A method for extracting oryzanol from rice bran oil refined soapstock

A technology of rice bran oil and oryzanol, which is applied in the field of extracting oryzanol and using rice bran oil refined soapstock as raw material to extract oryzanol, can solve the problems of excessive solvent residue, reduce the content of oryzanol, use illegal solvents, etc., and achieve easy operation and realization, and production process Simple, low-cost-to-produce effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

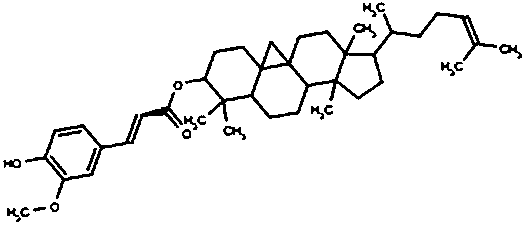

Image

Examples

Embodiment 1

[0063] (1) Alcohol extraction: Put 400kg of soapstock raw material refined from rice bran oil into 3m 3 In the extraction tank, turn on the steam, control the temperature at 45°C and heat to soften. After softening, add 2000L of edible ethanol with a volume concentration of 90% and stir to mix evenly. Then use 5% sodium hydroxide aqueous solution to adjust the pH of the solution system to 10 , heated and stirred at 55°C for 20 minutes, and filtered while hot by settling and centrifuging, discarding the centrifuged precipitate to obtain the extract;

[0064] (2) Solid-liquid separation: adjust the pH of the extract to 7.2 with a hydrochloric acid aqueous solution with a mass concentration of 15%, and let it settle for 6 hours. After the precipitation is complete, settle and centrifuge to filter, and collect the precipitate and the filtrate separately. The filtrate is used to prepare the by-product fatty acid. The precipitation is used to prepare oryzanol, and 256kg of centrifug...

Embodiment 2

[0072] (1) Alcohol extraction: Put 250kg of soapstock raw material refined from rice bran oil into 3m 3 In the extraction tank, turn on the steam, control the temperature at 50°C and heat to soften. After softening, add 1500L of edible ethanol with a volume concentration of 85% and stir to mix evenly. Then adjust the pH of the solution system to 9 with an aqueous sodium hydroxide solution with a mass concentration of 5%. , heating and stirring at 50°C for 30 minutes, and then centrifuging and filtering while hot, and discarding the centrifuged precipitate to obtain the extract;

[0073] (2) Solid-liquid separation: adjust the pH of the extract to 7.4 with a sulfuric acid aqueous solution with a mass concentration of 15%, and let it settle for 4 hours. After the precipitation is complete, settle and centrifuge to filter, and collect the precipitate and filtrate separately. The filtrate is used to prepare by-product fatty acids. Precipitation is used to prepare oryzanol, and cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com