Chemical mechanical polishing solution and application thereof

A chemical mechanical and polishing liquid technology, applied in the field of chemical mechanical polishing liquid, can solve the problems of unfavorable substrate utilization, corrosion, low polishing efficiency, etc., and achieve the effect of improving the polishing selection ratio, reducing the removal rate, and increasing the removal rate.

Pending Publication Date: 2018-07-06

ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

View PDF12 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] In summary, it can be seen that the polishing solution disclosed in the prior art corrodes the surface of the polished substrate in an acidic environment, which is not conducive to the utilization of the polished substrate, and the polishing efficiency is low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

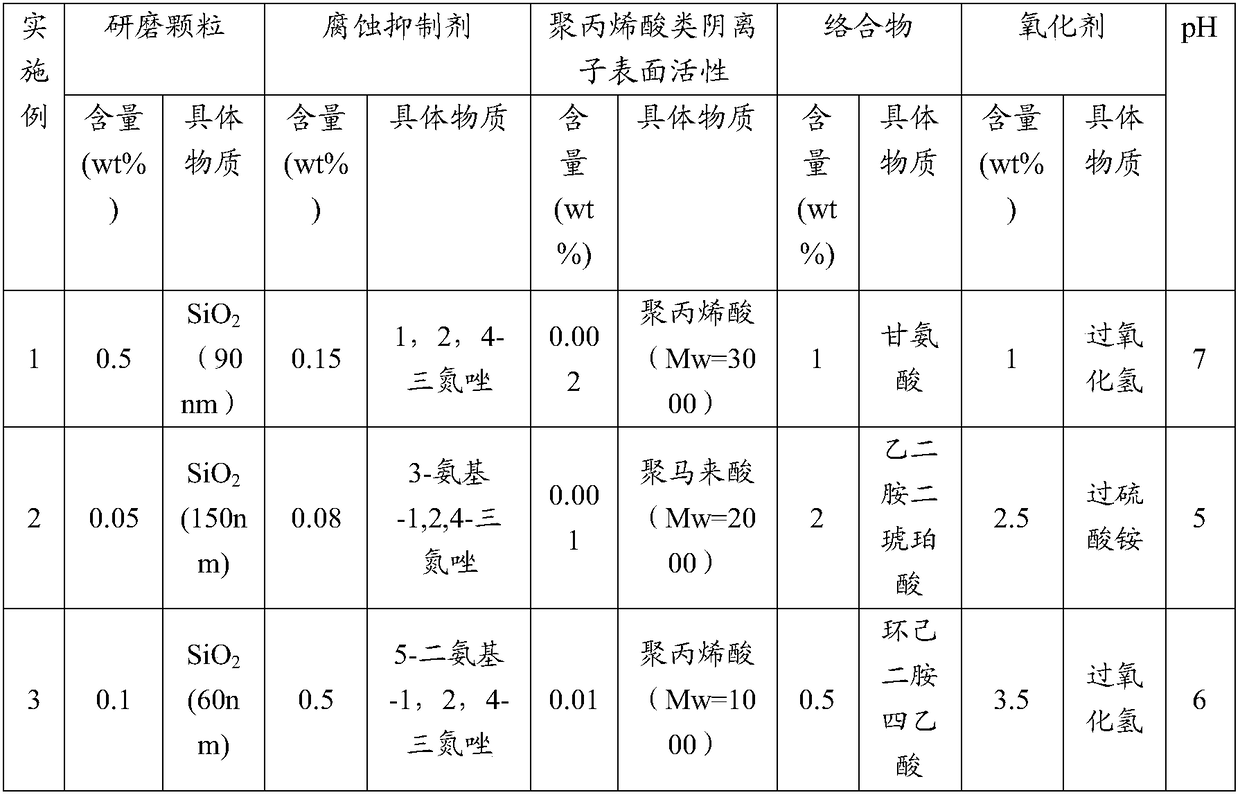

Embodiment 1~24

[0033]

[0034]

[0035]

[0036] Table 2 provides the examples 25-35 and comparative examples 1-4 of the chemical mechanical polishing liquid of the present invention. According to the formula given in the table, other components except the oxidizing agent are mixed uniformly, and the mass percentage is supplemented with water to 100 %. with KOH or HNO 3 Adjust to desired pH. Add oxidant before use and mix evenly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

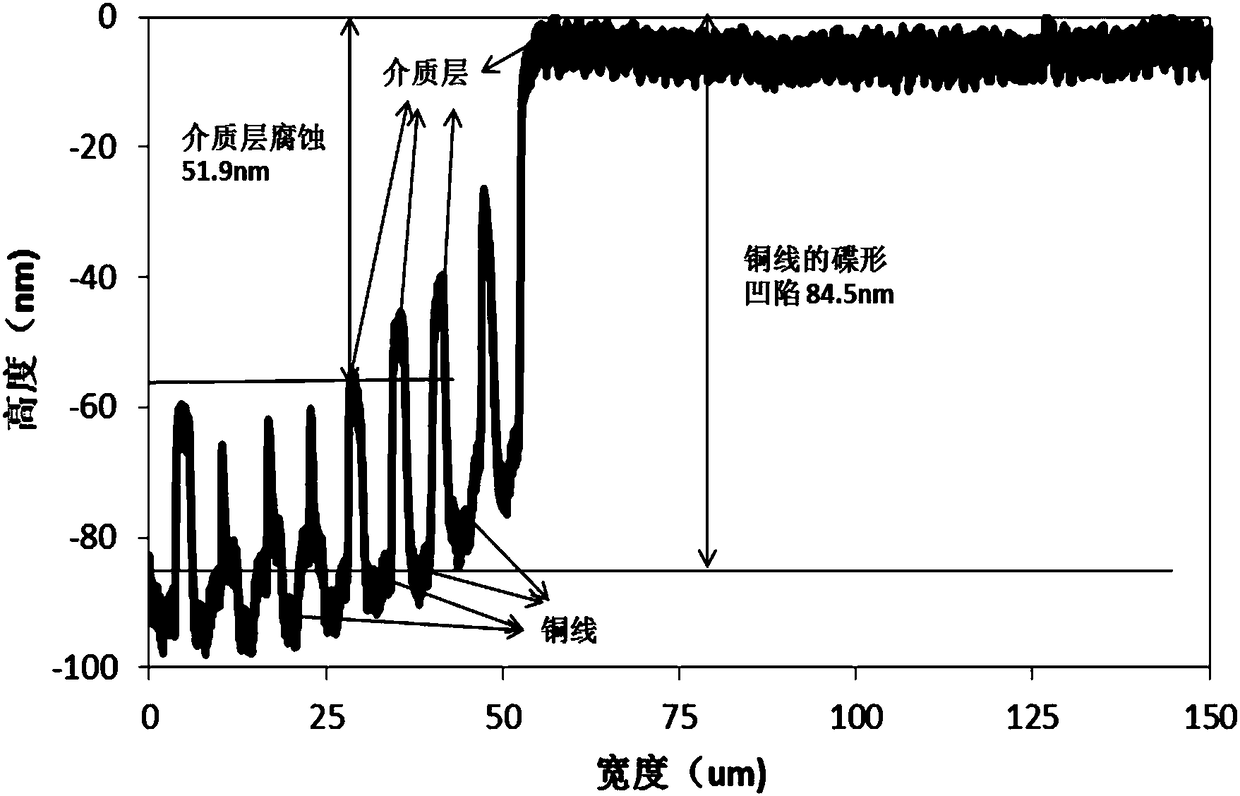

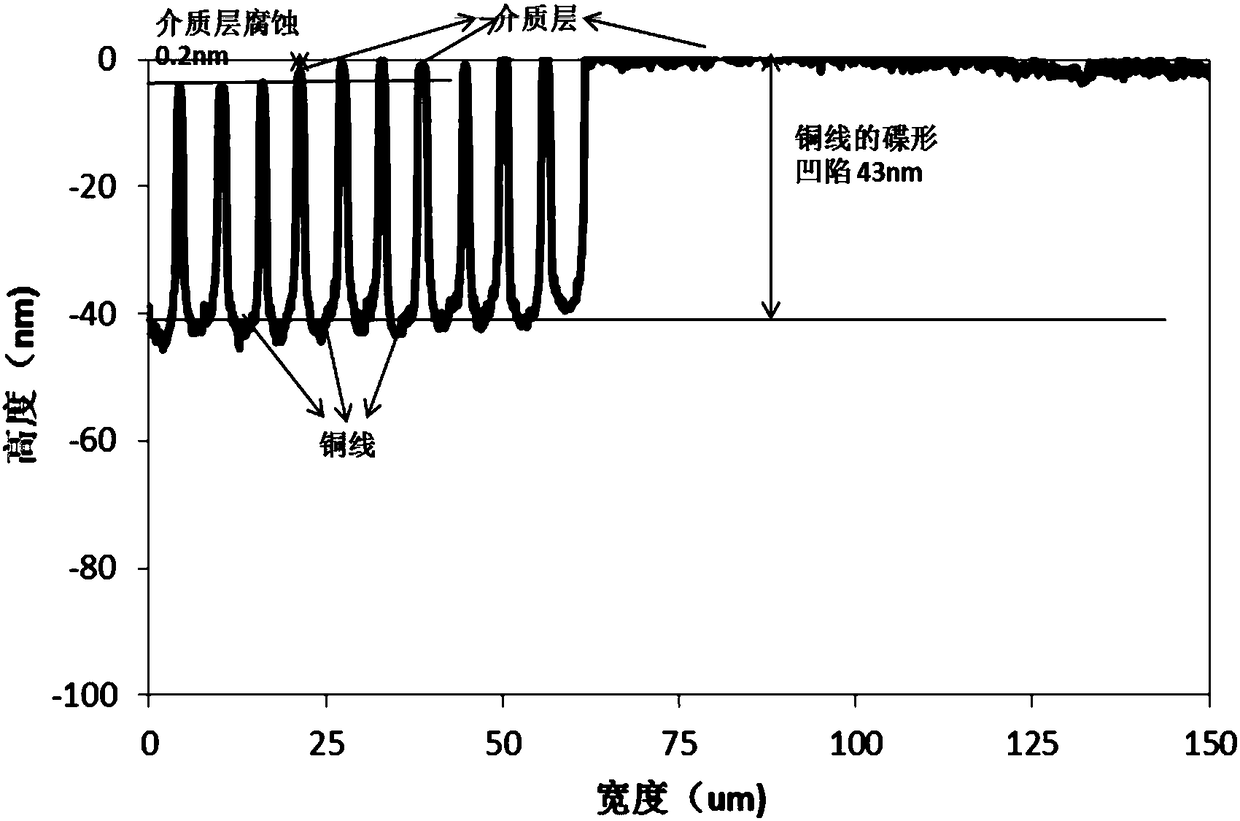

The invention provides a chemical mechanical polishing solution. The chemical mechanical polishing solution comprises grinding particles, a corrosion inhibitor, a complexing agent, an oxidizing agentand at least one polyacrylic acid anionic surfactant. The invention further provides application of the polishing solution in metal copper polishing. According to the chemical mechanical polishing solution and the application thereof, the effect of improving the polishing selection ratio of the polishing solution to the copper and tantalum barrier layer is achieved; and when the polishing solutionis used for polishing a wafer, dishing and dielectric layer erosion of the copper wire after polishing can be relieved, and the defects of copper residue, corrosion and the like after polishing are overcome.

Description

technical field [0001] The invention relates to the field of chemical mechanical polishing liquid, in particular to a chemical mechanical polishing liquid and its application in polishing metal copper. Background technique [0002] With the development of semiconductor technology and the miniaturization of electronic components, an integrated circuit contains millions of transistors. In the process of operation, after integrating such a large number of transistors that can switch quickly, the traditional aluminum or aluminum alloy interconnection wires reduce the speed of signal transmission, and consume a lot of energy in the process of current transmission. In a certain sense, It also hinders the development of semiconductor technology. For further development, people began to look for materials with higher electrical properties to replace the use of aluminum. As we all know, copper has low resistance and good conductivity, which speeds up the transmission speed of signa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F3/04

CPCC23F3/04

Inventor 张建荆建芬杨俊雅宋凯蔡鑫元姚颖潘依君杜玲曦王春梅王雨春

Owner ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com