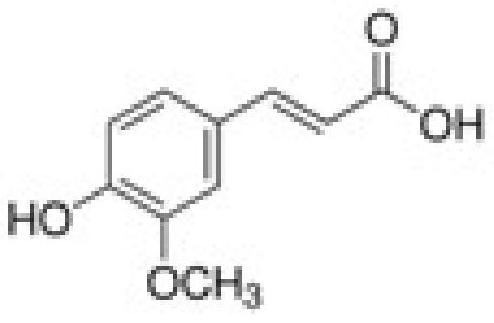

A method for preparing natural ferulic acid from soapstock containing oryzanol

A technology of oryzanol and ferulic acid, applied in the field of plant extraction and separation, can solve the problems of low purity, pollution, and complicated treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. Alkali-alcohol hot-melt filtration. 3m ahead 3 Add 1200L of edible ethanol with a concentration of 89% in the extraction tank, put 400kg of oryzanol-containing soapstock raw materials into the extraction tank under constant stirring, continue to add 1200L of edible ethanol with a concentration of 89%, keep stirring continuously and heat, and heat up to 52°C. The pH of the system was adjusted to 9.0 with a 6% dilute sodium hydroxide aqueous solution to dissolve the raw material, and the material was passed through a disc centrifuge while it was hot, and the filtrate was collected to obtain 2650 L of dissolved filtrate.

[0069] 2. Acid precipitation and separation. Adjust the pH of the dissolved filtrate to 6.5 with dilute sulfuric acid with a concentration of 5wt%, stir well, and let stand for 6 hours to make the oryzanol precipitate completely, and collect the centrifugal precipitate by a three-legged sedimentation centrifuge to obtain 261 kg of the centrifugal pre...

Embodiment 2

[0080] 1. Alkali-alcohol hot-melt filtration. 3m ahead 3 Add 1000L of edible ethanol with a concentration of 92% in the extraction tank, put 300kg of oryzanol-containing soapstock raw material into the extraction tank under constant stirring, continue to add 1000L of edible ethanol with a concentration of 92%, keep stirring and heating continuously, and heat up to 55°C. The pH of the system was adjusted to 10.0 with a 5% dilute sodium hydroxide aqueous solution to dissolve the raw material, and the material was passed through a three-legged sedimentation centrifuge while it was hot, and the filtrate was collected to obtain 2160 L of dissolved filtrate.

[0081] 2. Acid precipitation and separation. Adjust the pH of the dissolved filtrate to 7.0 with dilute hydrochloric acid with a concentration of 8 wt%, stir well, and let stand for 5 hours to make the oryzanol precipitate completely, and collect the centrifugal precipitate by a three-legged sedimentation centrifuge to obtain...

Embodiment 3

[0092] Others are the same as in Example 1, the difference is that the pH of the system is adjusted to 9.0 with dilute lye in step (1); the pH of the dissolved filtrate is adjusted to 7.0 with dilute acid in step (2); the alkali alcohol is adjusted with dilute sulfuric acid in step (6) The pH of the hydrolysis filtrate was 4.0. After testing, the finished product has a natural ferulic acid content of 98.73%, is pure white by visual inspection, and has a product yield of 82.31%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com