Whole-course analysis method for impact damage and residual intensity of sutured composite material

A composite material and impact damage technology, which is applied in the field of damage performance analysis of suture composite materials, impact damage and residual strength analysis of suture composite materials, can solve problems such as low engineering application prospects, little improvement in accuracy, and no consideration, etc. Achieve the effects of good scalability, high coherence, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

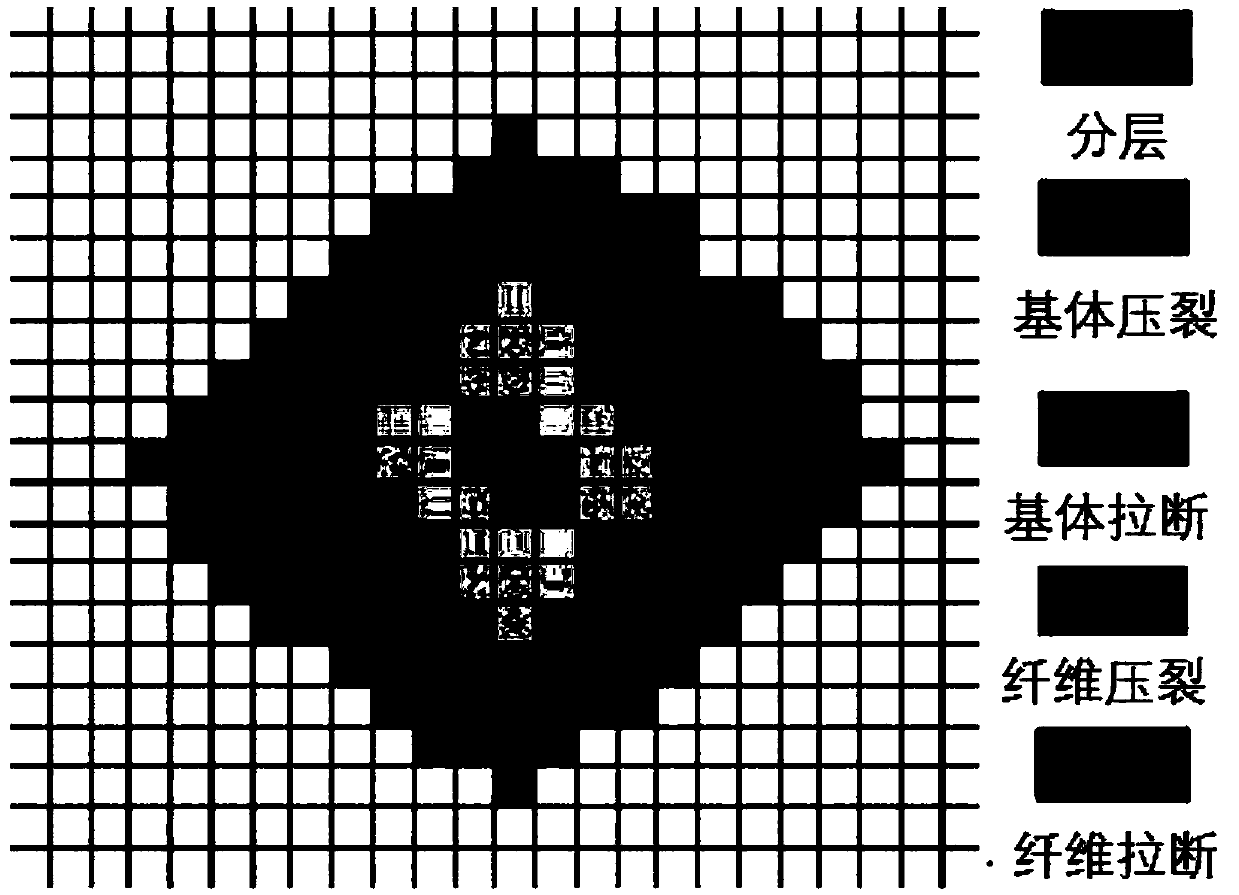

[0110] Example: G0827 / QY9512 Seamed Composite Laminate Impact Damage and Residual Strength Analysis

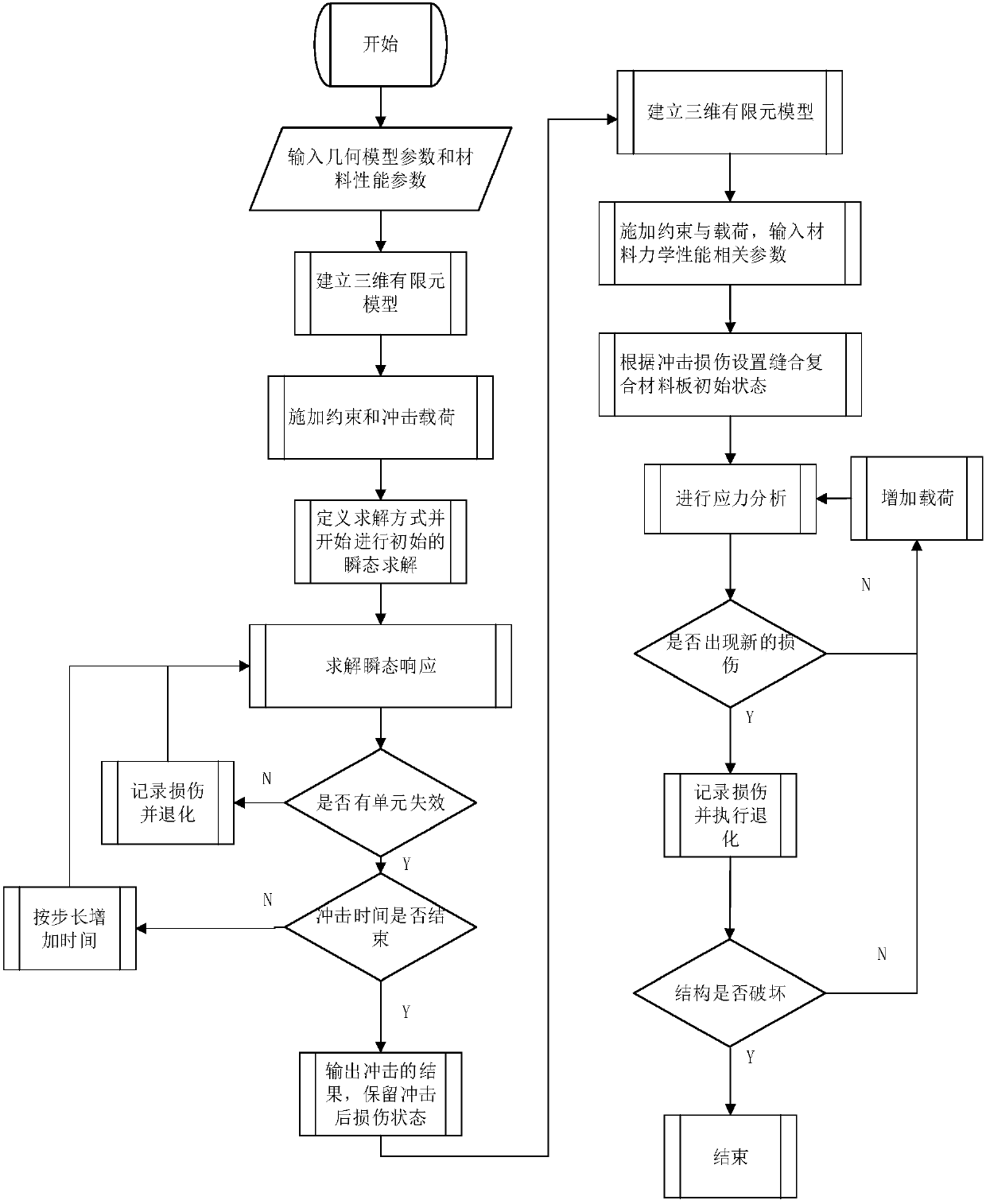

[0111] according to figure 1 The flow chart shown is a full-scale analysis of the impact damage and residual strength of G0827 / QY9512 stitched composite laminates, as follows:

[0112] (1) The geometric model parameters and material performance parameters of the impact process;

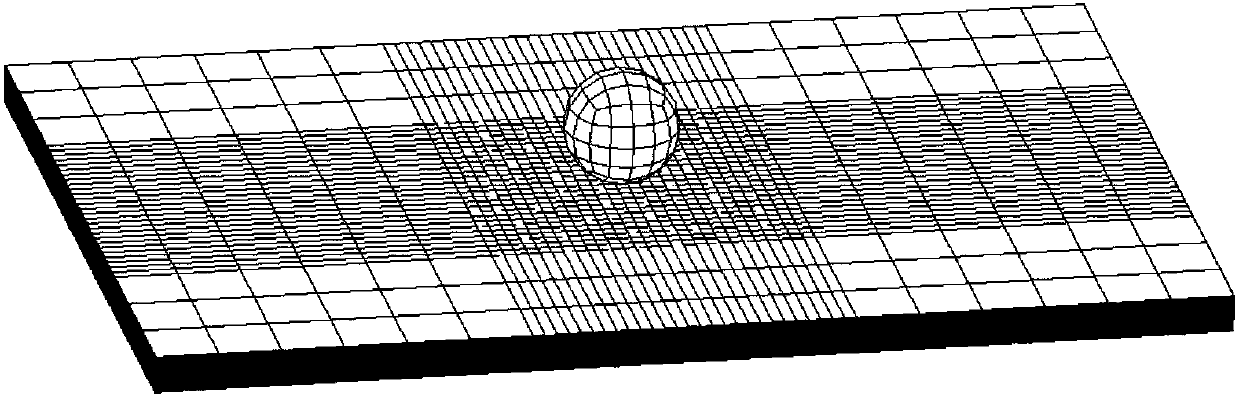

[0113] The stitching density of G0827 / QY9512 stitched composite laminates is 5mm×5mm; the stitching is kevlar29 (1500 denier); the stitching method is improved lock stitching, the stitching direction is 0°, and the thickness of each layer of the single-layer board is 0.15mm. The punch is a smooth ball punch with a diameter of 16mm and a hardness greater than 60HRC, and the weight of the punch is 5.5kg.

[0114] G0827 / QY9512 Mechanical properties of seamed composite laminates: longitudinal tensile modulus E 1 =128GPa; transverse tensile modulus E 2 =9.93GPa; normal tensile modulus E 3 =9.93GPa; in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com