Cutting method of optical element

A technology of optical elements and cutting methods, which is applied in metal processing and other directions, can solve the problems of high cost and rough cutting surface, and achieve the effects of low cost, small tool wear and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

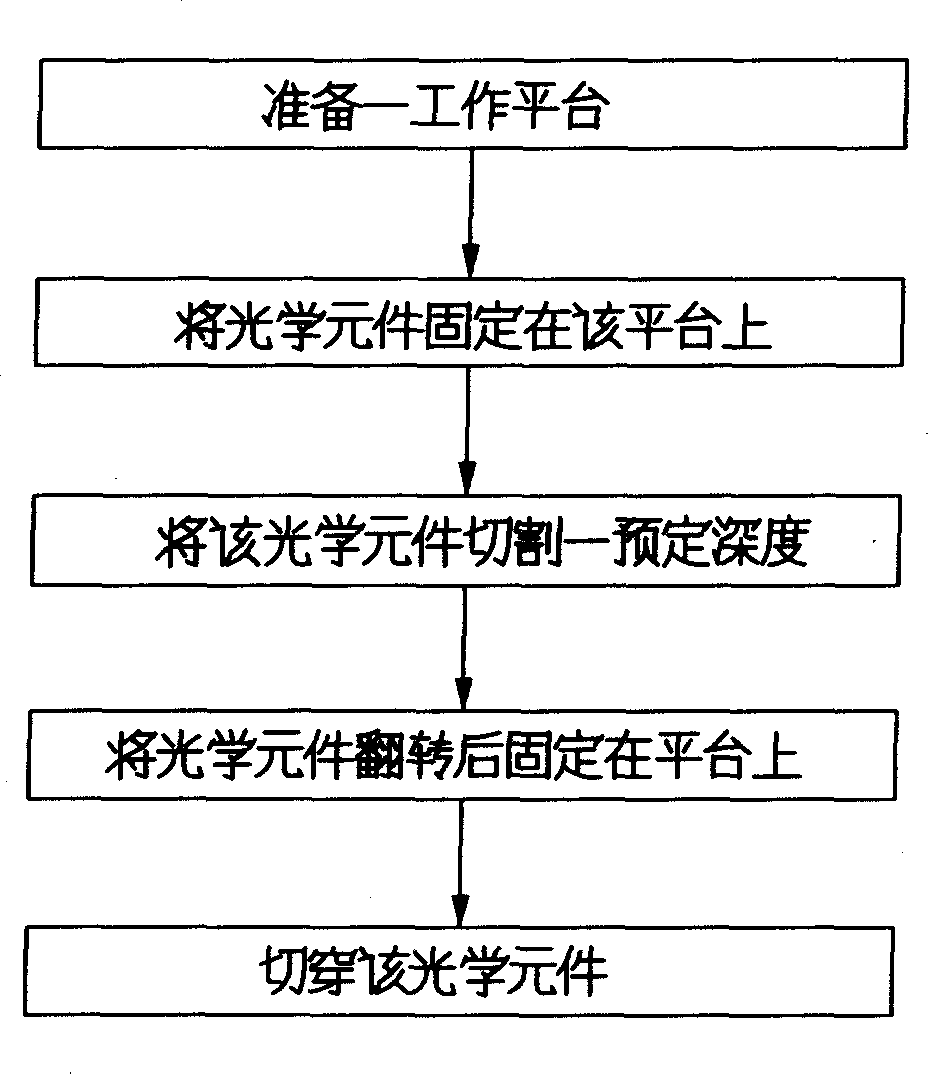

[0013] The flow chart of the cutting method of the optical element of the present invention is as figure 1 shown. First prepare a working platform; fix the optical element to be processed on the platform; cut the optical element to a predetermined depth; turn the optical element over and fix it on the platform; cut through the optical element along the relative cutting position , that is, the cutting of the optical element is completed.

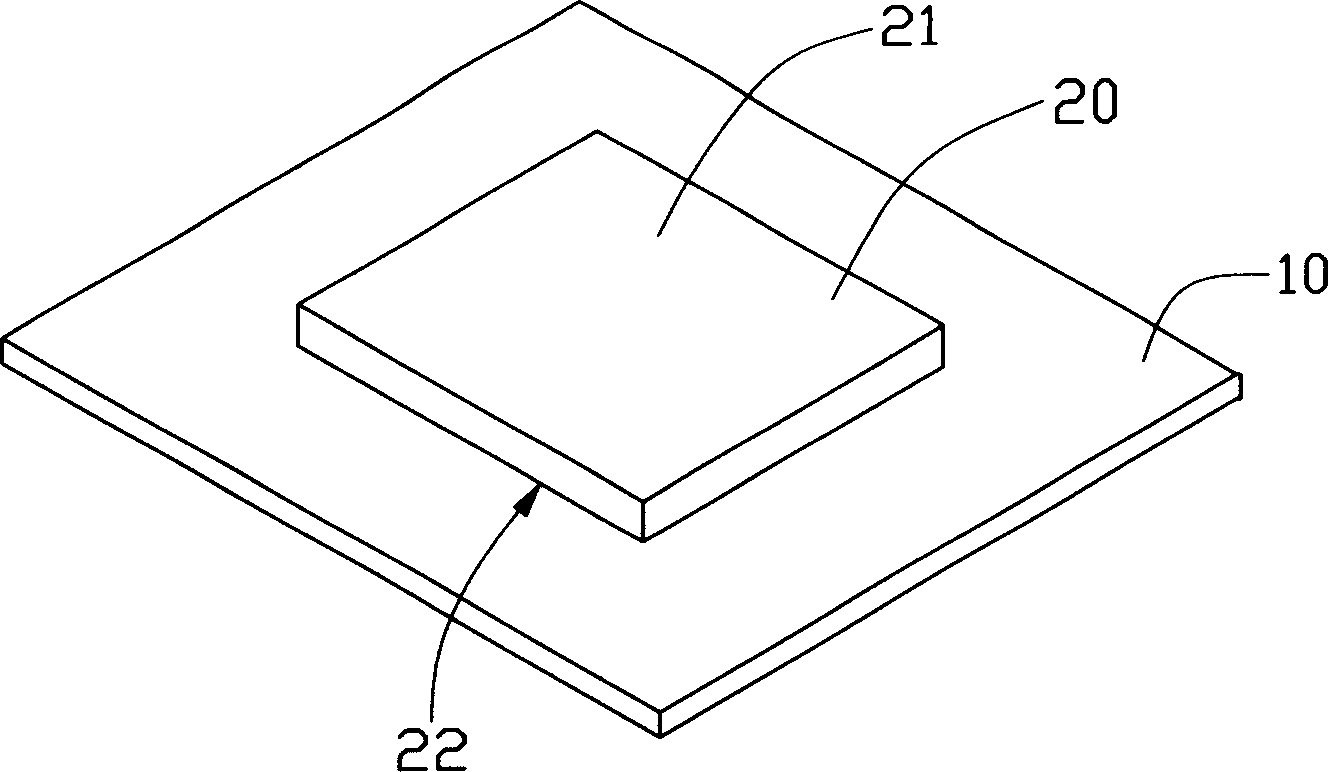

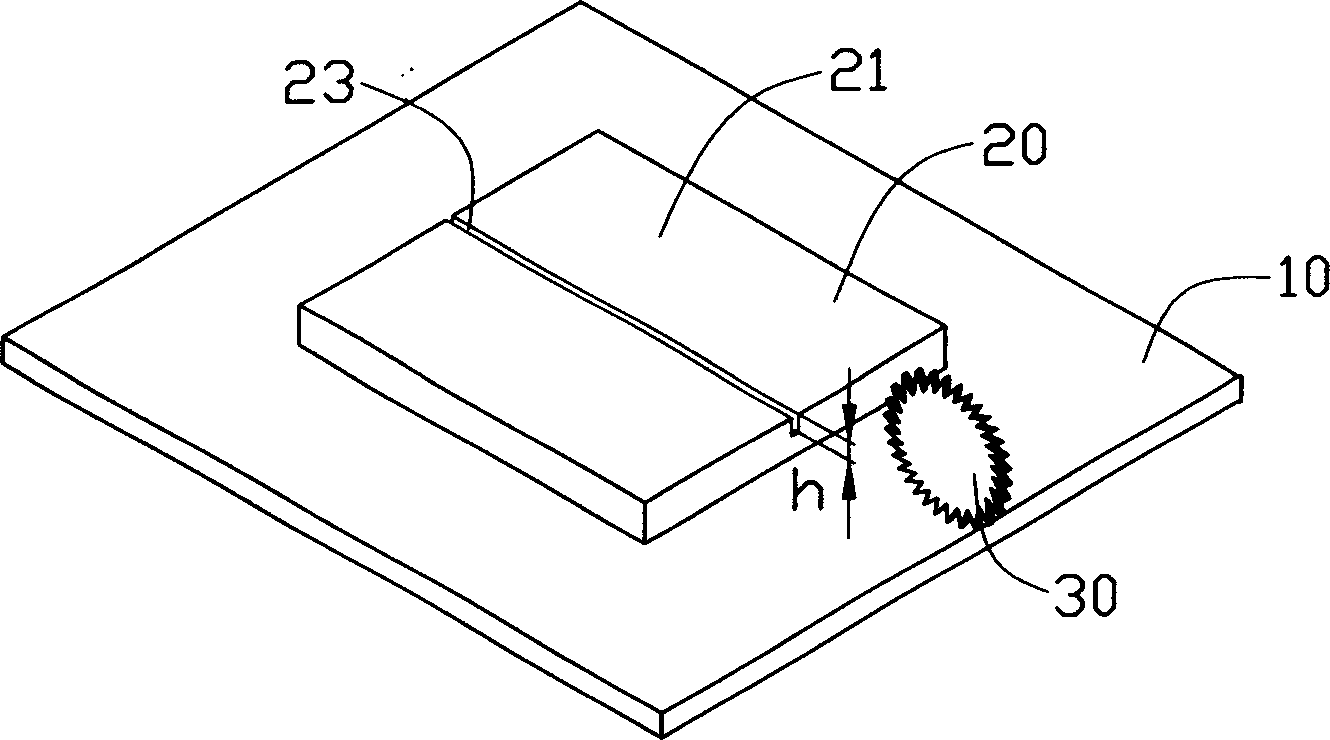

[0014] Figure 2 to Figure 5 It is a three-dimensional view between the elements during the cutting process of the optical element of the present invention. like figure 2 As shown, first a working platform 10 is prepared, and then the optical element 20 to be processed is fixed on the working platform 10 . Wherein the working platform 10 can be a hard and non-deformed glass platform with a smooth surface; a hard and non-deformed stainless steel platform can also be used, which has excellent surface smoothness. The optical element 20 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com