Infant paper diaper manufacturing method

A production method and technology of diapers, applied in baby underwear, medical science, absorbent pads, etc., can solve problems such as insufficient cutting force, incision wrinkles of cotton core, and cutting angle deflection, so as to increase the cutting effect, facilitate alignment, The effect of increasing flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described in detail below. The embodiments described below are exemplary, only for explaining the present invention, and should not be construed as limiting the present invention. If no specific technique or condition is indicated in the examples, the technique or condition described in the literature in the field or the product specification is used.

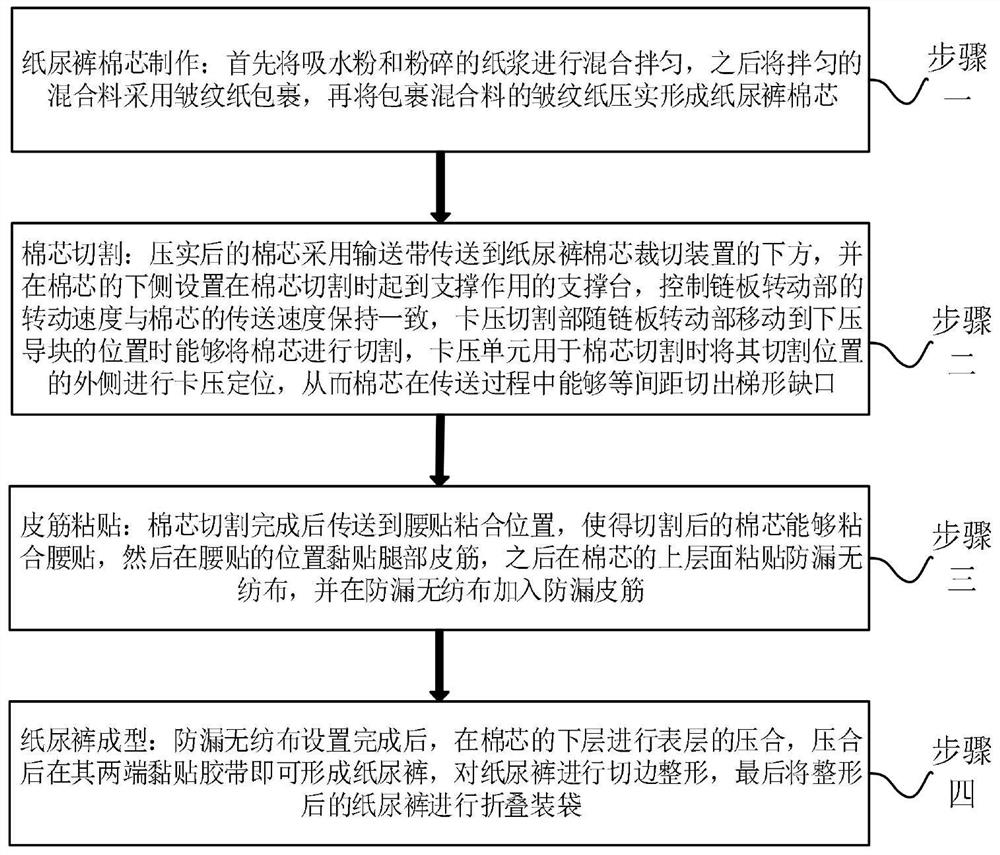

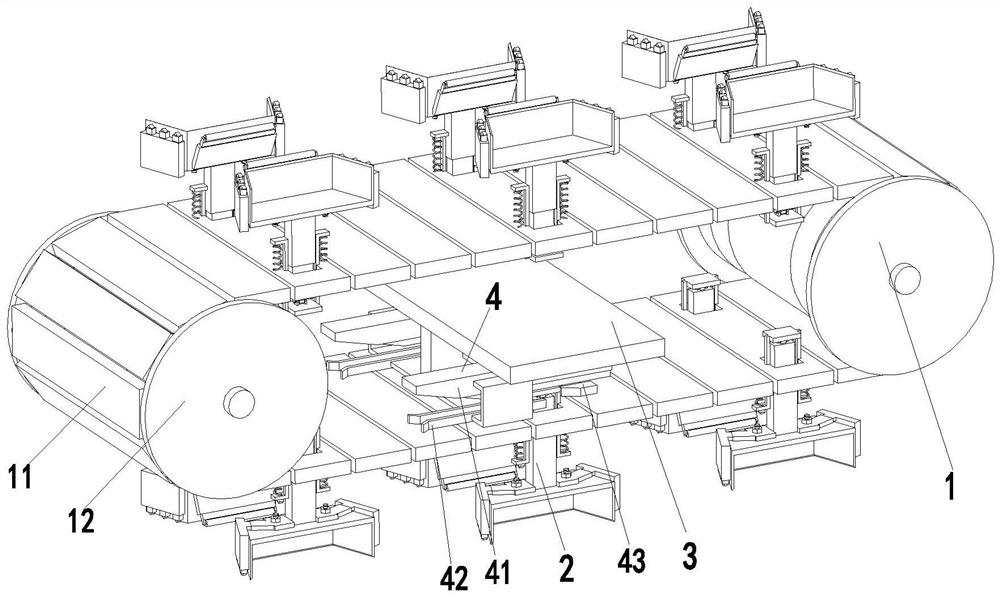

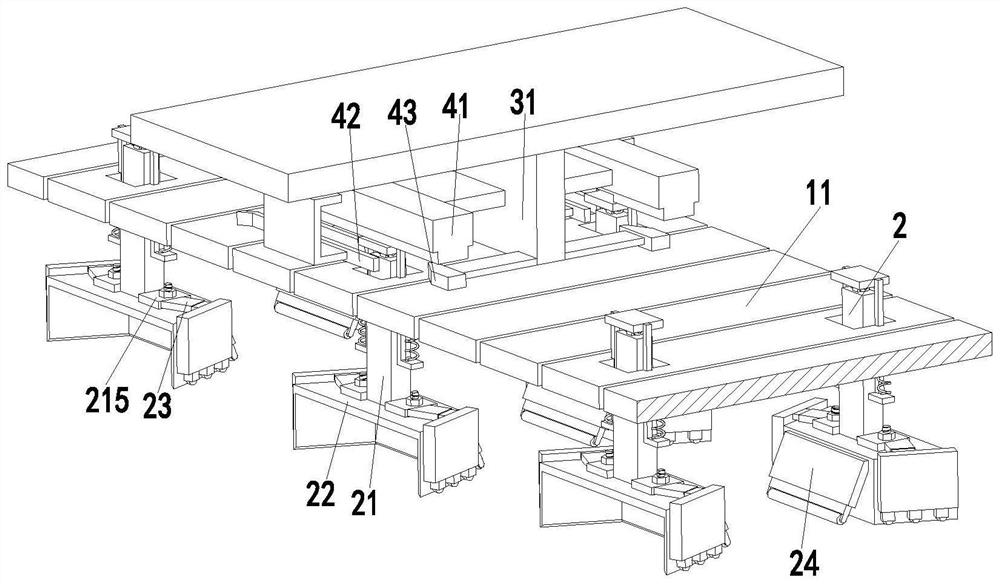

[0040] see Figure 2-Figure 3The present invention provides a method for making diapers for infants and young children. The method for making diapers for infants and young children is completed by using a diaper cotton core cutting device. The diaper cotton core cutting device includes a chain plate transmission belt 1. The chain plate transmission belt 1 includes two The chain plate rotating part 11 driven by the transmission part 12, the chain plate transmission belt 1 is the existing chain plate transmission belt, and the rotation of the chain plate transmission belt 1 is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com