Suspended abrasive water jet cutting equipment

An abrasive water jet and abrasive technology, which is applied in the direction of abrasive jet machine tools, abrasives, and used abrasive processing devices, etc., can solve the problems that the post-mixing technology abrasives are difficult to reach the nozzle, affect the flexibility of the robot, and cannot reach the cutting point, etc. , to achieve the effect of high hardness, low efficiency and low cutting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

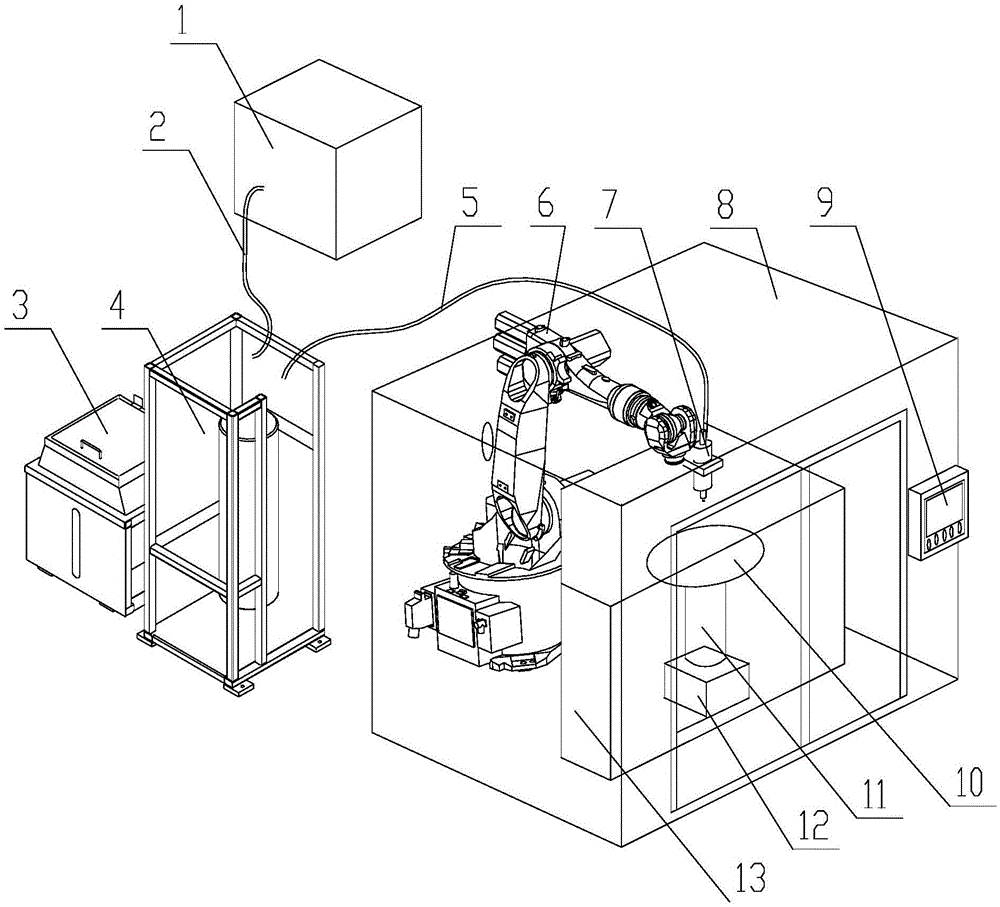

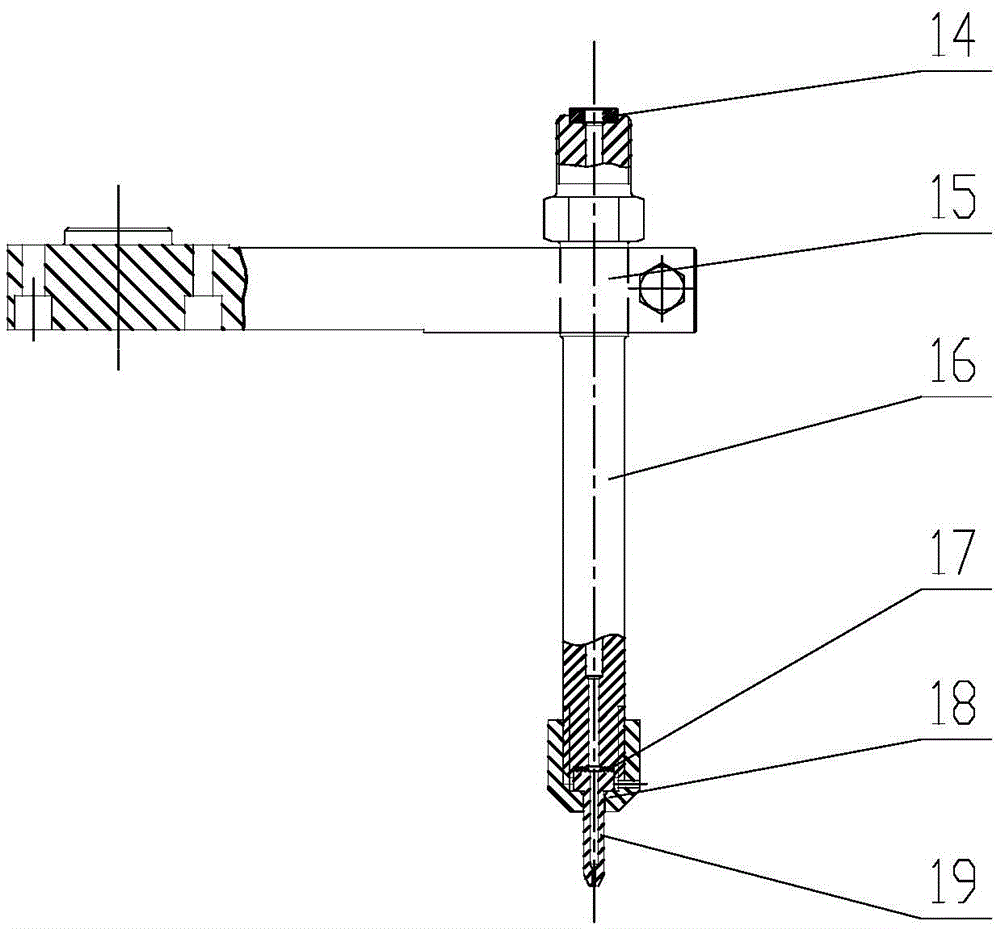

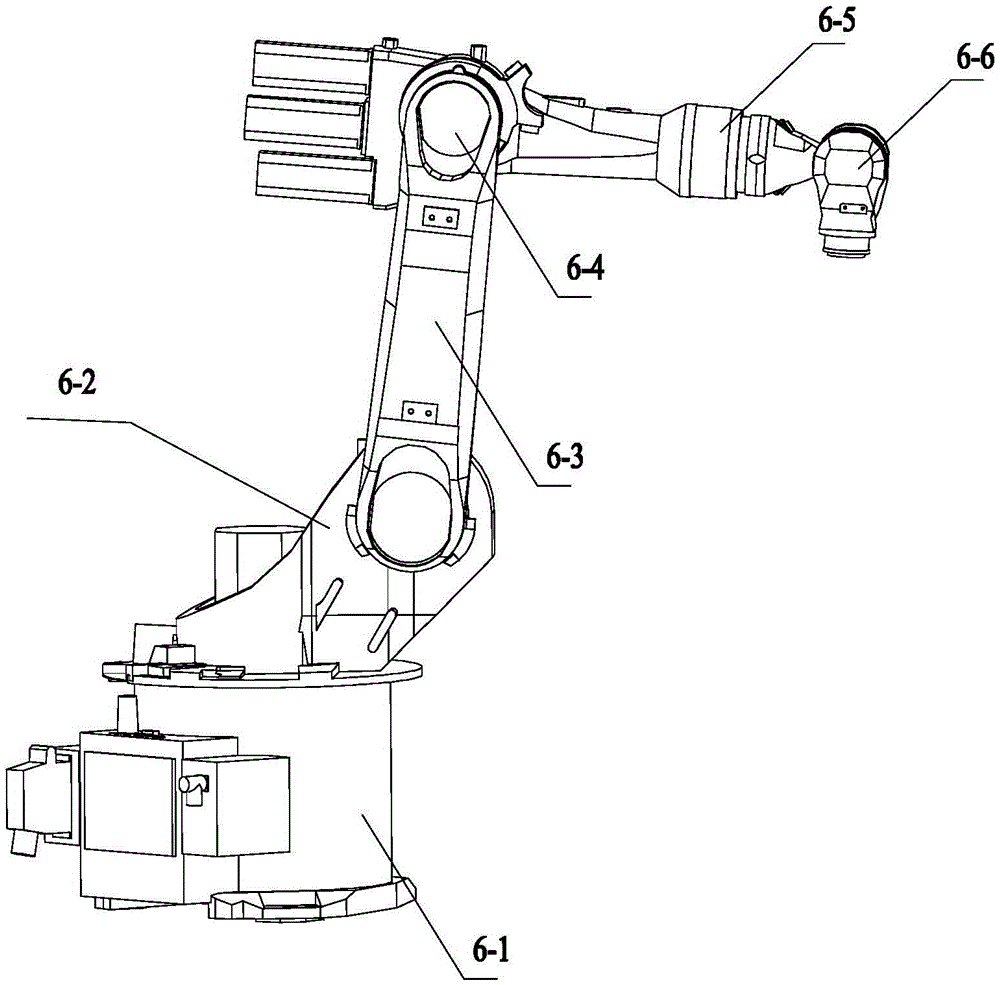

[0022] Figure 1~4 Among them, including high-pressure pump station 1, high-pressure pipe 2, abrasive filling device 3, suspended abrasive generating device 4, suspended abrasive conveying pipe 5, robot actuator 6, nozzle device 7, shield 8, operation panel 9, workbench 10, Rotary shaft 11, servo motor 12, working water tank 13, first gasket 14, nozzle bracket 15, nozzle body 16, second gasket 17, compression nut 18, nozzle 19, three-piston pump 20, safety valve 21 , frequency conversion regulator 22, pressure gauge 23, high-pressure check valve 24, throttle valve 25, manual unloading valve 26, injection valve 27, first air-controlled high-pressure valve 28, second air-controlled high-pressure valve 29, high-pressure container 30. Sand guide nut 31, third air-controlled high-pressure valve 32, load cell 33, fourth air-controlled high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com