Chemical-mechanical polishing solution

A chemical mechanical and polishing liquid technology, applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of limited removal rate and micro-scratches on the original surface of the wafer, achieve good smoothness and flatness, and solve the problem of micro-scratches , solve the effect of limited removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

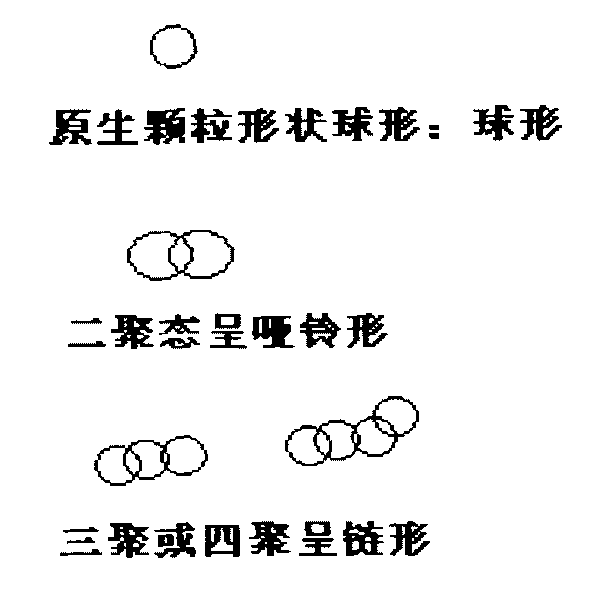

Image

Examples

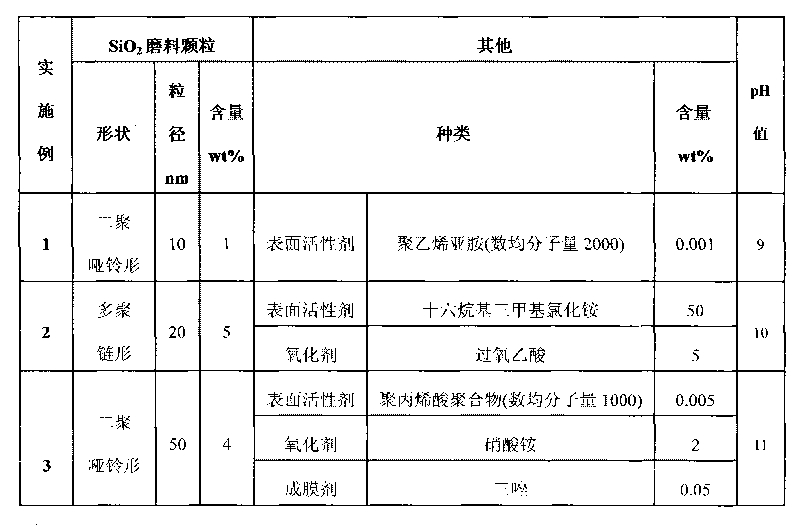

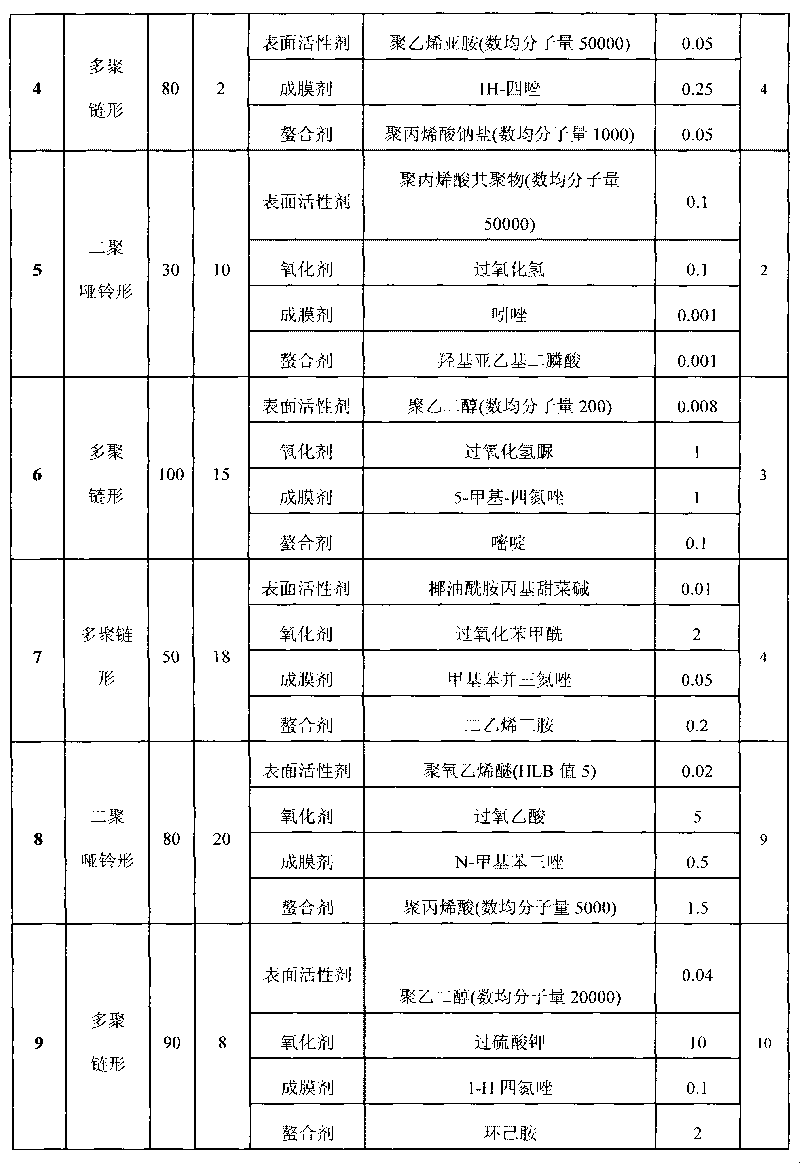

Embodiment 1~11

[0022] Table 1 has provided the formula of chemical mechanical polishing liquid embodiment 1~11 of the present invention, by the component listed in table 1 and content thereof, percentage is mass percentage and simply mixes evenly, and supplements polishing liquid content with deionized water to The mass percentage is 100%, and then the pH of the polishing liquid is adjusted to the listed value with a pH regulator to obtain various chemical mechanical polishing liquids.

[0023]

[0024]

[0025]

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com