A sulfur-containing gas purification process

A gas purification and process technology, applied in the direction of combustible gas purification, combustible gas purification/transformation, catalytic conversion of impurities, gas purification, etc., can solve the problem of inability to simultaneously adsorb volatile organic compounds in sulfur-containing gases, inability to achieve deep desulfurization, and specific surface area Small and other problems, to achieve the effect of increased removal rate, increased contact area, and larger specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

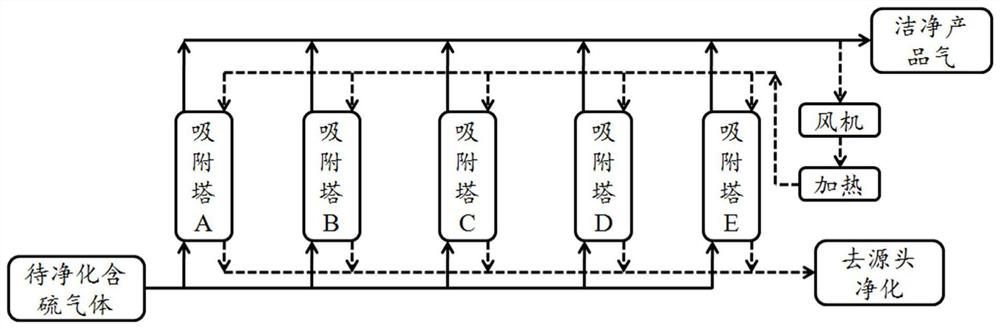

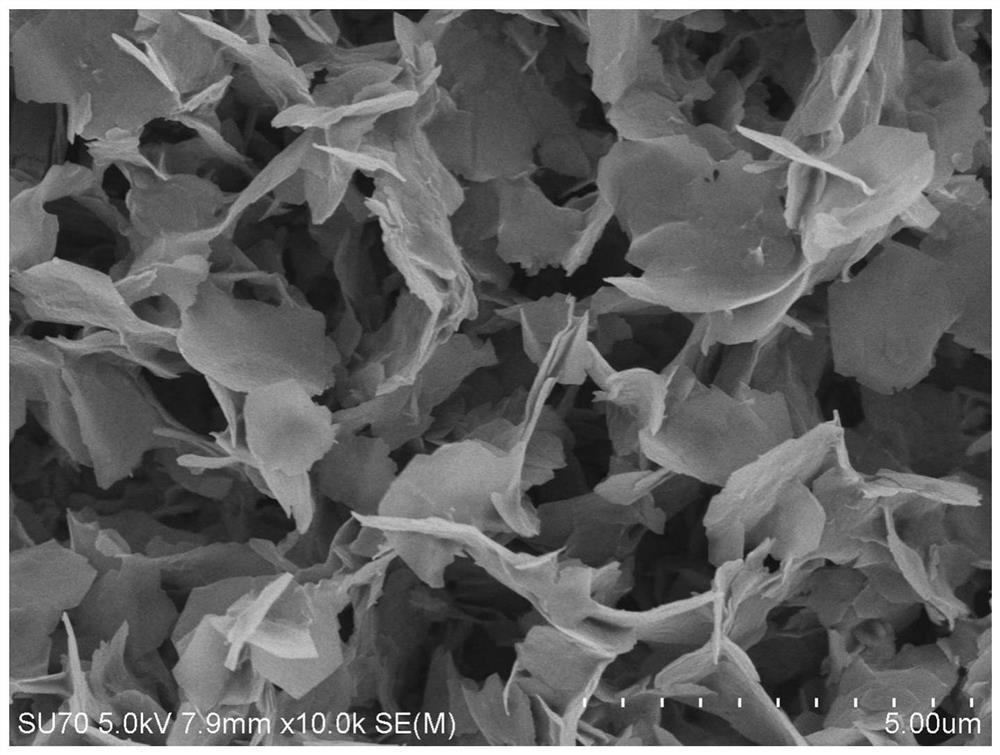

[0039] The preparation process of the modified molecular sieve filled in the adsorption tower of the present invention is:

[0040] (1) Prepare an aqueous solution A of dimethylimidazolium with a concentration of 0.3 to 0.6 M and a soluble cobalt saline solution B with a concentration of 40 to 60 mM, respectively;

[0041](2) The dimethylimidazolium aqueous solution A and the soluble cobalt saline solution B were mixed to give solution C, the molecular sieve was submerged in the solution C for 0.5 to 4h and then removed, washed and dried to obtain THE MOF in situ modified precursor D;

[0042] (3) The precursor D is heat treated at 400~600 °C, and MOF is converted into corresponding cobalt oxides, and the modified molecular sieve of cobalt oxide is modified in situ;

[0043] The molecular sieves used include sapo-type molecular sieves, ZSM-type molecular sieves, A-type molecular sieves, Y-type molecular sieves, X-type molecular sieves and ALPO-type molecular sieves in one or more,...

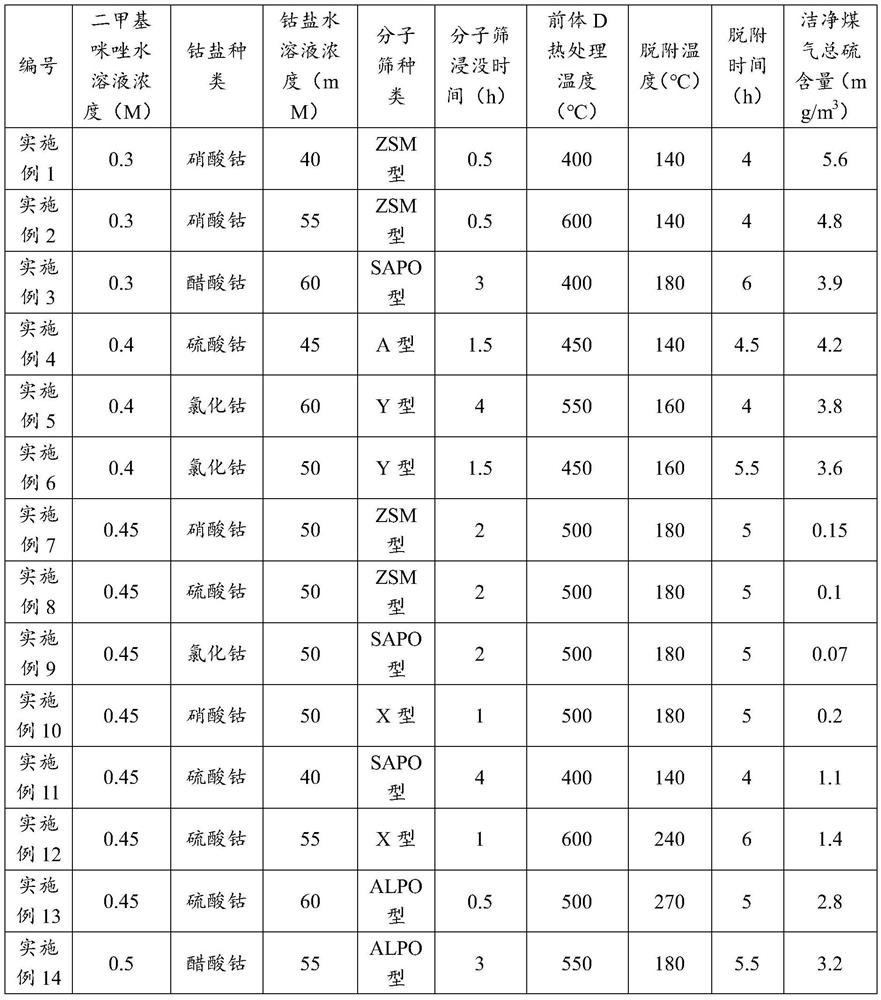

Embodiment 1

[0046] The preparation process of the modified molecular sieve is:

[0047] (1) Prepare aqueous solution A of dimethylimidazolium with a concentration of 0.3 M and a soluble aqueous solution of cobalt saline with a concentration of 40 mM, respectively;

[0048] (2) The dimethylimidazolium aqueous solution A and the soluble cobalt saline aqueous solution B were mixed to give solution C, the molecular sieve was submerged in the solution C 0.5 after removal, washed, dried to obtain MOF in situ modified precursor D;

[0049] (3) The precursor D is heat treated at 400 °C, and the MOF is converted into the corresponding cobalt oxide, and the modified molecular sieve with in situ modification of cobalt oxide is obtained;

[0050]The sulfur-containing gas used is blast furnace gas, and the desorption process heats the regenerative gas to 140-270 ° C, and the desorption time is 4h.

Embodiment 2 to Embodiment 20

[0052] In addition to the parameter changes, the preparation process and desorption process of the modified molecular sieve is consistent with Example 1, the specific material, parameters and results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com