Full groove floor with double tenon structural member

A technology for structural parts and floors, which is applied in the direction of building structures, floors, buildings, etc., can solve the problems of separation, expansion and arching, inability to freely expand and contract, and affect the strength of buildings, etc., so as to achieve short installation period, improve efficiency, increase The effect of housing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

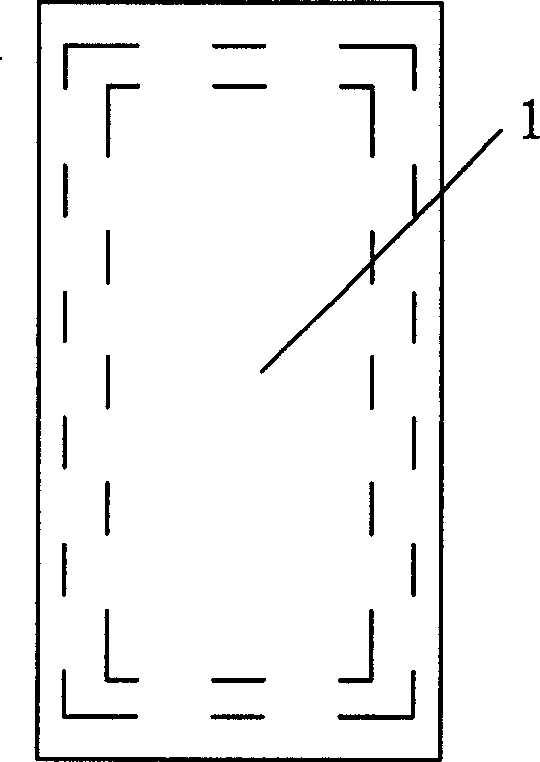

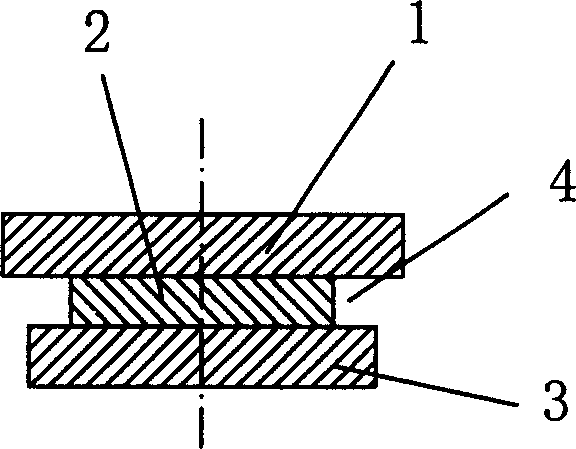

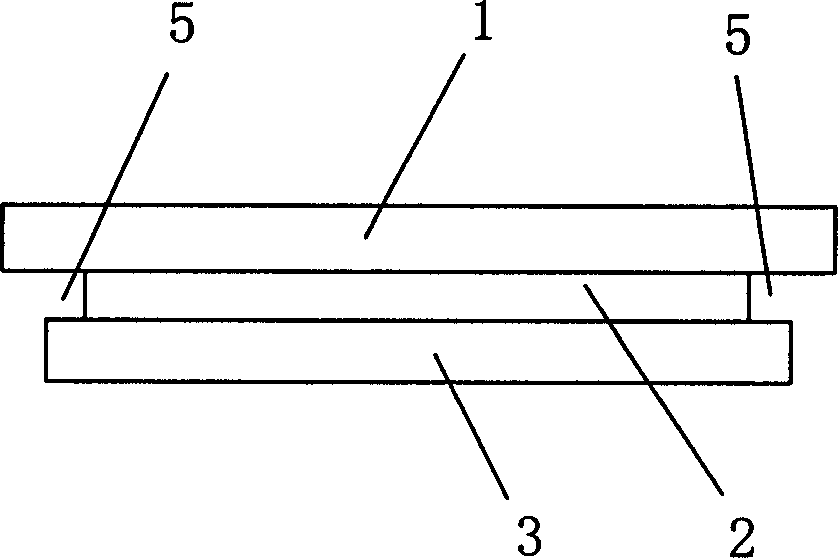

[0018] In the full-groove floor with double mortise structure according to the present invention, second slots 5 are respectively opened at both ends along the length direction, and first slots 4 are respectively opened on both sides along the width direction to form the upper part. It is a three-layer structure with a panel layer 1, a connection layer 2 in the middle, and a bottom layer 3 at the bottom; the width of the panel layer 1 is larger than the width of the bottom layer 3, and the width of the bottom layer 3 is larger than the width of the connection layer 2 in the middle. The length of the panel layer 1 is longer than the length of the bottom layer 3, and the length of the bottom layer 3 is longer than the length of the connecting layer 2 in the middle; the first slot 4 on both sides of the floor and the first tenon 6-1 of the double tenon structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com