Grafting type comb polymer solid electrolyte material and preparation method thereof

A comb-like polymer and solid electrolyte technology, which is applied in the direction of solid electrolyte, non-aqueous electrolyte, electrolyte immobilization/gelation, etc., can solve the problems of reduced mechanical properties, easy tearing, and high viscosity of polymer electrolytes, and achieve improved Electrochemical stability and ionic conductivity, improving exercise ability, and avoiding the effect of easy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

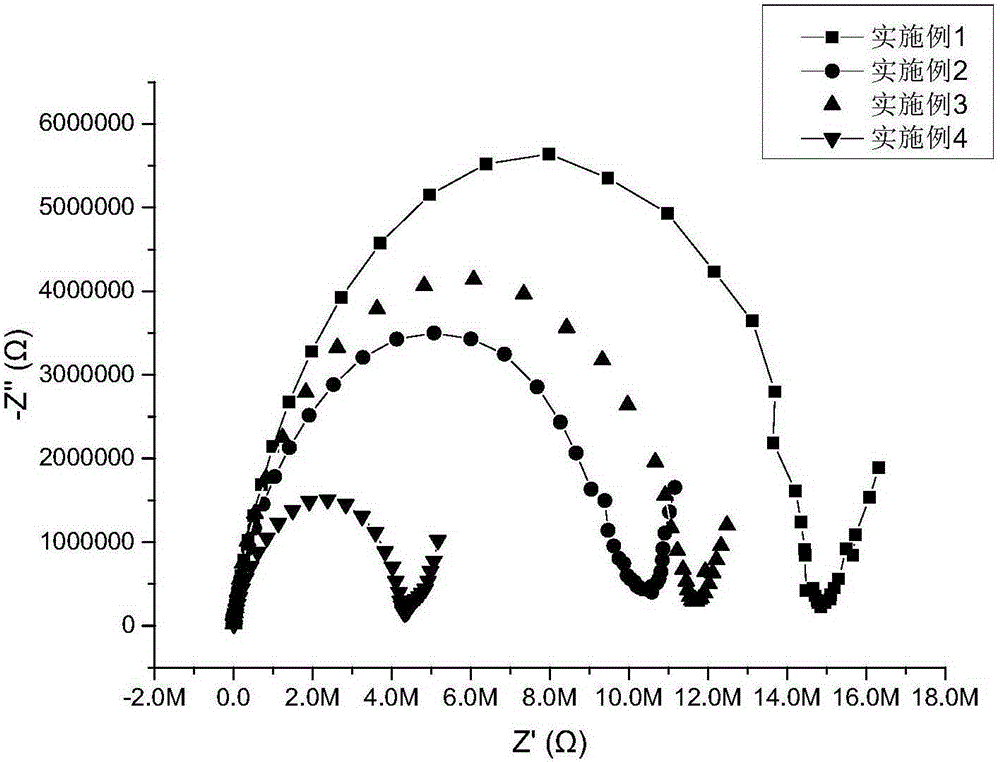

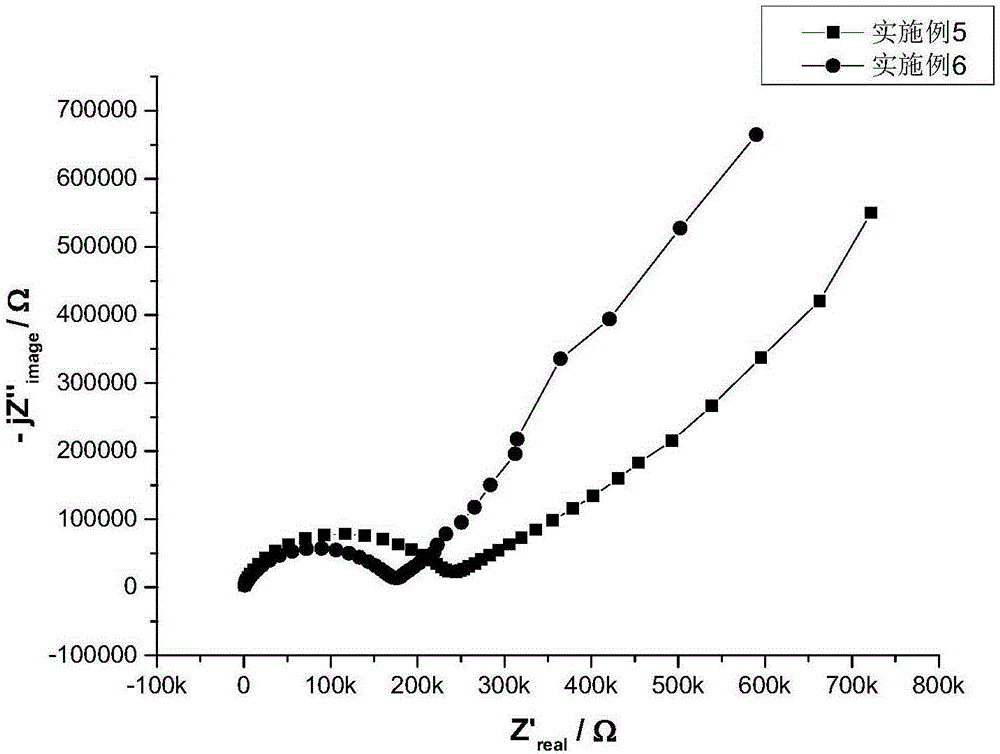

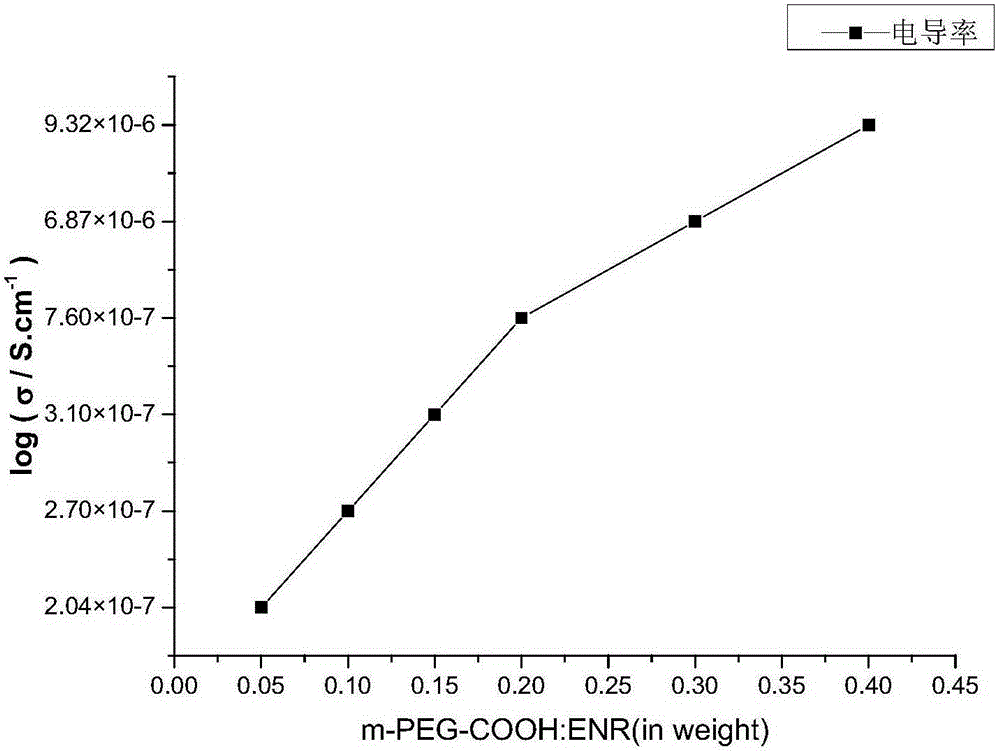

Embodiment 1~6

[0046] (1) Weigh the epoxidized natural rubber of the polymer matrix and dissolve it in the mixed solvent. After swelling, continue to add the mixed solvent and magnetically stir until it dissolves into a uniform solution;

[0047] (2) Dissolve methoxypolyethylene glycol carboxylic acid in tetrahydrofuran solution according to the formula and stir magnetically for 0.5h, then transfer to the solution obtained in step (1), and react the resulting mixed solution in an oil bath at 100°C for 5 hours Hours;

[0048] (3) adding an appropriate amount of lithium salt to the mixed solution prepared by the reaction of claim (2), and magnetic stirring for 10 hours to obtain a uniform and transparent mixed solution;

[0049] (4) casting the mixed solution of claim (3) gained in the polytetrafluoroethylene mould, volatilized naturally in fume hood for 12 hours, then transferred to dry in vacuum oven to obtain film, which is graft type comb polymerization solid electrolyte material.

[0050]...

Embodiment 7

[0063] This embodiment is basically the same as Embodiment 1, except that the amount of lithium perchlorate added is 300 mg. The prepared ENR / PEG-COOH comb-like polymer electrolyte film has electrochemical stability and high conductivity.

Embodiment 8

[0065] This embodiment is basically the same as Embodiment 1, except that the addition of lithium perchlorate is 500 mg. The prepared ENR / PEG-COOH comb-like polymer electrolyte film has electrochemical stability and high conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com