Patents

Literature

55results about How to "Reduce residual strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance ceramic mold shell for directional solidification, and production technology thereof

The invention discloses a high-performance ceramic mold shell for directional solidification. The ceramic mold shell is formed by laminating a surface layer, a transition layer, a reinforced layer and a slurry sealing layer, the reinforced layer is formed by alternatively laminating first reinforced layers and second reinforced layers from the surface layer to the slurry sealing layer, the refractory material of the first reinforced layers comprises zircon powder and fused pulverized corundum, and the refractory material of the second reinforced layers comprises fused alundum powder and fused pulverized corundum. The invention also discloses a production technology of the high-performance ceramic mold shell for directional solidification. The ceramic mold shell produced through the technology has the advantages of good dimension stability, moderate residual strength, safety and use convenience.

Owner:江苏永瀚特种合金技术股份有限公司

Special coating of hot-mould centrifugal casting mould for flexible joint ferrosteel pipe

InactiveCN1775415AImprove the level ofImprove liquidityFoundry mouldsFoundry coresSodium BentoniteColloid

The present invention relates to a soft joint grey cast-iron pipe hot-mould centrifugal casting special-purpose adhering moulding material. It includes fire-resisting aggregate, bonding agent, suspension agent and water. The described fire-resisting aggregate includes diatomite powder, perlite powder, vermiculite powder and silica flour, and the described bonding agent and suspension agent include sodium base bentonite and sodium cellalose glycollate. Said invention also provides its preparation method and concrete steps.

Owner:张鑫

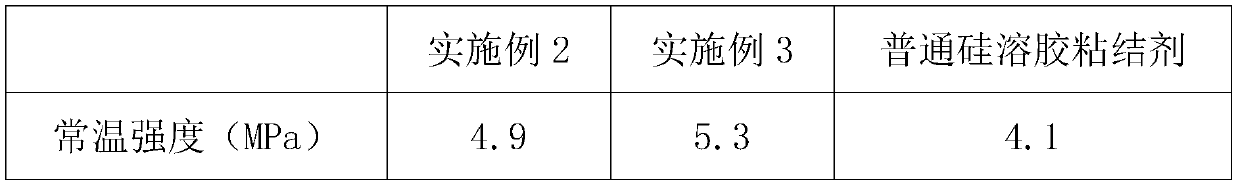

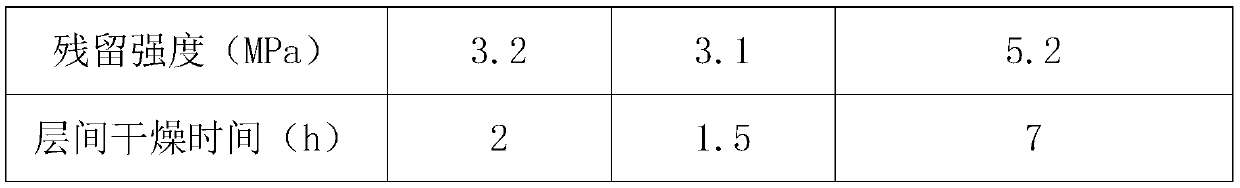

Modified formula for enhancing rapidly-dried silica sol

InactiveCN101885036AImprove wet strengthSpeed up evaporationFoundry mouldsFoundry coresFiberEvaporation

The invention relates to a modified formula for enhancing rapidly-dried silica sol. The technical scheme is that: the modified formula consists of the following components in part by weight: 8,500 to 9,800 parts of silica sol, 100 to 1,200 parts of emulsion, 80 to 160 parts of fiber, and 20 to 180 parts of antifoaming agent. The modified formula has the advantages that: by using the interpenetrating and complementary characteristics of the silica sol and the emulsion, coatings coated on the surface of a wax mold are in net distribution, the wet strength of the coatings is improved, and the next-layer sizing agent can be applied to the incompletely dried upper-layer sizing agent; by using the water conduction function of the fiber, the water inside and outside the coatings is balanced, the inner stress is reduced, the mold shell cracking probability is reduced, the evaporation of the water is accelerated, and the drying time is shortened; an ultra-micro gap of the fiber formed by high temperature carbonization can reduce the retained strength of the mold shell, also can improve the air permeability of the mold shell, and comprehensively improves the quality of casting products; and the period of shell making technology is shortened from 5-7 days to 1-2 days.

Owner:武汉市智发科技开发有限公司

Silicon-sol adhesive and preparing method

InactiveCN1438082AImprove room temperature strengthShorten drying timeFoundry mouldsFoundry coresInvestment castingAdhesive

The present invention discloses a silicon sol adhesive modified by using high polymer and its preparation method. Its composition comprises alkaline silicon sol containing 20-30%, SiO2 and PVA whose content is less than [(32-100XSiO2%) / 320]X100%. Its preparation method includes: a. preparing PVA aqueous solution; b. preparing alkaline silicon sol solution; and c. mixing said two solution uniformly, in which after the alkaline silicon sol solution is prepared or after the two solutions are mixed uniformly its pH value must be regulated. Said silicon sol adhesive can accelerate drying speed when it is used in investment casting industry, and can raise the normal temp. strength of pattern shell in the investment casting, and can reduce retained strength.

Owner:ZHEJIANG YUDA CHEM IND

Composite sodium silicate binder for sand mold and preparing method thereof

ActiveCN101941046AImprove room temperature compressive strengthReduce residual strengthFoundry mouldsFoundry coresSodium silicateSieve

The invention discloses a composite sodium silicate binder for sand mold and a preparing method thereof. The composite sodium silicate binder is formed by the following components in parts by weight: 100 parts of sodium silicate, 5-10 parts of straw powder paste and 0.5 to 2 parts of water. The preparing method thereof comprises the steps of: 1. drying, crushing and subjecting straws to a sieve not less than 325 meshes in order to obtain the straw powder paste; 2. adding 5-10 parts by weight of the straw powder paste obtained in the step 1 with 0.5 to 2 parts by weight of water, followed by uniform stirring to further obtain wet straw powder paste; and (3) adding the wet straw powder paste with 100 parts by weight of sodium silicate. The composite sodium silicate binder manufactured according to the method solves the problem that the silicate binder is poor in sand mold collapsibility and difficult in recycling when being used as binder; in addition, compared with other methods for improving the sand mold collapsibility of silicate binder, the method according to the invention, in which inexpensive straw is taken as raw material, lowers the cost of sand mold (core) dramatically.

Owner:河北天琦新材料科技有限公司

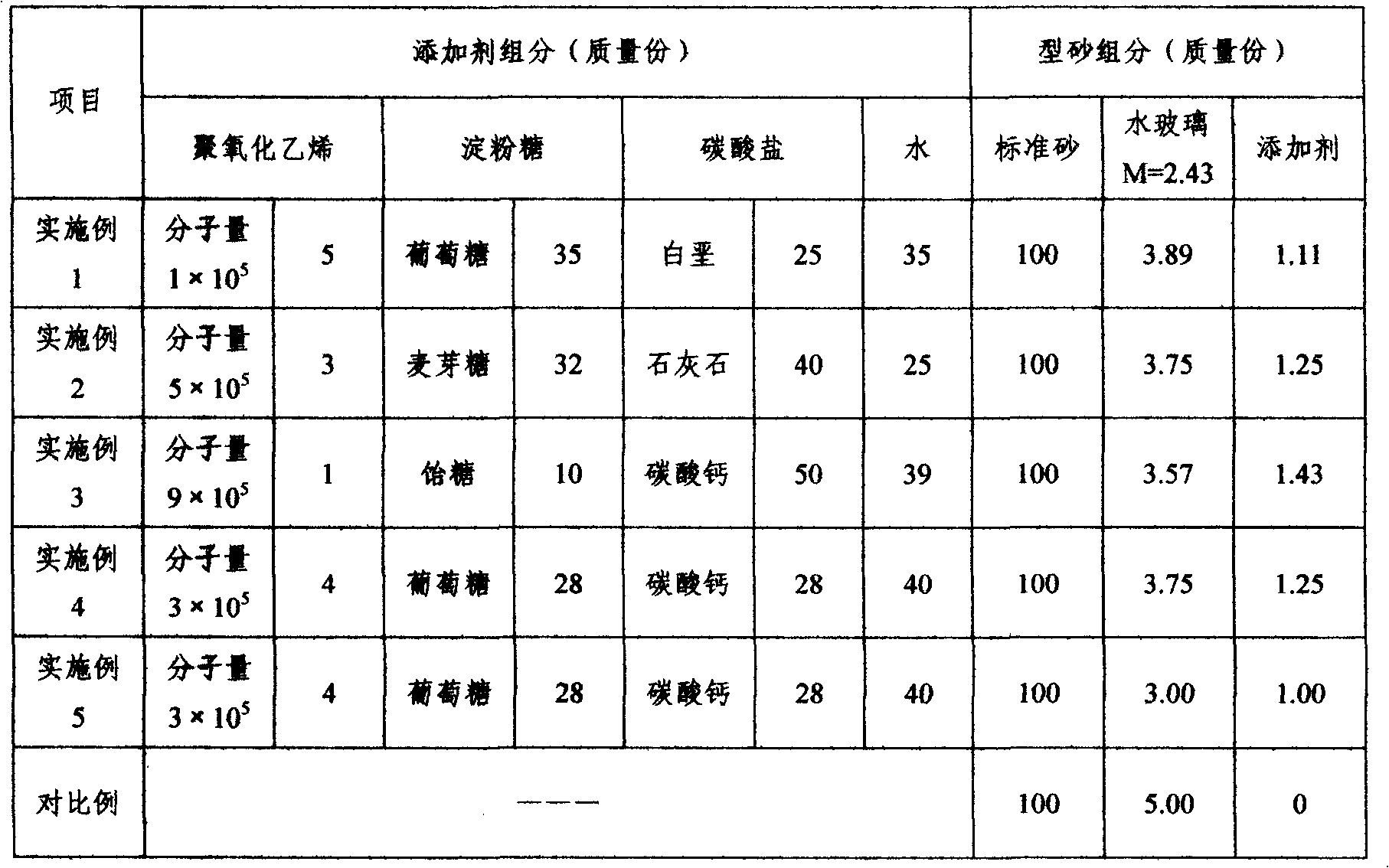

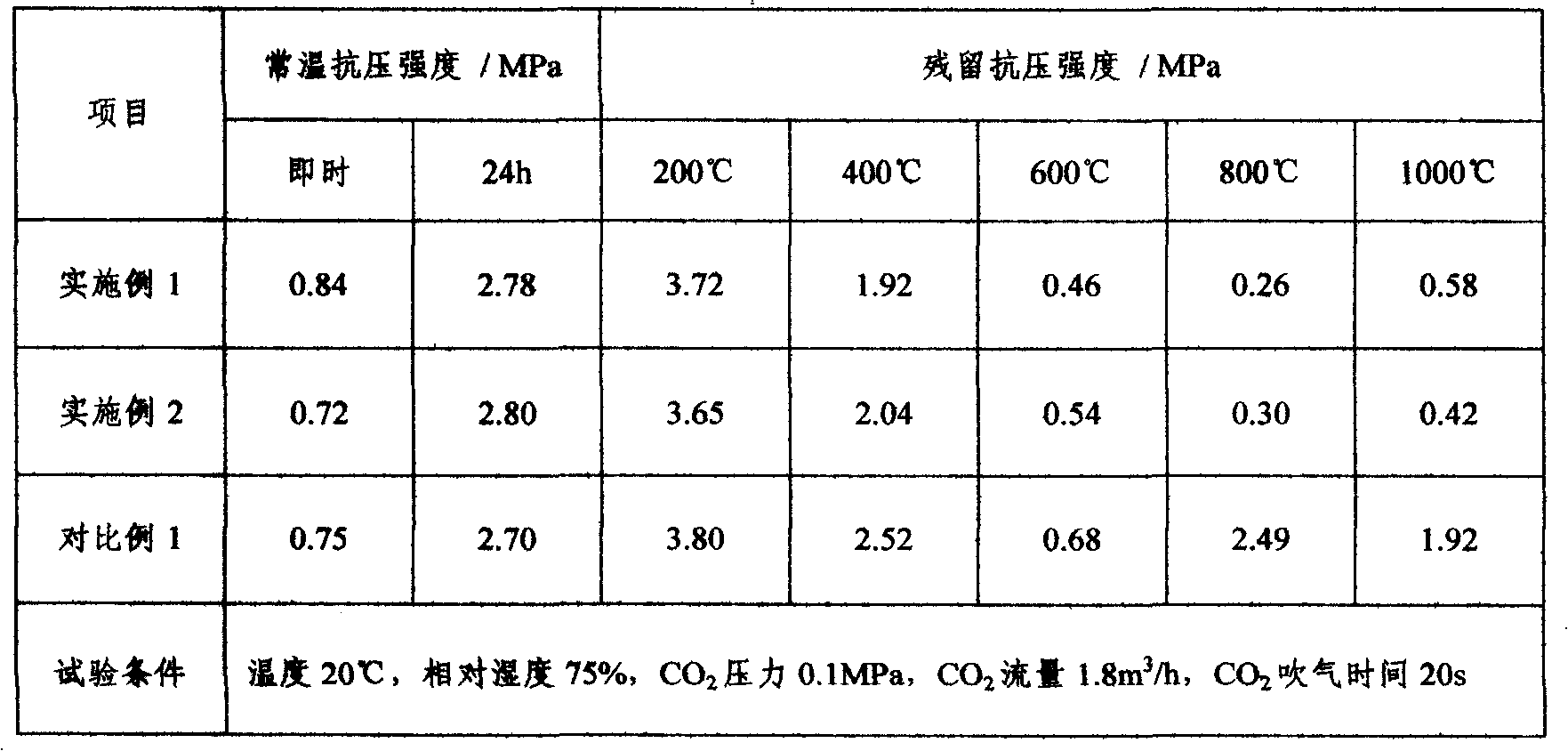

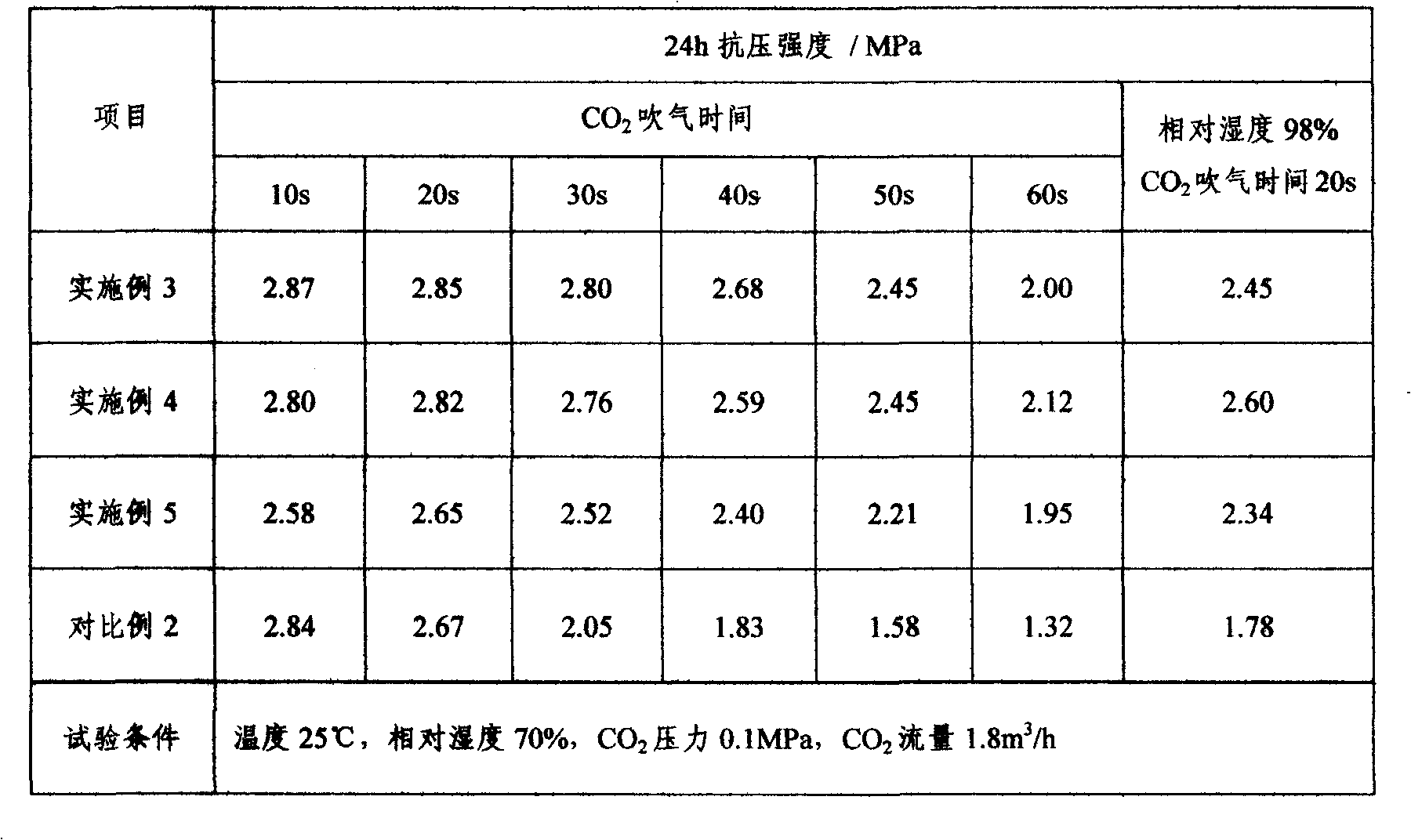

CO2 hardened silicate-bonded sand additive agent and formative technology thereof

InactiveCN101259515AHygroscopicReduce residual strengthFoundry mouldsFoundry coresHigh humidityMalt Grain

The invention discloses a CO2 hard sodium silicate sand additive; wherein, the mass proportion of each component is: 1 to 5 percent of PEO, 10 to 35 percent of starch sugar, 25 to 50 percent of carbonate and 25 to 40 percent of water; the molecular weight of the PEO is 1*10<5> to 9*10<5>. The starch sugar is selected from dextrose, maltose or malt extract; the carbonate is selected from chalk, limestone or calcium carbonate. The invention also provides a sanding mixing technique of casting sand mixture which uses the CO2 hard sodium silicate sand additive. The CO2 hard sodium silicate sand additive of the invention can effectively reduce the content of the sodium silicate sand in the sand mixture as well as maintains higher sand mixture intensity and better old sand collapsihility. The sodium silicate sand prepared by using the additive is not sensitive to the overblowing of CO2, is easy to control the hard technique and has the higher humidity resistance.

Owner:鑫工艺(上海)材料科技有限公司

Ceramic shell material for precision casting of superalloy castings and preparation method of ceramic shell material

The invention discloses a ceramic shell material for precision casting of superalloy castings and a preparation method of the ceramic shell material. A clean and dry blade wax pattern module is immersed into a surface layer coating; after the coating is uniformly coated on the surface of a wax pattern, zircon sand or fused corundum sand serving as fire resistant filler is uniformly spread; dryingis performed at room temperature; then, after a back layer coating of the module is stained with slurry, sintered mullite sand serving as fire resistant filler is uniformly spread and fully dried; theback layer coating is repeatedly stained with the slurry until a required thickness of a shell is achieved; then the back layer coating is used for slurry sealing and drying; the dried shell is dewaxed in a high-pressure steam dewaxing kettle; roasting is performed in air at 850-1100 DEG C for 2-6 hours; and the ceramic shell is obtained after air cooling to the room temperature. The shell manufactured according to the preparation method has high wet strength, high-temperature strength, low residual strength, excellent air permeability, excellent deformability, and excellent collapsibility. Compared with a common shell, the shell is decreased in coating frequency of back layers and reduced in thickness. The increase in heat dissipation rate during casting solidification cooling is facilitated, and the metallurgical quality of the castings is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Method for preventing decarburization of surface of constructional steel investment casting

InactiveCN101658897AImprove breathabilityReduce residual strengthFoundry mouldsFoundry coresInvestment castingSurface oxidation

A method for preventing decarburization of the surface of a constructional steel investment casting belongs to the field of preventing decarburization of the surface of a casting. Graphite powder isadded in the shell slurry of the constructional steel investment casting to prevent the decarburization of the surface of the casting; the mixture ratio of the slurry is that the graphite powder accounts for 5-6% of the weight percent of the whole slurry; and the function of adding the graphite powder is as follows: after alloy liquid is poured into the shell, the graphite powder in the shell forms a reductive protective layer under high temperature state so as to effectively prevent the alloy liquid from generating surface oxidation during the solidification process. The method has simple operation and convenient usage, increases the air permeability of the shell, is beneficial to filling when in casting, can properly reduce residual intensity of the shell, and is beneficial to unshelling and cleaning; and the method is suitable for the third layer, the fourth layer and the fifth layer of slurry of the shell of ethyl silicate coating or silica solution coating.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

Shell hardening agent

InactiveCN104525847AGuaranteed StrengthReduce residual strengthFoundry mouldsFoundry coresResidual strengthRoom temperature

The invention relates to a shell hardening agent. The shell hardening agent comprises the following components in parts by weight: 40-90 parts of crystalline magnesium chloride, 10-60 parts of crystalline aluminum chloride and 0.1-1 part of a nonionic surfactant. The shell hardening agent has the advantages of penetrative hardening capability and higher normal-temperature strength and high-temperature strength, the strength of the shell during the production process is ensured, the shell loss is decreased, the residual strength of the shell is reduced and the problem of difficulty in sand removal is solved, the subsequent process operation is facilitated, the produced finished product yield is increased, the labor intensity of workers is reduced and the simplicity in process and environment friendliness are achieved.

Owner:UNITED LASHING PRECISION CASTING

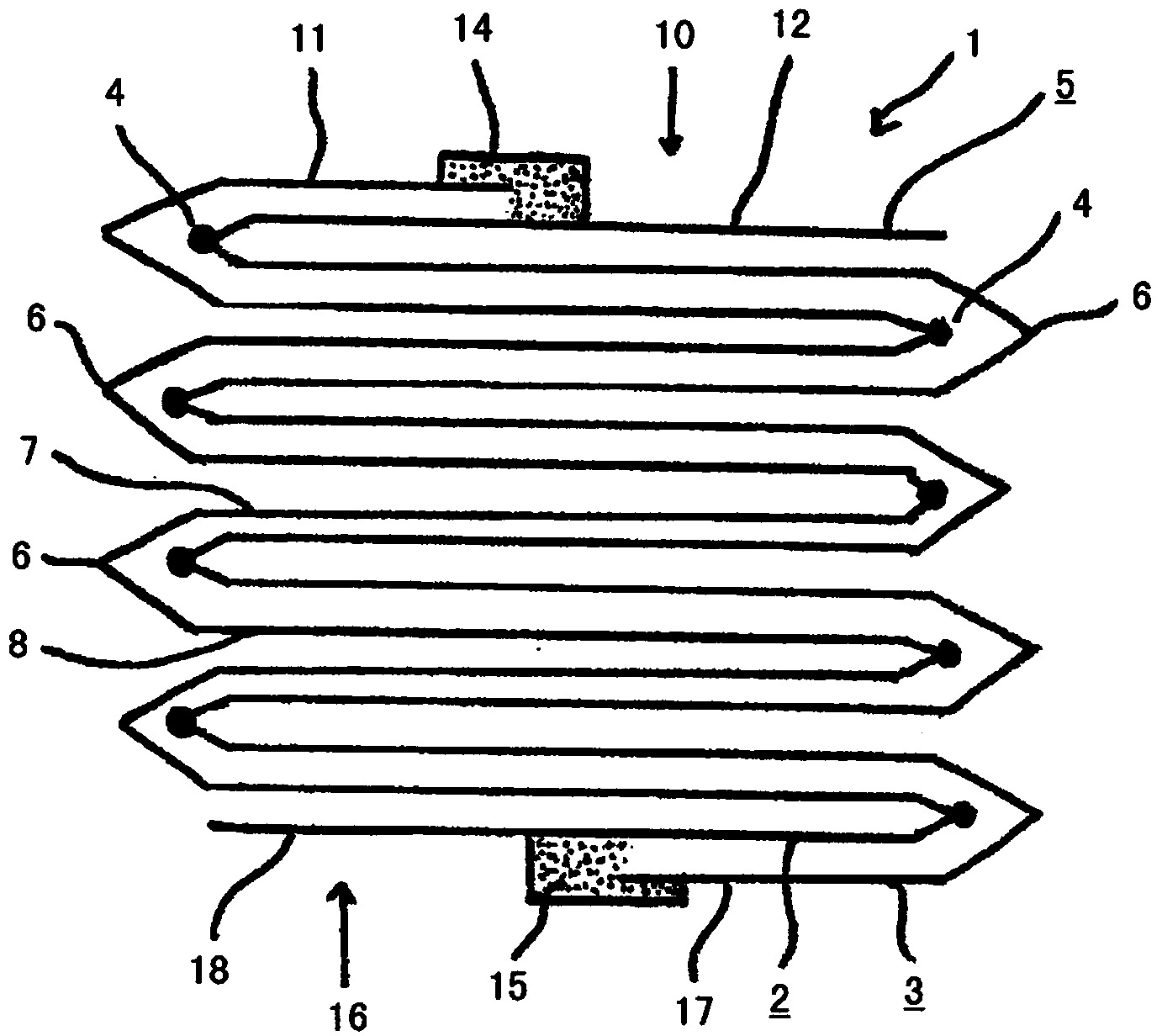

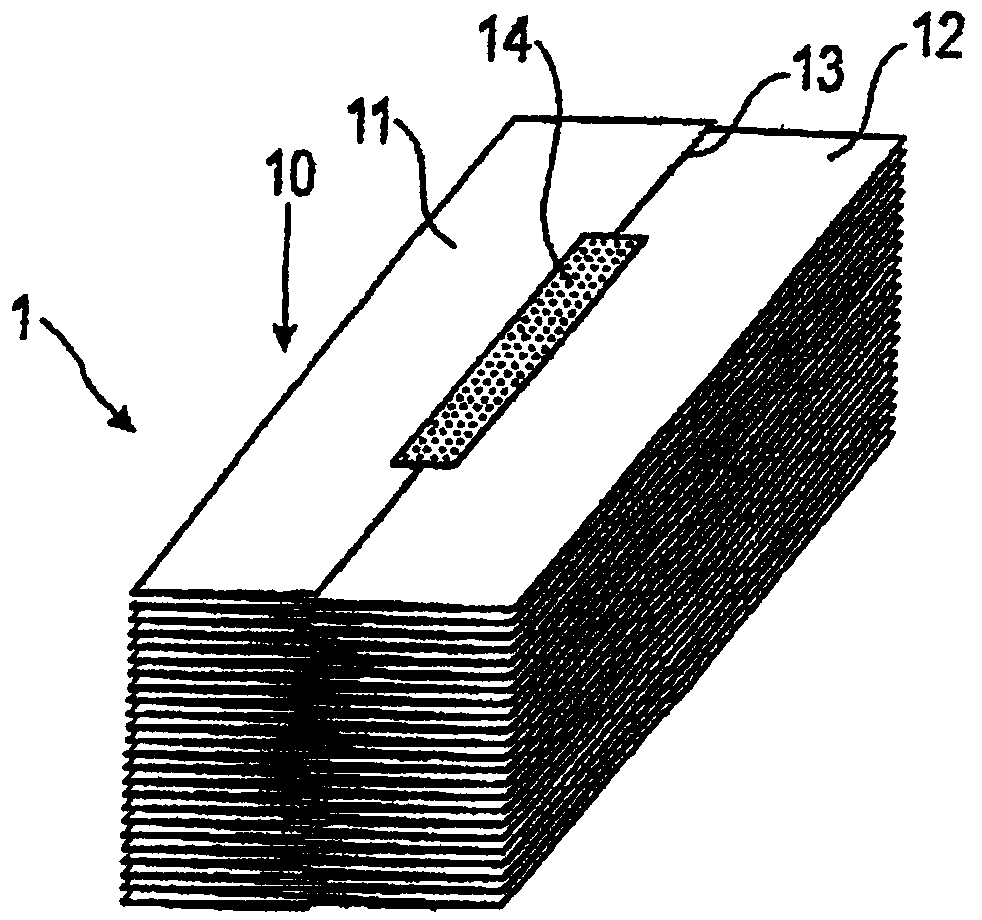

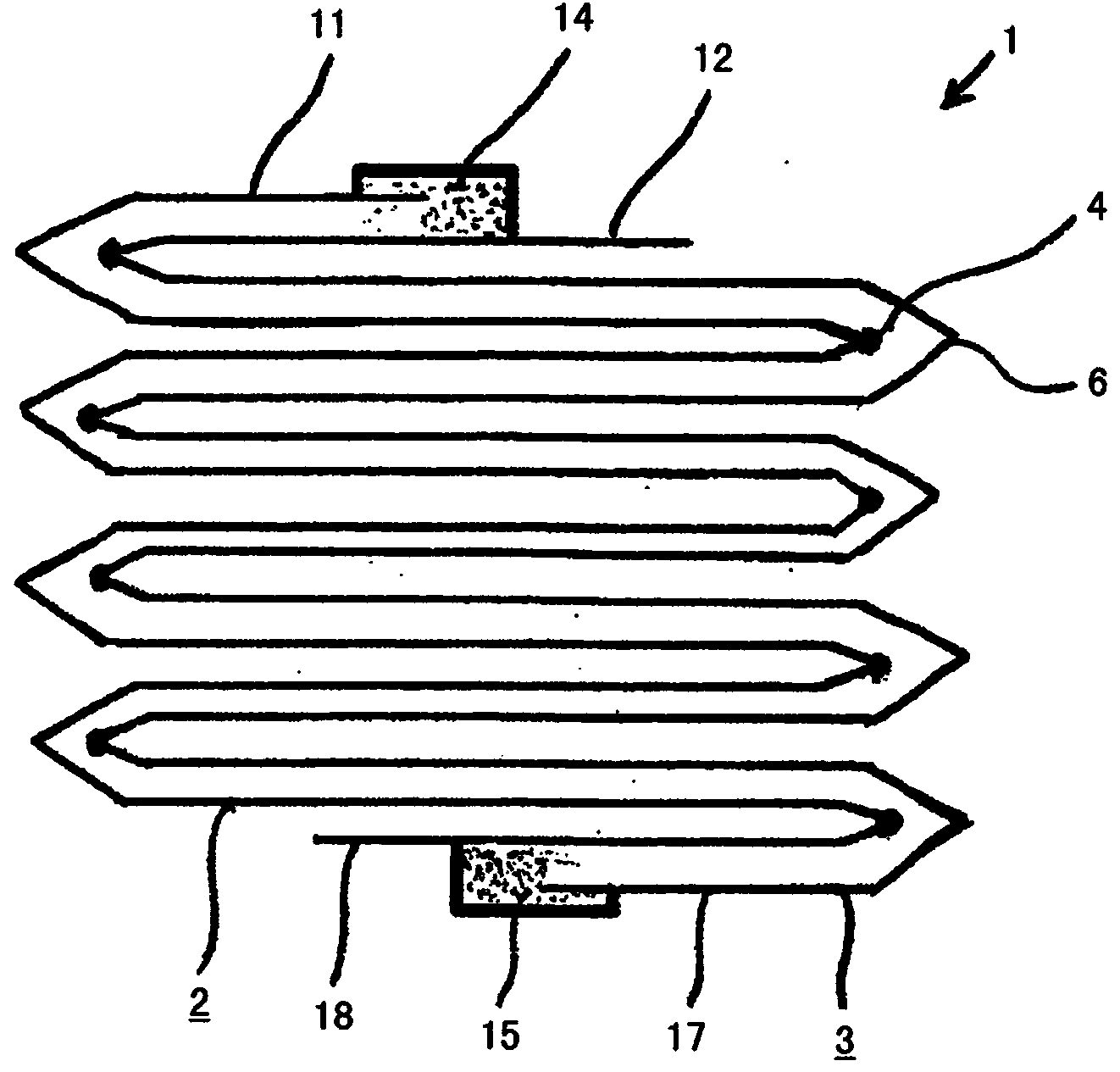

Stack of folded hygiene products and method and apparatus for producing same

InactiveCN103857613AReduce residual strengthExcellent adhesionFolding thin materialsMaterial PerforationHygiene

A method for producing stacks (1) of individual web sections (2; 3), such as tissue web sections from a continuous web of material (2a; 2b), comprises the steps: (a) directing the continuous web (2a; 2b) to a perforating station (27); (b) perforating the continuous web (2a; 2b) at predetermined intervals and forming sheets (5) of web material between consecutive perforation lines (4) extending laterally across the continuous web (2a; 2b), the perforating being carried out by means of at least one perforation element (26) arranged at the circumference of a perforation roller (24); (c) directing the continuous web (2a; 2b) to a cutting station (31; (d) cutting at second predetermined intervals the continuous web (2a; 2b) into web sections (2; 3) by means of a cutting element (38) acting against an anvil element (37), in order to generate a clear cut or a tab-bond; (e) folding the web sections (2; 3) by means of a folding roll (32); and (f) stacking the folded web section (2; 3) to generate a stack (1) of folded sheets.

Owner:ESSITY HYGIENE & HEALTH AB

Shell making process of silica sol shell with high deshelling property

InactiveCN108031789AGuaranteed high temperature strengthReduce residual strengthFoundry mouldsFoundry coresWaxKaolinite

The invention discloses a shell making process of a silica sol shell with high deshelling property. The shell making process comprises the following steps: S1, uniformly mixing powder with silica solwith stirring, and adding a wetting agent and a defoamer to form a first mixture; S2, immersing a wax mold into the first mixture, taking the wax mold out, scattering sand into the wax mold, and drying to obtain a first-layer mold shell; S3, repeating the step S2 until second to sixth layers of mold shells are obtained; S4, drying the wax mold including the first to sixth layers of mold shells tocomplete sealing; S5, calcining the wax mold including the first to sixth layers of mold shells to obtain a mold shell casting. According to the shell making process of the silica sol shell with highdeshelling property disclosed by the invention, fully-calcined aluminosilicate refractory sand powder, free iron and hard kaolinite with low diaspore content is taken as a main material of the silicasol shell, and is combined skillfully with quartz sand, so that the high-temperature strength of the mold shell is ensured, and the retained strength after mold shell pouring can be lowered greatly.

Owner:JIAXING YAYIDA SPECIAL STEEL CASTING

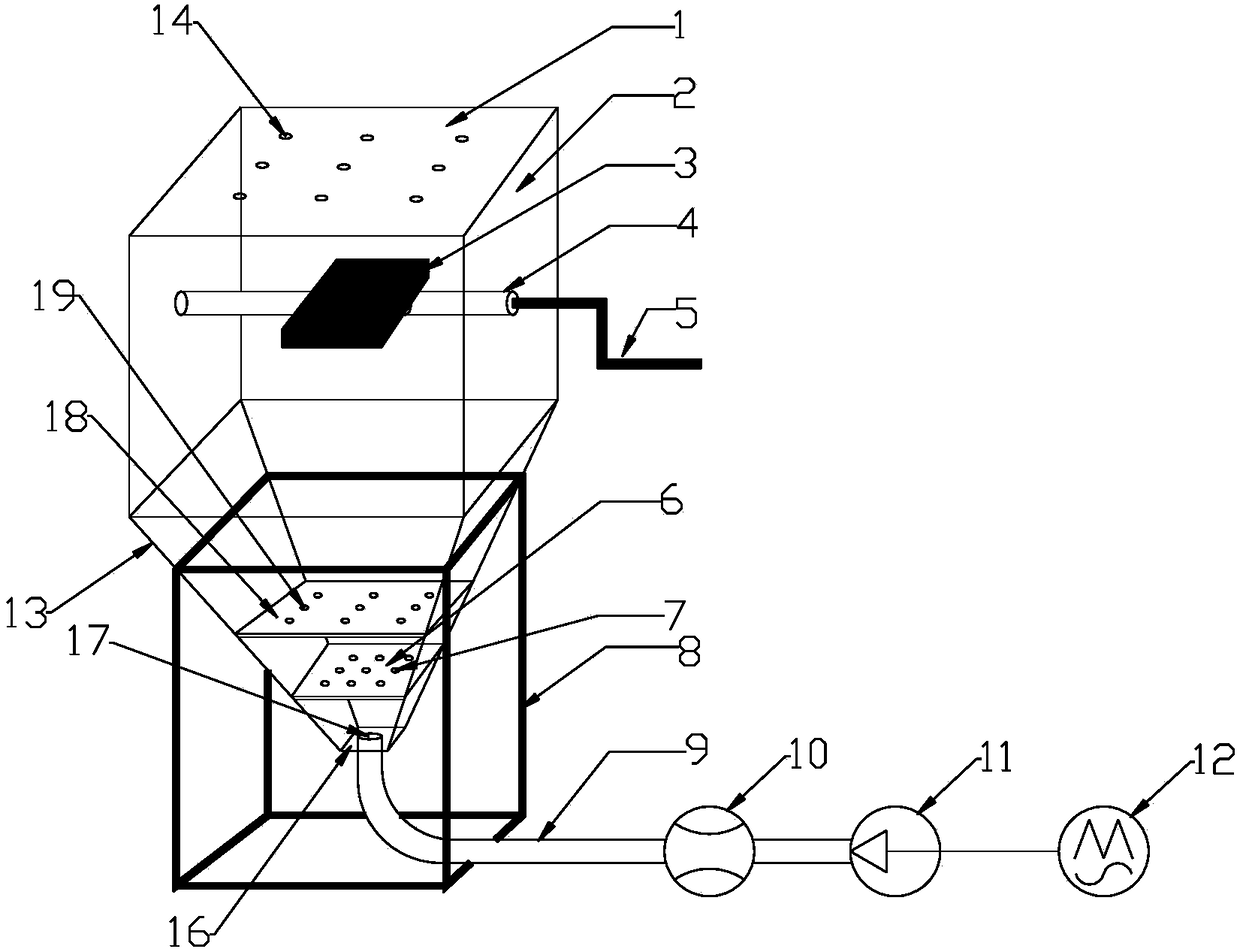

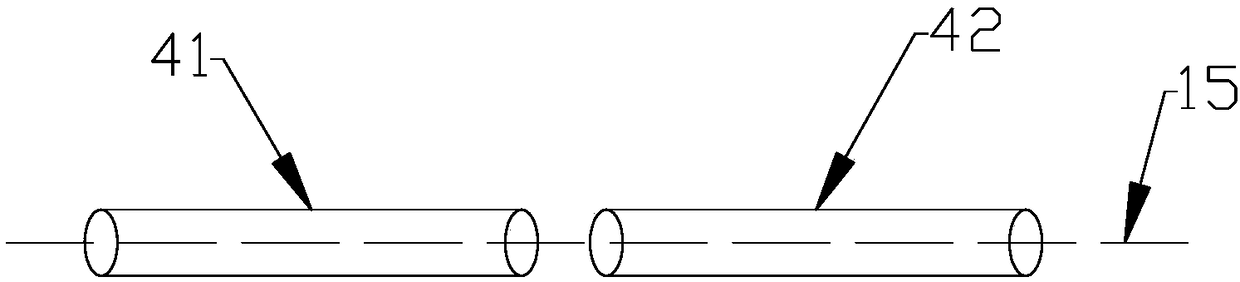

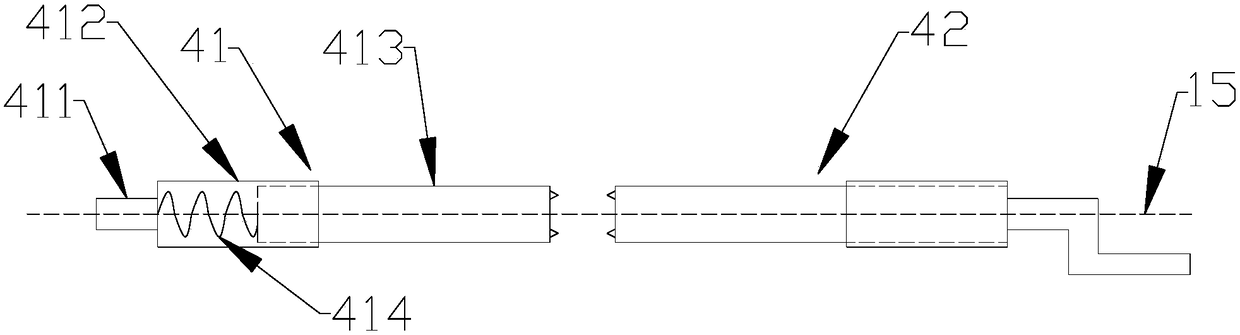

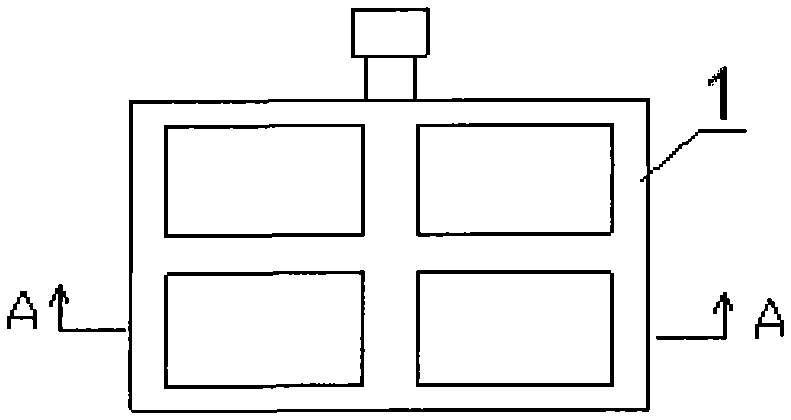

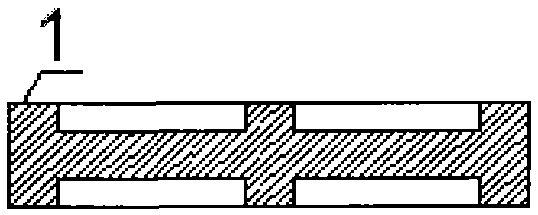

Device and method for preparing fiber reinforced silica sol composite shell through airflow laying

InactiveCN108213344AConsistent performanceImprove air permeabilityFoundry mouldsFoundry coresDiameter ratioAirflow

The invention discloses a device and a method for preparing a fiber reinforced silica sol composite shell through airflow laying. The device comprises a fiber laying chamber, a fiber storage chamber,an air supply unit and a support, wherein the fiber laying chamber is a hollow cube and is composed of four side vertical plates and an upper bottom surface exhaust hole plate and an upper bottom surface exhaust hole plate, and an exhaust hole is formed in the upper bottom surface exhaust hole plate; a rotating shaft used for bearing the shell sample is installed in the fiber laying chamber; the fiber storage chamber is of a hollow inverted quadrangular frustum shape formed by four side plates and a lower bottom surface air inlet plate, a fiber storage rack is arranged in the fiber storage chamber, and airflow guide holes are formed in the fiber storage rack; and the fiber spreading chamber is located right above the fiber storage chamber, the side length of the side vertical plate of thefiber spreading chamber is equal to the side length of the side plate of the fiber storage chamber, and the four side vertical plates and the four side plates are fixedly connected in a one-to-one correspondence manner. According to the device and the method, the fibers can be uniformly distributed in the shell, the fibers can be laid on the shell in a quantitative mode, so that the performance ofthe prepared shell is consistent, and the fiber with the large length-diameter ratio can also be added into the shell.

Owner:INNER MONGOLIA UNIV OF TECH

Novel precision-casting shell-making technology

InactiveCN107486542AReduce residual strengthHigh surfaceFoundry mouldsFoundry coresWaxResidual strength

The invention discloses a novel precision-casting shell-making technology. The novel precision-casting shell-making technology comprises the steps of (1) surface layer coating configuration, (2) wax mould sand coating, and (3) air drying, dehumidifying and reinforcing. The production period can be effectively shortened, the production cost is reduced, the surface and internal storage quality of casting shell making is improved, and the dimensional precision of a casting is ensured; and the casting yield is improved, the mould shell residual strength can be effectively reduced, and air overflowing in the molten steel mould filling process is facilitated.

Owner:ANHUI HUSN KEWAN SPECIAL CASTING

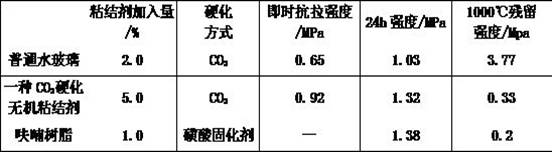

CO2 hardened inorganic binder and preparation method thereof

ActiveCN111718175ALow costStrong environmental protectionInorganic adhesivesSilicic acidPotassium hydroxide

The invention discloses a CO2 hardened inorganic binder and a preparation method thereof. The liquid binder comprises a sodium silicate solution, a potassium silicate solution, aluminum phosphate, potassium hydroxide and sodium hydroxide. A powder accelerator comprises silica fume, calcium oxide, titanium oxide, zirconium oxide, zinc oxide, yttrium oxide and graphite. The preparation method comprises the following steps: adding a sodium silicate solution, a potassium silicate solution and sodium hydroxide into a container, stirring, heating the liquid in the container, adding aluminum phosphate, continuously heating, adding potassium hydroxide, continuously stirring, cooling the liquid to the room temperature to obtain the liquid binder; and uniformly stirring silica fume, calcium oxide, titanium oxide, zirconium oxide, calcium oxide, yttrium oxide and graphite to obtain the powder accelerator. The inorganic binder is low in cost and high in environment friendliness, the organic binderenables the molding sand to be high in surface quality and good in surface stability, organic components are added, the residual strength of the molding sand is greatly reduced, the casting production of high manganese steel casting and product quality are improved, and the inorganic binder is applied to the technical field of casting.

Owner:SHENYANG RES INST OF FOUNDRY

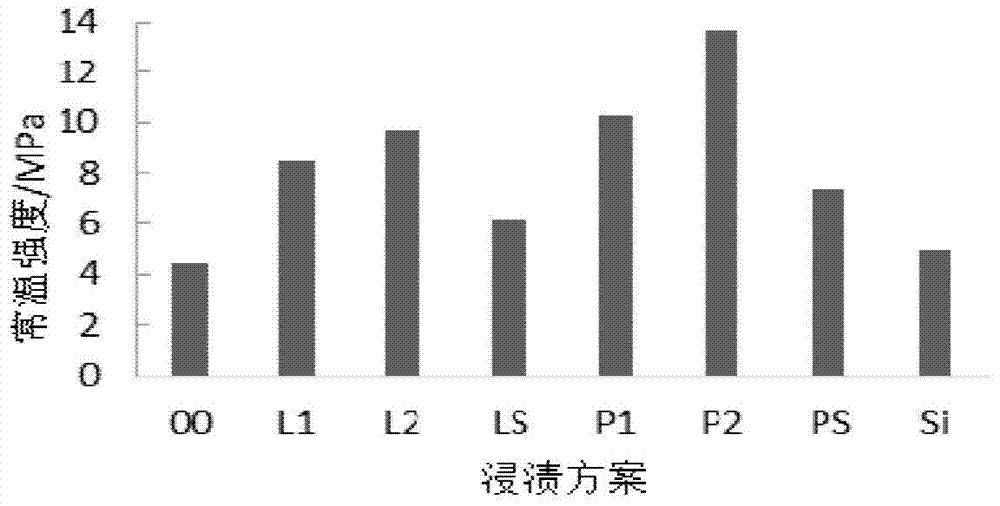

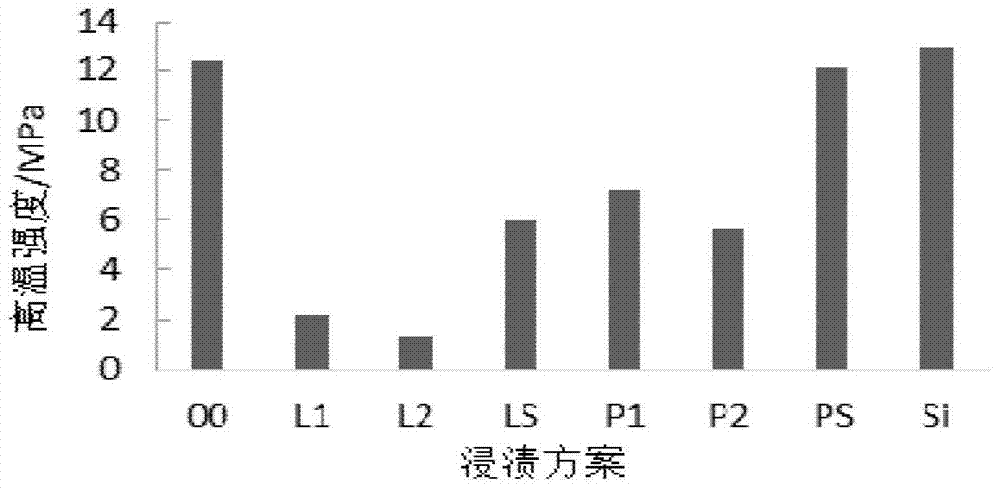

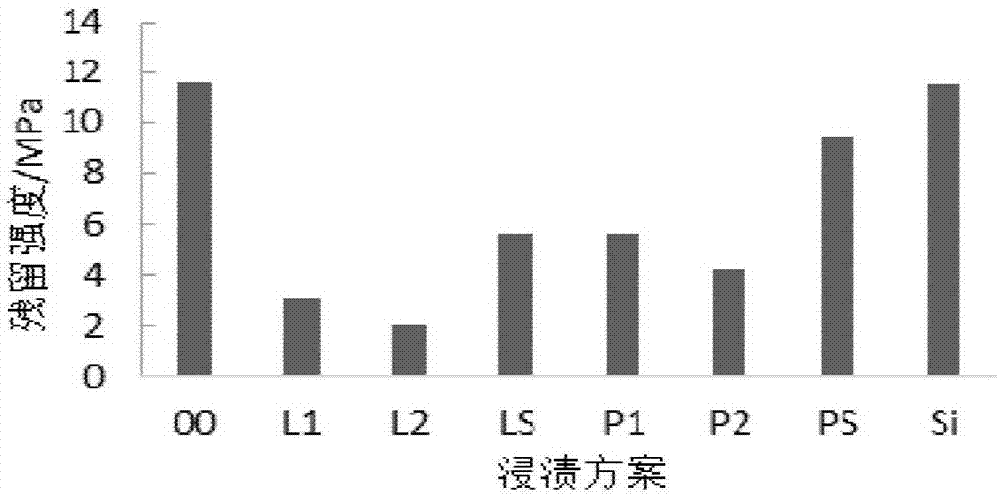

Method for changing strength of shell by impregnating with organic binder

ActiveCN103920851ADoes not affect propertiesDoes not affect the sanding processFoundry mouldsFoundry coresPolymer scienceCrazing

The invention discloses a method for changing strength of a shell by impregnating with an organic binder. An impregnating solution adopts 0.5-4 wt% of a PVA solution, 2-20 wt% of a latex solution or a liquid with preset viscosity. Impregnation time is 2-10 min. impregnation is carried out layer by layer, every few layers or only at a slurry seal layer. After the shell is dried, the next layer of shell is continuously prepared, or dewaxing is conducted after the slurry seal layer is impregnated and dried. The method provided by the invention has high reliability and is simple to operate. Through adjusting type and concentration of the impregnating solution and number of impregnation layers, strength performance of shells made of various materials can be conveniently changed. Through impregnation, layer strength is increased; normal temperature strength of the shell is raised; dewaxing crack resistance is enhanced; combination of front and rear impregnated layers is weakened; retained strength is reduced; shelling performance is improved; and the problem that strength of a mould investment casting shell is hard to coordinate and control is solved.

Owner:TSINGHUA UNIV

Silicon-sol adhesive and preparing method

InactiveCN1243619CImprove room temperature strengthShorten drying timeFoundry mouldsFoundry coresPolymer scienceAdhesive

The present invention discloses a silicon sol adhesive modified by using high polymer and its preparation method. Its composition comprises alkaline silicon sol containing 20-30%, SiO2 and PVA whose content is less than [(32-100XSiO2%) / 320]X100%. Its preparation method includes: a. preparing PVA aqueous solution; b. preparing alkaline silicon sol solution; and c. mixing said two solution uniformly, in which after the alkaline silicon sol solution is prepared or after the two solutions are mixed uniformly its pH value must be regulated. Said silicon sol adhesive can accelerate drying speed when it is used in investment casting industry, and can raise the normal temp. strength of pattern shell in the investment casting, and can reduce retained strength.

Owner:ZHEJIANG YUDA CHEM IND

Preparation method of fiber reinforced composite silica sol shell for investment casting

InactiveCN103962506BImprove wet strengthImprove filling abilityFoundry mouldsFoundry coresResidual strengthMass ratio

The invention relates to a preparation method of a fiber reinforced compound silica sol shell for investment casting, which aims to solve the problem that a shell preparedin the prior art is low in humidity and strength, and comprises the sequential steps as follows: 1), surface layer coating preparation; 2), surface layer shell preparation; 3) transition layer coating and shell preparation; 4) back layer coating preparation, that is, adding mullite powder into silica sol according to the mass ratio of (2.2-3.0):1 of the fireproof mullite powder to the silica sol in the back layer coating, so that paste-shaped coating is obtained, and agitating; adding polypropylene fiber which is 0.4 percent-2.0 percent of the fireproof mullite powder in mass in the back layer coating into the agitated paste-shaped coating, enabling the polypropylene fiber to uniformly disperse, adding the silica sol once again so as to lower the mass ratio of the mullite powder to the silicon sol to (1.1-1.5):1, and continuously agitating the mixture for 2 h for stand-by application; selecting the polypropylene fiber with the diameter of Phi 30 mum-Phi 50 mum and length of 2mm-6mm; 5) back layer shell preparation; 6) slurry sealing; 7) calcination, cooling and tapping off. The preparation method has the advantages that the shell is high in humidity and strength, and low in shell residual strength; the high-temperature air permeability is not affected after the fiber is burned at a high temperature; the effect of improving metal liquid mold-filling capacity to a certain degree is achieved; the number of coating and smearing layers is decreased; the production efficiency is improved.

Owner:INNER MONGOLIA UNIV OF TECH

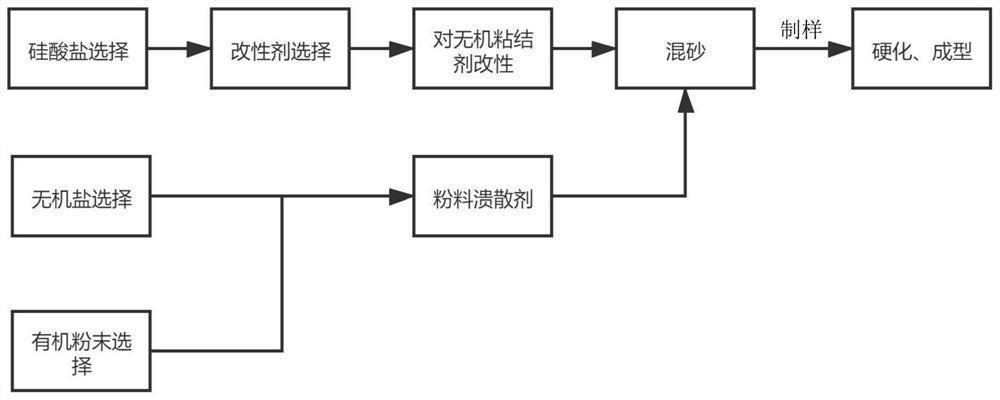

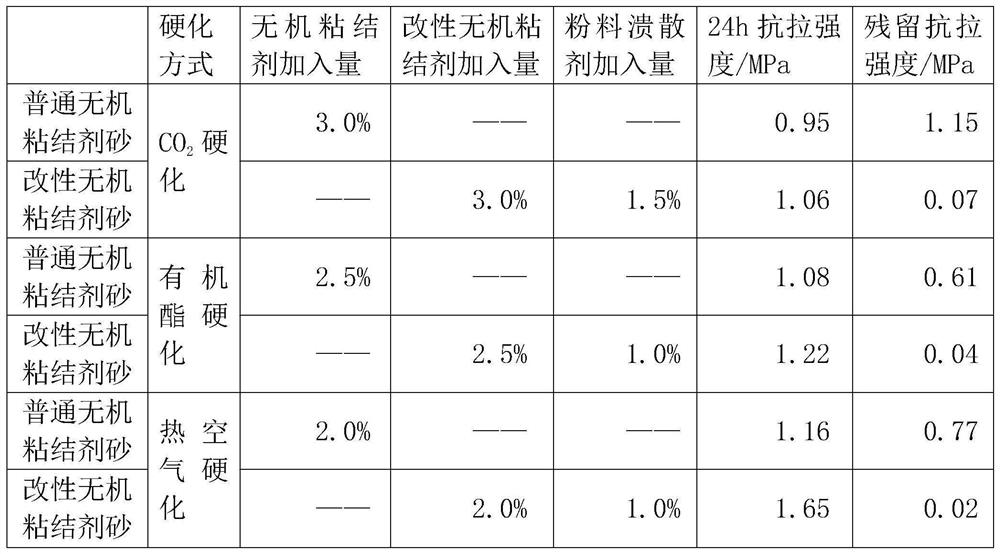

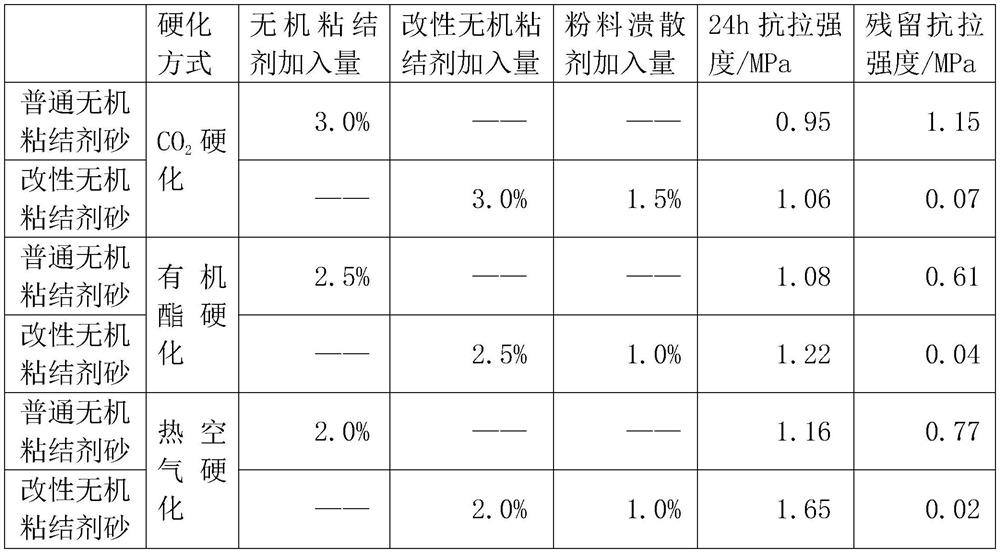

Modified inorganic binder sand with collapsibility and preparation method

PendingCN114472796AGood collapsibilityReduce labor intensityFoundry mouldsFoundry coresInorganic saltsPhosphate

The invention discloses modified inorganic binder sand with collapsibility. The modified inorganic binder sand comprises silica sand, a modified inorganic binder and a powder collapsibility agent, the modified inorganic binder comprises an inorganic binder and a modifier, the inorganic binder is a binder based on silicate, and the modifier comprises phosphate, borate and meta-aluminate and is used for modifying the inorganic binder; the powder collapsing agent is a mixture of inorganic salts and organic powder; comprising the following substances in parts by weight: 100 parts of silica sand, 2-5 parts of a modified inorganic binder and 1-3 parts of a powder collapsing agent, the collapsibility modifier is added in the modification process of the inorganic binder, and the powder collapsibility agent is added in the sand mixing process, so that the collapsibility of the inorganic binder type sand is remarkably improved, the residual strength of an inorganic binder sand mold is greatly reduced after pouring, a casting is easy to clean, the casting can be easily stripped from the molding sand, sand cleaning is facilitated, and the labor intensity of workers is reduced.

Owner:CHINA FIRST AUTOMOBILE +1

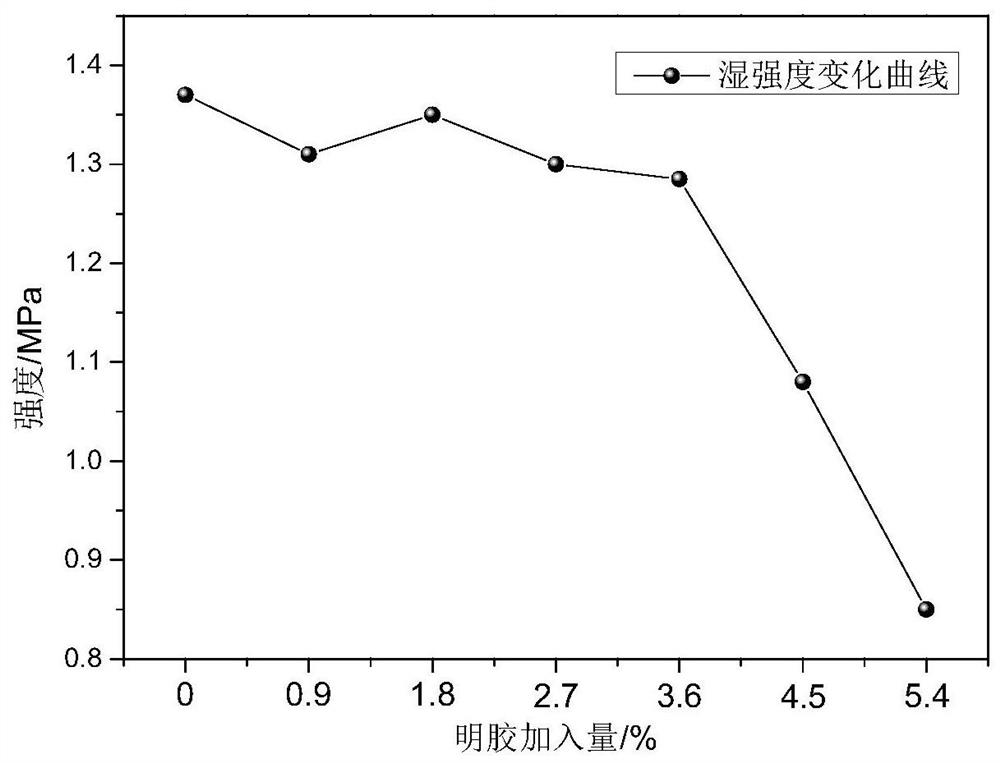

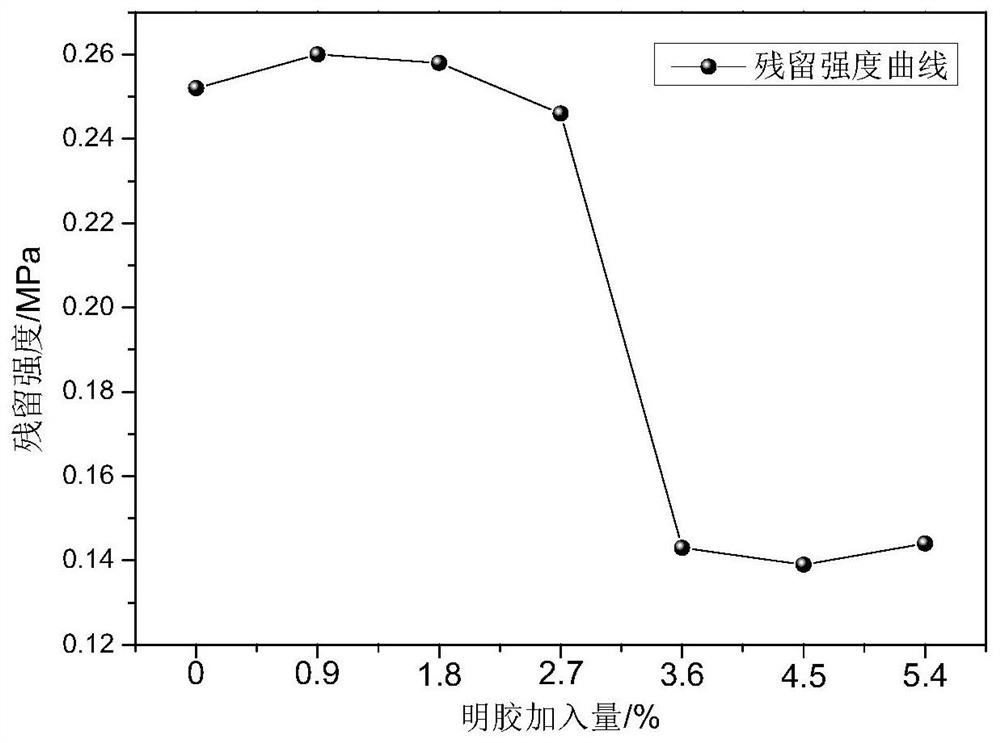

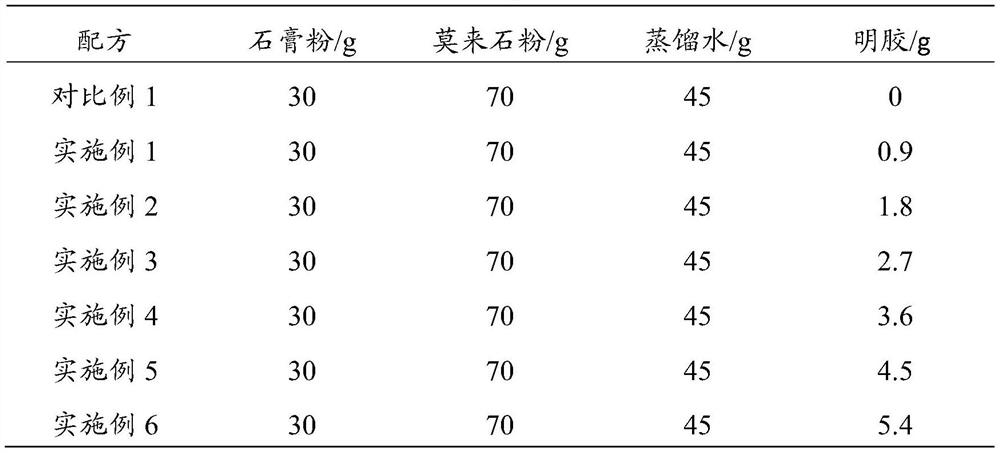

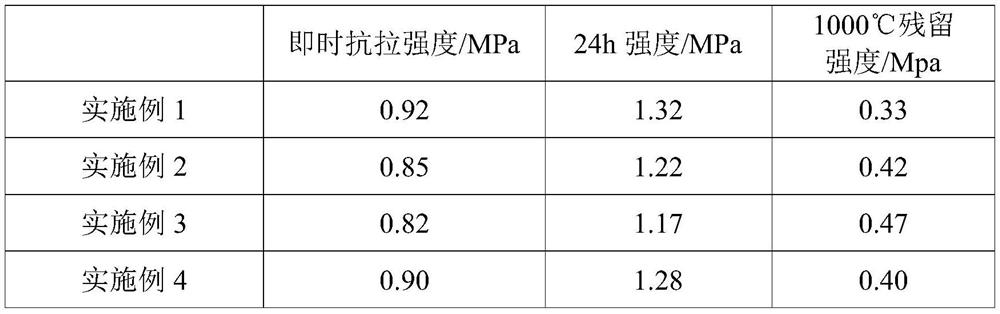

Gypsum shell low in retained strength and preparing method of gypsum shell

ActiveCN111604471AGuaranteed StrengthGuaranteed high temperature strengthFoundry mouldsFoundry coresPhysical chemistryEngineering

The invention discloses a gypsum shell low in retained strength and a preparing method of the gypsum shell. Gelatin is contained in the gypsum shell. The method comprises the steps that gypsum powderand filler are evenly mixed; after water is heated, the gelatin is added in the water, uniform mixing is conducted, and a transparent solution is obtained; gypsum powder and filler mixed powder is added in the transparent solution, and slurry is obtained; the slurry is poured into a die; after the slurry in the die is hardened, the die is dismounted, standing is conducted at the room temperature,and a wet gypsum shell is obtained; and the wet gypsum shell is naturally dried and roasted, and the gypsum shell low in retained strength is obtained. The gypsum shell is low in retained strength andeasy to clean, the preparing method is simple, and the production efficiency is high.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

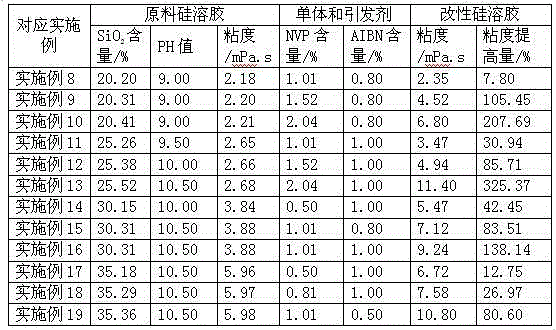

In-situ polymerization-modified silica sol and preparation method thereof

The invention discloses in-situ polymerization-modified silica sol. The in-situ polymerization-modified silica sol comprises alkaline silica sol and PVP obtained by in-situ polymerization. The in-situ polymerization-modified silica sol has the advantages of resource saving, low cost, popularization adaptability, less change of SiO2 content before and after modification, obvious improvement of modified silica sol viscosity, excellent interaction and performances between PVP and SiO2 in the silica sol, controllable modification degree and extensive applicability. The preparation method comprises the following steps of 1, uniformly dispersing a PVP monomer NVP in silica sol to obtain a mixture A, 2, dispersing an initiator in the mixture A to obtain a reaction system B, and 3, continuously stirring the reaction system B for a reaction lasting for 4-5h at a constant temperature of 90-100 DEG C to obtain modified silica sol. The preparation method has simple and convenient processes, realizes uniform dispersion of NVP in the silica sol by silica sol water as a solvent and in-situ polymerization on SiO2, and saves time and labor.

Owner:GUANGDONG WELL SILICASOL

Inorganic nanoparticle modified water glass and preparation method thereof

ActiveCN107243592BImprove performanceGood collapsibilityFoundry mouldsFoundry coresWater bathsHydrolysis

The invention discloses modified sodium silicate with inorganic nanoparticles and a preparation method thereof. The modified sodium silicate with the inorganic nanoparticles is mainly composed of the uniformly attached inorganic nanoparticles prepared by a hydrolysis precipitation method and ordinary sodium silicate. The specific preparation method mainly comprises the following steps that metal nitrate or metal chloride salt is dissolved by ethyl alcohol and then mixed with the sodium silicate, ultrasonic oscillation is carried out for 10-15 minutes to enable the mixture to be uniformly mixed, then stirring is carried out for 20-60 minutes at a water bath temperature of 40-60 DEG C, and then pH is adjusted to be 5-8 to obtain the modified sodium silicate with the inorganic nanoparticles which are uniformly mixed. According to the modified sodium silicate with the inorganic nanoparticles prepared by the method, the content of the sodium silicate in molding sand can be effectively reduced, so that the collapsibility of the sodium silicate sand is greatly improved; and the molding sand prepared by the modified sodium silicate with the inorganic nanoparticles also has good comprehensive high-temperature performance, the gas evolution of the molding sand is remarkably reduced, and the quality of a casting is improved.

Owner:浙江遂金特种铸造有限公司

Inorganic binder for 3D printing and preparation method thereof

ActiveCN114230211AEasy to useReduce residual strengthAdditive manufacturing apparatusSolid waste managementEpoxy3d print

The invention provides an inorganic binder for 3D printing and a preparation method thereof, the inorganic binder for 3D printing comprises an inorganic binder and a powder accelerator which are cooperatively used, and the mass part ratio of the inorganic binder to the powder accelerator is 100: (10-60); the inorganic binder comprises the following raw materials in parts by mass: 40-70 parts of a sodium silicate solution, 10-40 parts of a potassium silicate solution, 0.5-10 parts of gamma aluminum oxide, 0.5-15 parts of potassium hydroxide, 0.5-15 parts of sodium hydroxide, 0.5-10 parts of water-soluble epoxy resin, 0.5-10 parts of modified starch, 0.1-3 parts of a water reducing agent and 0.1-3 parts of a surfactant. The powder accelerant is prepared from the following raw materials in parts by mass: 40 to 70 parts of silica fume, 5 to 20 parts of superfine calcium oxide, 0.5 to 20 parts of superfine titanium oxide, 0.5 to 10 parts of superfine zirconium oxide, 1 to 10 parts of superfine zinc oxide, 1 to 10 parts of superfine yttrium oxide and 0.5 to 2 parts of graphite. When the inorganic binder is used, infrared heating or hot air is adopted as a hardening mode, and the use requirement for producing the 3D printing inorganic binder sand core can be met.

Owner:SHENYANG RES INST OF FOUNDRY

A High Performance Investment Casting Shell

Owner:ANHUI HUSN KEWAN SPECIAL CASTING

High-performance investment casting mould shell

ActiveCN107520405AHigh strengthReduce distortionFoundry mouldsFoundry coresTemperature resistanceWax

The invention discloses a high-performance investment casting mould shell, and relates to the technical field of casting. A manufacturing method for the high-performance investment casting mould comprises the following steps of: (1) uniformly mixing 500-mesh quartz sand, rare earth, an ethyl silicate-rosin complexing agent and activated bentonite to obtain a mixture I, adding the mixture I into a high-speed stirrer to stir, thereby obtaining mould shell inner-layer slurry; mixing 200-mesh quartz sand, the ethyl silicate-rosin complexing agent and activated bentonite to obtain a mixture II, adding the mixture II into a high-speed stirrer, and stirring to obtain mould shell outer-layer slurry; (2) uniformly coating the mould shell inner-layer slurry to the surface of a wax mould, drying, and uniformly coating the mould shell outer-layer slurry, thereby obtaining a coated wax mould; (3) uniformly bundling the surface of the coated wax mould by an iron wire; and (4) putting the coated wax mould at a high temperature to perform wax melting treatment, and completely melting the wax mould to obtain the needed casting mould shell. The manufactured investment casting mould shell can cast a cast piece with higher precision and surface roughness, is high in high temperature resistance and strength, and is low in retained strength.

Owner:ANHUI HUSN KEWAN SPECIAL CASTING

Silica sol binder for shell

InactiveCN110802196AImprove gelationFast dryingFoundry mouldsFoundry coresCelluloseSodium phosphates

The invention discloses a silica sol binder for a shell. The silica sol binder comprises the following components in percentage by mass: 85-90% of alkaline silica sol, 0.6-1.2% of mesoporous silica nanospheres, 0.1-0.2% of calcium hydroxide, 0.3-0.5% of nano-crystalline cellulose, 0.15-0.25% of a dispersing auxiliary and the balance of water, wherein the dispersing auxiliary comprises sodium hexametaphosphate, poly(ethylene glycol) methyl ether-2000 and triethanolamine. The silica sol binder has higher drying speed, can shorten the interlayer drying time, improves the production efficiency ofthe shell, is short in shell manufacturing period and high in shell manufacturing efficiency, can improve the normal temperature strength of the shell, and is low in residual strength, easy to clean and suitable for producing castings with complicated geometrical shapes.

Owner:东风精密铸造安徽有限公司

Method for preparing silica sol binding agent

Owner:ZHEJIANG YUDA CHEM IND

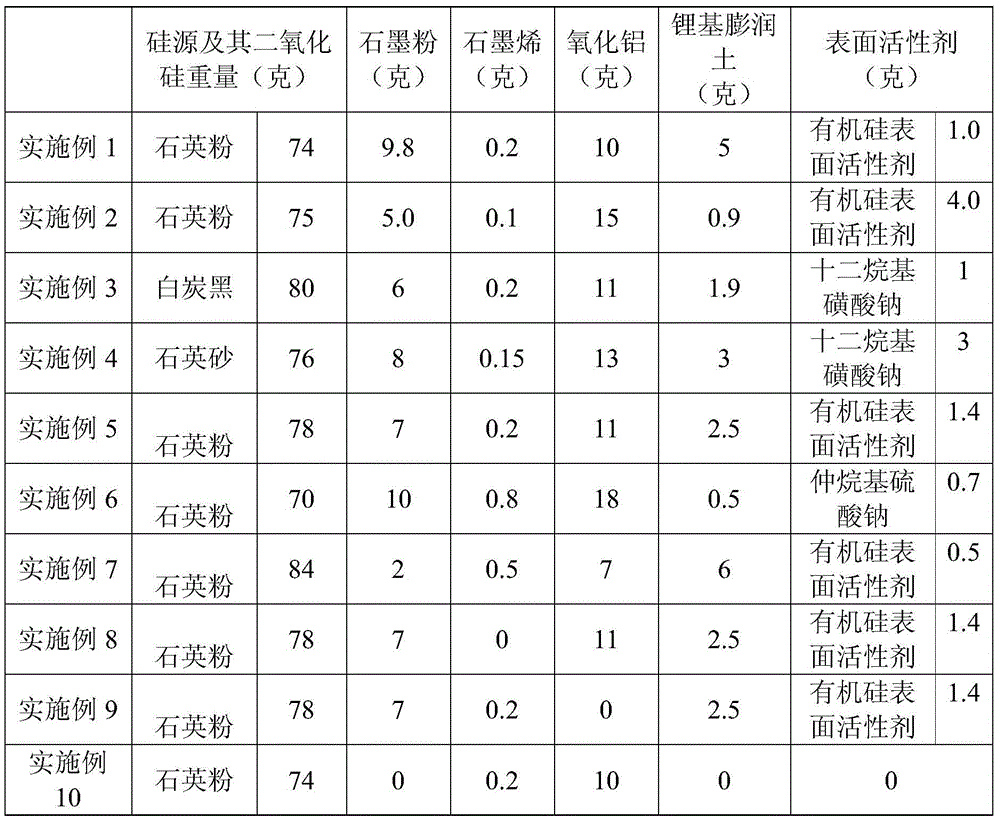

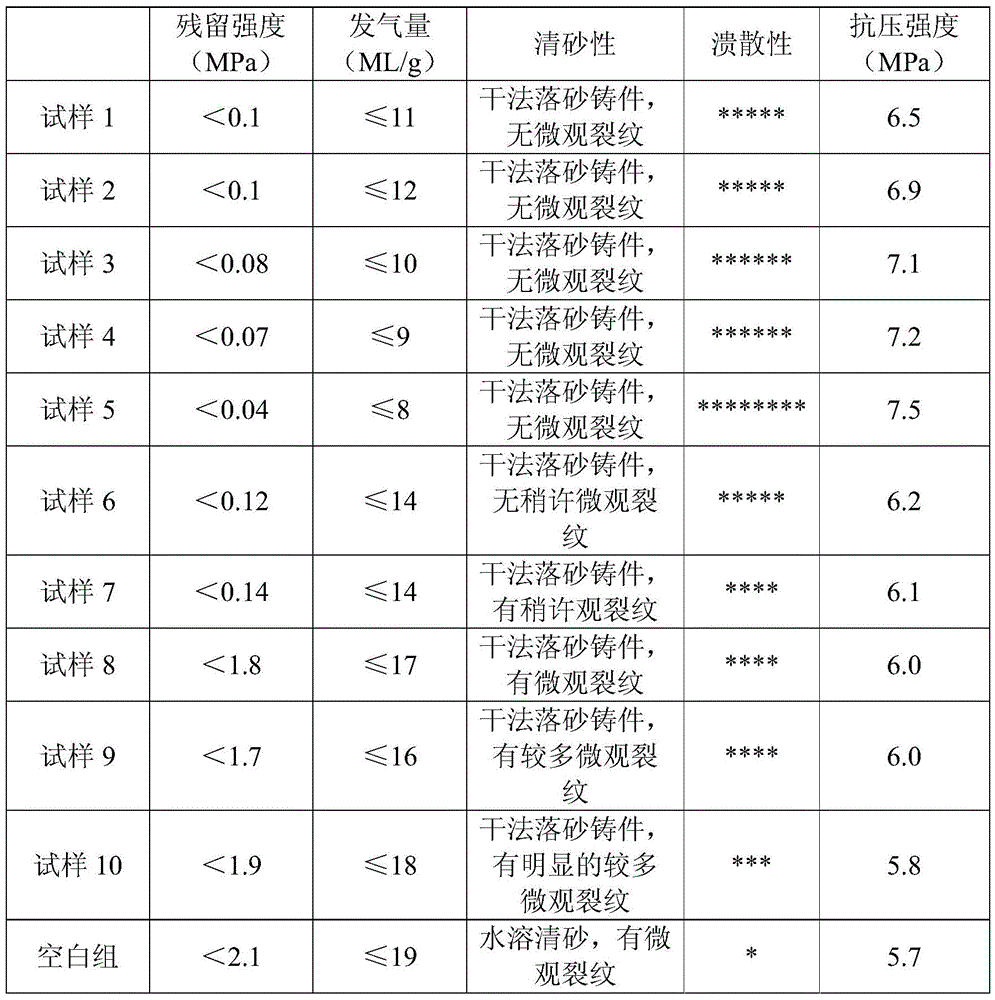

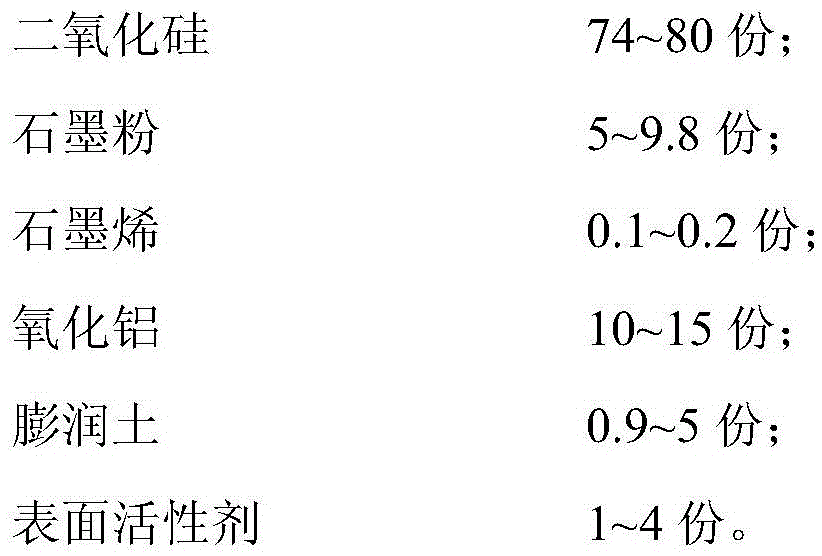

Collapse enhancer for water glass sand

ActiveCN104259379BHigh bonding strengthNo irritating smellFoundry mouldsFoundry coresSilicic acidPotassium silicate

The invention relates to a collapsibility enhancer for sodium silicate-bonded sand. Raw material components of the collapsibility enhancer for the sodium silicate-bonded sand comprise silicon dioxide, alumina and graphene. The inventor creatively adopts a mixture of the silicon dioxide, the alumina and the graphene as the collapsibility enhancer; no organic matters are contained in the collapsibility enhancer, so that no combustible gases generate; more importantly, the situation that the sodium silicate-bonded sand which takes sodium silicate, potassium silicate and lithium silicate as main bodies and is used for casting is difficult to clean after the sodium silicate-bonded sand is cast can be greatly improved; the collapsibility of the sodium silicate-bonded sand is remarkably improved, and the strength of molding sand of the sodium silicate-bonded sand is obviously improved. According to the collapsibility enhancer disclosed by the invention, on the premise that the organic matters are not added and the gas evolution of a sand core is not improved, the collapsibility of an inorganic binder taking the sodium silicate-bonded sand as a main component is greatly improved, the retained strength of the inorganic binder is greatly reduced, and the strength of the sodium silicate-bonded sand is improved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Polymer-modified silicasol and manufacturing method thereof

ActiveCN101786139BGood film formingIncreased water balance pointFoundry mouldsFoundry coresWaxPolymer modified

The invention provides polymer-modified silicasol which contains alkaline silicasol and polyvinyl pyrrolidone, wherein the weight percent of SiO2 in the alkaline silicasol in the polymer-modified silicasol is 20.0-36.0%, and the weight percent of the polyvinyl pyrrolidone in the polymer-modified silicasol is 0.1-5.0%. The preparation method comprises the following steps: (1) preparing a polyvinylpyrrolidone water solution; (2) preparing the alkaline silicasol; and (3) uniformly mixing the solutions prepared in step (1) and step (2) according to the required ratio to obtain the polymer-modified silicasol. The polymer-modified silicasol can obviously shorten the drying time of the investment casting shell-making interlayers, effectively increases the normal-temperature strength of a wax pattern shell, decreases the retained strength of the wax pattern shell without influencing the hot strength of the vax pattern shell, has the advantages of simple preparation method and low cost, and is applicable to popularization and application.

Owner:GUANGDONG WELL SILICASOL

Special coating of hot-mould centrifugal casting mould for flexible joint ferrosteel pipe

InactiveCN100339169CImprove the level ofImprove liquidityFoundry mouldsFoundry coresCelluloseSodium Bentonite

The present invention relates to a soft joint grey cast-iron pipe hot-mould centrifugal casting special-purpose adhering moulding material. It includes fire-resisting aggregate, bonding agent, suspension agent and water. The described fire-resisting aggregate includes diatomite powder, perlite powder, vermiculite powder and silica flour, and the described bonding agent and suspension agent include sodium base bentonite and sodium cellalose glycollate. Said invention also provides its preparation method and concrete steps.

Owner:张鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com