Multifunctional forming cutter of high-precision automobile condenser fixing flange liquid storage tank

A condenser and high-precision technology, applied in the direction of reamers, drilling/drilling equipment, drilling accessories, etc., can solve the problems of high tool cost and complicated processing technology, so as to improve the service life, improve the surface roughness, Guaranteed high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

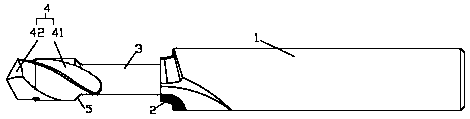

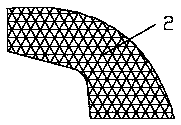

[0015] Such as figure 1 It is a structural schematic diagram of the present invention, a high-precision automotive condenser fixed flange liquid storage tank multifunctional forming knife, including a tool base 1, the front end of the tool base 1 is provided with a forming chamfering edge 2 and the center of the front end of the tool base 1 is provided with a Transition knife bar 3, the other end of described transition knife bar 3 is provided with drilling and reaming cutting part 4, and described drilling and reaming cutting part 4 comprises reamer part 41 and the front end of reamer part 41 is provided with pre-drilling bit 42, reamer The rear end of the knife portion 41 is provided with a reverse chamfering edge 5 .

[0016] Such as figure 1 As shown, the tool base 1 , the transition tool bar 3 and the drilling and reaming cutting part 4 are integrally processed and formed, and their materials are all cemented carbide. The helical groove of the pre-drilling bit and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com