Patents

Literature

125results about How to "Increase downforce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

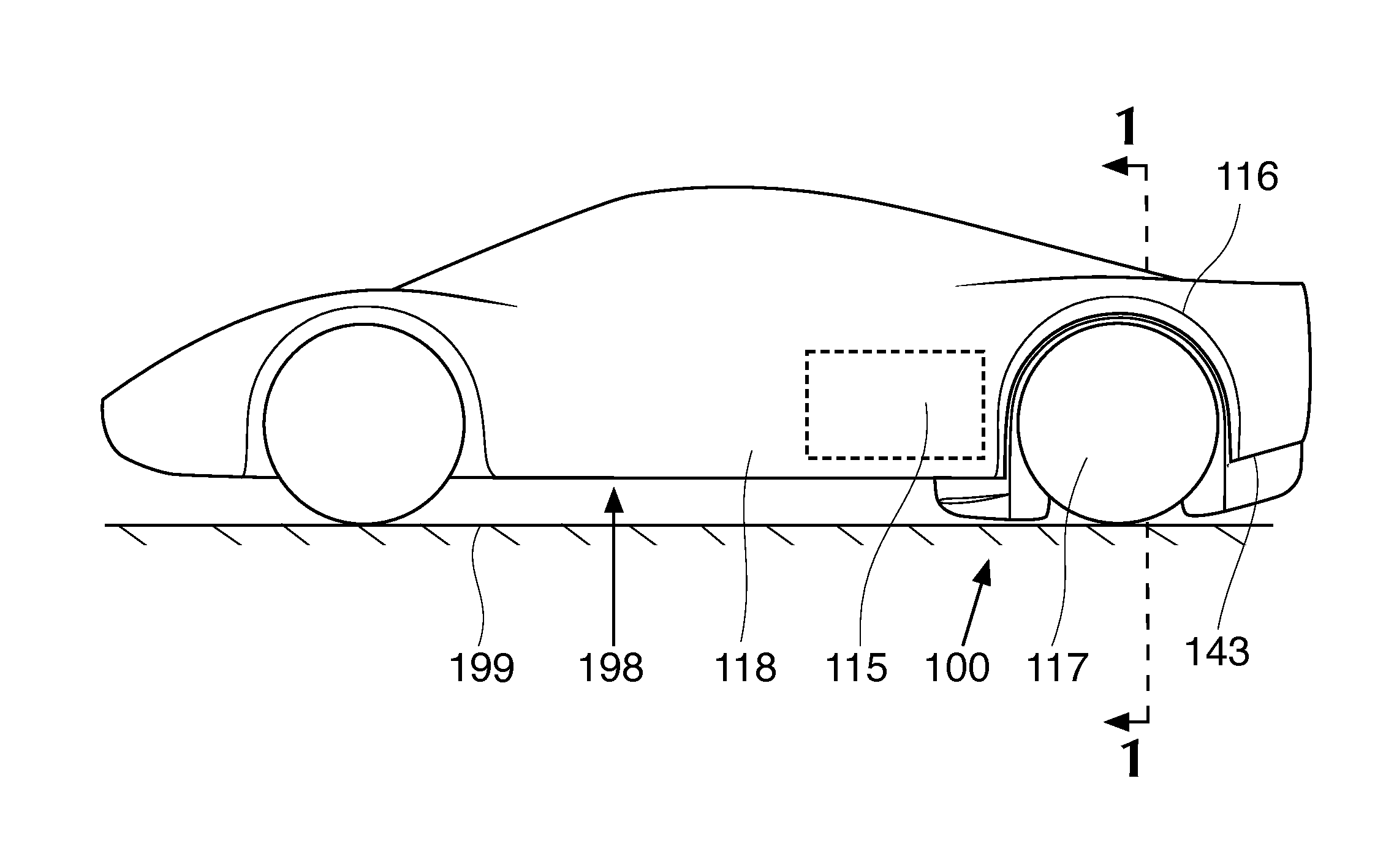

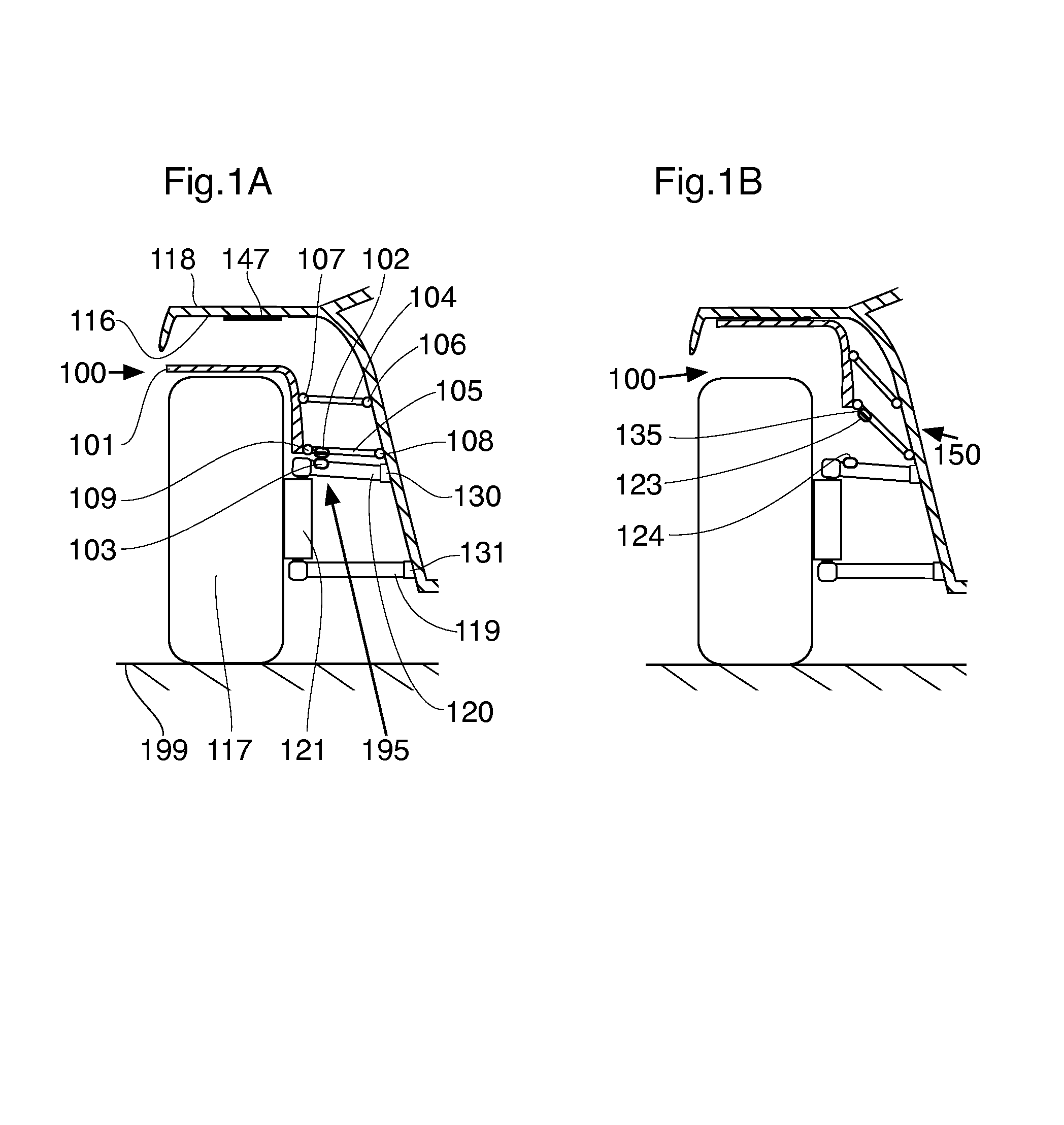

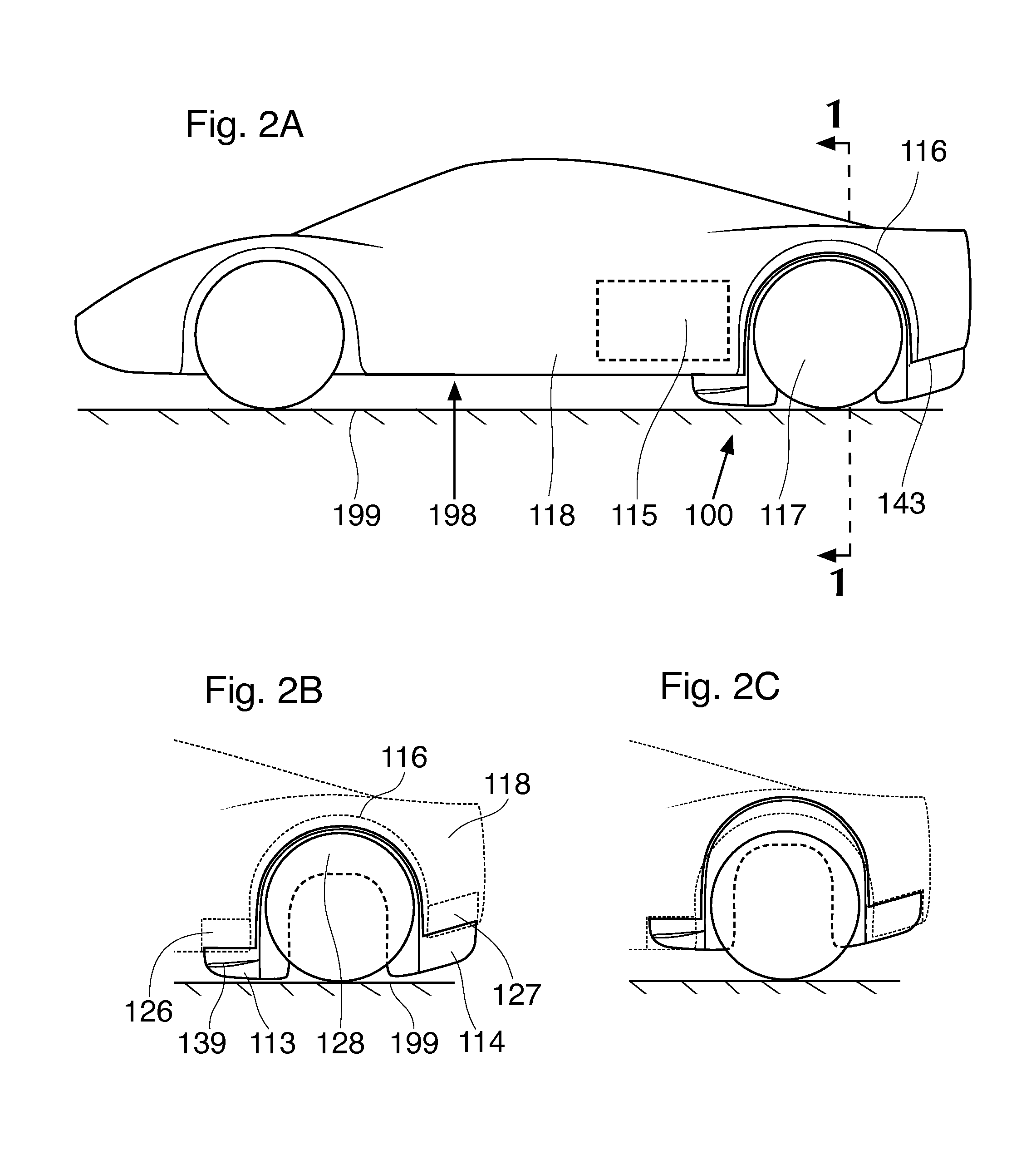

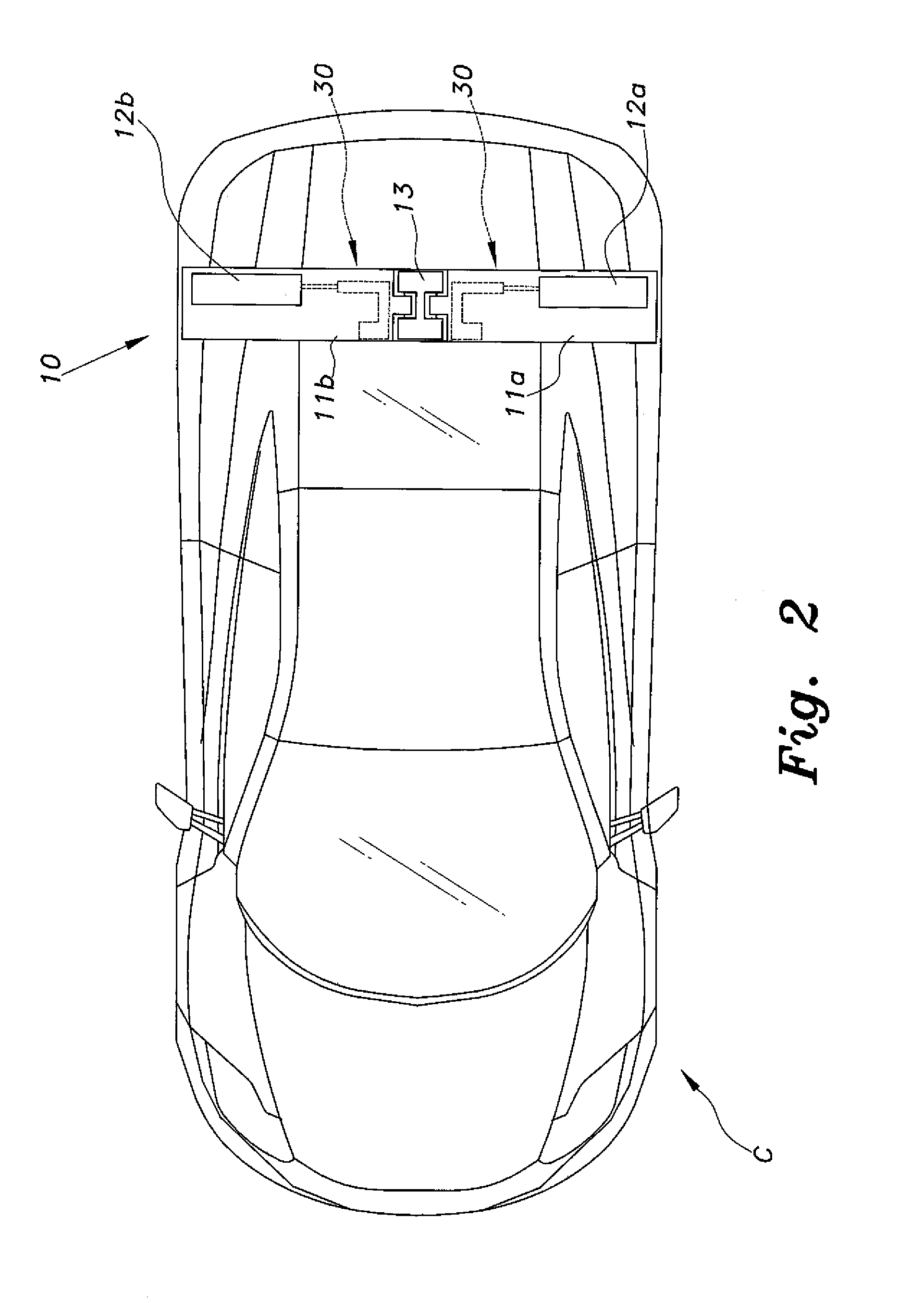

Retractable wheel fairings for motor vehicles

ActiveUS8979102B1Reduce air resistanceLower the volumeVehicle seatsVehicle body stabilisationSupporting systemAerodynamic drag

A retractable wheel fairing device for decreasing the aerodynamic drag and / or increasing downforce of a vehicle is described. The device includes a fairing body with a suspension-mounted support system such that the fairing body, when deployed, reciprocates up and downwardly with the corresponding wheel of the vehicle. The suspension-mounted support system is adapted to functionally or physically disengage the wheel fairing device from the suspension of the vehicle upon lifting of the wheel fairing device with a separate retraction system.

Owner:PRENTICE MICHAEL

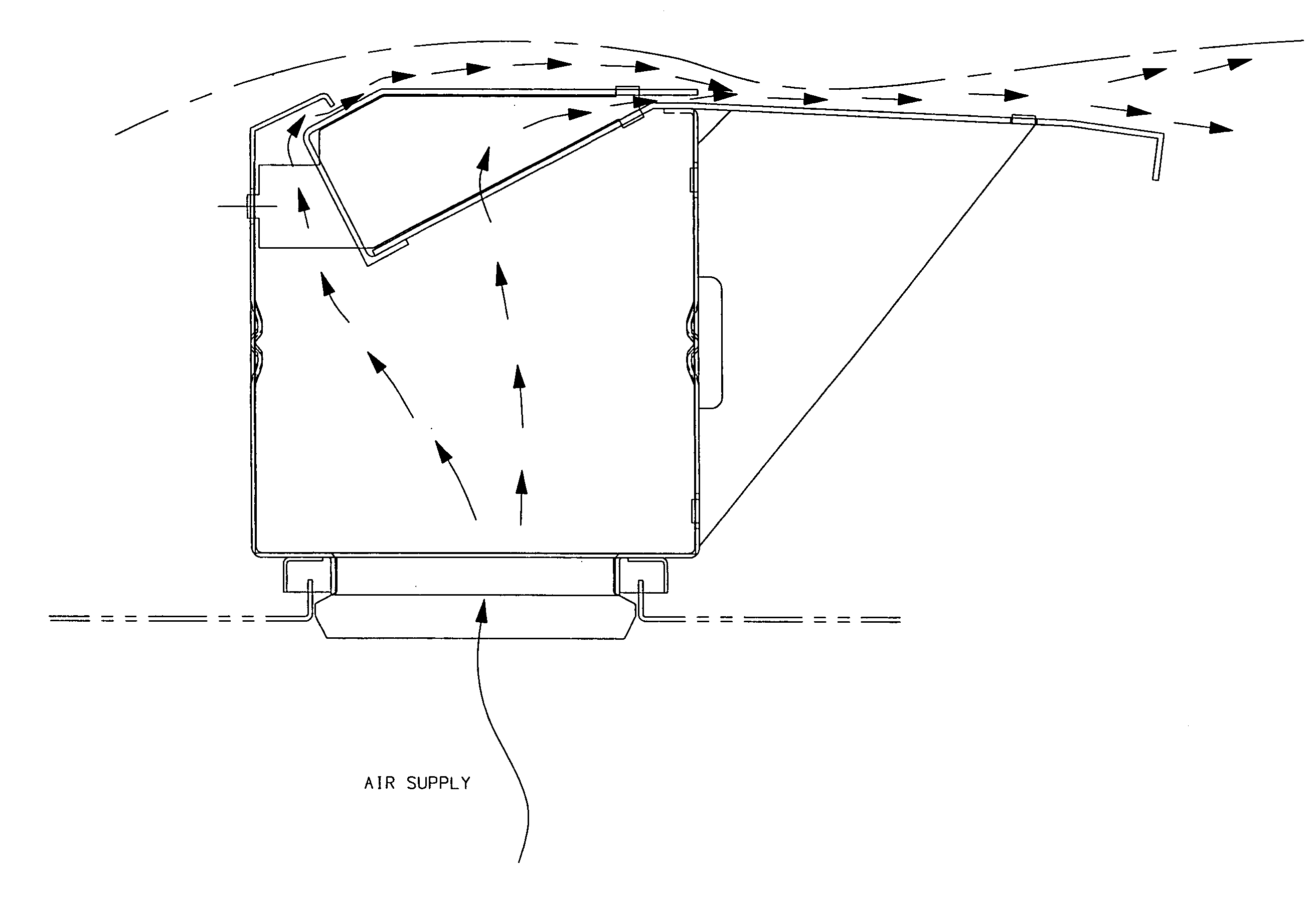

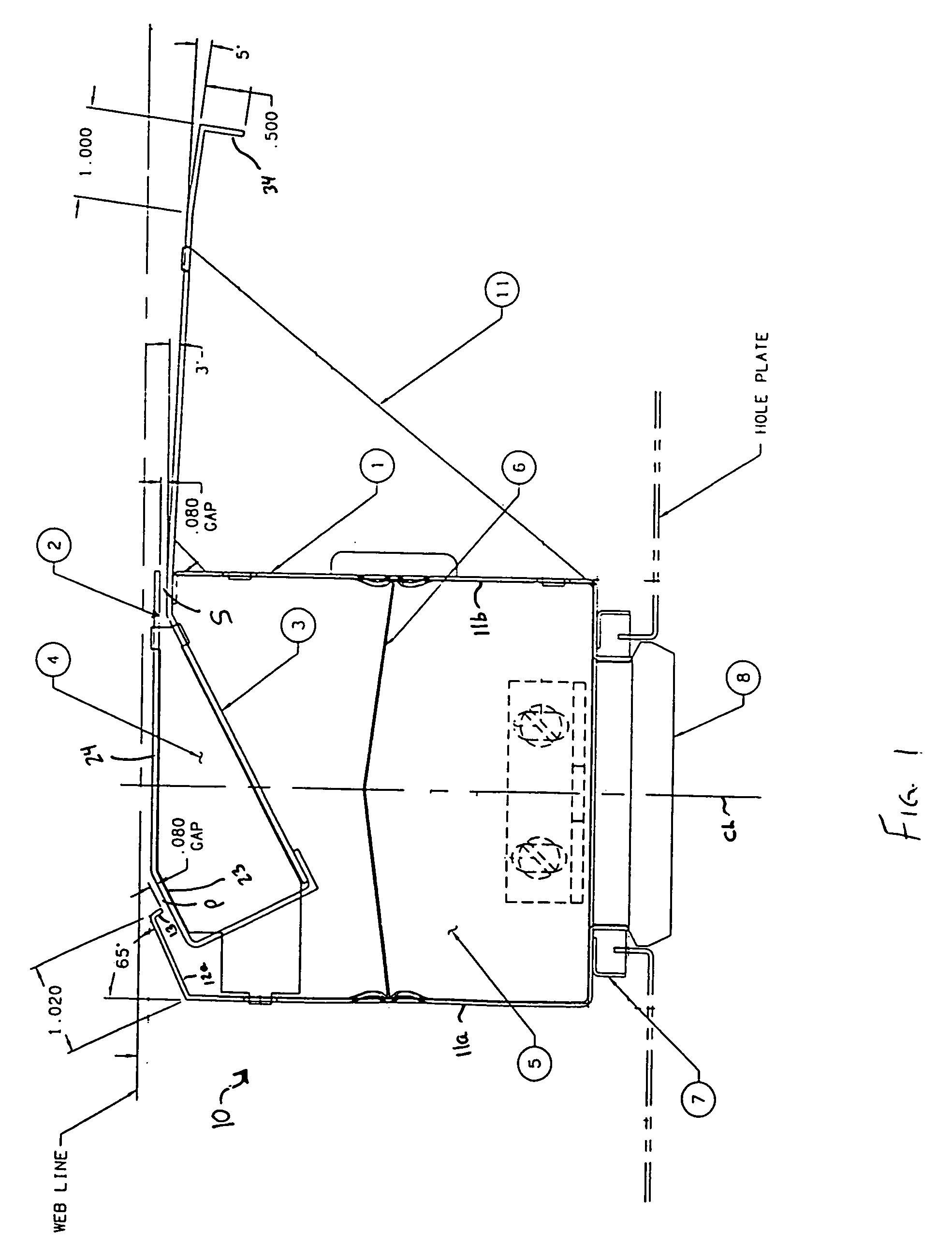

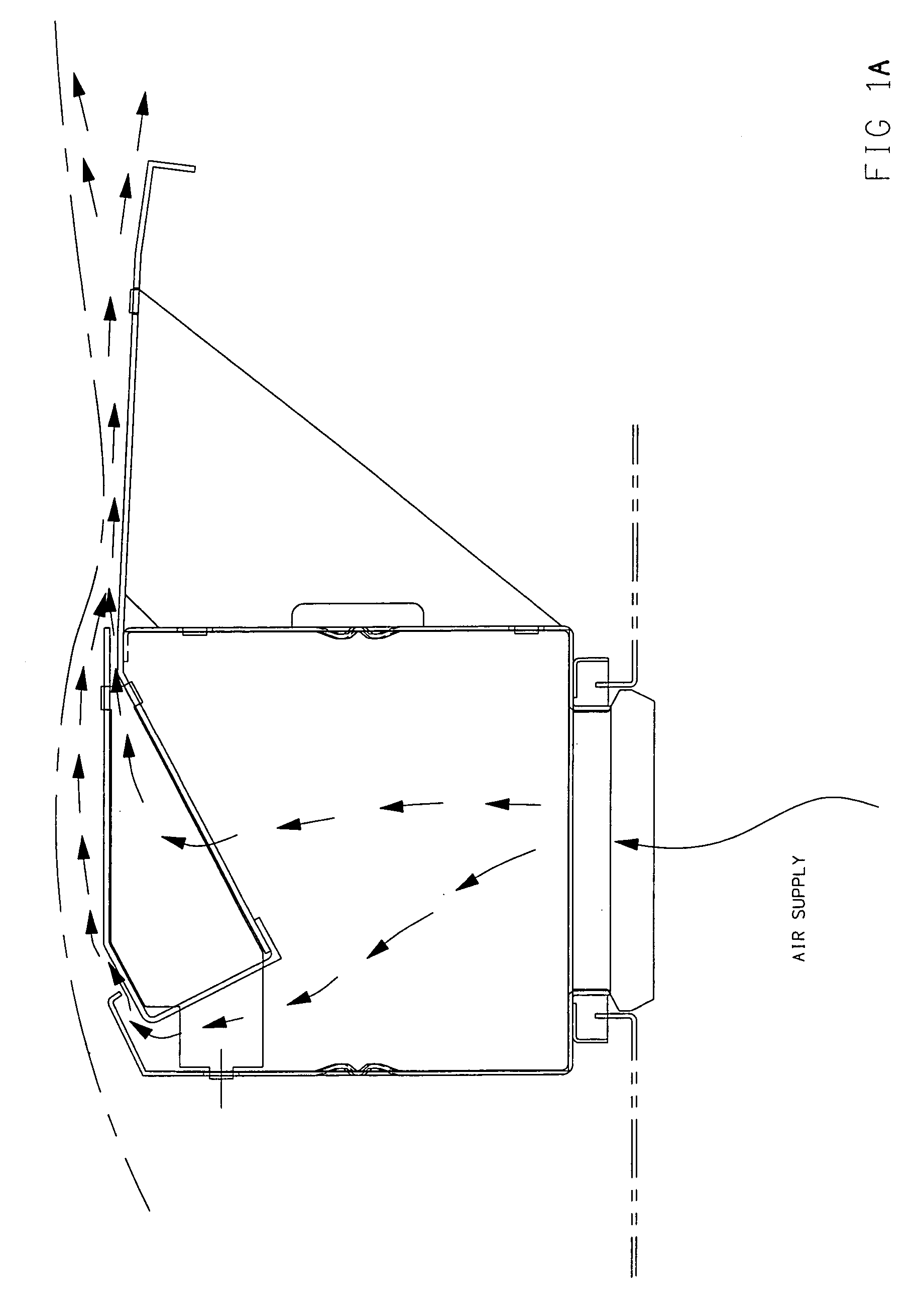

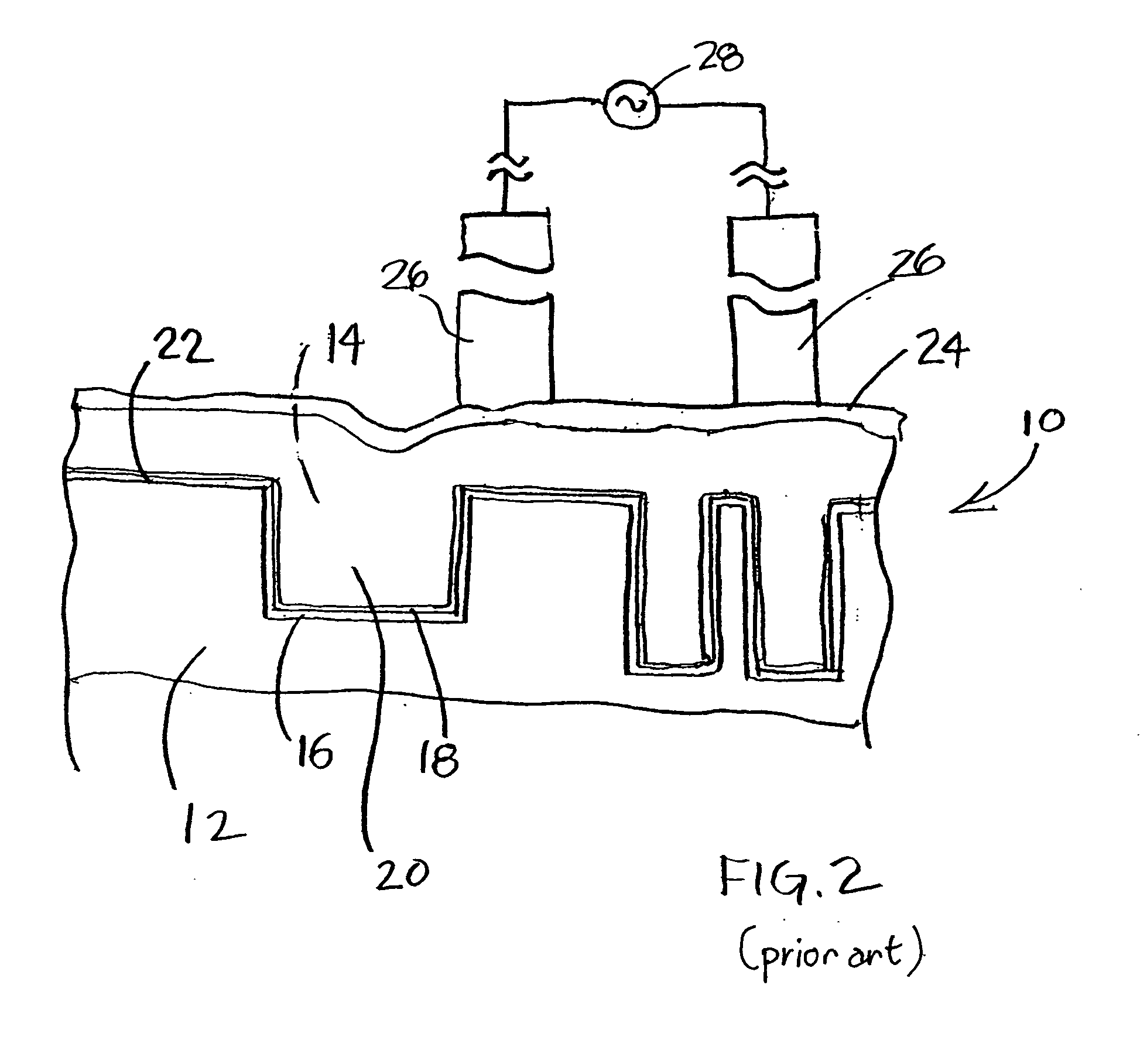

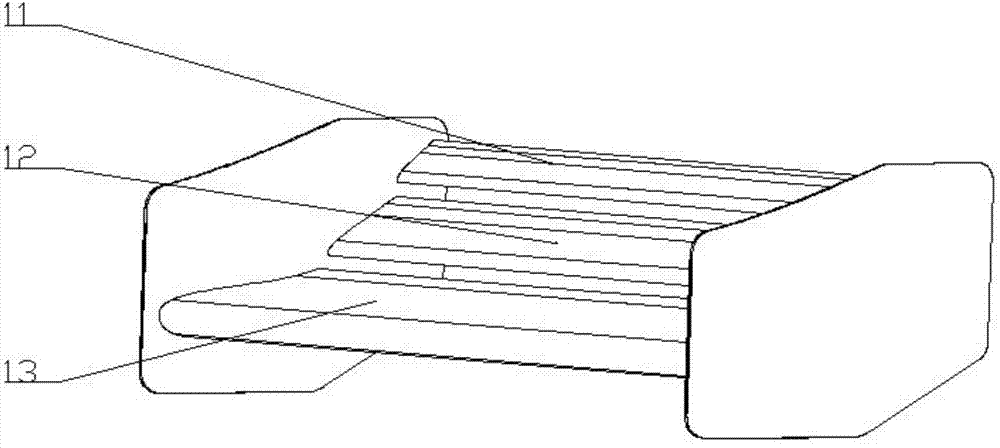

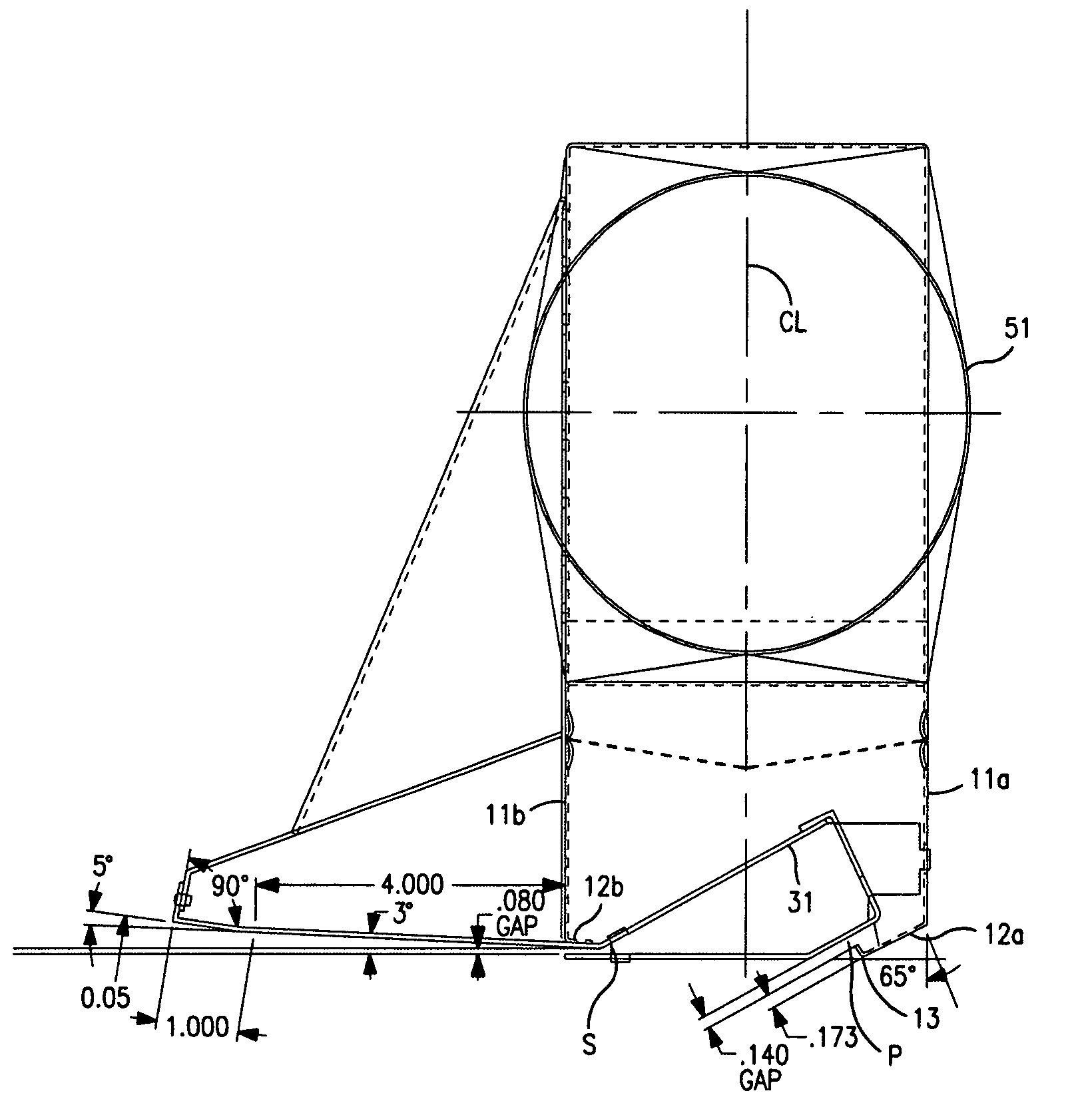

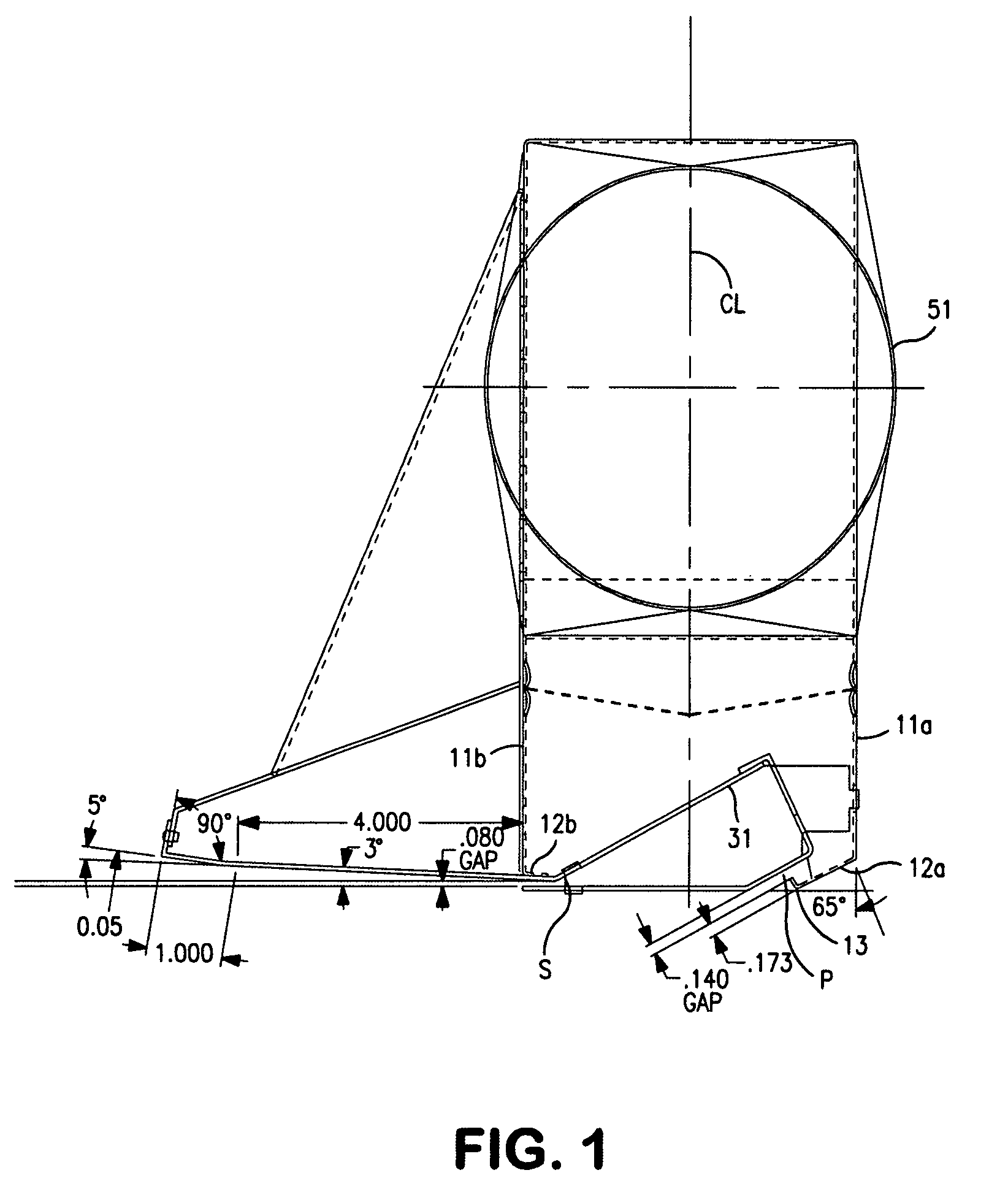

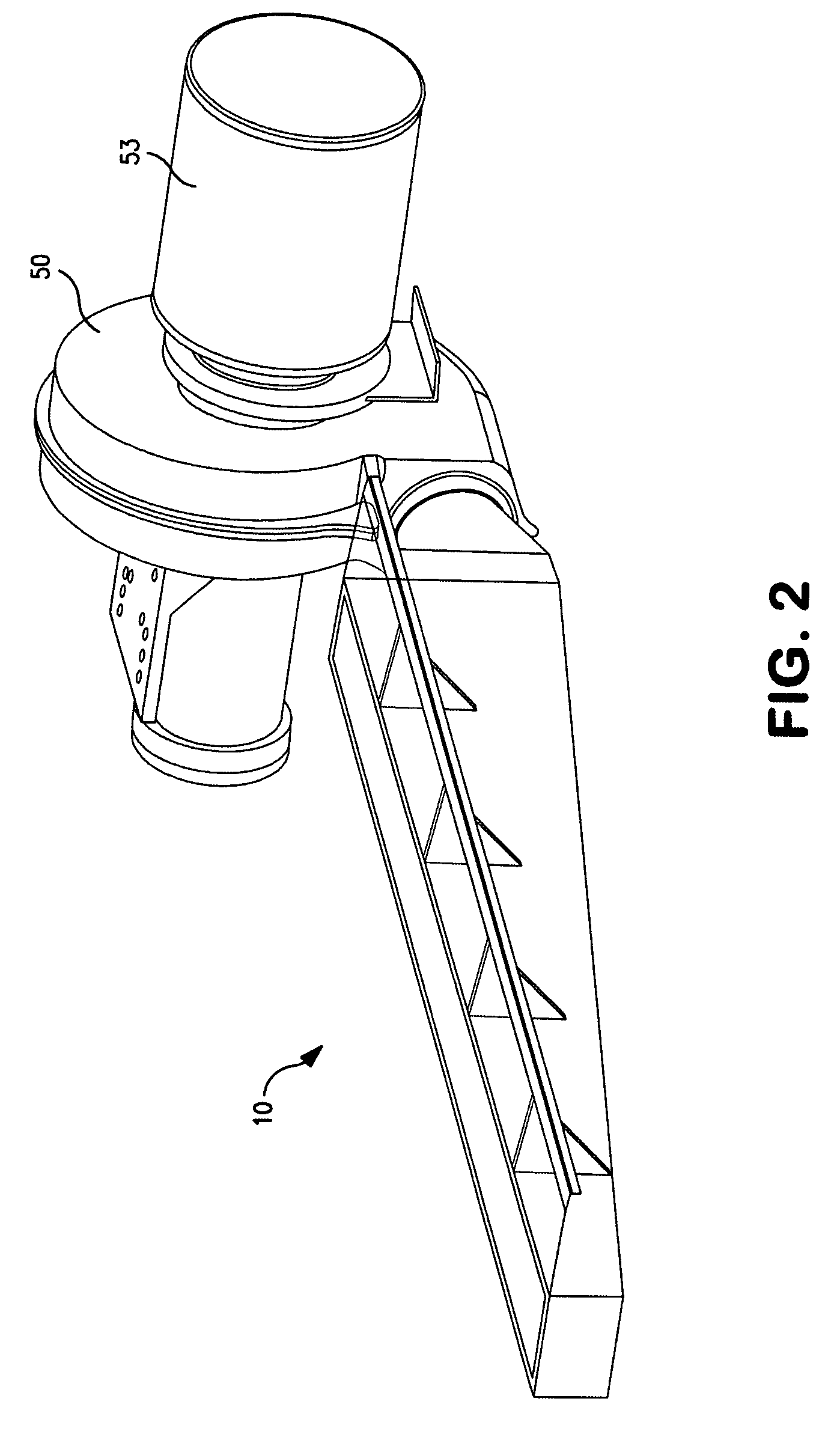

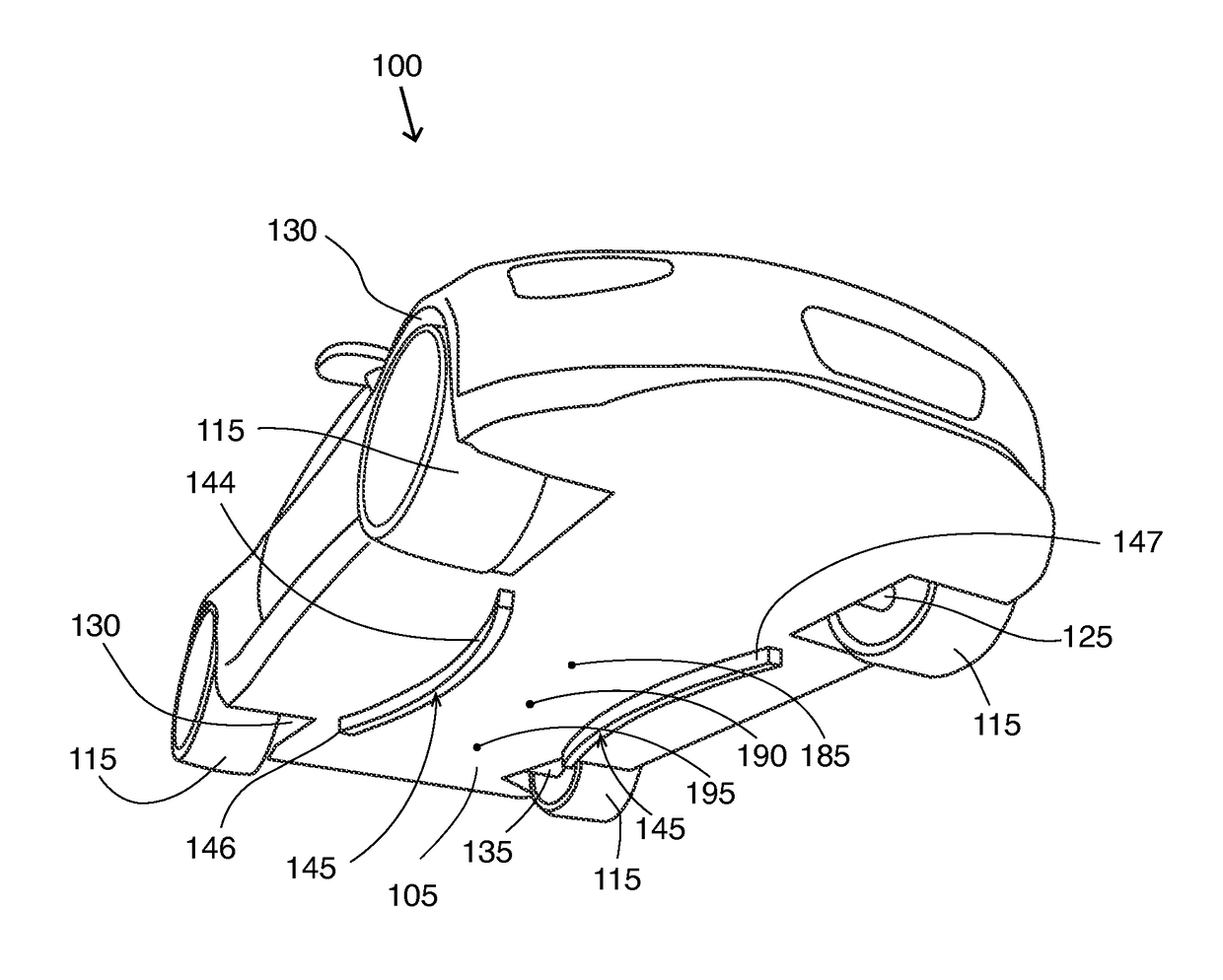

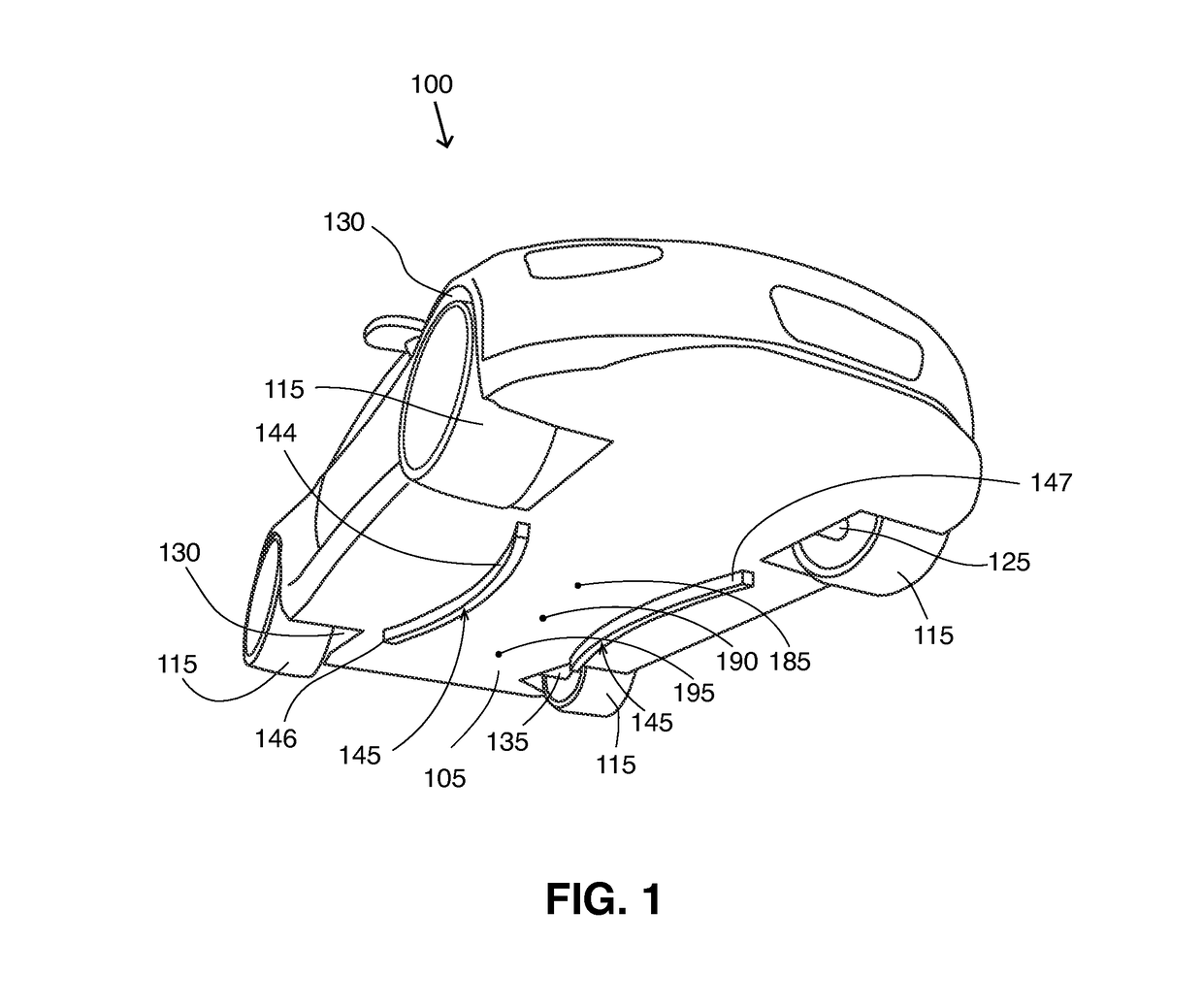

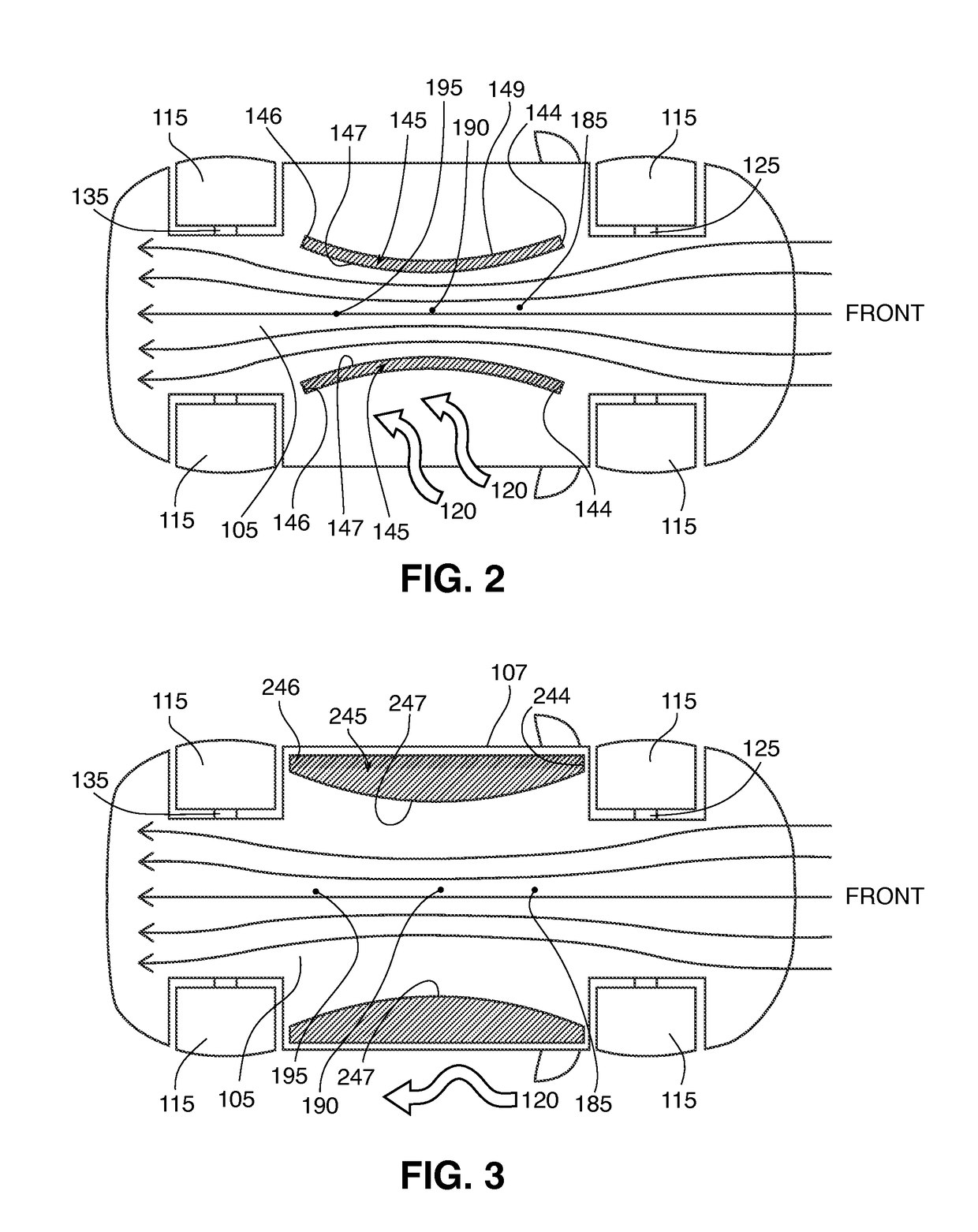

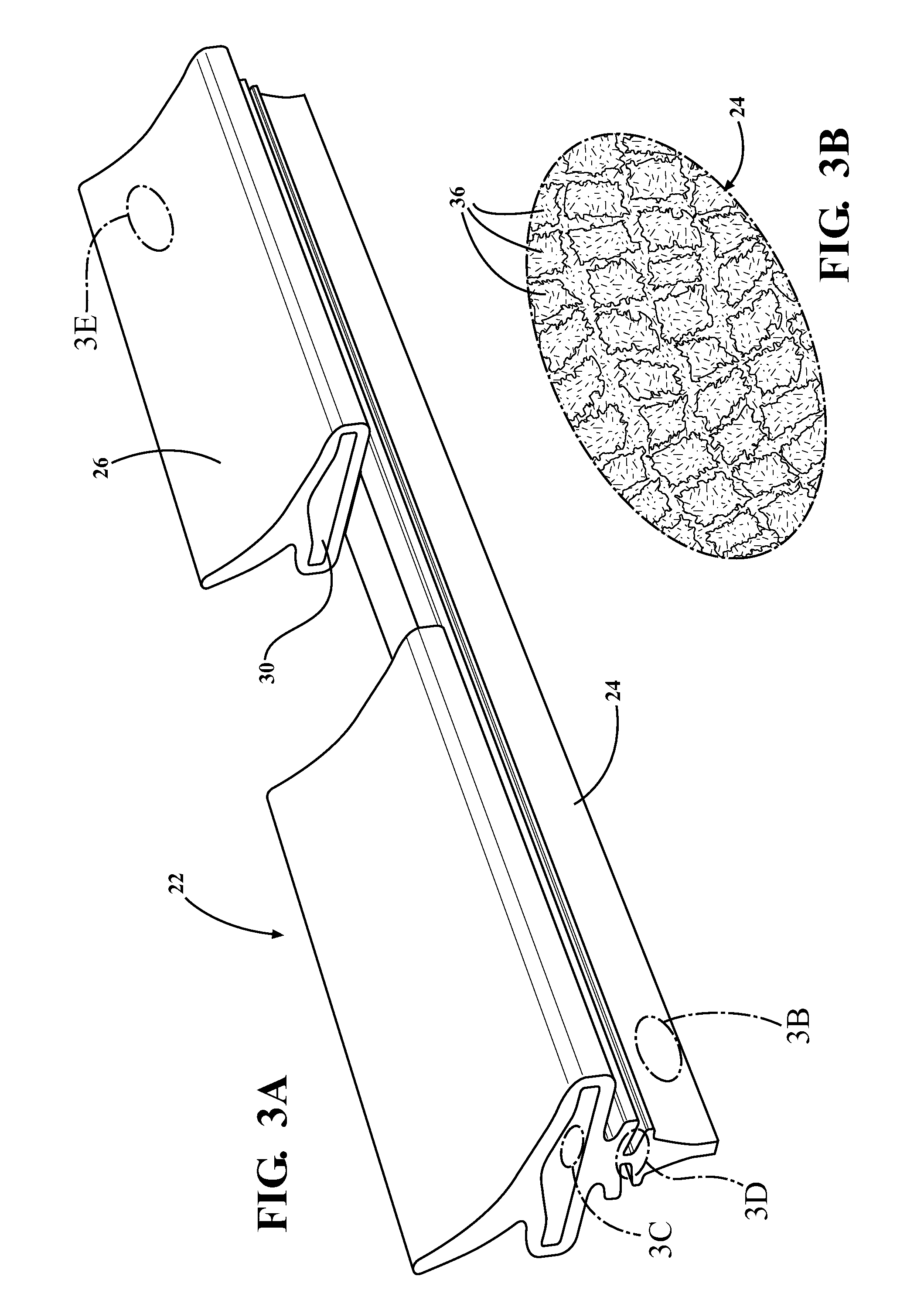

Step air foil

ActiveUS7530179B2Stable supportIncrease downforceProjector film strip handlingCamera film strip handlingWrinkle skinFiber

Step air foil particularly for one-sided flotation of a running web, and web dryer incorporating the same. The air foil includes two discharge slots which allow for increased draw down force, which flattens machine direction wrinkles in a floating web. The air foil includes a primary discharge slot and a second discharge slot spaced from and stepped down from the primary discharge slot, a first web support surface between the primary discharge slot and the secondary discharge slot, and a second web support surface downstream of the secondary discharge slot in the direction of web travel. The air foil is in communication with an air supply which provides a supply of air that is uniformly distributed to the primary and secondary slots. Air discharged from the primary slot is gathered into the air stream of the secondary slot and creates an increased air cushion to provide greater support to the moving web and thereby remove machine direction web wrinkles caused by higher tension in light weight webs.

Owner:DURR SYST INC

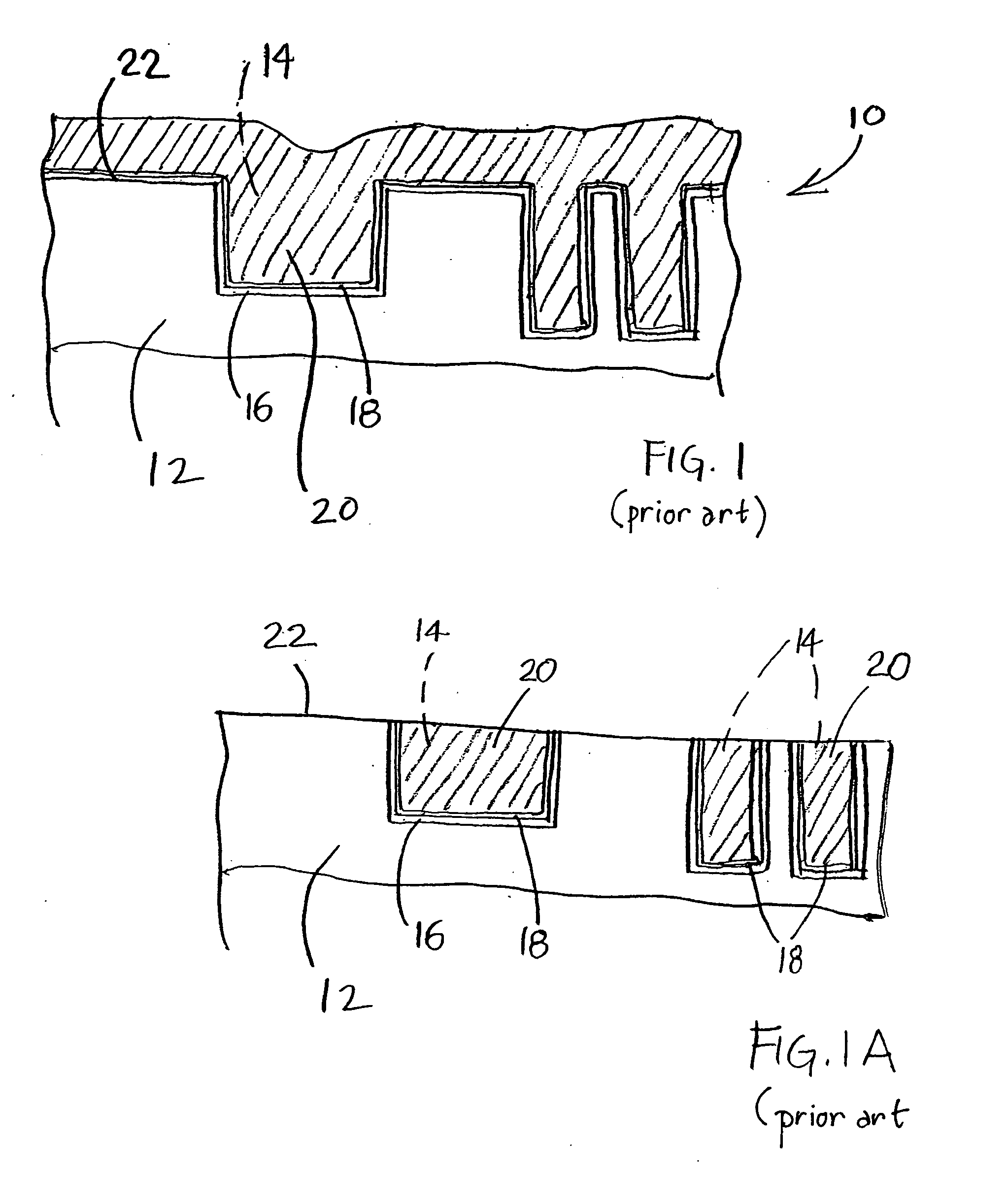

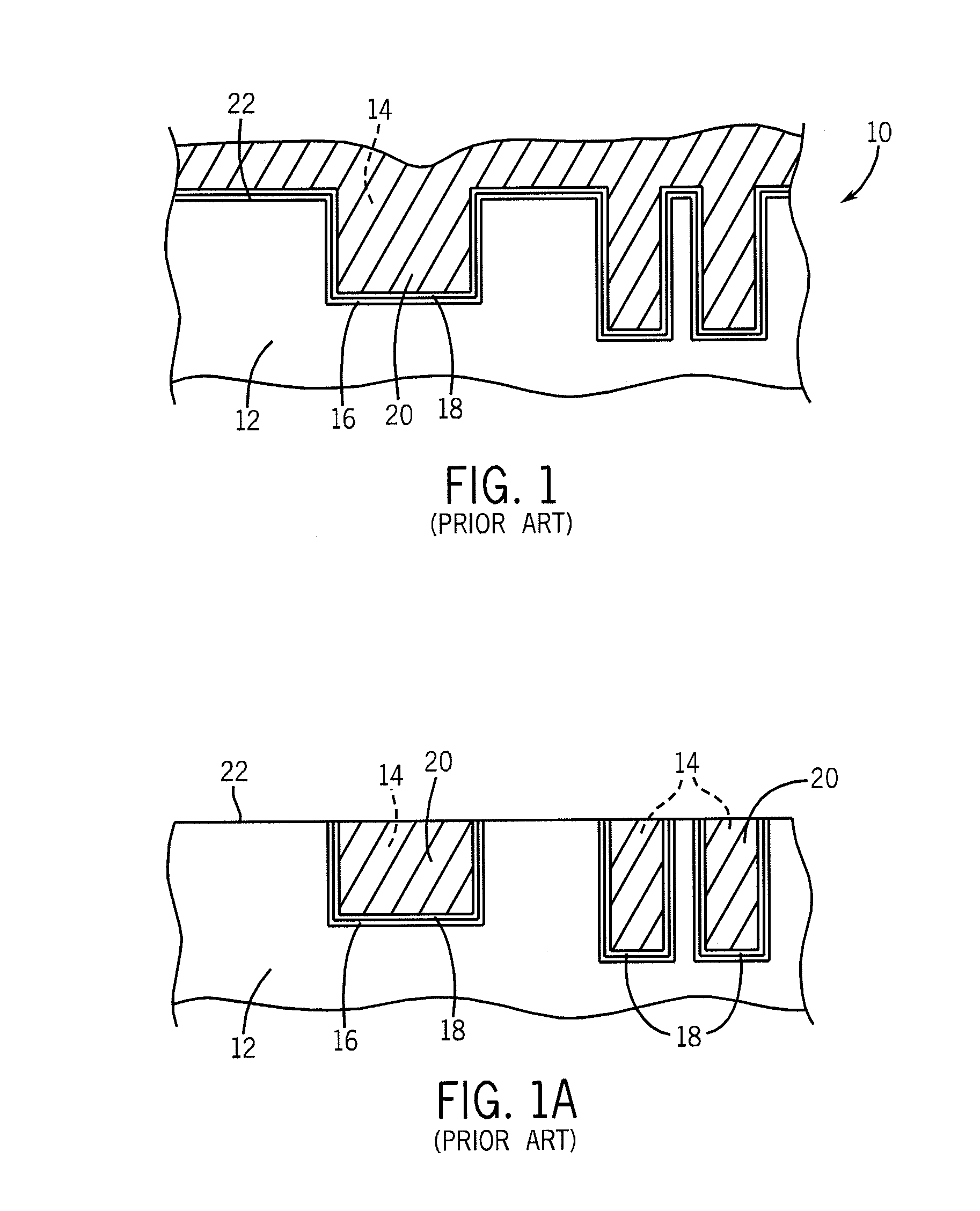

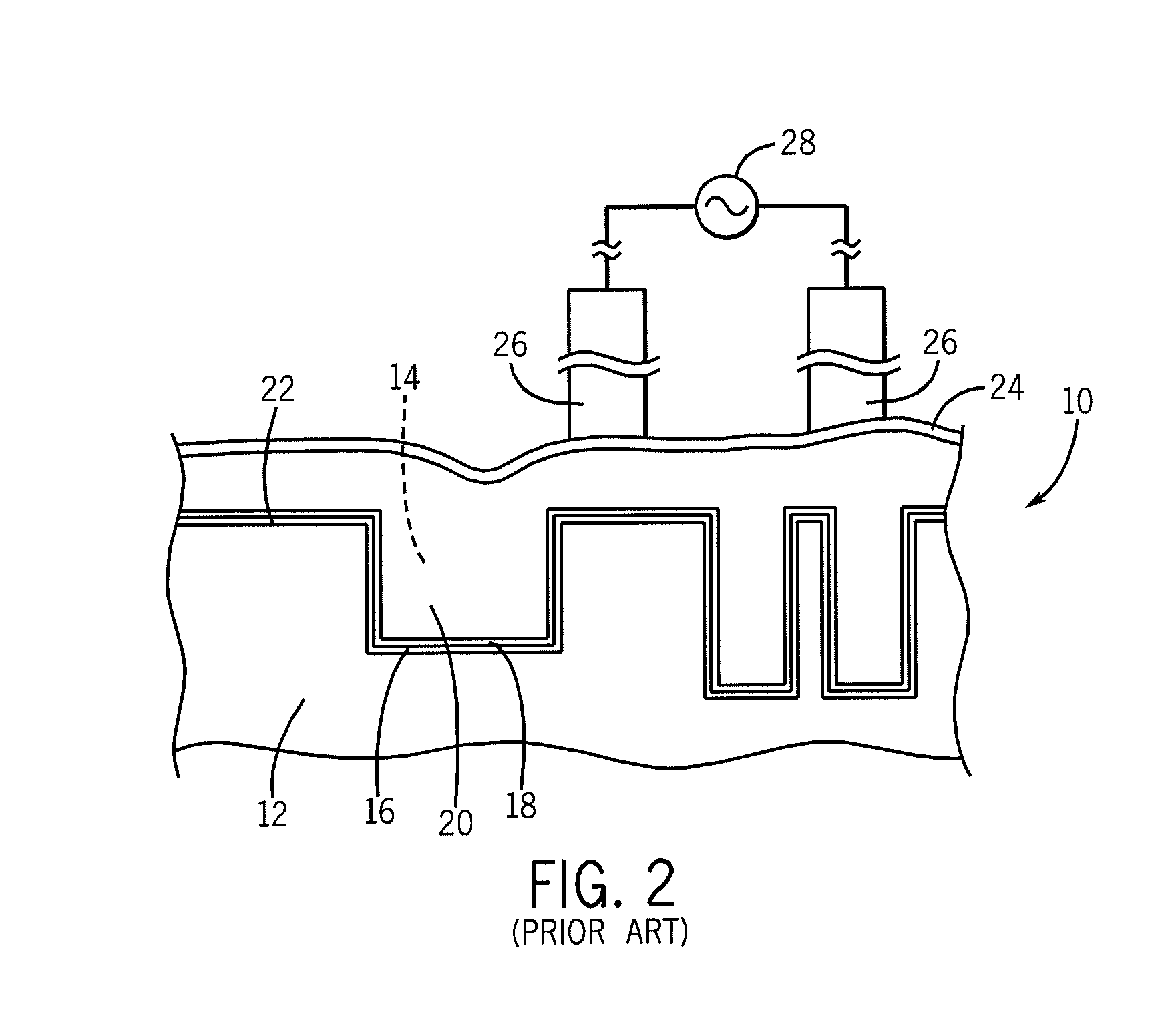

Method of selectively removing conductive material

InactiveUS20080041725A1Easy to disassembleSelective removal is facilitatedMaterial nanotechnologySludge treatmentCopper interconnectNanoparticle

An electrolyte solution, methods, and systems for selectively removing a conductive metal from a substrate are provided. The electrolyte solution comprising nanoparticles that are more noble than the conductive metal being removed, is applied to a substrate to remove the conductive metal selectively relative to a dielectric material without application of an external potential or contact of a processing pad with the surface of the substrate. The solutions and methods can be applied, for example, to remove a conductive metal layer (e.g., barrier metal) selectively relative to dielectric material and to a materially different conductive metal (e.g., copper interconnect) without application of an external potential or contact of a processing pad with the surface of the substrate.

Owner:MICRON TECH INC

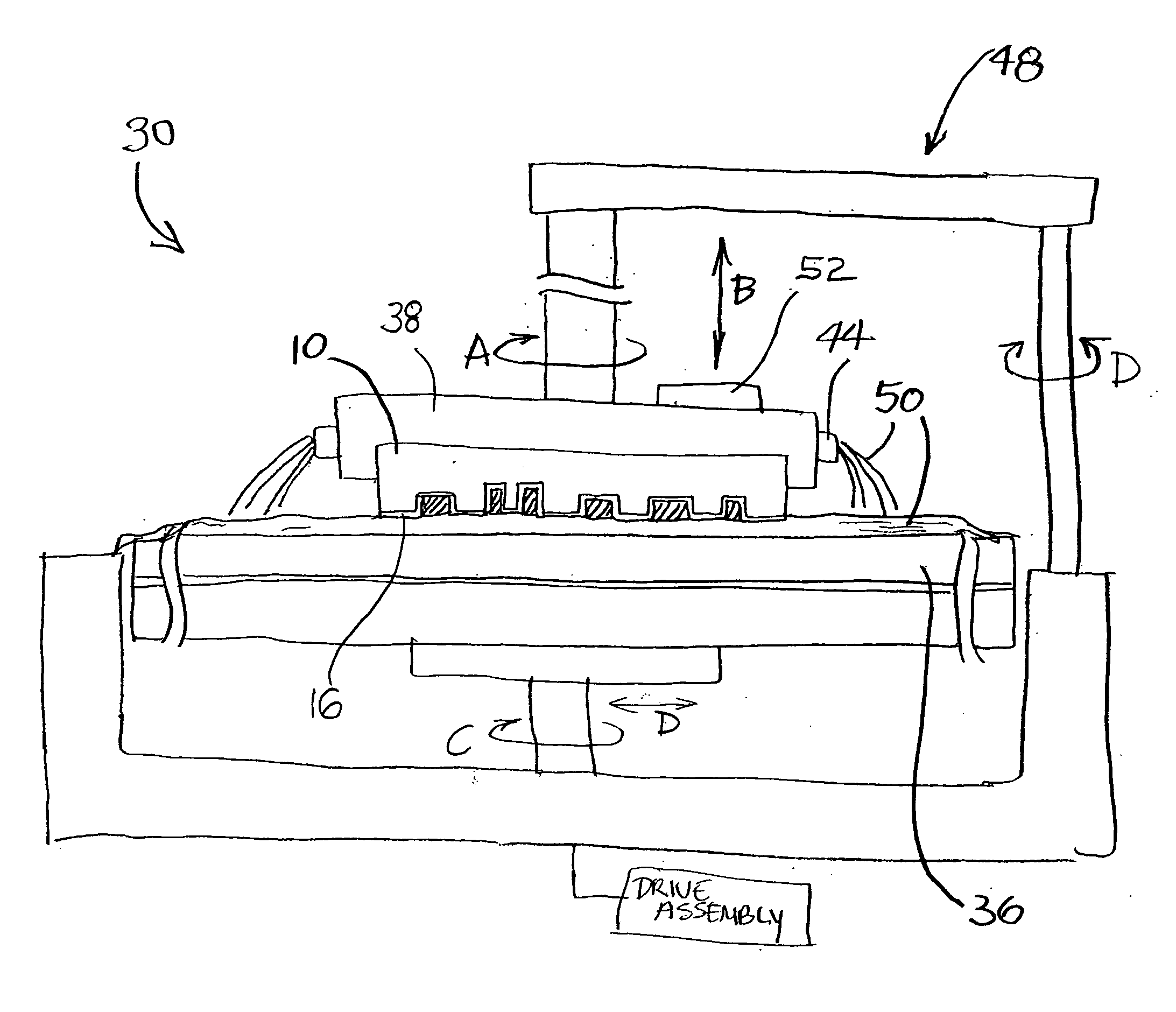

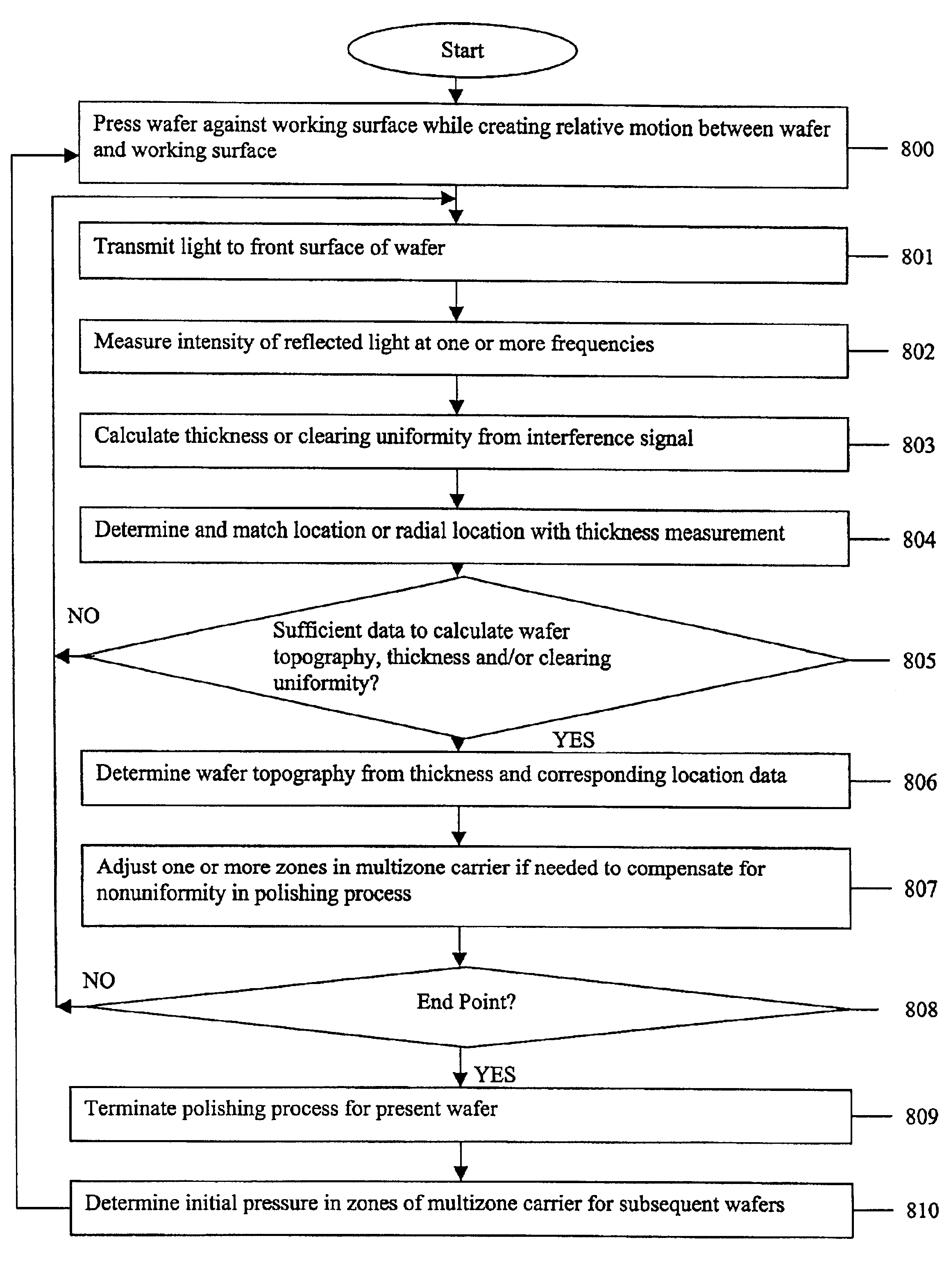

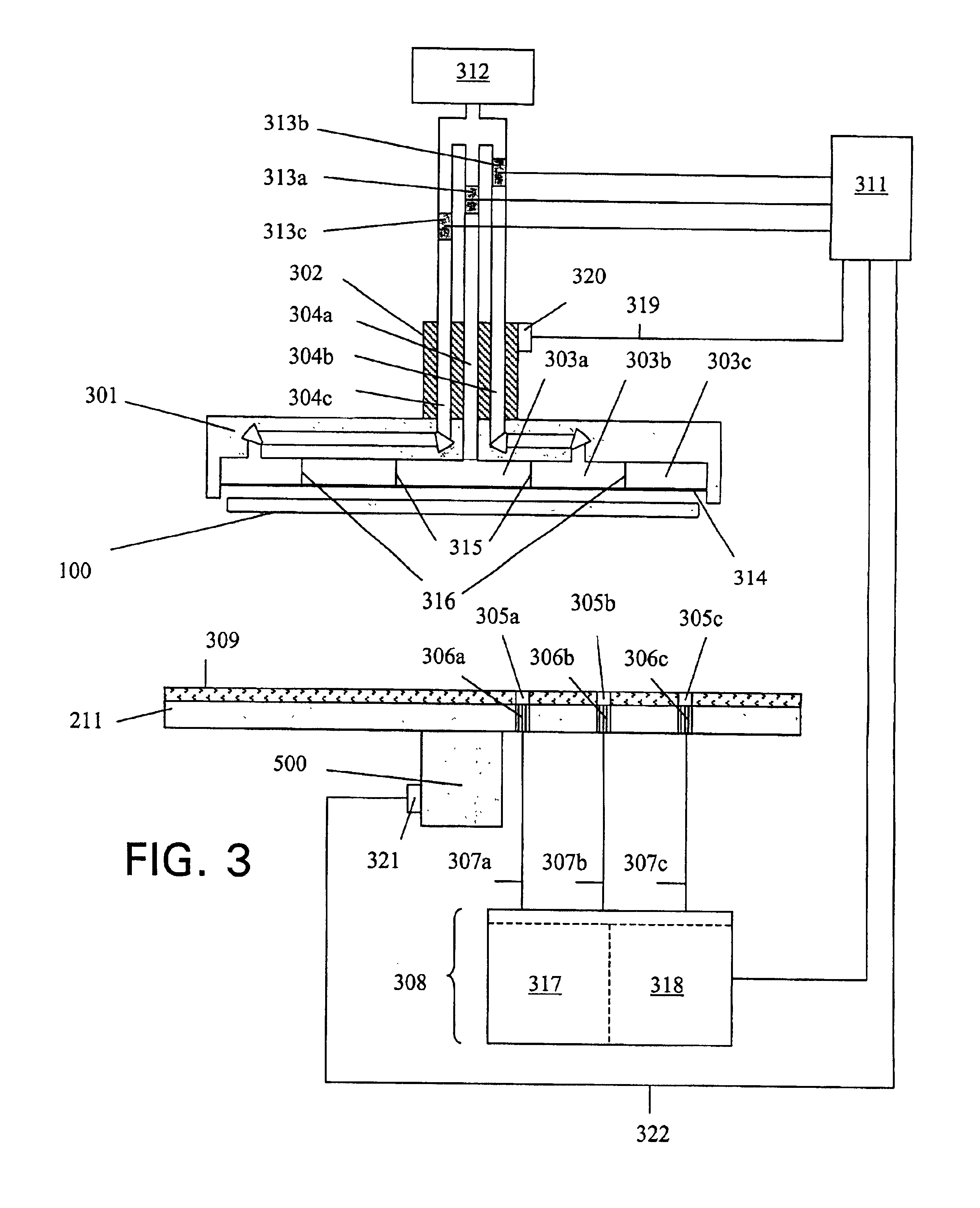

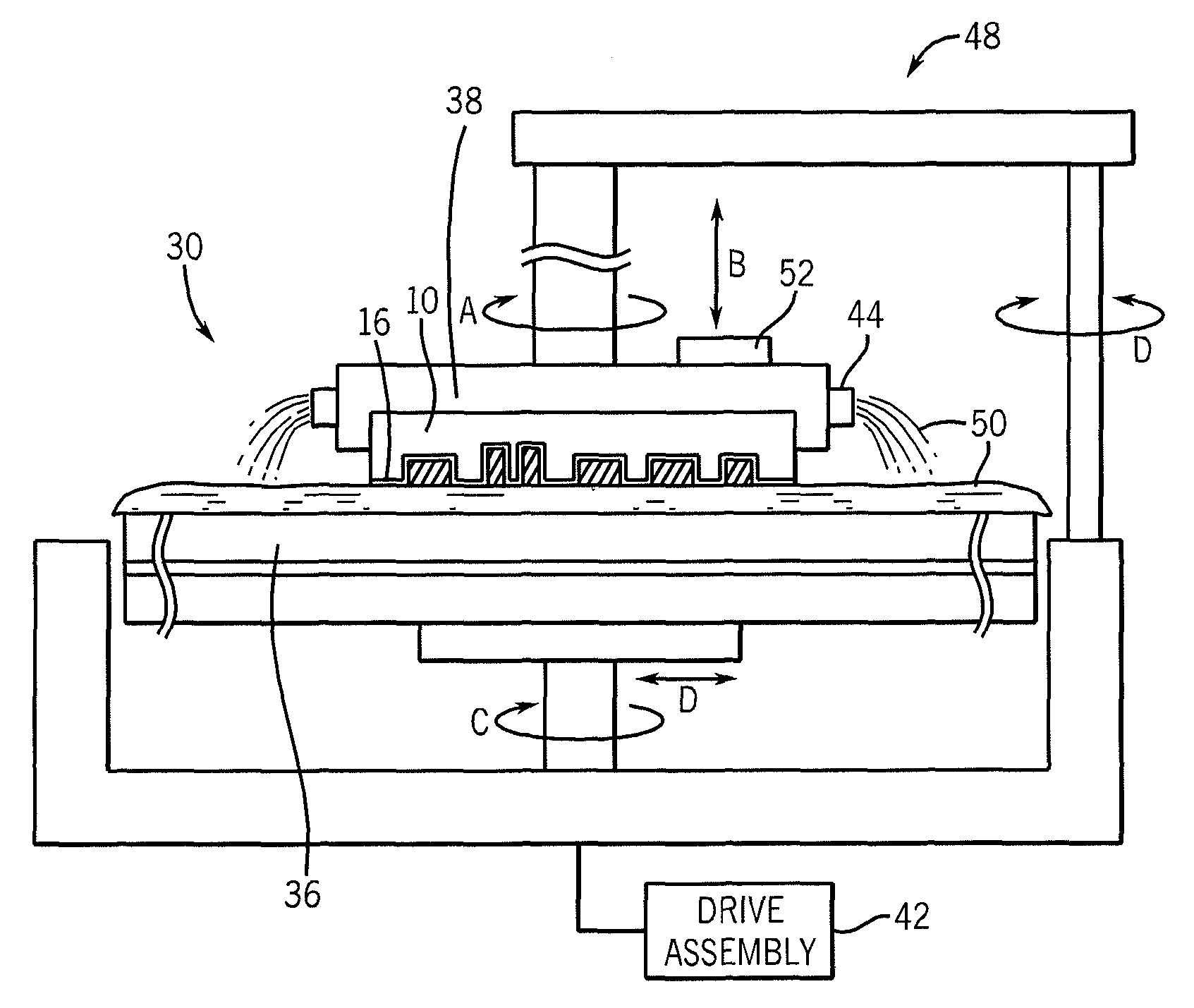

Multizone carrier with process monitoring system for chemical-mechanical planarization tool

InactiveUS6923711B2Increase downforceHigh removal ratePolishing machinesRevolution surface grinding machinesMetrologyRadial position

The invention improves a polishing process for a wafer retained in a multizone carrier in a chemical mechanical polishing tool. A light signal is communicated to the front surface of the wafer and the reflected light signal is captured by a metrology instrument. The metrology instrument communicates the intensity of the reflected light to a control system. The location or radial position corresponding to the reflected light signal from the front surface of the wafer may be determined by the control system. From the intensity measurements and corresponding locations, the control system is able to determine an approximate topography of the wafer. The control system may alter the pressure within one or more zones within the multizone carrier to improve the polishing process. The control system may also alter the initial pressures within the multizone carrier for future wafers based on the polishing results from the present wafer.

Owner:NOVELLUS SYSTEMS

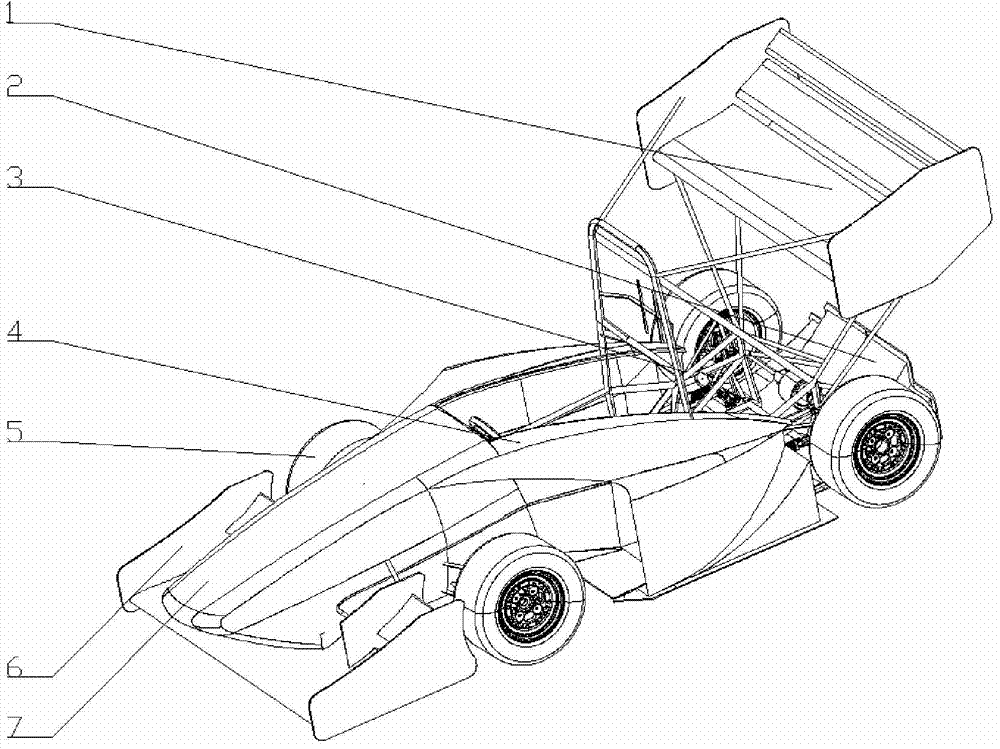

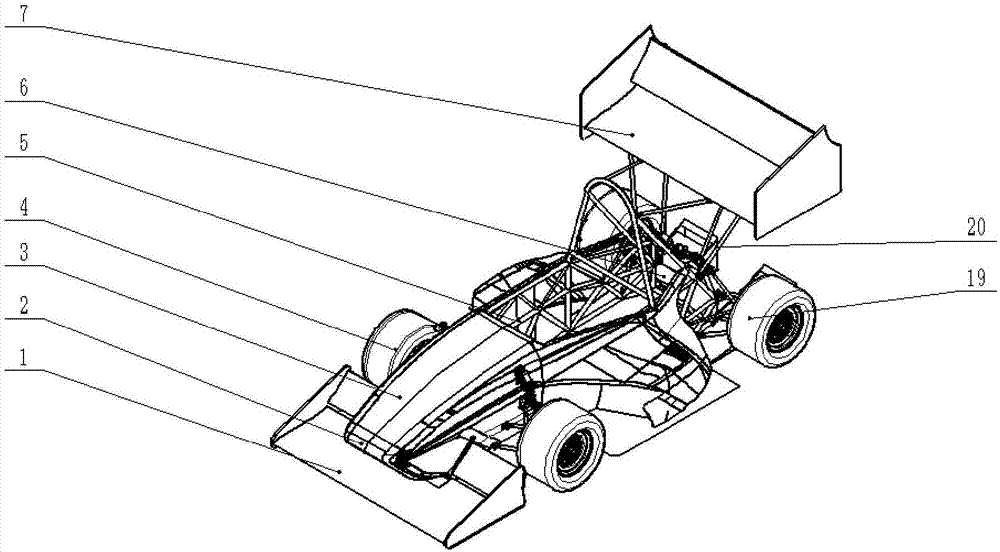

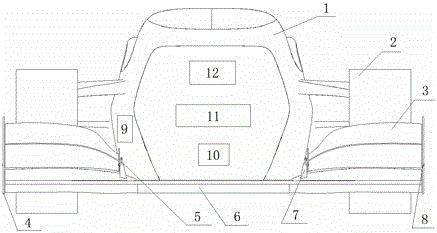

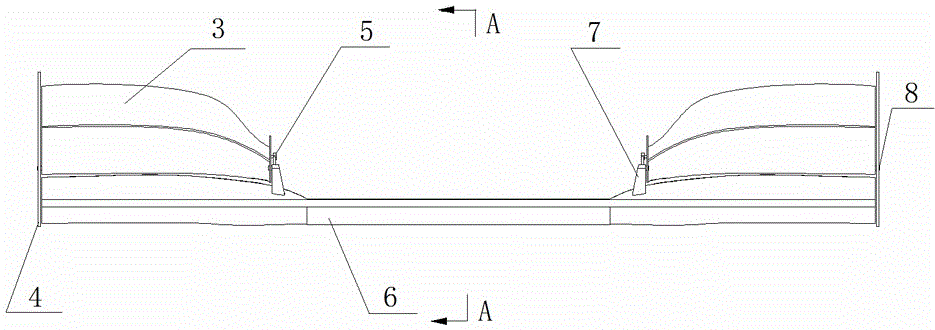

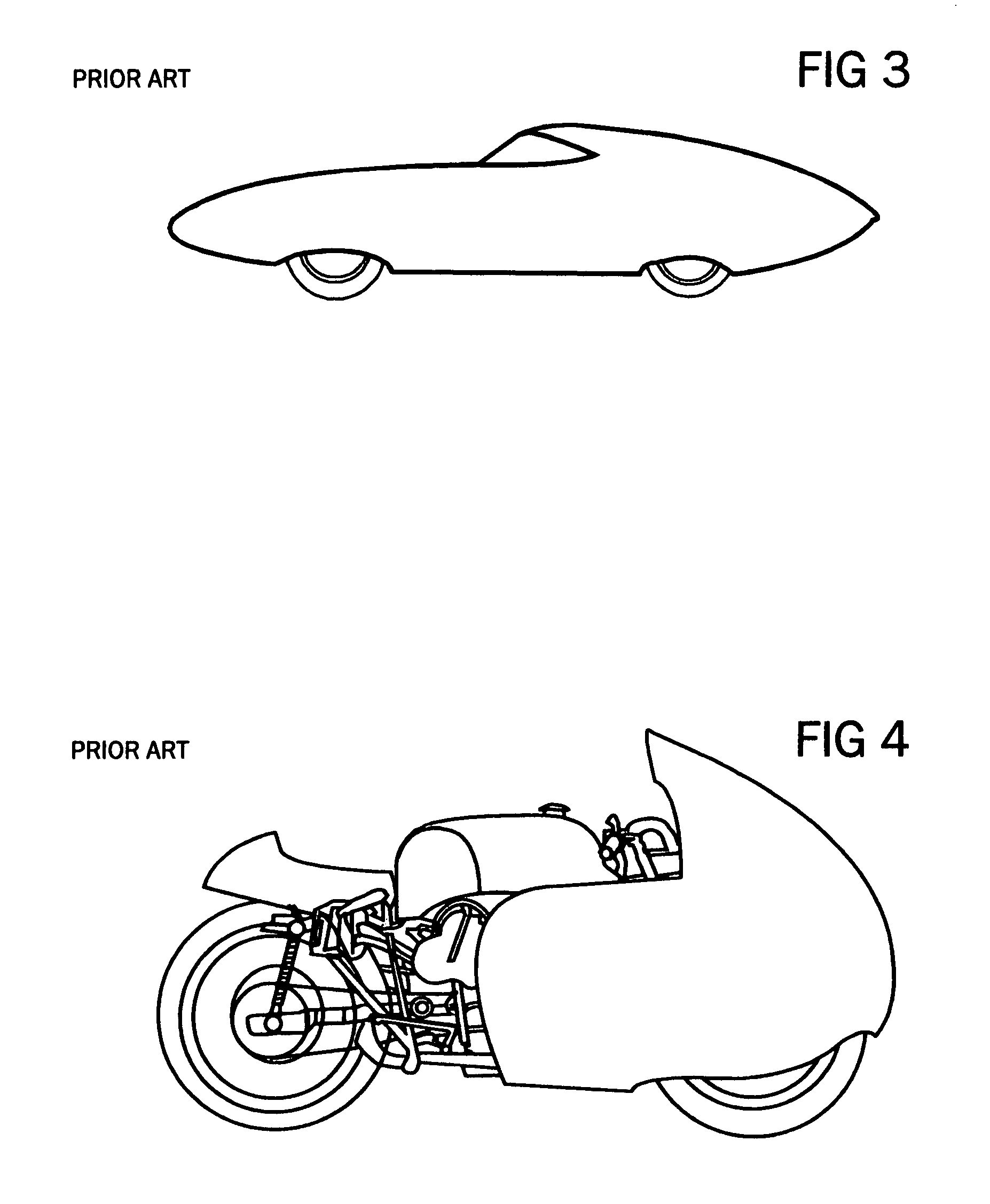

FSAE racing car aerodynamic suite

InactiveCN104742987AIncrease downforceImprove ground adhesionVehicle body stabilisationVehicle body streamliningVehicle frameObstacle avoidance

The invention discloses an FSAE racing car aerodynamic suite. The FSAE racing car aerodynamic suite comprises a rear wing (1), a tail-end diffuser (2) and a front nose wing (6) which are in rigidity connection with a car frame (3), wherein the front nose wing (6) is located at the lower portion of the racing car head, and the rear wing (1) and the tail-end diffuser (2) are upper-and-lower arranged and are installed at the tail of the racing car. The FSAE racing car aerodynamic suite can improve the down force of the FSAE racing car greatly, so that a good ground adhesive force is obtained by the racing car, and excellent dynamic property is acquired; the aerodynamic property and handling stability of the racing car can be improved, so that the speed and accelerated speed of the racing car when entering a curve and pulling out of the curve are greatly improved, and excellent turning driving property is obtained; thereby, the FASE racing car can acquire outstanding grades in the competition items of high-speed obstacle avoidance, eight-character circling and the like, and the FSAE racing car aerodynamic suite further has the advantages of being light in weight, simple in structure, convenient to assemble and disassemble, reliable in property, good in practicability and the like.

Owner:WUHAN UNIV OF TECH

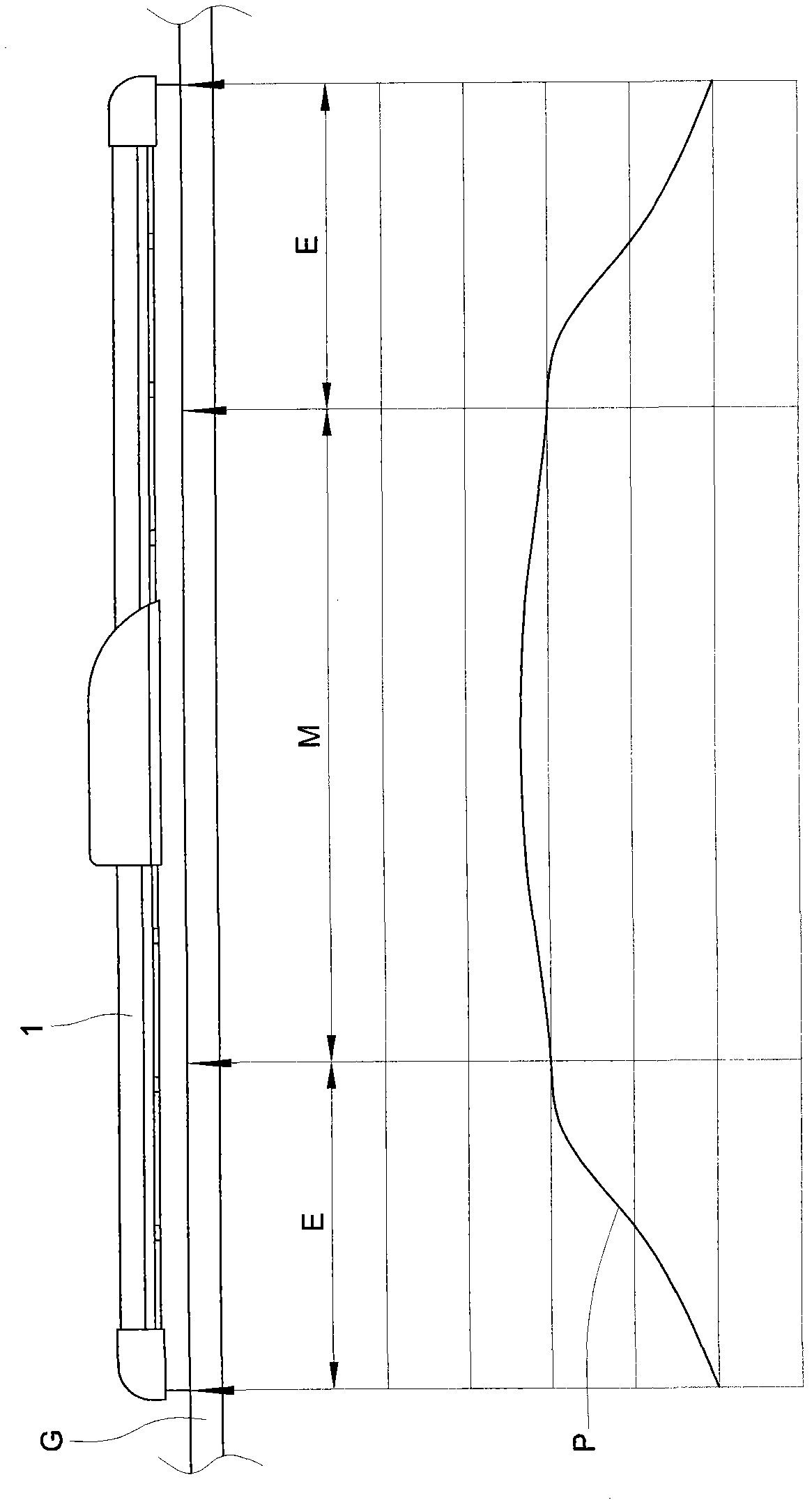

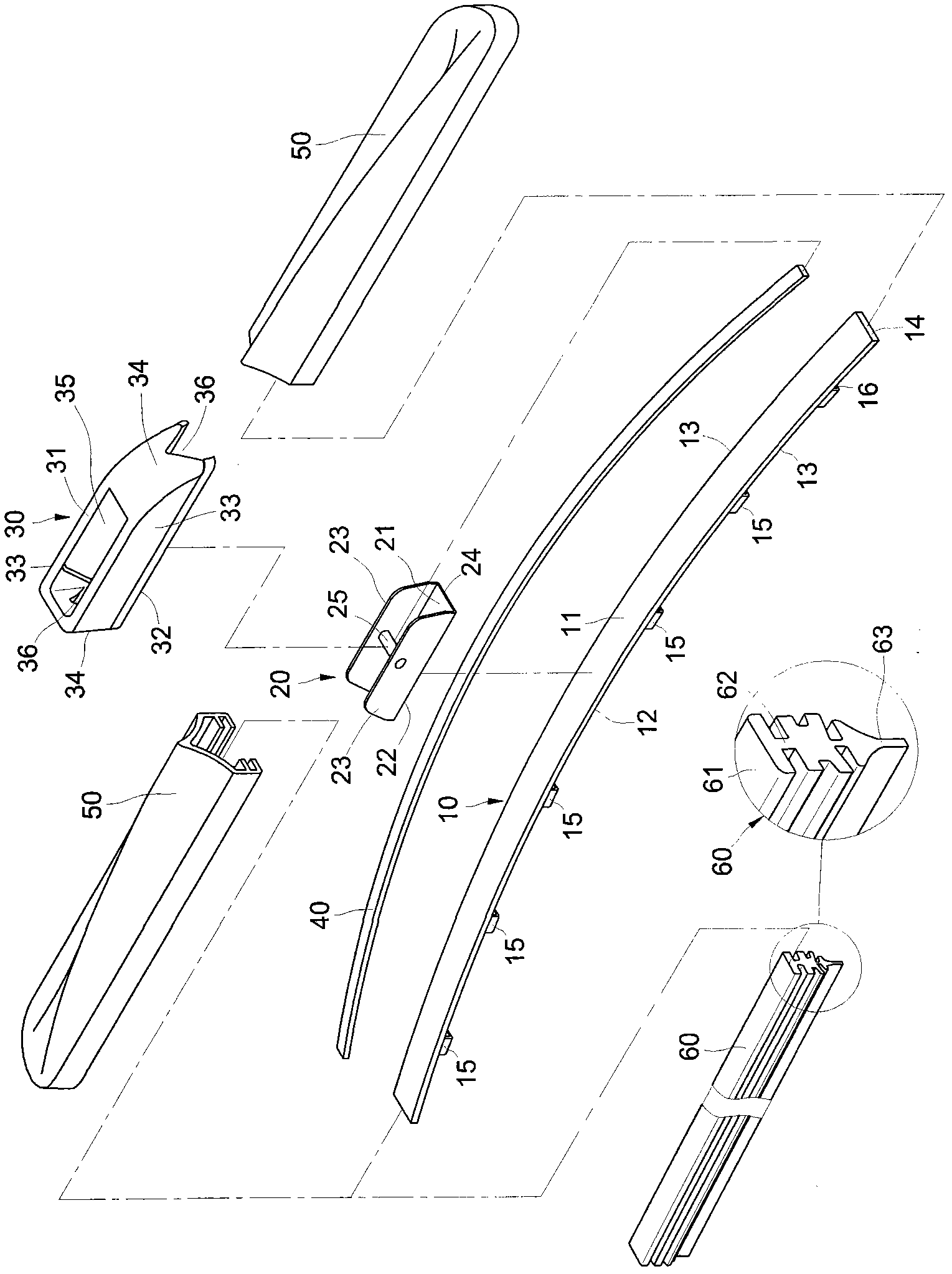

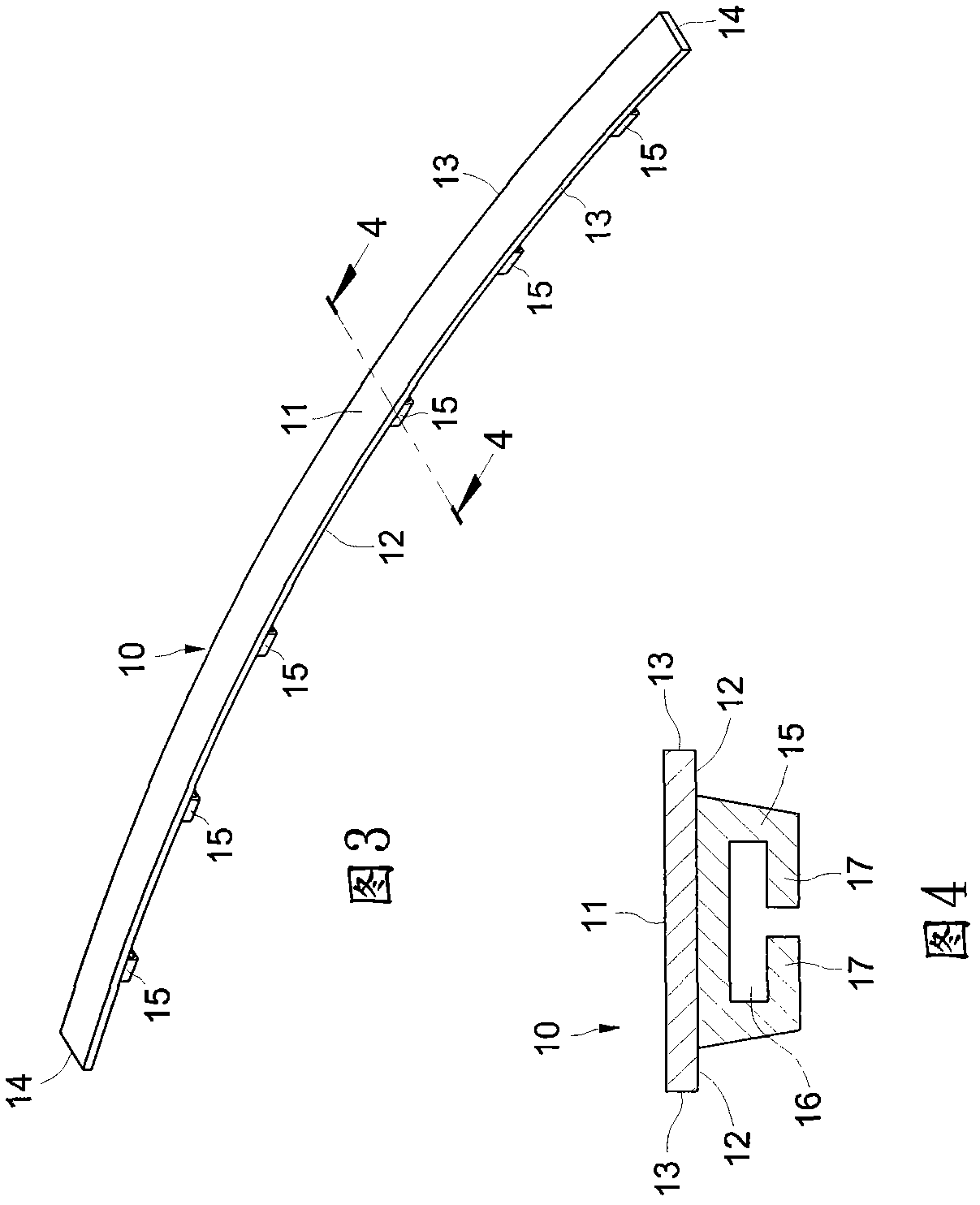

Docile non-bracket type windscreen wiper structure

The invention relates to a docile non-bracket type windscreen wiper structure, which comprises a metal elastic sheet body, a carrying seat, a carrying seat outer cover, an auxiliary steel bar, two outer cover sheaths and a long stripped wiper, wherein the downward bending radius of the auxiliary steel bar is smaller than the downward bending radius of the metal elastic sheet body, and in addition, the width of the metal elastic sheet body is smaller than the half of the width of the metal elastic sheet body, so after the auxiliary steel bar is downwards pressed to be butted and pasted on an automobile windscreen, the deformation elasticity of the auxiliary steel bar can be transmitted to two tail end positions of the metal elastic sheet body, better docile performance can be realized, the wiping cleanness can be improved, in addition, the serenity degree in an automobile cannot be damaged through great friction sound generated during the reciprocating wiping swinging, meanwhile, the motive power for driving a windscreen wiper rocker arm cannot be improved, and the oil consumption increase of the automobile is avoided.

Owner:东莞山多力汽车配件有限公司

Step air foil web stabilizer

ActiveUS20080276488A1Stable supportHigh tensionNon-fibrous pulp additionNatural cellulose pulp/paperWrinkle skinFiber

Web stabilizer particularly for one-sided flotation of a running web. The device includes two discharge slots which allow for increased draw down force, which flattens machine direction wrinkles in a floating web. There is a primary discharge slot and a second discharge slot spaced from and stepped down from the primary discharge slot, a first web support surface between the primary discharge slot and the secondary discharge slot, and a second web support surface downstream of the secondary discharge slot in the direction of web travel. An integral blower provides a supply of air that is uniformly distributed to the primary and secondary slots. Air discharged from the primary slot is gathered into the air stream of the secondary slot and creates an increased air cushion to provide greater support to the web and thereby remove machine direction web wrinkles caused by higher tension in light weight webs.

Owner:DURR SYST INC

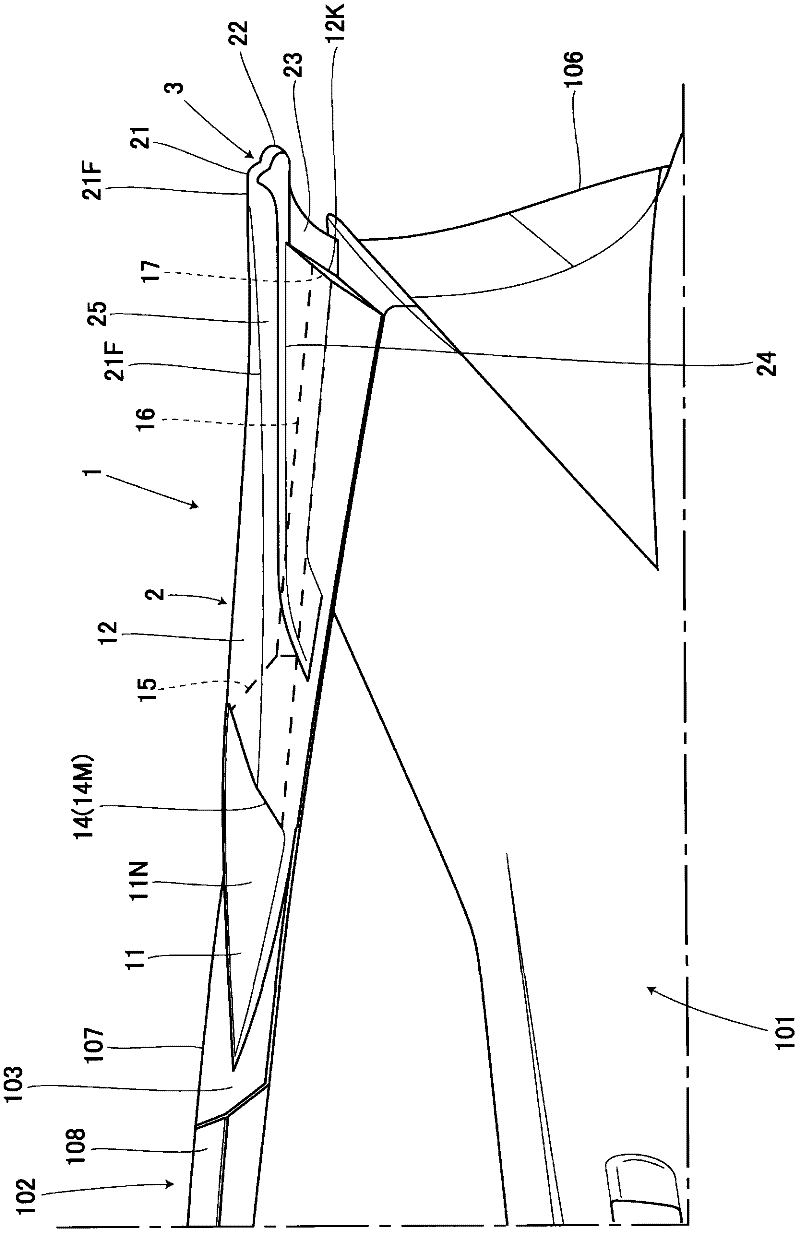

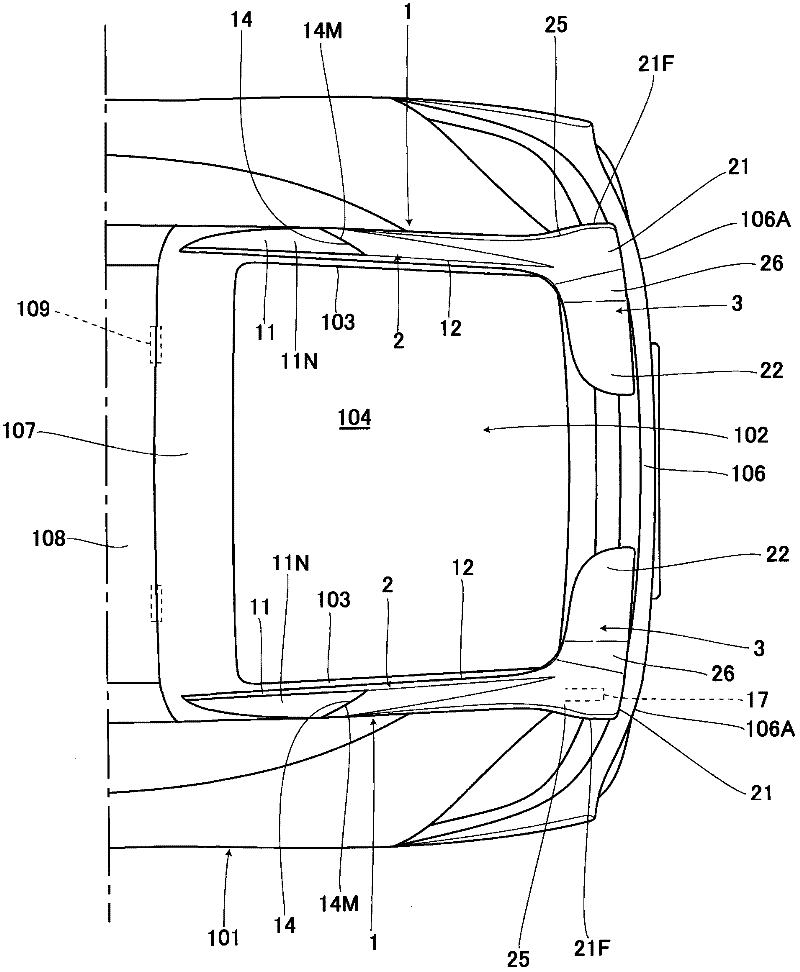

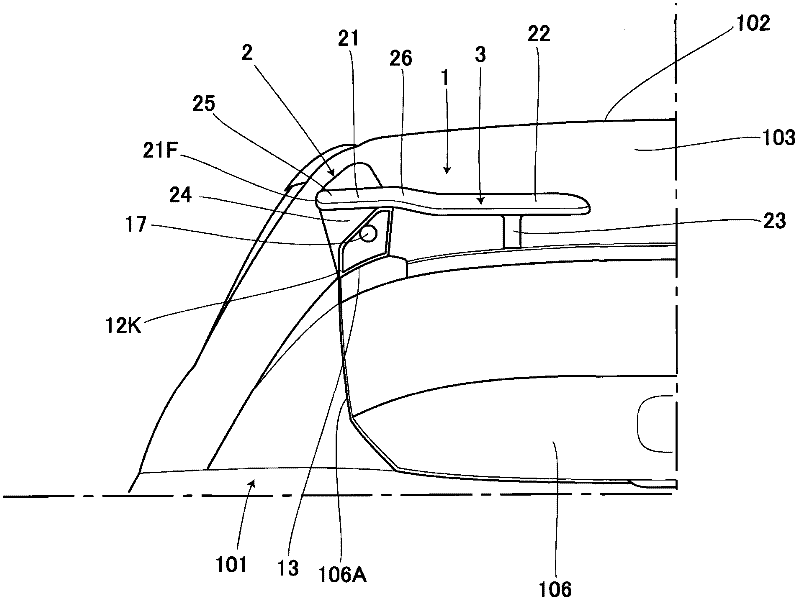

Rear spoiler

ActiveCN102556183AReduce driving resistanceIncrease the blowing speedVehicle body stabilisationAerodynamics improvementAerodynamic dragDownforce

The invention provides a rear spoiler which is capable of suppressing an increase in air resistance and applying a downforce to a vehicular rear portion during high-speed vehicle traveling. The rear spoiler (1) on the rear upside of a vehicle includes a main body (2) that is longer in a longitudinal direction than in a width direction. The main body (2) includes an air introduction opening (14) of air currents, and a wing (3) and an air outlet (17) communicating with the opening (14) at the rear. The air currents introduced from the opening (14) during traveling are blown off from the air outlet (17). Consequently, vortex flows generated at the rear is rectified, thus permitting travel resistance to be reduced. Further, the main body (2) is arranged in the vehicular lateral side and hence by rectifying the vortex flows generated by the air currents coming around the vehicular lateral side, the air resistance is restrained from increasing during high-speed traveling, permitting the travel resistance to be reduced.

Owner:HONDA ACCESS CORP

Active vehicle skirt panel and the method of controlling the same

ActiveUS9932074B2Increase downforceReduce pressureVehicle body stabilisationAerodynamics improvementActuatorAirflow

Owner:FARADAY&FUTURE INC

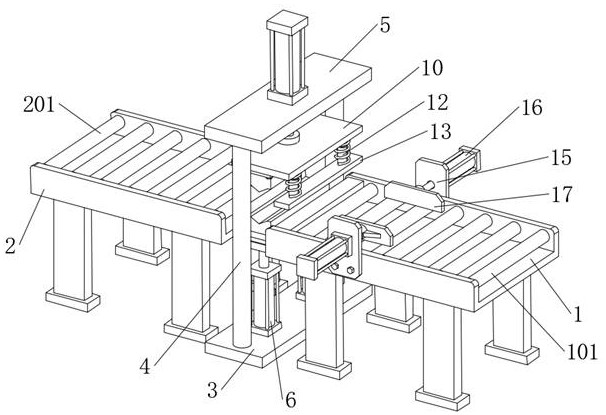

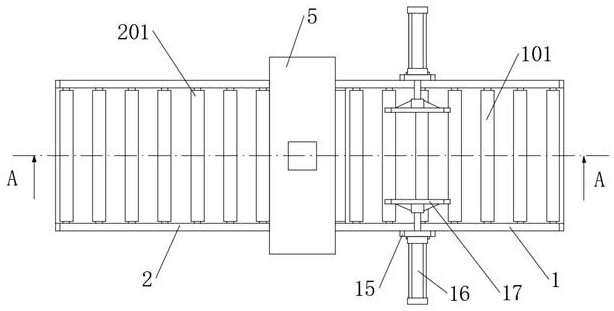

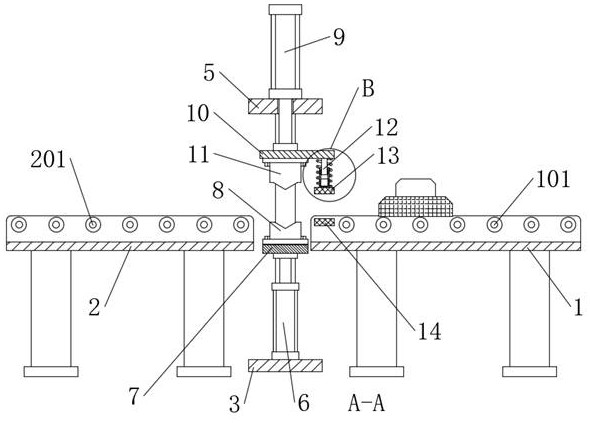

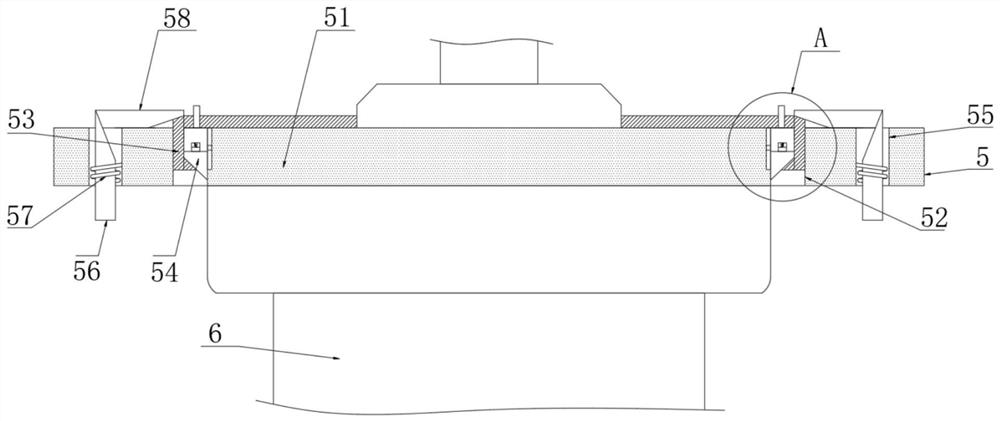

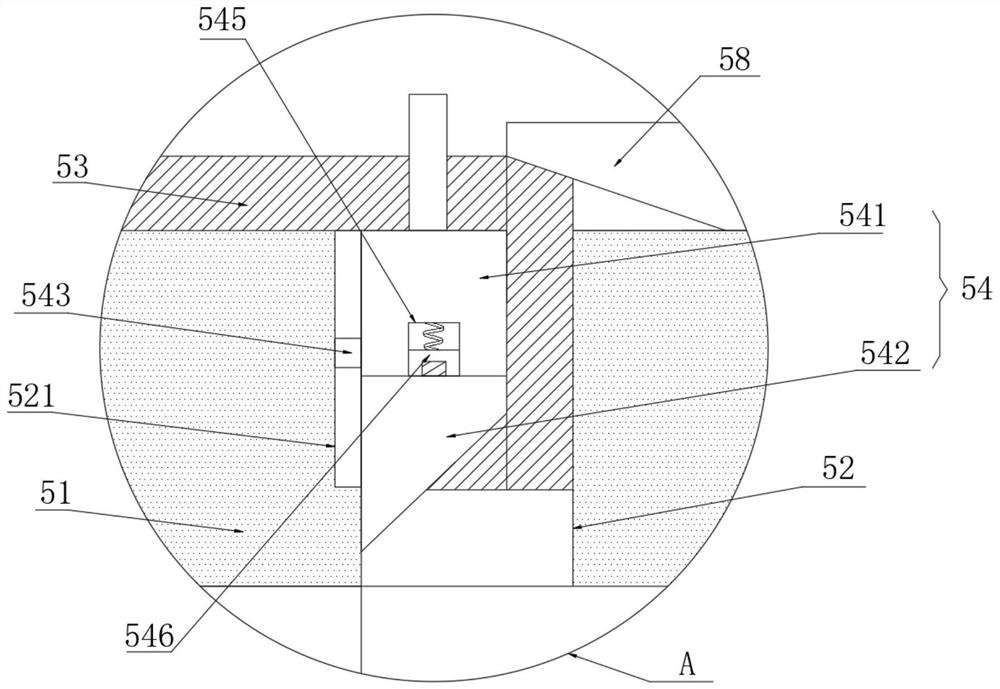

Aluminum plate bending device for machining high-stability aluminum profile

PendingCN111974888AGuaranteed alignmentPrevent pulling offsetShaping toolsMetal-working feeding devicesHydraulic cylinderPunching

The invention discloses an aluminum plate bending device for machining a high-stability aluminum profile, and relates to the field of aluminum plate processing equipment. The aluminum plate bending device comprises a feeding rack, a discharging rack and a punching and bending device arranged between the feeding rack and the discharging rack. An aluminum plate is placed on a feeding roller table arranged on the feeding rack for feeding, and telescopic rods of two third hydraulic cylinders are controlled for telescopic adjustment, so that two push plates press and straighten the two sides of thealuminum plate, and the alignment of the aluminum plate during feeding is ensured; and before punching and bending the aluminum plate, a pressing plate and a bearing plate press the aluminum plate inadvance, so that the drawing deviation of the aluminum plate is avoided during punching and bending.

Owner:陈建功

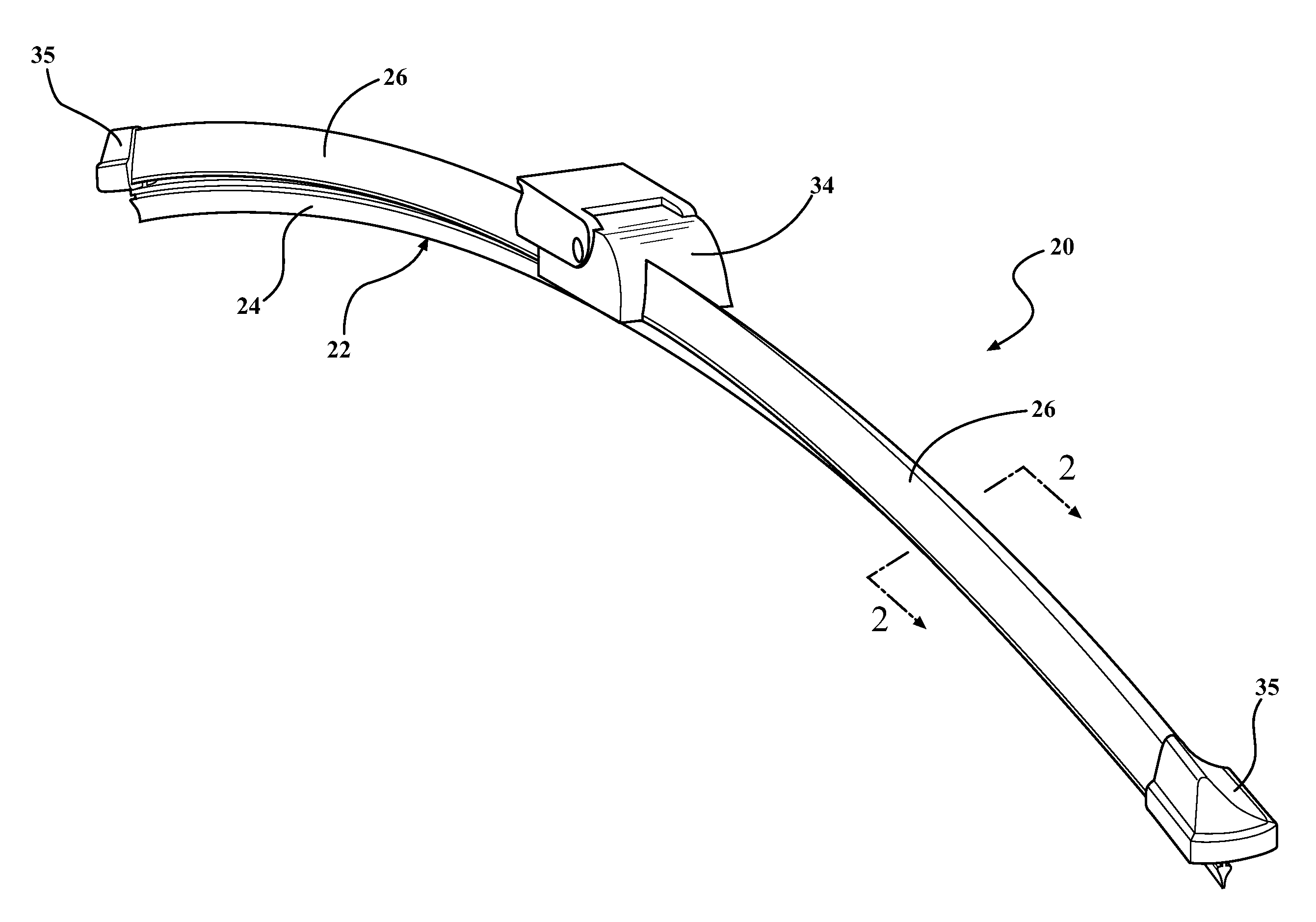

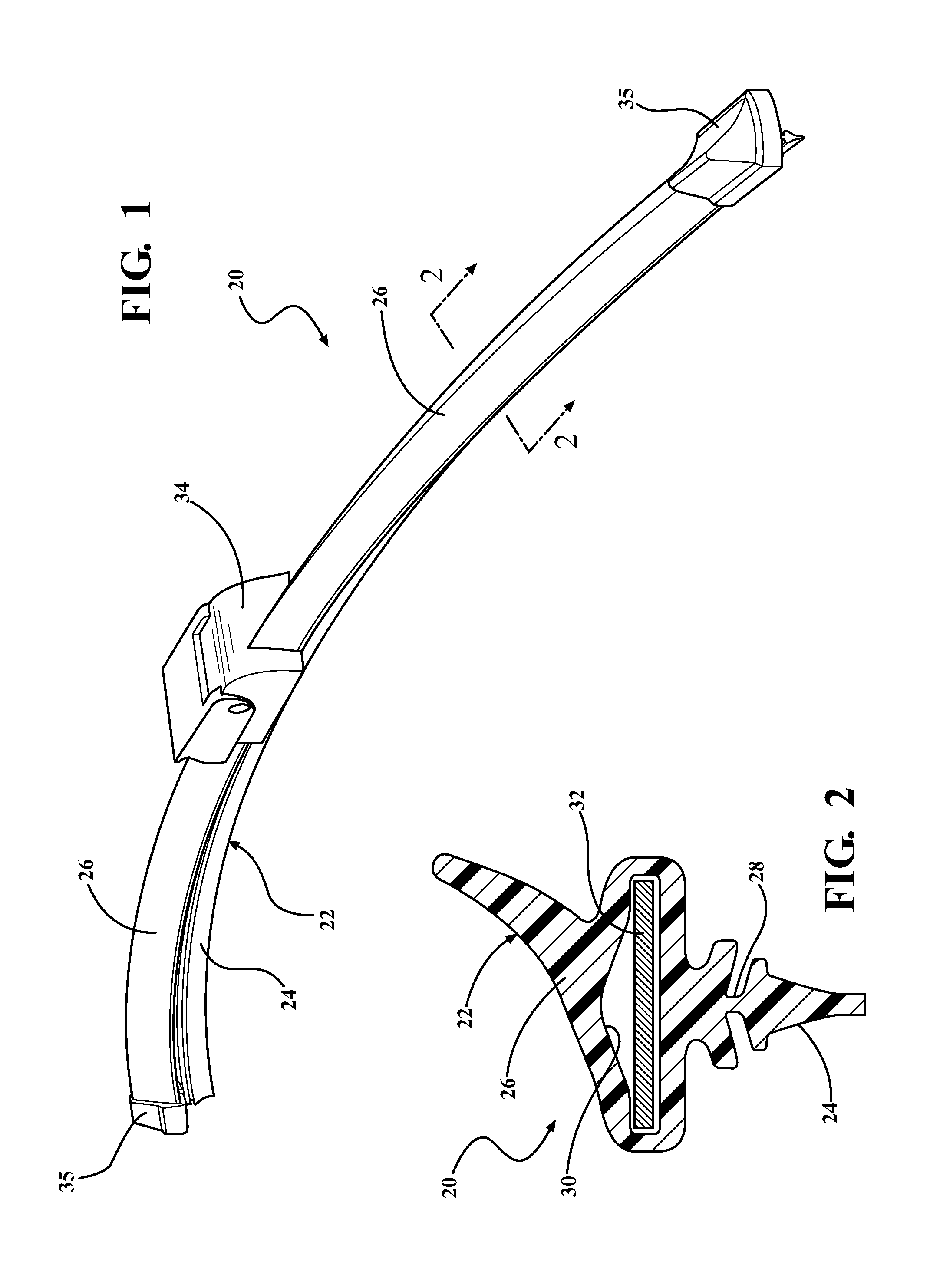

Windscreen wiper device

ActiveUS20130125332A1Improve performanceImprove the immunityCeramic shaping apparatusWindow cleanersWindshieldWindscreen wiper

A windscreen wiper device is provided including a longitudinally extending wiper strip of a flexible material. At least one carrier of a spring-like material operatively supports and biases the wiper strip into a predetermined configuration. The windscreen wiper device further includes a connecting device for connection with a wiper arm. At least a portion of the wiper strip has a microtextured surface formed directly into the flexible material. The microtextured surface may be on, for example, any one of or any combination of a wiping portion, a channel, a hinge portion and a spoiler portion of the wiper strip.

Owner:TRICO PROD CORP

Method of selectively removing conductive material

InactiveUS7935242B2Improved physical contactIncrease downforceMaterial nanotechnologySludge treatmentCopper interconnectNanoparticle

An electrolyte solution, methods, and systems for selectively removing a conductive metal from a substrate are provided. The electrolyte solution comprising nanoparticles that are more noble than the conductive metal being removed, is applied to a substrate to remove the conductive metal selectively relative to a dielectric material without application of an external potential or contact of a processing pad with the surface of the substrate. The solutions and methods can be applied, for example, to remove a conductive metal layer (e.g., barrier metal) selectively relative to dielectric material and to a materially different conductive metal (e.g., copper interconnect) without application of an external potential or contact of a processing pad with the surface of the substrate.

Owner:MICRON TECH INC

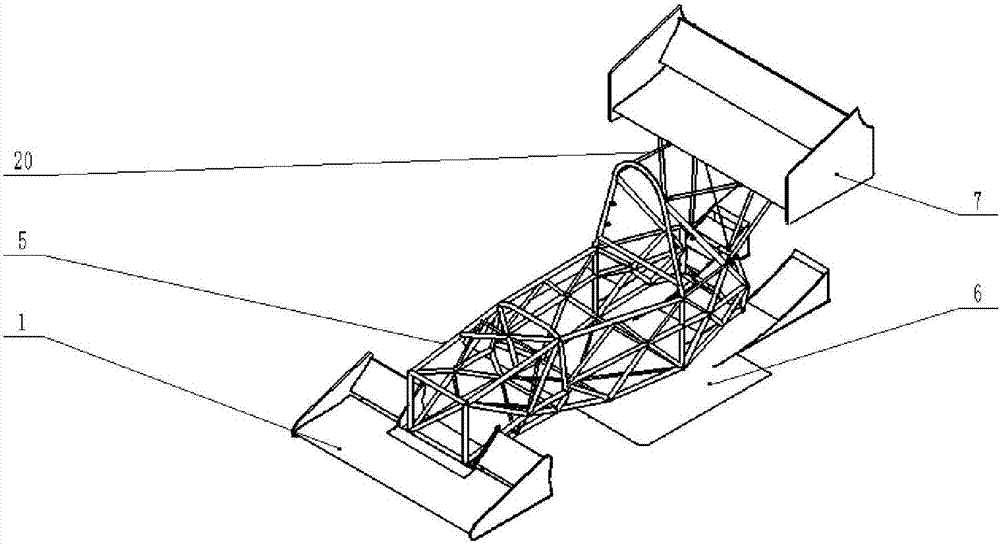

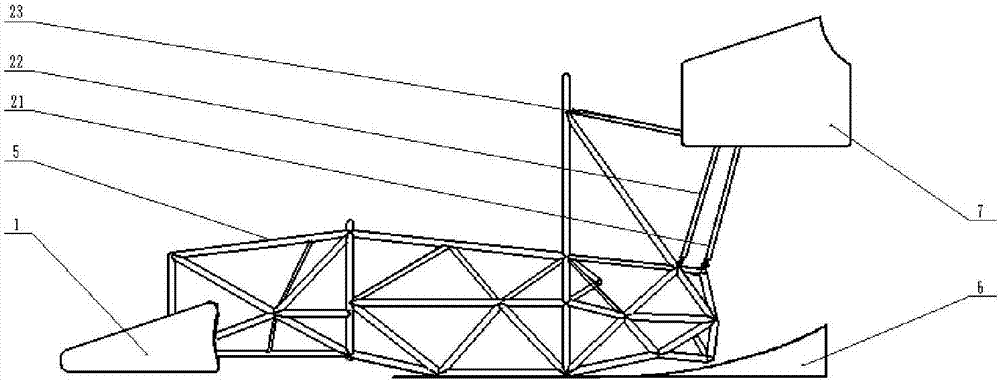

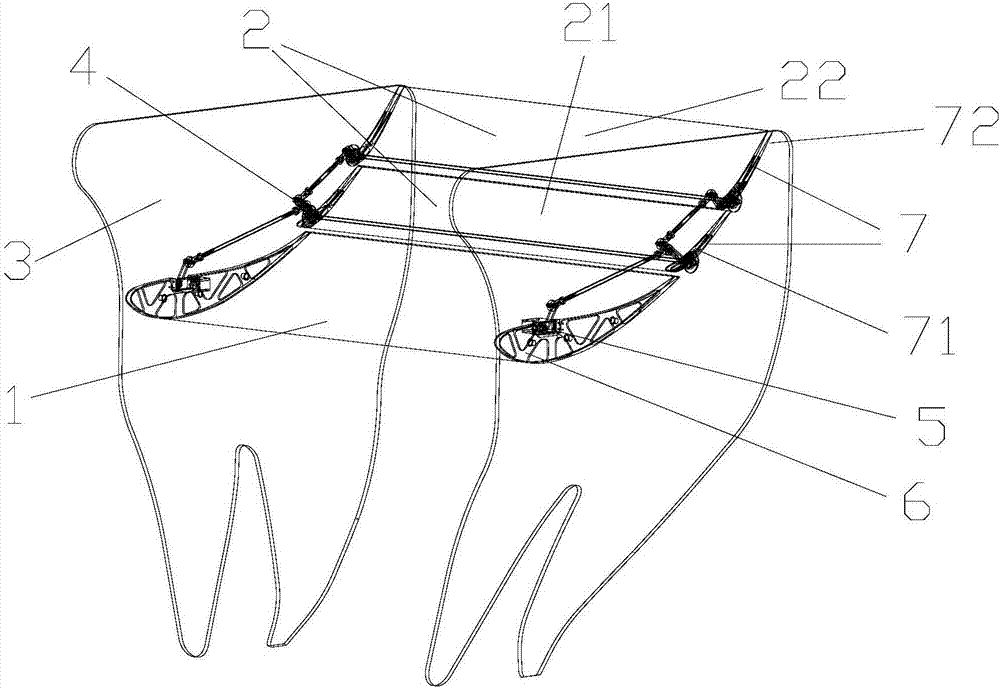

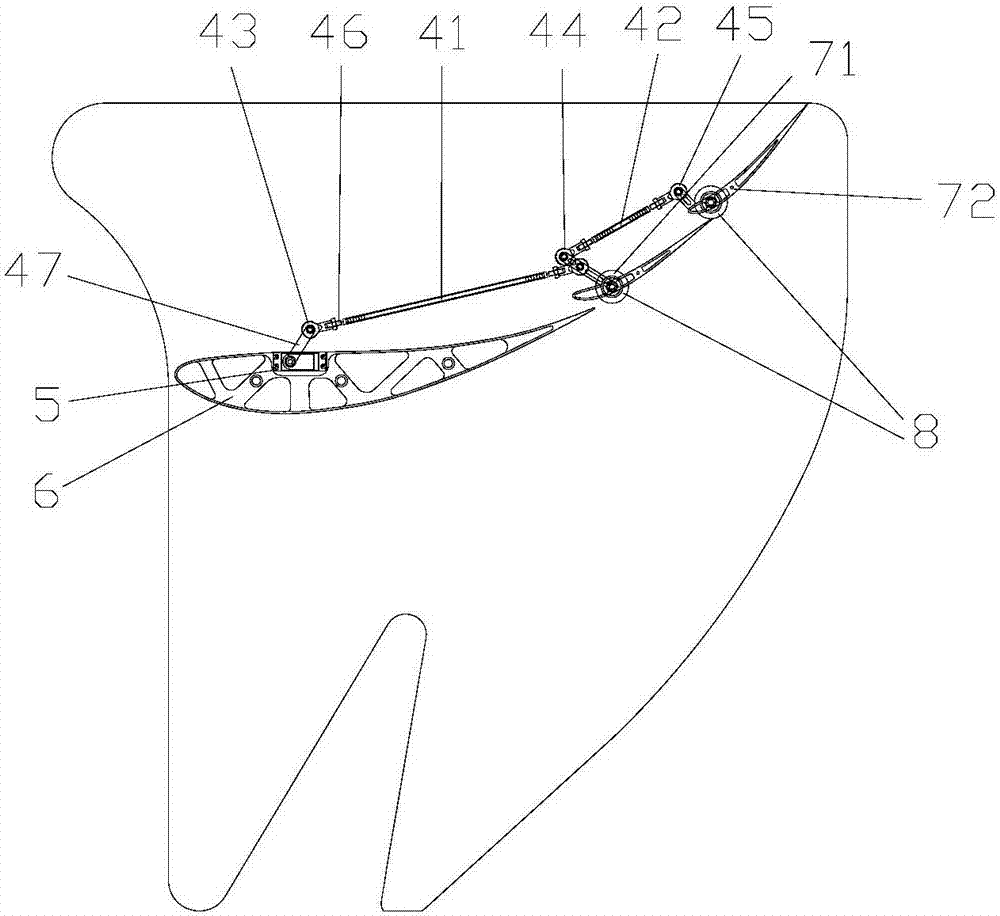

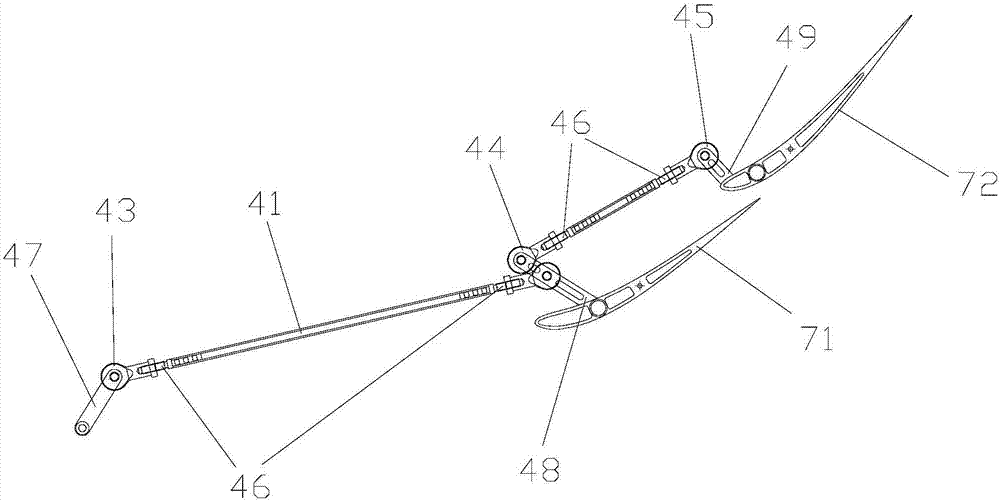

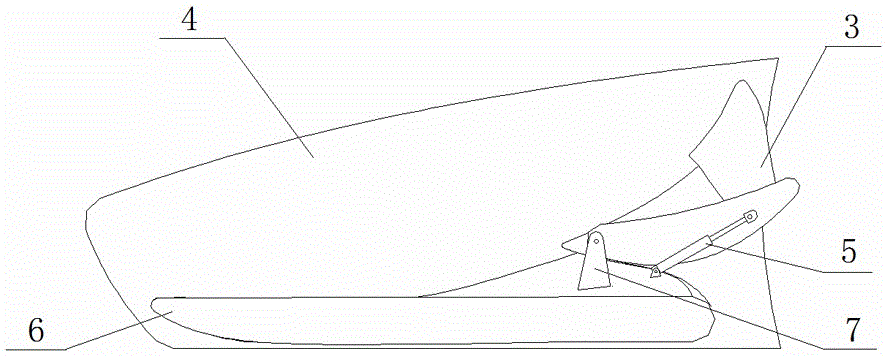

Aerodynamic package for FSAE racing cars

ActiveCN107226140AIncrease downforceImprove ground adhesionVehicle body stabilisationVehicle body streamliningGratingVehicle frame

The invention discloses an aerodynamic package for FSAE racing cars. The aerodynamic package comprises a front wing, a tail wing and a diffuser, wherein the front wing is rigidly connected to the bottom of the front end of a car frame and is located at the lower part of the head of a racing car; the tail wing is symmetrically supported by six supporting rods at the rear end of the car frame; the diffuser is connected to the bottom of a cab and is integrated with the floor of the cab; a main wing of the front wing is elongated to form a connecting plate which is connected with the car frame together with an inner end plate, and connection is stabler and disassembly is convenient; a Gurney flap is additionally arranged on the tail wing to increase the down force of the racing car and enhance the stability during braking; and a diversion groove is additionally formed in the bottom of the diffuser, and a grating wing is additionally arranged at the tail of the diffuser, so that the down force of the racing car is increased. According to the aerodynamic package disclosed by the invention, the down force of the FSAE racing car can be significantly increased, so that the racing car can obtain big ground adhesive force and excellent dynamic property; the aerodynamic performance and handling stability of the racing car can also be improved so that the racing car can obtain good turning driving performance; and in addition, the package also has the advantages of being light in weight, simple in structure, convenient in disassembly and assembly and the like.

Owner:JIANGSU UNIV

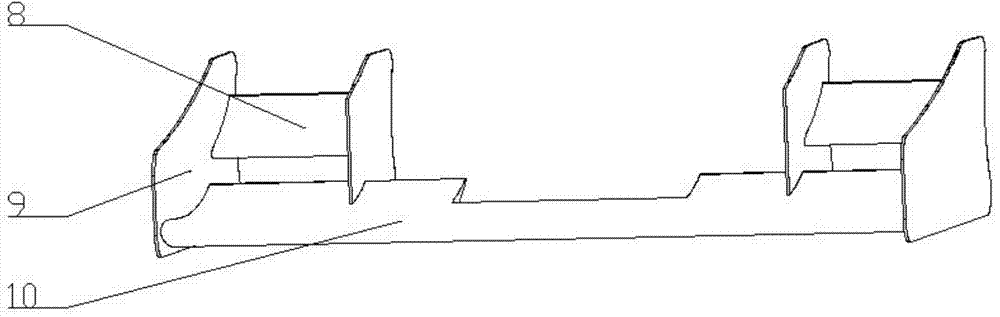

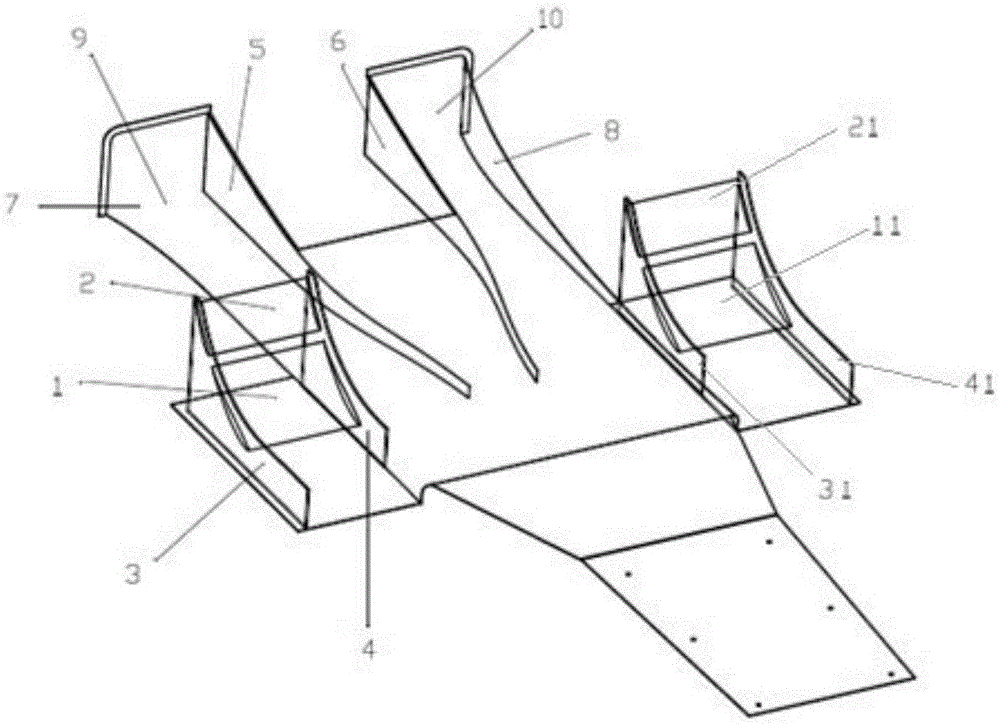

Integrated formula car diffuser with additional side wings

ActiveCN105460087APrevents racing understeerAvoid tire shockVehicle body streamliningAerospace engineeringAirflow

The invention discloses an integrated formula car diffuser with additional side wings. The diffuser adopting an integrated structure comprises a left-part side wing main wing, a right-part side wing main wing, a left-part side wing flap and a right-part side wing flap, wherein the left-part side wing main wing and the left-part side wing flap are in front-rear arrangement in a manner that an angle a and an angle b are respectively formed between the left-part side wing main wing and a level surface and between the left-right side wing flap and the level surface through a left-part left-end plate and a right-part right-end plate, the right-part side wing main wing and the right-part side wing flap are in front-rear arrangement in a manner that an angle a and an angle b are respectively formed between the right-part side wing main wing and the level surface and between the right-part side wing flap and the level surface through a right-part left-end plate and a right-part right-end plate, and two side wing components, of the diffuser, which are symmetrically arranged, are formed; a left flow deflector and a right flow deflector which are in V-shaped arrangement are arranged between the two side wing components, the left flow deflector and a left surface form a left guide groove, and the right flow deflector and a right surface form a right guide groove. According to the diffuser disclosed by the invention, the downward pressure of the car can be increased, and besides, the centre of gravity of the car is moved forwards, so that understeer of the car is avoided, besides, the impact of air currents on rear wheels of the car is avoided, and the running resistance of the car is reduced.

Owner:SOUTHEAST UNIV

Adjustable spoiler system of formula car

PendingCN106926908AIncrease downforceReduce driving resistanceVehicle body streamliningSteering wheelControl theory

The invention discloses an adjustable spoiler system of a formula car. The adjustable spoiler system mainly comprises a main wing rear wing, flap rear wings, end plates, four-rod mechanisms, steering engines, main wing inner supporting plates and flap inner supporting plates. Spoilers adopt an upper rear wing spoiler, a middle rear wing spoiler and a lower rear wing spoiler which are separately the main wing rear wing and the two flap rear wings. The two ends of all the rear wings are each provided with the corresponding end plate. The two ends of the three rear wings are each internally provided with the corresponding wing inner supporting plate which is formed through bonding. The steering engines are fixed to wing inner supporting plates in rear wings. The lower main wing rear wing and the middle flap rear wing as well as the middle flap rear wing and the upper flap rear wing are both connected through the four-rod mechanisms. During turning of the racing car, the steering engines are controlled through a steering wheel rotating angle signal to drive the four-rod mechanisms so as to change flap attach angle transformation, and down force is increased; and during linear travelling, the steering wheel rotating angle signal recovers to a zero state and controls the steering engines to recover to original states so as to the drive the four-rod mechanisms to recover the flap attach angles, and travelling resistance is decreased.

Owner:HUAQIAO UNIVERSITY

Active variable front wing of formula car

InactiveCN106428257AIncrease air intakeImprove combustion efficiencyAerodynamics improvementVehicle body streamliningFixed wingCar controls

The invention discloses an active variable front wing of formula car which compromises a fixed wing piece arranged on the inner side of a front wing end plate, a connection device for forming a rotation between the fixed wing and the end plate, a driving mechanism for driving the fixed wind piece to rotate a certain angle, a speed detector and an acceleration detector which are arranged on a car and used for detecting the car running state, a water temperature detector arranged at a cooling system. The water temperature detector and the driving mechanism are respectively connected with a car control unit. The active variable front wing of formula car can adjust the angle of the front fixed wing piece according to the car running state and the temperature of the engine, thus, the air resistance is reduced in acceleration, the amount of air input in the side box of the formula car is increased, the efficiency of the engine is improved,and the dynamic performance of the car is improved.

Owner:JILIN UNIV

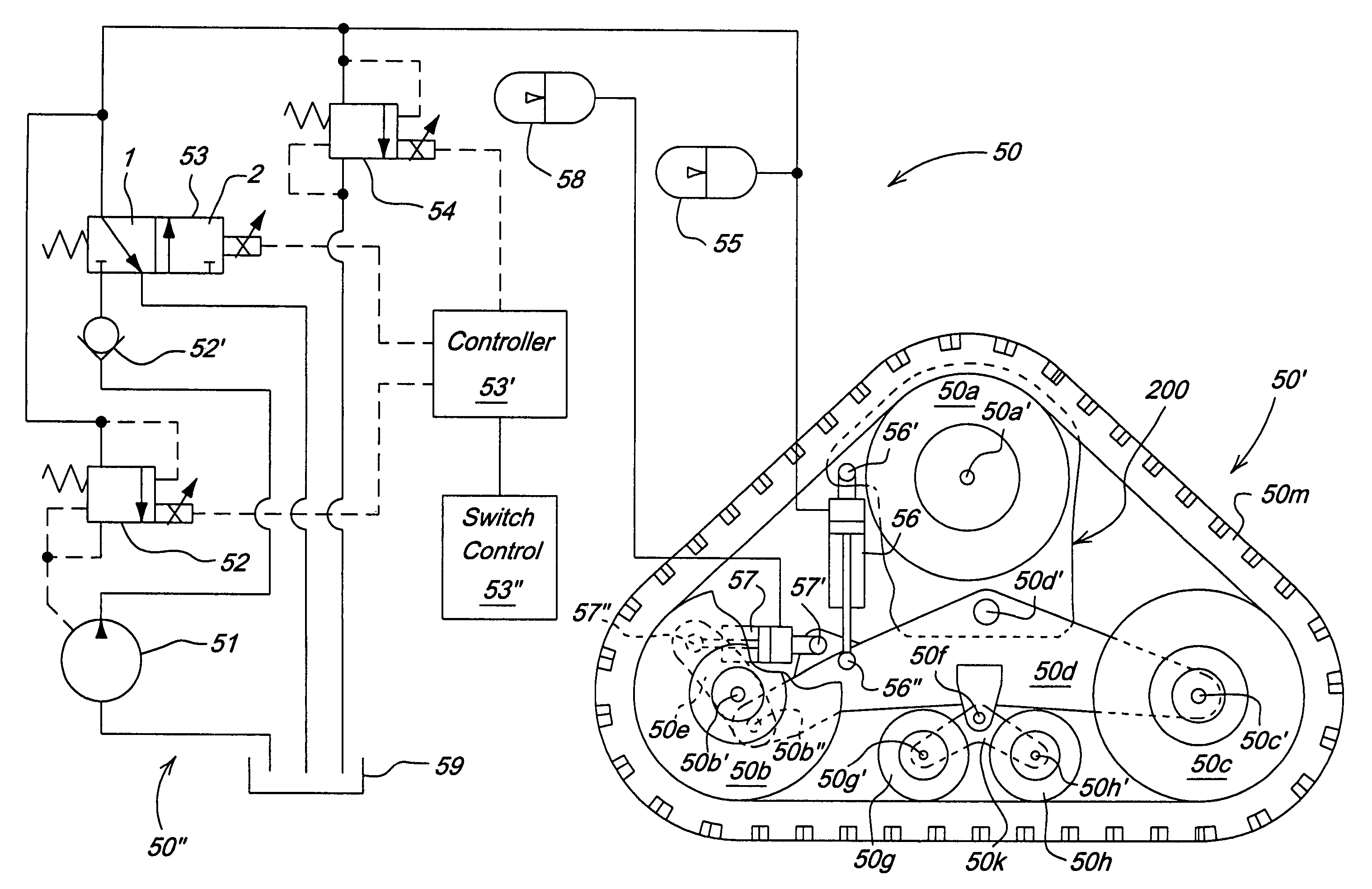

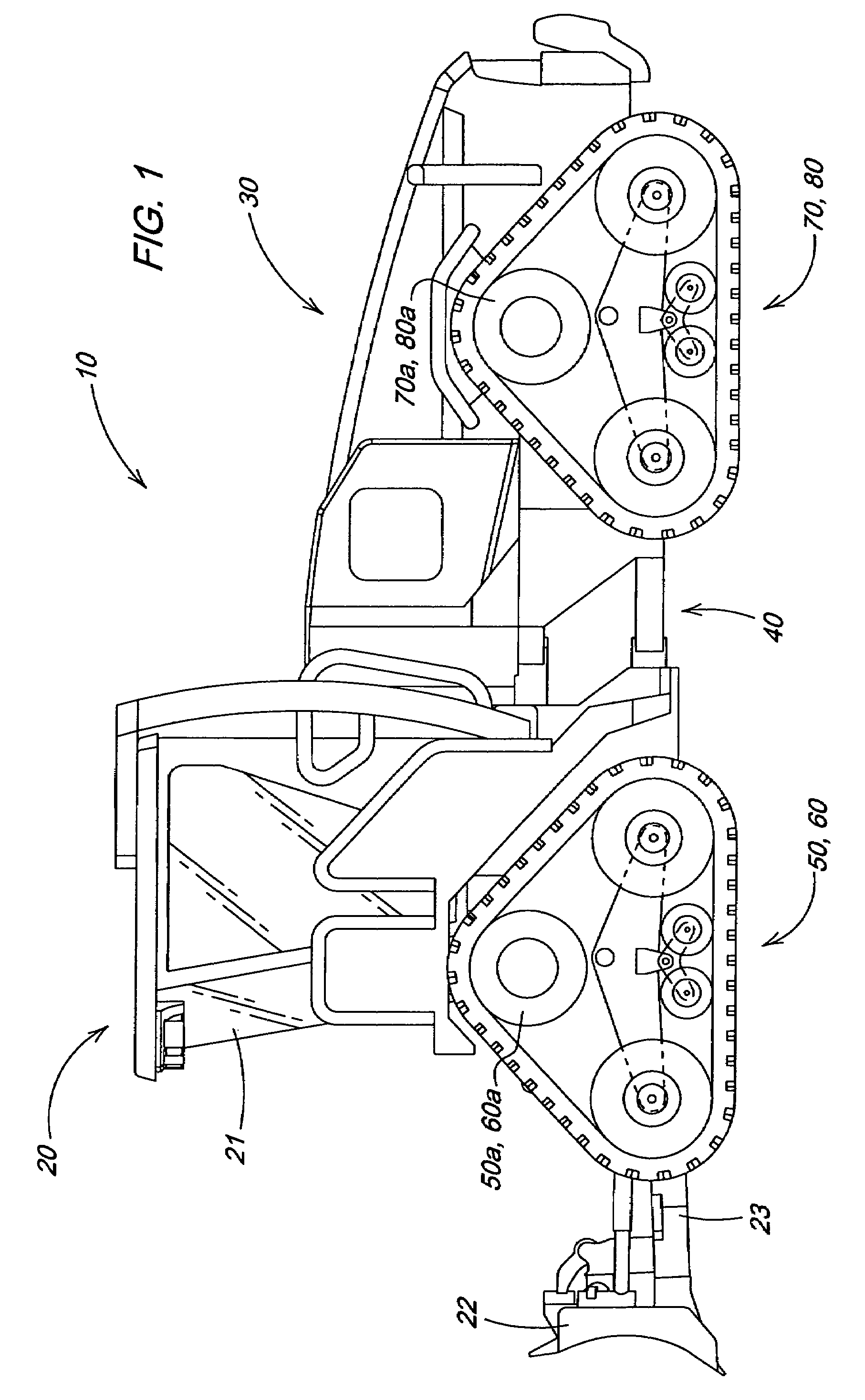

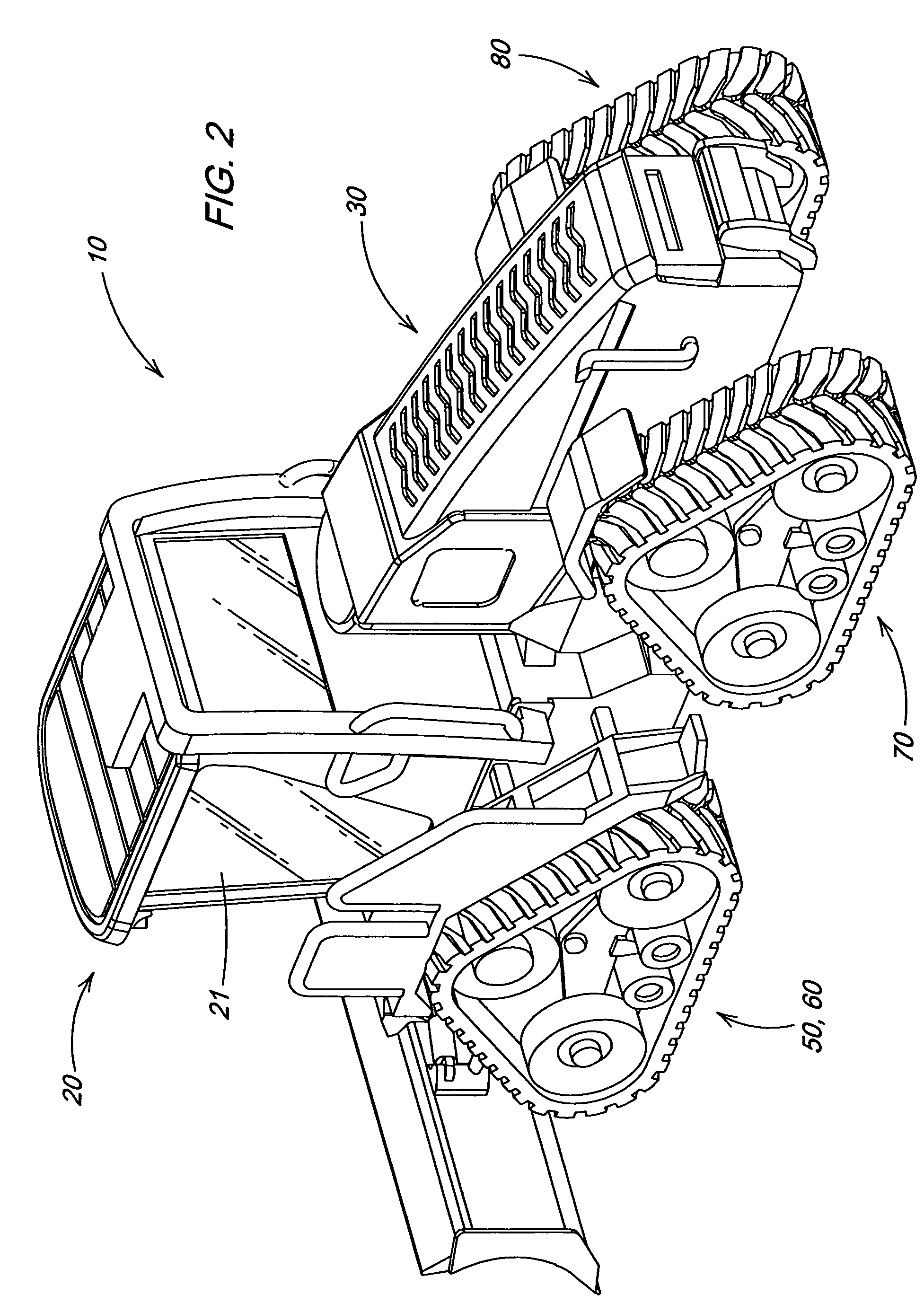

Dynamic blade distance ratio system and method

InactiveUS7641007B2Increase downforceImprove machine performanceMechanical machines/dredgersGearingHydraulic cylinderEngineering

The blade ratio of an articulated work vehicle with multiple tracks is adjusted by shifting a load from the weight of the vehicle toward the front or rear of one or more of the tracks. The load may be shifted through the actuation of a hydraulic cylinder that applies a biasing load between a frame on which a track frame is mounted and a front or rear portion of the track frame.

Owner:DEERE & CO

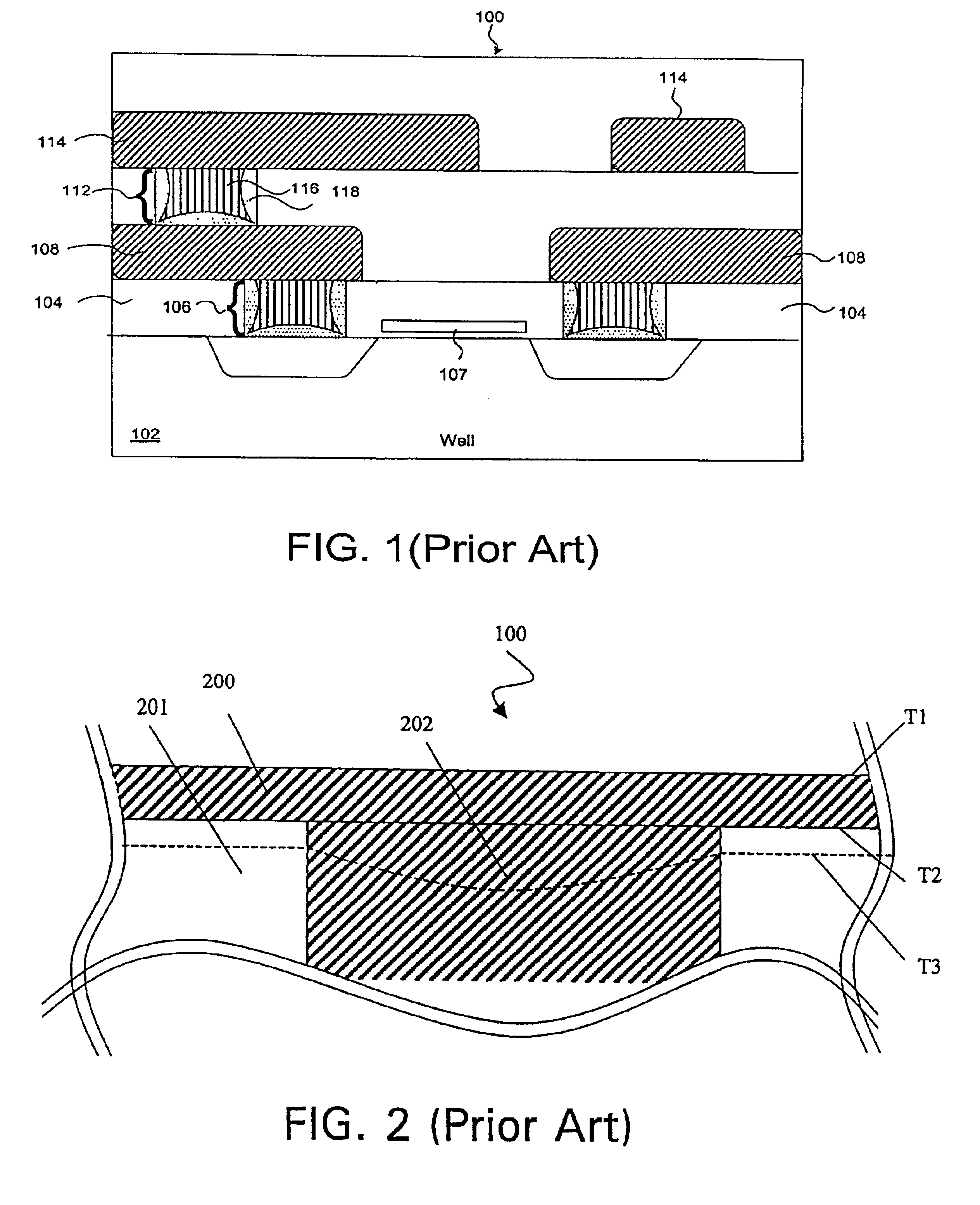

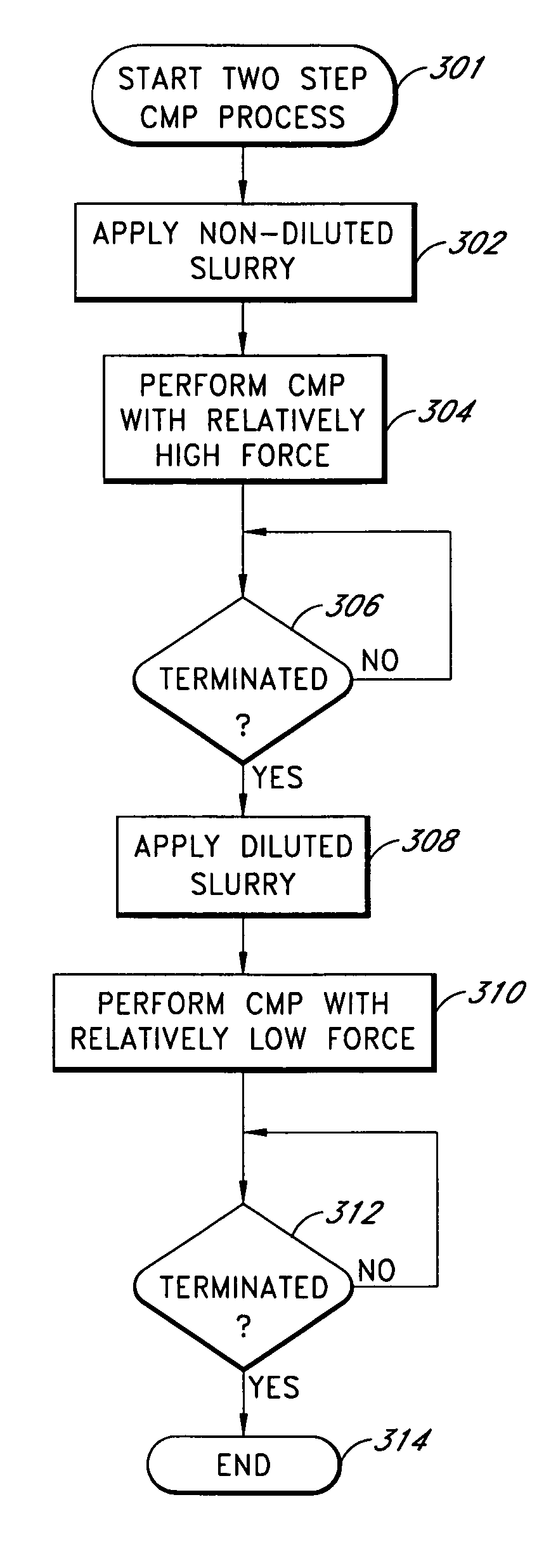

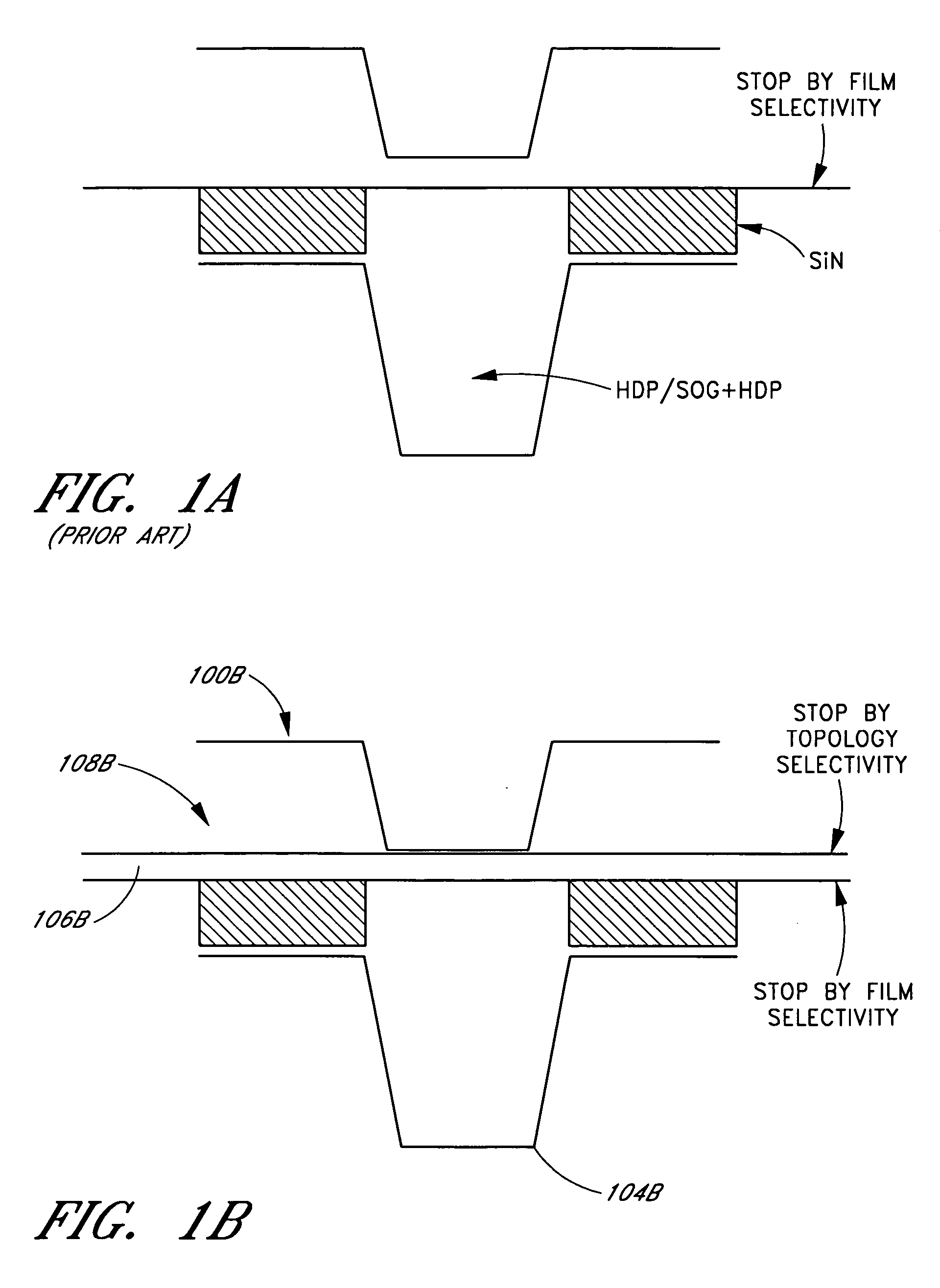

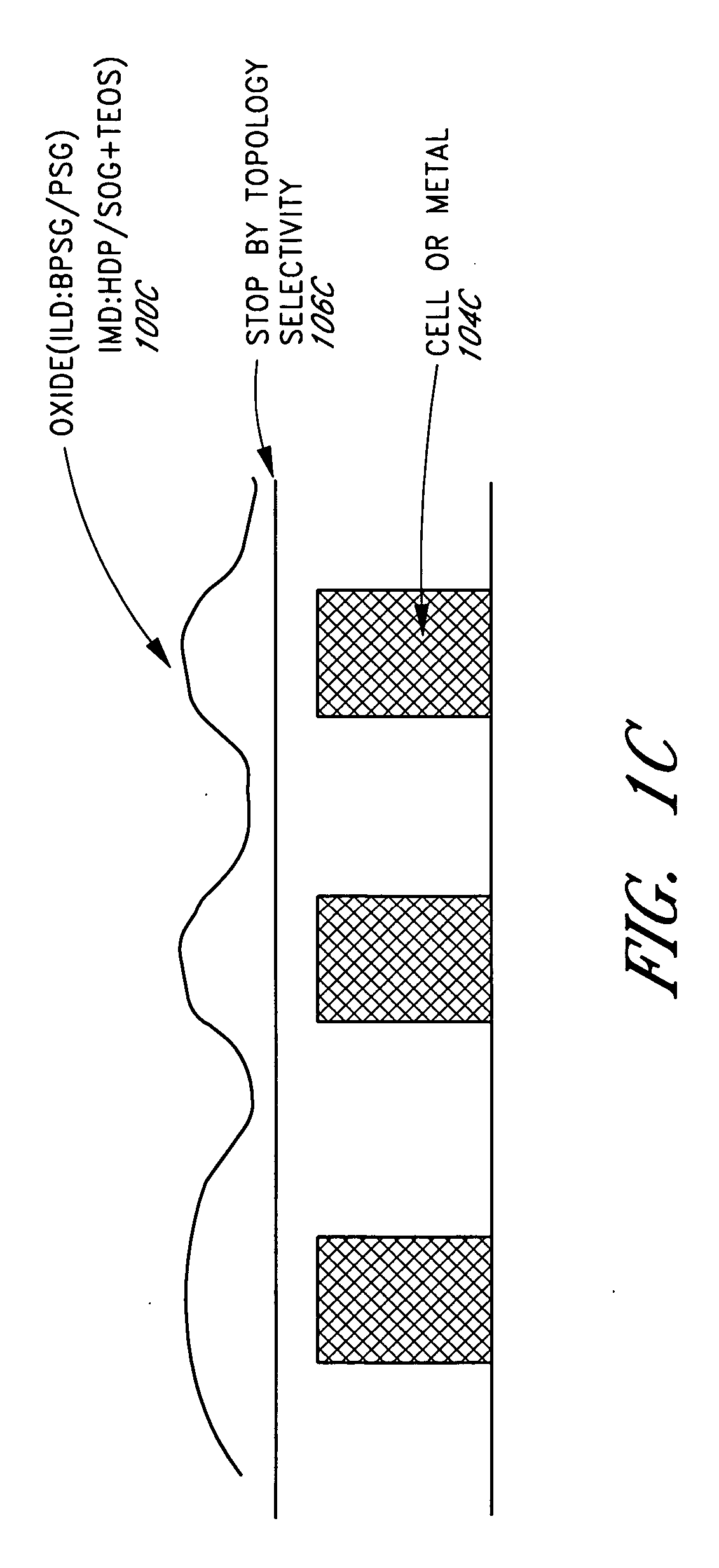

Topology-selective oxide CMP

InactiveUS20060252267A1Low selectivityIncrease downforceDecorative surface effectsSemiconductor/solid-state device manufacturingCompound (substance)Engineering

A method of performing chemical mechanical polishing (CMP) is described herein. By way of example, substantially undiluted slurry is applied to a polishing pad. A first CMP process is performed using the substantially undiluted slurry on a semiconductor wafer applying a first amount of pressure. The first CMP process is terminated. Diluted slurry is applied to the polishing pad. A second CMP process is performed using the diluted slurry on the semiconductor wafer while applying a second amount of pressure, wherein the second amount of pressure is less than the first amount of pressure. The second CMP process is terminated.

Owner:MACRONIX INT CO LTD

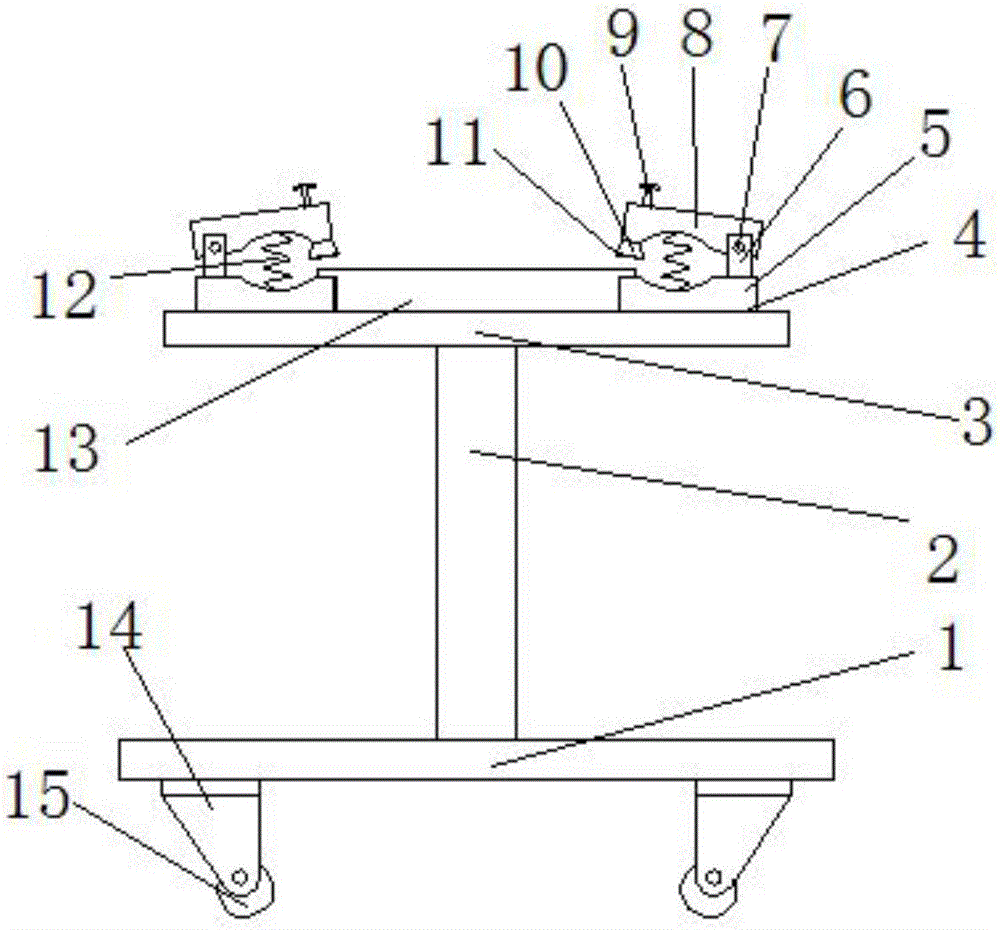

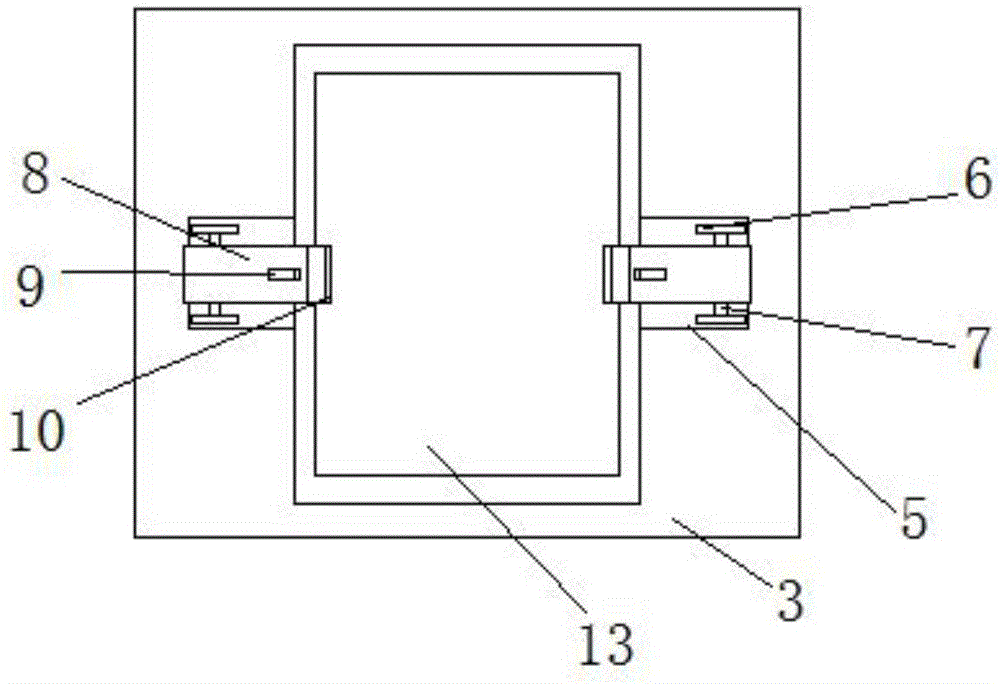

More stable medical tray carriage

InactiveCN106388942AAvoid damageEasy to liftSurgical furnitureNursing accommodationEngineeringMedical treatment

The invention discloses a more stable medical tray carriage. The medical tray carriage comprises a base; a support rod is fixedly connected to the middle of the top of the base; a tray frame is fixedly connected to the top of the support rod; clamping apparatuses are arranged on two sides of the top of the tray frame; a clamping sleeve seat is arranged at the bottom of each clamping apparatus; a connecting rod is connected to the top of each clamping sleeve seat; an inner cavity of each connecting rod is connected with a rotary shaft; two ends of the rotary shaft are connected with a downward pressing plate in a penetration manner; a lifting rod is fixedly connected to one side of the top of each downward pressing plate; a downward pressing block is connected to the bottom of each downward pressing plate; a convex particle is arranged at the bottom of each downward pressing block; an inner cavity of each clamping sleeve seat is connected with a spring; and a tray is arranged in the middle of the top of the tray frame. According to the medical tray carriage, the clamping apparatuses are arranged at the top of the tray frame, so that the stability of the tray is improved, a more stable effect is achieved, and the damage of medical appliances caused by shake of the tray is avoided.

Owner:姜元华

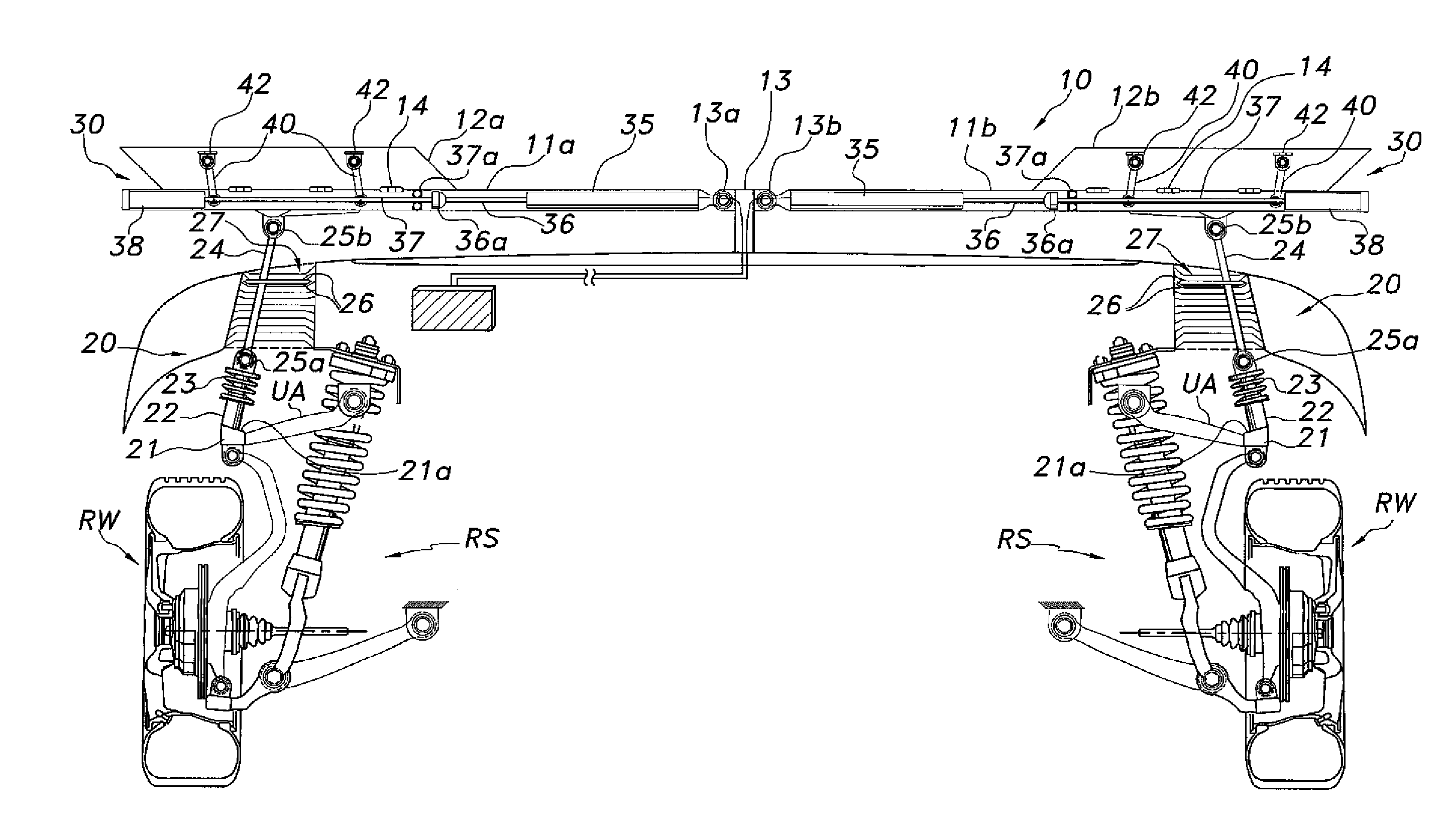

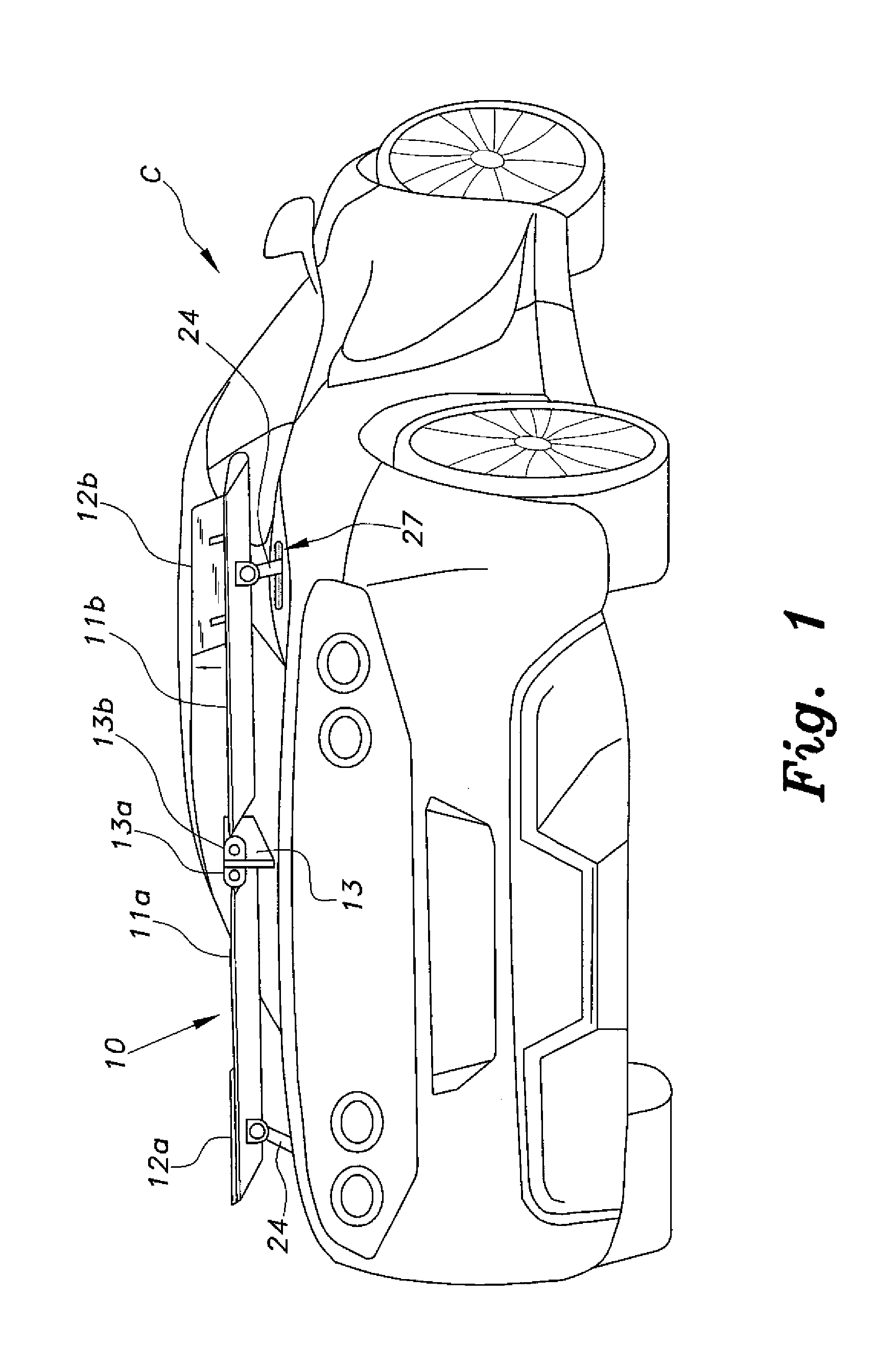

Dynamically adjustable airfoil system for road vehicles

ActiveUS20160236728A1Facilitate dynamic adjustable positioningIncrease downforceVehicle body stabilisationRace vehiclesActuatorDownforce

The dynamically adjustable airfoil system for road vehicles includes a pair of airfoils having their respective inner ends pivotally mounted to a central, vertical base on the rear of a road vehicle. An airfoil lift assembly is coupled to an outer end of each airfoil and to a rear wheel suspension system to facilitate dynamic adjustable positioning of the airfoils in response to movements of the suspension system. A split flap is pivotally mounted to each airfoil. A split flap actuator assembly is mounted inside each airfoil and coupled to a corresponding split flap to selectively and independently open or close the respective split flap. Opening of the split flap to various angles increases downforce exerted on the rear suspension system for improved performance. A controller controls deployment and angular disposition of the split flaps, depending on driving conditions.

Owner:AL HUWAIDER MUSTAFA ALI HUSSAIN

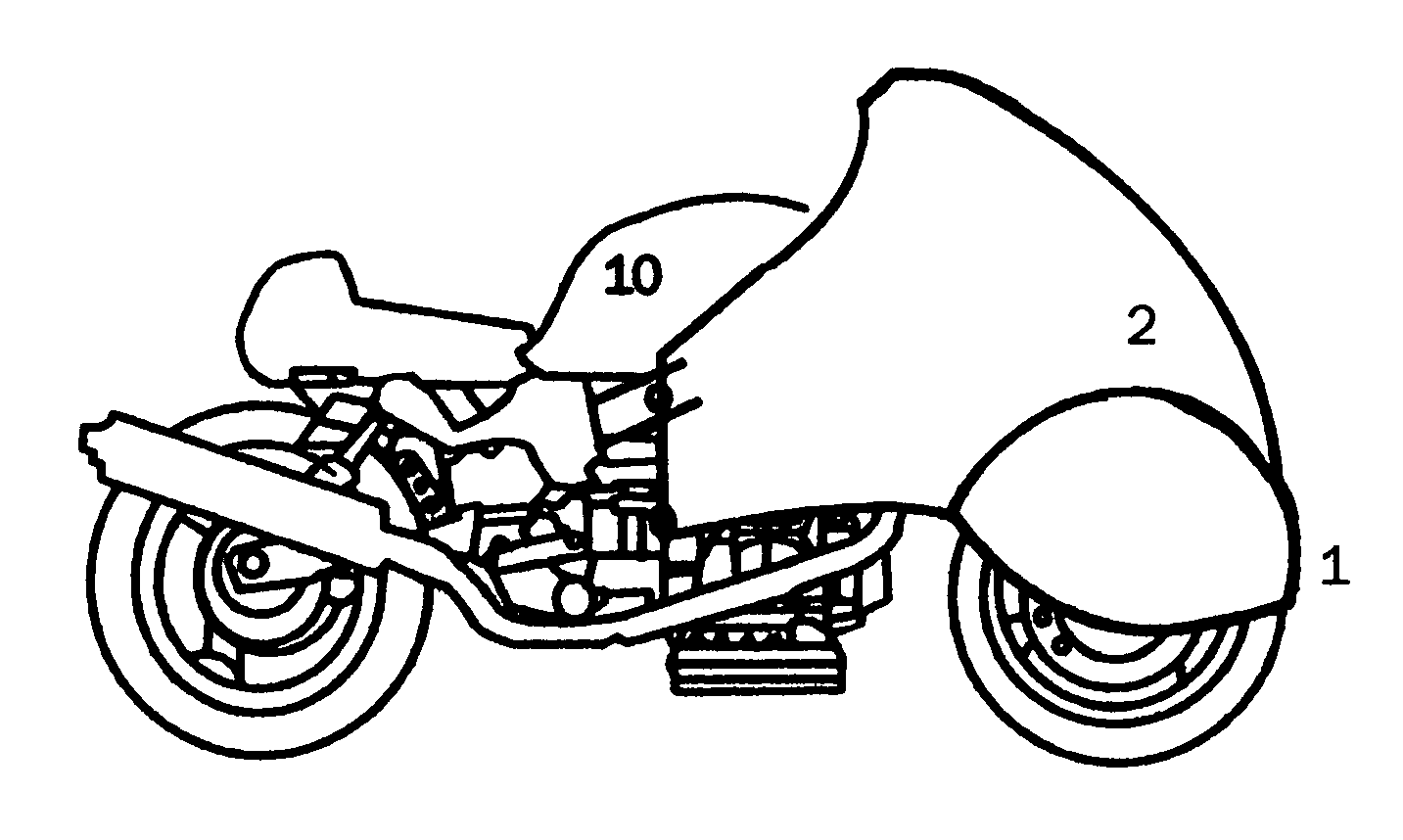

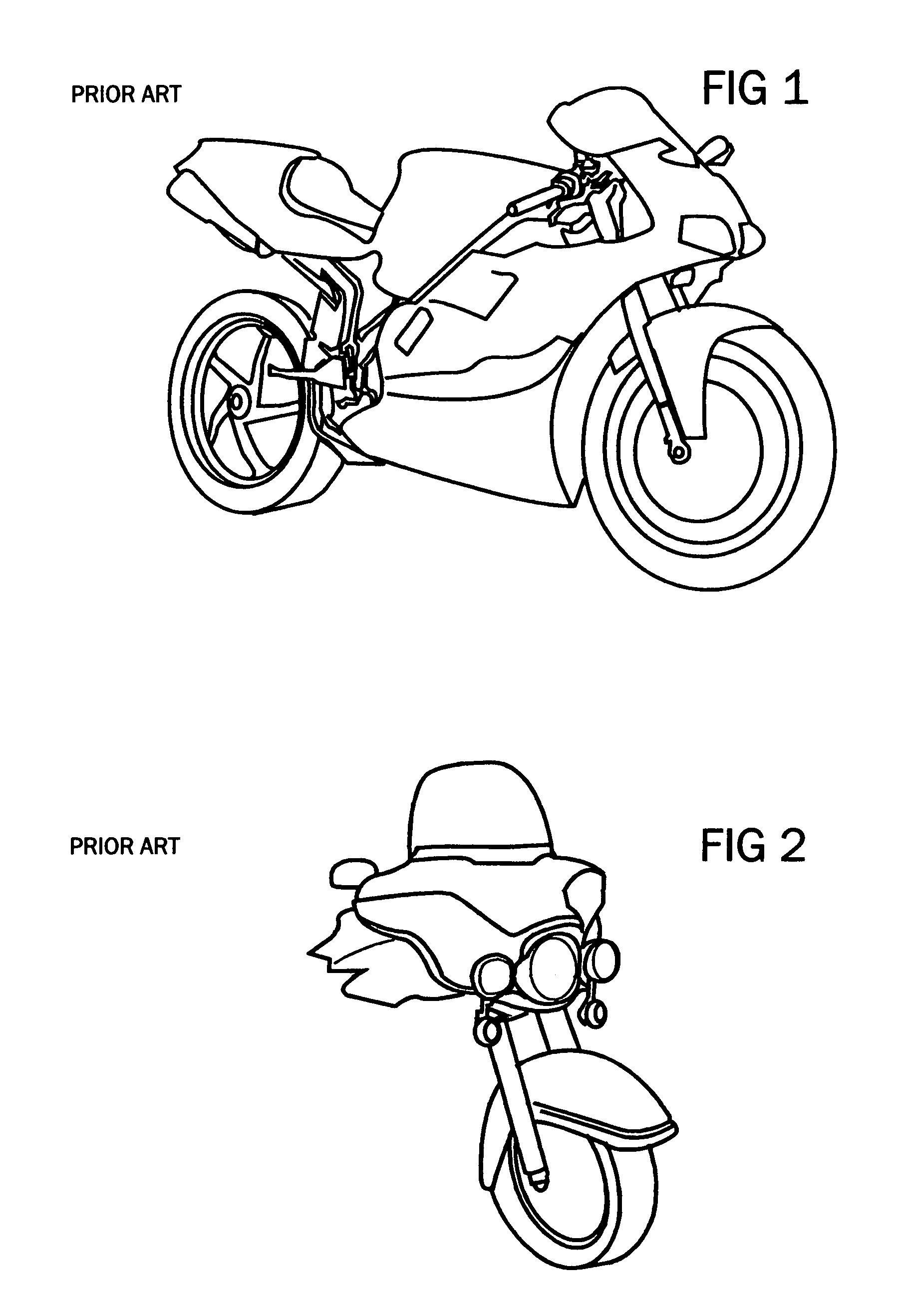

Aerodynamic hemisphere and socket motorcycle fairing

InactiveUS7404585B2Improve aerodynamic efficiencyEasy windingParking coversWeather guardsNacelleVehicle frame

A motorcycle fairing comprised of plastic or composite material fabricated and assembled to form: a front, substantially hemisphere shaped fender or nacelle fairing section which substantially encloses the front wheel of the motorcycle and is affixed to the upper front fork assembly of the motorcycle allowing the front wheel to be turned laterally independent of the attitude of the main frame of the motorcycle; and a frame mounted fairing which intersects and substantially encompasses the hemispherical front wheel fender section within a matching hemispherical shaped socket located in the frontal portion of said frame mounted fairing, which fairing then extends rearward along, and substantially parallel to the main frame of the motorcycle, with both fairing sections together substantially enclosing the front wheel, headlight, and engine of the motorcycle.

Owner:BUGNI CHARLES

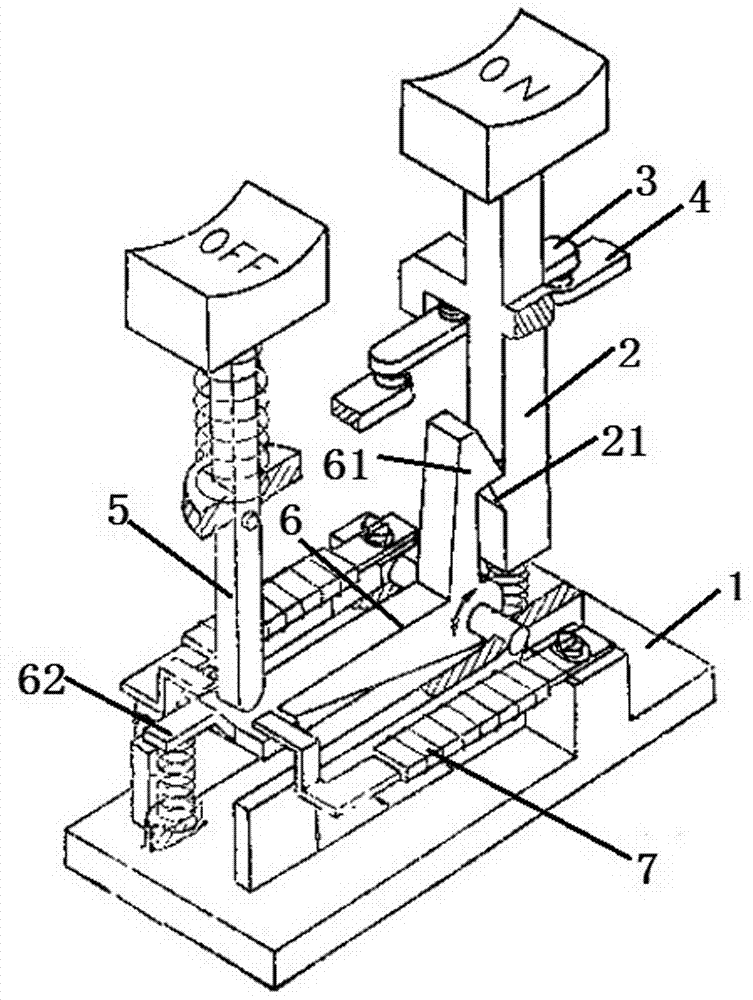

Overheating protection button switch

InactiveCN103578851AIncrease downforceRapid disconnectionThermal switch detailsEngineeringPush switch

The invention belongs to the field of electric switch parts and relates to an overheating protection button switch which comprises a base body, a connecting button and a disconnecting button. The connecting button comprises a button cap, a connecting rod, a movable contact and a fixed contact. The disconnecting button comprises a disconnecting rod and a reset spring. A jaw rod and double metal pieces are arranged on the base body. The jaw rod is fixed on the base body through a jaw rod rotating shaft. A hook jaw and a pressing plate are arranged at the two ends of the jaw rod respectively. The pressing plate is connected with a pressing spring. Deforming ends of the double metal pieces are fixed on the pressing plate. The front end of the connecting rod is provided with a clamping head which can be clamped with the hook jaw. The disconnecting rod abuts against the jaw rod pressing plate. The overheating protection button switch is safe, reliable and high in sensitivity and has a circuit overload protection function.

Owner:CHONGQING FENGGUO QIYANG TECH DEV

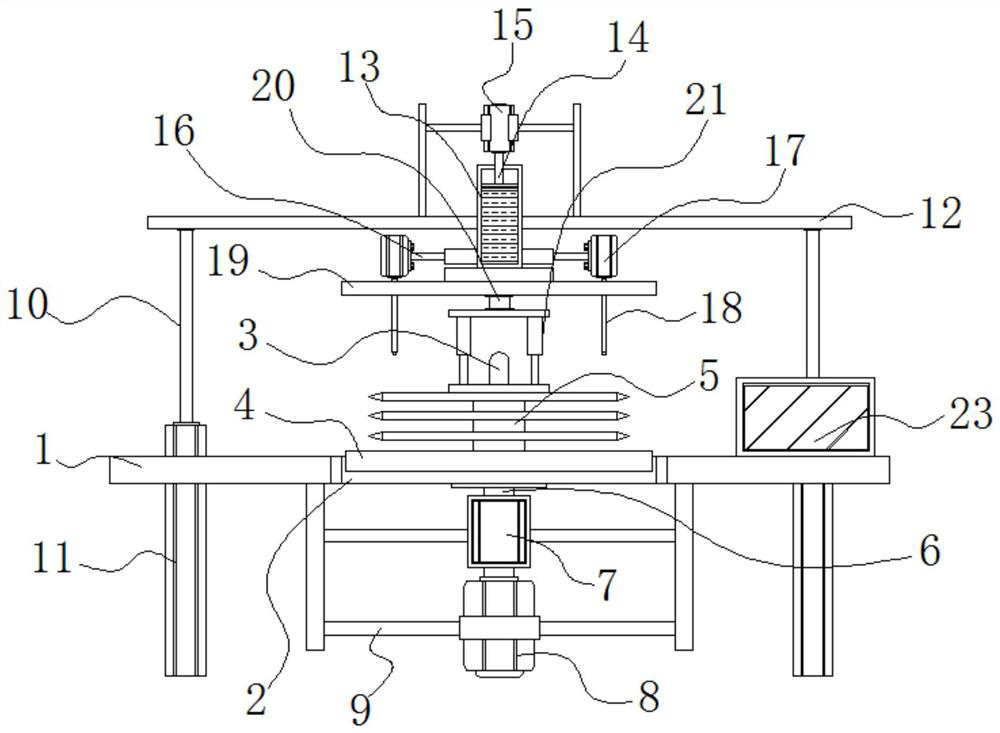

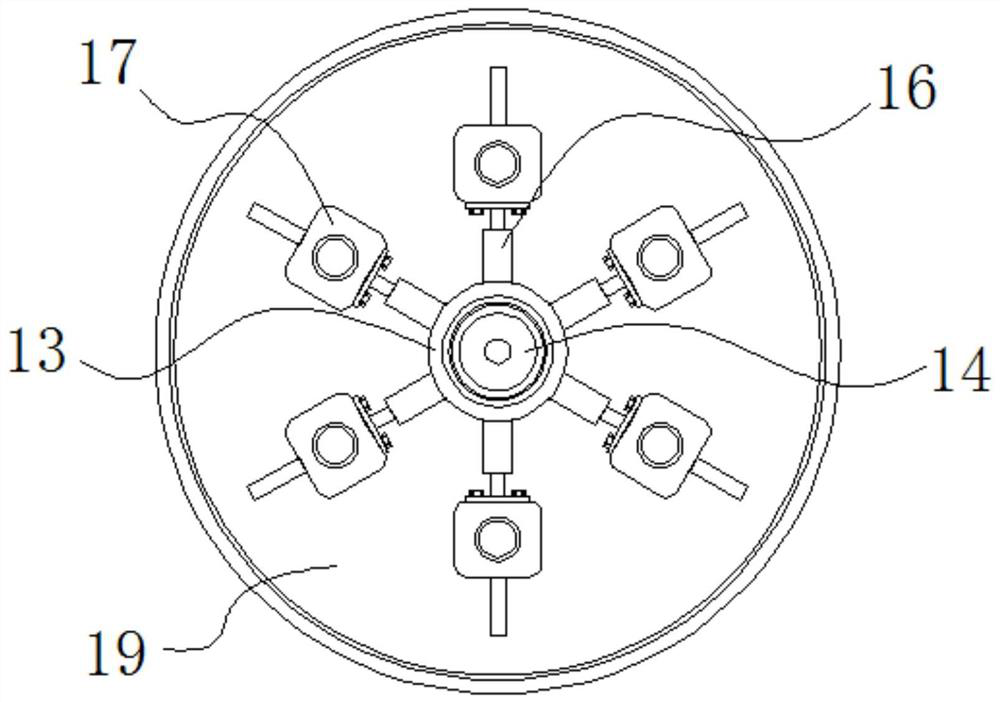

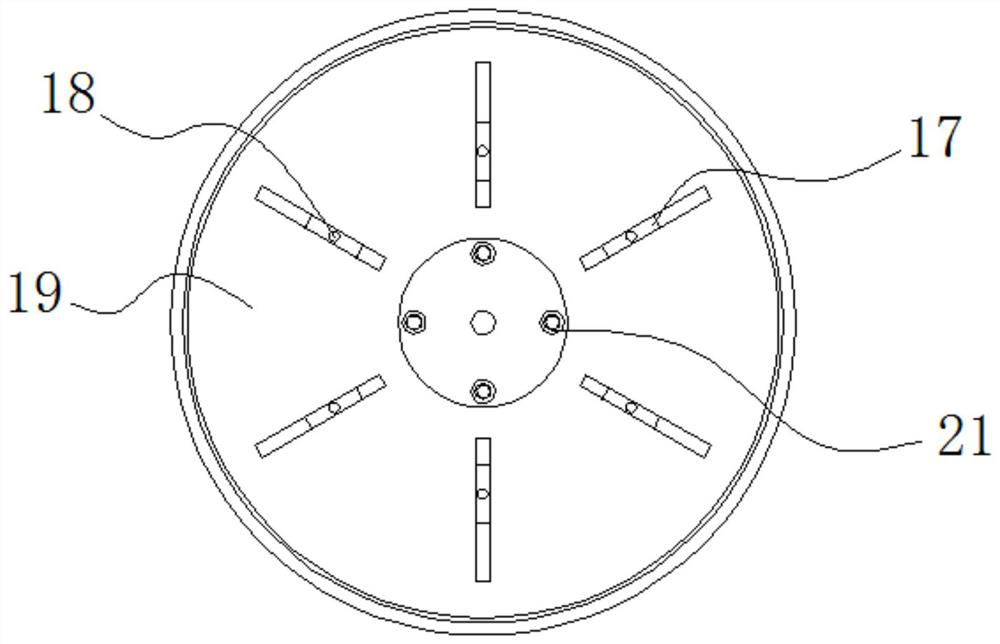

Grinding device with protection structure for alloy saw blade machining

ActiveCN111872756AEasy to GrindImprove work efficiencyGrinding drivesOther manufacturing equipments/toolsElectric machineAlloy

The invention discloses a grinding device with a protection structure for alloy saw blade machining, and relates to the technical field of grinding devices. The grinding device specifically comprisesa grinding platform and a saw blade grinding mechanism; a lifting plate is arranged in the middle part of the surface of the grinding platform, the bottom of the surface of a placement column is sleeved with a scrap collecting disc, the bottom of the lifting plate is connected with a rotating shaft, and the bottom of a gearbox is connected with a rotating motor; and the saw blade grinding mechanism is arranged on the two sides of the grinding platform, a liquid cylinder is embedded in the middle part of a plate frame, the bottom of a bearing is connected with spring telescopic rods, and a touch control screen is arranged at a corner of the right side of the grinding platform. According to the grinding device with the protection structure for alloy saw blade machining, the surface of the placement column is sleeved with to-be-ground alloy saw blades with the same size, every two alloy saw blades are separated in parallel through a partition piece, and then rotating grinding cylindricalrods enter coincident tooth grooves for grinding; and through the arrangement, the plurality of tooth grooves of the plurality of saw blades can be ground at the same time, so that the working efficiency is favorably improved.

Owner:浙江特佳利工具有限公司

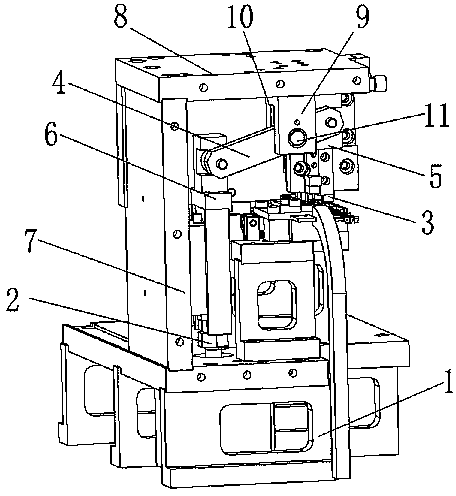

Connector iron shell cutting mechanism

InactiveCN103746263ASmooth rotationImprove cutting effectContact member cases/bases manufactureEngineeringMechanical engineering

The invention discloses a connector iron shell cutting mechanism. The connector iron shell cutting mechanism comprises a workbench, a push-up cylinder and an upper knife, and is characterized in that the push-up cylinder is arranged on the workbench, a connecting arm is arranged on a vertical moving piston rod of the push-up cylinder, one end of a balancing lever is connected with the connecting arm, the other end of the balancing lever is connected with a pressing block, and the bottom of the pressing block is provided with the upper knife. The top of the workbench is provided with a side plate, the top of the side plate is provided with a top plate, the bottom of the top plate is provided with a fixing block, the middle part of the fixing block is provided with a groove, and the balancing lever penetrates through the groove of the fixing block and is flexibly connected through a hinge pin. The connector iron shell cutting mechanism solves the problem that in a pressing process of the cylinder of the connector iron shell cutting mechanism, pressing force is not large enough, a product is easy to damage, thereby bringing unnecessary loss to a company, and increasing costs of the company, and the connector iron shell cutting mechanism is provided by which pressure is increased, cutting is steady and reliable, and product quality is substantially improved.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

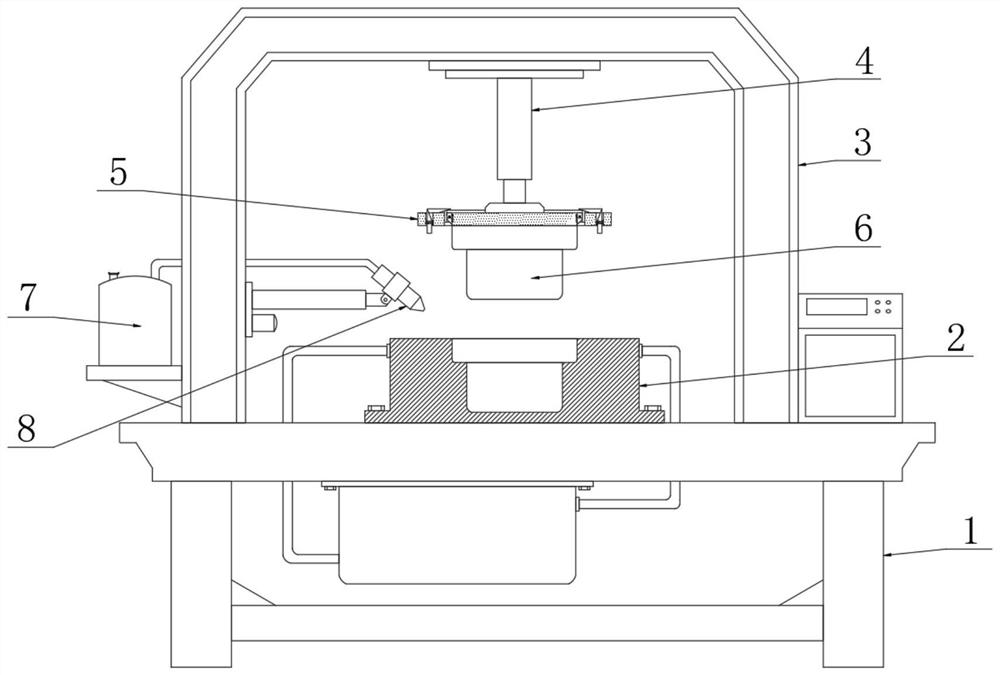

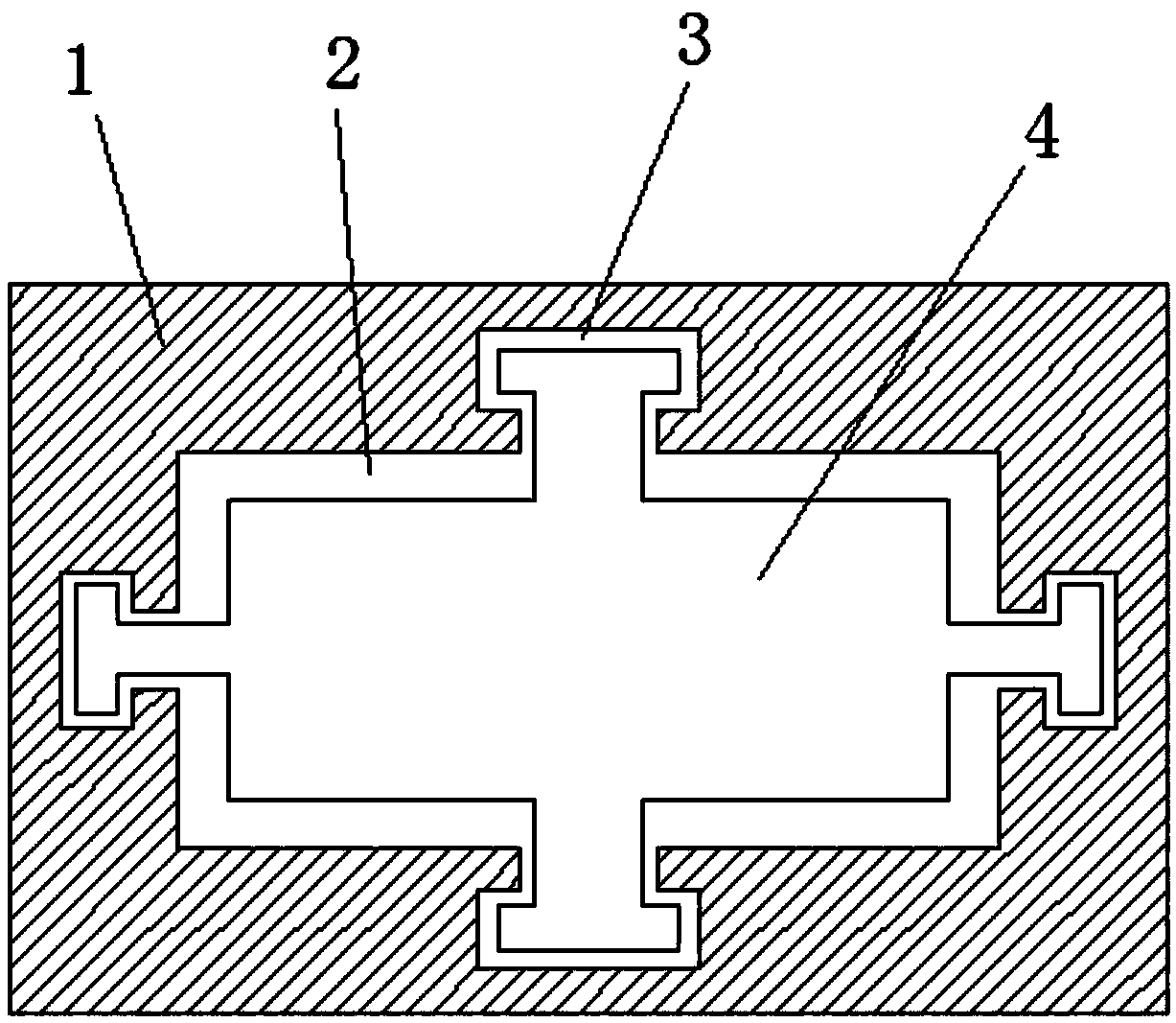

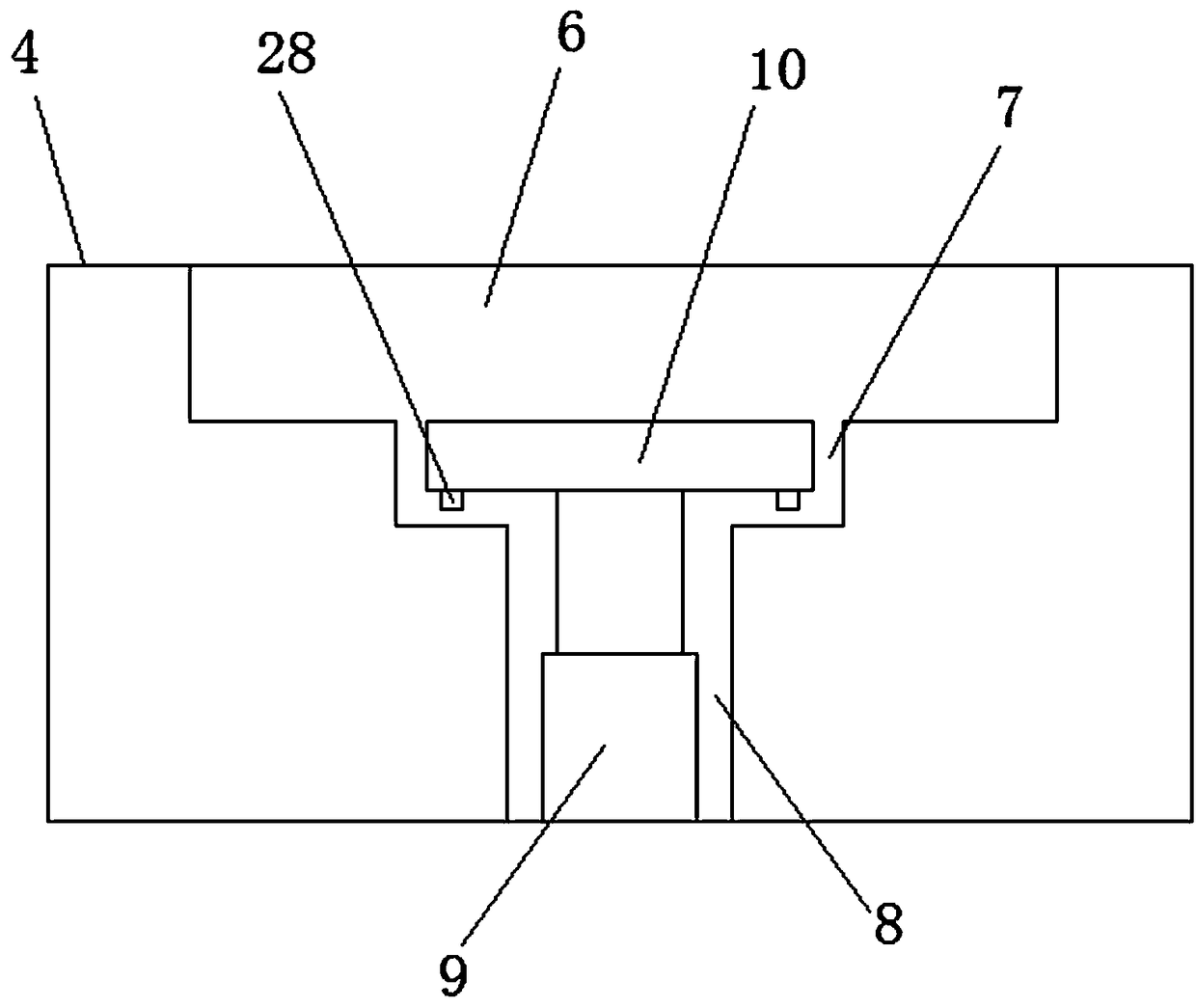

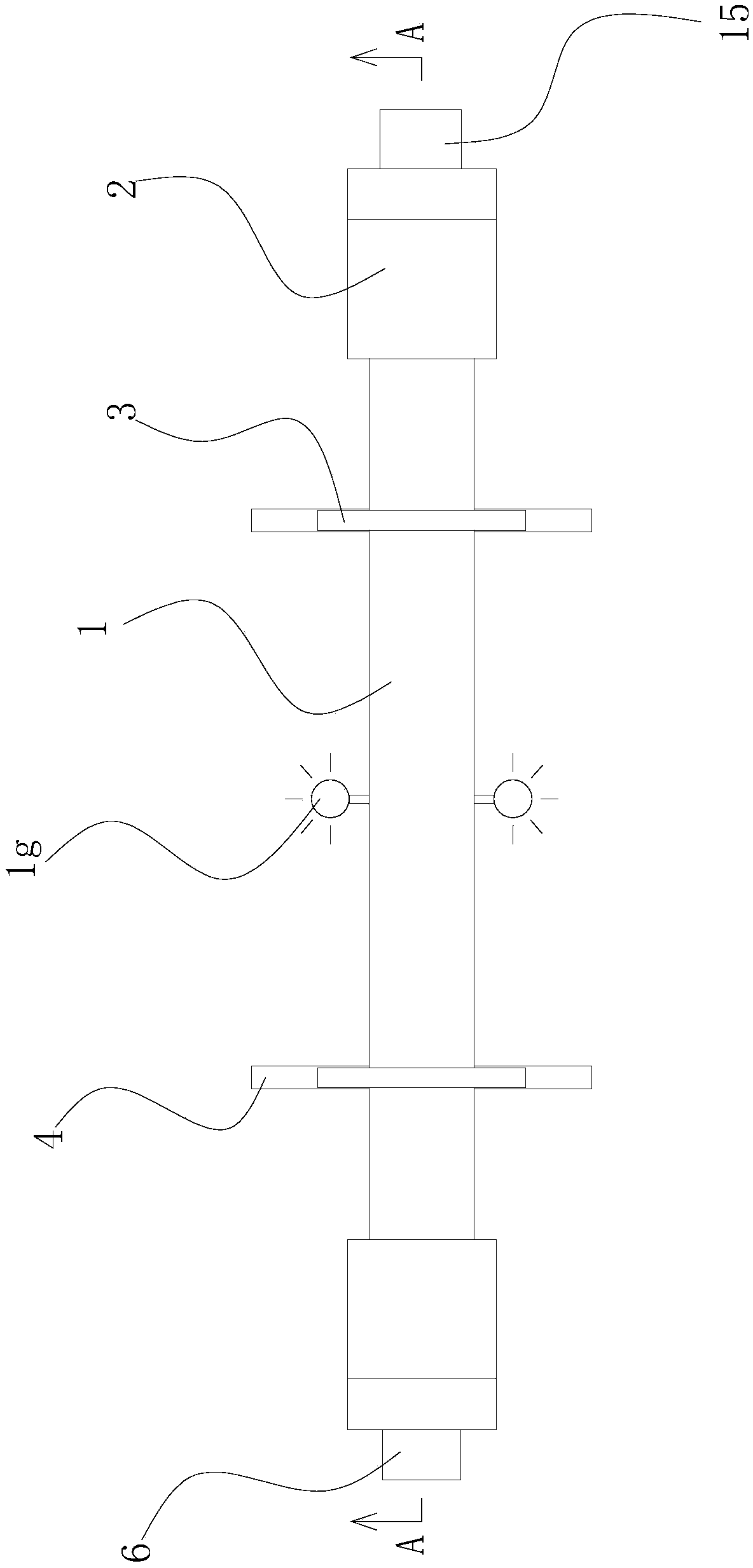

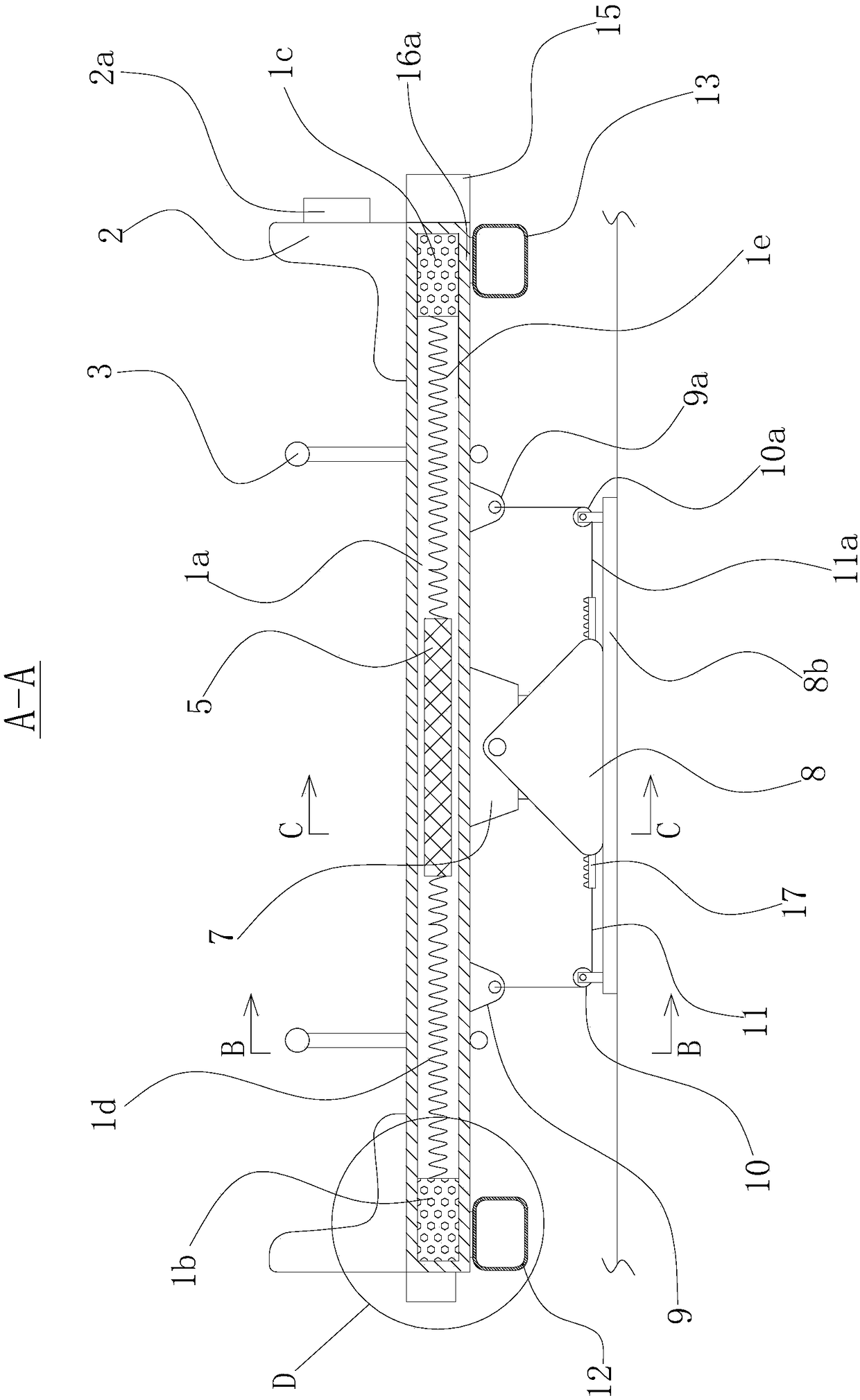

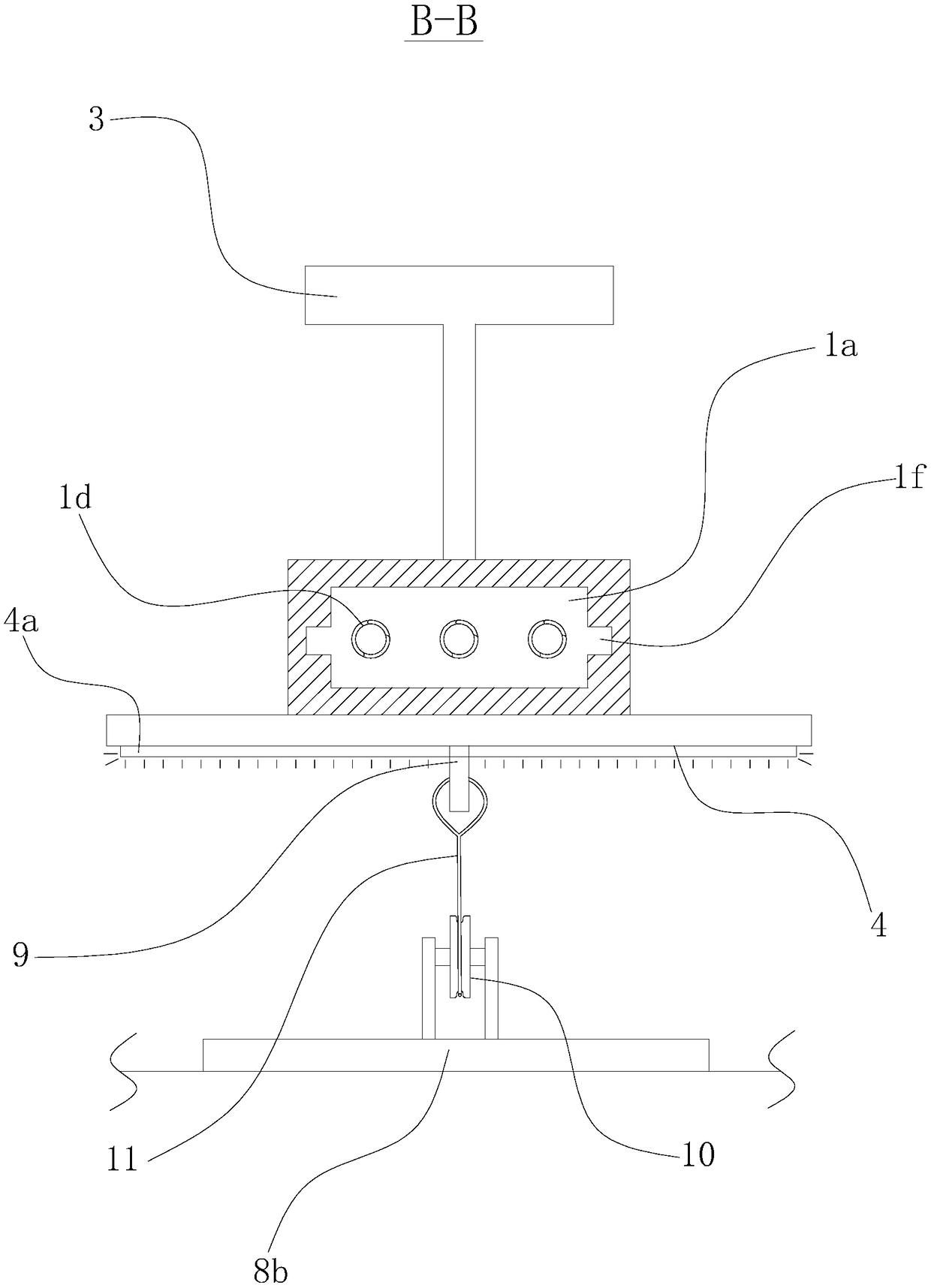

Die casting equipment and method

ActiveCN112355276ANo secondary treatment requiredImprove processing efficiencyHydraulic cylinderDie casting

The invention discloses die casting equipment, and belongs to the technical field of die casting equipment. The die casting equipment comprises a workbench, a fixed die is fixedly installed on the outer wall of the top of the workbench, the outer wall of the top of the workbench is fixedly connected with a rack, the inner wall of the top of the rack is fixedly connected with a hydraulic cylinder,a hydraulic rod at the bottom of the hydraulic cylinder is fixedly connected with a cleaning device, a movable die is arranged on the outer wall of the bottom of the cleaning device, a storage barrelis arranged on the outer wall of the left side of the rack, the outer wall of the top of the storage barrel communicates with a material injection head through a guide pipe, and the right end of an electric telescopic rod is connected with the material injection head through a clamp. When the movable die in the device is inserted into a cavity of the fixed die to machine a product, an installationplate can be in contact with the top wall of the fixed die, a movable rod is pushed upwards, a guide block moves towards the inner side, a movable sleeve drives a cutter to move downwards to be in contact with the top wall of the fixed die, overflowing raw materials are cut off, and the circumstance that the top of the product has redundant parts after the raw materials are cooled and formed is avoided.

Owner:临沂市铸信机械有限公司

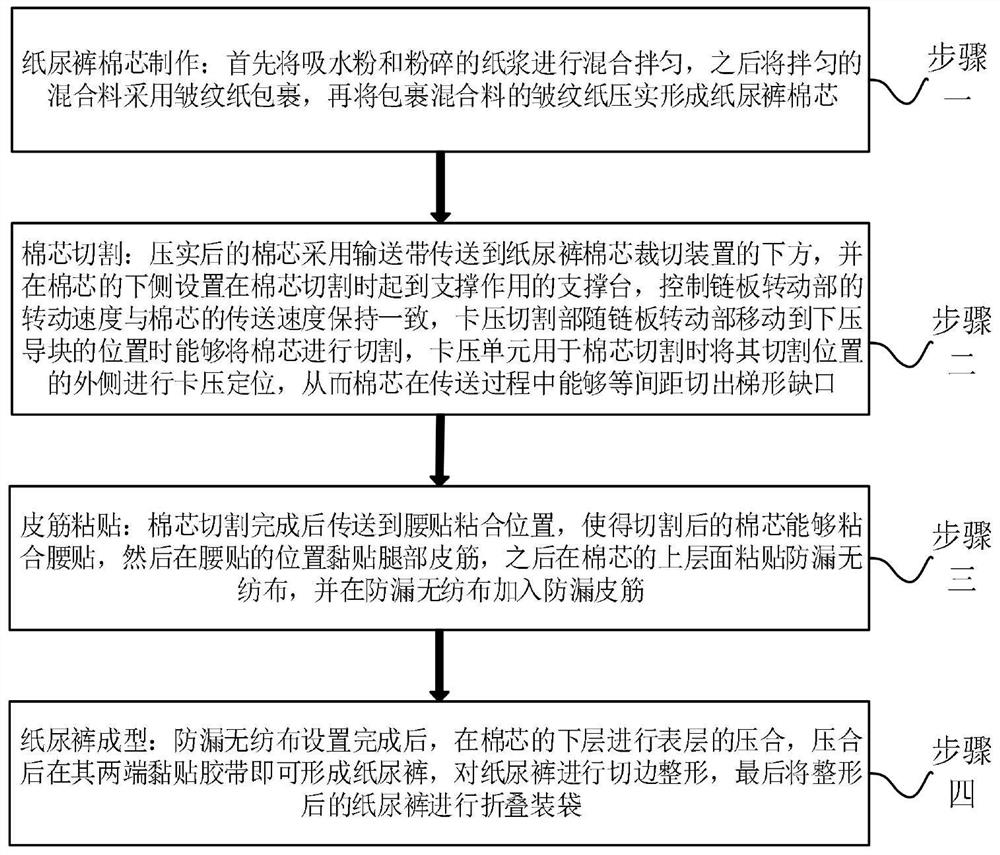

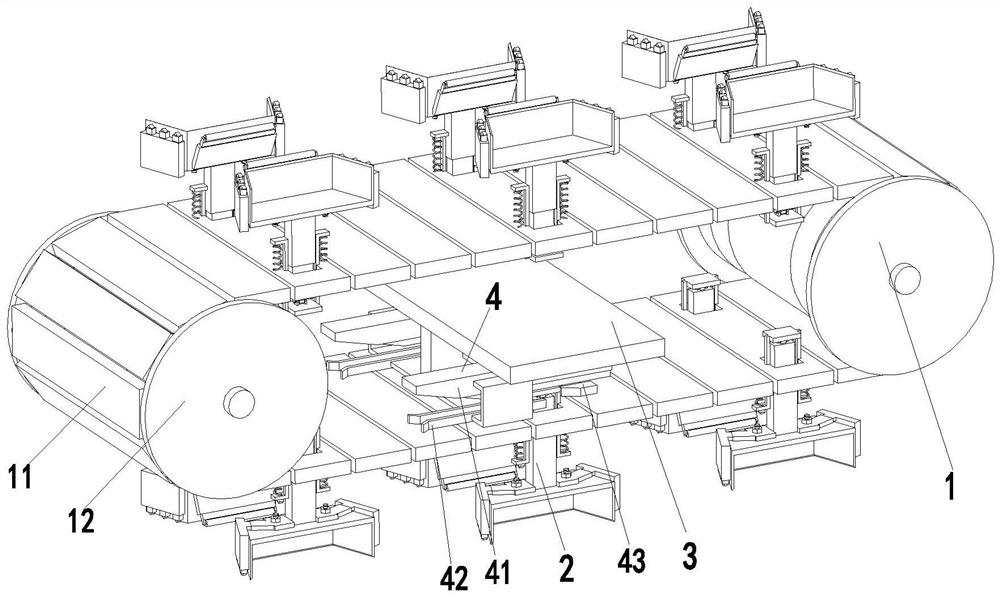

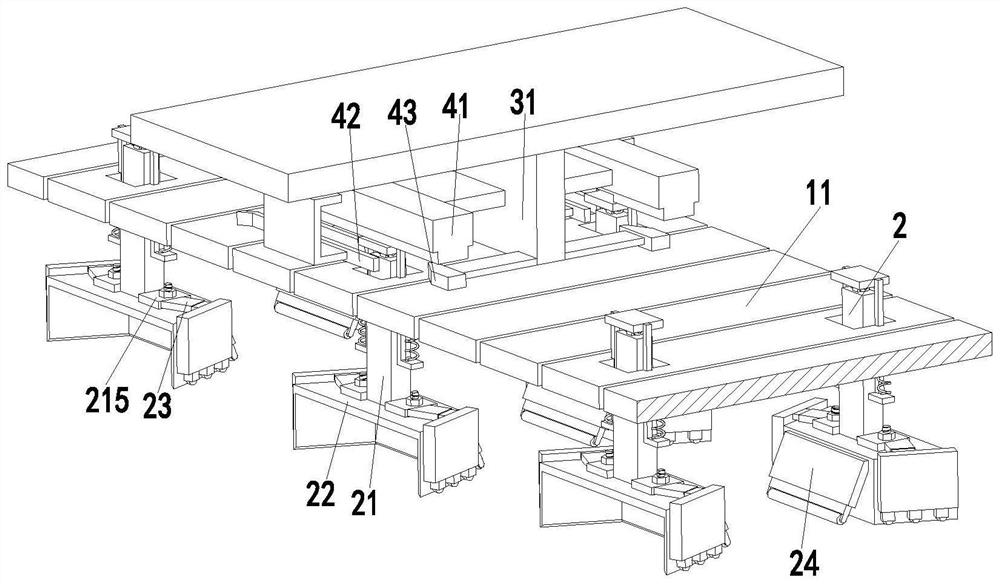

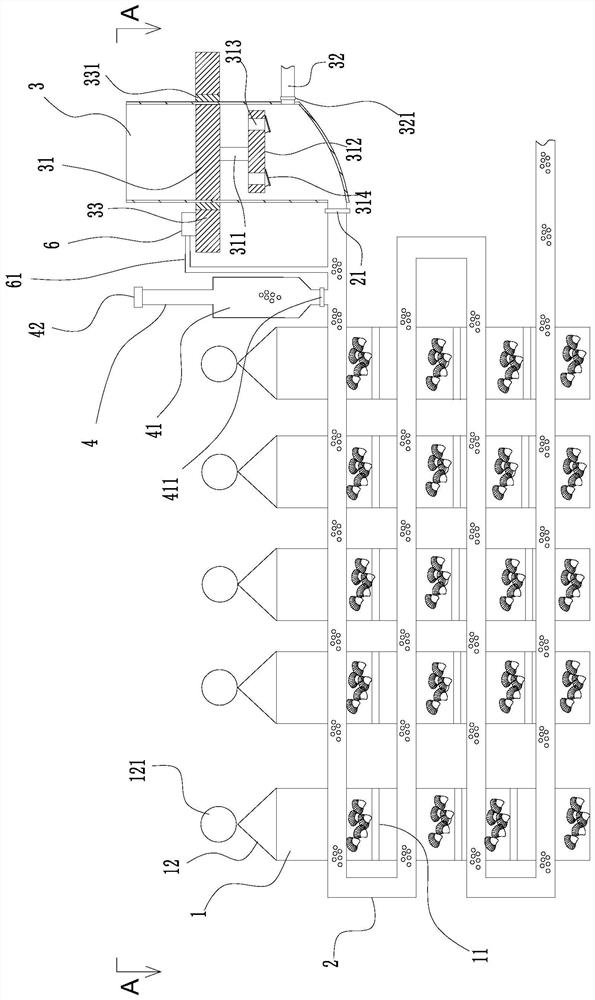

Infant paper diaper manufacturing method

ActiveCN114587795AImprove cutting effectNo skewPlastic recyclingAbsorbent padsWaste materialIndustrial engineering

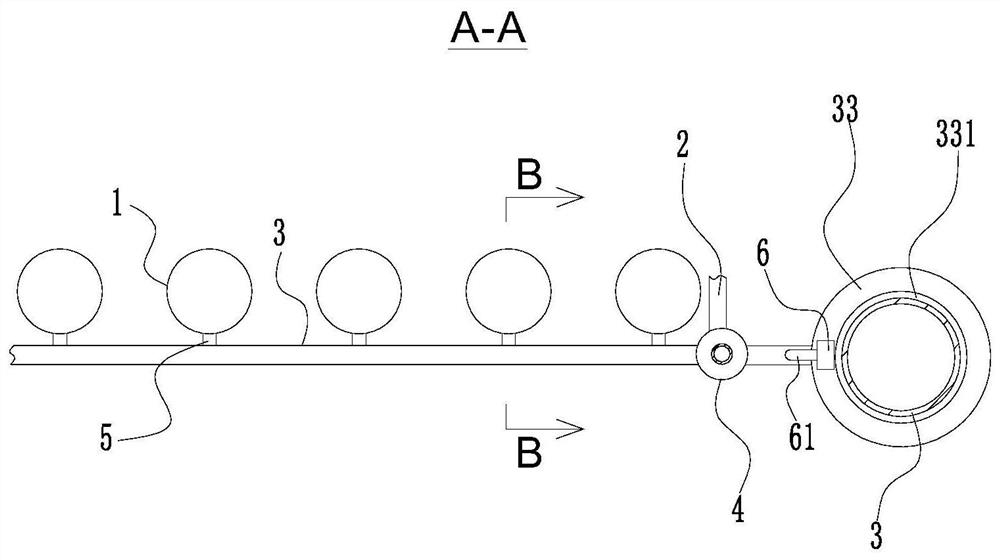

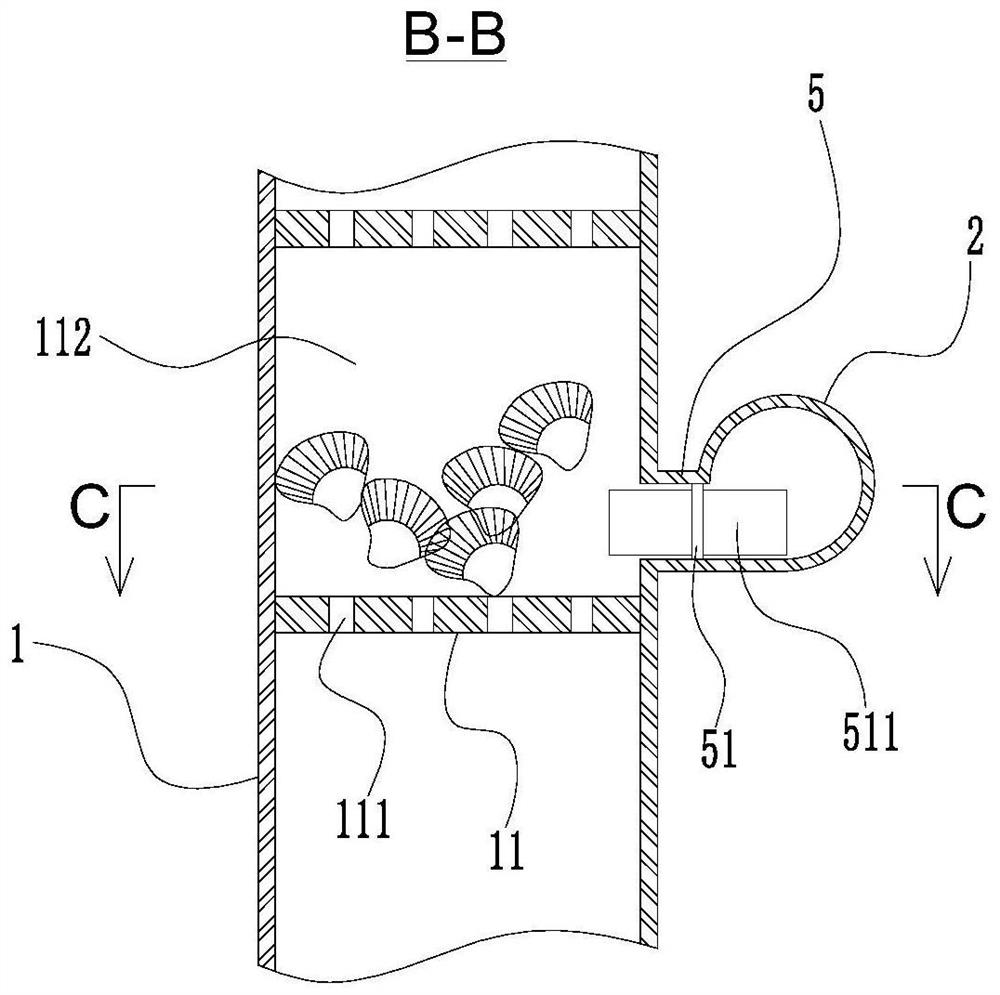

The invention relates to the technical field of paper diaper manufacturing, in particular to an infant paper diaper manufacturing method.The infant paper diaper manufacturing method is completed through cooperation of a paper diaper cotton core cutting device, the paper diaper cotton core cutting device comprises a chain plate conveying belt, and the chain plate conveying belt comprises a chain plate rotating part driven by two transmission parts; a plurality of groups of clamping and pressing cutting parts are uniformly arranged on the chain plate rotating part in the conveying direction of the chain plate rotating part, a guide mechanism is arranged between the transmission parts, and the guide mechanism is located above the clamping and pressing cutting parts arranged on the chain plate rotating part on the lower side of the transmission parts. According to the cotton core cutting device, the cutter can be controlled to be in a vertical state during cutting, and cut cotton core waste is automatically removed; the problems that in existing cotton core cutting, the cutting force is insufficient or the cutting angle is inclined, so that the cotton core cannot be completely cut, the cut cotton core cannot be removed in the cutting process, and the overall production efficiency of paper diapers in the later period is reduced are solved.

Owner:中科健(天津)科技集团有限公司

Aquaculture device utilizing wave energy

PendingCN112314496AIncrease productionEliminate the trouble of manual feedingClimate change adaptationPisciculture and aquariaEngineeringFodder

The invention discloses an aquaculture device utilizing wave energy, and belongs to the field of aquaculture. The device comprises a net cage, a piston pipe, a feed conveying pipe and a feeding pipe,a plurality of partition plates are arranged in the net cage, a floating ball is connected to the top of the net cage through a hanging rope, a piston is slidably arranged in the piston pipe, the upper end of the piston pipe communicates with the outside, and a driving mechanism capable of driving the piston to move up and down through the wave energy is arranged outside the piston pipe; the position, located below the piston, of the side wall of the piston pipe is connected with a water inlet pipe, the starting end of the feed conveying pipe is communicated with the bottom of the piston pipe,the feed conveying pipe is connected with a plurality of communicating pipes, the communicating pipes are communicated with corresponding breeding spaces, and feeding mechanisms are arranged in the communicating pipes; and the feeding mechanisms can convey feed in the feed conveying pipe into the breeding spaces corresponding to the communicating pipes, and the bottom of the feeding pipe is connected with the starting end of the feed conveying pipe. Feed can be conveyed into the net cage through the wave energy, and the conveying efficiency is improved.

Owner:ZHOUSHAN JUNYAO TECH DEV CO LTD

Automatic stamping equipment

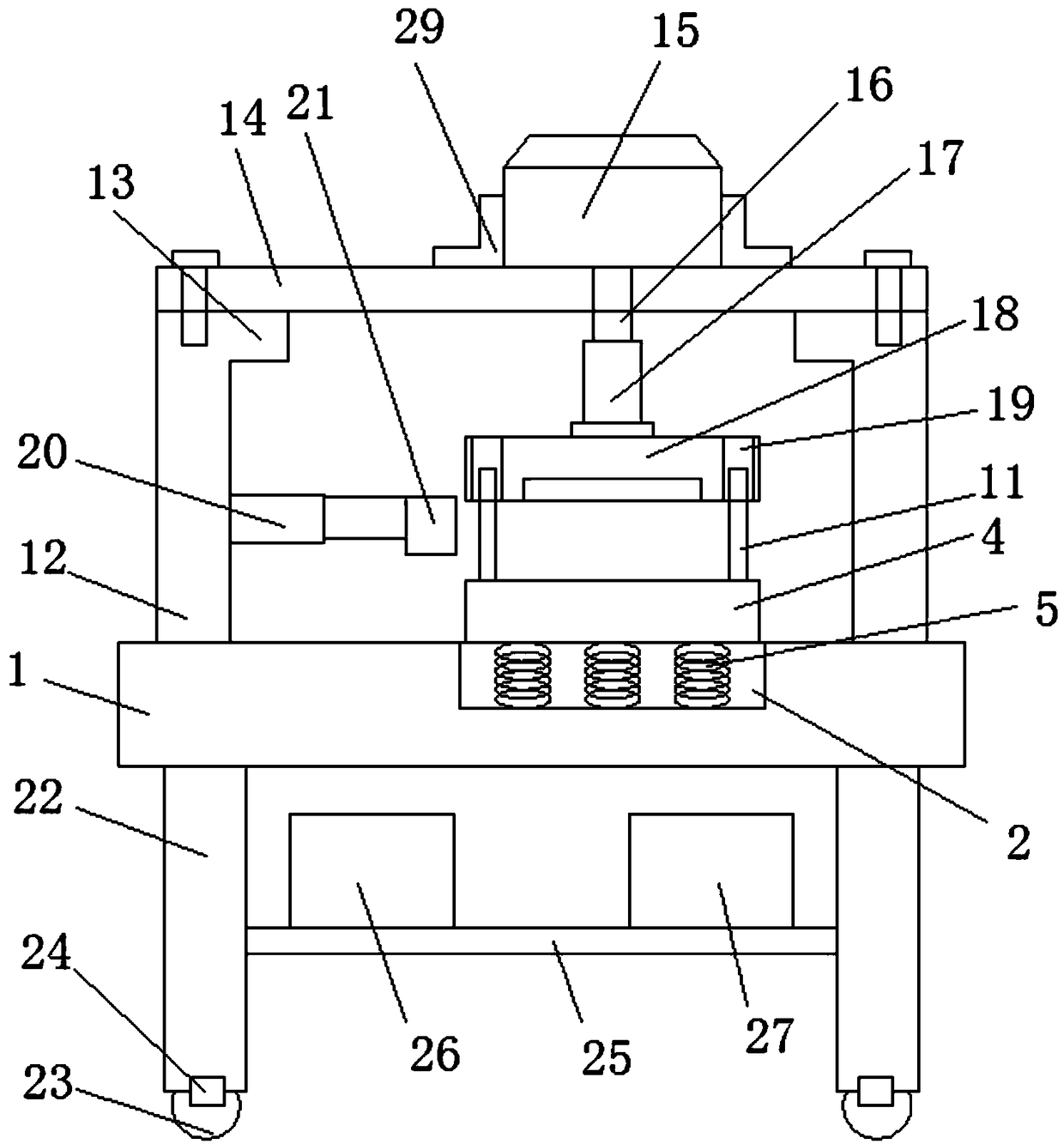

PendingCN108817182ASimple structureReasonable designShaping toolsCleaning using gasesHydraulic cylinderPulp and paper industry

The invention relates to automatic stamping equipment. The automatic stamping equipment comprises a working platform, a buffer slot is formed in the top of the working platform, and a sliding groove is formed in the buffer slot. A lower mould is connected to the sliding groove in a sliding mode through a sliding block, and the working platform is connected to the bottom of the lower mould througha buffer spring. A stamping groove is formed in the top of the lower mould, a groove is formed in the bottom of the stamping groove, and a vertical slot is formed in the bottom of the groove. A firsthydraulic cylinder is installed in the vertical slot, wherein a push plate is fixedly connected to the top of the first hydraulic cylinder, and the push plate is arranged in the groove. Through the arrangement of the buffer spring, the impact force to moulds is reduced when stamping, and the service life of the moulds is conveniently prolonged; through arranging the push plate, workpiece after stamping is pushed out, and blanking is convenient to carry out; through arranging air holes, impurities inside the stamping groove are blew away, and the product quality affected is avoided; through arranging blanking pieces, automatic blanking is carried out, and the labor cost is conveniently saved.

Owner:SUZHOU HONGQIRUI AUTOMATION

Power-assisted seesaw

The invention provides a power-assisted seesaw, and belongs to the technical field of body-building equipment. The seesaw comprises a seesaw body, a base plate and two seats, the seesaw body is made of a non-ferromagnetic material, and rotationally arranged on the two seats via a rotating shaft on a support block, the two seats are arranged on the pedestal in parallel, the seesaw body is internally provided with an installation cavity along the length direction, the left and right ends of the installation cavity are provided with first and second electromagnets respectively, a counterweight block which includes a permanent magnet is arranged in the installation cavity in a sliding way, the right end surface of the seesaw body is provided with a storage battery, the left end surface of theseesaw body is provided with a controller, the left and right ends in the lower side surface of the seesaw body are provided with first and second pressure sensors respectively, and the first and second pressure sensors and the first and second electromagnets are electrically connected with the storage battery via the controller. The counterweight block is additionally arranged in the seesaw body,so that the seesaw body can be played with by people in different weights.

Owner:ZHEJIANG OCEAN UNIV

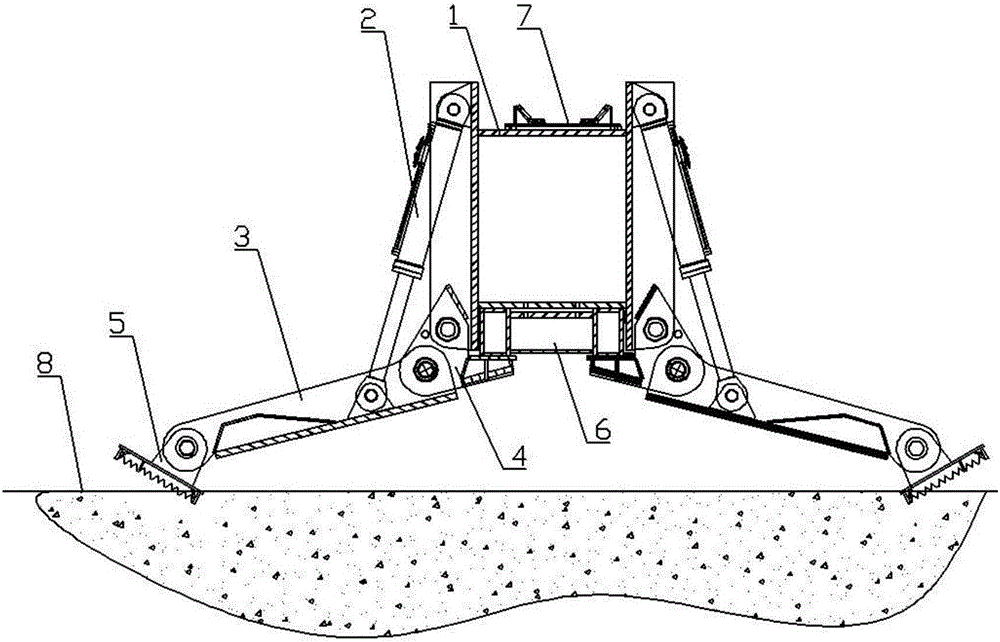

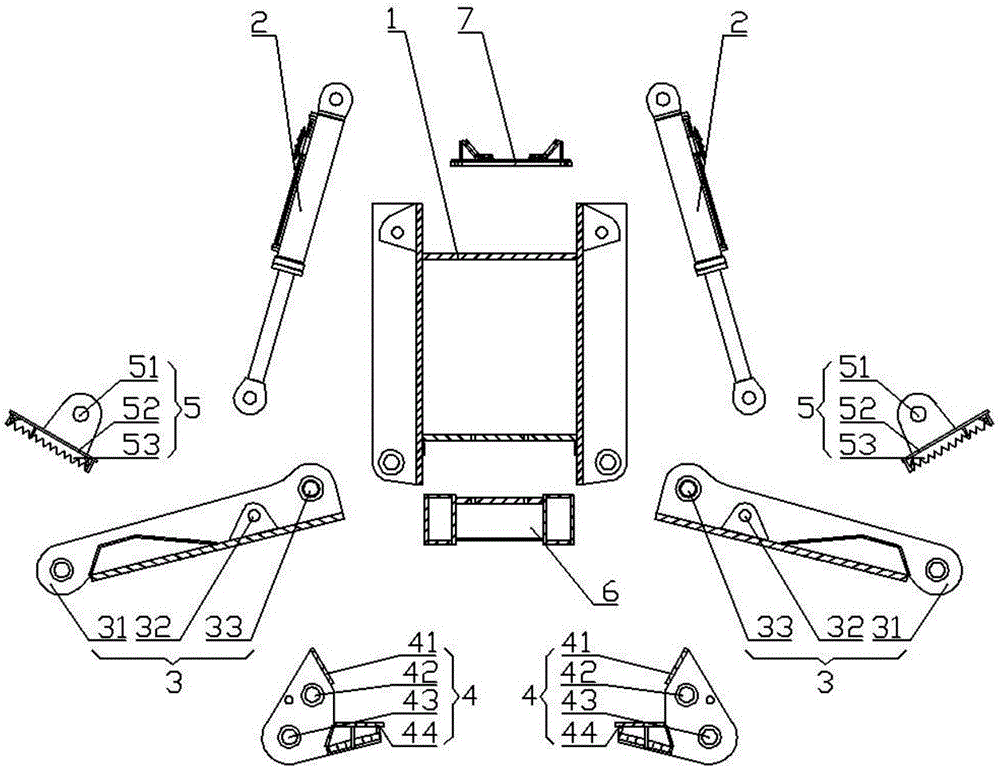

Counterweight device of rotary drilling rig and rotary drilling rig with same

ActiveCN105781429AIncrease downforceGuaranteed verticalityDerricks/mastsCounterweightsTelescopic cylinderEngineering

The invention discloses a counterweight device of a rotary drilling rig which comprises a rig body and an upper crossbeam mounted on the rig body.The counterweight device comprises a counterweight box frame for placement of a counterweight and an outward-unfolding supporting leg mechanism component connected with the outer side of the counterweight box frame, the counterweight box frame is fixedly mounted on the upper portion of the upper crossbeam of the rig body, the outward-unfolding supporting leg mechanism component comprises an extensible cylinder and a supporting leg, one end of the supporting leg is a supporting end while the other end of the same is hinging end, a middle hinging position is arranged between the supporting end and the hinging end, one end of the extensible cylinder is hinged to the upper portion of the counterweight box frame while the other end of the same is hinged to the middle hinging position of the supporting leg, and the hinging end is hinged to the lower portion of the counterweight box frame.Backward inclination caused by overhigh pressure applied on the ground by the front end can be prevented, so that adaptability and using effect of equipment are improved greatly.The invention further discloses the rotary drilling rig with the counterweight device.

Owner:赵鑫宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com