Patents

Literature

30results about How to "Reduce cutting pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

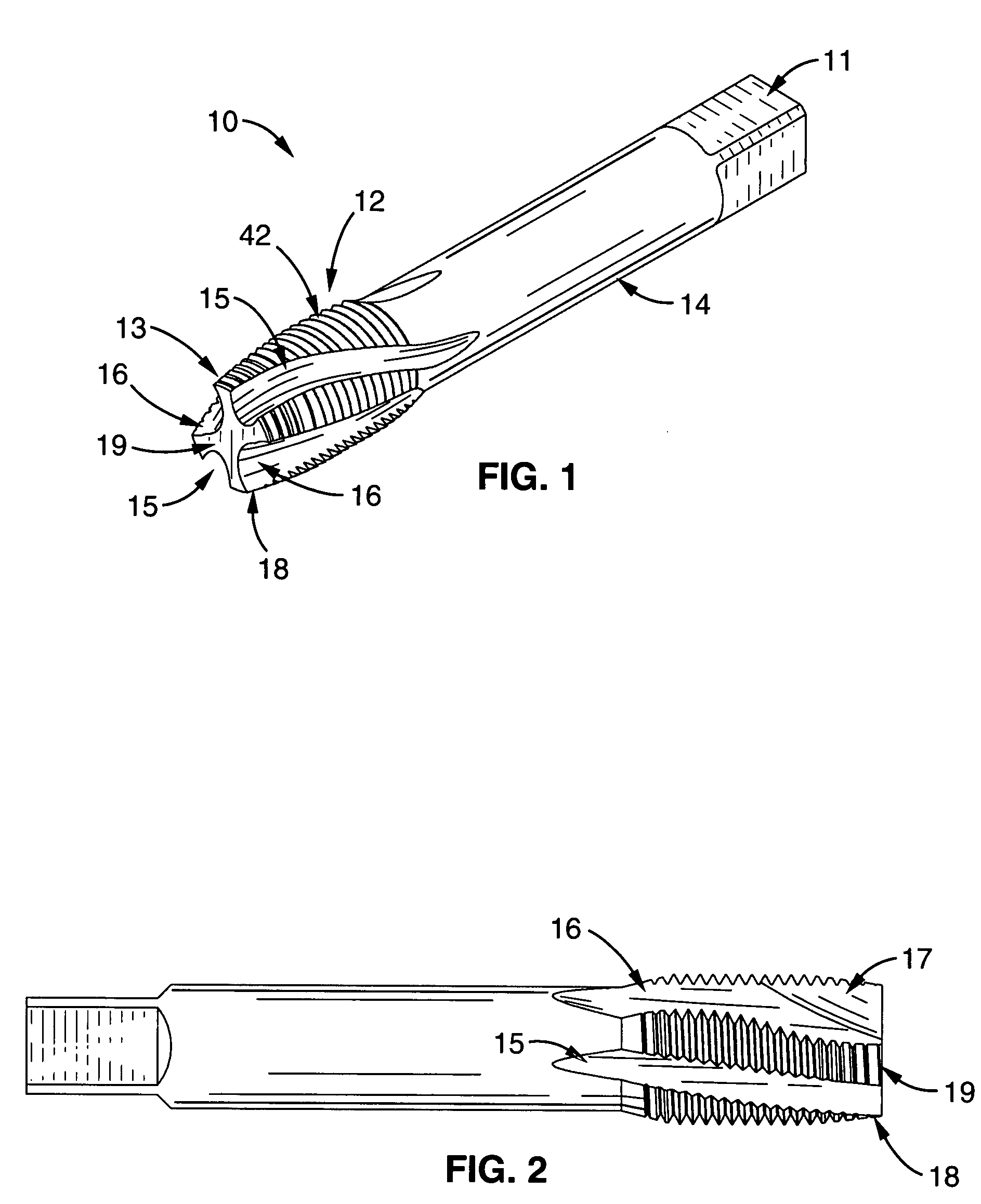

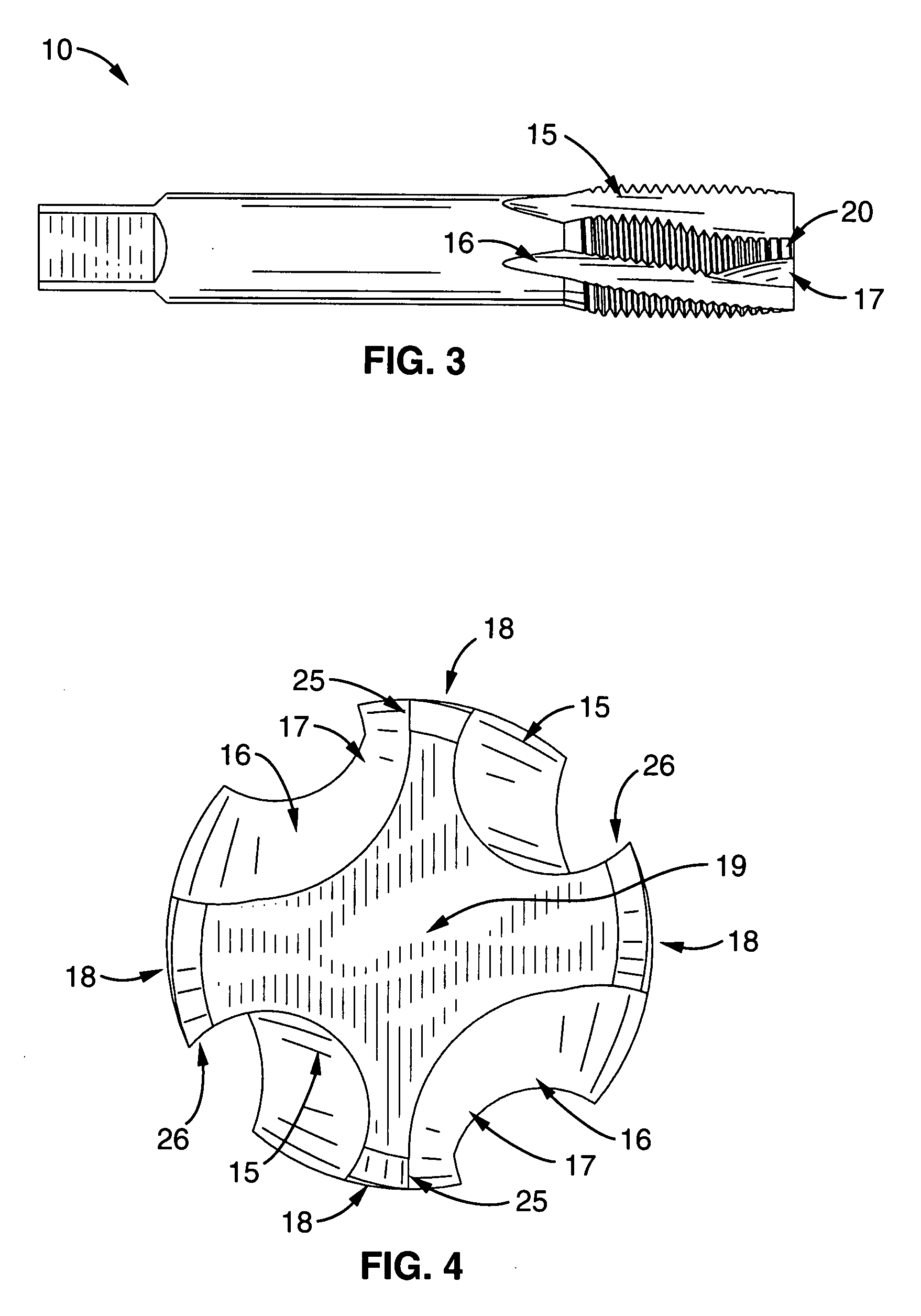

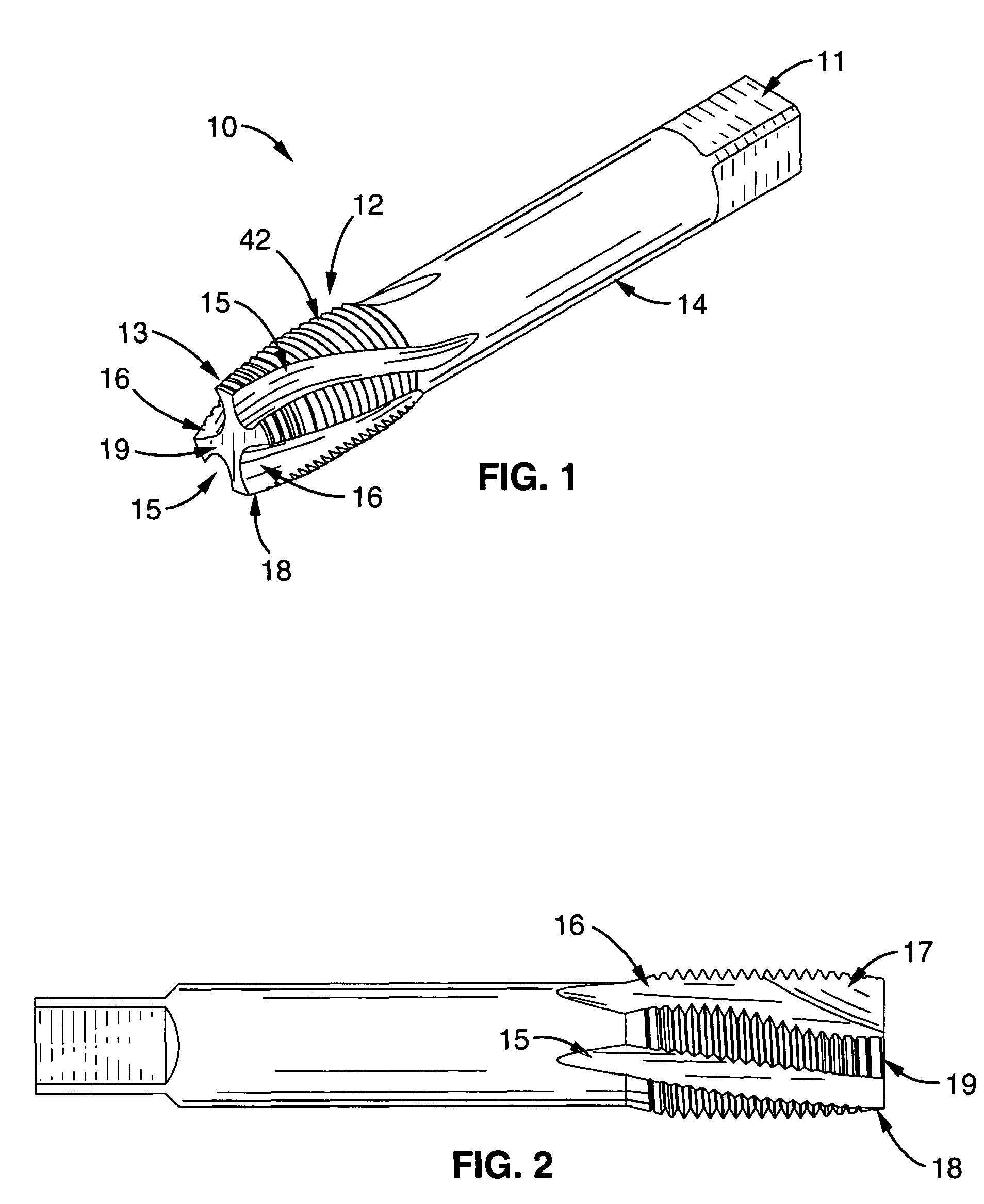

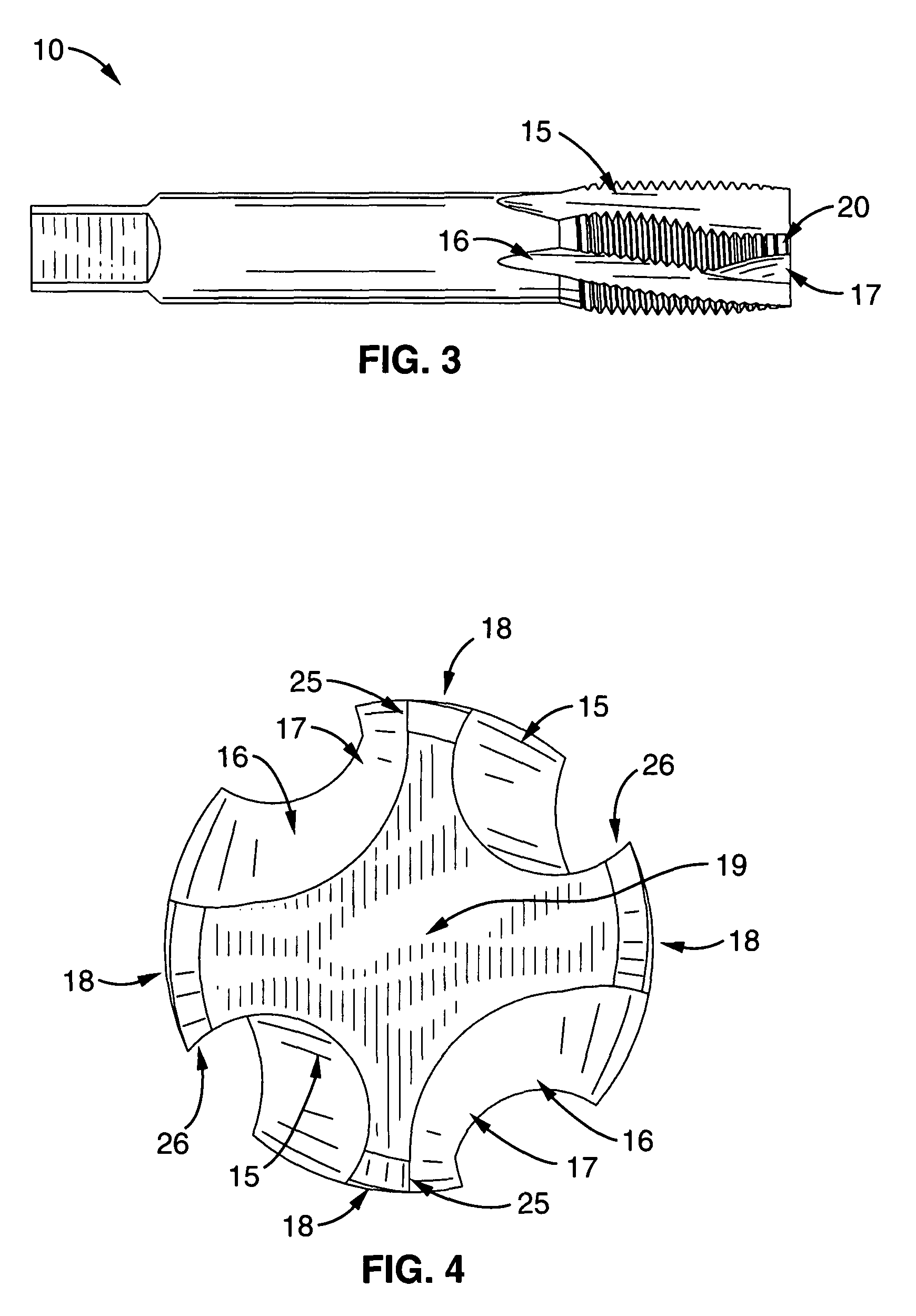

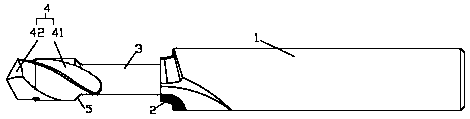

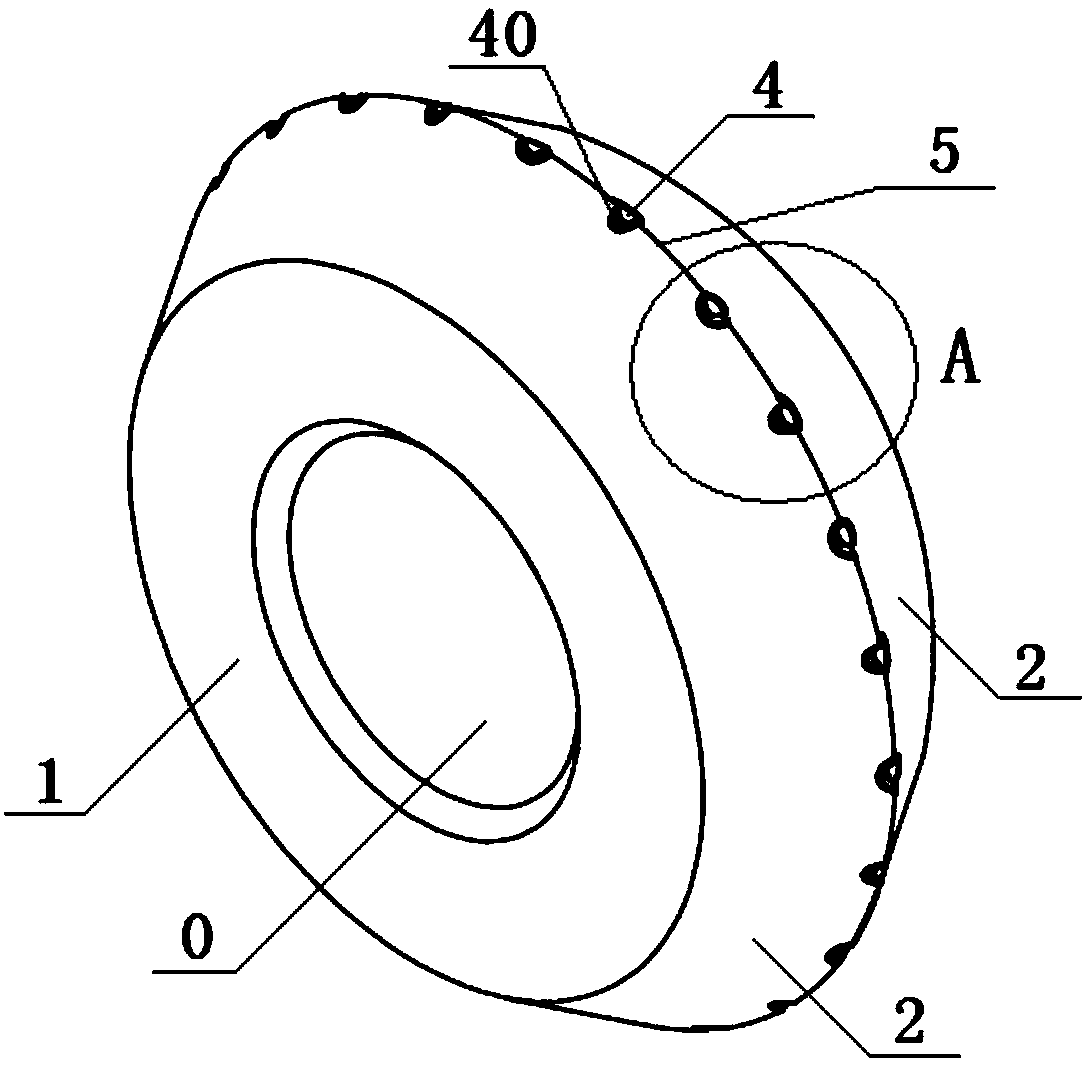

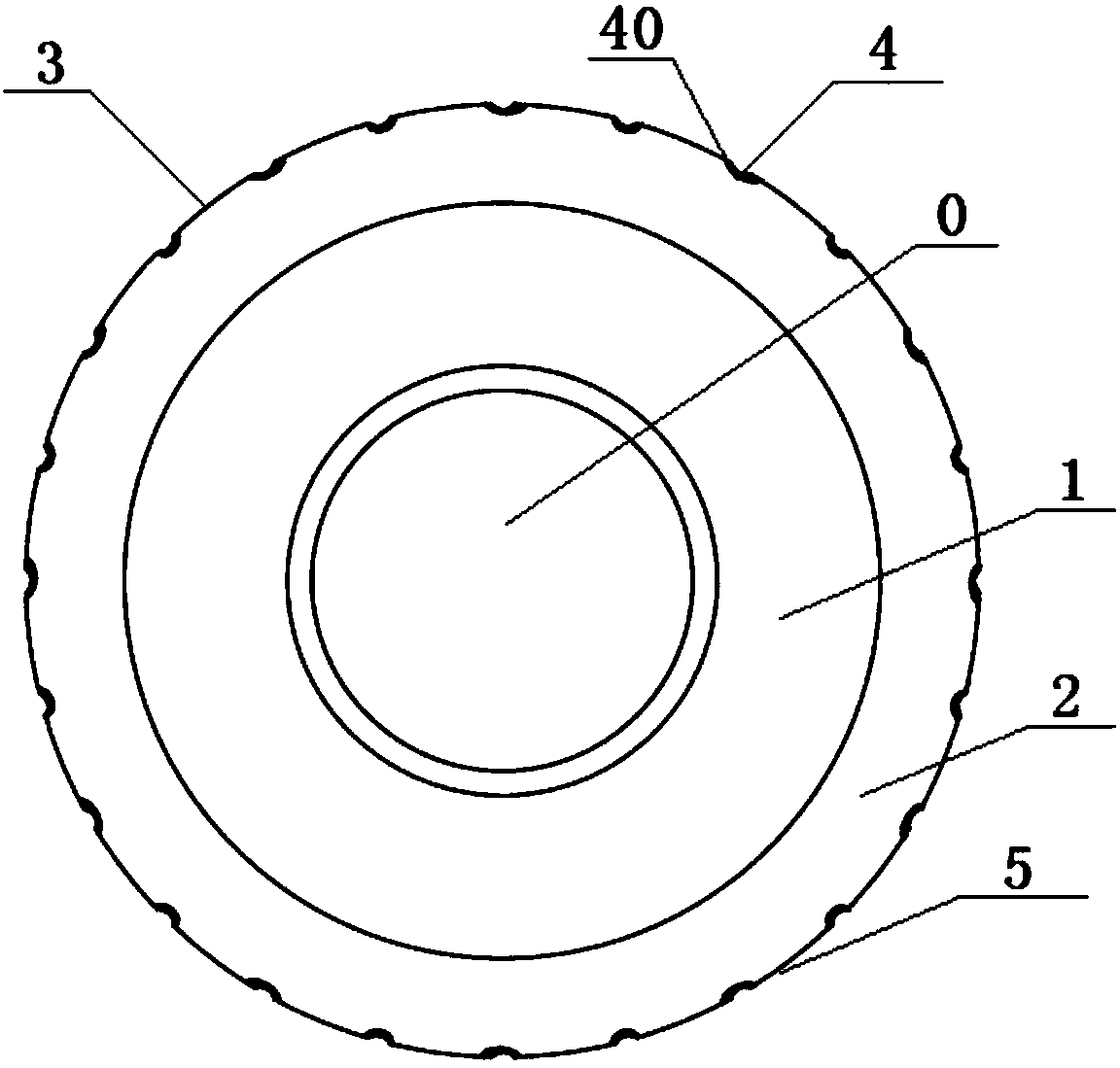

Contoured reamer teeth

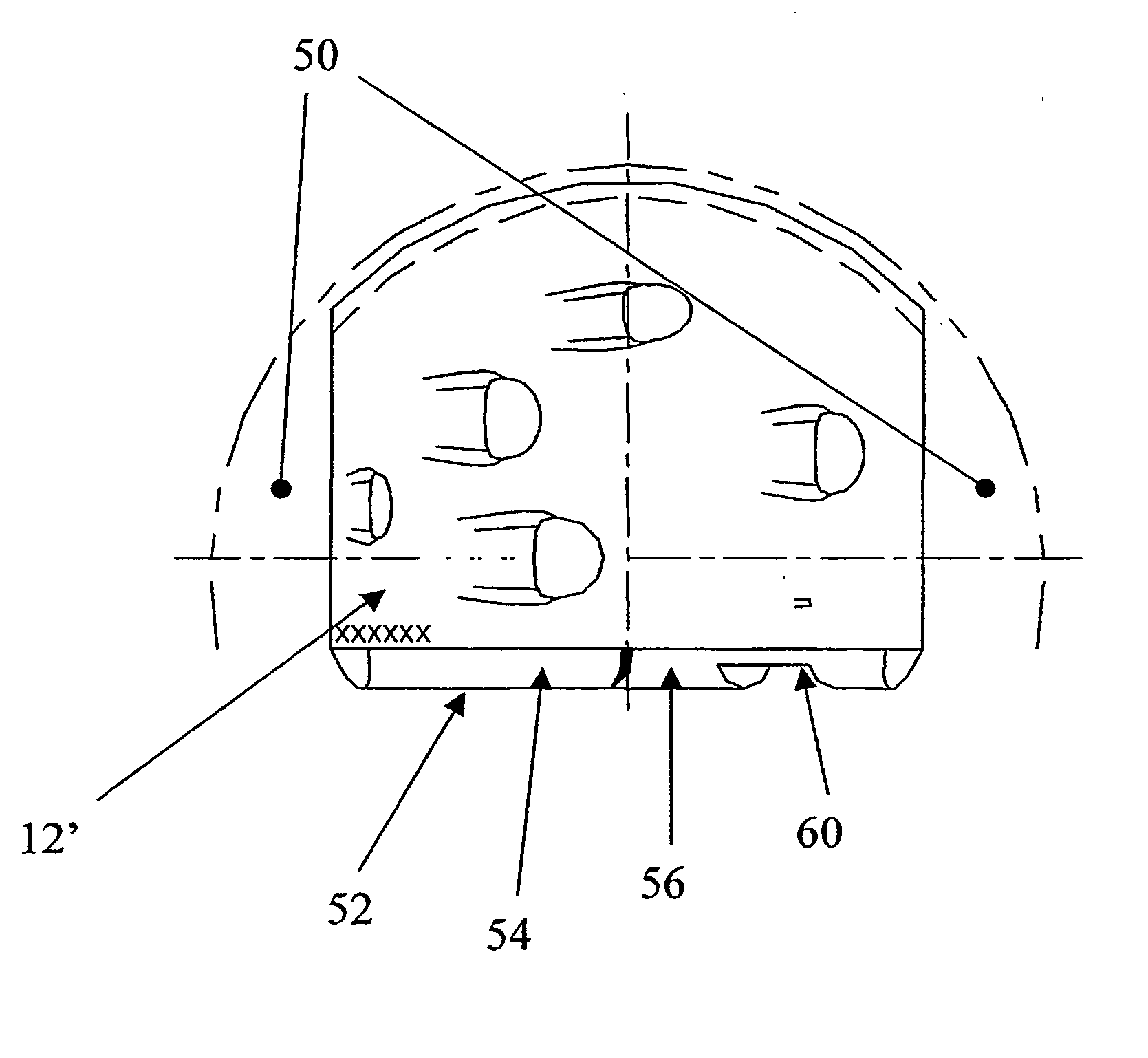

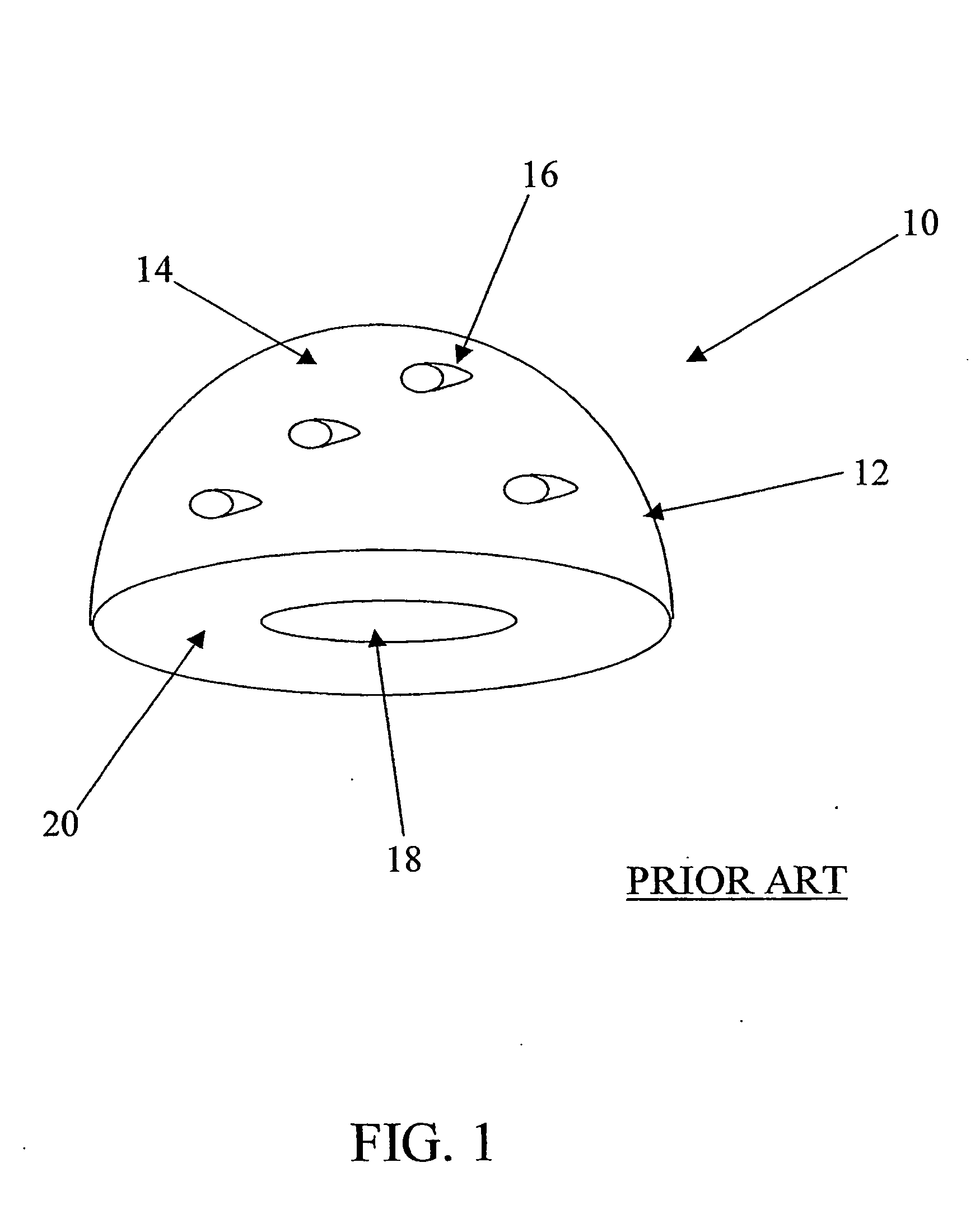

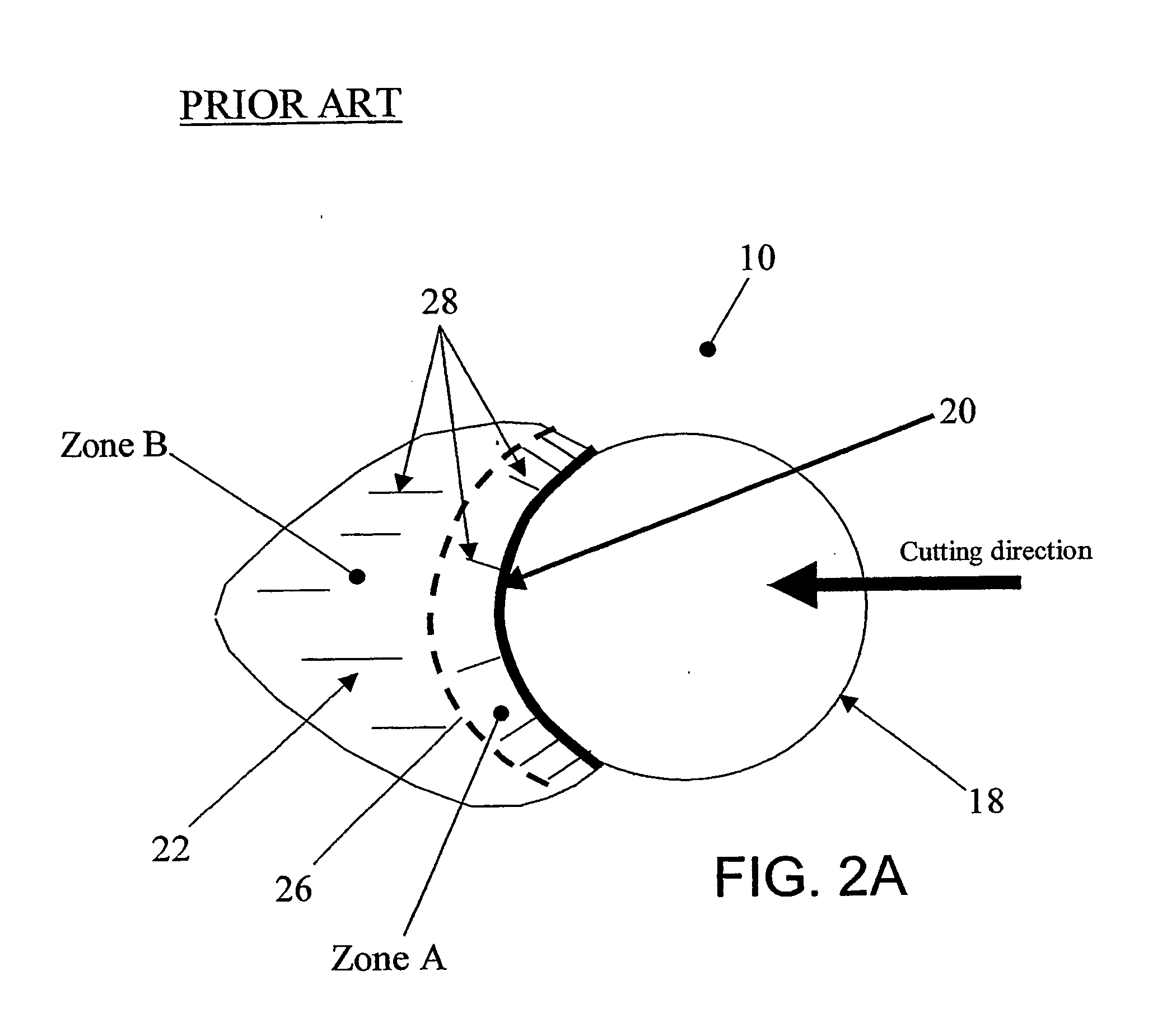

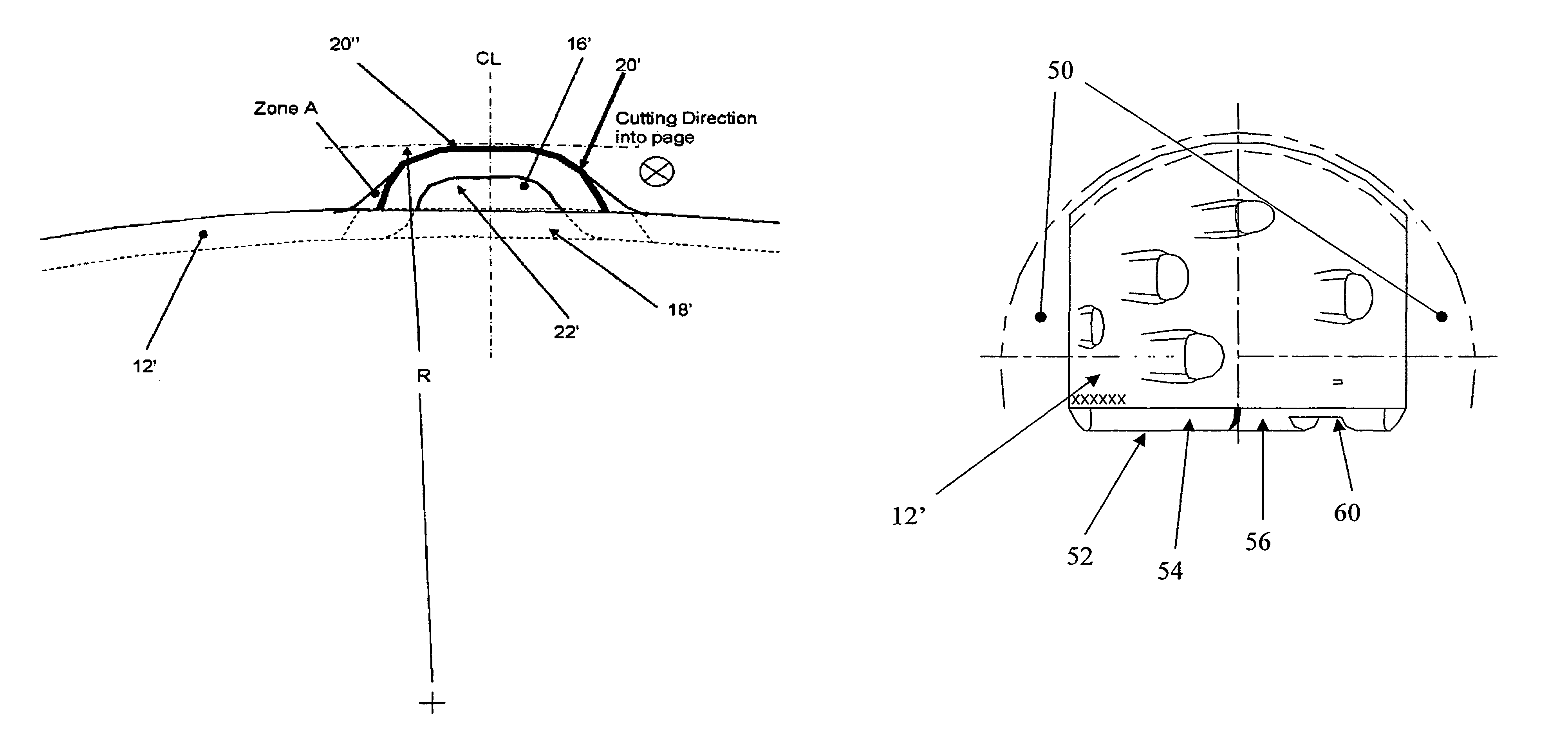

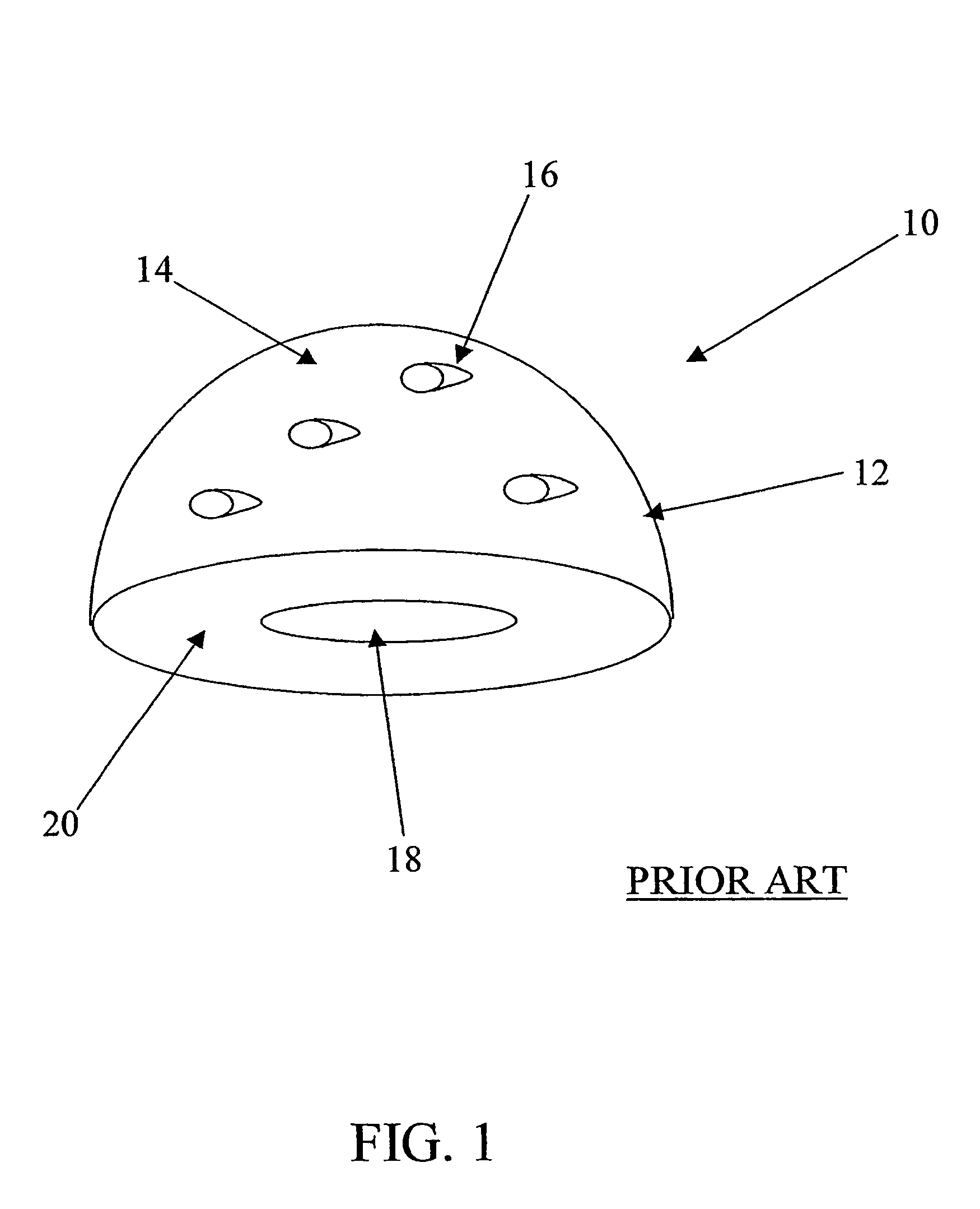

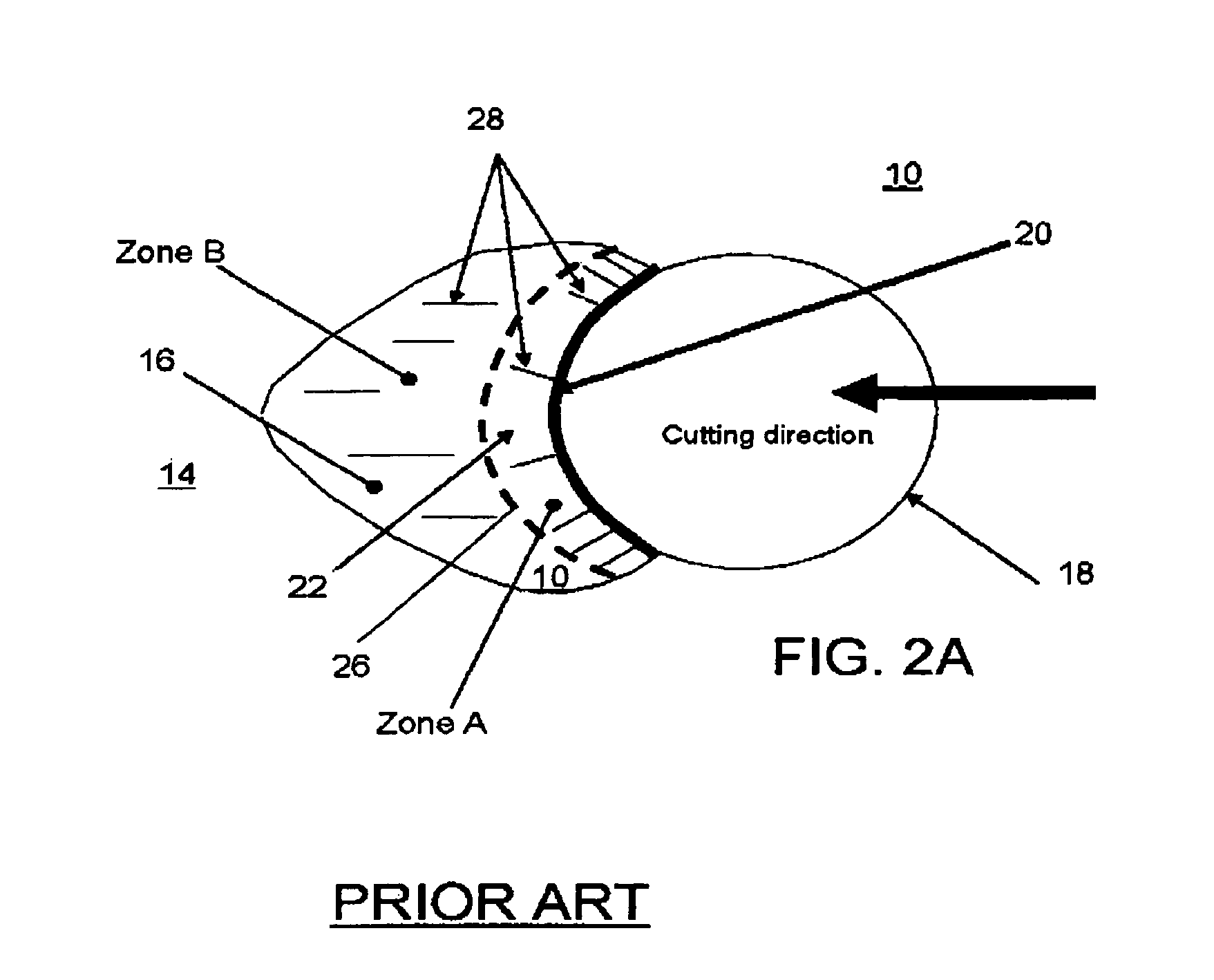

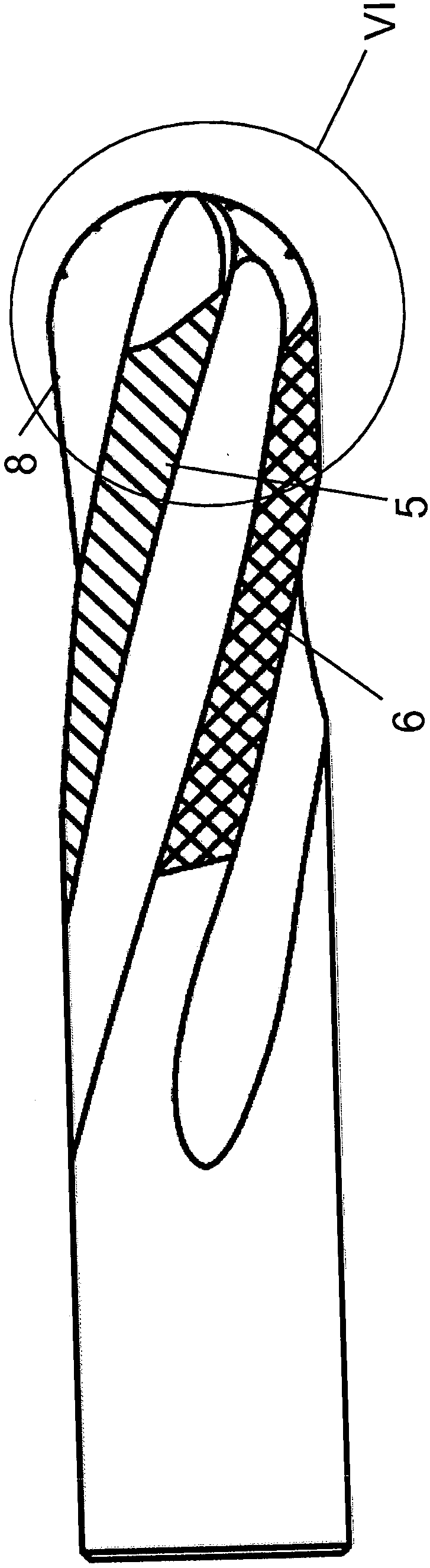

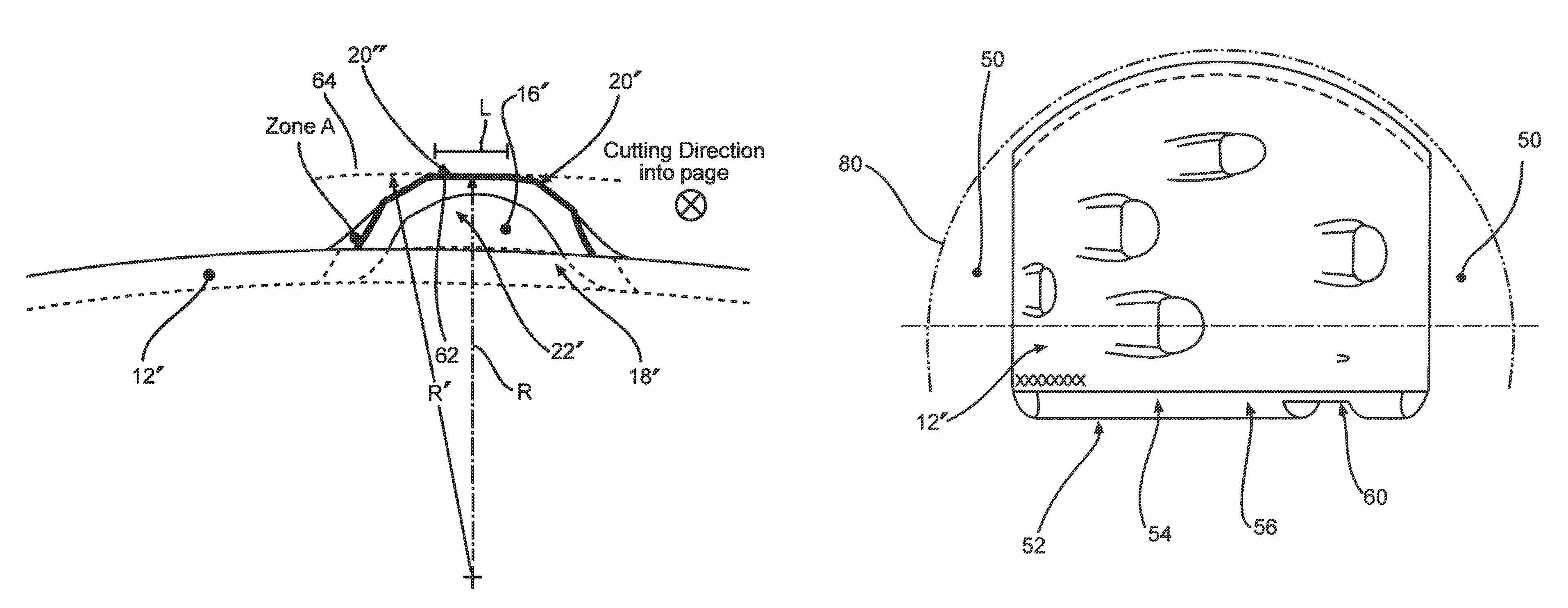

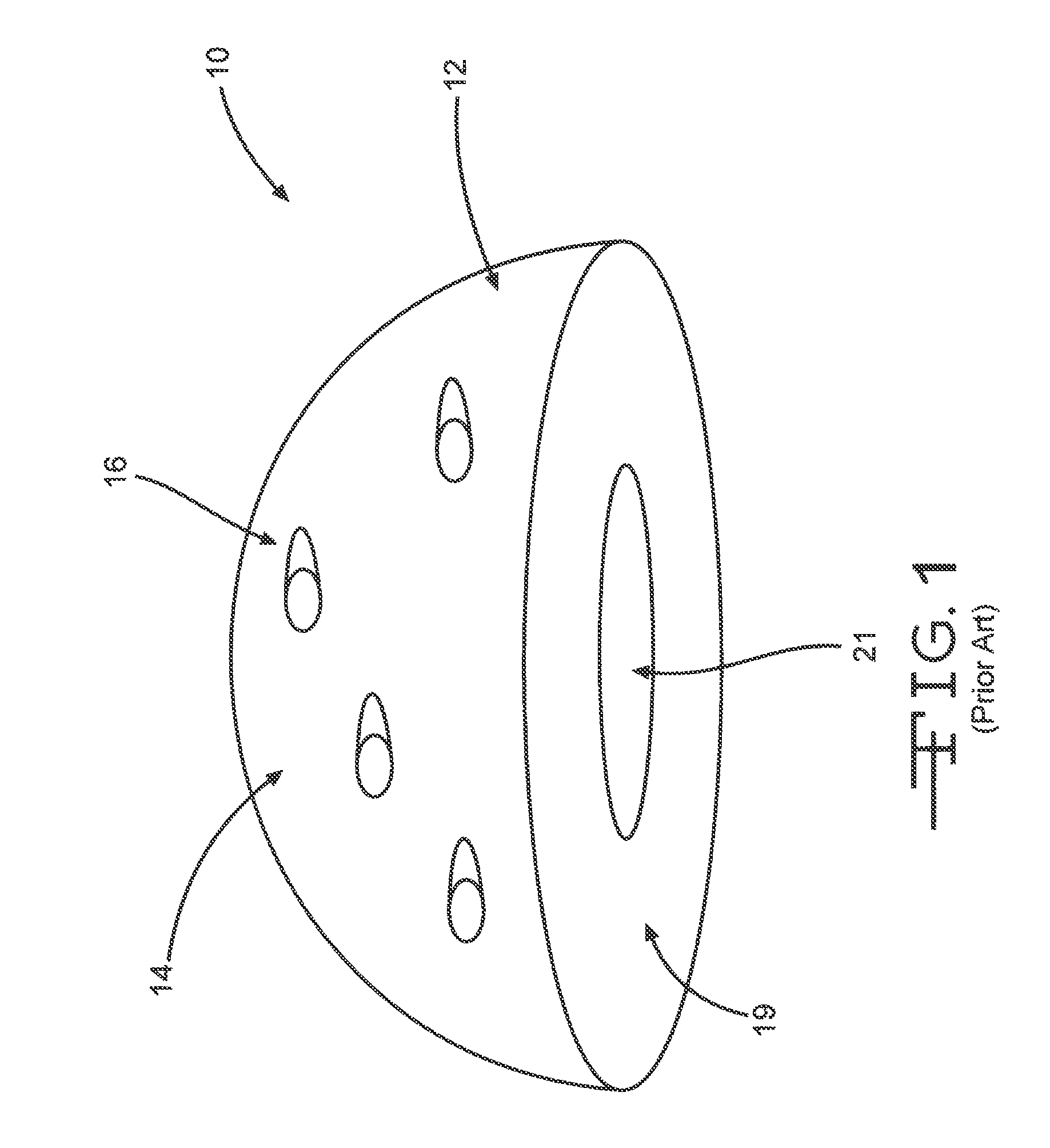

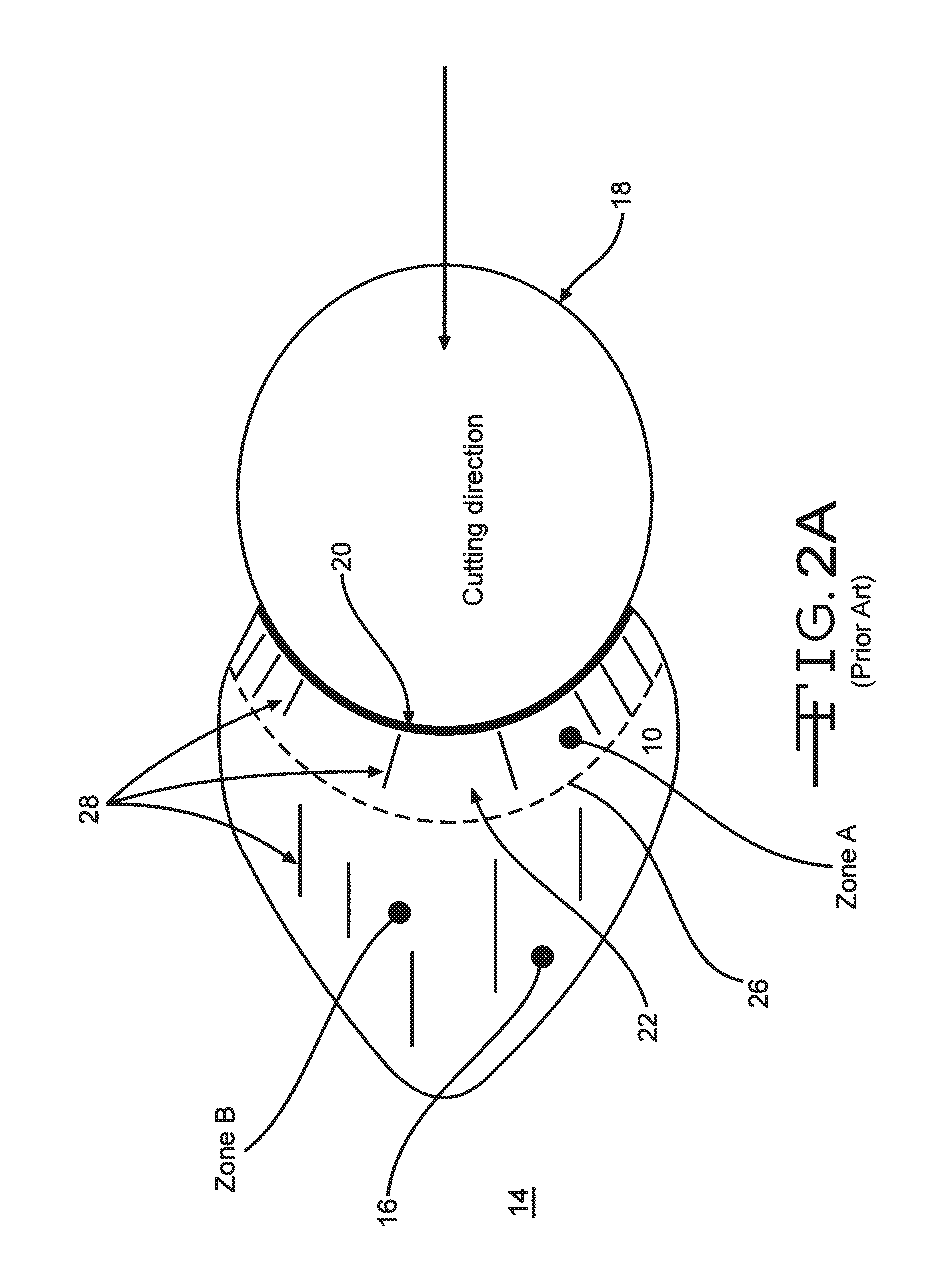

An acetabular reamer (10′) for cutting a required cut shape. The reamer has a cutting shell (12′) having a series of doubly curved cutting teeth (16′) thereon of a quantity to substantially reduce a cutting pressure on each tooth as well as to reduce a size of a typical chip generated upon cutting. Substantially all the teeth each have a matched arc cutting edge (20′) of substantial length that has a cutting profile which substantially matches a profile of a shape to be cut. Such a configuration reduces the number of teeth required to cut the shape.

Owner:VIANT AS&O HLDG LLC

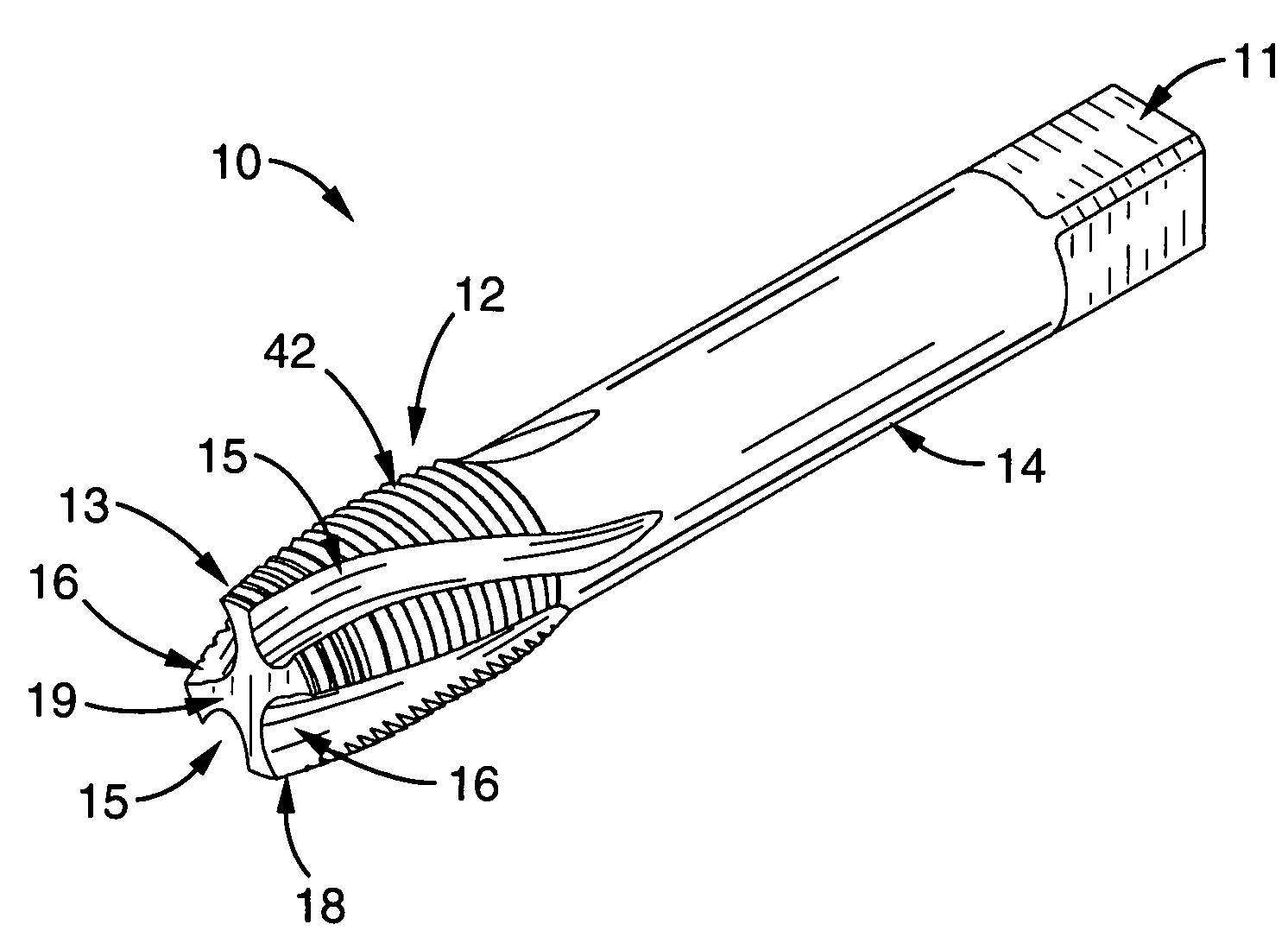

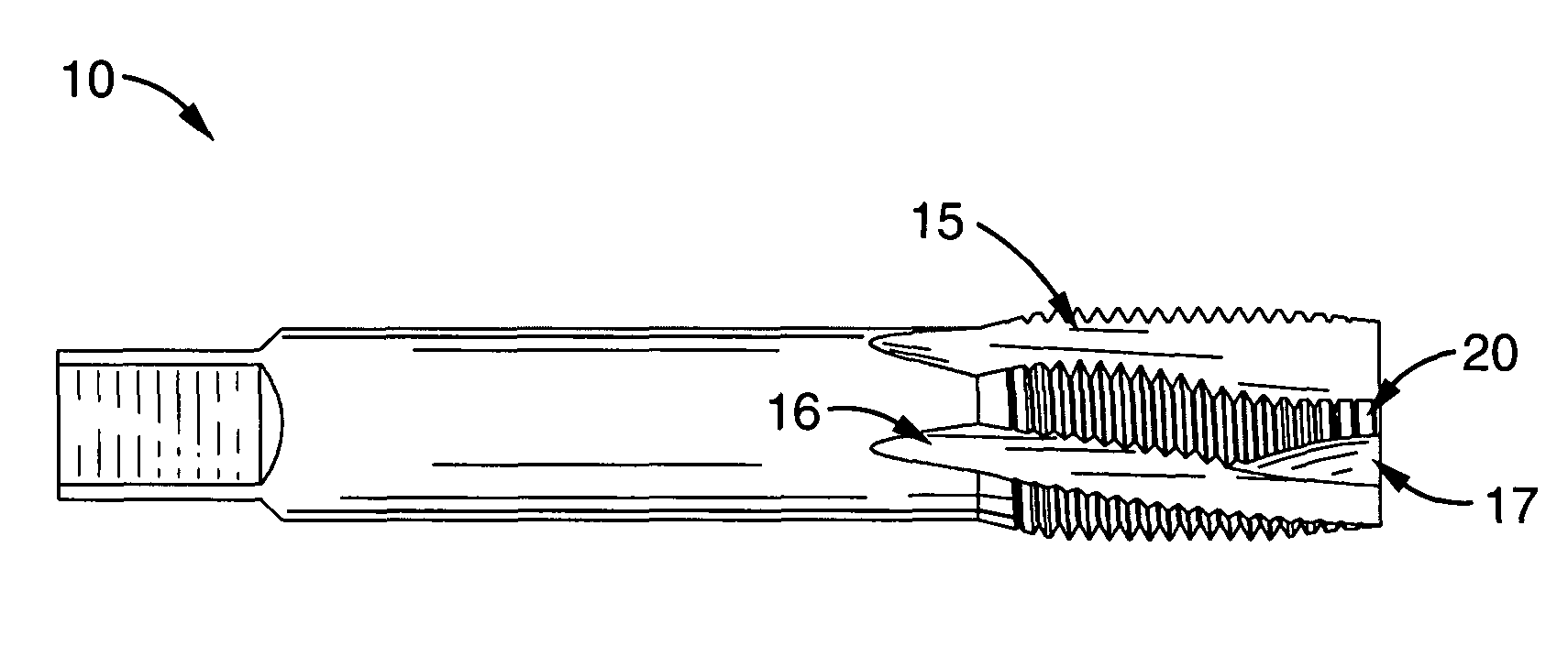

Double helix thread cutting tap

ActiveUS20080075550A1Poor surface finishReduce cutting pressureThread cutting toolsWood turning toolsFluteLeft handed

Owner:LOCK N STITCH INC

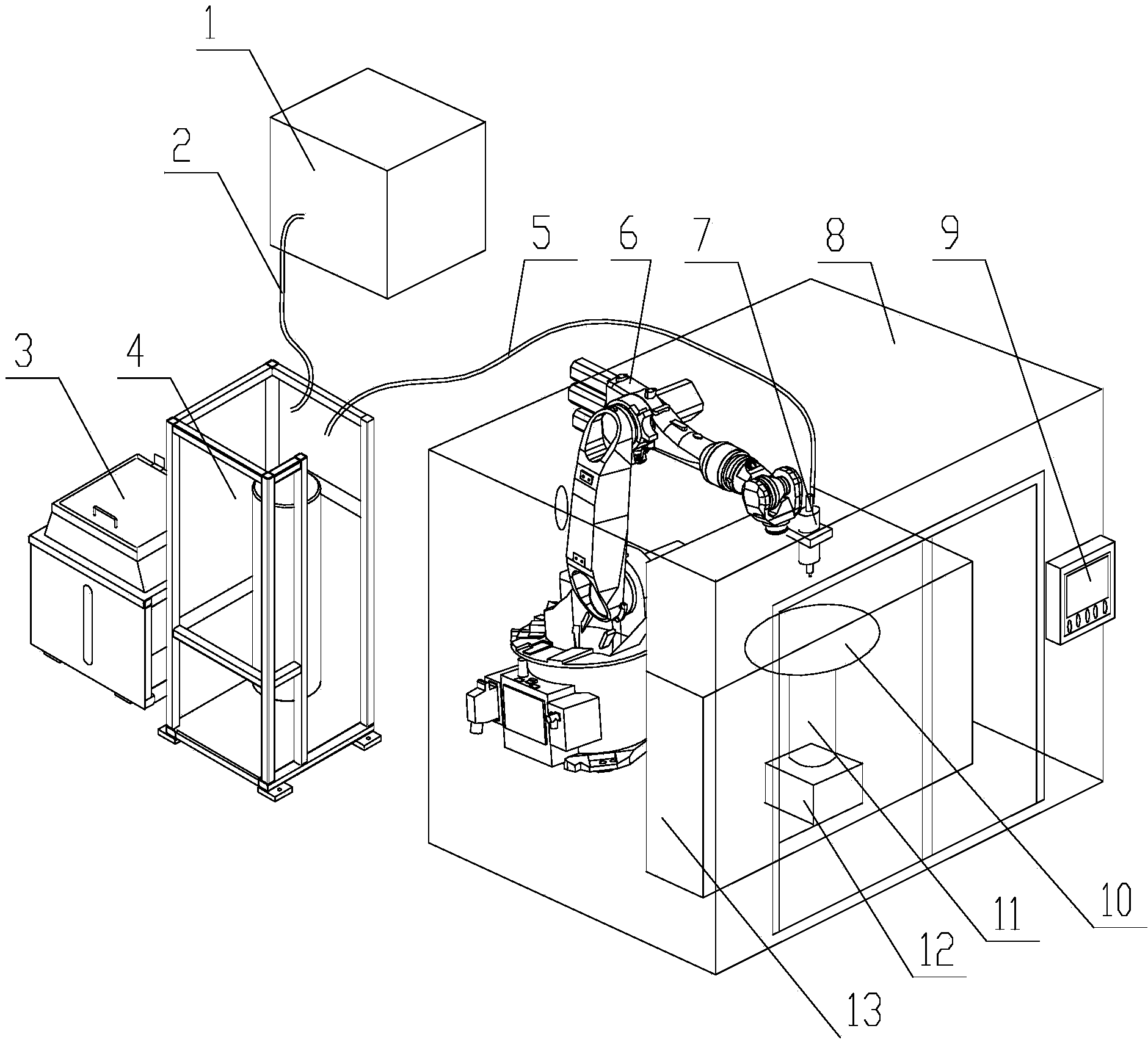

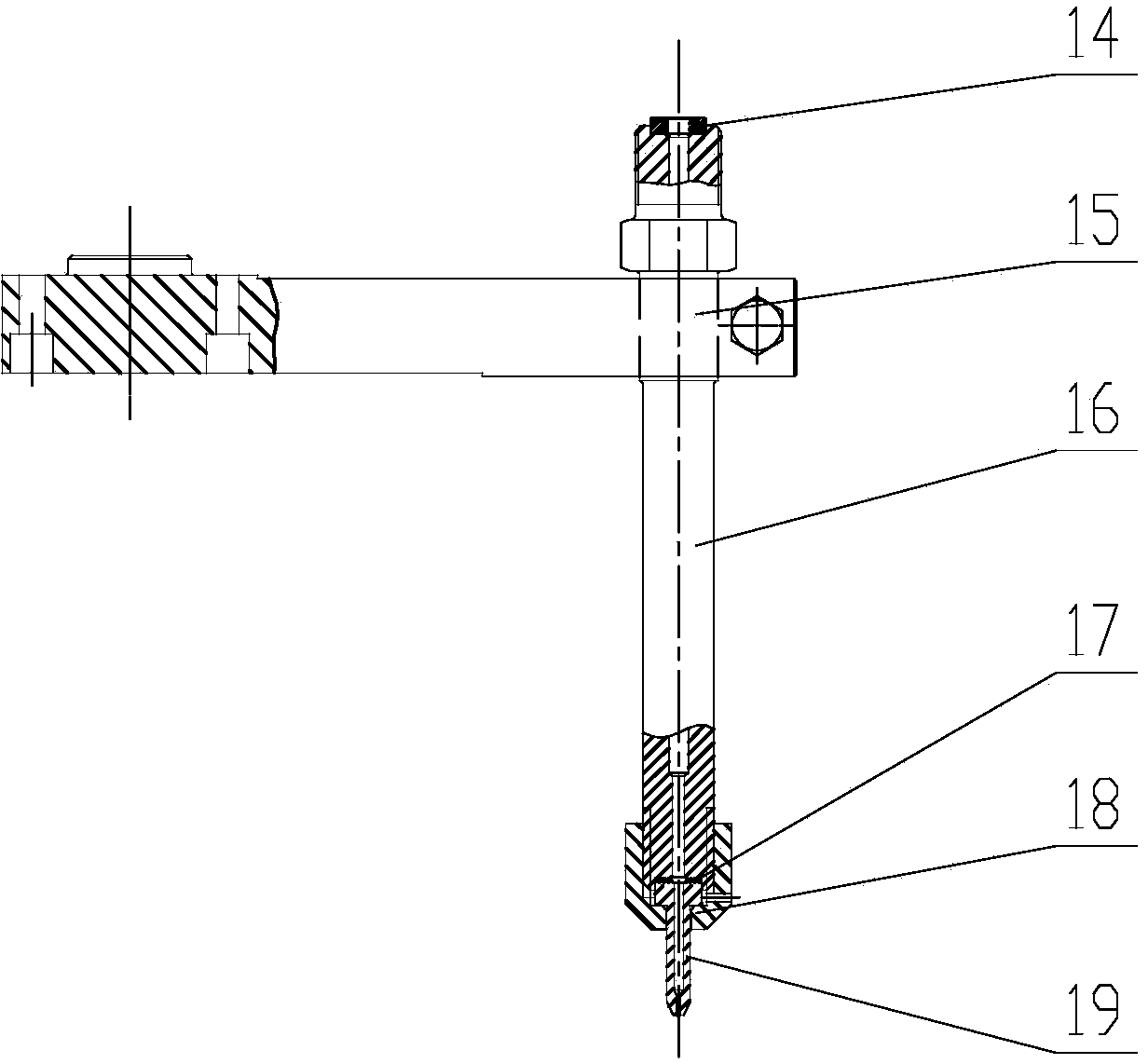

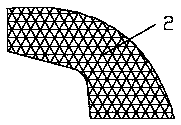

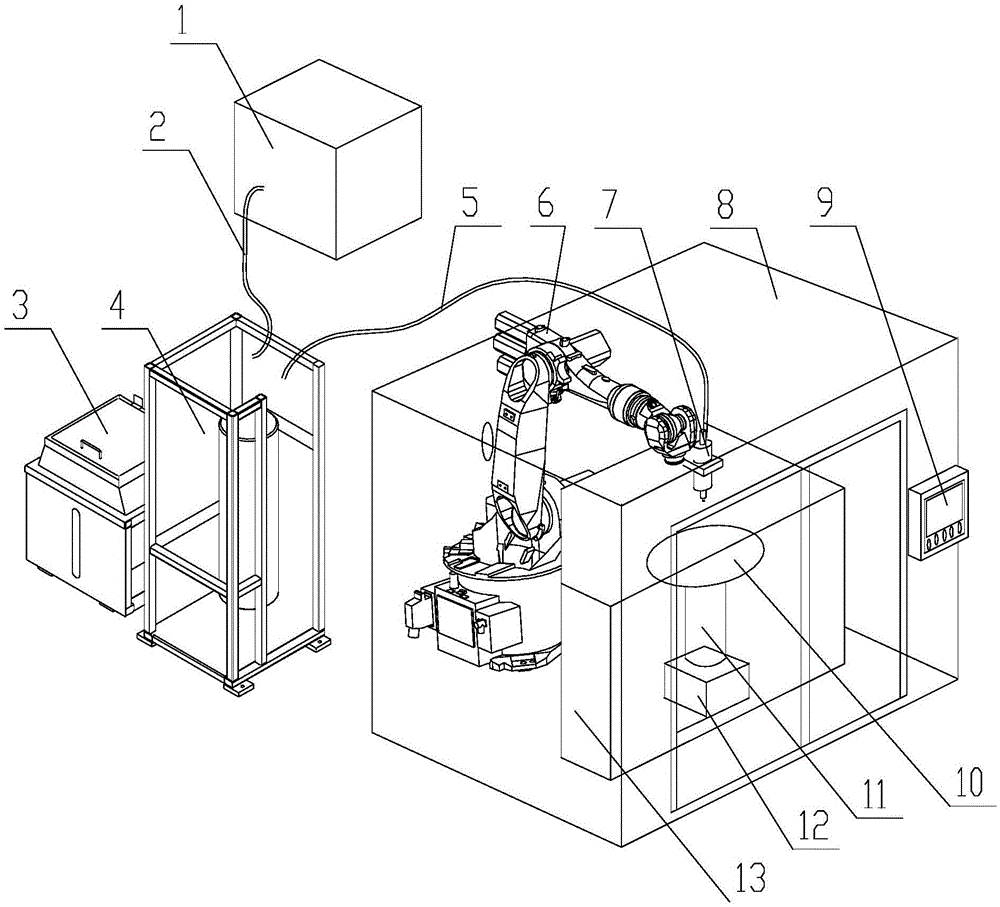

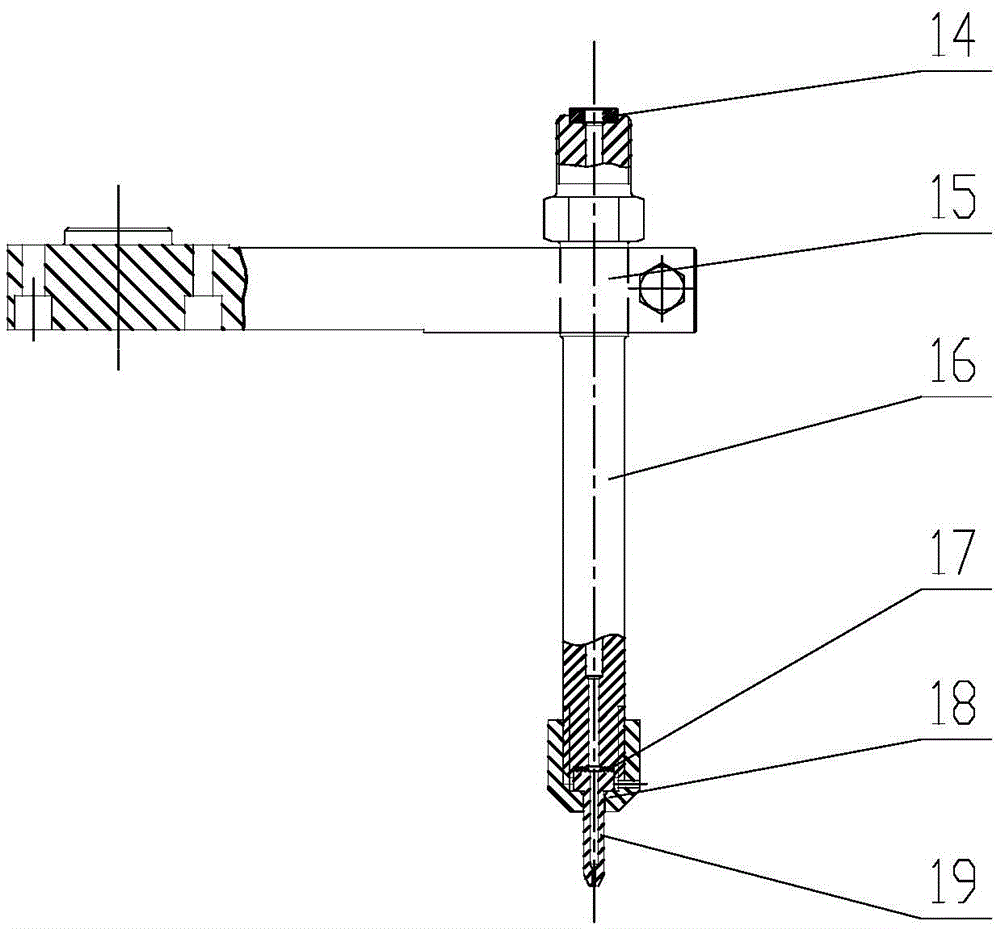

Suspension abrasive water jet cutting equipment

InactiveCN104175230AIncrease flexibilityLong conveying distanceAbrasive machine appurtenancesAbrasive blasting machinesEngineeringHigh pressure water

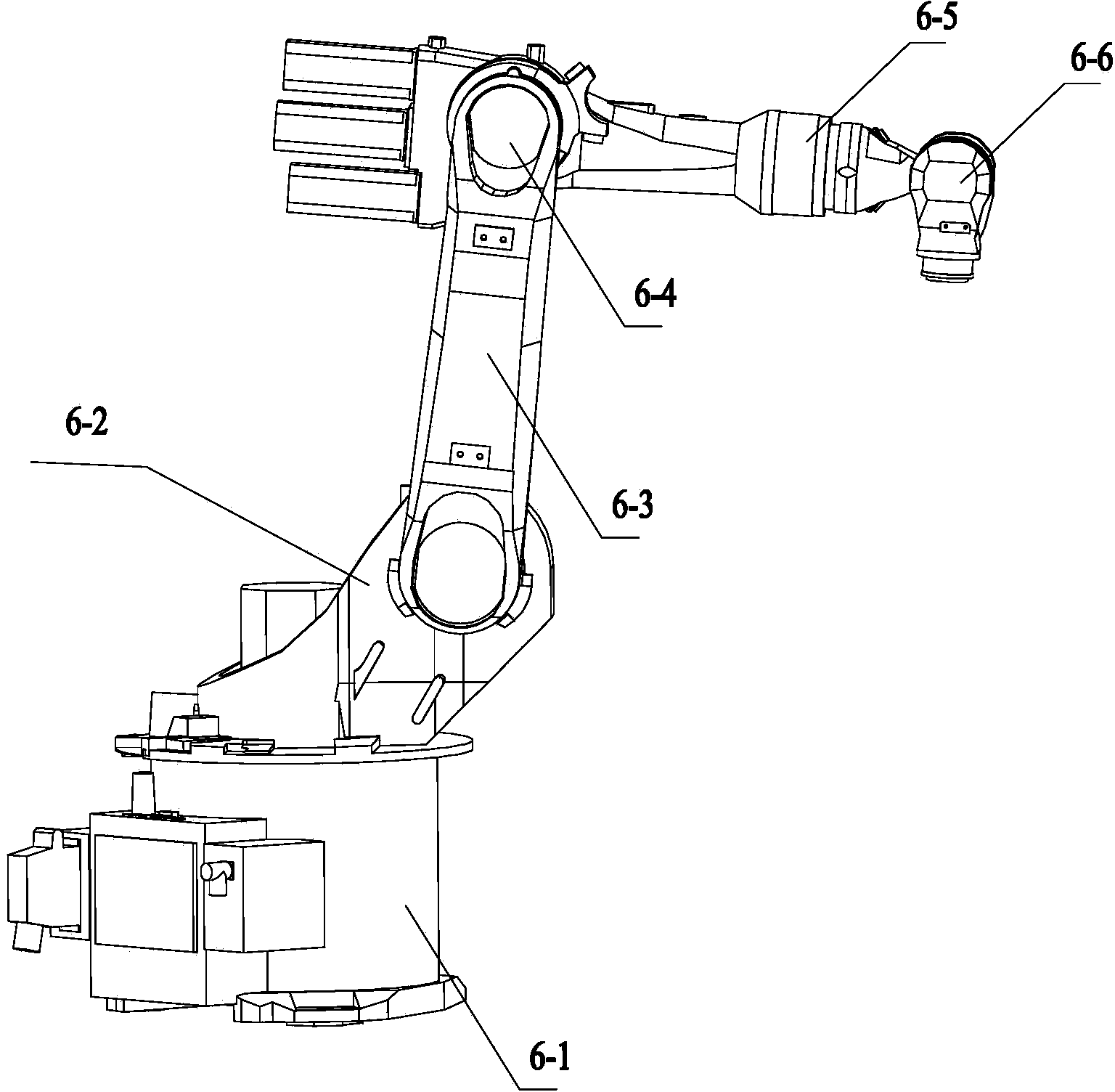

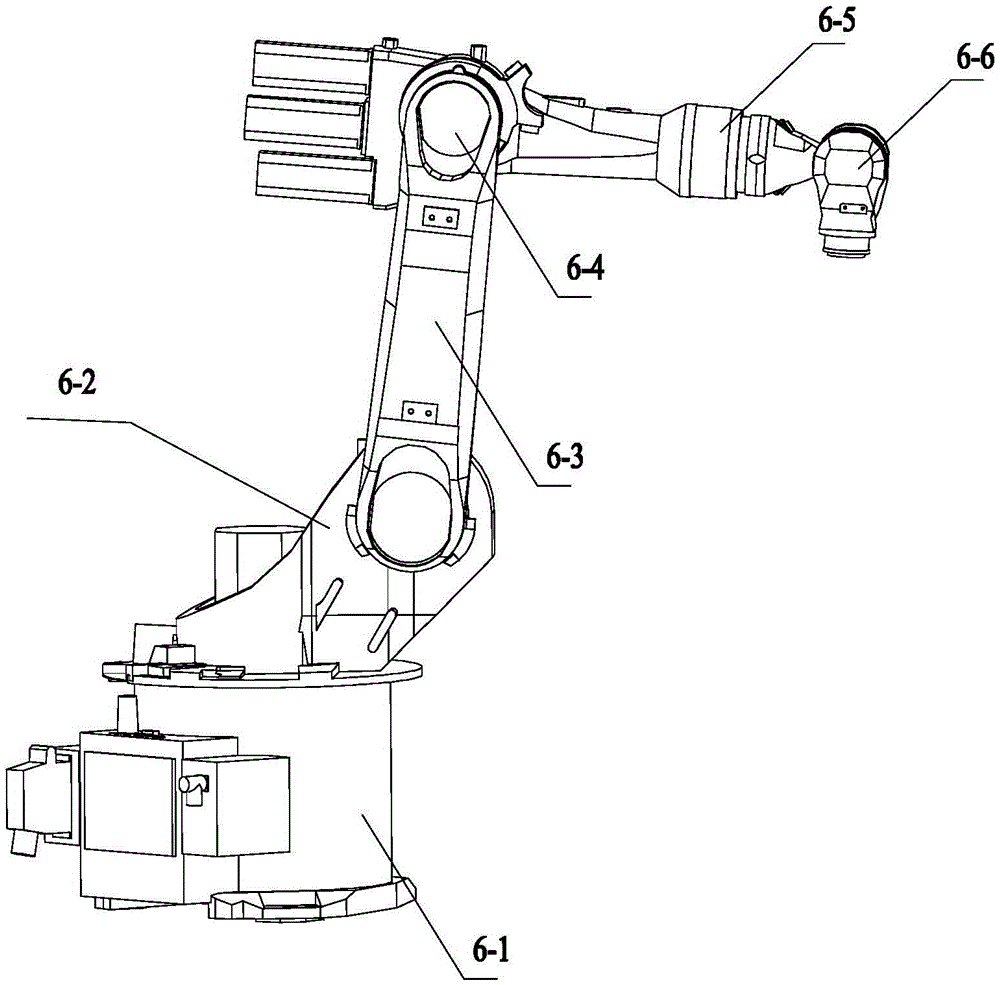

The invention relates to suspension abrasive water jet 3D cutting equipment adopting a seven-shaft intelligent robot, in particular to suspension abrasive water jet cutting equipment which comprises a high-pressure pump station used for providing cutting power, an abrasive filling device and a suspension abrasive generating device used for producing abrasive, wherein a discharge hole of the abrasive filling device is connected with a feed hole of a high-pressure container arranged in the suspension abrasive generating device through a feed pipe, a water inlet of the abrasive filling device is connected with a water outlet of the high-pressure container arranged in the suspension abrasive generating device through a water inlet pipe; high-pressure water generated by the high-pressure pump station is connected with a tee joint arranged in the suspension abrasive generating device through a high-pressure pipe. The product provided by the invention adopts a pre-mixing suspension abrasive cutting technology, the cutting pressure is low, and the efficiency is high; the equipment adopts a high-pressure hose as a suspension abrasive conveying pipeline, the conveying distance is long, and the equipment ensures that a nozzle device can realize high-precision motion of any track and any angle in space under the drive of a robot actuator.

Owner:西安远诚机电科技有限公司

Contoured reamer teeth

An acetabular reamer (10′) for cutting a required cut shape. The reamer has a cutting shell (12′) having a series of doubly curved cutting teeth (16′) thereon of a quantity to substantially reduce a cutting pressure on each tooth as well as to reduce a size of a typical chip generated upon cutting. Substantially all the teeth each have a matched arc cutting edge (20′) of substantial length that has a cutting profile which substantially matches a profile of a shape to be cut. Such a configuration reduces the number of teeth required to cut the shape.

Owner:VIANT AS&O HLDG LLC

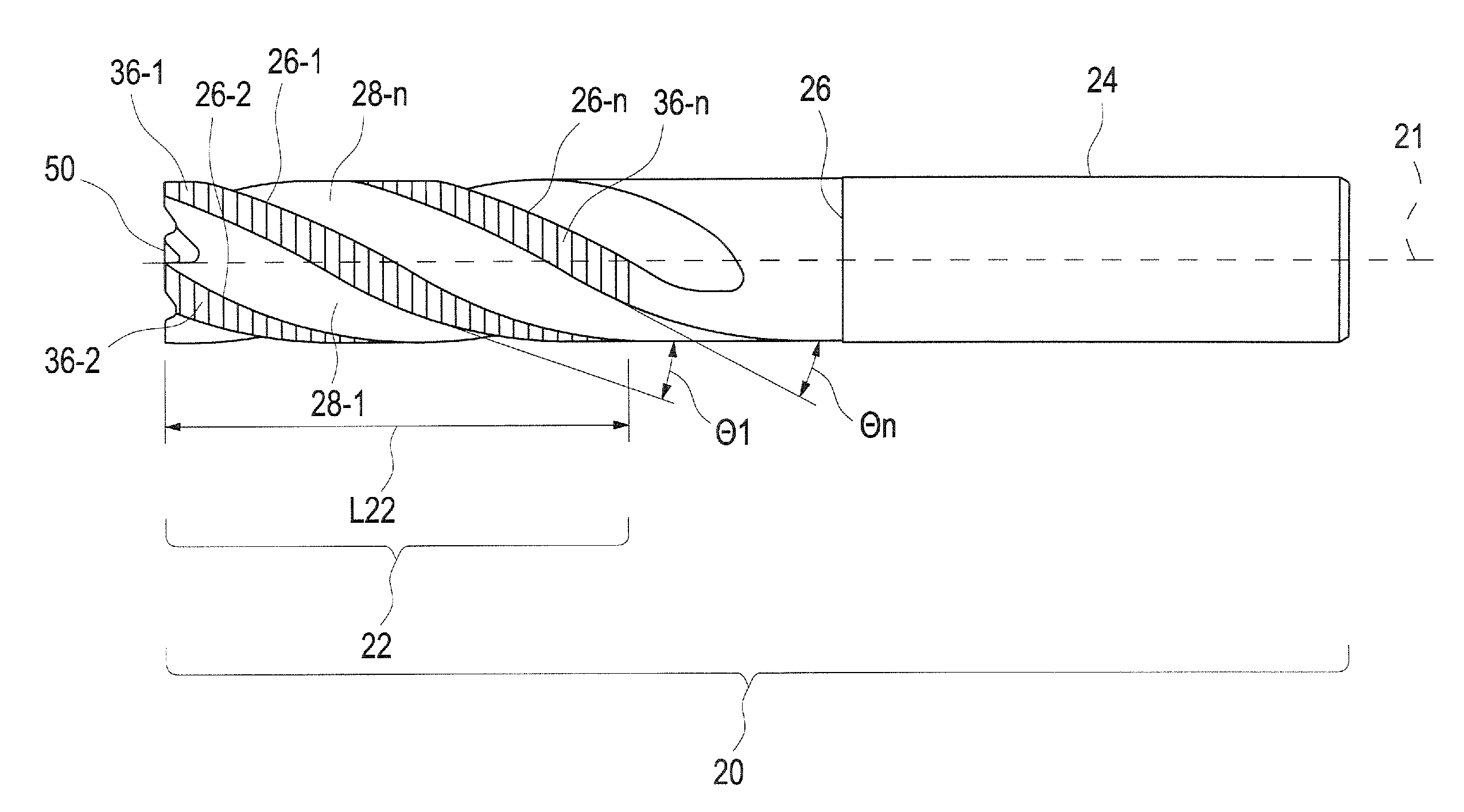

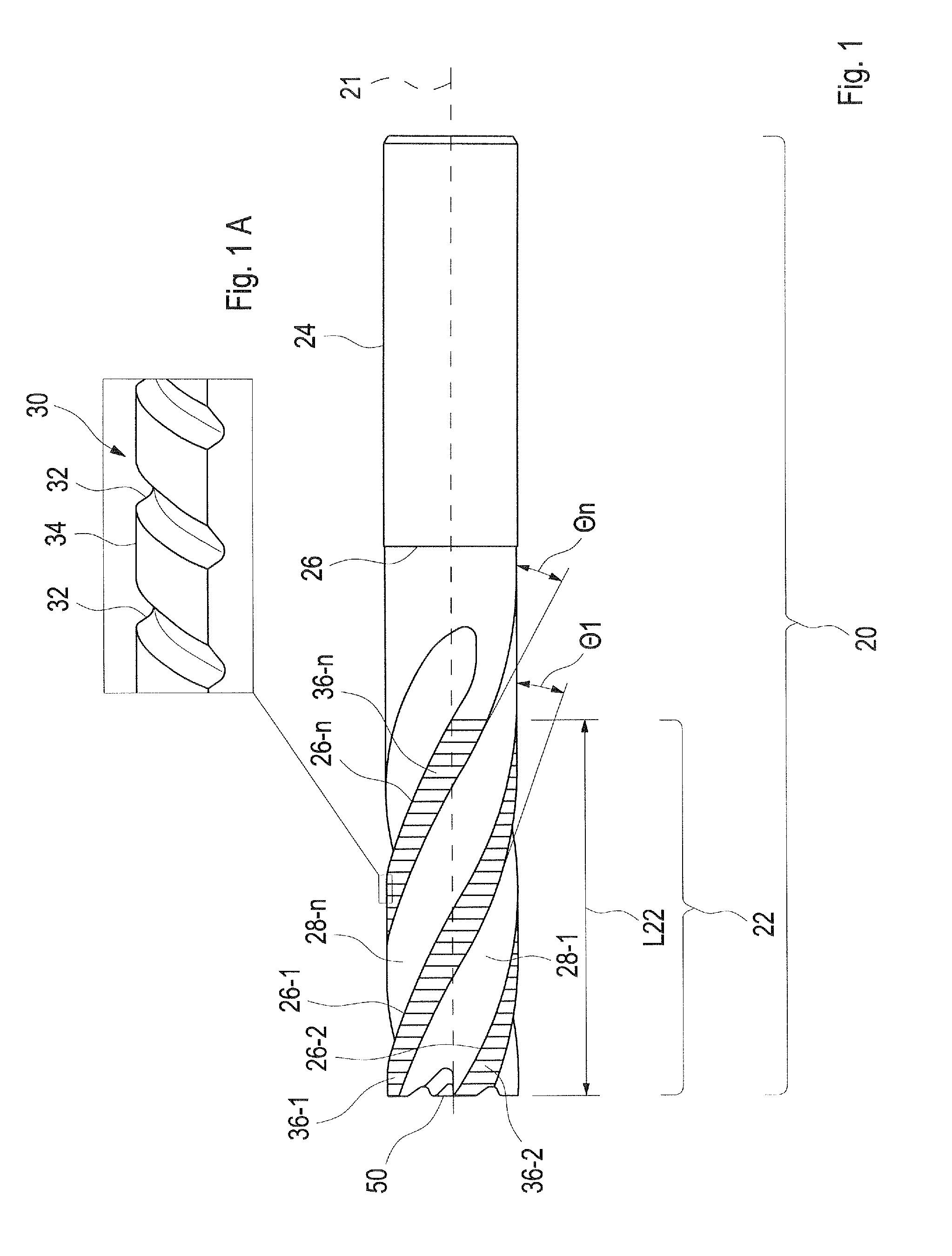

Shank drill

InactiveUS20130022416A1Improve surface qualityReduce power consumptionMilling cuttersAdverse effect compensationEngineeringDrill

Owner:JEORG GUEHRING

Double helix thread cutting tap

ActiveUS8087856B2Improve performanceMinimal cutting pressureThread cutting toolsWood turning toolsFluteEngineering

Owner:LOCK N STITCH INC

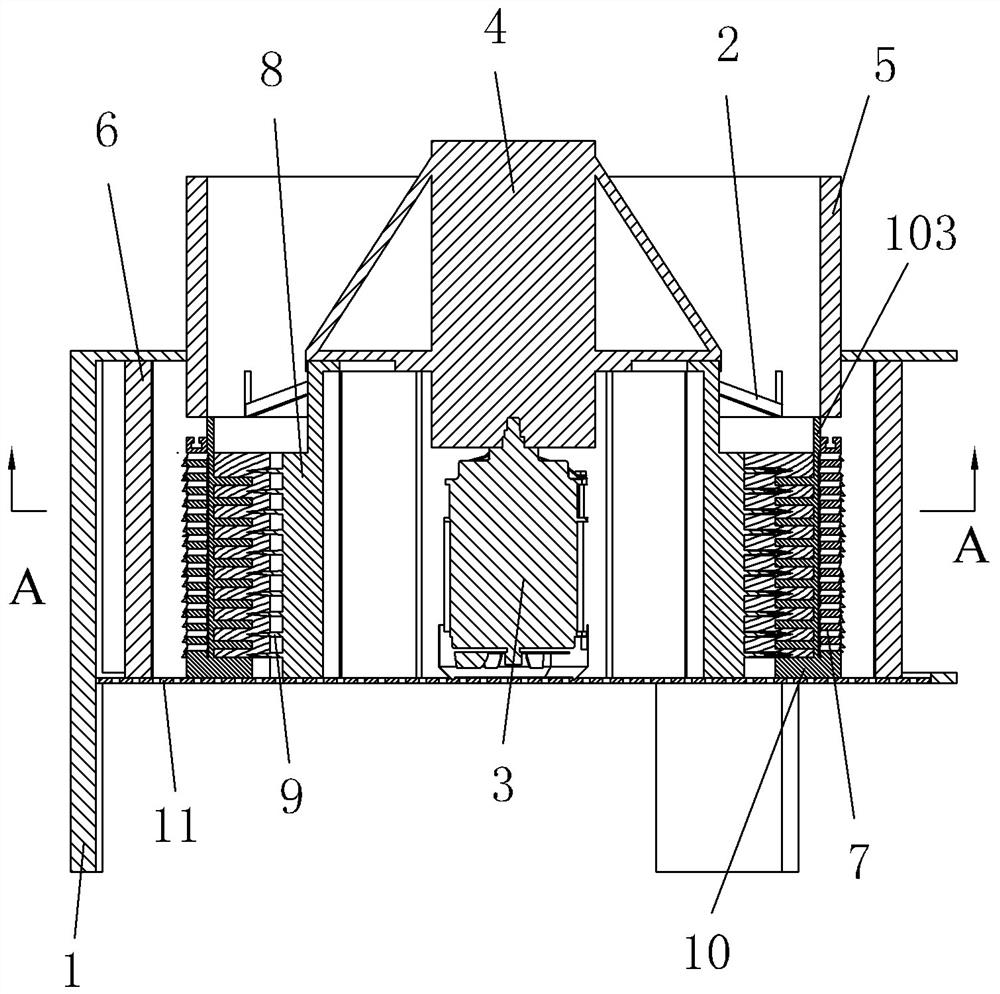

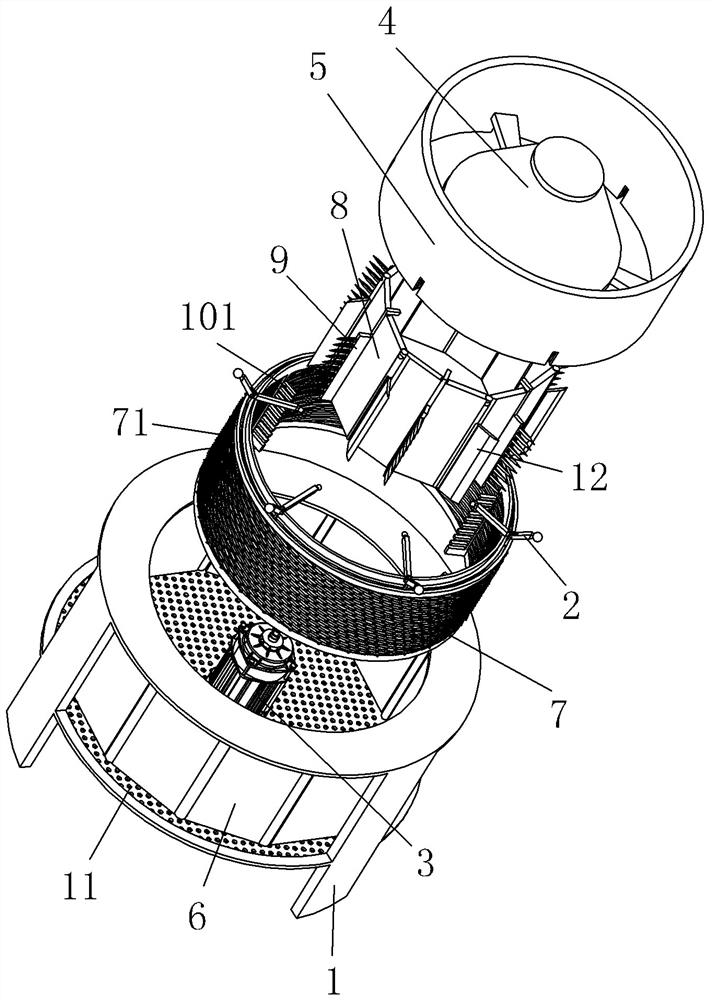

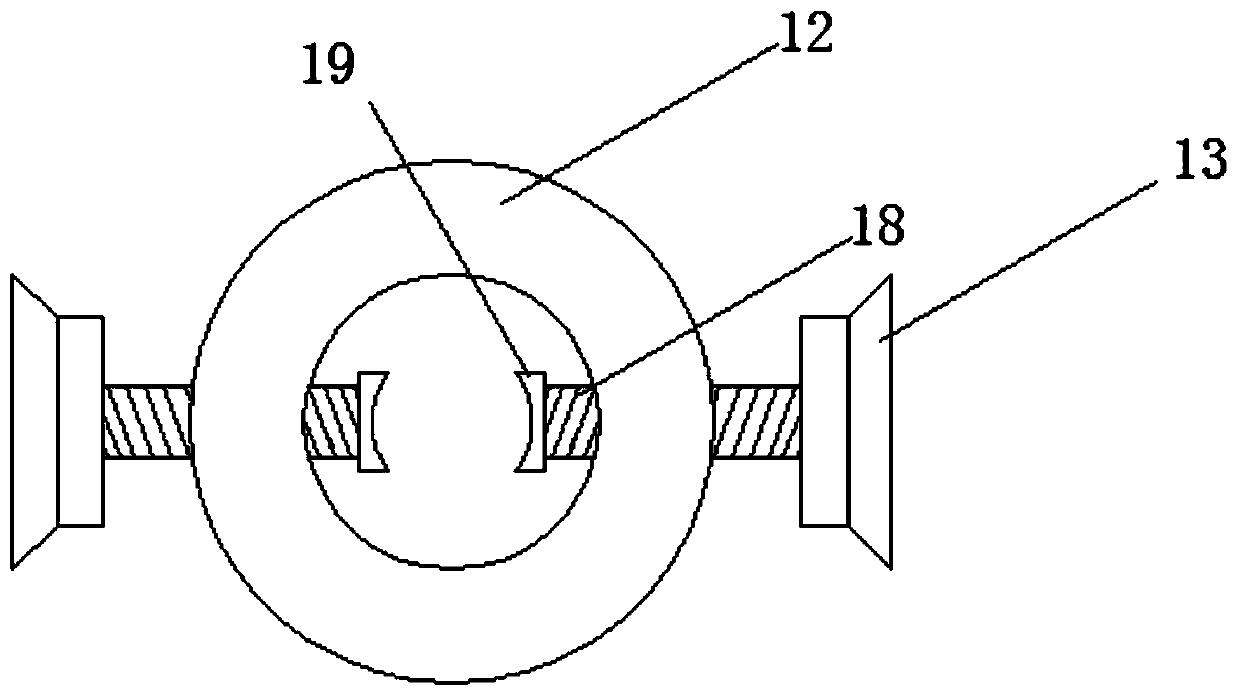

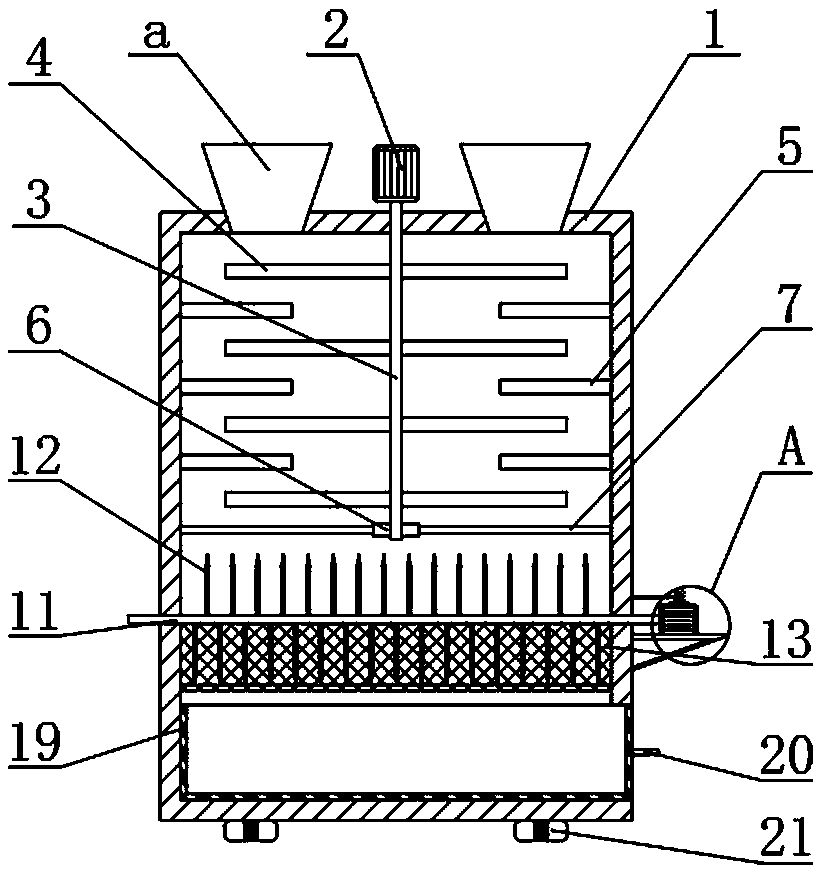

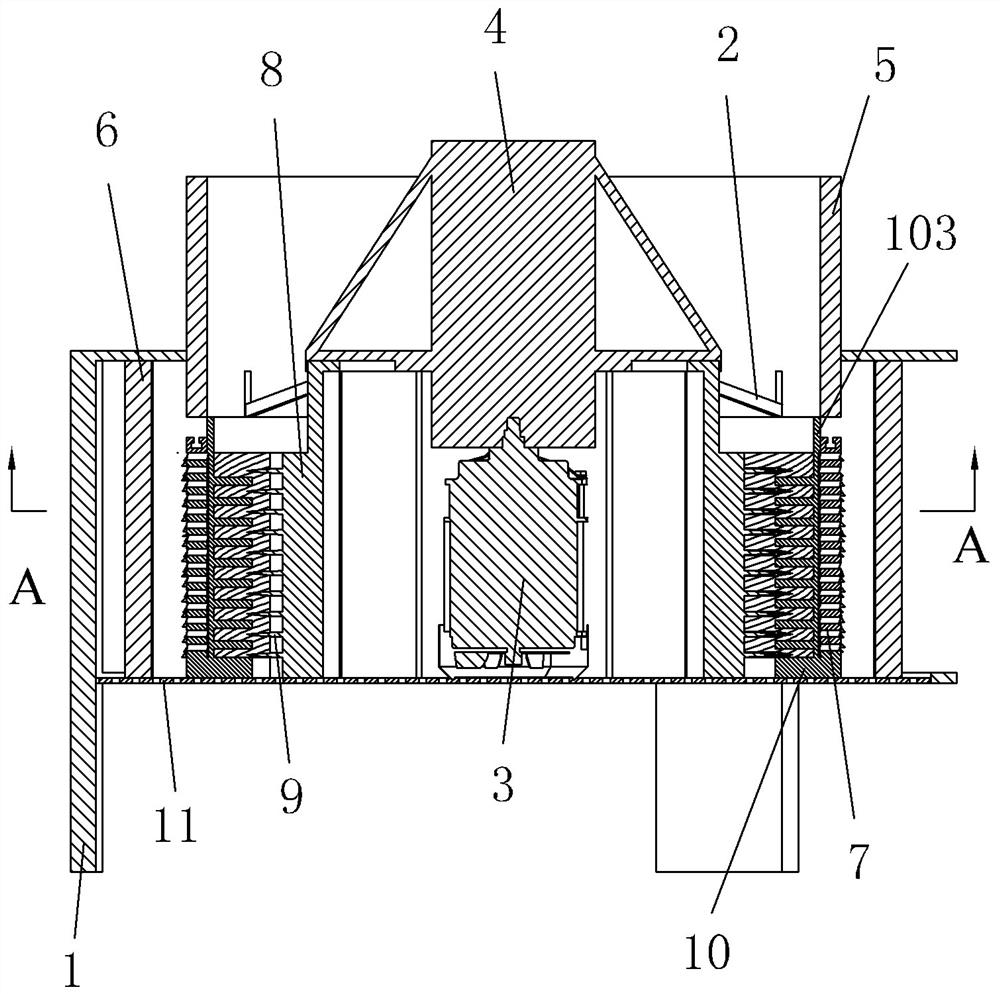

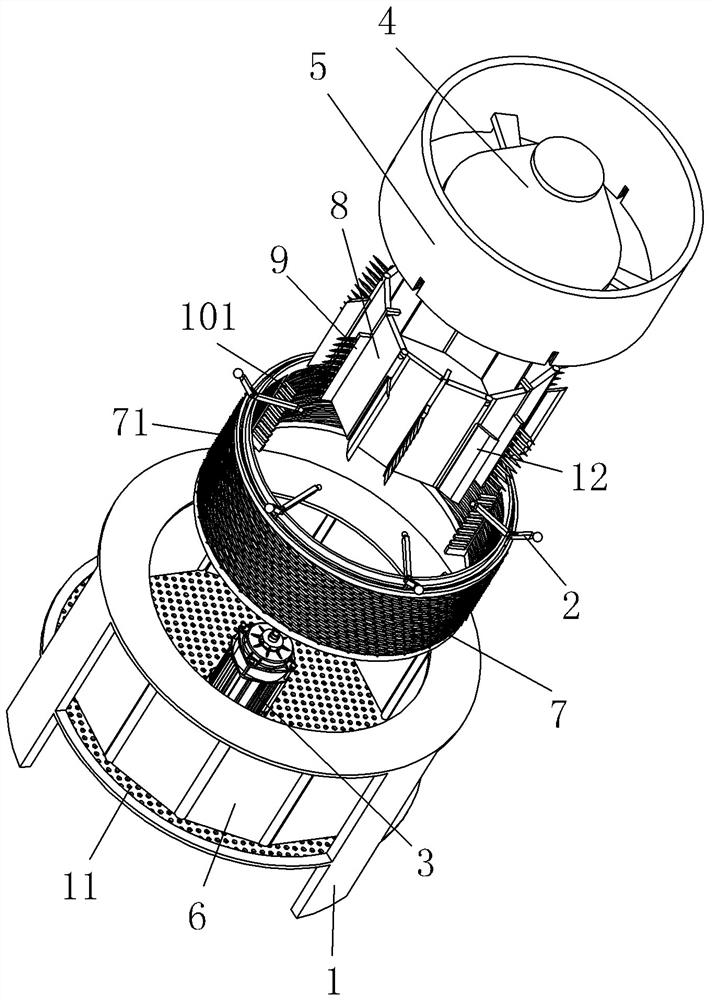

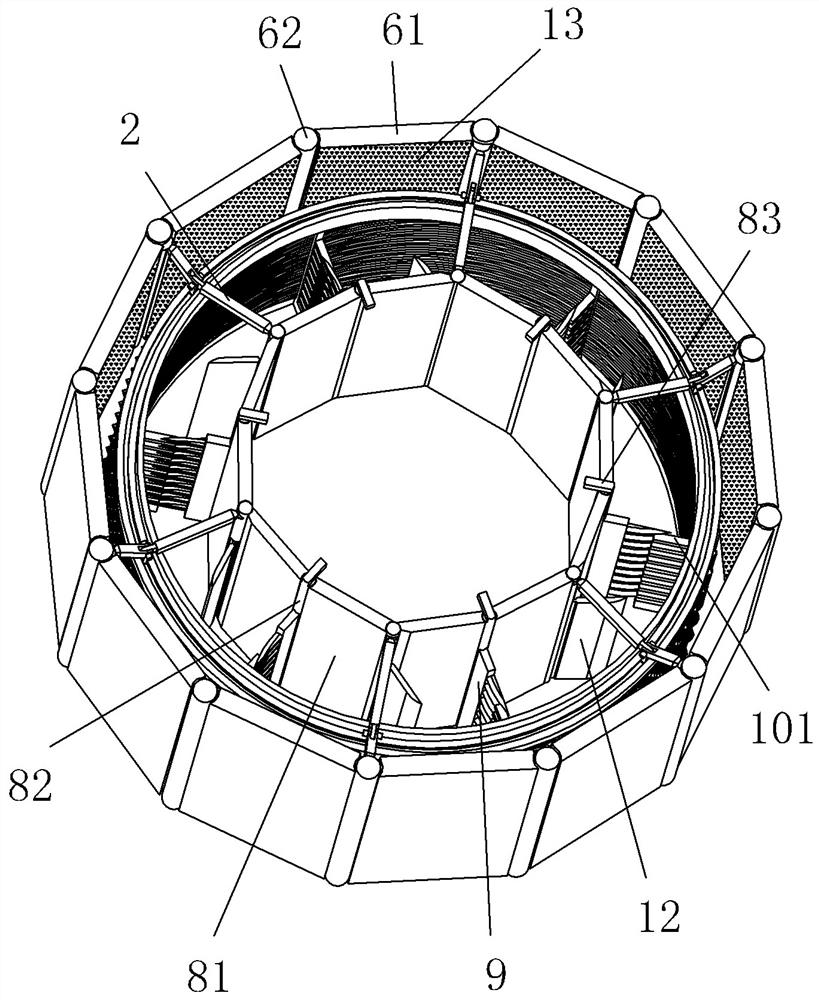

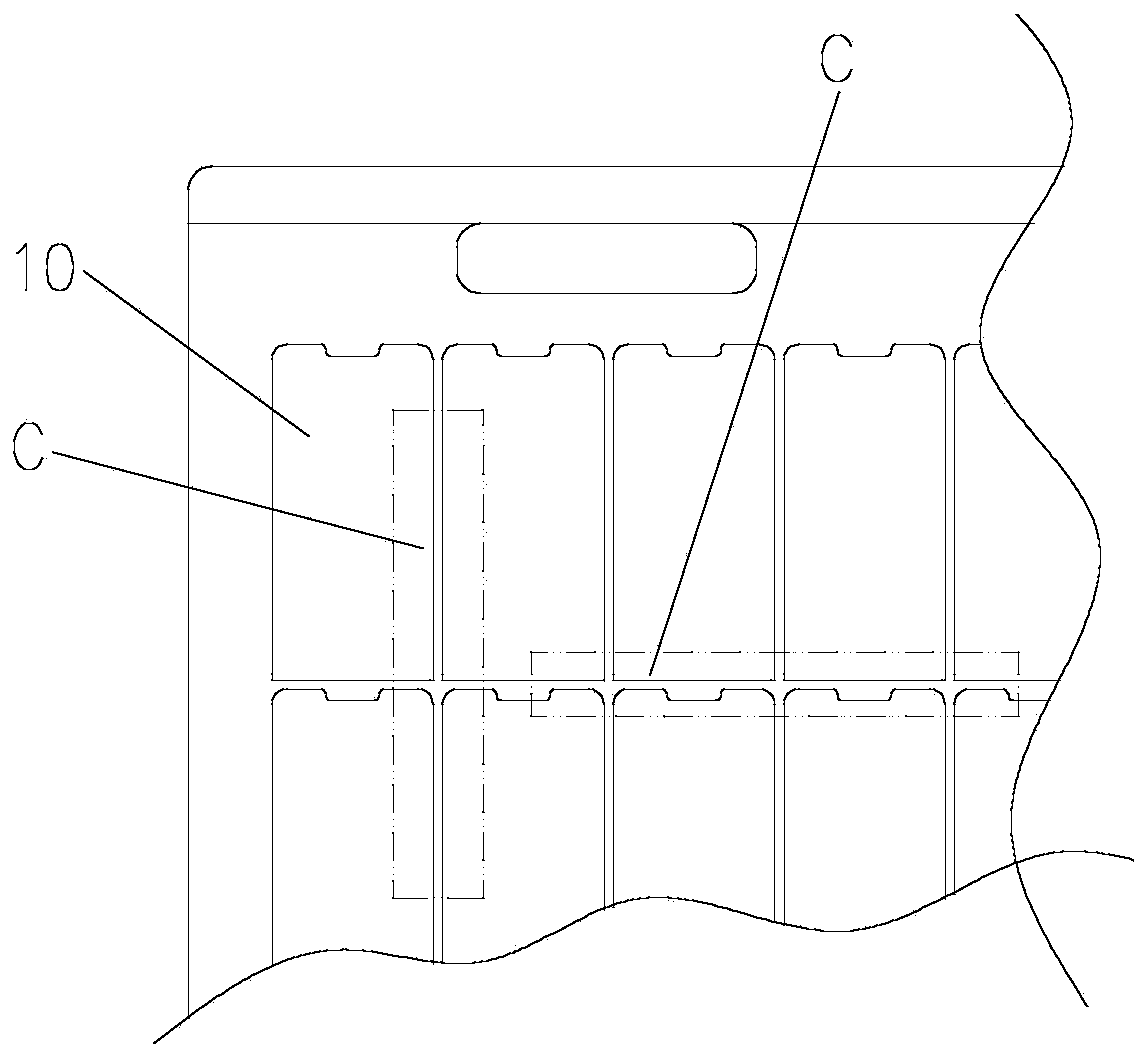

Mechanical part machining waste recycling crushing device

ActiveCN113426555AQuick cutReduce grinding resistanceGrain treatmentsStructural engineeringVertical axis

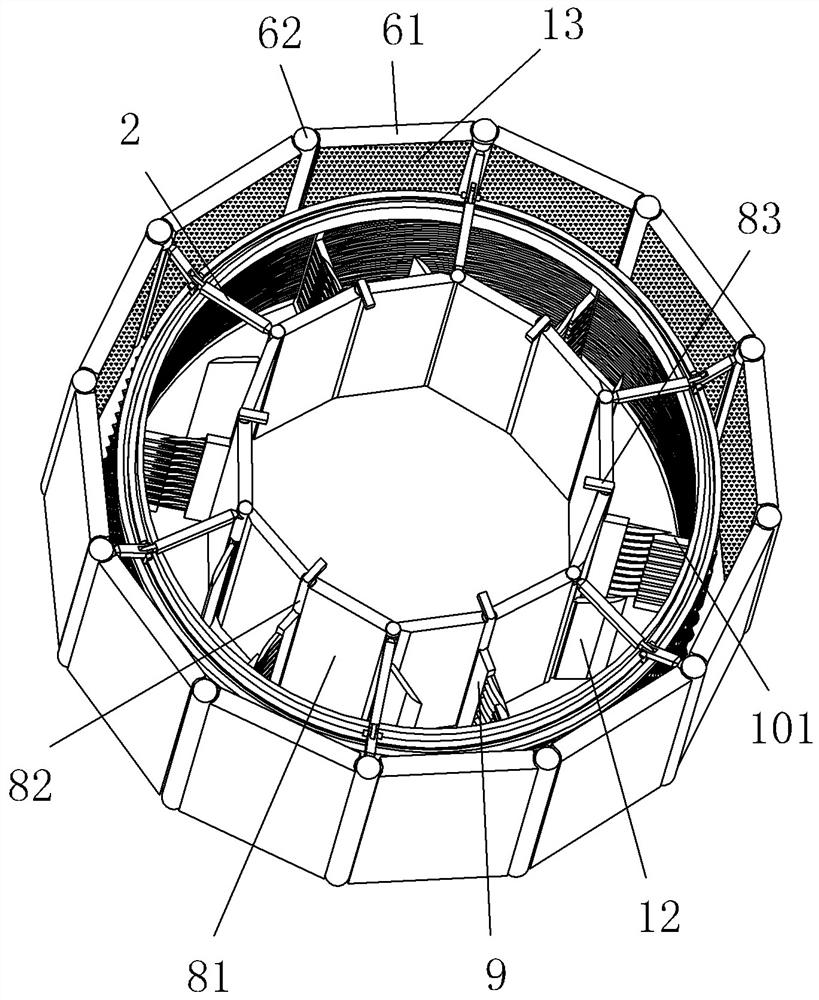

The invention relates to the technical field of machining, in particular to a mechanical part machining waste recycling crushing device. The device comprises a grinding outer ring, a cutting inner ring, an elastic piece and an adjusting rod, and the grinding outer ring is formed by hinging and enclosing an even number of outer ring pieces around a vertical axis; the cutting inner ring is positioned in the grinding outer ring, and is formed by hinging and enclosing a plurality of inner ring pieces with the same quantity as the outer ring pieces around the vertical axis; the elastic piece comprises an upper circular ring, a lower fixing ring and spiral elastic strips, a grinding cavity is defined between a barrel-shaped structure defined by the spiral elastic strips and the grinding outer ring, and a cutting cavity is defined between the barrel-shaped structure and the cutting inner ring; and the two ends of the adjusting rod are hinged to one hinge position of the outer ring pieces and one hinge position of the inner ring pieces respectively. The hinged position of the cutting inner ring is changed through waste extrusion, then the hinged position of the grinding outer ring is driven to be changed through the adjusting rod, the area of the grinding cavity is increased, the grinding resistance of the grinding cavity is reduced, more power of the device is distributed to the cutting cavity, and cutting of the waste in the cutting cavity is accelerated.

Owner:南通海隆磁业有限公司

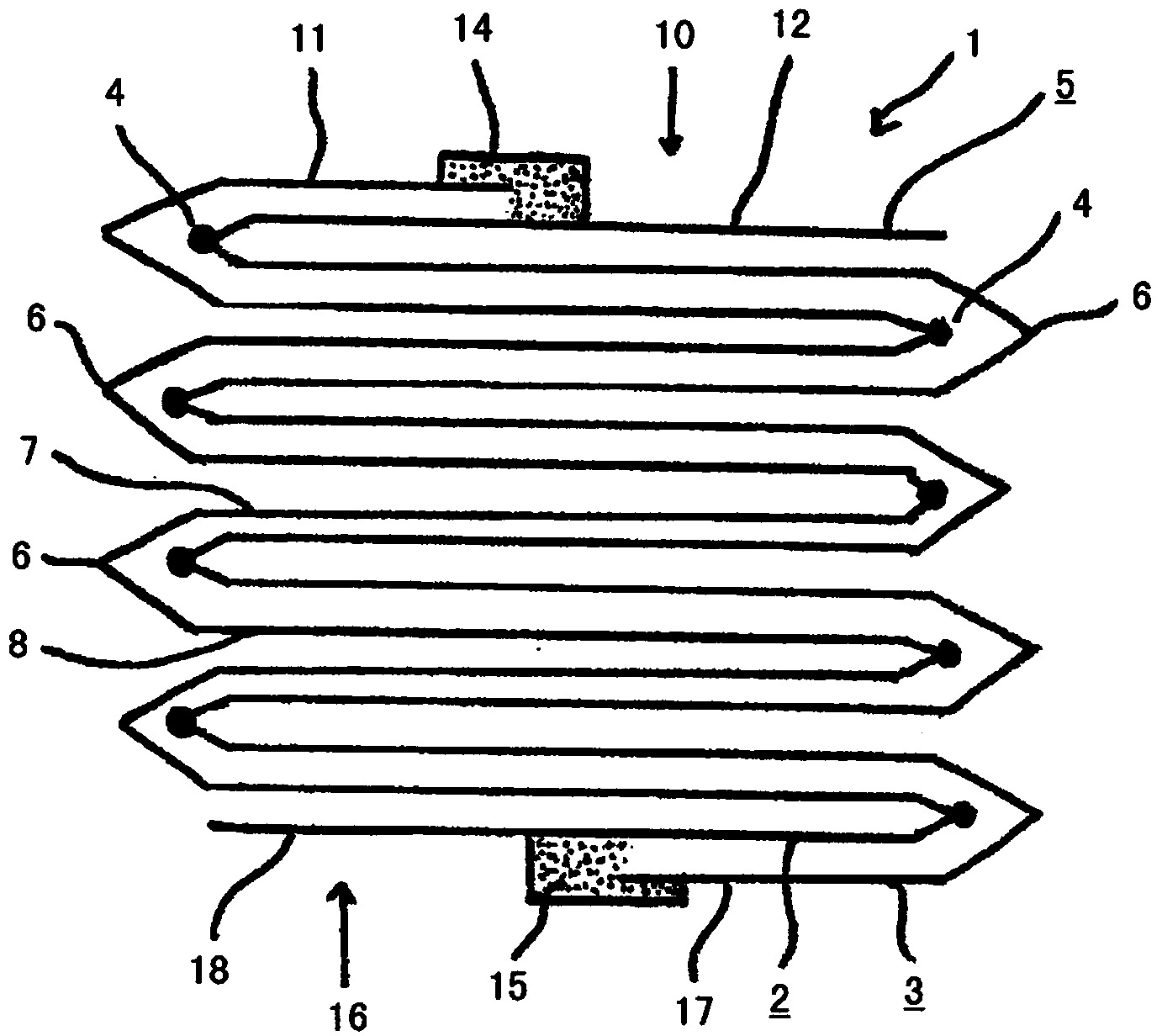

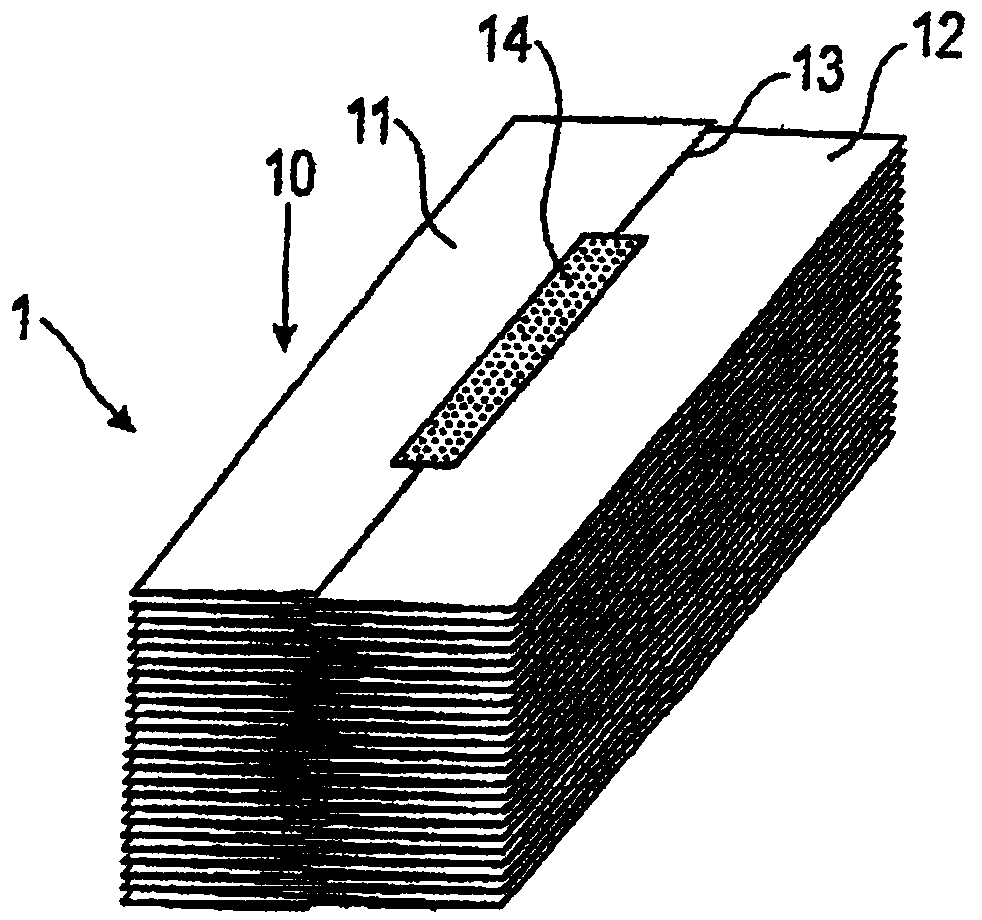

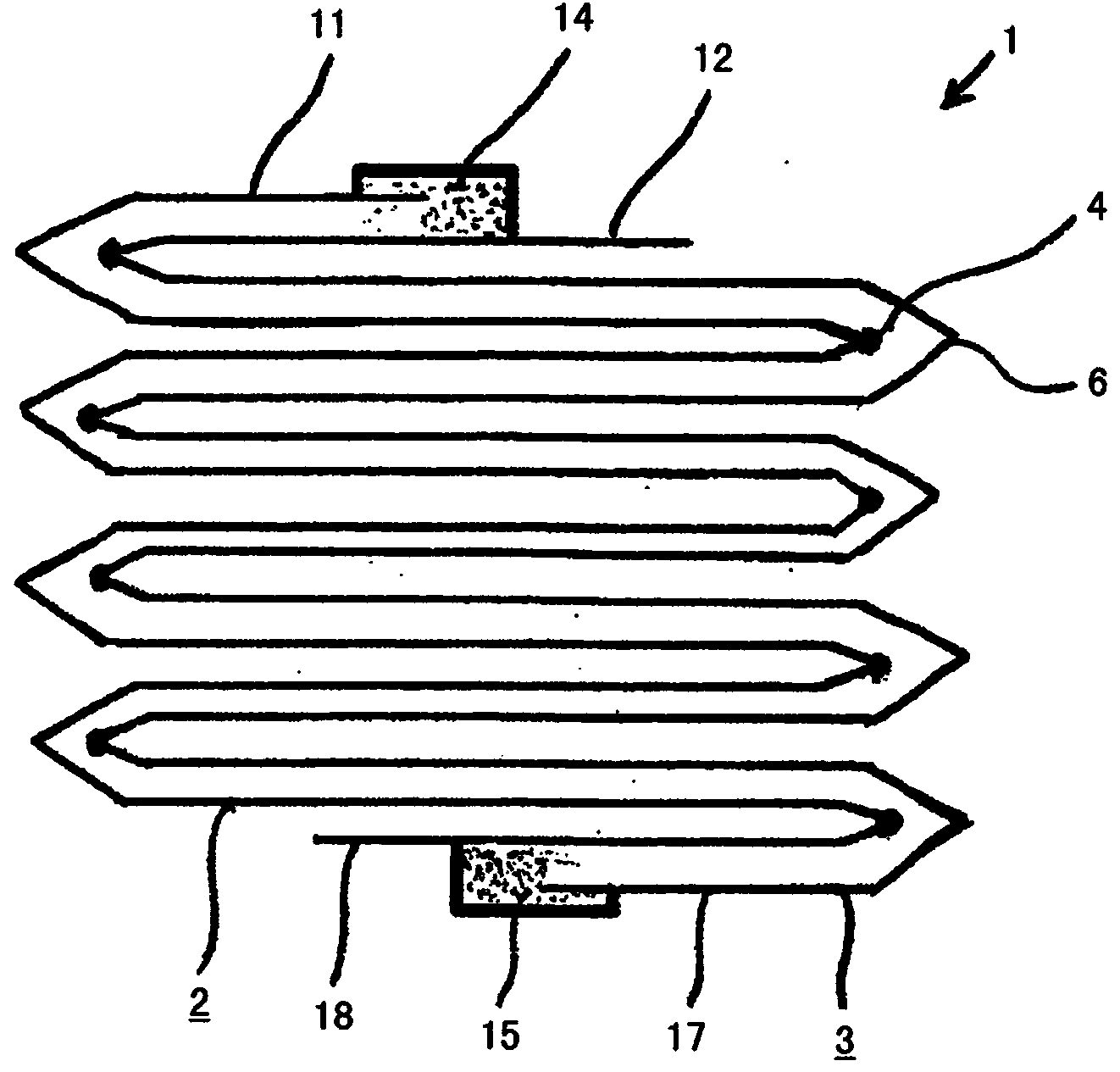

Stack of folded hygiene products and method and apparatus for producing same

InactiveCN103857613AReduce residual strengthExcellent adhesionFolding thin materialsMaterial PerforationHygiene

A method for producing stacks (1) of individual web sections (2; 3), such as tissue web sections from a continuous web of material (2a; 2b), comprises the steps: (a) directing the continuous web (2a; 2b) to a perforating station (27); (b) perforating the continuous web (2a; 2b) at predetermined intervals and forming sheets (5) of web material between consecutive perforation lines (4) extending laterally across the continuous web (2a; 2b), the perforating being carried out by means of at least one perforation element (26) arranged at the circumference of a perforation roller (24); (c) directing the continuous web (2a; 2b) to a cutting station (31; (d) cutting at second predetermined intervals the continuous web (2a; 2b) into web sections (2; 3) by means of a cutting element (38) acting against an anvil element (37), in order to generate a clear cut or a tab-bond; (e) folding the web sections (2; 3) by means of a folding roll (32); and (f) stacking the folded web section (2; 3) to generate a stack (1) of folded sheets.

Owner:ESSITY HYGIENE & HEALTH AB

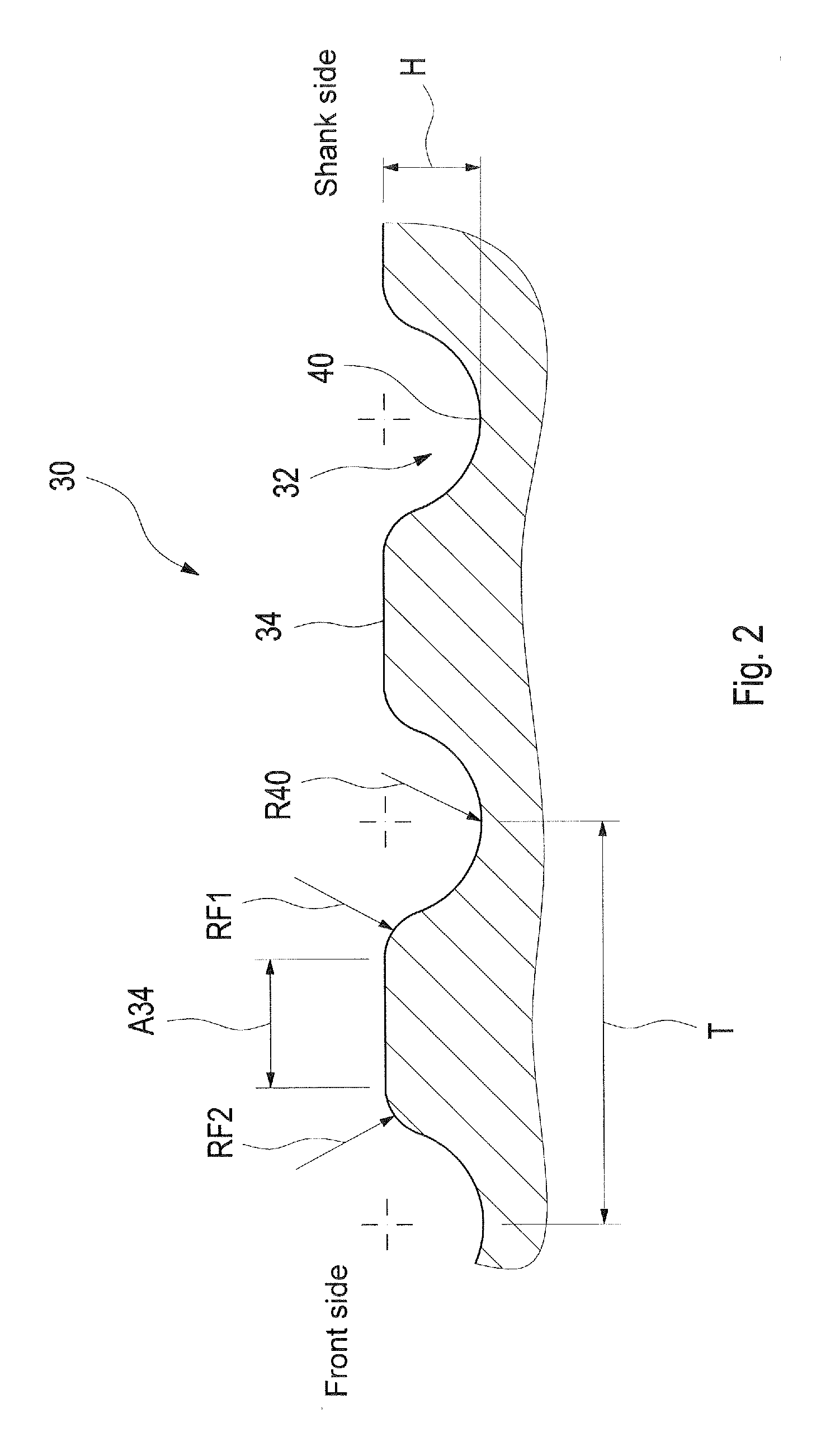

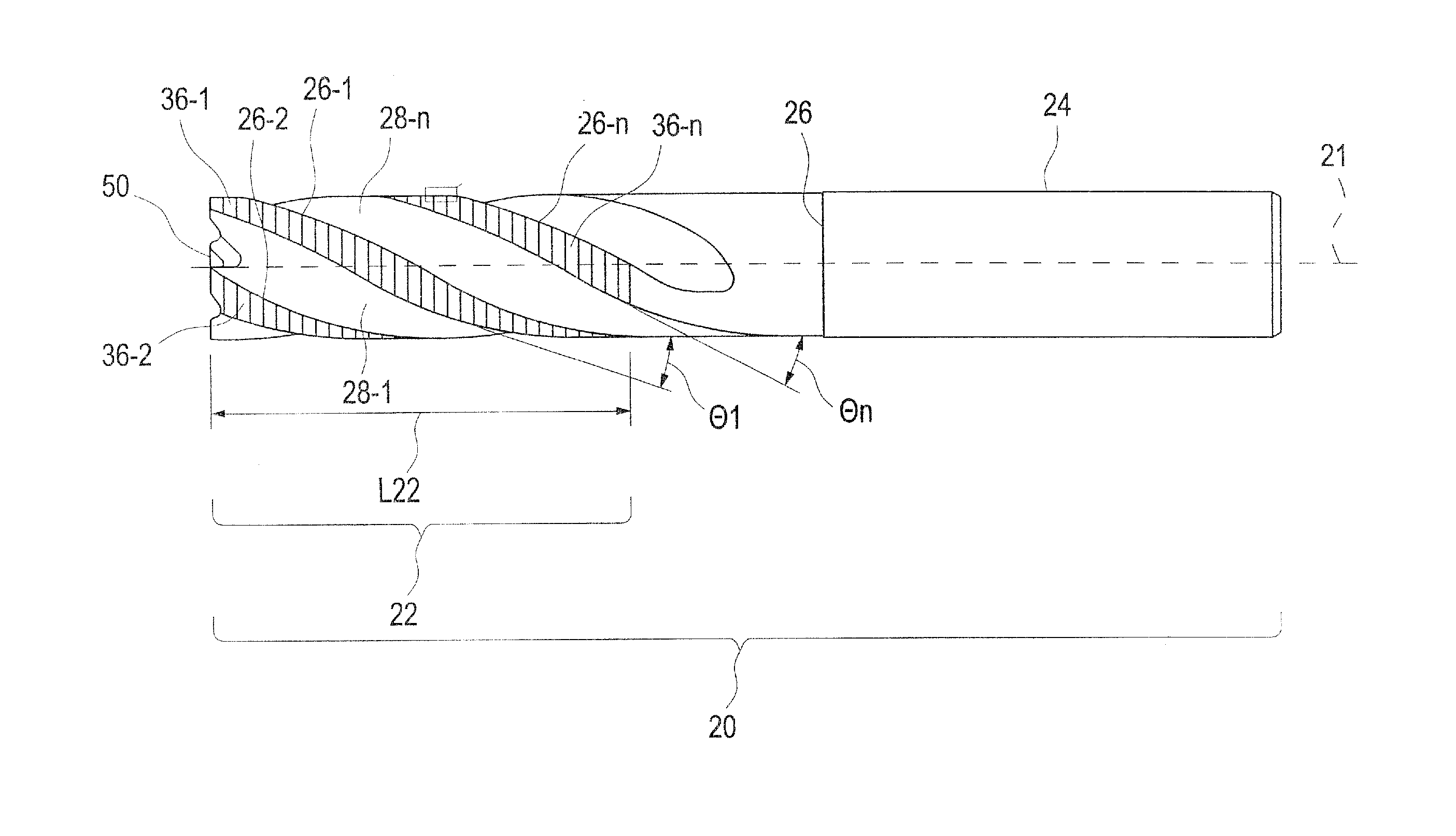

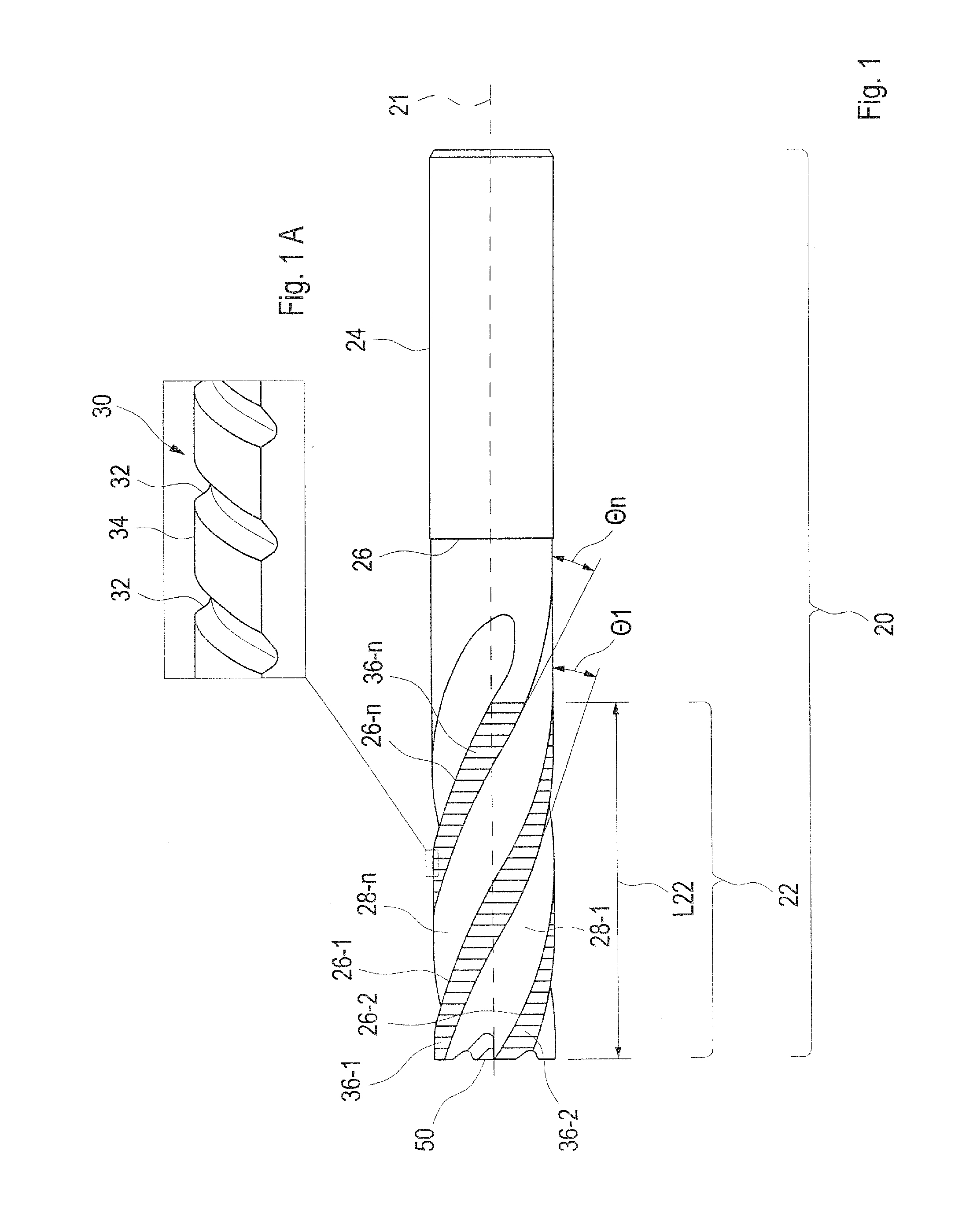

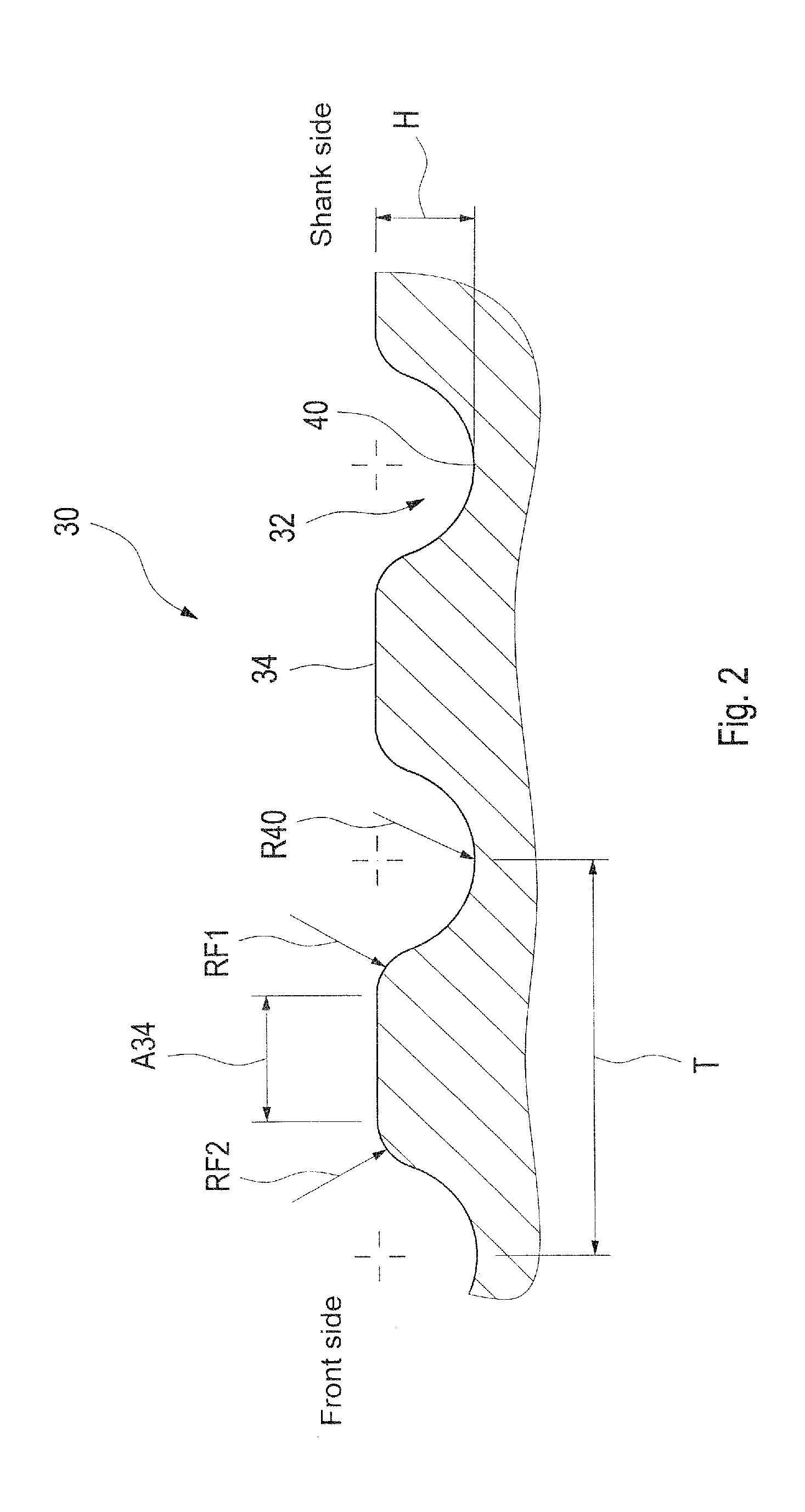

Shank drill

InactiveUS20150158095A1Improve surface qualityReduce power consumptionMilling cuttersAdverse effect compensationDrillHelix

A shank cutter has plural circumferential cutting edges which run in a helical manner in the region of its cutting section and of which at least one critical number are equipped in each case with a preferably essentially flattened roughing profile with chip-separating grooves with rounded bases, so that the chip-separating grooves of cutter ridges which are adjacent in the circumferential direction are axially offset relative to each other. To create a tool which provides long service life by combined advantages of a vibration-stabilized finishing cutter and a conventional roughing cutter, at least one circumferential cutting edge has an angle of twist which differs from that of another circumferential cutting edge. In addition, the chip-separating grooves of the circumferential cutting edges which are equipped with a roughing profile in each case merge into a preferably essentially flattened central section of the roughing profile by means of a predefined flank radius.

Owner:GUEHRING JOERG

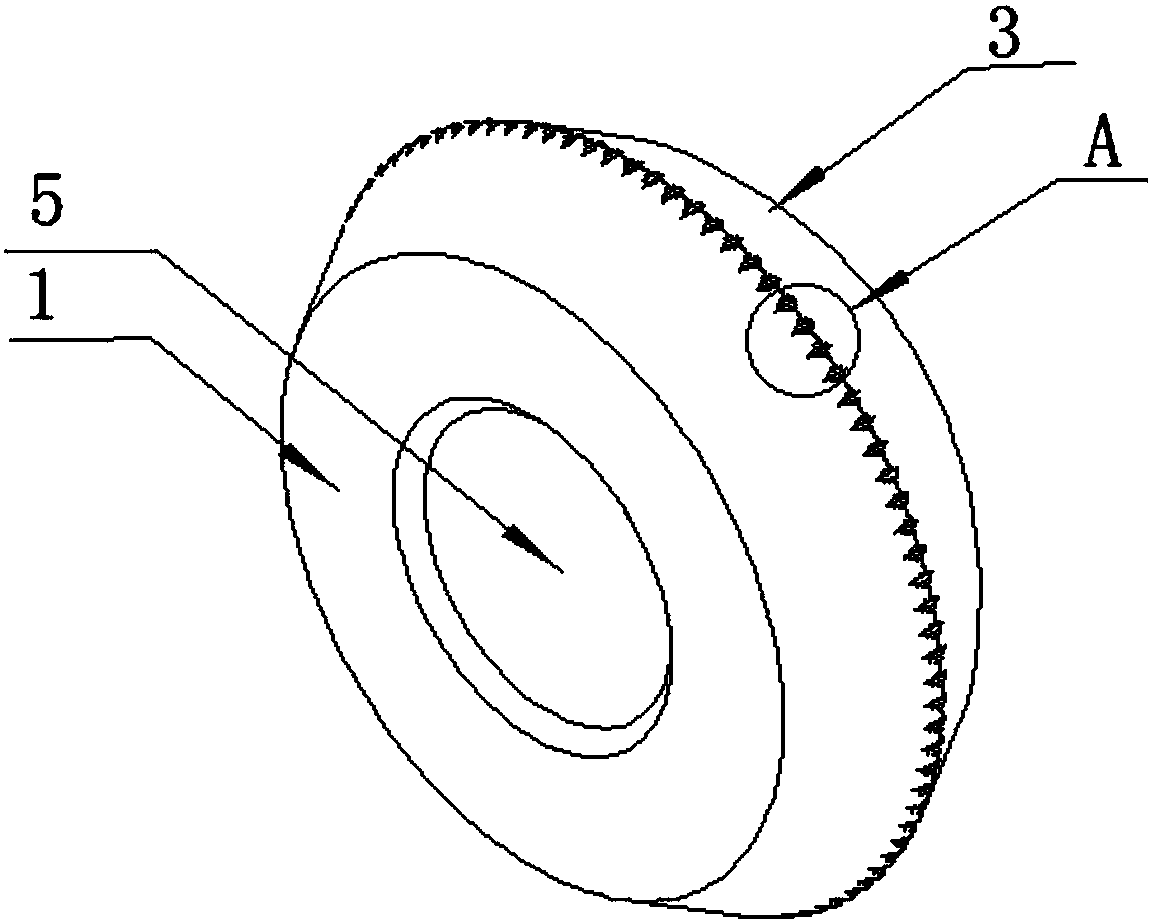

Knife wheel with platforms

PendingCN108341589AReduce wearExtended cutting lifeGlass severing apparatusMechanical engineeringEngineering

The invention discloses a knife wheel with platforms. The knife wheel comprises two symmetrical disk faces and a shaft hole for mounting a knife shaft, wherein the shaft hole is positioned in the center of the knife wheel and transversely extends to the disk faces; the disk faces extend to a longitudinal center cross section of the knife wheel along the outer edge and are intersected to form two symmetrical tapered faces; an intersection line of the tapered faces forms a peripheral edge; grooves are uniformly formed in the peripheral edge; cross sections of openings of the grooves are V-shaped; the openings of the grooves extend to a transverse center cross section of the knife wheel along the peripheral edge and are intersected to form first groove walls and second groove walls; the firstgroove walls and the second groove walls bulge outwards to form at least two platforms; and the platforms transversely extend to the tapered faces to form inner edges. According to the knife wheel with the platforms, a wear degree of the edges is reduced in a cutting process by dispersing cutting pressure at the edges; a cutting life is prolonged; at the same time, the platforms serve as the facial inner edges and can assist in cutting; a cutting scope is enlarged; and the inner edges formed by the platforms can allow a cutting pressure scope and an application scope of the knife wheel to bewider.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

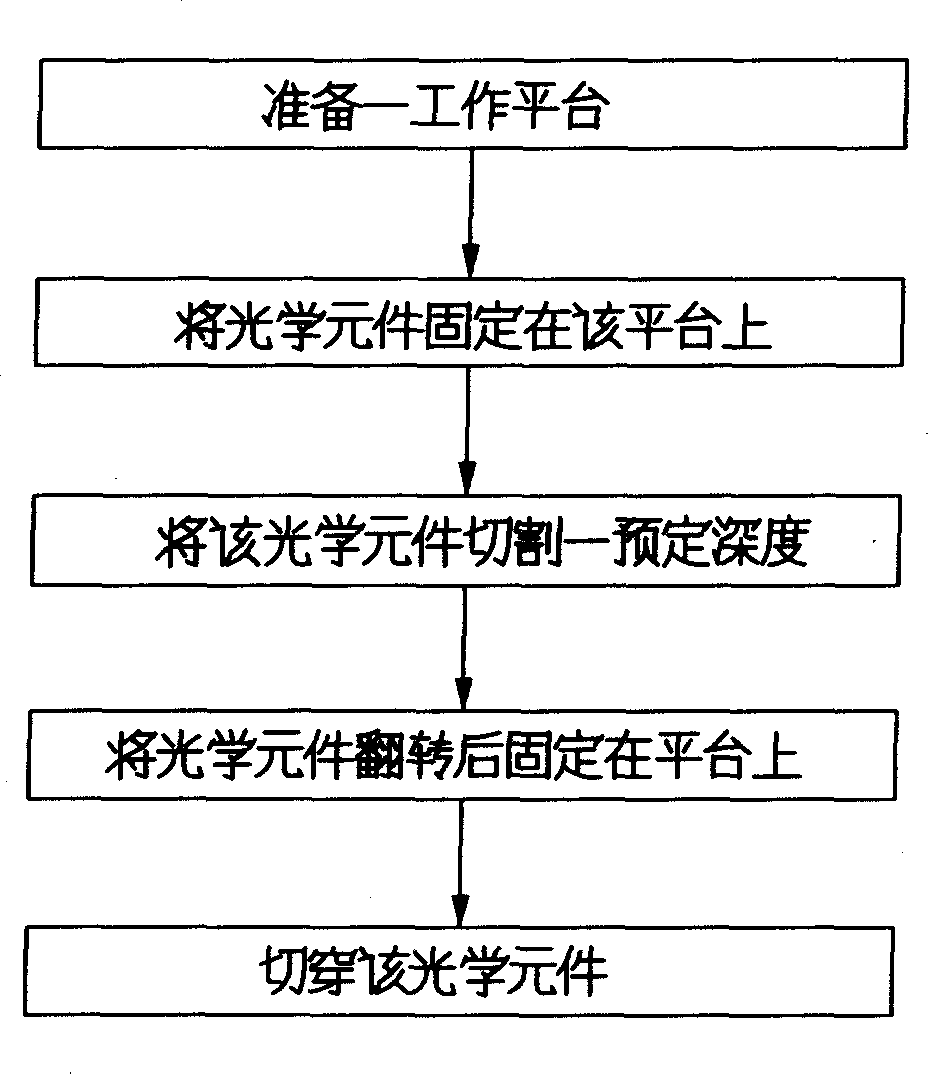

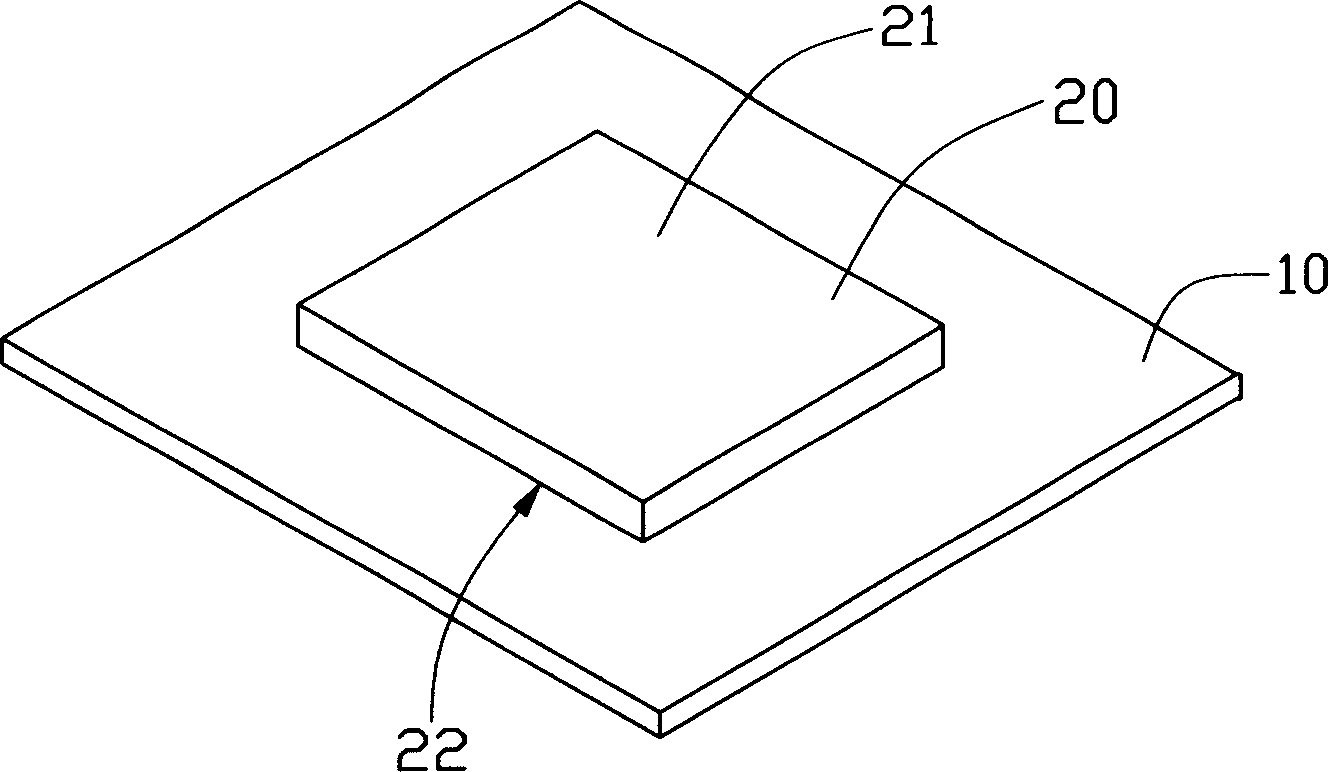

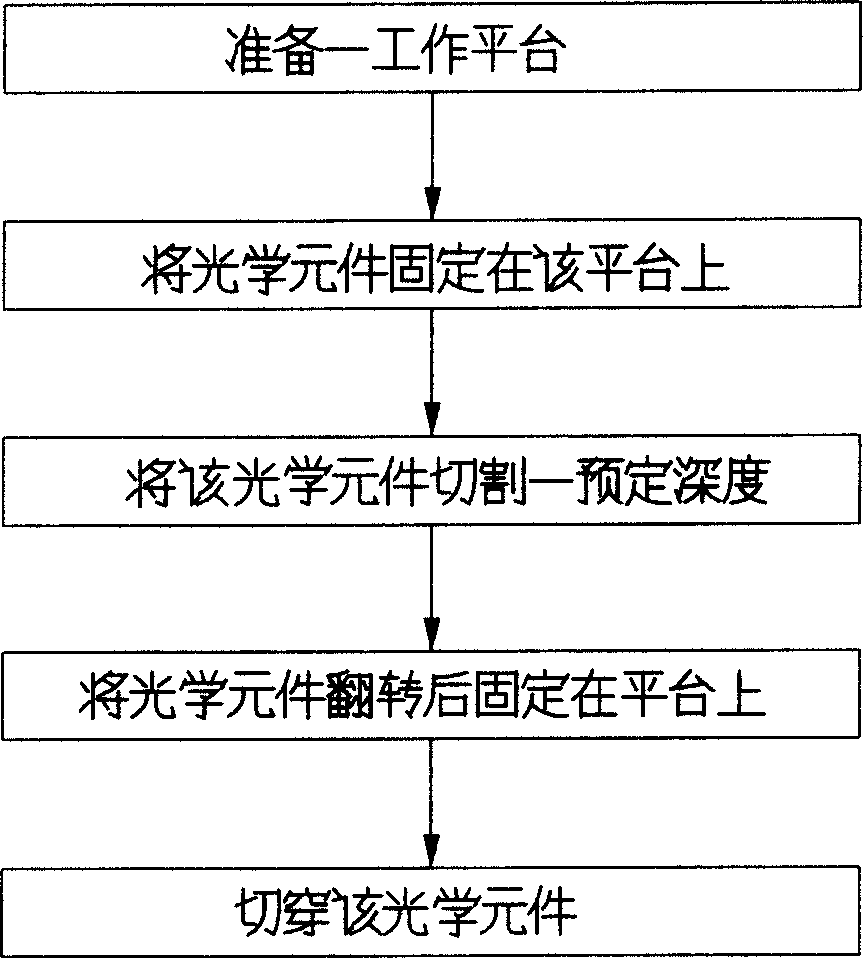

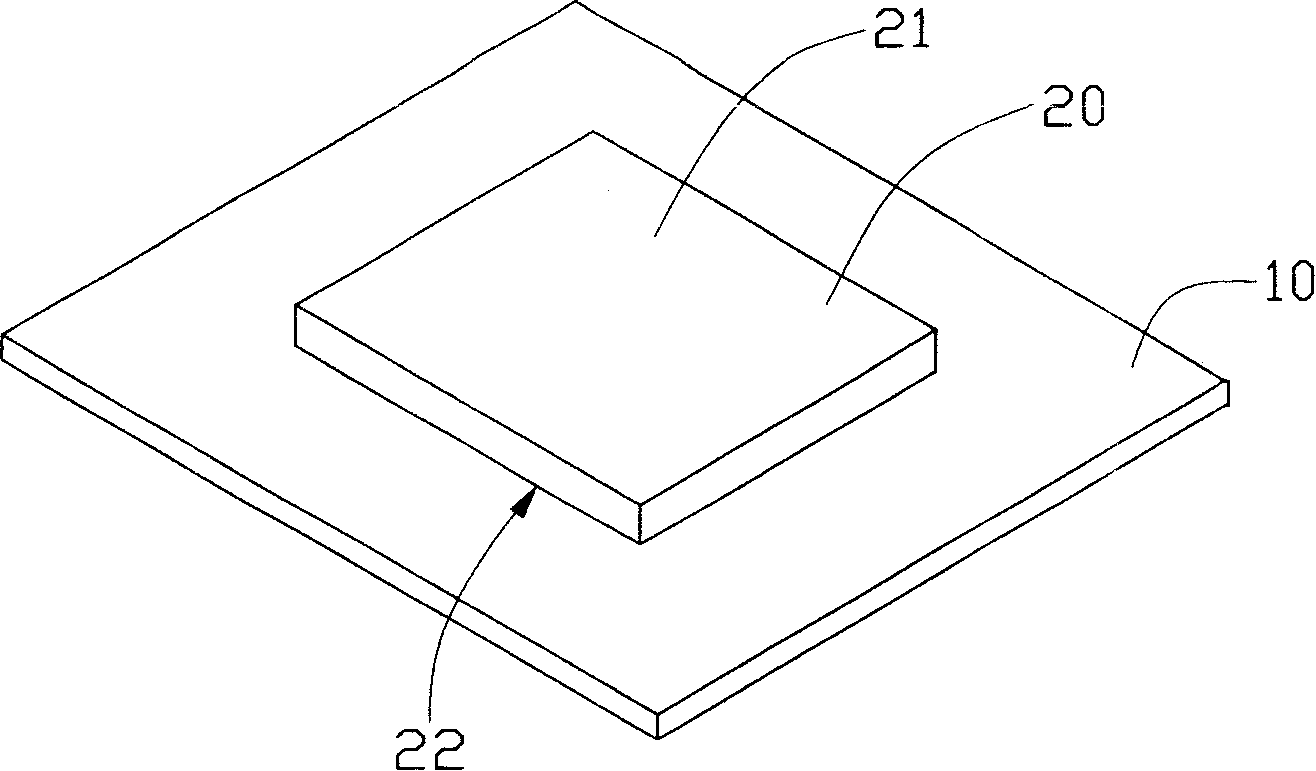

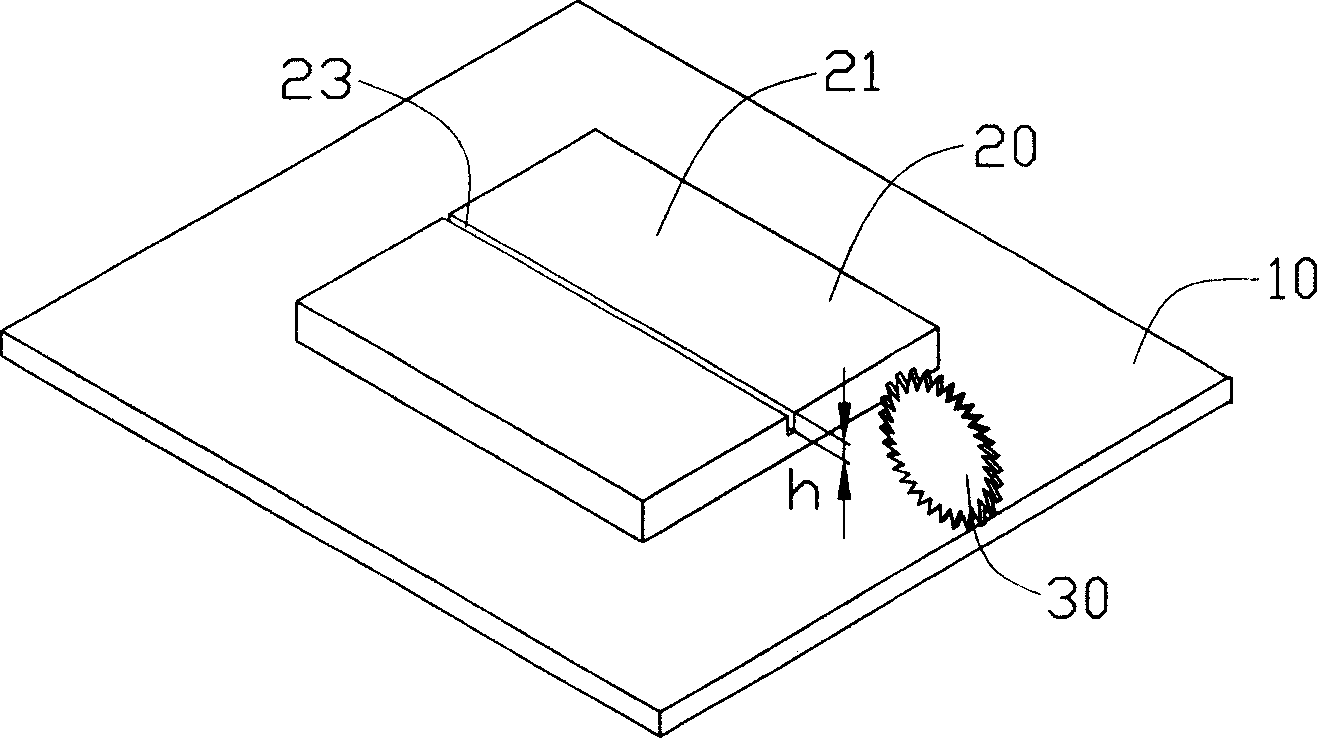

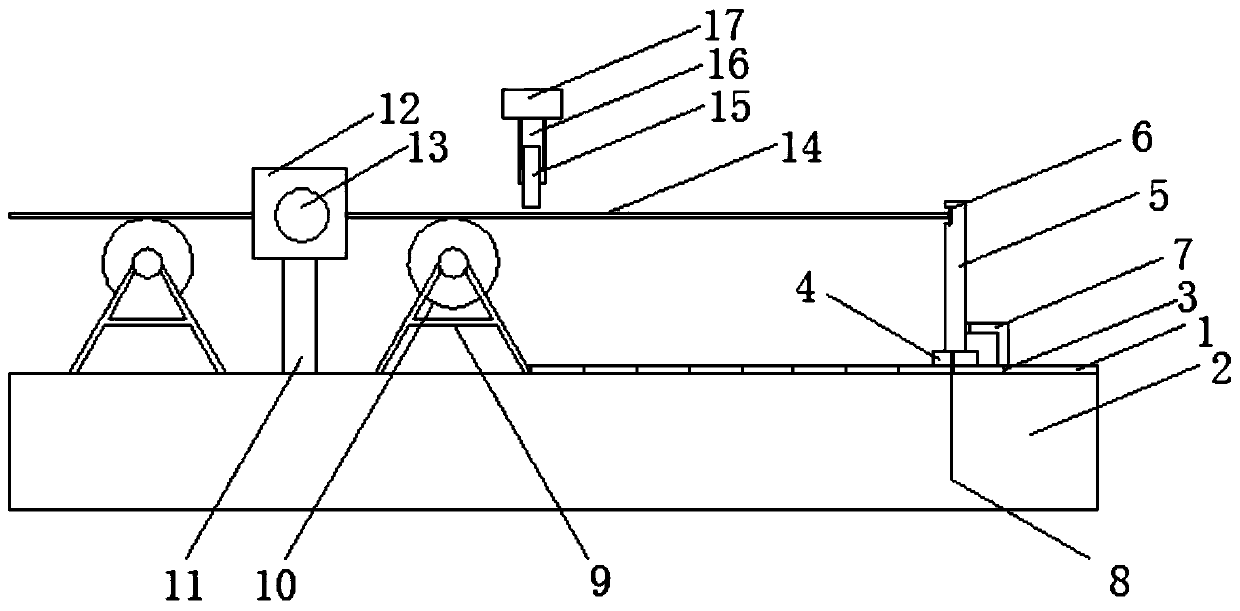

Cutting method of optical element

InactiveCN1537707AImprove machining accuracySimplify the processMetal working apparatusBiomedical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

High-molecular rubber cutting device

InactiveCN109318274AReduce cutting pressureImprove cutting efficiencyMetal working apparatusEngineeringMachining

The invention provides a high-molecular rubber cutting device, and relates to the technical field of high-molecular material processing. The high-molecular rubber cutting device comprises a frame. A conveying belt is fixedly installed on the left side of the frame, a rubber strip is placed on the conveying belt, and push wheels are fixedly installed on the right side of the conveying belt. A rotating shaft is fixedly installed on the frame through bearings, and cutter heads are fixedly installed on the rotating shaft. Sleeves are fixedly installed at the bottom of the frame, and rotating drumsare fixedly installed at the bottom ends of telescopic rods. Cooling tanks are fixedly installed at the bottom of the frame. A motor is fixedly installed at the top end of the frame, and the motor and the rotating shaft are movably connected through a belt. A base plate is fixedly installed on the frame. According to the high-molecular rubber cutting device, due to the synchronous effect of the four cutter heads, a device of cooling the cutter heads and a dust suction device which penetrates through cutting grooves, the working efficiency of cutting machining is improved, and the cutting effect is guaranteed.

Owner:ZHEJIANG HUANZHOU POLYMER MATERIAL TECH CO LTD

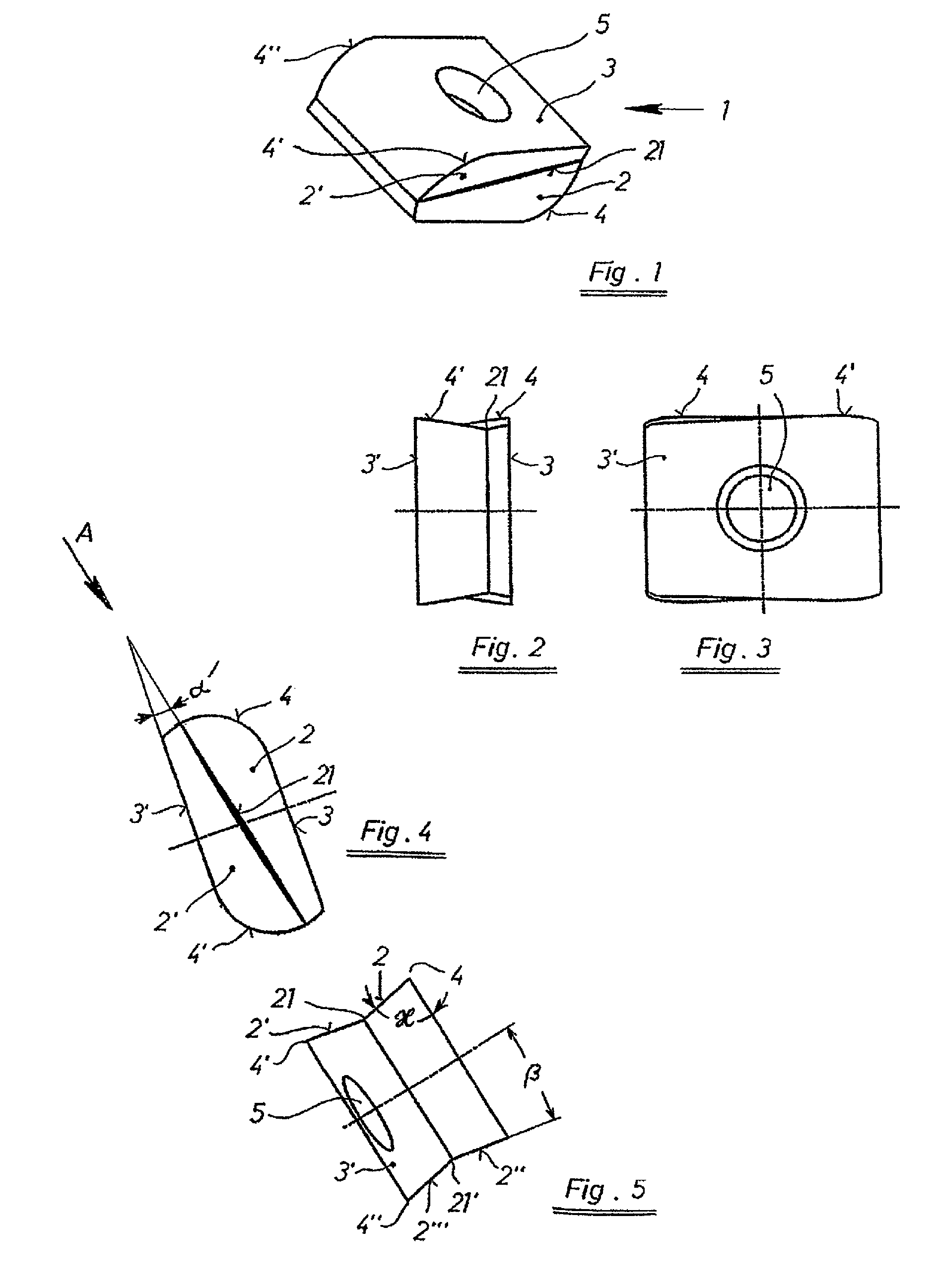

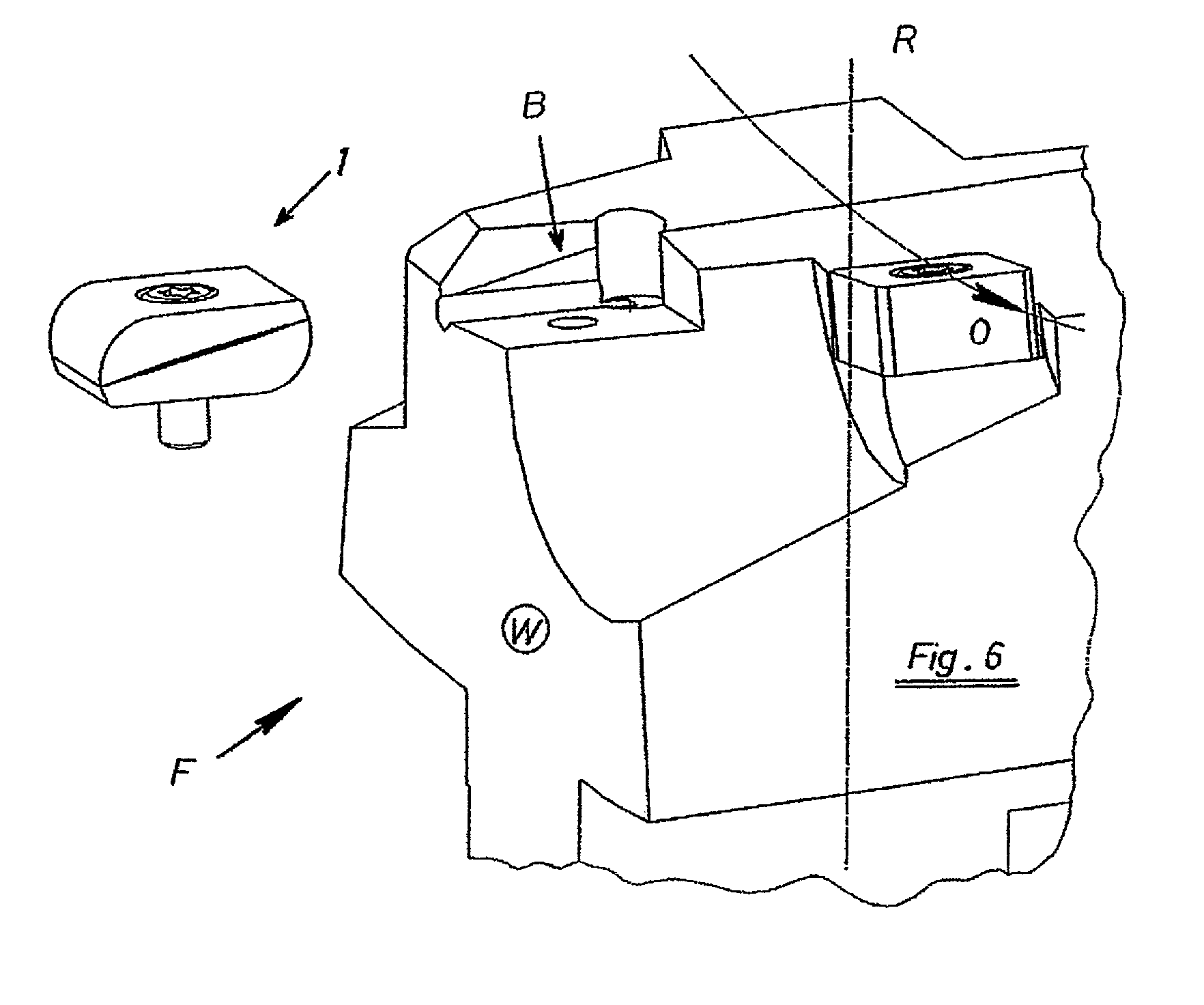

Indexable insert for milling tools

ActiveUS8100610B2Reduce cutting pressureCut force be reduceMilling cuttersWorkpiecesEngineeringMechanical engineering

An indexable insert for a milling tool that includes at least one mounting surface having a through bore for fixing the insert to a rotatable tool, a rounded cutting edge defined by at least one cutting face and a lateral surface, and the at least one cutting face being arranged on a lateral side of the insert and extending from a base. The base is angled with respect to the at least one mounting surface. This abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:BOEHLERIT GMBH & CO KG

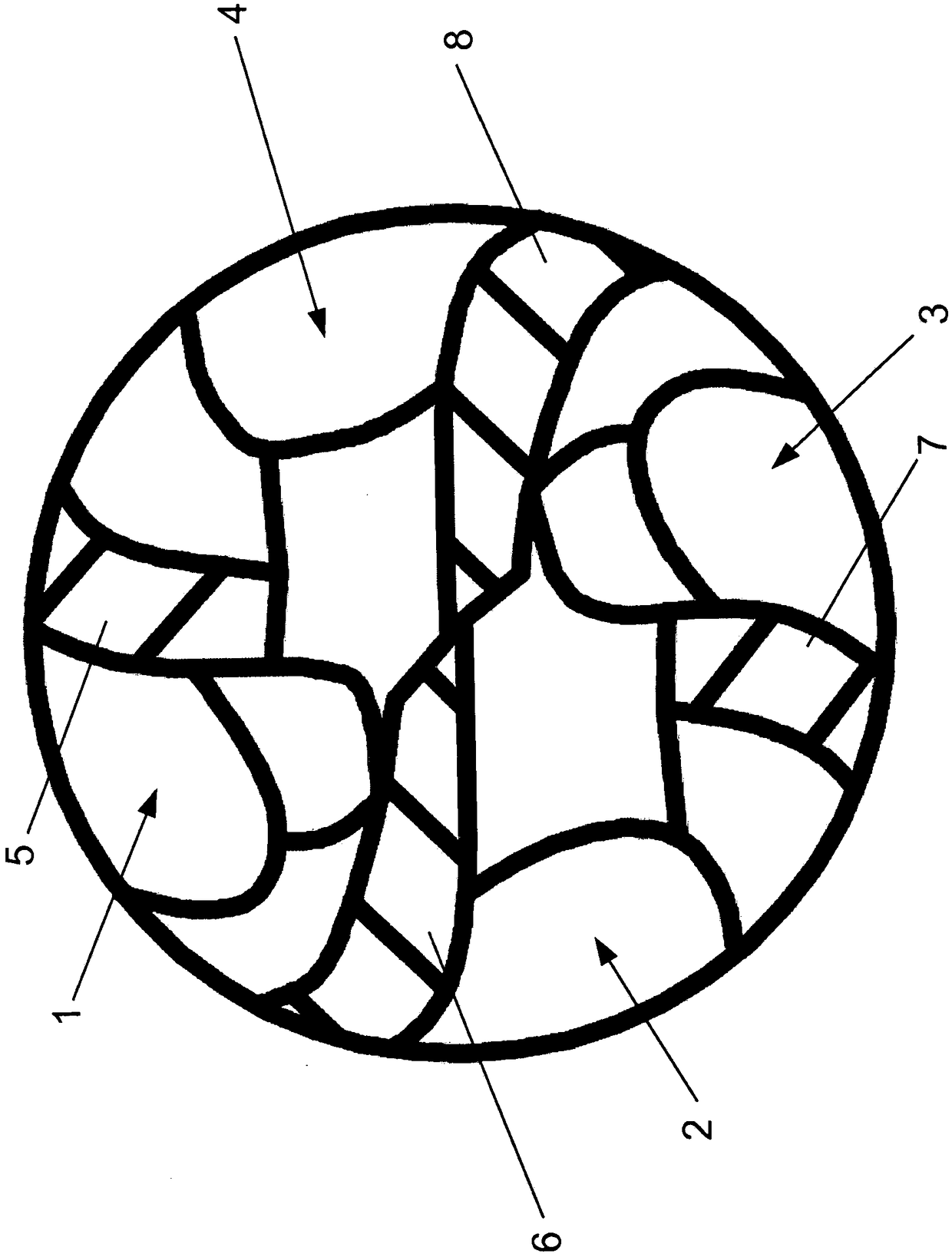

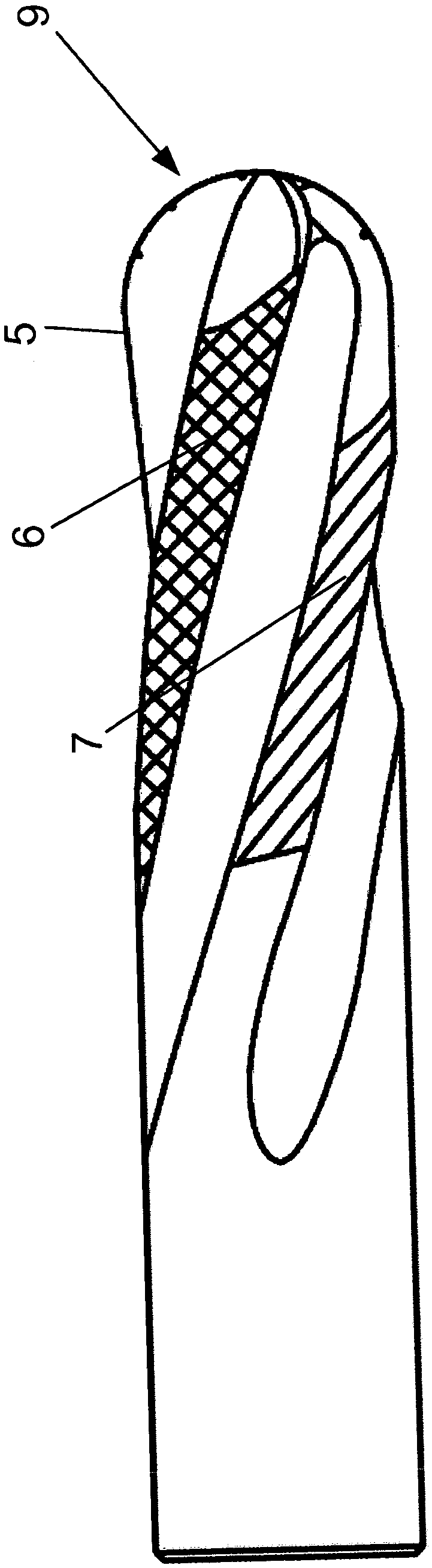

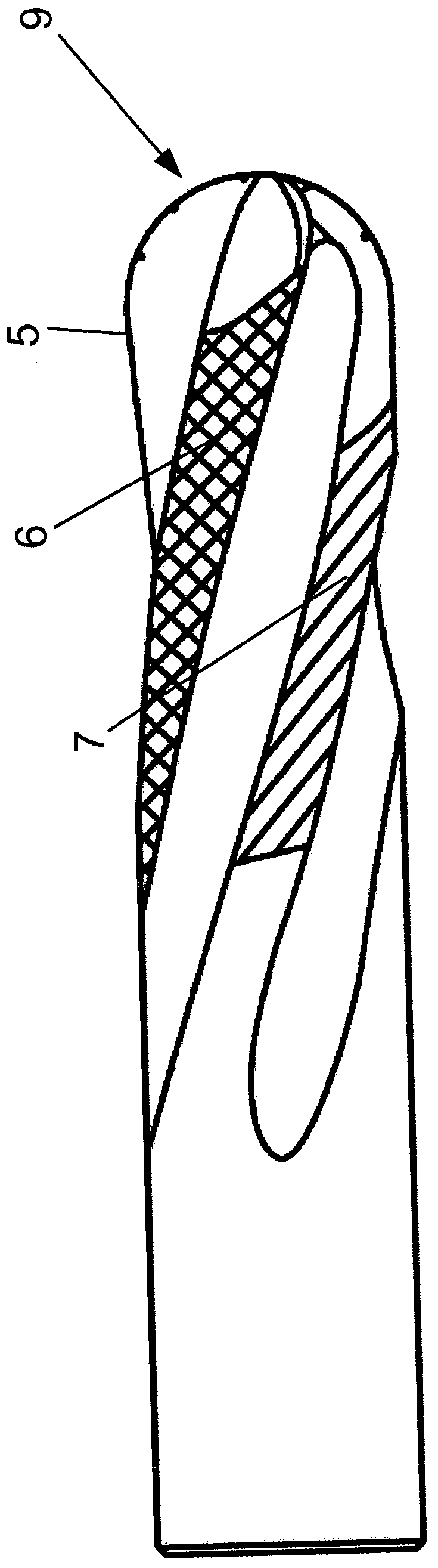

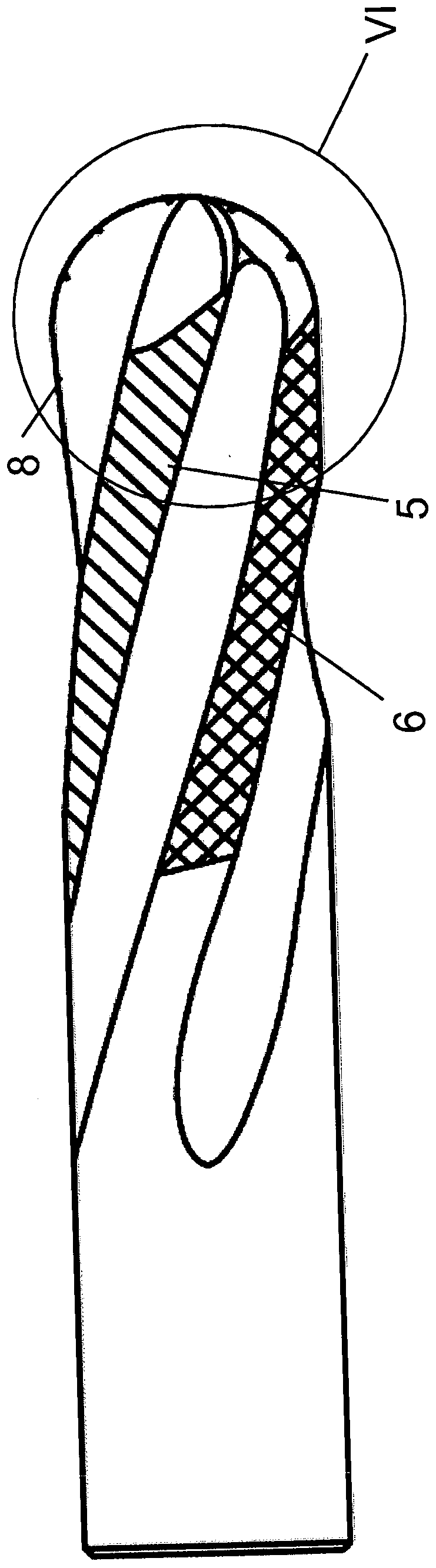

Electrode graphite milling cutter and face milling cutter for machining oxide ceramics

ActiveCN108367367AReduce cutting pressureTransportation and packagingMilling cuttersEngineeringRidge

The invention relates to an electrode graphite end milling cutter, comprising a ball head (9), at least one coarse machining ridge (6, 8), and at least one fine machining ridge (5, 7). Each coarse machining ridge (6, 8) is designed as a peripheral file having a plurality of teeth (10, 11); each fine machining ridge (5, 7) has a plurality of casing grooves extending with twist around the tool axis,wherein the casing grooves space apart casing ridges each having a peripheral cutting edge (12, 13), wherein the working regions of a first group (5, 6, 8) of the machining ridges (5, 6, 7, 8) extendfurther up to the tool tip than the working regions of a second group (7) of the machining ridges (5, 6, 7, 8).

Owner:HUFSCHMIED ZERSPANUNGSSYST

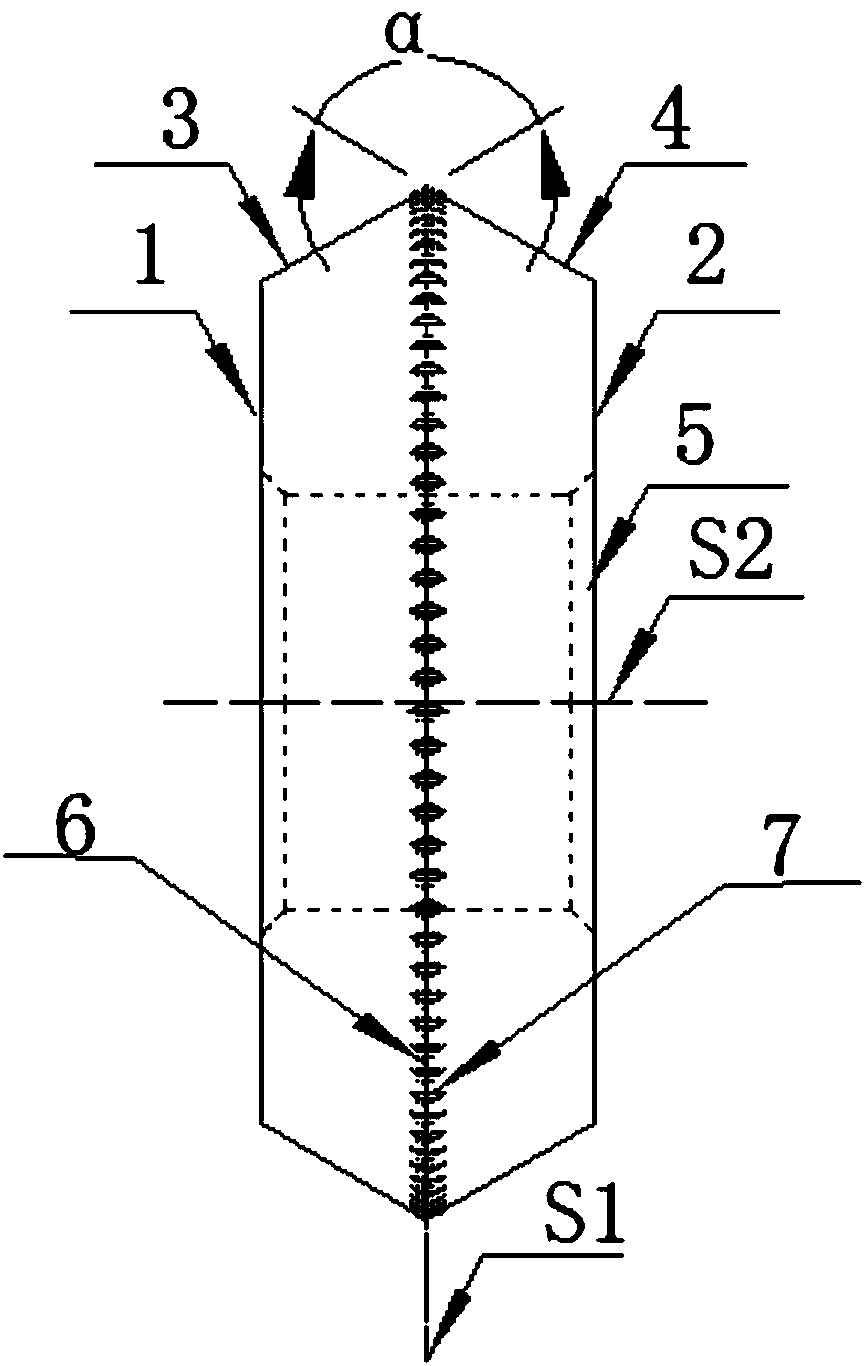

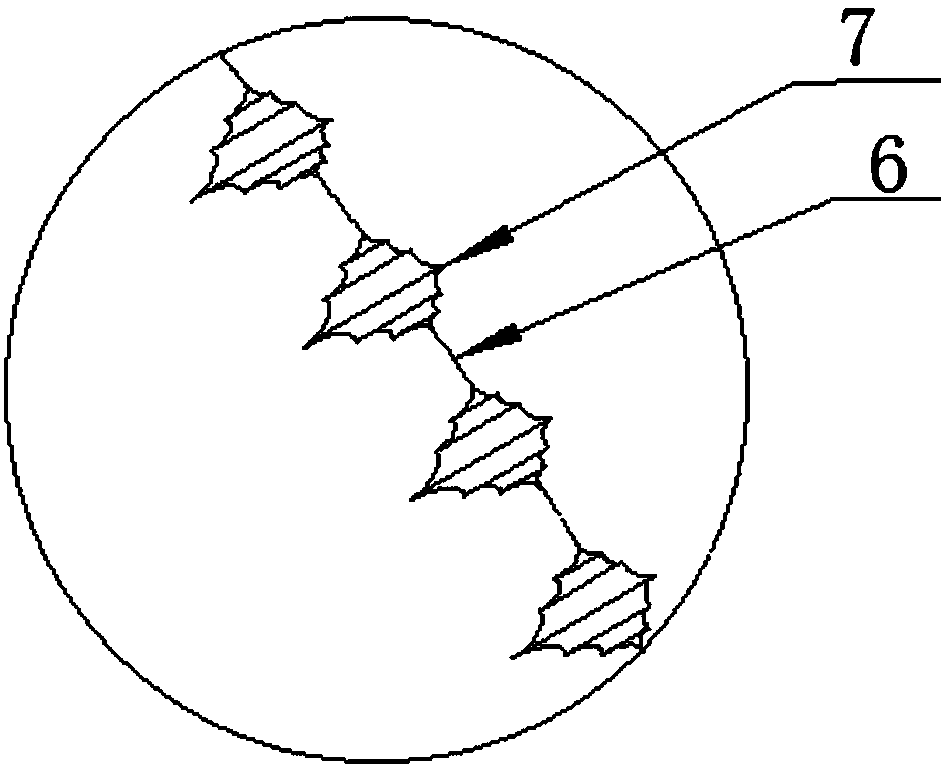

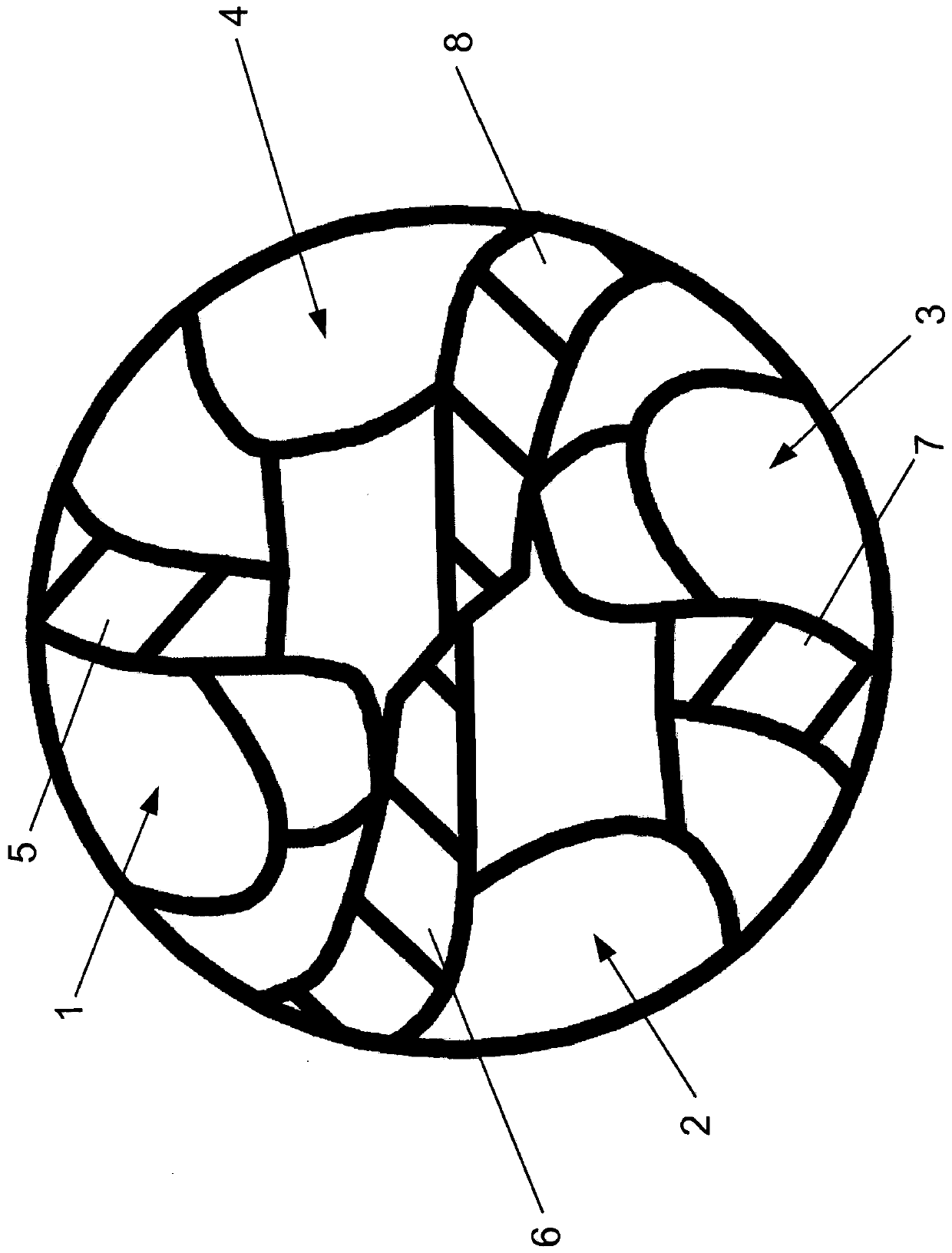

Contoured reamer teeth

An acetabular reamer (10′) for cutting a required cut shape. The reamer has a cutting shell (12′) having a series of doubly curved cutting teeth (16′) thereon of a quantity to substantially reduce a cutting pressure on each tooth as well as to reduce a size of a typical chip generated upon cutting. Substantially all the teeth each have a matched arc cutting edge (20′) of substantial length that has a cutting profile which substantially matches a profile of a shape to be cut. Such a configuration reduces the number of teeth required to cut the shape.

Owner:VIANT AS&O HLDG LLC

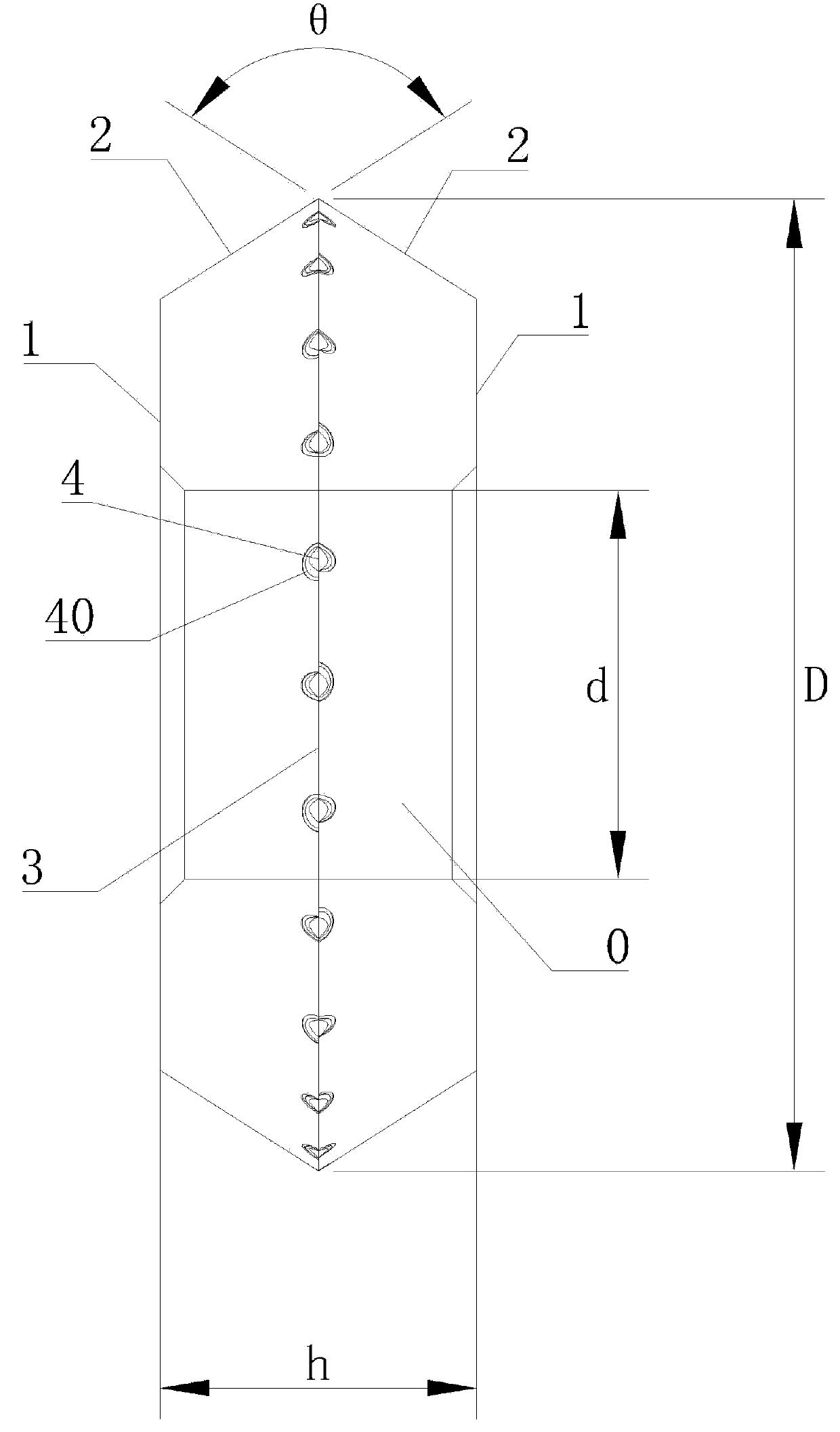

Rock-breaking PDC diamond bit

The invention relates to a rock-breaking PDC diamond drill bit. The drill bit comprises a body and at least three blades arranged on the body and used for fixed cutting; a bit leg is arranged betweenevery two adjacent blades; a cone is arranged on each bit leg; first cutting teeth are arranged on each cone; a main cutting layer is arranged on each blade; and a water spraying hole is formed in theside part of each blade. According to the rock-breaking PDC diamond drill bit provided, in the process of drilling into a hard stratum, diamond cutter particles are not prone to collapsing.

Owner:湖南屈原水利建筑工程有限公司

Cutting method of optical element

InactiveCN100382941CReduce wear and tearNo frequent replacementMetal working apparatusBiomedical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

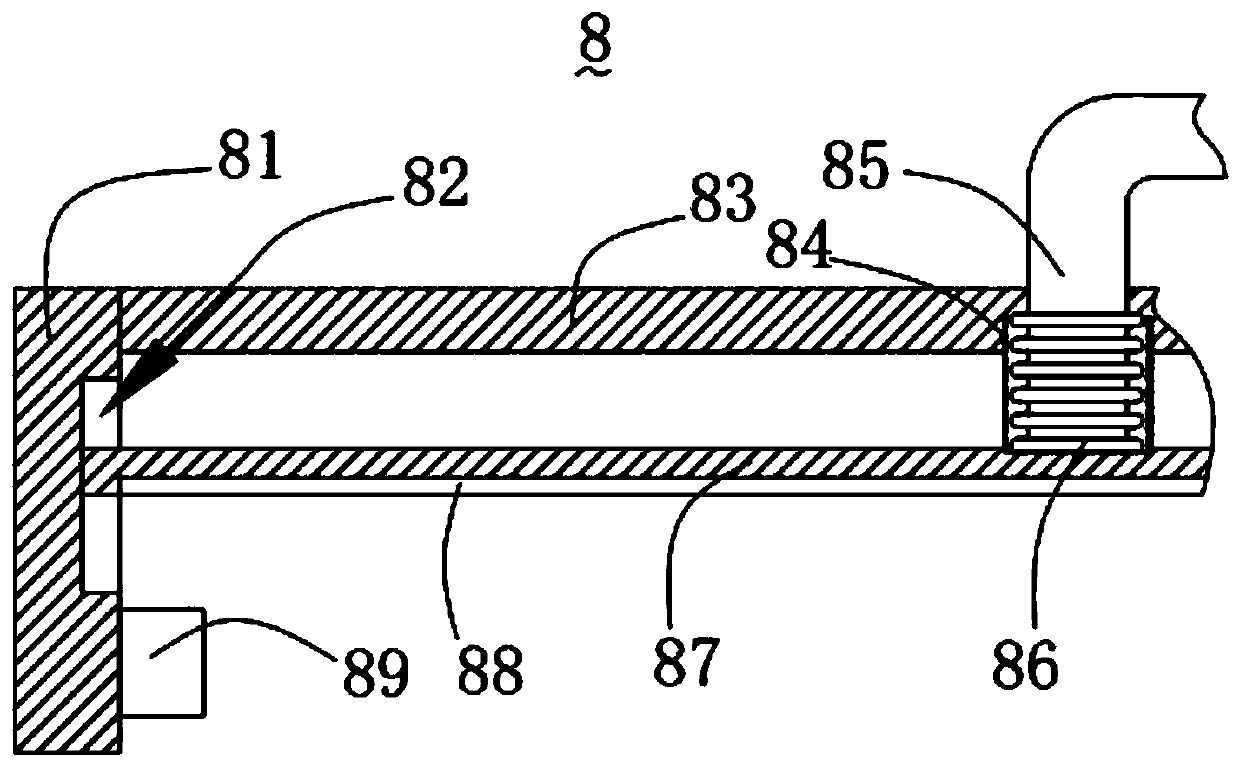

Preheating type reinforcing steel bar cutting device

PendingCN110465610AEasy to control the lengthTo achieve strict controlArchitectural engineeringRebar

The invention relates to the technical field of bridge construction, and discloses a preheating type reinforcing steel bar cutting device. The preheating type reinforcing steel bar cutting device comprises a working table, wherein a slide block is movably connected with the right side of the upper end of the working table, a support block is movably connected with a part, close the left side of anA-shaped support, of the upper end of the working table, a heating box body is movably connected with the upper end of the support block, a connection rod is movably connected with the reverse side of a bottom housing, a cutting tool is movably connected with the lower end of the connection rod, a hydraulic rod is movably connected with the upper end of the connection rod, a bolt is movably connected with the left end of a rotary handle, and a heat conduction block is movably connected with the left end of the bolt. The preheating type reinforcing steel bar cutting device can achieve the purpose of easily controlling the length of a reinforcing steel bar by using structures of the slide block, a long column, a groove, a vernier and the like cooperatively, thereby achieving the effect of strictly controlling the length of the reinforcing steel bar, and by using the structures of the heating box body, the rotary handle, the bolt, the heat conduction block and the like, the effect of reducing cutting pressure of the reinforcing steel bar is achieved, and use life of the cutting device is prolonged.

Owner:龙桂桃

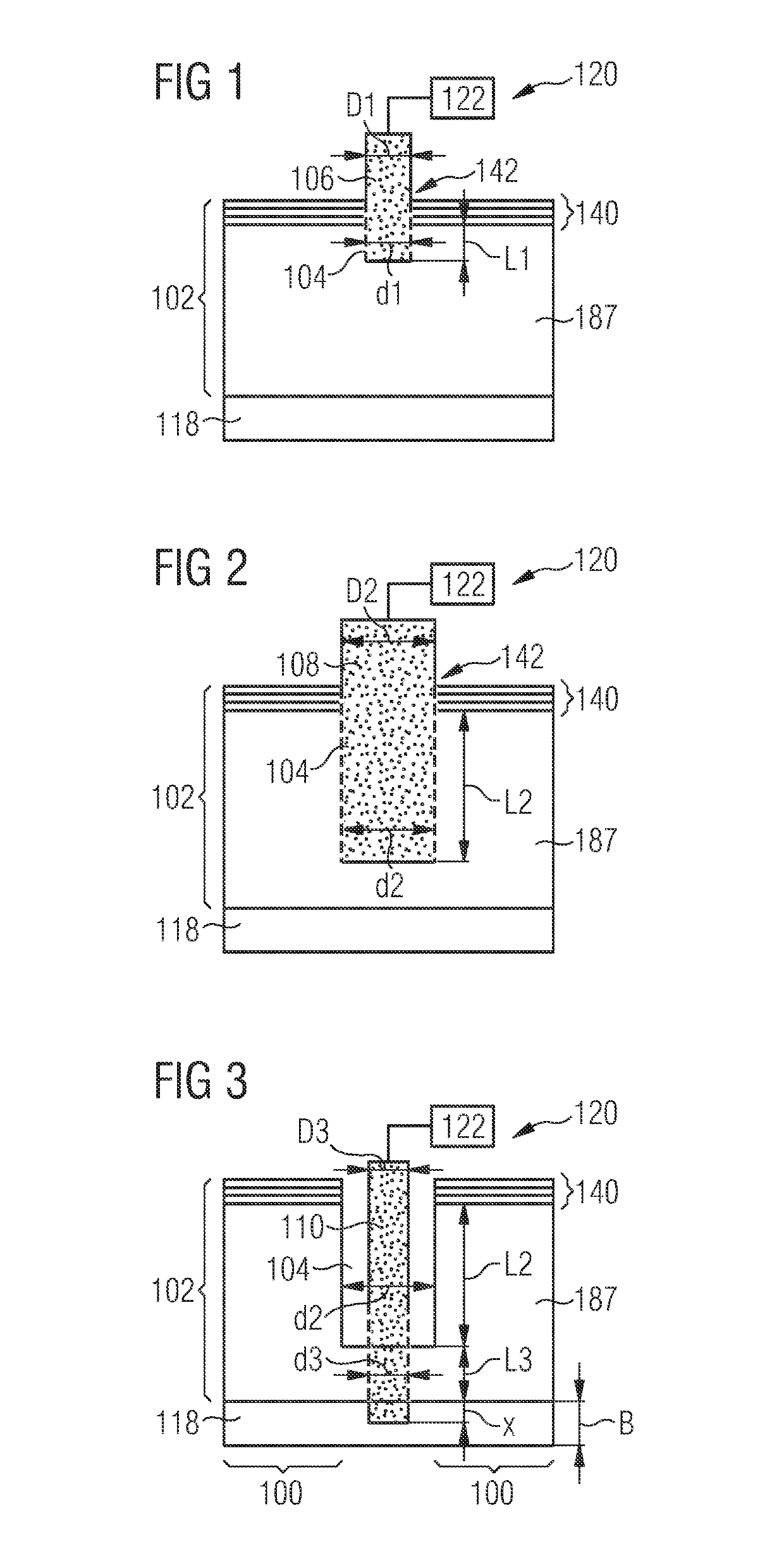

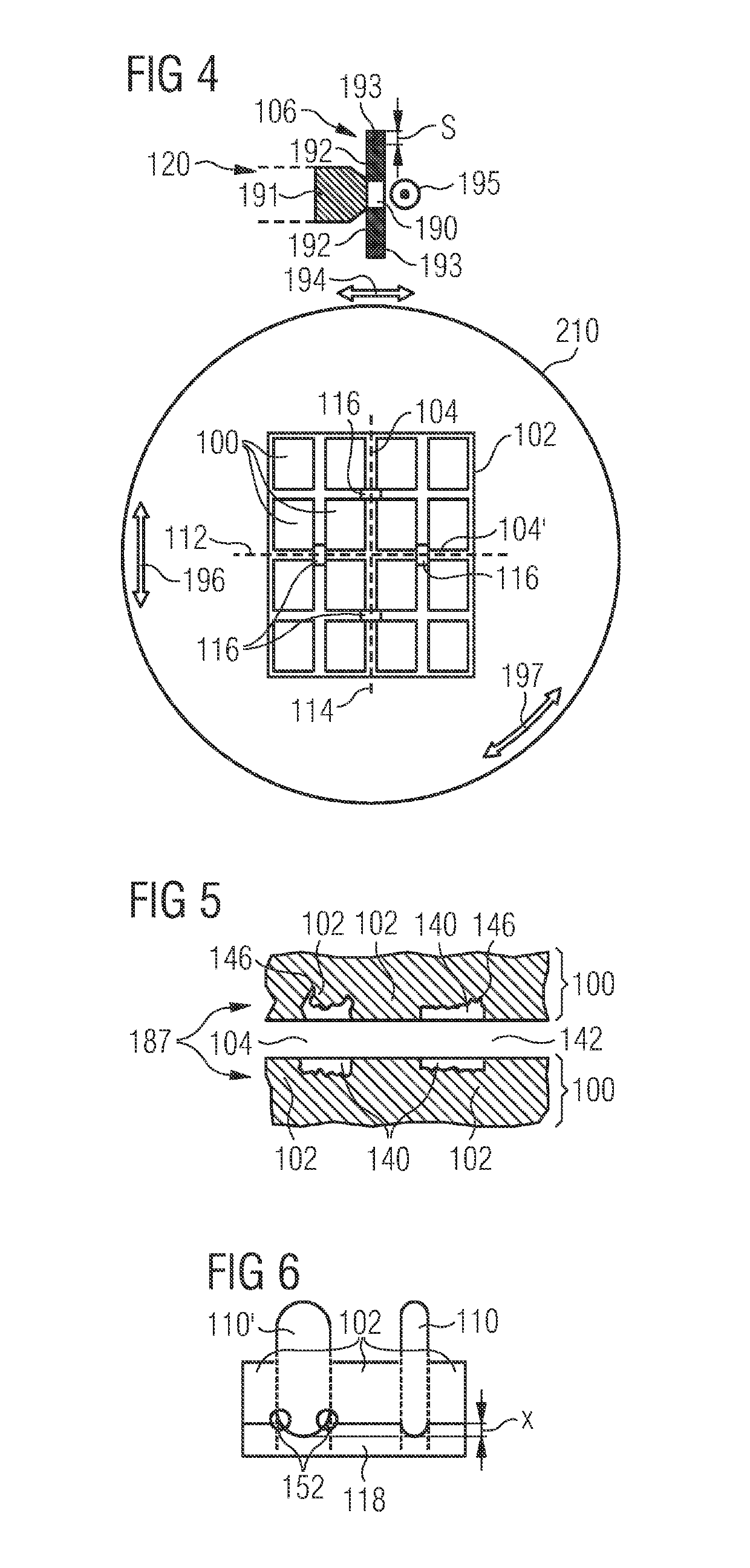

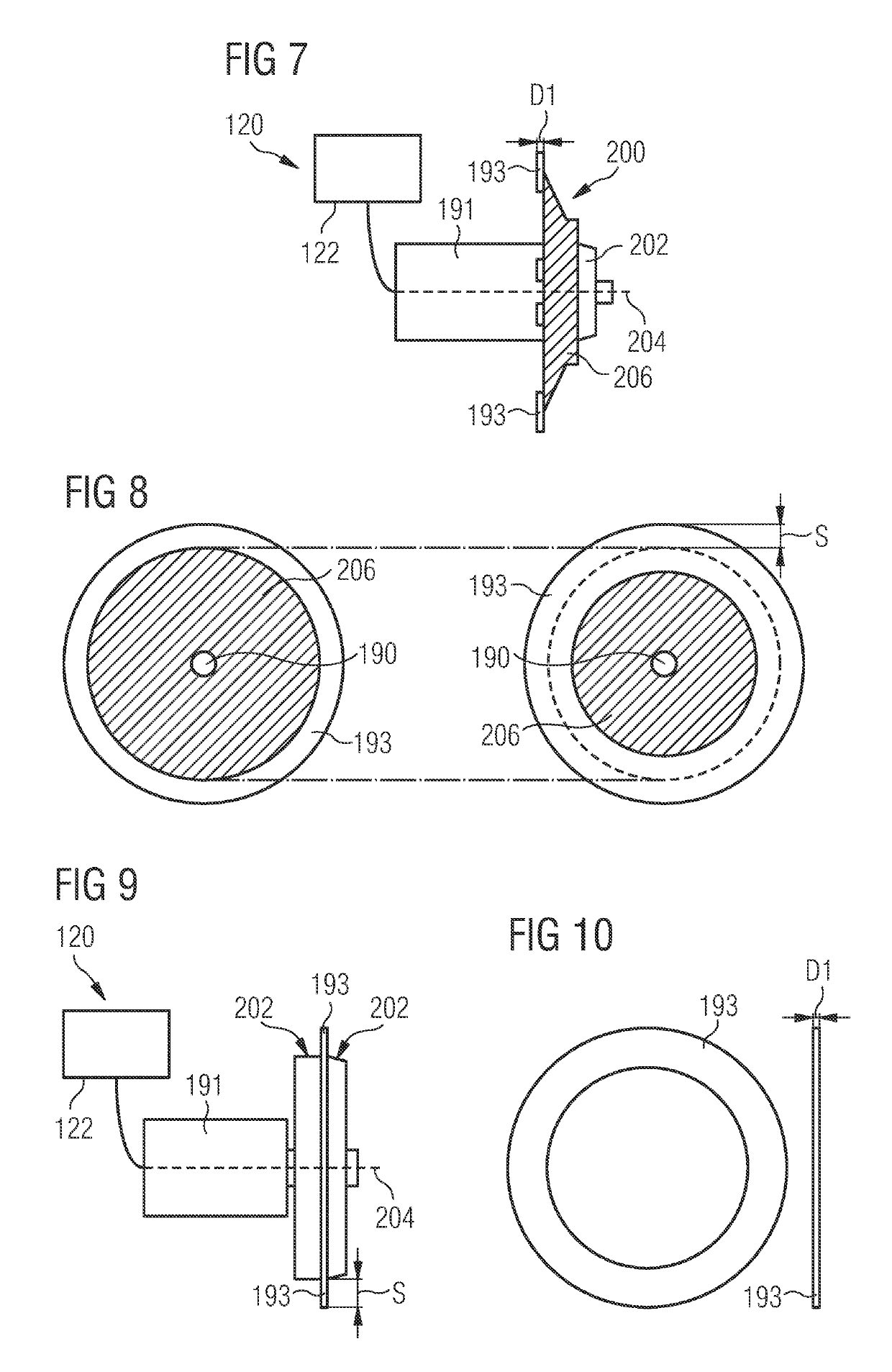

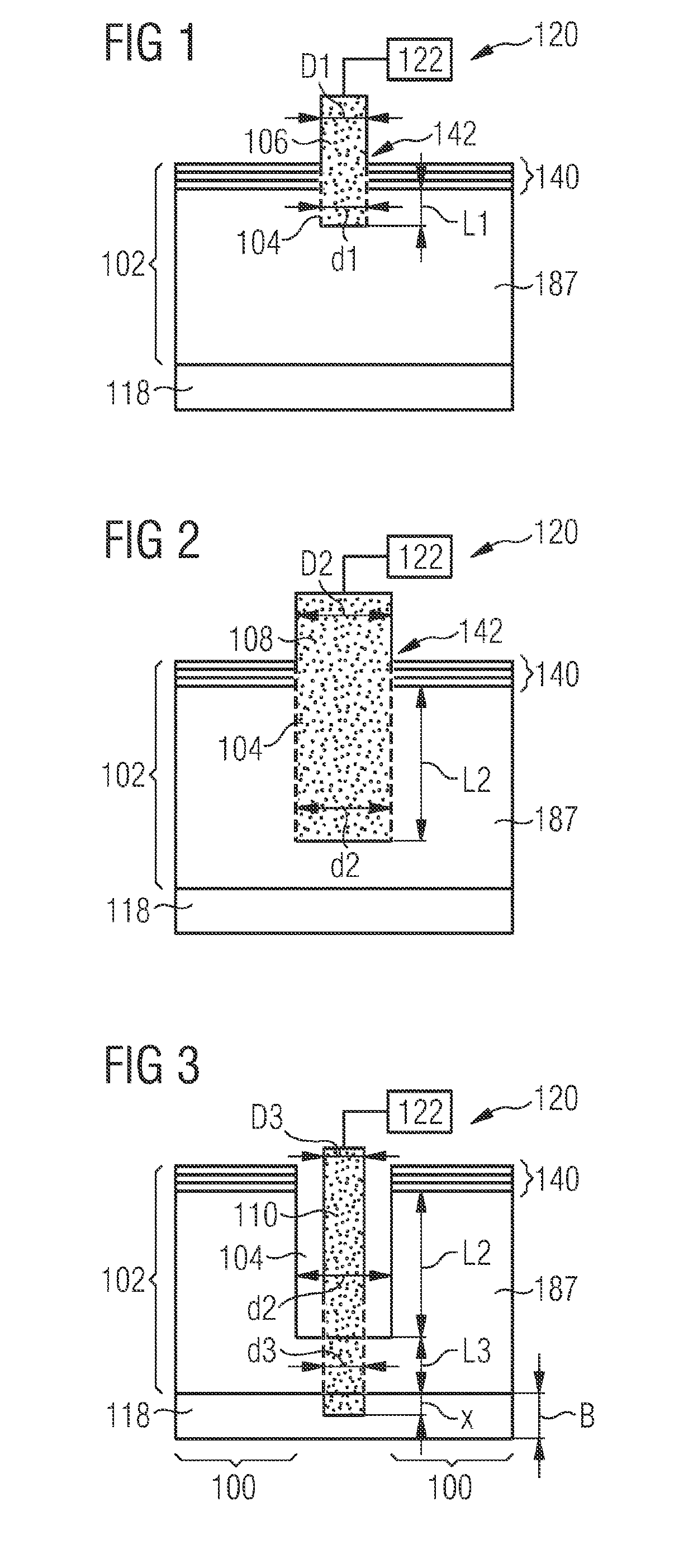

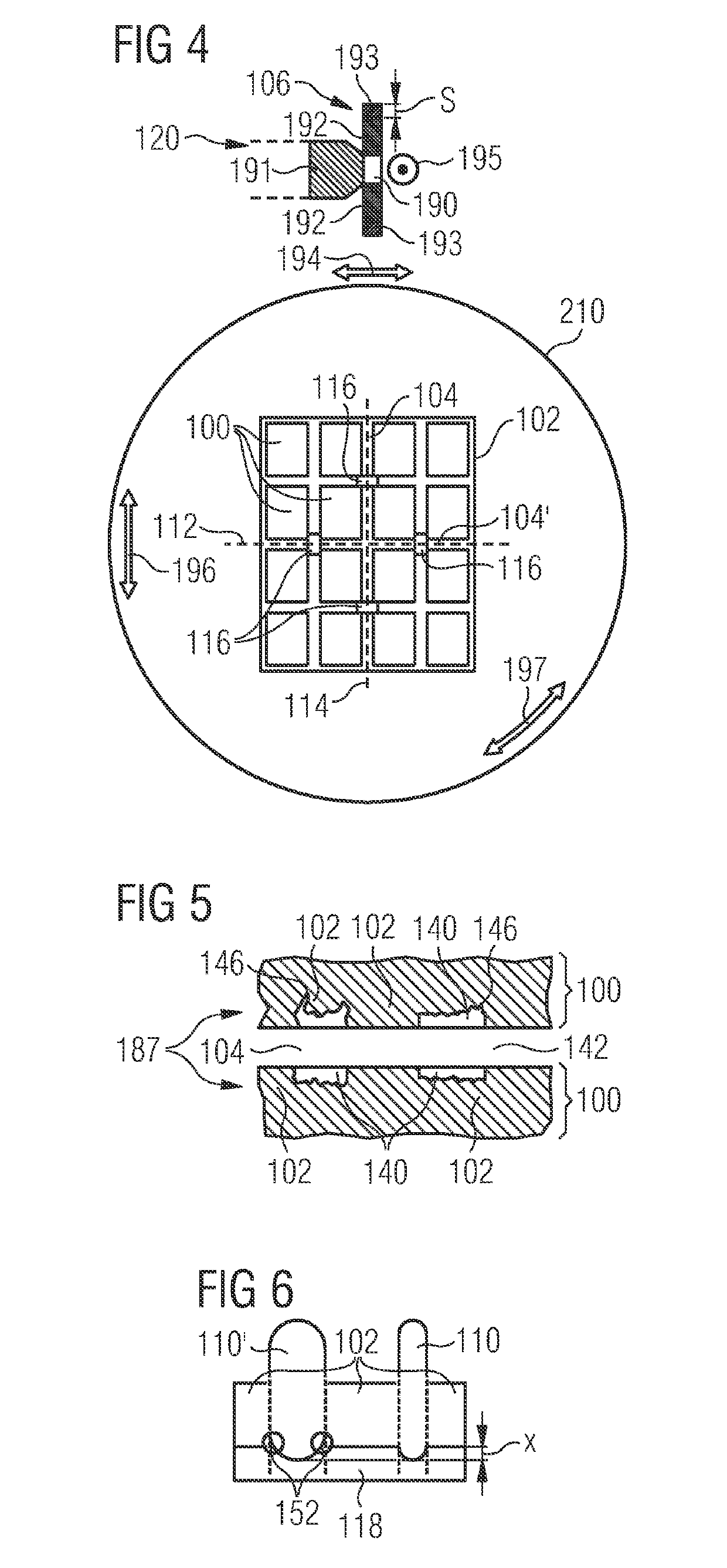

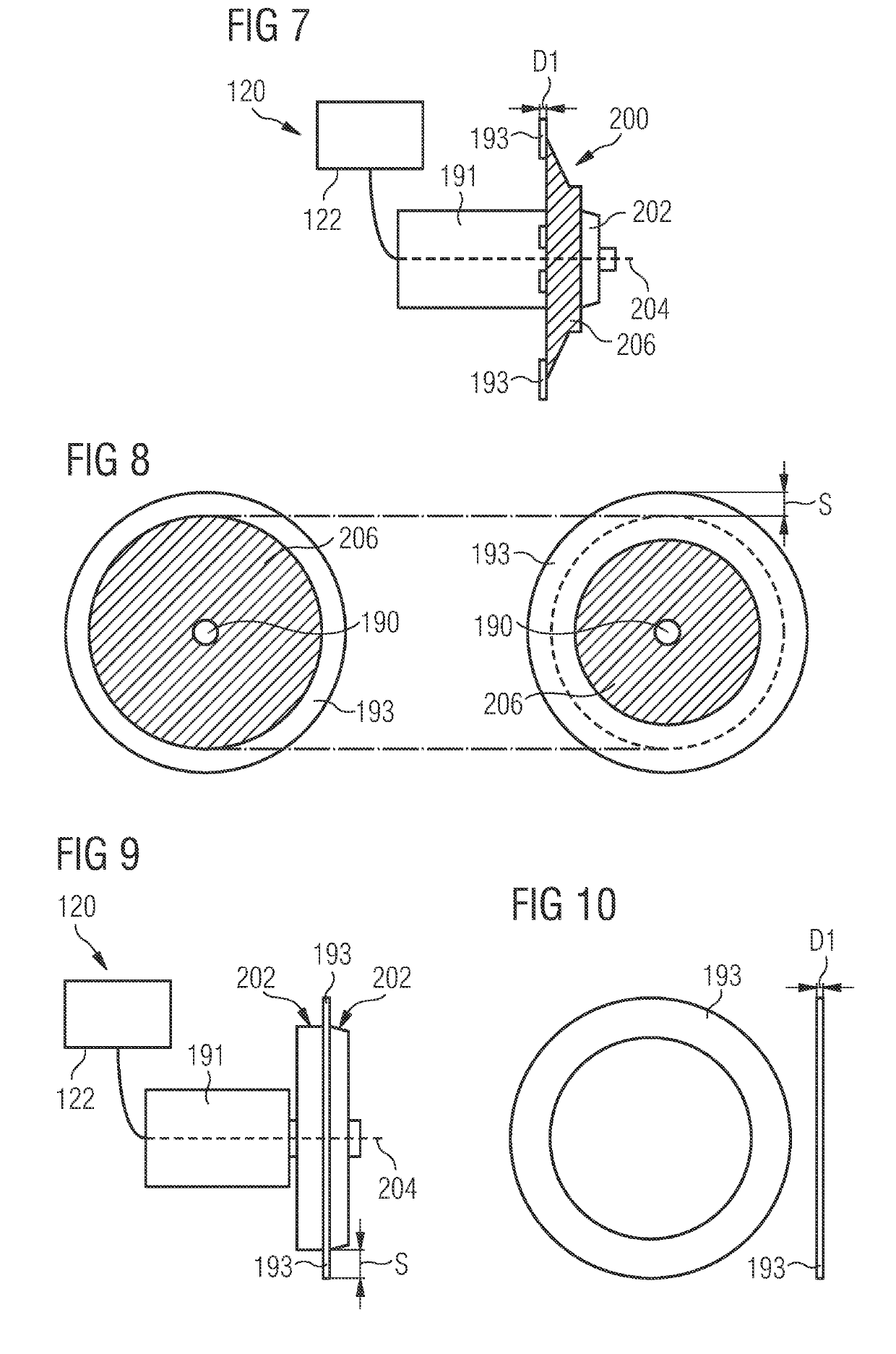

Separation of workpiece with three material removal stages

ActiveUS10403506B2Suppress undesired nose formationReduce cutting pressureSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMaterial removalEngineering

A method of manufacturing electronic dies by separating a wafer into electronic dies, wherein the method comprises forming a groove in the wafer with a first material removal tool having a first thickness, enlarging the groove by a second material removal tool having a second thickness larger than the first thickness, and subsequently increasing a depth of the groove by a third material removal tool having a third thickness smaller than the second thickness until the wafer is separated.

Owner:INFINEON TECH AG

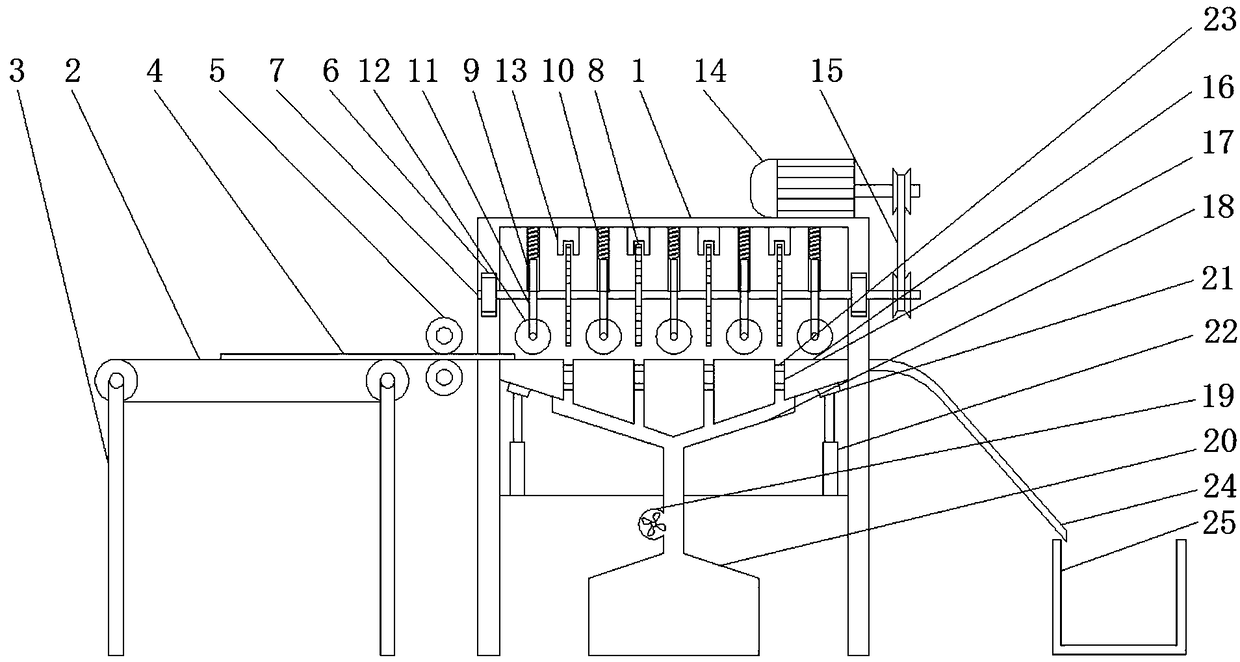

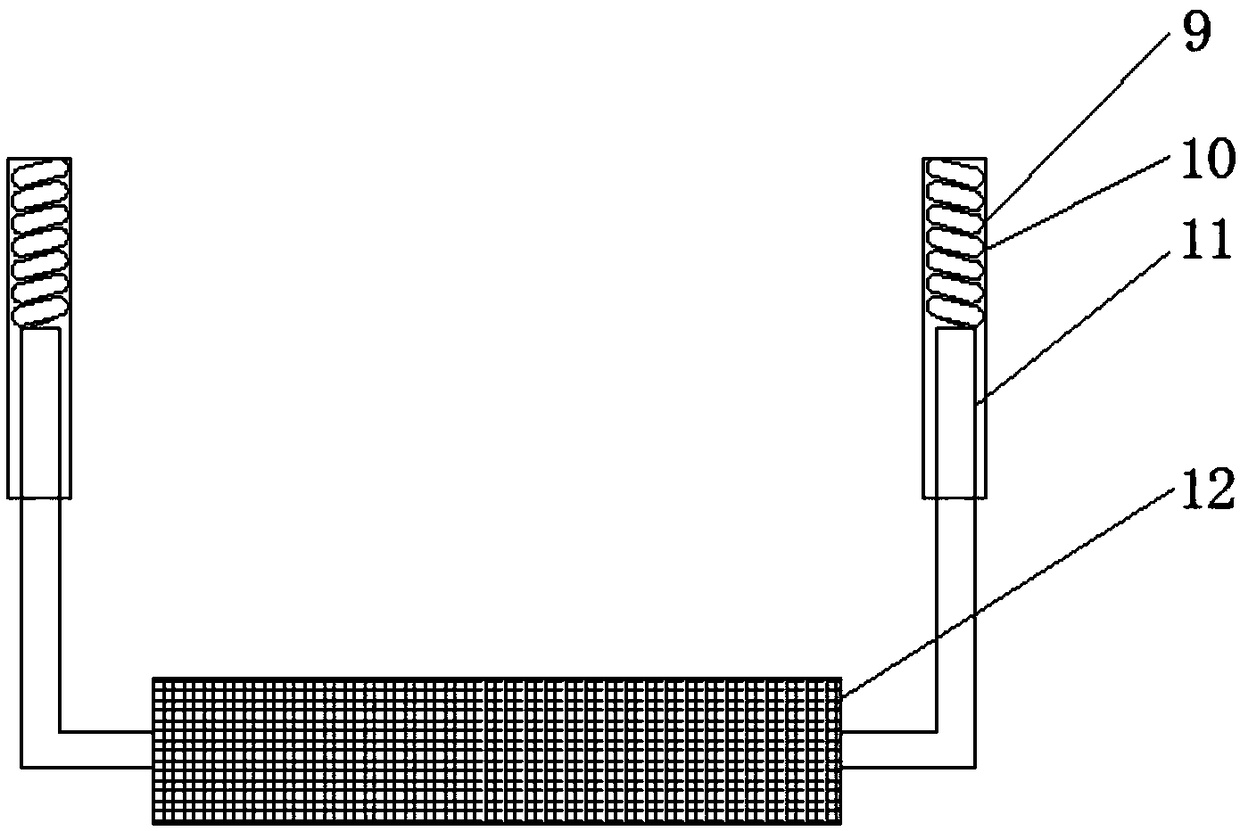

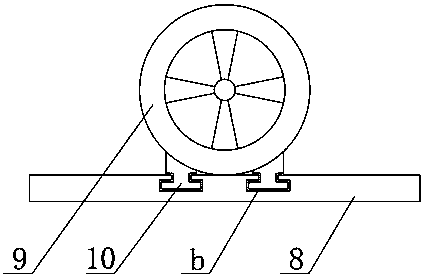

Briquetted straw feed cutting equipment

The invention relates to the technical field of feed processing, in particular to a straw briquette feed cutting equipment, comprising a box body, the right end surface of the box body is fixedly connected to a support plate, a second motor is arranged on the support plate, and the second The bottom end of the motor is fixedly connected with a slider, the upper end surface of the support plate is provided with a chute, the slider is slidably connected with the chute, the left end of the second motor is fixedly connected with a second rotating shaft, the second A blade is fixedly connected to the rotating shaft, a circular ring is arranged on the bottom end surface of the second motor, an eccentric cam is connected to rotate in the circular ring, and a third motor is fixedly connected to the top of the eccentric cam. In the present invention, by setting The second motor, the second rotating shaft, the blade, the third motor and the eccentric cam can cut the scattered feed back and forth. This setting cuts the feed more completely. This design is novel and has huge economical advantages. Benefits and broad market prospects, it is worth popularizing and using.

Owner:邛崃驰阳农牧科技有限公司

Separation of workpiece with three material removal stages

ActiveUS20190214299A1Suppress undesired nose formationReduce cutting pressureSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMaterial removalEngineering

A method of manufacturing electronic dies by separating a wafer into electronic dies, wherein the method comprises forming a groove in the wafer with a first material removal tool having a first thickness, enlarging the groove by a second material removal tool having a second thickness larger than the first thickness, and subsequently increasing a depth of the groove by a third material removal tool having a third thickness smaller than the second thickness until the wafer is separated.

Owner:INFINEON TECH AG

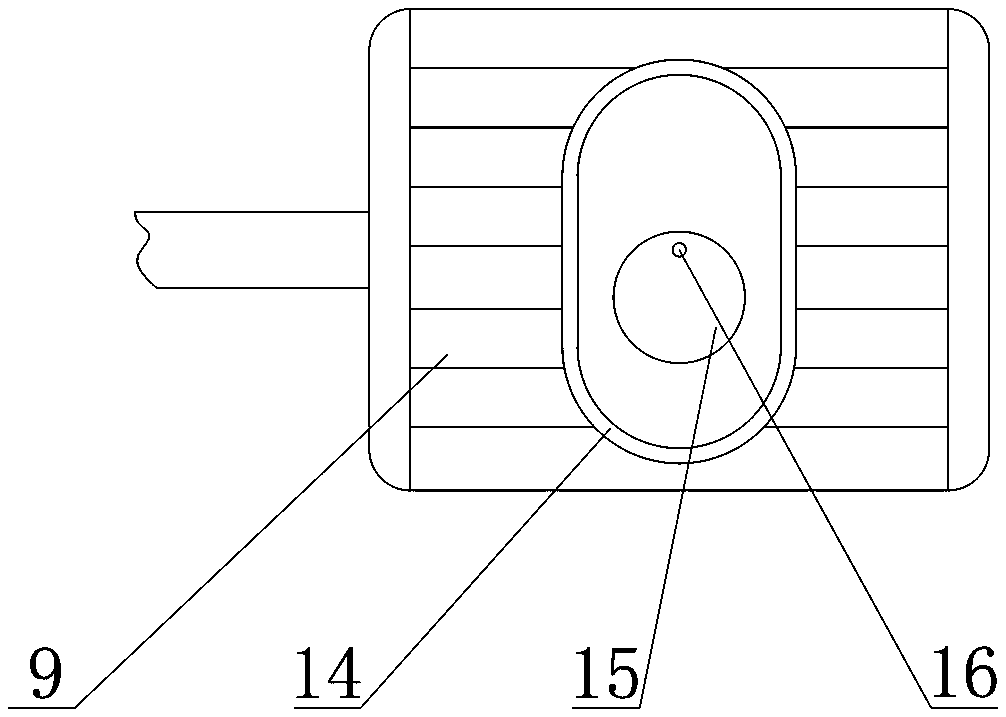

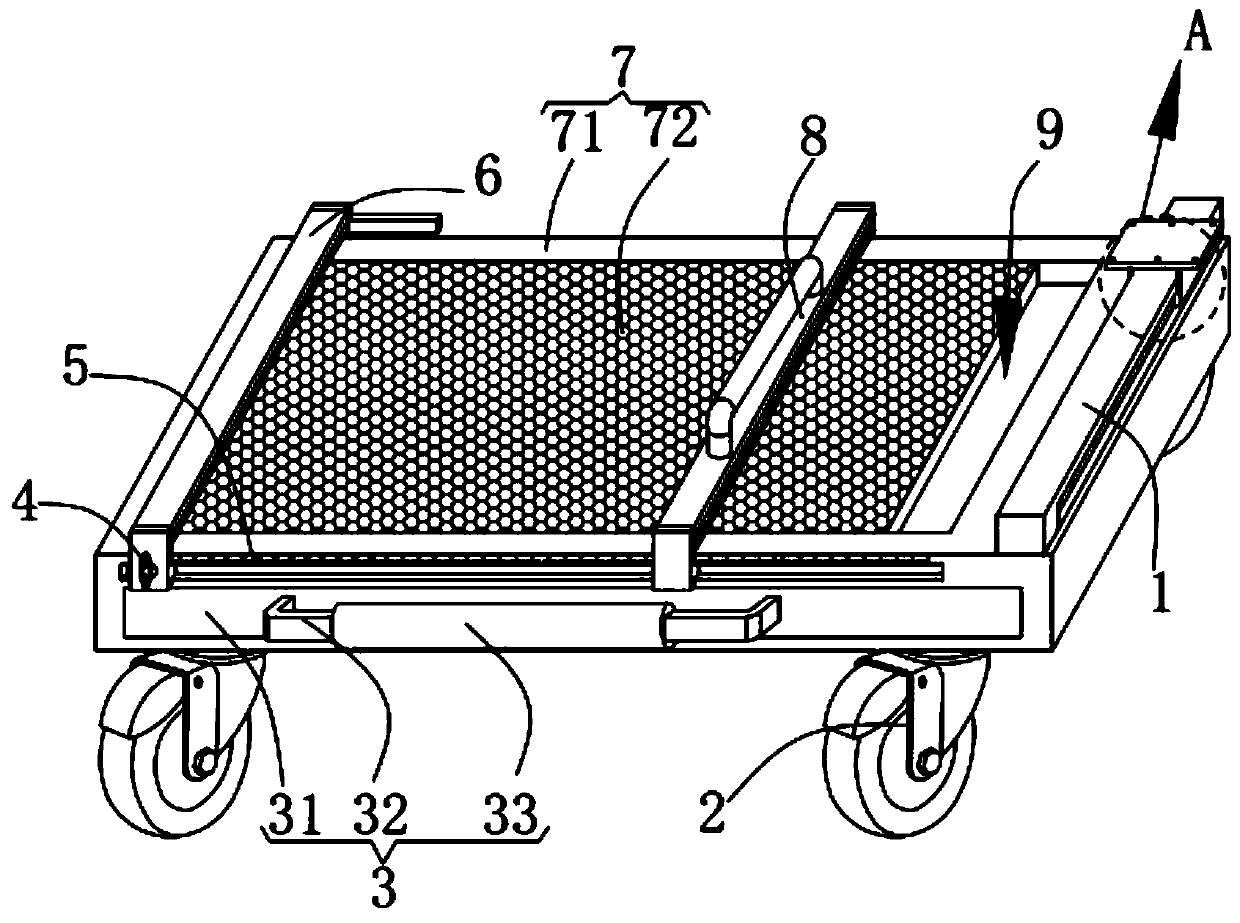

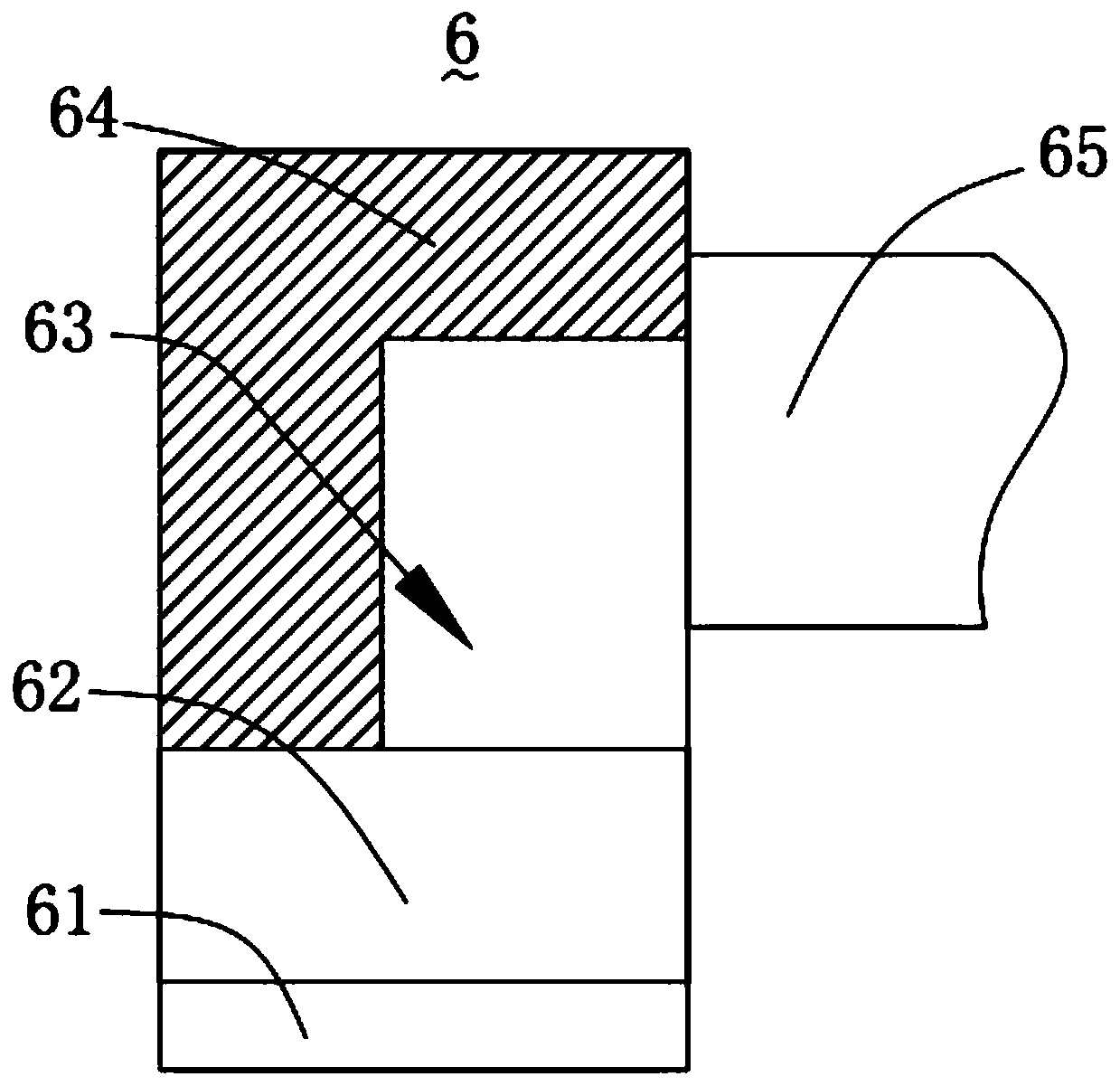

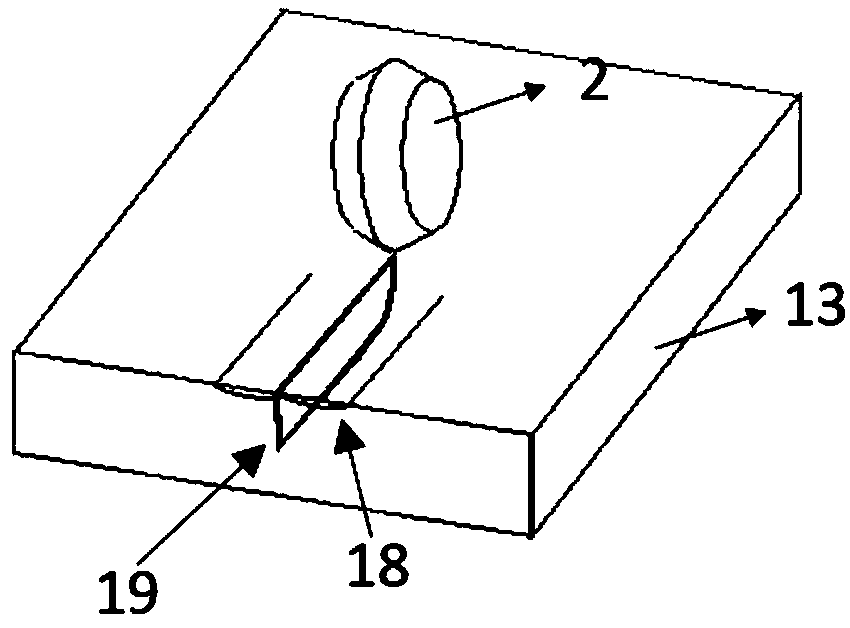

Auxiliary positioning device for ceramic tile cutting

ActiveCN108214943BPrecise positioningEasy to limitWorking accessoriesPositioning apparatusEngineeringMechanical engineering

The invention relates to the field of buildings, in particular to an auxiliary positioning device for ceramic tile cutting. The auxiliary positioning device comprises a translation structure, universal wheels, a dust collecting structure, a fixing structure, a scale strip, a limiting structure, a supporting structure, a driving structure and a cutting groove; the translation structure is used forfixing a cutting machine; the cutting groove is used for being coordinated with the cutting machine for cutting; the universal wheels are used for conveniently moving the device; the dust collecting structure is used for conveniently collecting cutting dust; the limiting structure and the driving structure are used for fixing a ceramic tile; and the scale strip is used for conveniently and visually measuring the length of the ceramic tile. According to the auxiliary positioning device, the limiting structure is coordinated with the driving structure so that the ceramic tile can be limited conveniently, and the cutting quality is improved; the position of the ceramic tile to be cut can be conveniently and visually measured by the use of the scale strip; the translation structure is used forconveniently fixing a cutting motor, so that sliding of the cutting motor is facilitated, cutting pressure of constructors is reduced, and the working efficiency is greatly improved; and the supporting structure is coordinated with the dust collecting structure, so that cut waste chips can be collected conveniently.

Owner:绍兴市侨陆智能科技有限公司

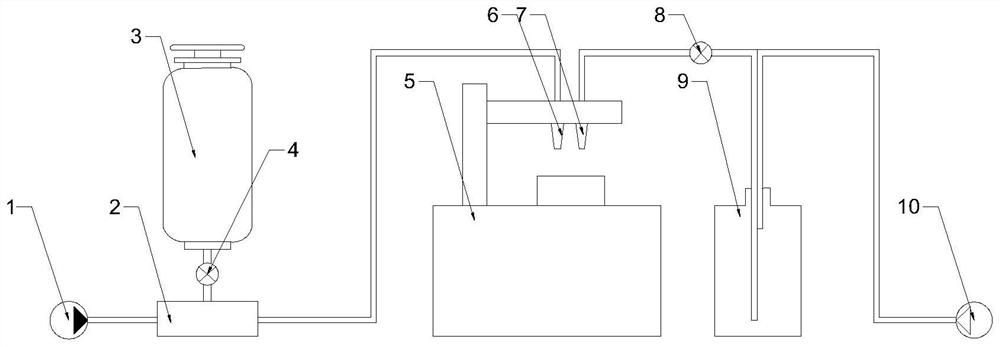

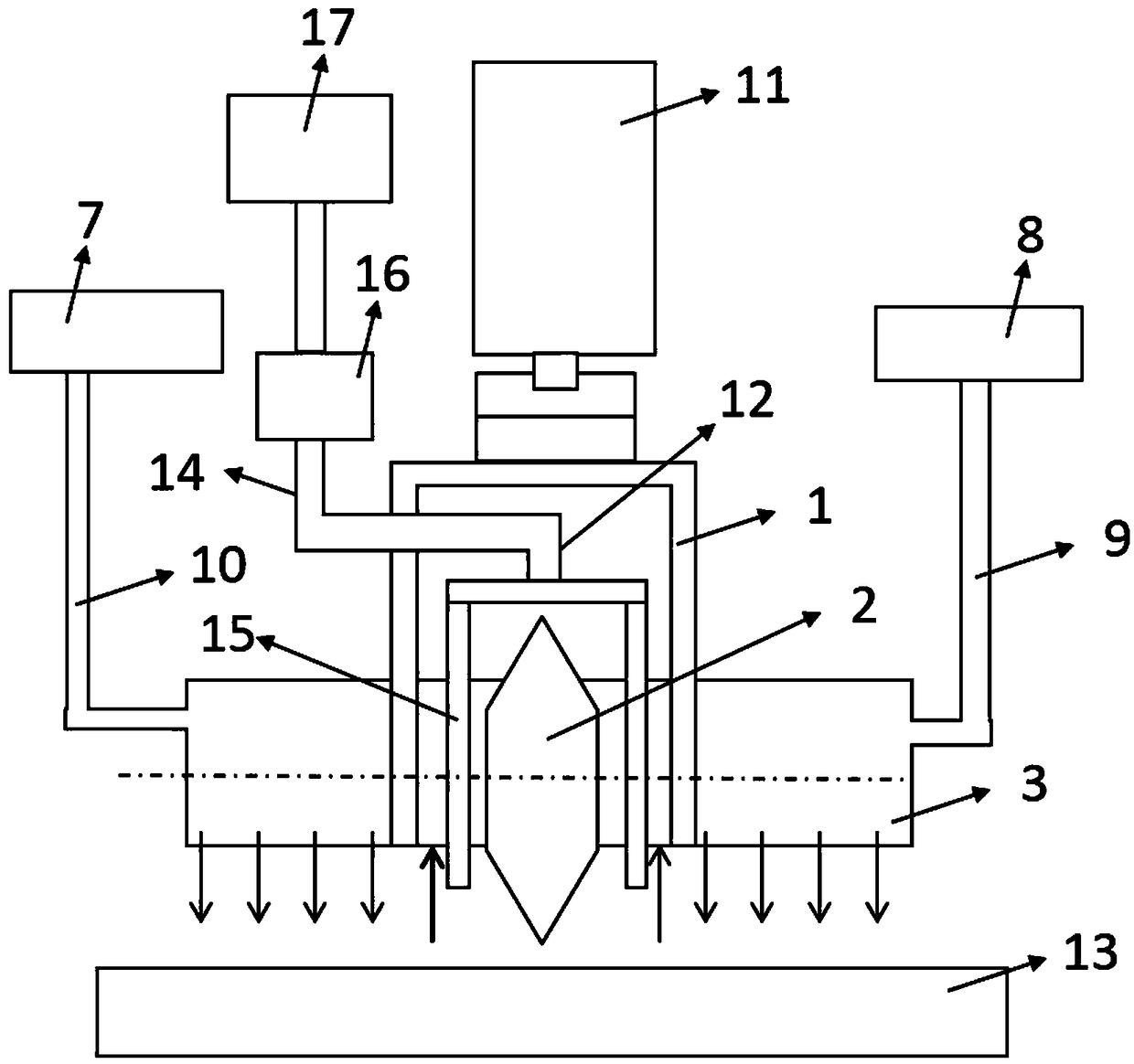

Low-temperature auxiliary pre-mixed abrasive water jet device and method

PendingCN114851084AReduce the temperatureReduce cutting pressureDomestic cooling apparatusLighting and heating apparatusAbrasive water jetWater jet

The invention provides a low-temperature auxiliary pre-mixed abrasive water jet device and method.The low-temperature auxiliary pre-mixed abrasive water jet device comprises a pre-mixed abrasive water jet device body and a low-temperature auxiliary device.The pre-mixed abrasive water jet device body is provided with a high-pressure water pump, a mixing cavity, an abrasive tank, a sand valve, a numerical control platform and a high-pressure water nozzle which are sequentially connected; the low-temperature auxiliary device is provided with a liquid nitrogen nozzle, an air valve, a liquid nitrogen tank and an air pump which are sequentially connected. According to the low-temperature-assisted pre-mixed abrasive water jet method, high-pressure abrasive water jet is sprayed out of water jet through a central pipeline and a high-pressure water nozzle, liquid nitrogen forms liquid nitrogen jet through a liquid nitrogen nozzle, the liquid nitrogen jet beats a target object in the front to form a low-temperature area, and the high-pressure water jet beats the low-temperature area in the rear, namely, the low-temperature-assisted pre-mixed abrasive water jet method is achieved. The low-temperature auxiliary device is additionally arranged on the pre-mixed abrasive water jet device, so that the temperature of abrasive water jet in the cutting process is reduced, the cutting pressure is reduced to a certain extent, and the surface cutting quality is improved.

Owner:ANHUI UNIV OF SCI & TECH

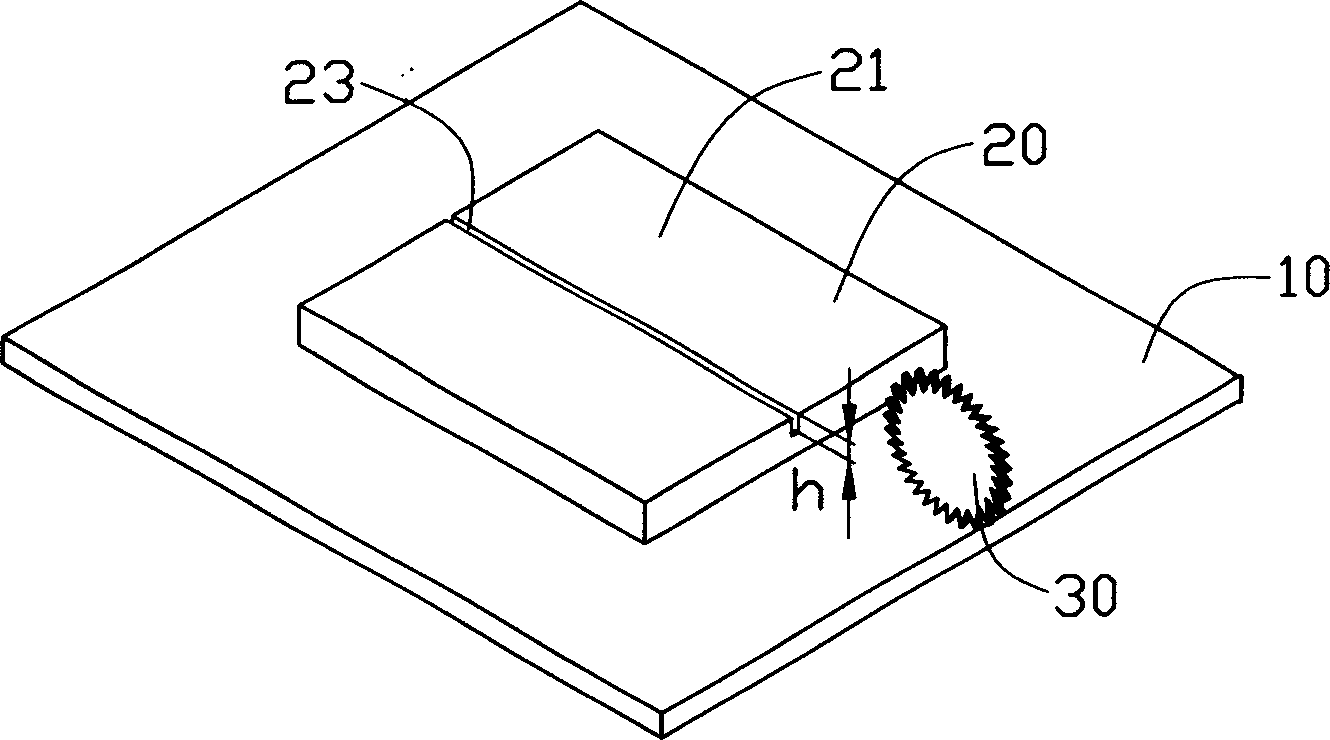

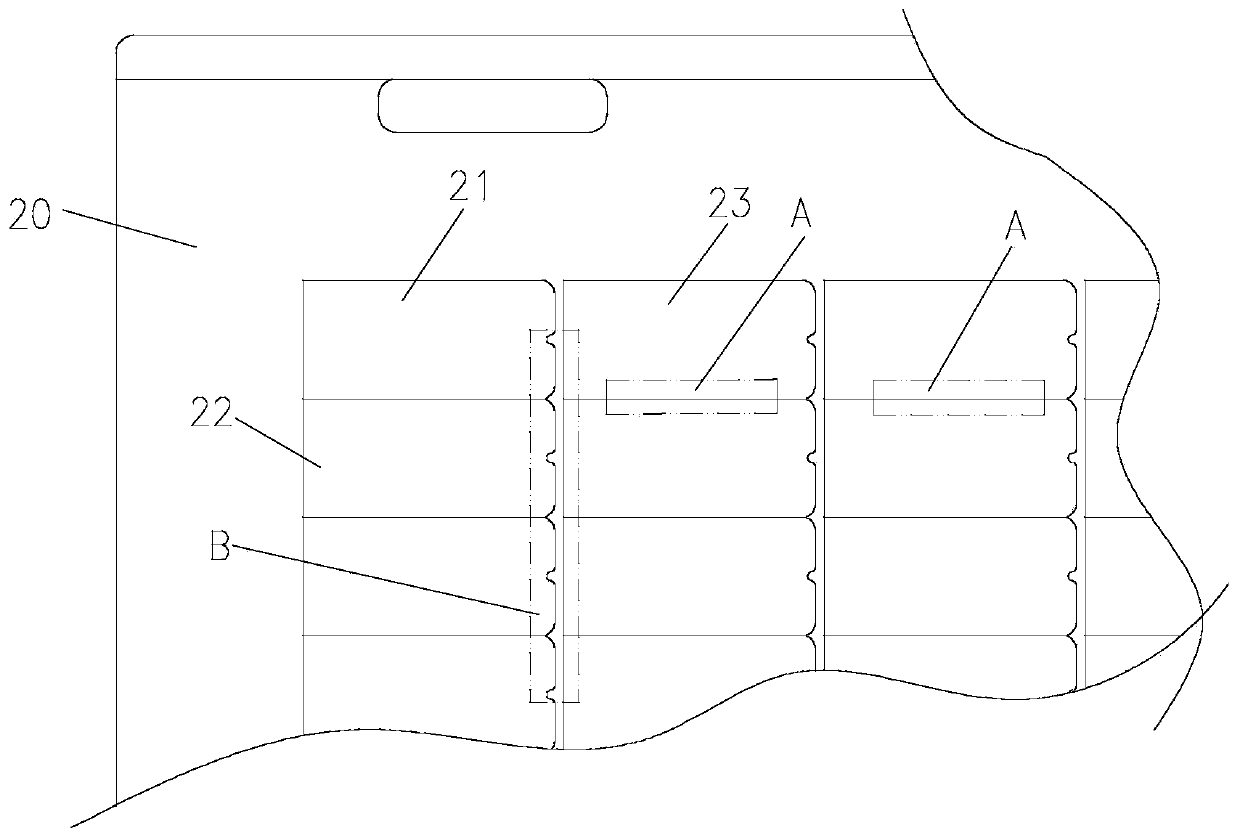

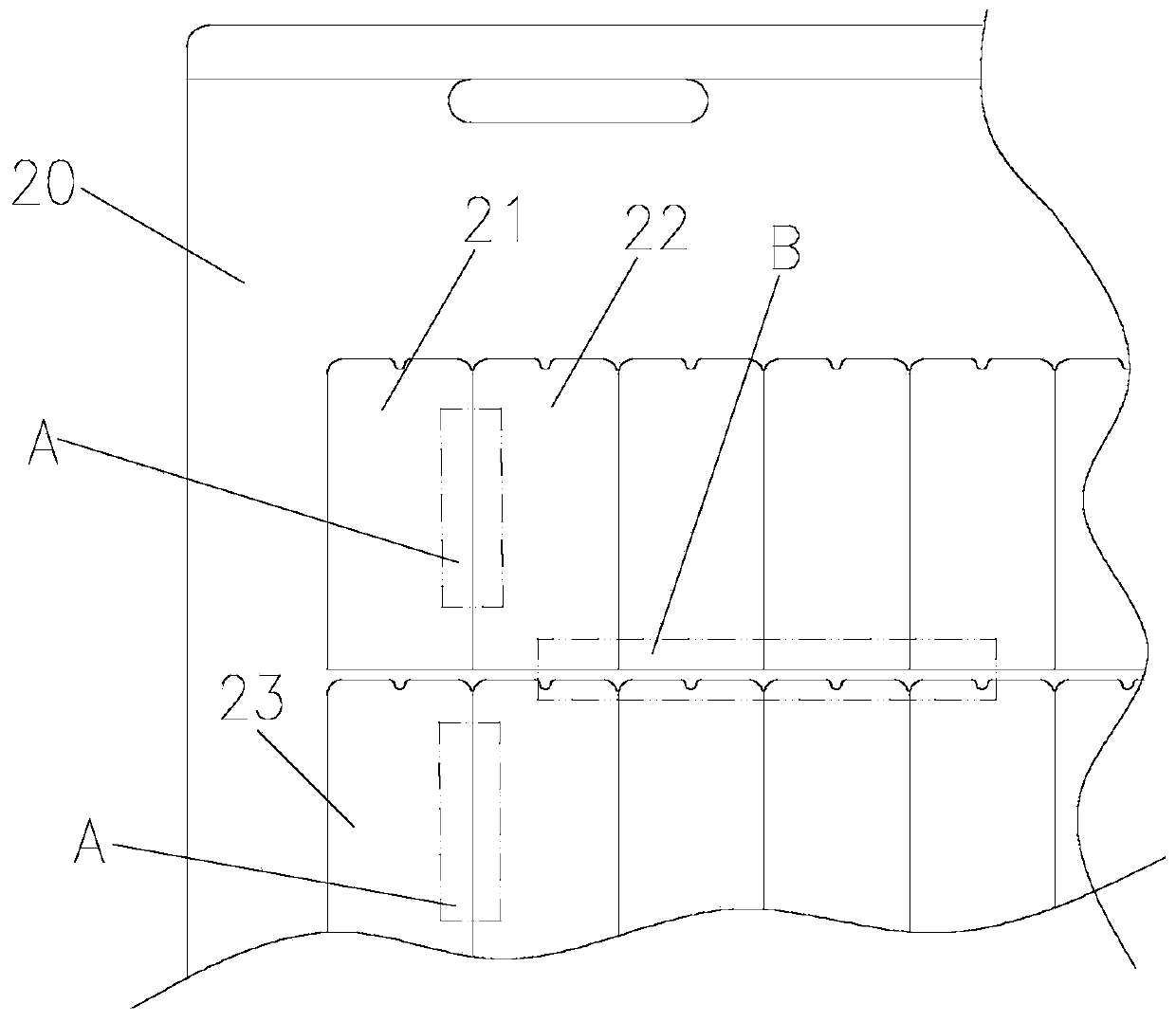

Base plate cutting cutter wheel device and base plate cutting method

The invention discloses a base plate cutting cutter wheel device. The base plate cutting cutter wheel device comprises a mounting frame and a cutter wheel arranged on the mounting frame, and furthermore comprises an air floating platform, wherein the air floating platform comprises a cutter wheel mounting groove and air holes formed in the periphery of the cutter wheel mounting groove; the cutterwheel is arranged in the cutter wheel mounting groove; when the cutter wheel is used for cutting a base plate through air flow formed by the air floating platform, a cutting position of the base platecan slightly protrude and the planeness problem of a cutting platform is solved, so that the cutting pressure is smaller and the abrasion of the cutter wheel is reduced; meanwhile, the airflow of theair floating platform can realize the effect of collecting dust and a bad condition that cutting fragments are splashed to cause foreign matters is prevented.

Owner:NANJING CEC PANDA LCD TECH

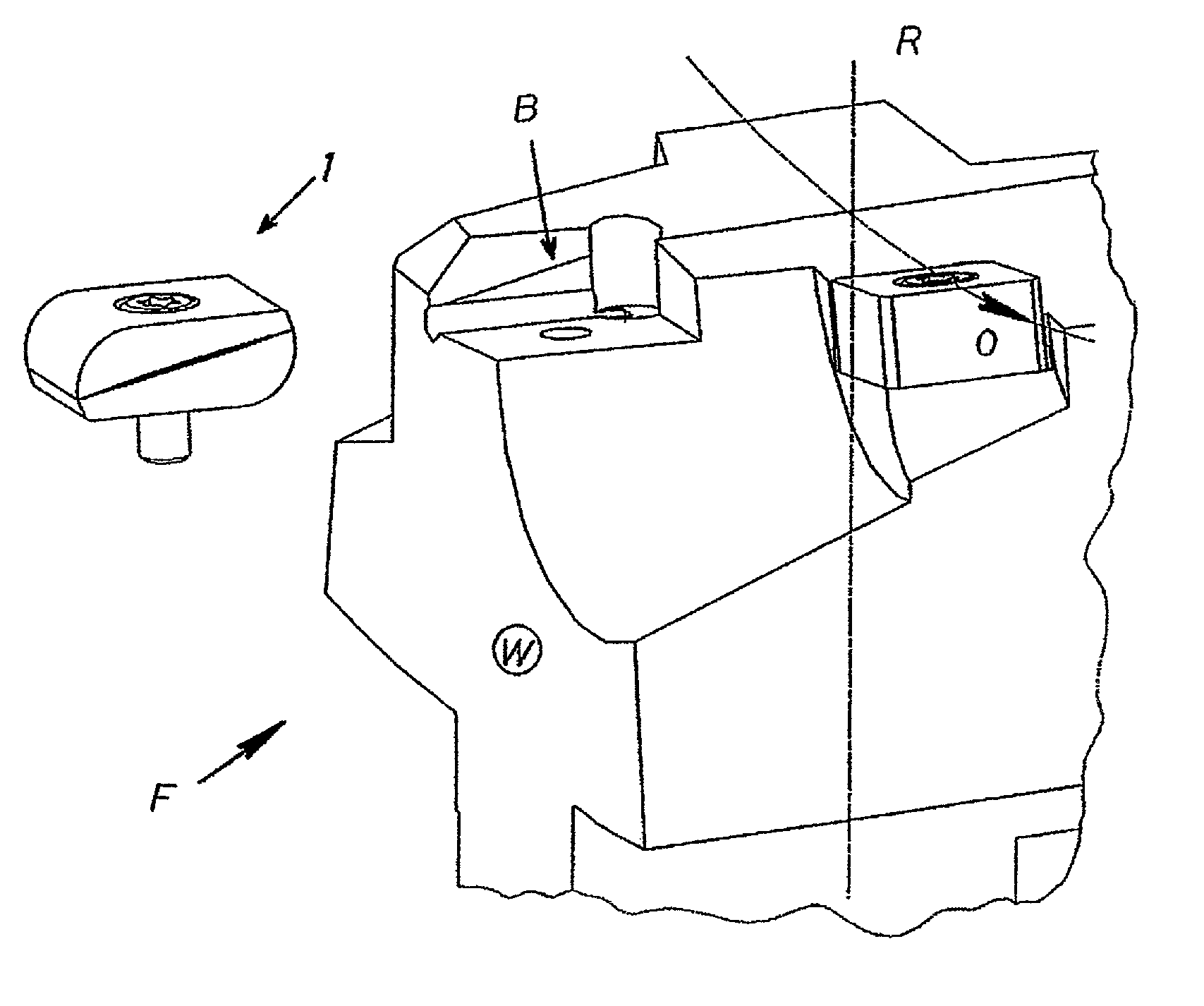

Multifunctional forming cutter of high-precision automobile condenser fixing flange liquid storage tank

PendingCN110238431AImprove surface roughnessReduce cutting pressureTransportation and packagingReaming toolsLiquid storage tankEngineering

The invention relates to the technical field of machining tools, in particular to a multifunctional forming cutter of a high-precision automobile condenser fixing flange liquid storage tank. The multifunctional forming cutter comprises a cutter base body, wherein a forming chamfer blade is arranged at the front end of the cutter base body, a transition cutter bar is arranged at the center of the front end of the cutter base body, a drill reaming cutting part is arranged at one end of the transition cutter bar, the drill reaming cutting part comprises a reamer part, a pre-drilling bit is arranged at the front end of the reamer part, and a reverse chamfer blade is arranged at the tail end of the reamer part. According to the multifunctional forming cutter of the high-precision automobile condenser fixing flange liquid storage tank, the pre-drilling bit positioned at the forefront end of a cutter is used for drilling so as to remove most of the allowance, so that the subsequent cutting pressure of the reamer part is relieved, the abrasion of the cutter of the reamer part is reduced, and the final machining quality of a reamed hole is guaranteed; and the drilling, the reaming, the reverse chamfering and the front high-precision hole surface forming can be completed only through one-time clamping and one cutter, being efficient and rapid.

Owner:CHANGZHOU TENGLONG AUTO PARTS CO LTD

Cutter wheel with cutting edge grooves

ActiveCN107555774AExpand the cutting rangeImprove cutting lifeGlass severing apparatusEngineeringStructural engineering

The invention relates to a cutter wheel with cutting edge grooves. The cutter wheel comprises two disks, the circumference of each disk outward extends to form a conical surface, the intersection lineof the two conical surfaces is formed into a cutting edge, the cutter wheel is provided with concave cutting tooth spaces along the cutting edge, and is provided with cutting edge grooves respectively corresponding to each cutting tooth space, each cutting edge groove is arranged around the cutting tooth space, and each cutting edge groove is circumferentially arranged around the cutting tooth space.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

Suspended abrasive water jet cutting equipment

InactiveCN104175230BIncrease flexibilityLong conveying distanceAbrasive machine appurtenancesAbrasive blasting machinesEngineeringHigh pressure water

The present invention relates to a 7-axis intelligent robot suspended abrasive water jet 3D cutting equipment, specifically a suspended abrasive water jet cutting equipment, including a high-pressure pump station for providing cutting power, an abrasive filling device and a suspended abrasive for producing abrasives Generating device, the discharge port of the abrasive filling device is connected to the feed port of the high-pressure container built in the suspended abrasive generating device through the feed pipe, and the water inlet of the abrasive filling device is connected to the high-pressure container built in the suspended abrasive generating device through the water inlet pipe. The water outlets are connected; the high-pressure water generated by the high-pressure pump station is connected with the built-in tee of the suspended abrasive generating device through a high-pressure pipe. The product of the present invention adopts the pre-mixing suspension abrasive cutting technology, which has low cutting pressure and high efficiency; the present invention uses a high-pressure hose as the suspension abrasive transportation pipeline, and the transportation distance is long, ensuring that the nozzle device can realize arbitrary cutting in space under the drive of the robot actuator. Trajectory, high-precision movement at any angle.

Owner:西安远诚机电科技有限公司

Electrode graphite milling cutters and end mills for machining oxide ceramics

ActiveCN108367367BReduce cutting pressureTransportation and packagingMilling cuttersOxide ceramicTool bit

The invention relates to an electrode graphite end mill comprising a ball head (9), at least one roughing land (6, 8) and at least one finishing land (5, 7). Each roughing land (6, 8) is formed as a peripheral side file comprising a plurality of teeth (10, 11); each finishing land (5, 7) has a plurality of teeth extending helically around the tool axis Peripheral grooves, wherein the peripheral grooves space apart peripheral lands respectively having peripheral cutting edges (12, 13), machining the first set (5, 6) of the lands (5, 6, 7, 8) , 8) than the working area of the second group (7) of the machining lands (5, 6, 7, 8) extends farther towards the tool head.

Owner:HUFSCHMIED ZERSPANUNGSSYST

Waste recycling and crushing device for mechanical parts processing

The invention relates to the technical field of mechanical processing, in particular to a waste recycling and crushing device for mechanical parts processing, which includes a grinding outer ring, a cutting inner ring, an elastic member, and an adjustment rod. The grinding outer ring is hinged around a vertical axis by an even number of outer ring pieces Enclosed; the cutting inner ring is located in the grinding outer ring, and is formed by hinged and enclosed by a plurality of inner ring pieces equal to the outer ring piece around the vertical axis; the elastic member includes an upper ring, a lower fixed ring, a spiral The elastic bar, the cylindrical structure enclosed by the spiral elastic bar defines the grinding cavity with the grinding outer ring, and defines the cutting cavity with the cutting inner ring; the two ends of the adjusting rod are respectively hinged at a hinge position of the outer ring piece and a hinged position of the inner ring piece; the hinged position of the cutting inner ring is changed by squeezing the waste, and then the hinged position of the grinding outer ring is changed through the adjustment rod, which increases the area of the grinding chamber and reduces the grinding resistance of the grinding chamber, so that The power of the device is more distributed to the cutting chamber, which accelerates the cutting of waste in the cutting chamber.

Owner:南通海隆磁业有限公司

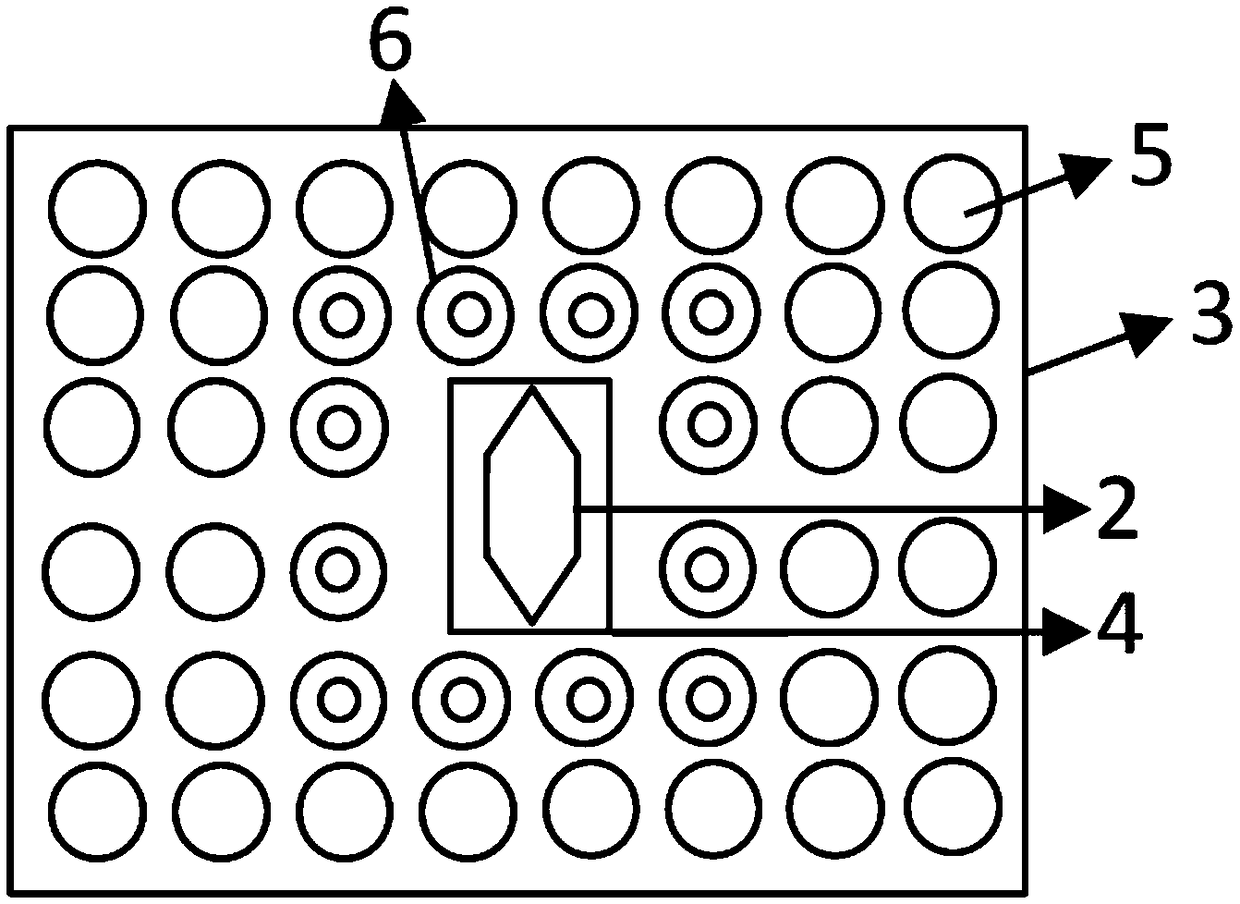

Special-shaped cutter mold and preparation method thereof

The invention discloses a special-shaped cutter mold and a preparation method thereof. The special-shaped cutter mold comprises a cutter mold base body, mold cavities and blades; the mold cavities arearranged on the cutter mold base body; two adjacent mold cavities of the same row or column are marked as a first mold cavity and a second mold cavities correspondingly, wherein the first mold cavitycomprises a first linear mold cavity and a first non-linear mold cavity, the second mold cavity comprises a second linear mold cavity and a second non-linear mold cavity, the first linear mold cavityand the second linear mold cavity are overlapped, and the first non-linear mold cavity is connected to the second non-linear mold cavity left and right; the two opposite mold cavities of different rows or columns are marked as a first mold cavity and a third mold cavity correspondingly, wherein the third mold cavity comprises a third linear mold cavity and a third non-linear mold cavity, and a gap is formed between the first linear mold cavity and the third non-linear mold cavity; and the blades are arranged in the mold cavities. According to the special-shaped cutter mold, the common cutterdesign is adopted among the mold cavities, so that the use quantity of the blades is greatly reduced, then the manufacturing cost of the cutter mold is reduced, the number of the blades is reduced, the cutting pressure is correspondingly reduced, and the product reject ratio is reduced.

Owner:SHENZHEN SUNNYPOL OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com