Preparation method of crosslinkable block-grafted type high-molecular polymer

A high-molecular polymer and branch-type technology, applied in the field of macromolecular chemistry, can solve the problem of weak resistance to external interference of the hydration layer, achieve good cross-linking function and particle binding performance, good water resistance, and enhance dispersion stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

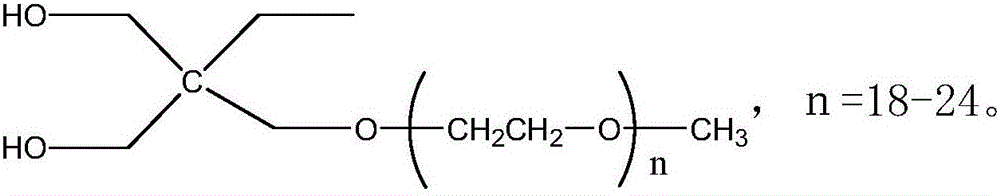

[0023] Example 1: The mixture of TMPEG with a molecular weight of 1000 and polyethylene glycol with a molecular weight of 1200 was distilled under reduced pressure for 1 hour at a temperature of 120° C. and a vacuum of 0.09 MPa, then cooled and sealed for use. 10.7 g of glyceryl monostearate was added to a four-necked flask equipped with a stirrer and a thermometer, and the temperature was 120° C., and the vacuum was 0.09 MPa and vacuum distillation was carried out for 1 hour. Cool down to 60°C, add 0.02g of dibutyltin dilaurate, then dropwise add 12g of toluene diisocyanate, stir and raise the temperature to 80-85°C, and react for 2 hours. Then add 33.53g of TMPEG with a molecular weight of 1000 and a polyethylene glycol mixture with a molecular weight of 1200 (wherein 15.24g of TMPEG; 18.29g of polyethylene glycol), and add 20g of butanone for dilution, and continue the reaction for 3 hours. Then add 0.2g of 1,4-butanediol, react at 45°C for 45 minutes, add 1.06g of butanone...

Embodiment 2

[0024] Example 2: Distill the mixture of TMPEG and polyethylene glycol with a molecular weight of 1200 under reduced pressure for 1 hour at a temperature of 120° C. and a vacuum of 0.09 MPa, then cool down and seal for use. Add 9.87 g of glyceryl monostearate to a four-neck flask equipped with a stirrer and a thermometer, and distill under reduced pressure for 1 hour at a temperature of 120° C. and a vacuum of 0.09 MPa. Cool down to 60°C, add 0.02g of dibutyltin dilaurate, then dropwise add 11.67g of toluene diisocyanate, stir and raise the temperature to 80-85°C, and react for 2 hours. Then add 29.94g of TMPEG and polyethylene glycol mixture (23.02g of TMPEG; 6.92g of polyethylene glycol) with molecular weight of 1200, and add 20g of ethyl acetate to dilute, and continue to react for 3 hours. Then add 0.2g of 1,4-butanediol, react at 45°C for 45 minutes, then add 2.37g of 3,5-dimethylpyrazole, and continue the reaction for half an hour. Cool to room temperature, add 220 g of...

Embodiment 3

[0025] Example 3: The mixture of TMPEG and polyethylene adipate with a molecular weight of 2000 and polyethylene adipate was distilled under reduced pressure for 1 hour at a temperature of 120° C. and a vacuum of 0.09 MPa, then cooled and sealed for use. Add 14.34 g of glyceryl monostearate to a four-necked flask with a stirrer and a thermometer, and distill under reduced pressure for 1 hour at a temperature of 120° C. and a vacuum of 0.09 MPa. Cool down to 60°C, add 0.02g of dibutyltin dilaurate, then dropwise add 29g of toluene diisocyanate, stir and raise the temperature to 80-85°C, and react for 2 hours. Add the mixture (wherein 10.37g TMPEG; 61.13g polyethylene adipate) of TMPEG and polyethylene adipate that 71.5g molecular weight is 2000 then, and add 20g butanone and dilute, continue reaction 3 Hour. Then add 5.98g of bismethylolpropionic acid, react at 45°C for 45 minutes, add 8.0g of butanone oxime, and continue to react for half an hour. Cool to room temperature, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com