Patents

Literature

394results about How to "Improve removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

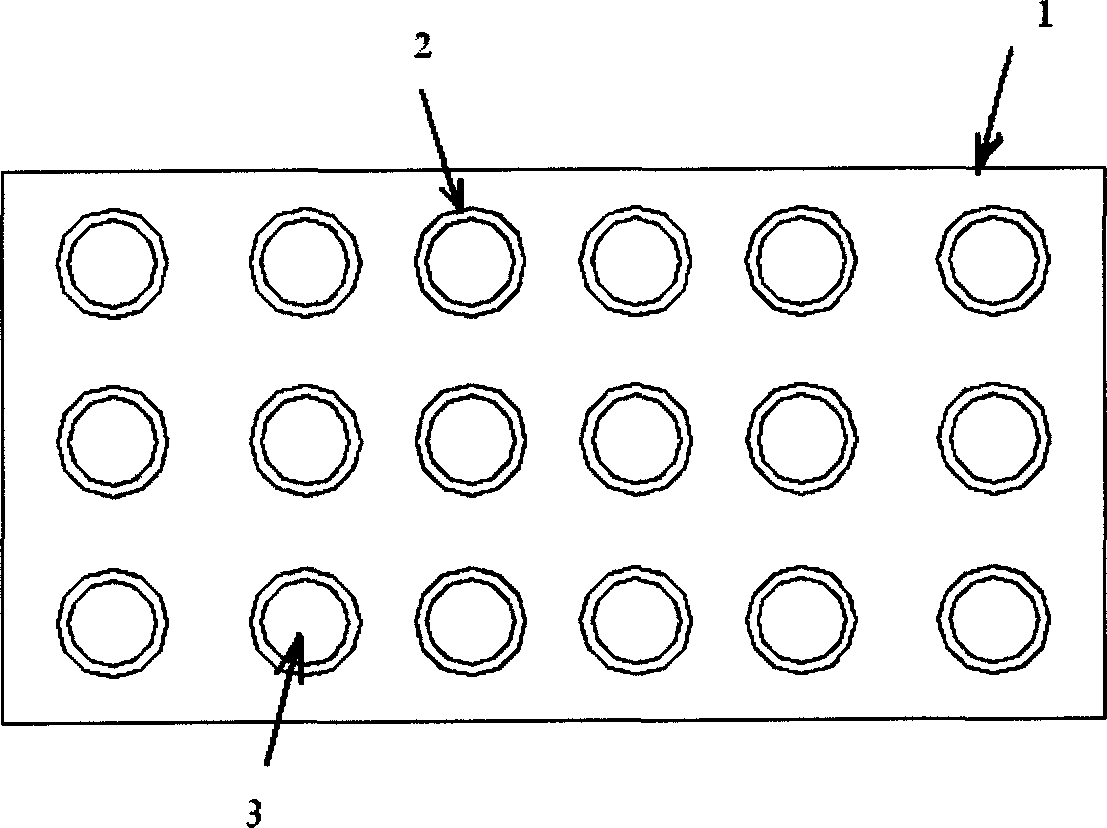

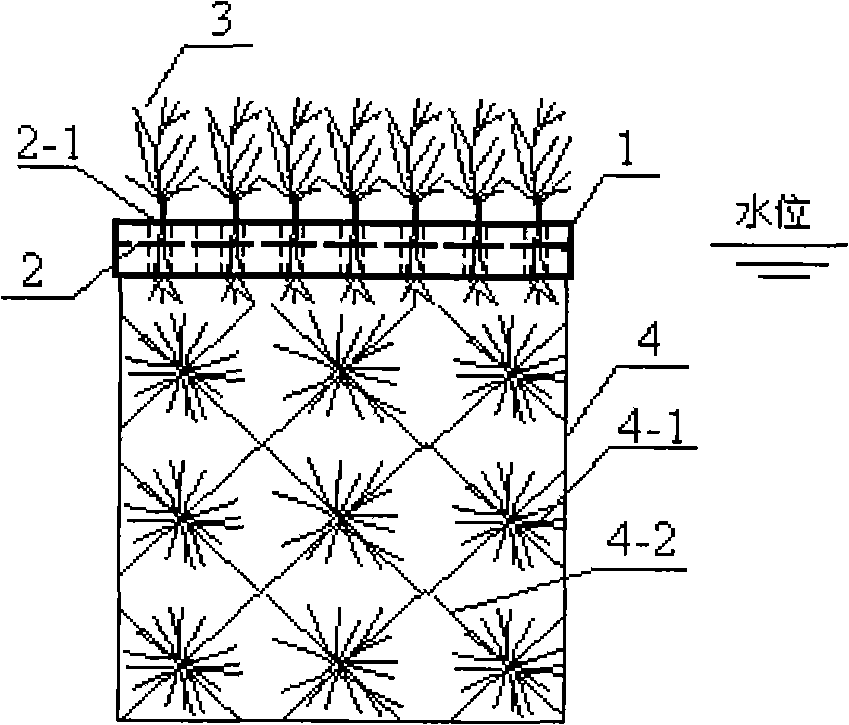

Biological adsorbing sightscene floative bed for treating water body as sightscene

InactiveCN1644533ARich in nutrientsImprove removal rateSustainable biological treatmentBiological water/sewage treatmentEutrophicationExpanded clay aggregate

An ecological absorptive landscape float bed for treating landscape water body achieves low cost and short treating period. Multiple holes are arranged on the float supporting basilar plate of float consists of light float materials, an ecological absorptive layer is arranged on the holes bottom by coated netting bag, the ecological absorptive layer contacts with landscape surface directly, high-efficient phosphorus absorptive material, ammonia nitrogen absorptive material and biological ceramic particles are filled, water-planting flowers, aquatic ornamental plants and commercial crops are planted on the ecological absorptive layer. It can improve nitrogen and phosphorus removing speed and capacity.

Owner:SHANGHAI JIAO TONG UNIV

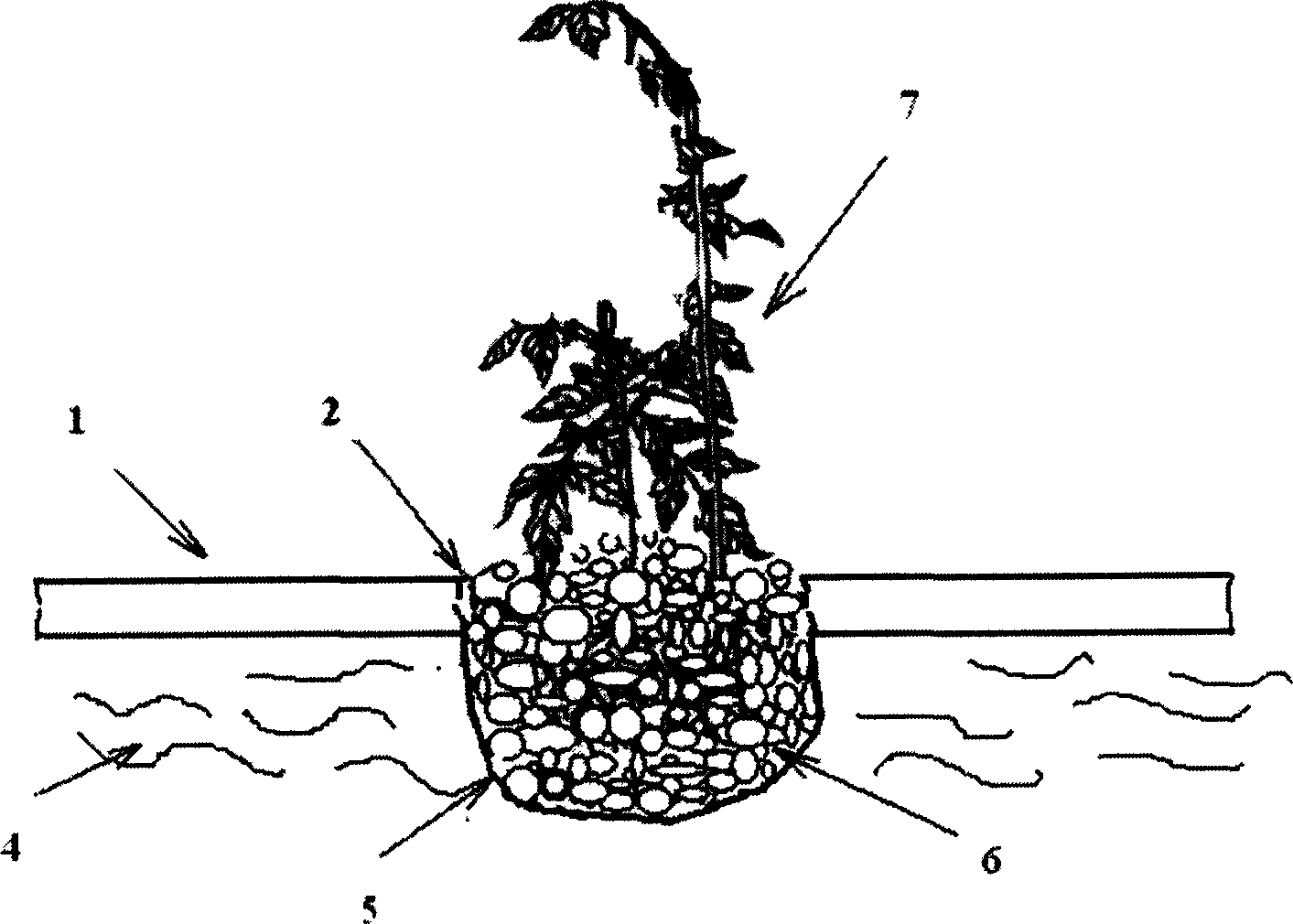

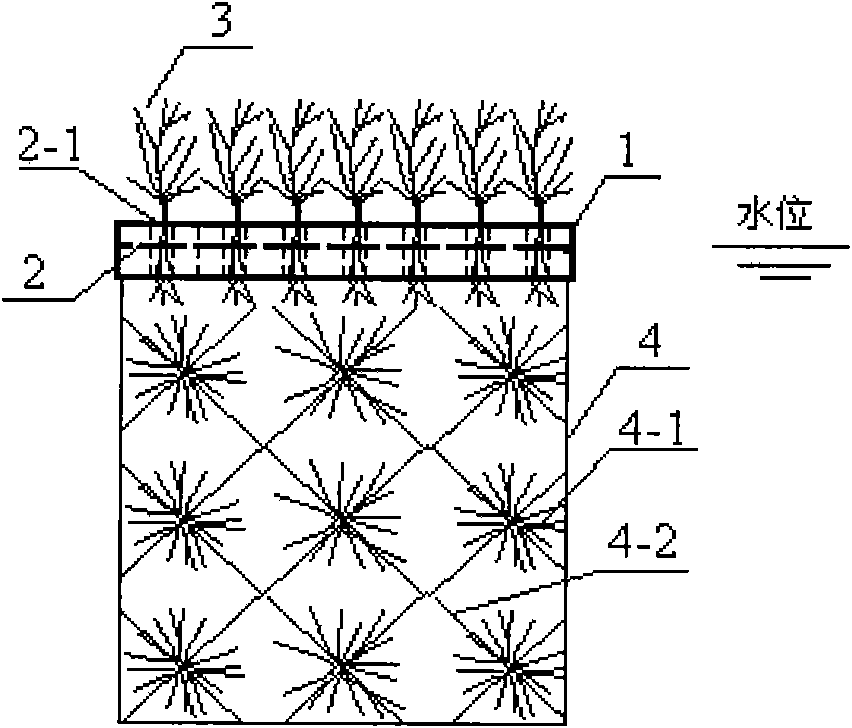

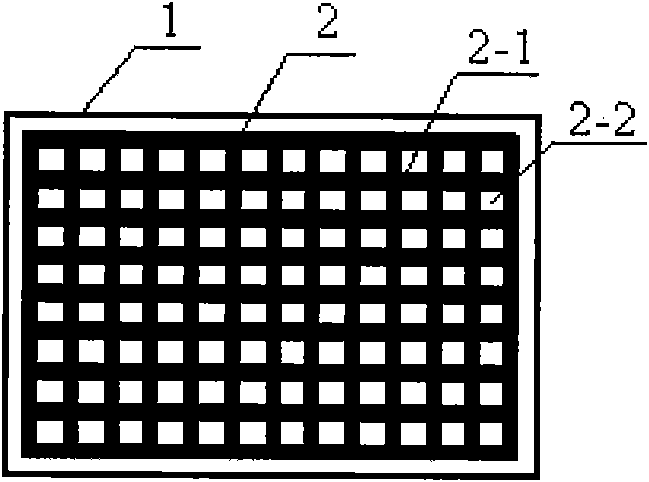

Combined type ecological floating bed water purifying device

InactiveCN101851024AFavorable for attachment growthAvoid the disadvantages of churnBiological water/sewage treatmentEutrophicationWater quality

The invention relates to a combined type ecological floating bed water purifying device used for in-situ purification treatment of polluted water in rivers and lakes. A floating body frame of a floating bed is provided with a grid-like bamboo charcoal floating bed main board made of bamboo charcoal pieces which are processed intensely by a compound enzyme biological promoter before being used, and when the bamboo charcoal pieces are used, the bamboo charcoal pieces can quite well adsorb nitrogen and phosphorus in the water and effectively promote the attached growth of indigenous microorganisms in the water; grid holes on the bamboo charcoal floating bed main board are used as planting holes of plants, and various aquatic plants or economic plants with water purification function can be mixedly planted; and biological fillers are arranged on the lower part of the floating bed, and biomass-based materials which are natural vegetable fibers are used by biofilm formation of microorganisms. The device can greatly improve the capability of removing nitrogen, phosphorus and organic matters from the eutrophication water of the ecological floating bed device and has the characteristics of simple structure, convenient mounting and control, high water flow impact resistance and the like, so that the device is quite suitable to be used for the in-situ purification treatment of water in natural rives, lakes and reservoirs and scenic water.

Owner:TONGJI UNIV

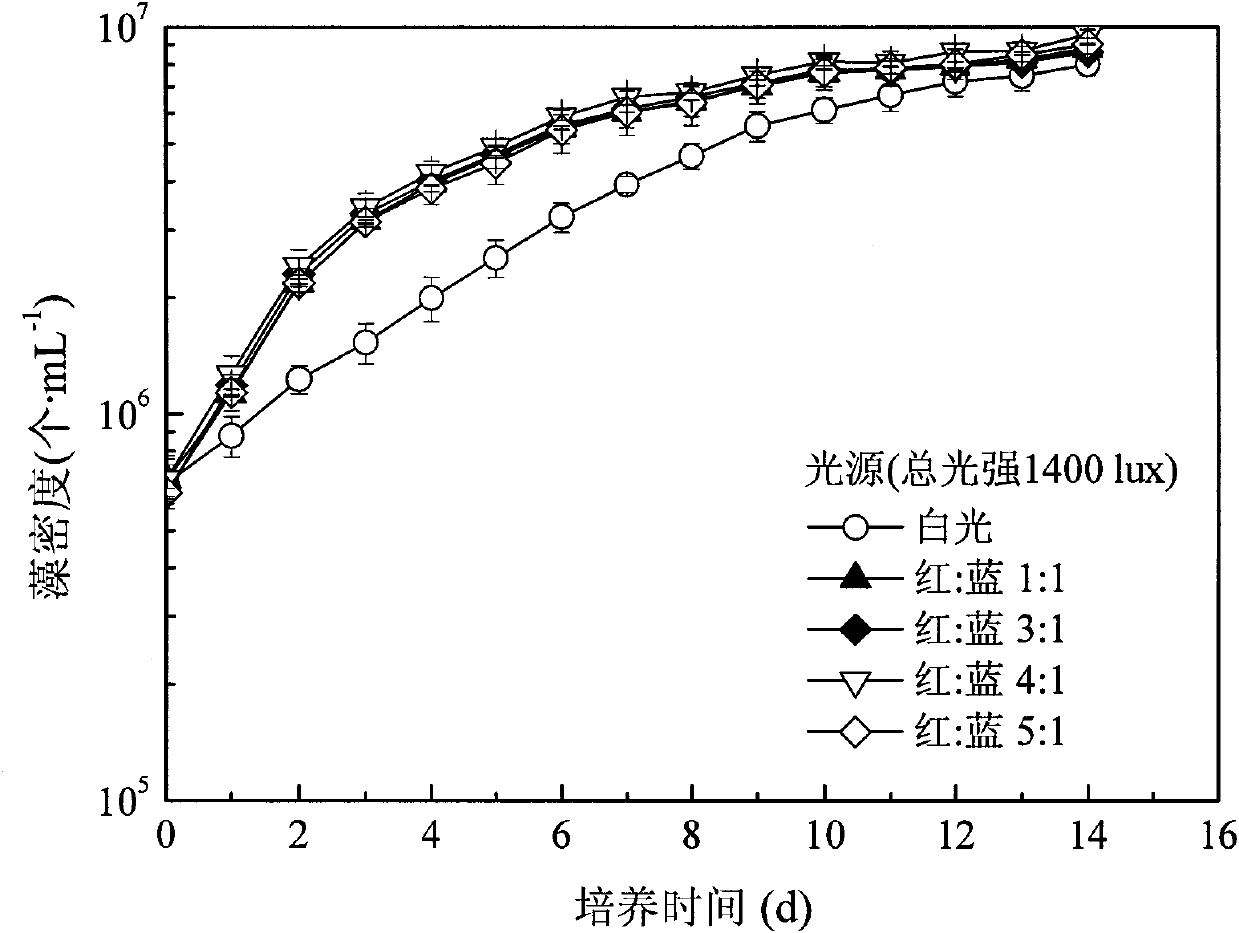

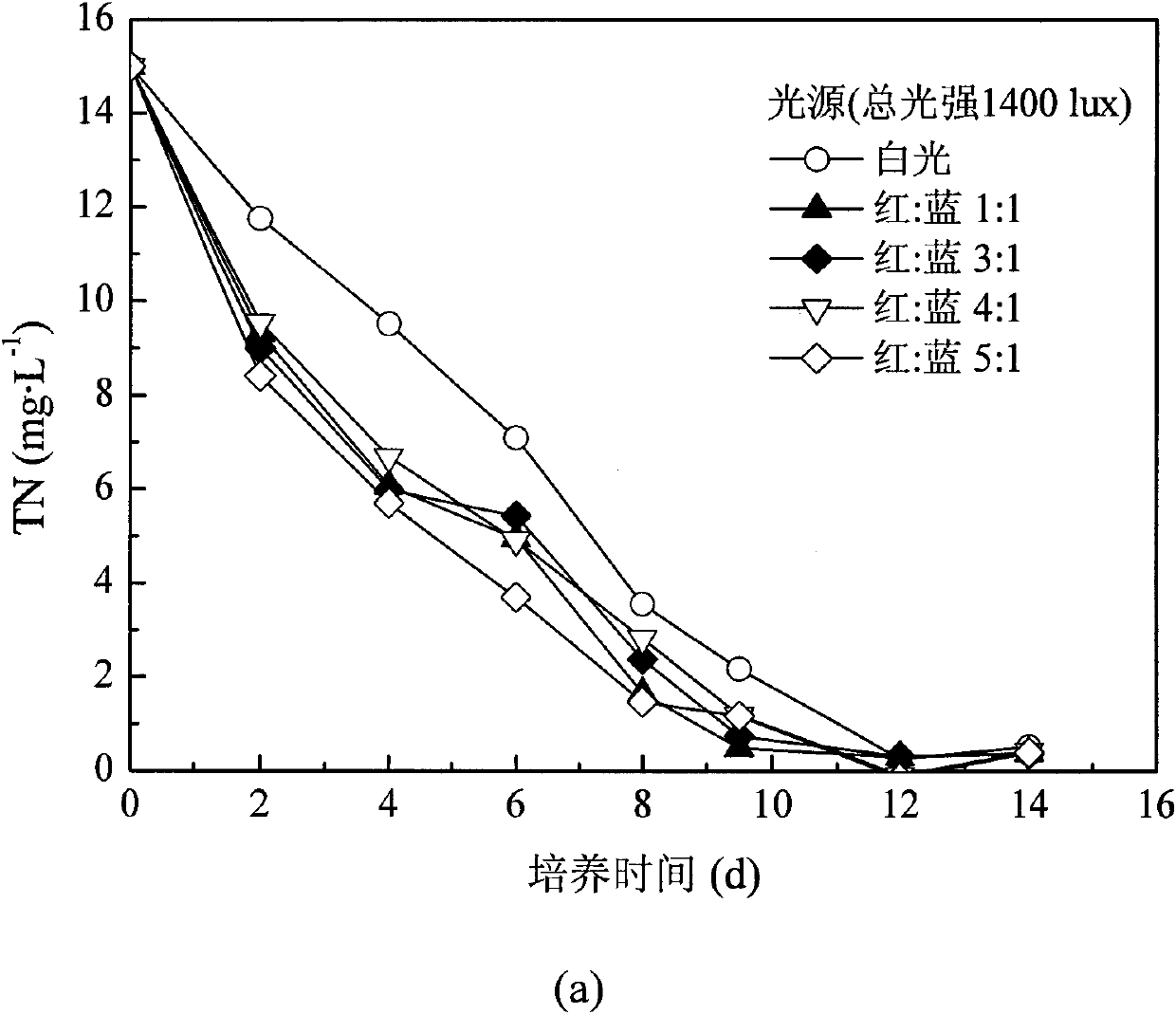

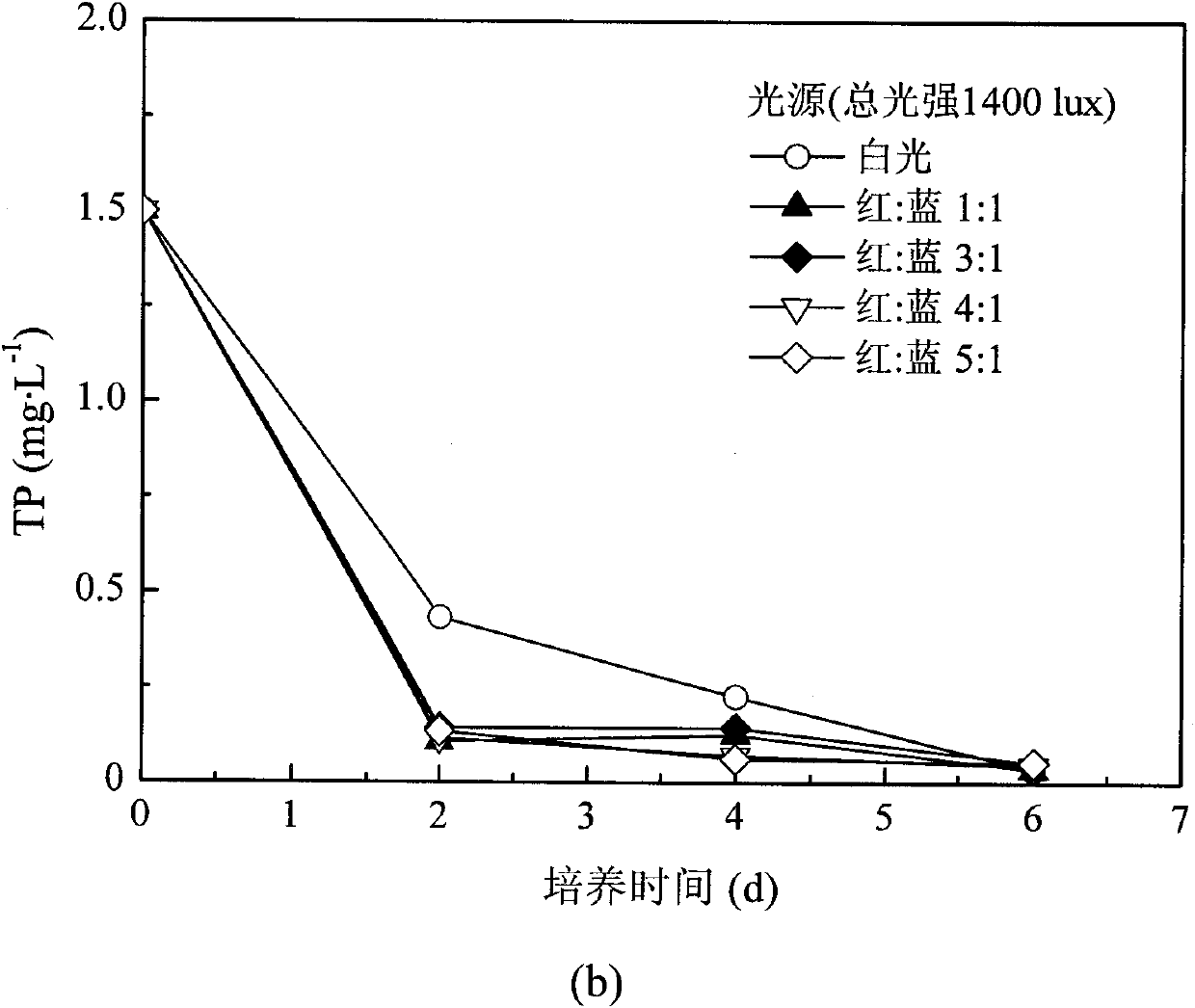

Device and method for coupling producing biological oil by utilizing microalgae to deeply treating wastewater

InactiveCN101767893AReduce nitrogen and phosphorus contentImprove removal rateWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisScenedesmusBiology

The invention discloses a device and a method for coupling producing biological oil by utilizing microalgae to deeply treating wastewater, which belongs to the technical field of water pollution control. The device is arranged after secondary wastewater treatment, and nutrient elements of nitrogen, phosphorus and the like can be absorbed by the photosynthesis of algae cells, and thus, the nitrogen and phosphorus concentration in secondary wastewater treatment effluent can be further reduced, thereby lowering the risk of water bloom eruption because the sewage plant effluent is discharged behind scenic water; the device can be applied to the deep treatment of the wastewater. The growth rate of the algae cells and the nitrogen and phosphorus removal rate can be increased by taking Scenedesmus sp.LX1 as a nitrogen and phosphorus removal dominant algae by adopting an LED red and blue light source; and the algae density in a reactor and the nitrogen and phosphorus removal can be increased by adopting a membrane separation mode and a dense algae liquid reflux mode. Meanwhile, grease can be further extracted by separating the obtained dense algae liquid, and the wastewater is taken as the resource to produce the biological oil. The method has the advantages of good nitrogen and phosphorus removal effect, high economic benefit and the like.

Owner:TSINGHUA UNIV +1

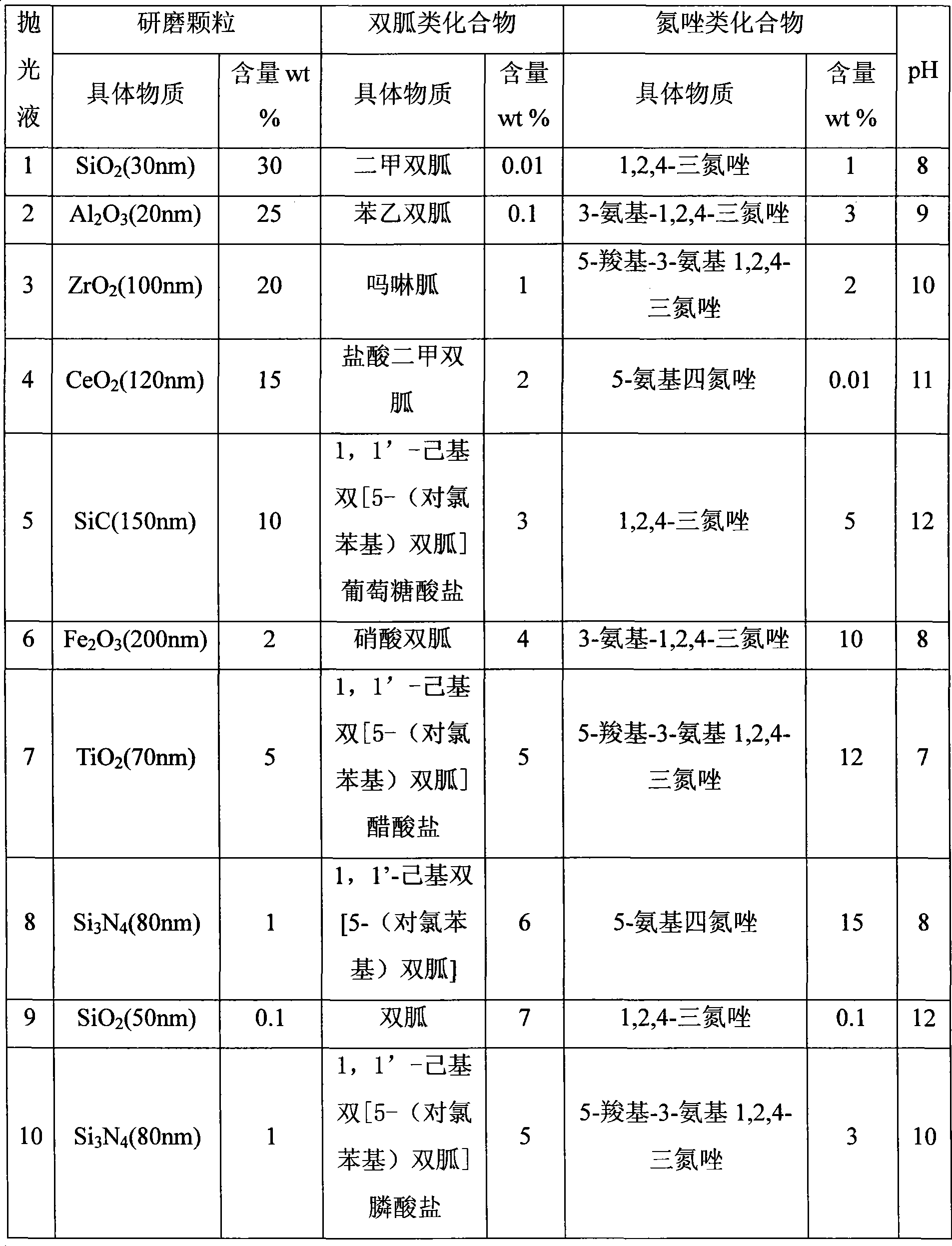

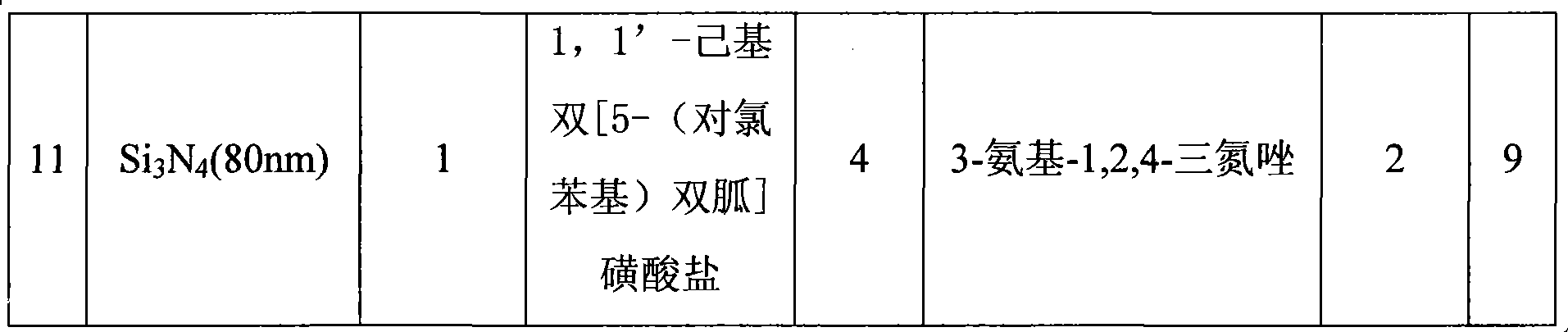

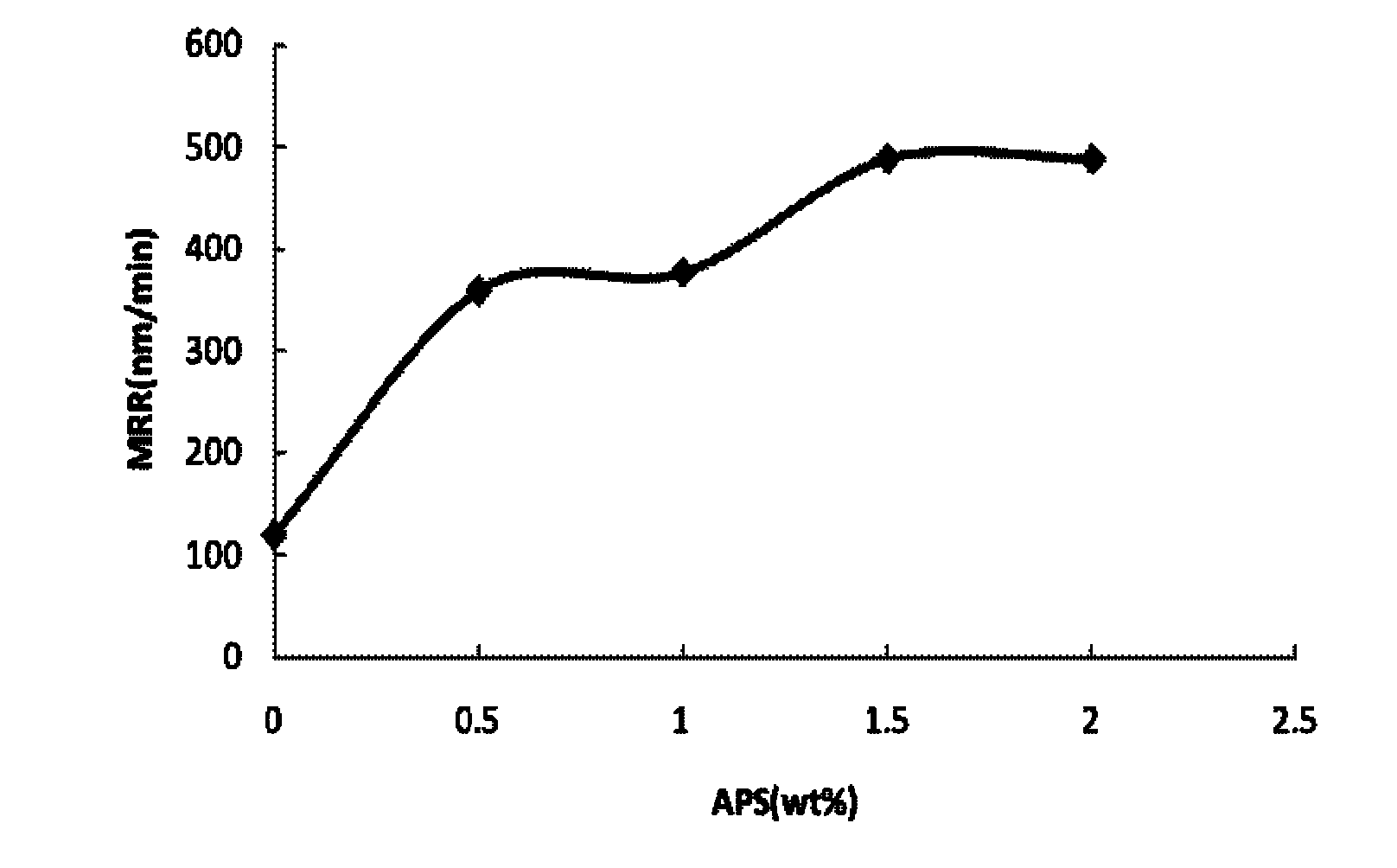

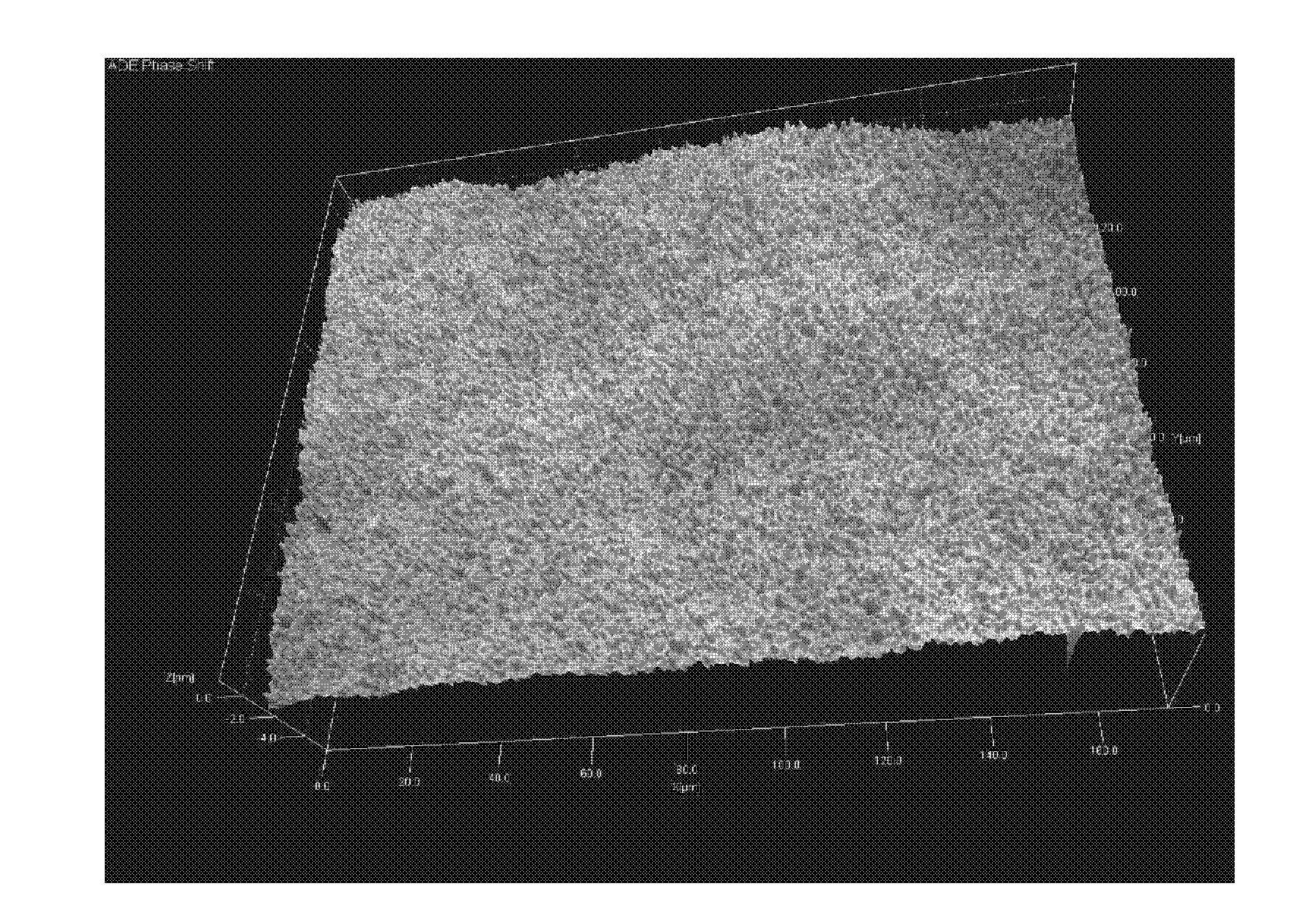

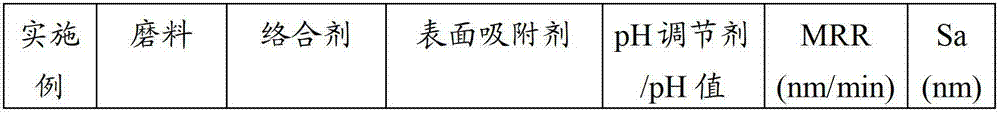

Chemico-mechanical polishing solution

InactiveCN101497765AImprove removal rateOther chemical processesSemiconductor/solid-state device manufacturingCompound (substance)Nitrogen

The invention discloses a chemical-mechanical polishing solution. The chemical-mechanical polishing solution contains ground particles and water and also contains biguanide compound and nitrogen and azole compound, wherein the biguanide compound and the nitrogen and azole compound have synergistic effect and can remarkably improve the elimination rate of polysilicon.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

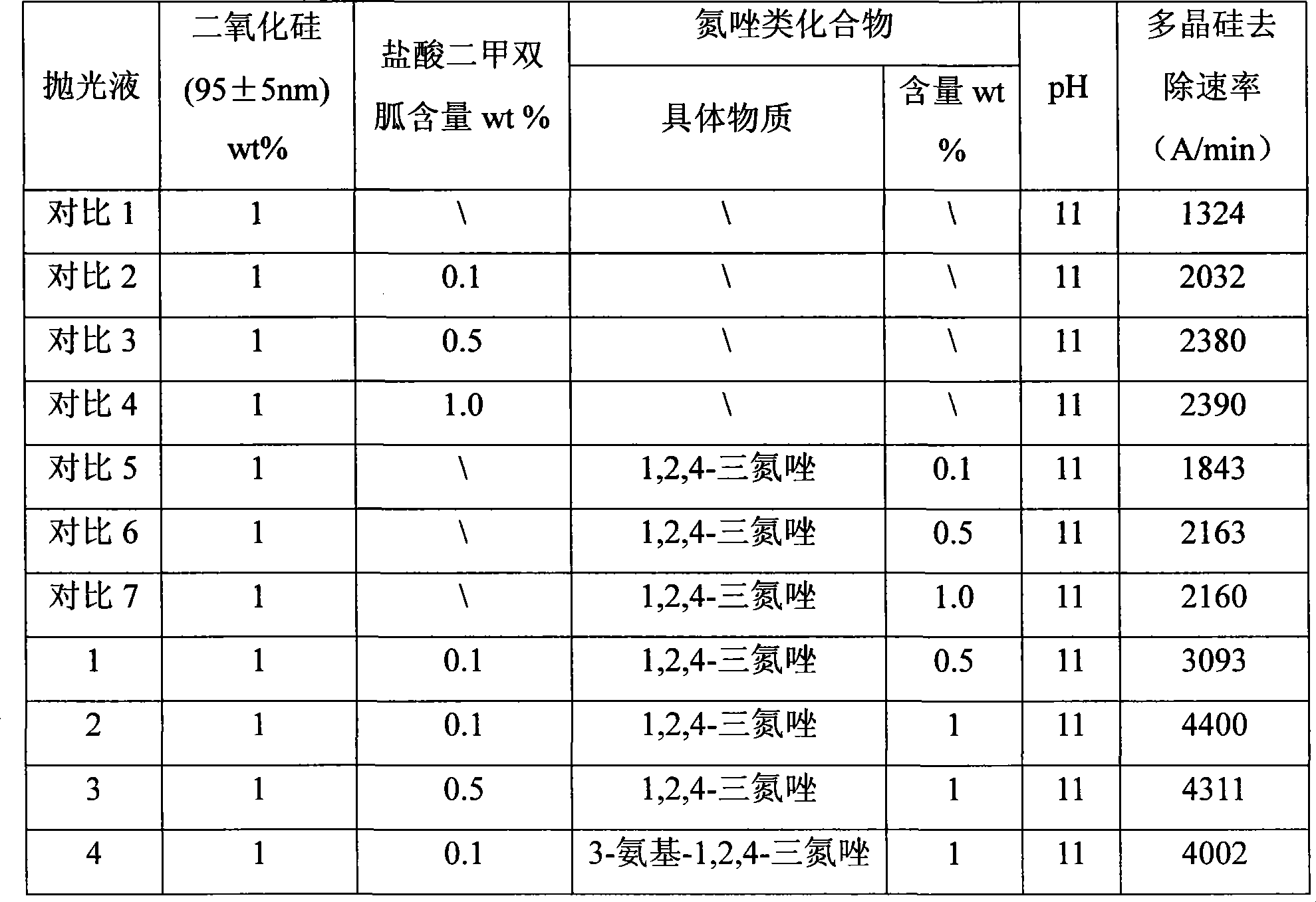

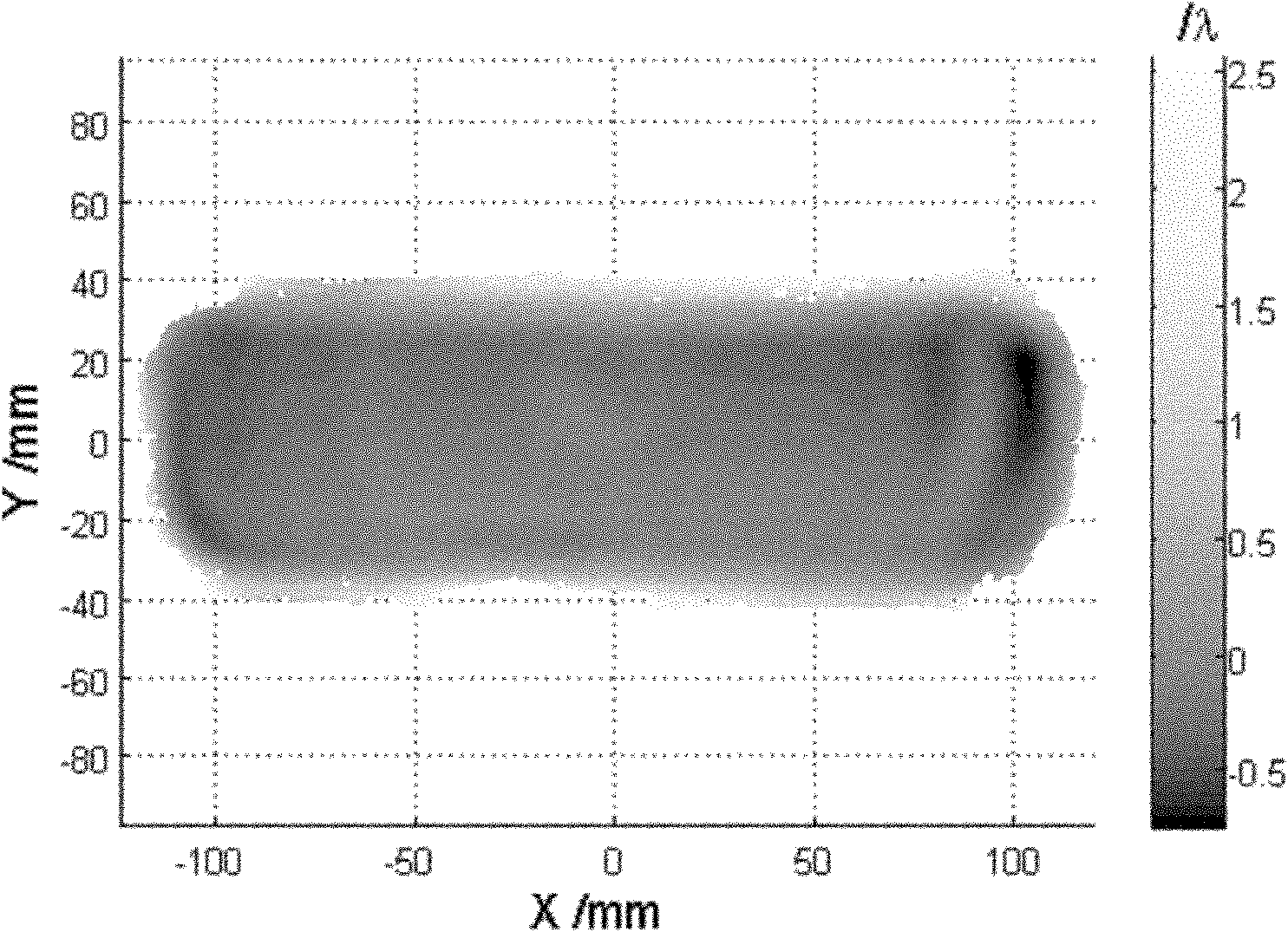

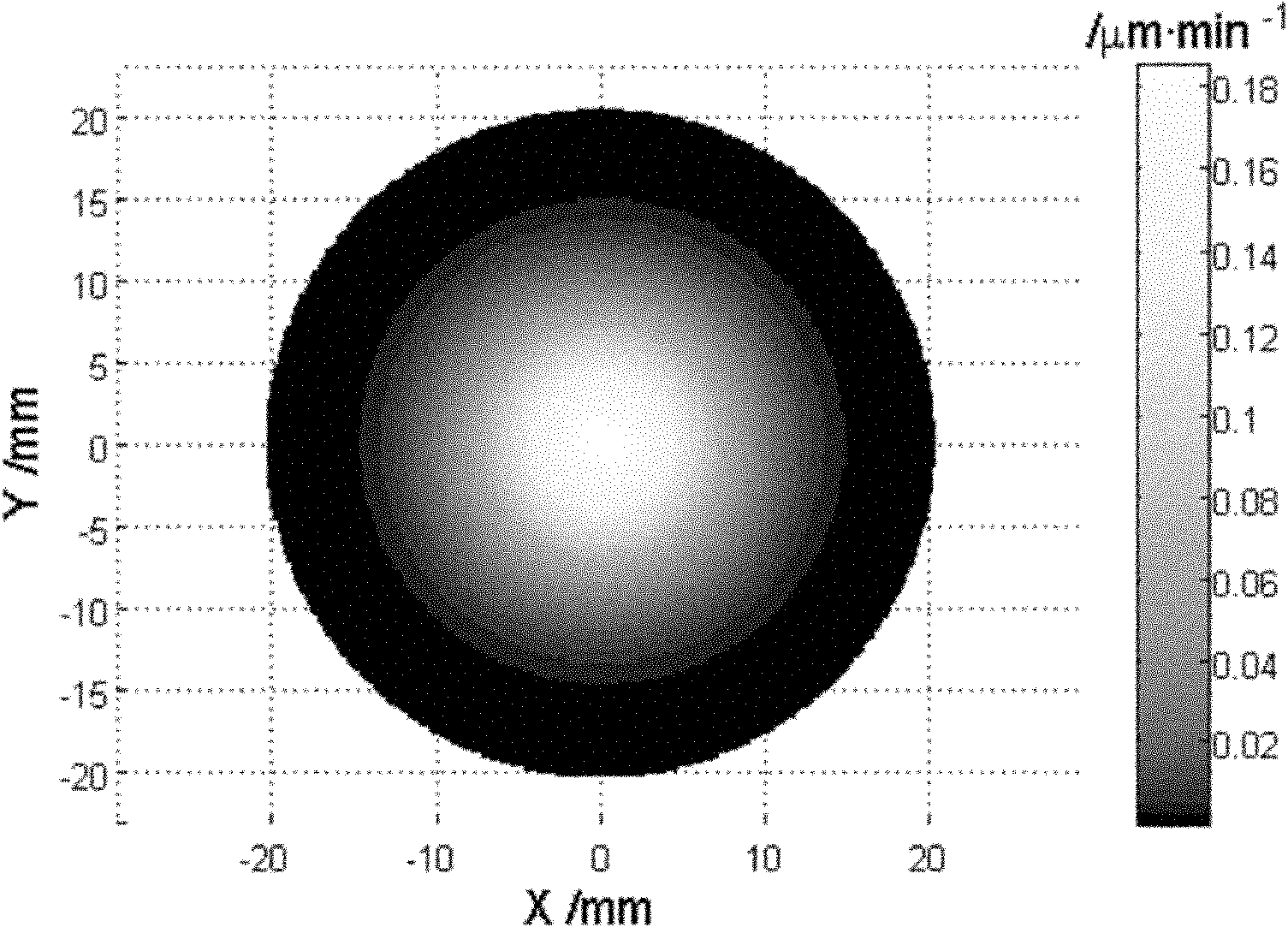

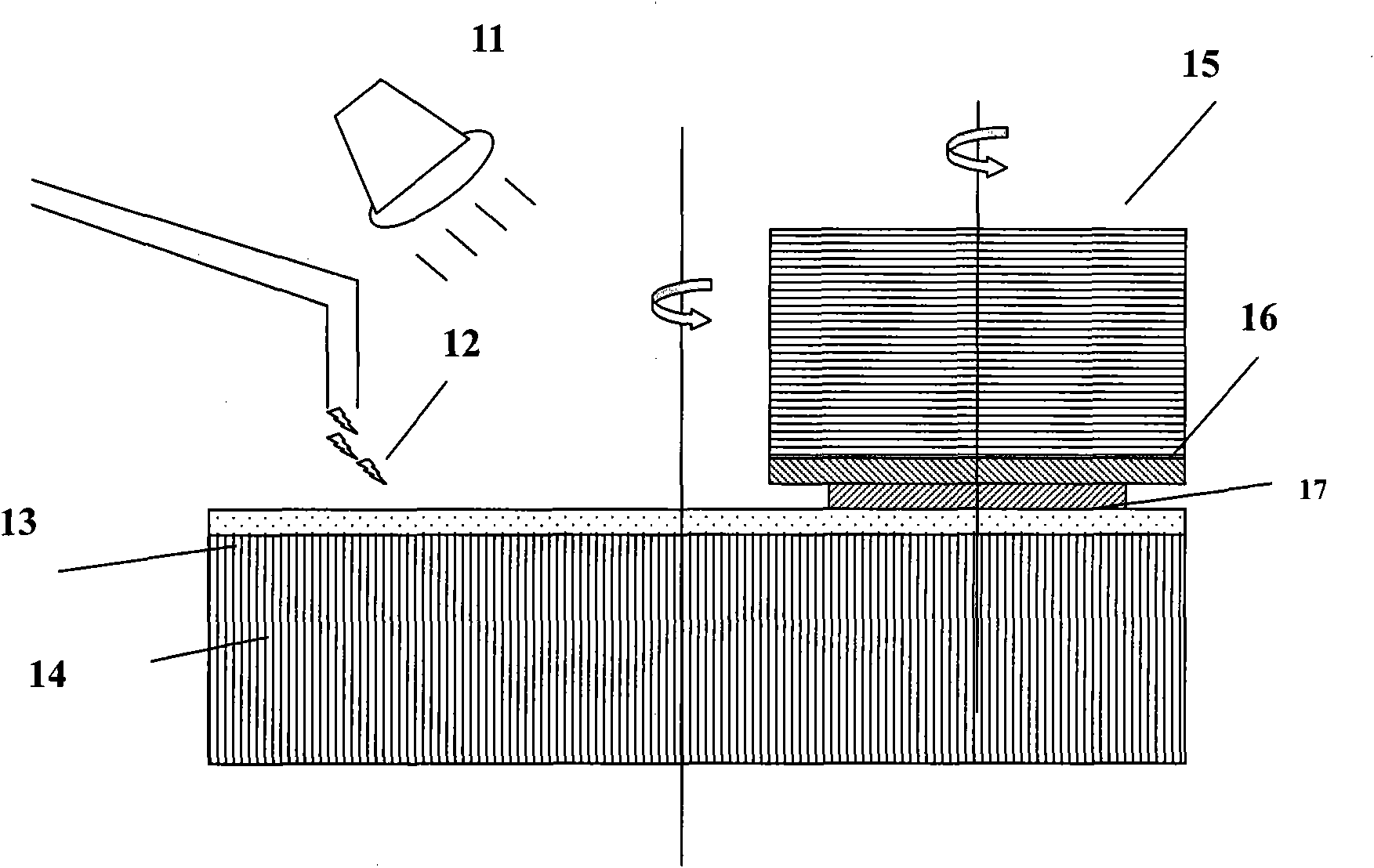

Ion beam figuring processing method for aspheric surface processing

InactiveCN102092929ALow costImprove dynamic characteristicsGlass severing apparatusGlass productionNumerical controlMaterial removal

Owner:NAT UNIV OF DEFENSE TECH

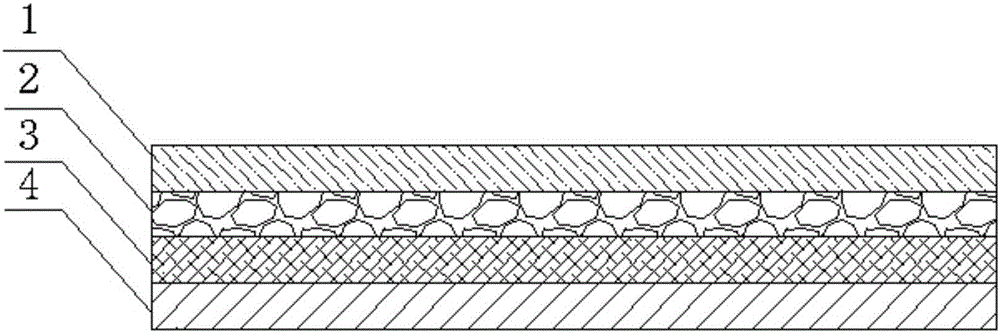

Composite air purifying filter paper material and filter element using same

InactiveCN106334373AImprove fast purification adsorption performanceImprove removal rateGas treatmentDispersed particle filtrationFiberEnvironmental engineering

The invention relates to a composite air purifying filter paper material and a filter element using the same. The composite air purifying filter paper material comprises an active carbon fiber pre-filtering layer, an adsorption catalytic particle layer, a particulate matter filtering layer and a sterilizing supporting layer which are superposed according to any sequence. Compared with the existing filter paper material, the composite air purifying filter paper material is provided with the active carbon fiber pre-filtering layer; an air purifying filter element prepared from the composite air purifying filter paper material can significantly improve quick purification and adsorption performance on pollutant molecules, such as peculiar smell and the like, in the environment, and the removal rate of the whole filter element on gas-state pollutant molecules is increased.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

Polishing solution containing ceric oxide powder/colloid silicon dioxide mixed abrasive and preparing process thereof

ActiveCN103992743AImprove removal rateImprove surface qualityPolishing compositions with abrasivesSilica particleCerium(IV) oxide

The invention relates to a chemically mechanical polishing solution and a preparation process thereof, and particularly to a polishing solution containing a ceric oxide powder / colloid silicon dioxide mixed abrasive and a preparing process thereof. The polishing solution containing the mixed abrasive is simple in preparing process, practical and prone to production. Raw materials of the polishing solution comprise 3-10% of ceric oxide powder having a particle size of 100-2000 nm, 5-50% of colloid silicon dioxide having a particle size of 10-200 nm, and 0.001-0.5% of a dispersing agent, with the balance being water. The polishing solution is prepared by selecting a container, adding the colloid silicon dioxide solution, adding the ceric oxide powder, stirring uniformly, adding the dispersing agent and the water to the required volume, and stirring uniformly. The ceric oxide powder and the colloid silicon dioxide of different particle sizes are adopted as the abrasive. In the polishing solution, the smaller silicon dioxide particles decrease scratches, pits, and other defects so as to improve the surface quality, and the larger ceric oxide particles obtain a high removing rate.

Owner:杰明纳微电子股份有限公司 +1

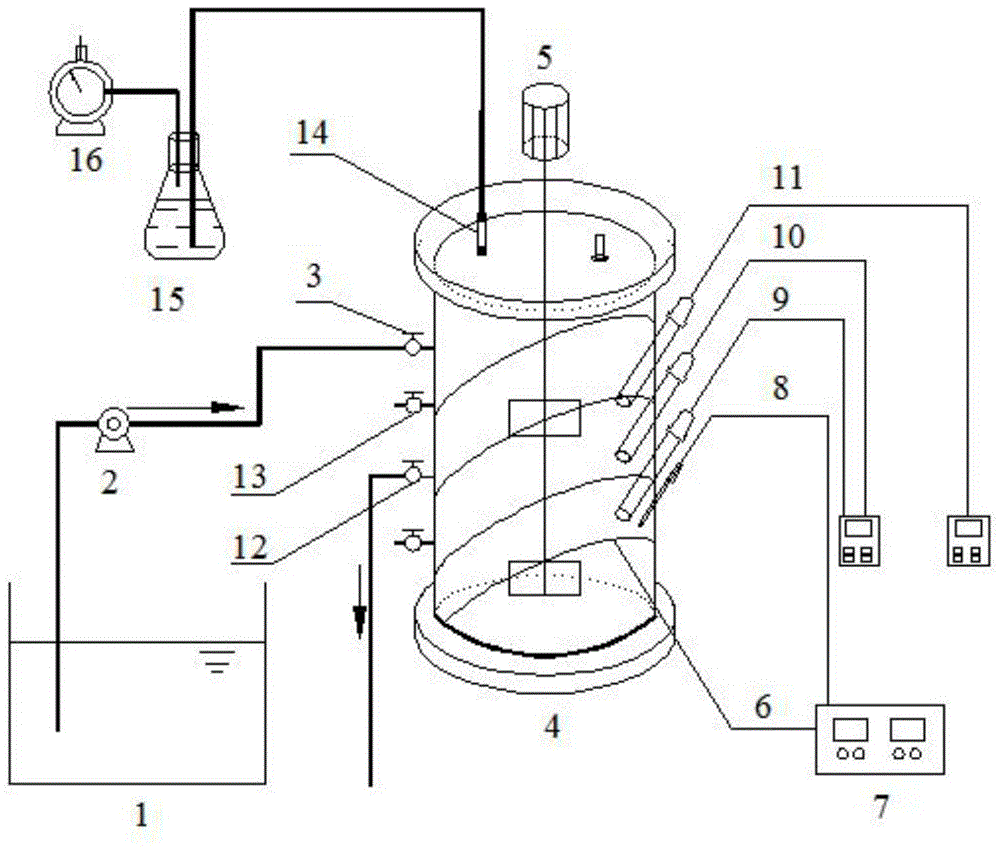

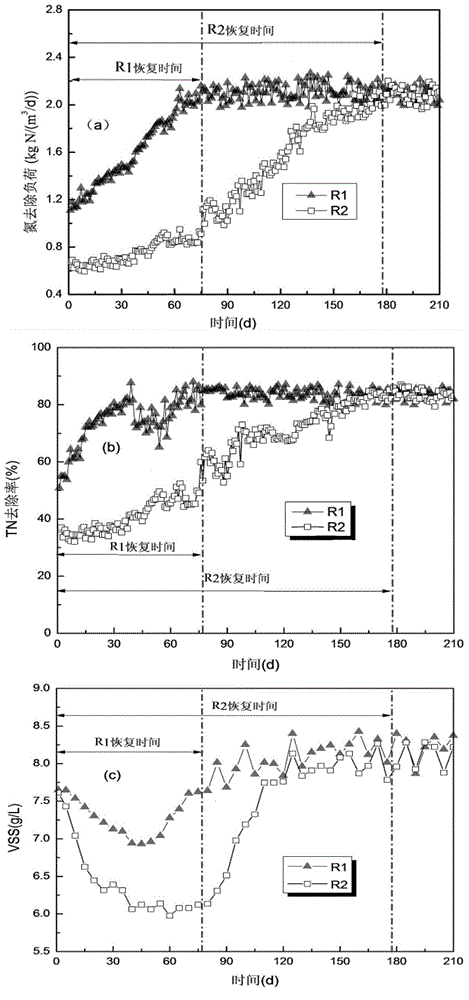

Electrically enhanced ANAMMOX biologic nitrogen removal method

ActiveCN102336472AEfficient redox processEnhanced and Regulated ReleaseTreatment with anaerobic digestion processesStart timeEffective height

The invention provides an electrically enhanced anaerobic ammonia oxidation reaction method belonging to the technical field of water treatment. The device comprises a cylindrical anaerobic ammonia oxidation reactor, two electrodes are arranged in the anaerobic ammonia oxidation reactor, a tubular iron electrode is used as an anode, a cylindrical graphite electrode is used as a cathode, and the electrodes are connected with an external DC stabilizing power supply through wires. The lengths of the electrodes are 30-40% of the effective height of the reactor, and the lowest inserting positions of the electrodes are 1 / 2 parts of the effective height of the reactor. Under the action of externally applied voltage (optimally, 0.6V voltage and less than 5mA current), the dissolution of iron in the anode is effectively controlled, and the growth of anaerobic ammonia oxidation bacteria is promoted. The results of experiment tests show that the nitrogen removal efficiency of the anaerobic ammonia oxidation bacteria is increased by electrochemical action and coupling in a biologic treatment process, the removal of nitrate nitrogen byproducts in the ANAMMOX process is enhanced, and the device has higher total nitrogen removal efficiency than reference reactors. The starting time of the ANAMMOX technology is shortened, and the total nitrogen removal capability of the ANAMMOX process is effectively improved.

Owner:DALIAN UNIV OF TECH

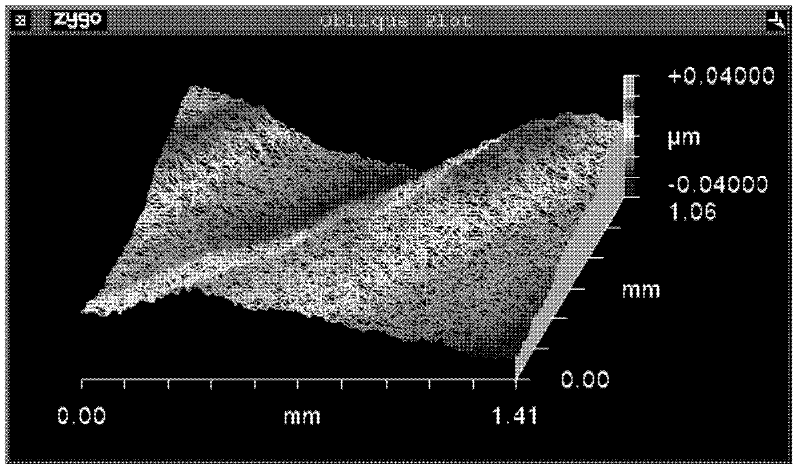

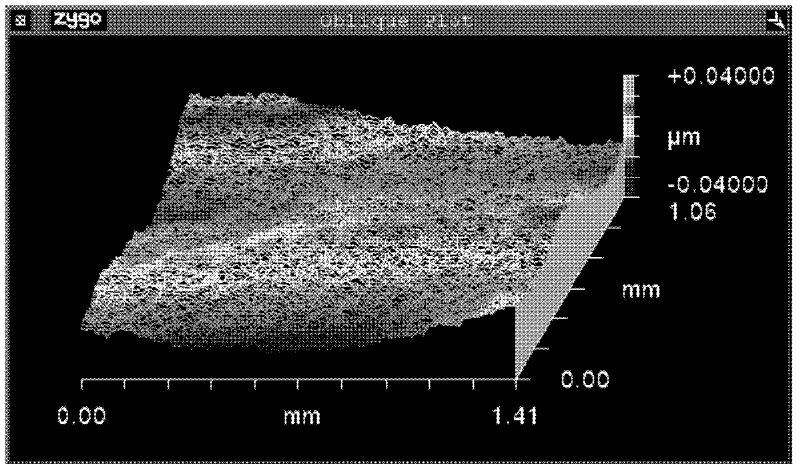

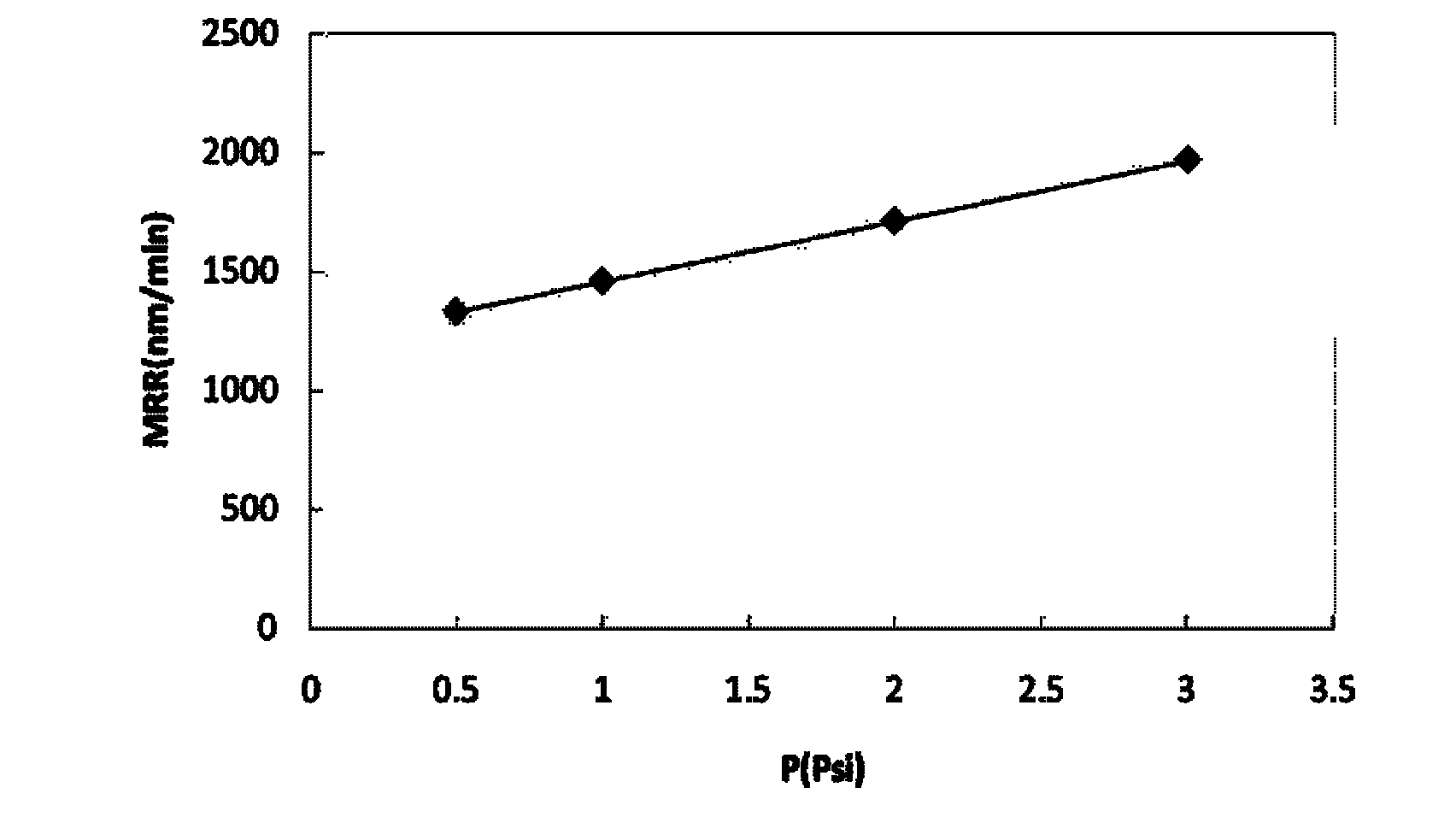

Polishing fluid for smoothing treatment of refined surface and use method thereof

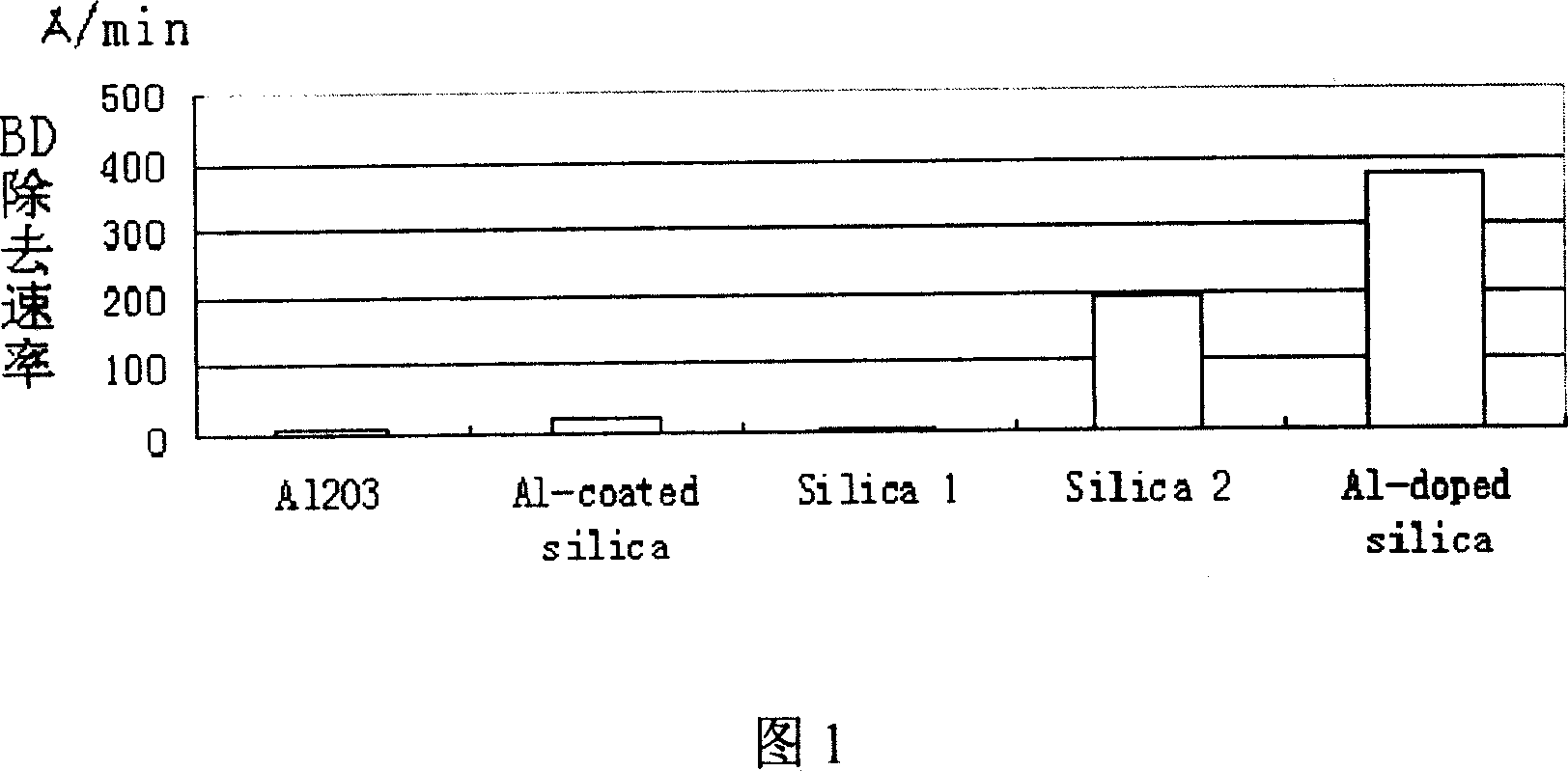

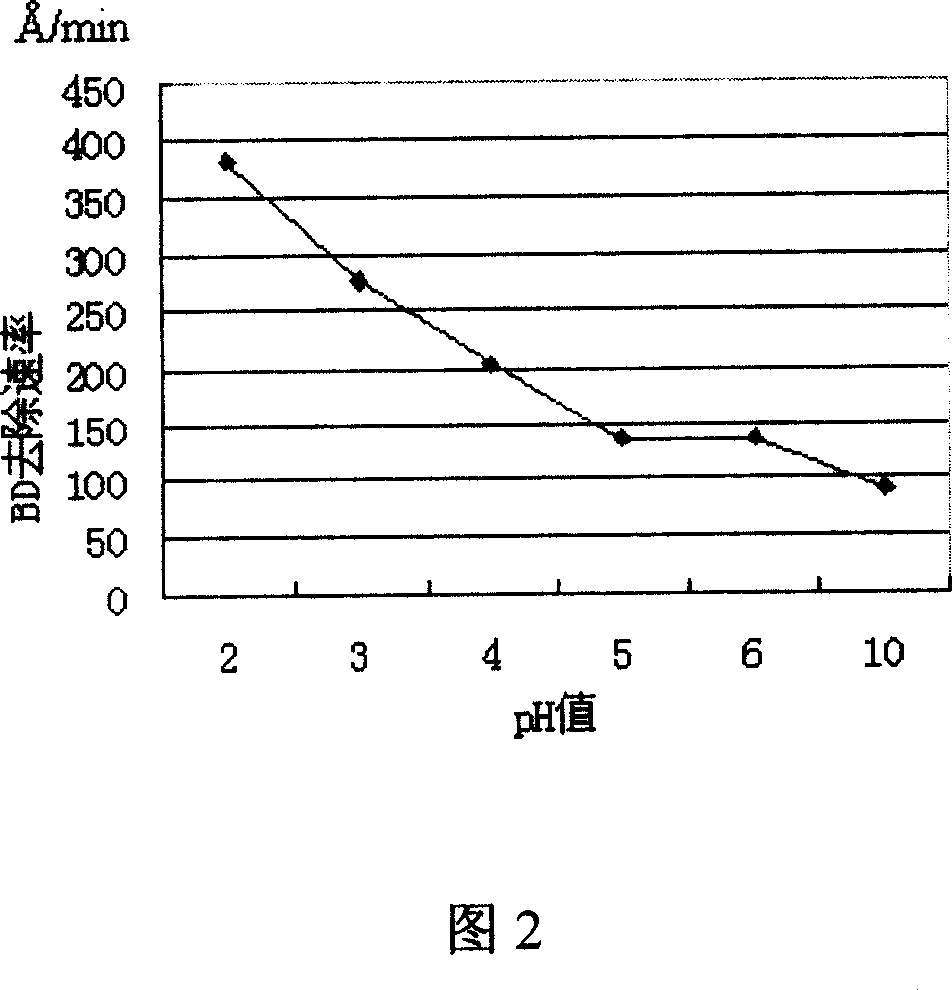

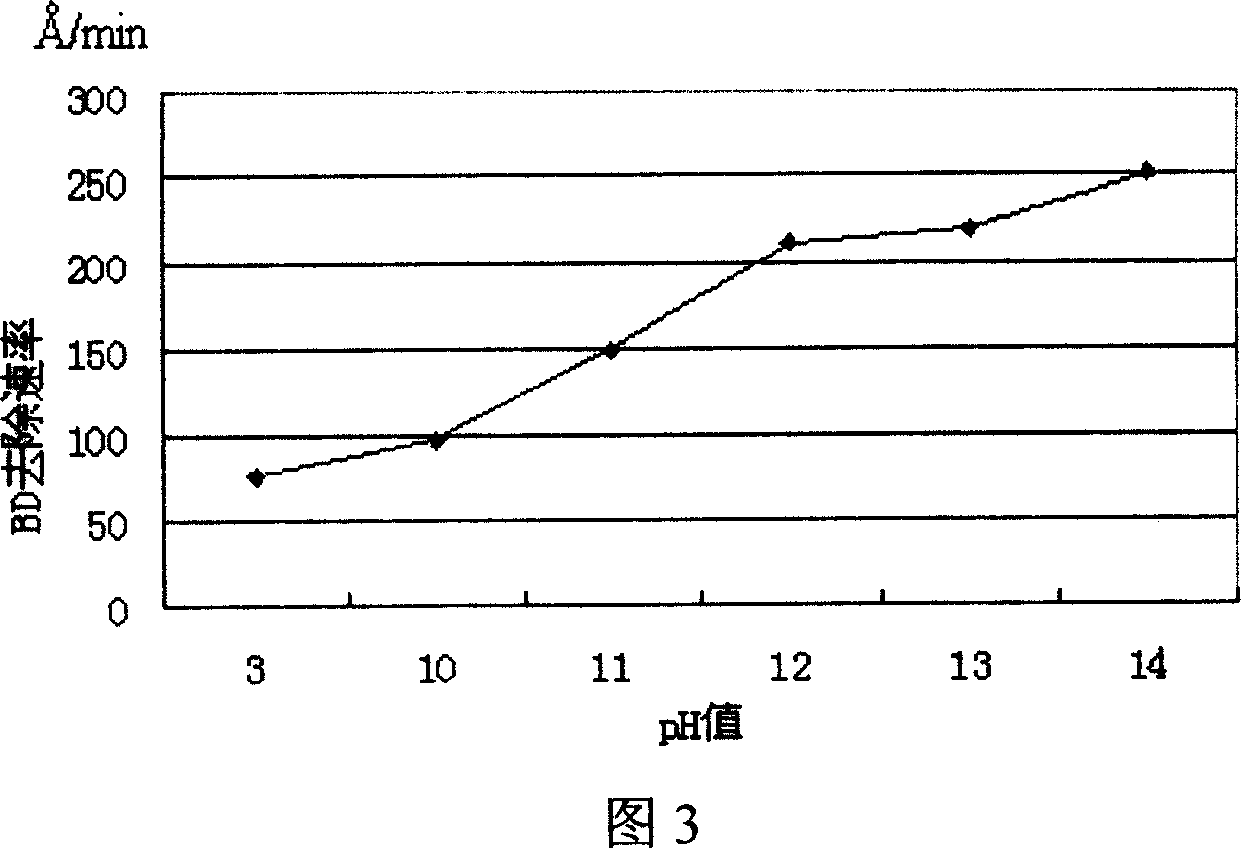

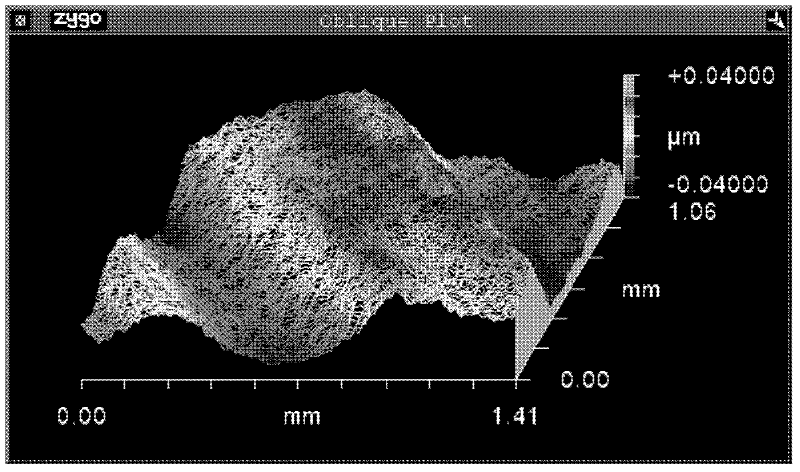

ActiveCN101077961AImprove removal rateEfficient removalOther chemical processesSemiconductor/solid-state device manufacturingSilicon dioxideMaterials science

The present invention discloses one kind of polishing fluid for fine surfacing and its usage. The polishing fluid includes abradant and water, and the abradant is water dispersed sol type aluminum mixing silica abradant. When the polishing fluid is used in chemomechanical polishing, the downward pressure is 0.5-3 psi. The polishing fluid may be used to eliminate Ta, TaN, TEOS, FSG, BD and other low dielectric constant material effectively, and has especially high low dielectric constant material eliminating efficiency.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Copper chemical and mechanical polishing combination

InactiveCN102329572AReduce surface residueReduce surface corrosion defectsPolishing compositions with abrasivesCompound (substance)Copper

The invention discloses a copper chemical and mechanical polishing combination, which belongs to the technical field of microelectronic auxiliary materials and ultra-precision machining processes. The copper chemical and mechanical polishing combination comprises abrasive particles, an oxidant, a complexing agent, a polishing accelerating agent and a pH regulator. The copper chemical and mechanical polishing combination is characterized by further comprising a long chain corrosion inhibitor and a surface active agent. By using the polishing combination provided by the invention, surface residues, particularly surface granular residues, can be obviously decreased; surface corrosion defects can be obviously decreased; a higher removal speed rate is obtained; and the polishing combination provided by the invention further has the advantages of simple process, cheap price, low cost and the like.

Owner:SHENZHEN LEAGUER MATERIAL +2

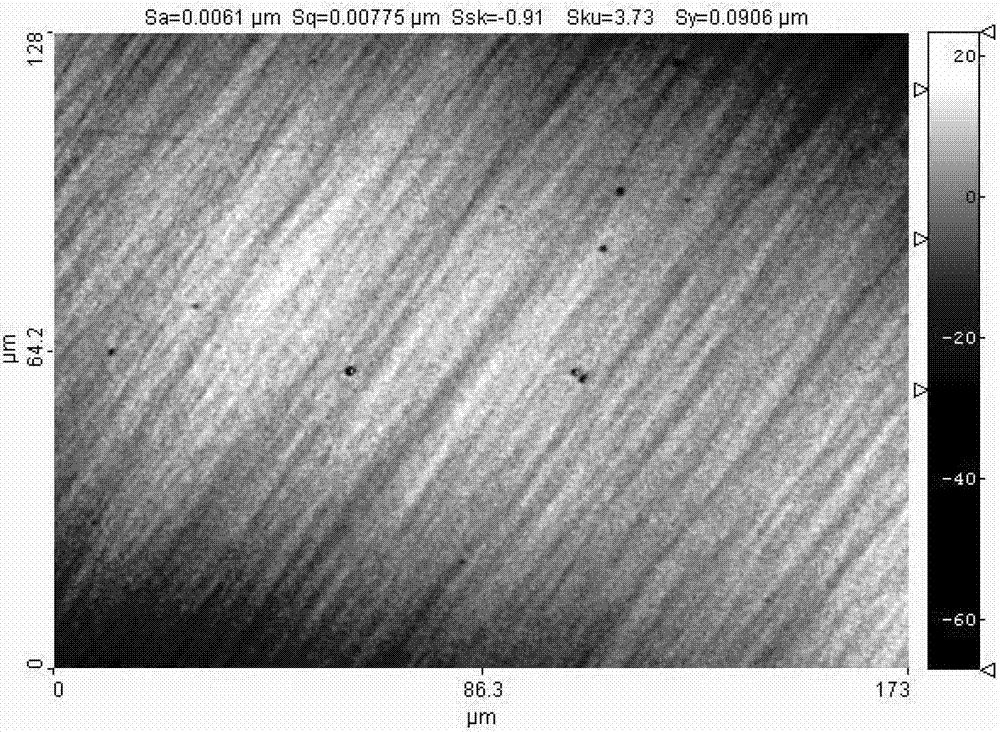

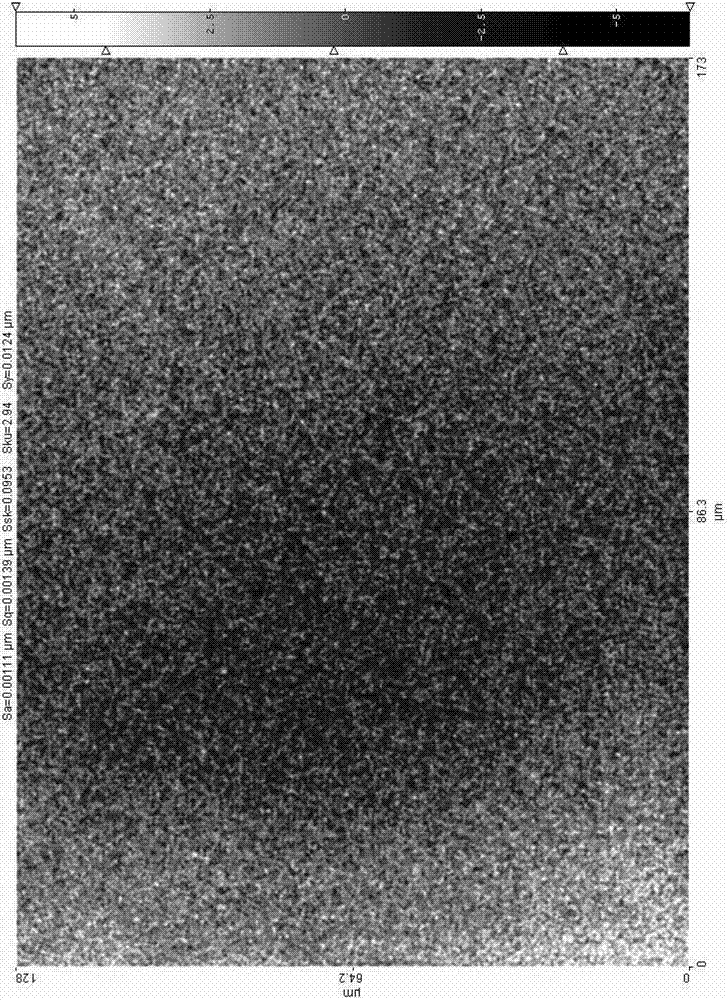

Chemical mechanical polishing solution for large-sized silicon wafers and preparation method thereof

ActiveCN101870852AImprove consistencyReduce hardnessPolishing compositions with abrasivesCompound (substance)Cleansing Agents

The invention relates to a chemical mechanical polishing solution for large-sized silicon wafers and a preparation method thereof, and the chemical mechanical polishing solution is mainly applied to the ultraprecision machining of large-sized semiconductor silicon substrate slices, and can obtain a nanometer-level ultrasmooth surface. The polishing solution consists of the following components inpercentage by weight: 5 to 50 percent of silicon dioxide abrasive, 1 to 10 percent of pH value regulator, 0.01 to 5 percent of surfactant, 0.01 to 0.05 percent of cleaning auxiliary, 0.01 to 2 percent of chelator and the balance of deionized water; and the silicon dioxide is added in the state of silicasol. Under proper polishing technological conditions, the polishing solution prepared with the components according to the contents can obtain a high-quality polished surface and meet the requirement of the semiconductor industry on the surface quality and removal rate of silicon substrate slices, and moreover, the invention has the advantages of low cost, easy cleaning, low corrosiveness and the like, and has a good application prospect.

Owner:BEIJING GRISH HITECH

Composition for low downforce chemically mechanical polishing of coppers in ULSI (Ultra Large Scale Integrated Circuit) multi-layered copper wiring

ActiveCN102181232AImprove performanceStay decentralizedSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesVery large scale integrated circuitsSemiconductor chip

The invention provides a composition for low downforce chemically mechanical polishing of coppers in ULSI (Ultra Large Scale Integrated Circuit) multi-layered copper wiring, which belongs to the field of chemically mechanical polishing aqueous composition. The invention provides an aqueous composition suitable for polishing coppers on a semiconductor chip under a downforce of less than 1.0 Psi (6.89 kPa); and the composition contains abrasive, an oxidant, a pH regulator, a buffering agent and water and also mainly contains a sulfur-containing corrosion balancing agent applicable to a situation with low downforce weak mechanical effect. Low downforce polishing is carried out on the coppers in the ultra large scale integrated circuit multi-layered copper wiring by using the polishing composition provided by the invention, high smoothing efficiency and high polishing speed are obtained and polishing defects can be furthest avoided.

Owner:TSINGHUA UNIV

Polishing solution for sapphire substrate

ActiveCN103450812AImprove removal rateThe preparation method is simple and easyPolishing compositions with abrasivesPhysical chemistryBULK ACTIVE INGREDIENT

The invention discloses a polishing solution for a sapphire substrate, and relates to the technical field of preparation of polishing materials. The polishing solution is prepared from the following active ingredients in percentage by weight: 90-95% of silica sol, 0.05-2% of polishing accelerator, 0.05-3% of complexing agent, 0.05-3% of pH regulator, and the balance of deionized water. The polishing solution has the characteristics of being high in removal rate, good in polishing effect, easy to clean, low in cost and the like, and is applicable to the polishing of sapphire substrate materials.

Owner:HUNAN HAOZHI TECH

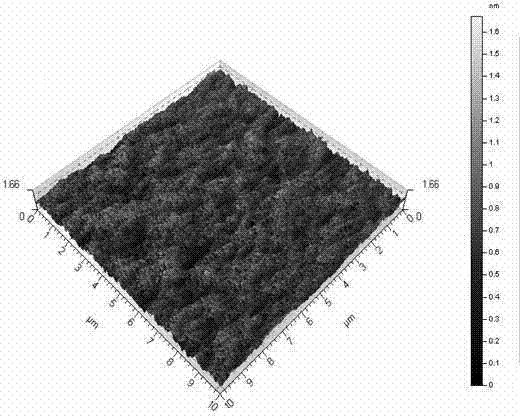

Polishing solution for precision polishing of LED sapphire substrate

InactiveCN103184010AImprove liquidityConsistent removal ratePolishing compositions with abrasivesOrganic baseActive agent

The invention relates to a preparation formula of a polishing solution for precision polishing of an LED sapphire substrate. The polishing solution comprises the following components in percentage by weight: 0.7-1.0% of organic base diethanol amine, 25-35% of silica solution with grain diameter of 50-70nm, 0.4-0.7% of dispersing agent ethanediamine, and 0.1-0.3% of activating agent nonylphenol polyoxyethylene ether. The removal rate of the polishing solution can be up to 28 nm / min; the surface roughness Ra is smaller than 0.5 nm, which can meet the main performance index requirements for sapphire substrate CMP (chemical mechanical polishing). The polishing solution has the advantages of high removal rate, low surface roughness and cost, non-pollution to the environment and non-corrosion to equipment.

Owner:铜陵市琨鹏光电科技有限公司

Barium titanate chemico-mechanical polishing aqueous composition and its application

ActiveCN102786879AImprove removal rateReduce concentrationPolishing machinesPolishing compositions with abrasivesBarium titanateSorbent

The invention relates to a barium titanate chemico-mechanical polishing aqueous composition and its application. Specifically, the barium titanate chemico-mechanical polishing aqueous composition comprises: 1-20 wt%, preferably 8-15 wt% of an abrasive; 0.5-10 wt%, preferably 1-3 wt% of a complexing agent; and 0.01-5 wt%, preferably 0.1-1 wt% of a surface adsorbent, wherein the barium titanate chemico-mechanical polishing aqueous composition has a pH value of 8.0-12.0, preferably 10.0-11.5. The barium titanate chemico-mechanical polishing aqueous composition provided in the invention can be effectively applied to a barium titanate substrate chemico-mechanical polishing process, thereby being able to effectively obtain a polished barium titanate layer with a high polishing rate and high surface quality.

Owner:TSINGHUA UNIV

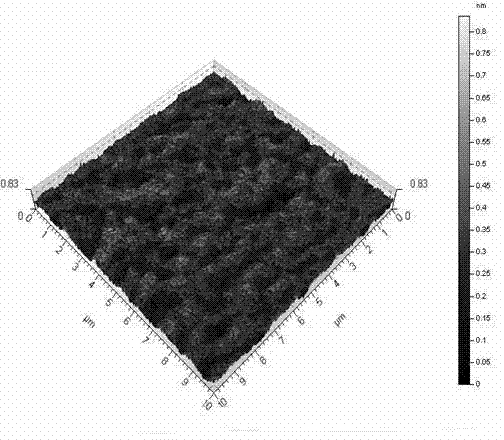

Method for controlling roughness of silicon crystal substrate material surface

InactiveCN1864926ALow roughness controlImprove removal ratePolishing machinesSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

The invention relates to a method for controlling the surface roughness of silicon single-crystal liner material. According to the chemical property of silicon single-crystal liner material, the invention selects alkali medium; uses SiO2 hydrosol as abrasive; uses pH adjuster to adjust the pH value of solution 9-13.5; adds surface activator as FA / O to prepare the polish liquid. The invention uses two polishing steps as roughly polishing and finely polishing at different polishing conditions; roughly polishes for 10-20mins while the flux is 100-200ml / min, the temperature is 30-40Deg. C, the rotation speed is 40-120rpm and the pressure is 0.10-0.20MPa; finely polishing for 4-7mins while the flux is 800-1000ml / min, the temperature is 20-30Deg. C, the rotation speed is 30-60rpm, and the pressure is 0.05-0.10MPa. The invention can realize low roughness of single-crystal liner material.

Owner:HEBEI UNIV OF TECH

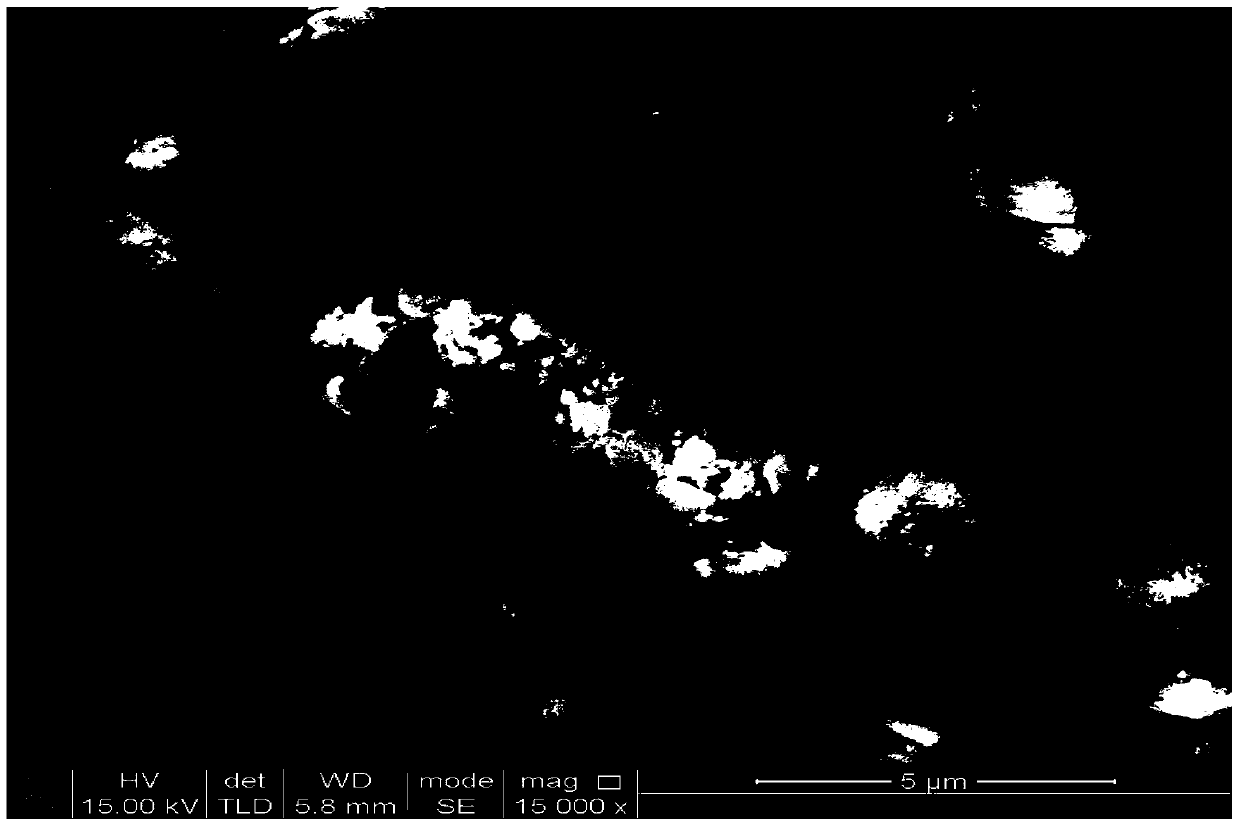

CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for alkaline sapphire substrate and preparation method thereof

ActiveCN103571333ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesNano sio2SURFACTANT BLEND

The invention relates to a CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for an alkaline sapphire substrate and a preparation method thereof. The CMP polishing liquid consists of the following components in percentage by weight: 0.5-35% of a main grinding material, 0.015-0.09% of an auxiliary grinding material, 0.005-0.05% of a chelating agent, 0.005-0.05% of a surfactant, 0.01-0.5% of a pH adjustor, and the balance of deionized water, wherein the main grinding material is a nano SiO2 sol and the auxiliary grinding material is an Al2O3 sol. The auxiliary grinding material, the chelating agent, the surfactant and the alkaline pH adjustor are sequentially added into a nanosilicon sol suspension. In the polishing liquid, as the content of the main grinding material SiO2 sol is reduced, the phenomenon that the polishing liquid residue on the surface of the substrate after CMP is relatively severe is reduced to facilitate subsequent cleaning. A less amount of the auxiliary grinding material Al2O3 is added, so that the polishing speed is remarkably increased, and the roughness of the substrate after CMP is reduced.

Owner:江西伟嘉创展企业管理有限公司

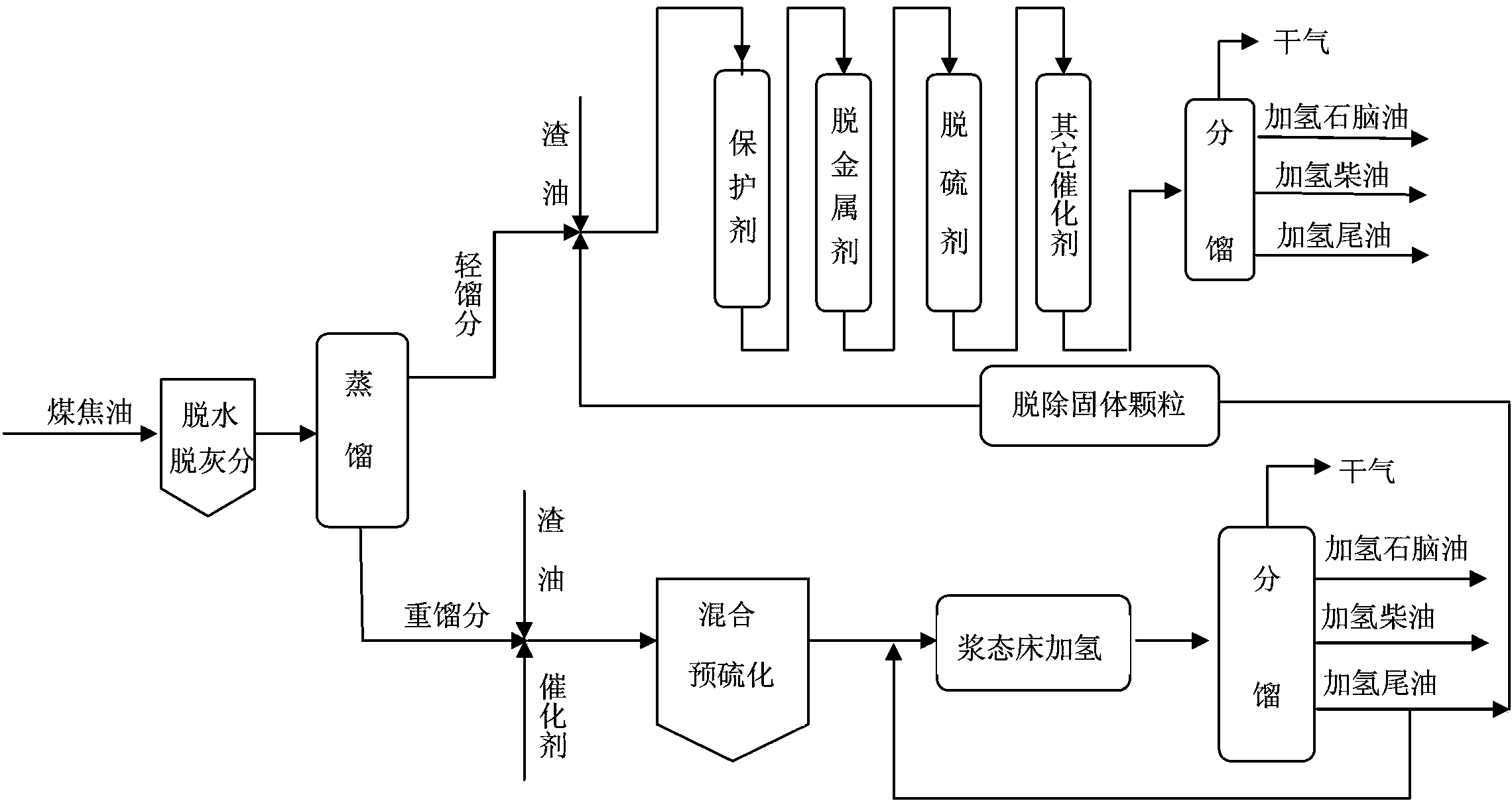

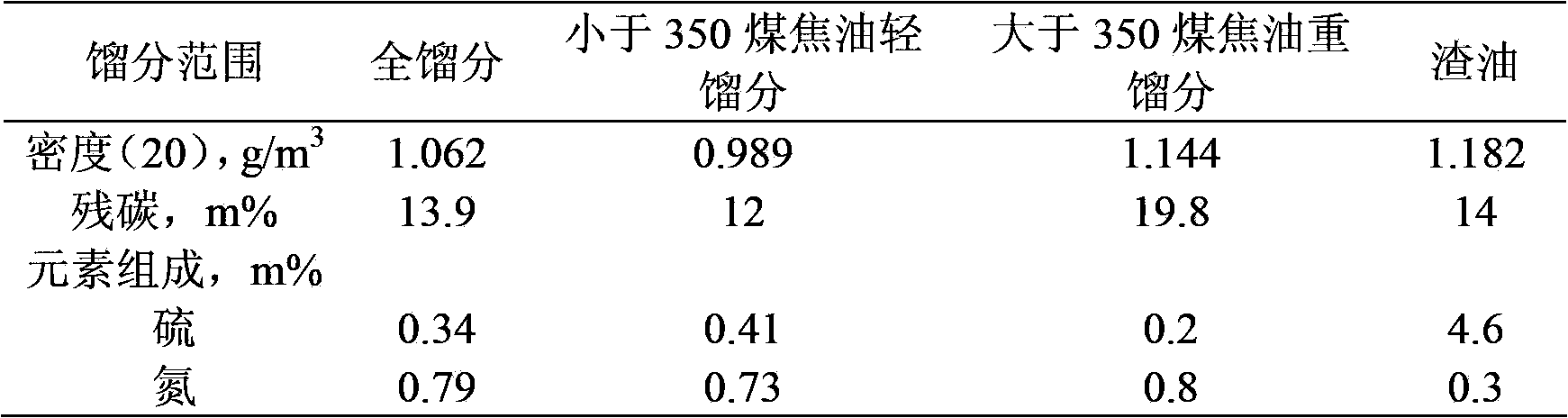

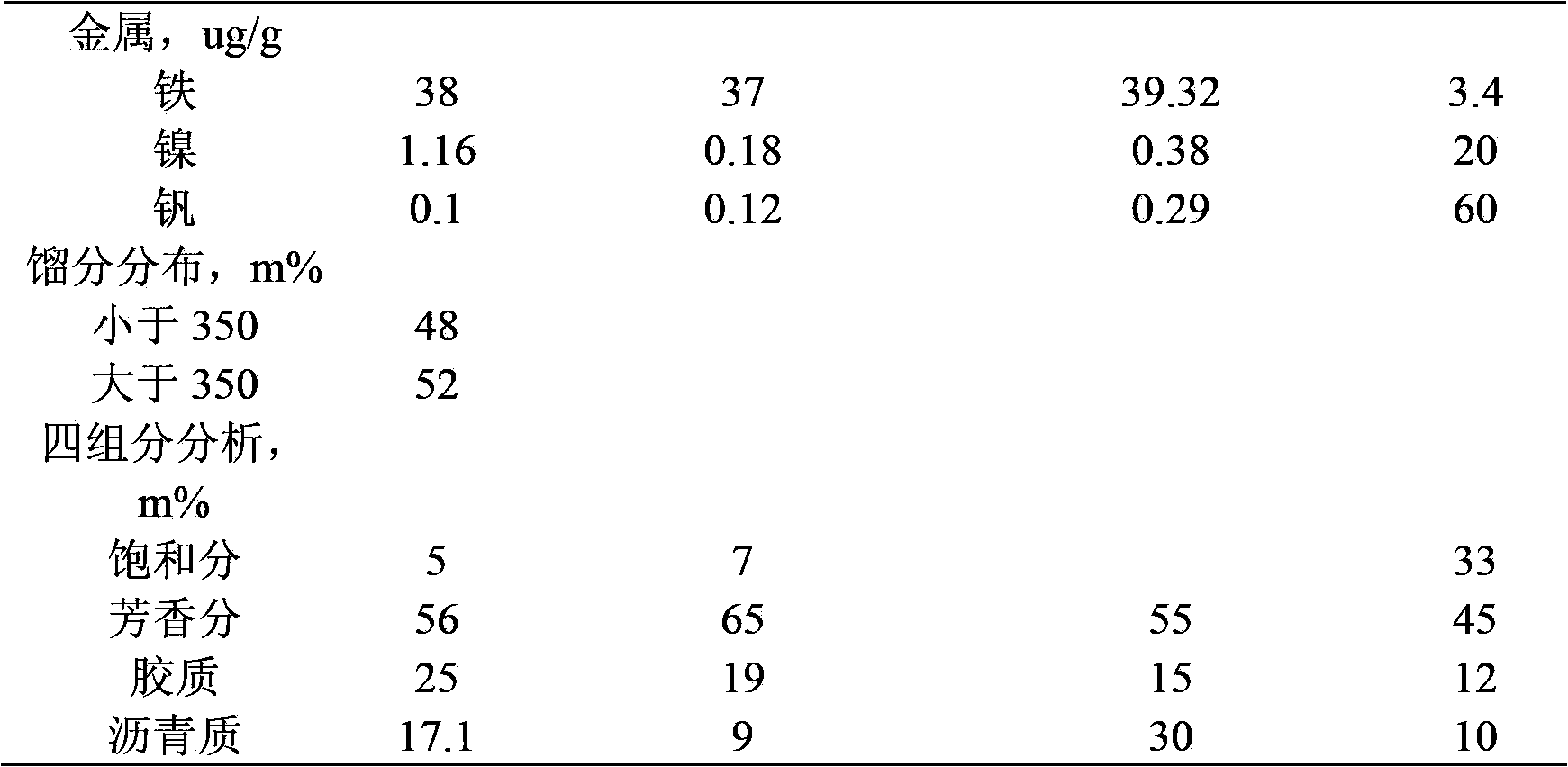

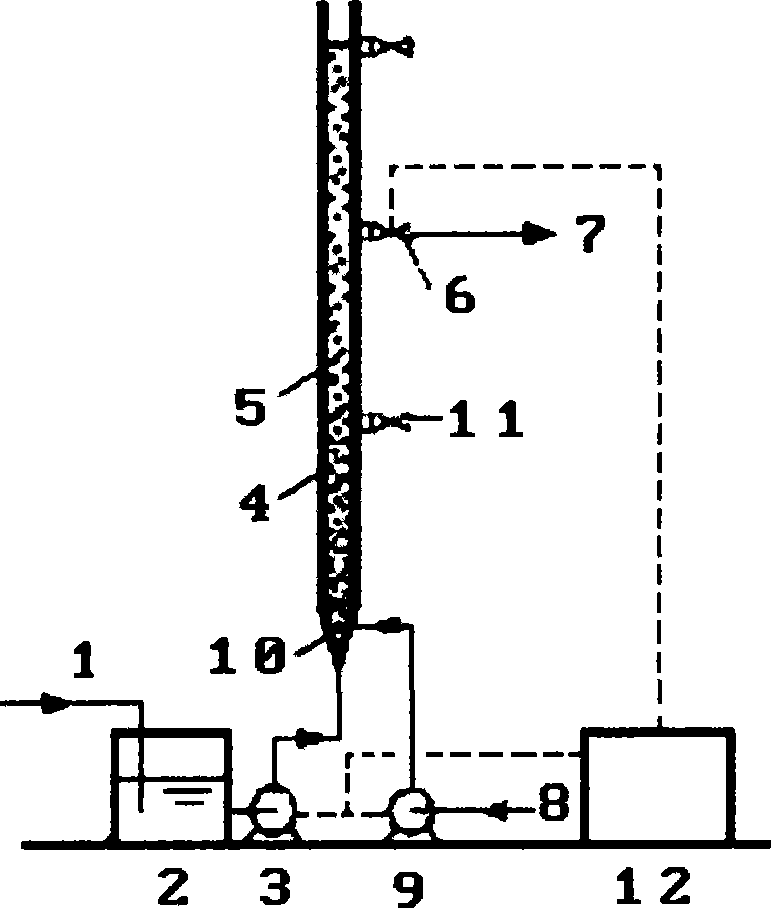

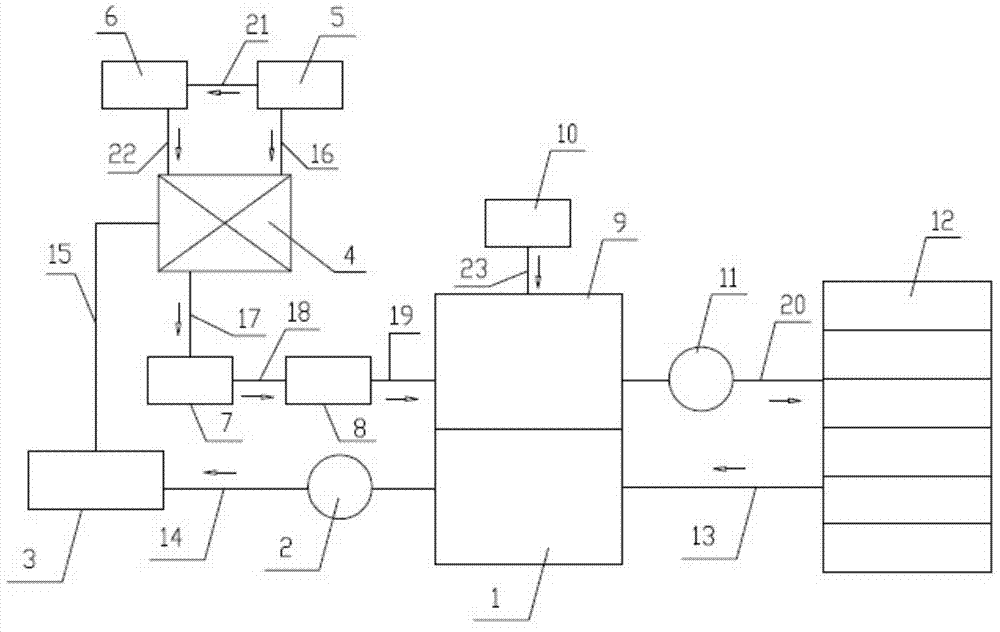

Combined hydrogenation process method for treating coal tar and residual oil

InactiveCN103540353ALow viscosityImprove diffusion abilityTreatment with hydrotreatment processesFixed bedSlurry

The invention relates to a combined hydrogenation process method for treating coal tar and residual oil. The method comprises the following steps: distilling coal tar with water and solid particles removed to obtain light coal tar fraction not larger than 350 DEG C and heavy coal tar fraction larger than 350 DEG C; mixing the heavy coal tar fraction larger than 350 DEG C with residual oil, hydrogen and a catalyst, reacting the mixture in a slurry bed hydrogenation reactor, and conveying hydrogenation tail oil of 350-470 DEG C to a fixed bed residual oil hydrogenation unit; reacting the light coal tar fraction not larger than 350 DEG C with the residual oil and the hydrogen or the hydrogenation tail oil in the fixed bed residual oil hydrogenation unit, and separating the reaction products to obtain a dry gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil. According to the method, slurry bed hydrogenation treatment is organically combined with the fixed bed residual oil hydrogenation process to process all coal tar fractions so as to improve the utilization rate of the coal tar, expand the source of residual oil hydrogenation raw materials, prolong the operation period of the fixed bed residual oil hydrogenation unit and improve the impurity removal rate of the residual oil hydrogenation product.

Owner:PETROCHINA CO LTD

System and method for cultivation of aerobic particle sewage sludge and for treating organic waste water

InactiveCN101508485AFine grainShorten the timeWater contaminantsSustainable biological treatmentSodium bicarbonateAeration system

The invention relates to a system and a method for culturing aerobic grain sludge(AGS) and treating organic waste water generated during the culture of the aerobic grain sludge. An SBR system with short period is adopted to culture the aerobic grain sludge(AGS) and treat the organic waste water. The system consists of a main reactor, a water charging system, a water discharging system, an aeration system and a corresponding self-control device. A 2.5h short-period SBR operating mode is adopted, and four stages of water charging, aeration, precipitation and water discharging are included in each period. The water charging time is 5 min, the aeration is started while charging water, the aeration time is 132 to 144 min, the precipitation time is 3 to 15 min, and the water discharging time is 3 min. The pH value of the culture and treatment system is controlled by adding bicarbonate. The bicarbonate is sodium bicarbonate, and the adding range is between 0 and 1,200 mg / L. By utilizing the system and the method, the AGS can be quickly and economically cultured, and the organic substances, nitrogen and phosphorus in the organic waste water can be treated in high efficiency. The system and the method can be applied to the culture and production of the aerobic grain sludge and the treatment of the organic waste water, so that the system and the method have important practical values.

Owner:TIANJIN URBAN CONSTR COLLEGE

Oxygen enriching and sterilizing device and oxygen enriching and sterilizing method for soilless culture nutrient solution

ActiveCN103535247AReduce releaseExtended retention timeAgriculture gas emission reductionCultivating equipmentsMicro nanoMicroorganism

The invention discloses an oxygen enriching and sterilizing device and an oxygen enriching and sterilizing method for soilless culture nutrient solution. The method includes dissolving air or oxygen into the nutrient solution by the aid of a micro-nano bubble generation technology to form micro-nano bubble oxygen-enriched water so as to enrich the oxygen in the nutrient solution; dissolving ozone in the nutrient solution by the aid of the micro-nano bubble generation technology to form micro-nano bubble ozone water and jointly sterilizing the nutrient solution by an ultraviolet sterilizer. The oxygen enriching and sterilizing device and the oxygen enriching and sterilizing method have the advantages that the dissolved oxygen in the nutrient solution can be effectively increased, root rotting phenomena of hydroponics plants can be reduced, and the yield can be increased; spreading of microbial diseases in the nutrient solution can be effectively suppressed, and the application amount of pesticides can be reduced.

Owner:BEIJING ZHONGNONG TIANLU MICRO NANO BUBBLE WATER S&T

Method for relieving anaerobic ammonium oxidation system salinity shock with betaine as additive

ActiveCN104909455AShorten the timeImprove removal rateTreatment with anaerobic digestion processesBetaineSludge

The invention relates to a method for relieving anaerobic ammonium oxidation system salinity shock with betaine as an additive. According to the invention, a successfully started anaerobic ammonium oxidation SBR reactor is used for processing salt-containing wastewater, wherein a volatile suspended sludge concentration is maintained at 6-9g / L, an inlet water NH4<+>-N concentration is 180-220mg / L, and the molar ratio of NH4<+>-N to NO2<->-N is controlled at 1:1-1:1.32 through adding (NH4) 2SO4 and NaNO2; the betaine concentration in the reactor is maintained at 0.1-5mmol / L through adding betaine; with a heating band, the temperature of the reactor is controlled at 30-35 DEG C; DO is controlled at 0-0.1mg / L; inlet water pH is stabilized at 7.0-8.5 through dropping NaOH / HCl; anoxic stirring is carried out for 4-8h after water feeding; when stirring is finished, the material is allowed to stand and to precipitate; when precipitation is finished, a supernatant is discharged. With the method provided by the invention, anaerobic ammonium oxidation activity recovery time when the anaerobic ammonium oxidation system is under salinity load shock can be effectively shortened, nitrogen removal rate can be improved, and a higher total nitrogen removal rate can be realized.

Owner:BEIJING UNIV OF TECH

Polishing compositions for controlling metal interconnect removal rate in semiconductor wafers

InactiveCN1699444AReduced removal rateChange in removal rateOther chemical processesDecorative surface effectsWaferingPyrrolidinones

A polishing composition suitable for polishing semiconductor substrates comprises 0.001 to 2 wt % of a thermoplastic polymer; and 0.001 to 1 wt % of polyvinylpyrrolidone; wherein varying the weight ratio of thermoplastic polymer to the polyvinylpyrrolidone controls the removal rate of the non-ferrous interconnect.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Chemo-mechanical polishing slurry for metal, and its application

InactiveCN103866326AImprove removal rateCorrosion controlOther chemical processesPolishing compositions with abrasivesPhosphateSlurry

The invention provides a chemo-mechanical polishing slurry for copper, and its application. The slurry comprises abrasive particles, a complexing agent, an oxidant, a corrosion inhibitor, and at least one organic phosphate surfactant. The slurry has the advantages of maintenance of a high copper removal rate, improvement of the saucerization and the over polishing window of polished core wires, few pollutants the surface of polished copper, and no corrosion.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Denitrifying method for ammonia-containing waste water discharged in acrylic production process

ActiveCN103373758AImprove impact performanceImprove denitrification effectWater contaminantsTreatment with aerobic and anaerobic processesWater dischargeTotal nitrogen

The invention discloses a denitrifying method for ammonia-containing waste water discharged in an acrylic production process. The denitrifying method comprises the following step: adding a certain quantity of denitrifier in a sewage treatment system, wherein the treatment temperature of the ammonia nitrogen-containing sewage is 18-40 DEG C, the dissolved oxygen is 0.2-3mg / L, and the pH is 7.5-8.5. Heterotrophic bacteria is used for performing superiority combination to be used as an enhanced microorganism of the waste water treatment so as to remove the ammonia nitrogen, total nitrogen and CODcr in the one reactor, and the waste water treatment effect is good; and in combination with an efficient device, the denitrifying method realizes the standard discharge of the ammonia nitrogen and persistent organic pollutant in the waste water.

Owner:CHINA PETROLEUM & CHEM CORP +1

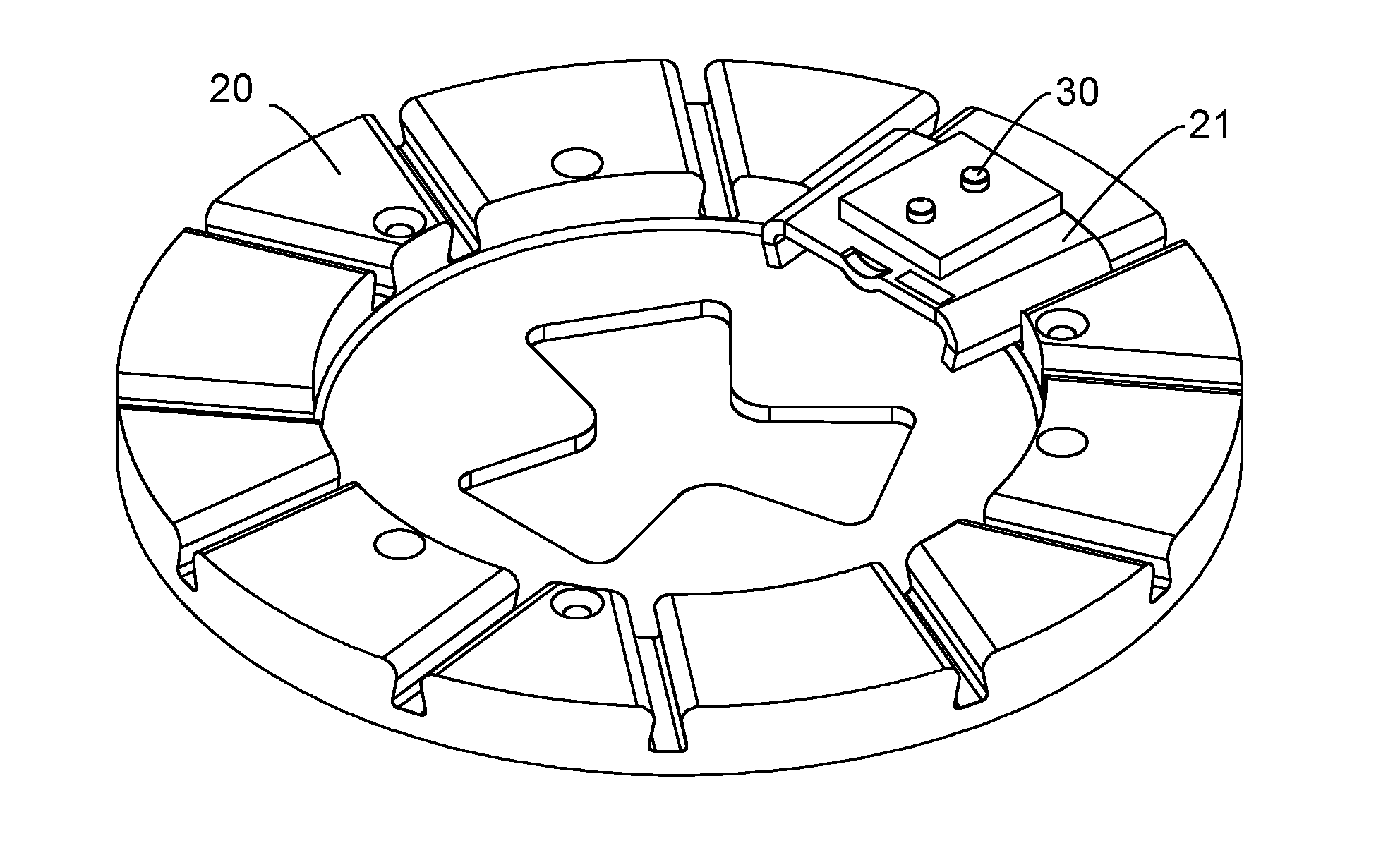

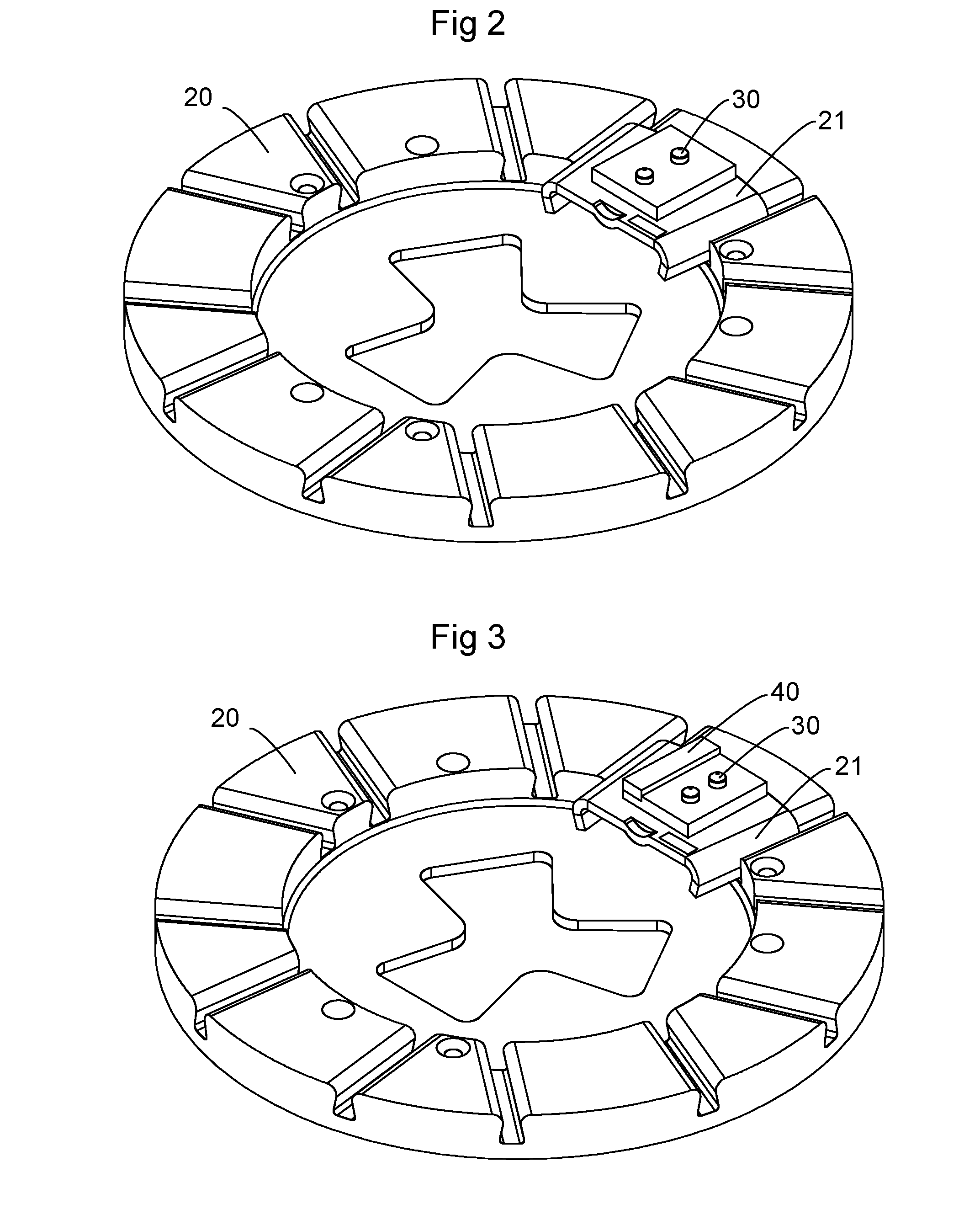

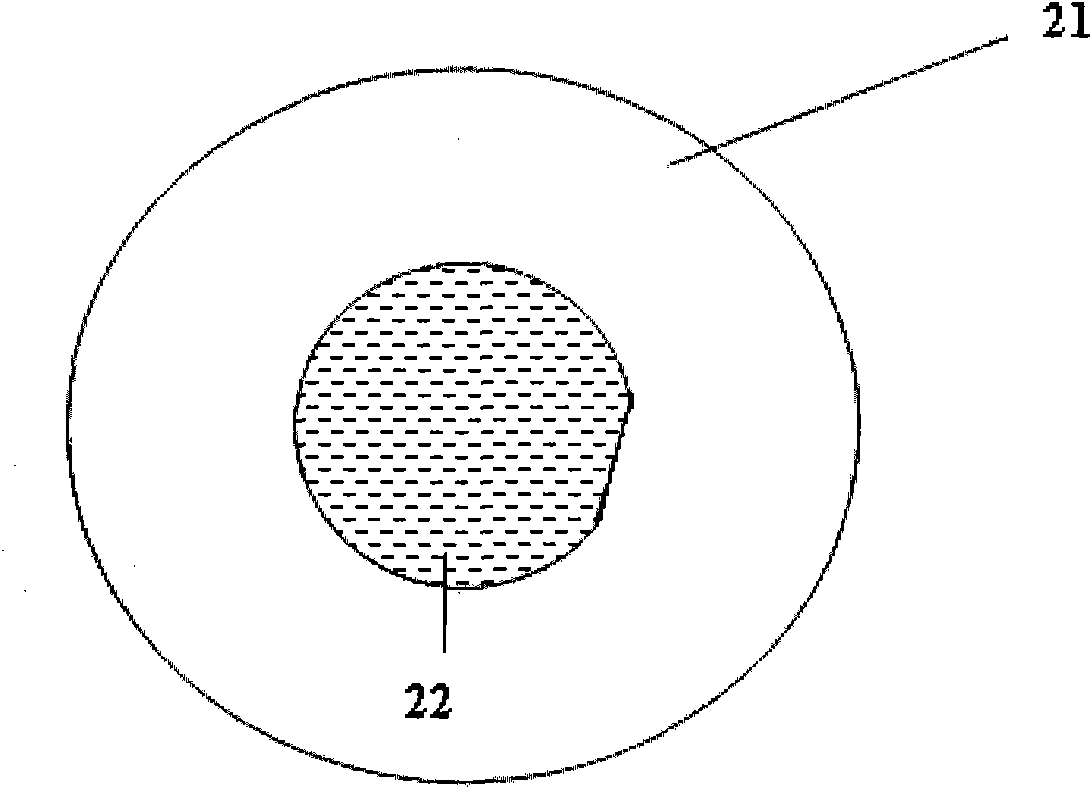

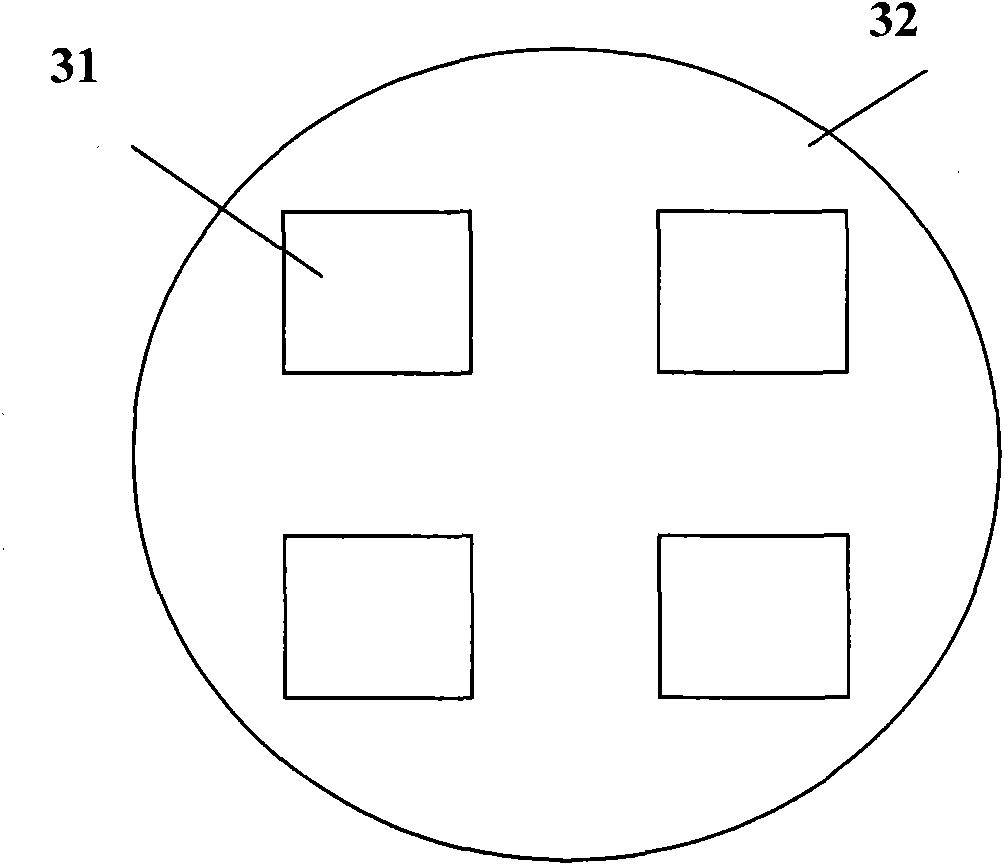

Tool for machining stone or concrete floors

InactiveUS20100136889A1Increase engagementImprove removal rateRevolution surface grinding machinesPortable grinding machinesEngineeringMachining

The invention relates to a machine and at least one tool (10) for machining floor and road surfaces. The tool comprises at least one rotatably mounted disc (20) driven during use, which disc (20) comprises at least one machining element (30) being attached at one end (30a) to the disc. The machining element has a free end (30b) with a symmetrically blunt shape, so that the disc can be driven in different directions with the same machining element in a plane essentially in parallel with the plane of the disc.

Owner:HTC SWEDEN AB

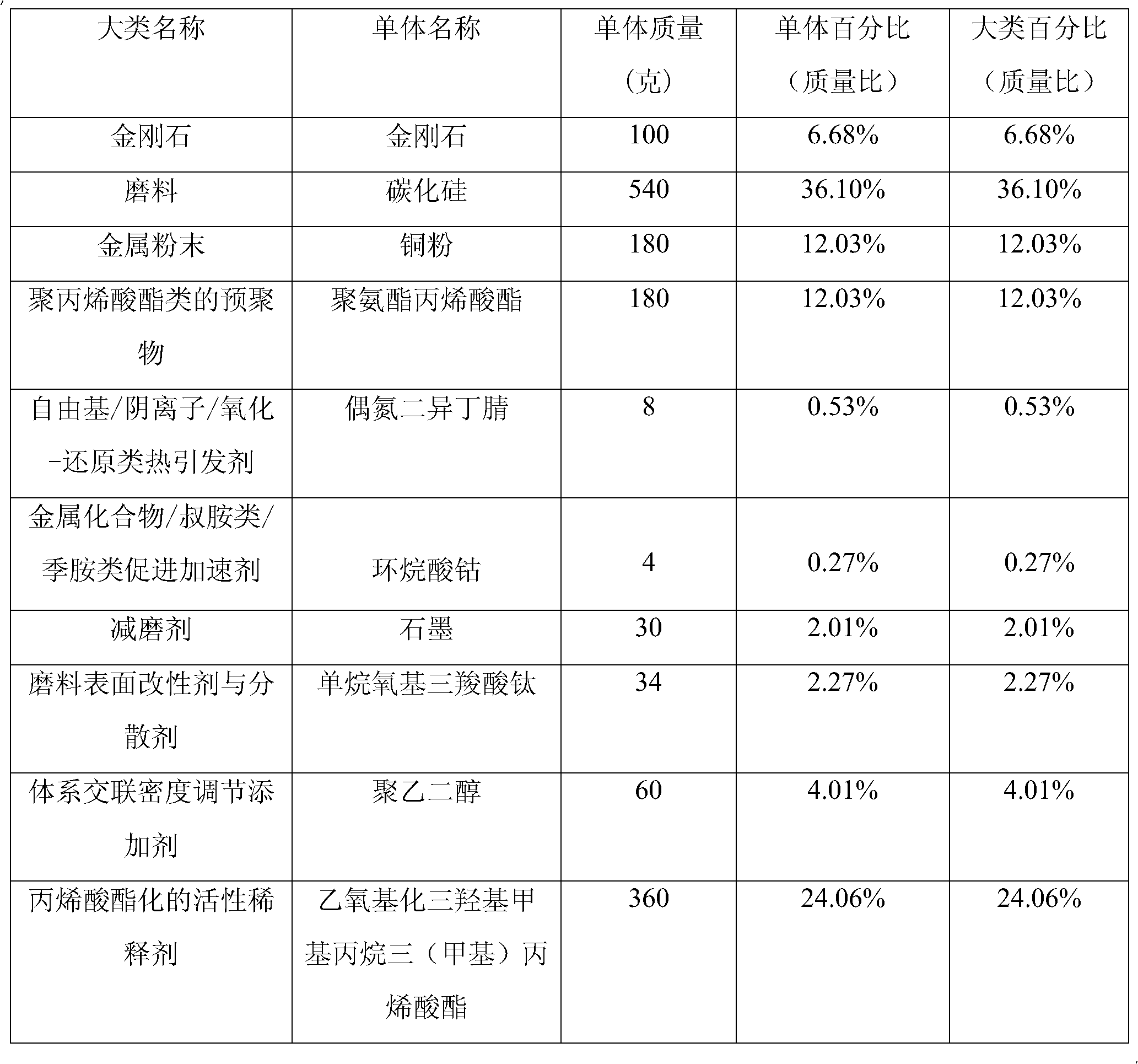

Thermosetting resin grinding pad and preparation method thereof

InactiveCN102632453AHigh densityHigh hardnessGrinding devicesLapping toolsReactive diluentMetal powder

The embodiment of the invention discloses a thermosetting resin grinding pad and a preparation method thereof. The thermosetting resin grinding pad comprises a diamond, a grinding material and a resin base body and contains the following components in percentage by mass of: 4 to 7 percent of diamond with the particle size being between 40 and 50 microns, 9 to 40 percent of grinding material with the particle size being between 20 and 70 microns, 10 to 55 percent of metal powder with the particle size being between 20 and 70 microns, 10 to 60 percent of polyacrylic prepolymer, 0.1 to 1 percent of radical / anion / oxidation-reduction thermal initiator, 0 to 0.7 percent of metal compound / tertiary amine / quaternary amine promote accelerator, 0.5 to 5 percent of antifriction composition, 0 to 4 percent of grinding material surface modifier and dispersing agent, 0 to 20 percent of system crosslinking density adjustment additive and 5 to 40 percent of acyclic acid esterification reactive diluent. According to the thermosetting resin grinding pad, the density, the mechanical strength and the abrasion resistance of the thermosetting resin grinding pad are improved.

Owner:ZHEJIANG PUJIANG MINRUI PRECISION MACHINERY TECH

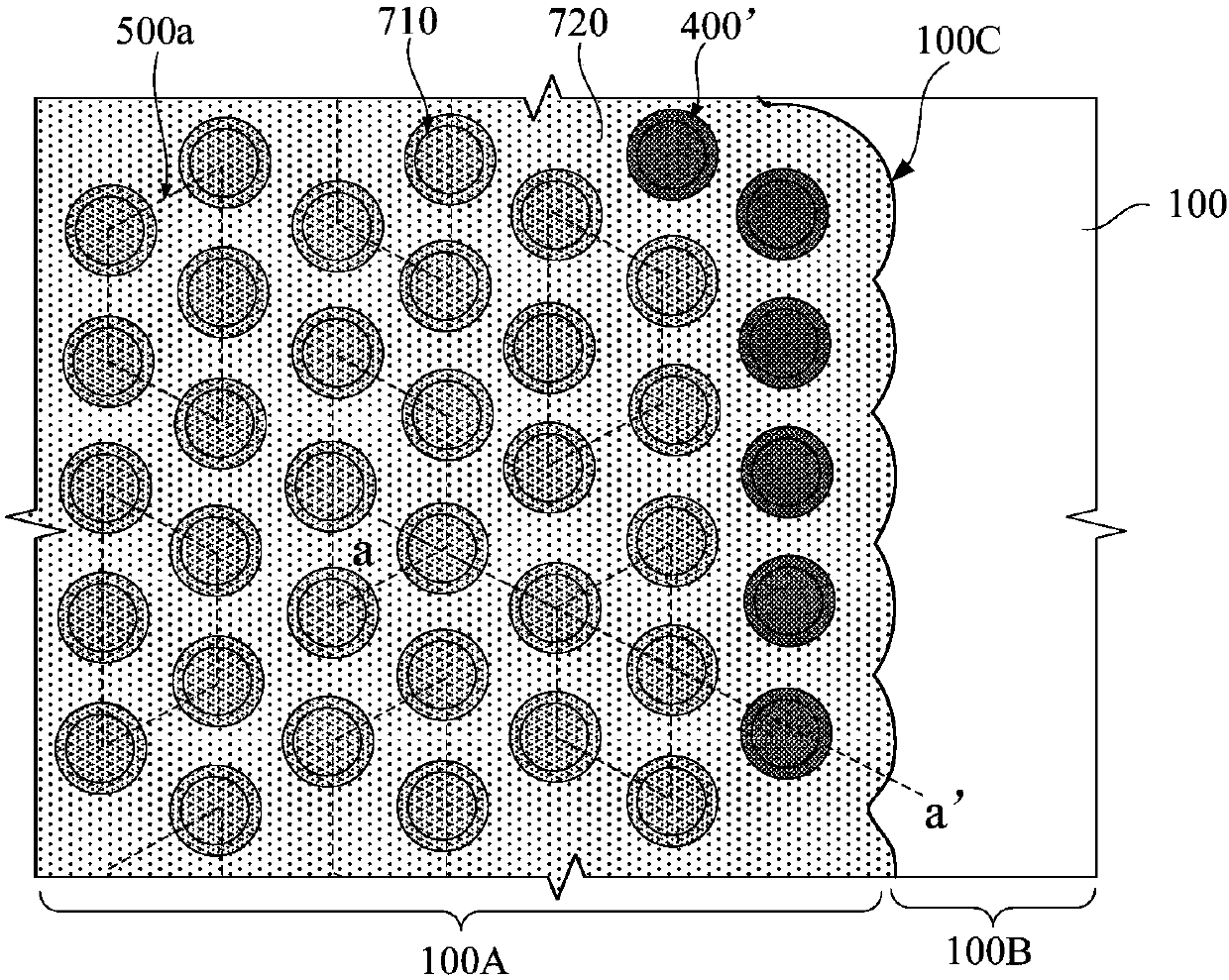

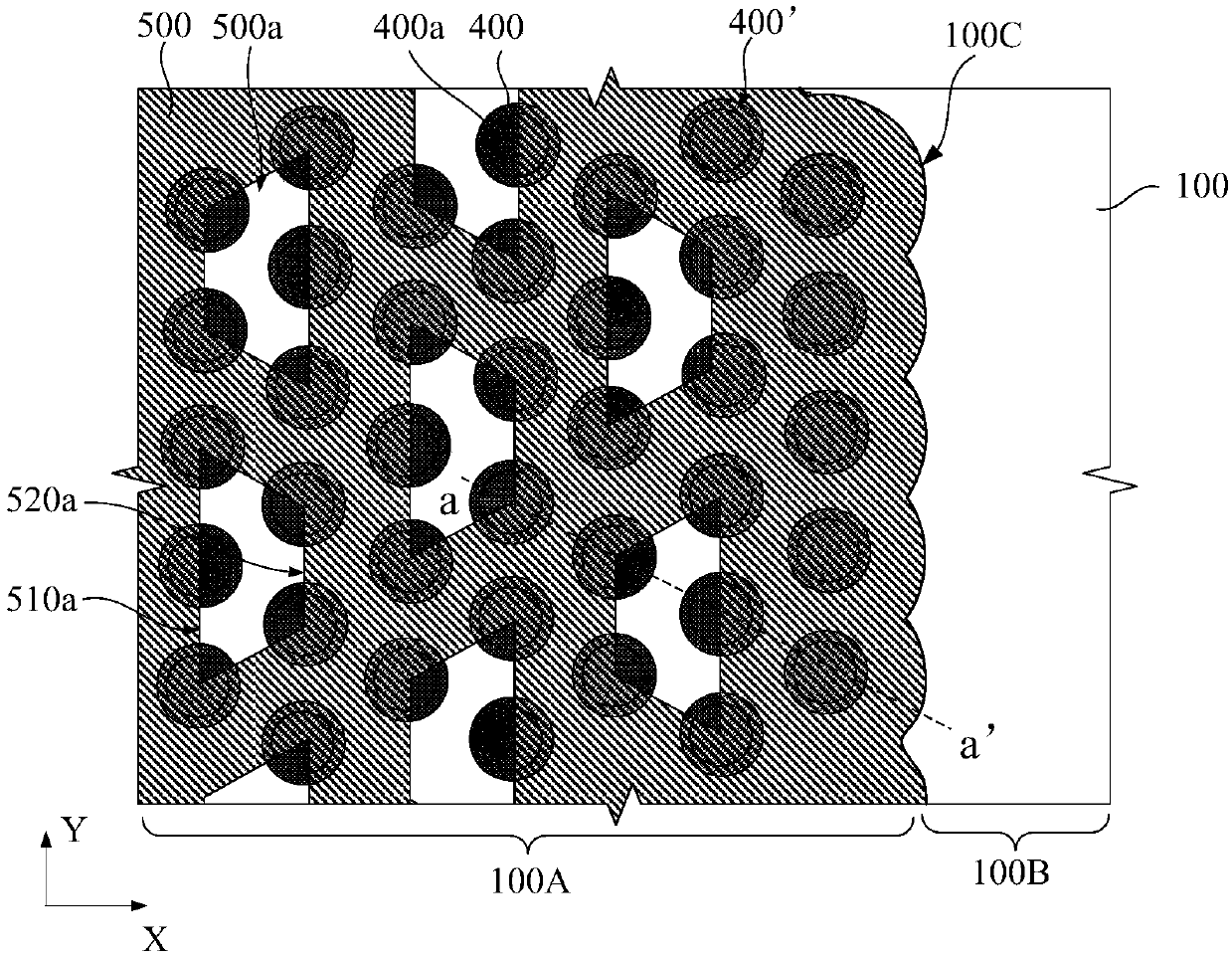

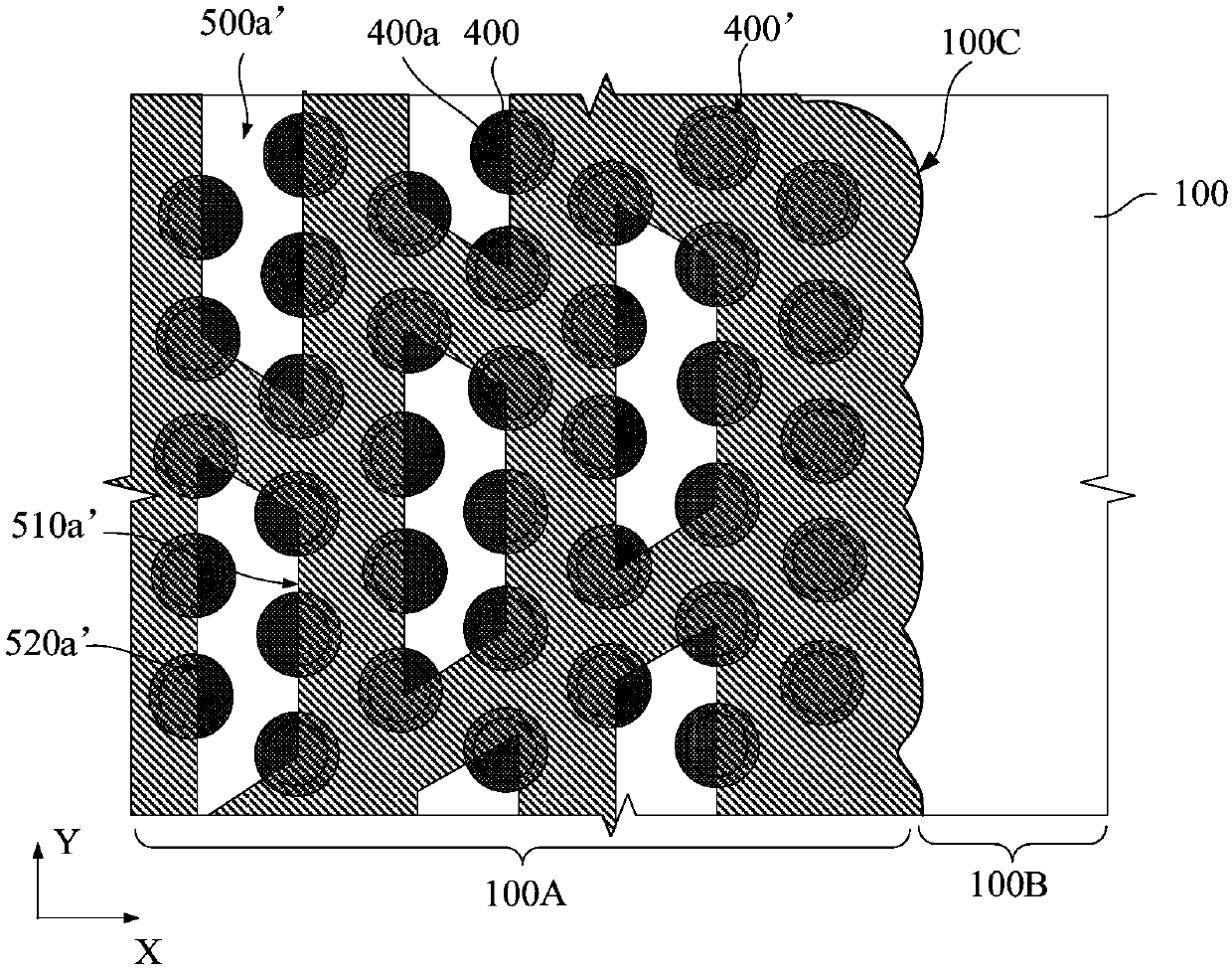

Container array, formation method thereof and semiconductor device

PendingCN107706206AIncrease capacitanceEasy accessSolid-state devicesSemiconductor devicesCapacitanceDevice material

The invention provides a container array, a formation method thereof and a semiconductor device. In the container array, a penetrating hole in an electrode group pattern layer communicates with a cylindrical internal part and a cylindrical external part of a cylindrical structure of a lower electrode, the projection of a linear boundary of the penetrating hole in a height direction penetrates through at least one top port of the lower electrode, thus, the area size, corresponding to the penetrating hole, of the top port of the lower electrode still cannot be effected even displacement deviation exists in the penetrating hole in an extension direction of the linear boundary, and a complete capacitance dielectric layer and an upper electrode can be enabled to be formed on an inner surface and an outer surface of the lower electrode. Moreover, the opening size of the penetrating hole is relatively large, so that the corresponding etching rate and the film formation rate are also favorablyimproved during etching an etching process and a film formation process via the penetrating hole.

Owner:CHANGXIN MEMORY TECH INC

Method for polishing gallium nitride crystals

InactiveCN101673668AIncrease the rate of chemical reactionsImprove removal ratePolishing machinesSemiconductor/solid-state device manufacturingWater bathsWafering

The invention discloses a method for polishing gallium nitride crystals, comprising the following steps: sticking gallium nitride wafers on a quartz plate; grinding the gallium nitride wafers stuck onthe quartz plate by a grinder; heating up the polishing solution, irradiating the polished gallium nitride wafers by ultraviolet light and carrying out chemical mechanical polishing on the ground gallium nitride wafers by a polisher. In the method, based on the chemical mechanical polishing of the traditional gallium nitride wafers, the ultraviolet light is used for irradiating the wafers and a self-made water-bath heating system is simultaneously used for heating up the polishing solution, thus increasing the chemical reaction rate in the process of chemical mechanical polishing, and by adjusting the weight of the heavy objects, the physical removing effect and the chemical effect are balanced, thus not only solving the problem that the gallium nitride wafers are difficult to polish andincreasing the removal rates of N surface and Ga surface, but also obtaining satisfactory shiny surfaces. The method features obviously lower cost and simple process implementation and effectively increases the polishing efficiency.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

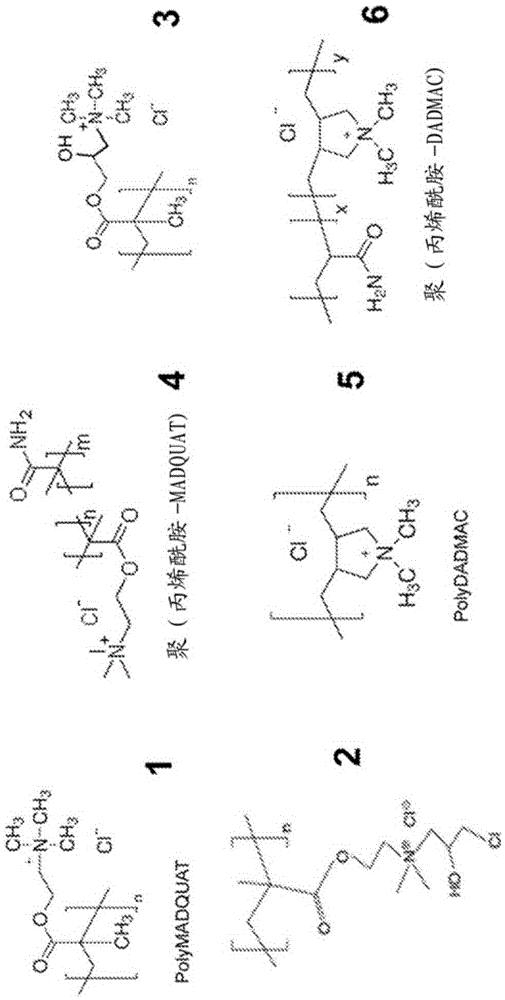

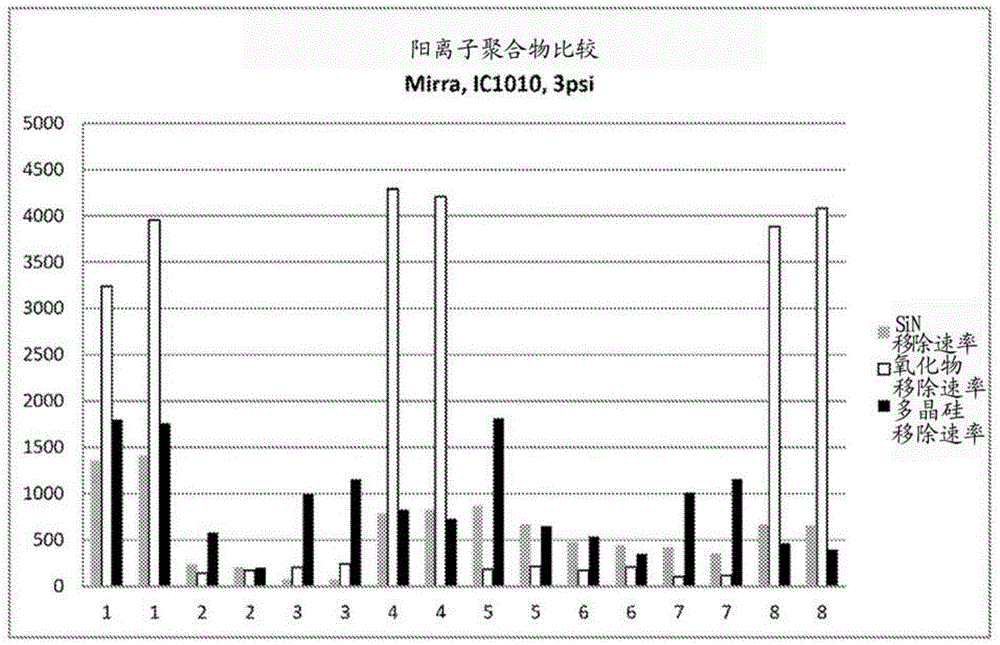

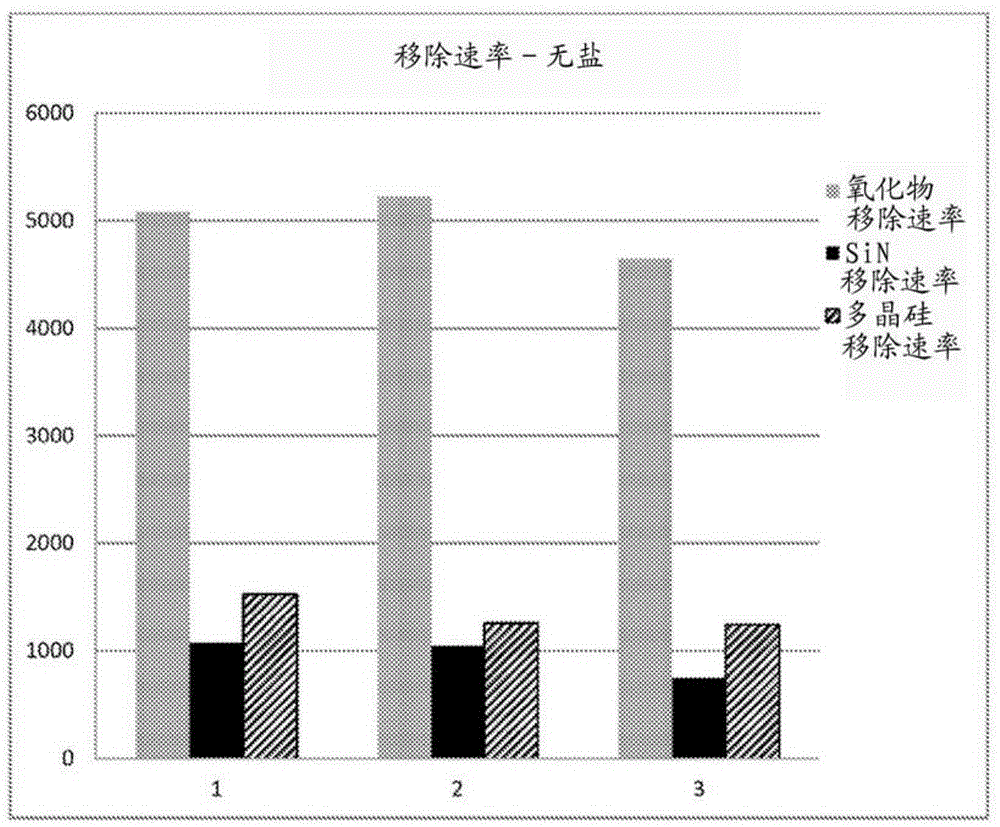

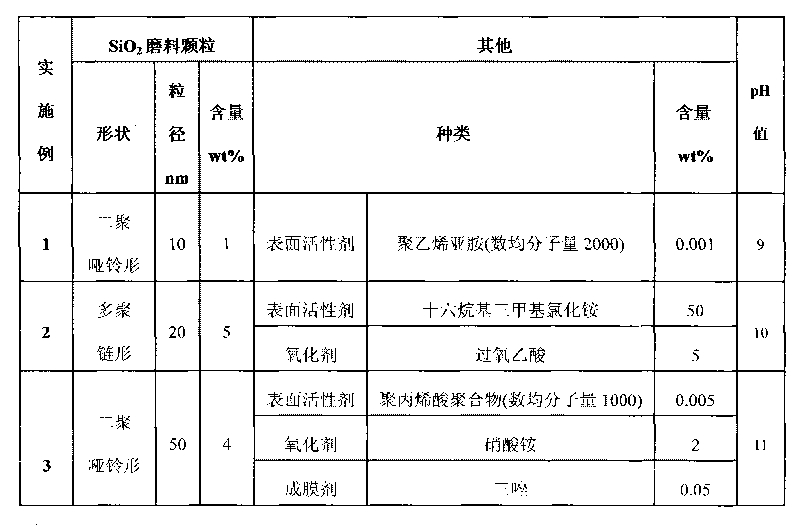

Compositions and methods for CMP of silicon oxide, silicon nitride, and polysilicon materials

InactiveCN105393337AImprove removal rateOther chemical processesSemiconductor/solid-state device manufacturingParticulatesSilicon oxide

The present invention provides a chemical mechanical polishing method for polishing a substrate comprising silicon dioxide, silicon nitride, and polysilicon. The method comprises abrading a surface of the substrate with a CMP composition to remove at least some silicon dioxide, silicon nitride and polysilicon therefrom. The CMP composition comprising a particulate ceria abrasive suspended in an aqueous carrier having a pH of about 3 to 9.5 and containing a cationic polymer; wherein the cationic polymer consists of a quaternary methacryloyloxyalkylammonium polymer.

Owner:CABOT MICROELECTRONICS CORP

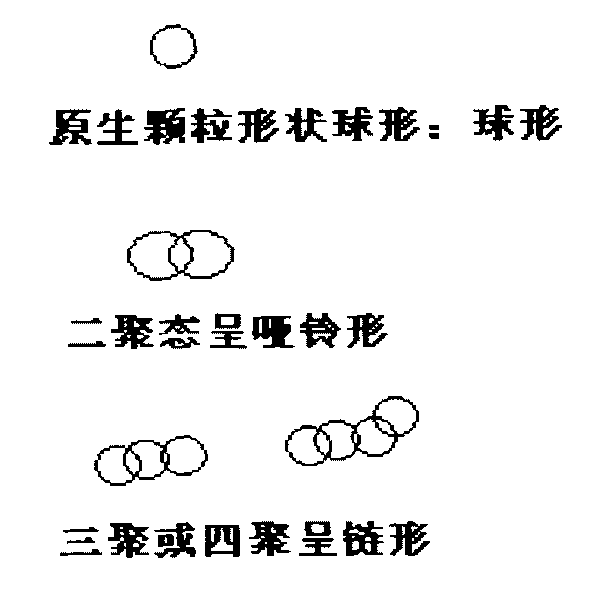

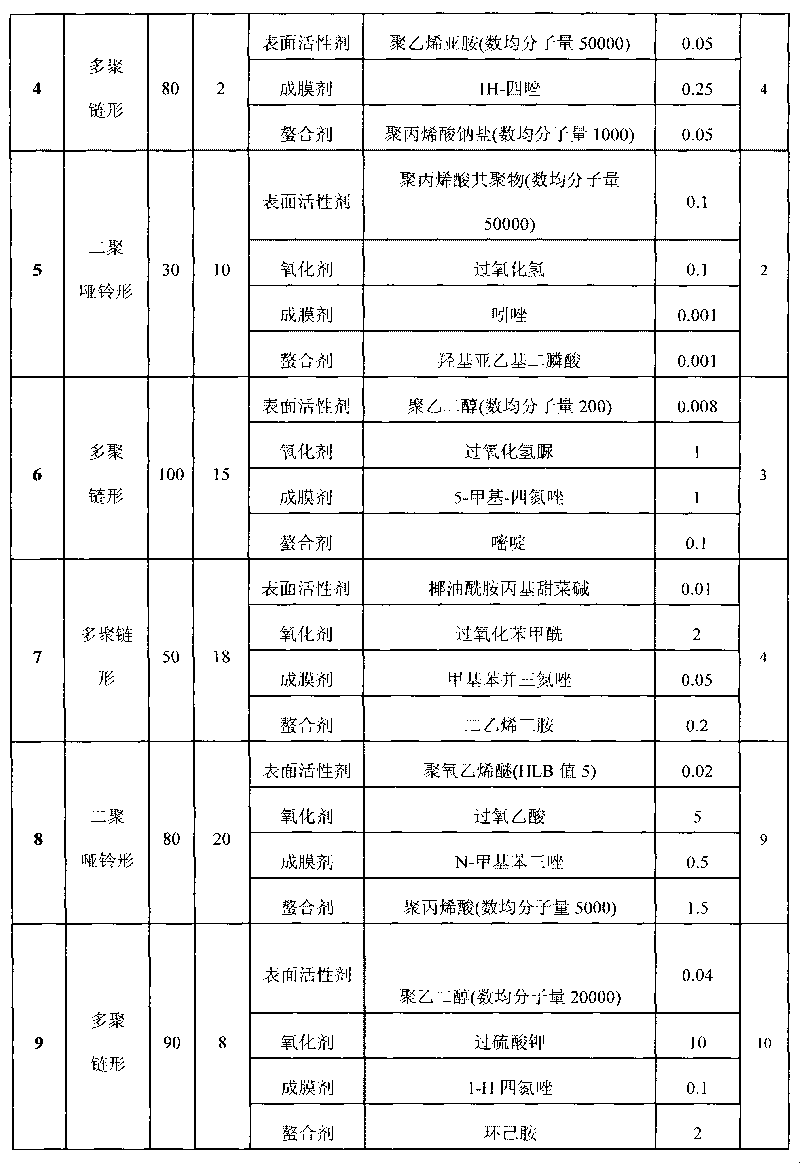

Chemical-mechanical polishing solution

InactiveCN101747841ASolve the speed problemSolving micro-scratchesPolishing compositions with abrasivesSurface finishCompound (substance)

The invention discloses chemical-mechanical polishing solution, which has good effect on polishing dielectric materials and higher rate of removing dielectric materials and simultaneously contains dimer dumbbell shaped and / or poly chain shaped silica sol ground particles. The particles have regular shapes. The wafer after polishing has better surface finish and flatness and can meet the requirements for the surfaces of the dielectric materials under various technological conditions.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com