CO2 hardened inorganic binder and preparation method thereof

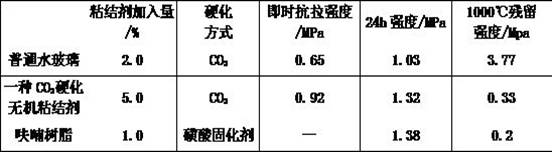

A technology of inorganic binder and liquid binder, which is applied in the field of CO2 hardening inorganic binder and its preparation, CO2 hardening inorganic binder and its preparation field, which can solve the problem of increasing the amount of water glass added and difficult molding sand for castings. Separation, high residual strength of sand mold, to achieve the effect of reducing residual strength, good stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] One of the CO 2 The preparation method of hardening inorganic binder, described a kind of CO 2 The preparation method of hardened inorganic binder comprises the following steps:

[0026] (1) Weigh the raw materials. The liquid binder includes the following mass fractions of raw materials: 50-90 parts of sodium silicate solution, 10-40 parts of potassium silicate solution, 5-20 parts of aluminum phosphate, and 5-20 parts of potassium hydroxide , 0.1-20 parts of sodium hydroxide; the powder accelerator includes the following raw materials in mass fractions: 50-90 parts of silica fume, 5-20 parts of calcium oxide, 2-20 parts of titanium oxide, 2-20 parts of zirconia, zinc oxide 1-10 parts, 1-10 parts of yttrium oxide, 0.1-2 parts of graphite.

[0027] (2) Preparation of liquid binder: first add sodium silicate solution, potassium silicate solution and sodium hydroxide into the container for stirring, heat the liquid in the container, when the liquid temperature is 60-75°...

Embodiment 1

[0036] One of the CO 2 The preparation method of hardened inorganic binder comprises the following steps:

[0037] (1) Weigh raw materials: liquid binder including mass fraction of raw materials: 60 parts of sodium silicate solution, 20 parts of potassium silicate solution, 10 parts of aluminum phosphate, 7 parts of potassium hydroxide, 3 parts of sodium hydroxide; powder The accelerator includes the following raw materials in mass fractions: 75 parts of silica fume, 10 parts of calcium oxide, 5 parts of titanium oxide, 5 parts of zirconium oxide, 2.5 parts of zinc oxide, 2 parts of yttrium oxide, and 0.5 part of graphite.

[0038] (2) Preparation of liquid binder: first add sodium silicate solution, potassium silicate solution and sodium hydroxide into the container for stirring, heat the liquid in the container, when the liquid temperature is 60-75°C, add aluminum phosphate , continue heating, when the temperature of the liquid reaches 95-105°C, keep the temperature for 60 ...

Embodiment 2

[0042] One of the CO 2 The preparation method of hardened inorganic binder comprises the following steps:

[0043] (1) Weigh raw materials: liquid binder including mass fraction of raw materials: 50 parts of sodium silicate solution, 20 parts of potassium silicate solution, 15 parts of aluminum phosphate, 12 parts of potassium hydroxide, 3 parts of sodium hydroxide; powder The accelerator includes the following raw materials in mass fractions: 55 parts of silica fume, 20 parts of calcium oxide, 10 parts of titanium oxide, 7 parts of zirconium oxide, 5.5 parts of zinc oxide, 2.4 parts of yttrium oxide, and 0.1 part of graphite.

[0044] (2) Preparation of liquid binder: first add sodium silicate solution, potassium silicate solution and sodium hydroxide into the container for stirring, heat the liquid in the container, when the liquid temperature is 60-75°C, add aluminum phosphate , continue heating, when the temperature of the liquid reaches 95-105°C, keep the temperature for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com