Polyurethane, product and preparation method thereof

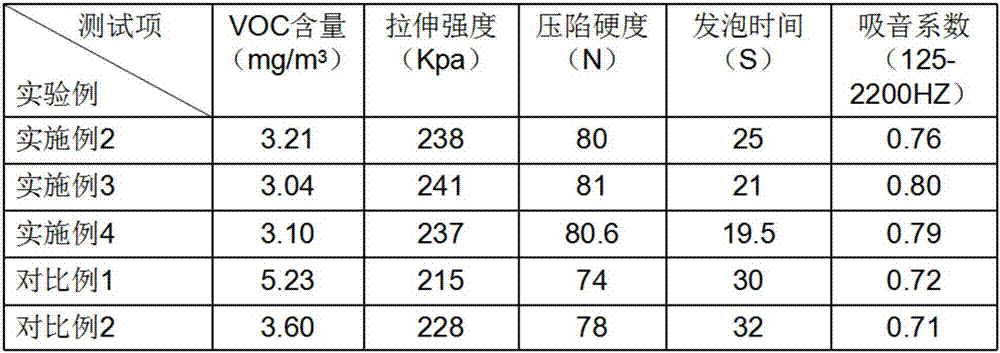

A technology of polyurethane and isocyanate, which is applied in the field of polyurethane and its products and preparation, can solve the problems of danger, difficulty in reaching, and carcinogenicity, and achieve good sound absorption and sound insulation performance, low VOC content, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of polyurethane, described polyurethane is made with polyether polyol mixture and isocyanate as raw material, and described polyether polyol comprises highly active polyether polyol, graft type polyether polyol, crosslinking agent, opening agent, Catalyst, foaming agent, formaldehyde removal agent A and formaldehyde removal agent B, above-mentioned raw material composition ratio is:

[0035] Highly reactive polyether polyol: 30-50 parts;

[0036] Graft polyether polyol: 20-40 parts;

[0037] Cross-linking agent: 1 to 3 parts;

[0038] Cell opener: 2 to 6 parts;

[0039] Catalyst: 2 to 3.3 parts;

[0040] Foaming agent: 4 to 6 parts;

[0041] Aldehyde remover A: 0.2 to 0.8 parts;

[0042] Aldehyde remover B: 0.5-2.0 parts;

[0043] Isocyanate: 60-100 parts.

[0044] Specifically, the preparation steps:

[0045] S1: Pretreatment: Mix the aldehyde remover A with the aldehyde remover B, and add it into water to melt in proportion (mixture of aldehyde remover:...

Embodiment 2

[0049] A kind of polyurethane, described polyurethane is made with polyether polyol mixture and isocyanate as raw material, and described polyether polyol comprises highly active polyether polyol, graft type polyether polyol, crosslinking agent, opening agent, Catalyst, foaming agent, formaldehyde removal agent A and formaldehyde removal agent B, above-mentioned raw material composition ratio is:

[0050] Highly active polyether polyol: 40 parts;

[0051] Graft type polyether polyol: 30 parts;

[0052] Cross-linking agent: 2 parts;

[0053] Cell opener: 4 parts;

[0054] Catalyst: 2.7 parts;

[0055] Foaming agent: 5 parts;

[0056] Reactive formaldehyde remover: 0.5 parts;

[0057] Aldehyde remover B: 1.4 parts;

[0058] Isocyanate: 80 parts.

[0059] Specifically, the preparation steps:

[0060] S1: Pretreatment: Mix the reactive aldehyde remover with the aldehyde remover B, and add it into water to melt in proportion (mixture of aldehyde remover: water) = 1:1;

[0...

Embodiment 3

[0064] A kind of polyurethane, described polyurethane is made with polyether polyol mixture and isocyanate as raw material, and described polyether polyol comprises highly active polyether polyol, graft type polyether polyol, crosslinking agent, opening agent, Catalyst, foaming agent, formaldehyde removal agent A and formaldehyde removal agent B, above-mentioned raw material composition ratio is:

[0065] Highly active polyether polyol: 30 parts;

[0066] Graft type polyether polyol: 20 parts;

[0067] Cross-linking agent: 1 part;

[0068] Cell opener: 2 parts;

[0069] Catalyst: 2 parts;

[0070] Foaming agent: 4 parts;

[0071] Reactive aldehyde remover: 0.2 parts;

[0072] Catalytic decomposition type aldehyde remover: 0.5 parts;

[0073] Isocyanate: 60 parts.

[0074] Specifically, the preparation steps:

[0075] S1: Pretreatment: Mix the reactive aldehyde remover with the catalytic decomposition aldehyde remover, and add it into water in proportion (mixture of aldeh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com