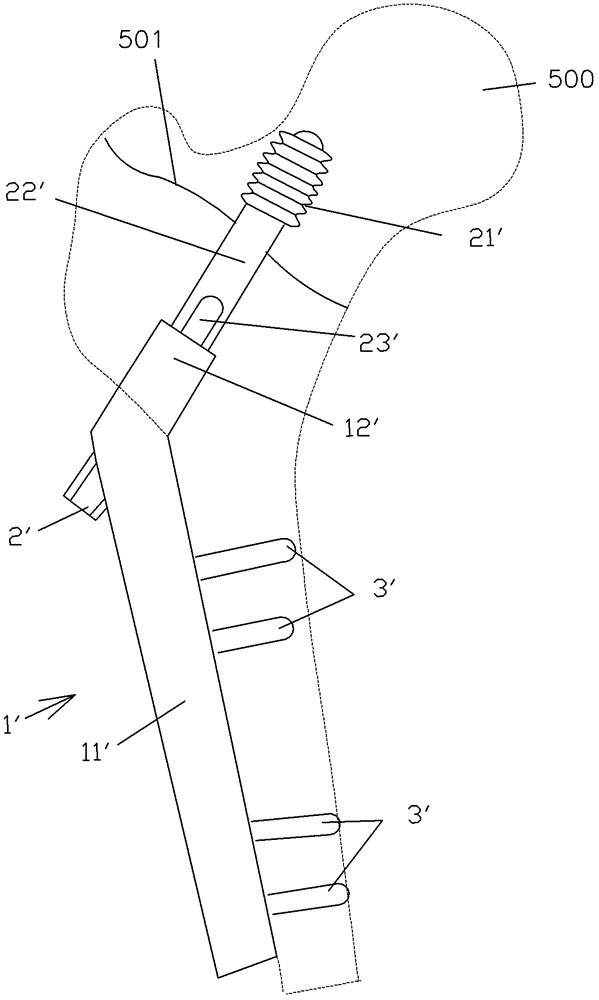

Hollow bone grafting type dynamic hip screw

A hip screw, hollow technology, applied in the direction of internal osteosynthesis, medical science, fastening devices, etc., can solve the problems of femoral head necrosis, nonunion, withdrawal, etc., achieve reliable internal fixation, promote early healing, and reduce failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

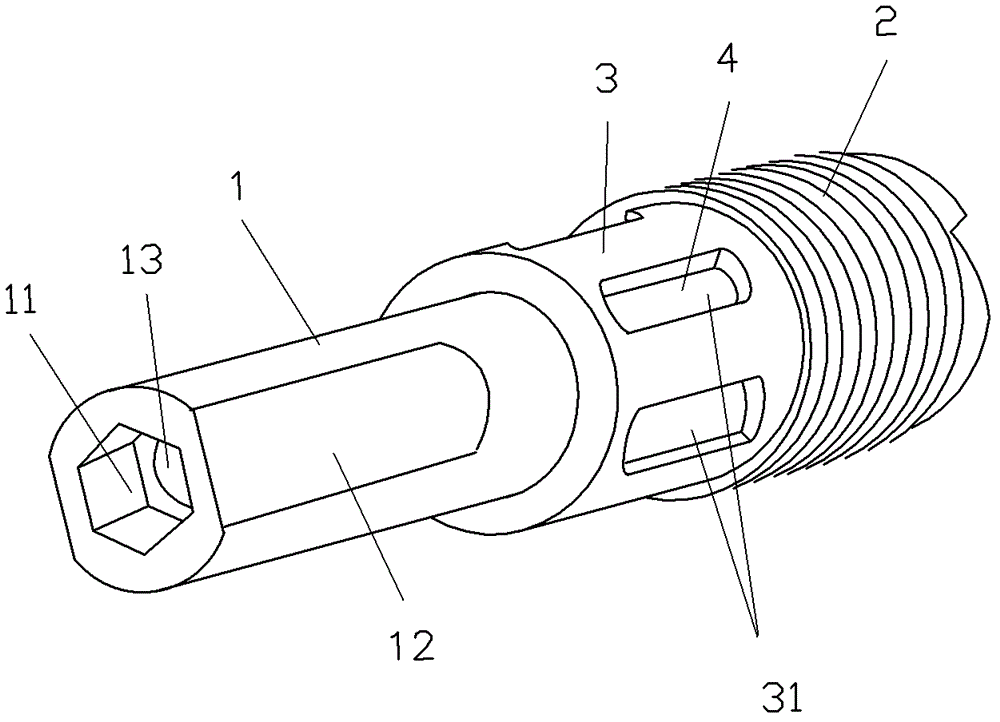

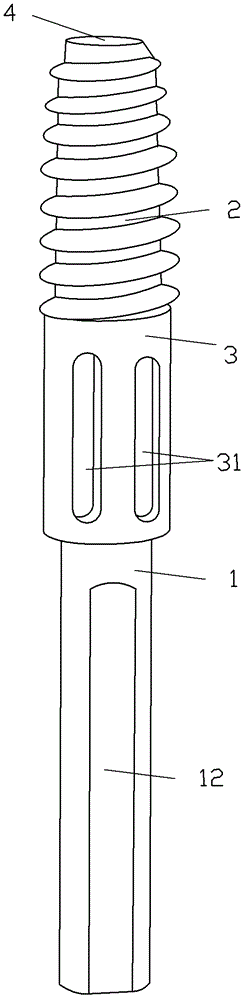

[0021] The three-dimensional structure of a preferred embodiment of the hollow bone graft type dynamic hip screw of the present invention, such as figure 2 and image 3 shown. The hollow bone graft type dynamic hip screw is an improvement of the lag screw used in orthopedic surgery. Its whole body is provided with a guide pin hole 13 penetrating along the central axis, and the front end of the nail body 1 has a bone thread 2; the outer peripheral surface of its circular tubular nail body 1 rear part has two opposite planes 12, so that the nail body 1 rear part The cross-section of the screw is oblate; the rear end of the nail body 1 is provided with an inner hexagon socket 11, which is very convenient for doctors to use a lag screw to insert a driver to rotate the dynamic hip screw during operation. The nail body 1 is provided with a cage-shaped part 3 which is hollow inside and has a plurality of elongated windows 31 extending along the central axis direction on the outer ...

Embodiment 2

[0024] The structure of another preferred embodiment of the hollow bone graft type dynamic hip screw of the present invention, as Figure 6 and Figure 7 shown. The overall length of the hollow bone graft type dynamic hip screw is much smaller than that of the previous embodiment. The whole body of this embodiment is provided with a guide pin hole 130 penetrating along the central axis, and the front end of the nail body 10 has a bone thread 20; the outer peripheral surface of the circular tubular nail body 10 rear part has two opposite planes 120, so that the nail body 10 is The cross-section of the part is oblate; the rear end of the nail body 10 is provided with an inner hexagon socket 110 . The nail body 10 is provided with a cage-shaped portion 30 that is hollow inside and has a plurality of elongated windows 310 extending along the central axis direction on the outer peripheral surface near the bone thread 20 . The cage-like part 30 protrudes outward along the outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com