High-strength carbon fiber reinforced halogen-free flame-retardant PA66 (Polyamide 66) composite material and preparation method

A high-strength carbon fiber and composite material technology, which is applied in the field of high-strength carbon fiber-reinforced halogen-free flame-retardant PA66 composite material and its preparation, can solve the problems of difficult processing, large dependence on environmental humidity, and large performance damage, and achieve comprehensive performance. High, excellent appearance, high mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

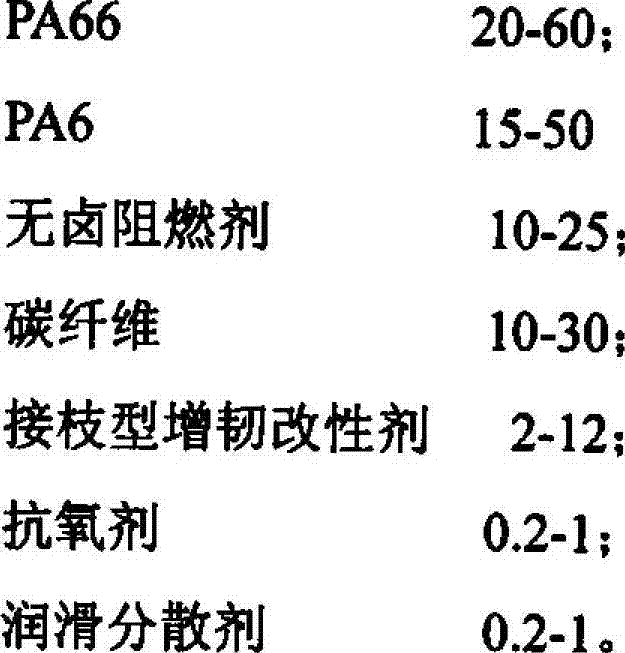

Embodiment 1-4

[0023] A preparation method of high-strength carbon fiber reinforced halogen-free flame-retardant PA66 composite material, comprising the following steps:

[0024] (1) Prepare materials according to the components and contents in Table 1. The resin viscosity of PA66 is 2..7, and the resin viscosity of PA6 is 2.4. The halogen-free flame retardant is a nitrogen-phosphorus composite flame retardant, and the phosphorus content 24-28%. Carbon fiber is polyacrylonitrile-based carbon fiber, and its tensile strength is >500kg / mm 2 , tensile modulus > 250G·Pa, graft type toughening modifier is ethylene-octene graft copolymer. The antioxidant is compounded by HD98 and 168 in a weight ratio of 1:1, and the lubricating and dispersing agent is silicone.

[0025] (2) Put the above-mentioned raw materials into a high mixer and mix them for 3-5 minutes before discharging to obtain a mixture, then control the processing temperature of the twin-screw extruder at 230-250°C, the screw speed at ...

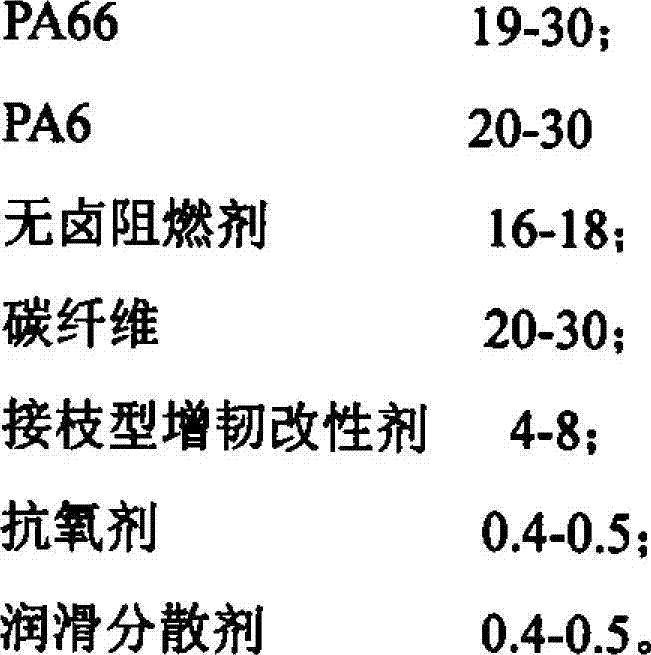

Embodiment 5

[0032] A method for preparing a high-strength carbon fiber reinforced halogen-free flame-retardant PA66 composite material, the method comprising the following steps:

[0033] (1) prepare materials according to the following components and weight percentage content:

[0034]

[0035]

[0036] (2) Put the above raw materials into the high mixer and mix them for 3-5 minutes, then discharge to obtain the mixture, add carbon fiber from the side feeding port, and then control the processing temperature of the twin-screw extruder to 230-250°C, and the screw speed to 180 -600 rpm, put the mixture in a twin-screw extruder to extrude and granulate to obtain the product.

[0037] Both PA66 and PA6 are ordinary injection molding grade resins, the resin viscosity of PA66 is 2.4-3.2, and the resin viscosity of PA6 is 2.2-3.0. The halogen-free flame retardant is a nitrogen-phosphorus composite flame retardant compounded by OP1312 and MPP, wherein the phosphorus content is 24-28%. Th...

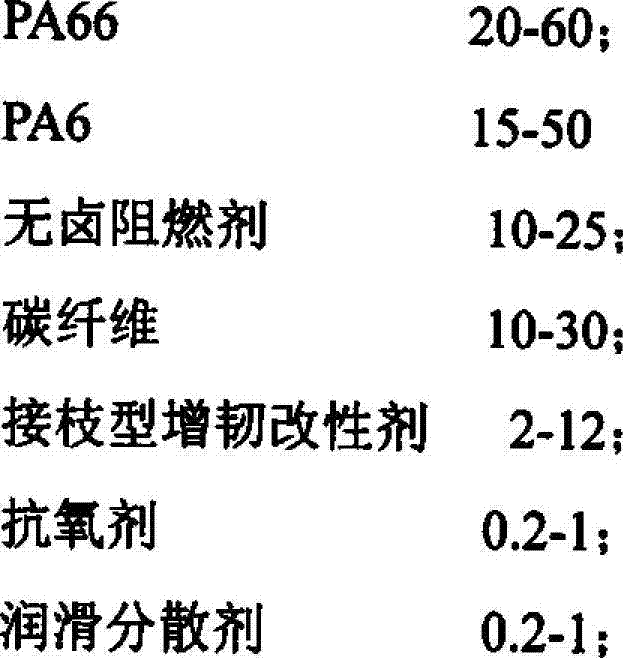

Embodiment 6

[0039] A method for preparing a high-strength carbon fiber reinforced halogen-free flame-retardant PA66 composite material, the method comprising the following steps:

[0040] (1) prepare materials according to the following components and weight percentage content:

[0041]

[0042] (2) Put the above raw materials into the high mixer and mix them for 3-5 minutes, then discharge to obtain the mixture, add carbon fiber from the side feeding port, and then control the processing temperature of the twin-screw extruder to 230-250°C, and the screw speed to 180 -600 rpm, put the mixture in a twin-screw extruder to extrude and granulate to obtain the product.

[0043] Both PA66 and PA6 are ordinary injection molding grade resins, the resin viscosity of PA66 is 2.4-3.2, and the resin viscosity of PA6 is 2.2-3.0. The halogen-free flame retardant is OP1240 nitrogen-phosphorus compound flame retardant of Ryan Company, wherein the phosphorus content is 24-28%. The carbon fibers are m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com