High-strength and wear-resistant polyamide composite material and preparing method thereof

A technology of composite materials and polyamides, which is applied in the field of polymer materials, can solve the problems of large amount of addition, decline in mechanical properties, and low installation accuracy, and achieve the effects of high wear-resistant processing accuracy, high processing performance, and short molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

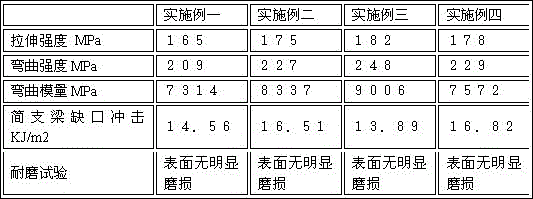

Examples

Embodiment 1

[0021] Use the following raw materials in weight percentage

[0022] Polyamide 66 (hereinafter referred to as A) (viscosity 2.6-3.0) 42%

[0023] Graft toughening agent (hereinafter referred to as B) 7%

[0024] Copolymerized toughening agent (hereinafter referred to as C) 3%

[0025] Wear-resistant masterbatch (hereinafter referred to as D) 15%

[0026] Wear-resistant reinforcing filler (hereinafter referred to as E) (composite material, short fiber) 30%

[0027] Heat stabilizer (hereinafter referred to as F) 0.7%

[0028] Nucleating agent (hereinafter referred to as G) 0.8%

[0029] Lubricant (hereinafter referred to as H) 1%

[0030] Silane coupling agent (hereinafter referred to as I) 0.5%

[0031] Prepare the PA66 composite material by the above components through the following process

[0032] Step 1, preparation of wear-resistant masterbatch:

[0033] Low viscosity polyamide nylon 66 (viscosity 2.0-2.6), 82.5%

[0034] Wear-resistant filler 1 (molybdenum disulf...

Embodiment 2

[0045] Adopt the raw material of following weight percentage:

[0046] Polyamide 66 (viscosity 2.6-3.0) 46%

[0047] Graft toughener 6%

[0048] Copolymer toughener 3%

[0049] Wear-resistant masterbatch 12%

[0050] Wear-resistant reinforcing filler (giant stone fiberglass, 988A-2000) 30%

[0051] Heat stabilizer 0.7%

[0052] Nucleating agent 0.8%

[0053] Lubricant 1%

[0054] Silane coupling agent 0.5%

[0055] The preparation of wear-resistant masterbatch adopts the following weight percentages:

[0056] Low viscosity polyamide nylon 66 (viscosity 2.0-2.6), 86.5%

[0057] Wear-resistant filler 1 (molybdenum disulfide from Hefei Jinxin, molecular weight 160.07) 6%

[0058] Wear-resistant filler 2 (Shanghai Huayi Graphite No. 0, 900 mesh) 6%

[0059] Lubricant 1%

[0060] Silane coupling agent 0.3%

[0061] Heat stabilizer 0.2%

[0062] The preparation of the wear-resistant masterbatch is the same as in Example 1.

[0063] For the preparation of the composite ma...

Embodiment 3

[0065] Adopt the raw material of following weight percentage:

[0066] Polyamide 66 46%

[0067] Graft toughener 5%

[0068] Copolymer toughener 3%

[0069] Wear-resistant masterbatch 13%

[0070] Wear-resistant reinforcing filler (giant stone fiberglass, 988A-2000) 30%

[0071] Heat stabilizer 0.7%

[0072] Nucleating agent 0.8%

[0073] Lubricant 1%

[0074] Silane coupling agent 0.5%

[0075] The preparation of wear-resistant masterbatch adopts the following weight percentages:

[0076] Low viscosity polyamide nylon 66 (viscosity 2.0-2.6), 81.5%

[0077] Wear-resistant filler 1 (molybdenum disulfide from Hefei Jinxin, molecular weight 160.07) 7%

[0078] Wear-resistant filler 2 (Japan Daikin L-5) 10%

[0079] Lubricant 1%

[0080] Silane coupling agent 0.3%

[0081] Heat stabilizer 0.2%

[0082] The preparation of the composite material of embodiment 3 is the same as that of embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com