Patents

Literature

227 results about "Residual strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Residual strength is the load or force (usually mechanical) that a damaged object or material can still carry without failing. Material toughness, fracture size and geometry as well as its orientation all contribute to residual strength.

Aircraft health monitoring and design for condition

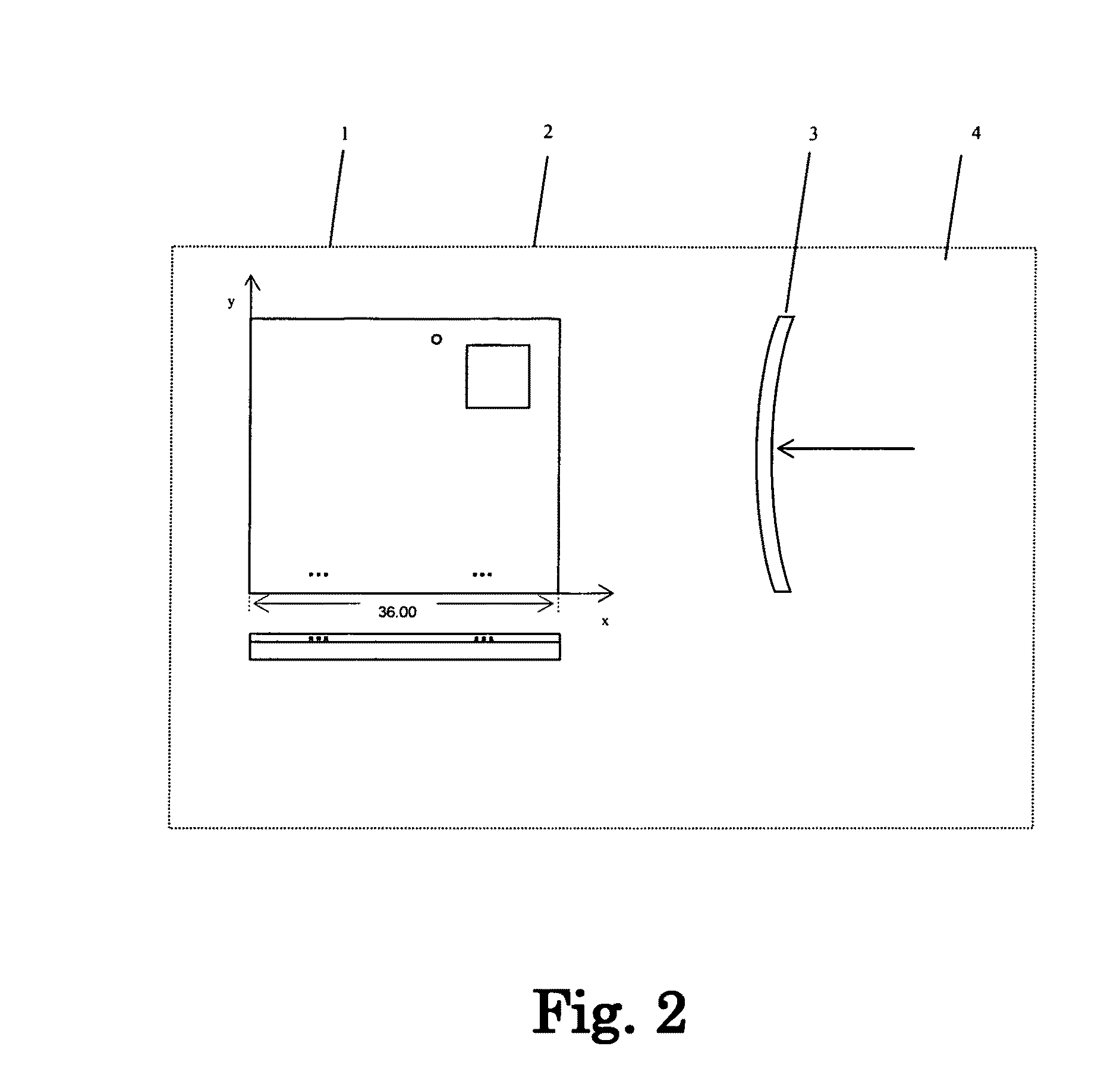

ActiveUS20110245999A1Vehicle testingRegistering/indicating working of vehiclesResidual strengthStructural health monitoring

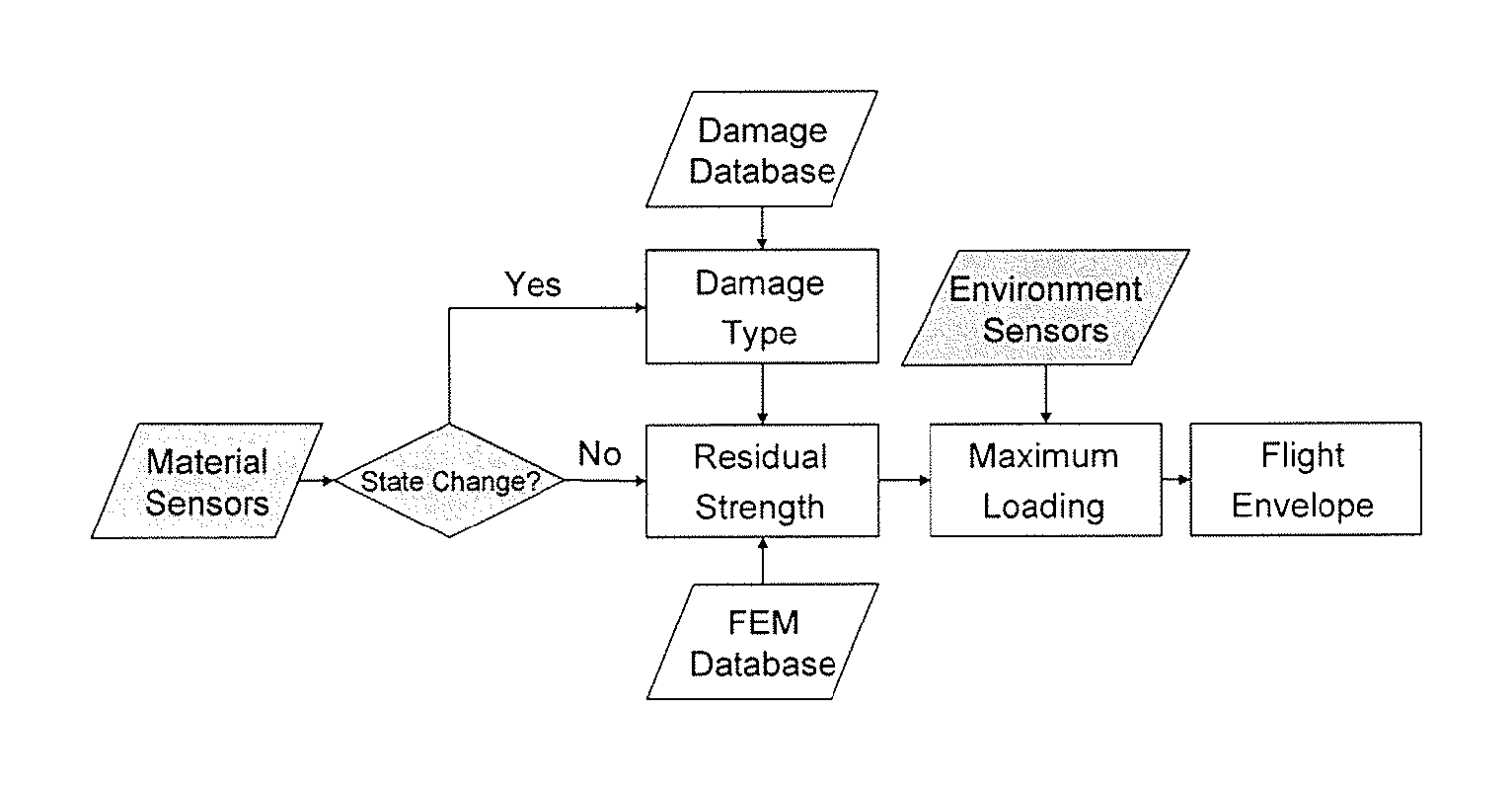

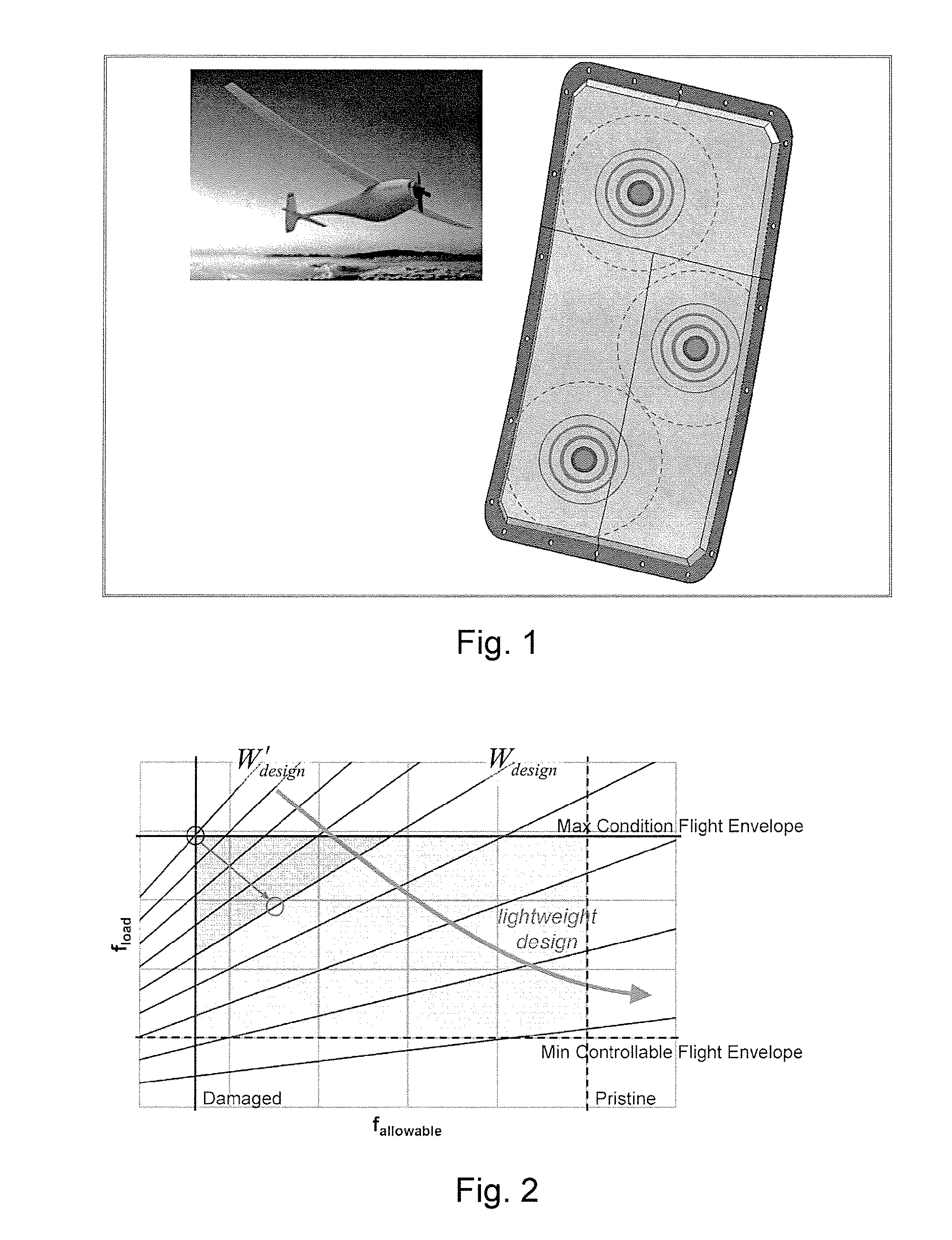

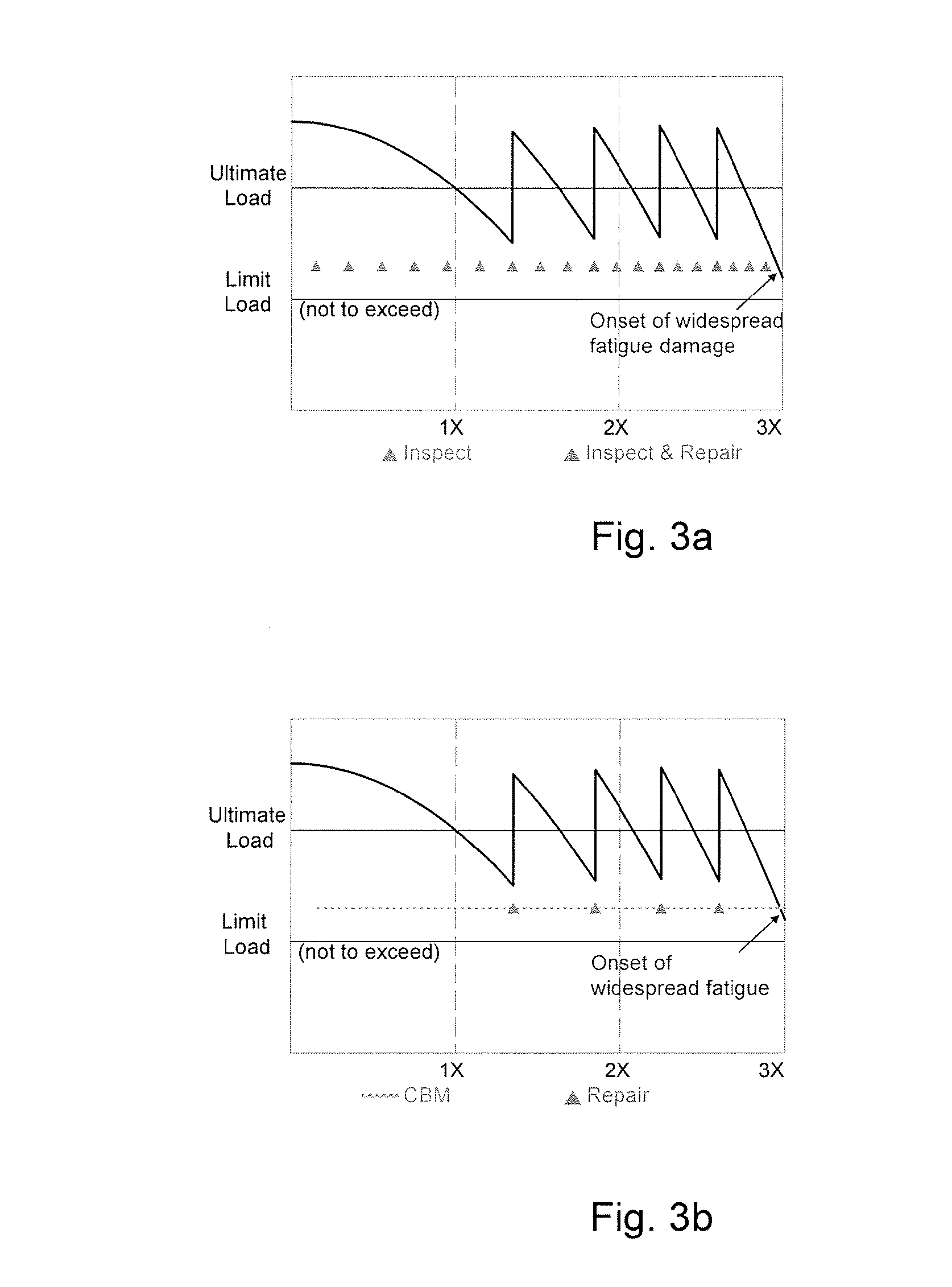

A system and method for automatically varying the flight envelope of an aircraft based upon the material health of the aircraft and the flight environment is provided. The system includes a plurality of structural health monitoring and load sensors that determine the approximate size and the approximate location of the damage. The system performs residual strength calculations for individual aircraft components to determine the overall aircraft residual strength. The system uses these calculations to determine a maximum flight envelope based on the overall aircraft residual strength, and transmits this information to the flight controller and optionally to the pilot.

Owner:AURORA FLIGHT SCI CORP

Aircraft fuselage shell component with crack propagation resistance

InactiveUS6595467B2Increasing weight and costEasy to crackFuselage bulkheadsWelding apparatusResidual strengthFiber-reinforced composite

Owner:AIRBUS OPERATIONS GMBH

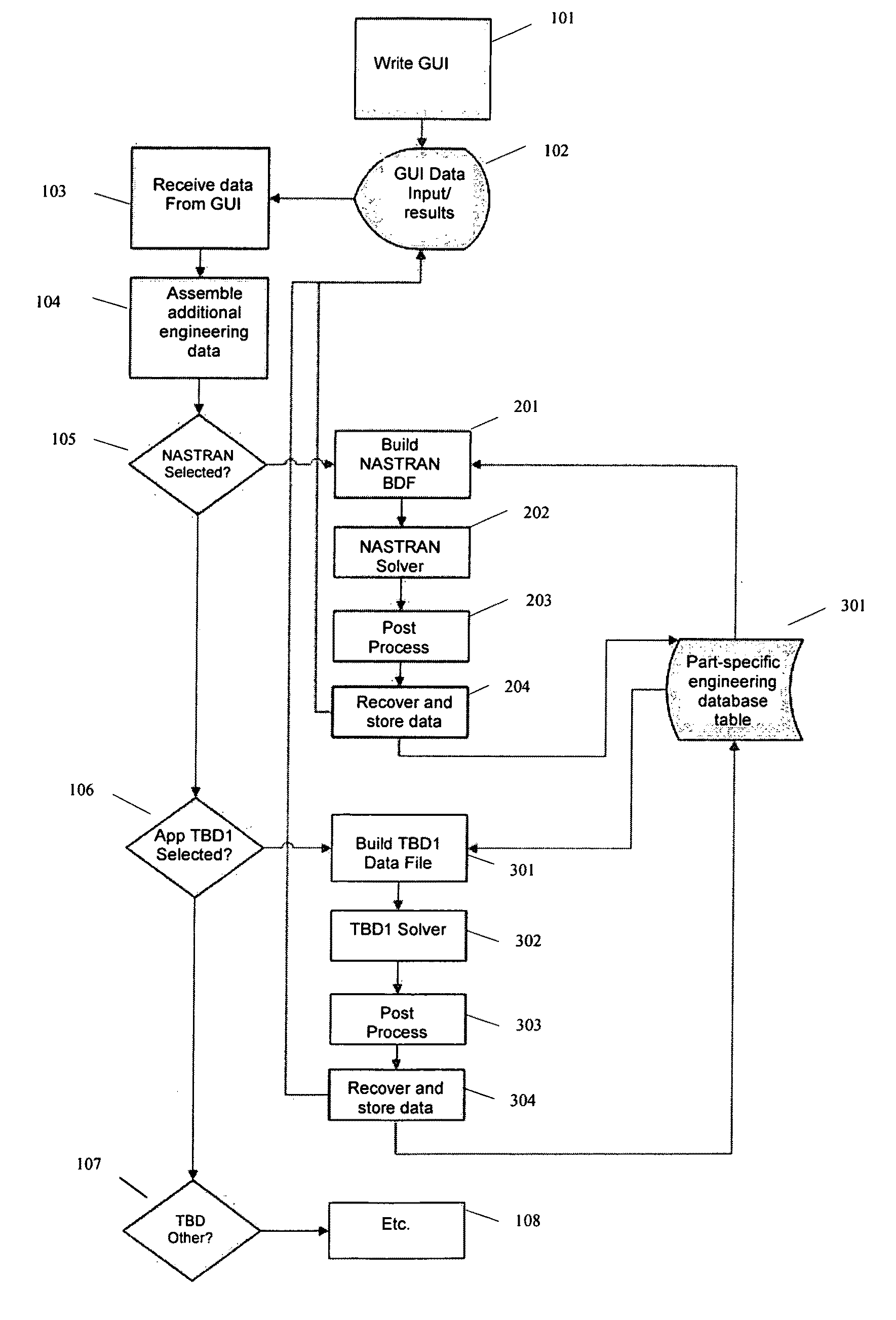

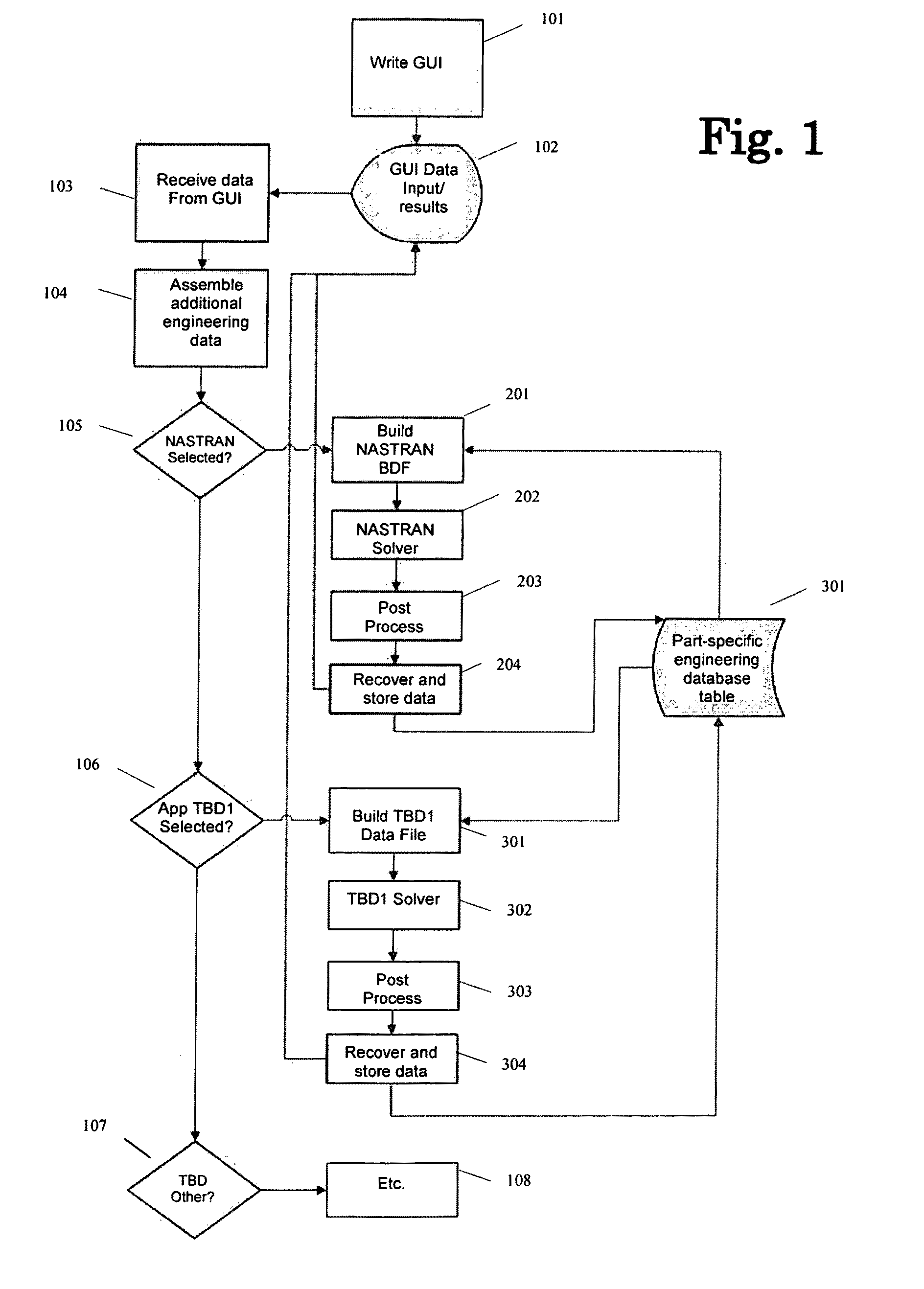

Automatic Repair Planning and Part Archival System (ARPPAS)

InactiveUS20090234616A1Easy accessGuaranteed maximum utilizationNuclear monitoringDigital computer detailsResidual strengthStructural analysis

An automated repair structural analysis processing system for aircraft composite parts is disclosed, combining a method for digitally describing damage on composite components with a system that evaluates composite aircraft repair options for a given part design, damage set, and repair history, and provides automatic calculation of the residual strength of damaged metal and composite parts. In addition, this invention provides a system that automatically informs maintenance specialists when they will not be allowed to repair a part based on an automatic structural analysis of that part, and automatically generates an assessment of conformity with engineering acceptance standards that can be used to generate a request for engineering disposition automatically sent to the appropriate engineering or executive authority.

Owner:SYNCRETEK

Metallic composite low carbon magnesium carbon brick for ladle slag wire and manufacture method thereof

The invention discloses a metal complex low-carbon magnesia carbon brick used for ladle slag lines, the weight percentage of the added materials is as following, 50 to 70 percent of magnesia particles, 25 to 35 percent of magnesia powder, and 3 to 6 percent of organic binder, furthermore, the following components are added which are produced by mixing, striating materials, forming and heat-treatment, 0 to 4 percent of flake graphite, 3 to 15 percent of metal powder, and 0.5 to 3 percent of antioxidant containing boron. The antioxidant properties, slag-resistance performance, high temperature strength and the thermal shock resistance of the ladle slag line used metal complex low-carbon magnesia carbon brick are greatly improved, the service life is prolonged, the consumption cost of each ton of refractories is lowered. The preparation method of ladle slag line used metal complex low-carbon magnesia carbon bricks is also disclosed, and the carbon content in the ladle slag line used metal complex low-carbon magnesia carbon bricks produced by the method is less than or equal to 6 percent, little carbon is added so as to reduce the pollution towards liquid steel, and residual strength ratio of the thermal shock resistance is kept at 70 to 80 percent.

Owner:ZHENGZHOU UNIV +1

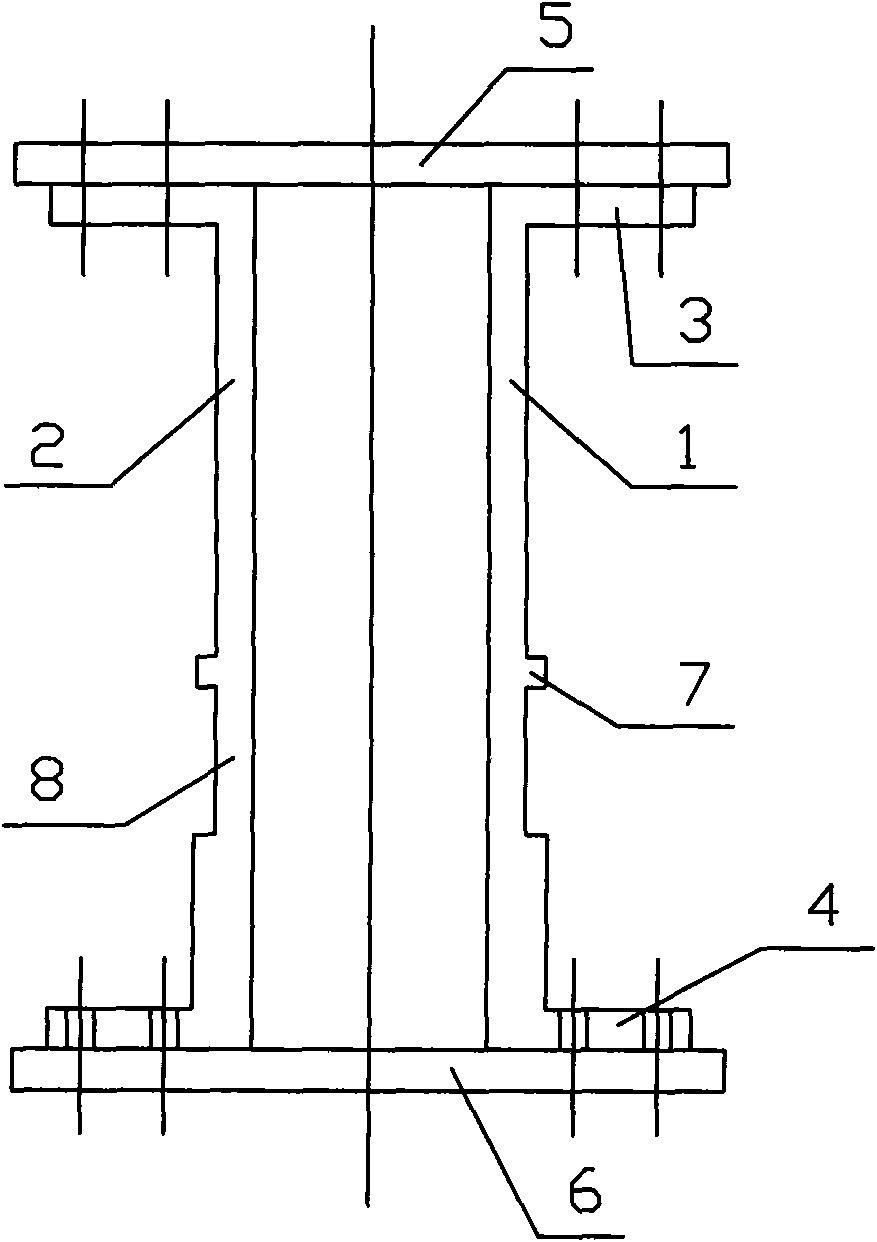

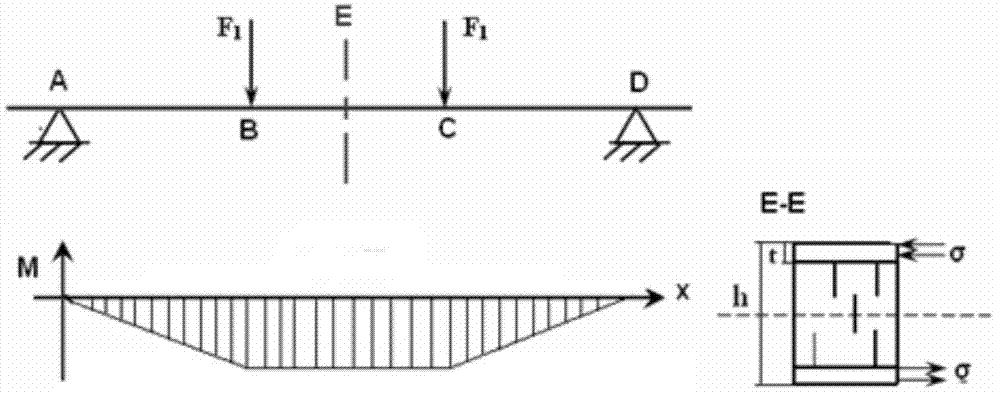

Damage-tolerance testing method for whole wing spar of airplane

InactiveCN101561365ASolve scalabilitySolve the strength problemStructural/machines measurementJet aeroplaneResidual strength

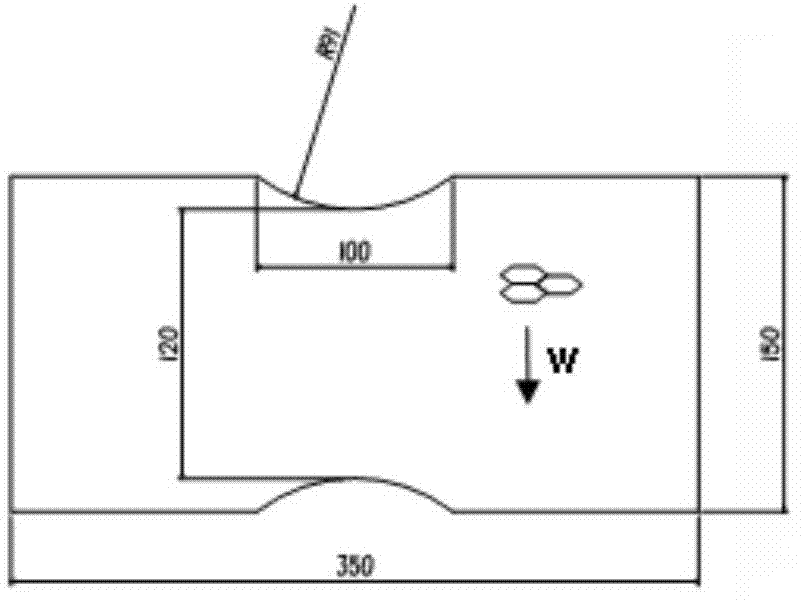

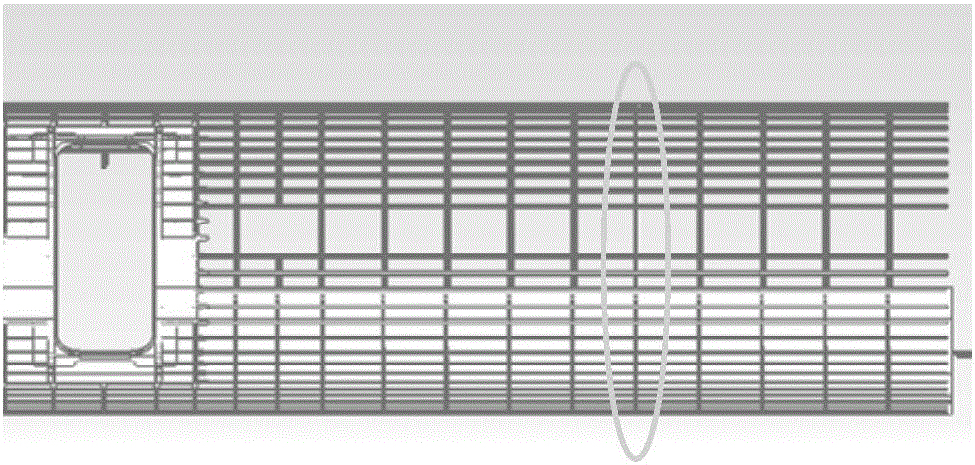

The invention pertains to airplane fatigue and damage-tolerance testing technologies, and relates to a damage-tolerance testing method for the whole wing spar of an airplane. The method comprises the steps of: (I) choosing a part with large load from the whole wing spar for serving as a testing part examining segment, (II) producing two same testing parts according to the examining segment, (III) reserving an interval of 20 to 30mm between the two back-to-back testing parts which are respectively provided with a coating in the upper part and the lower part (the coating is connected with an upper spar edge strip and a lower spar edge strip to form a case segment), (IV) fixing the root of the testing case segment completing assembly on a load-bearing wall, (V) exerting concentrated load at one end of the testing parts to simulate the bending moment of the spar at the testing segment and the shearing force of a web, without considering the influence of the shearing flow of the coating and (VI) using a finite element method to conduct damage tolerance analysis on the testing parts and comparing testing results. The method solves the difficulty that the crack expansion and remaining strength of the present airplane whole wing spar structure lack theoretical evidence; and the design of the testing parts adopts a method of simultaneously conducting tests to the two back-to-back testing parts, thereby eliminating the distortion of a single spar.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

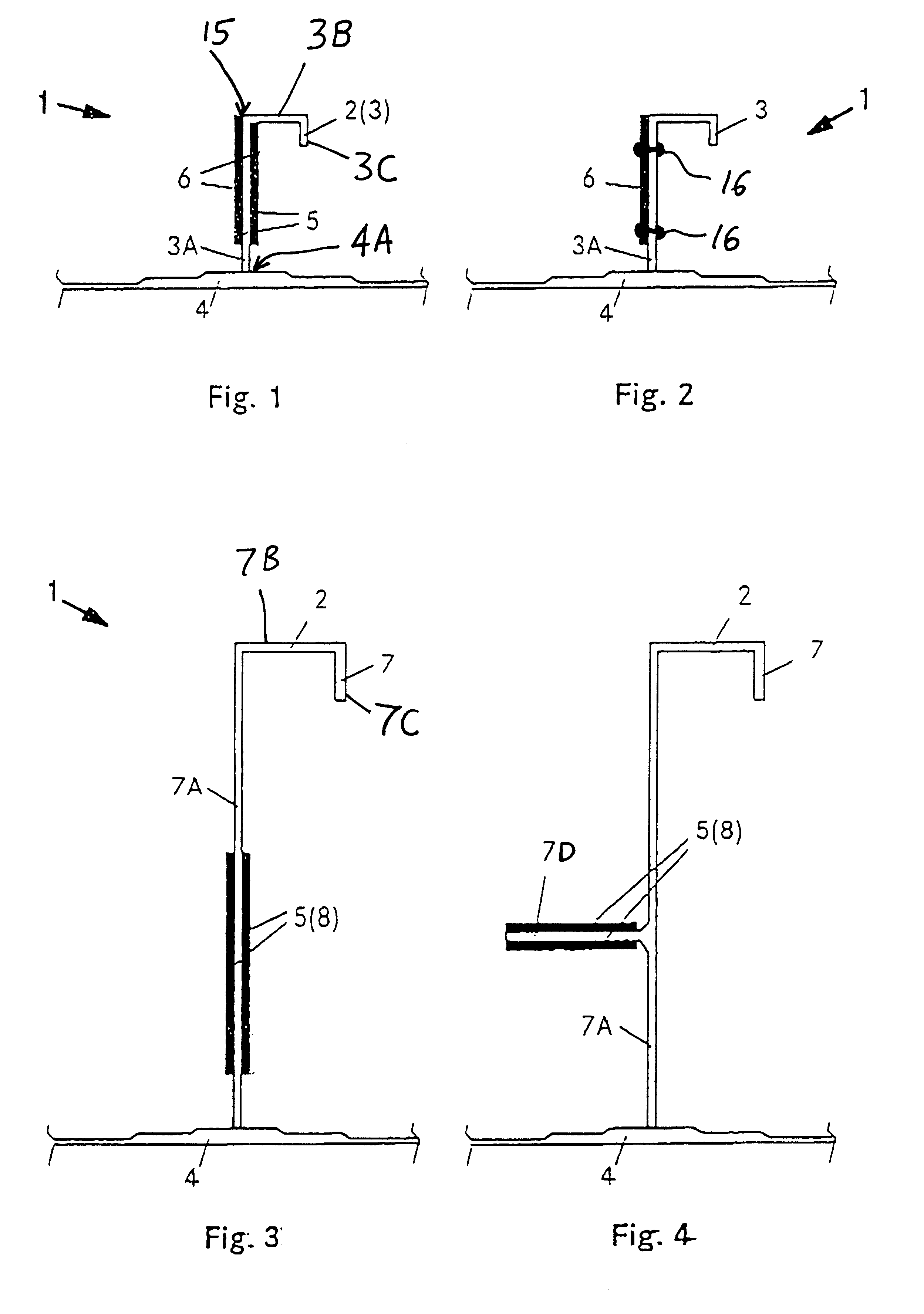

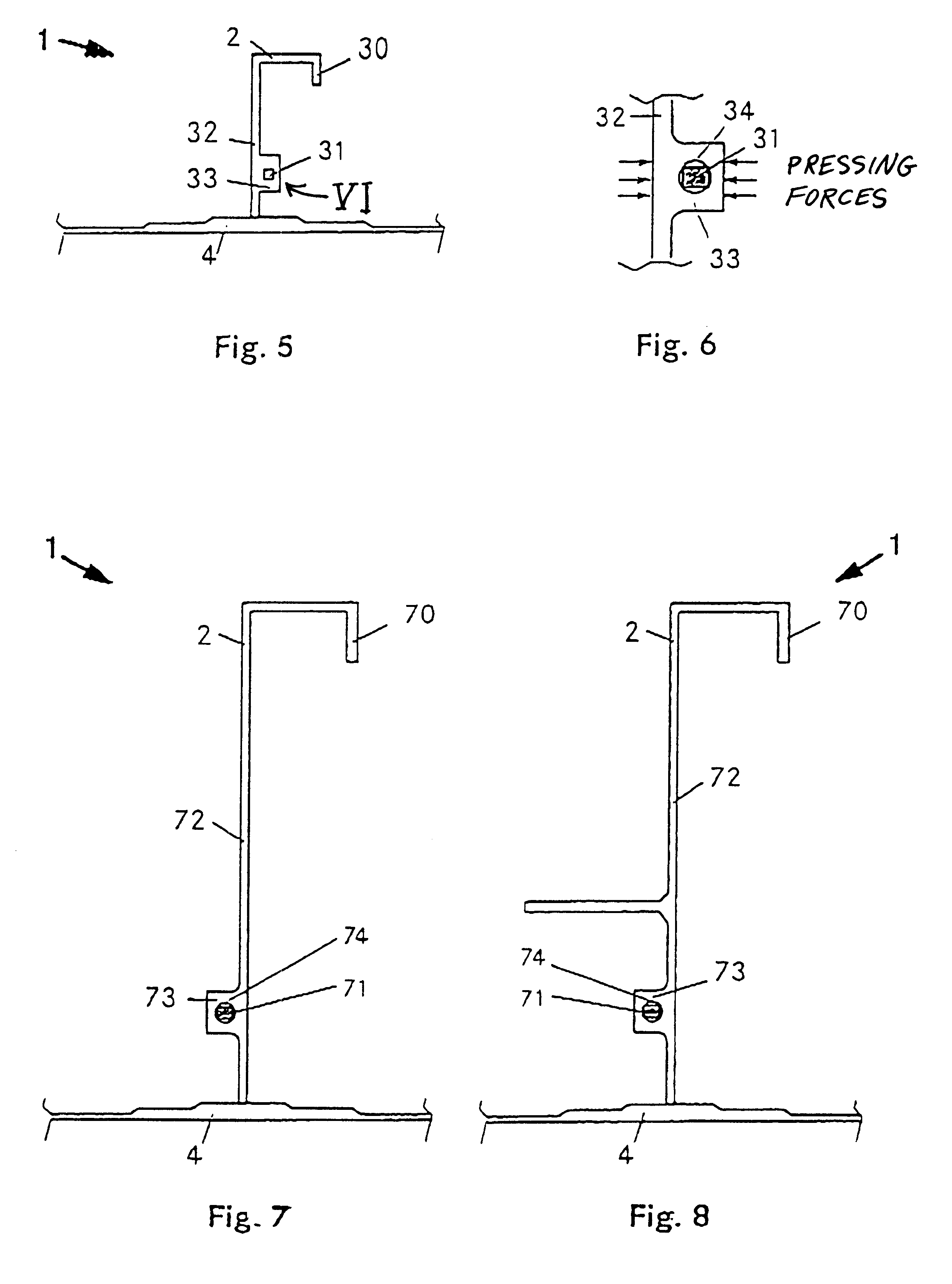

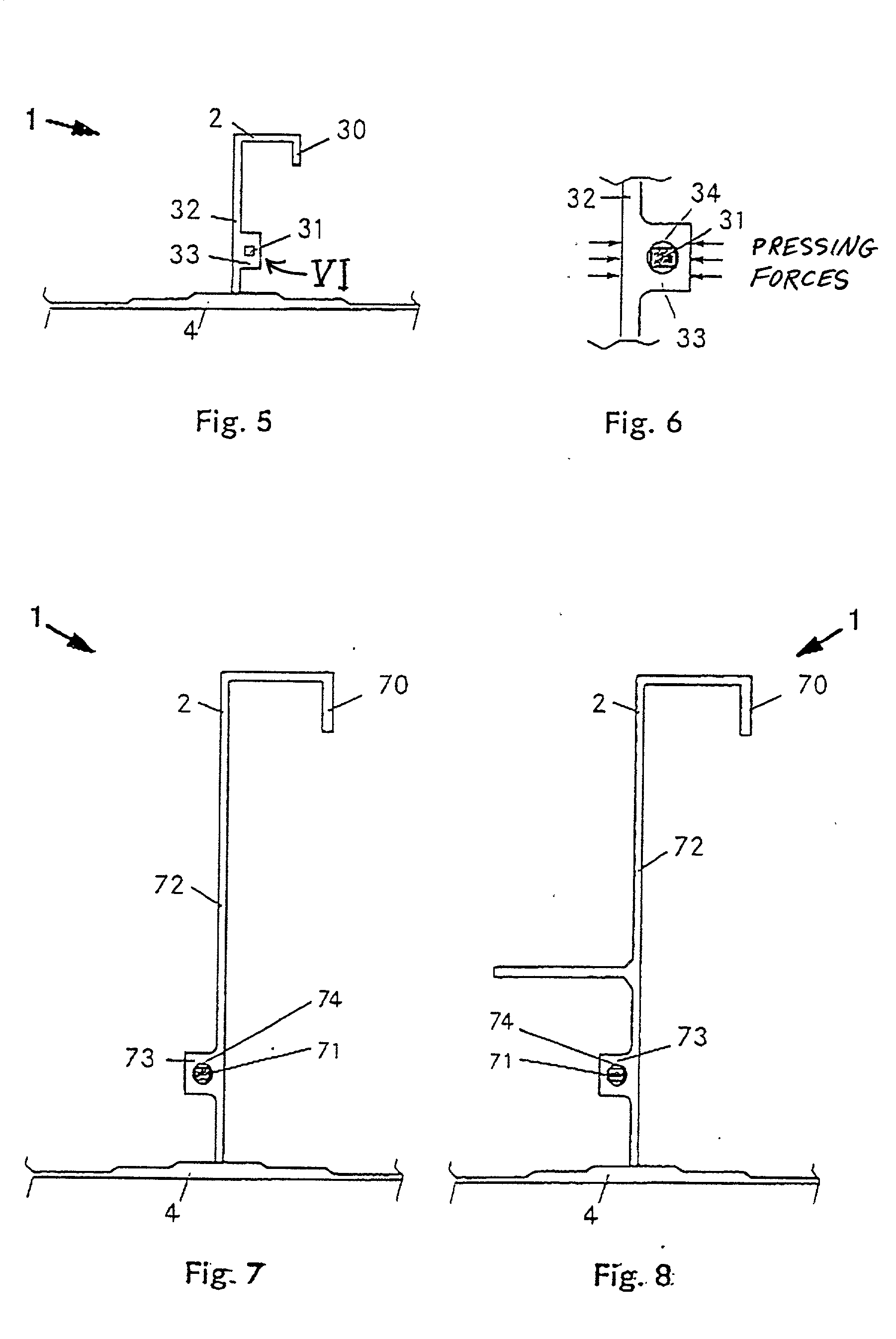

Metal structural component for an aircraft, with resistance to crack propagation

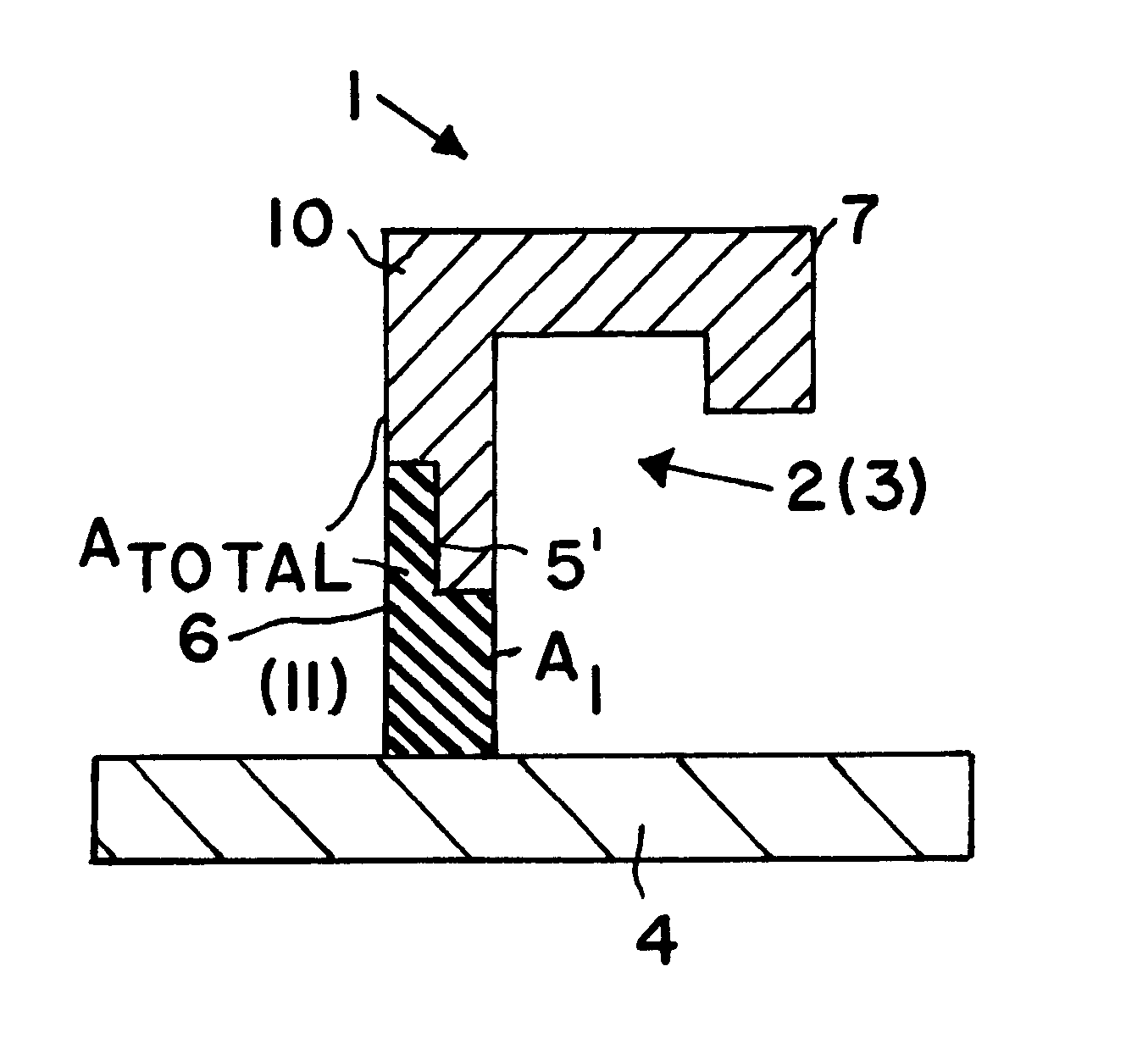

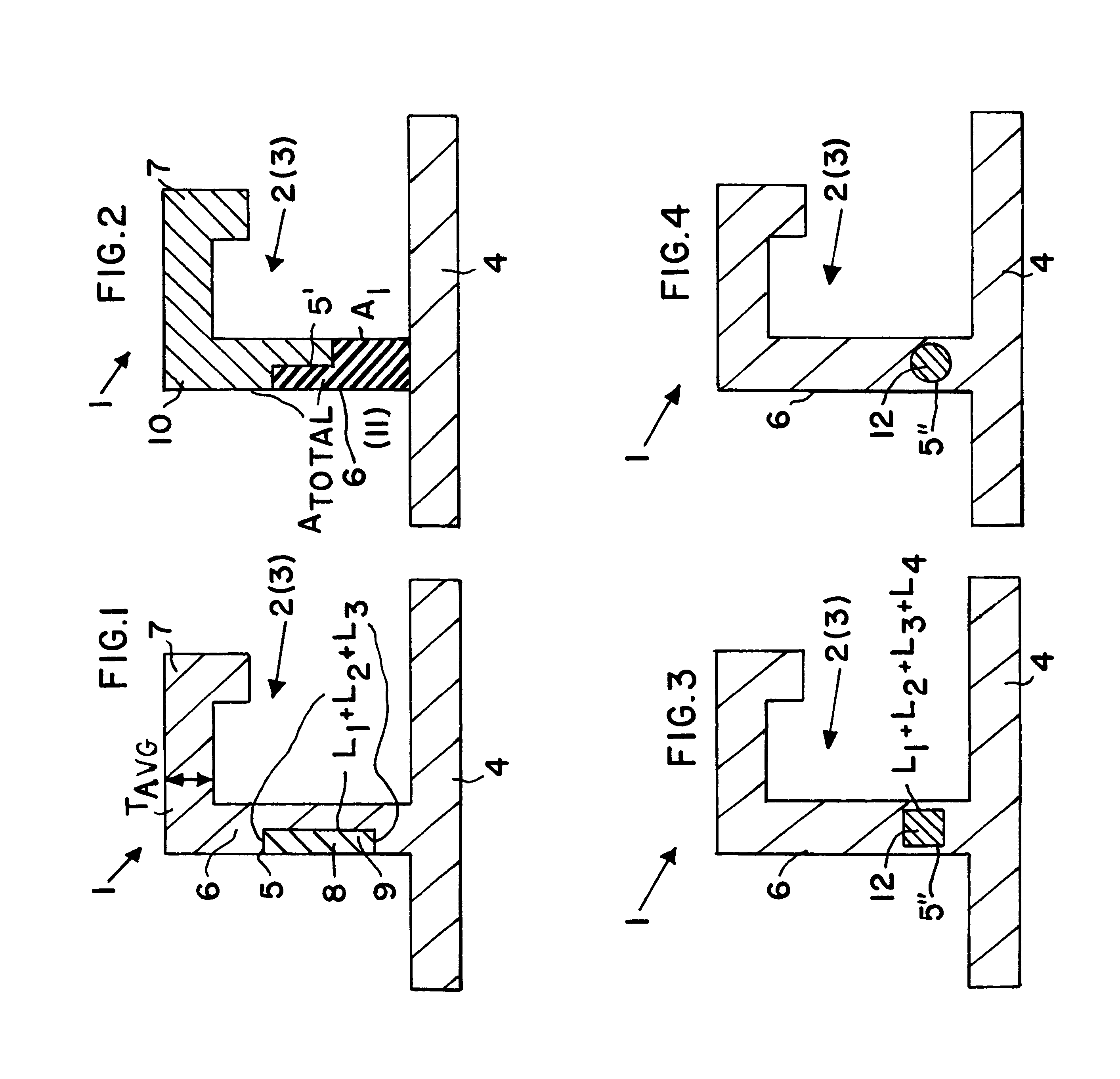

InactiveUS6712315B2Reduces effort and expenseImprove residual strengthFuselage framesAircraft stabilisationResidual strengthCrazing

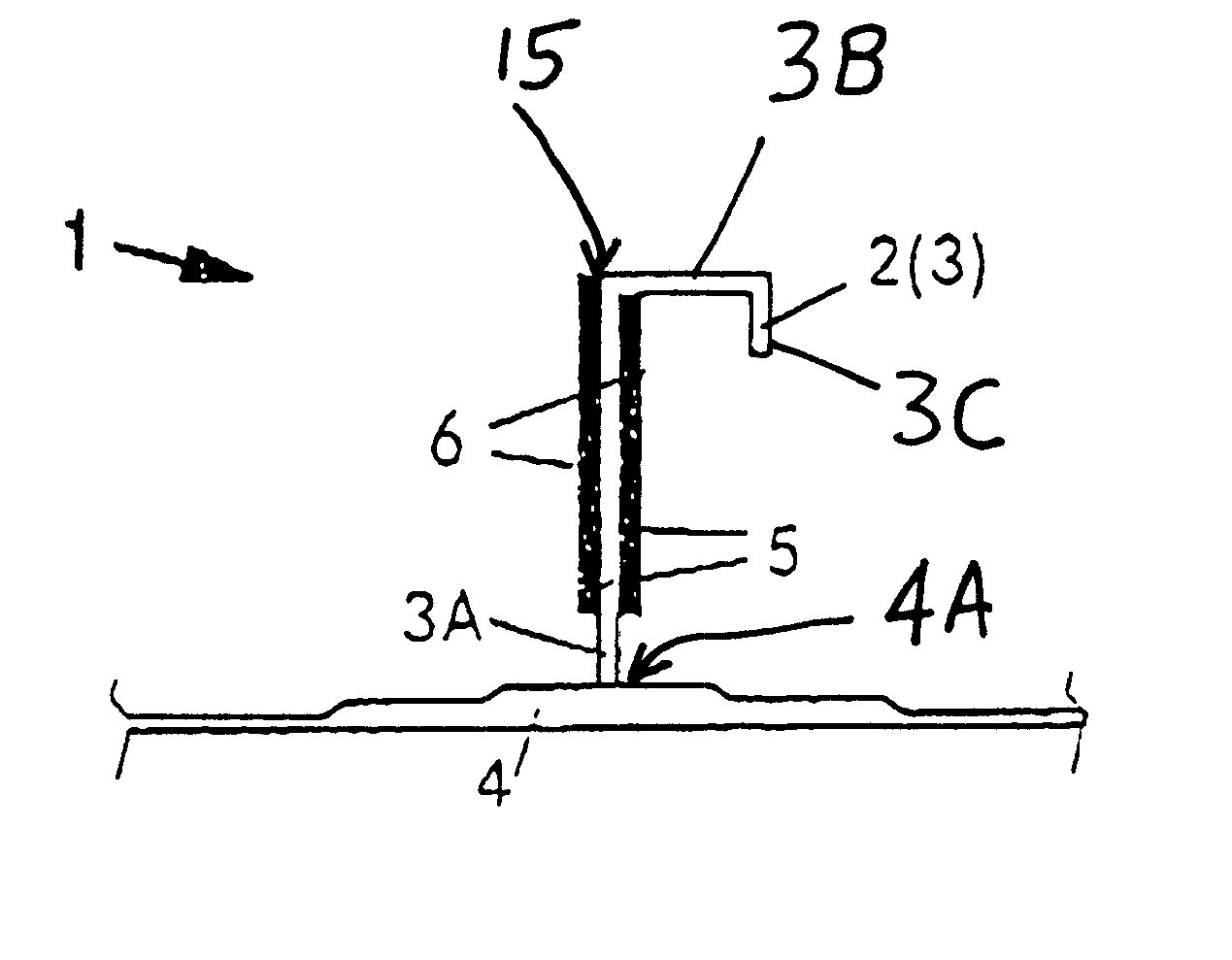

A metallic structural component for an aircraft includes stiffening profile members integrally formed or connected onto a skin sheet. Each stiffening profile member includes a first part integrally connected to the skin sheet, and a second part non-integrally connected to the first part so as to form an internal boundary surface within the multi-part stiffening profile member. If a crack forms in the skin sheet and propagates into the first part of the stiffening profile member, the internal boundary surface resists the further propagation of the crack past this boundary surface. The crack propagation resistance is improved, the remaining strength of the structural component after formation of a crack is increased, and the overall structural component is light in weight. The outer contour of the stiffening profile member is not affected by the provision of the separate first and second parts or the internal boundary surface therebetween.

Owner:AIRBUS OPERATIONS GMBH

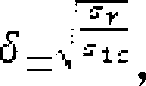

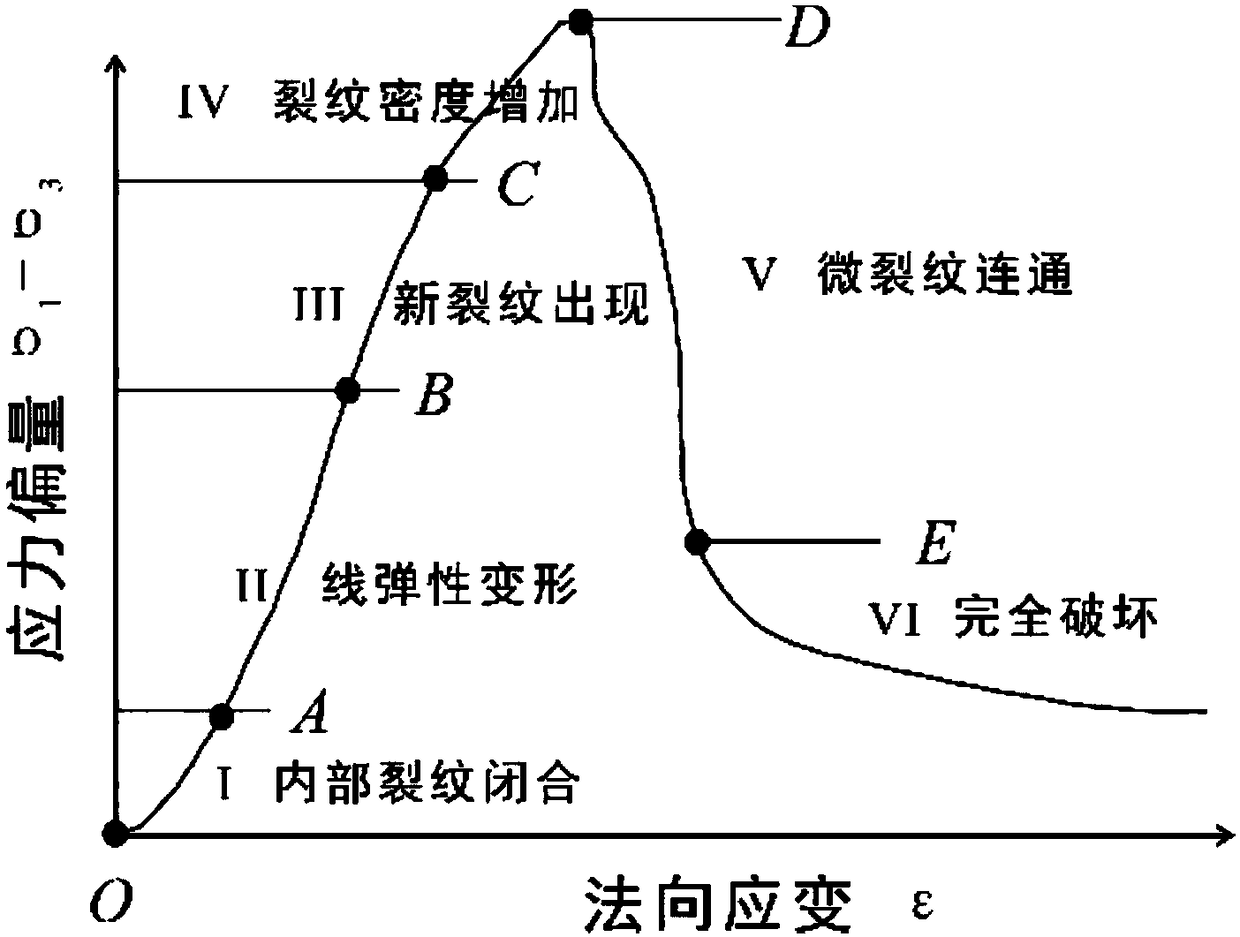

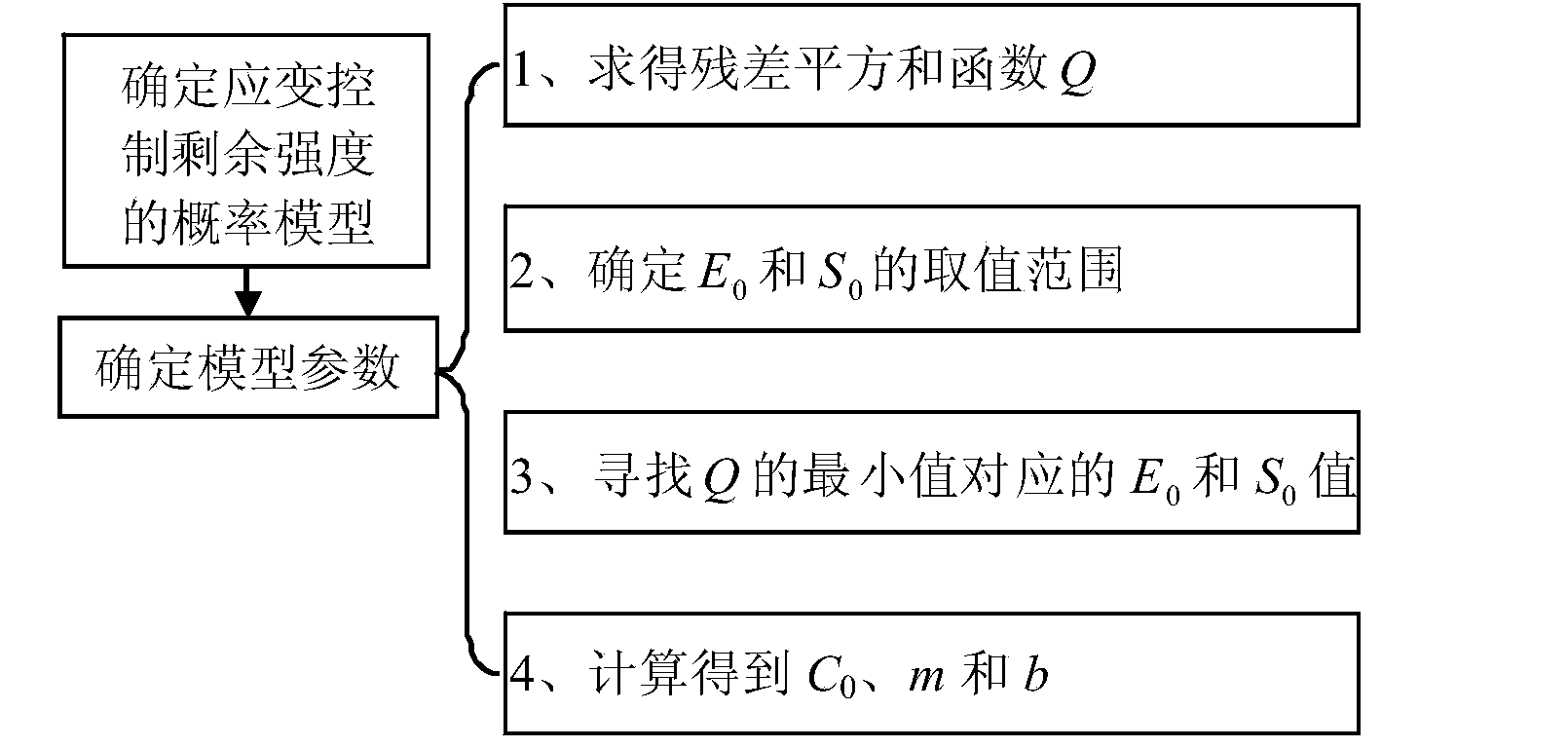

Method for establishing damaged rock constitutive relation by utilizing residual strength

InactiveCN102998180AEasy to implementDescribe the full stress-strain relationshipMaterial strength using tensile/compressive forcesResidual strengthStress–strain curve

The invention relates to a method for establishing damaged rock constitutive relation by utilizing residual strength. The method comprises the following steps of: carrying out a rock indoor triaxial compression experiment, measuring the axle load sigma1, the confining pressure sigma 3, the peak value intensity strain Epsilon 1c and the residual intensity sigma r of a rock sample, calculating the rock elastic modulus E and poisson ratio Mu, carrying out data regression according to triaxial compression test results, and calculating the uniaxial compressive strength sigma ci and an experience intensity parameter mi of a rock block; then establishing a three-dimensional damage statistic constitutive relation capable of reflecting a rock post-peak softening characteristic; and finally, solving constitutive relation parameters n and F0 according to four boundary conditions of a rock full-stress-strain curve geometric characteristic, and drawing a constitutive relation curve by utilizing Matlab software. The constitutive relation can fully reflect rock post-peak softening and residual intensity characteristics, and can describe the full-stress-strain relation of the rock damage process well, so that a theory formula well corresponds to the actual condition of a rock material; and the method can be realized simply, is widely applied to the theory analysis of the rock material, and has an actual value.

Owner:BEIJING JIAOTONG UNIV +1

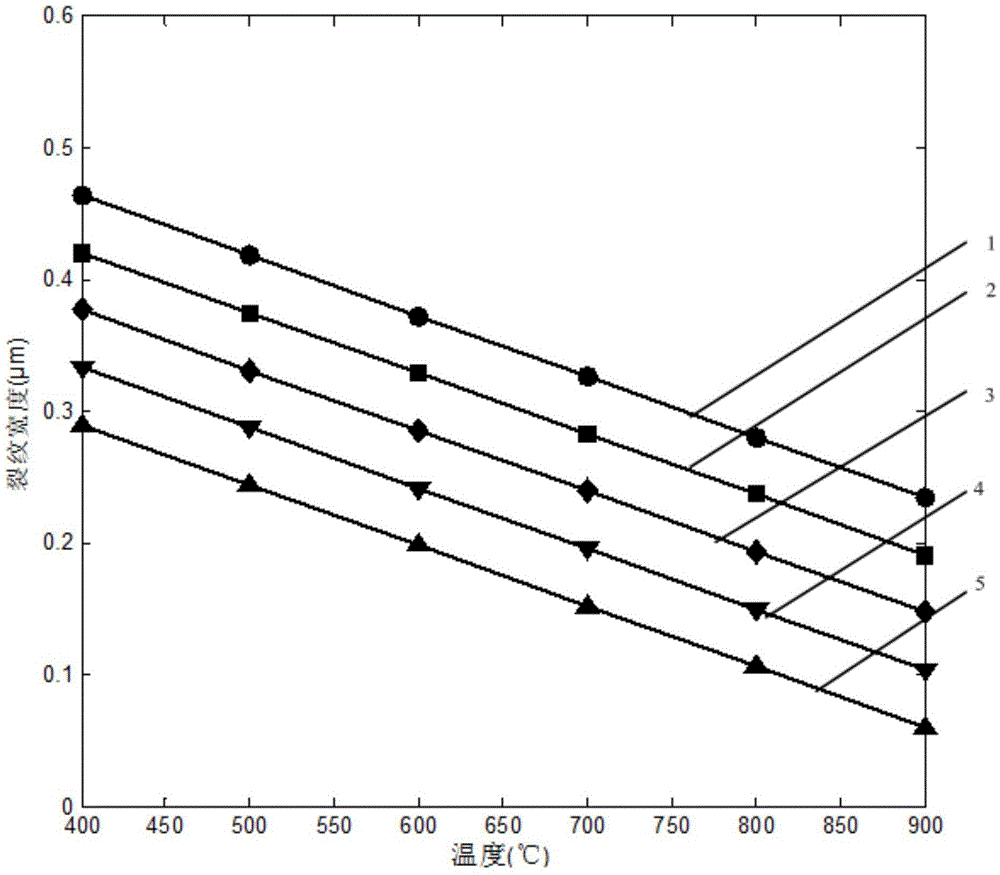

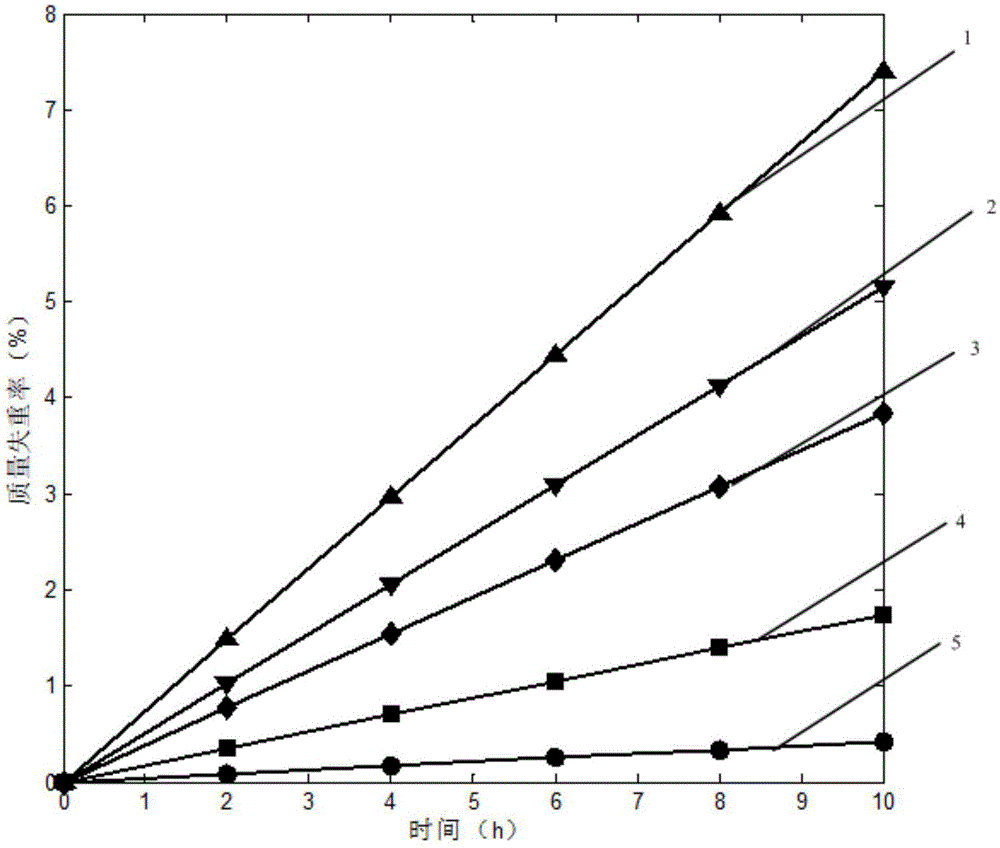

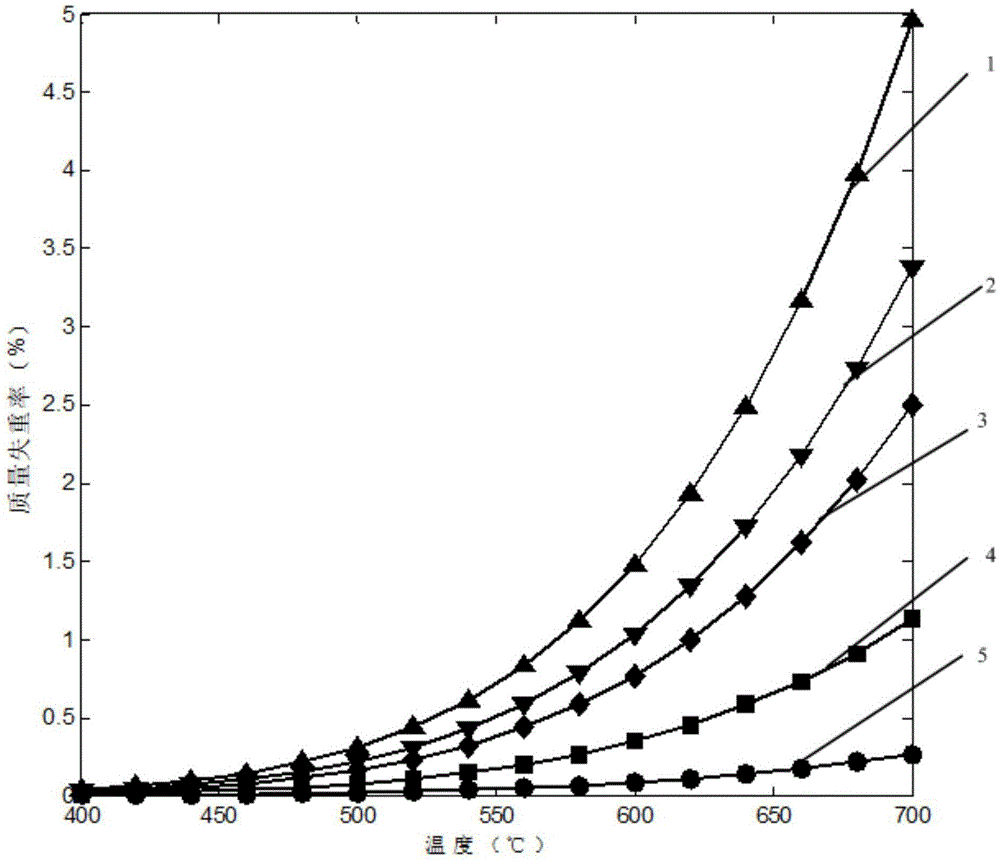

Method for analyzing mechanical property of UD-CMC (Unidirectional Ceramic Matrix Composite) under stress oxidation environment

ActiveCN105631148AFit closelyBig errorSpecial data processing applicationsResidual strengthUltimate tensile strength

The invention discloses a method for analyzing the mechanical property of a UD-CMC (Unidirectional Ceramic Matrix Composite) under a stress oxidation environment. The method comprises the following steps: determining the crack number, which changes along with stress, of a base of the UD-CMC; determining a crack width change rule; determining influence of cracking of the base of the UD-CMC on the change of a mass weight-loss ratio lambda by considering a stress reaction according to an oxidation mechanism of the UD-CMC under an existing unstressed oxidation environment of 400 to 900 DEG C; determining a change rule of residual modulus of the UD-CMC under a stress oxidation environment by considering the situation that the base of the UD-CMC cracks; determining a change situation of residual strength of the UD-CMC under the stress oxidation environment by considering the situation that the base cracks according to a change rule of the volume fraction of the UD-CMC. According to the method for analyzing the mechanical property of the UD-CMC under the stress oxidation environment, disclosed by the invention, a relevant theoretical support is provided for analyzing the mechanical property of the UD-CMC under the stress oxidation environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

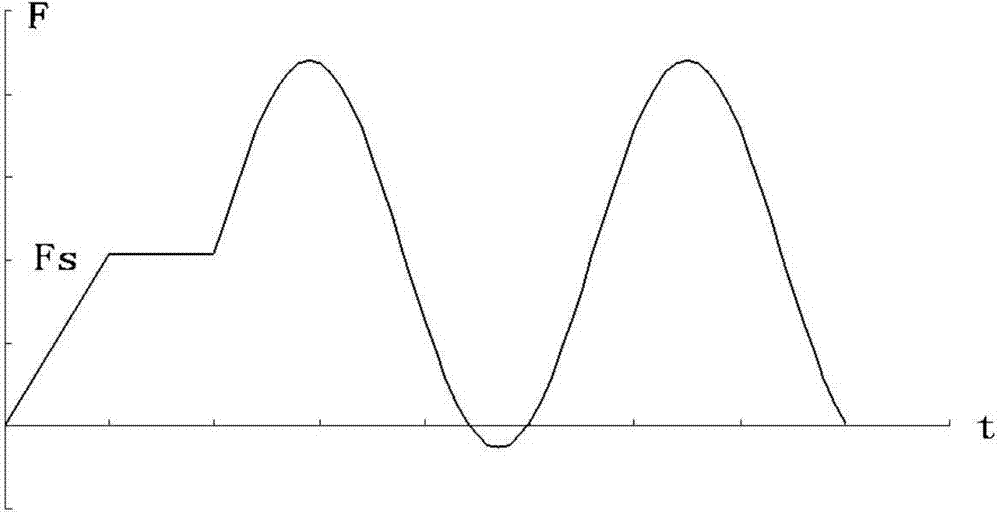

Method for rapidly and nondestructively prediction of residual strength and residual lifetime

InactiveCN101231222APredictive science and accuracyStrength propertiesResidual strengthPredictive methods

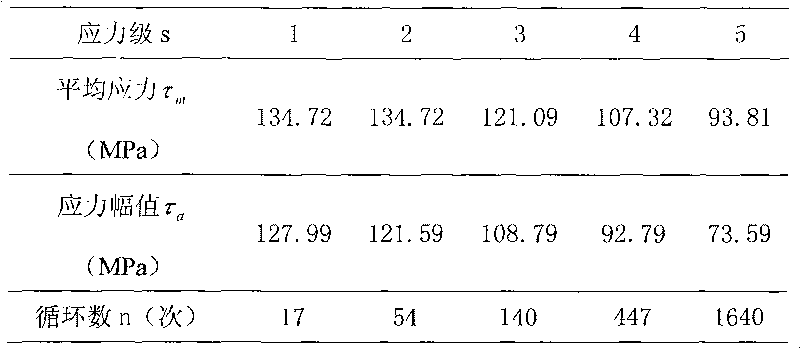

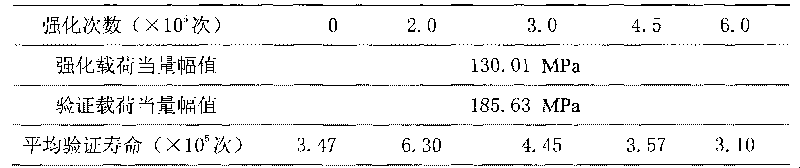

The invention discloses a method for predicting the residual intensity and the residual service life rapidly and intactly, comprising the following steps that: firstly, the stress-service life curve of a material or a part, i.e. the S-N curve, is measured; secondly, the corresponding relation between the surface hardness and the residual intensity of the material or the part under a random load spectrum of reinforcing, damaging and considering small load strengthening is established; thirdly, the surface hardness in the process of using the material or the part is measured, according to the corresponding relation between the surface hardness and the residual intensity of the material or the part, the residual intensity of the material or the part is predicted rapidly and intactly; forthly, the residual service life of the material or the part under the different load spectrum is predicted rapidly and intactly by adopting the predicted residual intensity and the stress-service life curve of the material or the part, that is the S-N curve. The rapid and intact prediction of the residual intensity and the residual service life of the material or the part can be realized by the simple measurement of the surface hardness by adopting the method.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

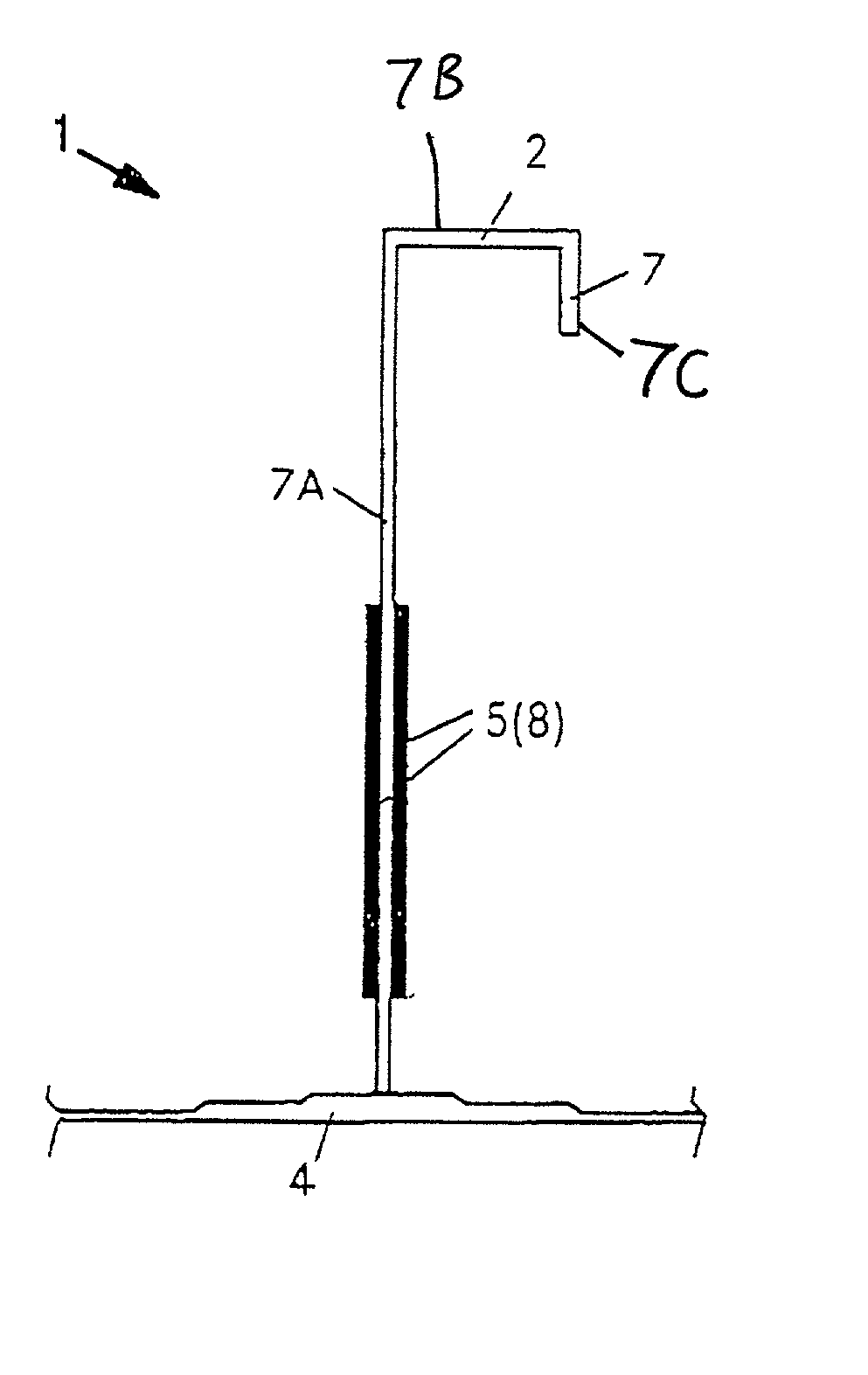

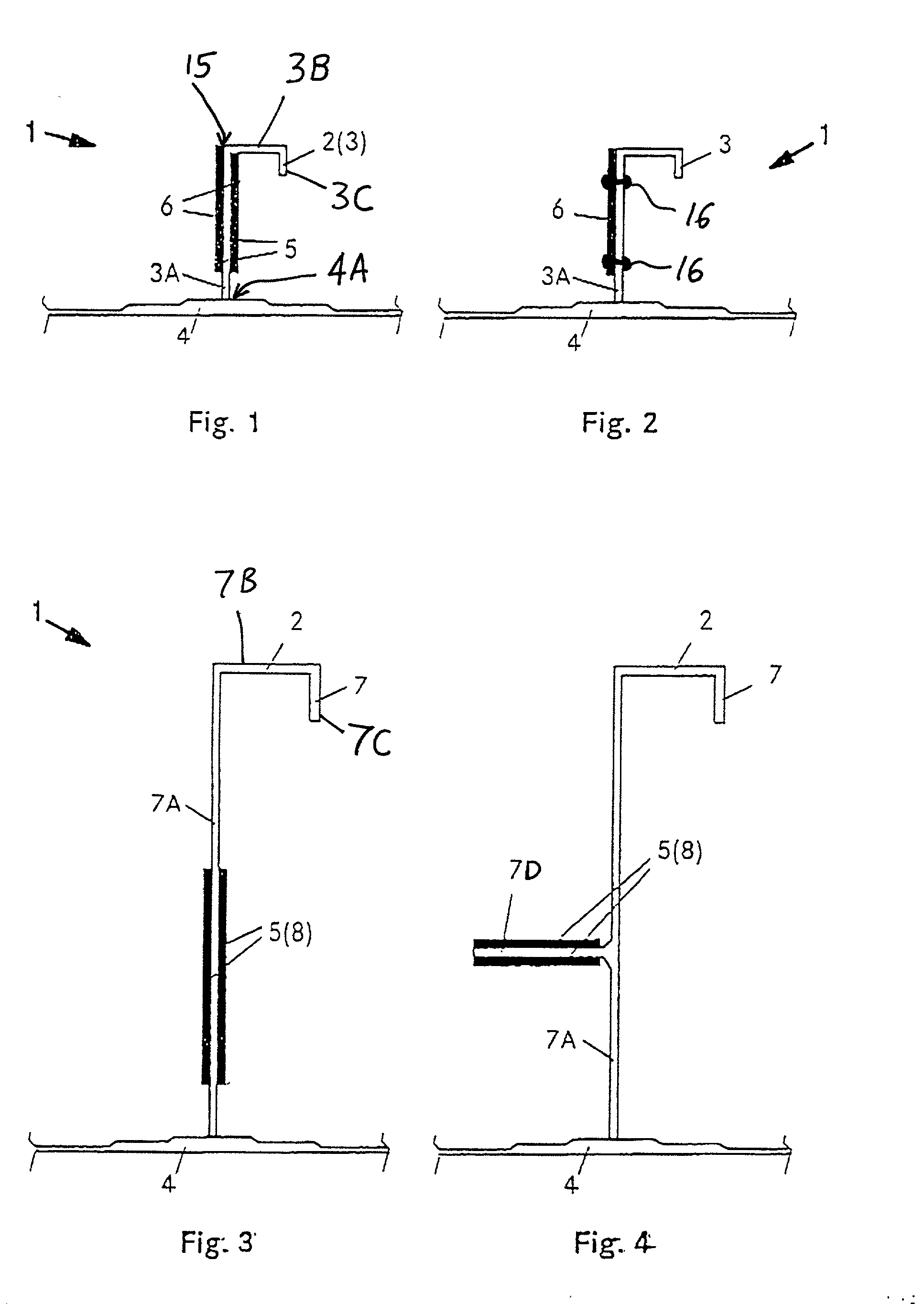

Aircraft fuselage shell component with crack propagation resistance

InactiveUS20020000492A1Increasing weight and costEasy to crackFuselage bulkheadsNon-rigid airshipsResidual strengthEngineering

When stiffening members, such as stringers and frame members, are welded onto a skin sheet to form an aircraft fuselage shell, a crack originating in the skin sheet tends to propagate through the weld joints into the stiffening members. In order to prevent crack propagation into a stiffening member, the stiffening member is reinforced with a web doubler plate or a tension band made of high strength steel or titanium alloys or fiber-reinforced composites. The doubler plate is riveted or adhesively bonded onto a stiffening member web, or the tension band is crimped into the stiffening member web. The resulting fuselage shell structure has crack stopping properties and thus an increased residual strength, so it can be used with welded joints at all areas of the fuselage shell, including the top and sides as well as the bottom of the fuselage.

Owner:AIRBUS OPERATIONS GMBH

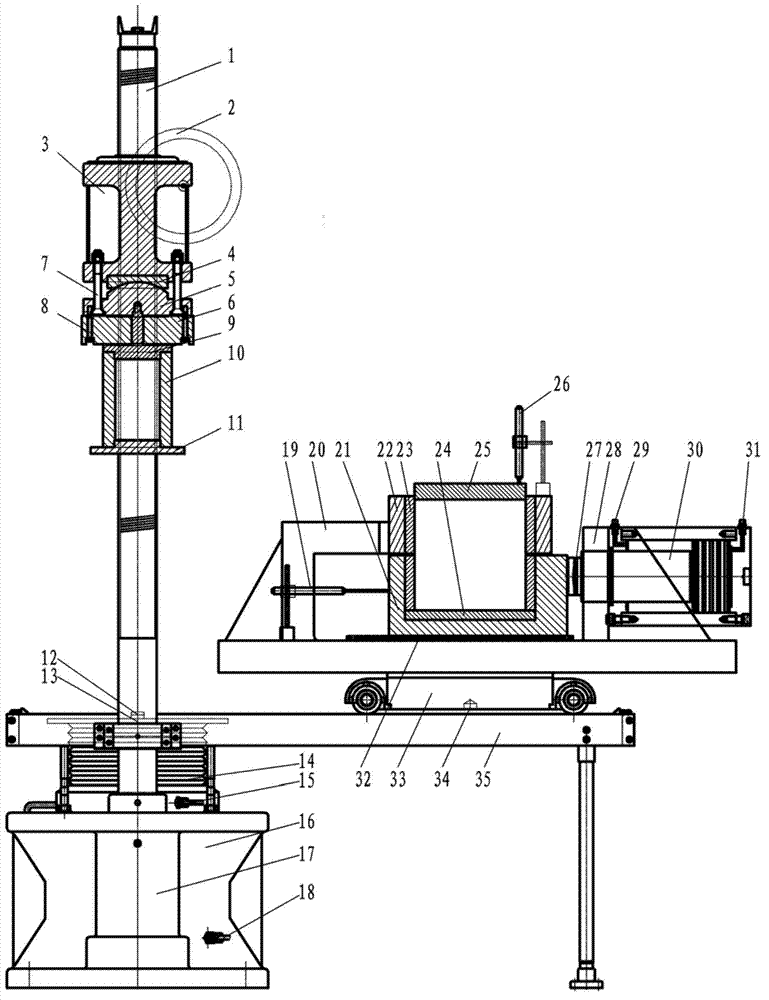

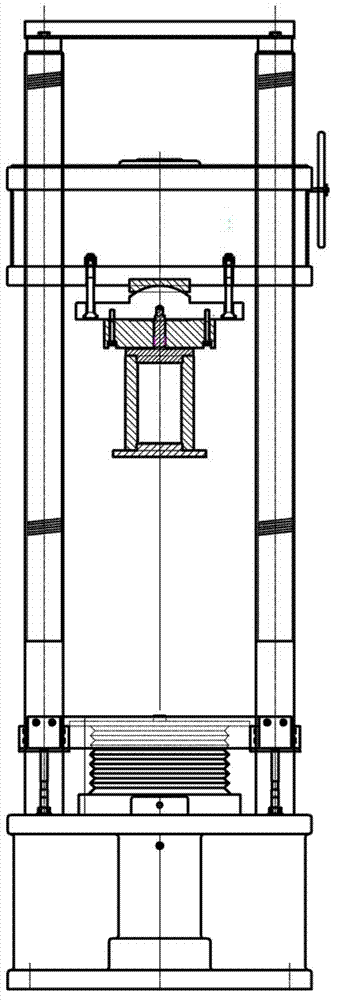

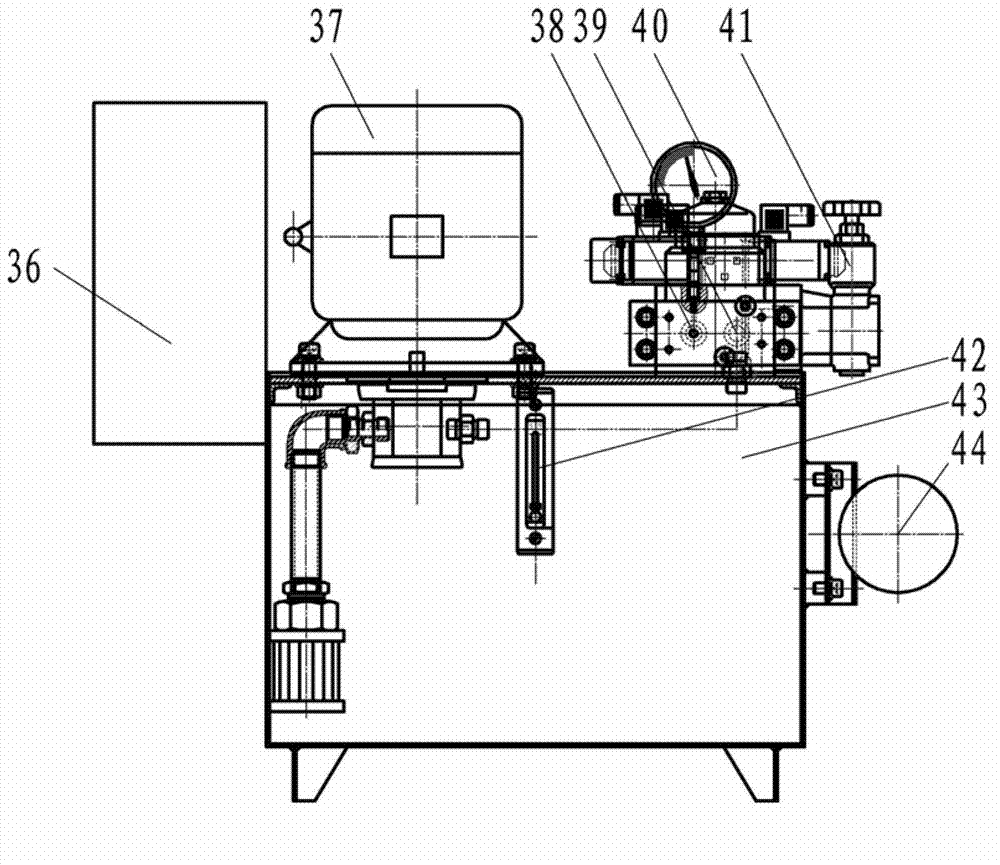

Rock-soil pressure shear rheological testing machine and testing method

InactiveCN103163026AReal-time acquisitionStable handlingMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesResidual strengthTest material

The invention discloses a rock-soil pressure shear rheological testing machine and a testing method, the testing machine comprises a mainframe, a vertical loading system and a horizontal loading system are provided on the mainframe, and a servo oil pressure system controlled by a computer provides oil pressure to the vertical loading system and the horizontal loading system. According to the invention, a shearing apparatus, the horizontal loading system, a servo hydraulic system and an electric control system are added for realizing automation, control and accuracy of the tests. An original waste and old press mainframe and a vertical oil cylinder are used by the testing machine, thereby about 50% of cost can be saved, the testing machine aims at test materials such as rock, rock mass and soil / stone compound body, and can perform with the following tests: a compression test, a shearing test, a residual strength shearing test, a compression rheological and shearing rheological test.

Owner:CHANGAN UNIV

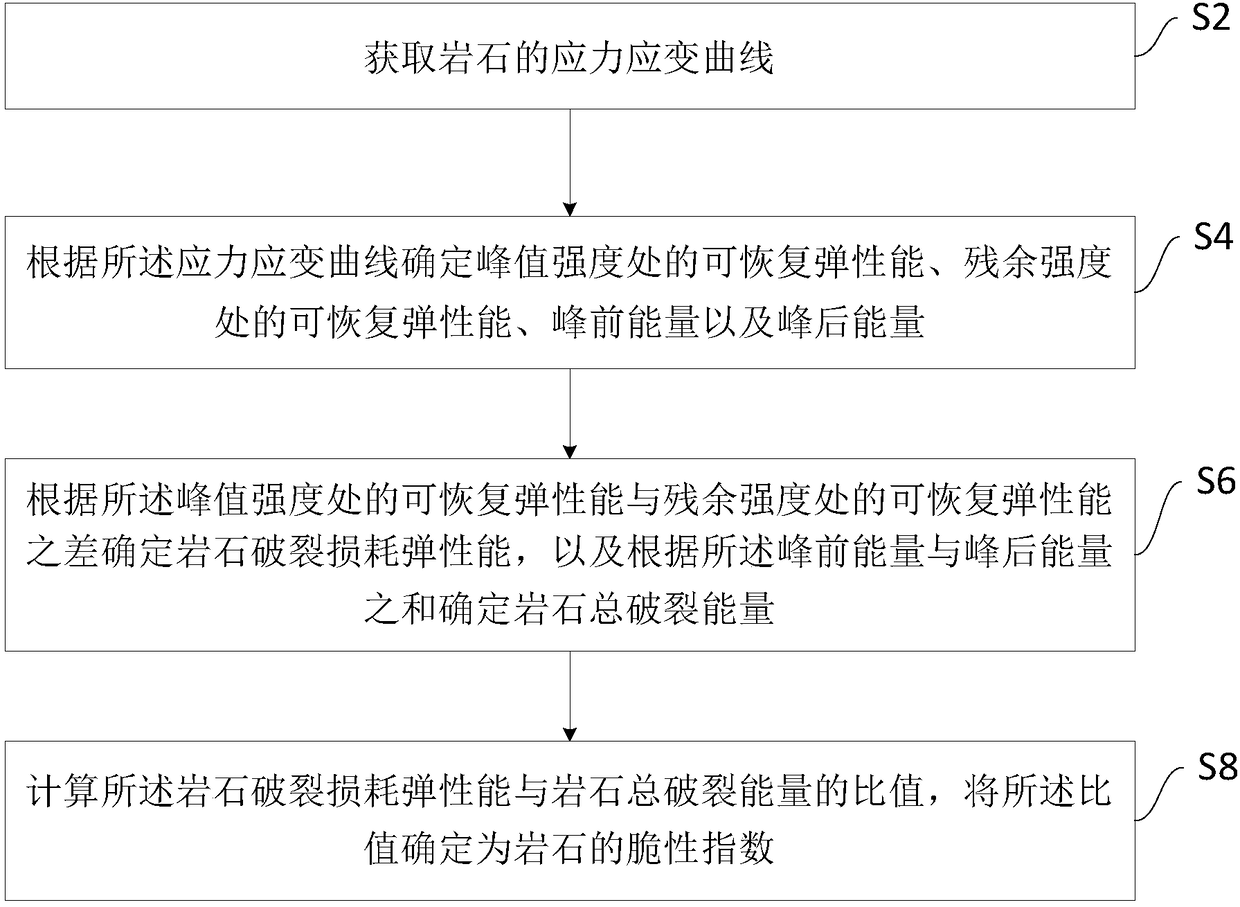

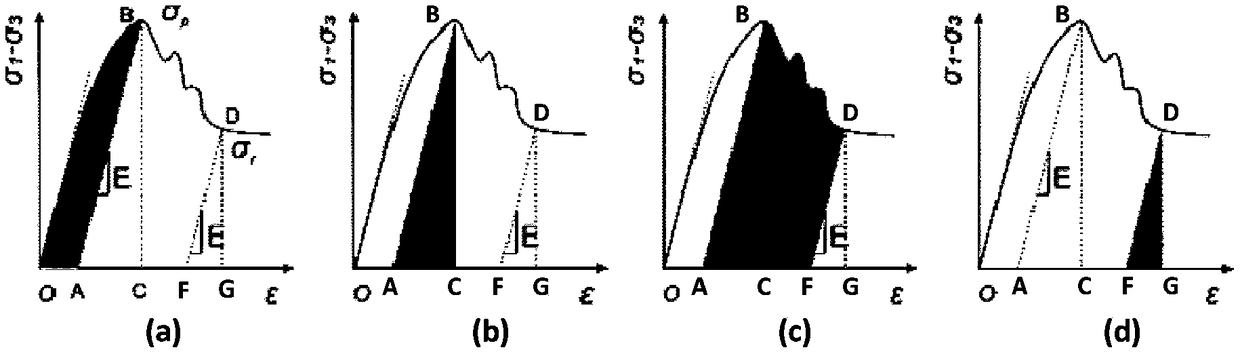

Method, device and system for determining brittleness index of rocks

ActiveCN108519281AImprove accuracyMaterial strength using tensile/compressive forcesResidual strengthStress–strain curve

The embodiment of the invention discloses a method, a device and a system for determining a brittleness index of rocks. The method comprises the following steps: obtaining a stress strain curve of therocks; determining recoverable elastic energy of peak value strength, recoverable elastic energy of residual strength, pre-peak energy and post-peak energy according to the stress strain curve; determining rock cracking loss elastic energy according to the difference between the recoverable elastic energy of the peak value strength and the recoverable elastic energy of the residual strength; determining rock total cracking energy according to the sum of the pre-peak energy and the post-peak energy; calculating the ratio of the rock cracking loss elastic energy to the rock total cracking energy and determining the ratio as the brittleness index of the rocks. By adopting the method provided by the embodiment of the invention, the brittleness of the rocks can be more accurately evaluated.

Owner:PETROCHINA CO LTD

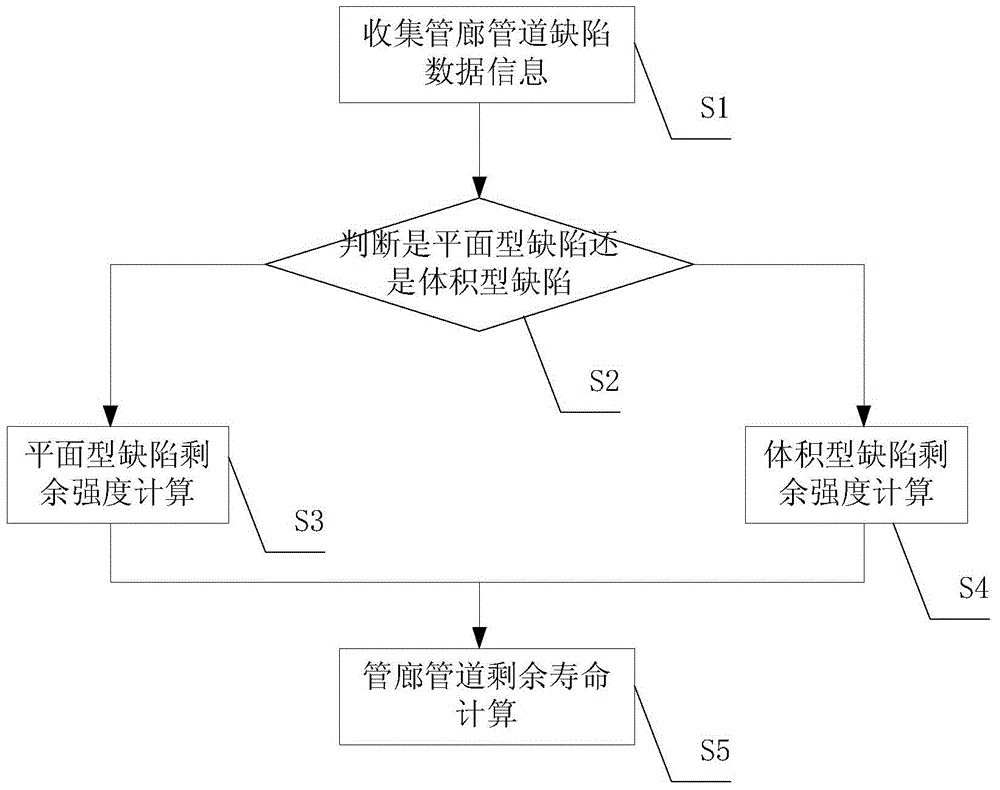

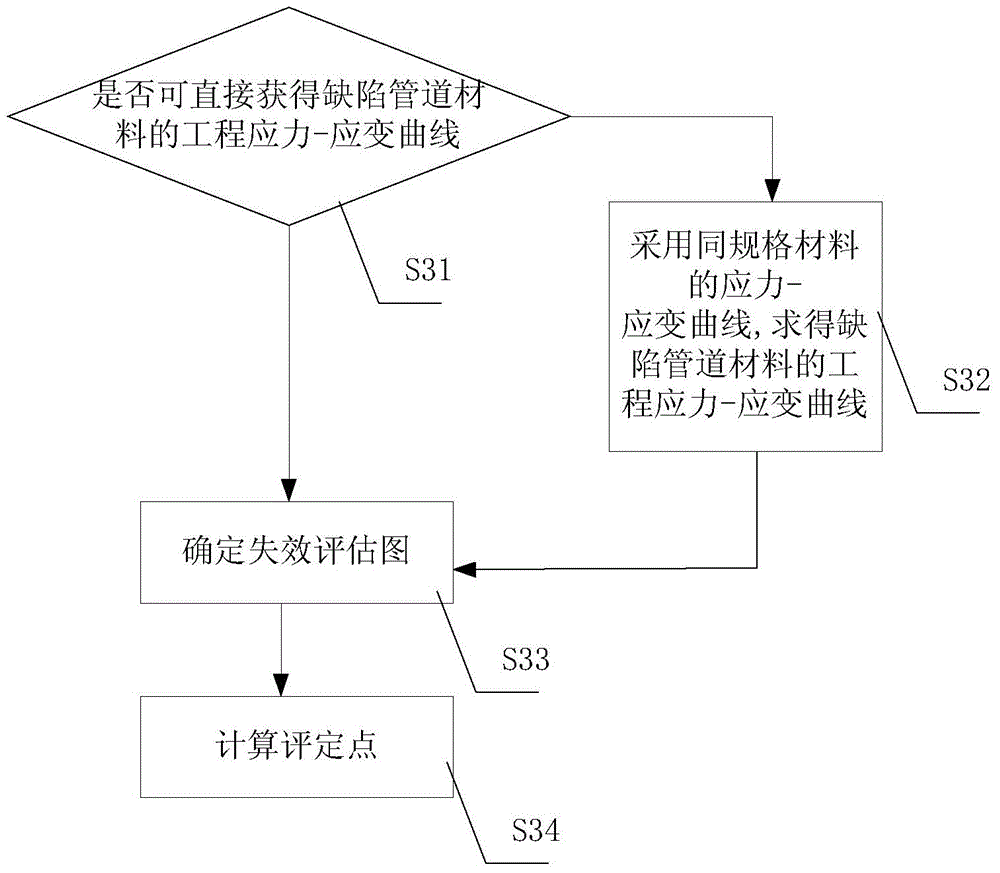

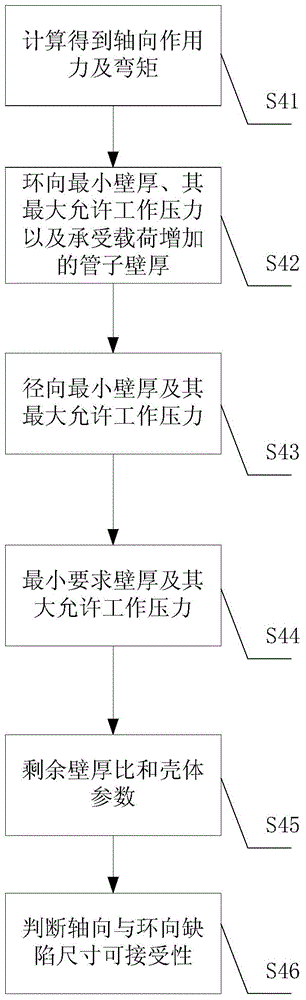

Residual intensity and residual life computing method for pipe gallery pipelines

ActiveCN104807966AGuaranteed safe operationSimple and fast operationMaterial analysisFailure assessmentNormal density

The invention discloses a residual intensity and residual life computing method for pipe gallery pipelines. The residual intensity and residual life computing method comprises the following steps: collecting the data information of defects of the pipe gallery pipelines; judging the defects are plane type defects or volume type defects; for the plane type defects, obtaining the engineering stress-strain curve of a defect pipeline material from the data information of the defects of the pipe gallery pipelines, determining a failure assessment diagram, and then computing assessment points to obtain the residual intensity of the pipe gallery pipelines; for the volume type defects, obtaining the design factors, the weld joint factors and the minimum measurement wall thickness from the data information of the defects of the pipe gallery pipelines, and obtaining the residual intensity of the pipe gallery pipelines through computing; computing basic numerical values according to the data information of the defects of the pipe gallery pipelines, and computing the residual lives of the pipe gallery pipelines according to a maximum value distribution probability density function, a reliability function, maximum corrosion depth point estimation and maximum likelihood estimation. Therefore, the residual intensity and residual lives of the pipelines in a pipe gallery area are effectively and accurately computed and predicted.

Owner:SHANGHAI CHEM IND PARK PUBLIC PIPE RACK

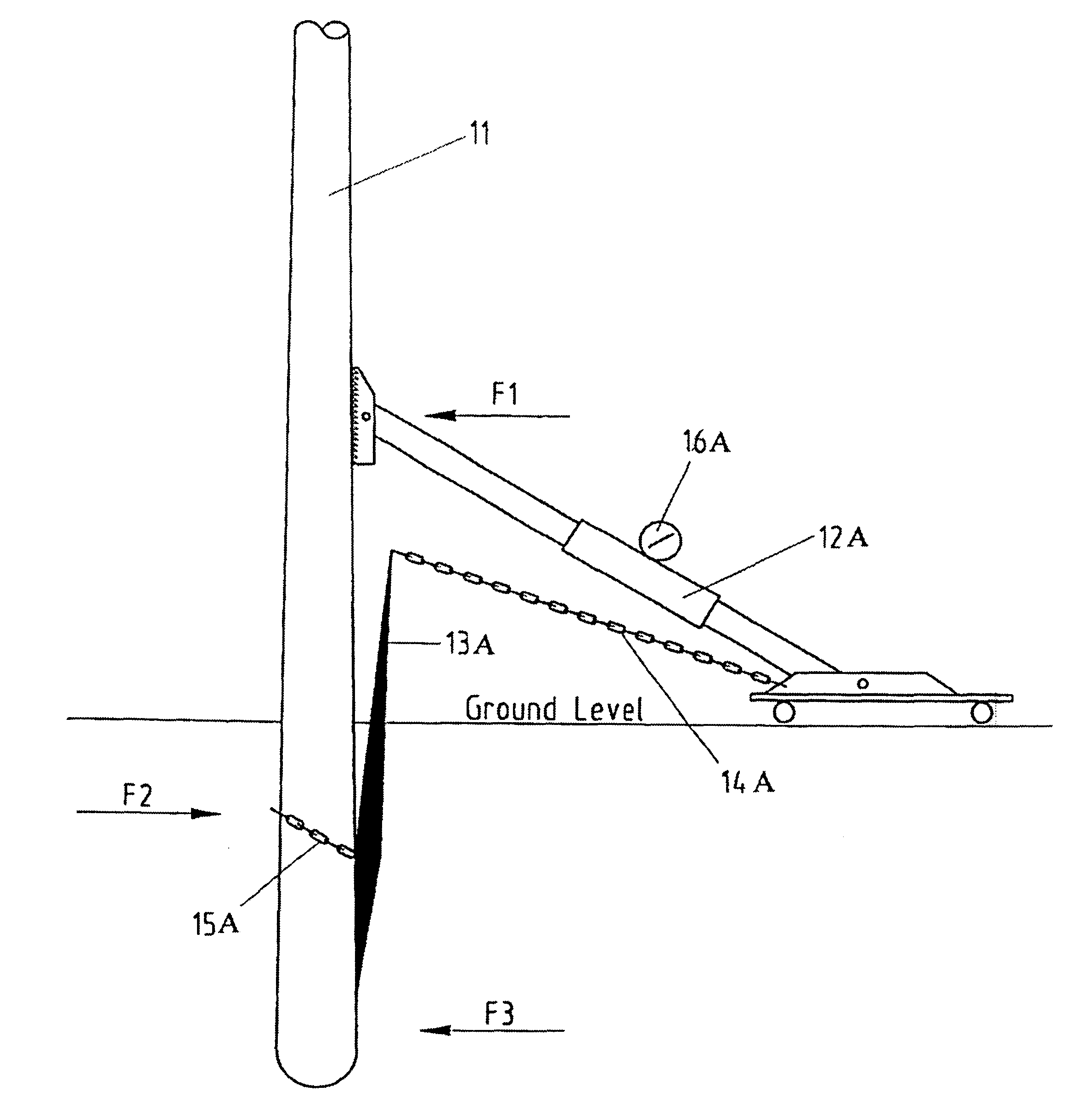

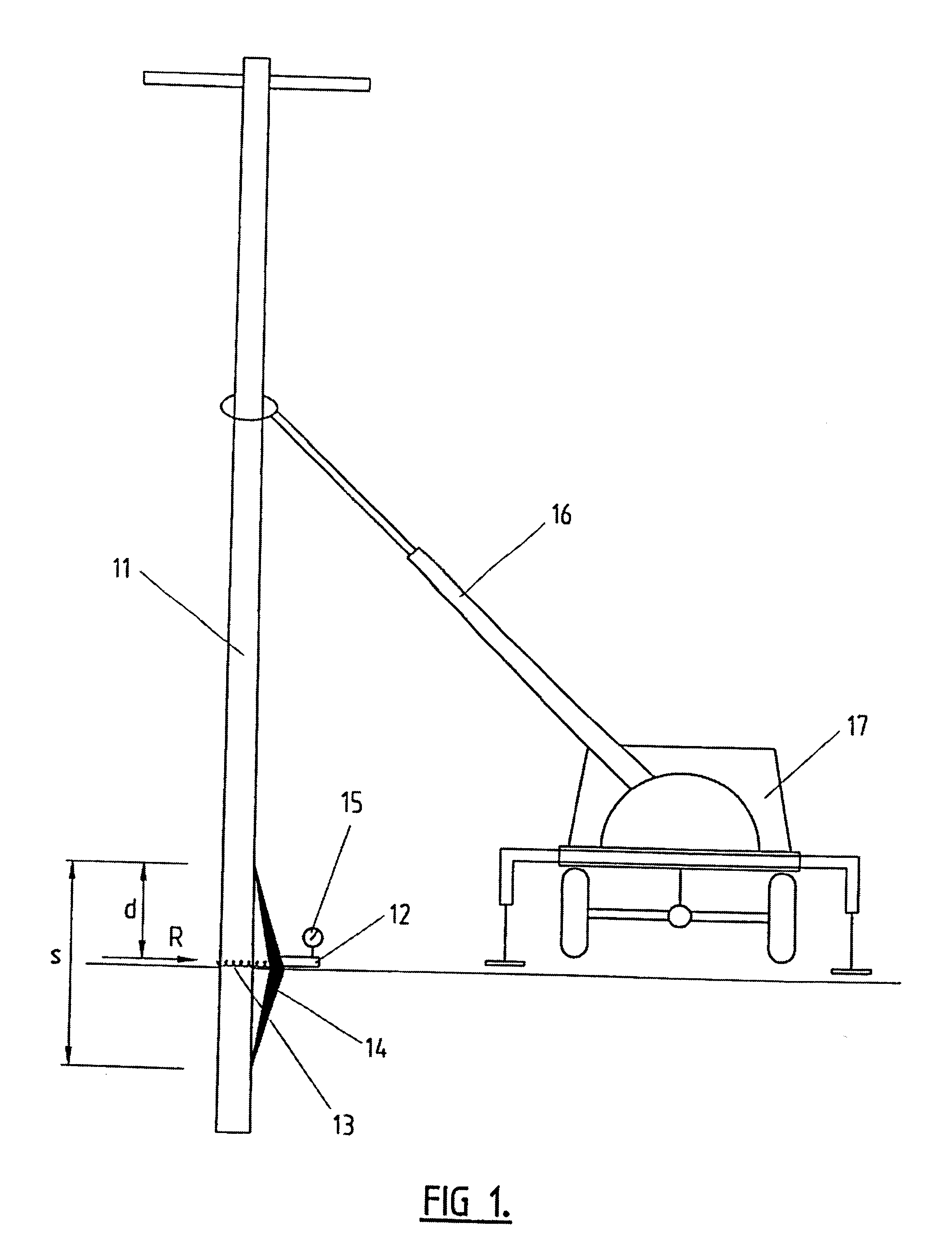

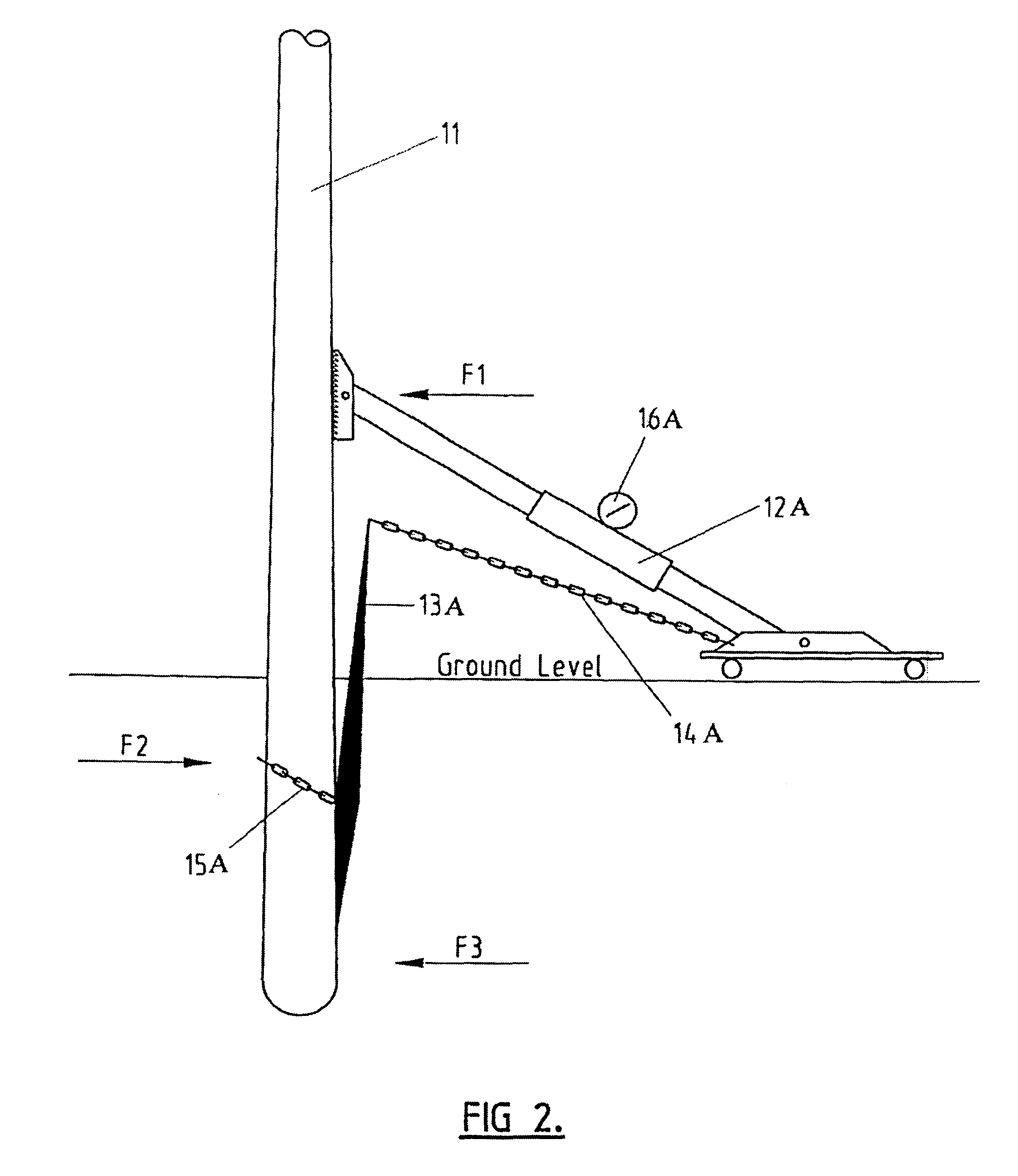

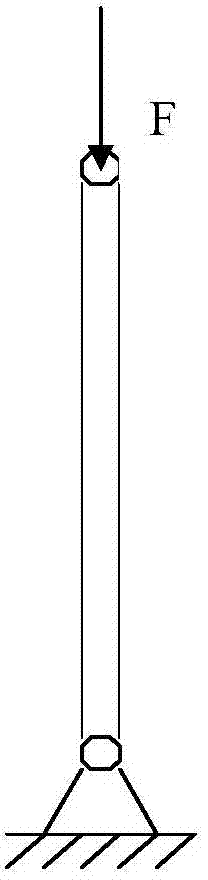

Method, apparatus and support for testing poles

InactiveUS6647801B1Improve abilitiesIncrease stiffnessFlow propertiesForce measurementResidual strengthEngineering

A pole support for ground poles, such as telephone poles and power poles, is disclosed. The support can be driven into the ground next to the pole. It has a pair of spaced apart longitudinal end plates which are interconnected intermediate their ends by an intermediate plate. The end plates are spaced apart to allow the ground pole to pass at least partially between the end plates. Each end plate has a front longitudinal edge which, in use, is adjacent to the pole and a rear longitudinal edge which, in use, is directed away from the pole. The pole support has means to reduce sharp edges on the rear longitudinal edges. Also disclosed is a method for testing pole strength which comprises applying a load to the pole and either measuring its displacement or observing if it withstands the load. The amount of load applied to the pole and the degree of displacement is undergoes can be used to calculate the residual strength of the pole.

Owner:DEUAR ANNA TERESA

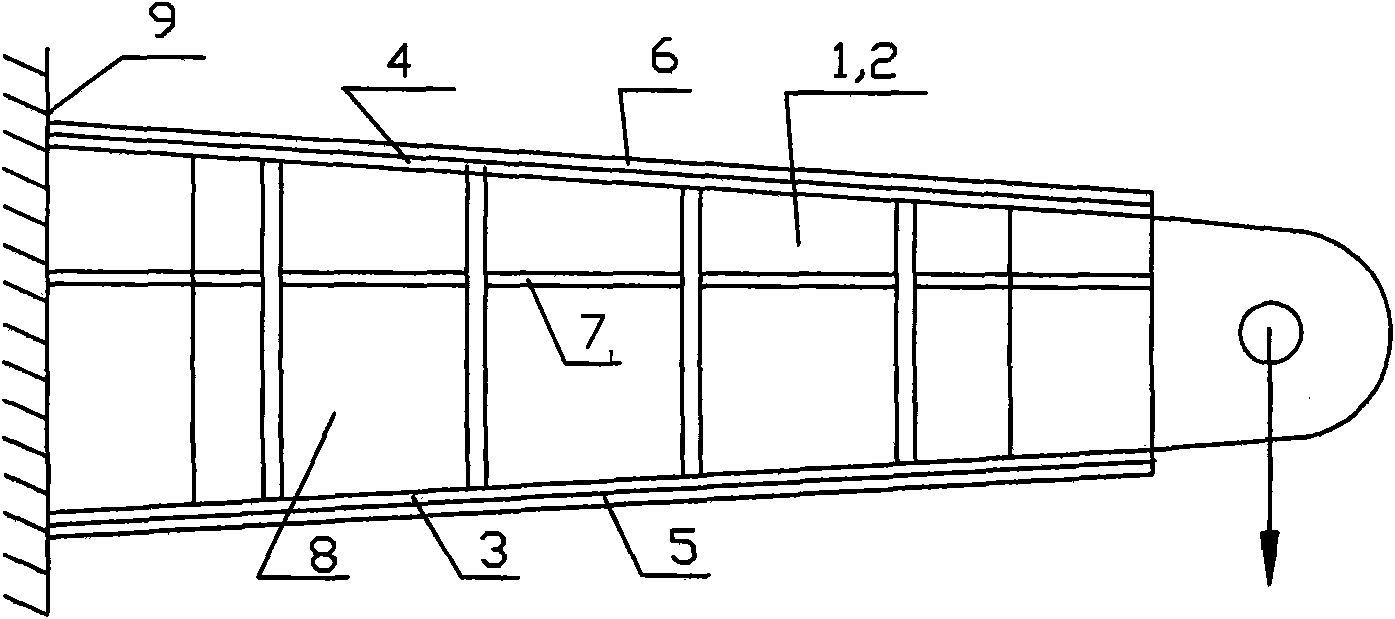

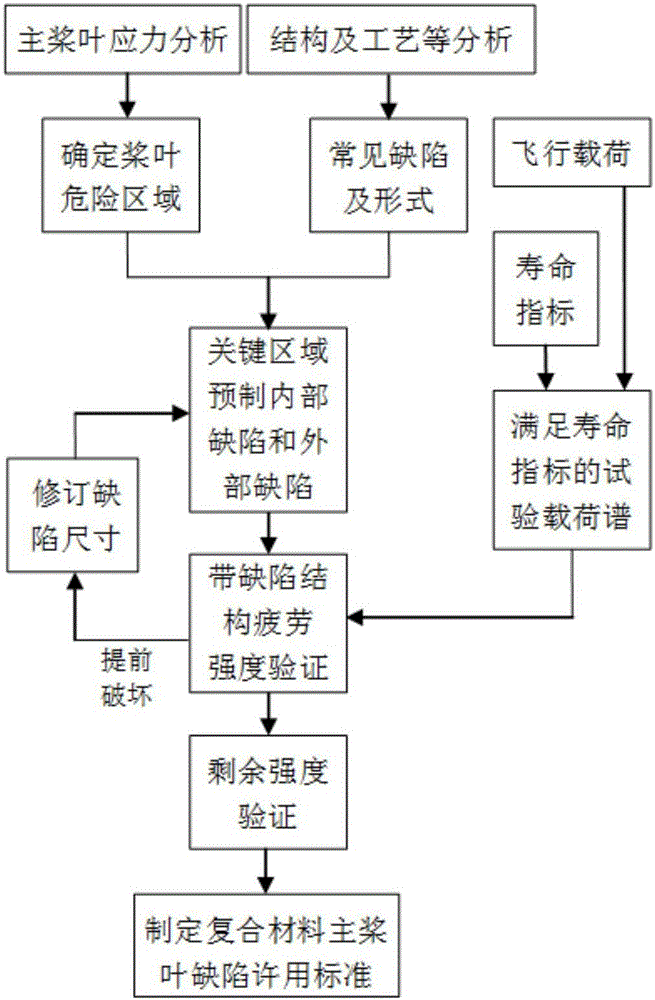

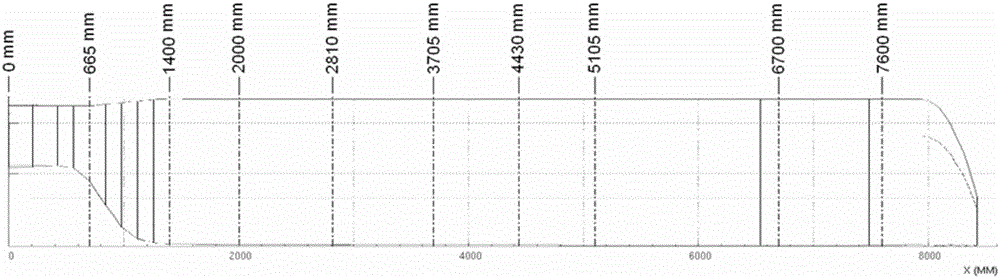

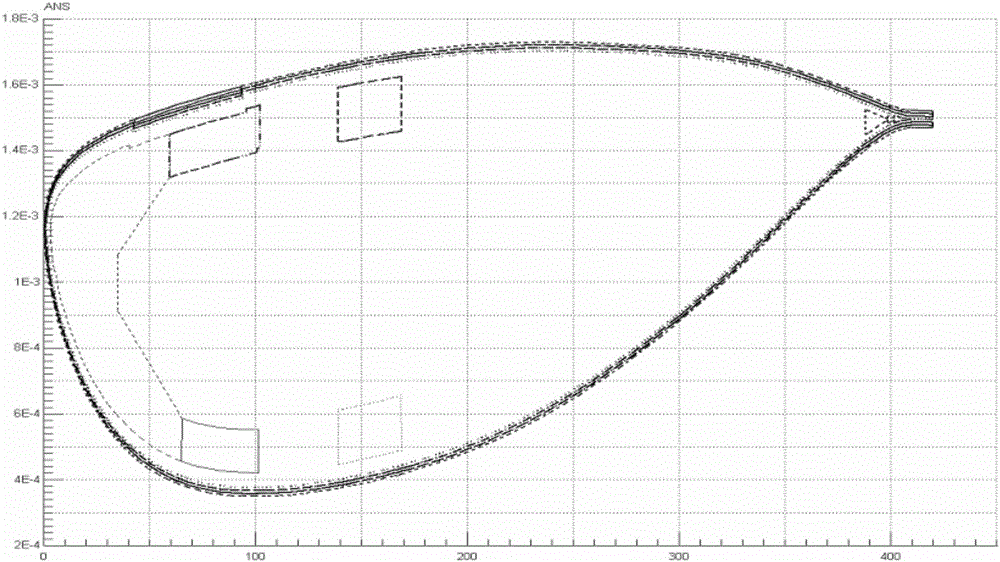

Method for determining allowable defects of helicopter composite main rotor blade

InactiveCN105760623ALow costReduce the risk of useGeometric CADMachine part testingResidual strengthStructural fatigue

The invention relates to a method for determining allowable defects of a helicopter composite main rotor blade and belongs to the technical field of structural fatigue design of helicopters. The method comprises the following steps: determining forms and easily occurring areas of a defect according to the function and structure of each area of a main rotor blade and process control and other conditions in the manufacturing process; predicting the maximum allowable size of the defect based on the principles such as detection simplicity, statistics and process controllability, and prefabricating on a full-sized test piece; determining the rationality of defect parameters by adopting a test of simulating fatigue and residual strength in a real load environment, determining the defect types in critical prevention and control of the composite main rotor blade, and establishing the defect allowable standard. According to the method, a technical basis can be provided for treatment of the various defects in the production, usage and maintenance processes.

Owner:CHINA HELICOPTER RES & DEV INST

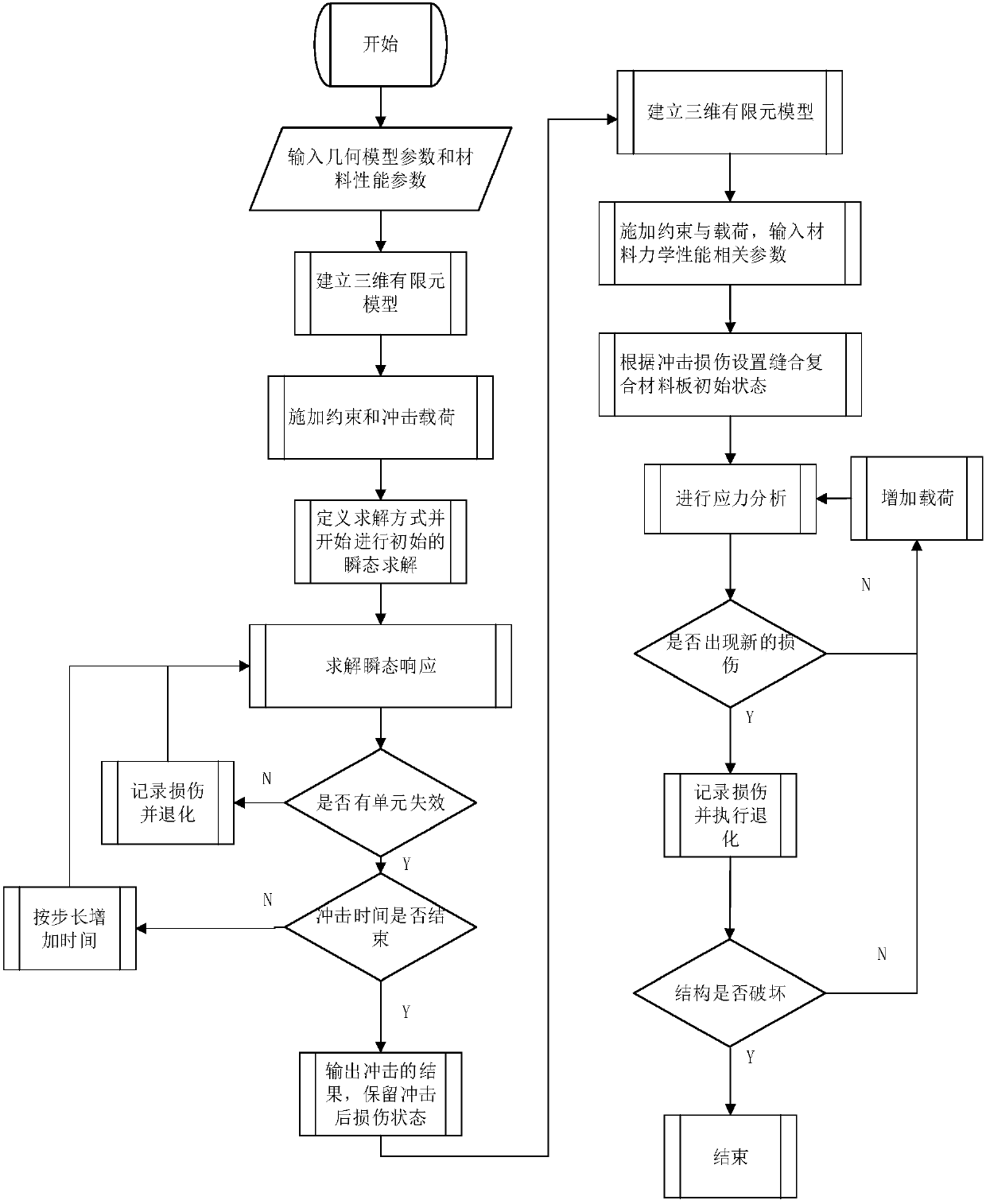

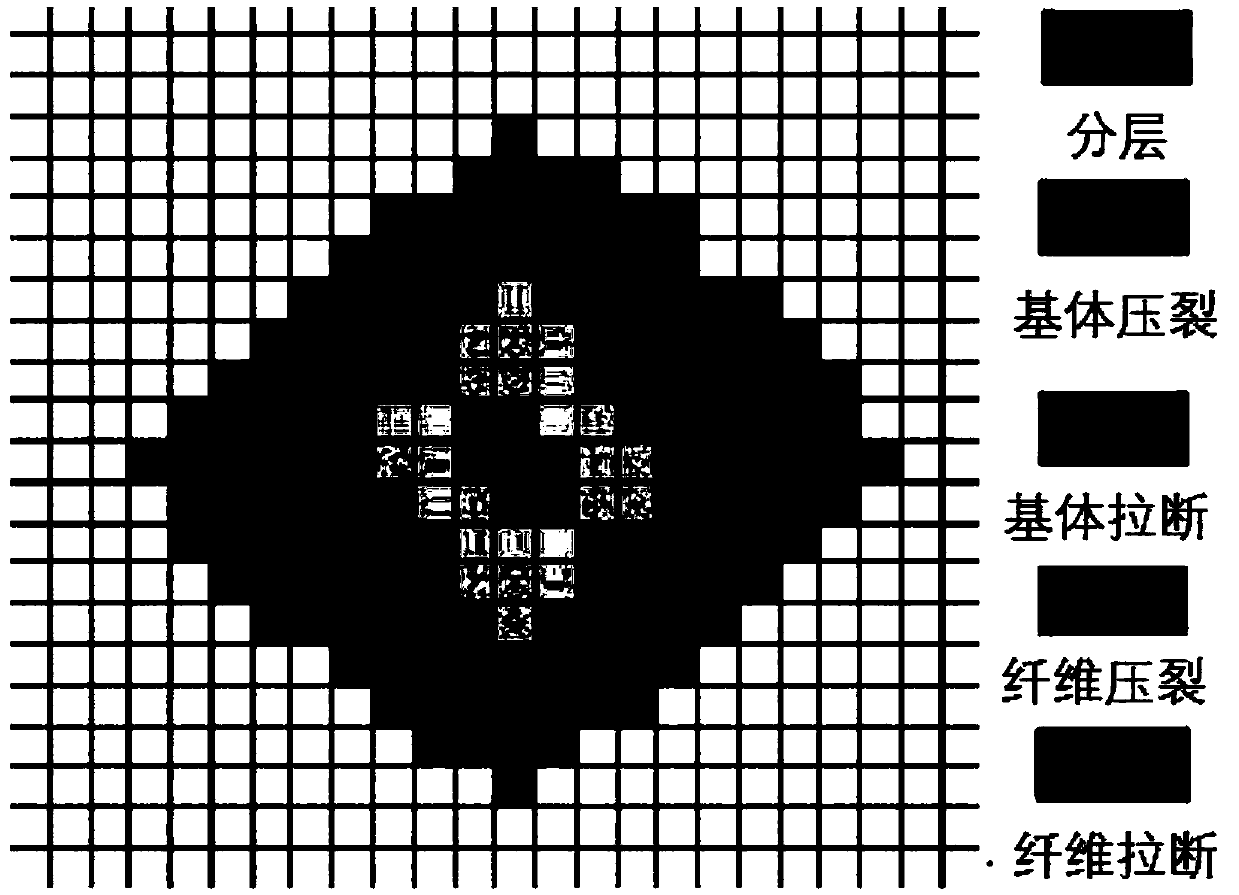

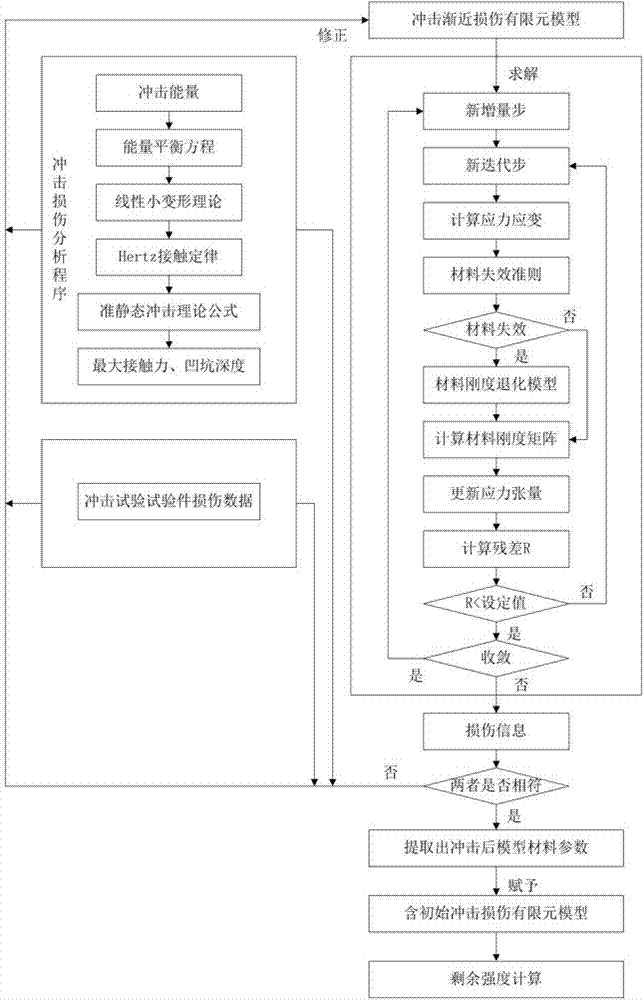

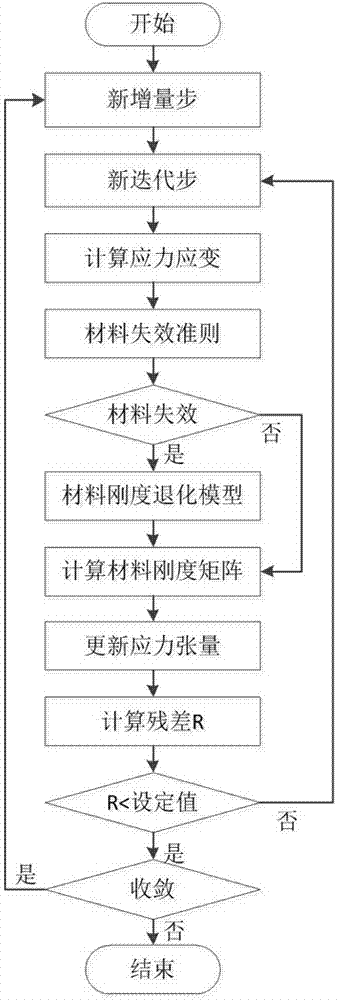

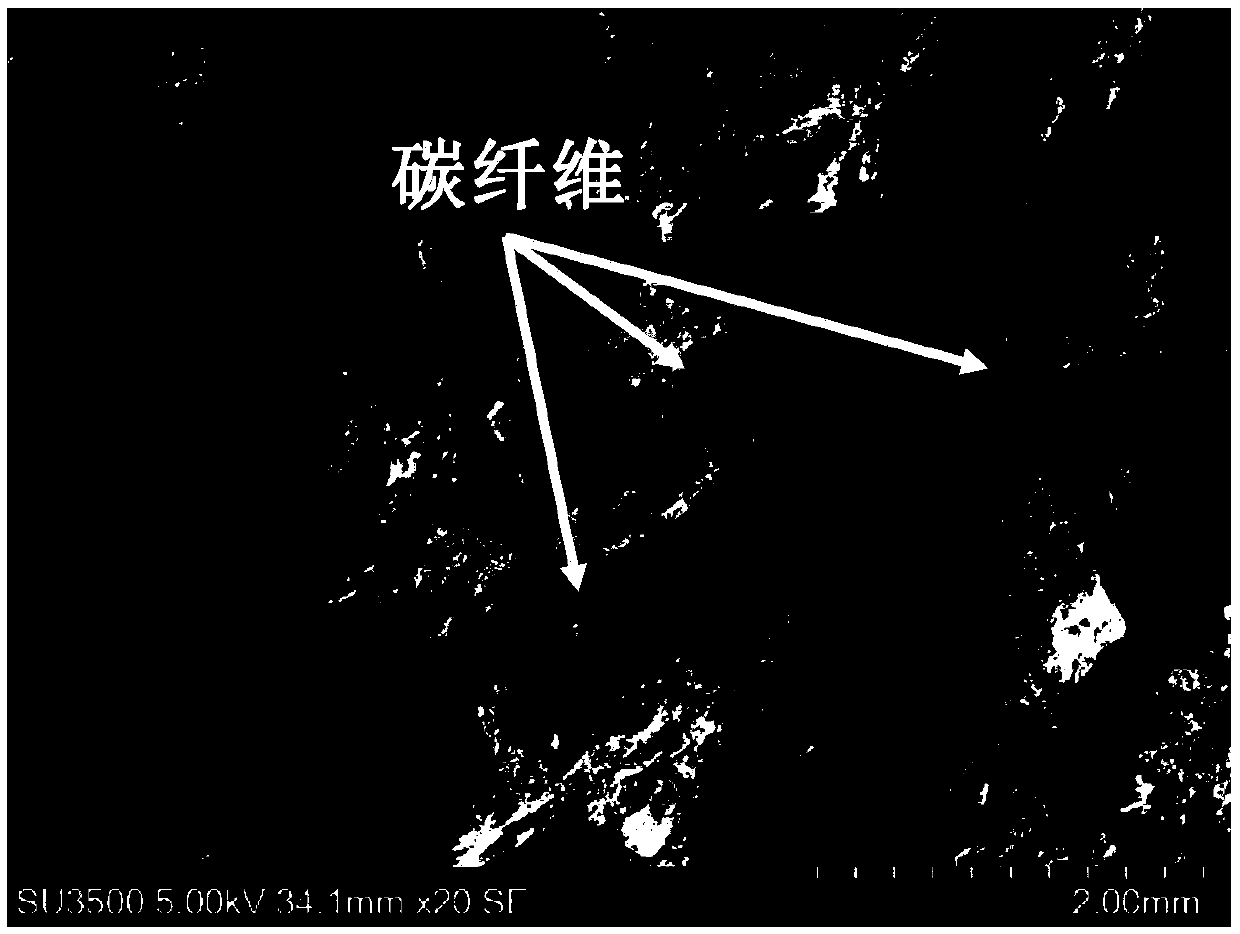

Whole-course analysis method for impact damage and residual intensity of sutured composite material

ActiveCN108427826AImprove fluencyStrong expandabilityDesign optimisation/simulationSpecial data processing applicationsExtensibilityResidual strength

The invention discloses a whole-course analysis method for the impact damage and the residual intensity of a sutured composite material. The method comprises the following steps that: (1) carrying outtransient stress analysis on the sutured composite material under an impact load; (2) determining the impact damage criterion of the sutured composite material; (3) determining the mechanical property degeneration method of the impact damage of the sutured composite material; (4) carrying out the statics analysis of the sutured composite material; (5) determining the residual intensity damage criterion of the sutured composite material; (6) determining the material performance degeneration method of the sutured composite material; and (7) determining the structure failure criterion of the sutured composite material. The invention provides the whole-course analysis method for the impact damage and the residual intensity of the sutured composite material, practical situations, including thepractical damage type, the damage degree and the like, of the impacted composite material structure are considered, and in addition, accuracy fore predicting the residual intensity can be improved without observing the impact damage. The method disclosed by the invention is high in consistency, good in extensibility, high in prediction accuracy and has a considerable engineering application prospect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

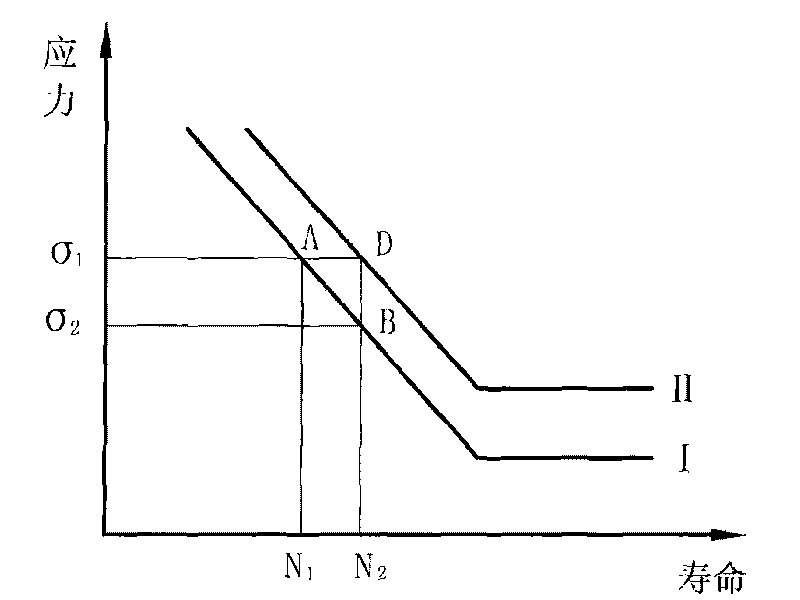

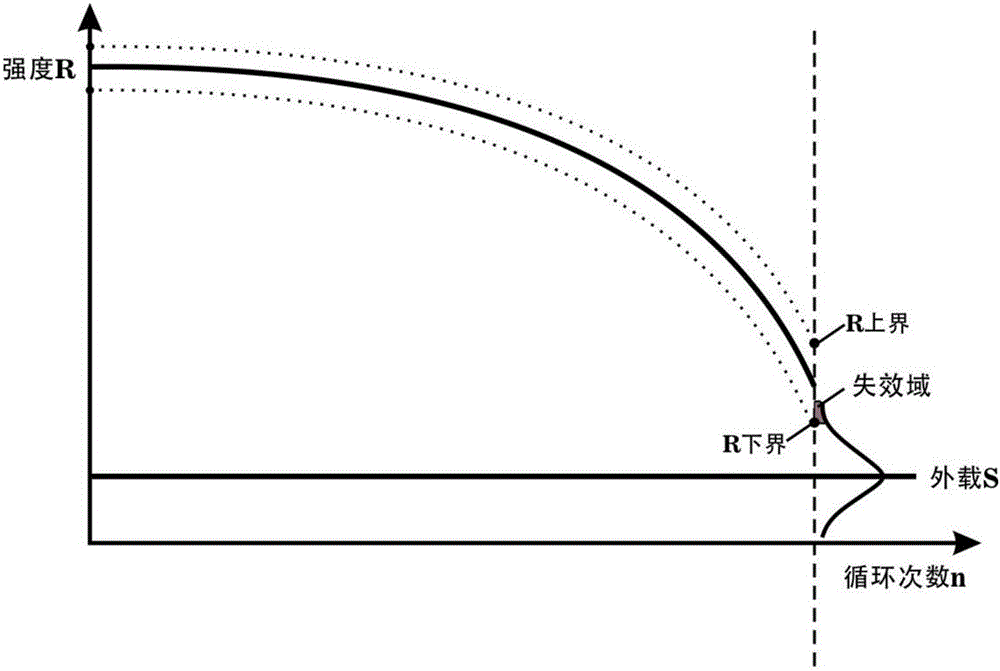

Evaluation method of residual strength and service life under strengthening and damaging combined action

InactiveCN101718651AAccurately assess durabilitySolve the disadvantages of strength attenuationStrength propertiesFatigue IntensityResidual strength

The invention relates to an evaluation method of residual strength and service life under strengthening and damaging combined action, which is characterized in that: (A) virtual stress-life curve of a material or a part is obtained by test or technical resources, and the fatigue strength and low amplitude loading range are determined; (B) the low-load strengthening general rule of the material or the part with different strength grades are built according to low-load strengthening performance data of low-strength and high-strength materials or parts by virtue of a numerical method of spline interpolation; (C) the fatigue strength changing rule is built according to the stress-life curve of the material or the part under the strengthening and damaging combined action; in addition, according to the loading grade and frequency of a loading spectrum, the instantaneous fatigue strength value, that is, the residual fatigue strength of the part with given using mileage is calculated; (D) according to the instantaneous stress-life curve, the life evaluation of the material or the part is carried out according to Miner linear damage theory. The invention provides a specific method for the service life of the part and the light-weight design.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

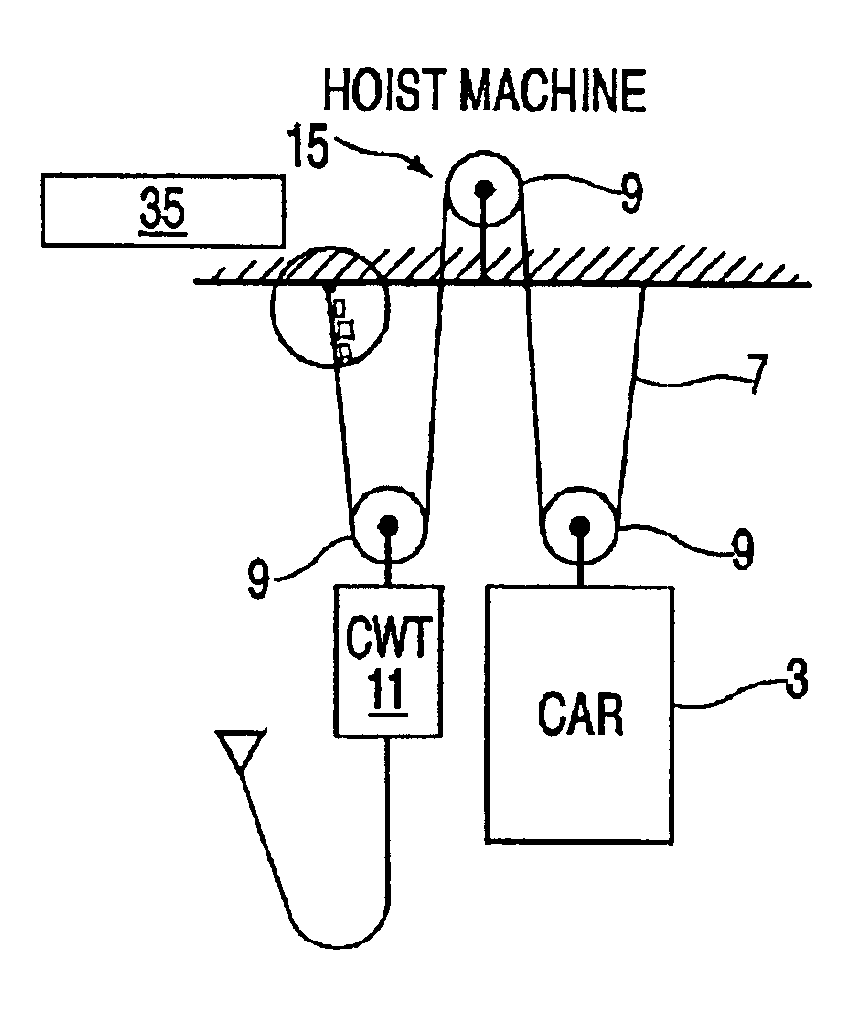

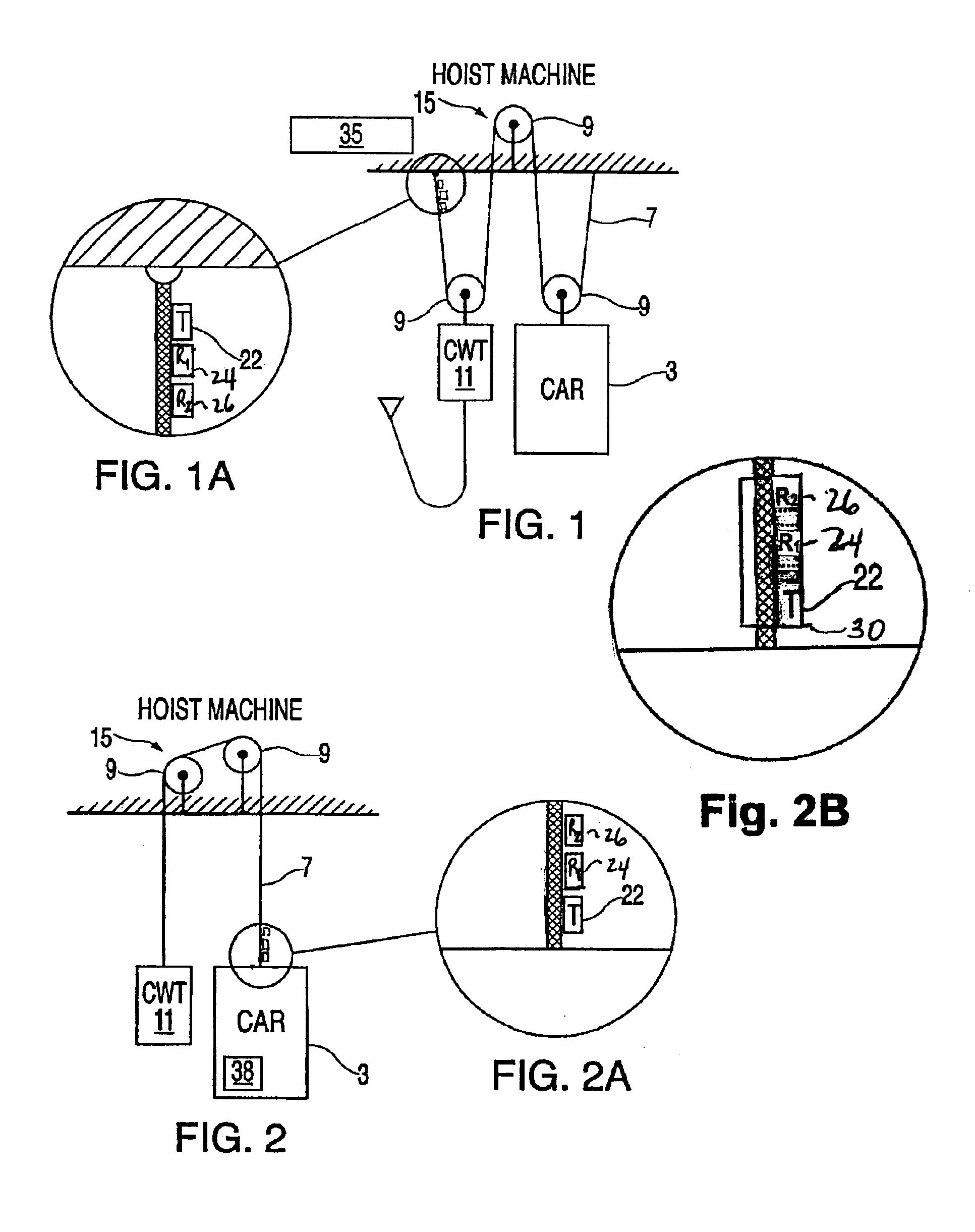

Apparatus for testing aramid fiber elevator cables

InactiveUS6923065B2Help positioningAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesResidual strengthAramides

An apparatus and method for inspecting and calculating the residual strength of an aramid fiber rope driving an elevator to determine when such rope is in need of replacement. The apparatus comprises a transmitter for introducing an acoustic wave that will travel along the aramid fiber rope and a plurality of receivers for receiving the acoustic wave after its has traversed a designated section of the rope. The transmitter and receiver provide signals indicating the times the wave was sent by the transmitter and thereafter received by the receiver. From these signals, a program calculates the wave velocity, and the modulus and residual strength of the aramid rope.

Owner:THYSSENKRUPP ELEVATOR AG (DE)

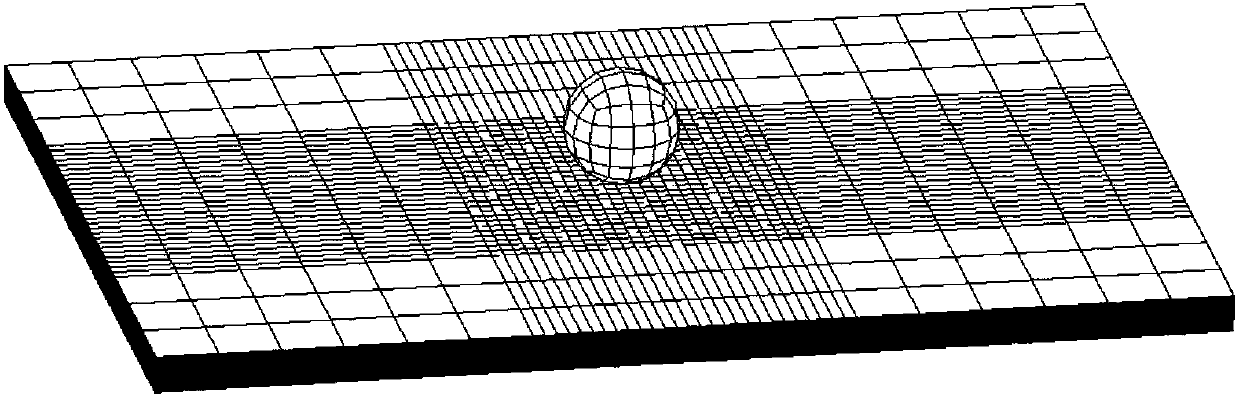

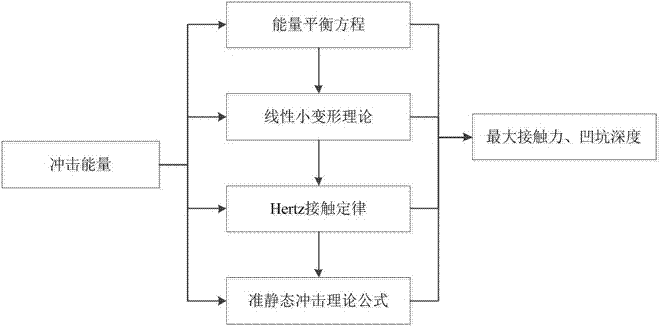

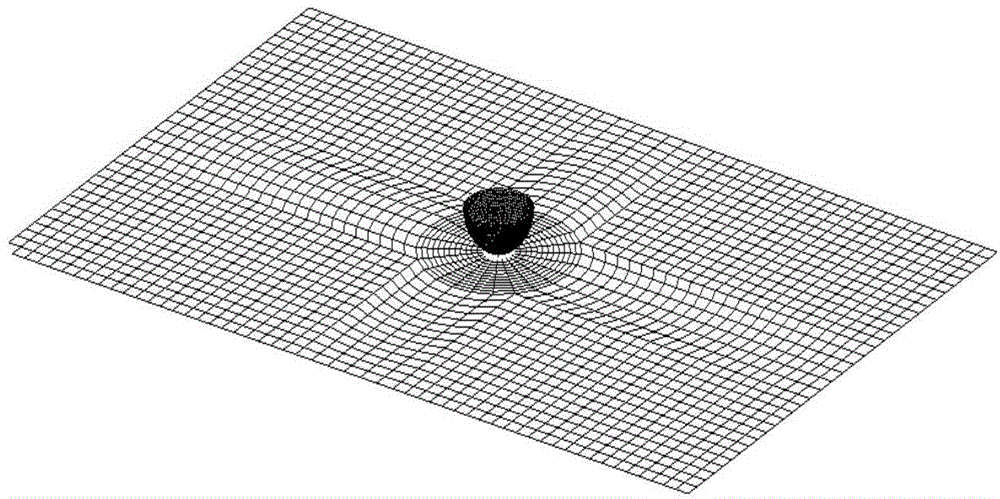

Method for assessing residual intensities of composite material structures with low-speed impact damage

InactiveCN107092721AGuaranteed accuracyHigh precisionDesign optimisation/simulationSpecial data processing applicationsResidual strengthElement model

The invention discloses a method for assessing residual intensities of composite material structures with low-speed impact damage. The method comprises six steps of: 1, obtaining a curve relationship between impact energy and damage characteristic parameters through low-speed impact test results; 2, obtaining a maximum contact force and a maximum pit depth under corresponding impact energy by adoption of an impact damage theory; 3, establishing a low-speed impact progressive damage finite element model; 4, correcting the low-speed impact progressive damage finite element model; 5, establishing a residual intensity finite element model with impact damage; and 6, solving the residual intensity finite element model with the impact damage to obtain a residual intensity value. According to the method disclosed by the invention, finite element simulation is applied to impact damage models, and the impact test results and the impact damage theory are combined, so that the accurate simulation for damage states, the accurate building of finite element models with initial impact damage and the continuity of assessment processes are realized, and a relatively high practical value is provided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

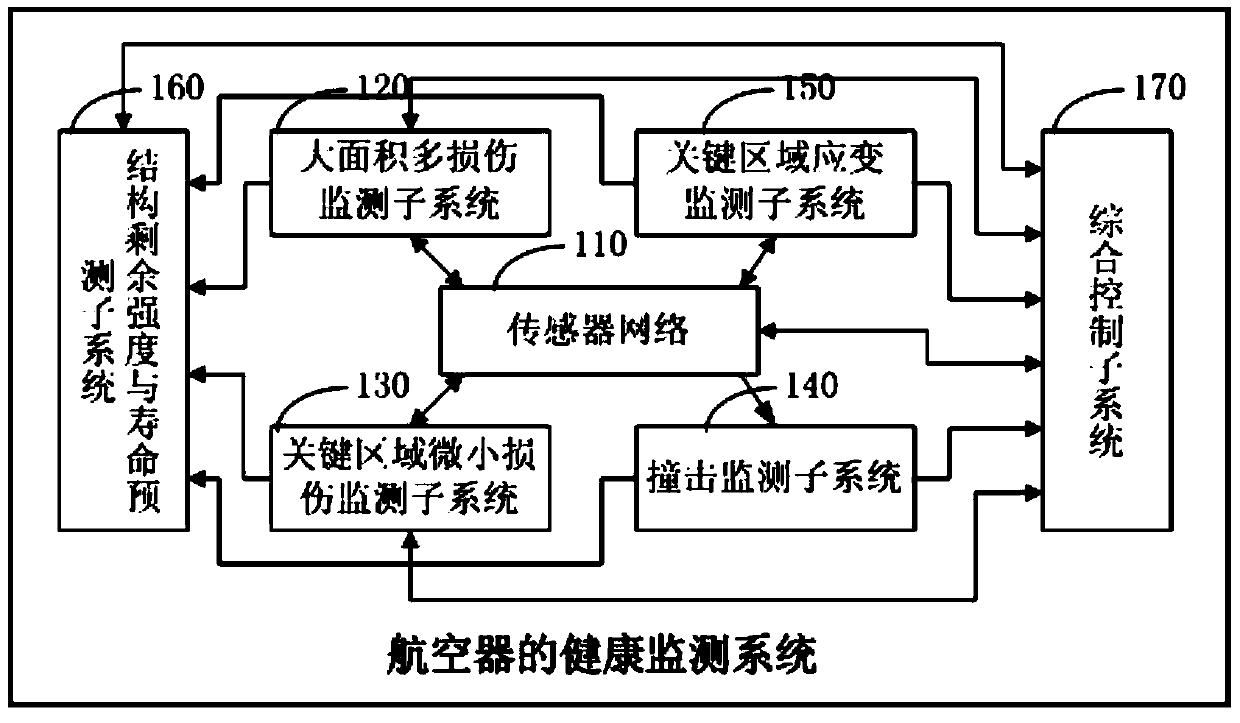

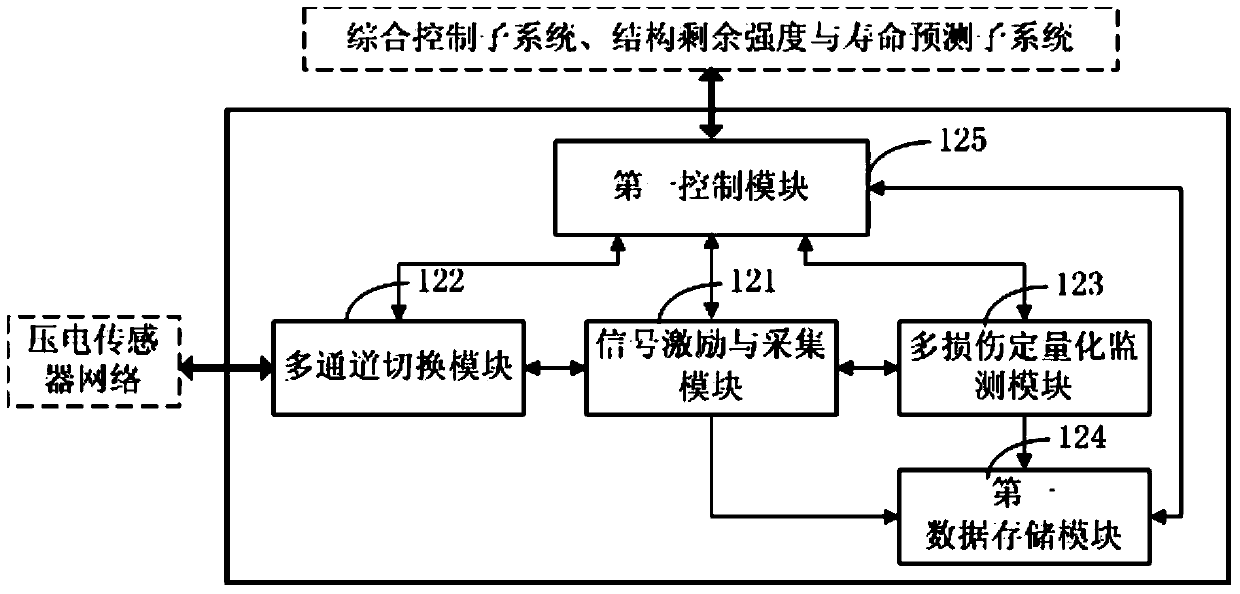

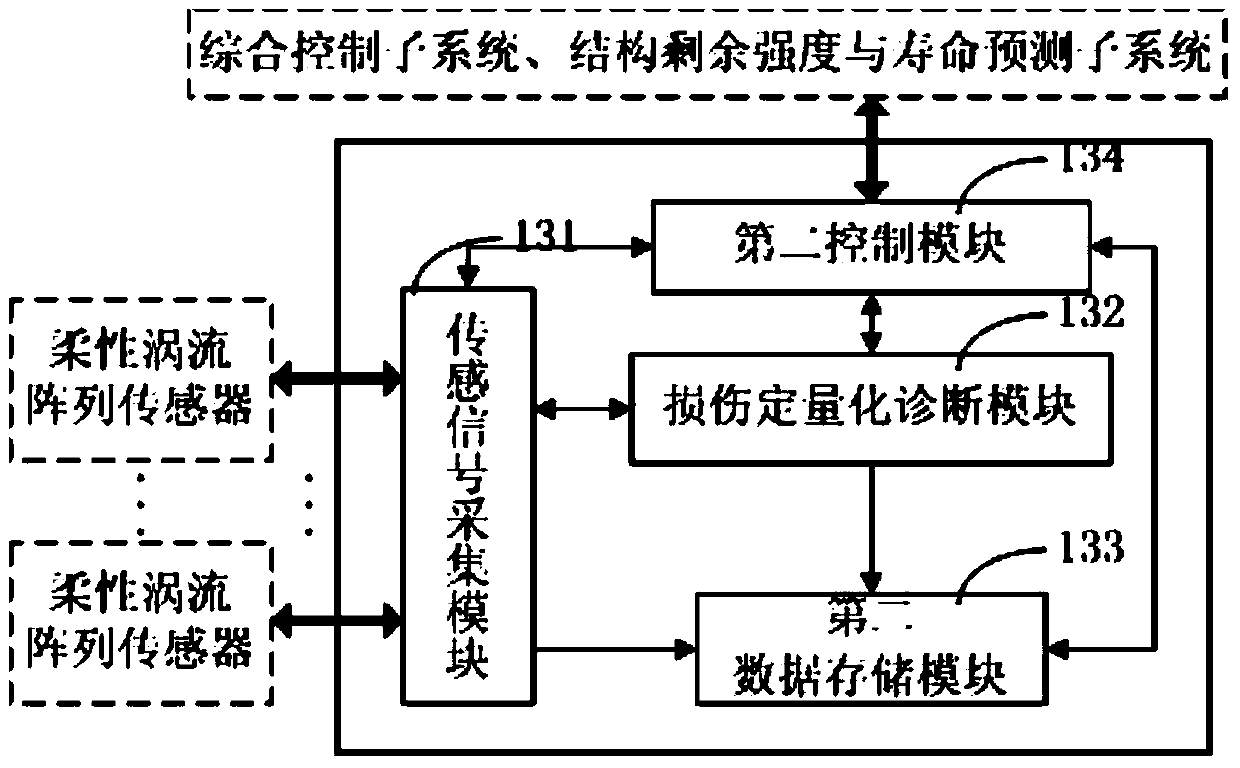

Structural health monitoring system for aircraft

InactiveCN104181000AHighly integratedWith micro-damage monitoring functionStructural/machines measurementFiberAviation

The invention discloses a structural health monitoring system for an aircraft. The structural health monitoring system comprises a sensor network for providing sensor signals to each subsystem; a first subsystem for carrying out quantitative monitoring on multiple damage of a large-size aviation structure; a second subsystem for monitoring tiny cracks in a high-stress area of an aviation metal structure and monitoring the damage of delamination, debinding and fibre breakage and the like in the high-stress area of an aviation composite material structure; a third subsystem for carrying out positioning on external bumping of the aviation composite material structure and load reconstruction; a fourth subsystem for carrying out distributed real-time measurement on strain of a key area of the aviation structure and corresponding load reconstruction; a fifth subsystem for carrying out prediction on the service life and residual intensity of the aviation structure; and a sixth subsystem for controlling and coordinating the work of the other subsystems. The structural health monitoring system provided in the embodiment of the invention overcomes the defect that the function of a conventional aircraft structure health monitoring system is single.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

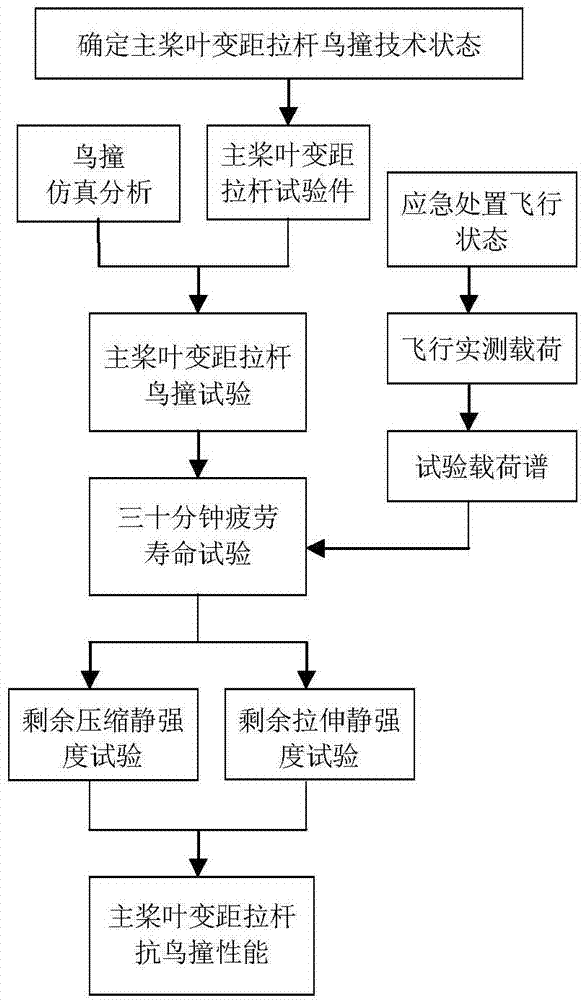

Method for verifying bird strike resistance performance of pitch link of main blade of helicopter

ActiveCN104776970AAccurate acquisition of anti-bird strike performanceWithout catastrophic consequencesShock testingResidual strengthValidation methods

The invention discloses a method for verifying the bird strike resistance performance of a pitch link of a main blade of a helicopter, and belongs to the field of helicopter structural strength tests. The method is used for determining the performance of the pitch link of the main blade of the helicopter after bird strike damage is generated in the flight process. Aiming at the characteristics that the pitch link of the main blade of the helicopter is high in bird strike probability in low airspace, and damage is serous, the bird strike resistance performance of this kind structures is assessed accurately through the bird strike tests of the full size structure under simulated real working environment, fatigue life verification tests half hour after striking and residual strength tests, and it is guaranteed that catastrophic results cannot be generated even if bird strike occurs to the helicopter in the harshest flight process.

Owner:CHINA HELICOPTER RES & DEV INST

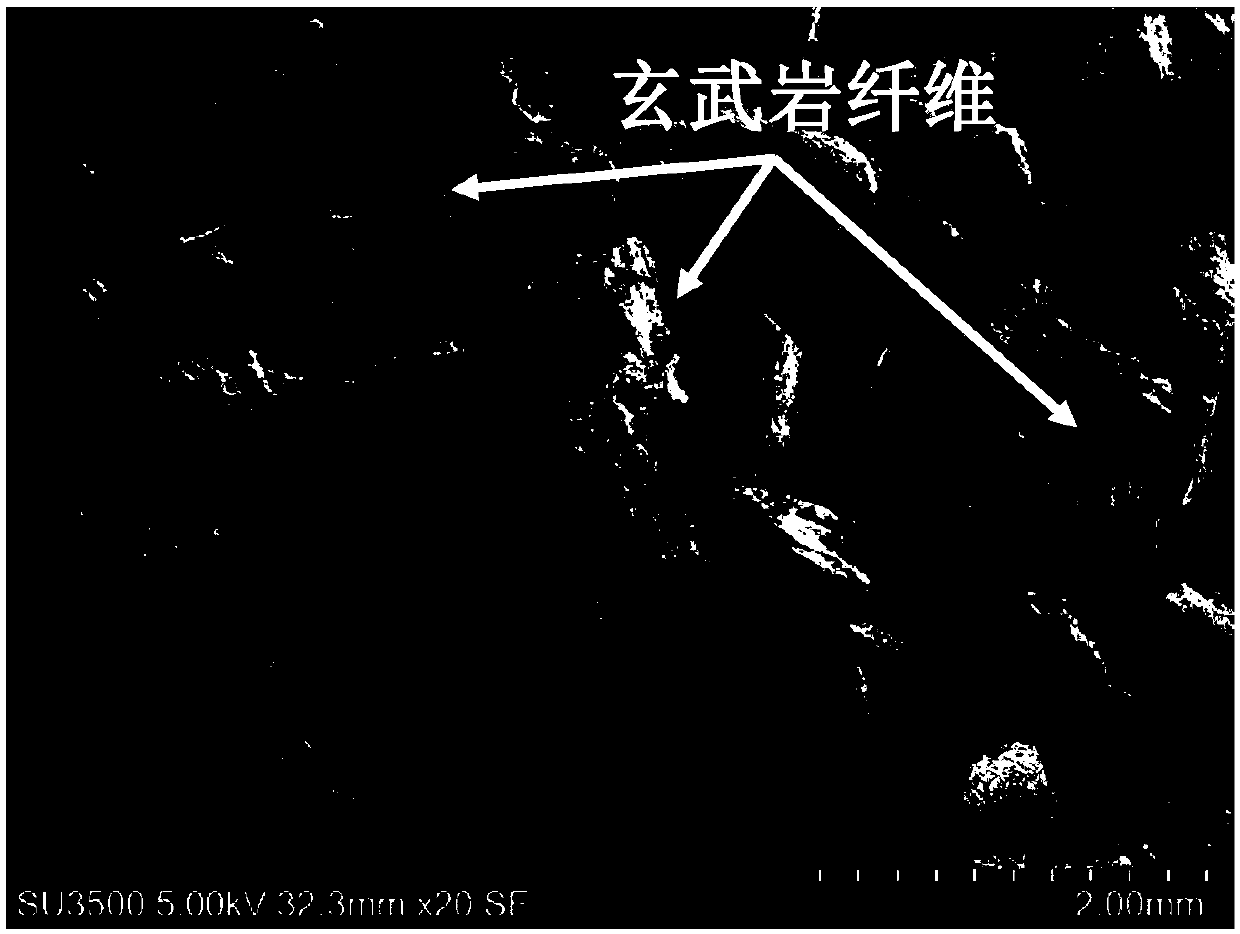

Microbial curing-fiber reinforcement combined sandy soil modification method

ActiveCN109594552AHigh strengthImprove toughnessSoil preservationResidual strengthEngineering structures

The invention discloses a microbial curing-fiber reinforcement combined sandy soil modification method and belongs to the field of geological engineering-microbial interdiscipline. The method comprises the steps as follows: 1) adding a fiber material to sandy soil, adding water, performing uniform stirring, putting the mixture in a mold, and leaving the mixture to stand and drying the mixture after compacting and filling the mold; 2) activating a microbial solution with mineralization; 3) soaking the sandy soil in the activated microbial solution; 4) transferring the treated sandy soil to a maintenance device, and filling the maintenance with a gluing solution for gluing and curing. An MICP technology and a fiber reinforcement technology are combined to modify the sand soil, so that loosesandy soil is cured, the forming strength is improved, meanwhile, brittleness of a sandy soil cured body can be significantly reduced and residual strength and toughness of the sandy soil cured body can be improved due to addition of the fiber, the engineering properties of traditional MICP cured sandy soil are improved as a whole, and the method has great significance in further improving safetyand stability of engineering structures.

Owner:南京南智碳中和研究院有限公司

Method for analyzing residual compression strength of composite materials after impact damage

ActiveCN106202598AEfficiently predict residual strengthSpecial data processing applicationsUltrasound attenuationResidual strength

The invention belongs to the field of structural damage tolerance design of composite materials, and specifically relates to a method for analyzing residual compression strength of composite materials after impact damage; and the method is used for determining the residual compression strength of composite materials after impact damage. The method comprises three steps of 1, selecting a Hanshin failure criterion as a damage failure criterion for low-speed impact of a laminated plate according to failure characteristics of a composite material; 2, importing the Hanshin failure criterion by adopting a large-scale dynamic finite element program DYTRAN, so as to calculate a damage area under the low-speed impact of the laminated plate; and 3, carrying out rigidity attenuation on a damage area after the low-speed impact according to the damage area determined in the second step, and calculating the residual compression strength of the laminated plate after the low-speed impact by adopting a global-local model analysis method. The invention discloses a brand new analysis method, so that the residual strength of typical components of composite materials after impact damage can be effectively predicted, and basis is provided for the structural design, analysis and verification of the composite materials of airplanes.

Owner:HARBIN

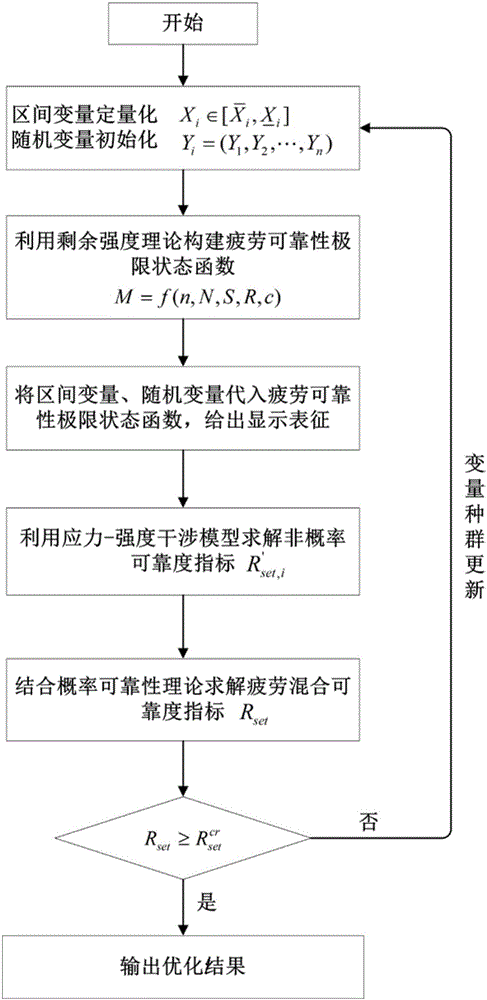

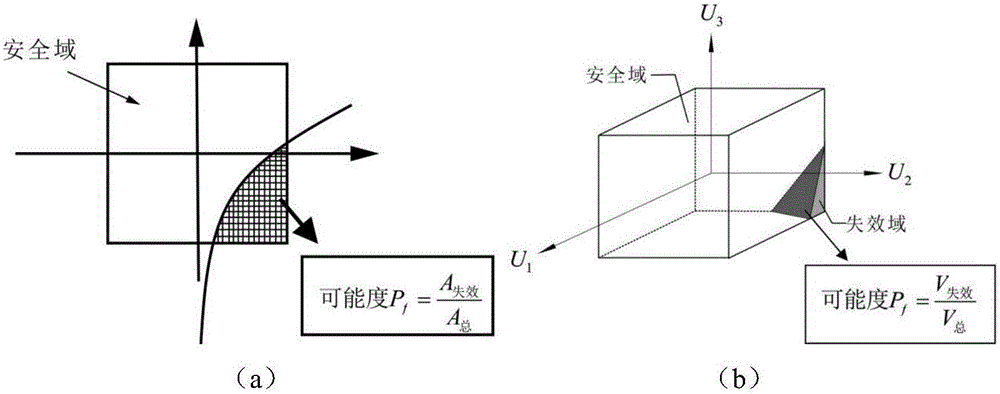

Mixed fatigue reliability optimization method aiming at composite material laminated plate

ActiveCN105930618AReduce dependenceMake up for and perfect limitationsComputer aided designSpecial data processing applicationsProbabilistic methodResidual strength

The invention discloses a mixed fatigue reliability optimization method aiming at a composite material laminated plate. The mixed fatigue reliability optimization method comprises the steps of firstly taking a full consideration to existing multisource uncertain factors such as material intensity and useful load based on a small sample non-probabilistic method, integrating irregular sample data by applying a gray theory, exploring potential regularity of the irregular sample data and giving out a reasonable quantized result; then establishing a residual intensity model under the action of a fatigue load, introducing an uncertain parameter into a model and developing a non-probabilistic reliability solving method; then taking an overall consideration to a mixing form of a random variable and an interval variable, solving a mixing reliability index by utilizing an established non-probabilistic reliability solving method and combining with the probability reliability solving method; and finally carrying out composite material laminated plate thickness optimization design by regarding the mixing reliability index as constraint. Based on the mixed fatigue reliability optimization method aiming at the composite material laminated plate, intensity optimization design of large-scale structures in the presence of poor information and less data can be realized, and the design per se which considers both security and economy is ensured.

Owner:BEIHANG UNIV

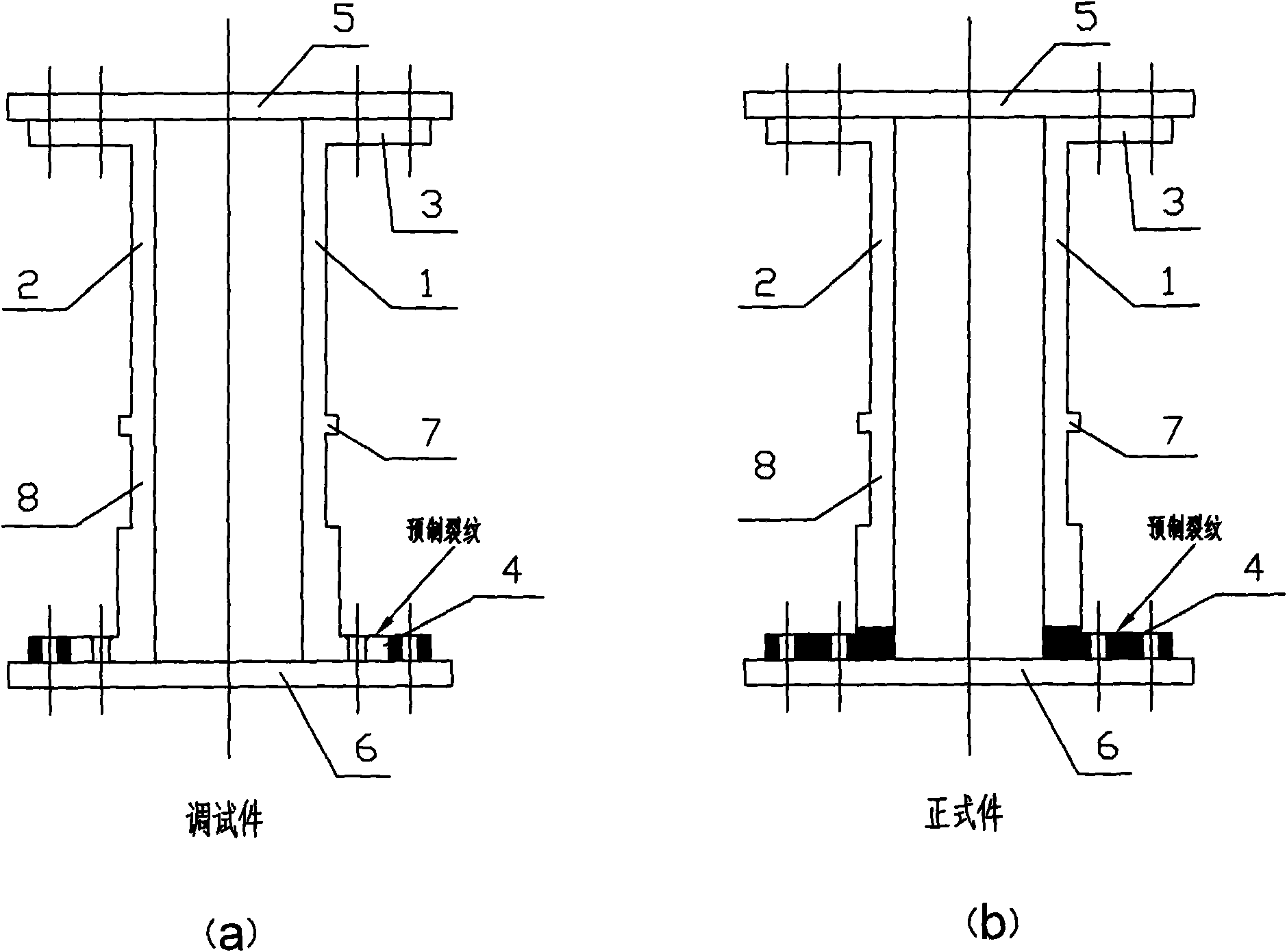

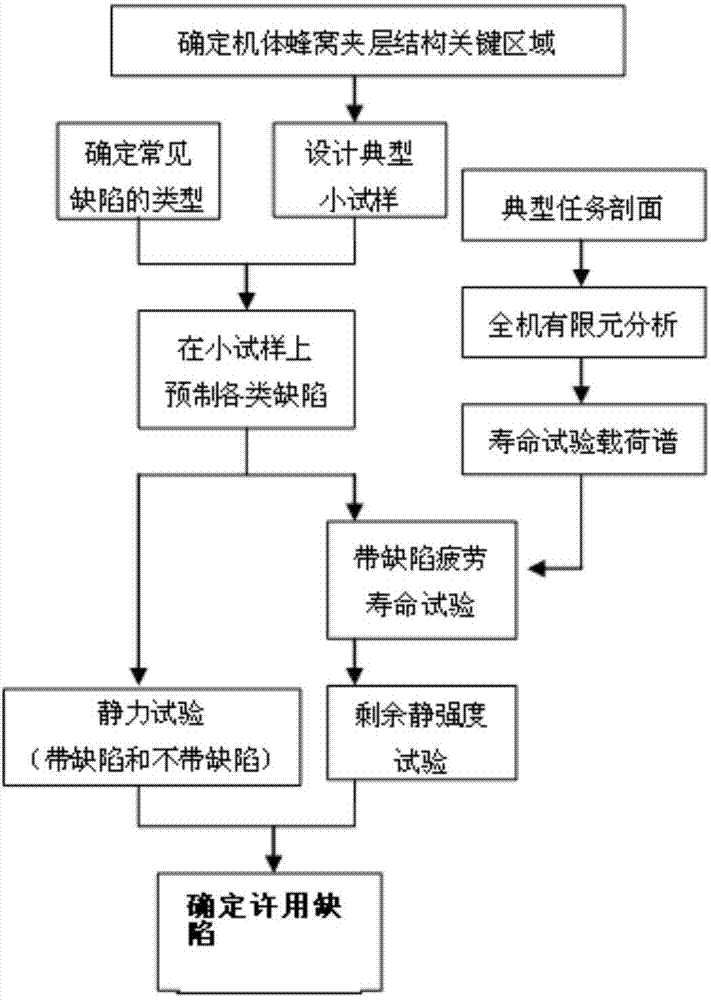

Method for determining allowable defect of honeycomb sandwich layer of helicopter

InactiveCN104778372AReduce manufacturing costReduce the risk of structural defectsSpecial data processing applicationsComparative testResidual strength

The invention discloses a method for determining allowable defects of a honeycomb sandwich layer of a helicopter, belongs to the technical field of structural fatigue design of helicopters and particularly relates to a method for determining honeycomb sandwich layer structure defects of a helicopter body with defects. By prearranging internal and external defects on a honeycomb sandwich layer test piece and determining the rationality of defect parameters by adopting static strength, fatigue and remaining strength comparative tests under real load-bearing environments, bases are provided for the design and handling of such manufacturing deviations, the manufacturing and using costs of the honeycomb sandwich layer structure can be decreased and the risk in use of the defective structure is reduced.

Owner:CHINA HELICOPTER RES & DEV INST

Silica collosol binder and its manufacturing method

InactiveCN1414054AImprove performanceImprove the binding effectMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer scienceResidual strength

A silicone sol adhesive modified by PVA, modified starch, or modified cellulose is prepared through preparing the aqueous solution of PVA, modified starch, or modified cellulose, preparing the solution of alkaline silicon sol, and mixing. It can be used for investment casting to increase drying speed, wet strength and residual strength with low cost.

Owner:章浩龙

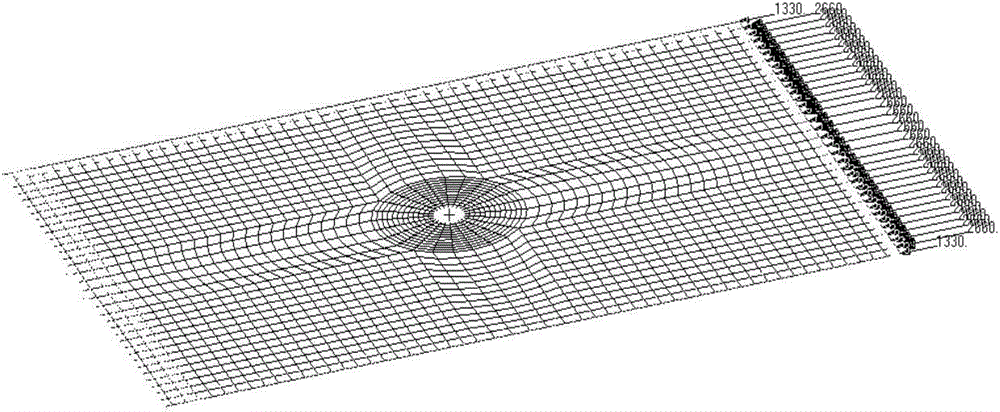

Stiffened wallboard damage tolerance analysis method based on finite element analysis solving

ActiveCN106354934ADesign optimisation/simulationSpecial data processing applicationsElement modelResidual strength

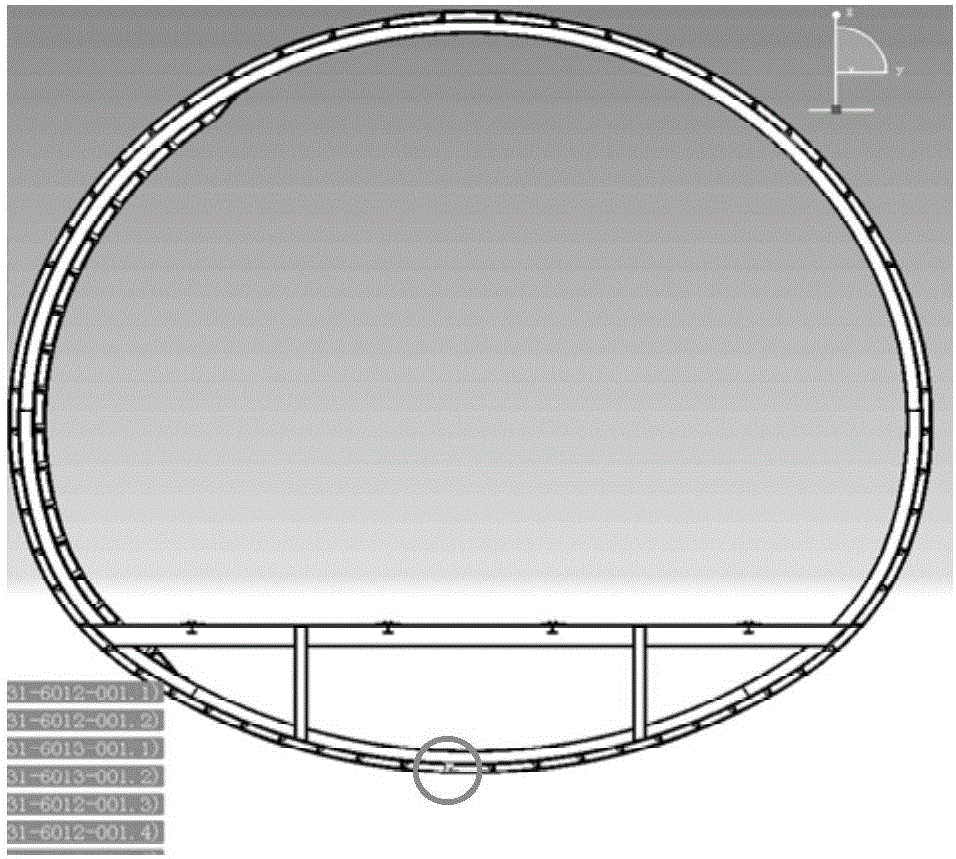

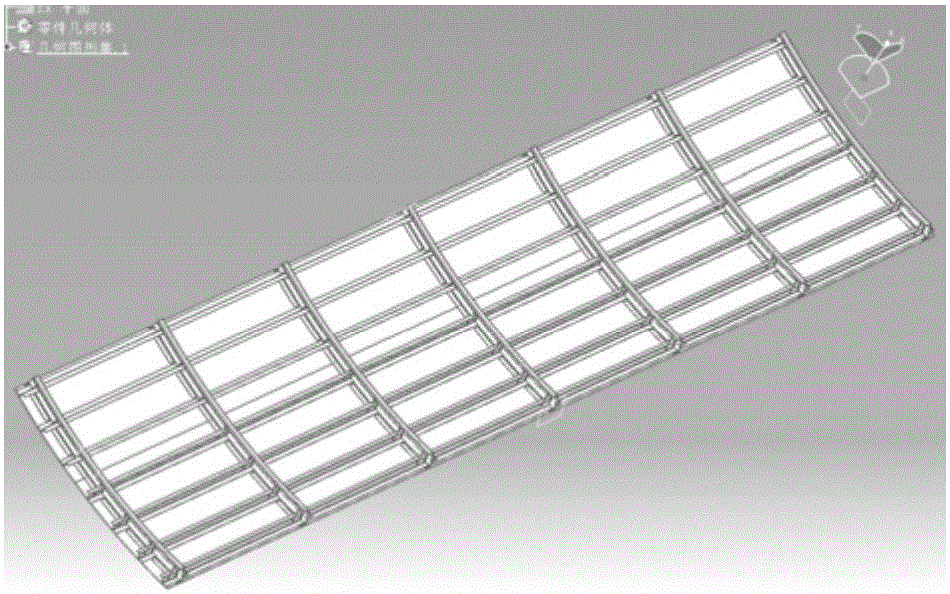

The invention relates to a stiffened wallboard damage tolerance analysis method based on finite element analysis solving, comprising the steps of first, determining a crack growth direction according to aircraft wallboard structural form and load-bearing condition; setting limit crack length to determine model scale; second, establishing a crack-free stiffened wallboard details finite element model; third, applying total load to the model to solve wallboard stress distribution; fourth, simulating cracks different in length in the finite element model, and extracting note balance force and displacement of a crack tip unit; fifth, solving stress strength factor K for tips with different crack lengths of a stiffened wallboard in fourth step by applying virtual crack closure technique VCCT; sixth, subjecting the stiffened wallboard to crack growth life and structural residual strength analysis. The method can provide real simulation for stiffened wallboard different-size cracks, crack tip stress and strain condition, stiffened wallboard different-size crack stiffener stress level, and fastener load; crack growth analysis is performed on stiffened wallboard skin based on analysis results.

Owner:AVIC SAC COMML AIRCRAFT

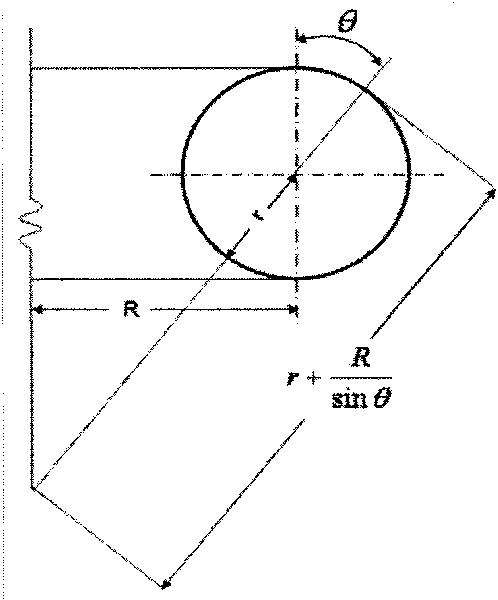

Residual intensity evaluation method of corrosion defect contained steam injection pipeline compensator bent pipe

ActiveCN101726456AAvoid stress concentrationHigh engineering practical valueMaterial strength using tensile/compressive forcesUsing mechanical meansMean diameterFlow stress

The invention relates to a residual intensity evaluation method of a corrosion defect contained steam injection pipeline compensator bent pipe, which comprises the following steps of: computing the bearing capacity of the bent pipe through a formula plimit=Sigma f / (r Eta+3r2 Alpha Eta 2), wherein plimit in the formula is the ultimate bearing capacity of the bent pipe, Sigma f is the flow stress of a pipe, r is the mean radius of the bent pipe, alpha is the ellipticity of the bent pipe, Eta is an intermediate variable, t in the formula is the wall thickness of a pipeline, d is a defect depth, k is an intermediate variable, L in the formula is a defect length and Dm is the mean diameter of the bent pipe; carrying out full-size hydrostatic bursting test verification by utilizing the compensator bent pipe with corrosion defects, and comparing a measured value with a theoretical value, wherein the theoretical value is smaller, and an error is 24.7 percent. A result indicates that the method has higher engineering utility value and reasonable safe reliability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

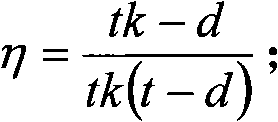

Strain control method for measuring residual strength and residual service life of composite material

InactiveCN104020254AEasy to operateImprove calculation accuracySpecial data processing applicationsMaterial analysisResidual strengthModel parameters

The invention relates to a strain control method for measuring residual strength and residual service life of a composite material. The strain control method comprises three steps of (1) a strain control residual strength model; (2) a random model of the strain control residual strength; and (3) model parameter estimation. The strain control method is simple and practical, is convenient for operations and has high calculation precision. The strain control method has relatively good practical value and wide application prospects in the field of measurement technology.

Owner:BEIHANG UNIV

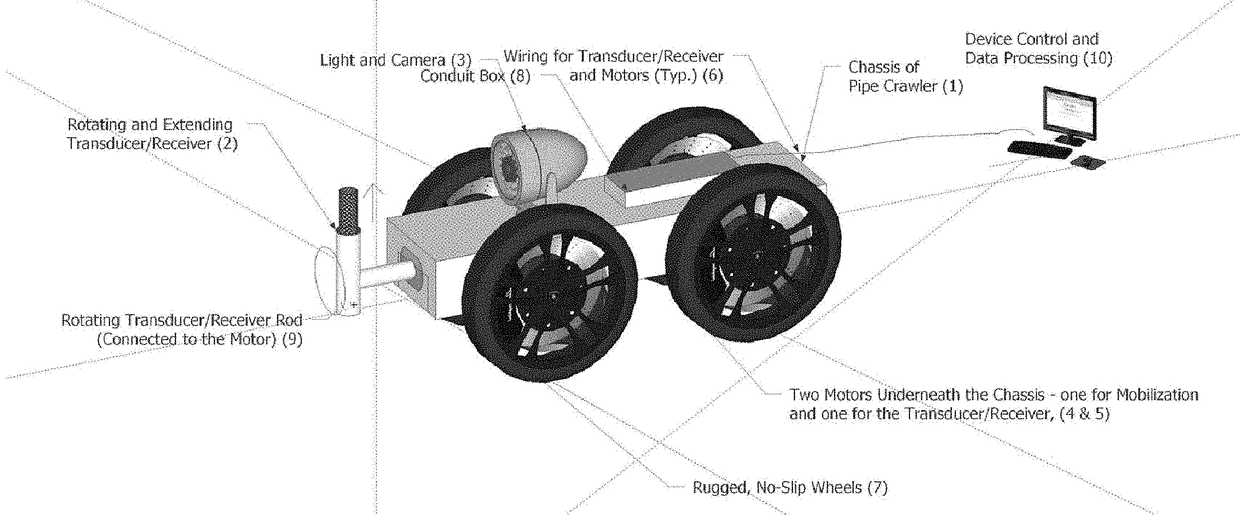

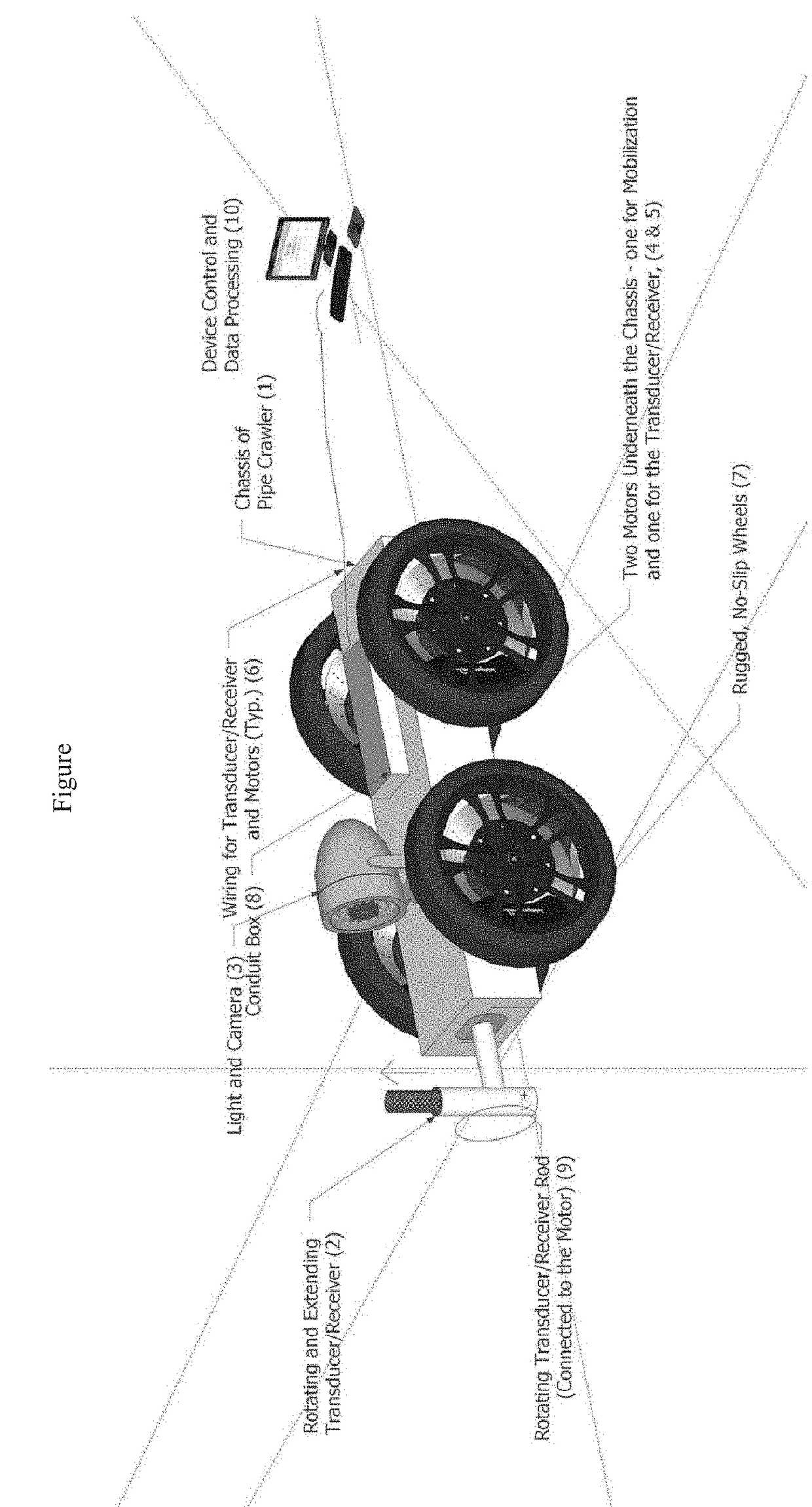

Pipeline Inspection Device

InactiveUS20170191601A1Measure the residual strength (stiffness)Material analysis using sonic/ultrasonic/infrasonic wavesPigs/molesNon destructiveResidual strength

The present invention relates to a robotic pipeline inspection device that measures the residual strength of the pipe. Aging underground infrastructure is a major problem around the globe. There is a need for a deterministic, non-destructive, pipeline condition assessment device. Some of the other internal pipeline inspection devices work well, but the data obtained by using them is limited to thickness of the pipe or internal video of the pipeline. The invention presented herein can send and receive ultrasonic pulse into the pipe wall within millimeters, thereby, determining the residual strength of the pipe material. The embodiment of the present invention provides a pipeline inspection device comprising: a body comprising mounted wheels; a transducer and receiver connected to the body; at least one motor to power the wheels and the transducer and receiver; and wiring that connects the transducer and receiver to the at least one motor.

Owner:SEVER VEYSEL FIRAT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com