Patents

Literature

67 results about "Graft Type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and wear-resistant polyamide composite material and preparing method thereof

InactiveCN105885399AEasy to processGood physical and mechanical propertiesWear resistantHeat resistance

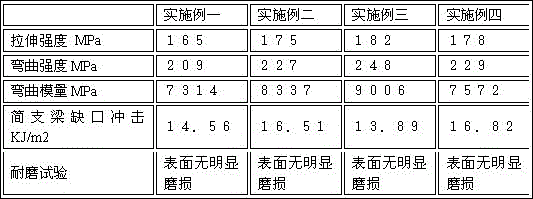

The invention discloses a high-strength and wear-resistant polyamide composite material and a preparing method thereof. The composite material comprises, by weight, 30-70 parts of polyamide66, 3-10 parts of grafting-type toughening agent, 3-10 parts of copolymerization-type toughening agent, 10-50 parts of wear-resistant master batches, 20-40 parts of wear-resistant reinforcing filler, 0.1-3 parts of heat stabilizer, 0.1-3 parts of nucleating agent, 0.1-3 parts of lubricating agent and 0.1-1 part of silane coupling agent. The preparing method includes the steps that the polyamide66, the grafting-type toughening agent, the copolymerization-type toughening agent, the wear-resistant master batches and the wear-resistant reinforcing filler are weighed according to the weight, added into a mixing machine and mixed to be even; the heat stabilizer, the nucleating agent, the lubricating agent and the silane coupling agent are weighed according to the weight, poured into the mixing machine and mixed with the mixture to be even; the final even mixing liquid is put into a double-screw extruder and extruded to be subjected to injection molding through an injection molding machine, and the composite material is obtained. The high-strength and wear-resistant polyamide composite material and the preparing method thereof have the advantages of being high in rigidity, toughness, heat resistance, wear resistance, processing accuracy and the like.

Owner:NANJING DELLON ENG PLASTICS

High-strength carbon fiber reinforced halogen-free flame-retardant PA6 (Polyamide) composite material and preparation method thereof

InactiveCN103450668AOvercome efficiencyOvercome the disadvantage of temperature differenceCarbon fibersAntioxidant

The invention relates to a high-strength carbon fiber reinforced halogen-free flame-retardant PA6 (Polyamide) composite material and a preparation method thereof. The composite material is composed of the following components by weight percent: 47.1-64.1% of PA6, 15-20% of halogen-free flame retardant, 3-5% of expansive type synergist, 10-30% of carbon fiber, 2-4% of graft type toughening modifier, 0.3% of couping agent, 0.4% of antioxidant and 0.2-0.5% of lubricating dispersant. The invention also relates to the preparation method of the high-strength carbon fiber reinforced halogen-free flame-retardant PA6 composite material. The nylon composite material provided by the invention is high in strength, high in rigidity, good in electric conductivity, halogen-free and flame-retardant, good in appearance and excellent in combination properties; the high-strength carbon fiber reinforced halogen-free flame-retardant PA6 composite material is a functionally integrated material and can be potentially used for substituting for the aluminium and magnesium metal materials used by the shells of electrical and electronic parts at present, and thus makes up for the gap in the field of similar products.

Owner:SHANGHAI SUNNY

Potted tray vegetable automatic needle grafting type grafting device

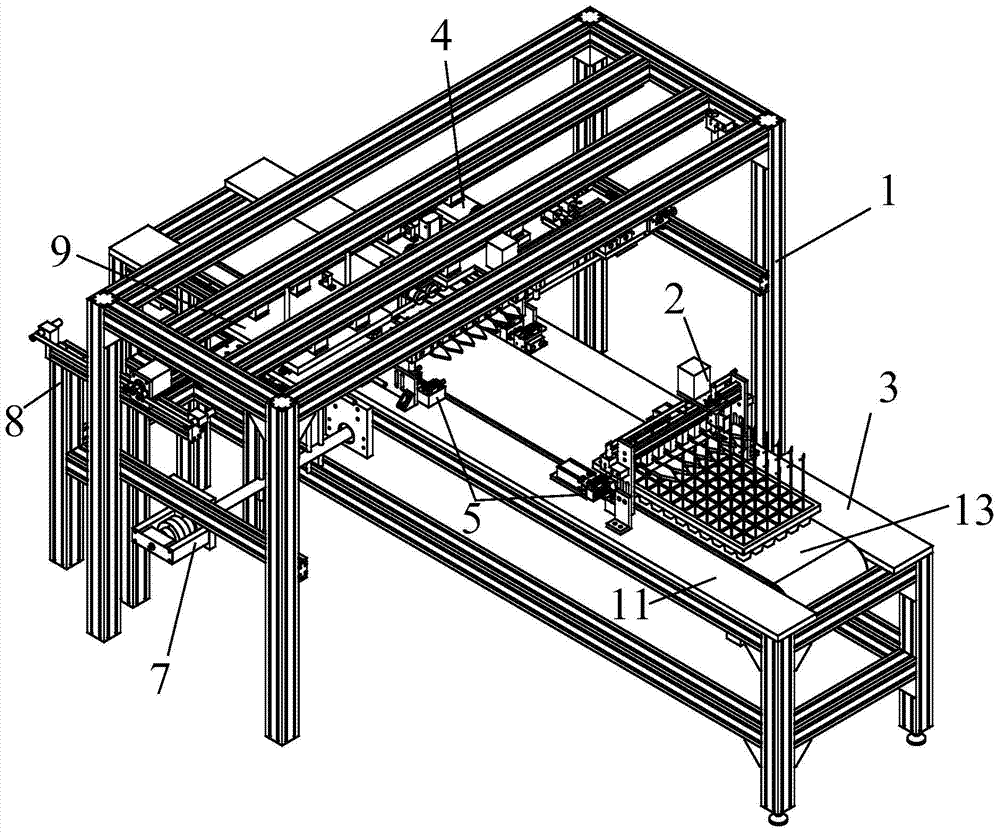

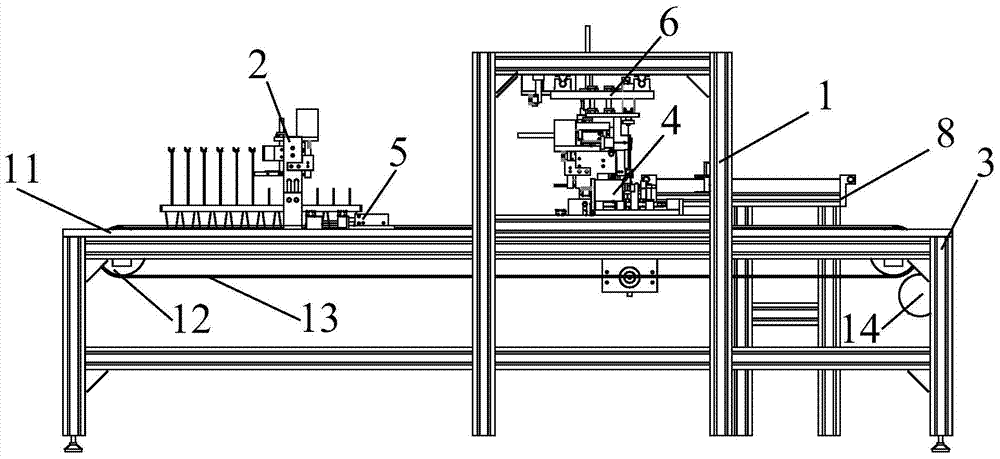

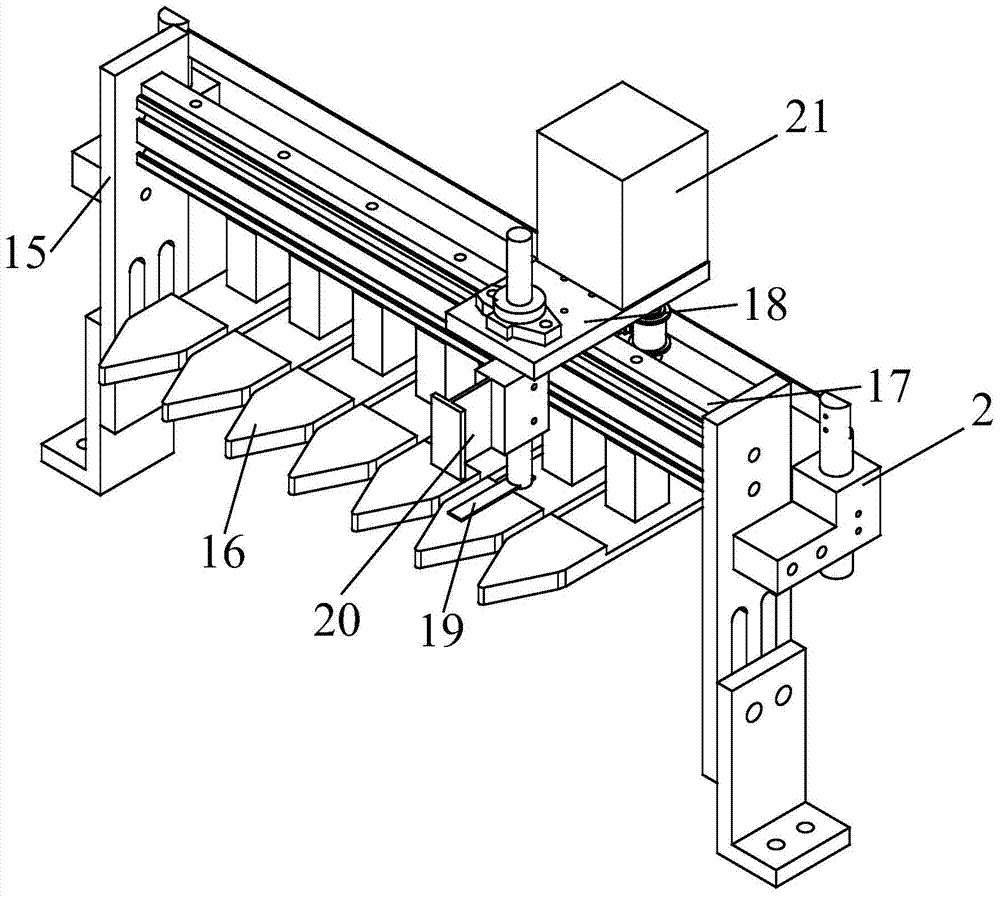

The invention discloses a potted tray vegetable automatic needle grafting type grafting device. The potted tray vegetable automatic needle grafting type grafting device comprises a machine frame (1). A potted tray conveying mechanism (3) is arranged under the machine frame (1). A stock rough cutting mechanism (2) and a stock positioning inclined cutting mechanism (4) are sequentially arranged on the potted tray conveying mechanism (3), and the portion, below the stock rough cutting mechanism (2), of the potted tray conveying mechanism (3) and the portion, below the stock positioning inclined cutting mechanism (4), of the potted tray conveying mechanism (3) are provided with potted tray inching mechanisms (5) respectively. A scion seedling feeding mechanism (8) is arranged on the portion, corresponding to the stock positioning inclined cutting mechanism (4), on the left side of the potted tray conveying mechanism (3). A scion rotating cutting mechanism (7) is further arranged on the portion, corresponding to the scion seedling feeding mechanism (8), on the left side of the potted tray conveying mechanism (3). A needle insertion mechanism (6) and a scion clamping mechanism (9) are connected with each other and hung on the portion, corresponding to the stock positioning inclined cutting mechanism (4) and the scion seedling feeding mechanism (8), on the machine frame (1).

Owner:ZHEJIANG UNIV

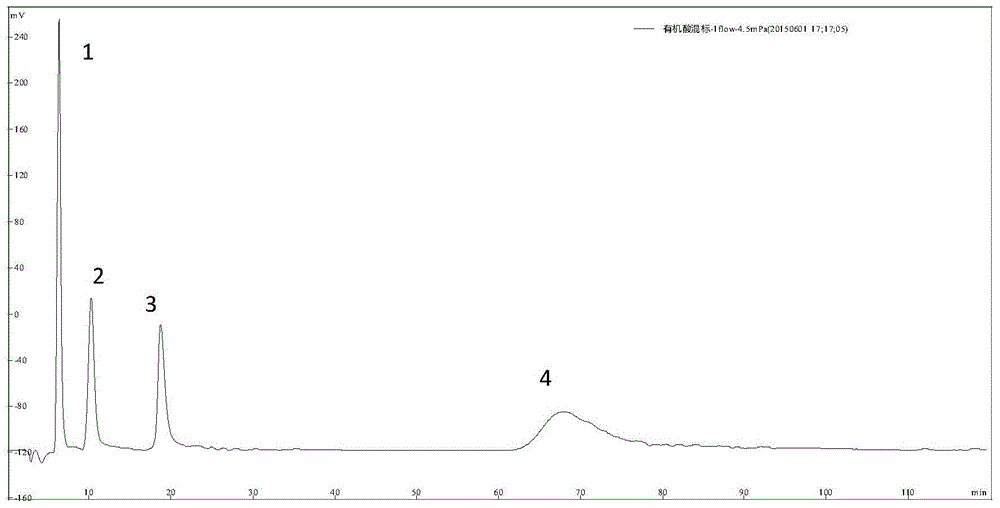

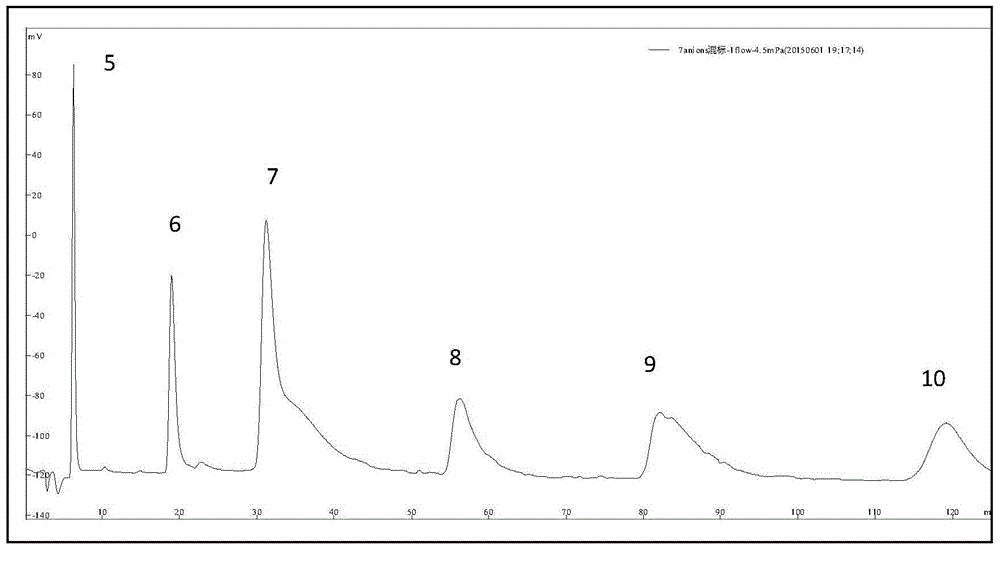

Preparation method of surface-grafted type anion chromatographic filling material

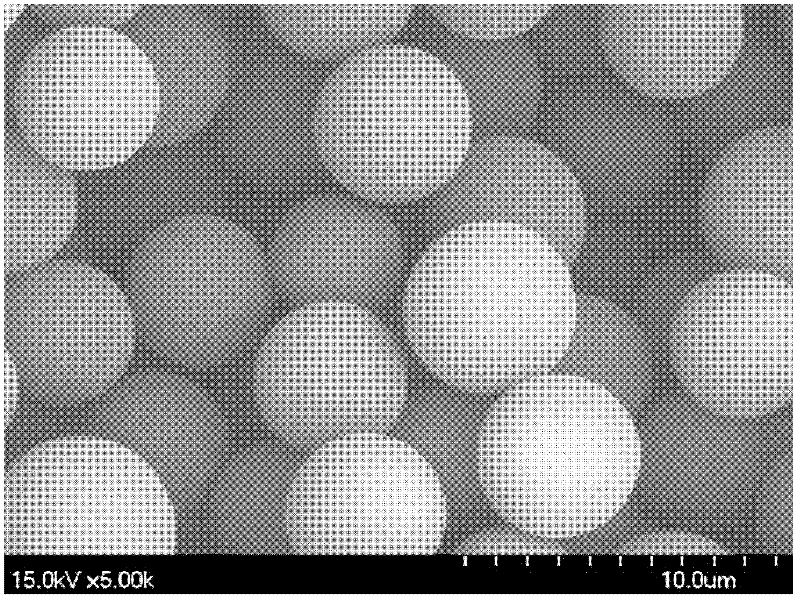

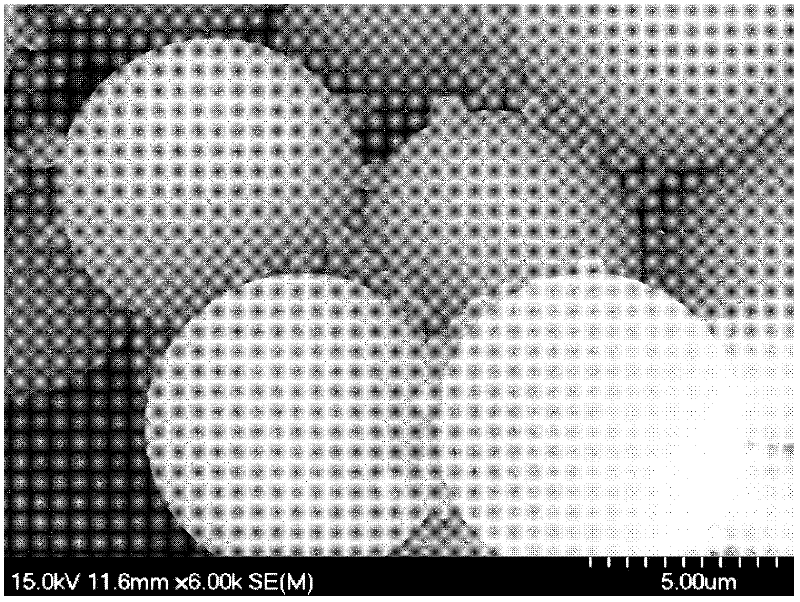

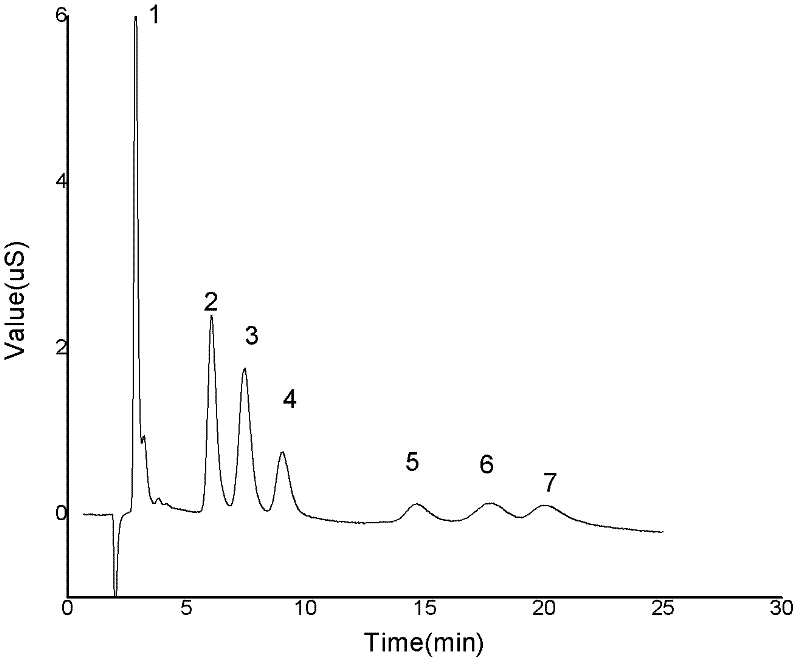

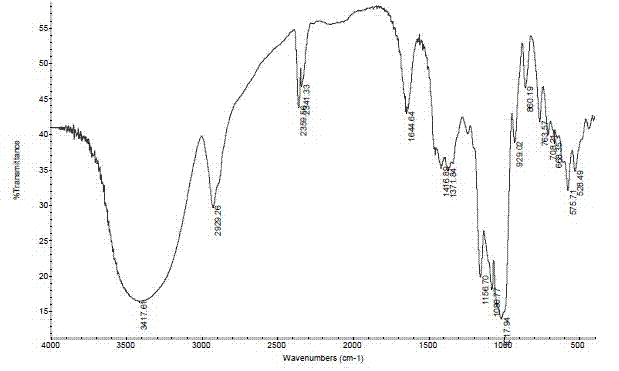

InactiveCN102500431AEasy to separateImprove stabilityChromatographic anion exchangersDivinylbenzeneMicrosphere

The invention relates to an anion chromatographic column and a preparation method thereof, and particularly relates to a preparation method of a surface-grafted type anion chromatographic filling material. The preparation method of a novel surface-grafted type anion chromatographic filling material comprises the steps of: preparing monodispersed linear polystyrene microsphere seeds with polystyrene-divinylbenzene as a medium by adopting a dispersion polymerization method, activating the seeds, synthesizing polystyrene-divinylbenzene microspheres by adopting a single-step seed swelling method,and extracting to remove the pore-forming agent. According to the invention, the preparation method of the polystyrene-divinylbenzene microspheres is low in cost and simple in process; and the prepared filling material is uniform in particle size, narrow in particle size distribution and good in chemical stability, and needs no screening.

Owner:ZHEJIANG UNIV

Preparation method of cassava starch type high-water absorbency and oil-oil absorbency resin by cross-linked grafting technology

ActiveCN102887978AImprove water absorptionImprove oil absorption capacityCross-linkChemical industry

Owner:建湖上冈产业园服务有限公司

Method of oreparing starch grafting type high water absorption resin by wave polymerization

A process for preparing starch grafted high-hydroscopicity resin in liquid phase system by wave polymerizing method includes mixing starch with water, water-bath heating while gelatinizing, neutralizing acrylic acid by sodium hydroxide, mixing it with the gelatinized starch, adding acrylamide, maleic acid, trigger, cross-linking agent, and additive, stirring, loading the mixture in cylindrical reactor, heating to trigger reaction, removing heat source, and polymerizing reaction by automatic transfer of heat waves.

Owner:UNIV OF SCI & TECH BEIJING

Graft type fracturing fluid and preparation process thereof

The present invention relates to grafting type fracturing fluid comprising grafting type glue 0.4-1.0 wt %, metal cross-linking agent 0.05-0.7wt %, cracking oxidant 0.05-0.5wt % and water for the rest. The grafting type fracturing fluid of the present invention may be used to replace glue of natural plant material, and has water insoluble matter content as low as 1.0-3.0 wt %, residue after cracking of 20-60 mg / L and low cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

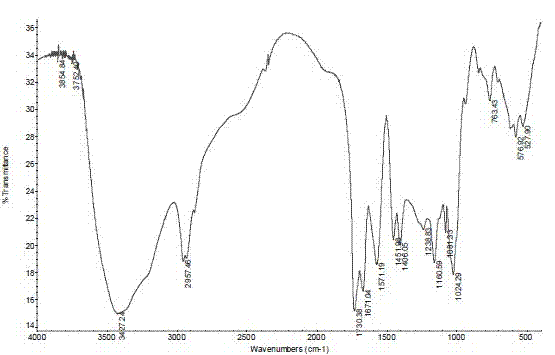

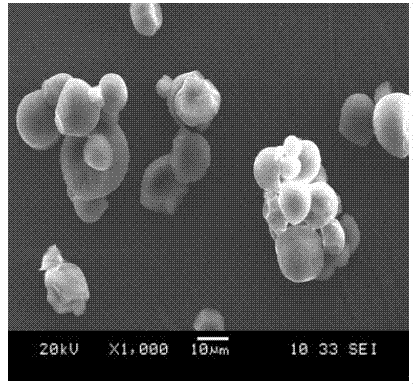

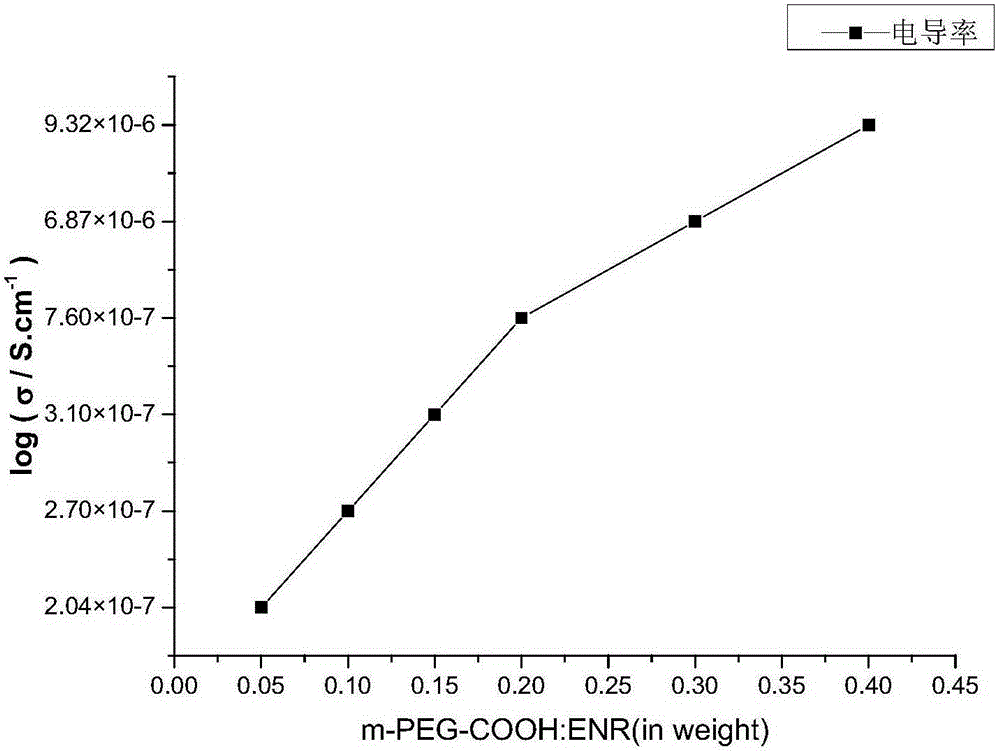

Grafting type comb polymer solid electrolyte material and preparation method thereof

InactiveCN105206872AImprove athletic abilityImprove electrochemical stabilitySolid electrolytesSecondary cellsVulcanizationPolymer science

The invention relates to a grafting type comb polymer solid electrolyte material and a preparation method thereof. The raw material comprises epoxidized natural rubber, methoxy polyethylene glycol carboxylic acid and lithium perchlorate, a flexible segment is introduced in the epoxidized natural rubber through a grafting reaction, the graft methoxy polyethylene glycol carboxylic acid provides the high segment motion ability and the ability of interaction with lithium salt, and ether oxygen atoms on the graft act with lithium perchlorate to dissociate the lithium perchlorate into lithium ions and form a coordinated complex. Compared with the prior art, no other plasticizer or active agent or vulcanization accelerator or rubber chemical is introduced, no small molecule product residue exists in the prepared material, and the electrochemical stability and ionic conductivity of the electrolyte can be improved.

Owner:SHANGHAI JIAO TONG UNIV

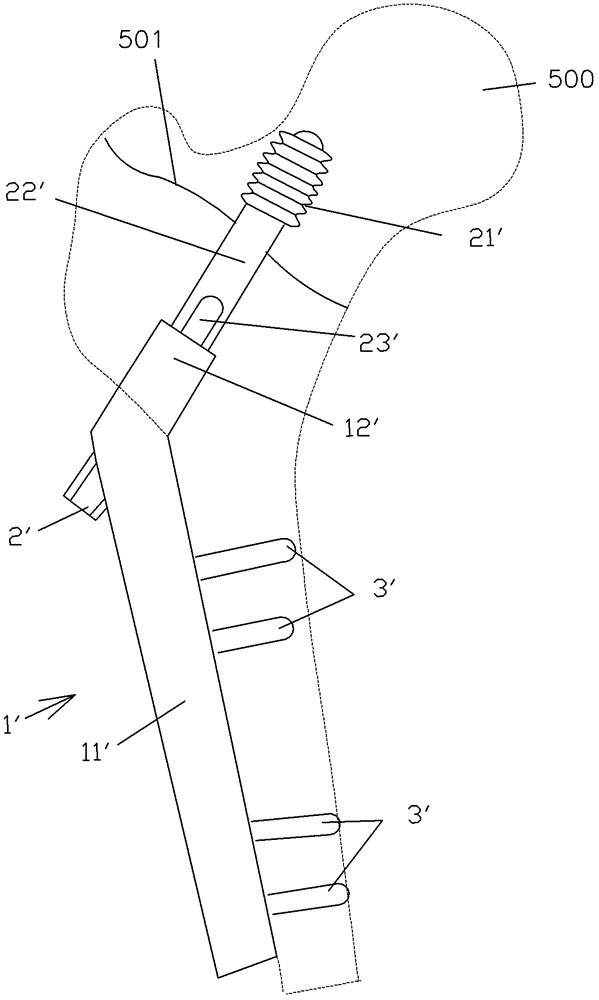

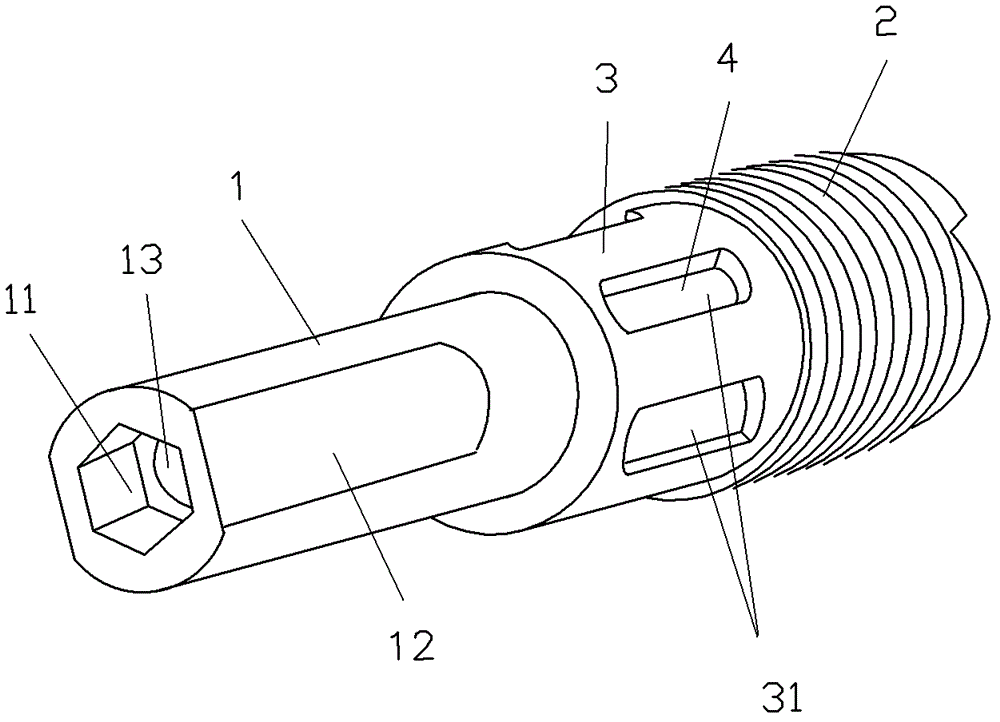

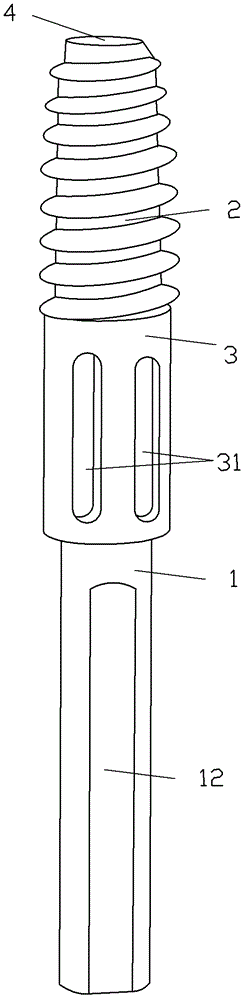

Hollow bone grafting type dynamic hip screw

The invention discloses a hollow bone grafting type dynamic hip screw, relating to a lag screw for orthopedic surgery. The hollow bone grafting type dynamic hip screw disclosed by the invention is a lag screw, wherein an entire body is provided with a guide pin hole which perforates along the central axis, a bone thread is arranged at the front end of a screw body, and a hollow cage-like part with a window on the outer peripheral surface is arranged at the tail end of the screw body, which is close to the bone thread. Before the dynamic hip screw is locked, autologous bone broken pieces of a patient are placed in the cage-like part. After the dynamic hip screw is locked at the part with a fracture of the neck of the femur of the patient, the pressurization of the fracture end can be completed, and the reliable internal fixation is achieved; and autologous cancellous bone can be also implanted on the surface on the periphery of the fracture end, which is in contact with the screw, and the autologous cancellous bone can penetrate through the window of the cage-like part and is combined with the bone of the neck of the femur, so that early healing of the fracture can be promoted.

Owner:练克俭 +1

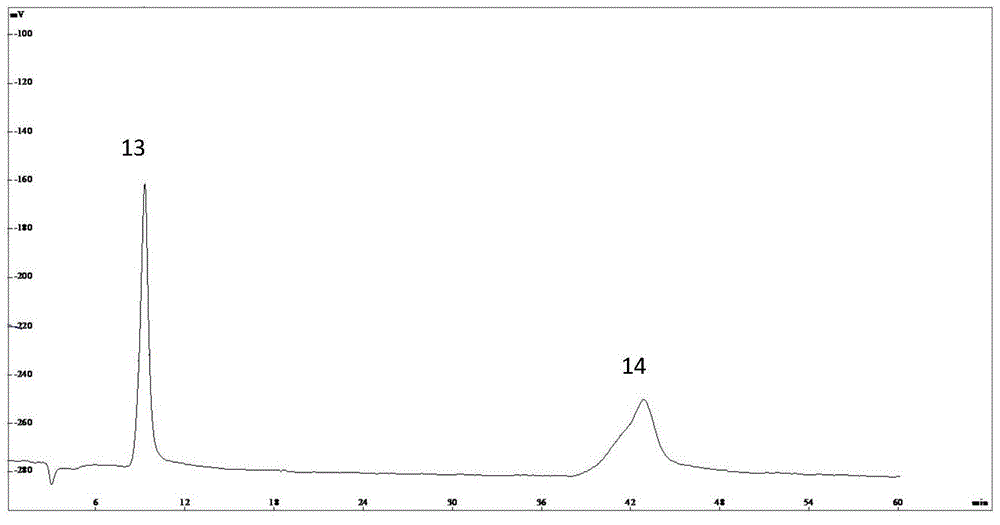

Method for preparing grafting type strong preservation anion chromatographic packing

InactiveCN104945637AUniform particle sizeControl the degree of quaternizationComponent separationOther chemical processesDendrimerGlycidyl methacrylate

The method provides a method for preparing grafting type strong preservation anion chromatographic packing made of polymer polystyrene-divinyl benzene-glycidyl methacrylate-dendrimer-2,3-glycidyl trimethyl ammonium chloride. The method comprises the steps of grafting polyamide-amine dendrimer compound to polymer base ball polystyrene-divinyl benzene-glycidyl methacrylate in a grafted mode, using active cationic reagent 2,3-glycidyl trimethyl ammonium chloride to perform quaterisation modification on the grafting type base ball, and obtaining quaternary ammonium type ion chromatographic column packing having high preservation effects on anions. The obtained quaternary ammonium type ion chromatographic packing undergoes packing through a homogenate method, and an obtained compound strong preservation anion chromatographic column has very high separation preservation effects on conventional anions such as F- and Cl- and organic acids such as oxalic acid.

Owner:ZHEJIANG UNIV

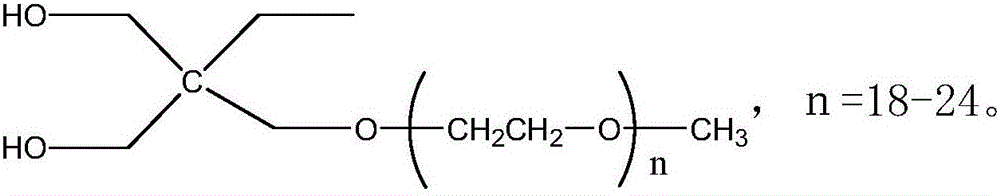

Preparation method of crosslinkable block-grafted type high-molecular polymer

ActiveCN106543402AImprove dispersion stabilityImprove adhesionTransportation and packagingMixingPolymer scienceDistillation

The invention discloses a preparation method of a crosslinkable block-grafted type high-molecular polymer. At present, the wide application of some polyurethane amphiphilic polymers in the fields of emulsion polymerization, pigment dispersion and the like is restricted due to limitation of the spatial topology structures of the hydrophilic chain segment and the oleophylic chain segment of the polyurethane amphiphilic polymer. Glycerin monostearate and polyisocyanate are used as raw materials and react with a mixed polyol of trimethylol propane poly(ethylene glycol) monomethyl ether and other polyols, finally chain extension, end sealing, emulsification, distillation and the like are performed to generate the crosslinkable block-grafted type high-molecular polymer. The special block-grafted structure of the polymer enables the polymer to have good surface activity, and the active groups in their structures are coordinated, so that the crosslinkable block-grafted type high-molecular polymer has a good application prospect in the fields of pigment dispersants, stabilizing agents, emulsion polymerization and the like; meanwhile a large amount of active groups are reserved on the polymer, and can be cross-linked with hydroxyl, amino or themselves during heating, and thus the polymer film has good water resistance, adhesive force and bonding strength.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

Approaching grafting type double-end bridge grafting method of diseased bergamot pear tree

The invention discloses an approaching grafting type double-end bridge grafting method of a diseased bergamot pear tree and belongs to the field of bergamot pear tree bridge grafting.The method includes the steps of firstly, selecting a bridge grafting tree; secondly, preparing the bridge grafting, to be more specific, processing a wound, collecting scions, and selecting the bridge grafting time and position; thirdly, grafting, to be more specific, selecting the scion 10-15cm longer than the wound, covering with a film, cutting off the parts 5-10cm longer than the distance between grafting openings, cutting the ends into horse-ear-shaped cutting faces of 2.5-3cm, and lightly cutting the outer sides to expose the green cortexes; cutting the upper and lower grafting openings into an inverted-T shape and a T shape with the vertical length being not larger than 1 / 3 of the length of the cutting faces and the transverse width being 1.5-2.5 times of width of the cutting faces, and respectively cutting into an inverted Y shape and a Y shape; prying up the cortexes on two sides of the cuts, inserting two ends of the scion into the grafting openings, and allowing the inserted ends to closely attach to the xylem; fourthly, tightly wrapping the grafting openings, and spraying protecting agent; fifthly, removing the films after healing.By the method suitable for being popularized, the survival rate of the diseased bergamot pear tree can reach above 95%, and the fruit setting rate, fruit quality, disease resistance and survival time are increased greatly.

Owner:XINJIANG TOP AGRI CO LTD

Hydrolysis-resistant polyamide composite and preparation method thereof

PendingCN105885398AImprove hydrolysis resistanceImprove mechanical propertiesThermoplasticAntioxidant

The invention discloses a hydrolysis-resistant polyamide composite and a preparation method thereof. The composite is prepared from, by weight, 60-70 parts of injection molding grade PA66 resin, 5-10 parts of POK resin, 3-5 parts of grafting type compatilizer, 27-33 parts of thermoplastic plastic roving, 0.5-1 part of hydrolysis-resistant agent, 0-1 part of complex antioxidant and 0-1 part of lubricant. By weight, the injection molding type PA66 resin A66, the POK resin and the grafting type compatilizer are weighed firstly and added into a high-speed mixer to be mixed to be uniform; by weight, the hydrolysis-resistant agent, the antioxidant and the lubricant are weighed, mixed and then poured into a mixer, and the mixture and the mixture obtained after uniform mixing are stirred together and fully mixed to be uniform; final uniformly-mixed liquid is put in a two-screw extruder to be extruded and then subjected to injection molding through an injection molding machine, and the composite is obtained. The hydrolysis resistance of the composite can be improved, the mechanical performance of the composite is excellent, and the service life of products is greatly prolonged.

Owner:NANJING DELLON ENG PLASTICS

Mechanized production of hybrid seeds by using combined parent strain hybridization crop

InactiveCN101317546AUse valueReduce investmentPlant genotype modificationHybrid seedAgricultural science

The invention discloses a hybrid crop mechanized seed production technique which utilizes the combination parents, belonging to the cross-breading of the crops. The invention is characterized in that on the basis that the combination parent is gained by using current parent strain of the hybrid crop or selecting the systems in the same types and different growing periods, the mechanized sowing or grafting type is carried out according to proper row ratio of male parent and female parent; the harvest process is carried out after mature by respectively harvesting the male parent and female parent and by the synchronous and alternative operation; alternatively, a single harvester can respectively harvest the male parent and the female parent at the same time and ensure the hybrid seeds and the male parent seeds are separated from each other and not mixed together. The hybrid crop seed production technique of the invention meets the requirement that the florescences of the male parent and the female parent are encountered, realizes the mechanized operation during the production process, lightens the labor intensity, obviously reduces the seed production cost, quickens the process that the hybrid crops, more particularly, the hybrid rice crops are generalized and applied all over the world, especially for the developed countries, and prompts the global economical development.

Owner:施建达

High-strength carbon fiber reinforced halogen-free flame-retardant PA66 (Polyamide 66) composite material and preparation method

InactiveCN102964830AComply with export requirementsImprove mechanical propertiesCarbon fibersPolyamide

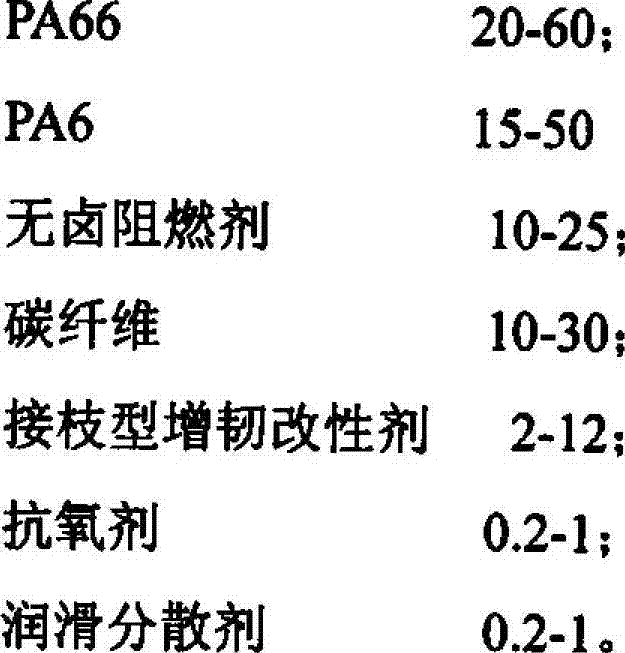

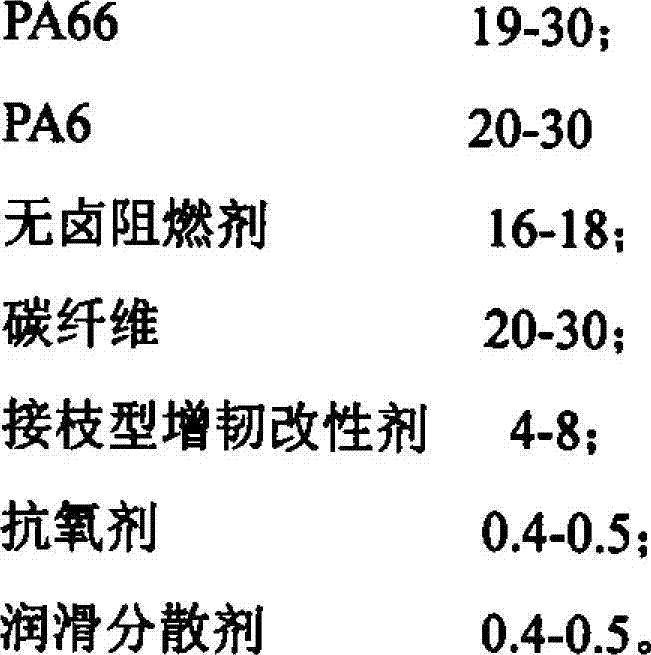

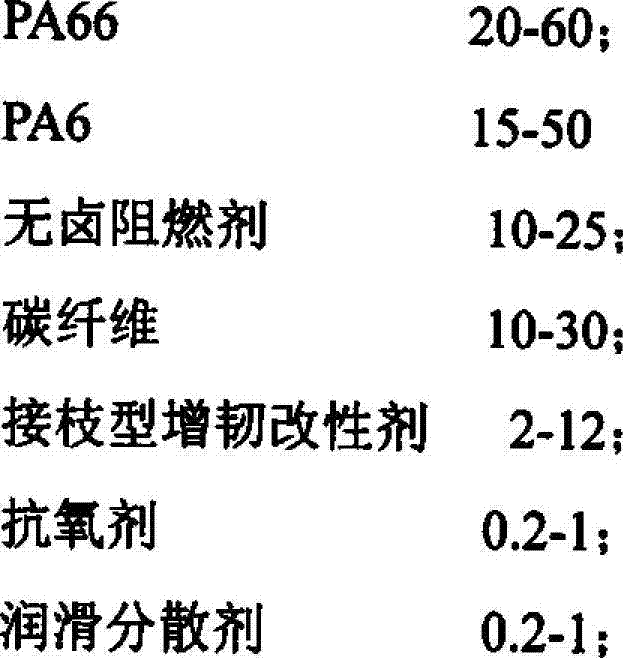

The invention relates to a high-strength carbon fiber reinforced halogen-free flame-retardant PA66 (Polyamide 66) composite material and a preparation method of the high-strength carbon fiber reinforced halogen-free flame-retardant PA66 composite material. The composite material comprises the following components: 20 to 60 parts of PA66, 15 to 50 parts of PA6, 10 to 25 parts of halogen-free flame retardant, 10 to 30 parts of carbon fiber, 2 to 12 parts of grafting type toughened modifier, 0.2 to 1 part of antioxidant, and 0.2 to 1 part of lubricating dispersant. The preparation method comprises the following steps in sequence: mixing all the raw materials mentioned above for 3 to 5 minutes by a high-speed mixer, except the carbon fiber; discharging to obtain the mixture; controlling the processing temperature of a twin-screw extruder to 230 to 250 DEG C, and controlling the revolutions of the screws to 180 to 600 rotation per minute; transferring the mixture into the twin-screw extruder; feeding the carbon fibers from the side; and extruding and pelleting, so as to obtain the high-strength carbon fiber reinforced halogen-free flame-retardant composite material. The high-strength carbon fiber reinforced halogen-free flame-retardant PA66 composite material is developed based on the special requirements on static resistance and flame retardant of the materials under the requirements of the electric appliances to the electromagnetic screening. Compared with the prior art, the high-strength carbon fiber reinforced halogen-free flame-retardant PA66 composite material has the advantages that the surface resistance is up to 10<3> to 10<6> ohms, the electromagnetic shielding performance and halogen-free environmental protection meet UL-94V0 standard, the mechanical strength is high, the appearance is nice, the comprehensive performance is outstanding, and the gap in the field of like products in China is filled.

Owner:SHANGHAI SUNNY

Low smoke halogen-free flame retardant reinforced nylon composite material and manufacture method

The invention relates to a low smoke halogen-free flame retardant reinforced nylon composite material and a manufacture method. The composite material comprises the following components, namely, 30-70 parts of nylon, 8-25 parts of fire retardants, 0.5-20 parts of smoke suppression modifying agents A, 0.5-5 parts of smoke suppression modifying agents B, 2-12 parts of stem grafting type toughening modification agents, 10-30 parts of glass fibers, 0.2-1 part of antioxygen, 0.2-1 part of lubrication dispersing agent. Raw materials are put in a high mixing machine for mixing for 3-5 minutes and discharged, and a mixture is obtained. The machining temperature within a range of 230 DEG C to 250 DEG C of a twin-screw extruder is controlled. The number of revolutions is 180-600 turns per minute, and the mixture is placed in the twin-screw extruder, particles are extruded and a product is obtained. Compared with the prior art, low smoke halogen-free flame retardant nylon 66 meets the requirement for low fuming amount, inflaming retarding performance achieves a UL94V0 level, mechanical performance and electric performance are good, and the low smoke halogen-free flame retardant reinforced nylon composite material and the manufacture method can be applied to devices of a circuit breaker, a low voltage switch, an arc extinguishing cover and the like.

Owner:SHANGHAI SUNNY

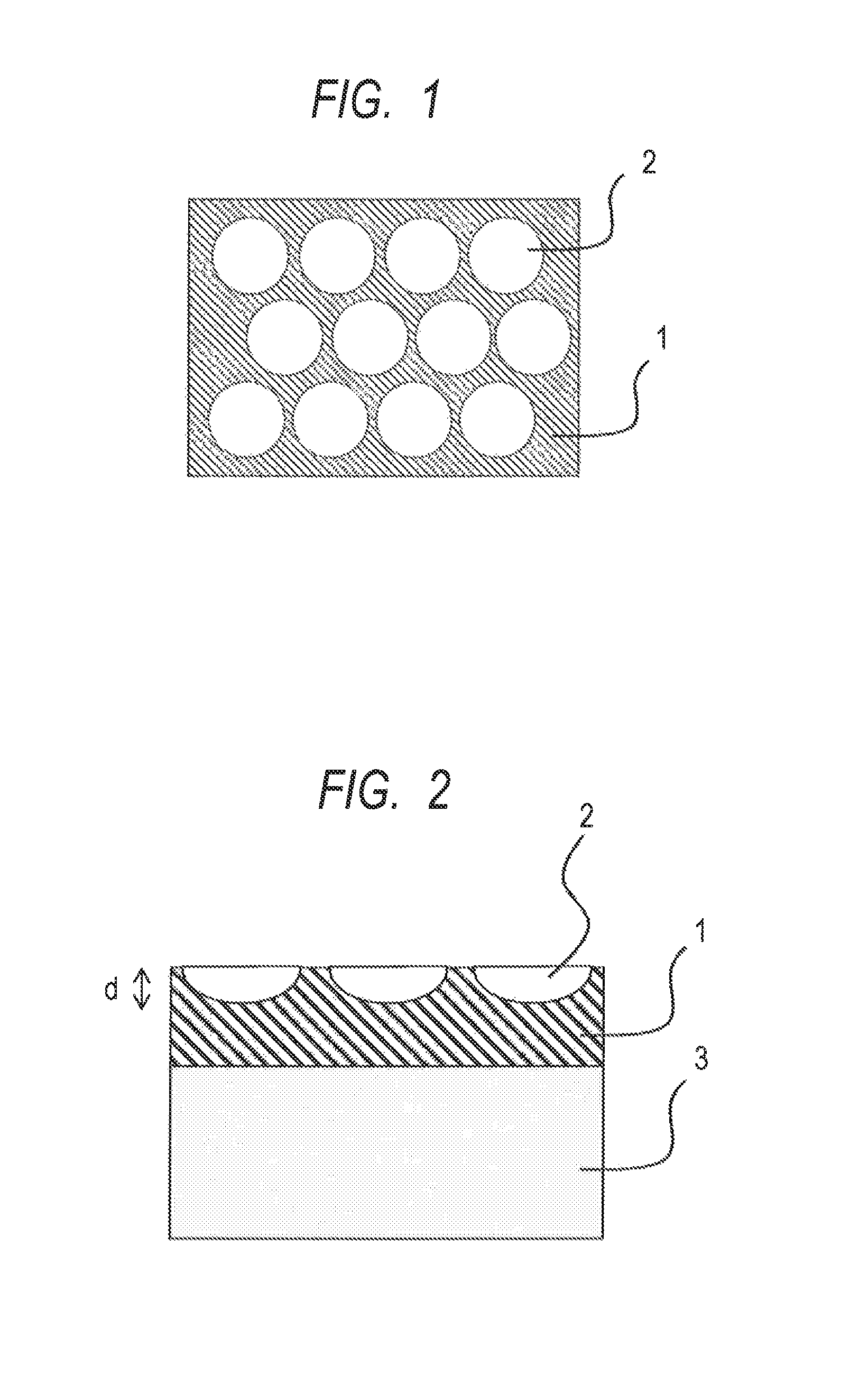

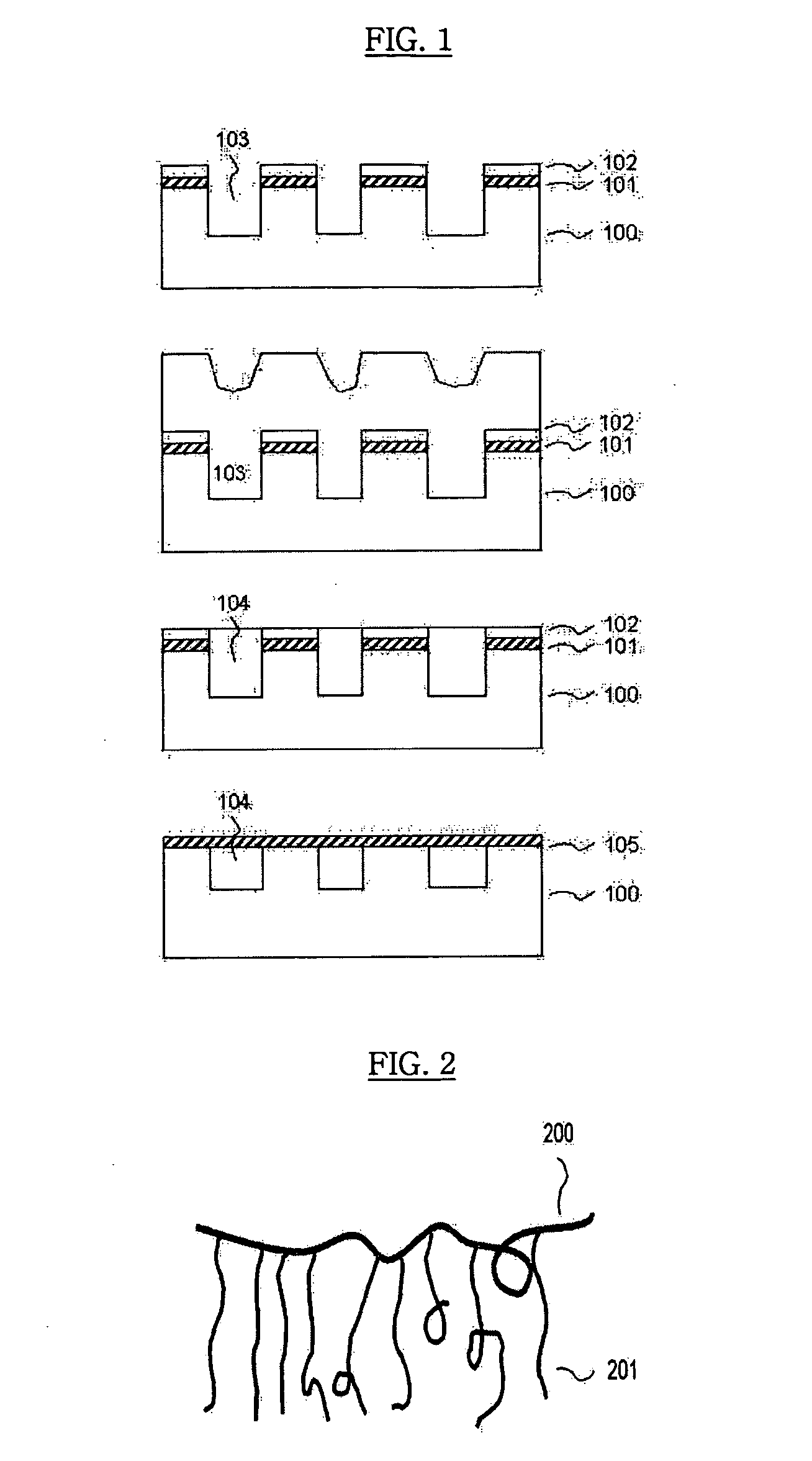

Transfer member for electrophotography and electrophotographic image forming apparatus

ActiveUS9575439B2Synthetic resin layered productsElectrographic process apparatusSurface layerPolymer science

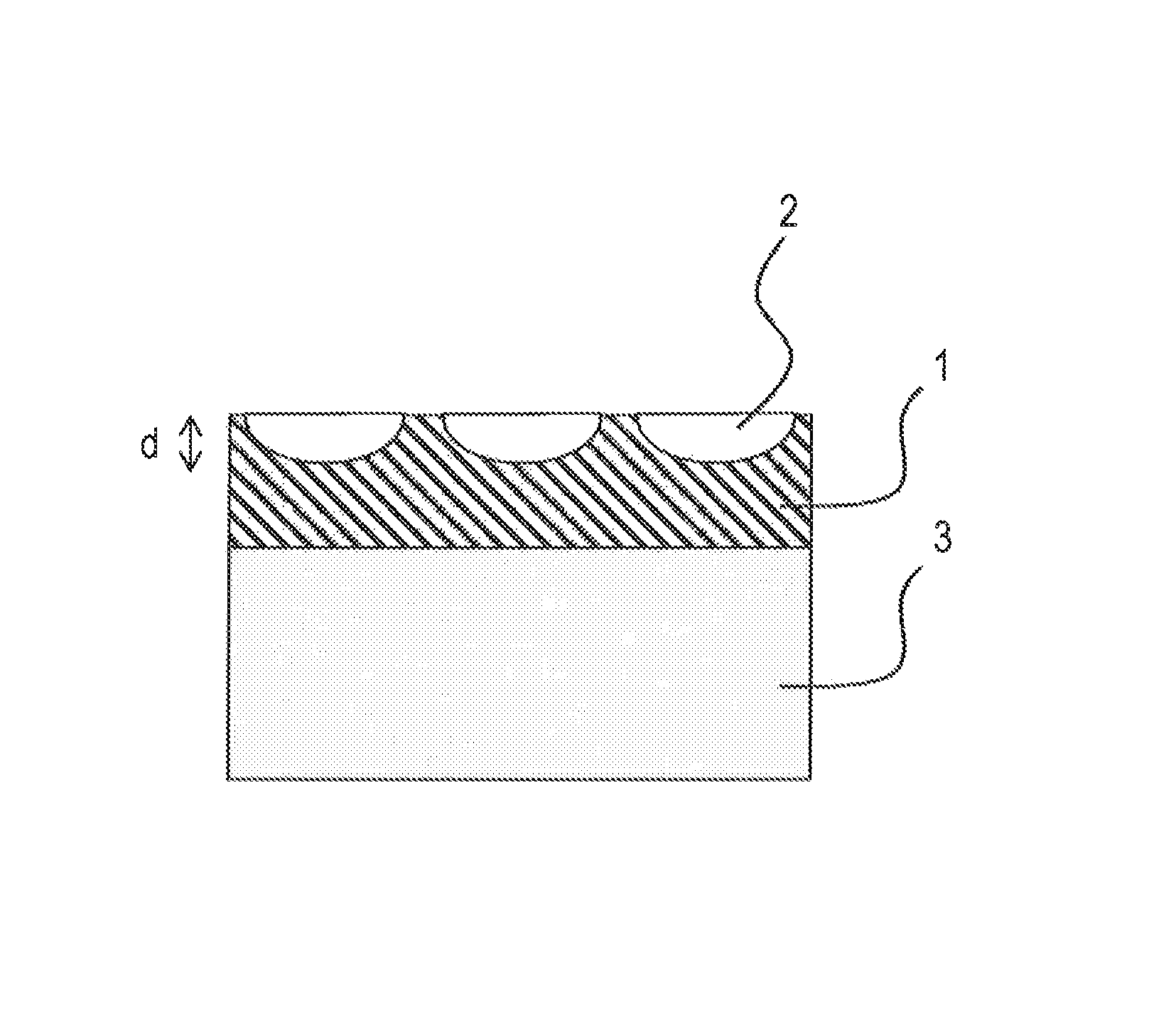

Provided a transfer member for electrophotography of a multilayer structure including a surface layer having a surface for carrying toner is provided.The surface layer contains a graft type copolymer comprising a polymer having a structure represented by formula (1) as a main chain, and a group containing a structure represented by formula (2) and a group containing a structure represented by formula (3) each bonded to the main chain as a side chain. The surface of the surface layer has a matrix phase formed by a group containing a structure represented by formula (2) and a domain phase formed by a group containing a structure represented by formula (3):

Owner:CANON KK

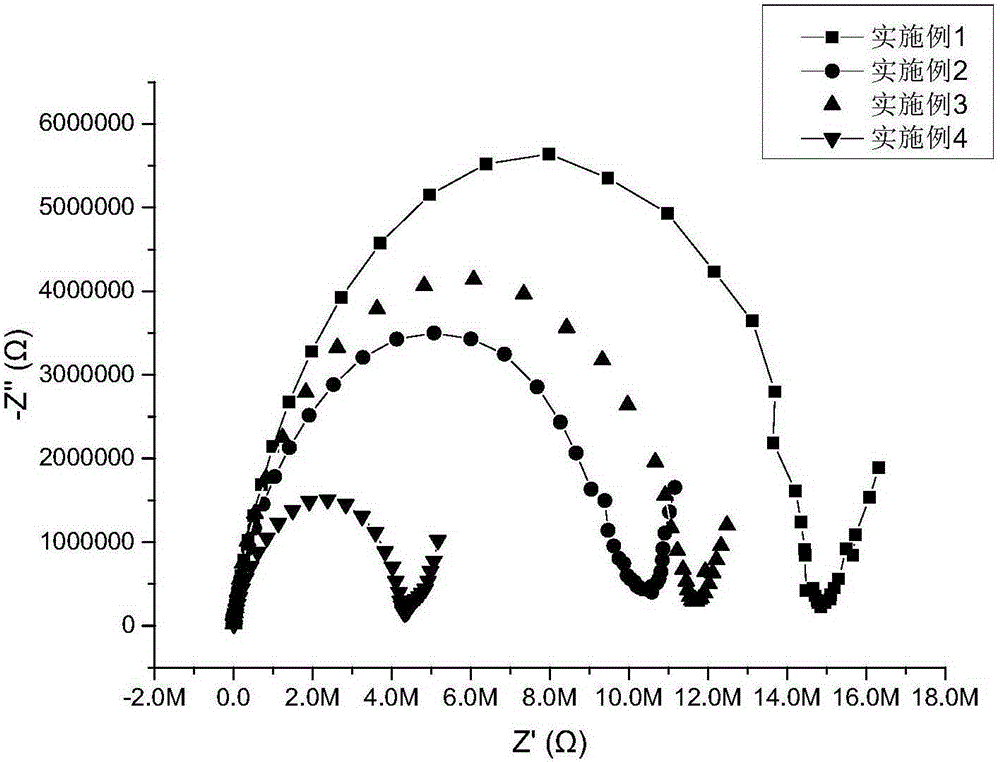

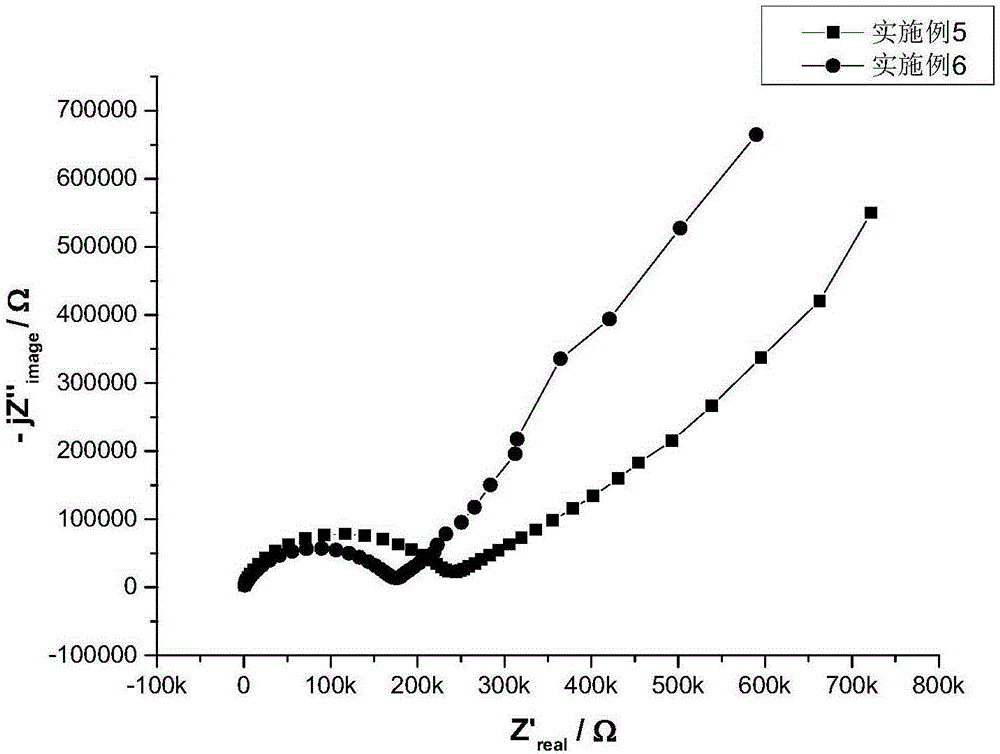

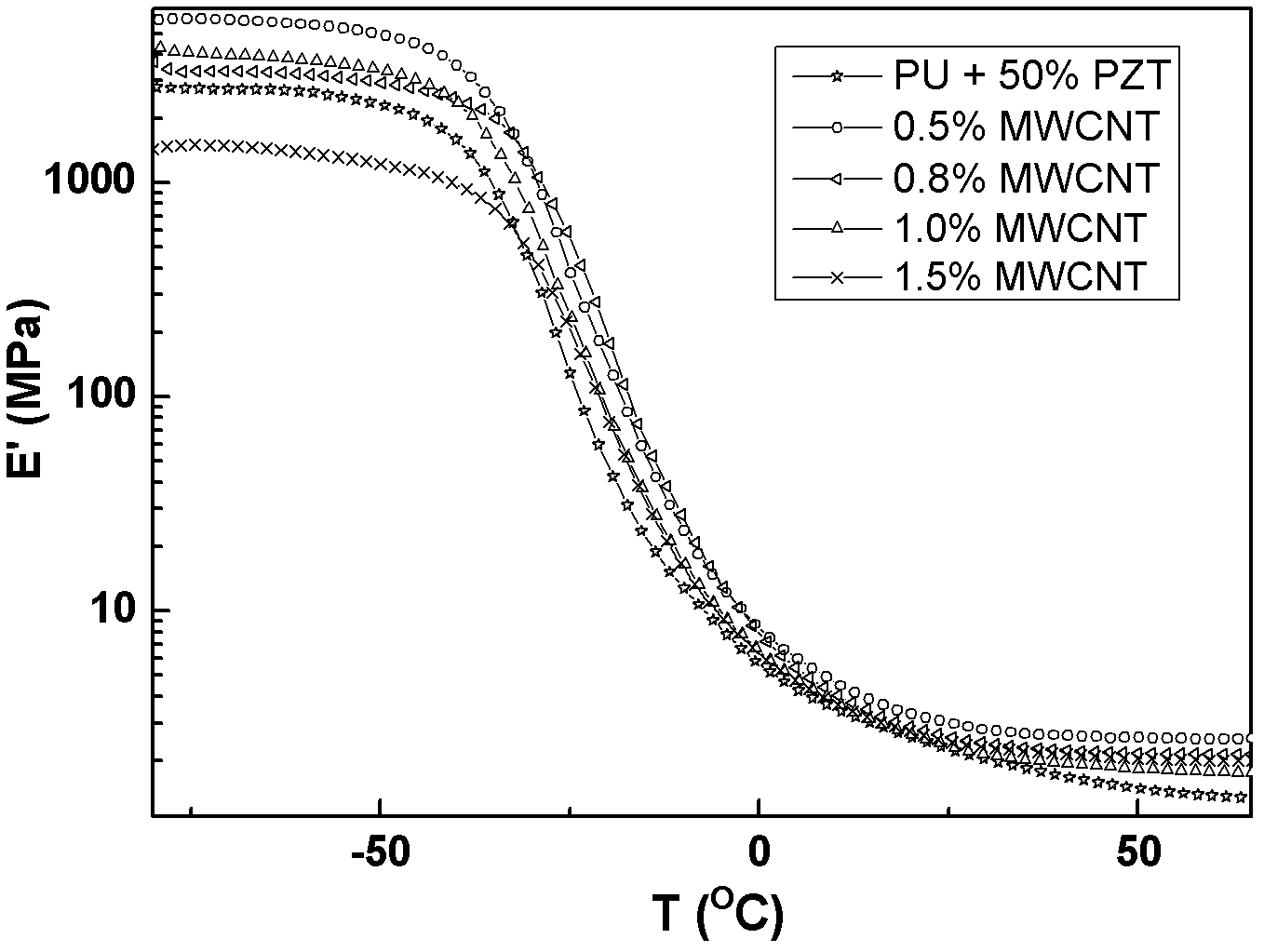

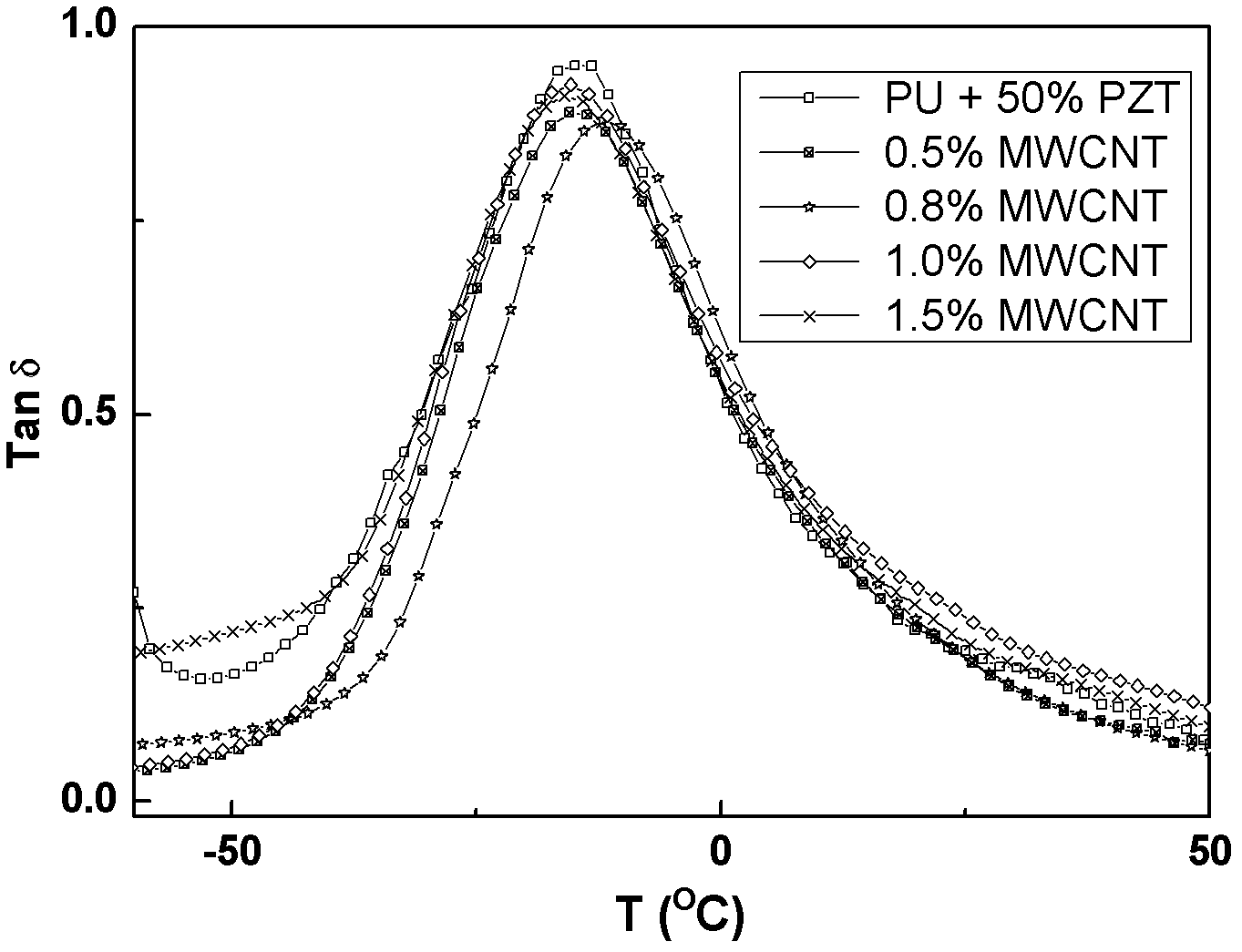

Piezoelectric and conductive grafting type polyurethane base composite damping material and preparation method thereof

The invention provides a piezoelectric and conductive grafting type polyurethane base composite damping material and a preparation method of the material. The preparation method comprises the following steps of: evenly mixing the mixture of main chain substrate and branch chain substrate with mass ration of 2:1 in grafting type polyurethane substrate, piezoelectric ceramic particles accounting for 20-70wt% of the mixture, conductive particles accounting for 0.5-1.5wt% of the mixture and cross-linking agent trimethylolpropane, wherein the molar ratio between -NCO in the main chain substrate and -OH in cross-linking agent is equal to 1: 1.2; and curing at the temperature of 10 DEG C, and obtaining the piezoelectric and conductive grafting type polyurethane base composite damping material. The damping material has the peak value of the loss factor tan delta reaching up to about 1.0, and the peak value reaches more than 0.3 within a wider temperature range. The damping material is simple in preparation technology, low in cost and good in damping performance. The damping material can be used as a damping noise reduction material and applied to the fields such as a ship, the ocean, traffic, a large machine and the like.

Owner:HARBIN ENG UNIV

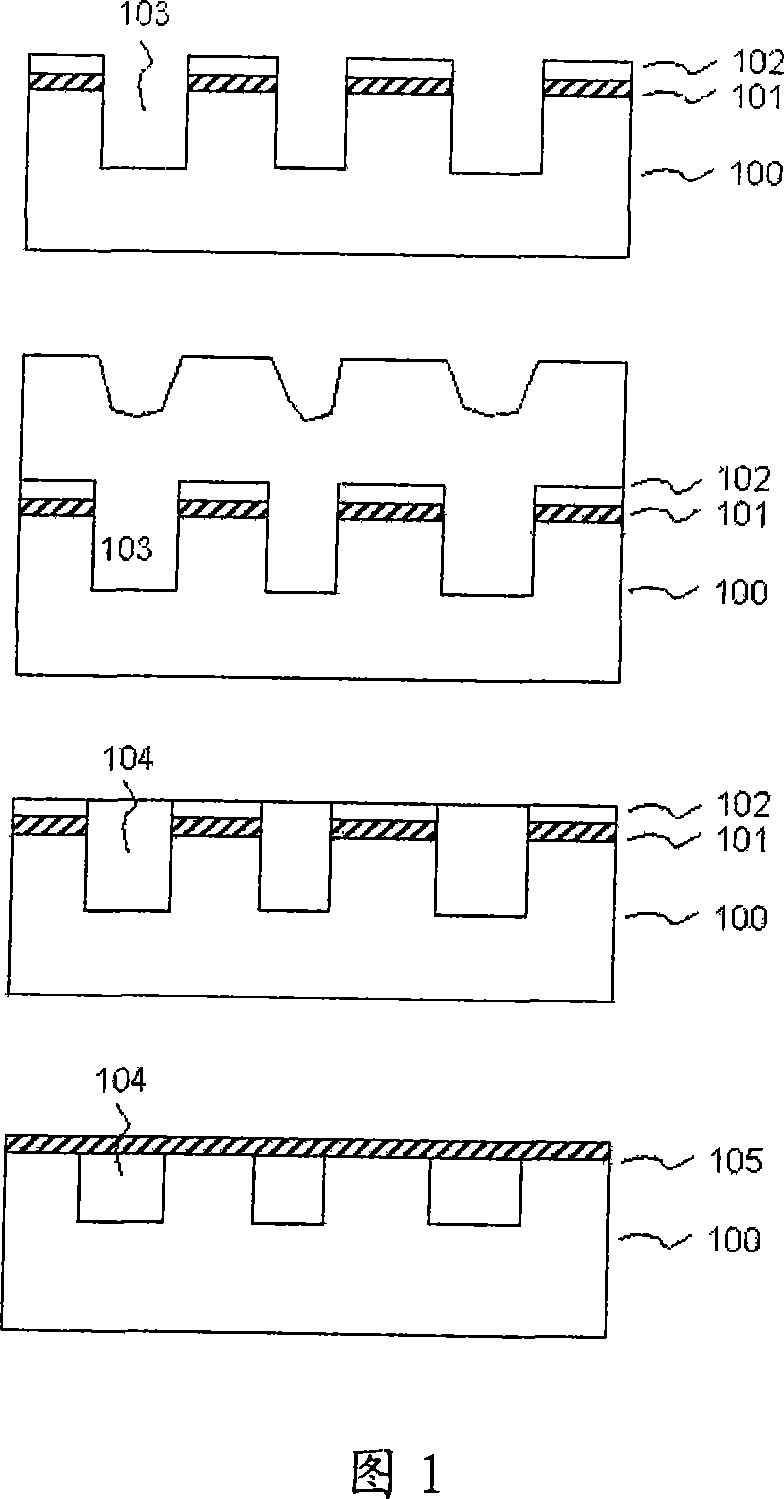

Adjuvant for chemical mechanical polishing slurry

ActiveUS20060141741A1Improve polishing selectivityMinimize agglomerationOther chemical processesDecorative surface effectsPolyelectrolyteAdjuvant

Disclosed is an adjuvant for use in simultaneous polishing of a cationically charged material and an anionically charged material, which forms a adsorption layer on the cationically charged material in order to increase the polishing selectivity of the anionically charged material to cationically charged material, wherein the adjuvant comprises a polyelectrolyte salt containing: (a) a graft type polyelectrolyte that has a weight average molecular weight of 1,000˜20,000 and comprises a backbone and a side chain; and (b) a basic material. CMP (chemical mechanical polishing) slurry comprising the above adjuvant and abrasive particles is also disclosed.

Owner:LG CHEM LTD

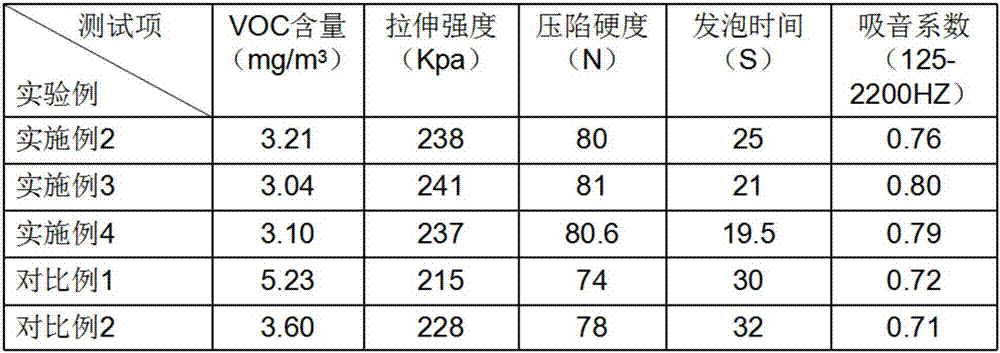

Polyurethane, product and preparation method thereof

The invention belongs to the technical field of preparation and application of polyurethane and provides polyurethane, a product and a preparation method thereof. The polyurethane is prepared by adopting a polyether polyol mixture and isocyanate as raw materials; the polyether polyol contains high-activity polyether polyol, grafting type polyether polyol, crosslinking agent, pore forming agent, catalyst, foaming agent, formaldehyde removing agent A and formaldehyde removing agent B. The polyurethane provided by the invention has good environment-friendly property and sound-absorbing property, simultaneously the polyurethane preparation method provided by the invention is applicable to large-mold foaming, and the production efficiency of polyurethane is improved.

Owner:苏州高夫高分子材料有限公司

Carbon fiber-reinforced halogen-free flame-retardant PA66 composite and preparation method thereof

The invention relates to a carbon fiber-reinforced halogen-free flame-retardant PA66 composite and a preparation method thereof. The composite comprises, by weight, 52.1 to 68.1% of PA66, 15 to 20% of a halogen-free fire retardant, 10 to 30% of carbon fibers, 2 to 4% of a grafting type toughening modifier, 0.4% of an anti-oxidant and 0.5% of a lubrication dispersing agent. The invention also relates to a preparation method for the carbon fiber-reinforced halogen-free flame-retardant PA66 composite. The PA66 composite provided by the invention is developed to meet special requirements of electric appliance products on antistatic performance and flame resistance of electromagnetic-shielding materials. Compared with the prior art, the PA66 composite provided by the invention has the advantages of high mechanical strength, surface resistance of 10<-2> to 10<6> omega, electromagnetic shielding performance, no halogen, environmental protection, flame-retardation performance reaching the level UL-94V0, good appearance and excellent comprehensive properties, and is especially applicable to thin-wall products with high requirements on precision.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Grafting type asphalt modified masterbatch and method for preparation

An grafted asphalt modified masterbatch contains 65~95 wt.% polymer modifier, 0.5~30 wt.% asphalt, 0.5~30 wt.% compatilizer, 4~12 wt.% grafting reaction adjuvant. The preparation method comprises uniformly mixing 65~95 wt.% polymer modifier, 0.5~30 wt.% asphalt, 0.5~30 wt.% compatilizer, 4~12 wt.% grafting reaction adjuvant, controlling the mixture fusant temperature between 80íµ and 200íµ, extruding, palletizing on the double screw extruder to obtain the grafted asphalt modified masterbatch; heating 85~98 wt.% asphalt to 100~220íµ, charging 2~15 wt.% said grafted asphalt modified masterbatch and stirring for 30~80 minutes to obtain the modified asphalt. The asphalt modified masterbatch provided by the invention can effectively improve the dispersibility of the polymer modifier in asphalt, maximumly exert the modification effect of the polymer modifier, and obviously improve the performances and storage stability of the modified asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

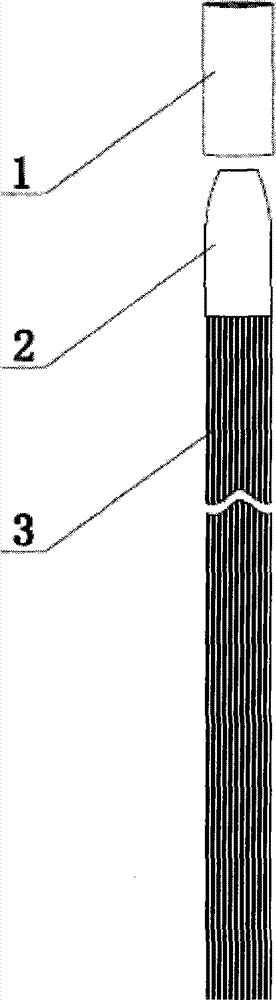

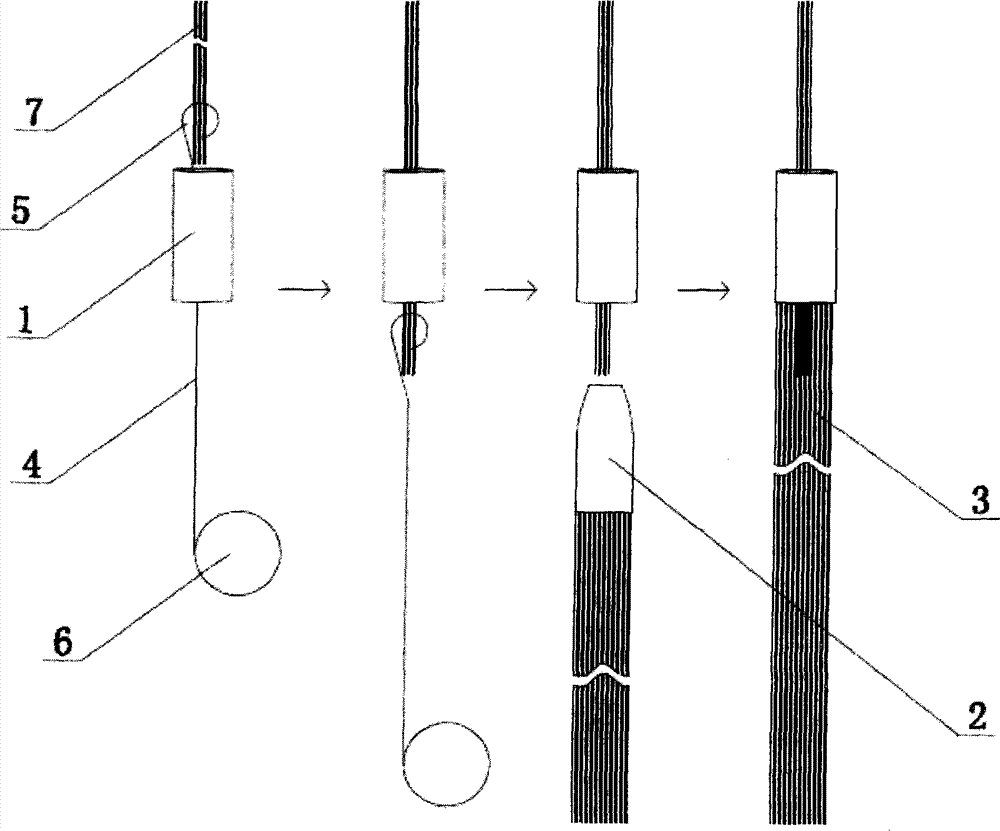

Grafting type wig, wig grafting tool and wig grafting method

The invention discloses a grafting type wig, a wig grafting tool and a wig grafting method. The grafting type wig comprises a topknot, wherein the topknot is stuck on a hard connector clip, and the hard connector clip is externally matched to a soft coating sleeve. After human hair to be grafted is drawn in and passes through the soft coating sleeve, the hard connector clip is extruded into the soft coating sleeve, so that a grafting process of the wig and the human hair can be completed very conveniently and quickly, an average person can learn the grafting process quickly, and the human hair cannot be hurt in a wig removal process.

Owner:YIWU SIDAI CULTURAL & CREATIVE CO LTD

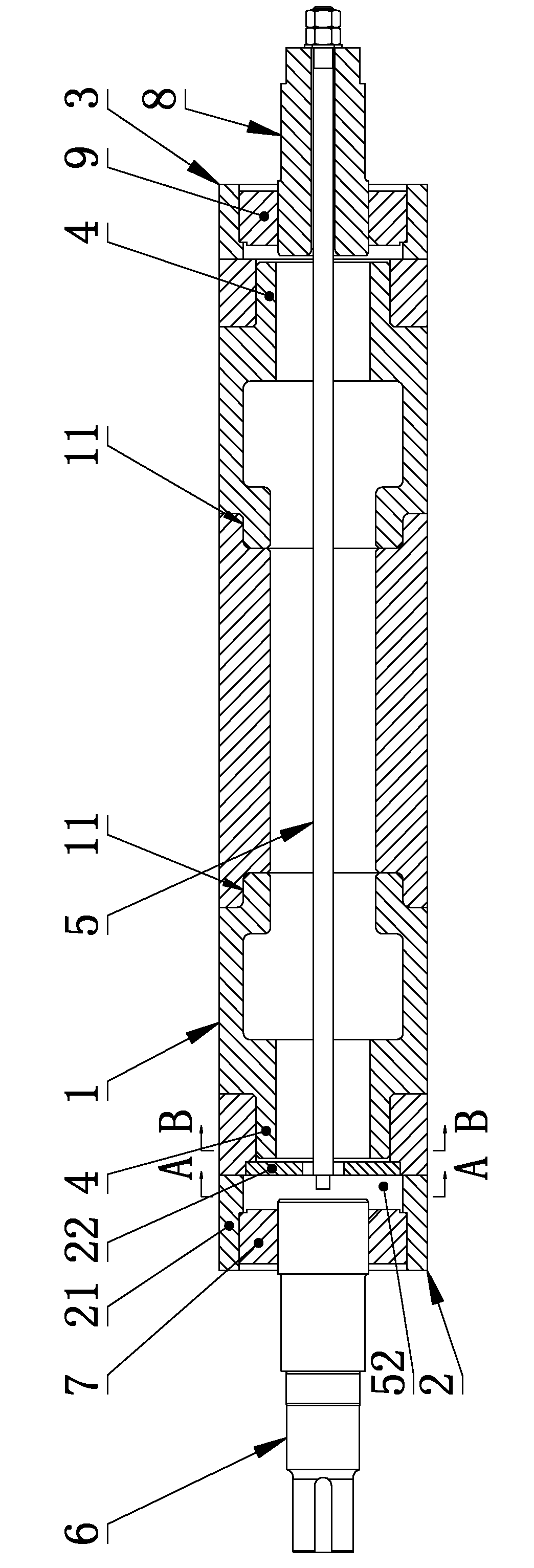

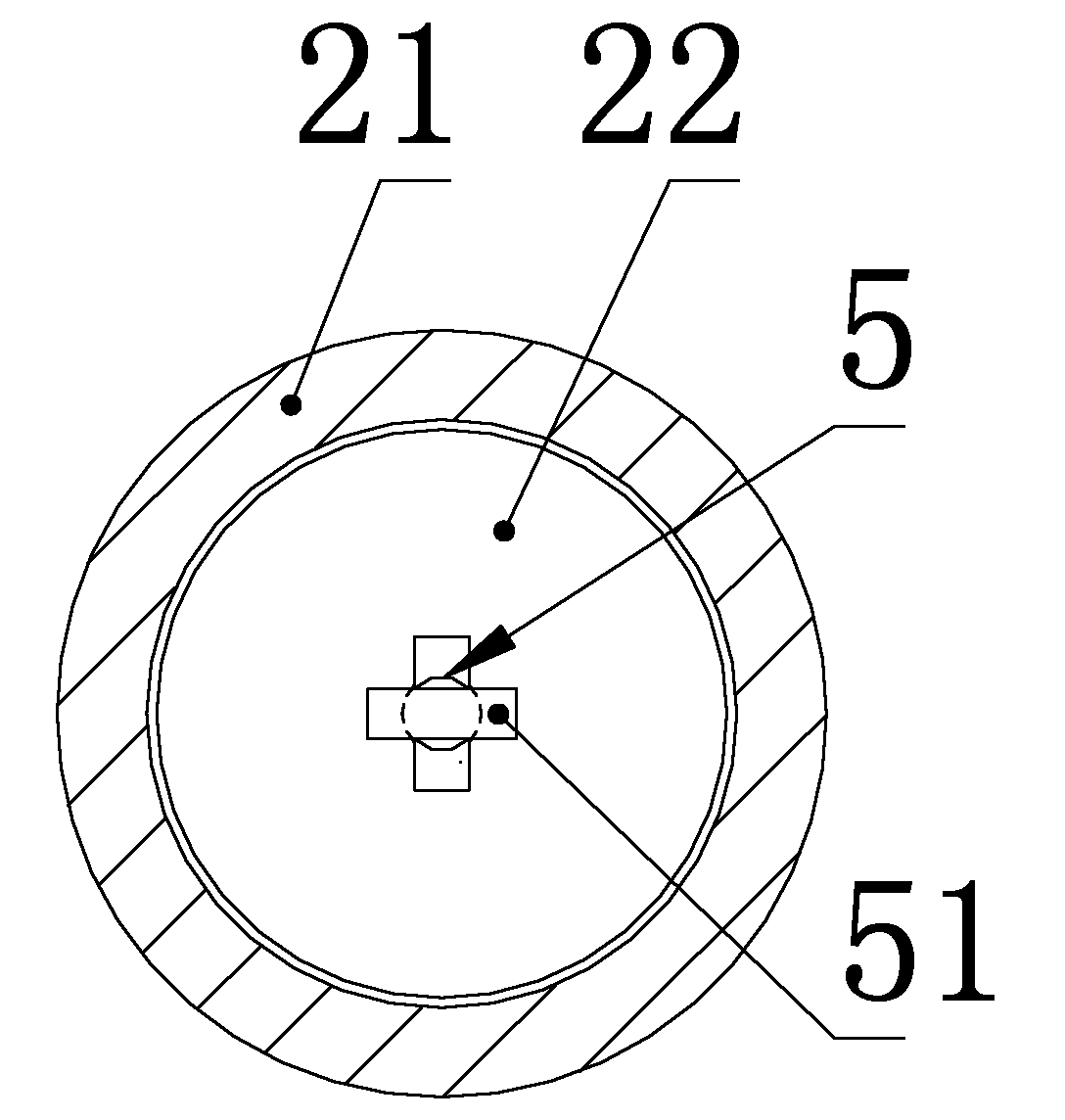

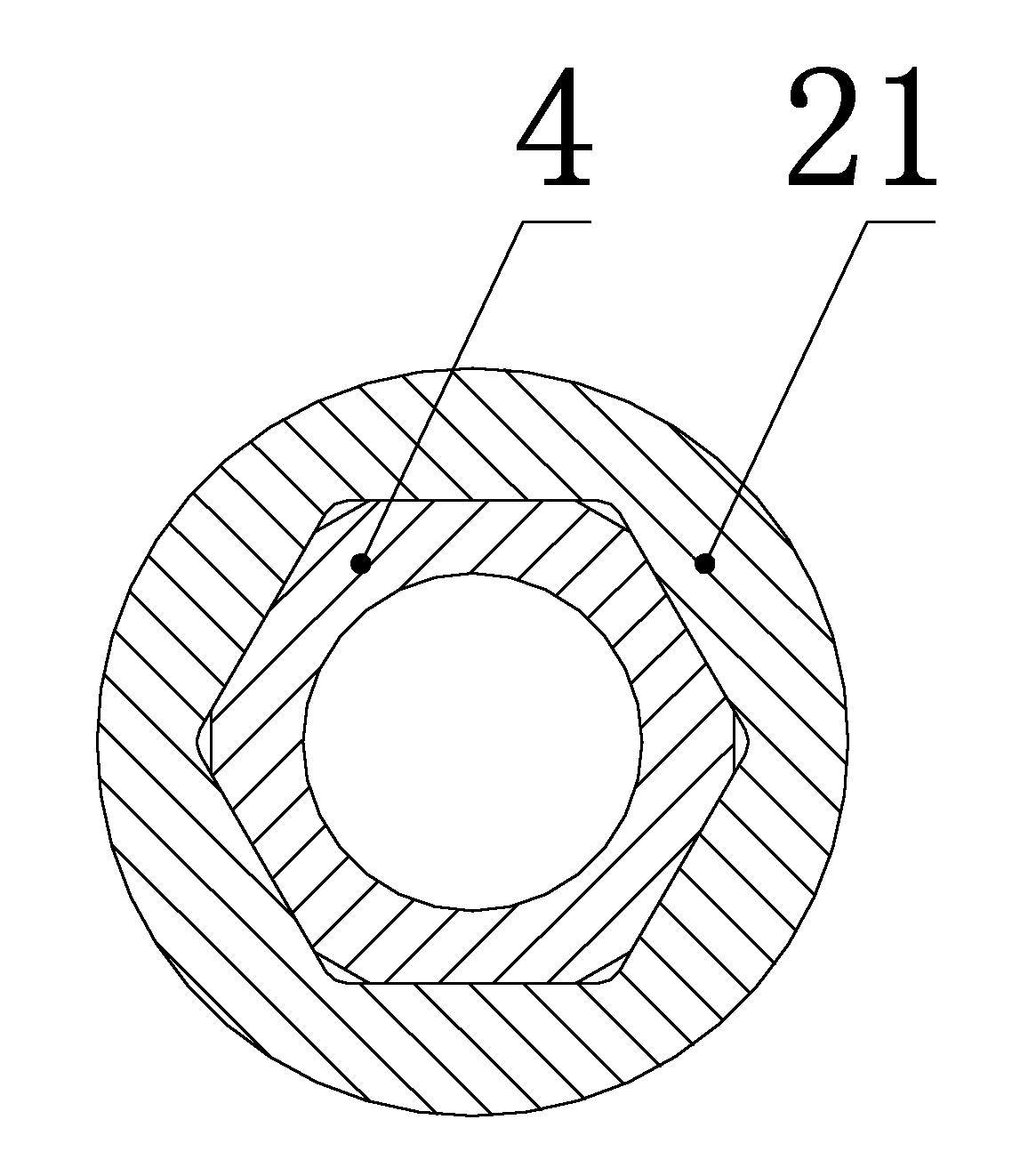

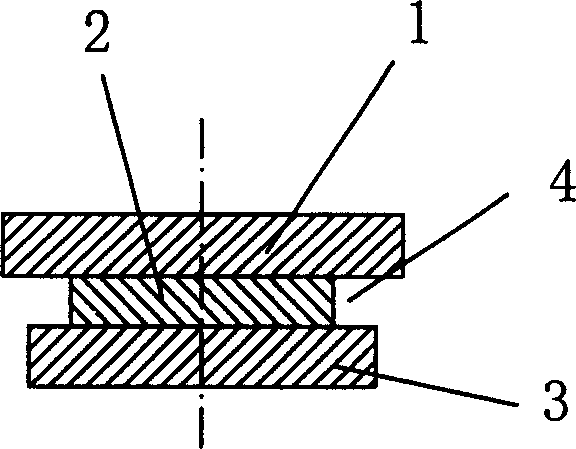

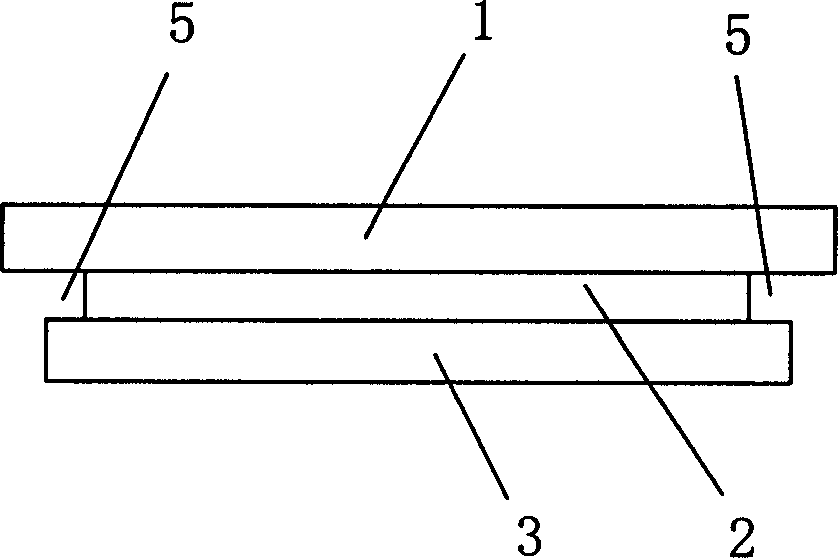

Hollow roll for roller way

InactiveCN101830343AFor quick maintenanceQuality improvementRollersProduction lineMaterials processing

The invention relates to a transportation roller way for sectional material processing, in particular to a hollow roll for a roller way. The hollow roll comprises a roll body (1), a driving side extremity piece (2), a driven side extremity piece (3), a driving side spindle head (6) and a driven side spindle head (8), wherein the driving side extremity piece (2) and the driven side extremity piece (3) are respectively located at two ends of the roll body (1) through grafting type coordination, and the roll body (1), the driving side extremity piece (2) and the driven side extremity piece (3) are detachably and fixedly connected into a whole; the grafting type coordination is formed by a plug (4) and a slot which are coordinated. The invention can realize the rapid maintenance of the roller way, improve the quality of the surface of a rolled piece, reduce the maintenance time, and increase the utilization ratio of a rolling production line and the yield of the sectional material. The replaced roll body is maintained offline and is not influenced by time and fields, which can ensure the quality of the maintained roll body and the surface thereof, thereby the roll consumption is reduced. The invention is suitable for various transportation roller ways.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

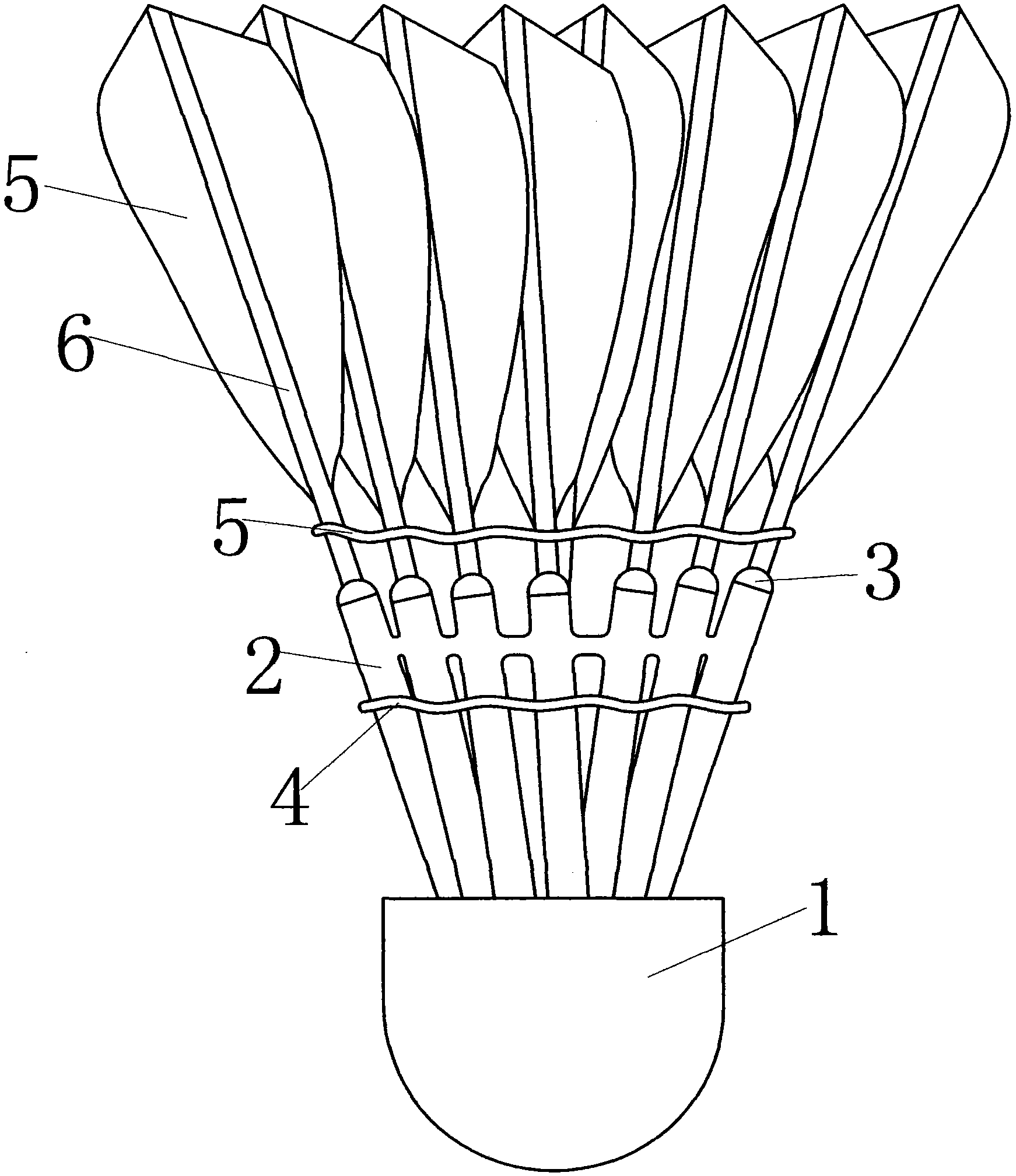

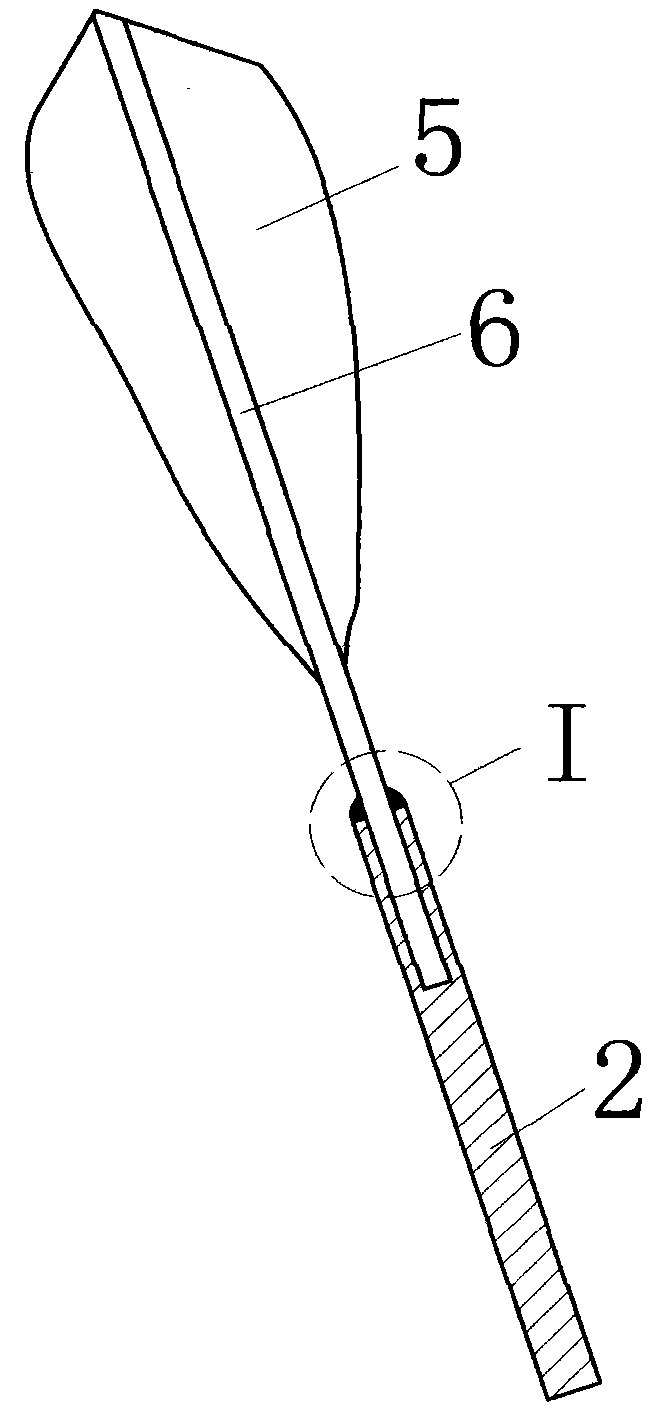

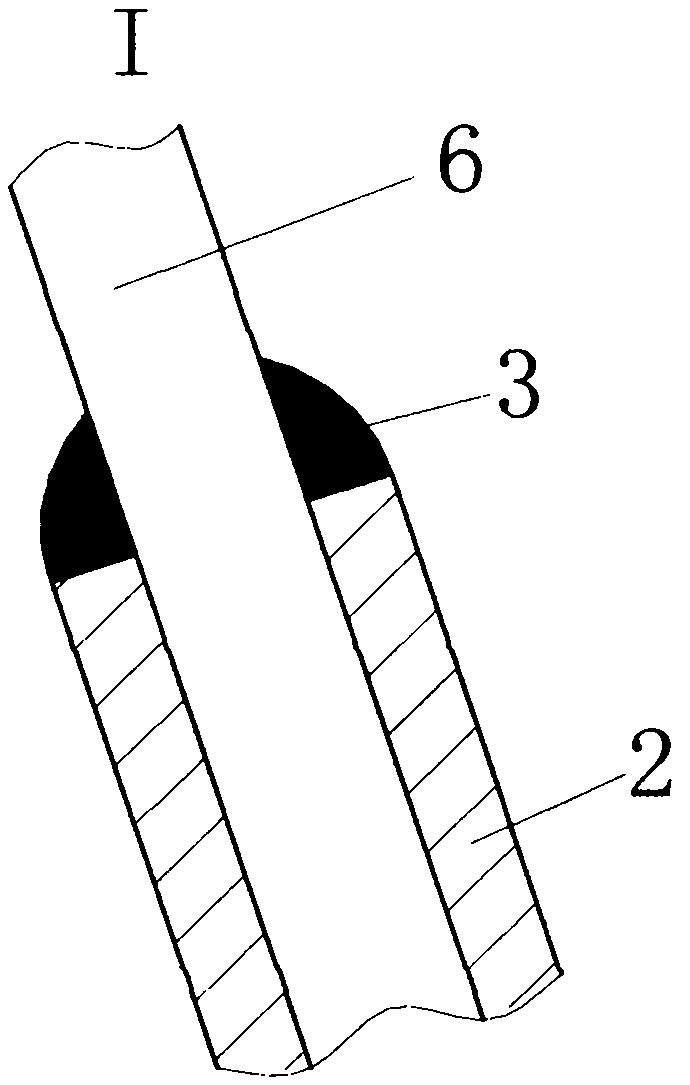

Grafting type shuttlecock

The invention relates to a grafting type shuttlecock. The grafting type shuttlecock comprises a shuttlecock head, wherein feather fixing rods are inserted in the upper portion of the shuttlecock head, insertion holes are formed in the upper ends of all the feather fixing rods, the middle portions of the feather fixing rods are connected through a first fixing string, the feather fixing rods are integrally formed through one-time machining, only one connecting rib is adopted, the strength can be guaranteed, and the mass of the feather fixing rods is reduced; feather pieces are inserted into the insertion holes; each feather piece comprises underfur and an underfur rod, the underfur rods are inserted into the insertion holes of the feather fixing rods and fixed to the feather fixing rods through an adhesive, and the middle portions of the underfur rods are connected through a second fixing string; the length of each piece of underfur is 39.5 mm; the overall length of each underfur rod is 48.5 mm. The grafting type shuttlecock has the advantages that the structural design is reasonable, the manufacturing cost is low, and the hitting resistance is high. The size of the shuttlecock is reduced to a certain degree, the flying performance of the shuttlecock is improved, and the hitting resistance of the shuttlecock is improved.

Owner:ANHUI HUA LING FEATHER PROD

Adjuvant for chemical mechanical polishing slurry

ActiveCN101068901AOther chemical processesSemiconductor/solid-state device manufacturingPolyelectrolyteAdjuvant

Disclosed is an adjuvant for use in simultaneous polishing of a cationically charged material and an anionically charged material, which forms a adsorption layer on the cationically charged material in order to increase the polishing selectivity of the anionically charged material to cationically charged material, wherein the adjuvant comprises a polyelectrolyte salt containing: (a) a graft type polyelectrolyte that has a weight average molecular weight of 1,000-20,000 and comprises a backbone and a side chain; and (b) a basic material. CMP (chemical mechanical polishing) slurry comprising the above adjuvant and abrasive particles is also disclosed.

Owner:LG CHEM LTD

Full groove floor with double tenon structural member

The invention designs a kind of belt double structural element the entire trough floor, plays the role of along the length direction beginnings and ends separately opens has the second slot, separately operates the first slot along the width direction two sides, has formed upside is the surface flag, middle is the connection level, lower part for base level three structures; Flag width ratio flag width big, flag width ratio middle connection level width big, surface flag length compared to place flag length long, the flag length is longer than the middle connection level length; The floor two sides first slot as soon as assumes the peg grafting type coordination with the double structural element; The floor beginnings and ends second slot as soon as assumes the peg grafting type coordination with another pair of structural element. The invention merit is: Does not need drive nails fixedly, is aerosol, the disassemblage is convenient, may repeatedly use also does not need to drill a hole; May reduce the original wood floor the altitude, increases the housing altitude, and has solved the wood floor material, reduced the cost, enhances the benefit.

Owner:朱俊华

Carbon fiber/carbon nanotube/epoxy resin/polyimide multi-dimensional mixed composite material and preparation process thereof

The invention discloses a carbon fiber / carbon nanotube / epoxy resin / polyimide multi-dimensional mixed composite material and a preparation process thereof. The preparation process comprises the following steps: purifying the surface of a carbon nanotube, performing carboxylation and acylating chlorination on the surface of the purified carbon nanotube, introducing diamine or polyamine with a characteristic structure to obtain a graft type carbon nanotube with active amino groups on the surface, and modifying the carbon nanotube grafted with active amino groups with a micromolecular aromatic polyanhydride compound to prepare a carbon nanotube with anhydride groups; ultrasonically shaking and stirring at a high speed to disperse the carbon nanotube in epoxy resin and a polyimide substrate, curing by adopting an organic anhydride type curing agent to obtain a carbon nanotube-containing epoxy resin and polyimide polymer, and compounding the polymer as a substrate with carbon fibers in a certain way to finally form the multi-dimensional mixed composite material structure connected by covalent bonds, wherein a large quantity of polymers are wound on the surfaces of the carbon fibers and the carbon nanotube.

Owner:DANYANG DANJIN AUTO FITTINGS

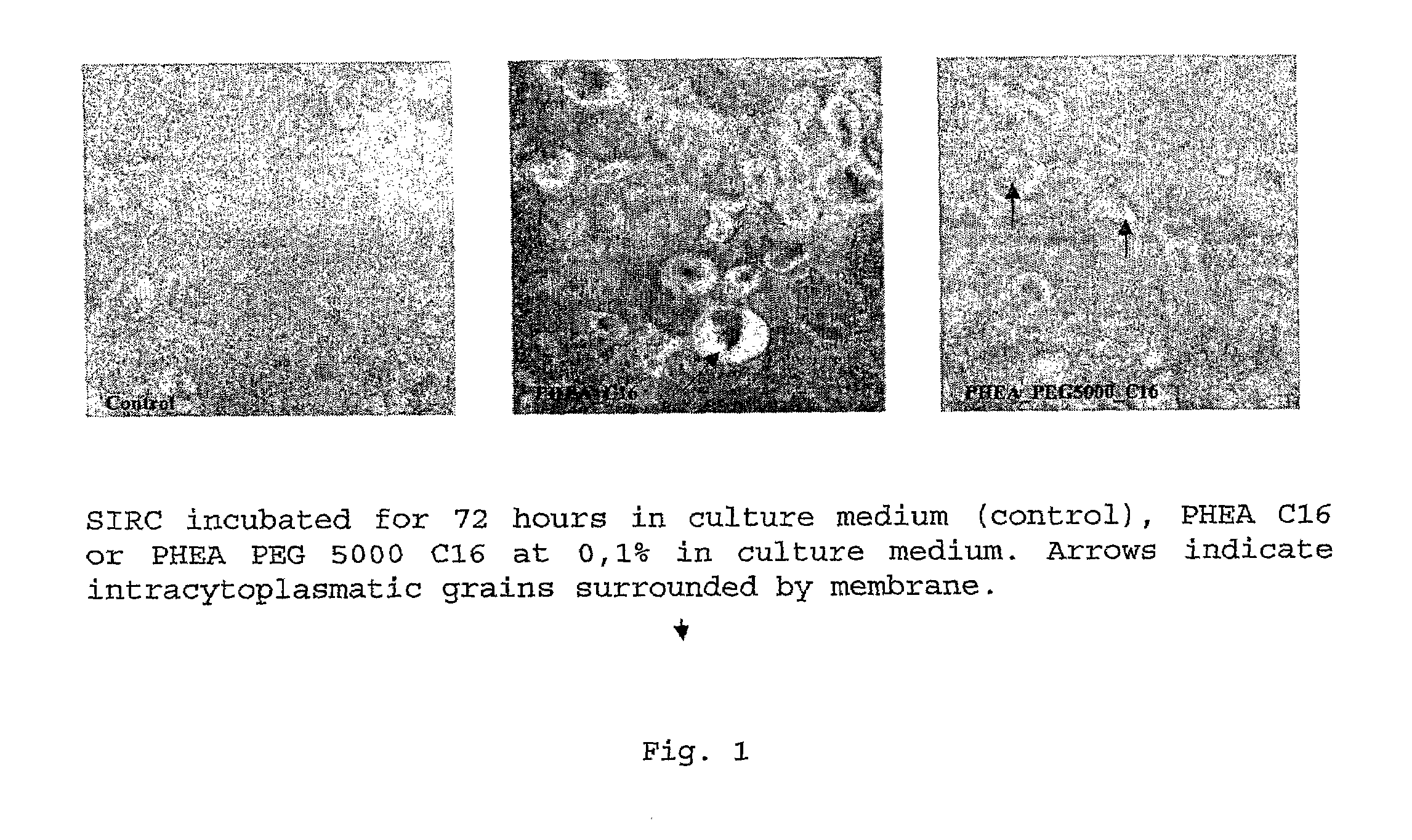

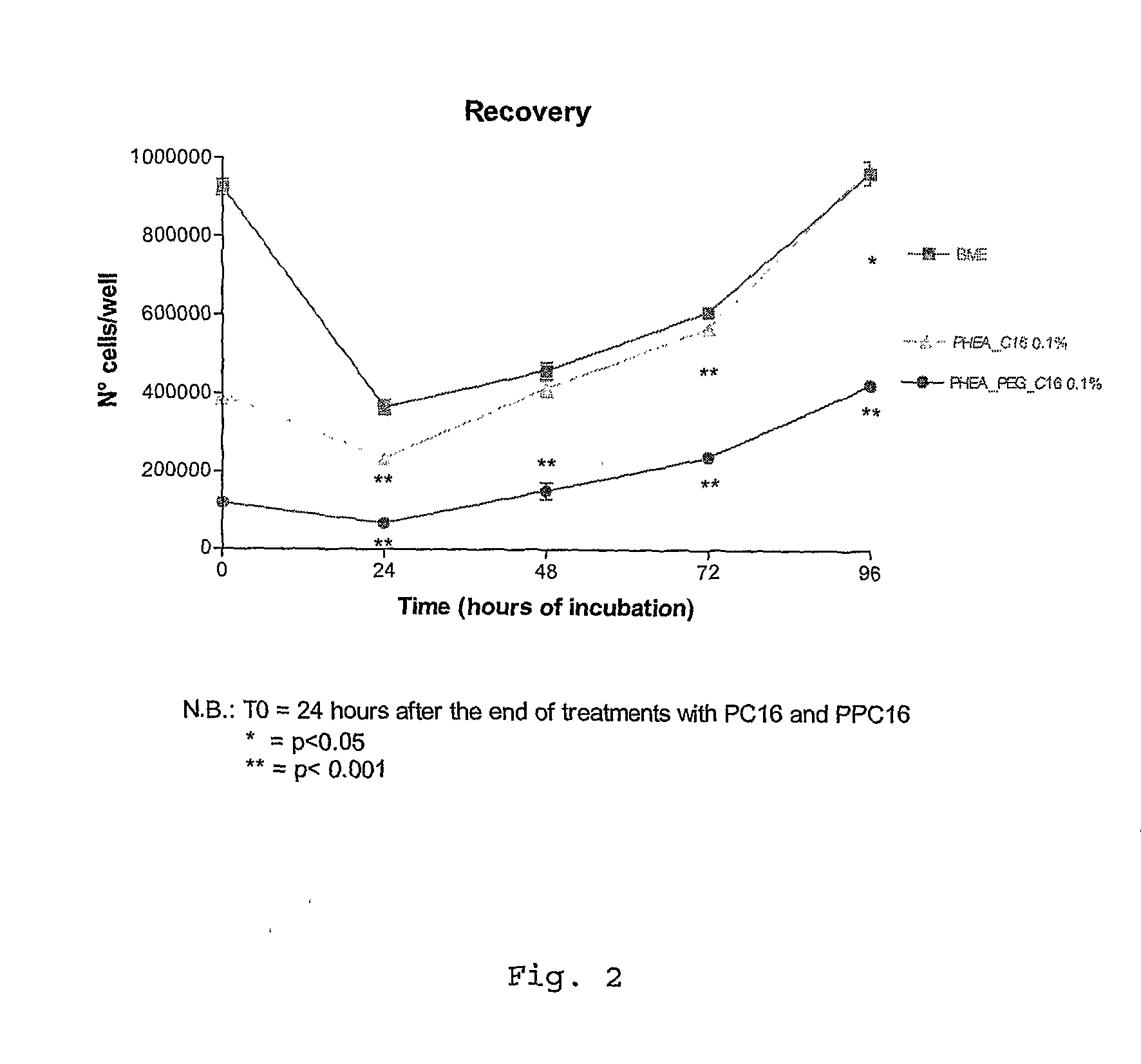

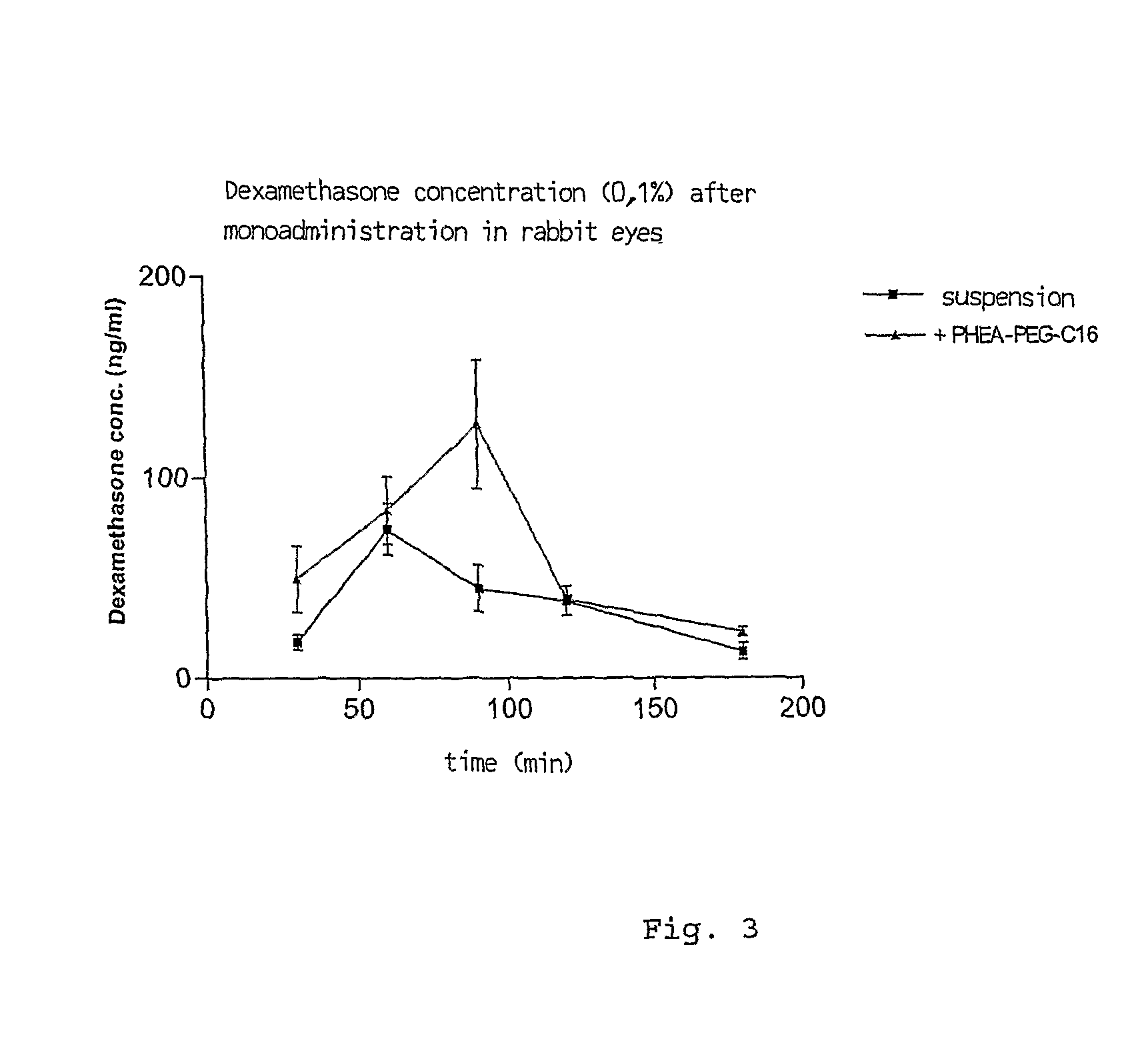

Ophthalmic Pharmaceutical Composition Containing Amphiphilic Polyaspartamide Copolymers

InactiveUS20090221545A1Increase the number ofLess non-productive absorptionBiocideAnimal repellantsPenicillinBeta blocker

The present invention relates in general to the use of amphiphilic graft-type copolymers of polyaspartamide for the ophthalmic administration of drugs, such as for example steroidal and non-steroidal anti-inflammatory agents, antimicrobial agents such as aminoglycosides, macrolides, cephalosporin, tetracycline, quinolones, penicillin, beta-lactams, anti-glaucoma agents such as prostaglandins, alpha- and beta-blockers, inhibitors of carbonic anhydrase, cannabinoids, antiviral agents, diagnostic agents, anti-angiogenic agents, antioxidants.

Owner:S I F I SPA

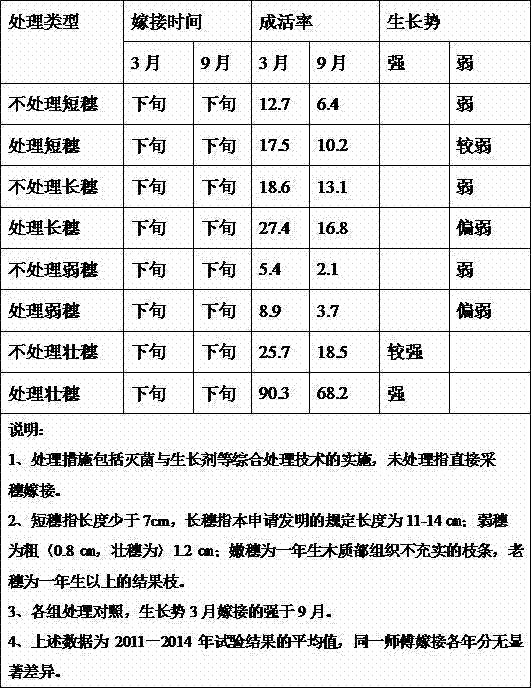

Method for increasing grafting survival rate of waxberry ploidy variation plants

InactiveCN104719001AGuaranteed growth qualityHigh activityGraftingHorticulture methodsGrowth plantPloidy

The invention discloses a method for increasing the grafting survival rate of waxberry ploidy variation plants. According to the method, specific selections and regulations are made for grafting time, scion selecting, scion specifications, grafting types, a binding method, unbinding time and an unbinding method, treated robust scions are adopted for grafting, the years and specifications of the scions are strictly limited, the growth quality of the scions can be guaranteed effectively, disinfection treatment is conducted before scion picking, pretreatment is conducted through plant growth accelerators before grafting, the activity of the scions can be improved, the grafting survival rate is guaranteed, and the grafting survival rate is further guaranteed by adopting the step-by-step unbinding method in the later period. In conclusion, by adopting the grafting method, the survival rate can be increased manyfold, reproductive cost is lowered, and technical support can be provided for commercial seedling culture.

Owner:ZHEJIANG CITRUS RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com