Counterweight device of rotary drilling rig and rotary drilling rig with same

A technology of rotary drilling rig and counterweight device, which is applied in the direction of support device, counterweight, drilling equipment, etc., which can solve the problems of drilling platform losing level, drilling hole not vertical, crawler warping, etc., to protect the drill pipe and improve the drilling efficiency. The effect of improving efficiency and ensuring verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

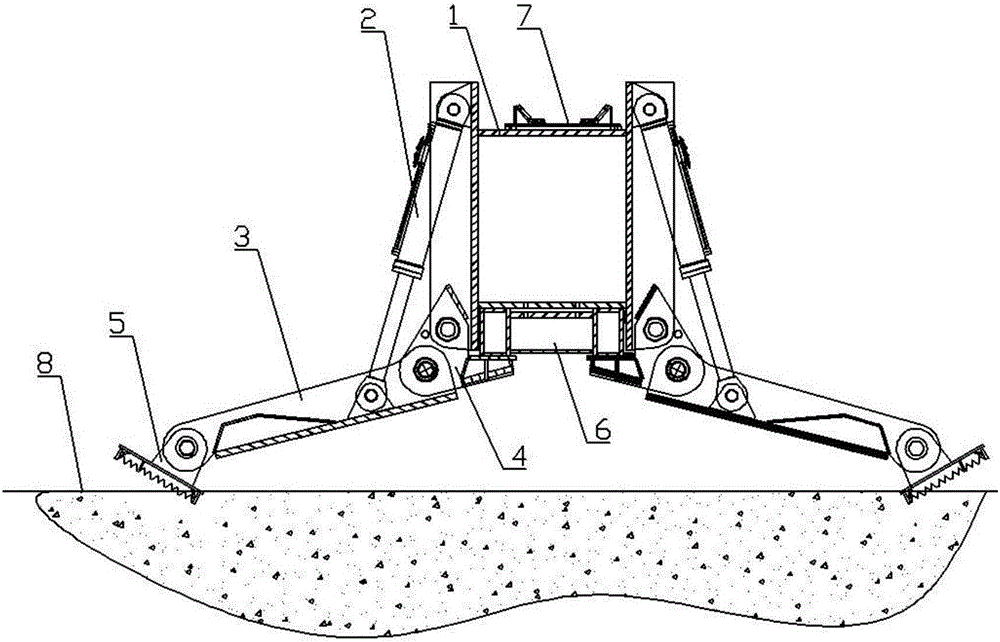

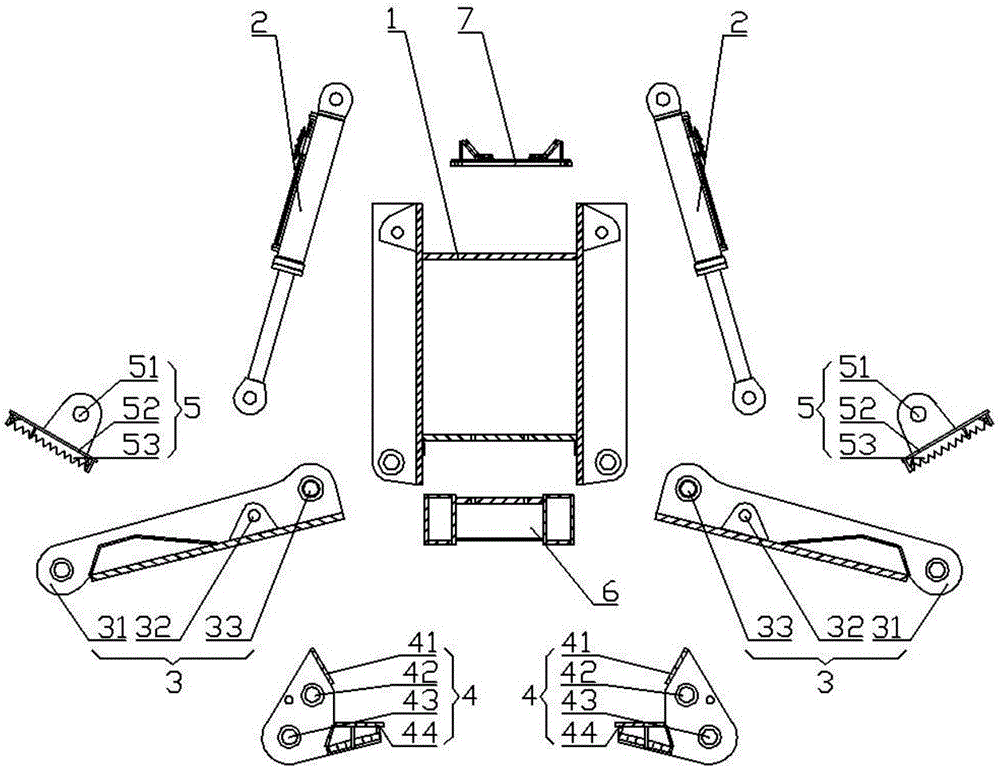

[0033] Such as figure 1 As shown, it is a schematic diagram of a specific embodiment of a rotary drilling rig and its counterweight device provided by the present invention, figure 2 An exploded view of each component.

[0034] A counterweight device of a rotary drilling rig provided by the present invention, the rotary drilling rig includes a machine body and an upper beam 6 installed on the machine body, the counterweight device includes a counterweight box frame 1 for placing counterweight blocks and Outreach outrigger mechanism assembly connected to the outside of the counterweight box frame 1, the counterweight box frame 1 is fixedly installed on the upper part of the boarding beam 6 of the body;

[0035] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com