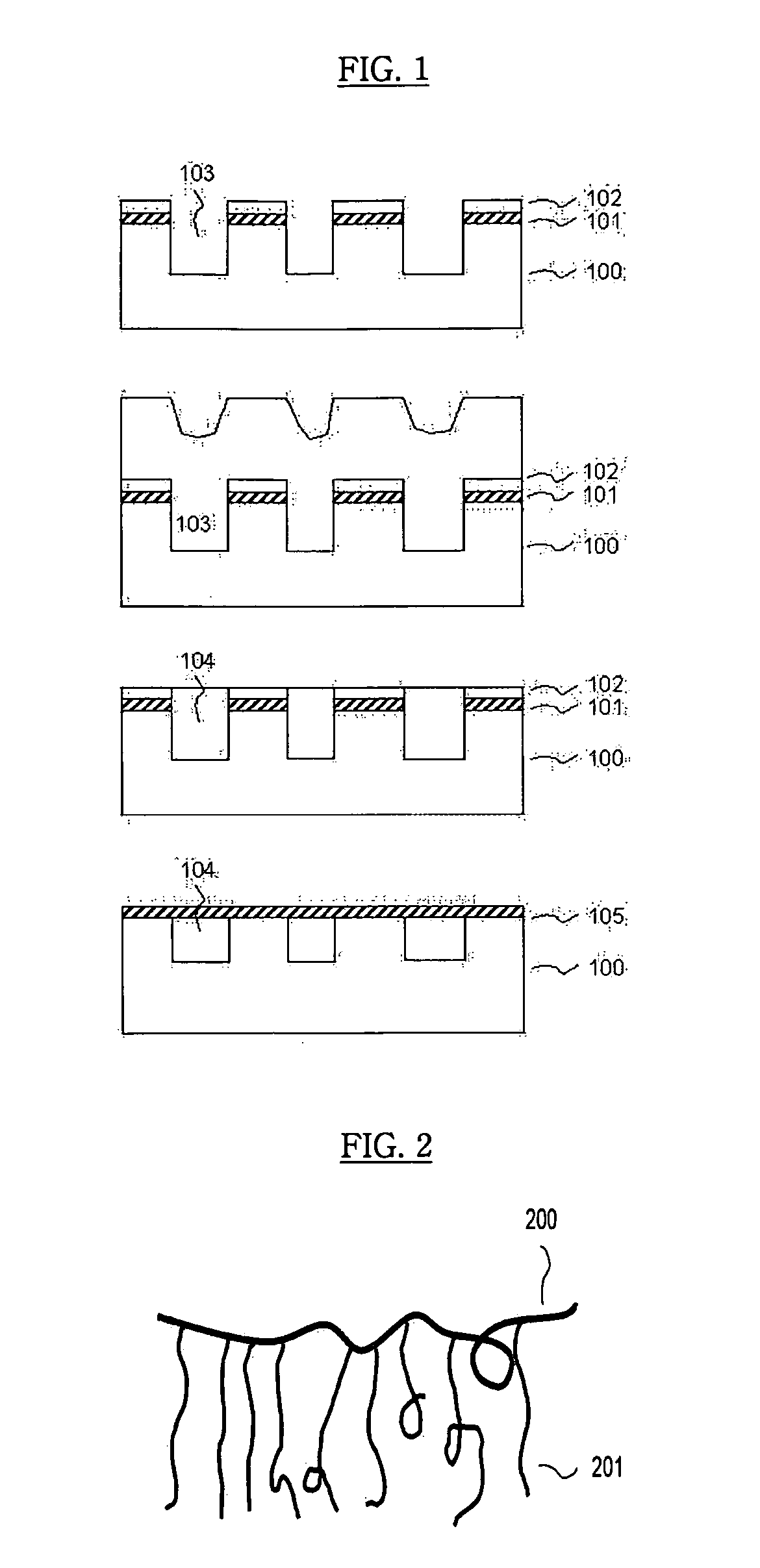

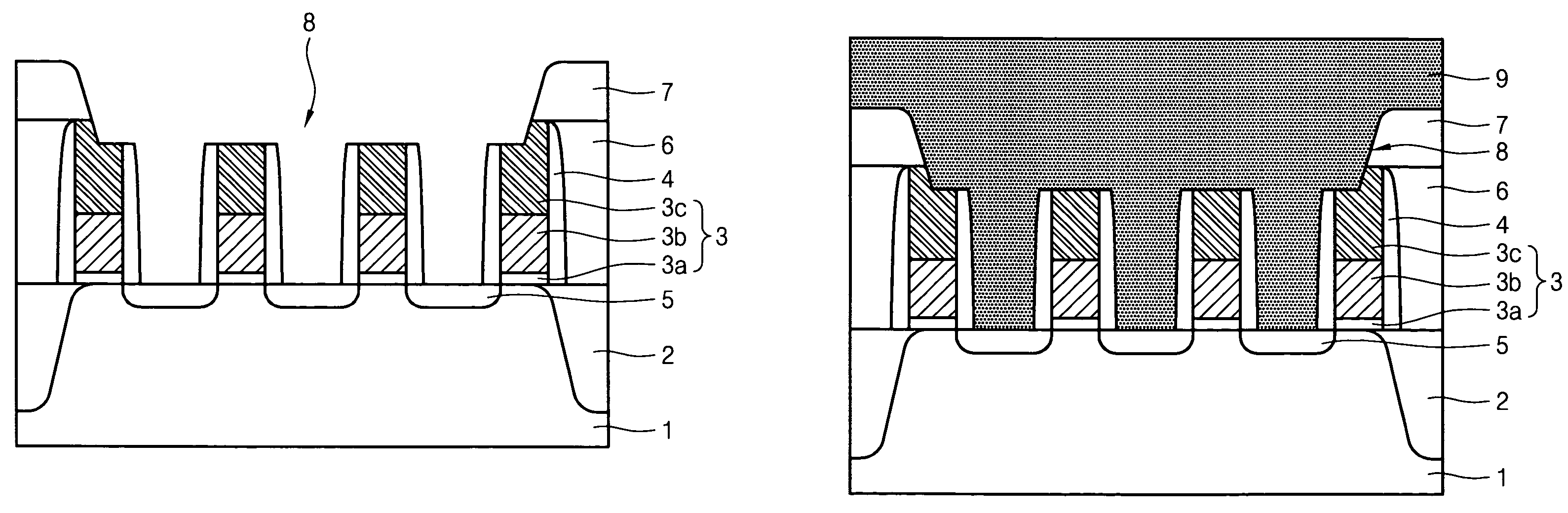

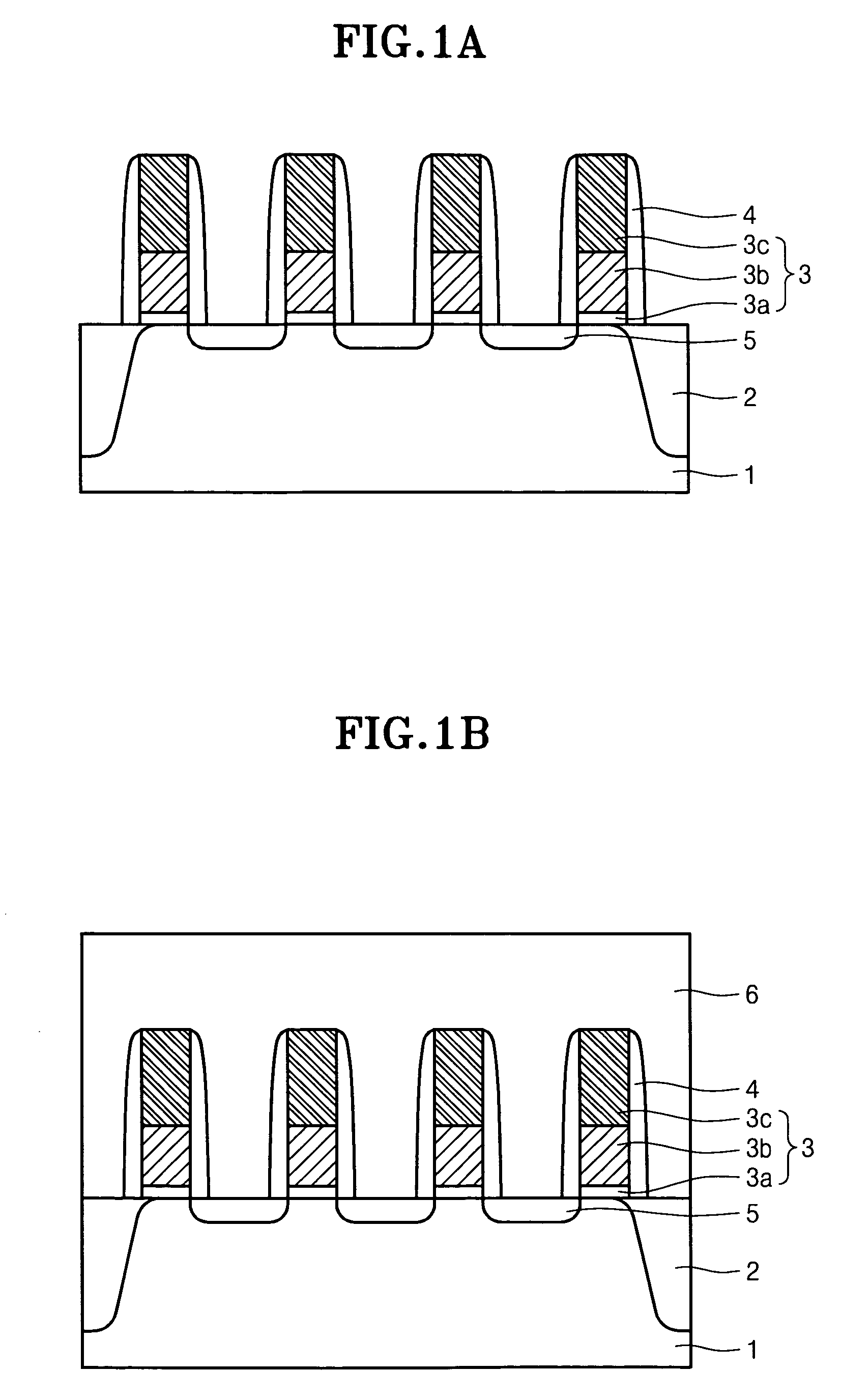

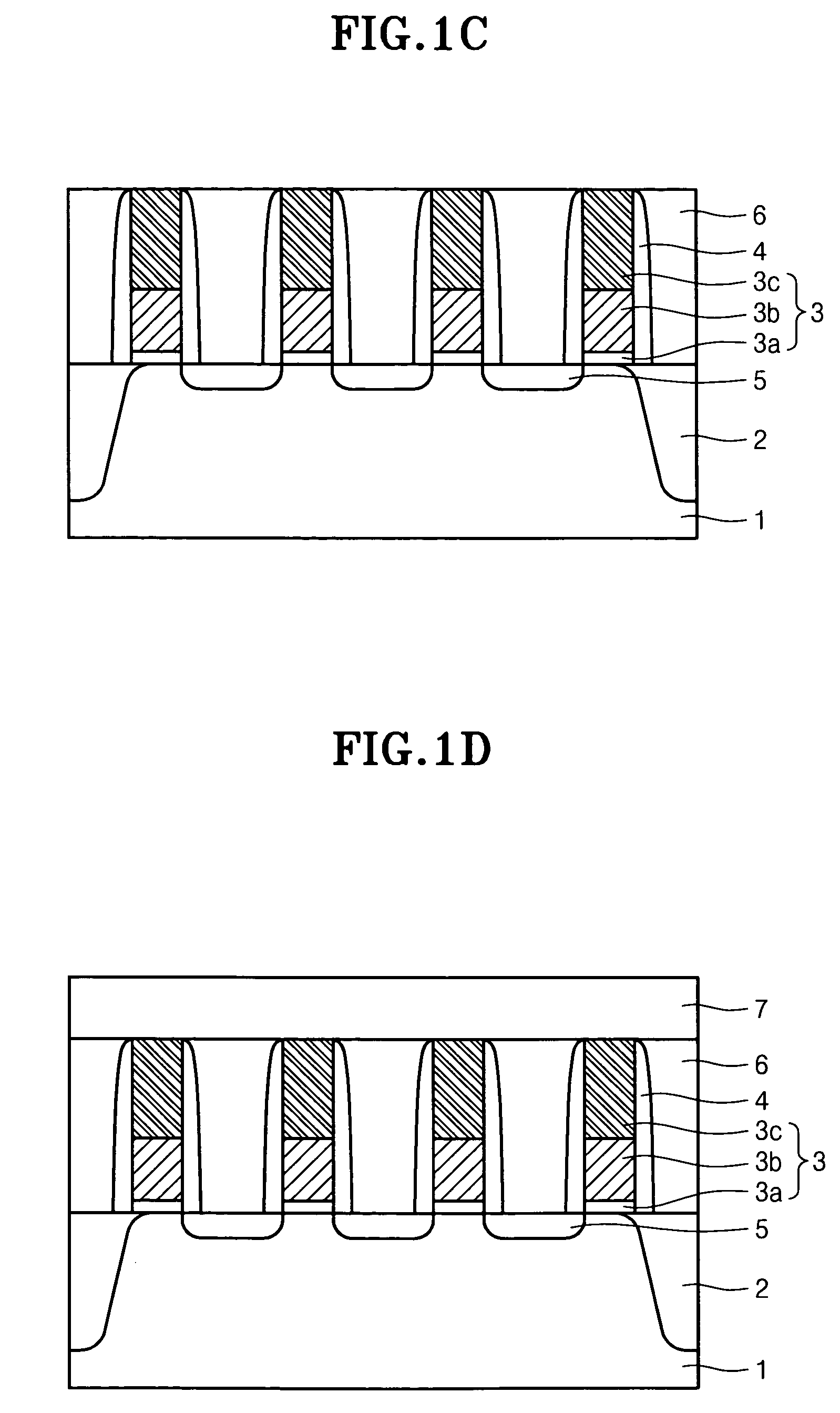

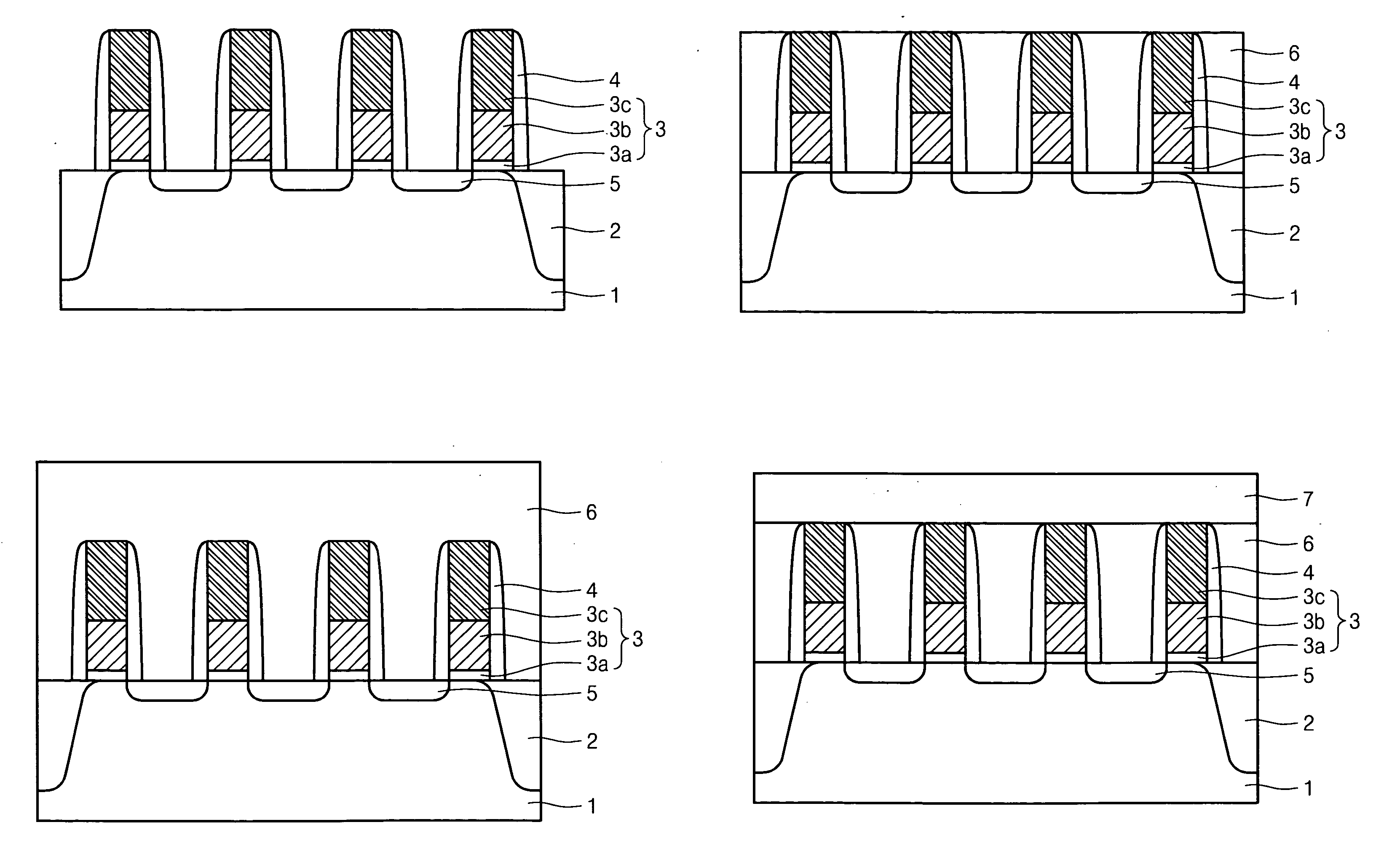

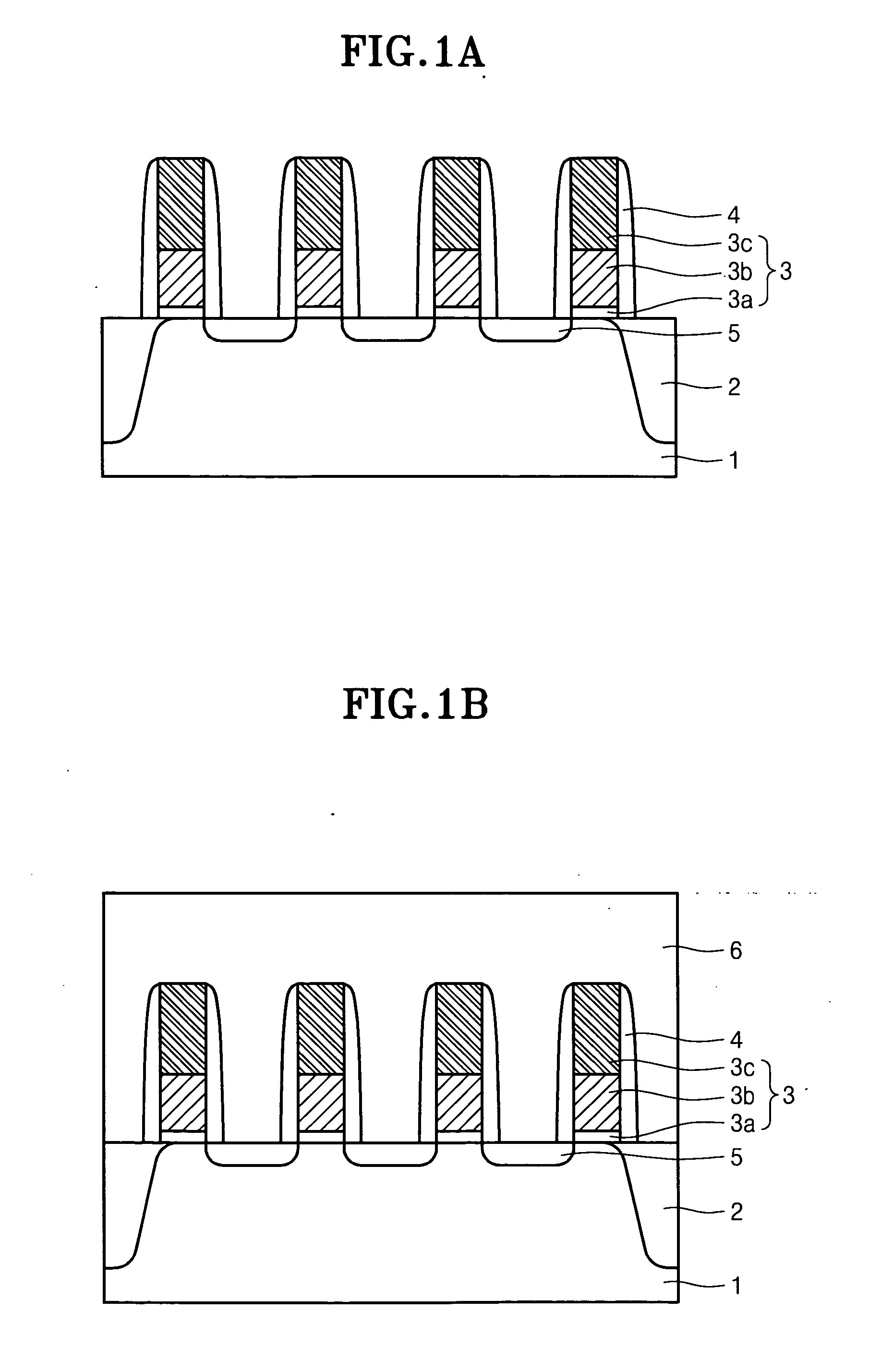

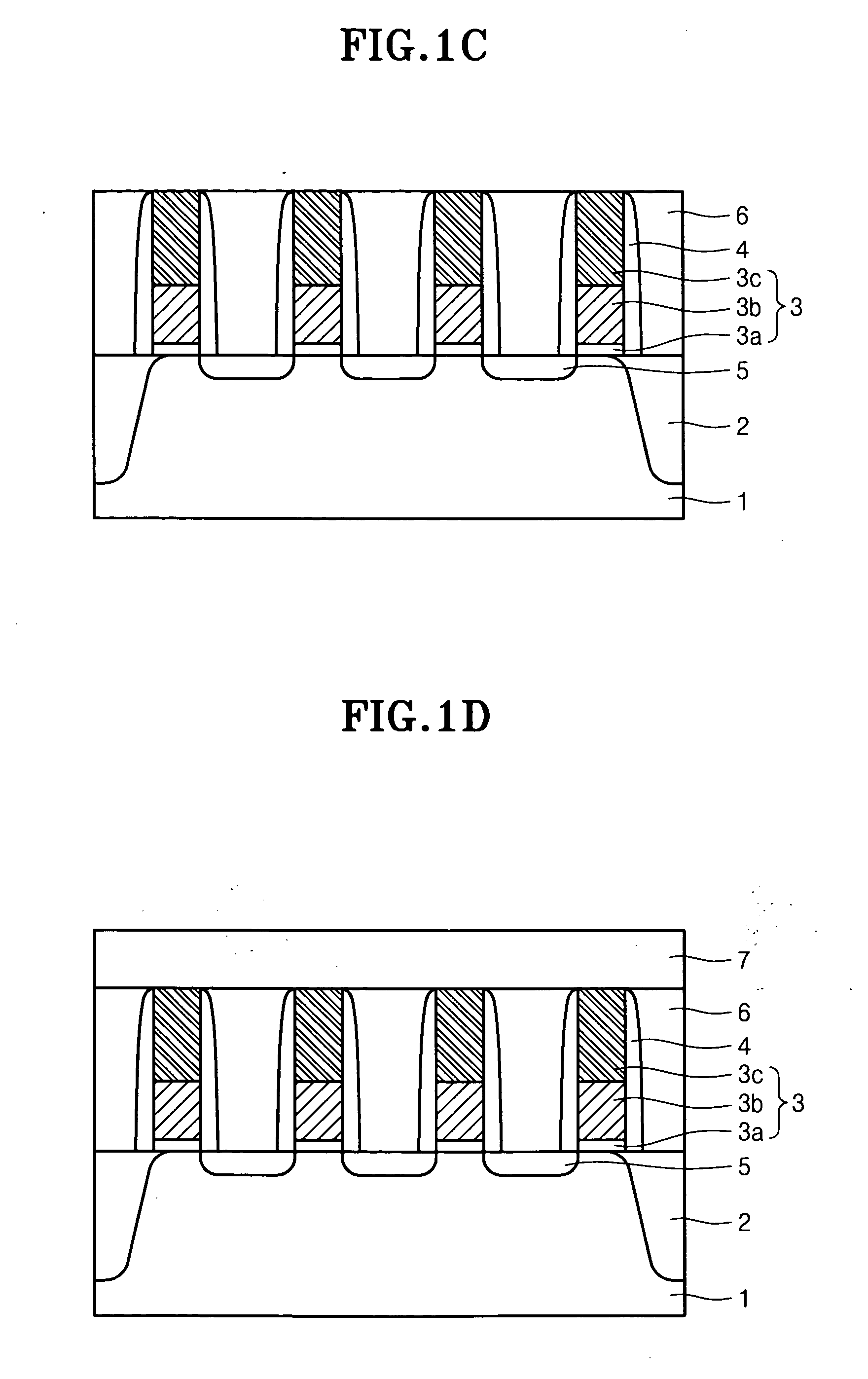

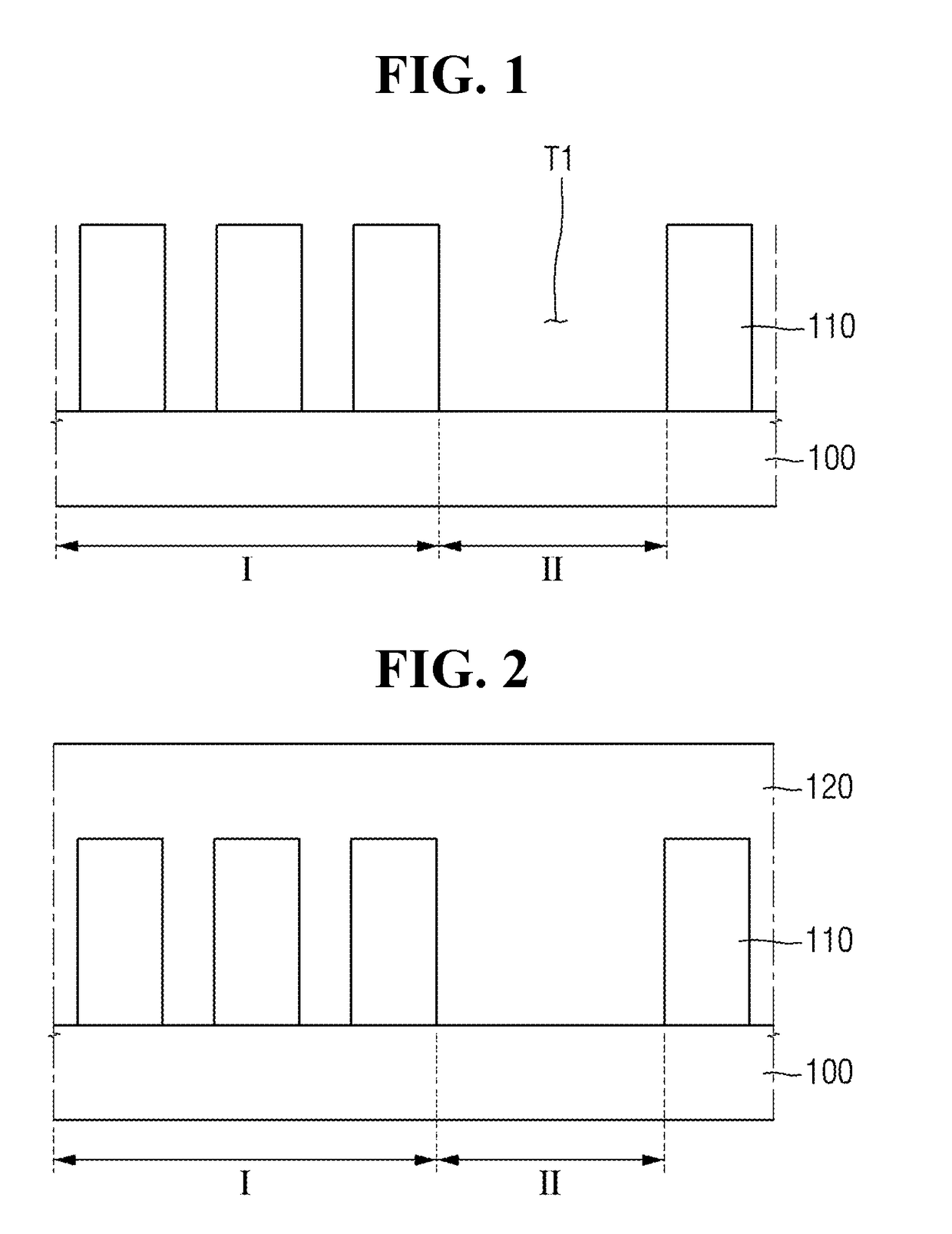

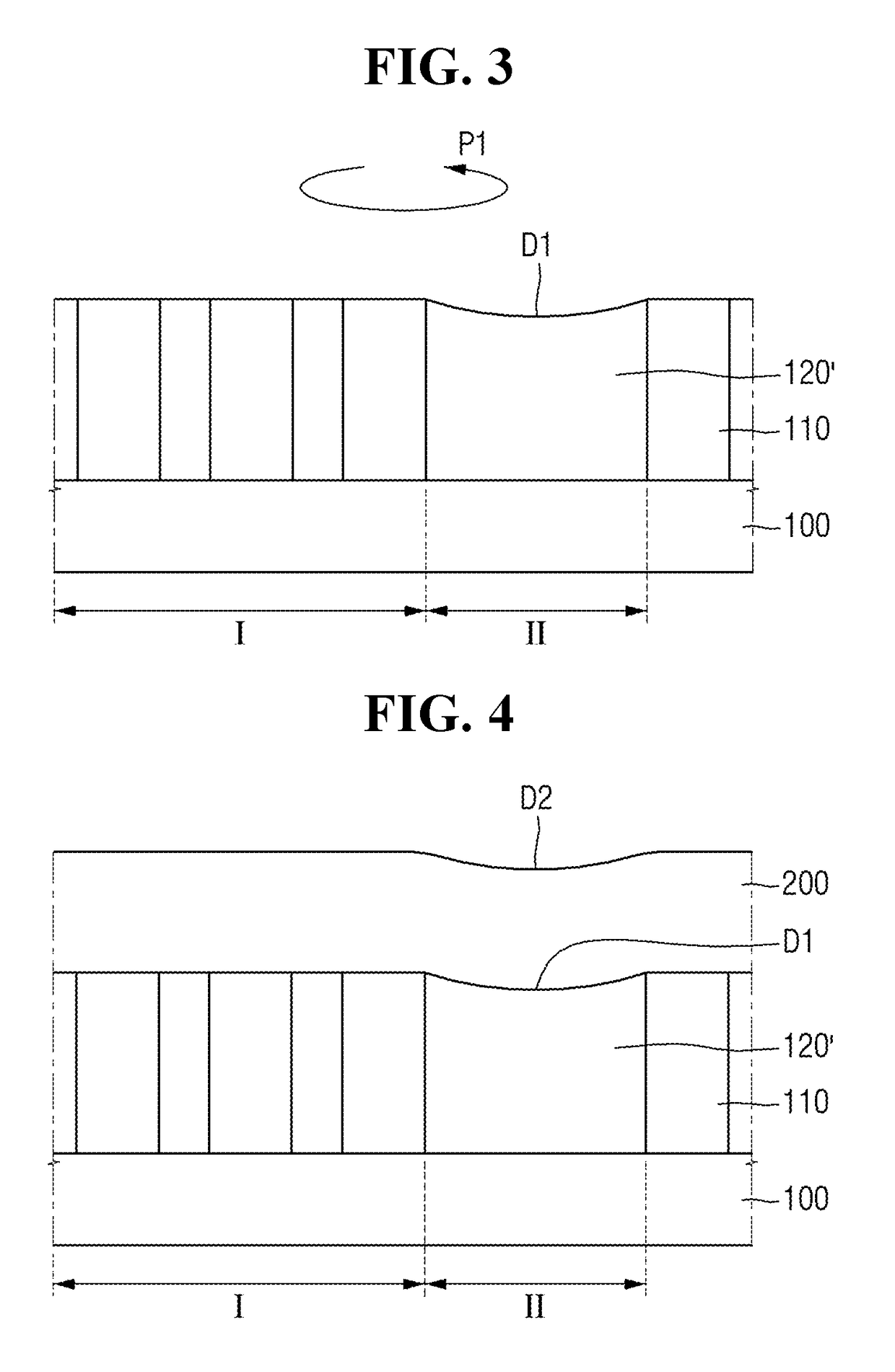

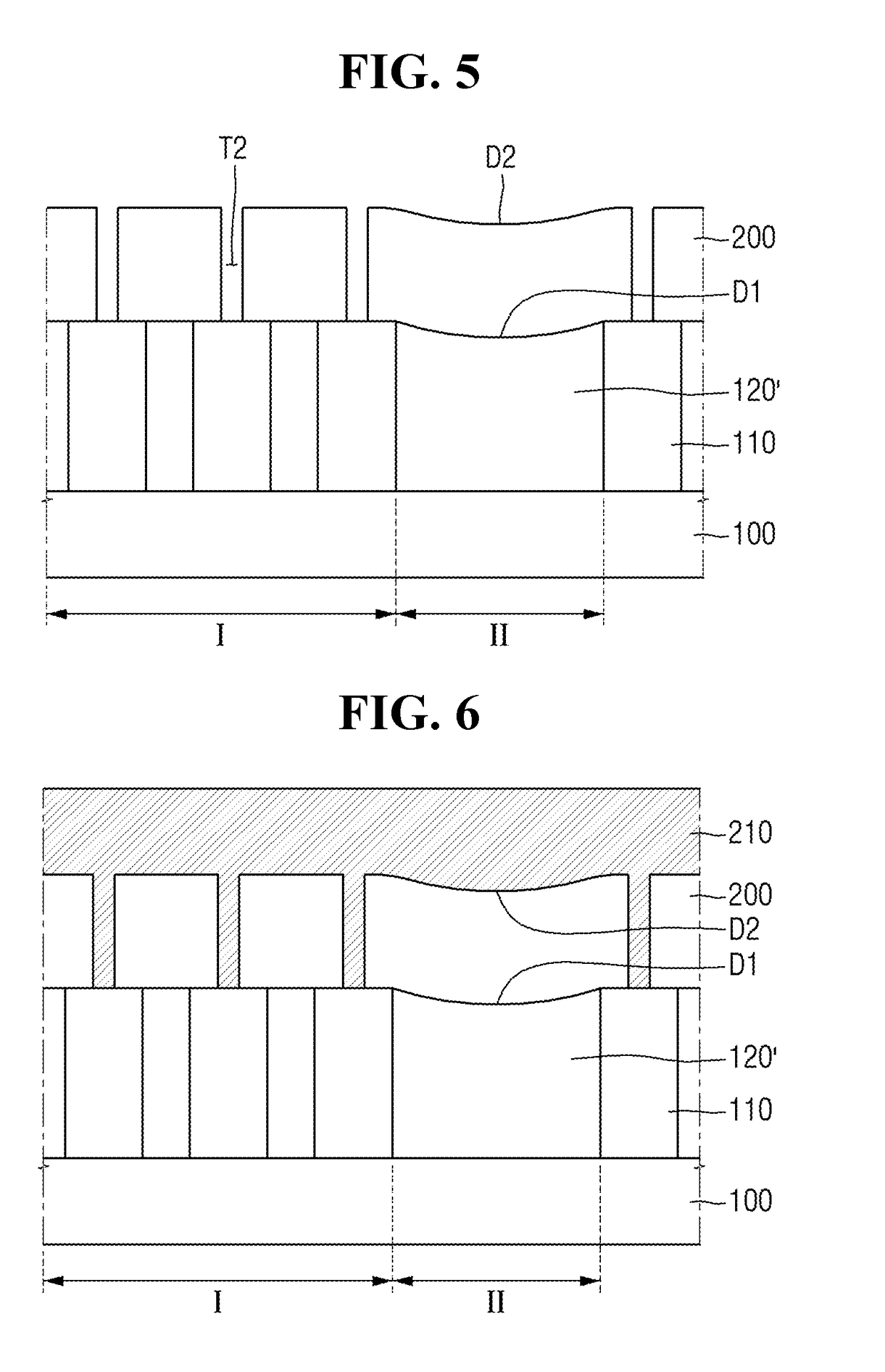

Method of manufacturing semiconductor device

InactiveUS7045450B2Avoid failureAvoid yield lossSolid-state devicesSemiconductor/solid-state device manufacturingCell regionSlurry

Owner:SK HYNIX INC

Method of manufacturing semiconductor device

InactiveUS20050095834A1Avoid failureAvoid yield lossSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialCell region

Disclosed is a method of manufacturing a semiconductor device. The method includes the steps of forming gates on a substrate, forming junction areas on a surface of the substrate, forming a first BPSG layer on a resultant structure of the substrate, performing a first CVD process for the first BPSG layer, forming a second BPSG layer on the first BPSG layer, forming a landing plug contact, depositing a polysilicon layer on a resultant structure of the substrate, and performing a second CMP process for the polysilicon layer, the second BPSG layer and the nitride hard mask. The CMP processes are carried by using acid slurry having a high polishing selectivity with respect to the nitride layer, so a step difference between the cell region and the peripheral region is removed, thereby simplifying the semiconductor manufacturing process and removing a dishing phenomenon.

Owner:SK HYNIX INC

Adjuvant for CMP slurry

ActiveUS8062395B2Prevent materialImprove polishing selectivityPigmenting treatmentOther chemical processesAdjuvantSlurry

Disclosed is an adjuvant in use for a process of polishing a cationically charged material and an anionically charged material at the same time with abrasive particles, which is absorbed onto the cationically charged material thereby to restrain the cationically charged material from being polished, resulting in raising a polishing selectivity of the anionically charged material, wherein the adjuvant comprises polymer particles having a core-shell structure with a nano-scale particle size smaller than that of the abrasive particles, surfaces of which are anionically charged. CMP (chemical mechanical polishing) slurry comprising the above adjuvant and abrasive particles is also disclosed.

Owner:LG CHEM LTD

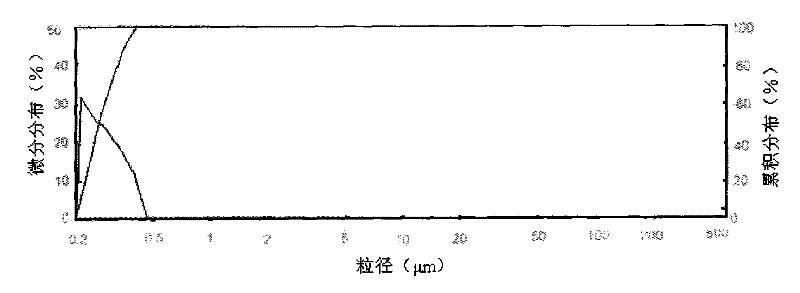

Cerium oxide powder, method for preparing the same, and CMP slurry comprising the same

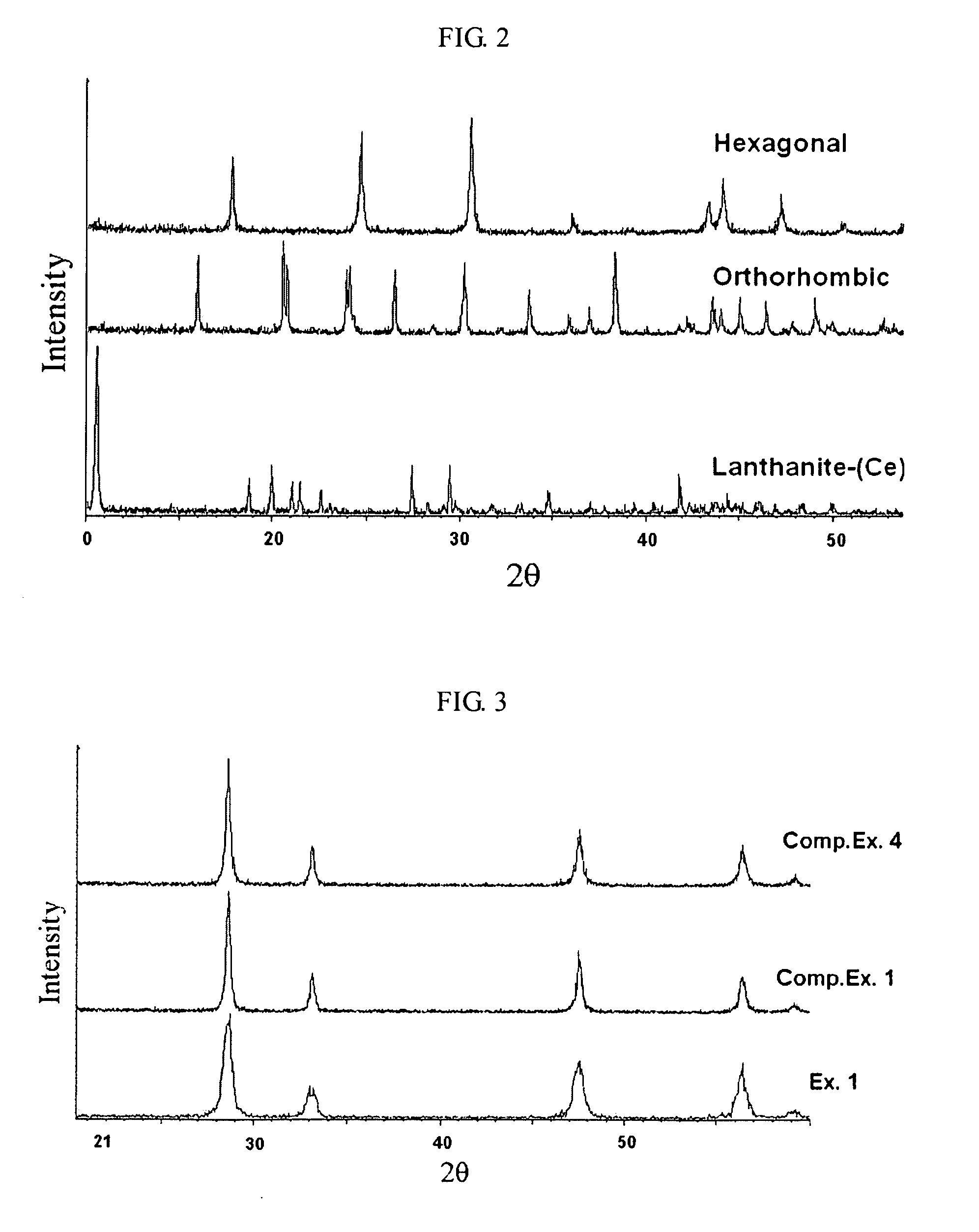

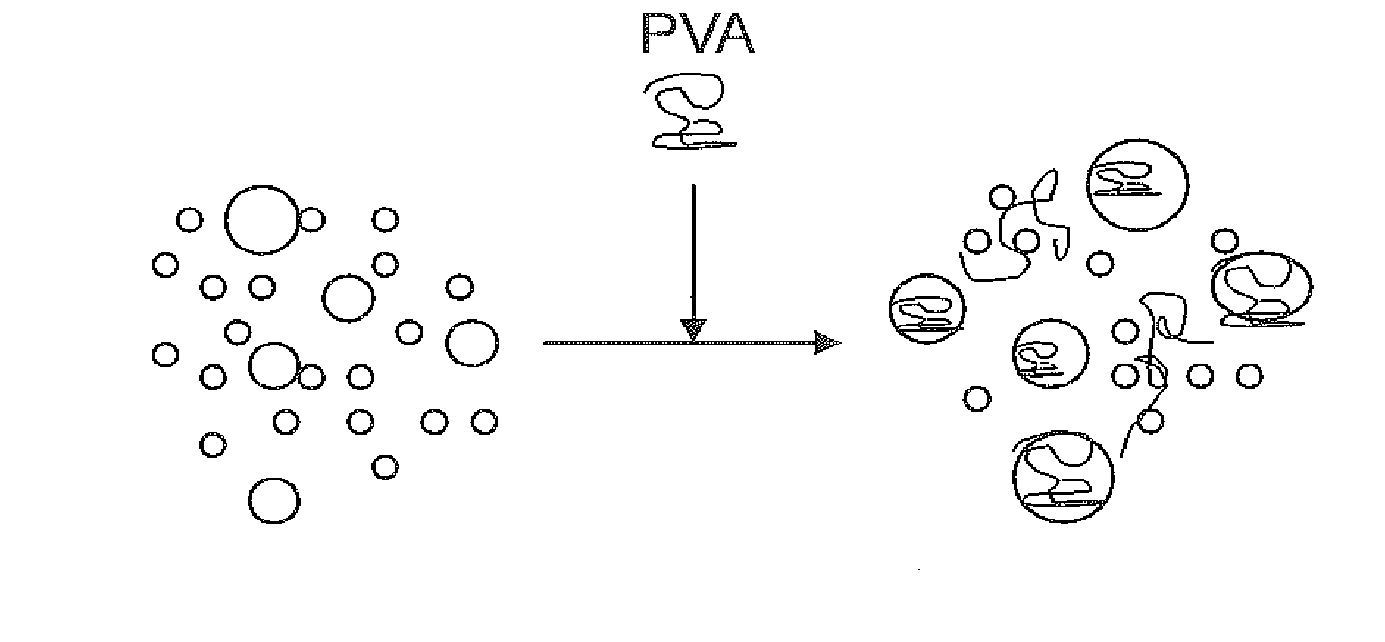

ActiveUS20080236050A1Improve polishing selectivityWide pore size distributionMaterial nanotechnologyPigmenting treatmentCeriumCrystal structure

Disclosed is cerium oxide powder for a CMP abrasive, which can improve polishing selectivity of a silicon oxide layer to a silicon nitride layer and / or within-wafer non-uniformity (WIWNU) during chemical mechanical polishing in a semiconductor fabricating process. More particularly, the cerium oxide powder is obtained by using cerium carbonate having a hexagonal crystal structure as a precursor. Also, CMP slurry comprising the cerium oxide powder as an abrasive, and a shallow trench isolation method for a semiconductor device using the CMP slurry as polishing slurry are disclosed.

Owner:LG CHEM LTD

Abrasive, abrasive set, and method for abrading substrate

ActiveUS20160040041A1Improve polishing rateImprove polishing selectivityOther chemical processesSemiconductor/solid-state device manufacturingMetalHydroxide

Owner:RESONAC CORP

Chemical mechanical polishing slurry composition and method of fabricating semiconductor device using the same

InactiveUS20180362806A1Improve polishing selectivityImproving dishingOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidCompound (substance)

Provided are a chemical mechanical polishing (CMP) slurry composition and a method of fabricating a semiconductor device using the same. The chemical mechanical polishing (CMP) slurry composition includes abrasive particles, a first cationic compound which comprises at least any one of an amino acid, a polyalkylene glycol, a polymer polysaccharide to which a glucosamine compound is bonded, and a polymer containing an amine group, a second cationic compound which comprises an organic acid, and a nonionic compound which comprises polyetheramine.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Application of chemical mechanical polishing slurry

InactiveCN103074632AStain and other residue reductionHigh polishing selectivityPollutantCompound (substance)

The invention discloses an application of a chemical mechanical polishing slurry in copper polishing. The chemical mechanical polishing slurry comprises grinding particles, an organic phosphonic acid, polyacrylic acid and / or its copolymer, an oxidant and a carrier. The chemical mechanical polishing slurry has the advantages of prevention of the partial and whole corrosion of a metal material, reduction of the pollutants on the surface of a liner, reduction of the content of the grinding particles, improvement of the copper removal rate and reduction of the tantalum removal rate, so the polishing selectivity of different substrates can be obtained.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

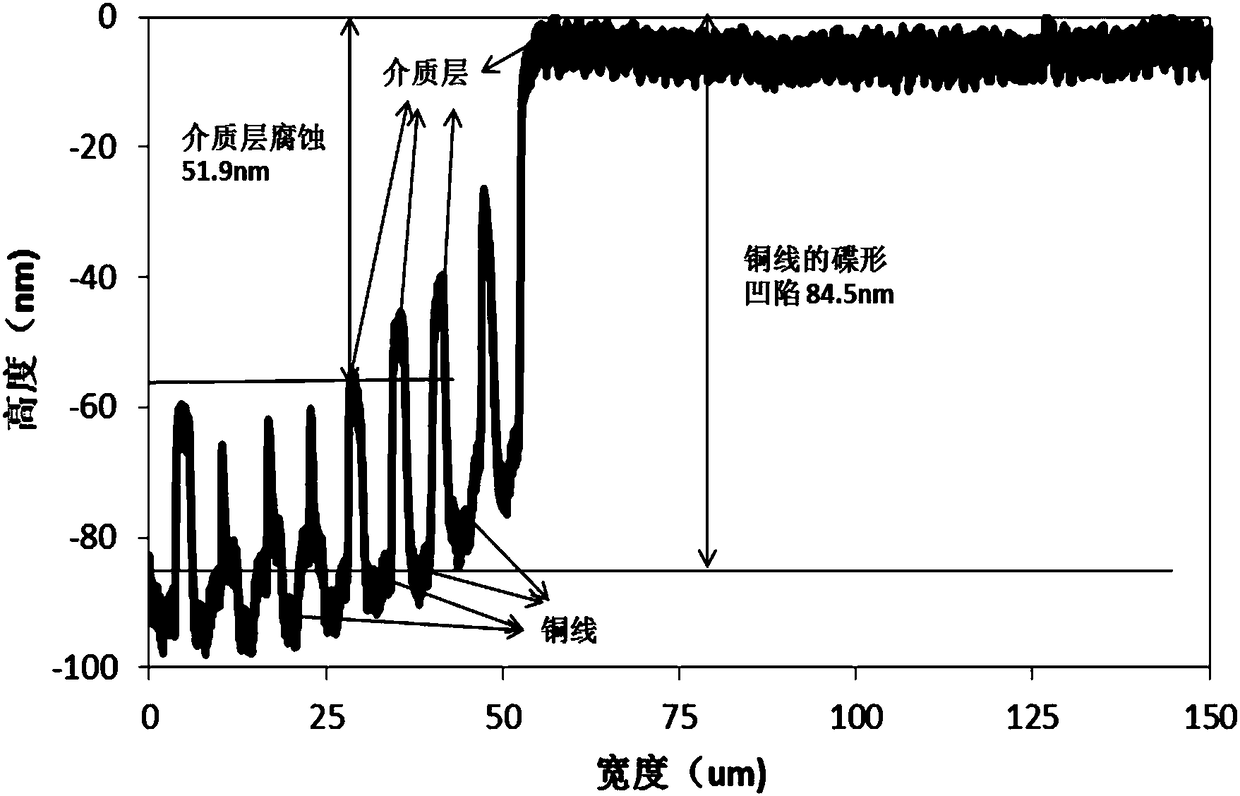

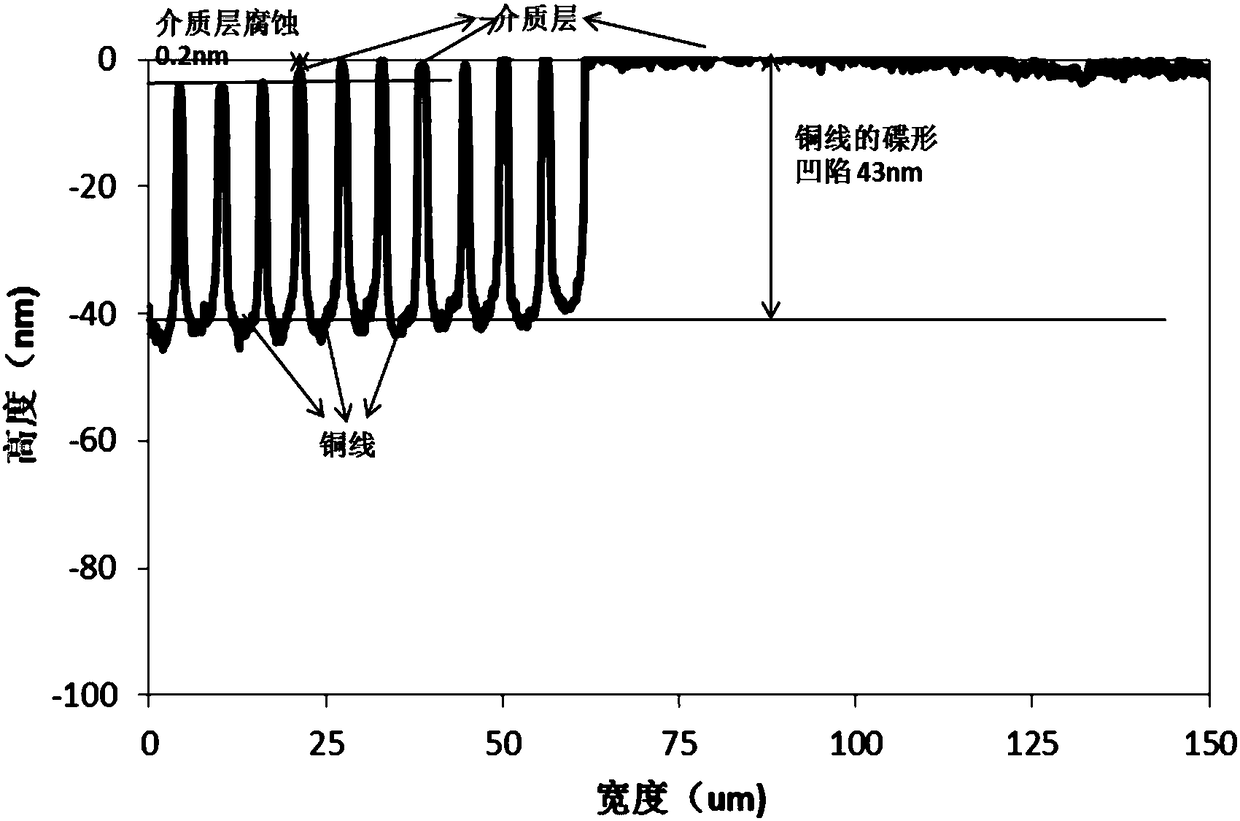

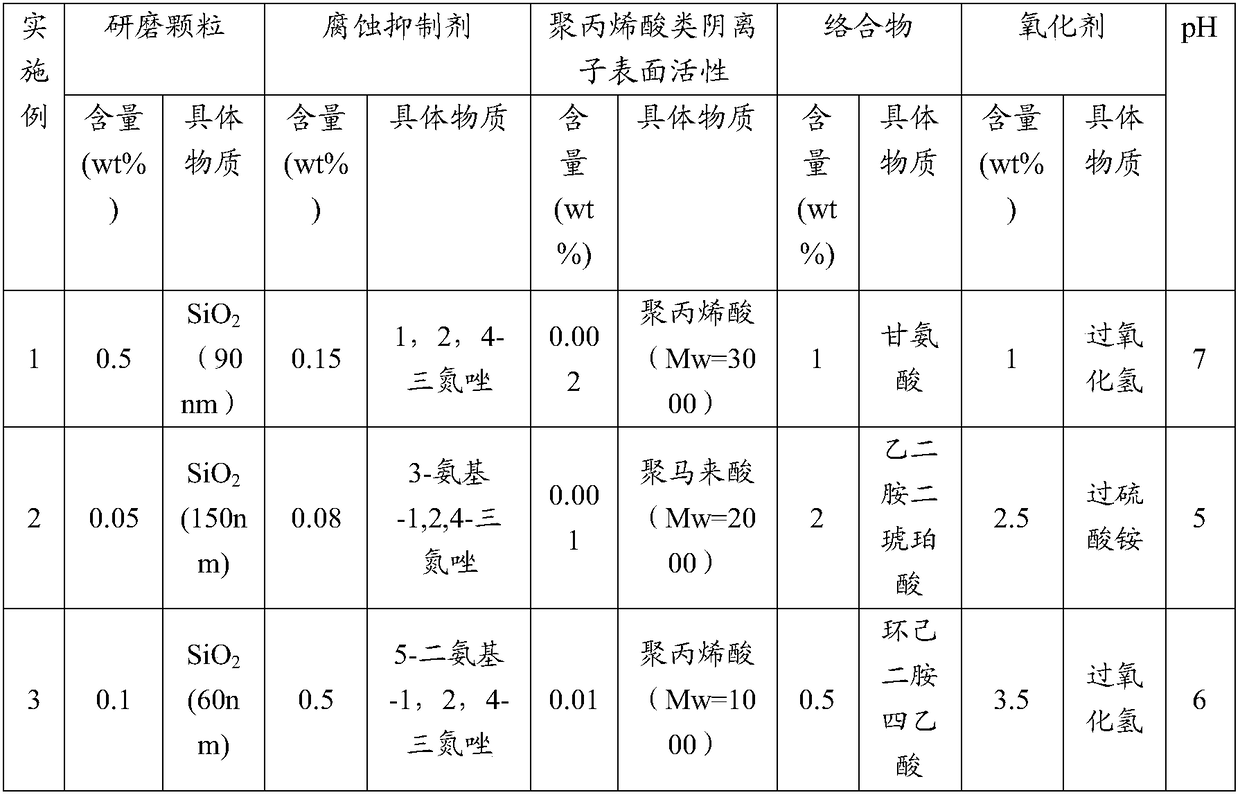

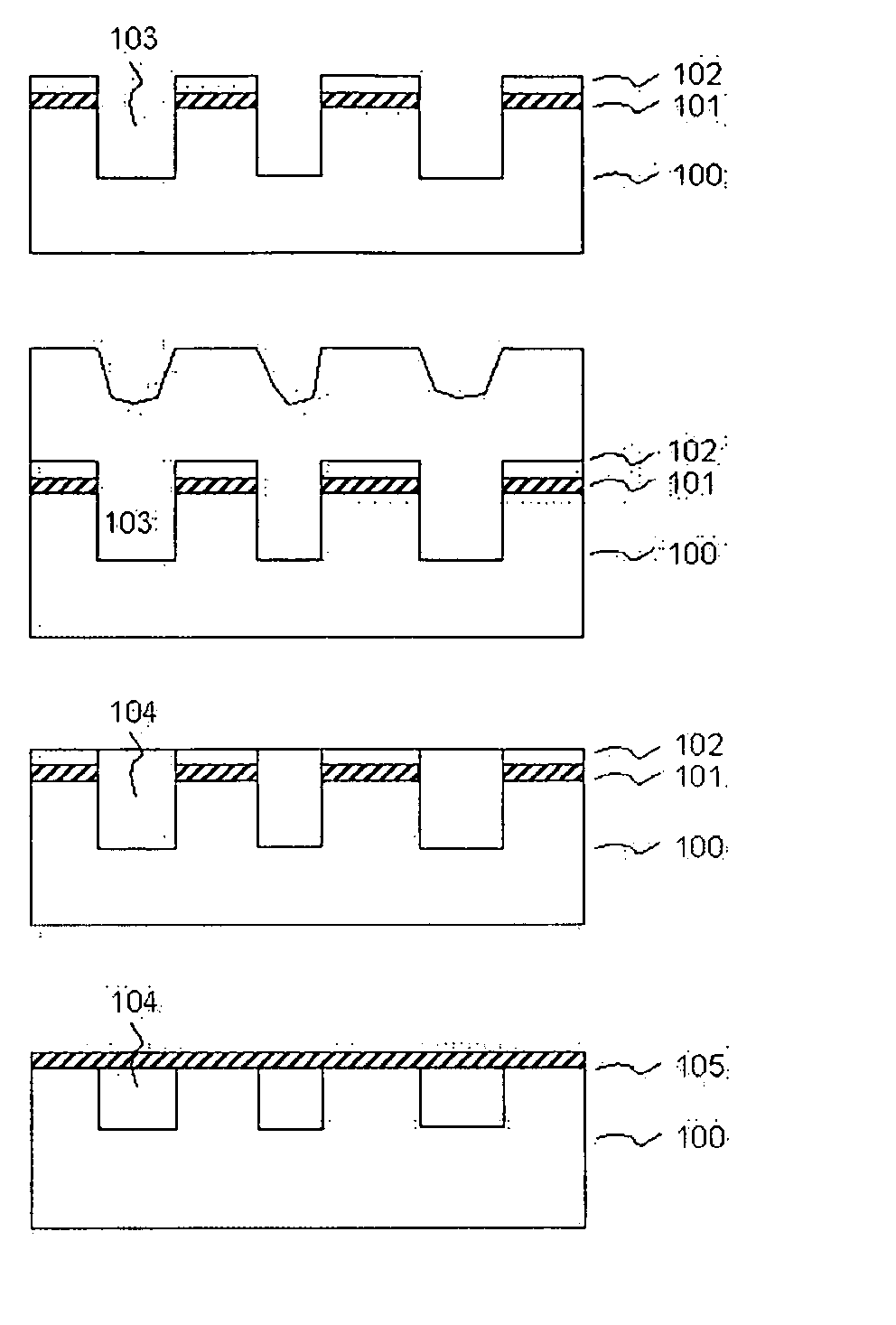

Chemical mechanical polishing solution and application thereof

The invention provides a chemical mechanical polishing solution. The chemical mechanical polishing solution comprises grinding particles, a corrosion inhibitor, a complexing agent, an oxidizing agentand at least one polyacrylic acid anionic surfactant. The invention further provides application of the polishing solution in metal copper polishing. According to the chemical mechanical polishing solution and the application thereof, the effect of improving the polishing selection ratio of the polishing solution to the copper and tantalum barrier layer is achieved; and when the polishing solutionis used for polishing a wafer, dishing and dielectric layer erosion of the copper wire after polishing can be relieved, and the defects of copper residue, corrosion and the like after polishing are overcome.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Adjuvant for controlling polishing selectivity and chemical mechanical polishing slurry comprising the same

ActiveUS20070132058A1Increase polish selectivityImprove polishing selectivityOther chemical processesDecorative surface effectsIonSide chain

Disclosed is an adjuvant for use in simultaneous polishing of a cationically charged material and an anionically charged material, which forms an adsorption layer on the cationically charged material in order to increase polishing selectivity of the anionically charged material, wherein the adjuvant comprises a polyelectrolyte salt containing: (a) a mixture of a linear polyelectrolyte having a weight average molecular weight of 2,000˜50,000 with a graft type polyelectrolyte that has a weight average molecular weight of 1,000˜20,000 and comprises a backbone and a side chain; and (b) a basic material. CMP (chemical mechanical polishing) slurry comprising the above adjuvant and abrasive particles is also disclosed. The adjuvant comprising a mixture of a linear polyelectrolyte with a graft type polyelectrolyte makes it possible to increase polishing selectivity as compared to CMP slurry using the linear polyelectrolyte alone, and to obtain a desired range of polishing selectivity by controlling the ratio of the linear polyelectrolyte to the graft type polyelectrolyte.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com