Auxiliary positioning device for ceramic tile cutting

An auxiliary positioning and ceramic tile technology, applied in positioning devices, manufacturing tools, working accessories, etc., can solve problems such as low work efficiency, tile damage, and inconvenient garbage disposal, so as to reduce cutting pressure, improve environmental quality, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

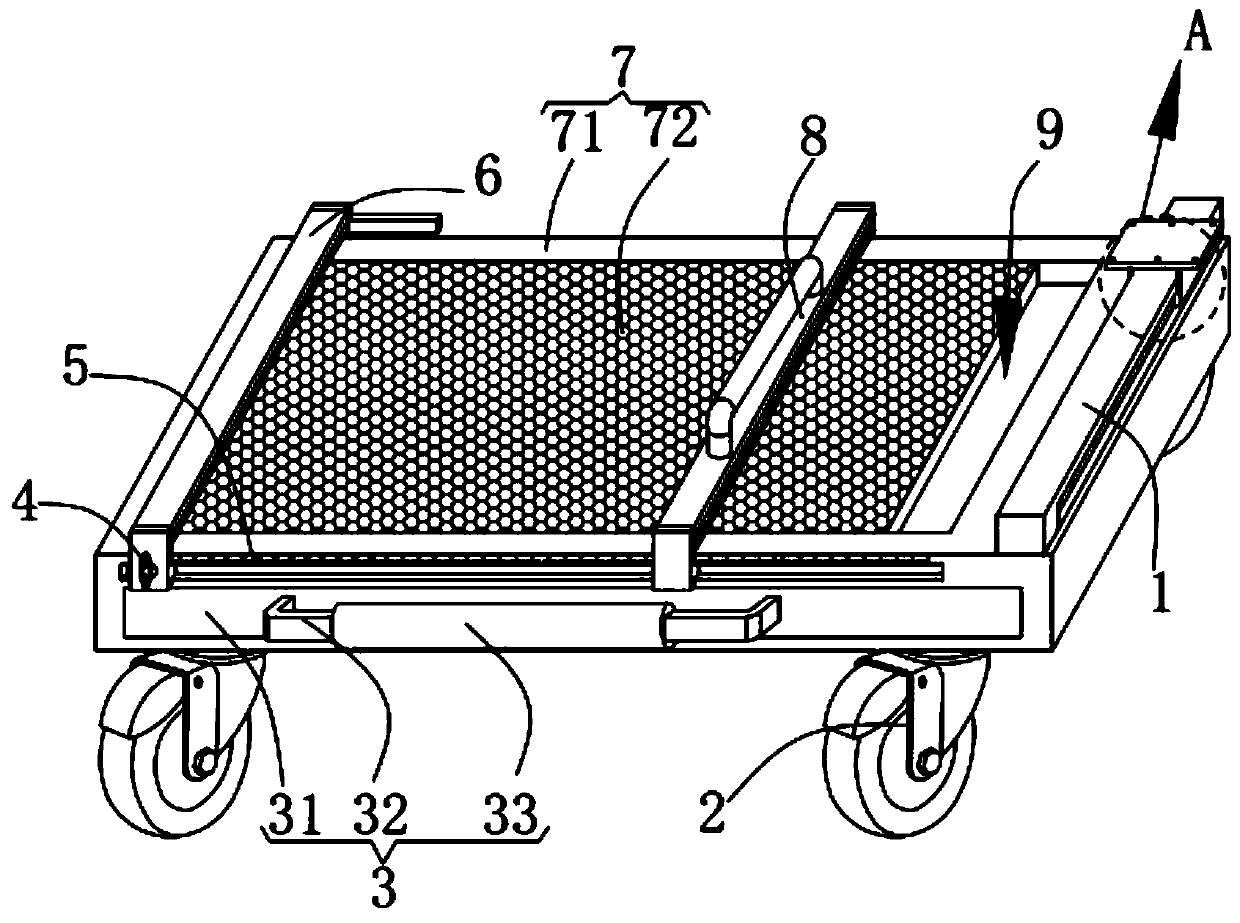

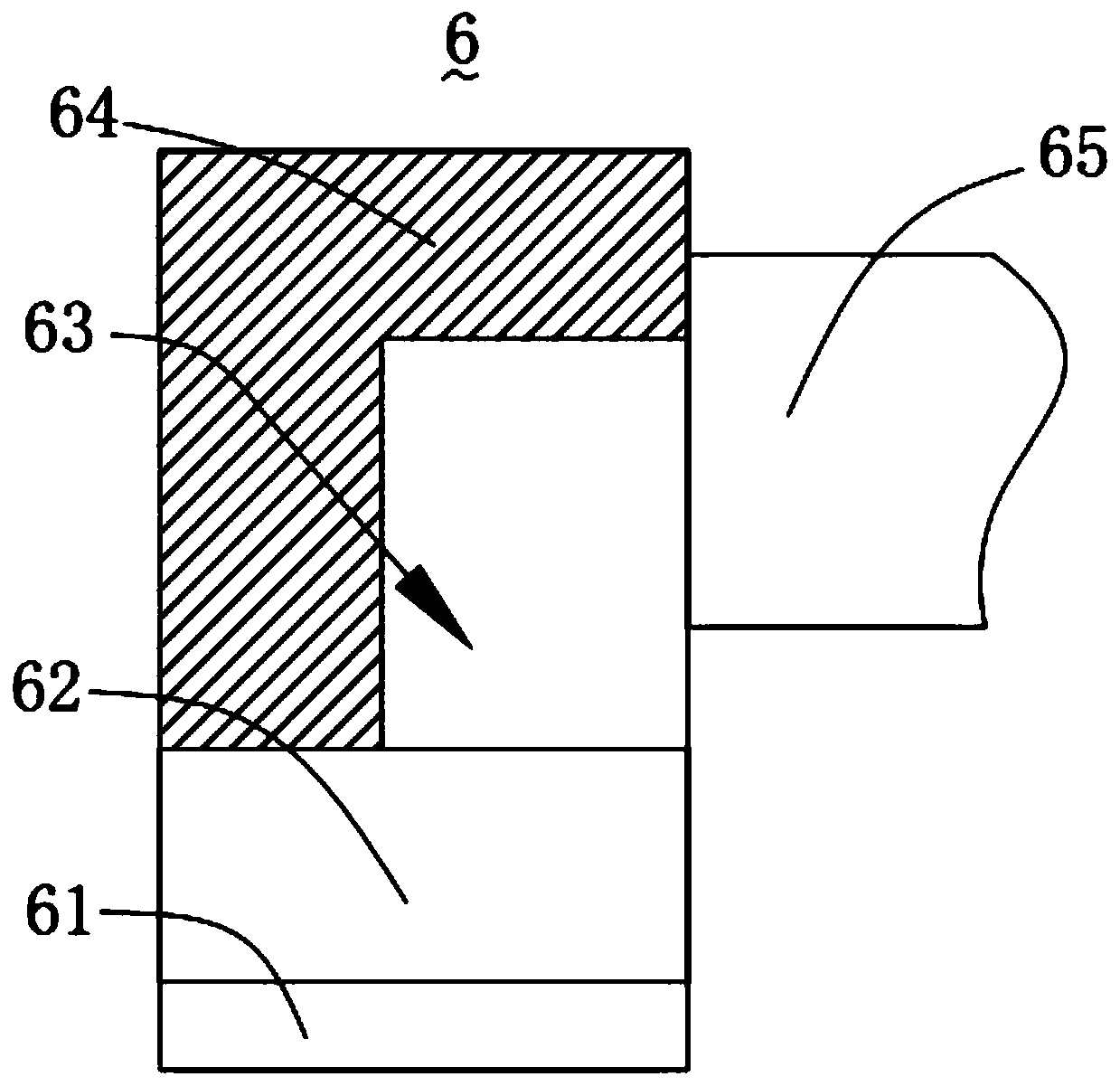

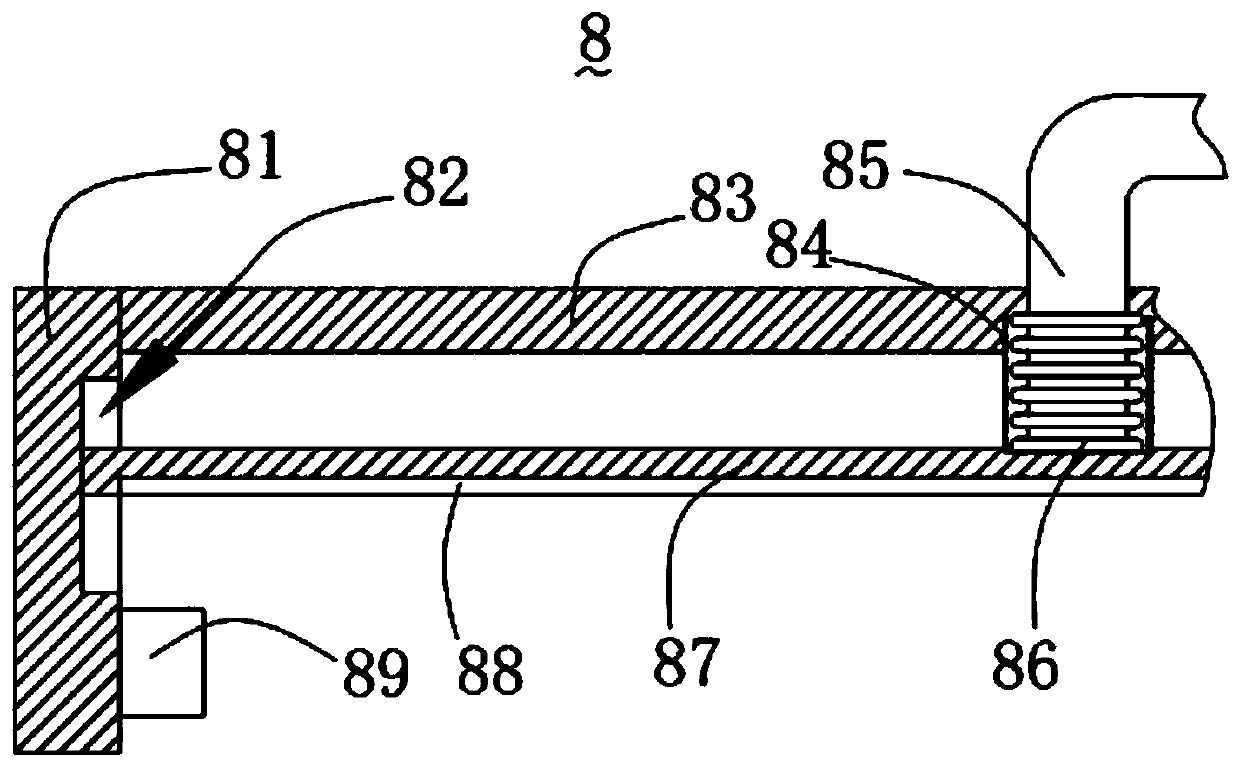

[0030] Such as figure 1As shown, an auxiliary positioning device for ceramic tile cutting according to Embodiment 1 of the present invention includes a translation structure 1, a universal wheel 2, a dust collection structure 3, a fixed structure 4, a scale bar 5, a limit structure 6, a support Structure 7, driving structure 8 and cutting groove 9; the universal wheels 2 are arranged at the bottom four corners of the support structure 7; the dust collection structure 3 is slidably connected with the support structure 7; the limit structure 6 is slidably connected to the support structure 7; the fixed structure 4 is connected through the limiting structure 6 and the support structure 7; the driving structure 8 is slidably connected to the support structure 7; the translation structure 1 It is fixed on the support structure 7 ; the cutting groove 9 is provided on the support structure 7 at the end of the translation structure 1 close to the driving structure 8 ; the scale bar 5 ...

Embodiment 2

[0038] Such as figure 1 As shown, an auxiliary positioning device for ceramic tile cutting according to the second embodiment of the present invention includes a translation structure 1, a universal wheel 2, a dust collection structure 3, a fixed structure 4, a scale bar 5, a limit structure 6, a support Structure 7, driving structure 8 and cutting groove 9; the universal wheels 2 are arranged at the bottom four corners of the support structure 7; the dust collection structure 3 is slidably connected with the support structure 7; the limit structure 6 is slidably connected to the support structure 7; the fixed structure 4 is connected through the limiting structure 6 and the support structure 7; the driving structure 8 is slidably connected to the support structure 7; the translation structure 1 It is fixed on the support structure 7 ; the cutting groove 9 is provided on the support structure 7 at the end of the translation structure 1 close to the driving structure 8 ; the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com