Patents

Literature

216 results about "Downforce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

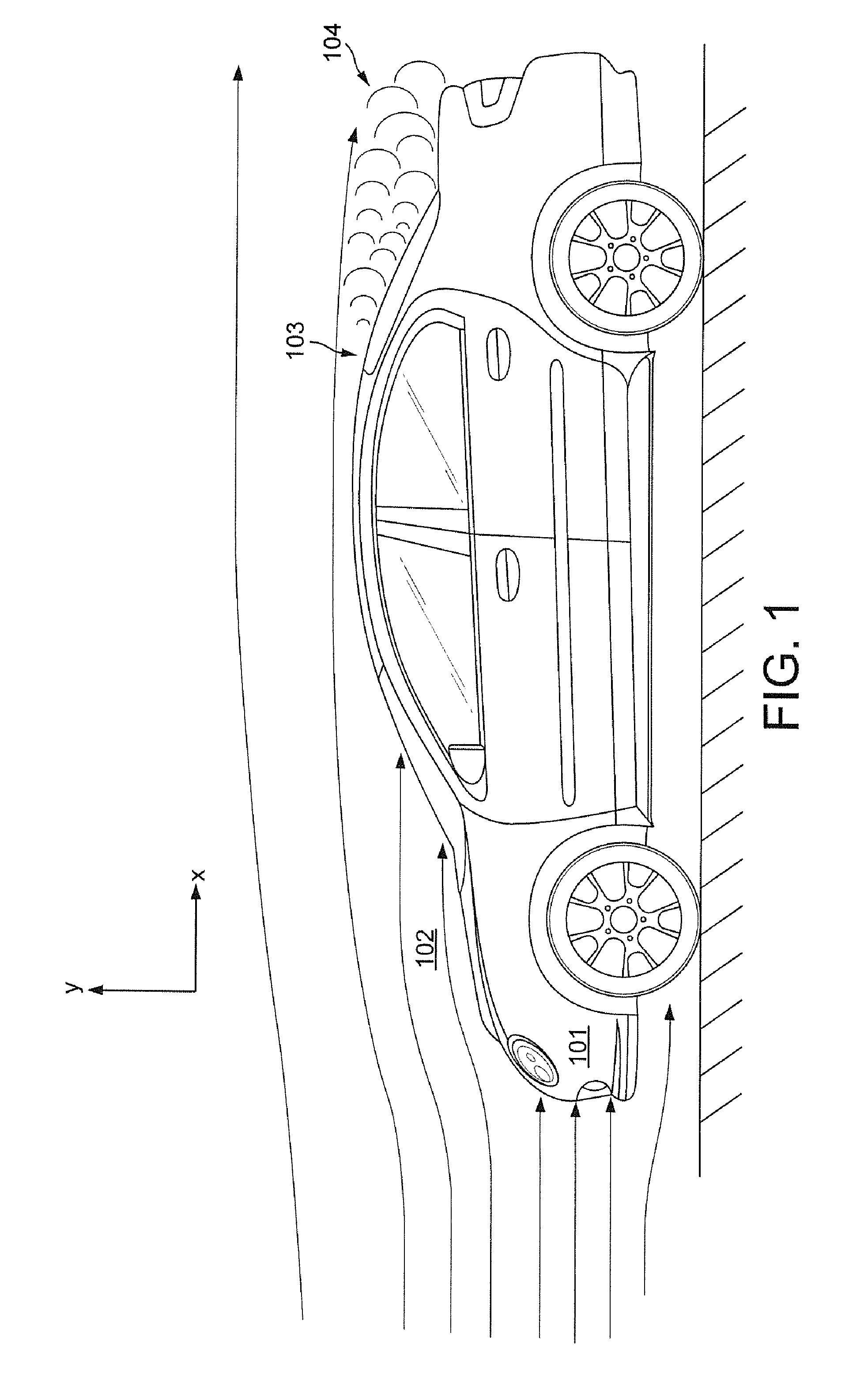

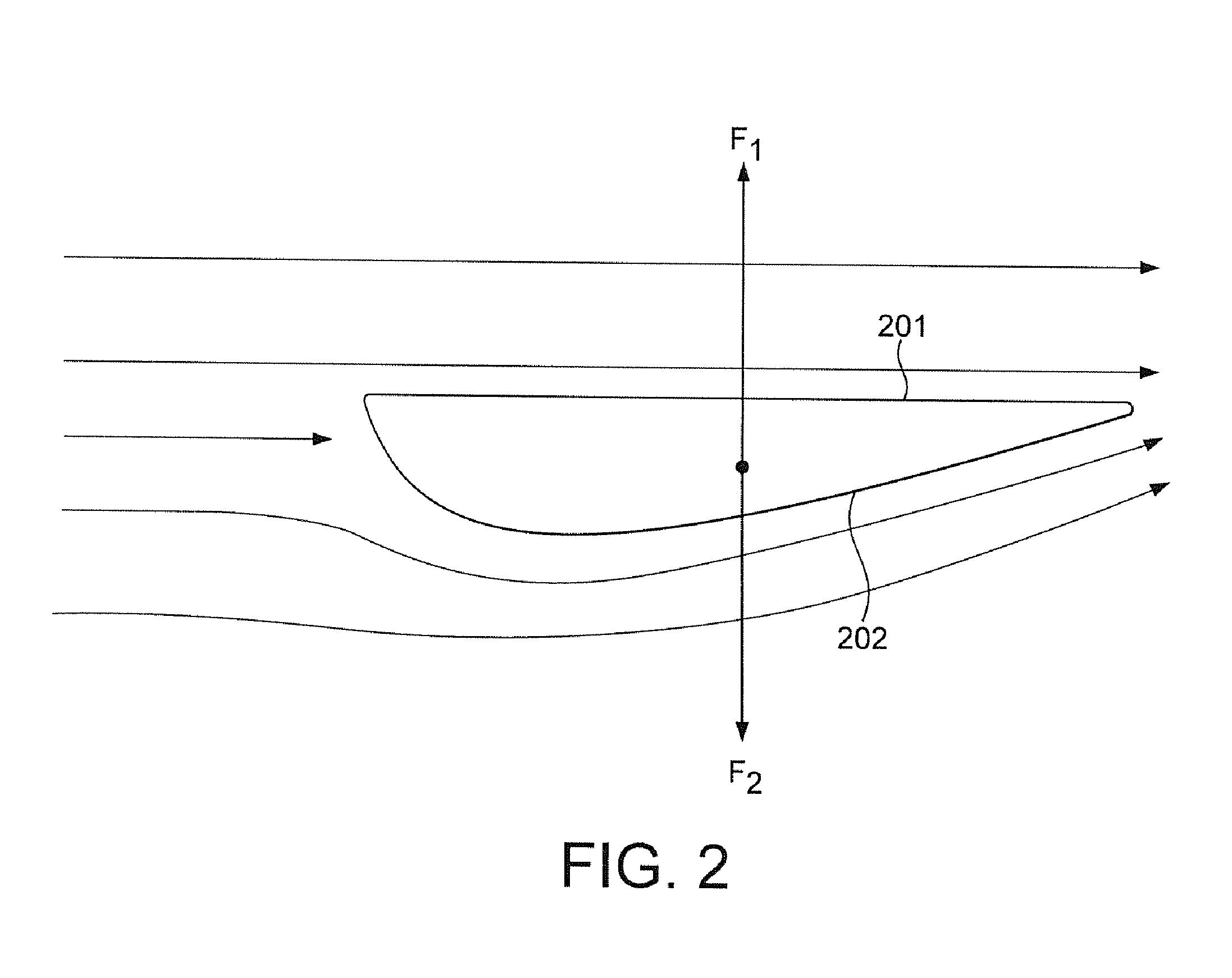

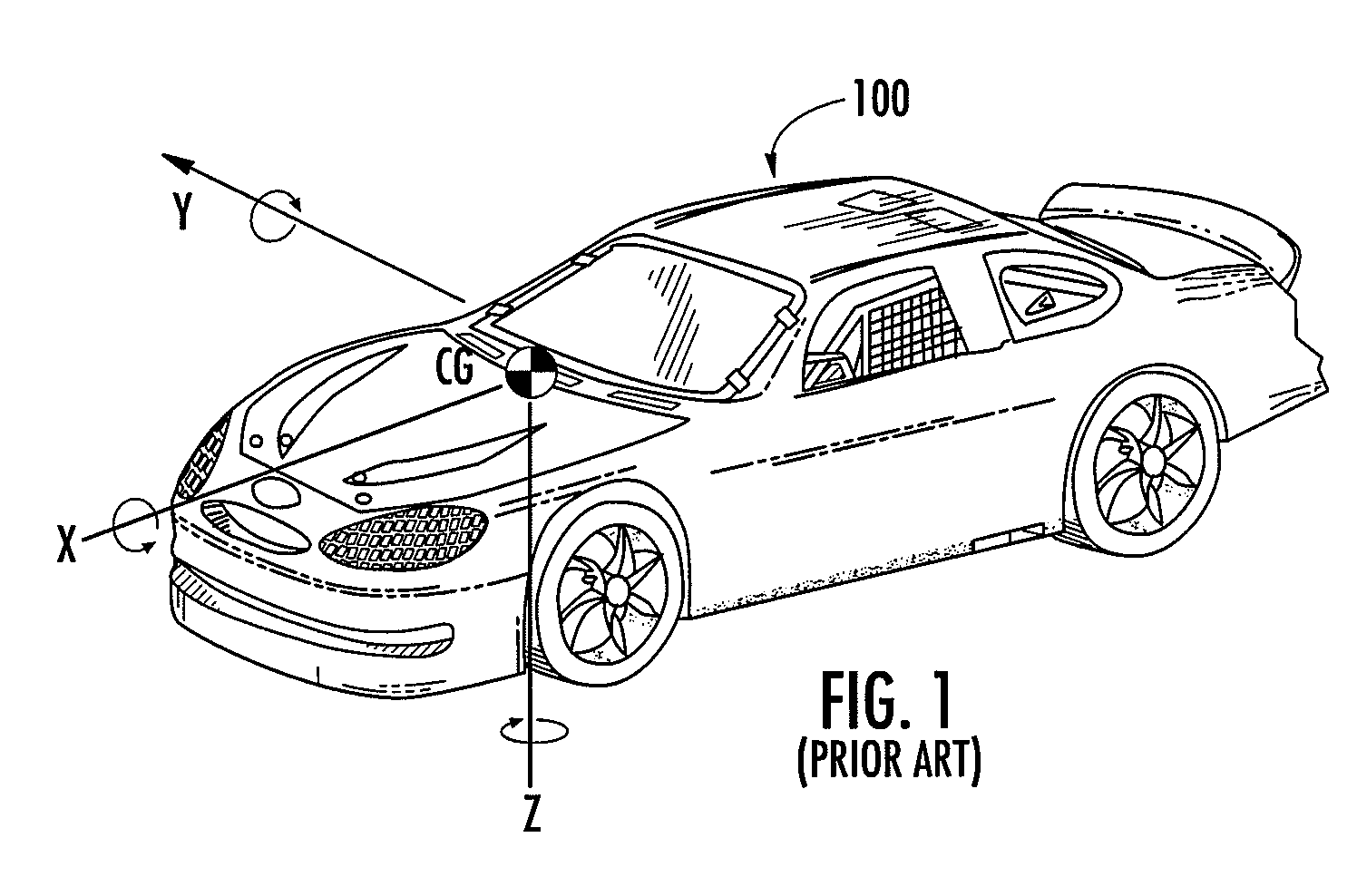

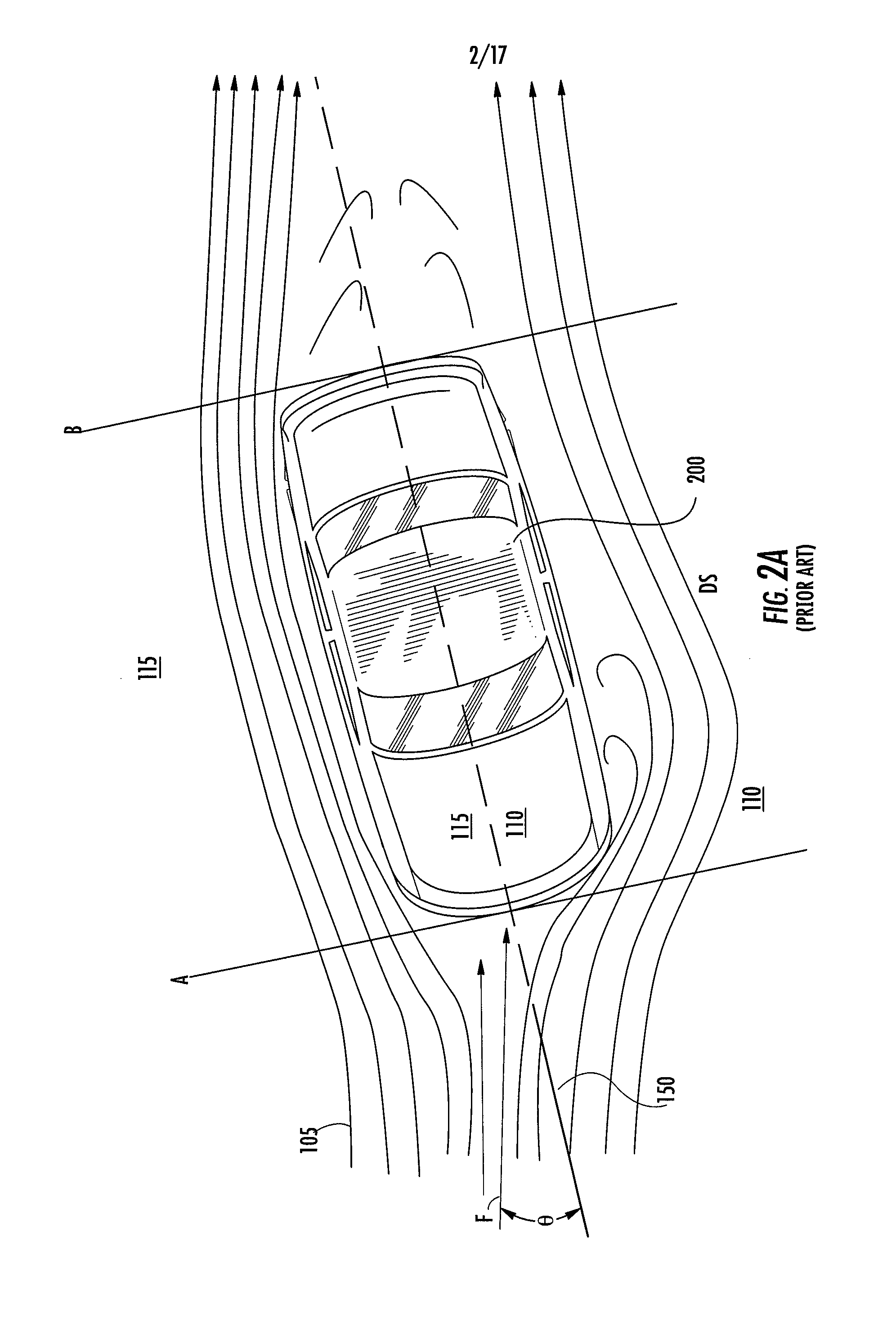

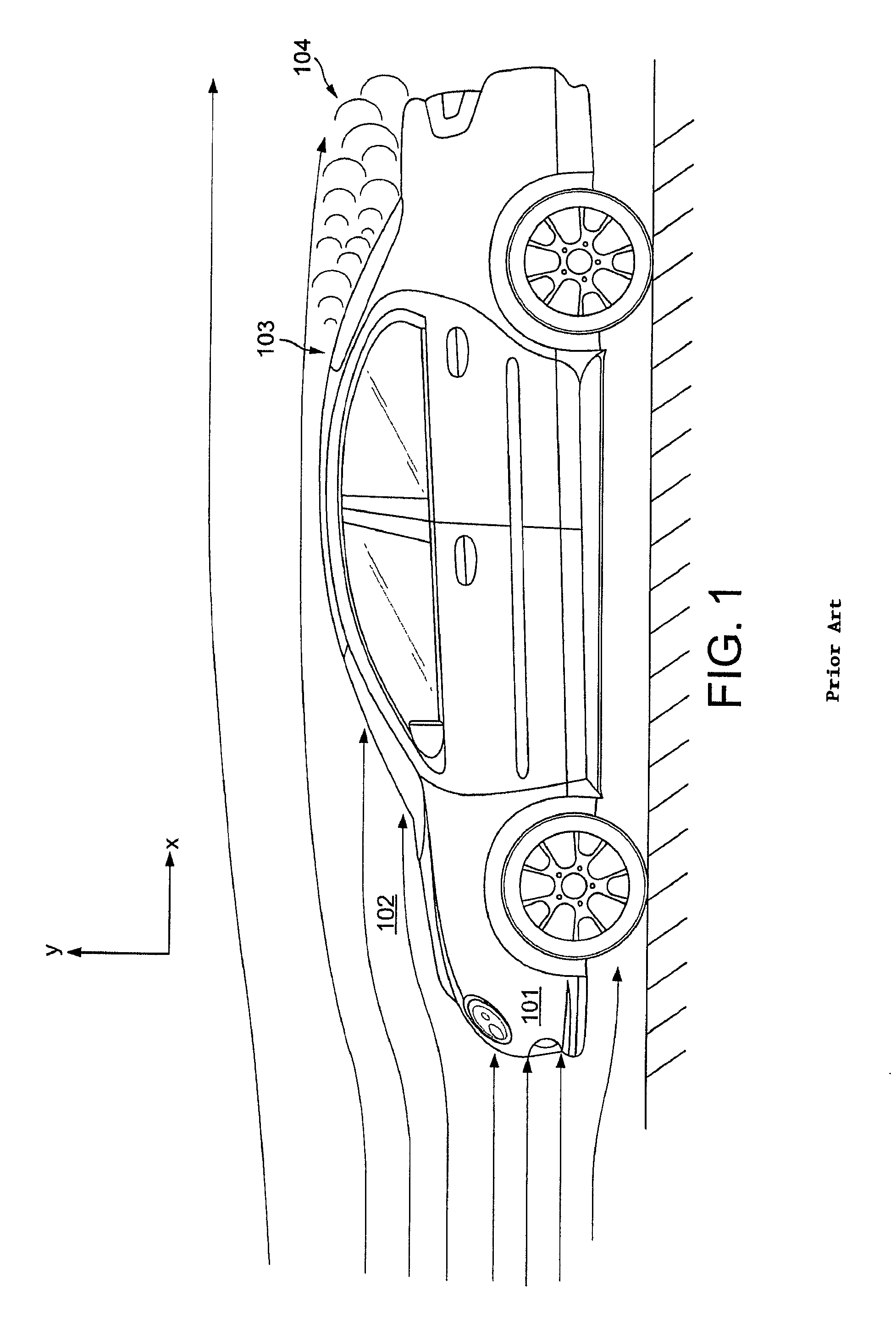

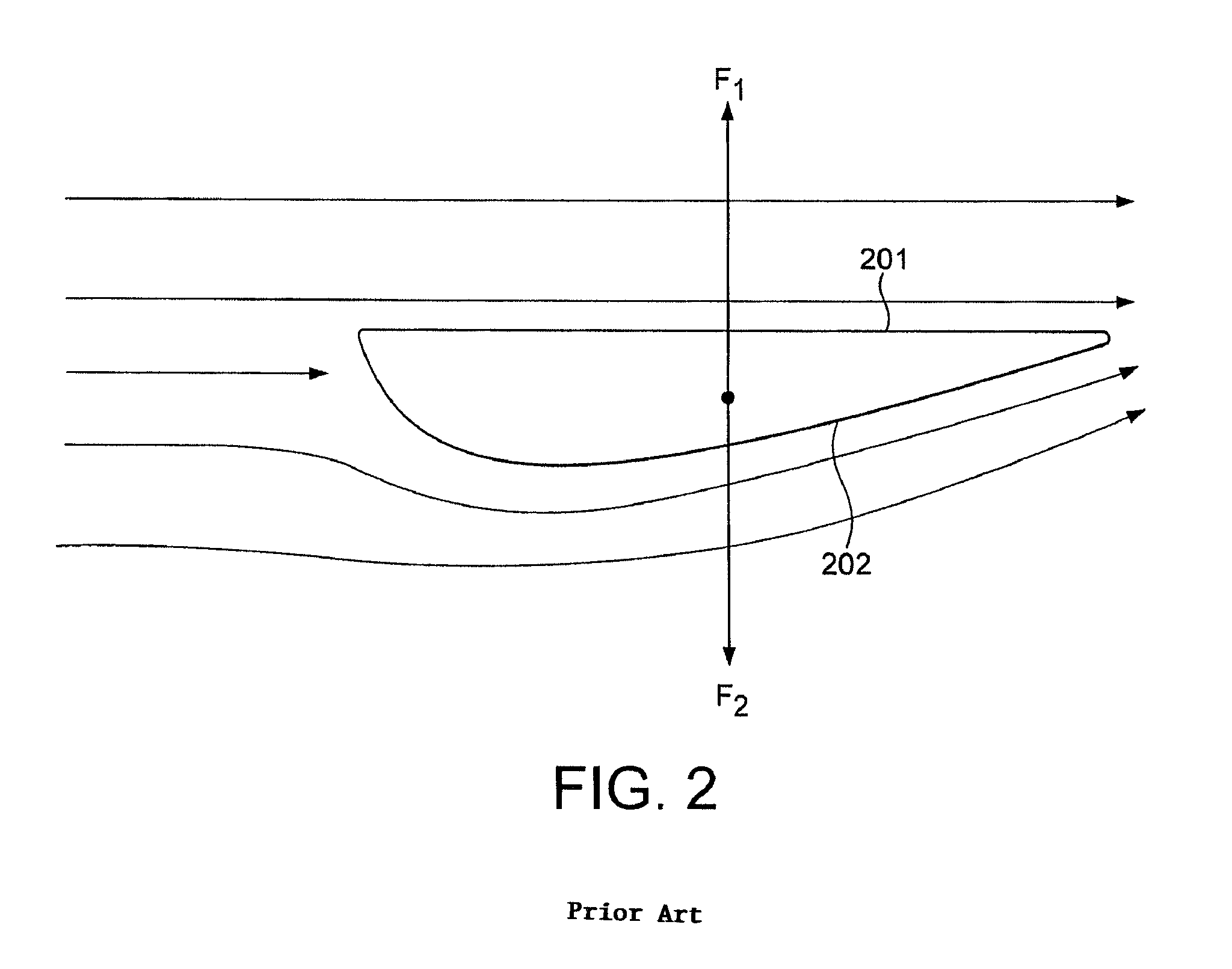

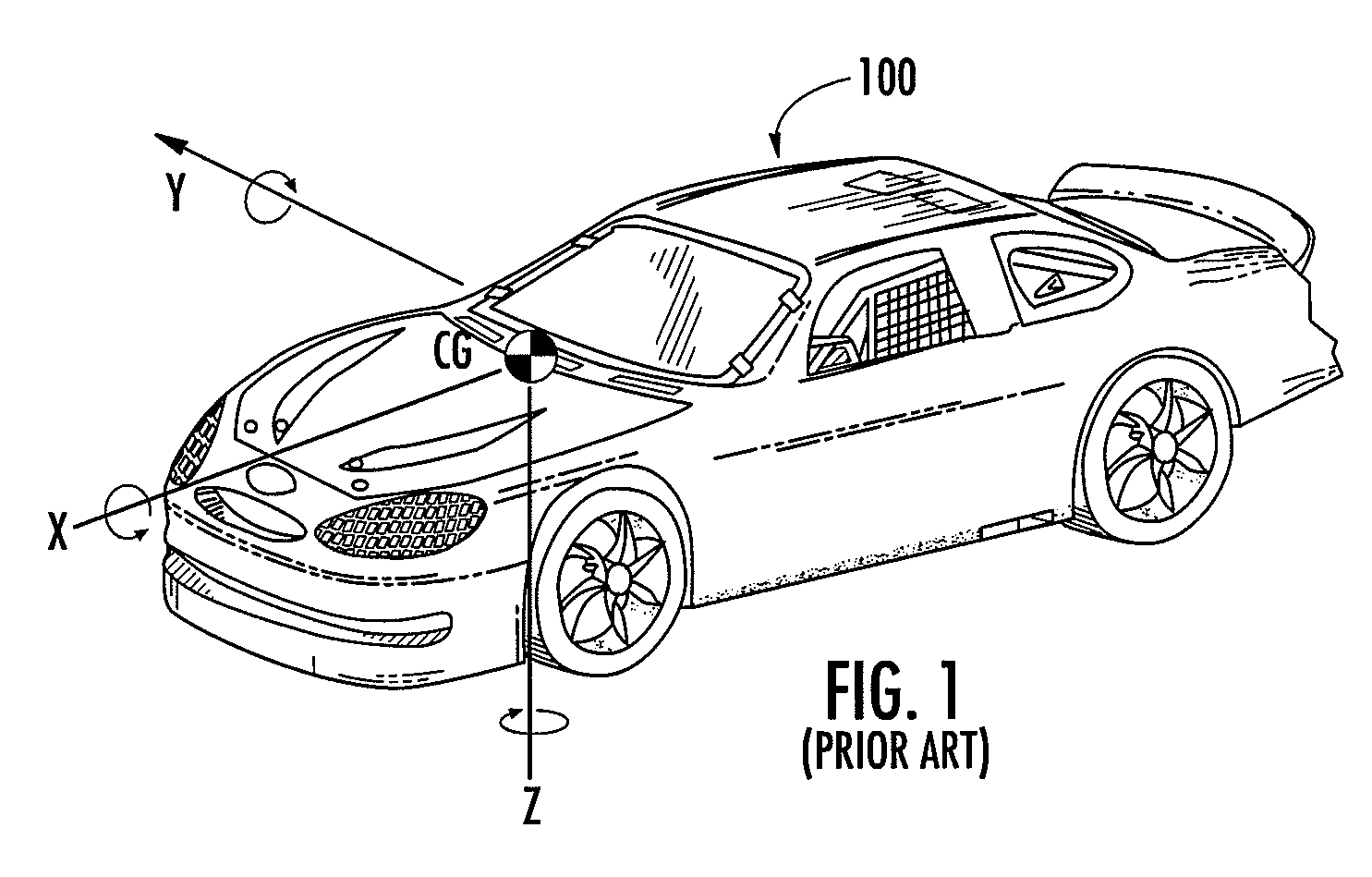

Downforce is a downwards lift force created by the aerodynamic characteristics of a vehicle. The purpose of downforce is to allow a car to travel faster through a corner by increasing the vertical force on the tires, thus creating more grip.

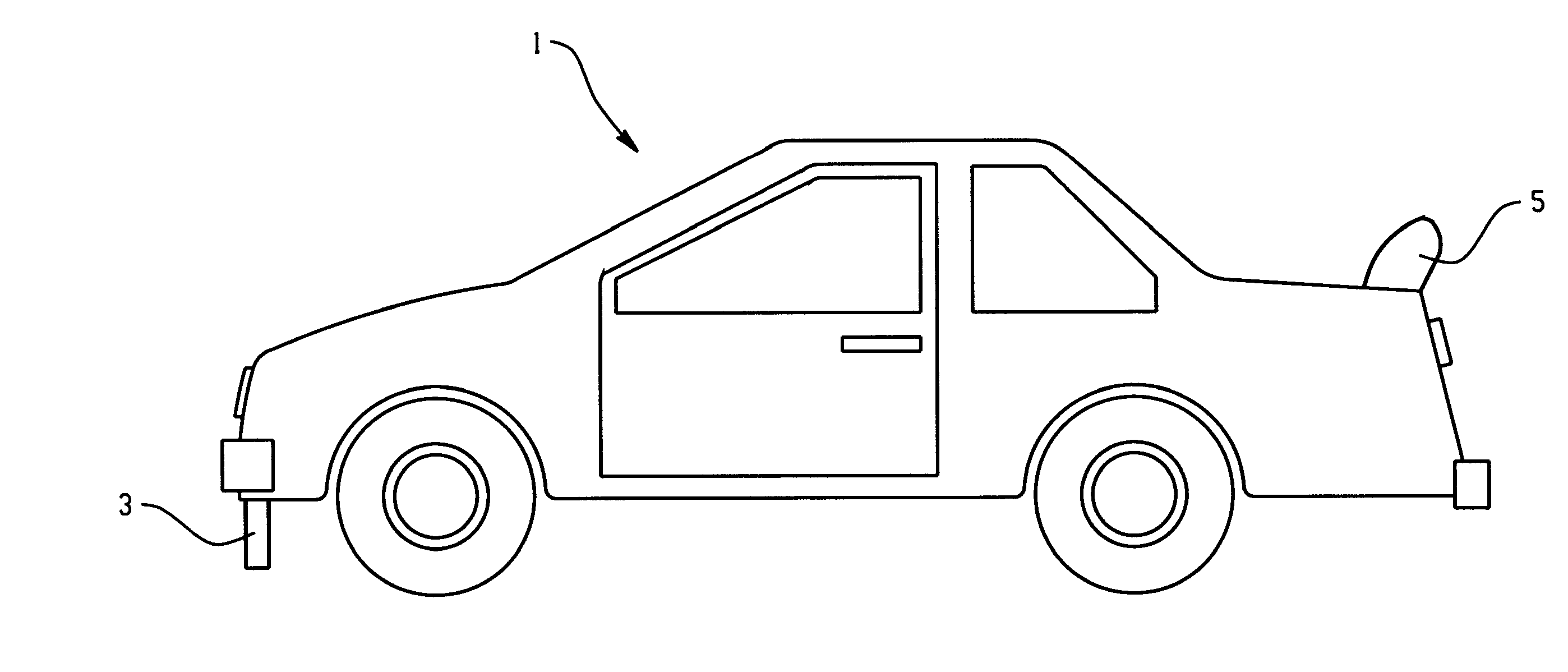

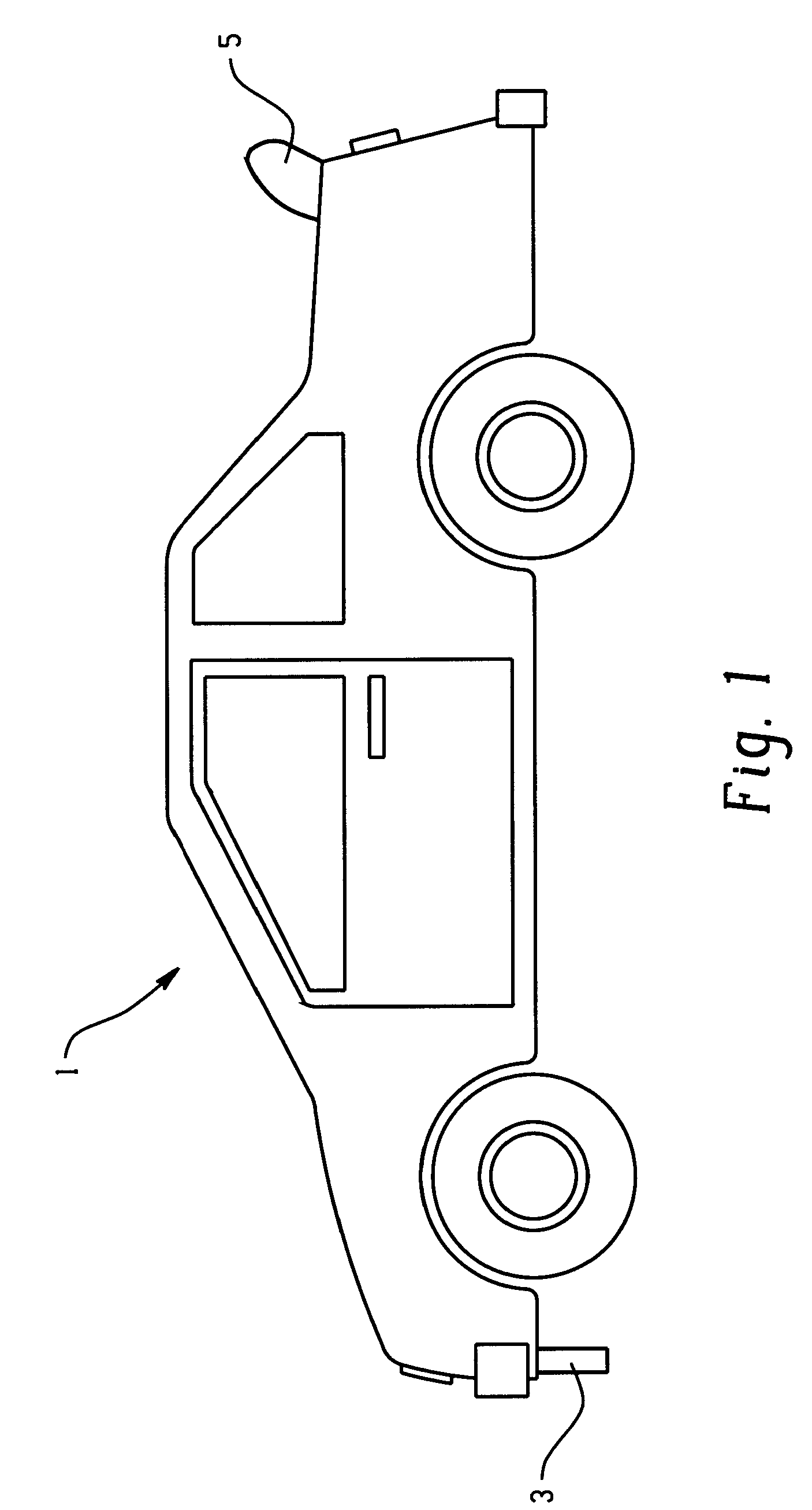

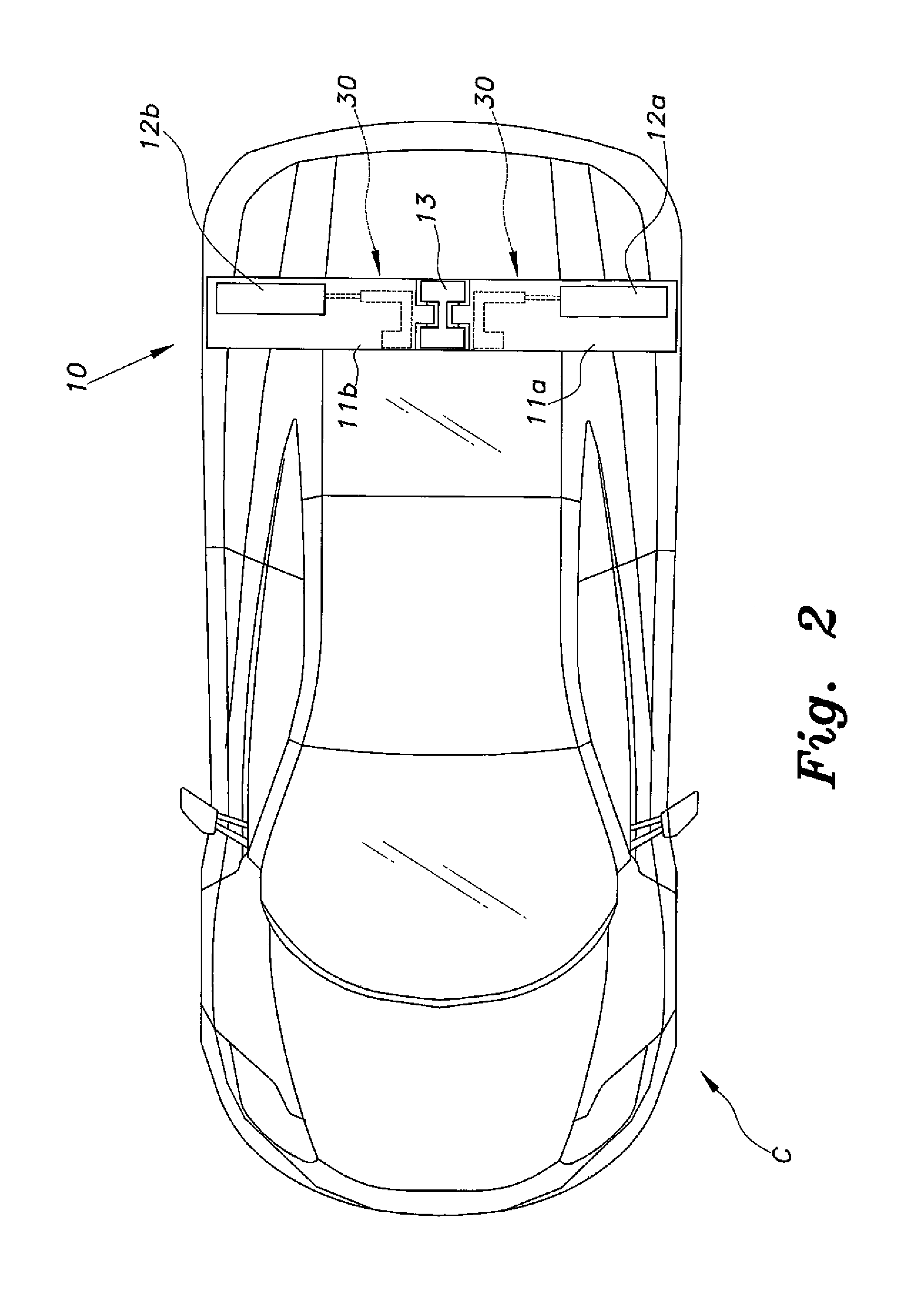

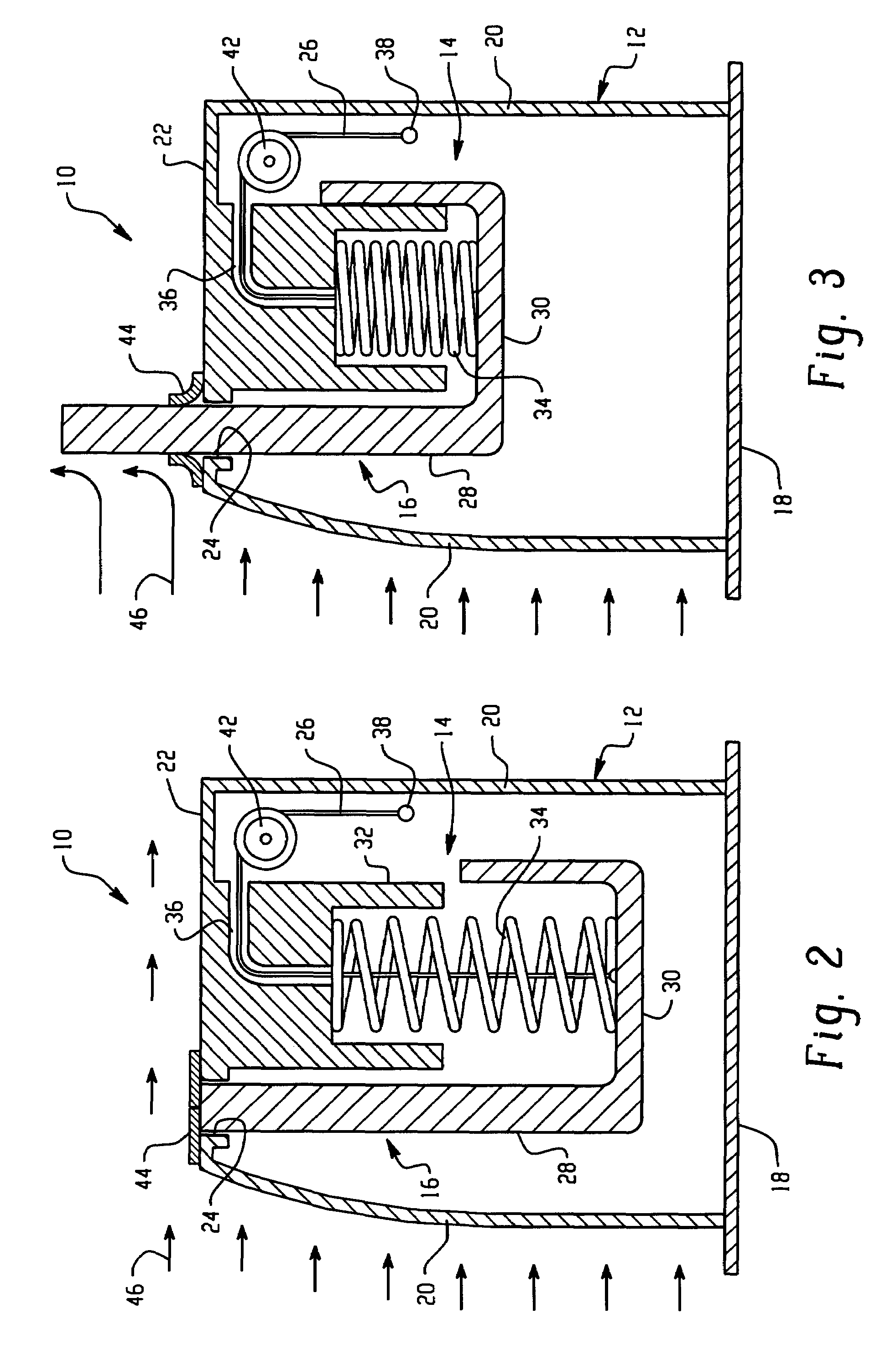

Reversibly Deployable Spoiler

A reversibly deployable spoiler for a vehicle comprises a body and an active material in operative communication with the body. The active material, such as shape memory material, is operative to change at least one attribute in response to an activation signal. The active material can change its shape, dimensions and / or stiffness producing a change in at least one feature of the active spoiler airflow control device such as shape, dimension, location, orientation, and / or stiffness to control vehicle airflow and downforce to better suit changes in driving conditions such as speed, while reducing maintenance and the level of failure modes. An activation device, controller and sensors may be employed to further control the change in at least one feature of the active spoiler airflow control device such as shape, dimension, location, orientation, and / or stiffness. A method for controlling vehicle airflow selectively introduces an activation signal to initiate a change of at least one feature of the device that can be reversed upon discontinuation of the activation signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

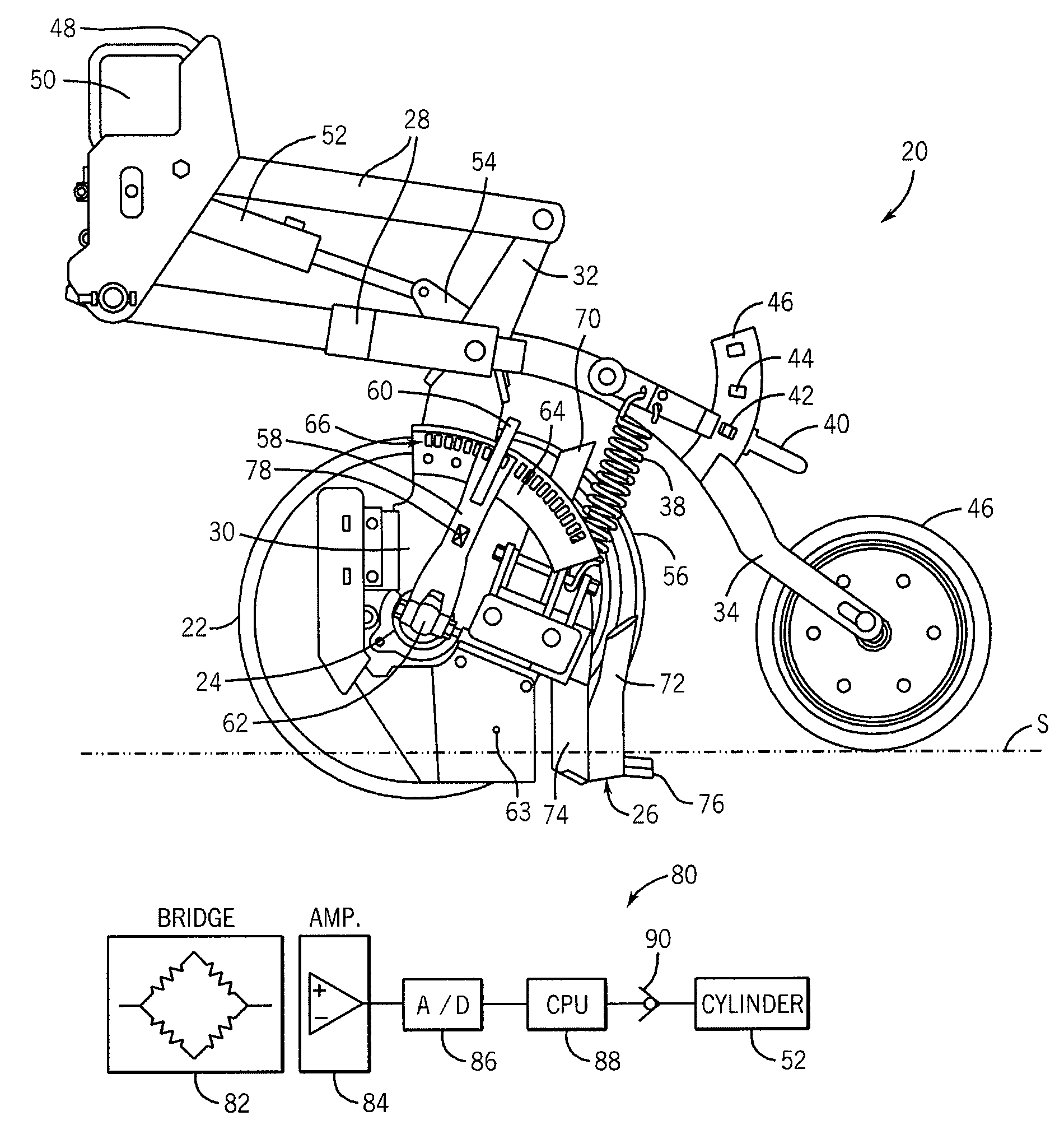

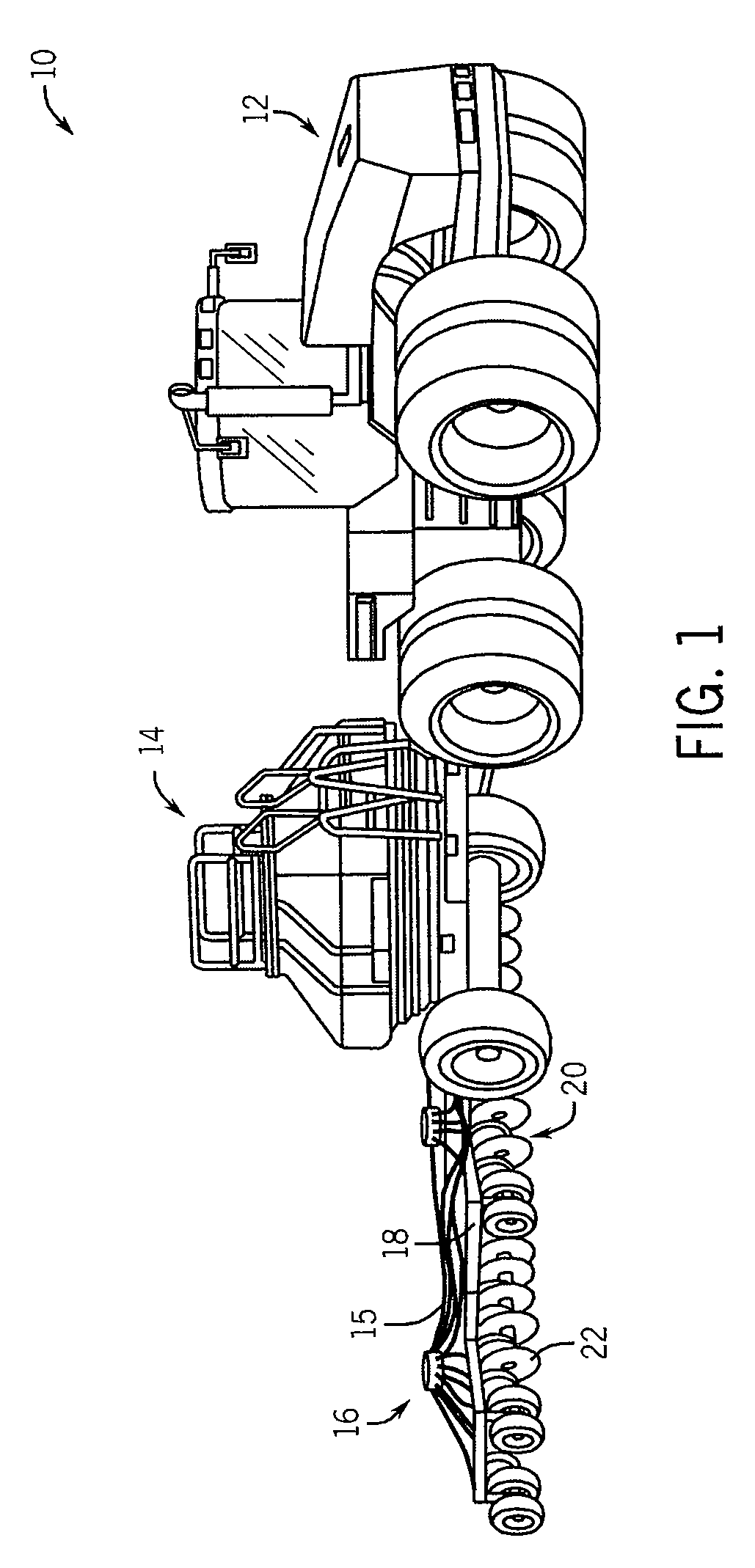

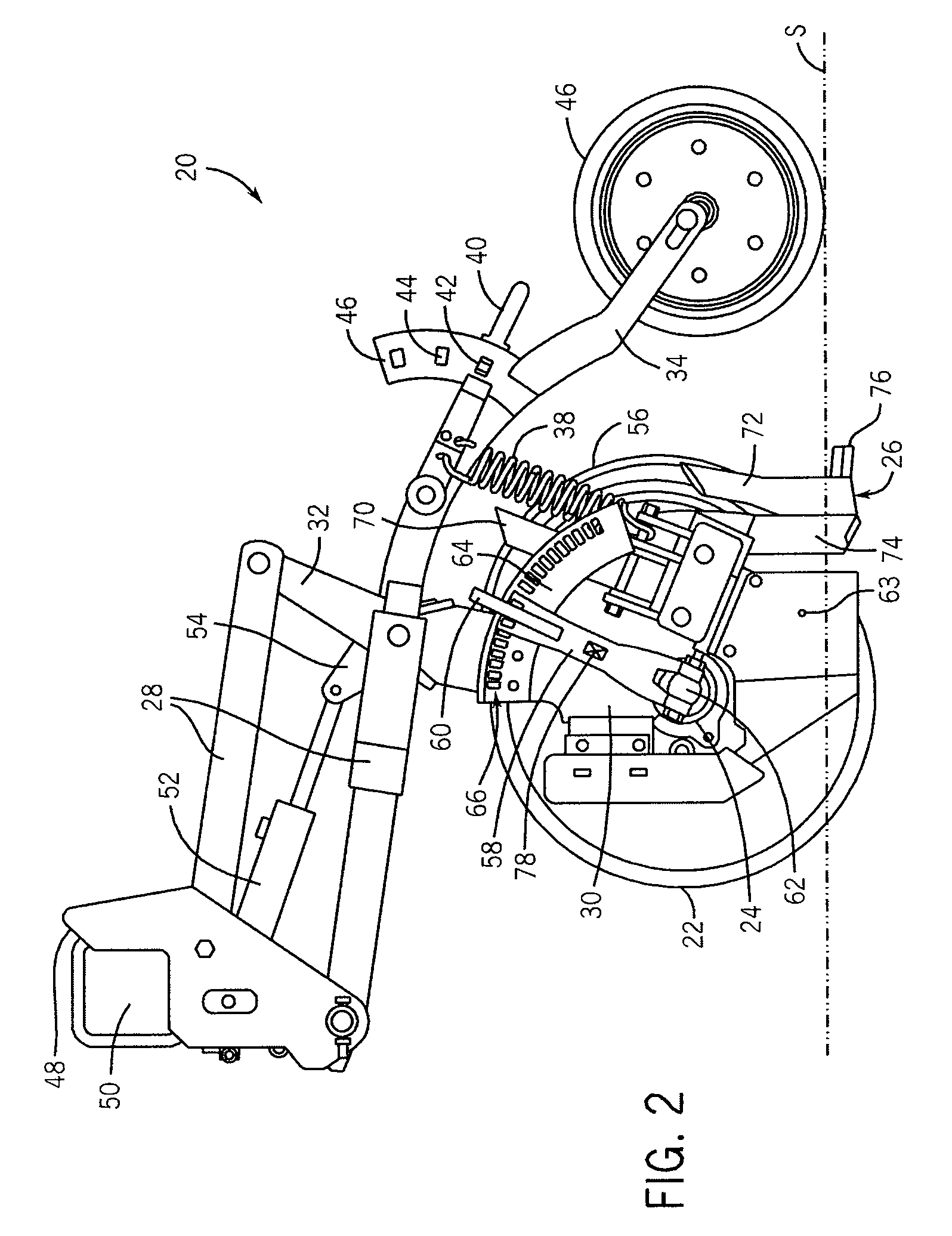

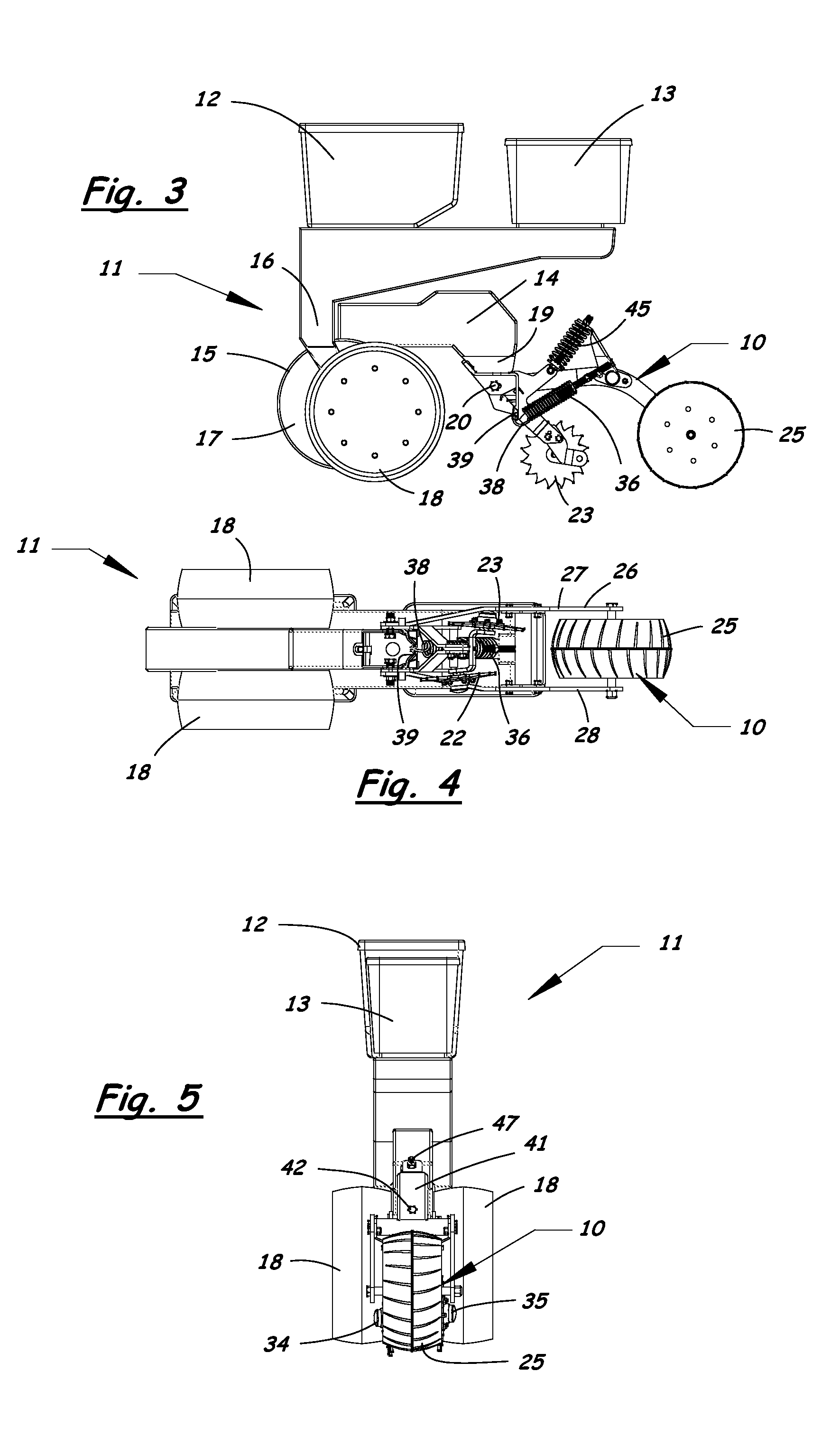

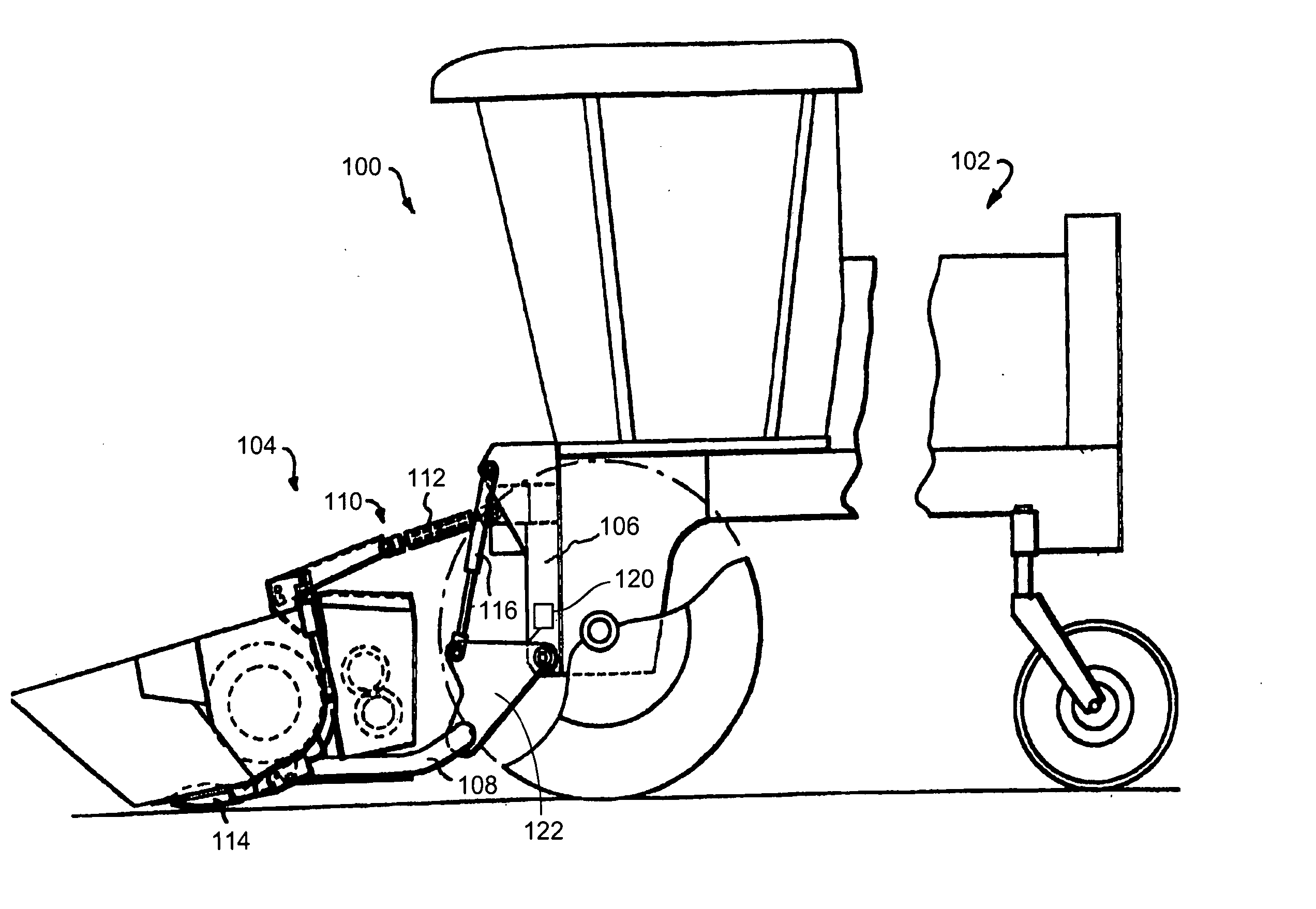

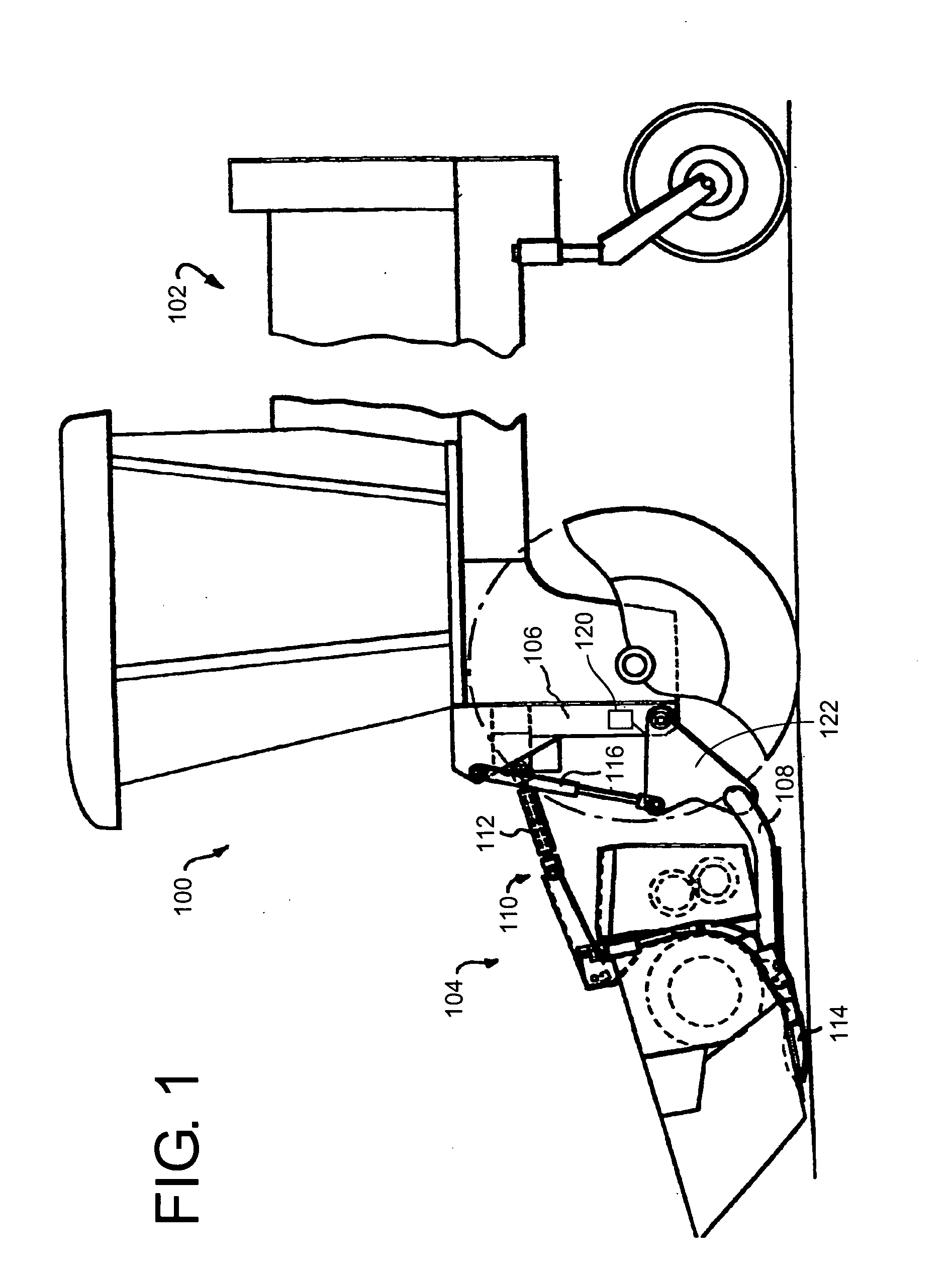

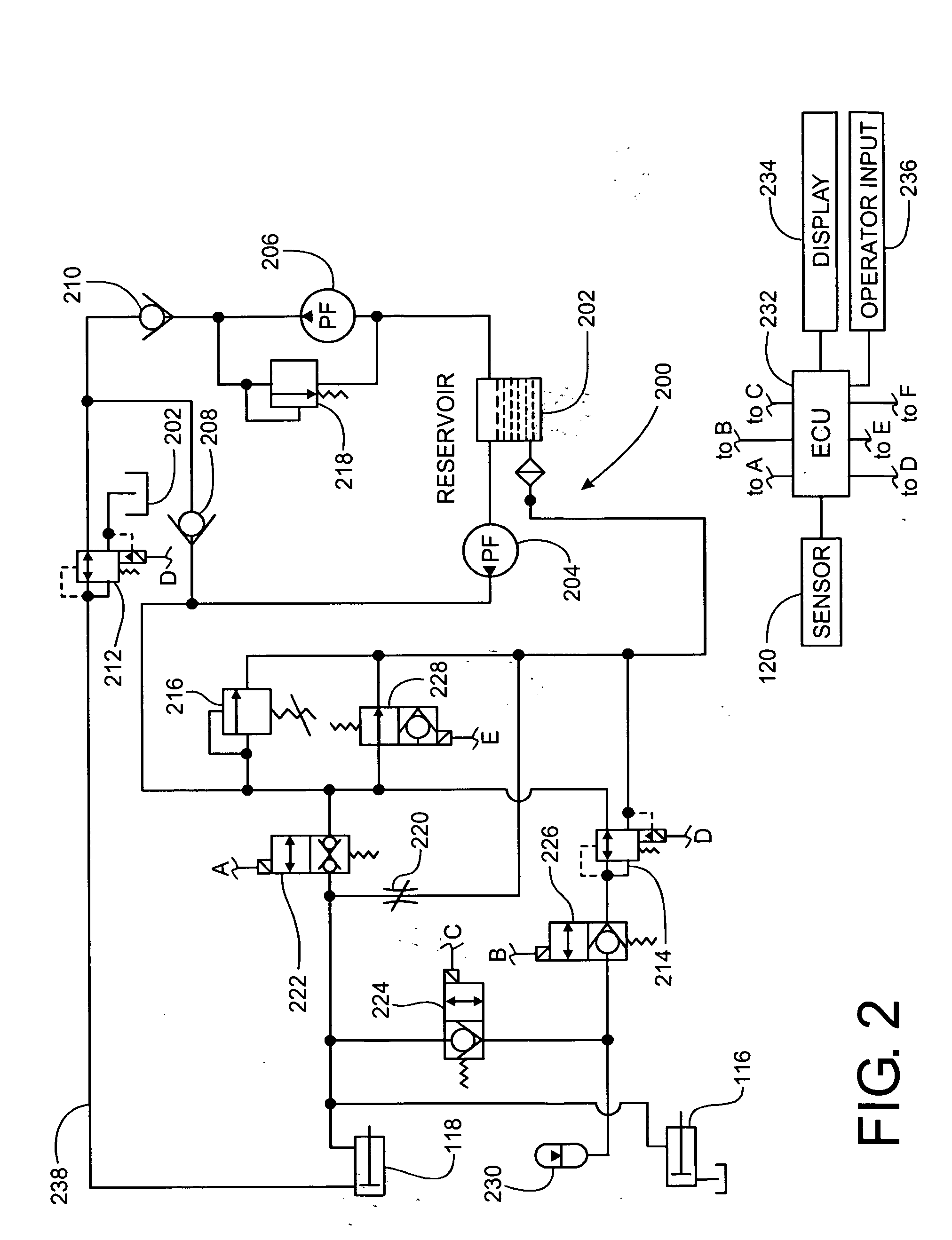

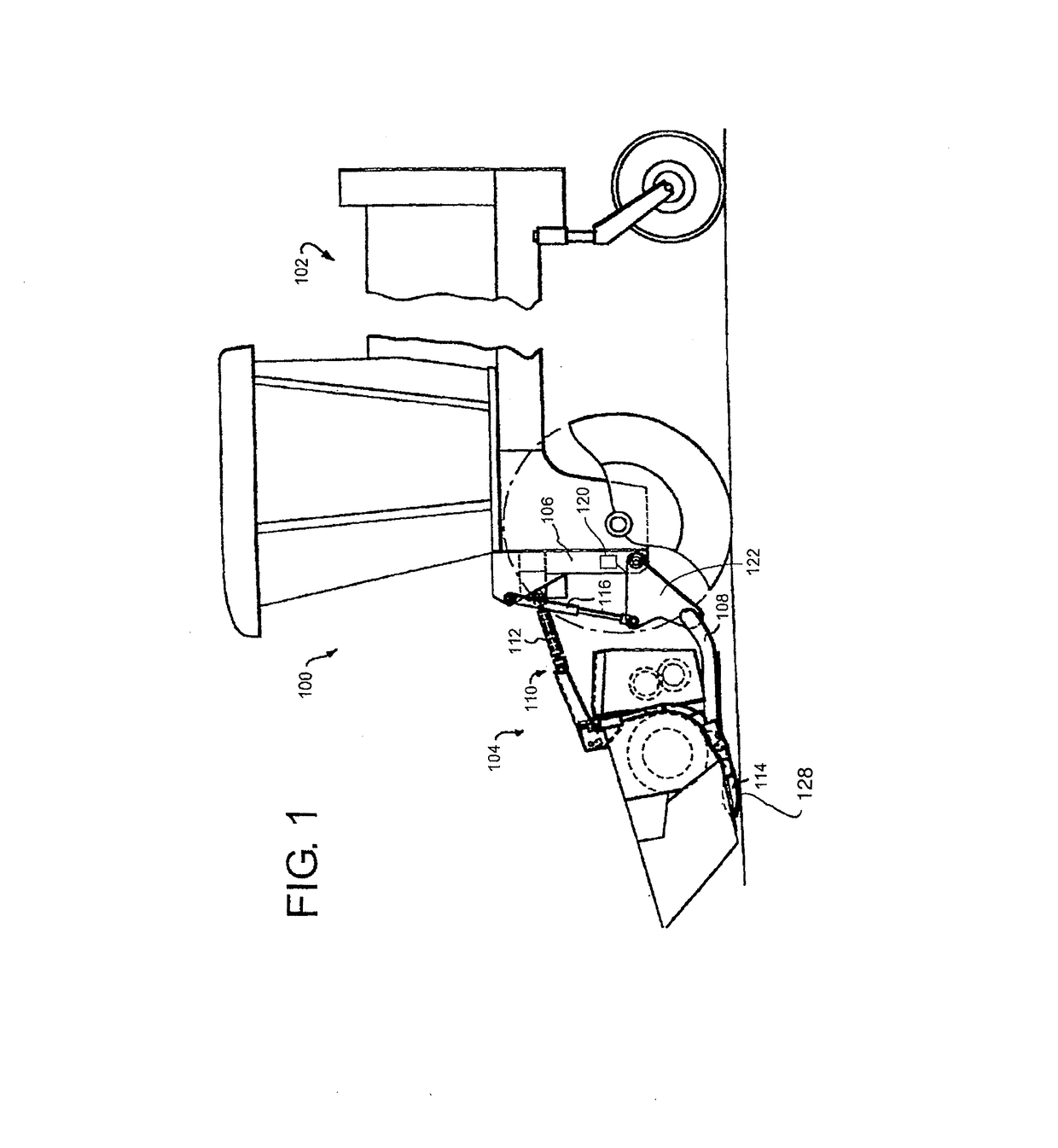

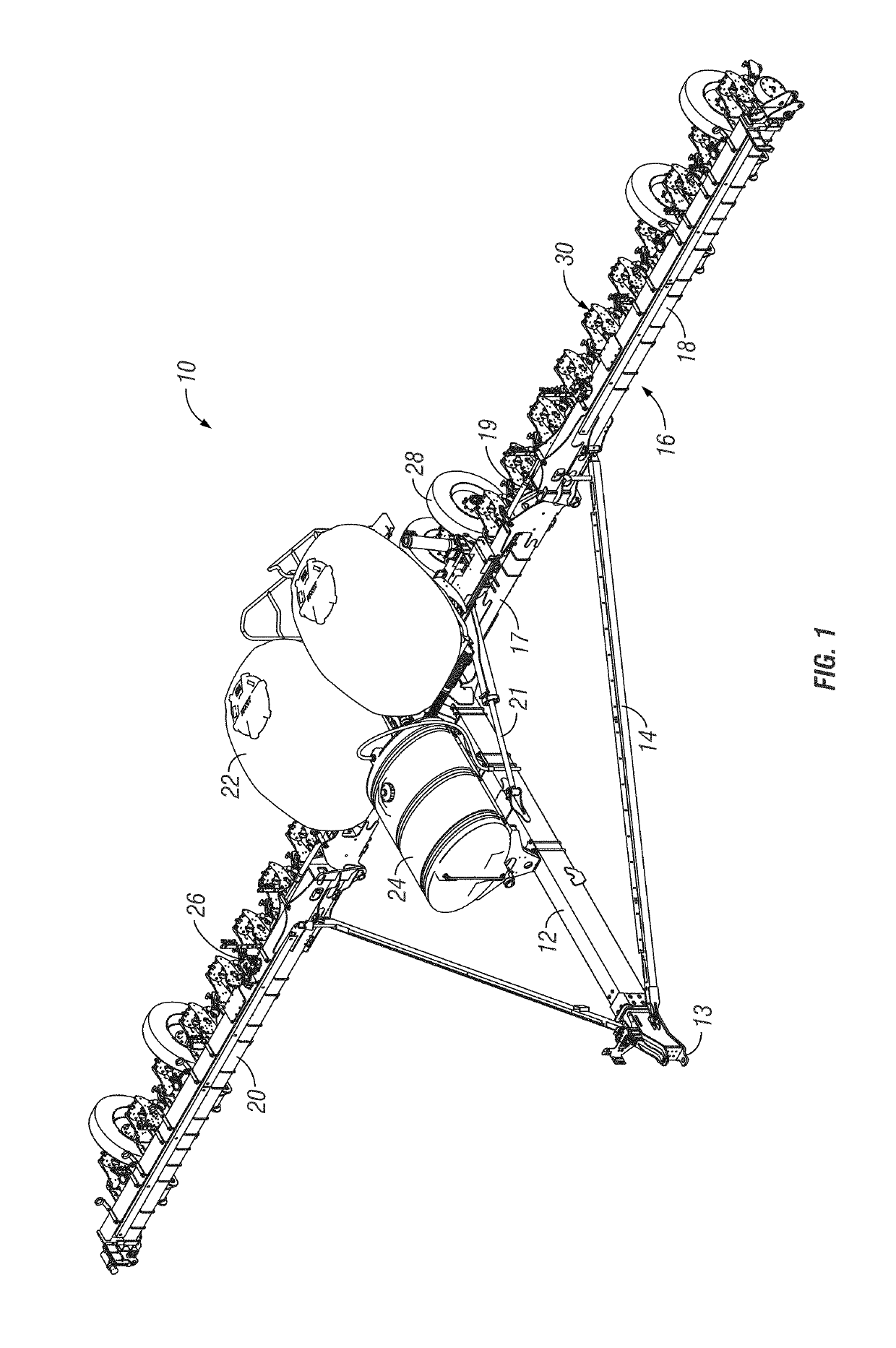

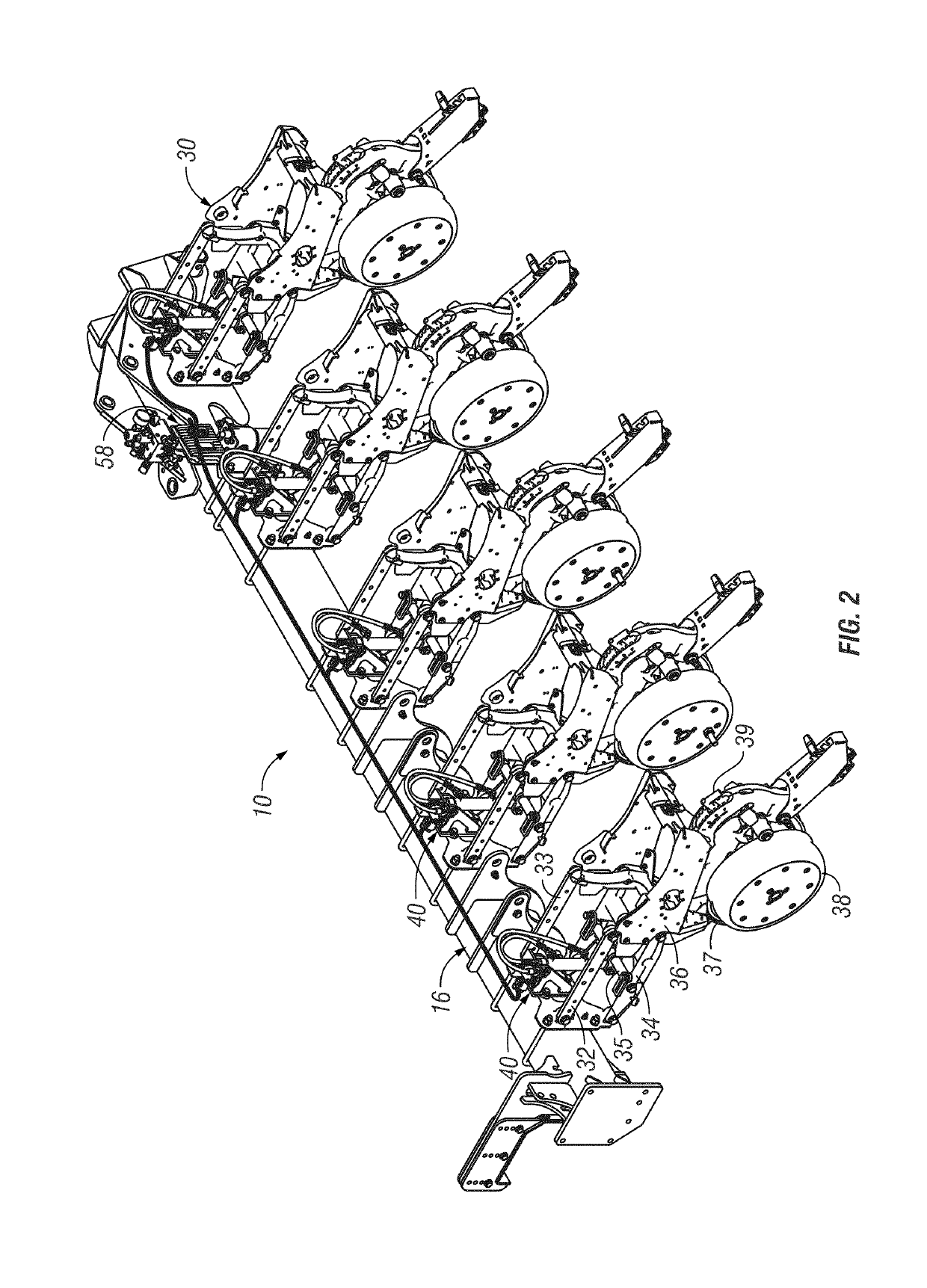

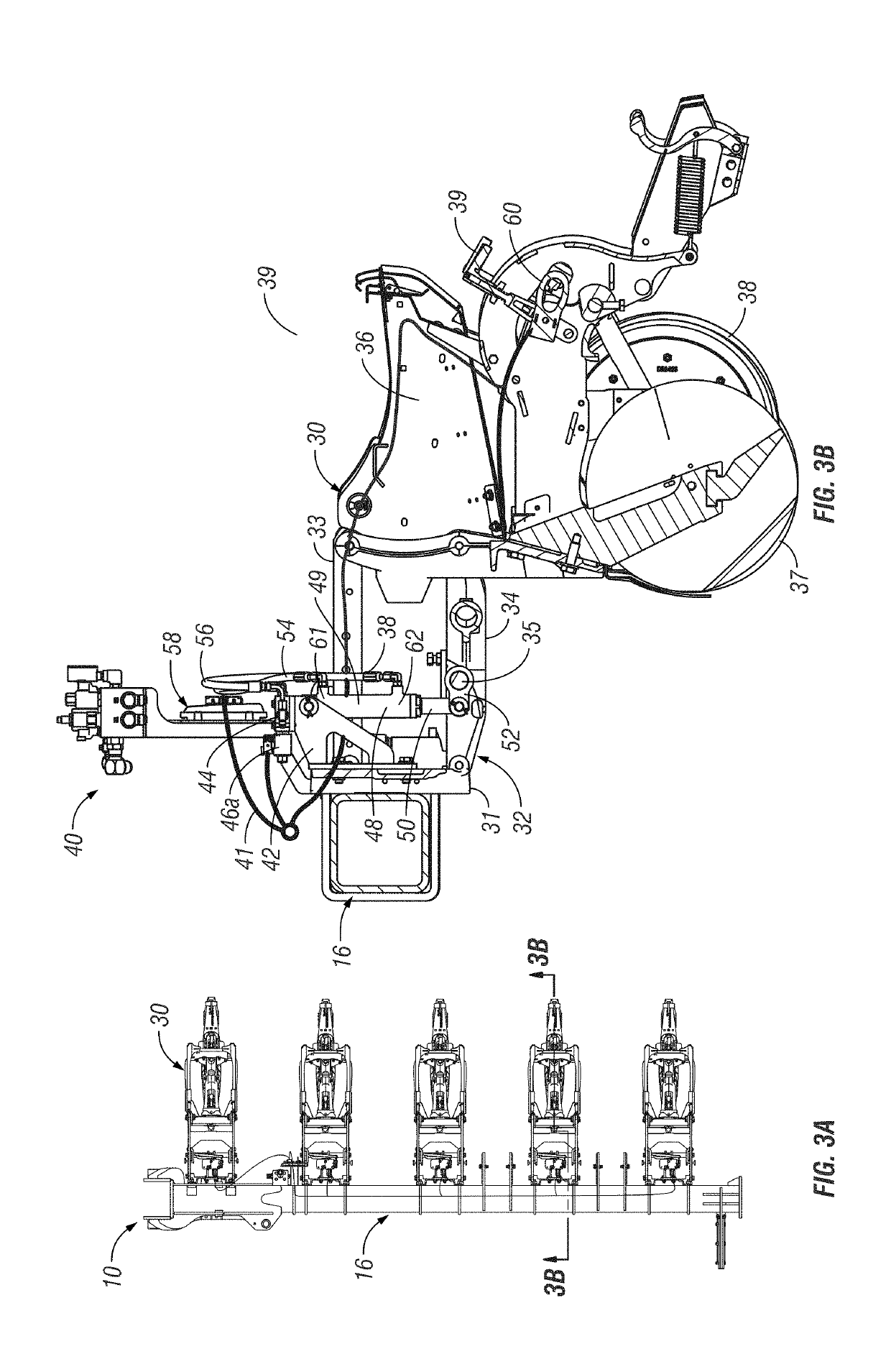

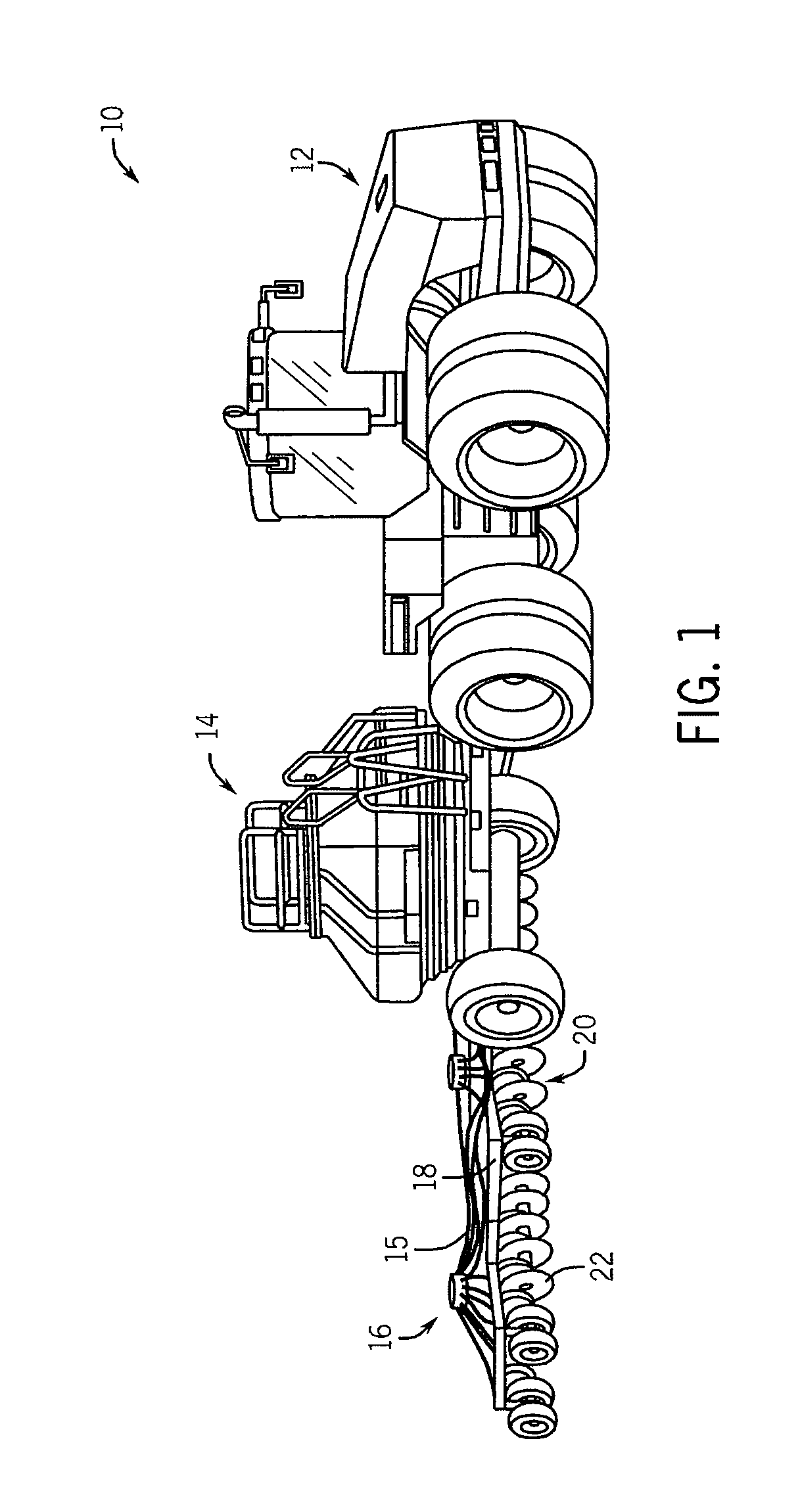

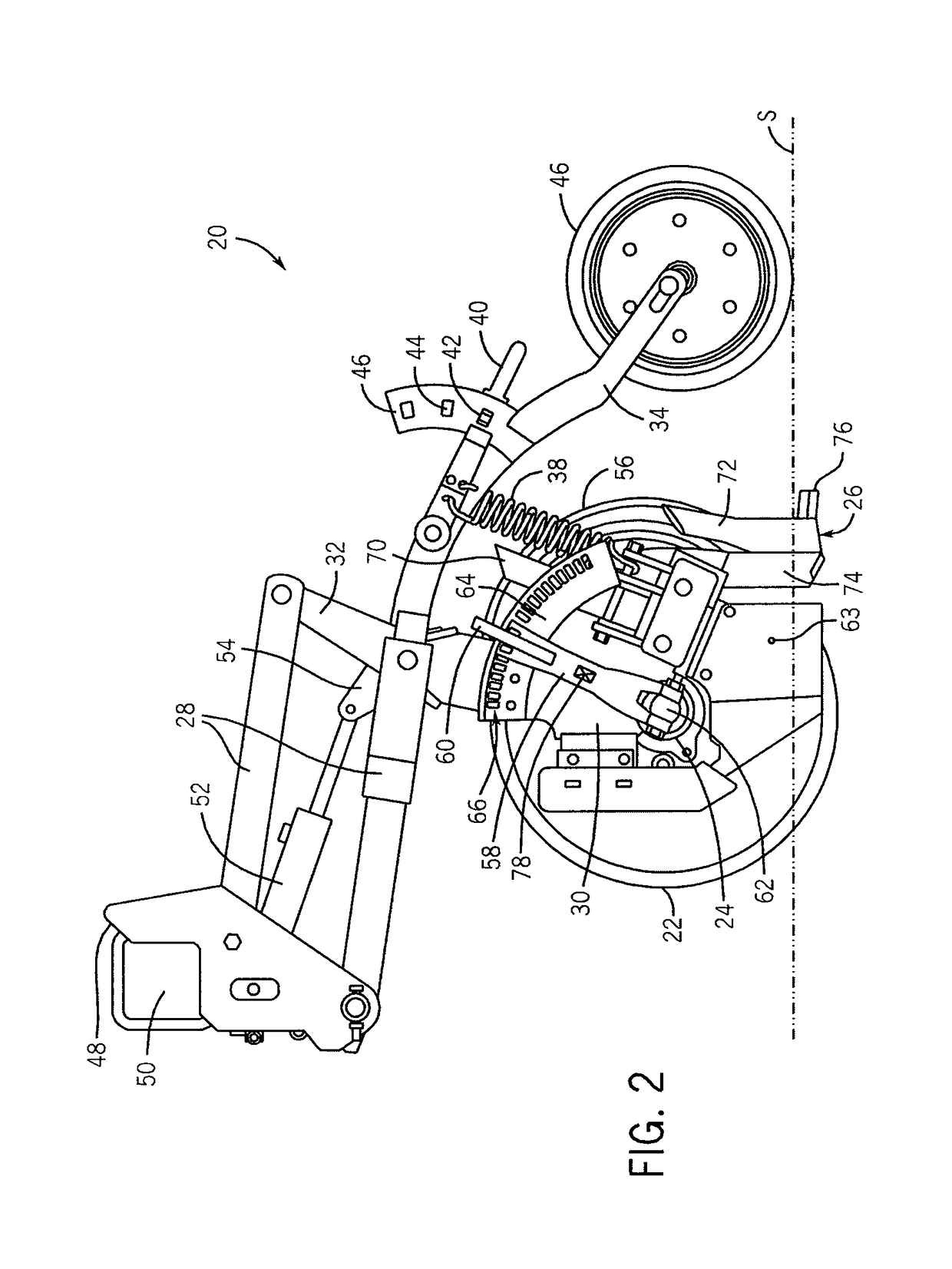

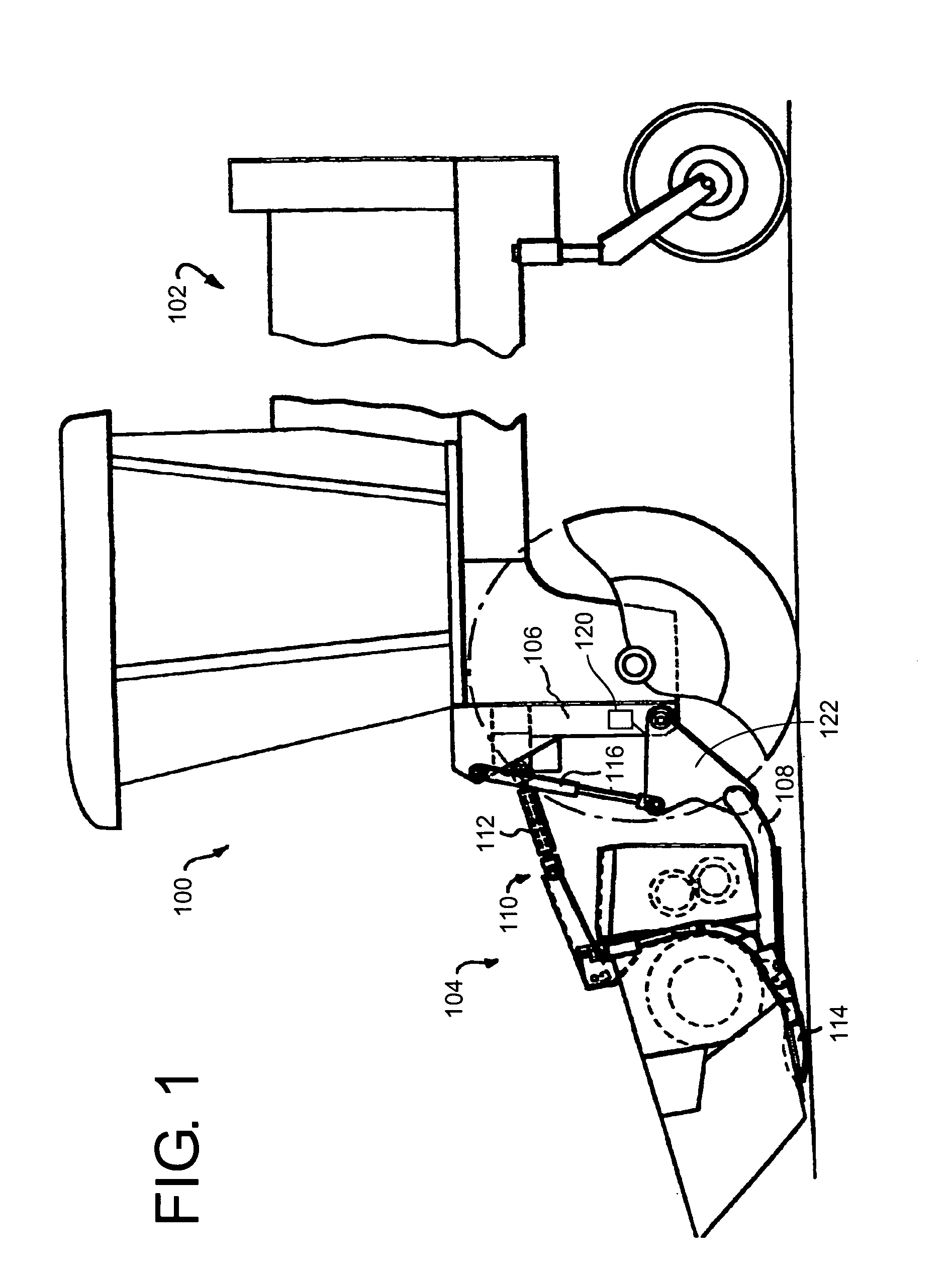

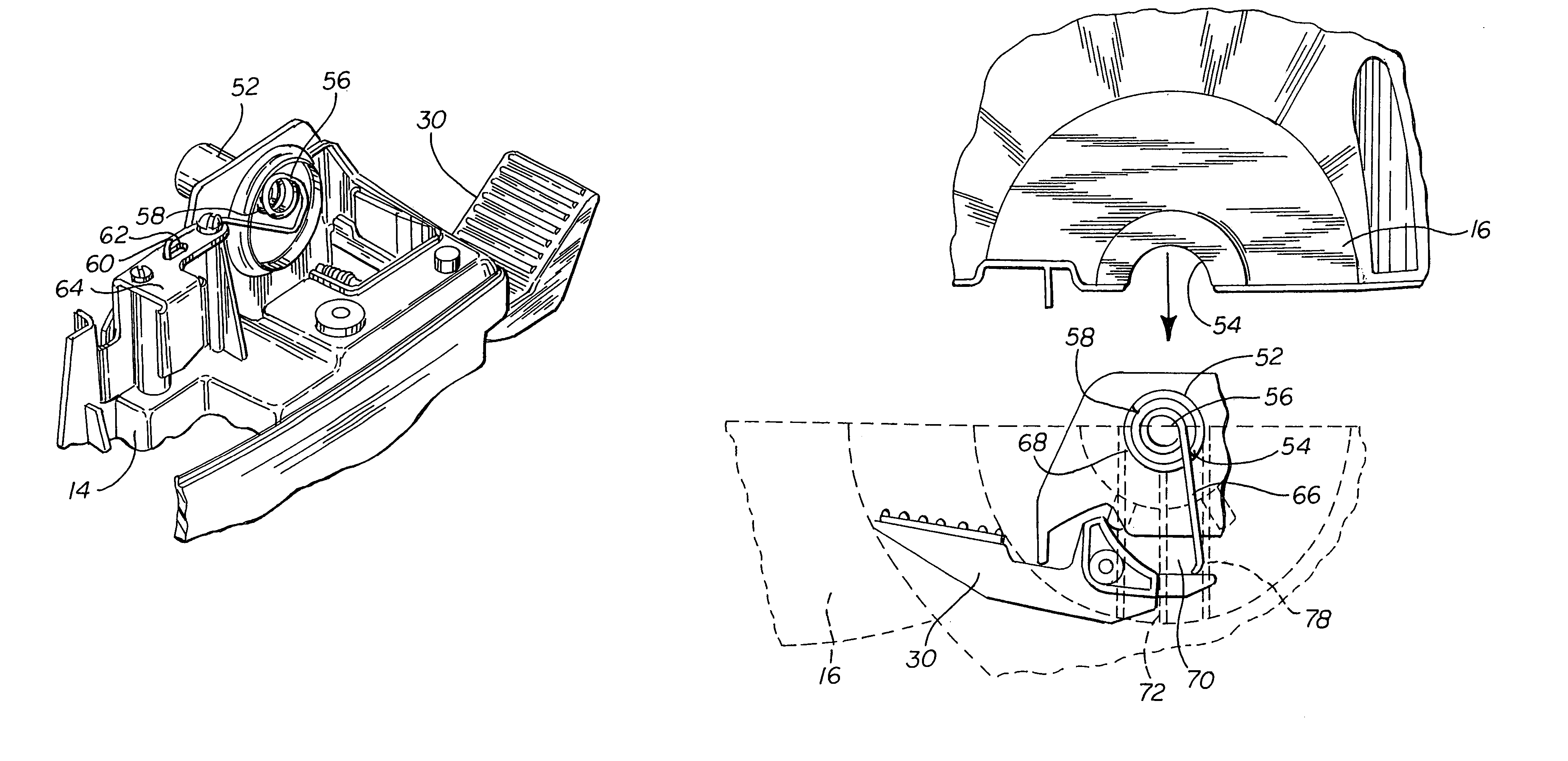

Automatic down pressure adjustment system for set of ganged disc openers

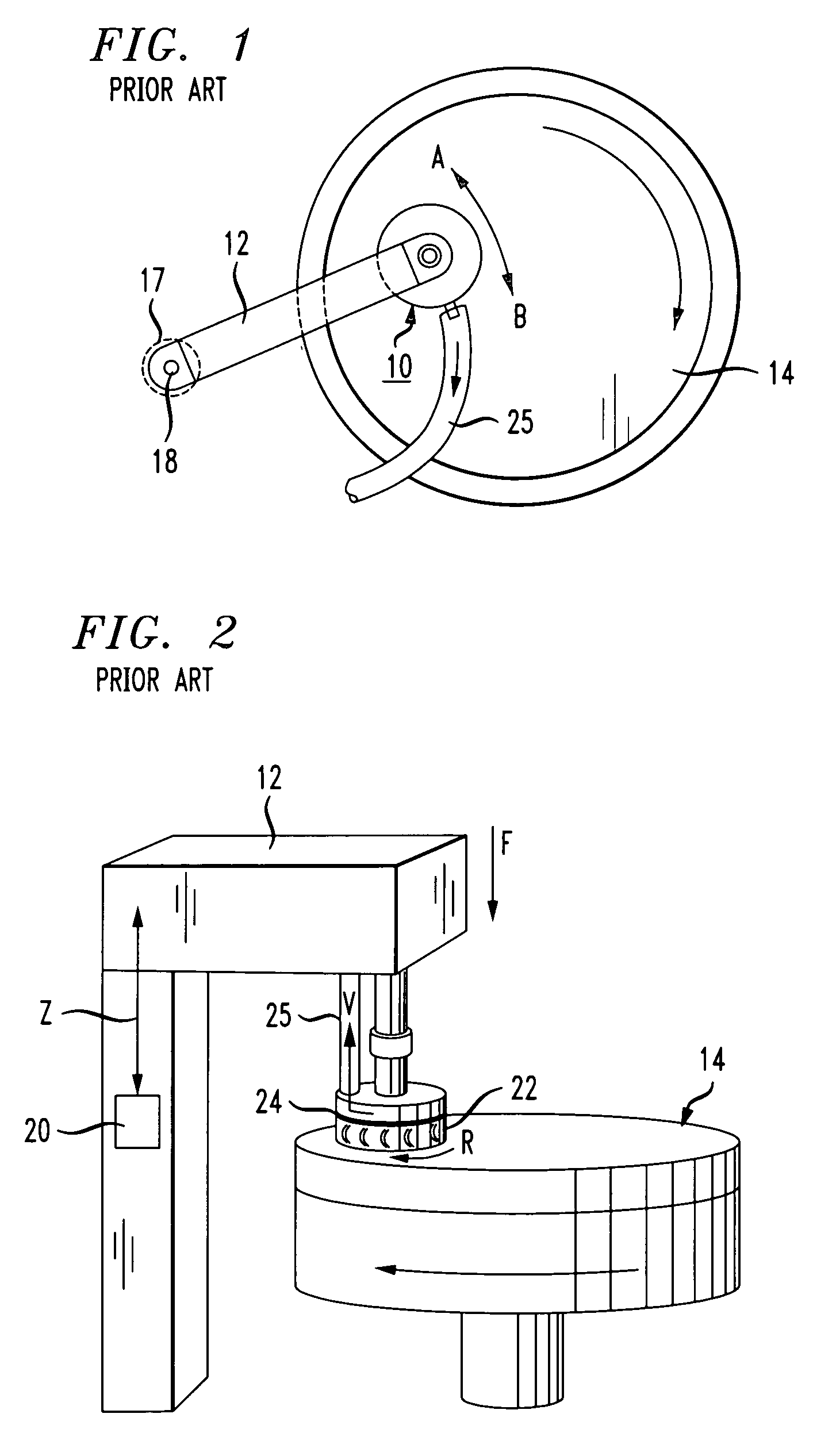

A disc opener unit for an agricultural implement has a down pressure adjustment device that automatically adjusts the amount of down pressure applied on a furrowing disc based on strain measurements taken by a strain gauge or load cell. The strain gauge, which may be mounted to an arm that is used to set the position of a depth setting gauge wheel, provides feedback to a processor that in turn controls the amount of hydraulic fluid in a hydraulic cylinder to adjust the down force applied on the disc. The amount of down pressure is therefore adjusted in substantially real-time in response to changes in field conditions, which improves furrow depth consistency and reduces wear on the gauge wheel and its components.

Owner:CNH IND CANADA

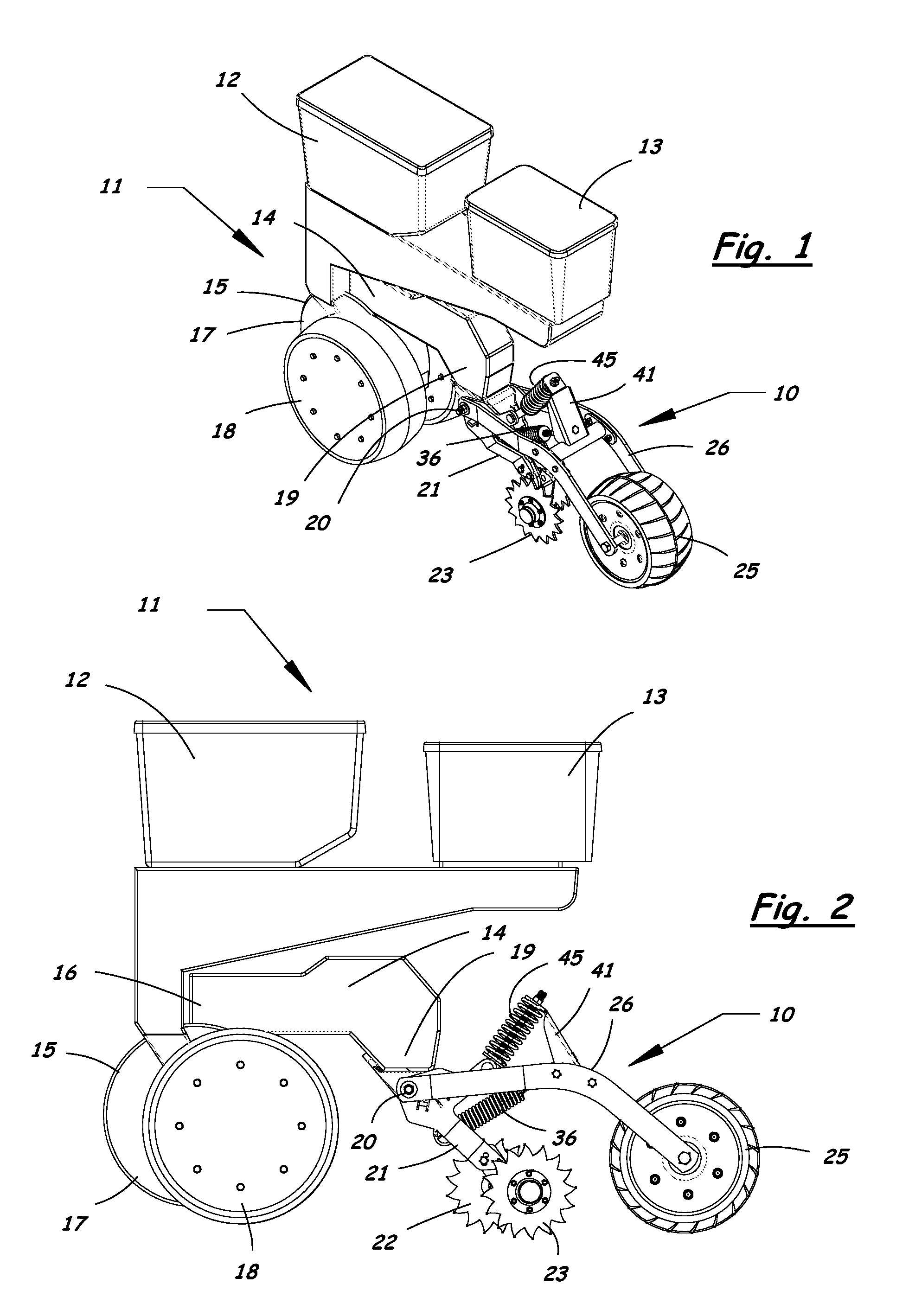

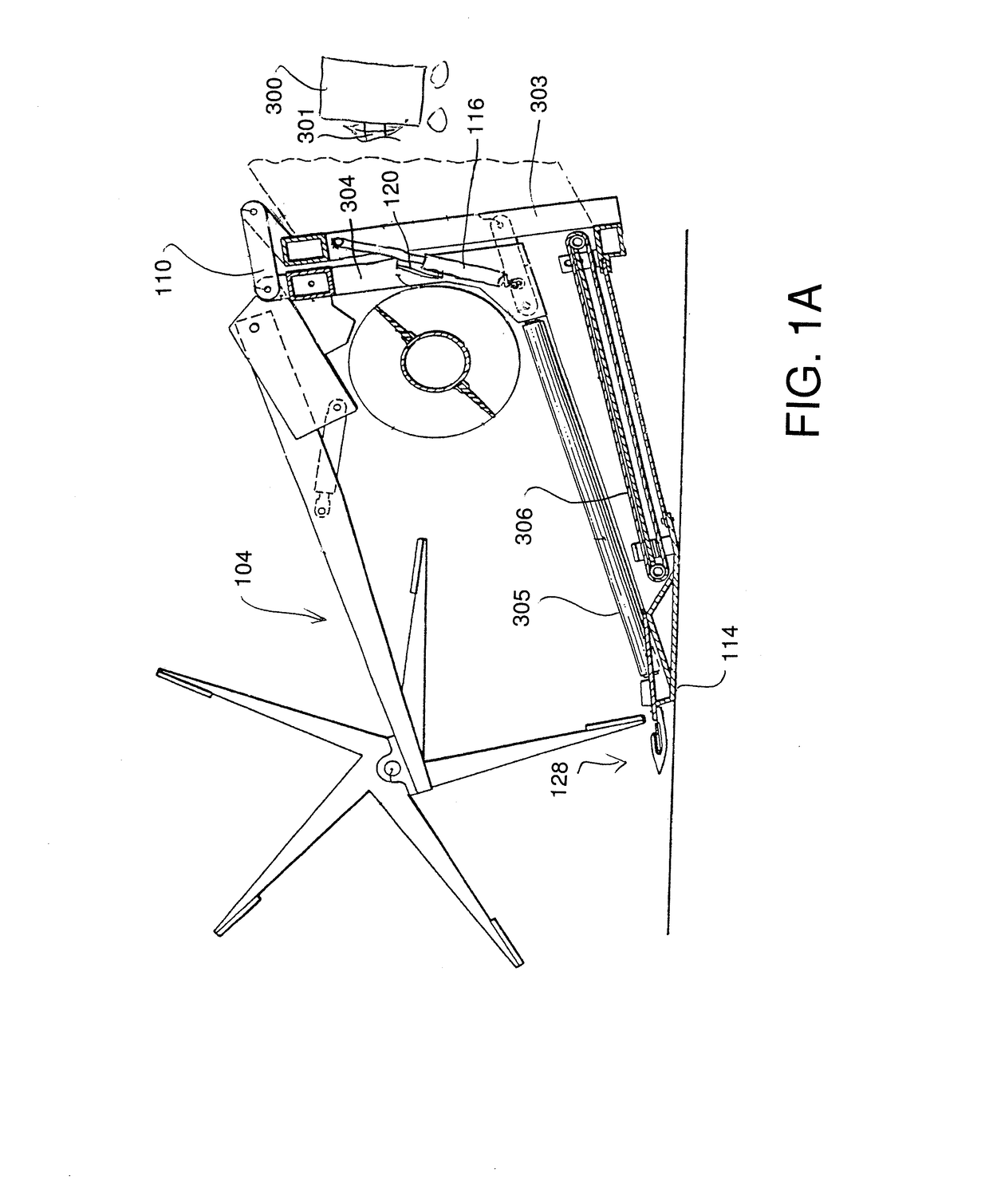

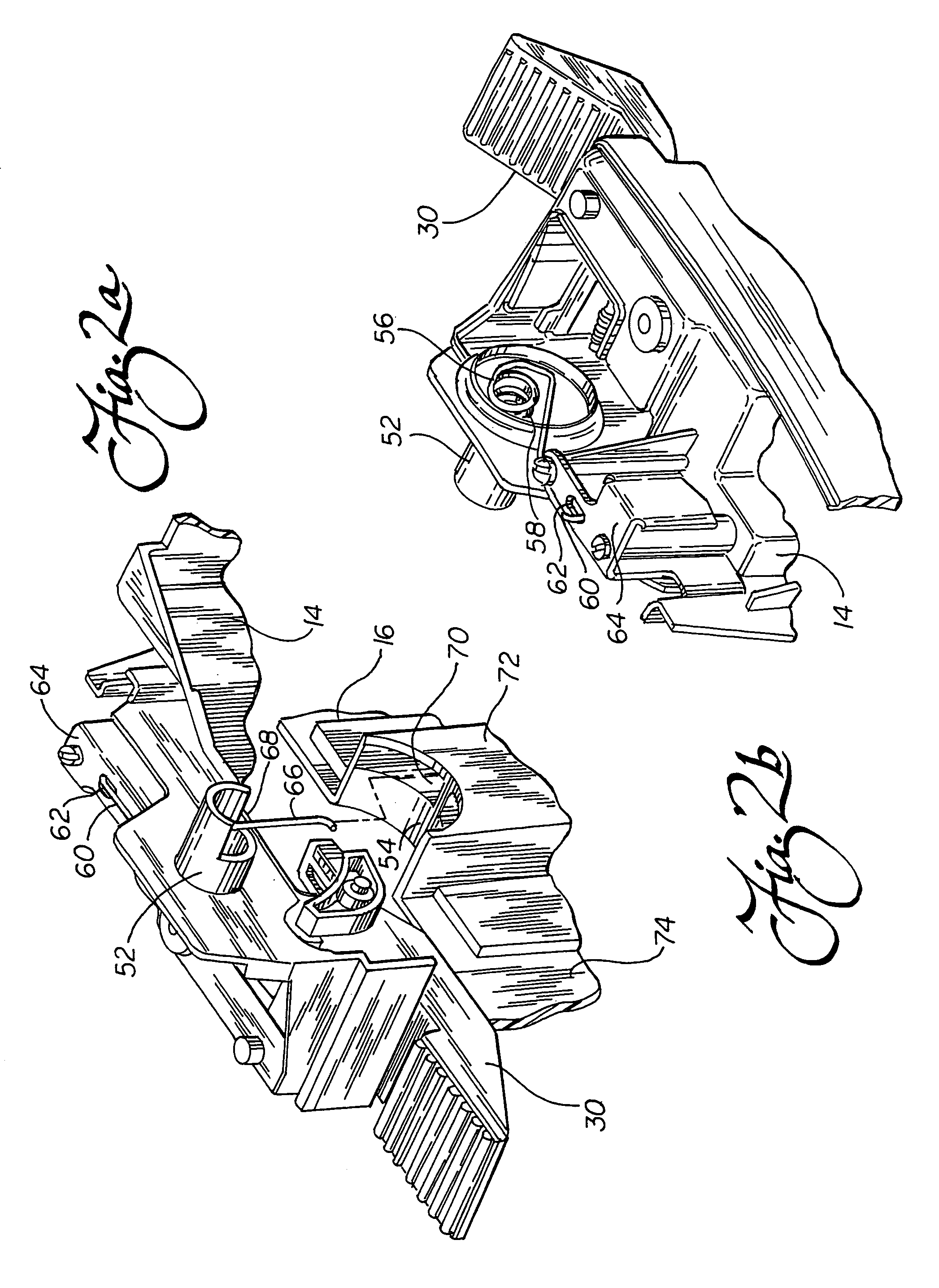

Furrow closing assembly and method

Agricultural planter row units feature soil finishing assemblies for closing a seed groove after seed is placed in the soil. An adjustable furrow closing assembly enhances upper seed groove coverage and closure with soil resulting in sustained relative humidity levels and optimum seed-to-soil contact for faster seed germination. The furrow closing assembly includes a closing wheel assembly having at least one closing wheel and a press wheel assembly having a press wheel following behind the closing wheels. The closing wheels and press wheel are attached to the planter row unit in a manner allowing the press wheel to move vertically relative to the closing wheels. Adjustable down-force systems are provided to vary the down force applied to the closing wheels and the press wheel to maintain optimum soil contact in irregular terrain and in varying soil densities and conditions to provide optimum soil coverage and compaction of the seed bed.

Owner:AG FOCUS LLC

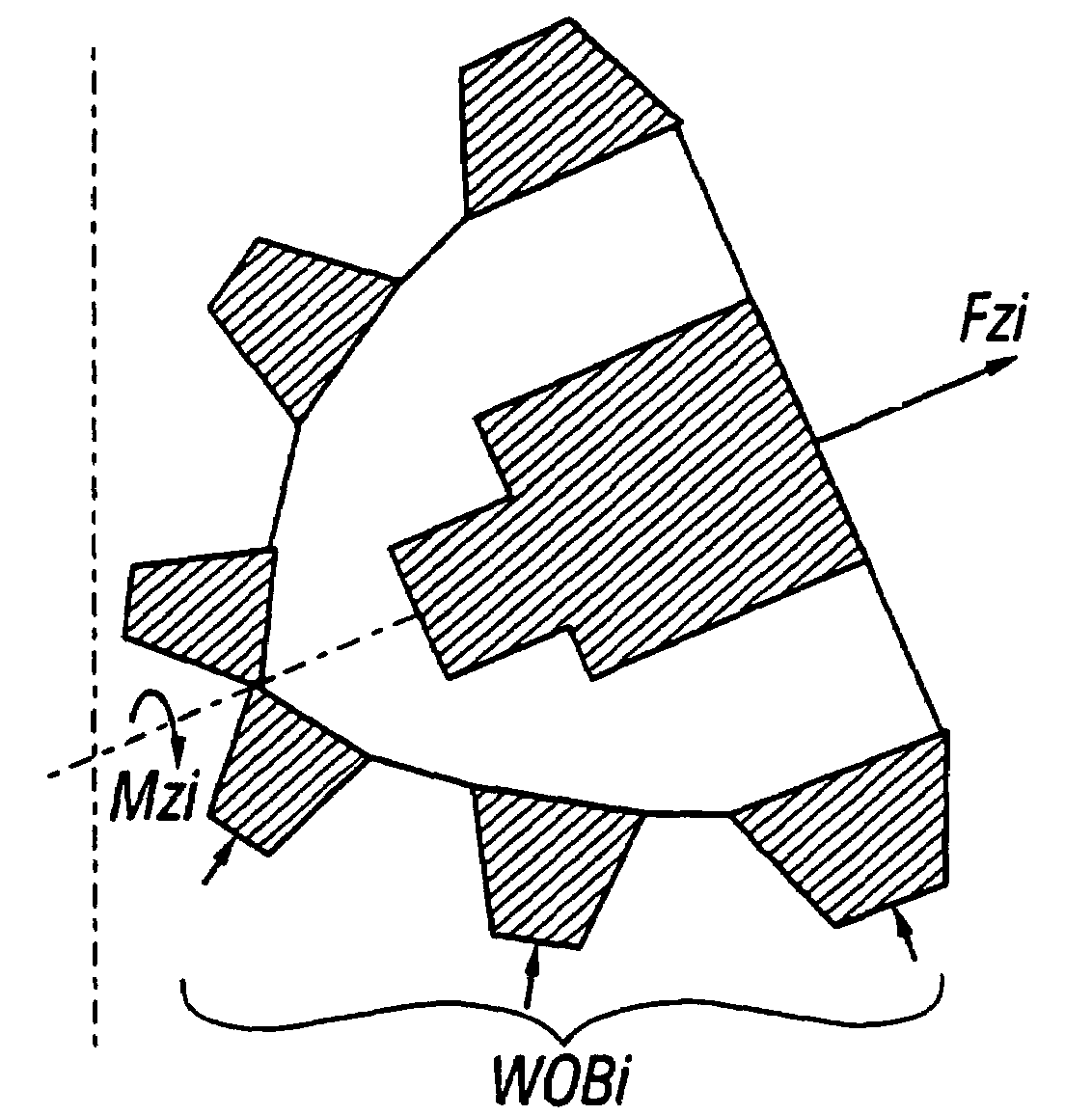

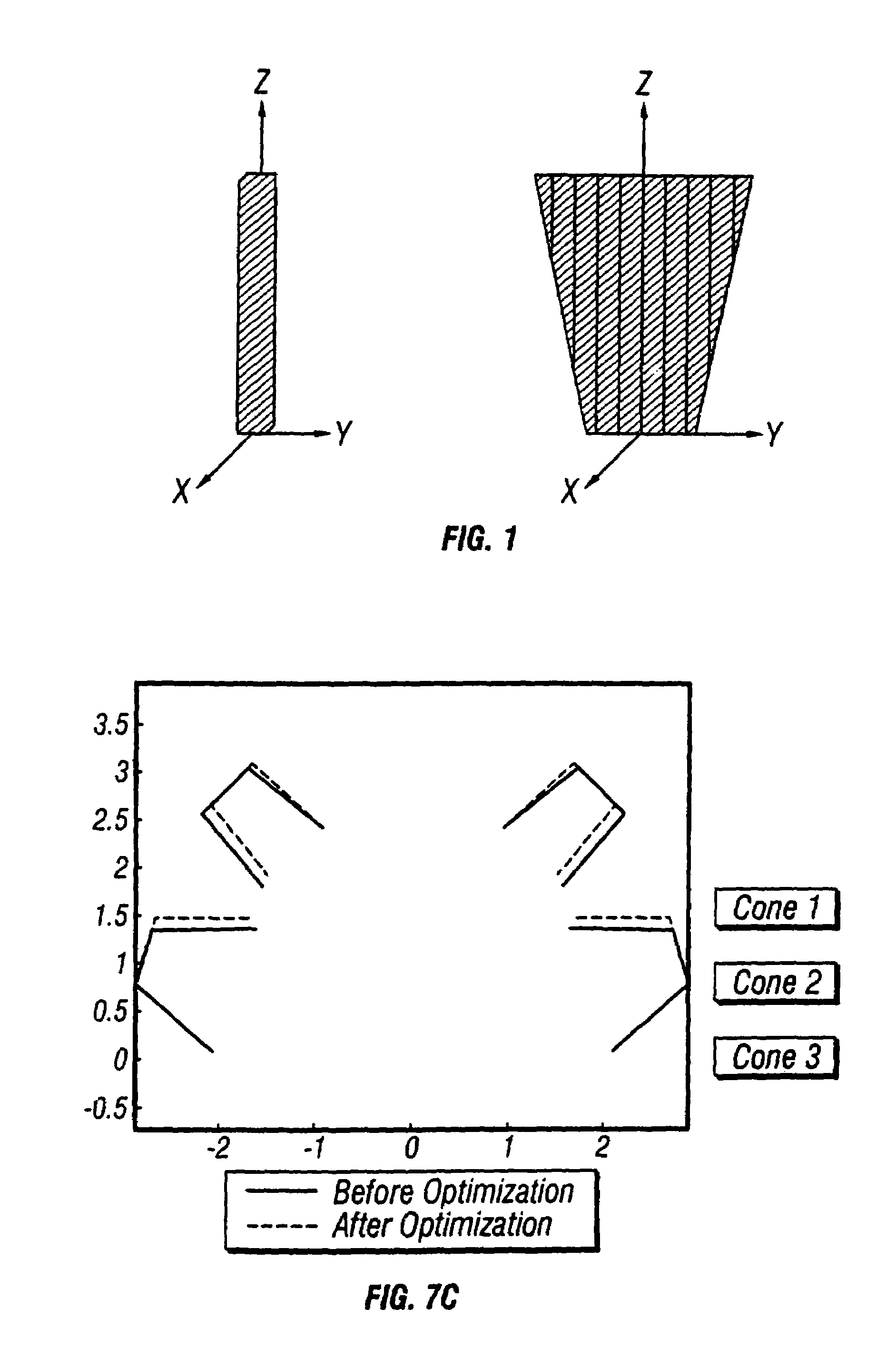

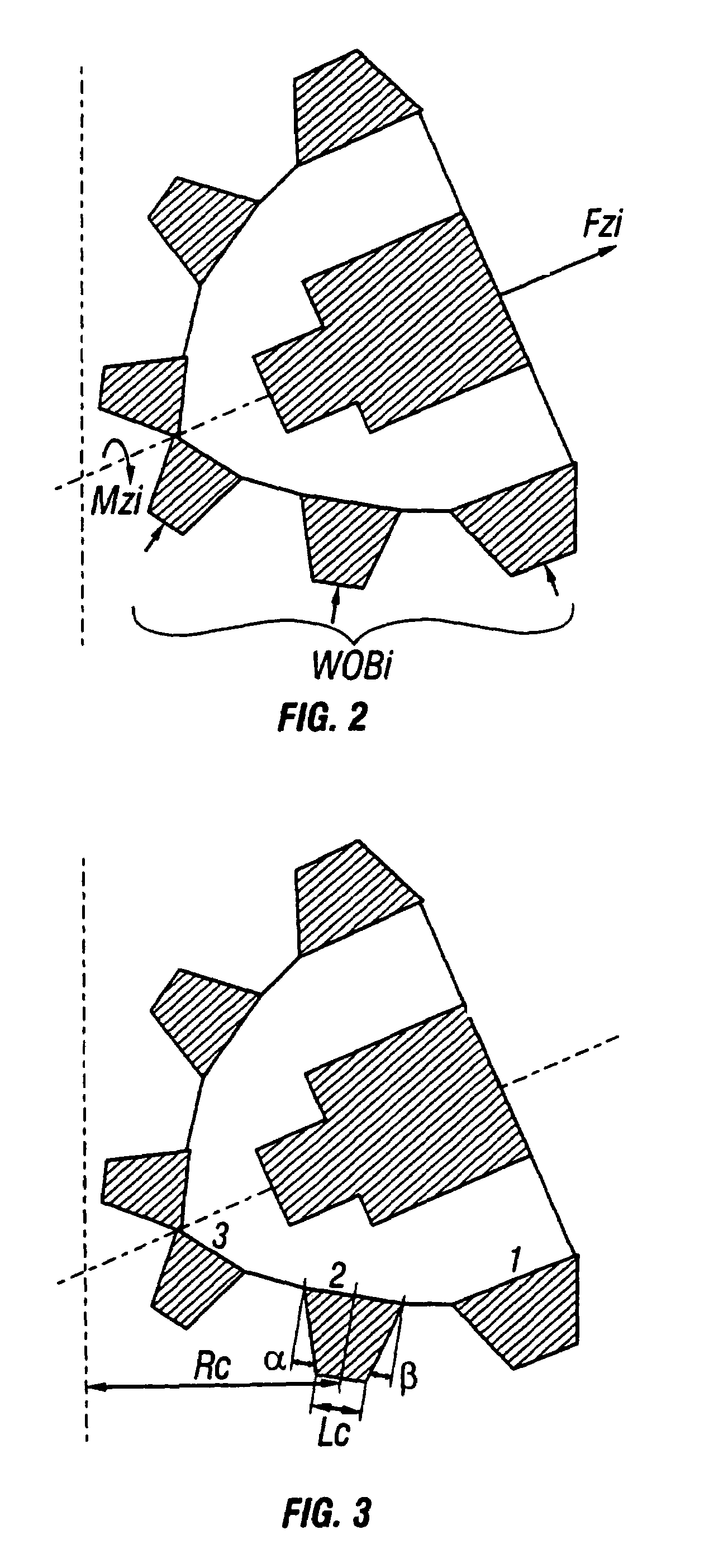

Force-balanced roller-cone bits, systems, drilling methods, and design methods

InactiveUS6986395B2Reduce rotationImprove drilling efficiencyEarth drilling toolsDrill bitsAxial forceEngineering

Roller cone drilling wherein the bit optimization process equalizes the downforce (axial force) for the cones (as nearly as possible, subject to other design constraints).

Owner:HALLIBURTON ENERGY SERVICES INC

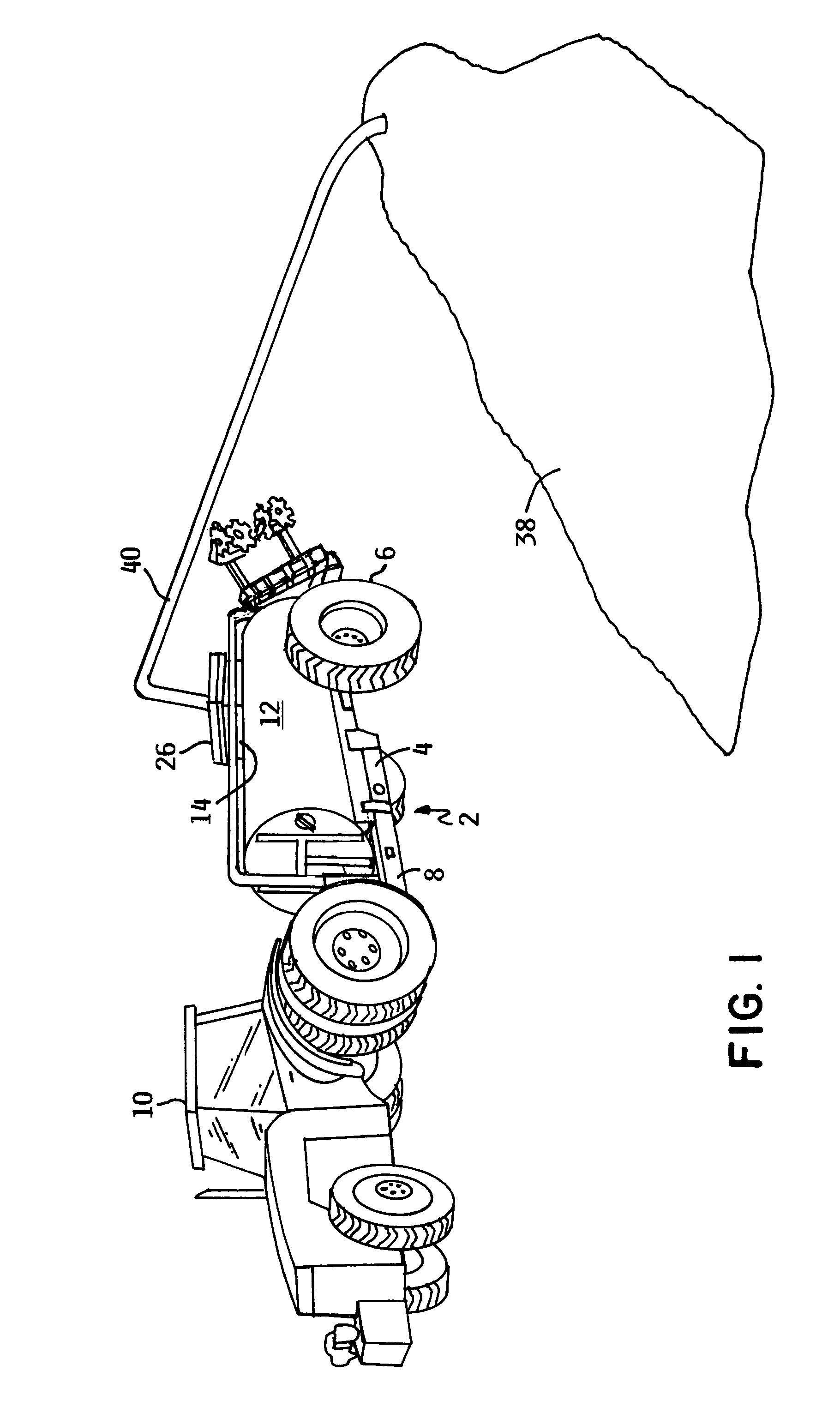

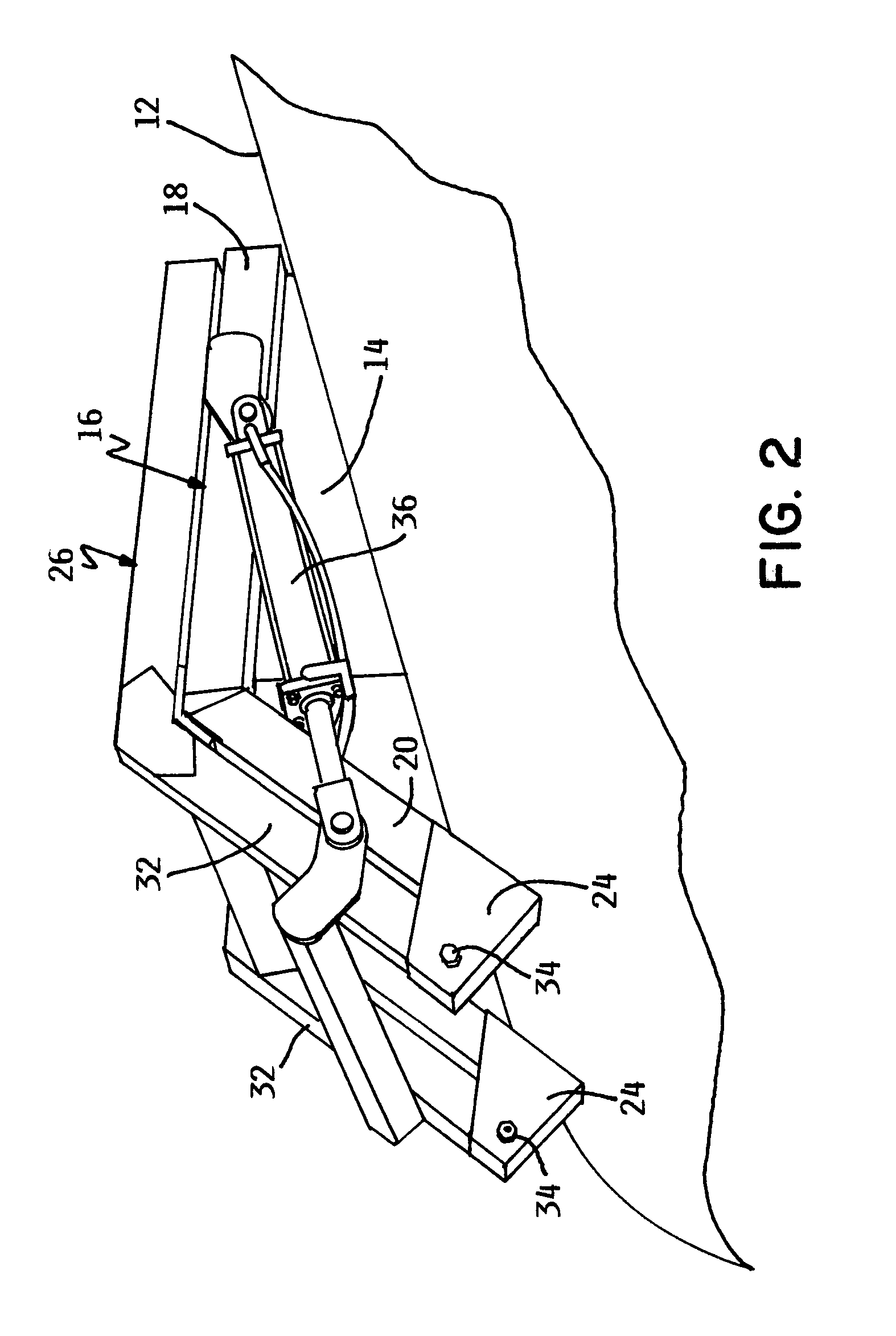

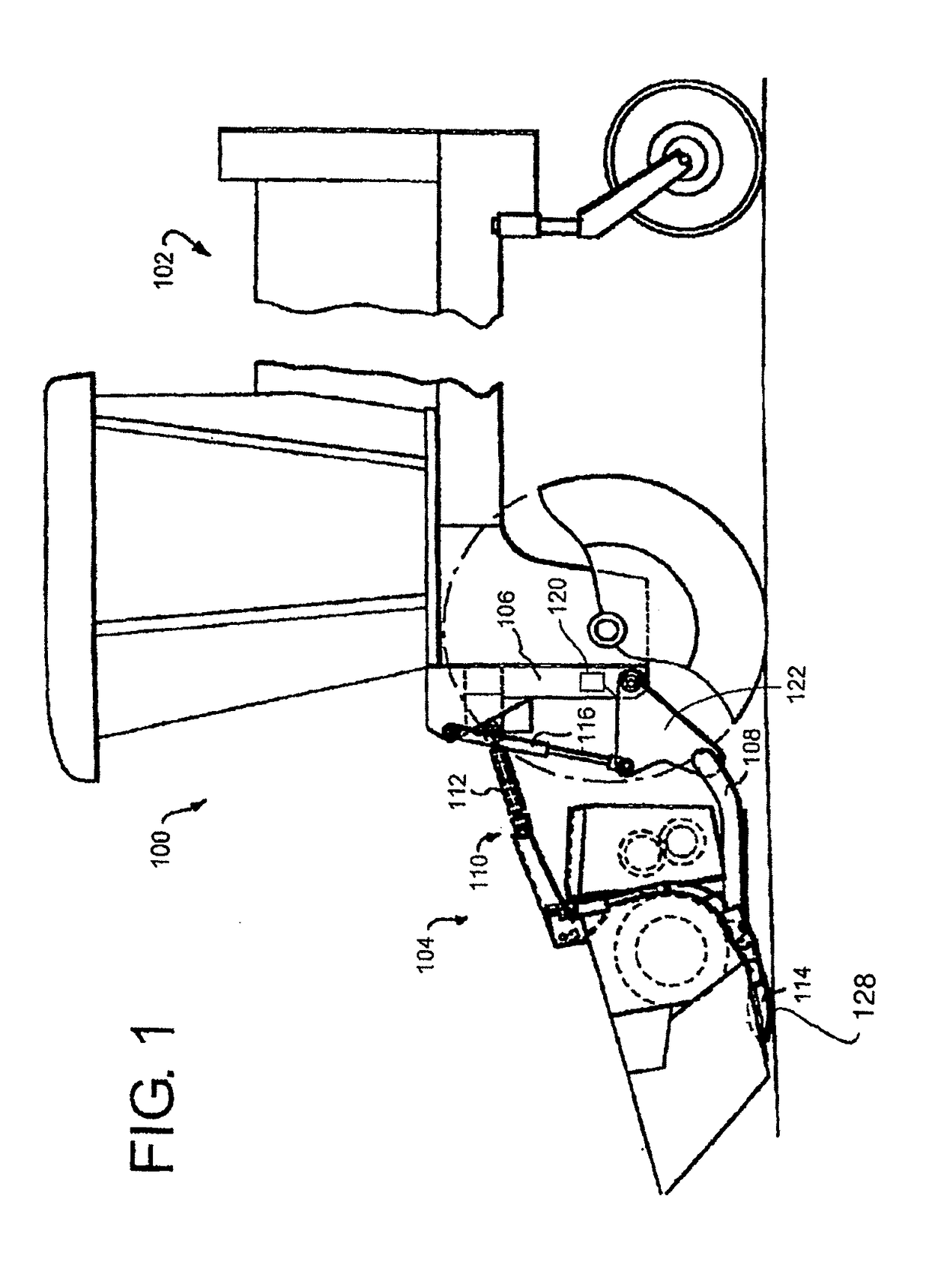

Header flotation calibration system

A system for calibrating a header flotation system of an agricultural vehicle having a header is provided that includes a control circuit configured to monitor the height of the header and to calculate an upforce that will maintain a desired downforce of the header against the ground. This calculation is based at least upon the position of the header during flotation.

Owner:BLUE LEAF I P INC

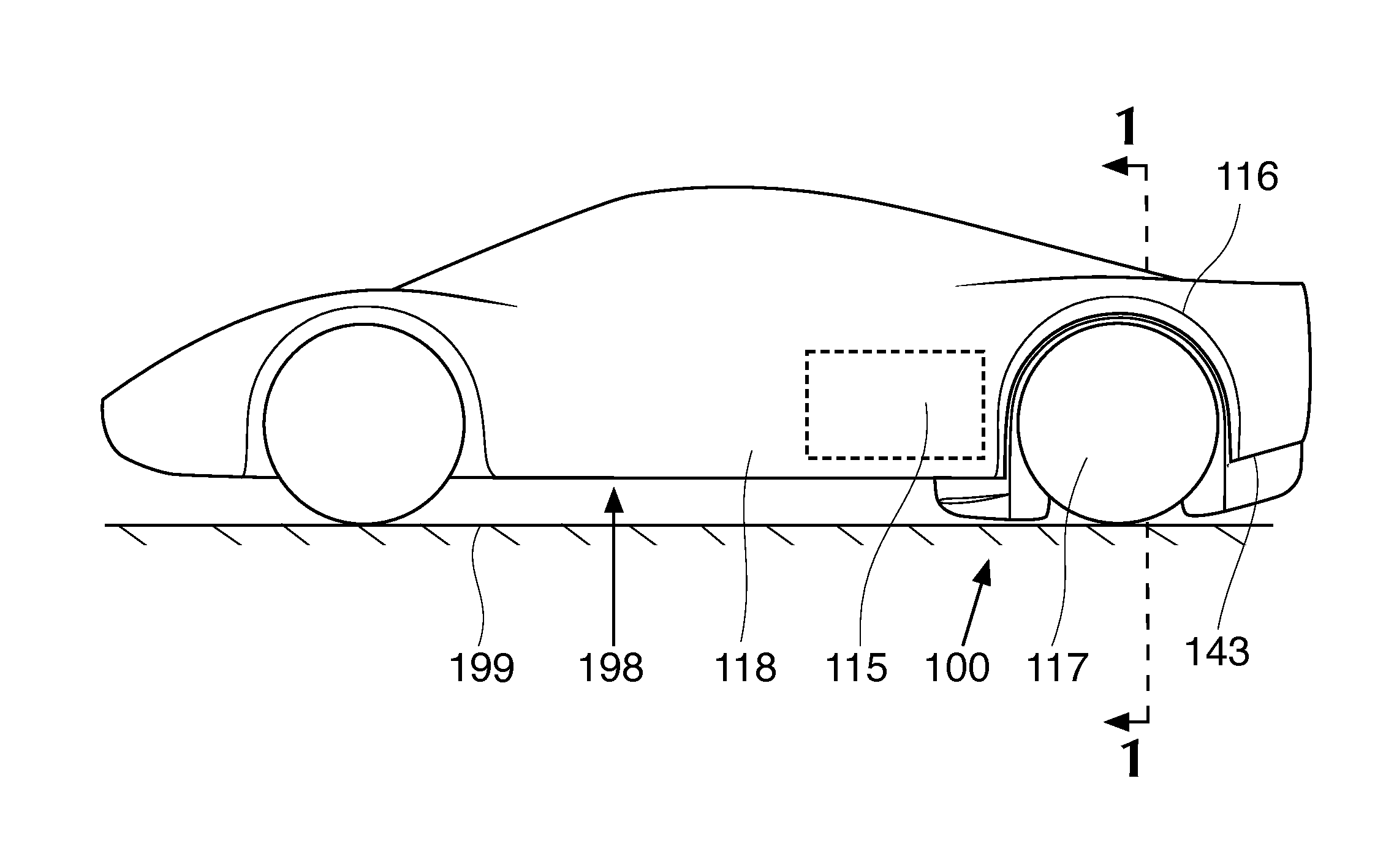

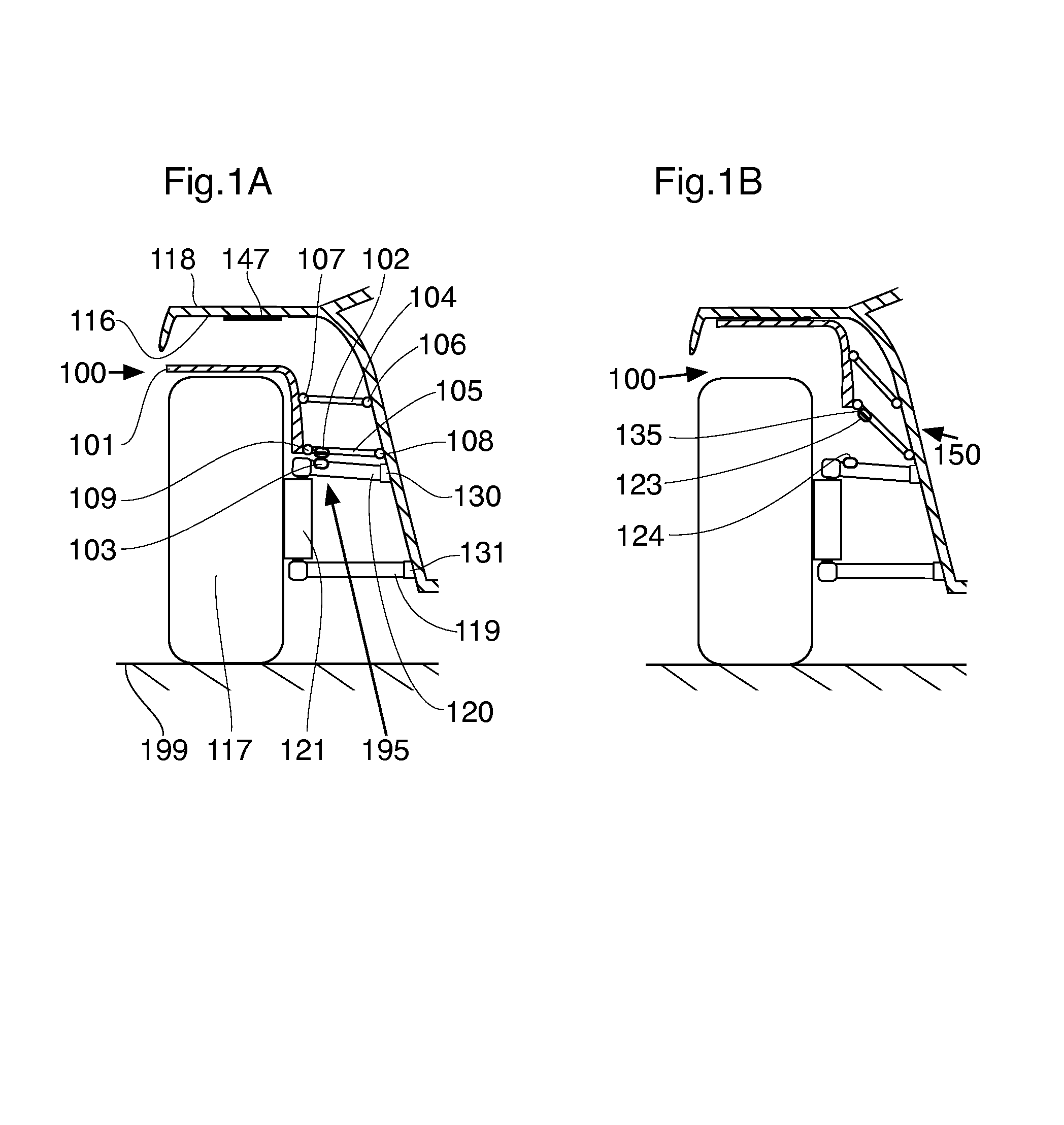

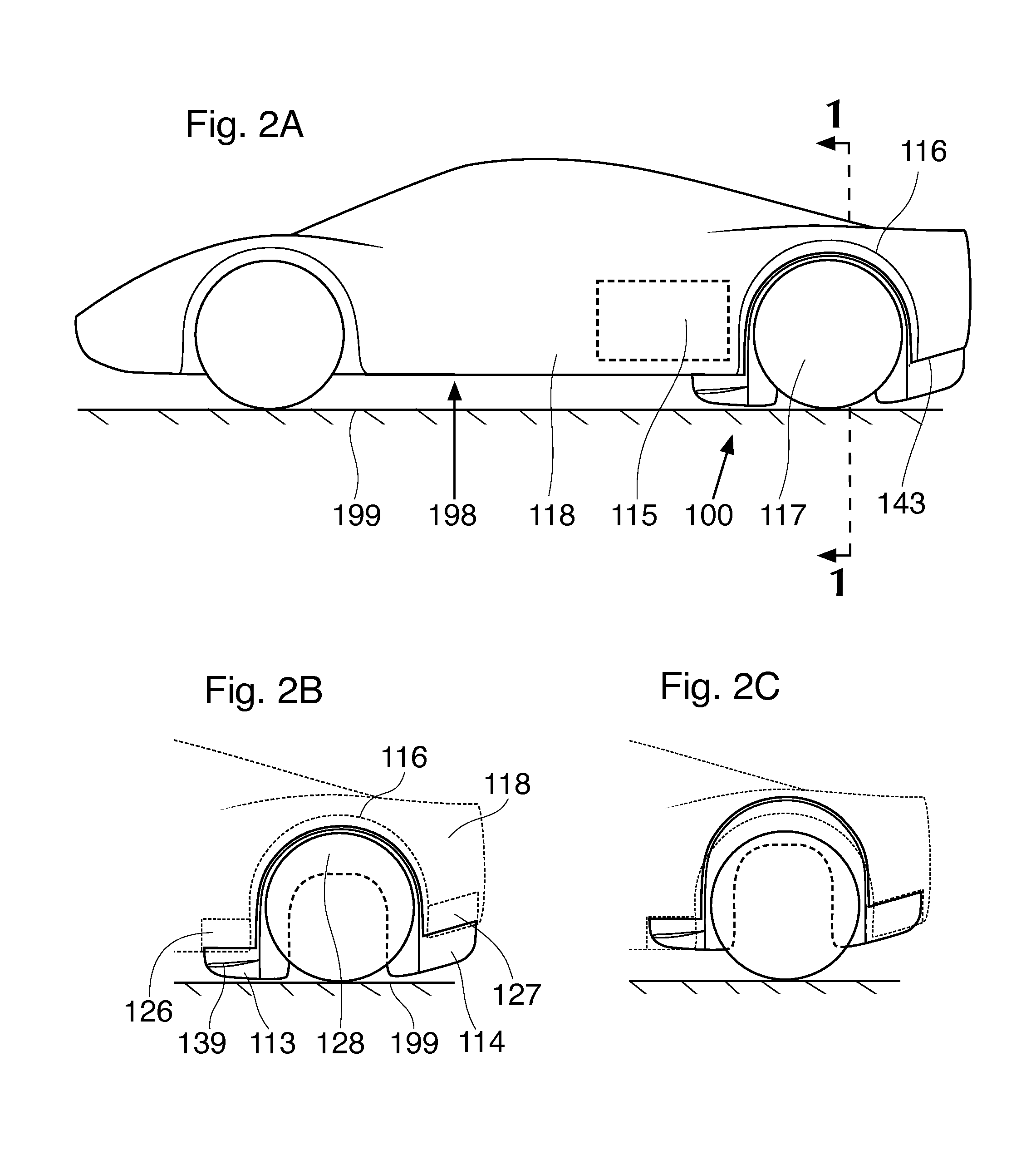

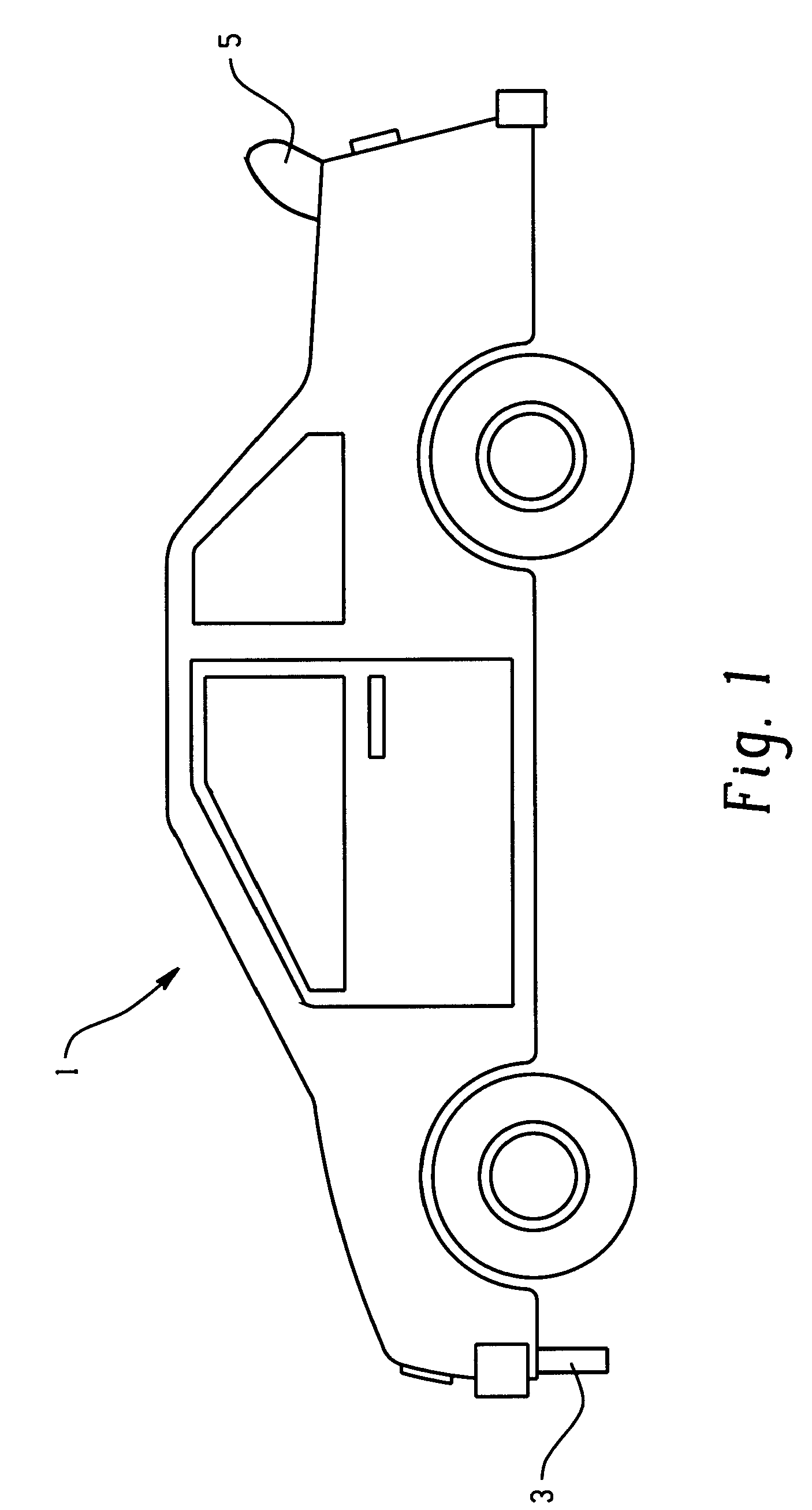

Devices for controlling the downforce generated by a vehicle

A vehicle comprising a flap that is attached to the vehicle in such a way as to permit movement of the flap from a first position to a second position, wherein the flap is configured to alter the downforce generated by the vehicle when the vehicle is in motion by affecting the airflow underneath the vehicle, the effect of the flap on the airflow being dependent upon the second position of the flap.

Owner:MCLAREN AUTOMOTIVE

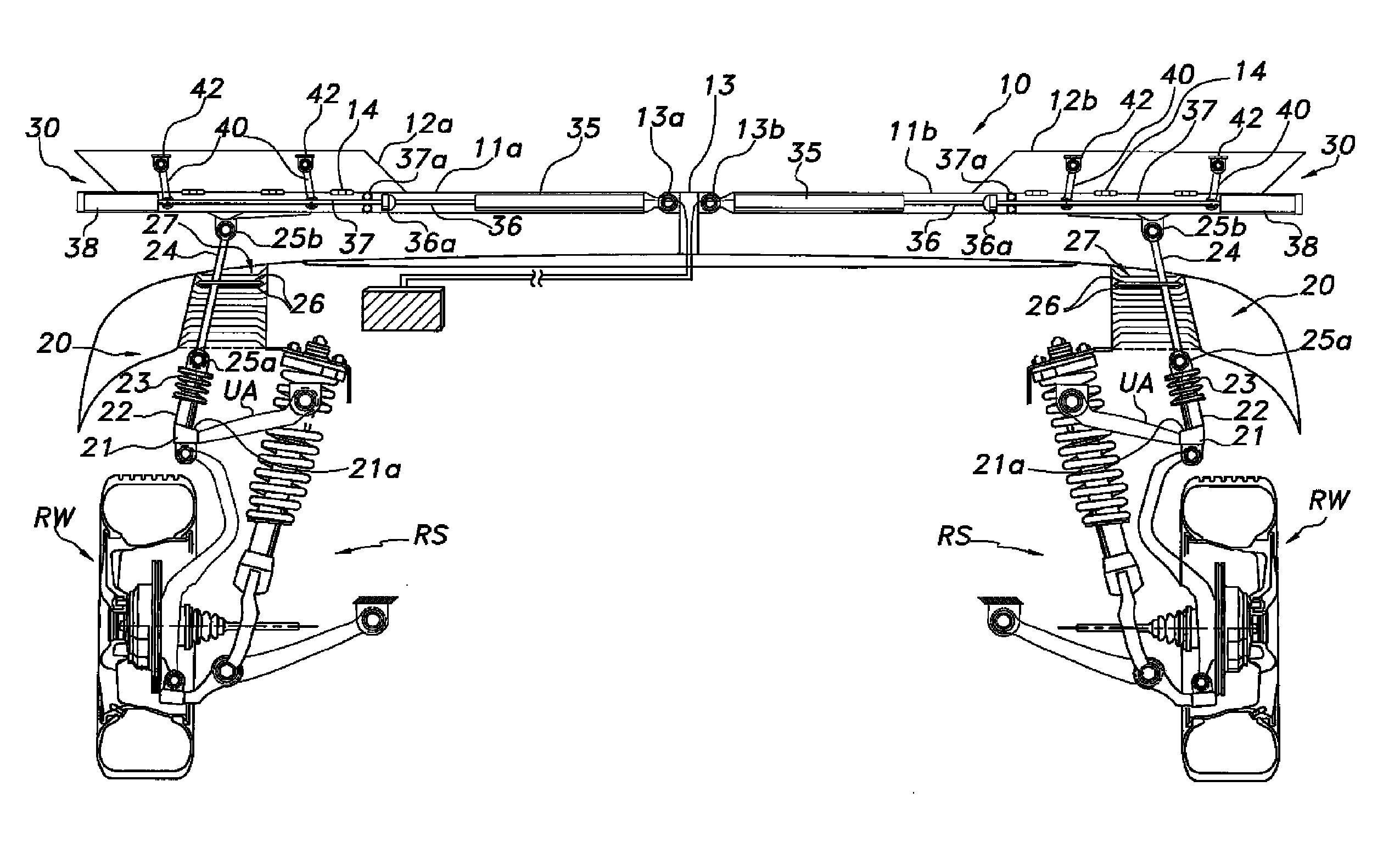

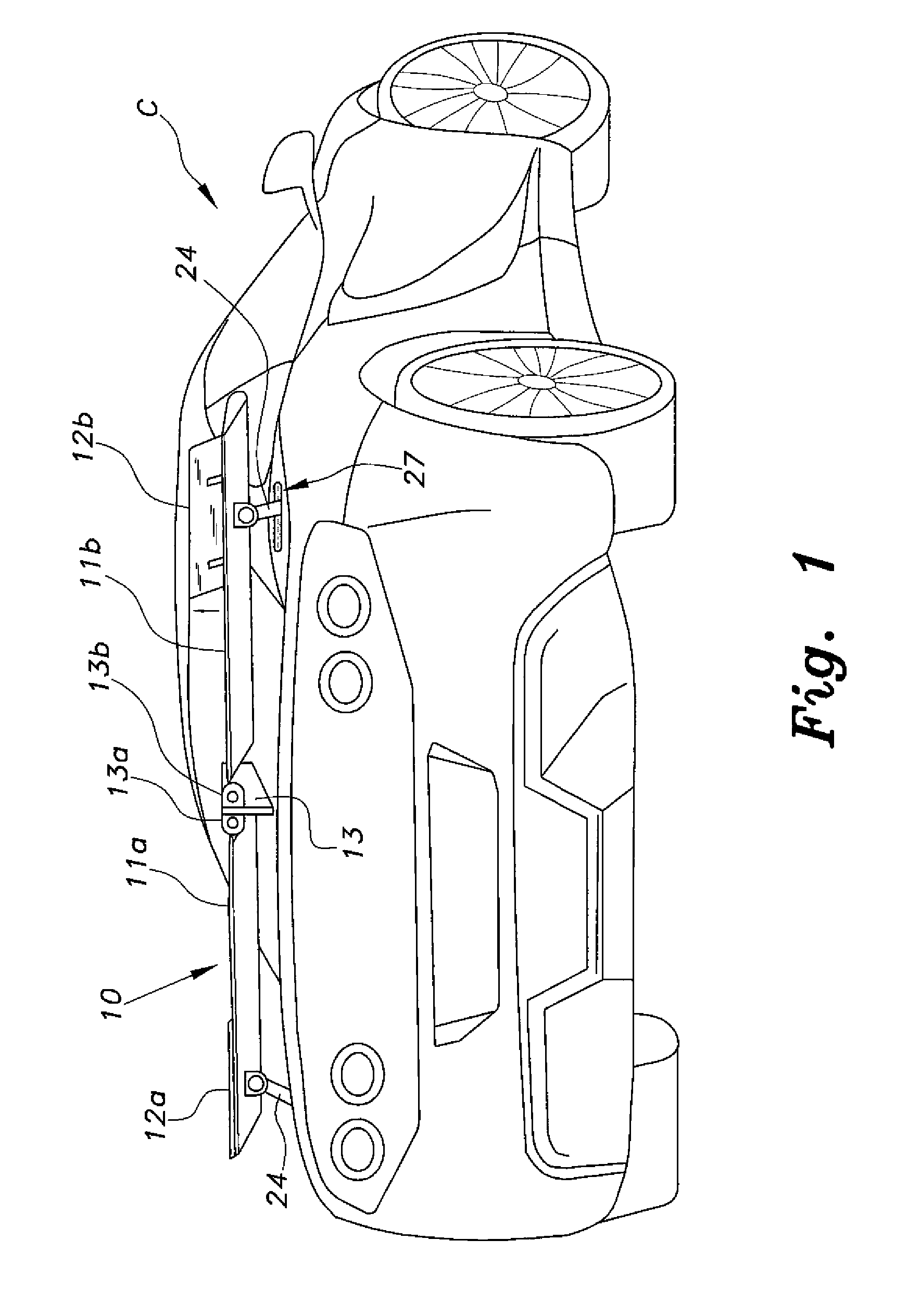

Dynamically adjustable airfoil system for road vehicles

ActiveUS9403564B1Facilitate dynamic adjustable positioningIncrease downforceVehicle body stabilisationRace vehiclesActuatorDownforce

The dynamically adjustable airfoil system for road vehicles includes a pair of airfoils having their respective inner ends pivotally mounted to a central, vertical base on the rear of a road vehicle. An airfoil lift assembly is coupled to an outer end of each airfoil and to a rear wheel suspension system to facilitate dynamic adjustable positioning of the airfoils in response to movements of the suspension system. A split flap is pivotally mounted to each airfoil. A split flap actuator assembly is mounted inside each airfoil and coupled to a corresponding split flap to selectively and independently open or close the respective split flap. Opening of the split flap to various angles increases downforce exerted on the rear suspension system for improved performance. A controller controls deployment and angular disposition of the split flaps, depending on driving conditions.

Owner:AL HUWAIDER MUSTAFA ALI HUSSAIN

Retractable wheel fairings for motor vehicles

ActiveUS8979102B1Reduce air resistanceLower the volumeVehicle seatsVehicle body stabilisationSupporting systemAerodynamic drag

A retractable wheel fairing device for decreasing the aerodynamic drag and / or increasing downforce of a vehicle is described. The device includes a fairing body with a suspension-mounted support system such that the fairing body, when deployed, reciprocates up and downwardly with the corresponding wheel of the vehicle. The suspension-mounted support system is adapted to functionally or physically disengage the wheel fairing device from the suspension of the vehicle upon lifting of the wheel fairing device with a separate retraction system.

Owner:PRENTICE MICHAEL

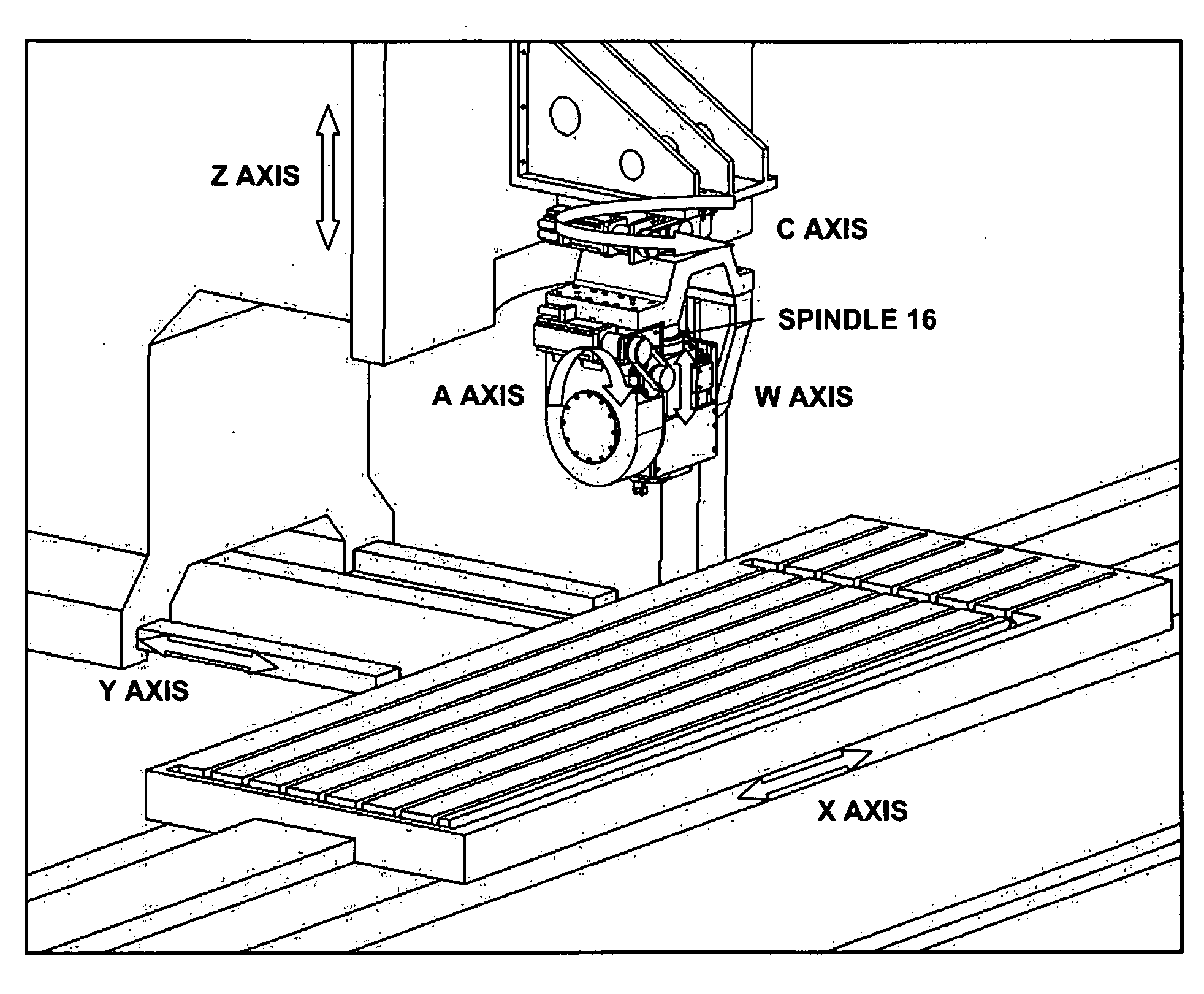

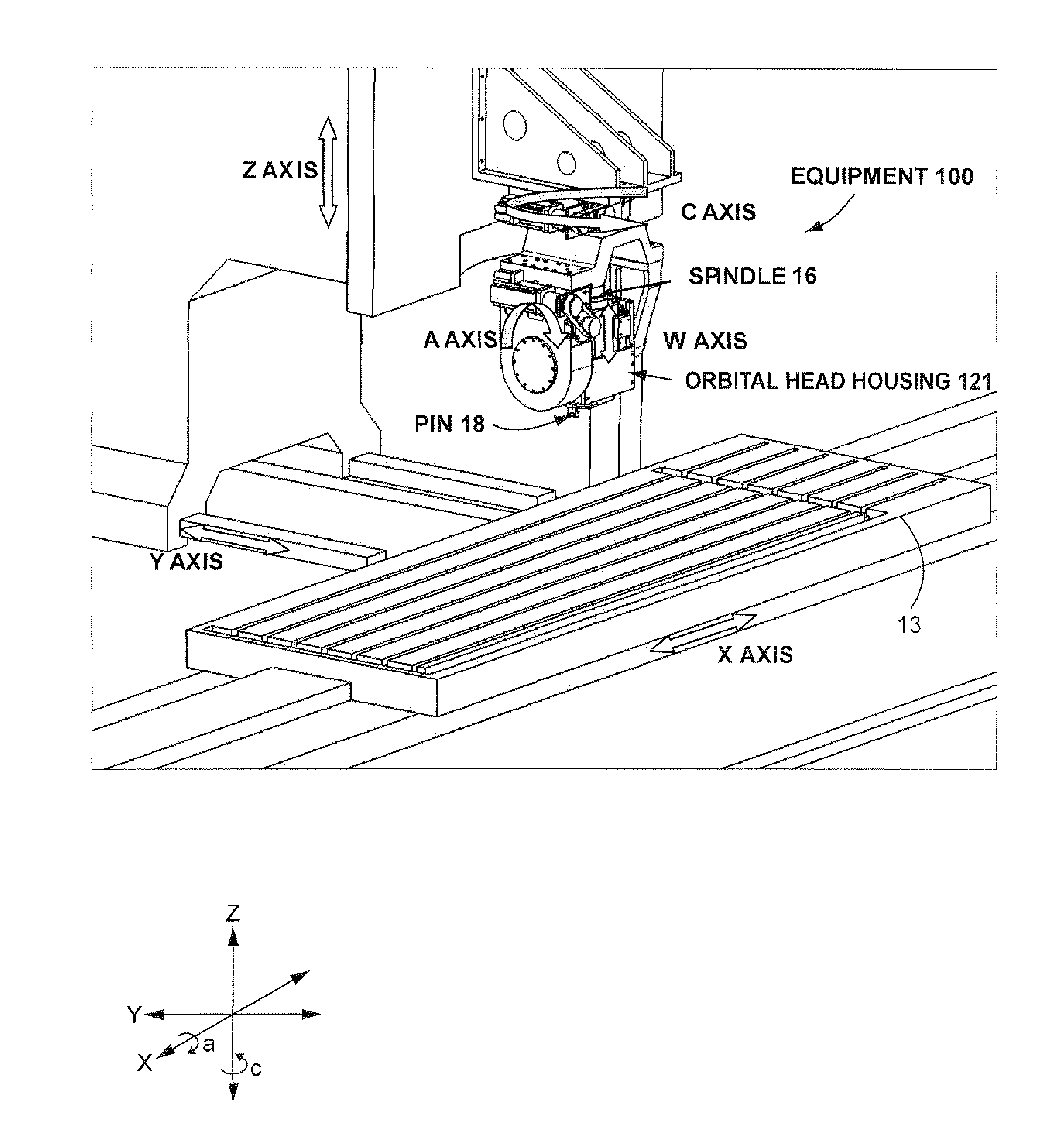

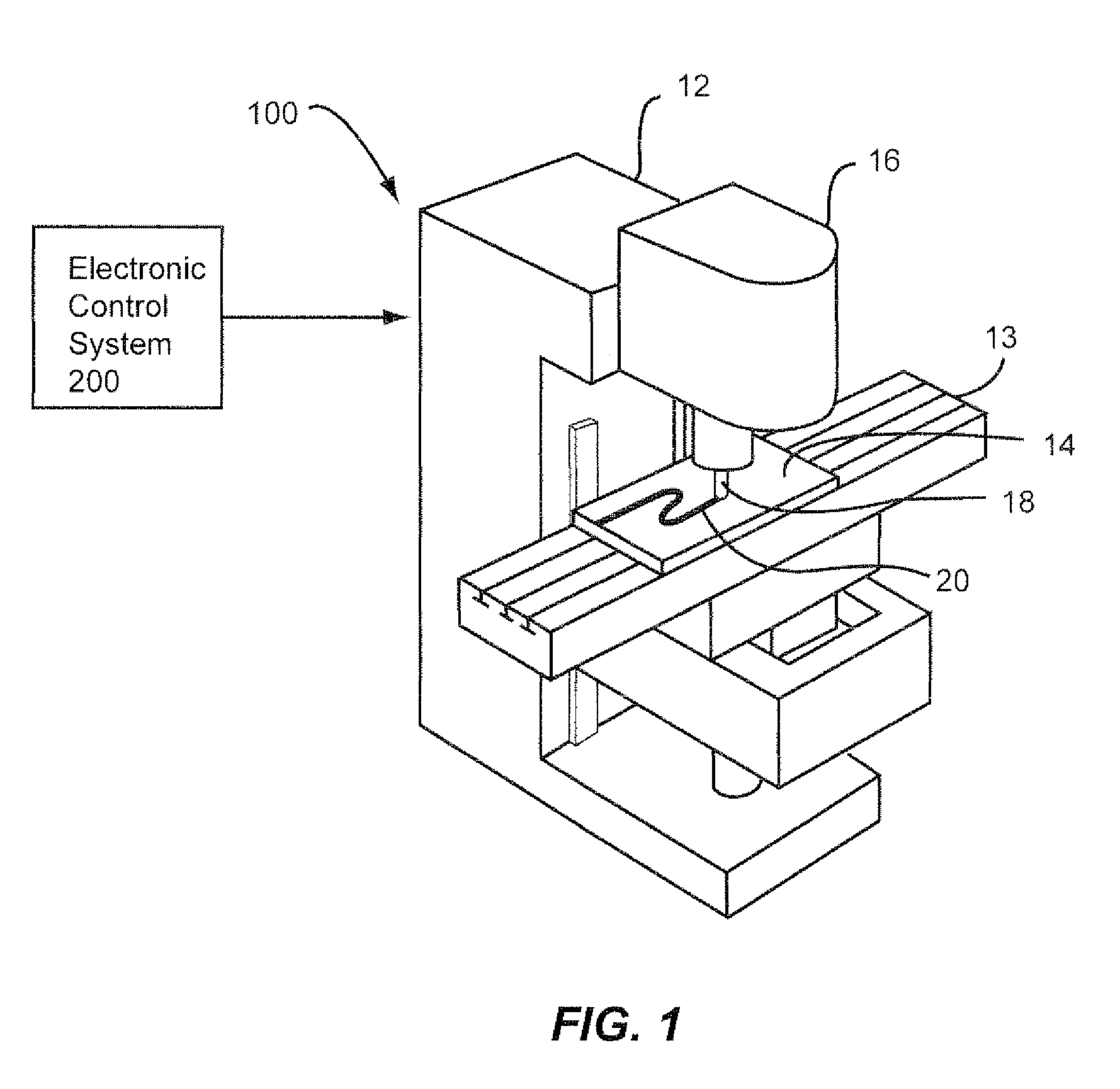

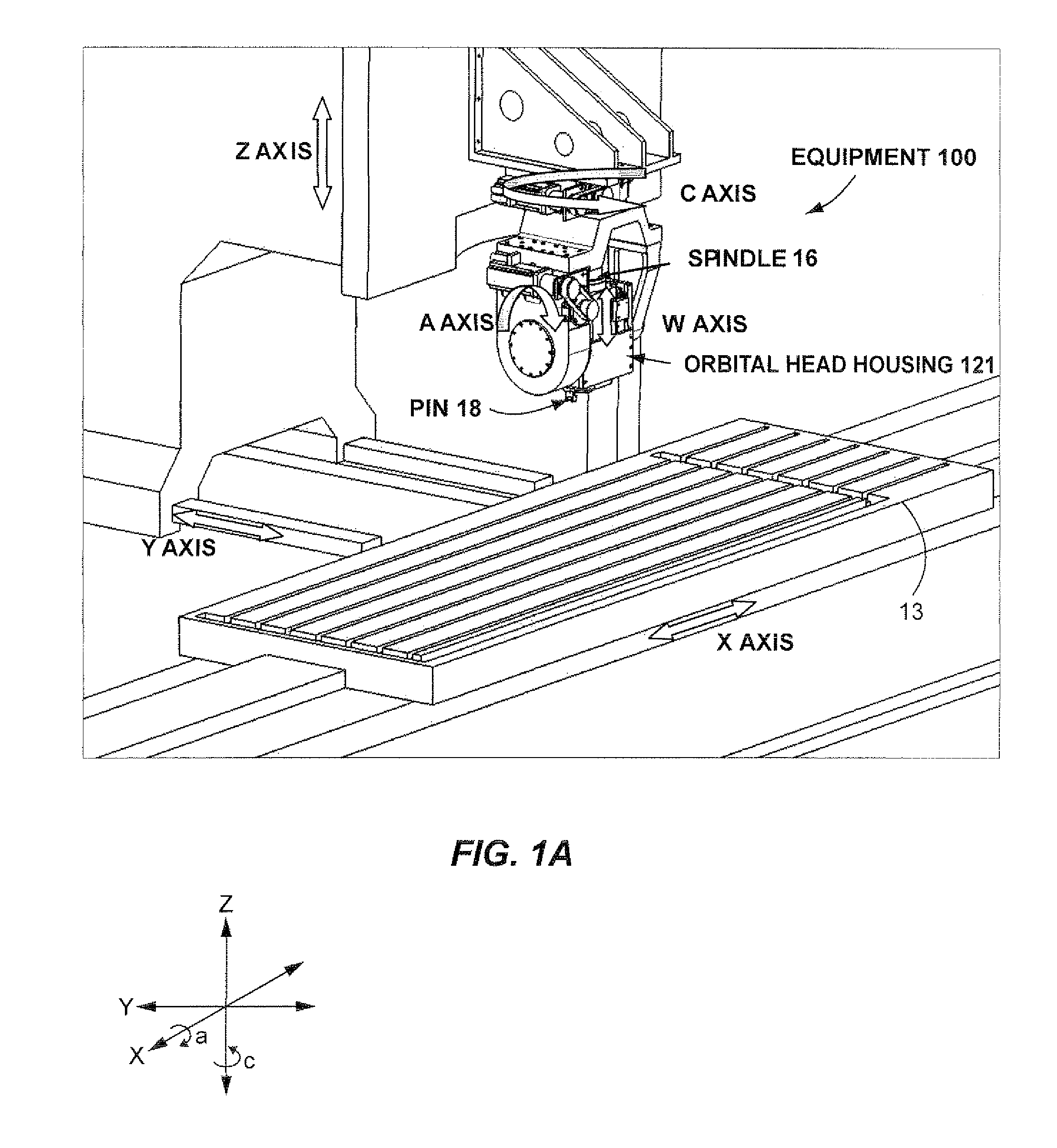

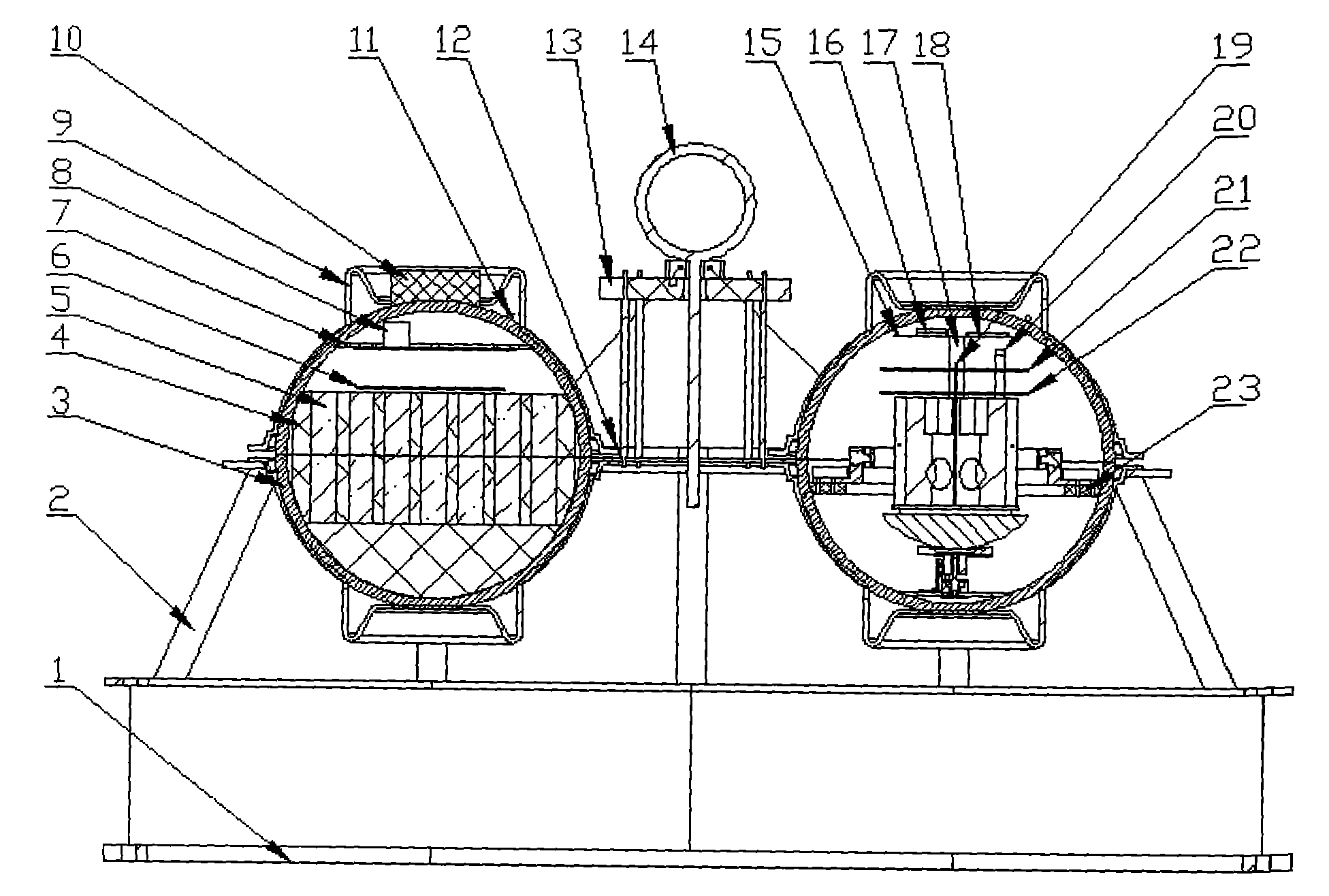

Friction stir welding spindle downforce and other control techniques, systems and methods

InactiveUS20100072261A1Welding/cutting auxillary devicesAuxillary welding devicesElectricityButt joint

Friction stirred welding equipment, developed according to requirements of high reliability, robustness, precision and low cost, weld lap and butt joints in complex surfaces with fixed pin tool under controlled downforce. Exemplary equipment comprises a control force orbital spindle, wherein a coaxial sensor measures the downforce and simultaneously the axial electrical actuator corrects axial tool position along the welding, by a direct axial force system control, in order to maintain controlled downforce according to previously set parameters. The equipment sets up, monitors and controls the spindle rotation speed, welding speed, acceleration speed and downforce and can record in a database the downforce and tool welding position during the welding. The exemplary equipment may also comprise a laser system that scans the backing surface before welding and corrects original tool path, in order to provide an offset tool path and precision alarm system to get a safe welding, avoiding tool collision with the backing.

Owner:EMBRAER SA

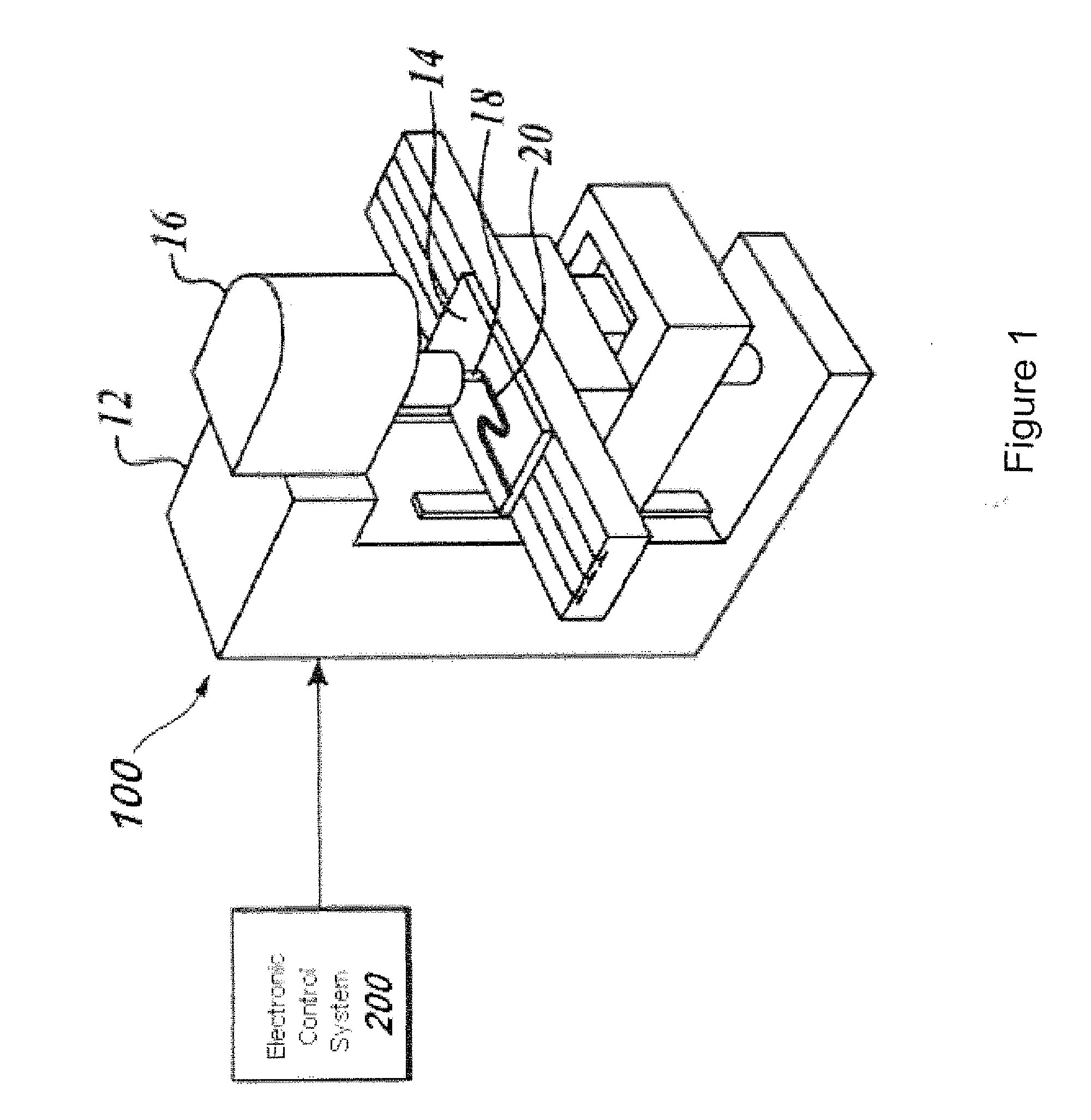

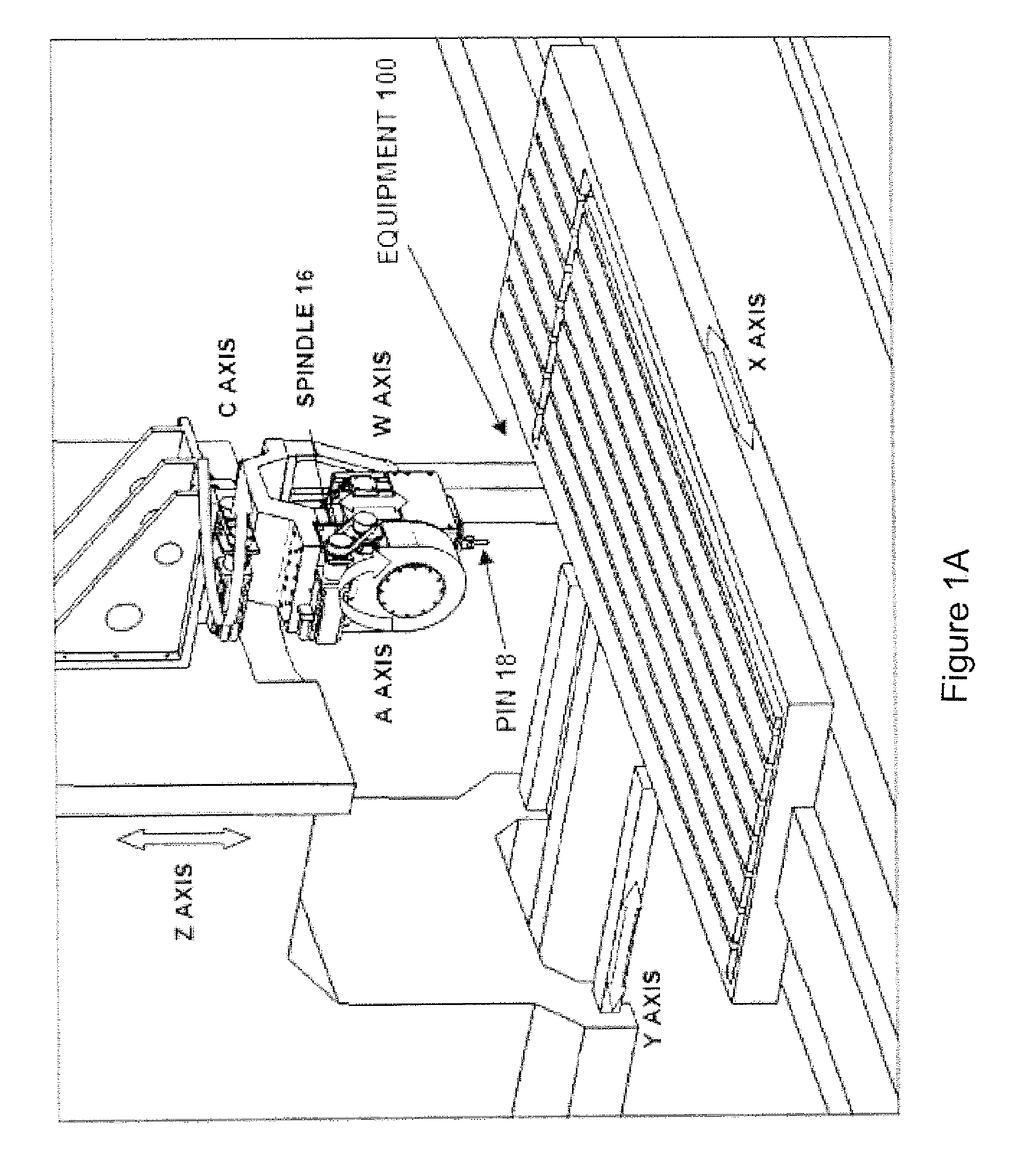

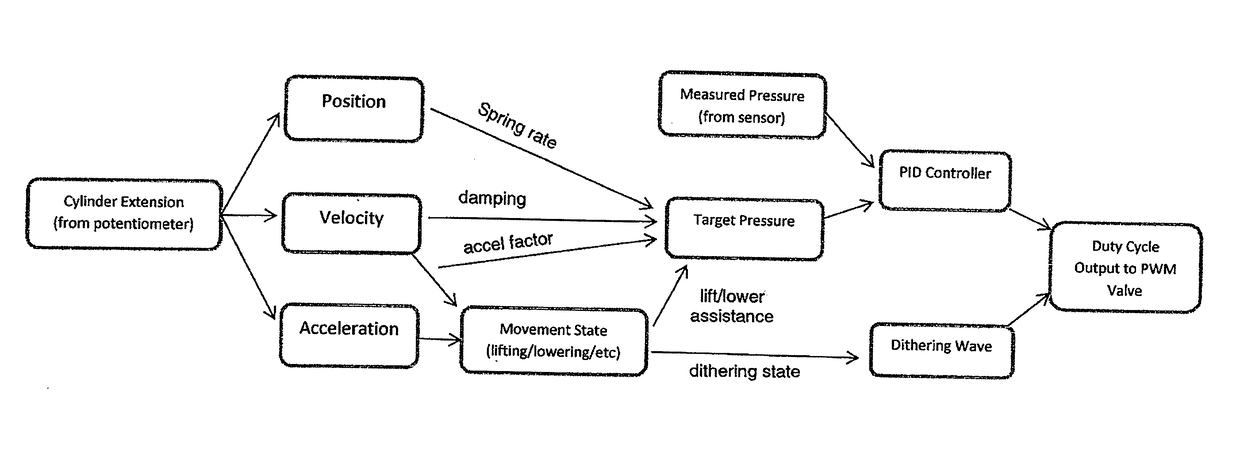

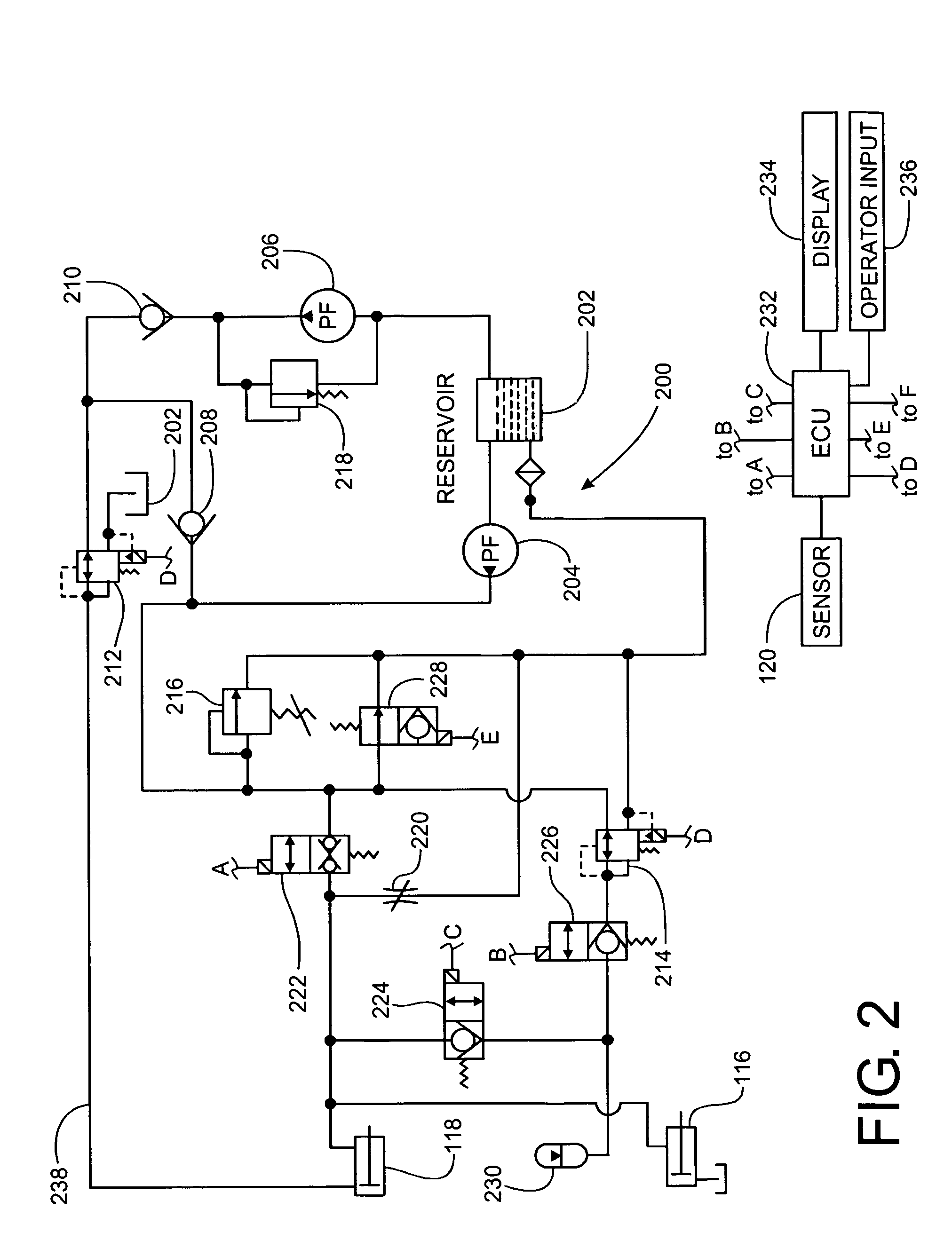

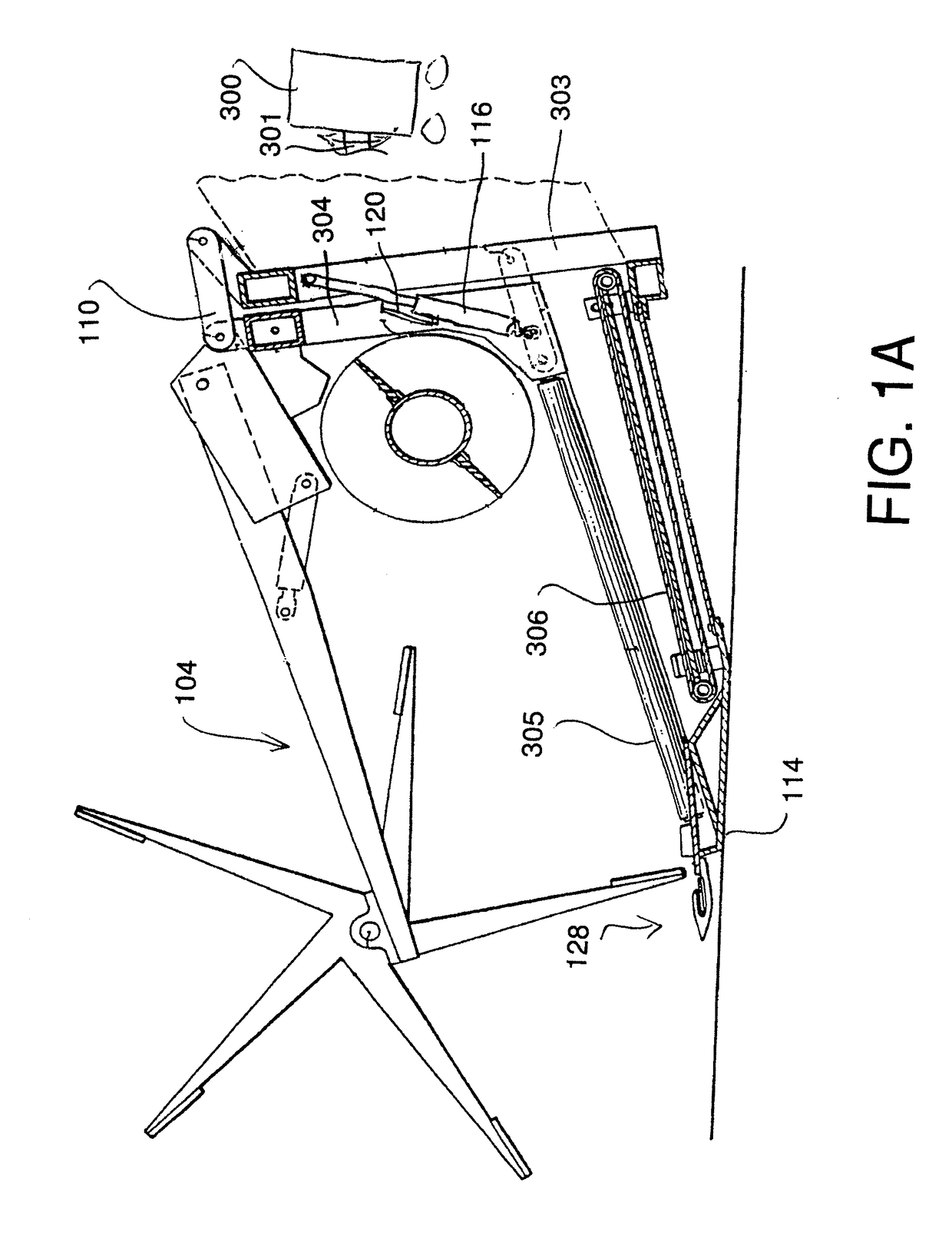

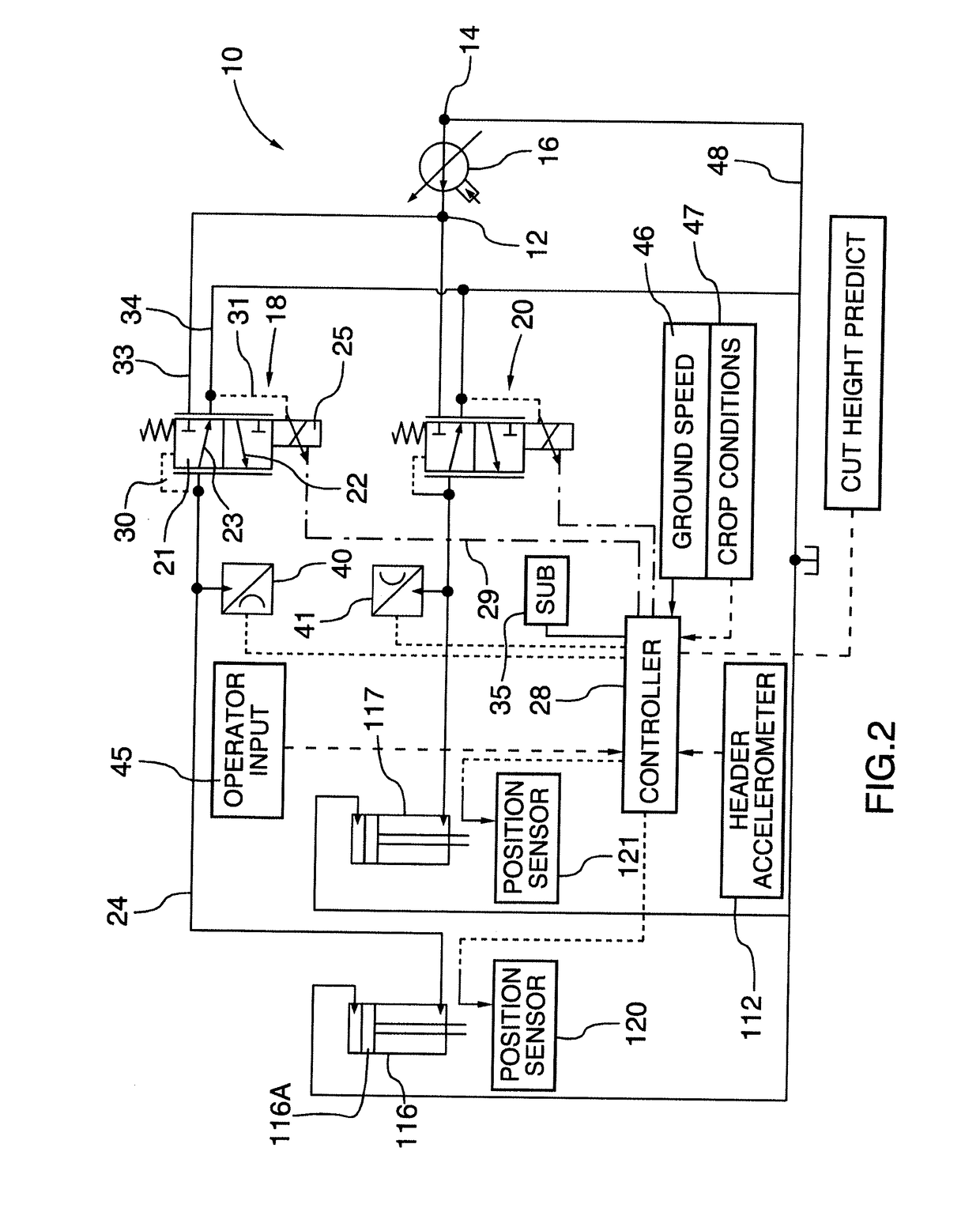

Crop Machine with an Electronically Controlled Hydraulic Cylinder Flotation System

ActiveUS20180153102A1Improve responseReduce lifting forceAgricultural machinesServomotor componentsHydraulic cylinderControl signal

A header is supported by a pair of hydraulic float cylinders, where a float pressure to the cylinders is directly controlled by an electronic control supplying a variable control signal to a PPRR valve arrangement to maintain the float pressure at a predetermined value. At the set pressure a predetermined lifting force is provided to the header. A position sensor is used to generate an indication of movement and / or acceleration and / or velocity. The electronic control is arranged, in response to changes in the sensor signal, to temporarily change the control signal to vary the lifting force and thus change the dynamic response of the hydraulic float cylinder. A lift force greater than that required to lift the header can be provided by a lift cylinder and can be opposed in a controlled manner to apply a controlled downforce by the back of the same cylinder or by a separate component.

Owner:MACDON INDS

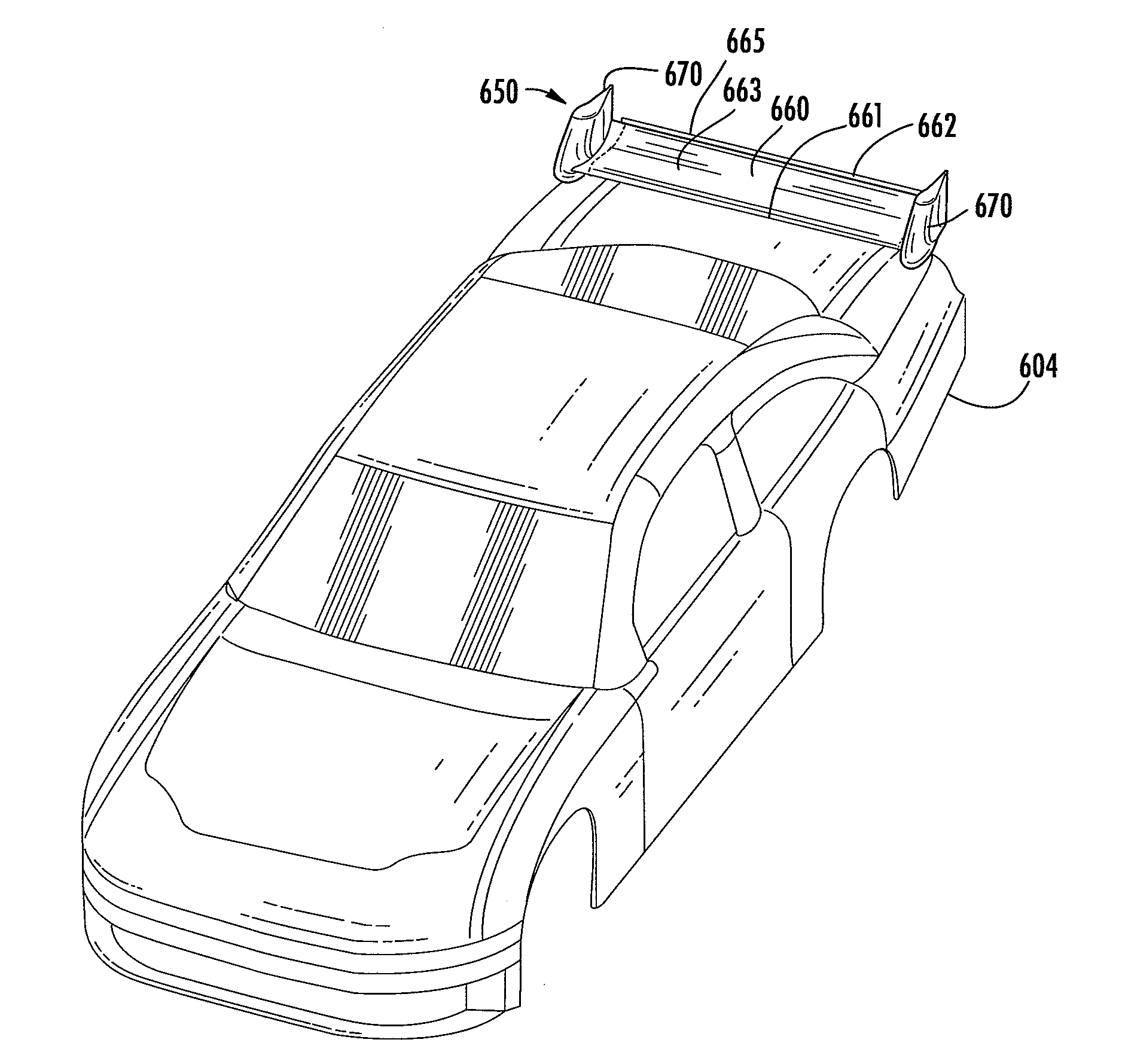

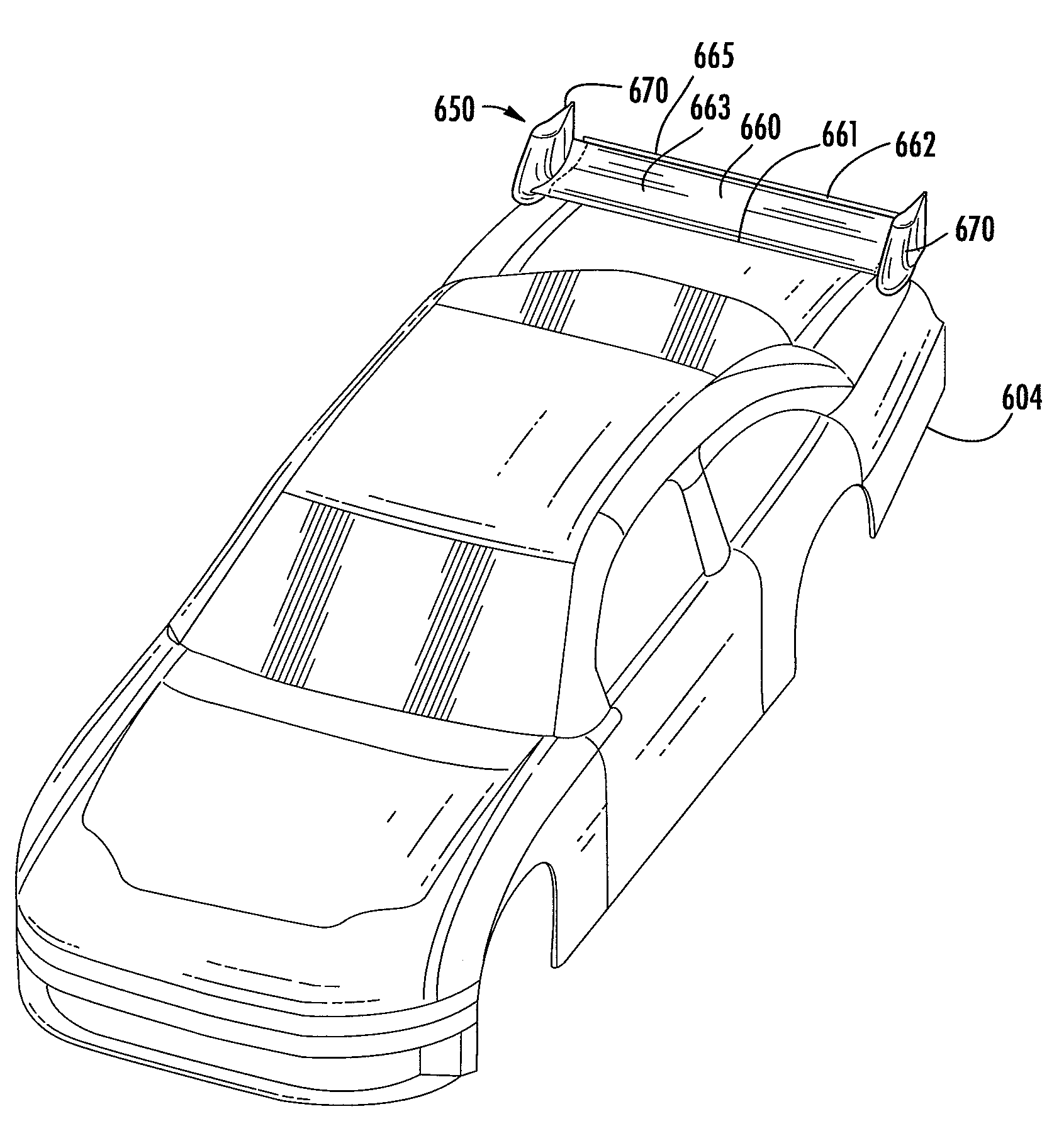

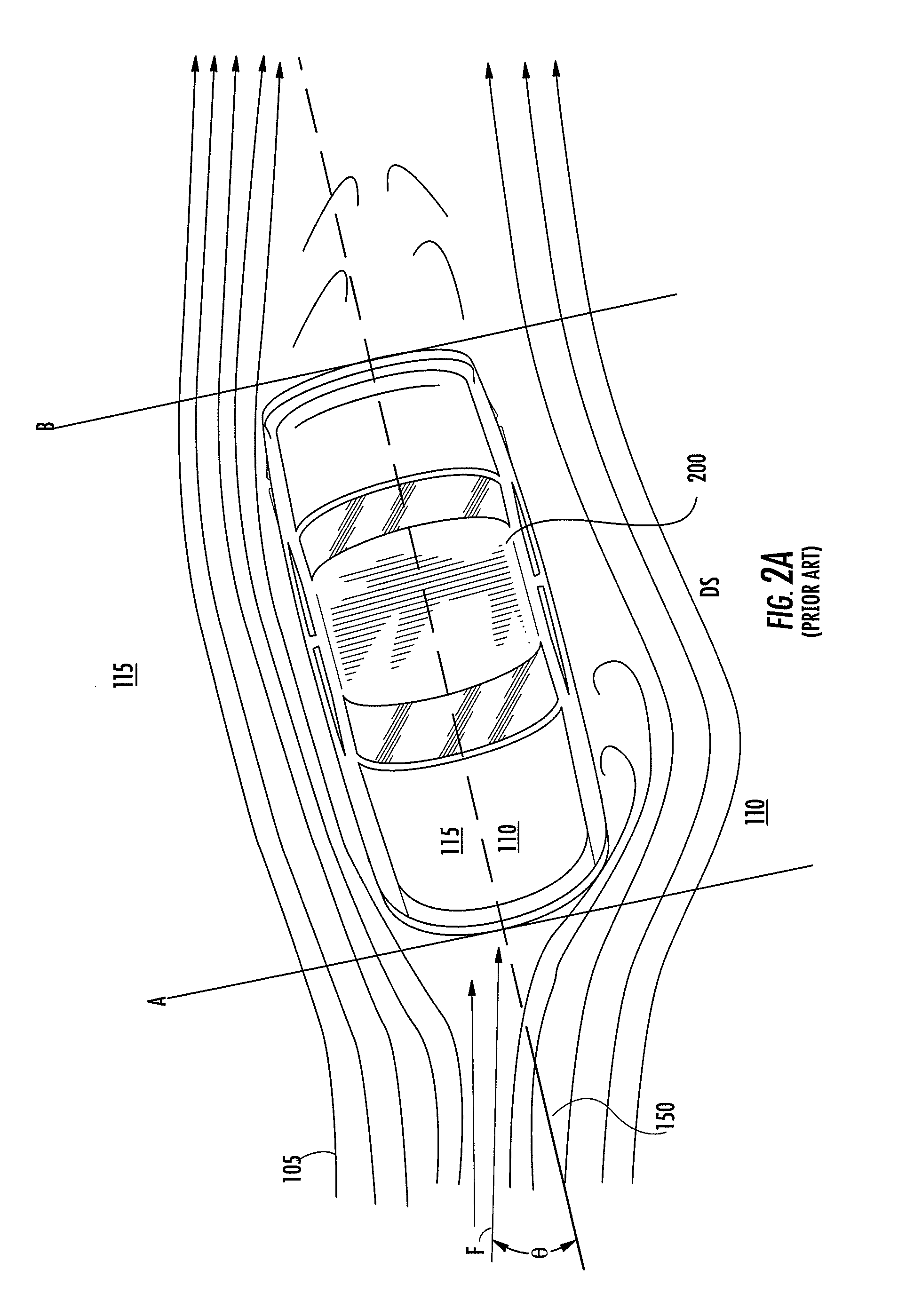

Air deflecting system for automobiles

Various embodiments of the present invention are directed to an air deflecting system positioned on an automobile and configured to produce an increased side force and / or a more favorable yawing moment when the automobile is cornering or is otherwise yawed relative to the direction of the free stream air flow. In one exemplary embodiment, the deflecting system comprises a downforce-producing horizontal rear wing located proximate the rear end of the automobile, the rear wing having an endplate on each end. In one embodiment, the endplates are angled or have cambered airfoil cross-sections such that they each generate an aerodynamic force towards the inside of a turn when the automobile is cornering.

Owner:NAT ASSOC FOR STOCK CAR AUTO RACING

Friction stir welding spindle downforce and other control techniques, systems and methods

ActiveUS20110079339A1Avoid oscillationPrecise positioningWelding/cutting auxillary devicesFeeding apparatusNumerical controlElectricity

Friction stir welding equipment control force spindle for mounting in an orbital head housing uses a coaxial sensor to measure downforce. Simultaneously, an axial electrical actuator is controlled to dynamically correct the axial tool position during the welding, by a direct axial force system control, in order to maintain controlled downforce according to parameters previously set, based on numerical control. The equipment also sets up, monitors and controls spindle rotation speed, welding speed, acceleration speed and downforce using for example closed loop control functions. A laser system may scan the backing surface before welding and correct original tool path, in order to get an offset tool path. A precision alarm system may provide safe welding while preventing the tool from colliding with the backing surface.

Owner:EMBRAER SA

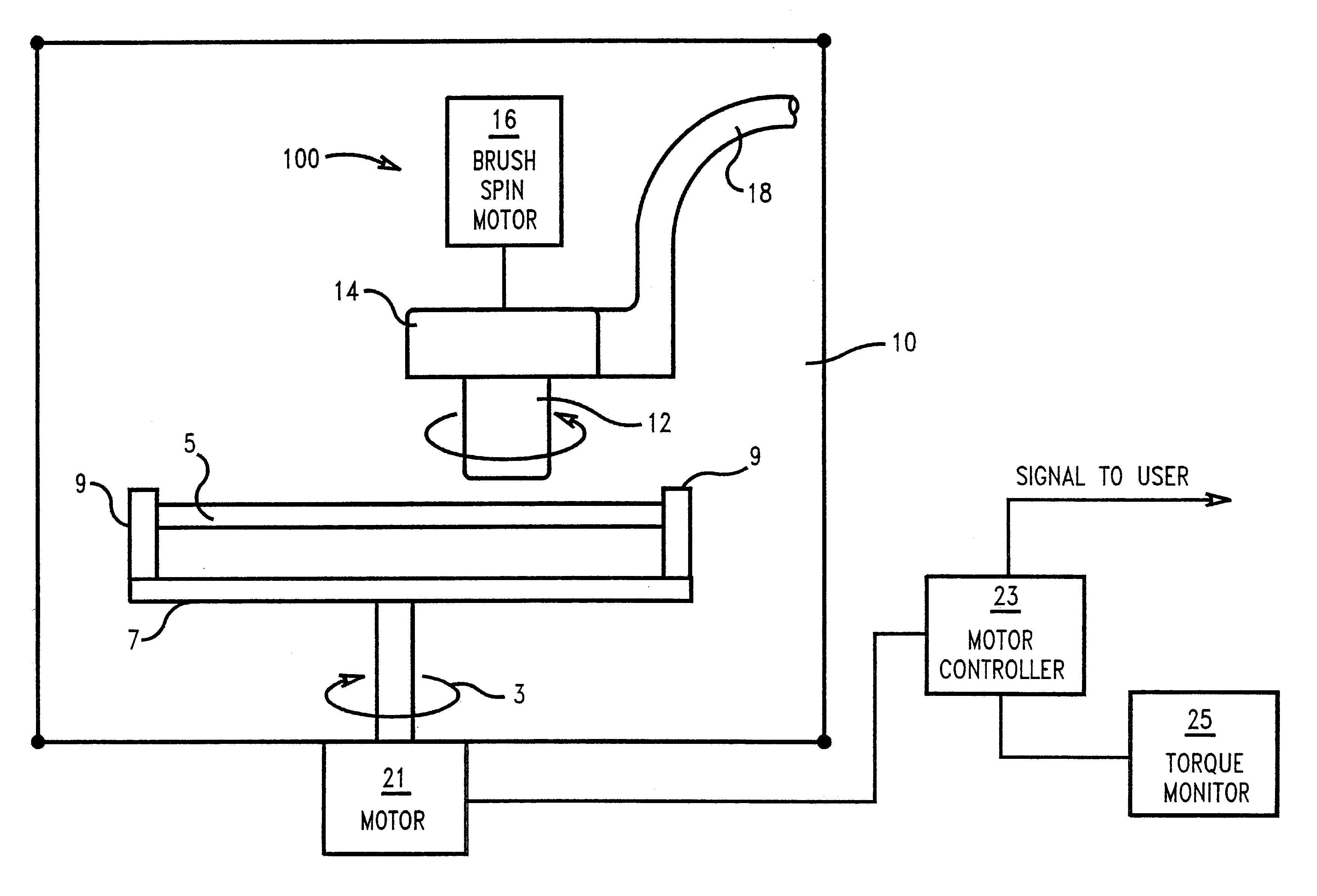

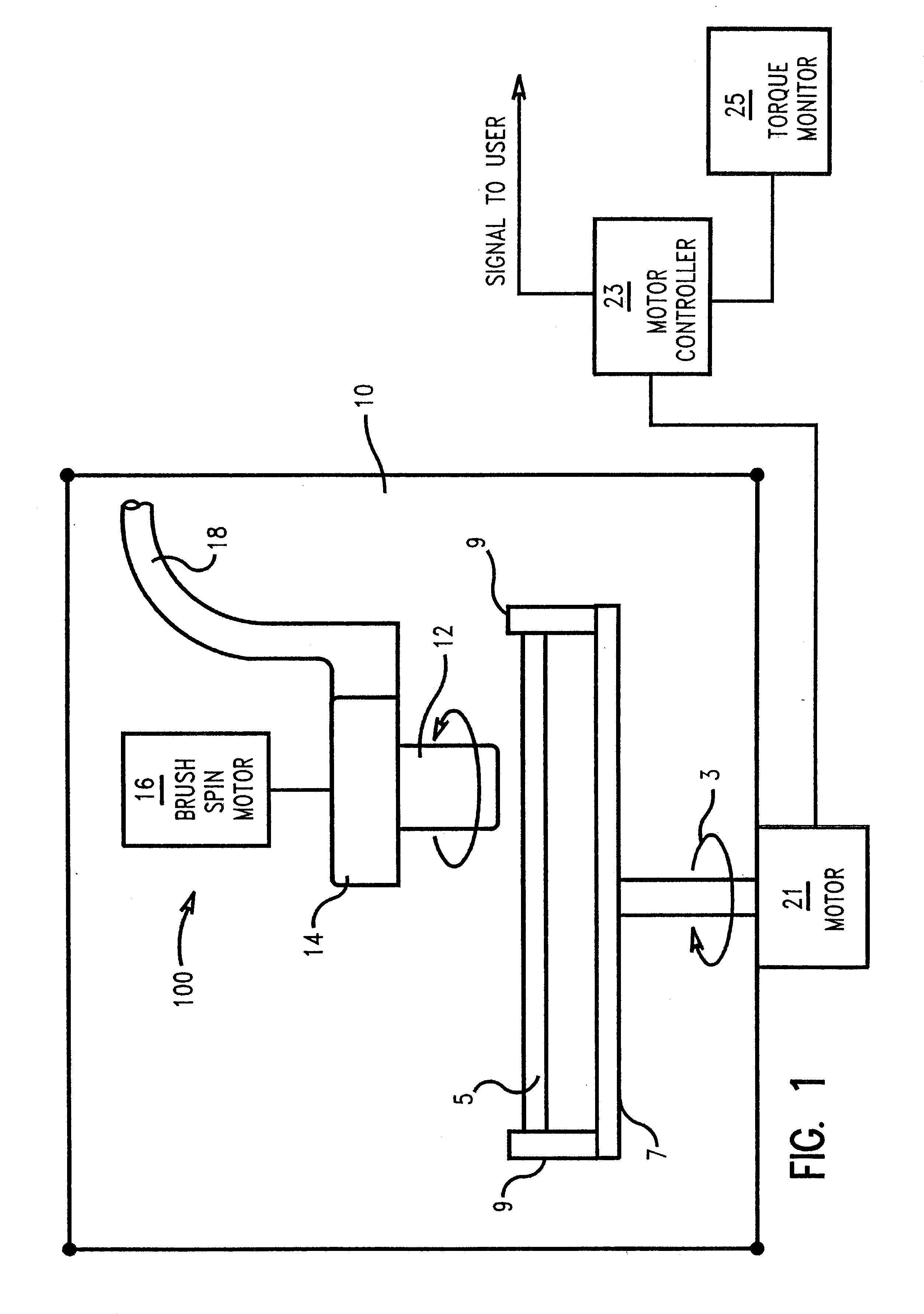

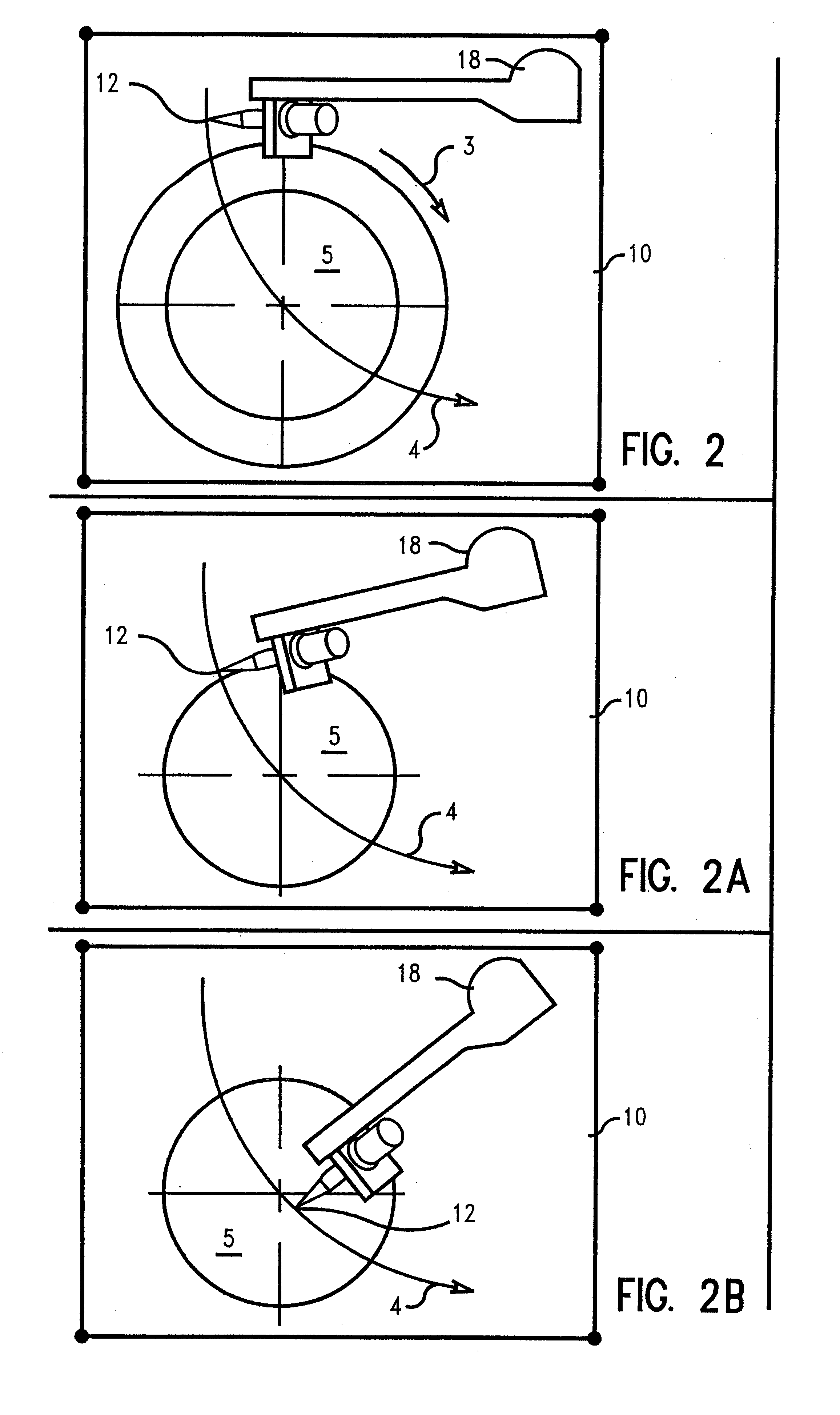

Post CMP clean brush with torque monitor

An apparatus for and method of detecting the presence of a brush used in a semiconductor wafer cleaner for post-CMP processing is described. Semiconductor wafers are loaded into the wet environment of the wafer cleaner, affixed to a rotatable fixture and rotated at high speed. The rotatable fixture is effectuated by a servo motor linked to a servo controller and a torque monitor. A first torque on the rotating wafer is calculated prior to the start of the brush cleaning cycle. During the brush cleaning cycle, as the brush within the brush cleaner contacts the rotating wafer, the torque on the wafer increases and a second torque is calculated. If, during the brush cleaning cycle, the second torque calculation is substantially equal to the first torque calculation, the brush cleaner is not contacting the wafer and cleaning has not progressed. A tool user can be notified to reaffix the brush within the cleaner. When the second torque calculation is greater than expected, the tool user can be notified that the brush downforce has been improperly set. Inadequate removal of CMP residue is detected before entire wafer lots have passed through an ineffective brush cleaning cycle prior to an inspection point.

Owner:IBM CORP

Devices for controlling the downforce generated by a vehicle

A vehicle comprising a flap that is attached to the vehicle in such a way as to permit movement of the flap from a first position to a second position, wherein the flap is configured to alter the downforce generated by the vehicle when the vehicle is in motion by affecting the airflow underneath the vehicle, the effect of the flap on the airflow being dependent upon the second position of the flap.

Owner:MCLAREN AUTOMOTIVE

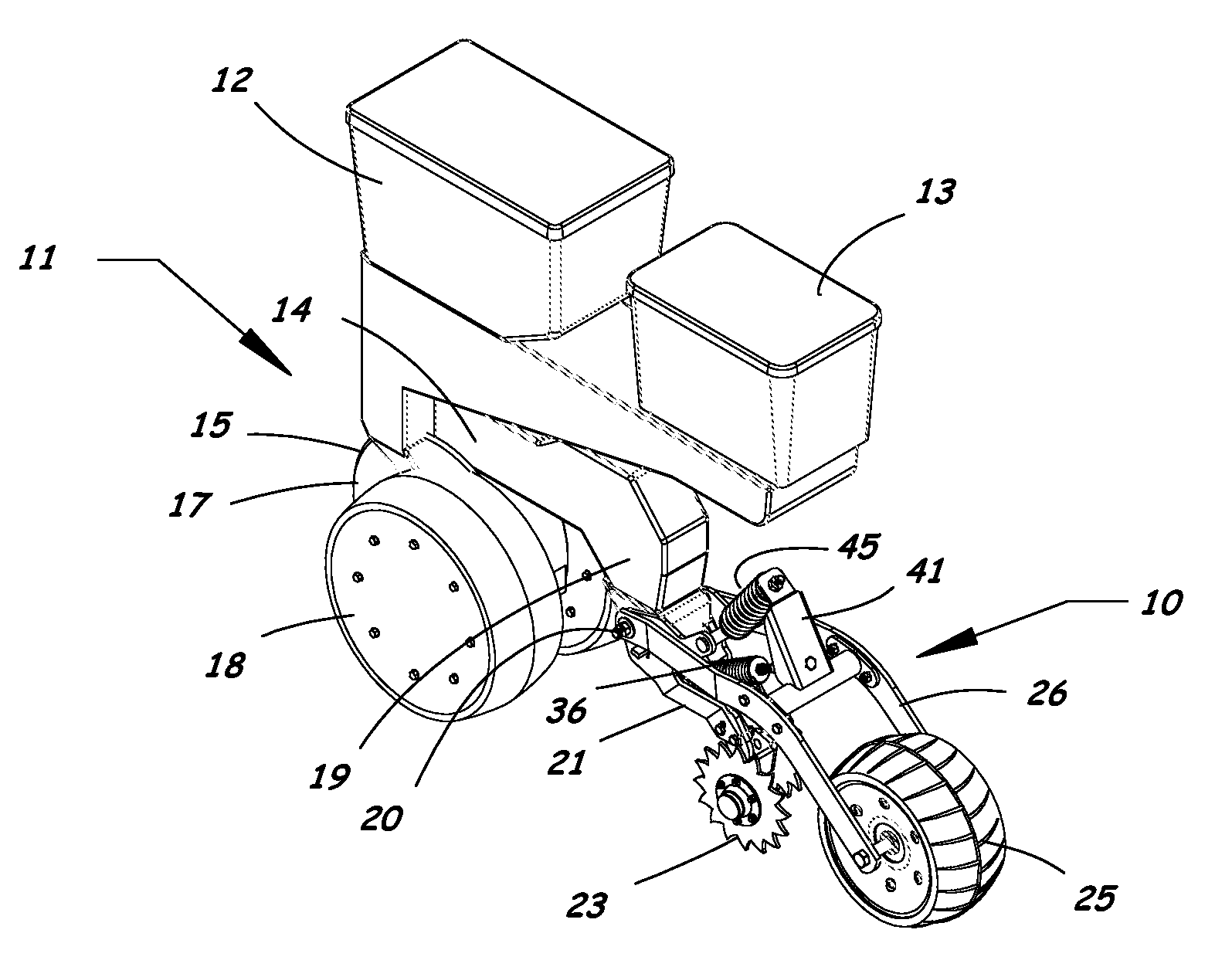

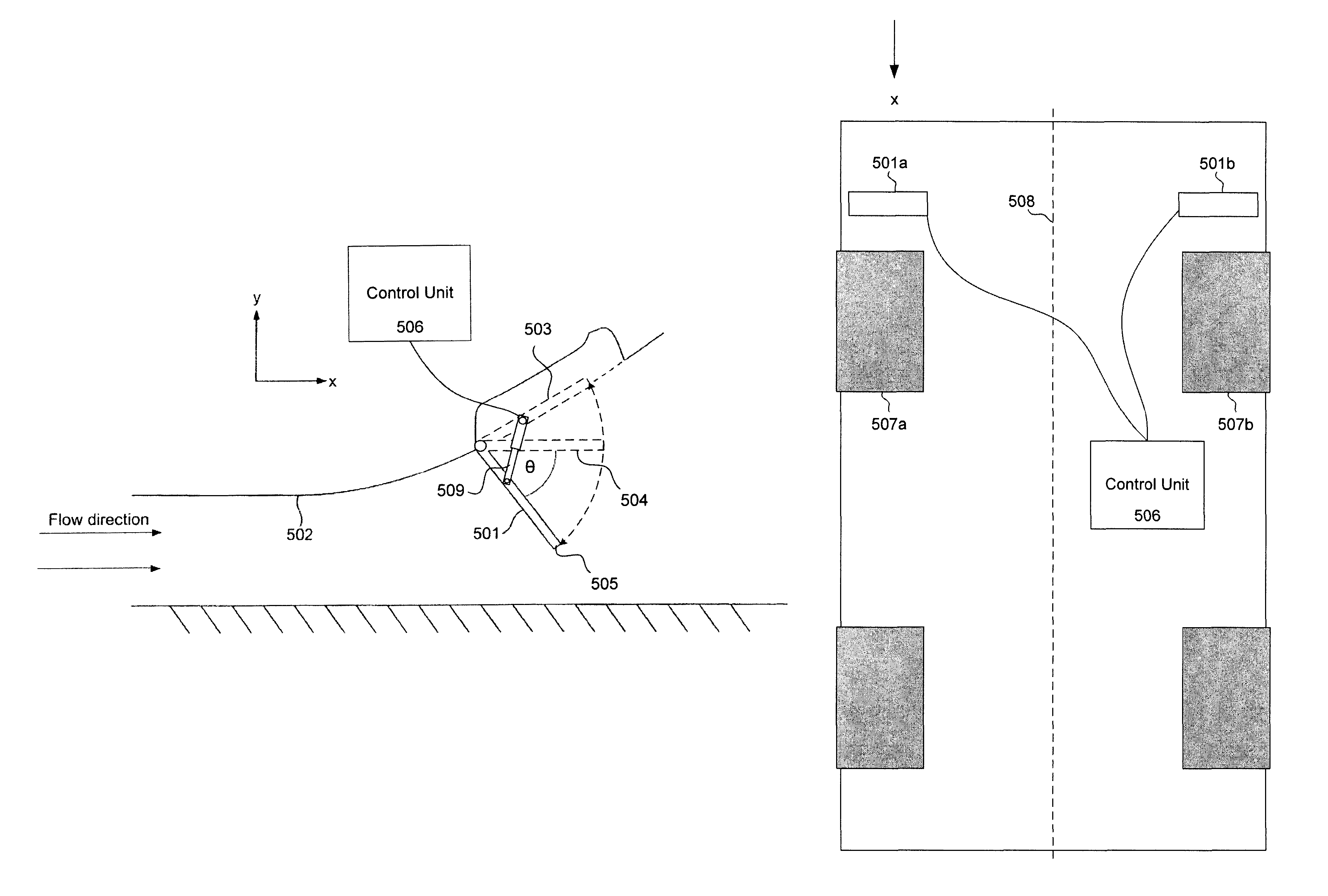

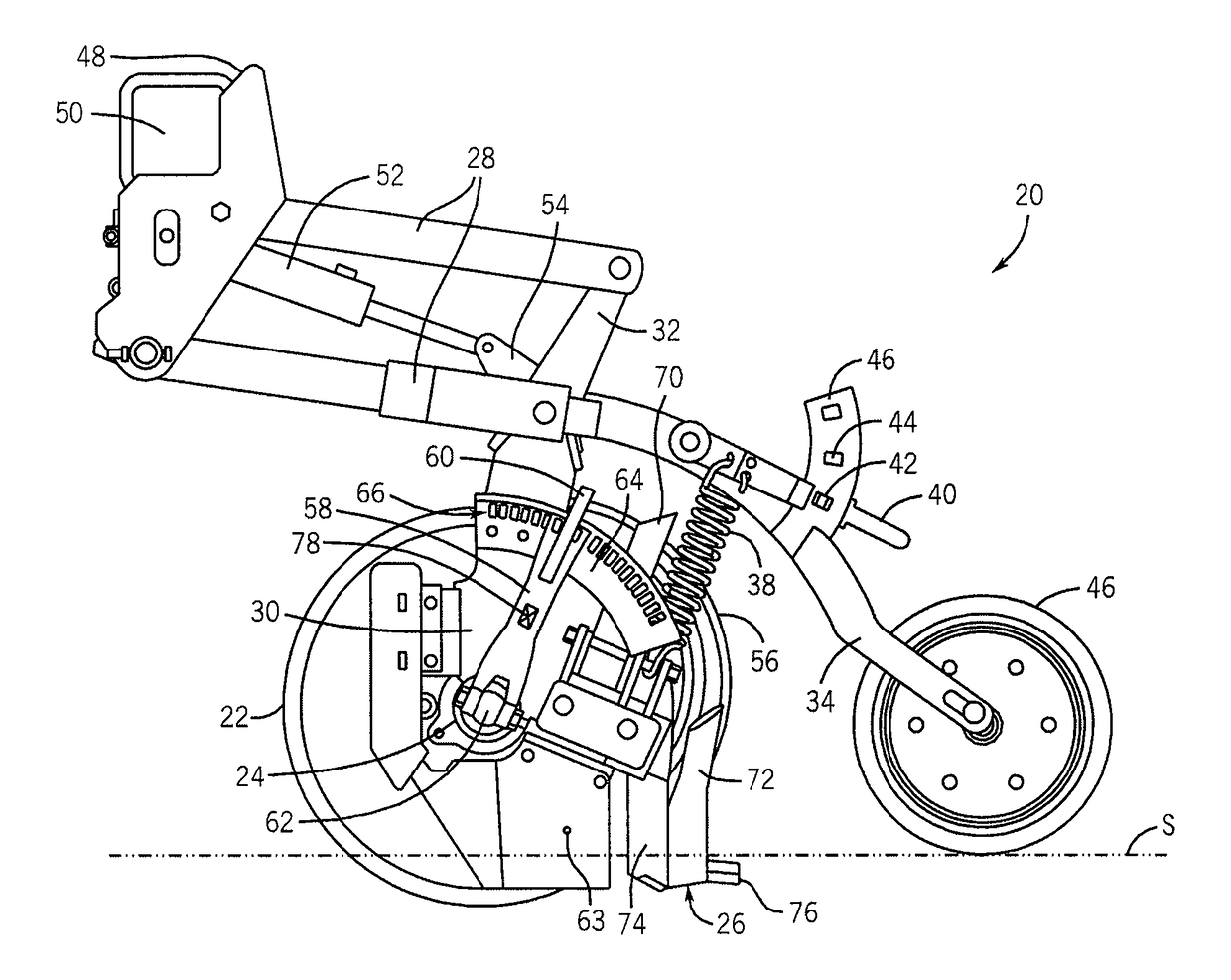

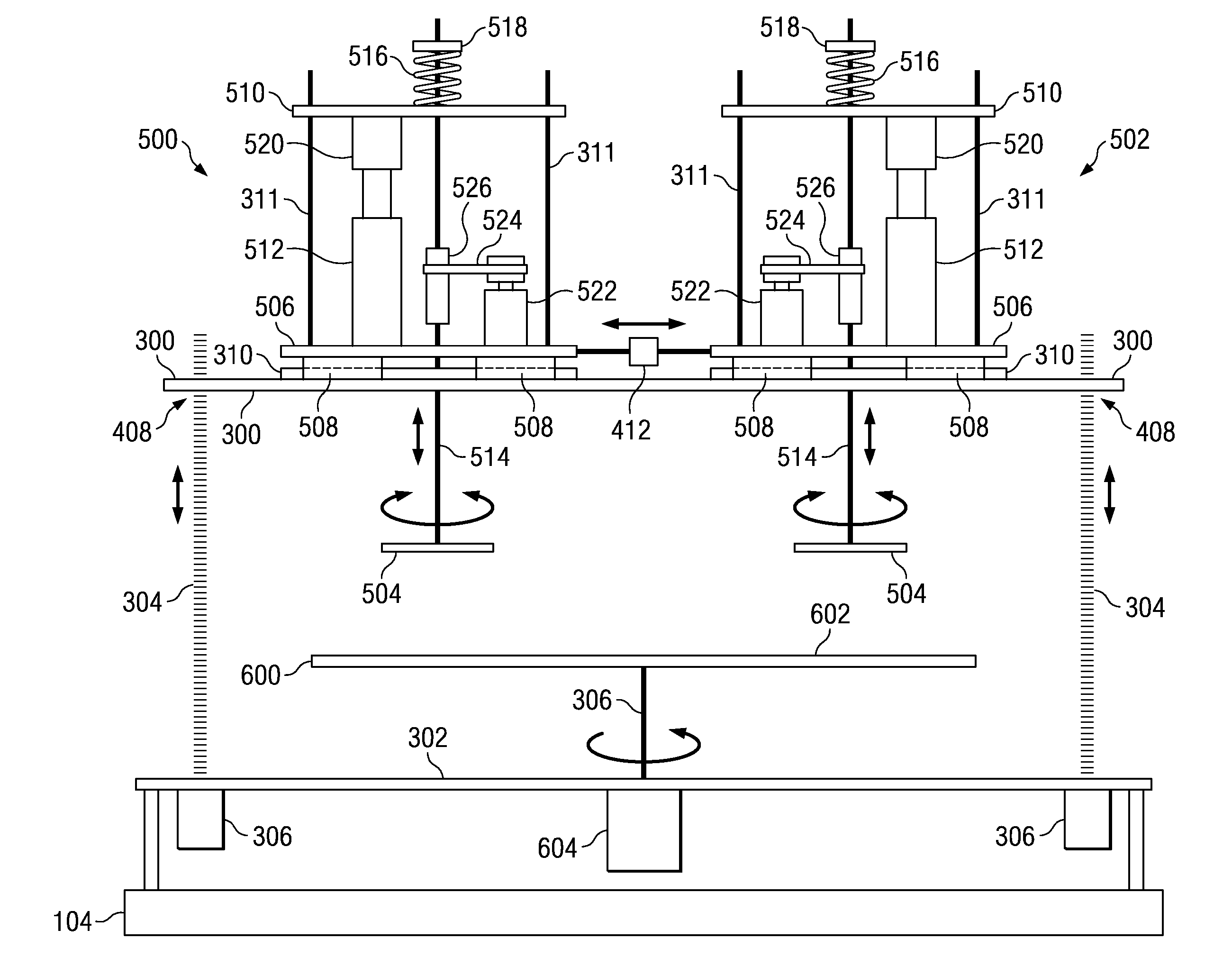

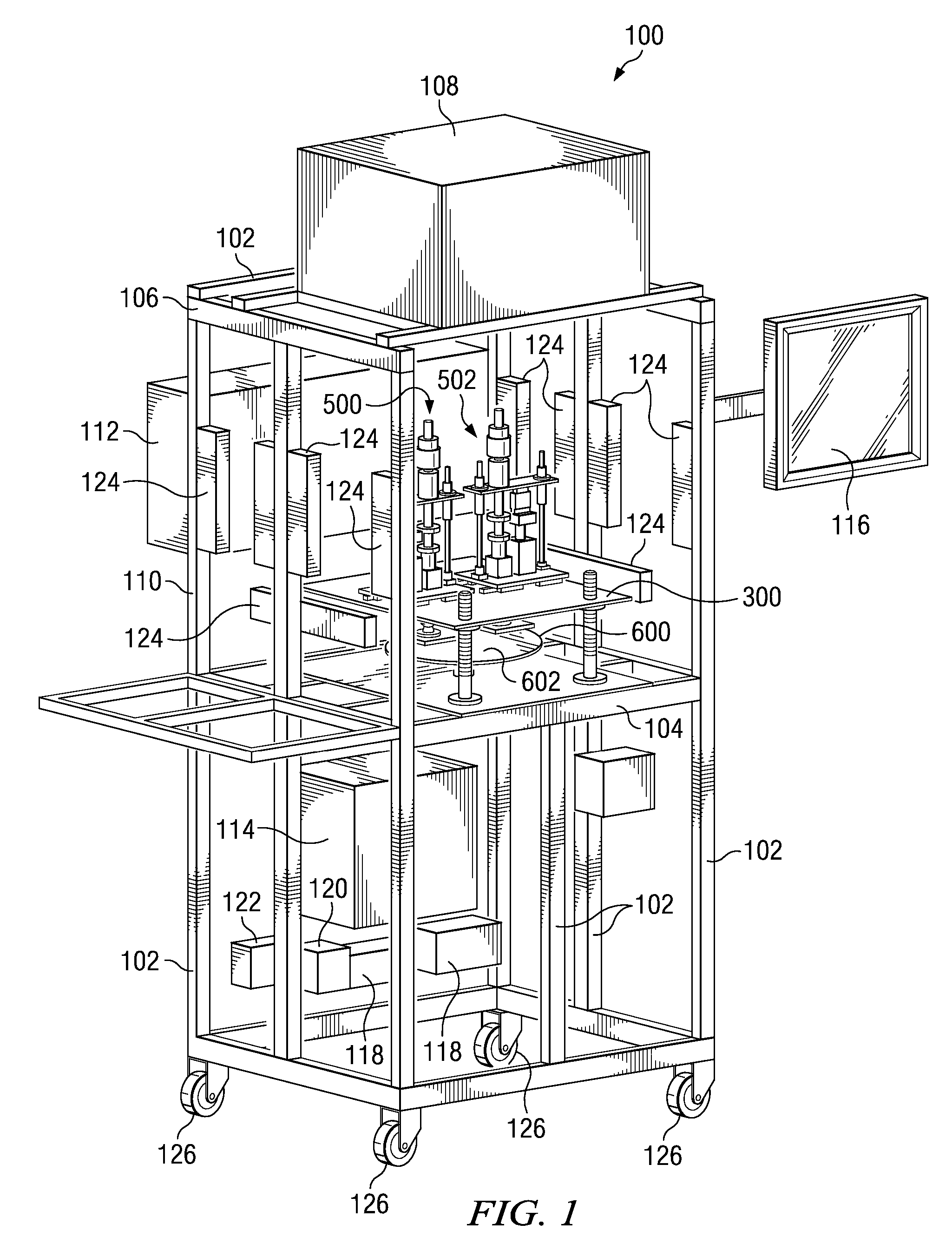

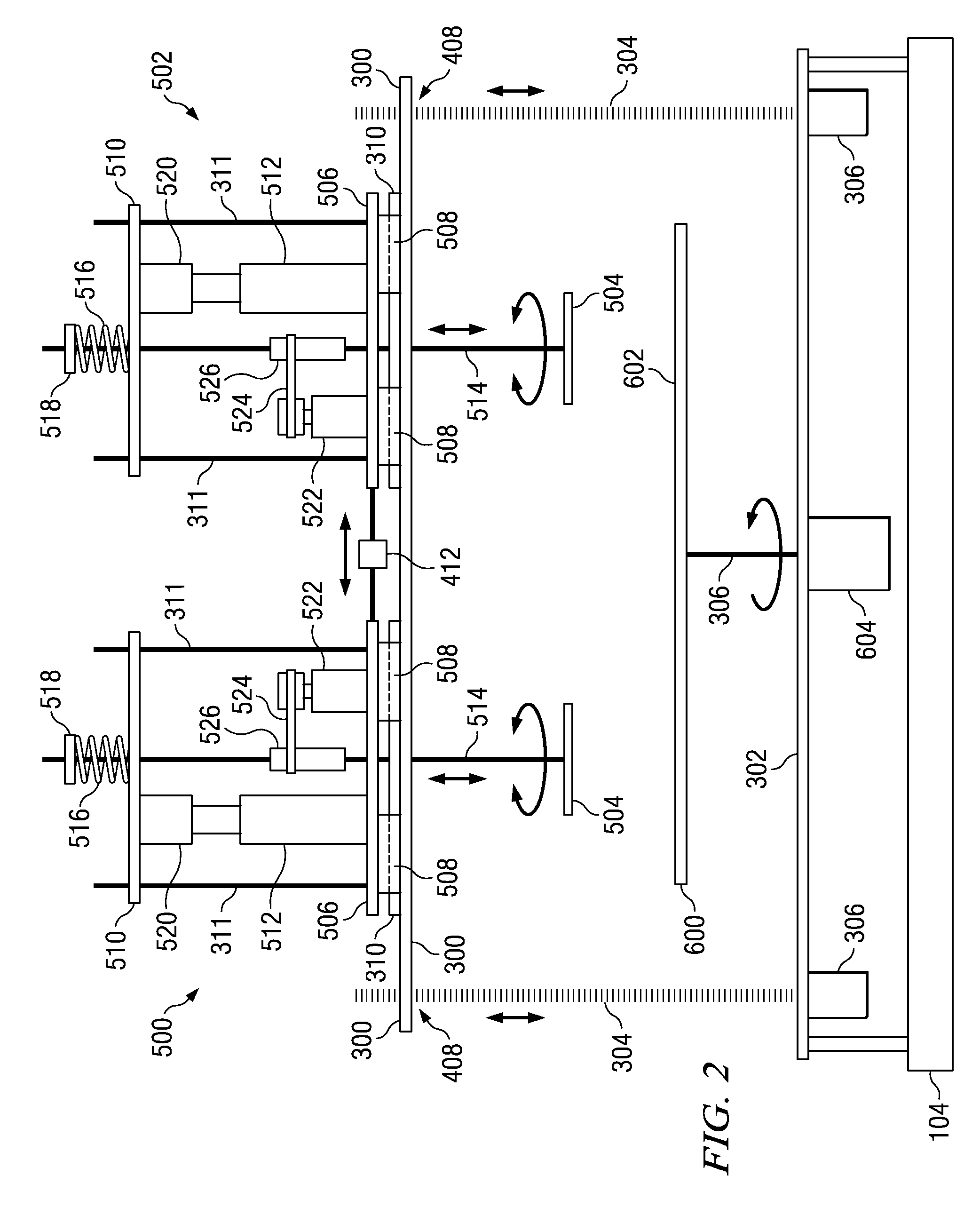

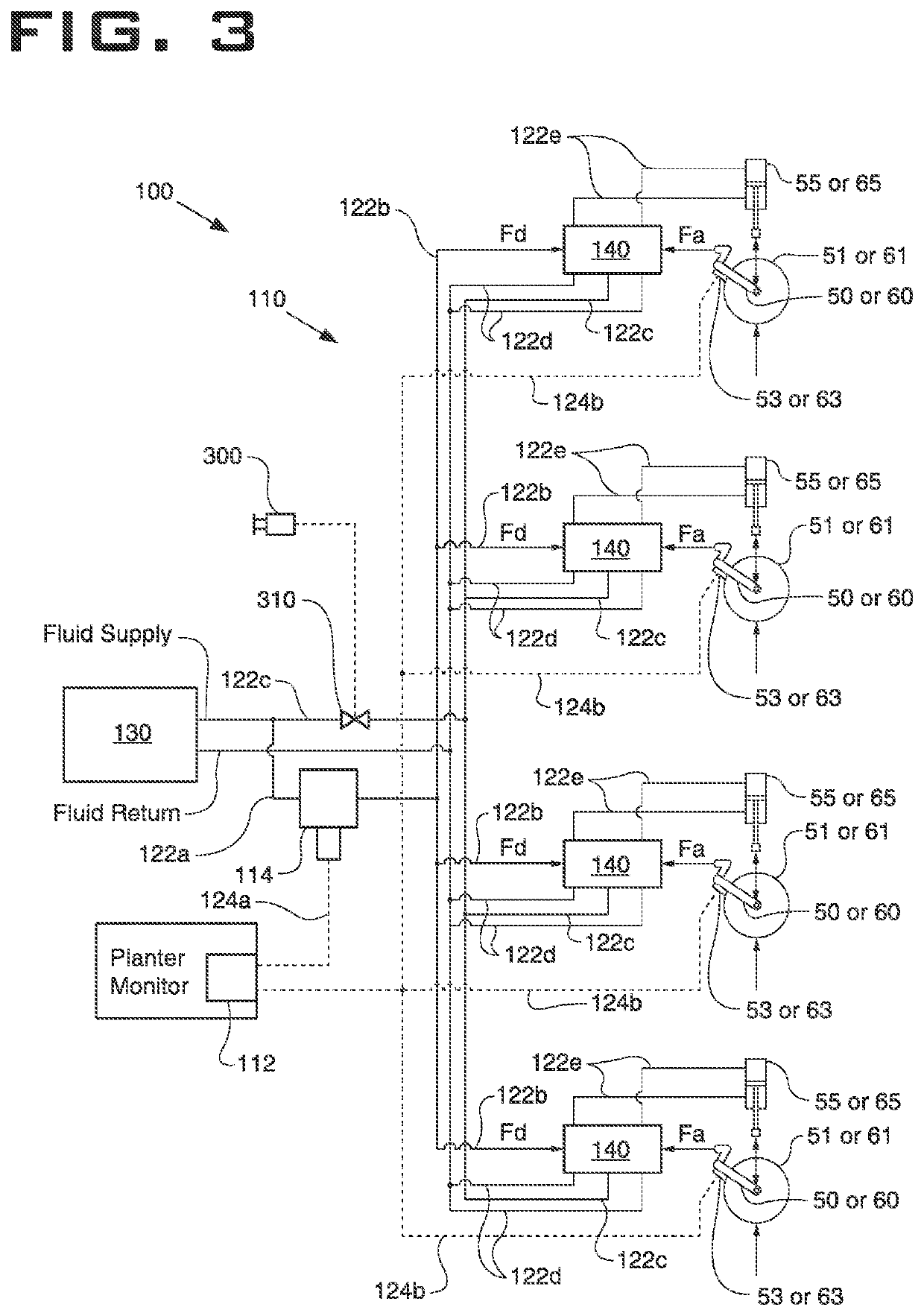

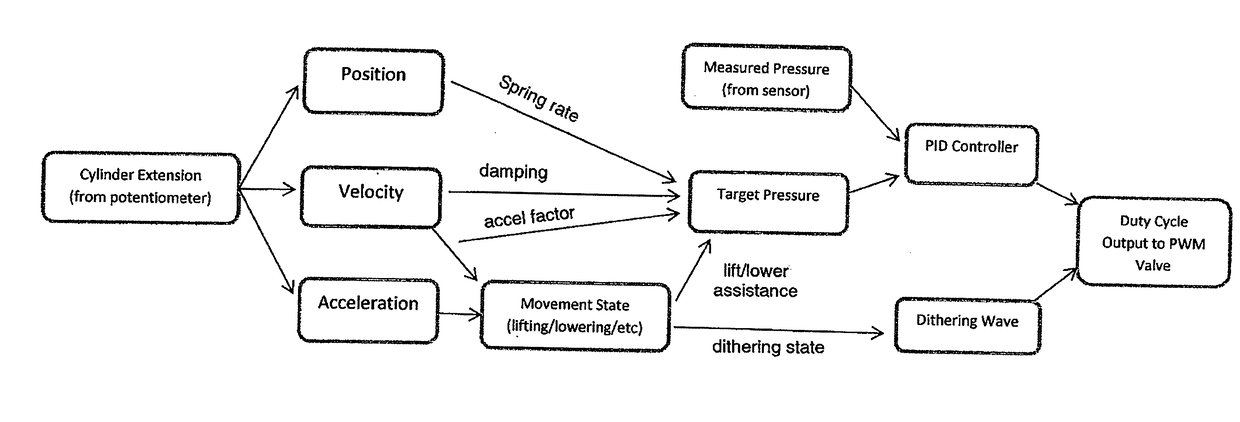

Systems, methods, and apparatus for controlling downforce of an agricultural implement

ActiveUS20190183036A1Maintain depthLittle strengthAgricultural machinesPlantingEngineeringUser defined

A downforce system adjusts the amount of downforce being applied to a row unit of an agricultural implement. The downforce system is controlled to increase or decrease the force on the row unit. A load is sensed at the row unit and compared to either or both of a user defined target and a lower threshold that can be based, at least in part, upon a percentage of a value. When the load is determined to be below the lower threshold, the user defined amount is increased at a rate of change until the load is above the threshold, at which point the increase is stopped, and reduced, if necessary.

Owner:KINZE MFG INC

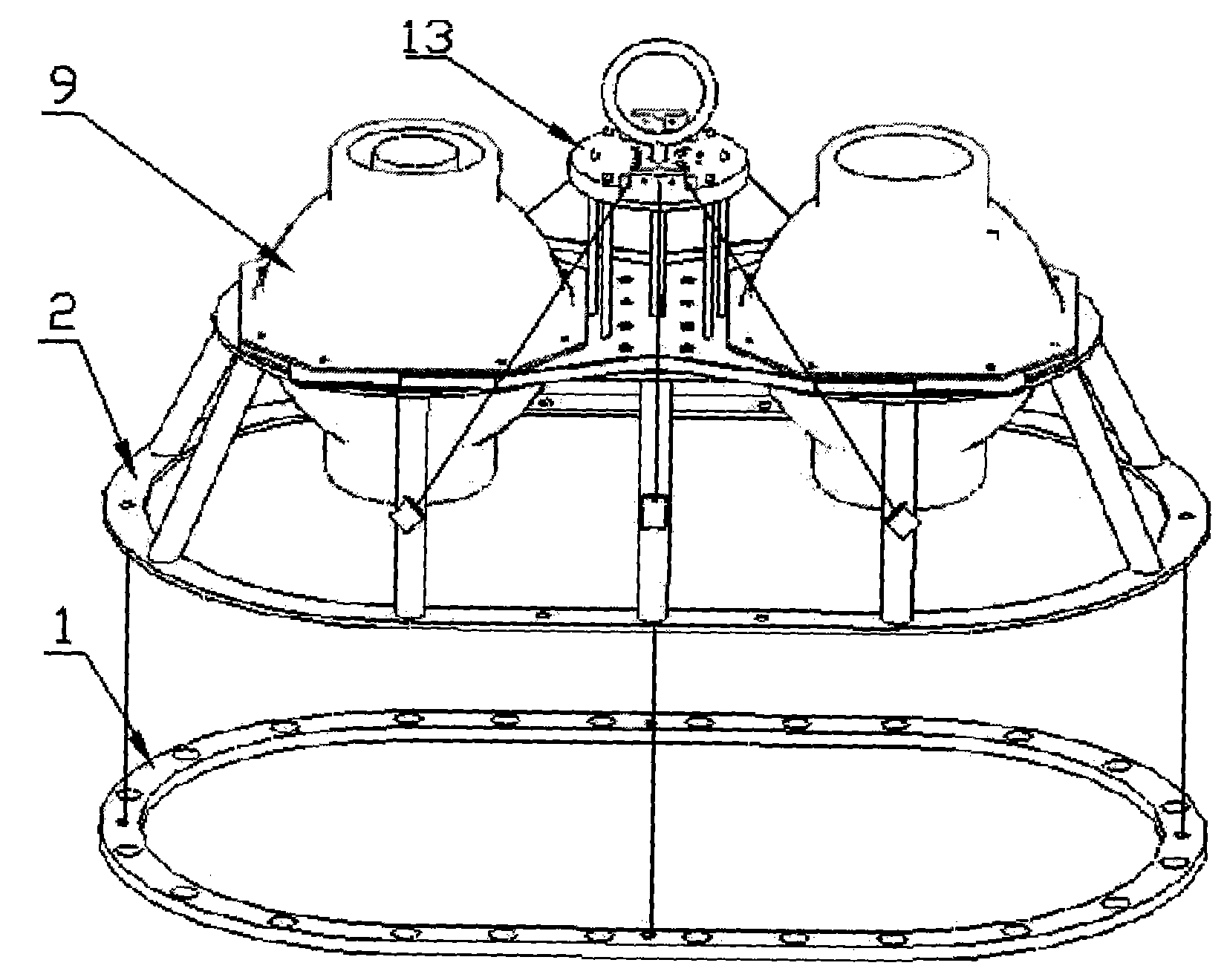

Broadband ocean bottom seismograph

InactiveCN101672927AExtended working hoursWork reliablySeismic signal receiversSeismology for water-covered areasData acquisitionEngineering

The invention discloses a broadband ocean bottom seismograph comprising two protecting shells and a connecting plate, wherein the two protecting shells are respectively fixed on both ends of the connecting plate; a sealed instrument storehouse ball and a sealed battery storehouse ball are respectively installed in the two protecting shells; a battery and an acoustic communication circuit are installed in the battery storehouse ball; two sealed storehouse balls are electrically connected by a cable; a gimbal for keeping the seismograph in a level state is arranged in the instrument storehouse ball and provided with a data collector and a seismograph; an electro erosion releasing mechanism for releasing a coupling frame is fixed on the connecting plate; the coupling frame for supplying downforces for the seismograph is positioned below the connecting plate and connected with the electro erosion releasing mechanism by wire ropes; and a weighting frame is connected below the coupling frame by an iron chain. The broadband ocean bottom seismograph can be used in deep ocean, and the observed broadband range is 40 s to 40 Hz; and the broadband ocean bottom seismograph is suitable not onlyfor viewing the ocean bottom natural earthquake, but also for viewing ocean bottom manmade earthquake source.

Owner:北京港震科技股份有限公司

Down pressure adjustment device and method for use with a disc opener assembly of an agricultural implement

A disc opener unit for an agricultural implement has a down pressure adjustment device that automatically adjusts the amount of down pressure applied on a furrowing disc based on strain measurements taken by a strain gauge or load cell. The strain gauge, which may be mounted to an arm that is used to set the position of a depth setting gauge wheel, provides feedback to a processor that in turn controls the amount of hydraulic fluid in a hydraulic cylinder to adjust the down force applied on the disc. The amount of down pressure is therefore adjusted in substantially real-time in response to changes in field conditions, which improves furrow depth consistency and reduces wear on the gauge wheel and its components.

Owner:CNH IND CANADA

Header flotation calibration system

A system for calibrating a header flotation system of an agricultural vehicle having a header is provided that includes a control circuit configured to monitor the height of the header and to calculate an upforce that will maintain a desired downforce of the header against the ground. This calculation is based at least upon the position of the header during flotation.

Owner:BLUE LEAF I P INC

Reversibly deployable spoiler

A reversibly deployable spoiler for a vehicle comprises a body and an active material in operative communication with the body. The active material, such as shape memory material, is operative to change at least one attribute in response to an activation signal. The active material can change its shape, dimensions and / or stiffness producing a change in at least one feature of the active spoiler airflow control device such as shape, dimension, location, orientation, and / or stiffness to control vehicle airflow and downforce to better suit changes in driving conditions such as speed, while reducing maintenance and the level of failure modes. An activation device, controller and sensors may be employed to further control the change in at least one feature of the active spoiler airflow control device such as shape, dimension, location, orientation, and / or stiffness. A method for controlling vehicle airflow selectively introduces an activation signal to initiate a change of at least one feature of the device that can be reversed upon discontinuation of the activation signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

Automated Chemical Polishing System Adapted for Soft Semiconductor Materials

InactiveUS20070270081A1High precisionVarying amountPolishing machinesRevolution surface grinding machinesSemiconductor materialsControl theory

Owner:DRS NETWORK & IMAGING SYST

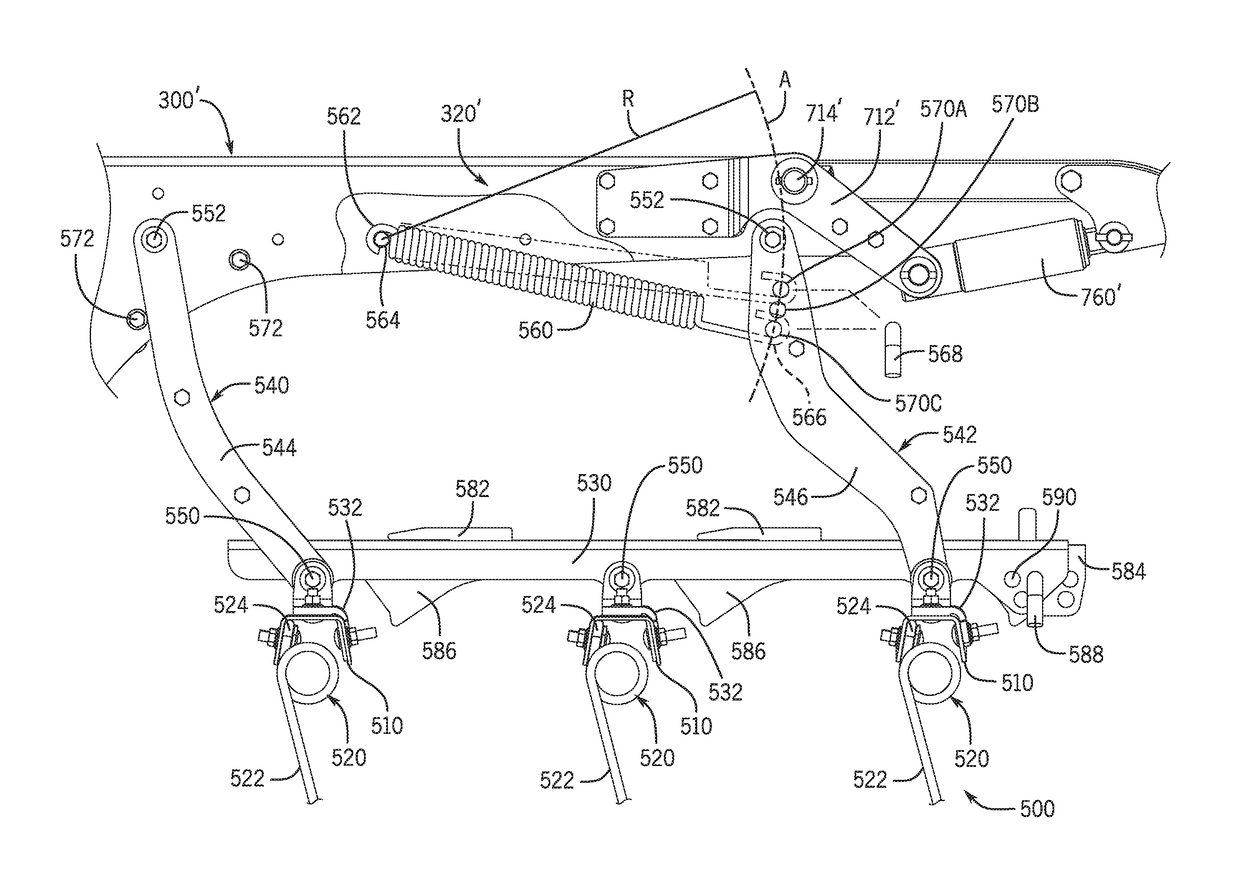

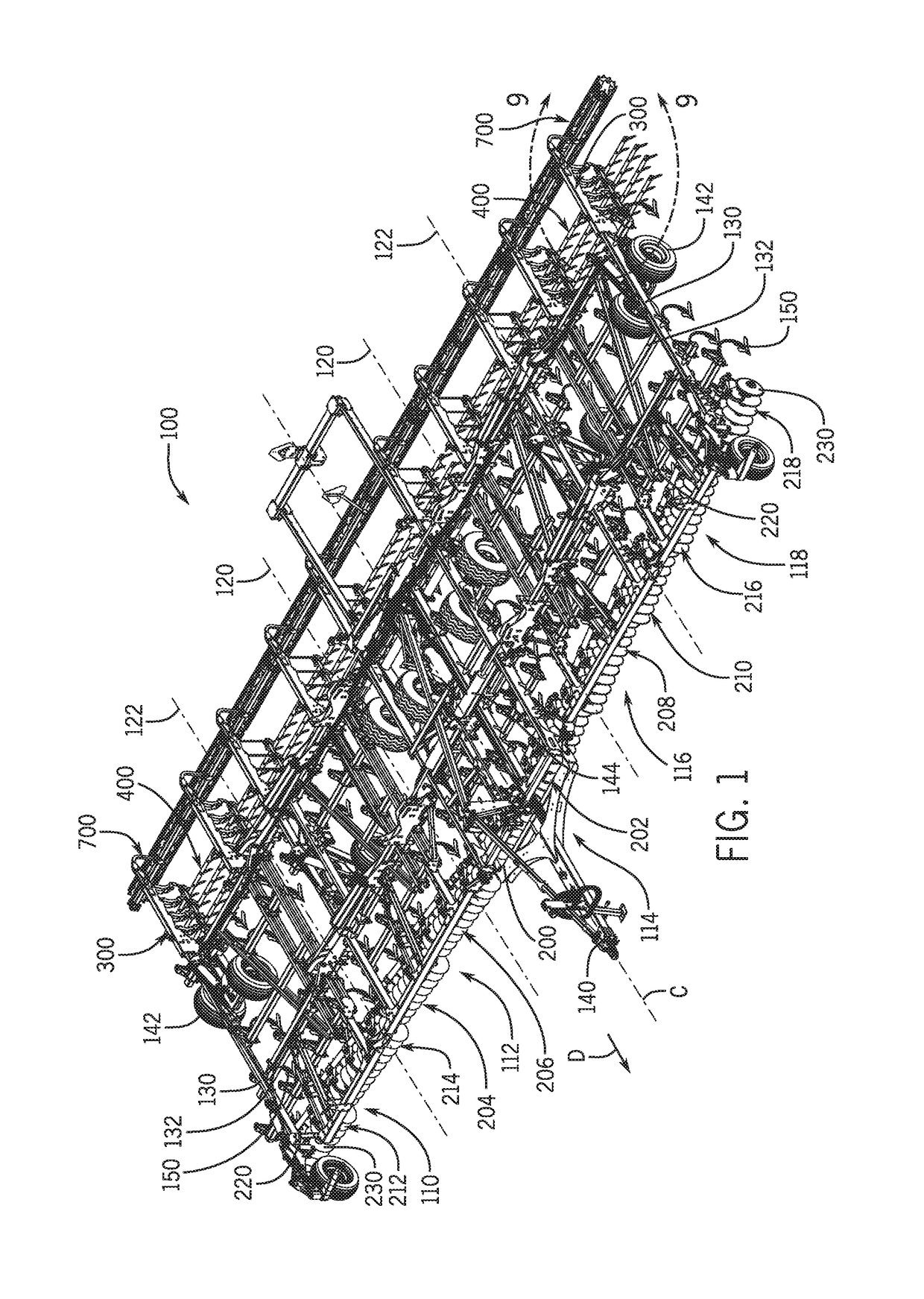

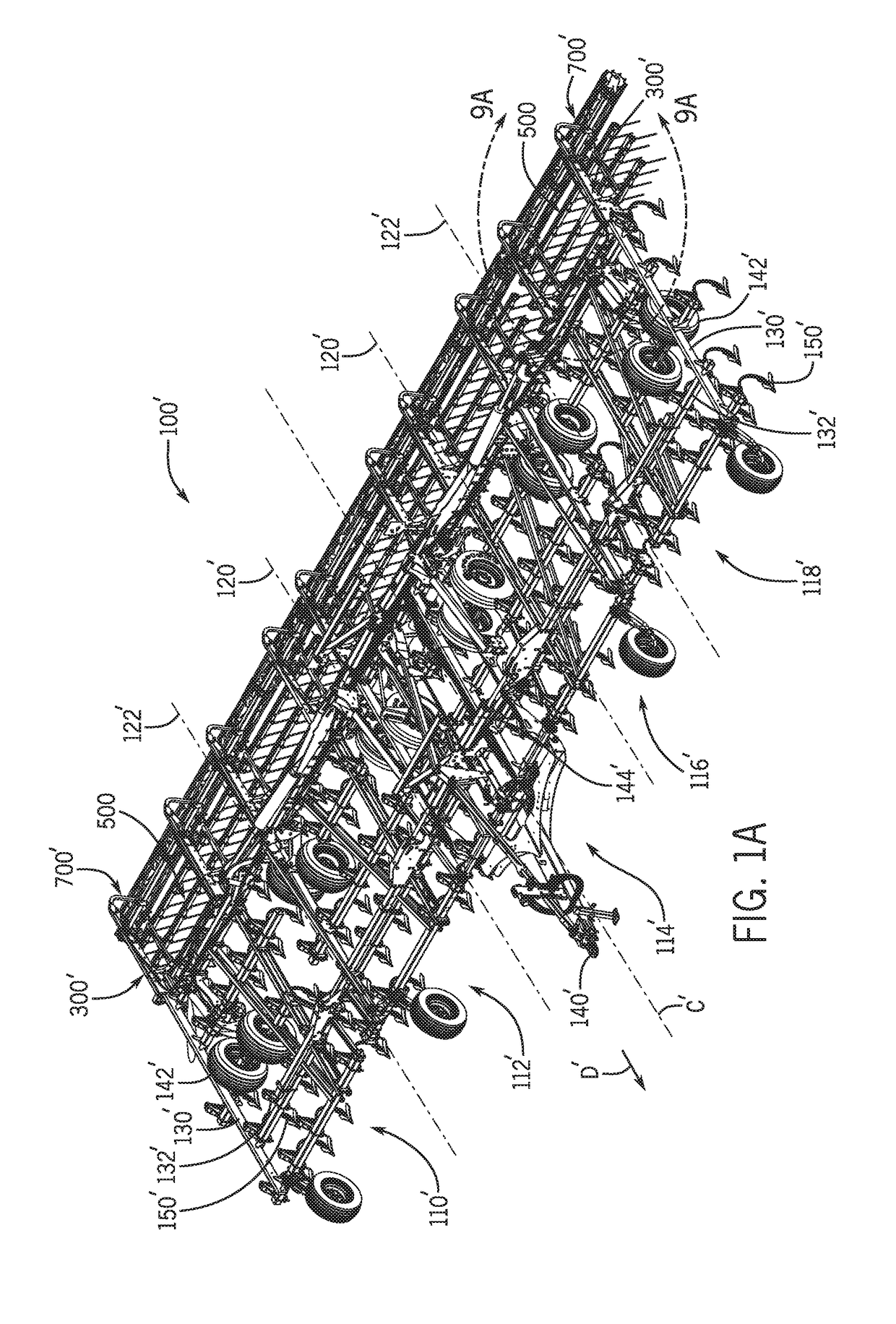

Harrow downforce adjustment

ActiveUS20170079190A1Improved downforce adjustmentSpadesAgricultural machinesEngineeringVariable length

A harrow attachment for a tillage implement includes a harrow drawbar mounting at least one rank of harrowing tools. A pivot link pivotally couples the harrow rank to the drawbar so it can trip by pivoting upward toward the drawbar from a home position in which the harrow rank is farthest away from the drawbar. A downforce spring is coupled to the drawbar and in a variable length state when the harrow rank is tripped to apply a return biasing force to the harrow rank. An adjustment mechanism couples the spring to the harrow rank and / or the pivot link in one of a plurality of adjustment locations in each of which the harrow rank is in the home position and the spring is in a fixed length state in which the biasing force is removed.

Owner:DEERE & CO

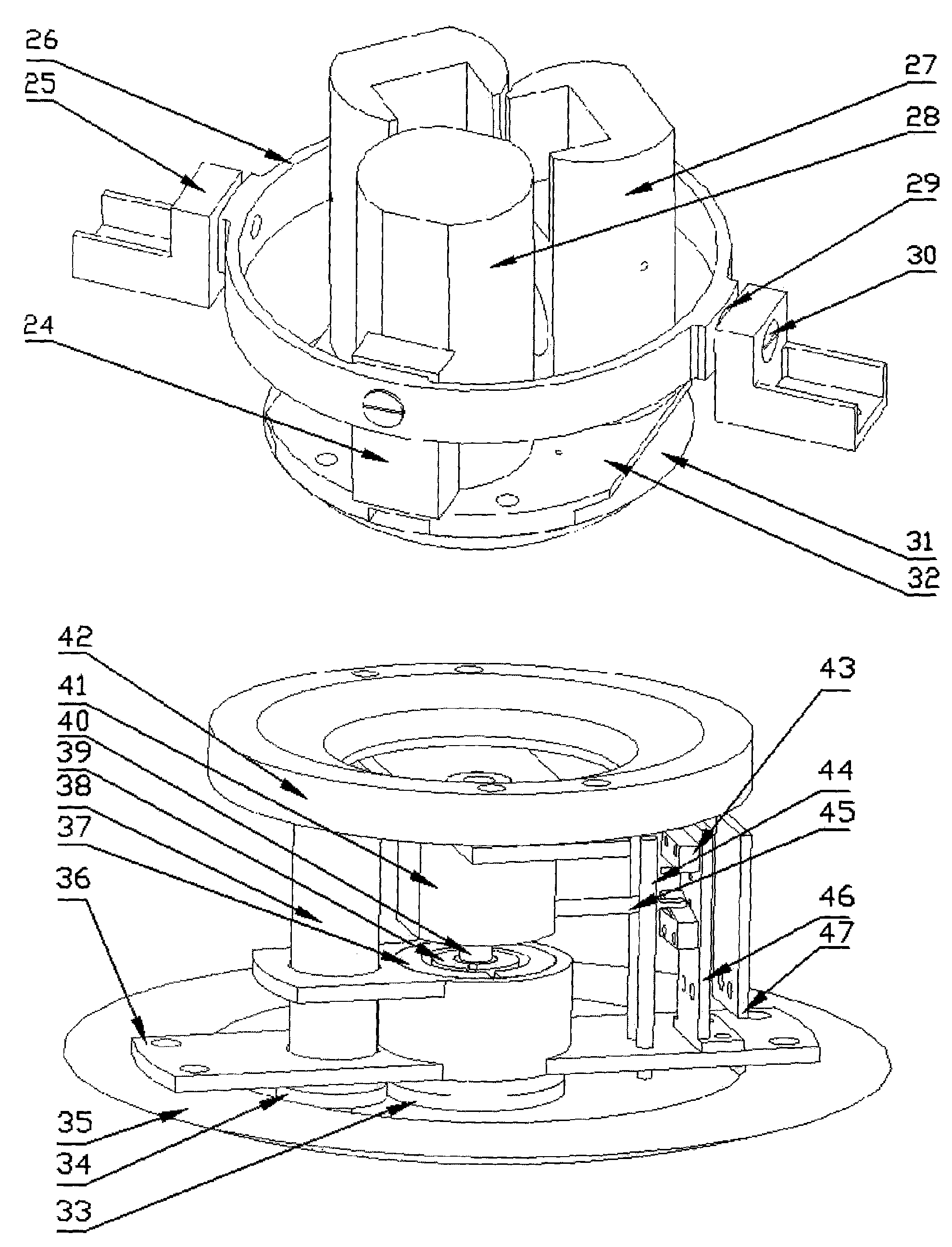

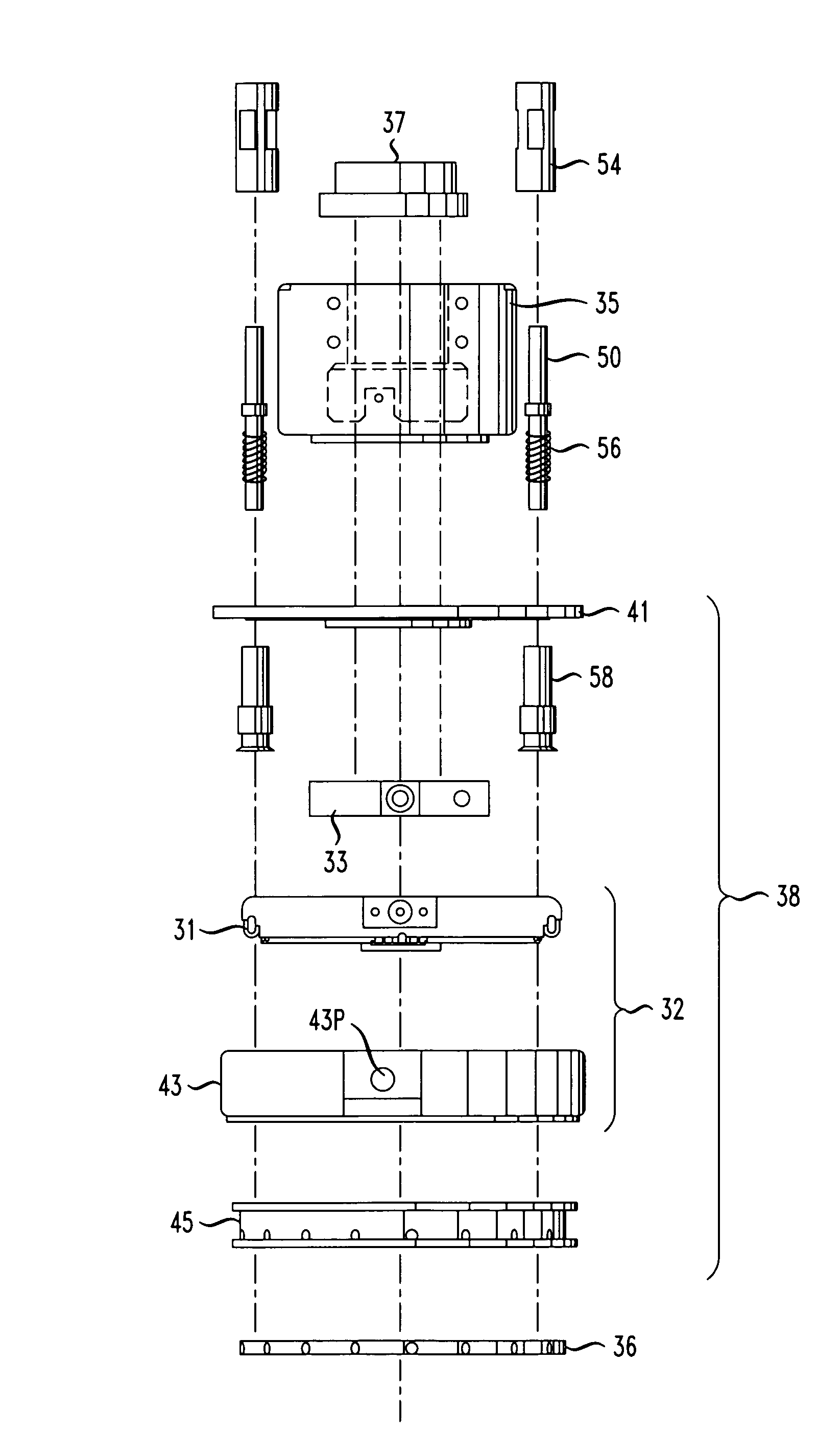

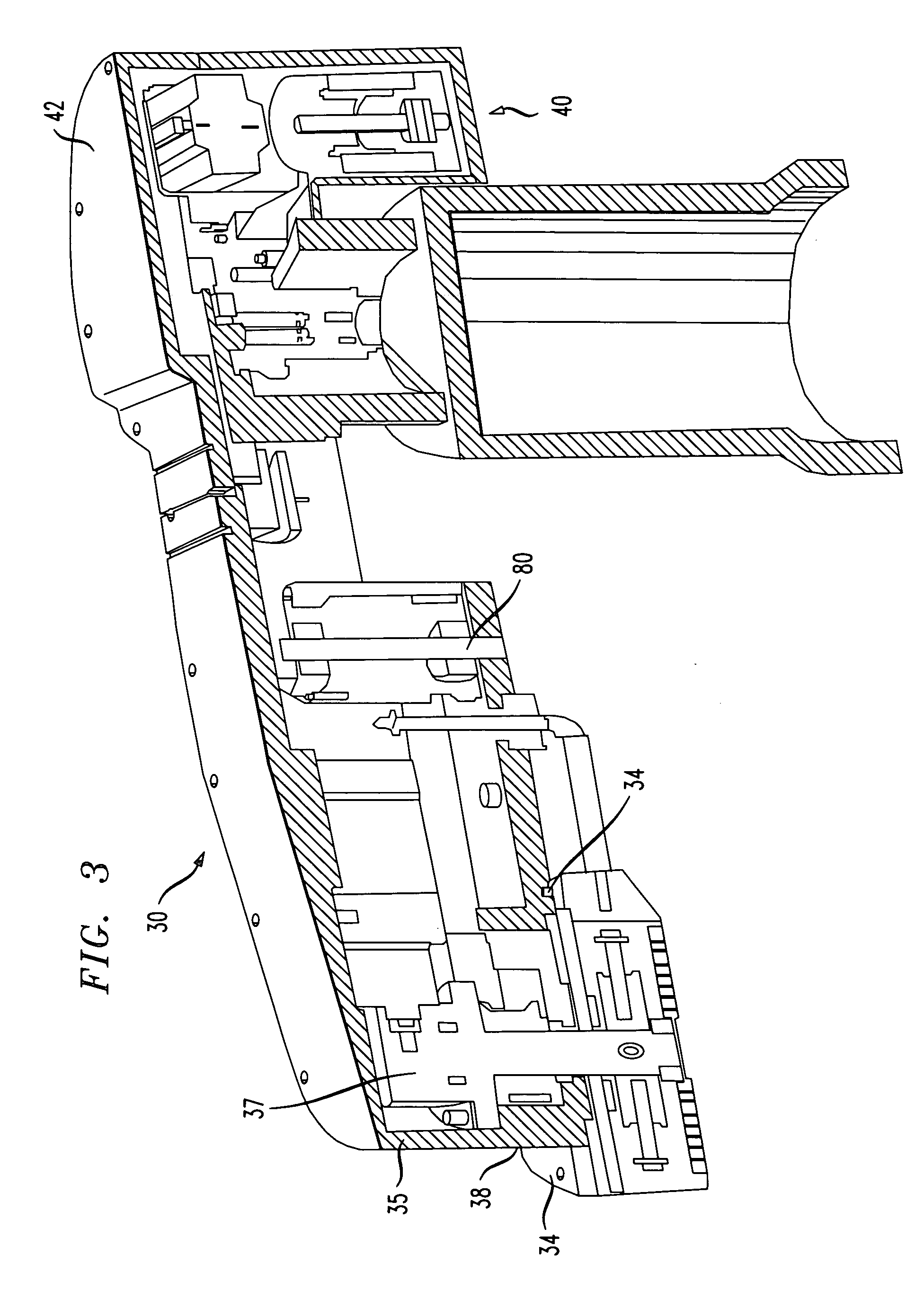

Enhanced end effector arm arrangement for CMP pad conditioning

InactiveUS7217172B2Well-controlled and efficient movement and operationEasy maintenanceEdge grinding machinesPolishing machinesStatic frictionActuator

A CMP conditioning apparatus enhanced end effector arm for improving the reliability of the apparatus and the quality of the conditioning and polishing operations includes a conditioner head with features that provide for simplified alignment / attachment of a conditioning disk to the arm, while also providing a “quick release” mechanism for maintenance operations. The enhanced arm also includes an improved actuator that provides for a static friction (“stiction”)-free movement of the arm and better control of the downforce applied by the conditioning disk to the polishing pad. A dual-drive pulley system is used within the enhanced end effector arm to minimize the tilting of the drive belts within the effector arm as the arm pivots to follow the contour of an “aging” polishing pad.

Owner:TBW IND INC

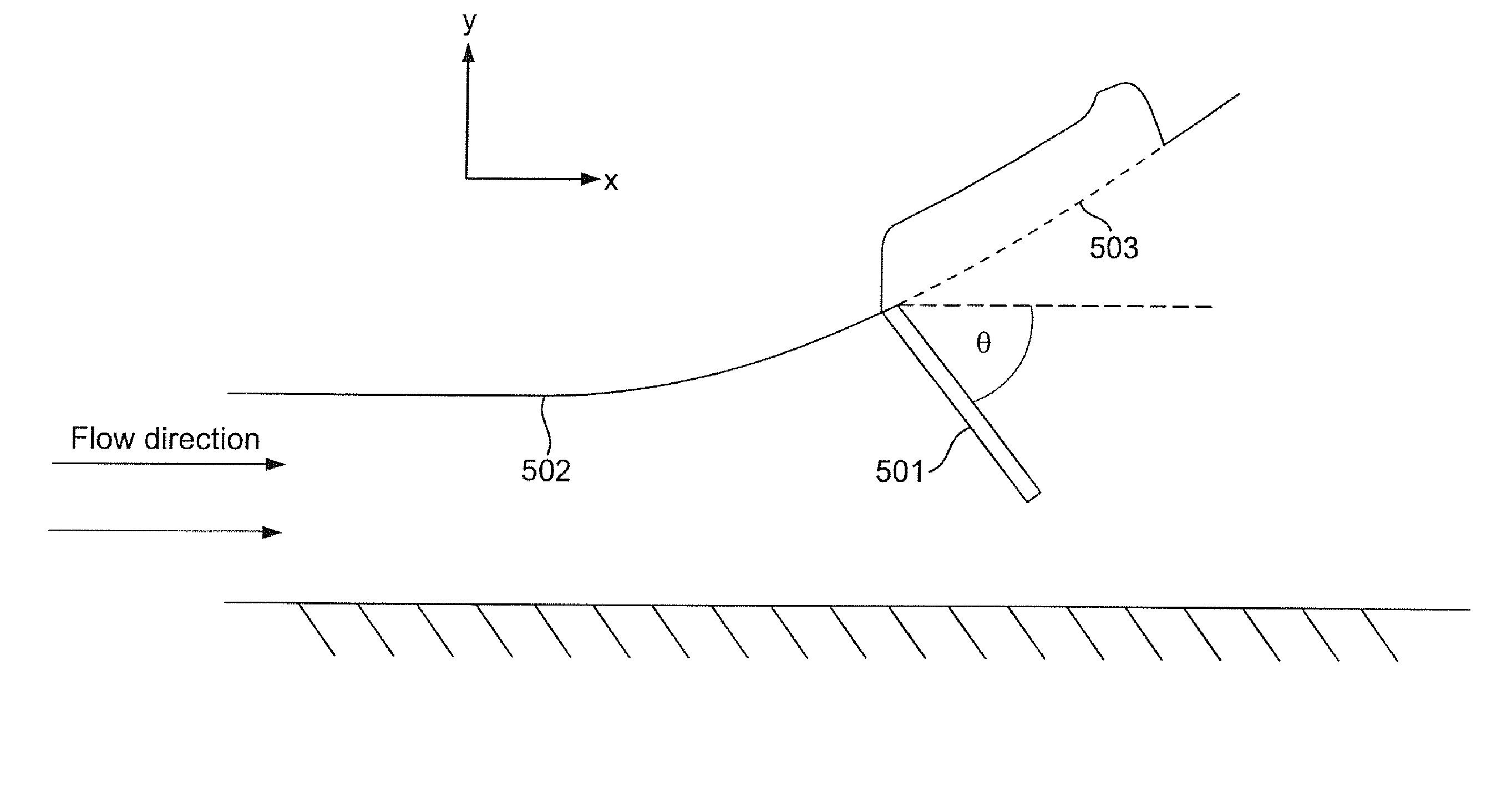

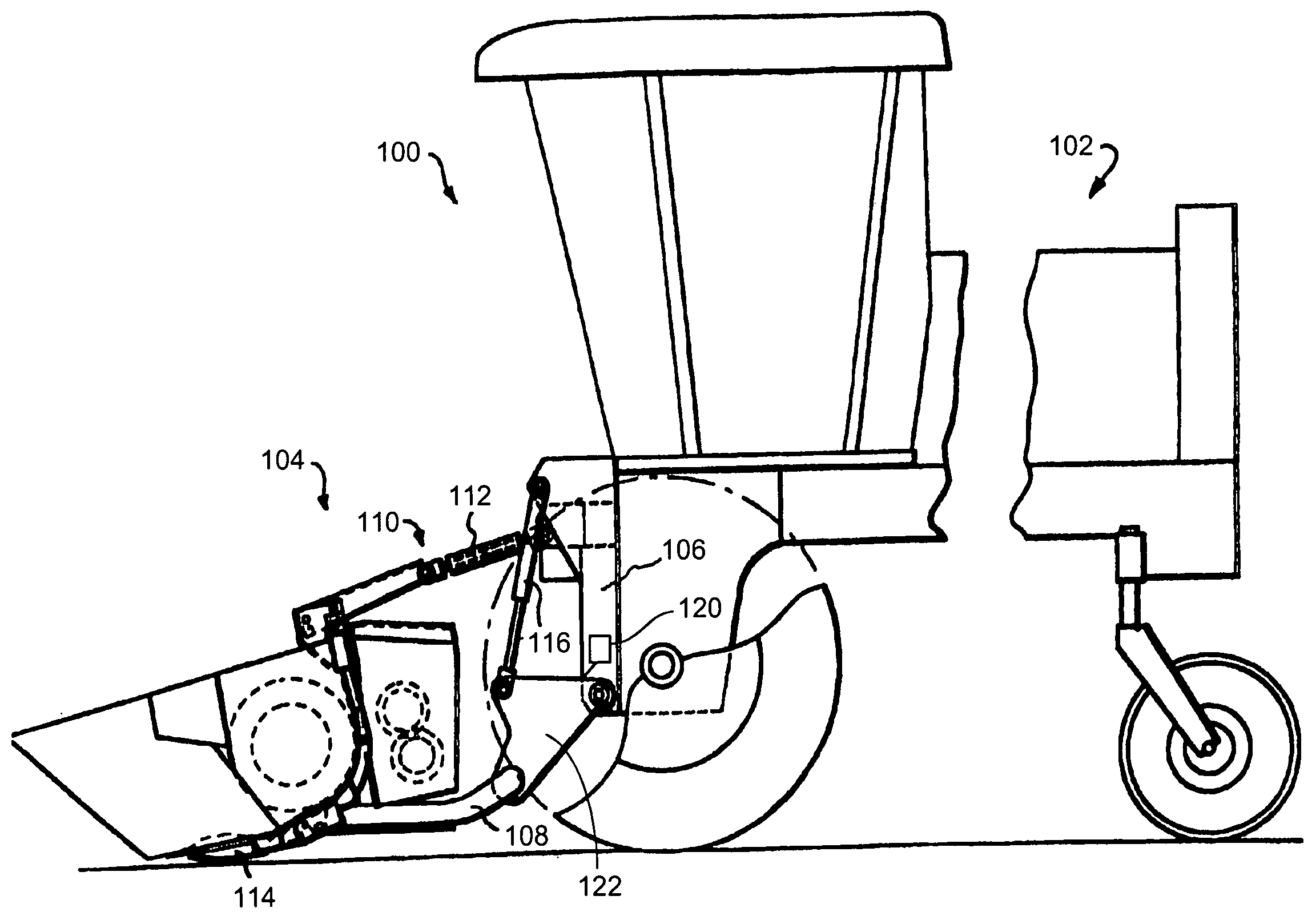

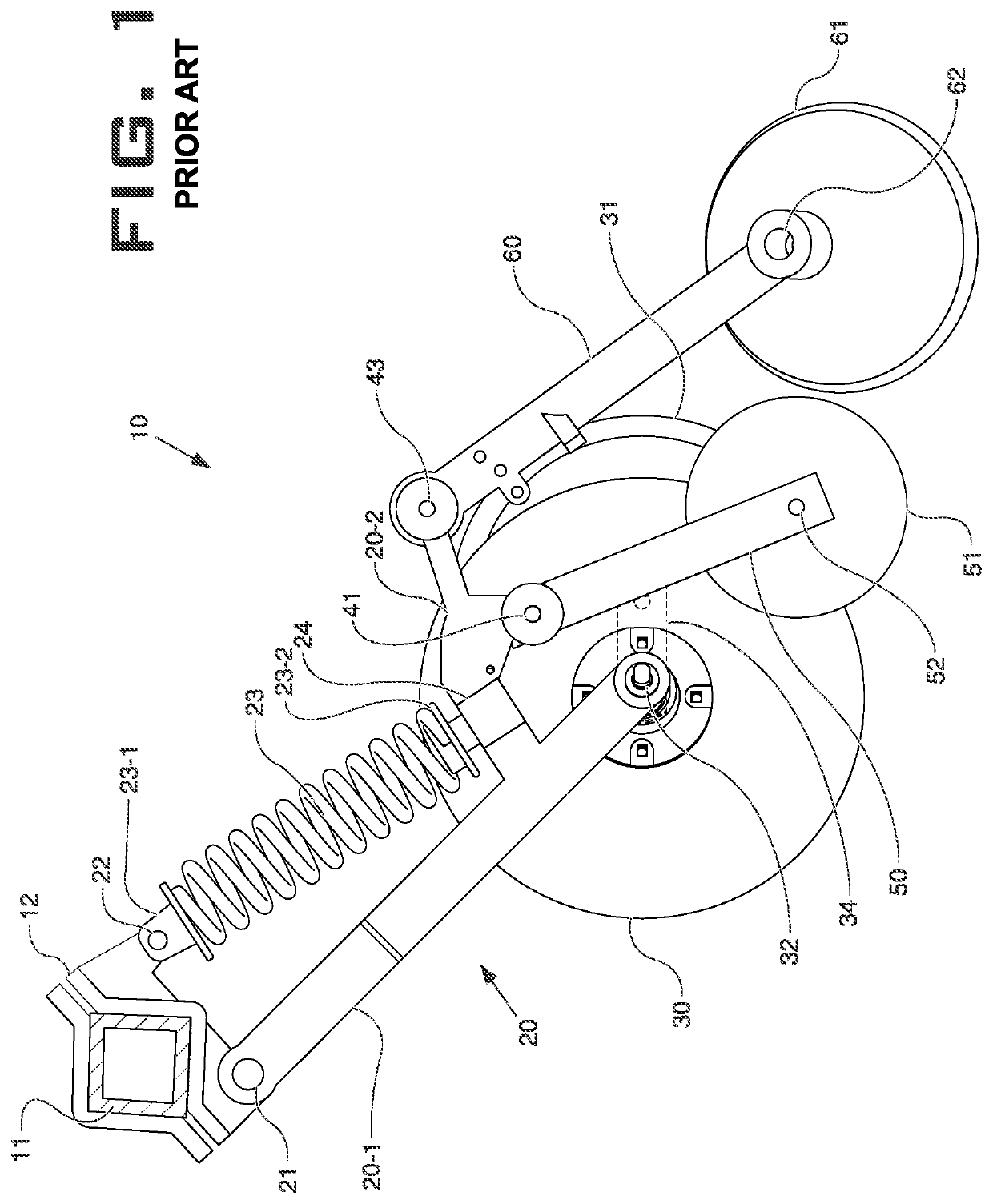

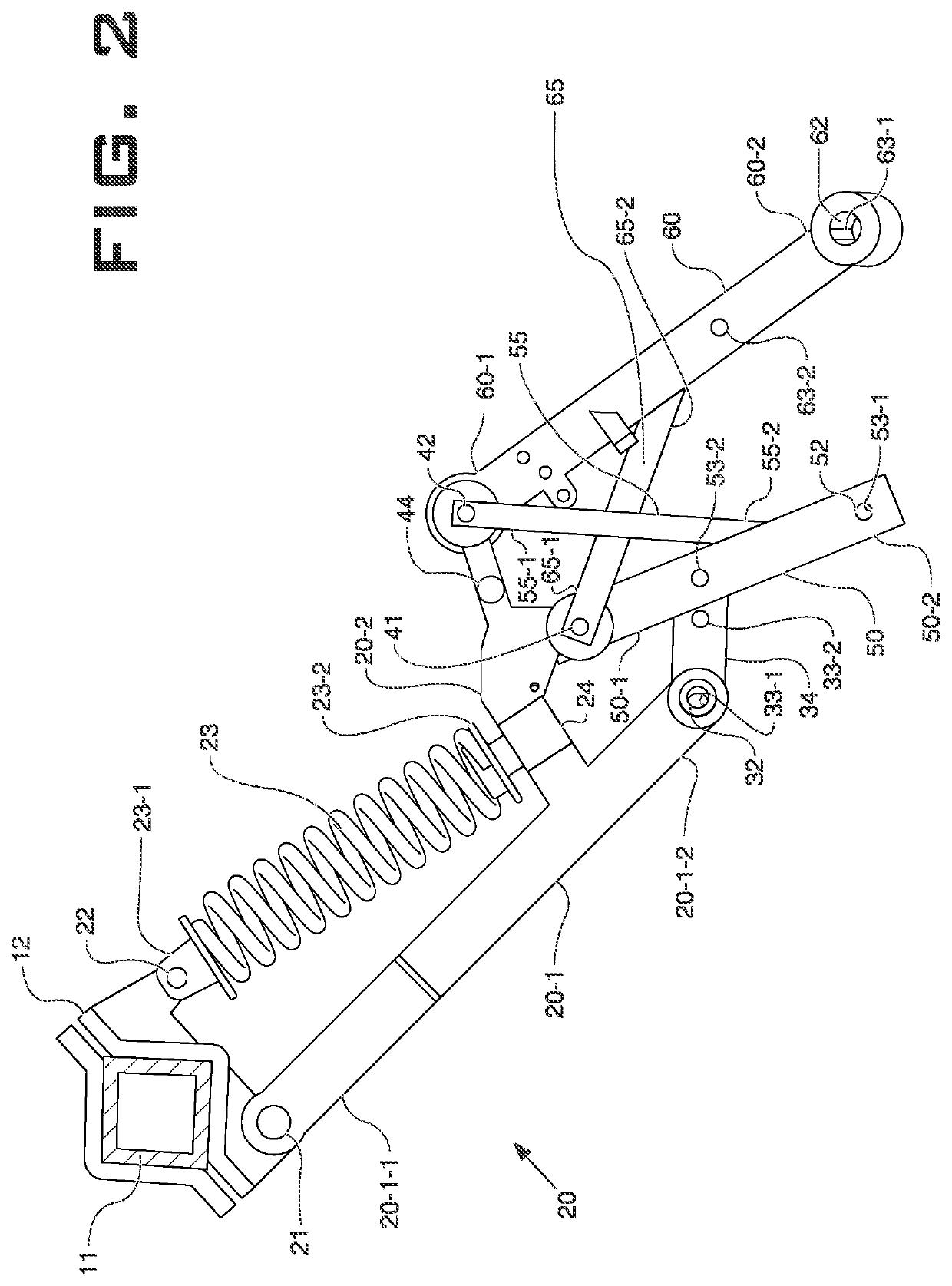

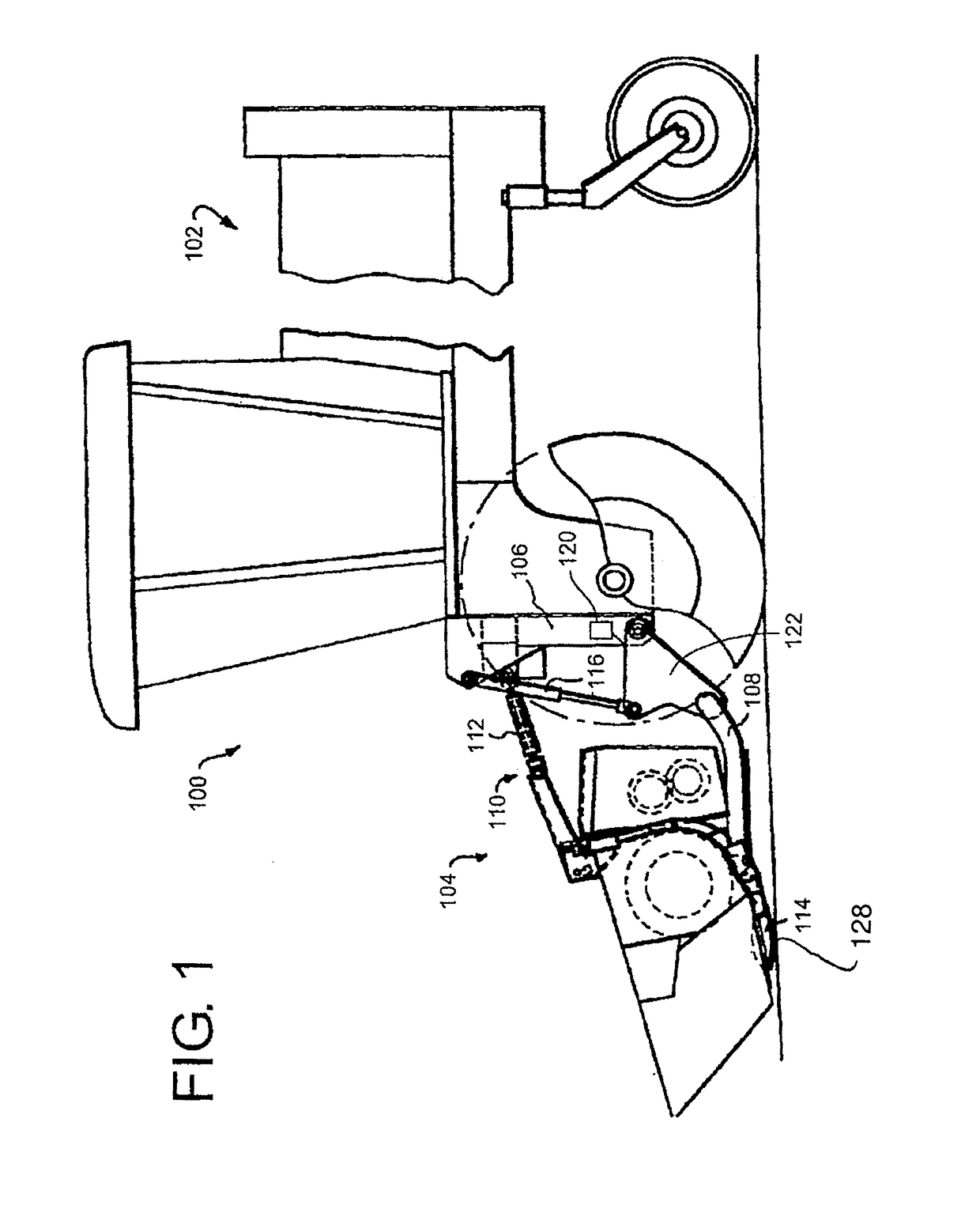

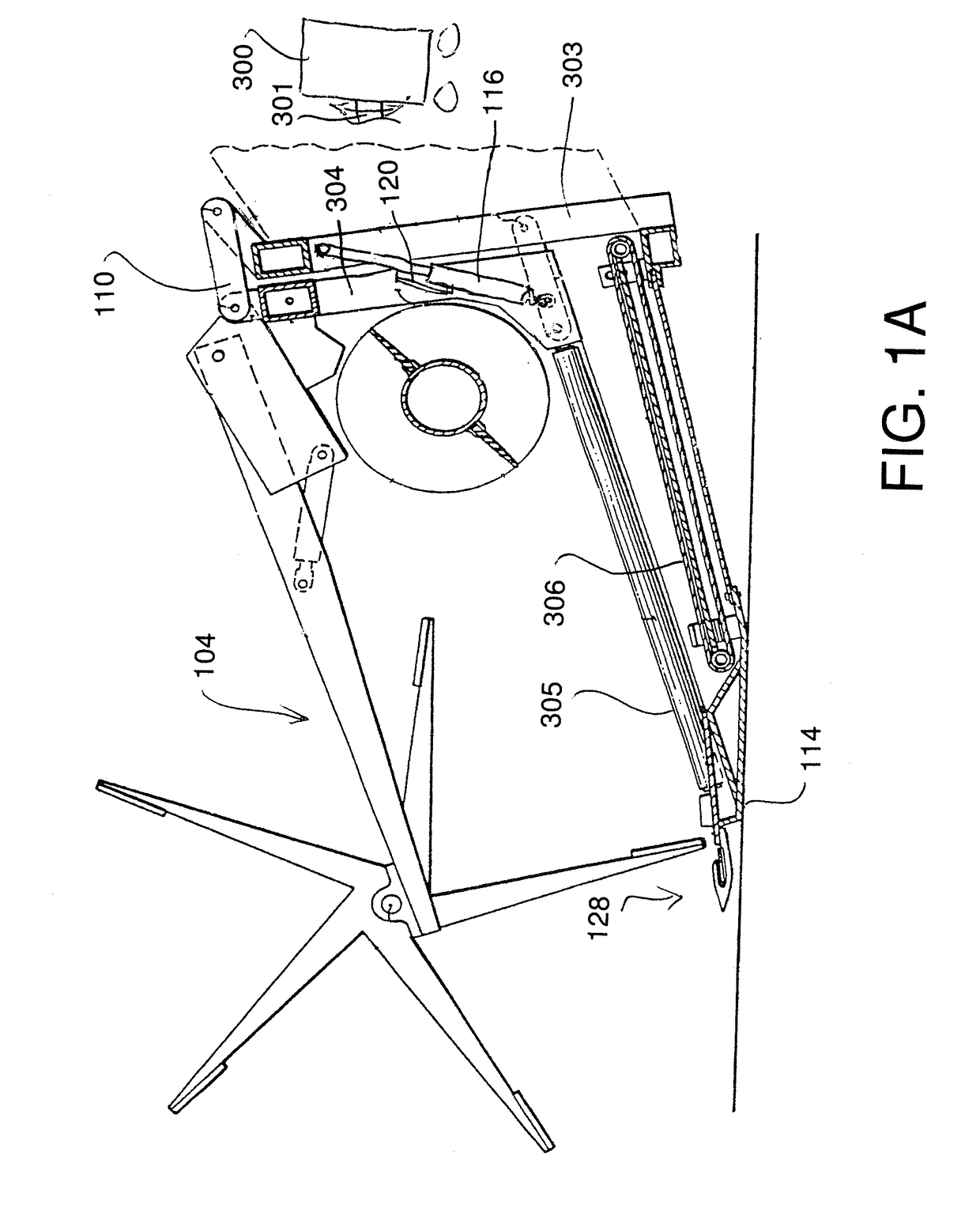

Air seeder press wheel and closing wheel force control

Air seeders that have force actuators acting on the firming implement and / or the closing wheel to adjust the downforce. In one example, the seeding implement includes a support arm having first and second portions. A finning implement support arm is pivotally connected to the support arm second portion at a first pivot at a first end of the finning implement support arm. A firming implement force actuator is pivotally connected to the support arm second portion at a first end of the firming implement force actuator and connected to the firming implement support arm at the second end of the firming implement force actuator.

Owner:PRECISION PLANTING LLC

Crop Machine with an Electronically Controlled Hydraulic Cylinder Flotation System

ActiveUS20180153101A1Reduce lifting forceEliminate the effects ofAgricultural machinesServomotor componentsHydraulic cylinderControl manner

A header is supported by a pair of hydraulic float cylinders, where a float pressure to the cylinders is directly controlled by an electronic control supplying a variable control signal to a PPRR valve arrangement to maintain the float pressure at a predetermined value. At the set pressure a predetermined lifting force is provided to the header. A position sensor is used to generate an indication of movement and / or acceleration and / or velocity. The electronic control is arranged, in response to changes in the sensor signal, to temporarily change the control signal to vary the lifting force and thus change the dynamic response of the hydraulic float cylinder. A lift force greater than that required to lift the header can be provided by a lift cylinder and can be opposed in a controlled manner to apply a controlled downforce by the back of the same cylinder or by a separate component.

Owner:MACDON INDS

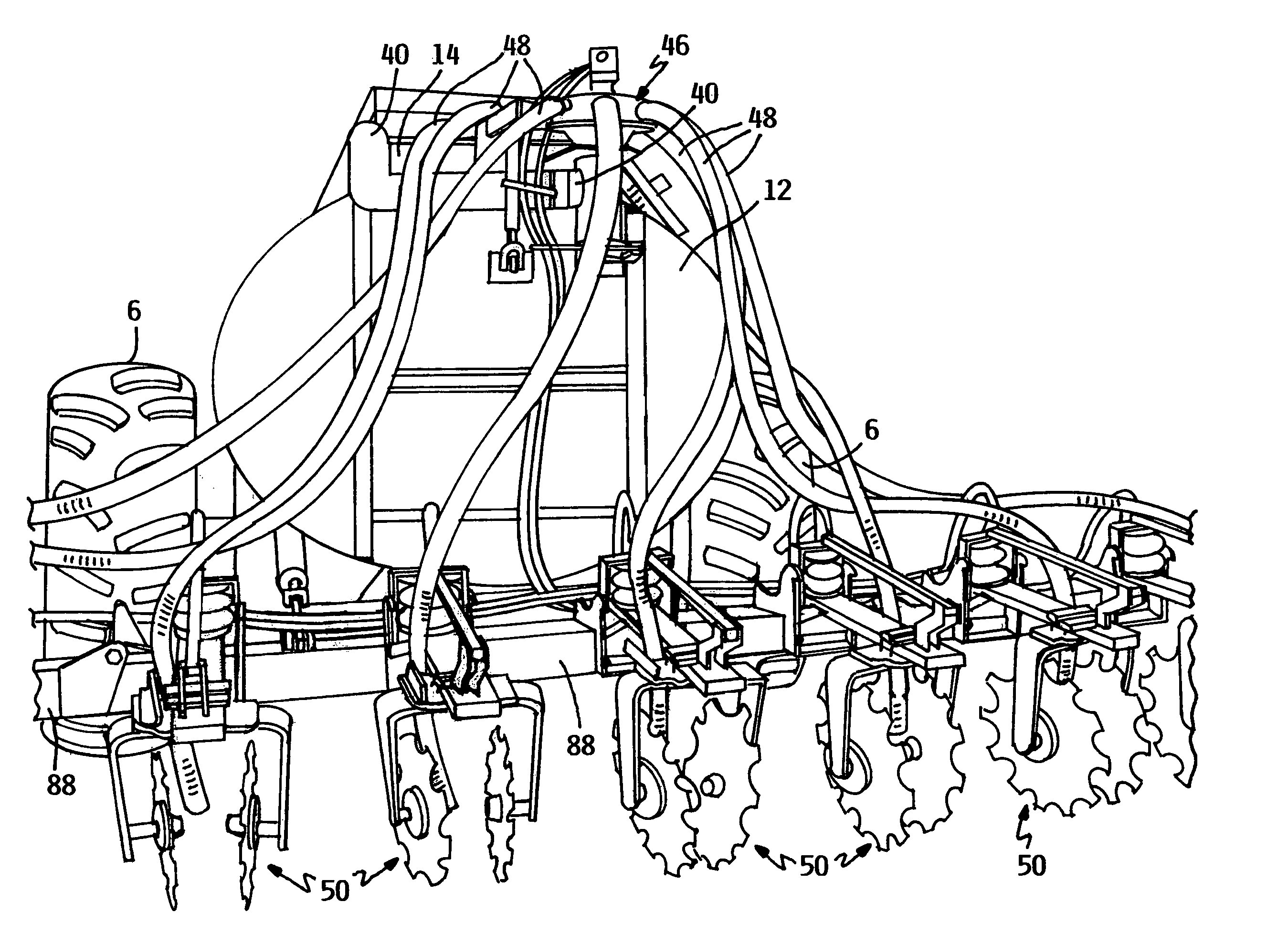

Liquid manure applicator, method, and tool with bellows type downforce system

ActiveUS7823807B1Downforce on armIncrease or decrease pressureBurnersManure treatmentLiquid manureDistributor

A liquid manure applicator comprises a tank for holding a supply of liquid manure that is distributed onto a farm field through a distributor having a plurality of distribution ports and hoses. The hoses lead to individual distribution tools that include a pair or rotary coulters and a bellows for applying downforce to the coulters. The distributor includes a ring that restricts the size of the solids entering the distribution ports and hoses to something substantially equal to or less than 50% of the cross-sectional area of the hoses. This prevents the hoses from plugging even when small diameter hoses are used to lower the application rates to values more consistent with the needs of a zone tilled field. A rotary chopper in the distributor reduces the size of larger solids until they have been broken up into pieces small enough to pass the restriction provided by the ring.

Owner:ENVIRONMENTAL TILLAGE SYST

Air deflecting system for automobiles

Owner:NAT ASSOC FOR STOCK CAR AUTO RACING

Compositions and methods for low downforce pressure polishing of copper

InactiveCN1644644AGood removal effectOther chemical processesSemiconductor/solid-state device manufacturingNonferrous metalCarboxylic acid

The present invention provides an aqueous composition useful for polishing copper on a semiconductor wafer at a down force pressure of at least less than 20.68 kPa, comprising by weight percent 1 to 15 oxidizer, 0.1 to 1 inhibitor for a nonferrous metal, 0.05 to 3 complexing agent for the nonferrous metal, 0.01 to 5 carboxylic acid polymer, 0.01 to 5 modified cellulose, 0.05 to 10 phosphorus-containing compound and 0 to 10 abrasive, wherein the phosphorus-containing compound increases removal of the copper.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

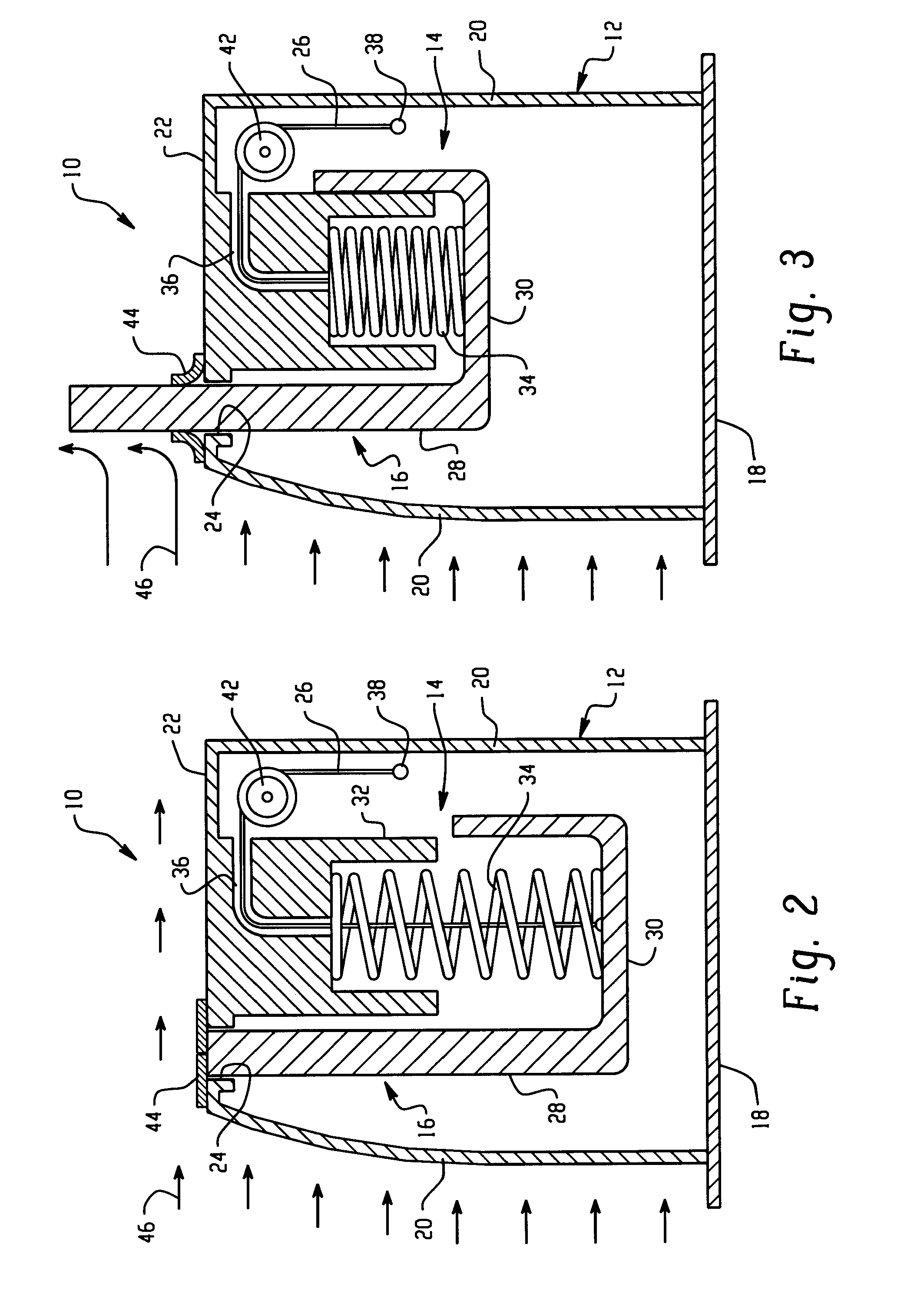

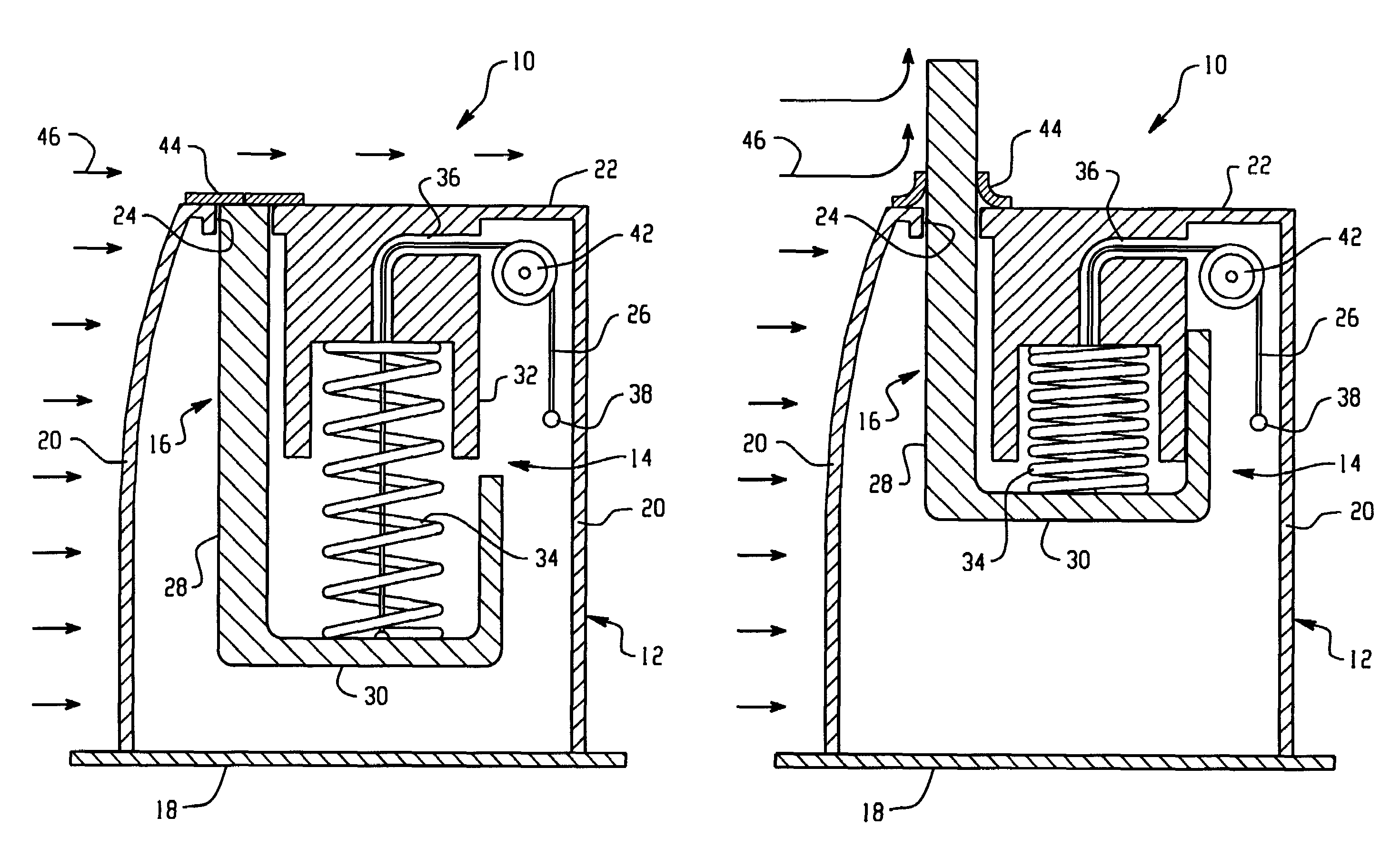

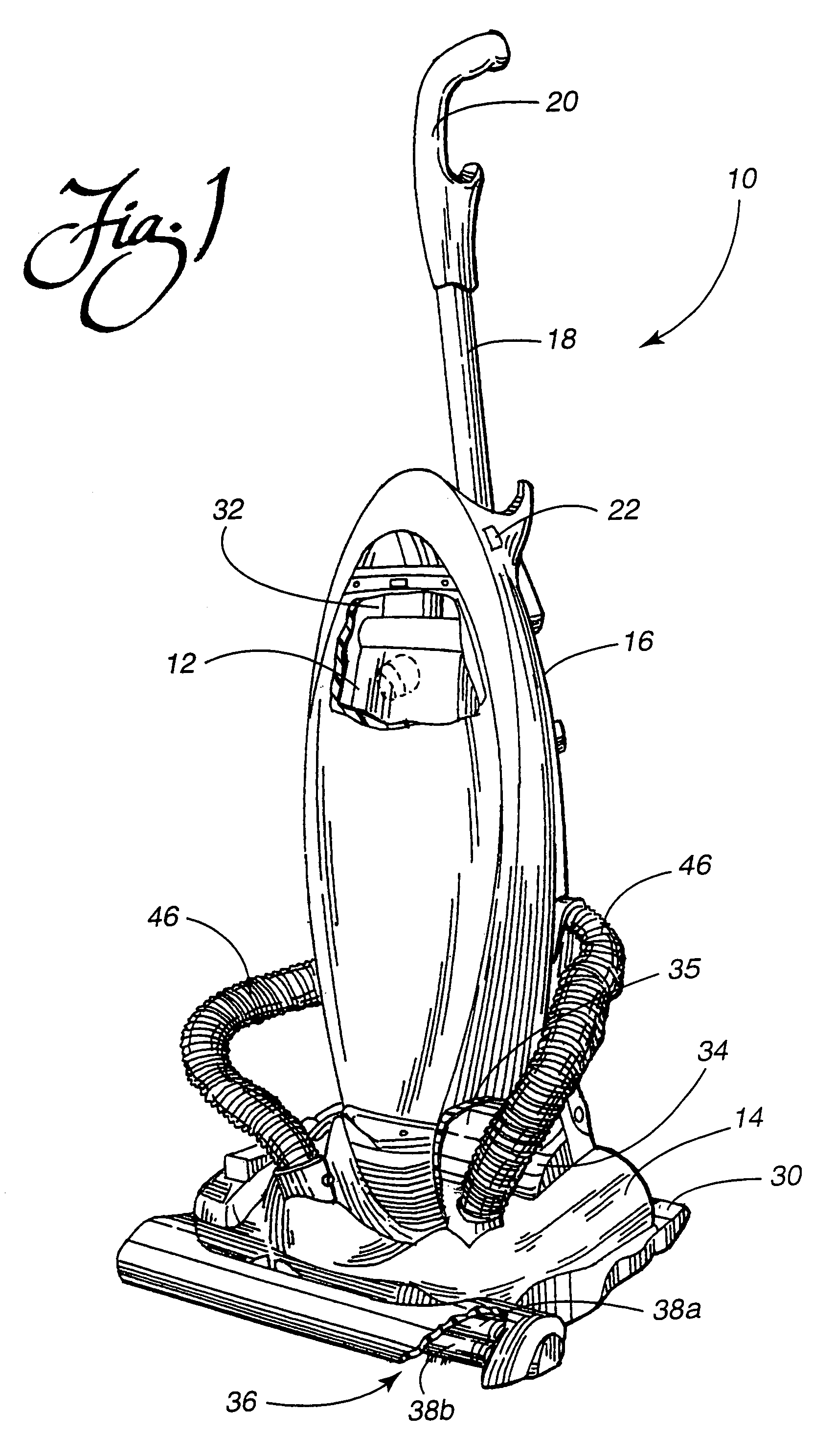

Upright vacuum cleaner with spring loaded nozzle

InactiveUS6957473B2Easy to cleanReduce vibrationCleaning filter meansSuction filtersSpray nozzleVacuum cleaner

An upright vacuum cleaner includes a nozzle assembly, a canister assembly pivotally mounted to said nozzle assembly, a suction fan and motor and a biaser. The biaser has a first end that engages the nozzle assembly and a second end that engages the canister assembly. The biaser provides a positive downforce urging the forward end of the nozzle assembly toward the surface being cleaned.

Owner:PANASONIC OF NORTH AMERICA

Crop Machine with an Electronically Controlled Hydraulic Cylinder Flotation System

ActiveUS20180359920A1Reduce supportReduce lifting forceServomotor componentsMowersHydraulic cylinderControl signal

A header is supported by a pair of hydraulic float cylinders, where a float pressure to the cylinders is directly controlled by an electronic control supplying a variable control signal to a PPRR valve arrangement to maintain the float pressure at a predetermined value. At the set pressure a predetermined lifting force is provided to the header. A position sensor is used to generate an indication of movement and / or acceleration and / or velocity. The electronic control is arranged, in response to changes in the sensor signal, to temporarily change the control signal to vary the lifting force and thus change the dynamic response of the hydraulic float cylinder. A lift force greater than that required to lift the header can be provided by a lift cylinder and can be opposed in a controlled manner to apply a controlled downforce by the back of the same cylinder or by a separate component.

Owner:MACDON INDS

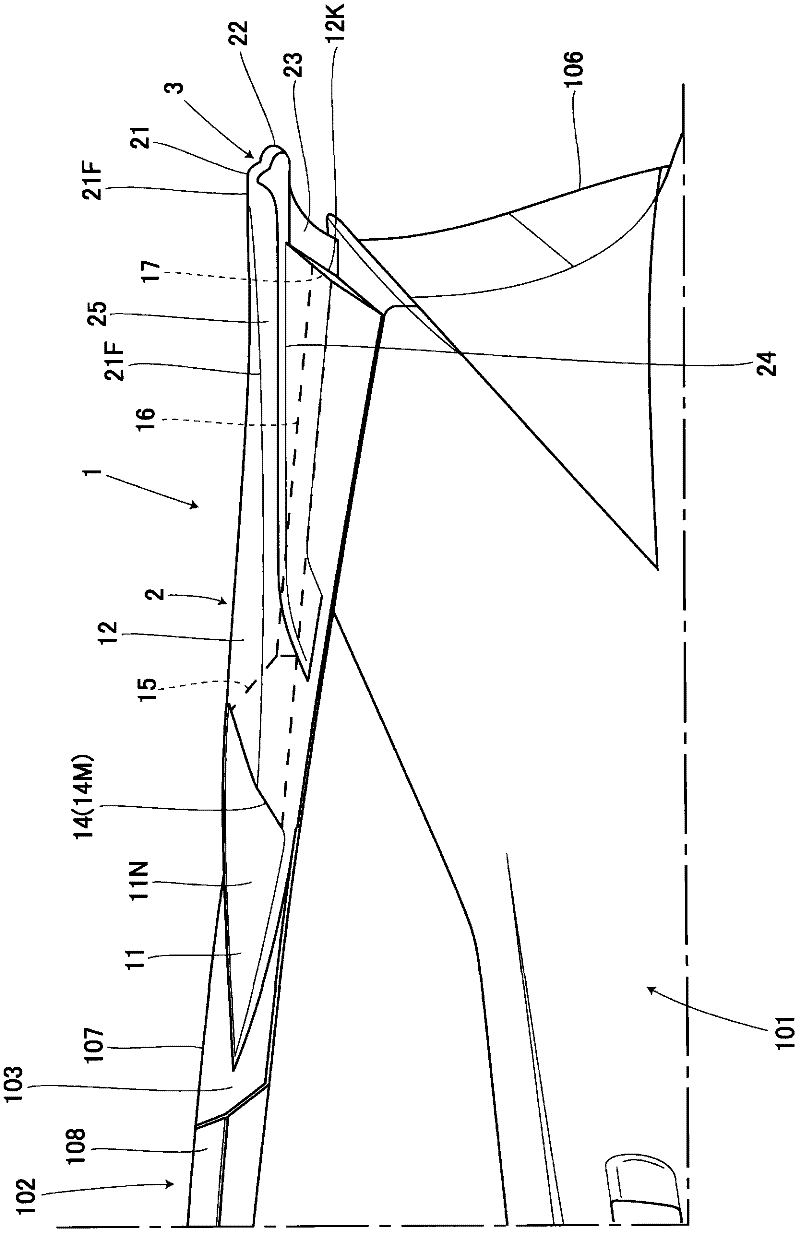

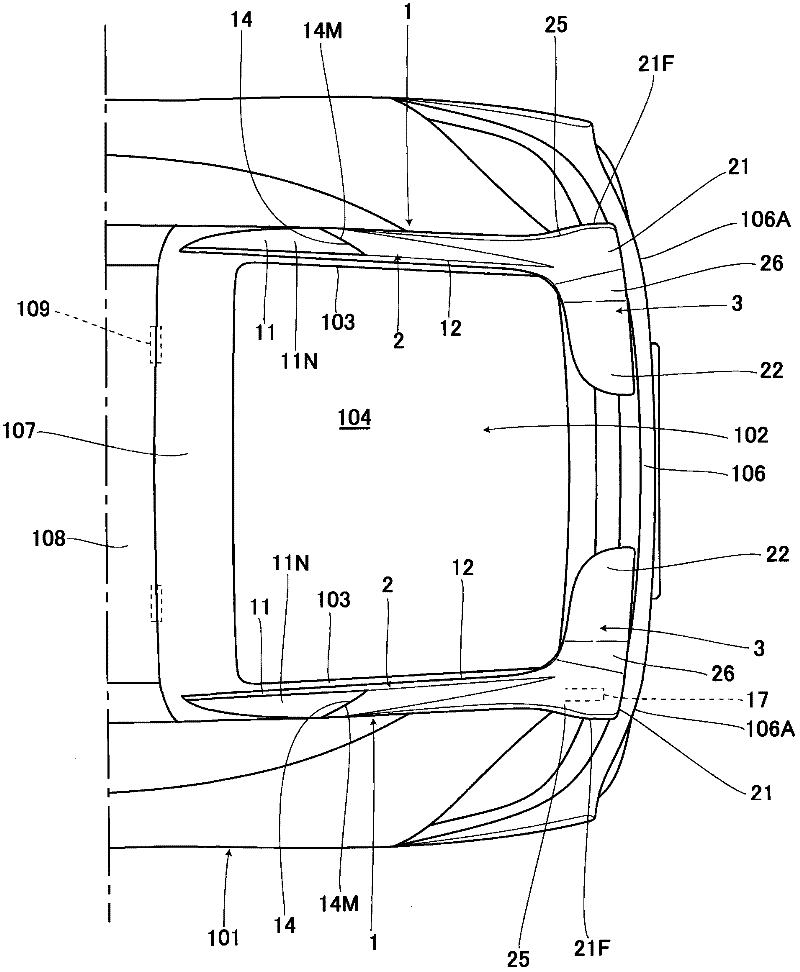

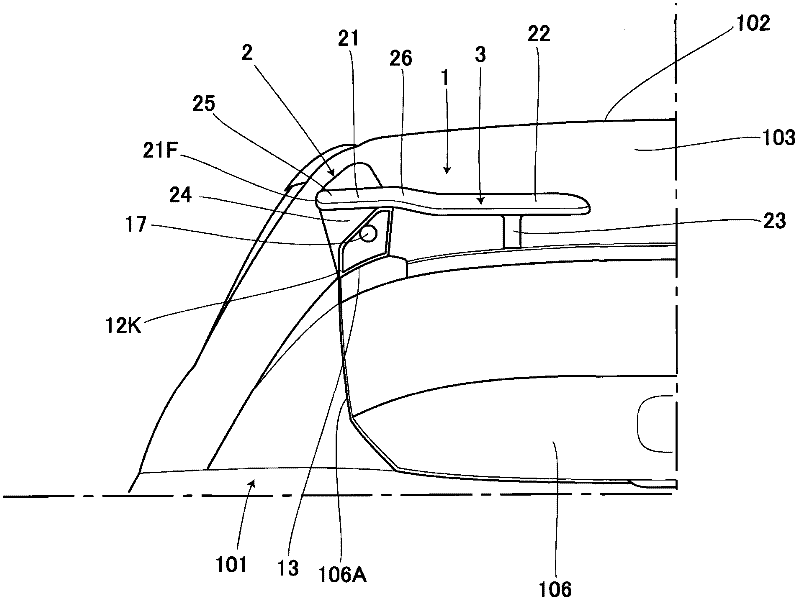

Rear spoiler

ActiveCN102556183AReduce driving resistanceIncrease the blowing speedVehicle body stabilisationAerodynamics improvementAerodynamic dragDownforce

The invention provides a rear spoiler which is capable of suppressing an increase in air resistance and applying a downforce to a vehicular rear portion during high-speed vehicle traveling. The rear spoiler (1) on the rear upside of a vehicle includes a main body (2) that is longer in a longitudinal direction than in a width direction. The main body (2) includes an air introduction opening (14) of air currents, and a wing (3) and an air outlet (17) communicating with the opening (14) at the rear. The air currents introduced from the opening (14) during traveling are blown off from the air outlet (17). Consequently, vortex flows generated at the rear is rectified, thus permitting travel resistance to be reduced. Further, the main body (2) is arranged in the vehicular lateral side and hence by rectifying the vortex flows generated by the air currents coming around the vehicular lateral side, the air resistance is restrained from increasing during high-speed traveling, permitting the travel resistance to be reduced.

Owner:HONDA ACCESS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com