Production method for improving strip steel through coil mechanical property uniformity

A production method and uniformity technology, which are applied in the production field of improving the uniformity of mechanical properties of strip steel through coils, can solve the problems of dimensional fluctuations, easy fractures, and user influences of cold-rolled products, so as to improve the coiling temperature and enhance the movement ability. , the effect of uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The chemical composition of the slab is: C: 0.032wt%, Si: 0.02wt%, Mn: 0.26wt%, P: 0.008wt%, S: 0.008wt%, Alt: 0.041wt%, N: 0.003wt%, the rest Basically Fe and other trace elements.

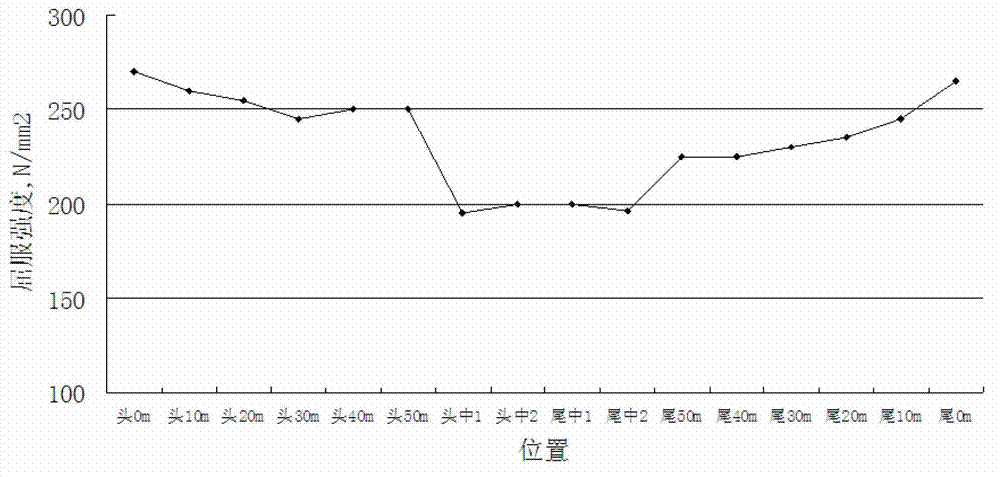

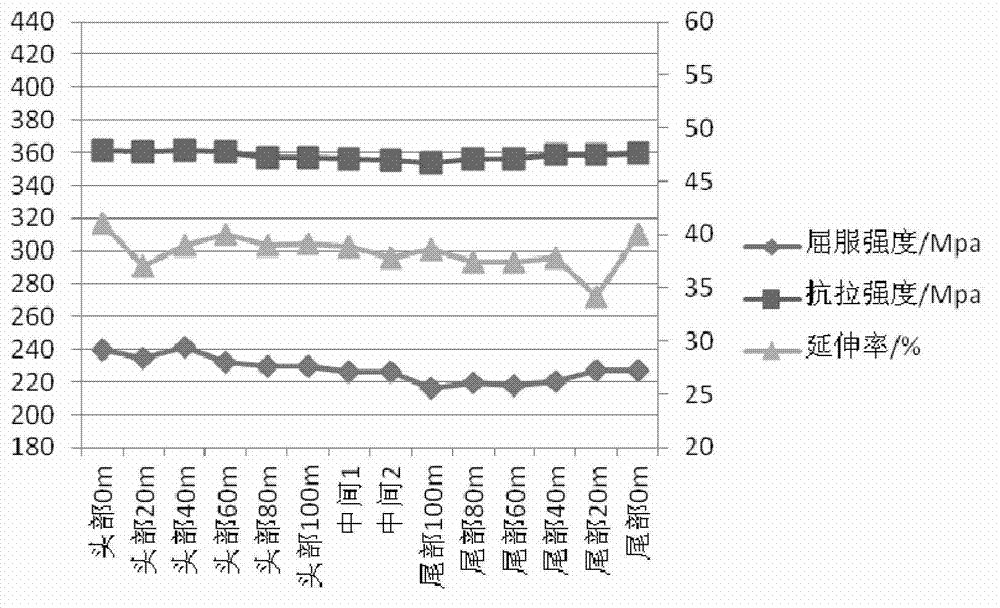

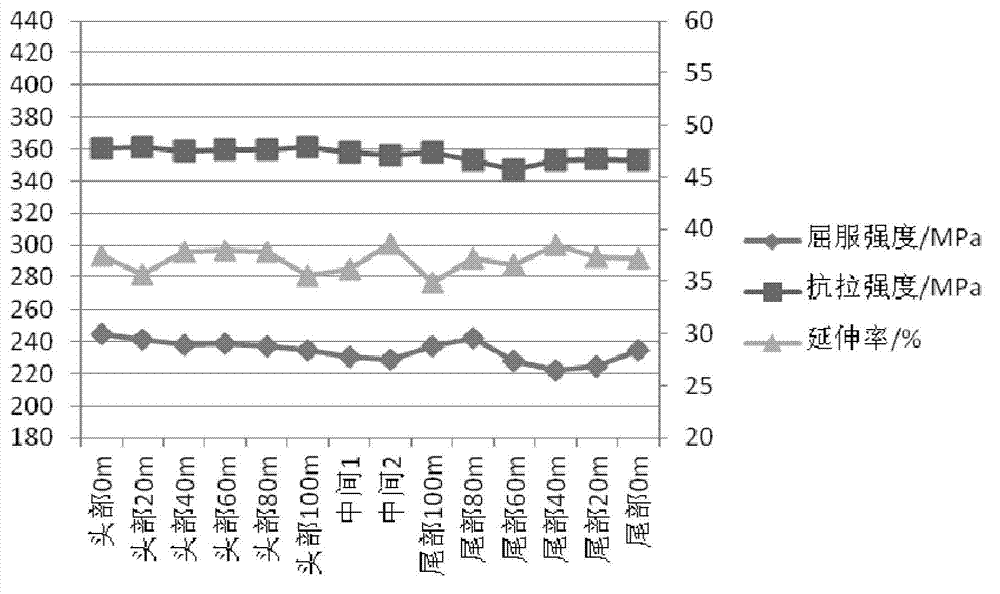

[0027] Reheat the head of the slab to 1250°C, the tail to 1270°C, the heating time is 3.2 hours, the final rolling temperature is 878°C, and the coiling process is: 30 meters at the head at 730°C, 40 meters at the tail at 730°C, and the remaining sections 680°C, the specification of hot-rolled coils is: 4.0×1282mm; the hot-rolled coils are uncoiled on the pickling mill, stretched, straightened and broken, and then enter shallow groove turbulent pickling to remove the surface oxide scale, and then enter the 5-stand cold tandem mill to obtain chilled hardness. Coil, the reduction rate is 75%. Chilled coils go through the cleaning section to remove the surface oil and then enter the vertical continuous annealing furnace. The temperature in the heating section is 760°C, and the temperature in ...

Embodiment 2

[0029] The chemical composition of the slab is: C: 0.037wt%, Si: 0.02wt%, Mn: 0.27wt%, P: 0.011wt%, S: 0.004wt%, Alt: 0.052wt%, N: 0.004wt%, the rest Basically Fe and other trace elements.

[0030] Reheat the head of the slab to 1250°C and the tail to 1270°C for 3.3 hours. The final rolling temperature is 882°C. 680°C, the specification of hot-rolled coils is: 4.0×1261mm; the hot-rolled coils are uncoiled on the pickling mill, stretched, straightened and broken, and then enter the shallow groove turbulent pickling to remove the surface oxide scale, and then enter the 5-stand cold tandem rolling mill to obtain chilled hardness. Coil, the reduction rate is 75%. Chilled coils go through the cleaning section to remove the surface oil and then enter the vertical continuous annealing furnace. The temperature in the heating section is 760°C, and the temperature in the fast cooling section is 440°C. Coiling is a finished product, and the flat elongation rate is 1.1%, and the finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com