An injectable calcium-phosphorus ceramic for promoting tendon-bone healing, its preparation method and application

A technology of calcium phosphorus ceramics and tricalcium phosphate ceramics, which is applied in the fields of pharmaceutical formulations, prostheses, drug delivery, etc., to promote early tendon-bone healing, enhance the effect of promoting tendon-bone healing, and alleviate the effect of low pull-off strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

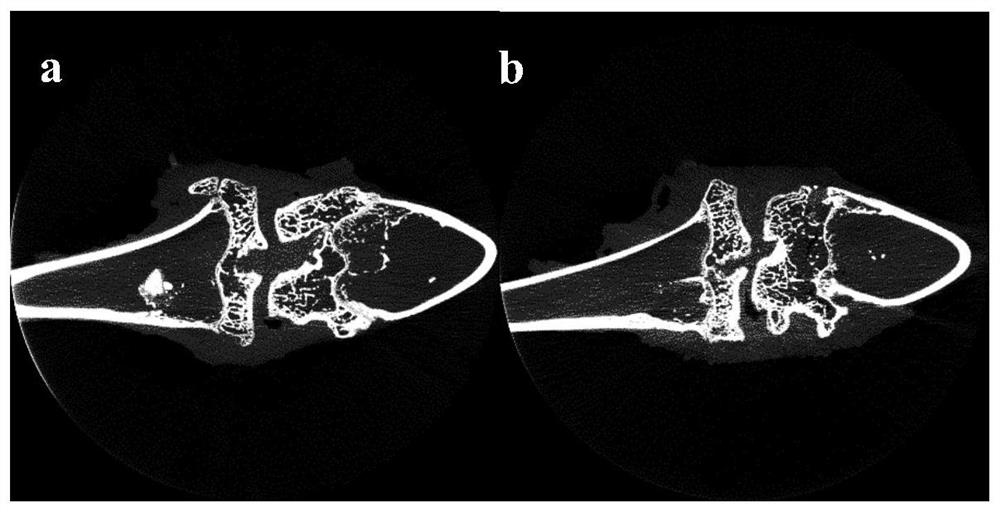

Image

Examples

Embodiment 1

[0032] 1) Take medical sterile collagen and prepare 10ml of 1.0% aqueous solution.

[0033] 2) Preparation of hydroxyapatite ceramic particles with a particle size of 10-100 μm: Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The powder is used as a raw material, and the hydroxyapatite ceramic particles are prepared by a hydrothermal synthesis method. The obtained suspension is configured into a slurry with a concentration of 80-100mg / ml and good particle dispersion, which is transported to a spray dryer by a peristaltic pump for spray drying treatment, and then the spray-dried powder is treated with a standard sampling sieve Sieving is carried out to obtain low-crystallinity, nearly spherical hydroxyapatite ceramic particles with a particle size of 10-100 μm, and the obtained calcium-phosphorus ceramic particles are kept at 250° C. for 2 hours for dry heat sterilization.

[0034] 3) Take 10 g of hydroxyapatite ceramic particles with a particle size of 10-100 μm obtained in step ...

Embodiment 2

[0037] 1) Take an appropriate amount of collagen solution with a concentration of 5mg / ml, add a corresponding amount of methacrylic anhydride at 4°C, adjust the pH of the reaction solution to 8.0-9.0 with 5mol / L NaOH, and react for 8 hours.

[0038] 2) Collagen modified with methacrylic anhydride (the degree of modification is 10%-30%) is prepared into 20 ml of a solution with a mass fraction of 2% in PBS.

[0039] 3) Add the photoinitiator to the above solution, mix well and keep away from light. The solid content of the initiator is 0.079‰.

[0040]4) Preparation of hydroxyapatite ceramic particles with a particle size of 10-100 μm: Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The powder is used as a raw material, and the hydroxyapatite ceramic particles are prepared by a hydrothermal synthesis method. The obtained suspension is configured to a certain concentration to form a slurry with good particle dispersion, which is transported to a spray dryer by a peristaltic pump f...

Embodiment 3

[0044] 1) Take medical sterile collagen and prepare 10ml of 1.0% aqueous solution.

[0045] 2) Preparation of tricalcium phosphate ceramic particles with a particle size of 20-50 μm: Disperse tricalcium phosphate micropowder into 1.0% polyvinyl alcohol aqueous solution, transfer to a ball mill and mill for 24 hours to form a slurry with good particle dispersibility, pass through a peristaltic pump Transport it to a spray dryer for spray drying, collect the spray-dried powder, and then sieve the powder with a standard sieve to obtain low-crystallinity, nearly spherical tricalcium phosphate ceramic particles with a particle size of 20-50 μm. The obtained calcium-phosphorus ceramic particles were incubated at 250° C. for 2 hours for dry heat sterilization.

[0046] 3) Get 10 g of tricalcium phosphate ceramic particles with a particle size of 20-50 μm obtained in step 2), add them to the above-mentioned collagen solution and stir evenly to form a paste compound (the solid content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com