An aqueous slurry composition for chemical mechanical polishing and chemical mechanical polishing method

A chemical-mechanical and water-slurry technology, which is applied in the direction of polishing compositions containing abrasives, chemical instruments and methods, and other chemical processes, can solve the problem that the slurry composition cannot meet the polishing selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

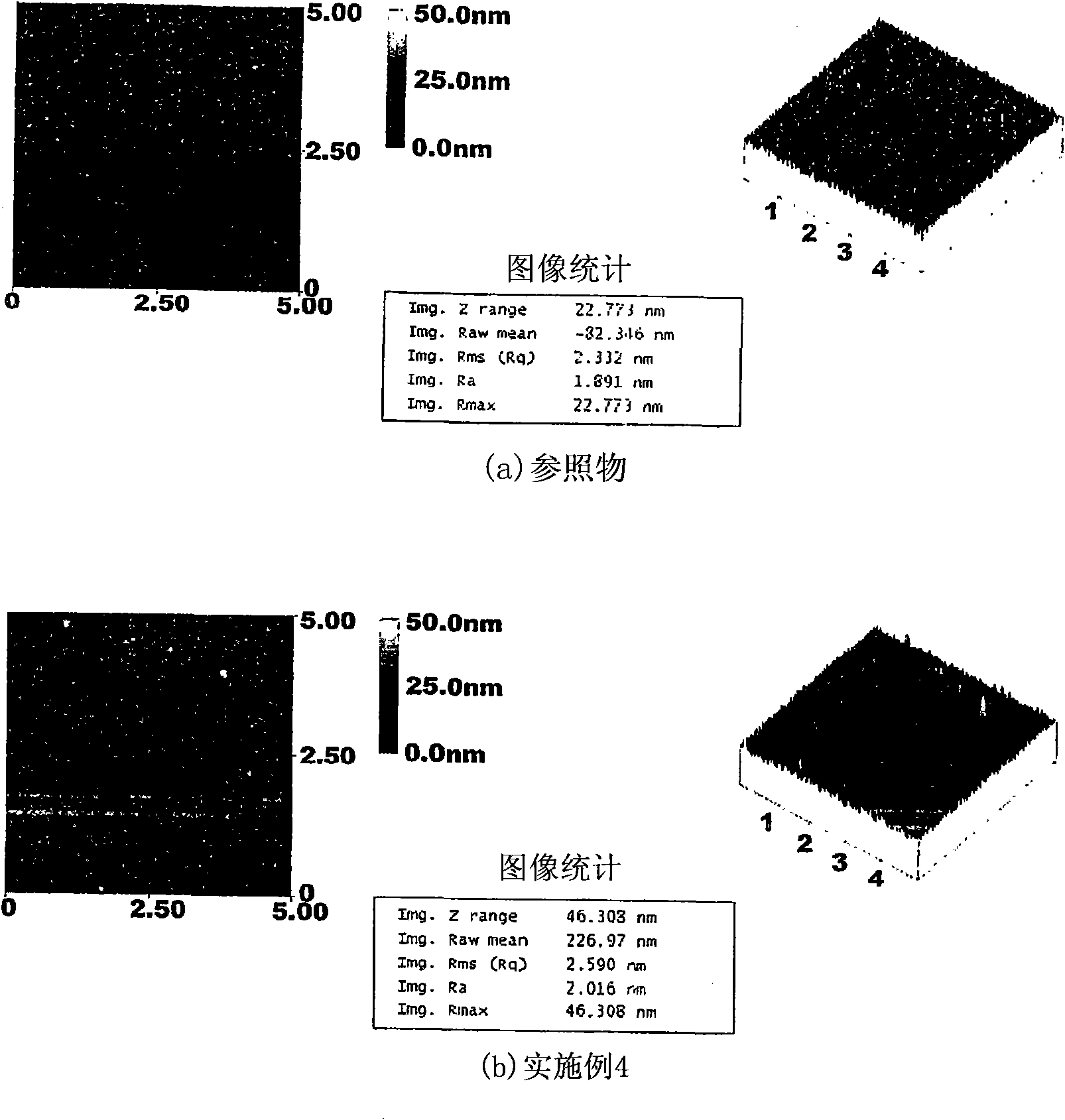

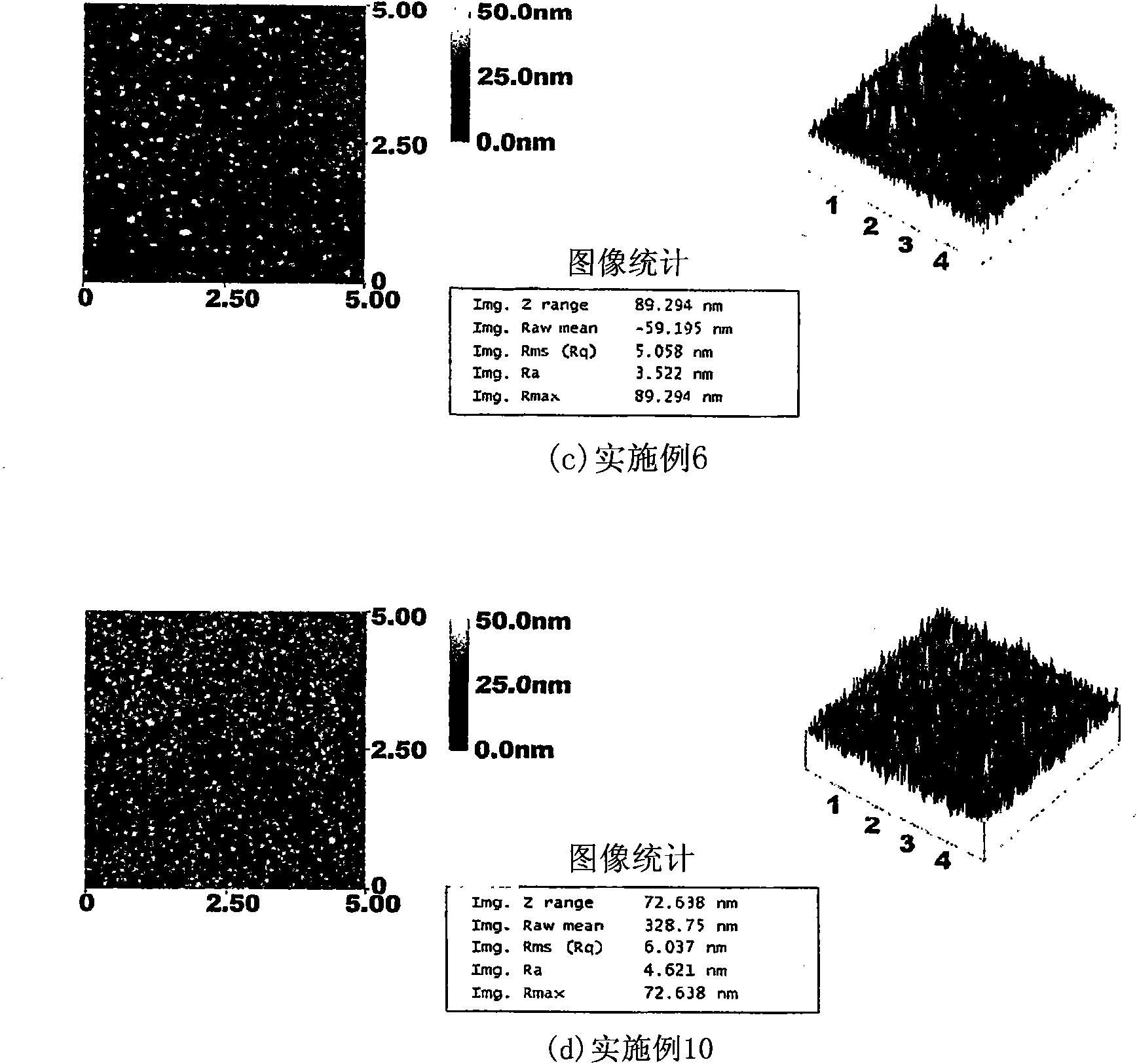

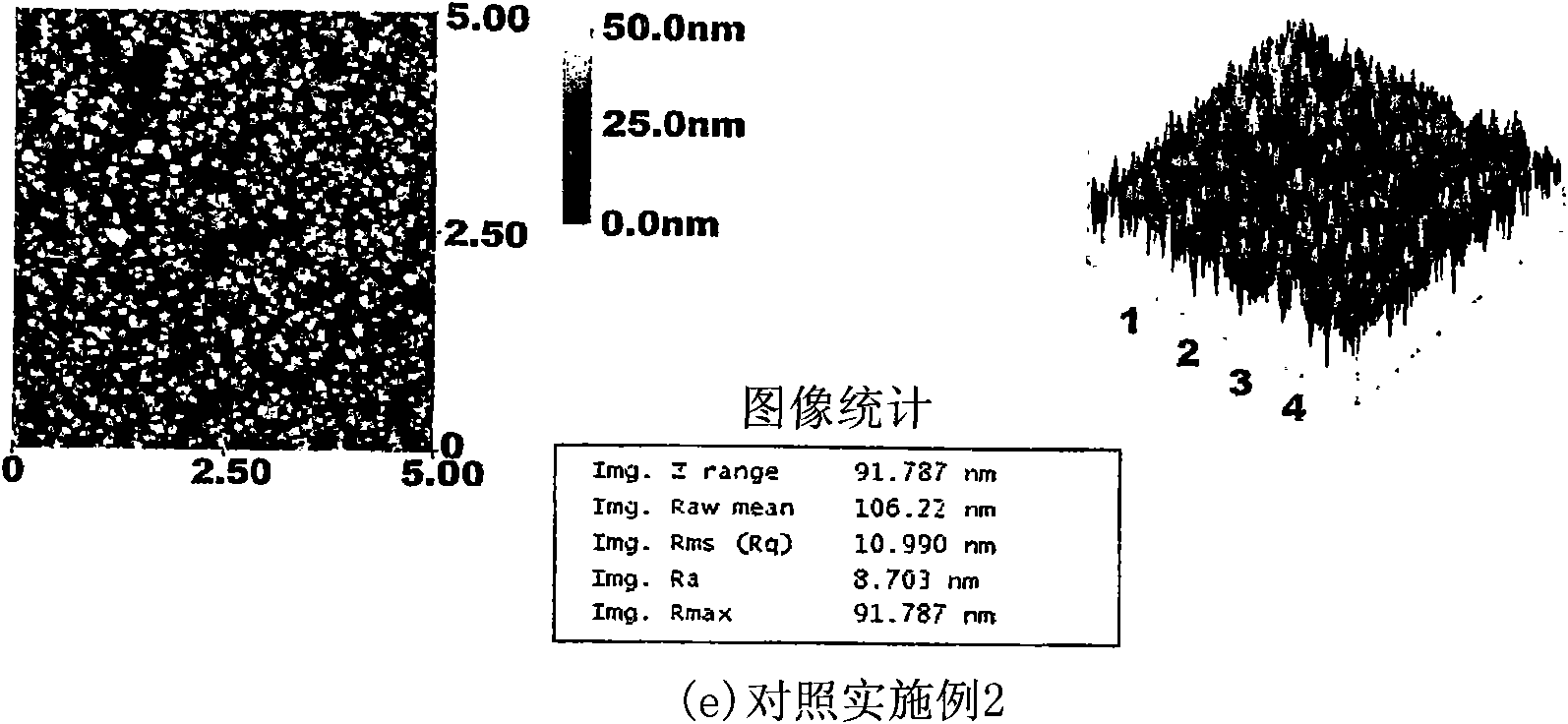

Image

Examples

Embodiment 1-23

[0082] Examples 1-23: Preparation of aqueous slurry composition for CMP

[0083] First, the following materials were used as components for preparing an aqueous slurry composition for CMP.

[0084] As the silica abrasive, PL-1 or PL-3L among colloidal silica of Quartron PL series by FUSO CHEMICAL Co. was used.

[0085] Use P-65 (a kind of copolymer of BASF Co., Mw=3500), L-64 (a kind of copolymer of BASFCo., Mw=3880), Random (a kind of random copolymer of Aldrich Co., Mw =2500) or a propylene oxide-ethylene oxide copolymer having the molecular weight and ethylene oxide repeating unit content disclosed in Table 1 below as a propylene oxide-ethylene oxide copolymer polymerization additive.

[0086] Use BRIJ-58 (a surfactant of Aldrich Co., with polyethylene glycol stearyl ether as the main component, Mw=1224), BRIJ-76 (a surfactant of Aldrich Co., with polyethylene glycol Glycol stearyl ether as main component, Mw=711) or BRIJ-78 (a kind of surfactant of Aldrich Co., take po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com