Patents

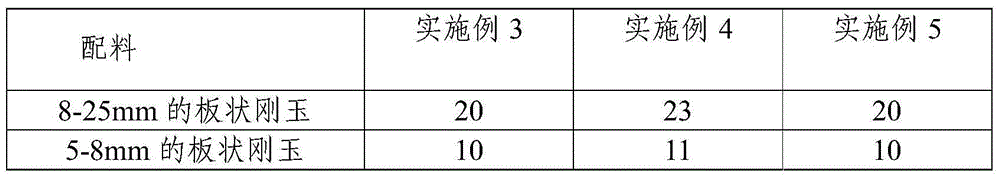

Literature

46results about How to "Reduce carbon increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

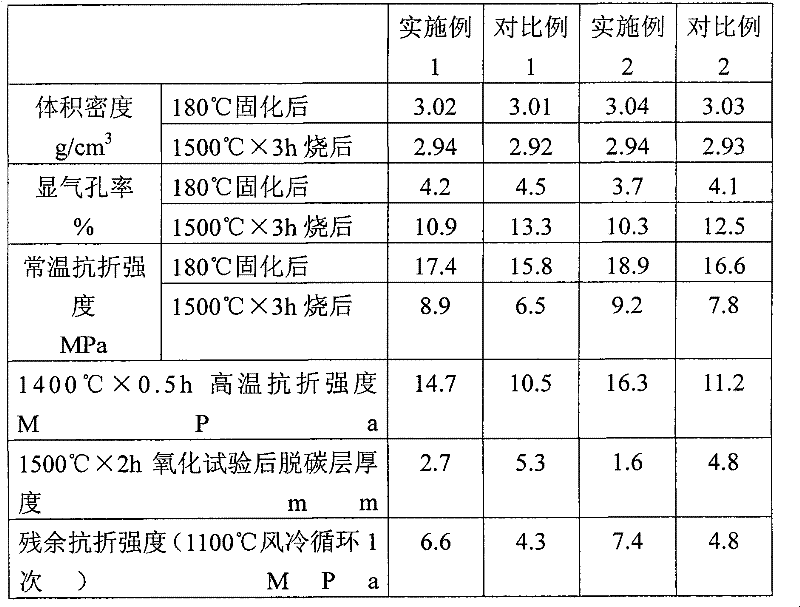

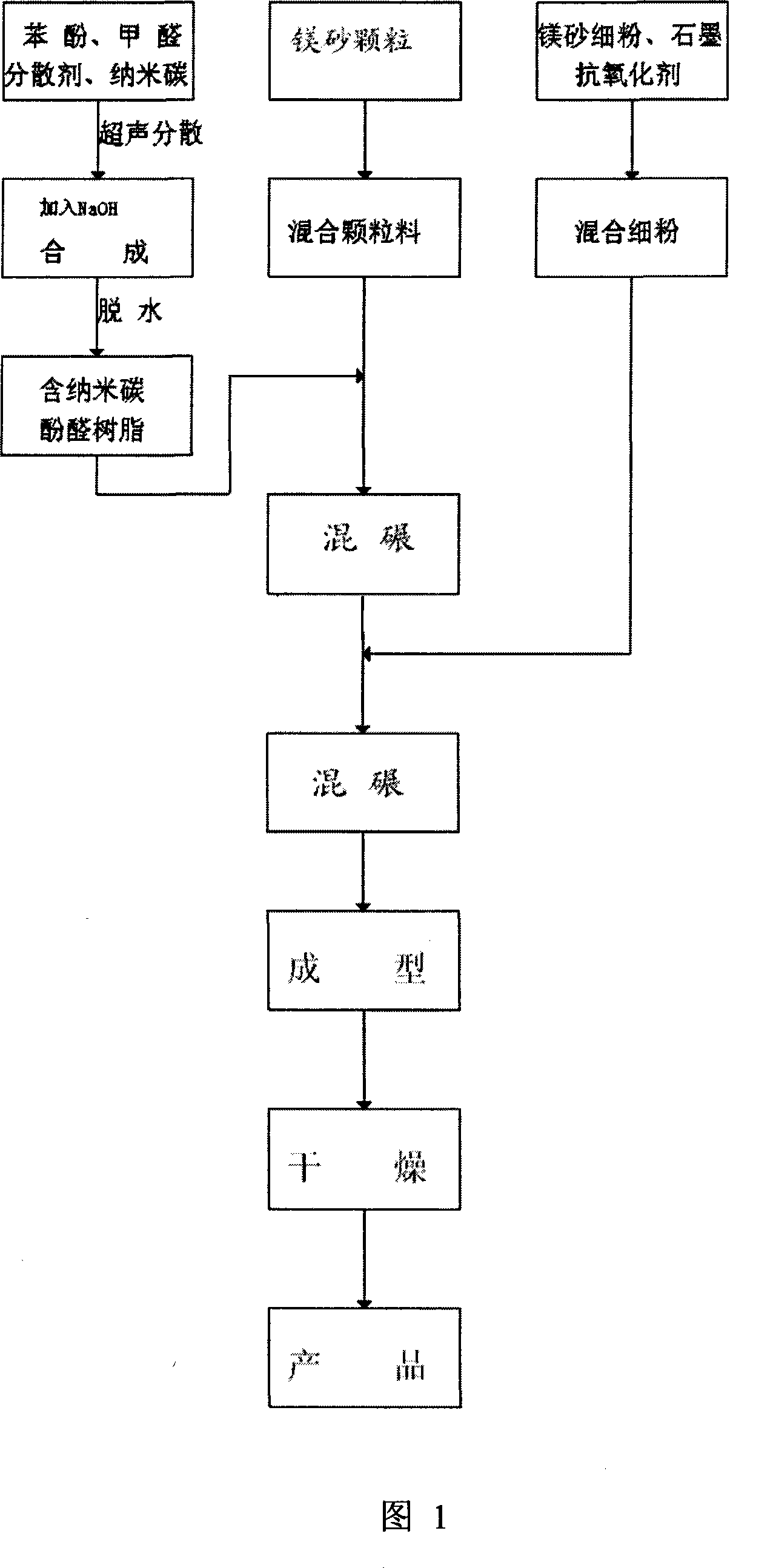

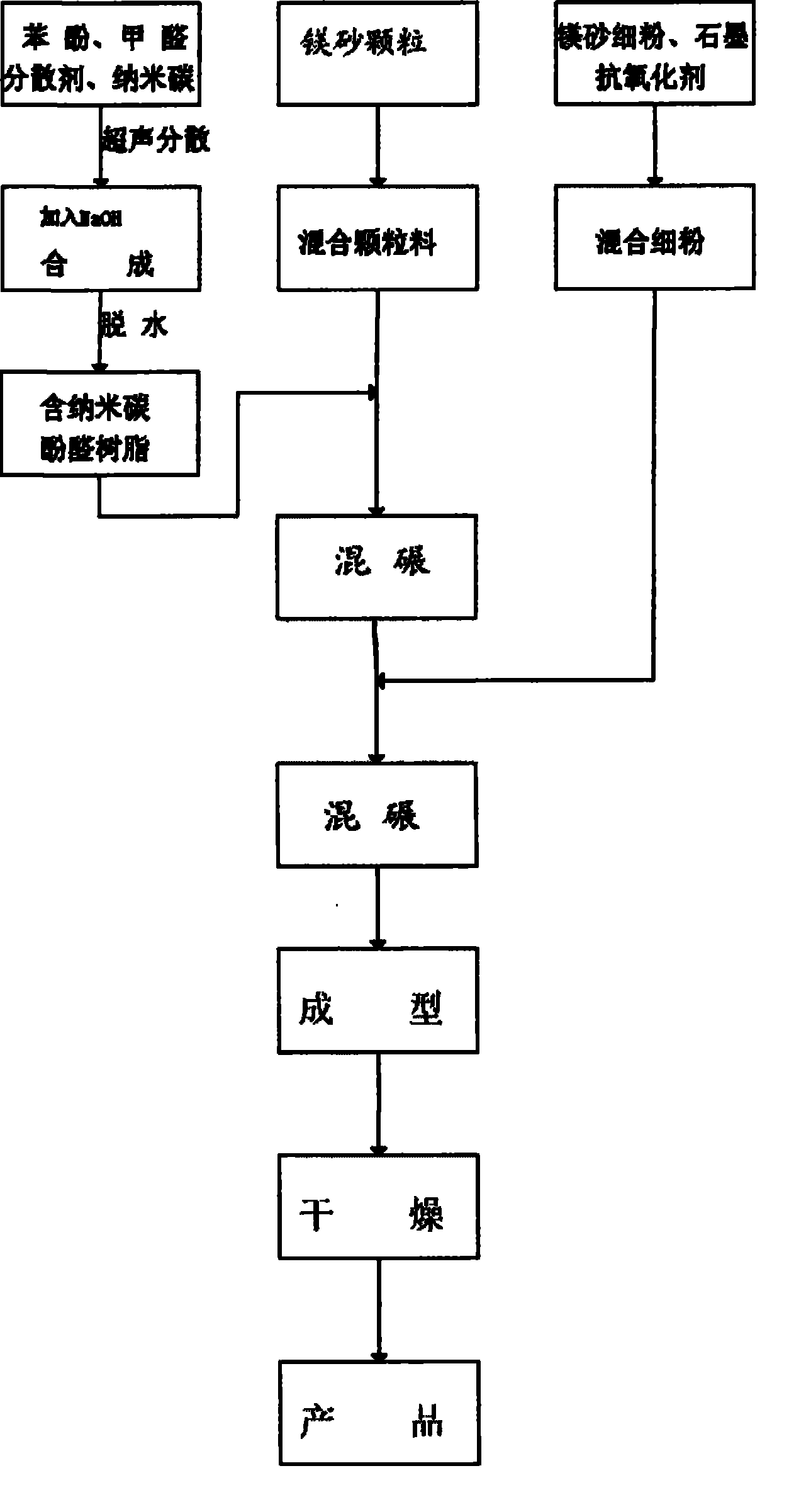

Phenolic resin containing nano-carbon powder, nano-carbon modified low carbon magnesium carbon brick and production method thereof

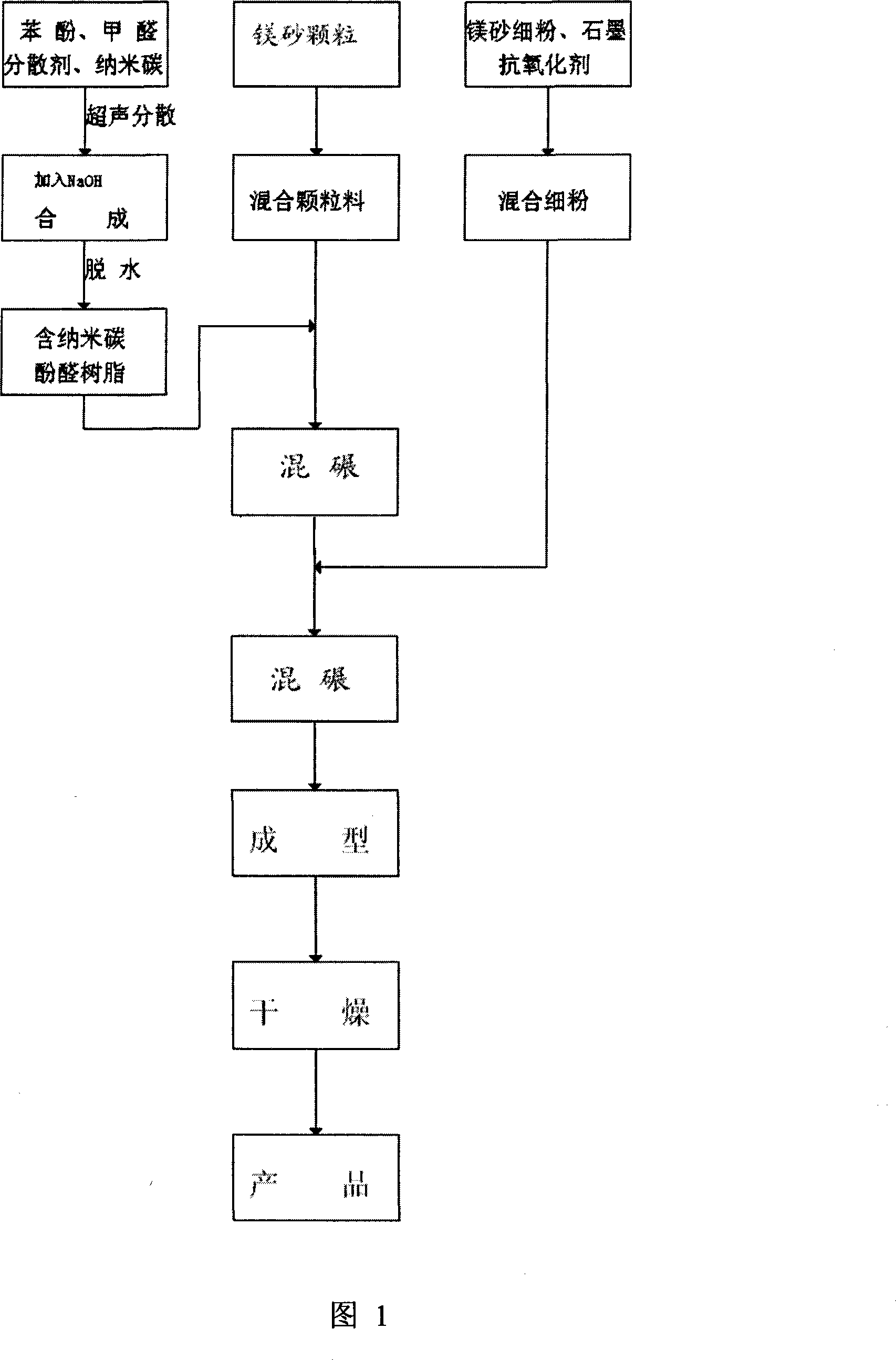

The invention relates to a low-carbon MgO-C brick containing modified phenolic resin and nanocarbon which are produced by nano carbon powder and a preparation method thereof. Phenolic resin bonding agent containing nano carbon powder is produced by ohenol, formaldehyde, a dispersant and nano carbon powder; the low-carbon MgO-C brick is produced by adopting fused magnesite, graphite, phenolic resin and an antioxidant as raw materials. The ultrasonic dispersion method adopted by the invention replaces partial graphite with the nano carbon powder and leads the nano carbon powder into the low-carbon MgO-C brick, thus obviously improving the anti-erosion ability and the oxidation resistance of the MgO-C brick. The brick has comparatively low thermal expansion coefficient, low thermal conductivity, low oxidative mass loss and thinner decarburized layer; a slag resistance experiment under conditions of 1600 DEG C, 3h heat preservation and carbon sequestration shows that erosion and osmosis phenomenon of the brick are not obvious, thereby being applicable to sites of converters, electric furnaces and ladle working linings, external scouring of furnaces, key components for continuous castings and refractories for blast furnace ironmaking etc., thus having comparatively large application range.

Owner:ZHENGZHOU UNIV +1

Method for producing tire cord steel wire by converter billet continuous casting process

ActiveCN102534094AGuaranteed surface qualityLow costManufacturing convertersMetal rolling arrangementsSlagSilicon alloy

The invention relates to a method for producing a tire cord steel wire according to a converter billet continuous casting process and belongs to the technical field of production of tire cord steel wires in the field of ferrous metallurgy. The method comprises the following process steps: desulfurizing by pre-treating molten iron, namely desulfurizing by spraying magnesium on a foundry ladle; smelting by using a converter, namely deoxidizing and alloying, modifying steel ladle slag, re-carburizing the molten iron and adding low-alkalinity pre-melted slag into the steel ladle after tapping; adding ferro-silicon alloy, manganese iron alloy and micronitrogen carburant in the tapping process and re-carburizing; and in the refining process and after the refining is finished, rolling the wire at high speed by adopting a two-stage steel ladle bottom blowing argon system and adopting billet continuous casting of 130mm*130mm or 160mm*160mm. The method has the advantages that: the production isreduced; the production efficiency is improved; and the method is particularly suitable for development and production of tire cord steel products in steel enterprises without big billet or rectangular billet continuous casting and without vacuum treatment equipment.

Owner:SHOUGANG CORPORATION

Non-oriented electrical steel plate and production method thereof

InactiveCN103572158AImprove thermal conductivityReduce carbon increaseMetal rolling arrangementsProduction lineElectrical steel

The invention relates to a non-oriented electrical steel plate Which comprises the following components in percentage by mass: less than or equal to 0.0060 percent of C, 0.60 to 0.80 percent of Si, 0.20 to 0.40 percent of Mn, less than or equal to 0.10 percent of P, less than or equal to 0.0080 percent of S, 0.015 to 0.025 percent of Als, 0.001 to 0.002 percent of B, and the balance of Fe and unavoidable impurity elements. The production method comprises the following steps of smelting in a converter, argon blowing to steel ladle, RH vacuum treatment, refining of an LF furnace, continuous casting of a sheet billet, heat equalizing through a tunnel, fine rolling, cooling, coiling, acid pickling, cold rolling and continuous annealing. Compared with the prior art, the method is high in magnetic induction and low in iron loss. A manufacturing process for producing the non-oriented electrical steel plate by continuously casting and continuously rolling the sheet billet is provided for the first time, and the technical support is provided for production of a novel non-oriented electrical steel hot-rolling raw material with excellent environmental-protection performance by utilizing a sheet billet continuous-casting and continuous rolling production line.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

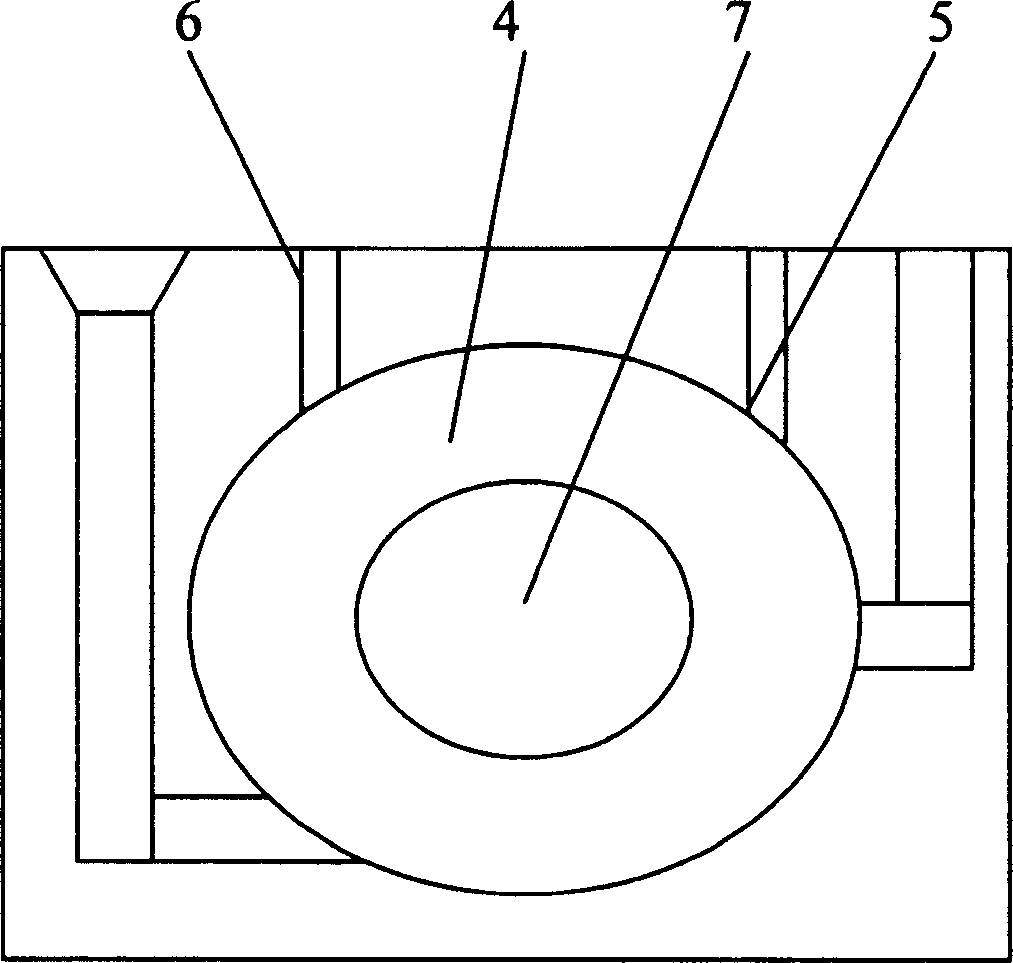

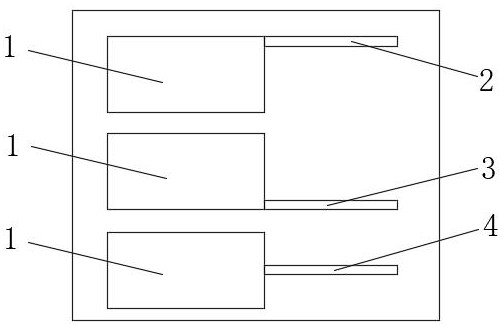

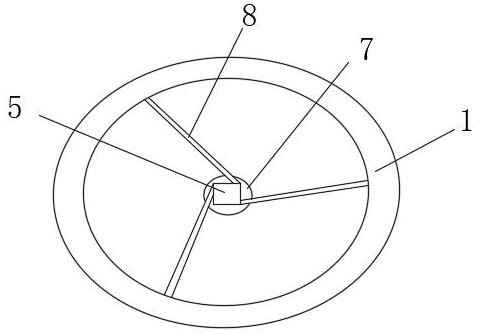

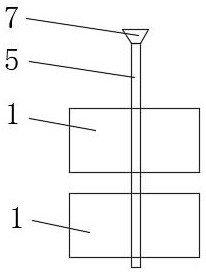

Bi-metal bent pipe manufacturing process based on evaporative pattern casting and vibration pouring

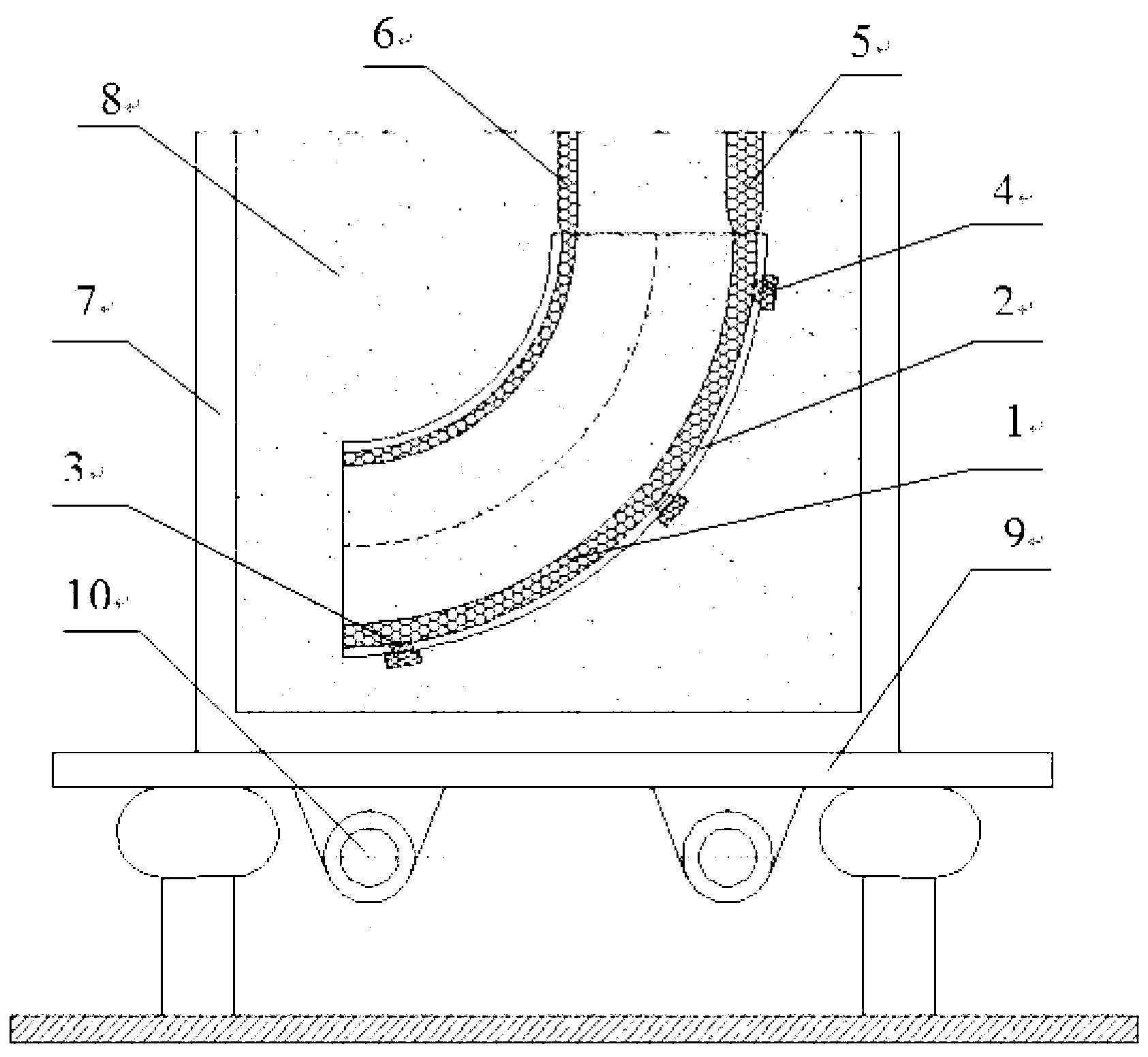

InactiveCN103008544AImprove bindingEliminate shrinkage gapsFoundry mouldsFoundry coresWear resistantWear resistance

The invention discloses a bi-metal bent pipe manufacturing process, which includes: assembling a foam pattern (1) of a bi-metal bent pipe lining and an outer steel pipe (2) that has through-holes (3) drilled on an outside wall, and plugging the through-holes (3) with foam bodies (4) so as to form a combined foam pattern; bonding the combined foam pattern with a pouring system (5) for foam molding of an evaporative pattern and a vent hole (6) to form an overall pattern, and placing the overall pattern in a sand box to conduct sand filling and molding; burning off the foam pattern in the overall pattern, then putting the sand box on a vibration pouring jolting platform to perform vibration pouring, carrying out heat preservation for some time, and then opening the box to clear up the casting, thus finishing manufacturing the bi-metal bent pipe. The process provided in the invention adopts non-vacuum vibration casting. The lining of the manufactured bi-metal composite bent pipe has a more compact and wear resistant texture, and the mechanical and metallurgical bonding degree outside the composite bent pipe is high, so that the outside toughness and wear resistance of the bi-metal bent pipe are effectively improved, the service life is prolonged, and the production cost of the bi-metal bent pipe is effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of aluminum-magnesium carbon steel ladle refractory bricks

The invention discloses a preparation method of aluminum-magnesium carbon steel ladle refractory bricks. A refractory brick consists of the following components in parts by weight: 28-32 parts of alpha-corundum, 38-42 parts of fused magnesite, 6-8 parts of fused aluminum-magnesium spinel, 3-4 parts of aluminum oxide micro powder, 1-2 parts of silicon carbide powder, 1.5-2.5 parts of metal aluminum powder, 3-5 parts of phenolic resin and 3-5 parts of crystalline flake graphite. The preparation method comprises the following steps: 1) mixing: firstly mixing the alpha-corundum, fused magnesite and fused aluminum-magnesium spinel in a mixer for 4-6 minutes, adding the phenolic resin, and mixing for 5-8 minutes; adding the crystalline flake graphite and mixing for 12-16 minutes; adding the aluminum oxide micro powder, silicon carbide powder and metal aluminum powder, and mixing for 20-30 minutes; 2) moulding with a press; 3) baking in a drying kiln, wherein the hot air temperature in the kiln body is kept at 200-250 DEG C, and the baking time is not shorter than 12 hours; 4) picking and packaging.

Owner:WUXI CHENGBO SCI & TECH DEV

Method for casting hollow mould

InactiveCN1748901AReduce possessionLow gas productionFoundry mouldsFoundry coresCasting moldCarbon steel

The casting method with hollow mold is an improved solid mold casting method, which has reduced carbon generation, improved carbon exhaust and reduced recarburization of casting by means of one or several measures of improving casting mold, exhausting gas to reduce pressure and setting reasonable casting system.

Owner:蒋斌沅

Low-carbon magnesia carbon brick containing nanometer zinc oxide

A low-carbon magnesia carbon brick containing a nanometer zinc oxide is characterized in that the low-carbon magnesia carbon brick comprises the four following raw materials by weight percentage: 80-94wt% of electric melting magnesia particles, 1-5wt% of crystalline flake graphite, 1-3wt% of metal Al and 1-5wt% of nanometer zinc oxide, and 2-4wt% of a phenol formaldehyde resin with the quantity of the weight percentage sum of the four raw materials. The low-carbon magnesia carbon brick utilizes the characteristics of the nanometer zinc oxide powders such as fine granularity, high activity at high temperature, moderate price, and the like to improve the microstructure of the low-carbon magnesia carbon brick, prompts the used metal Al antioxidant to sufficiently play the role and prepares the low-carbon magnesia carbon brick with excellent comprehensive performance and moderate price. The prepared low-carbon magnesia carbon brick can be used for the steel-making furnace, the refining furnace and the lining of the steel ladle in the steel metallurgical industry, reduces the carbon added in the molten steel, reduces the temperature reduction of the molten steel and is beneficial for improving the quality of the steel and saving the energy resource.

Owner:ZHENGZHOU UNIV

Refractory brick of ladle slag line

The invention discloses a refractory brick of a ladle slag line. The refractory brick is prepared from the following raw materials in parts by weight: 24-26 parts of waste magnesia brick, 46-48 parts of fused magnesite, 1-2 parts of -20mesh graphite powder, 3-5 parts of -100mesh silicon carbide, 15-17 parts of -100mesh zirconium oxide, 6-8 parts of -150mesh fused millite, 8-10 parts of magnesite powder, 2-3 parts of asbestos fibers, 4-6 parts of Suzhou bentonite, 10-12 parts of zirconium boride, 1.5-2.5 parts of -200mesh boron nitride, 2.5-3.5 parts of -200mesh cerium oxide, 2-3 parts of asphalt powder, 1-2 parts of phenolic resin, 3-5 parts of sodium hexametaphosphate and 16-18 parts of water, wherein the waste magnesia brick of which the granularity is -20 mesh to +40 meshes accounts for 50%; the waste magnesia brick of which the granularity is -40 mesh to +100 meshes accounts for 25%; the waste magnesia brick of which the granularity is -100 mesh to +200 meshes accounts for 25%; the fused magnesite of which the granularity is -5 mesh to +18 meshes accounts for 35%; the fused magnesite of which the granularity is -18 mesh to +80 meshes accounts for 35%; and the fused magnesite of which the granularity is -80 mesh to +150 meshes accounts for 30%.

Owner:偃师市诚鼎耐火材料有限公司

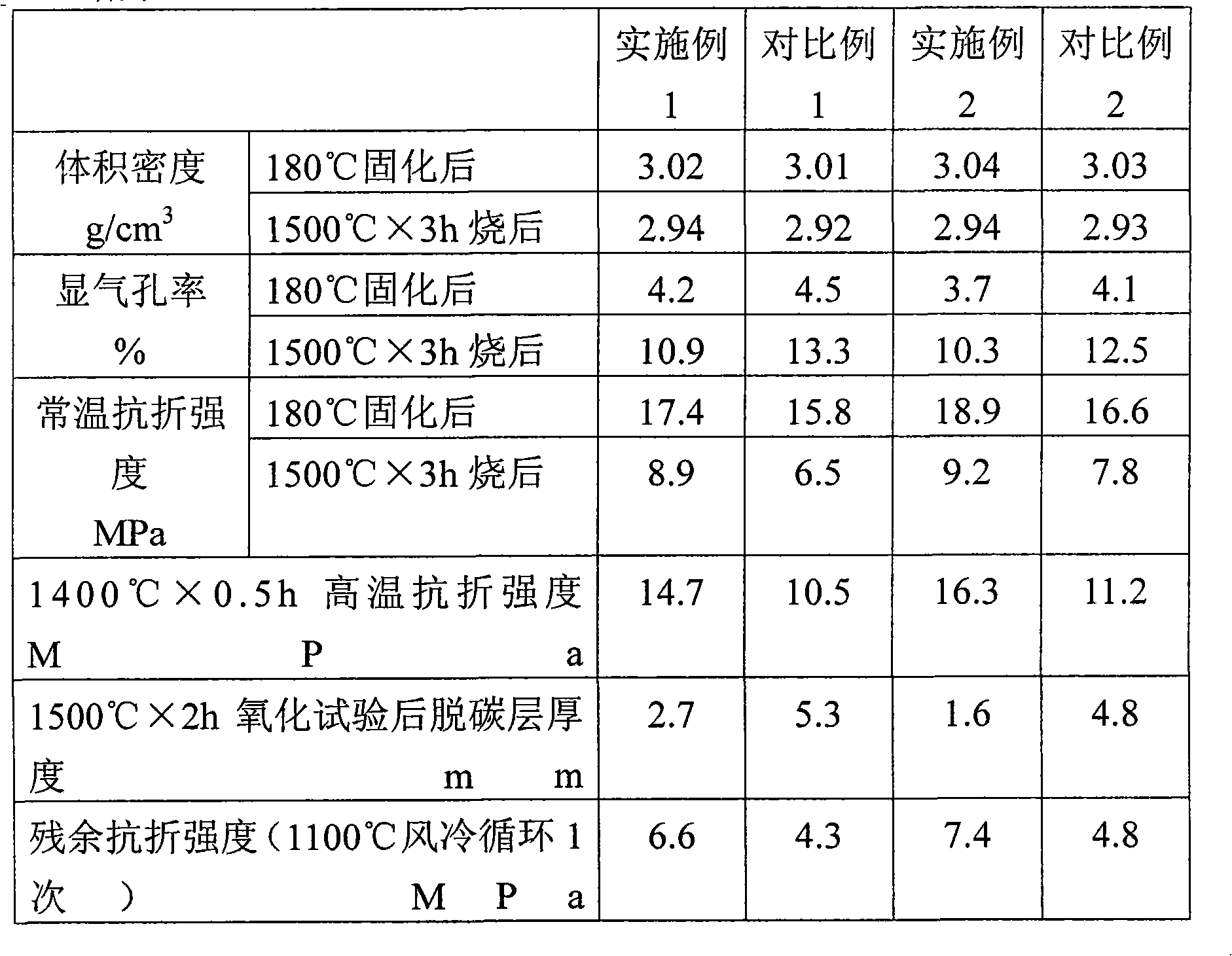

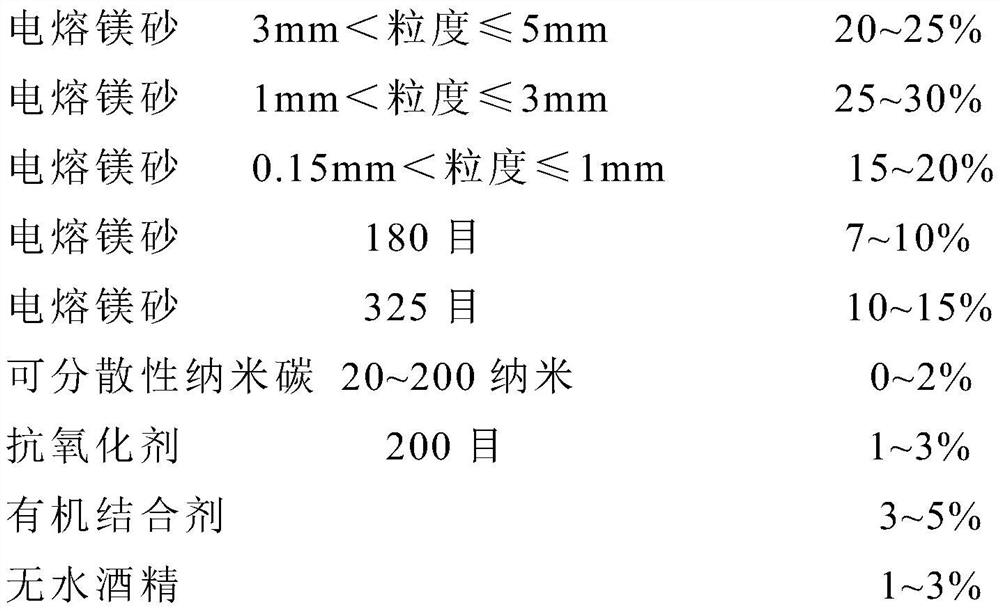

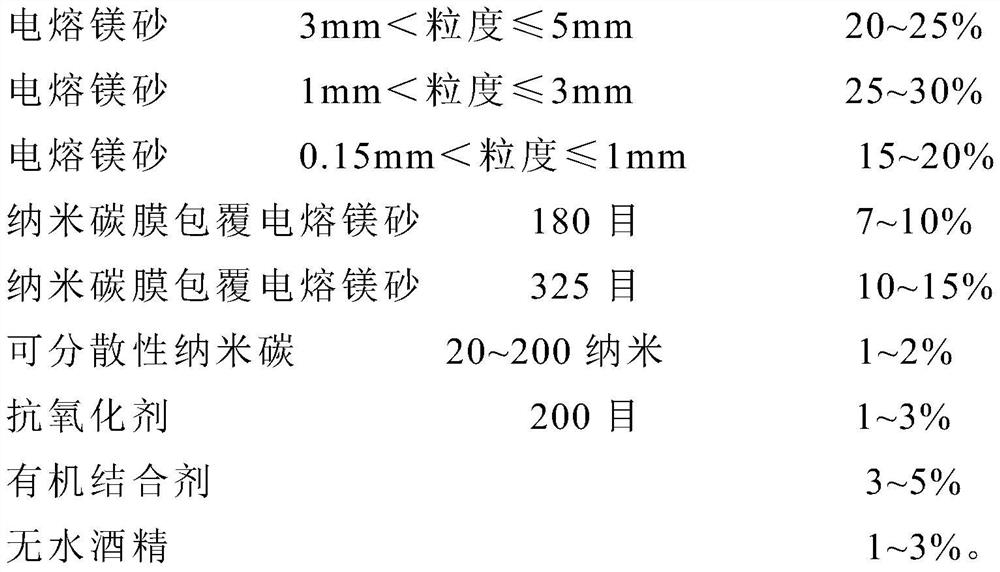

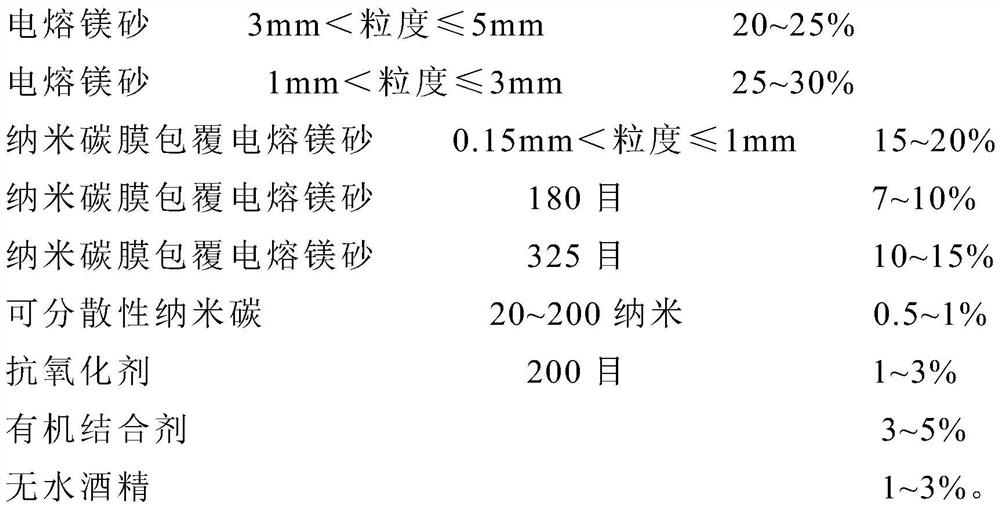

Nano-carbon low-carbon magnesia carbon brick for ladle slag line and preparation method

The invention discloses a nano-carbon low-carbon magnesia-carbon brick for ladle slag lines and a preparation method, wherein the magnesia-carbon brick comprises fused magnesia with five particle sizes, dispersible nano-carbon and an antioxidant, and through coating of nano-carbon films on the surfaces of fused magnesia particles with different particle sizes and application of the dispersible nano-carbon, the nano-carbon low-carbon magnesia-carbon brick can be used for ladle slag lines. By utilizing the characteristics that the nano carbon film and the dispersible nano carbon are mainly amorphous carbon, contain a small amount of graphite young crystals, can be infiltrated by a solvent and the like, infiltration and adsorption of the nano carbon film and the dispersible nano carbon to anorganic binding agent are improved, and uniform dispersion of the nano carbon in the magnesia carbon brick is realized; in addition, the size of carbon particles in the magnesia carbon brick is greatly reduced by controlling the sizes of the nanocarbon film and the dispersible nanocarbon with the thickness of 20-200 nanometers, the contact frequency of a refractory raw material of the magnesia carbon brick and the carbon particles is remarkably improved, the performance of the carbon particles is exerted under the condition of low carbon content, and the anti-erosion permeability of the magnesia carbon brick is improved.

Owner:武汉钢铁有限公司

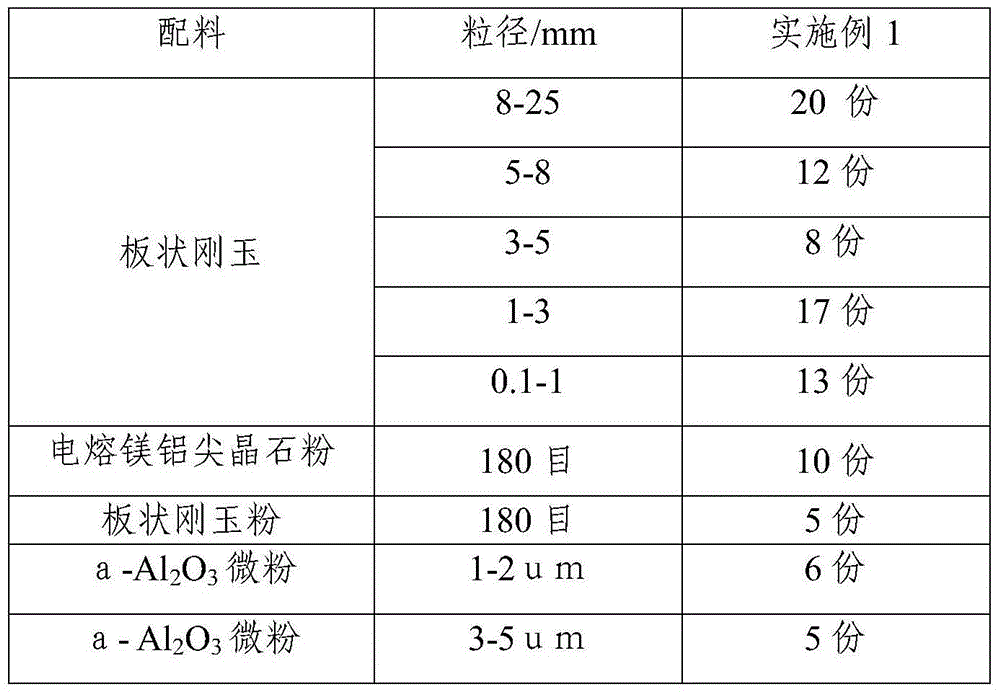

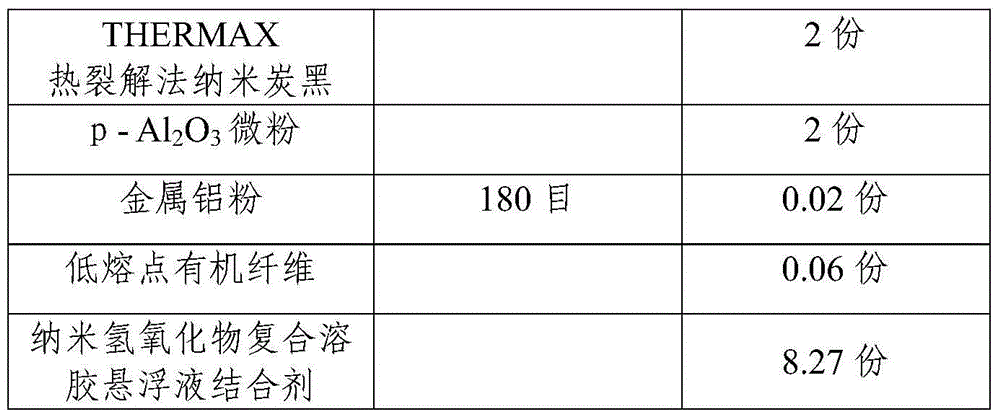

Castable for working layer of refining ladle slag line as well as preparation method and application of castable

The invention relates to the field of refractory materials and particularly relates to castable for a working layer of a refining ladle slag line as well as a preparation method and an application of the castable. The castable for the working layer of the refining ladle slag line comprises the following components in parts by mass: aggregates, matrix powder as well as a nano hydroxide composite sol suspension liquid. The refractory castable disclosed by the invention has slag penetration resistance and corrosion resistance which are equivalent to those of a magnesia carbon brick, but has relatively high bonding strength between the matrix and the aggregates, relatively strong integrity and relatively excellent impact resistance and thermal rock resistance, is suitable for integrally casting a slag line part to realize all casting of the ladle bottom, the ladle wall and the slag line part of the refining ladle, so that the construction time is greatly shortened, the labor power is saved, integral reinforcing is realized after one-time use, and the consumption of a great deal of refractory materials can be reduced.

Owner:北京利尔高温材料股份有限公司

Novel refractory material for low-carbon tundish working lining and building method

The invention provides a novel refractory material for a low-carbon tundish working lining and a building method. The refractory material comprises the following components in percentage by mass: 65-75% of magnesia particles or / and olivine particles, 20-25% of magnesia fine powder, 2-5% of silica powder, 0.5-1.5% of sodium tripolyphosphate, 0-0.5% of paper fibers, 0.3-0.7% of rice hull fragments,0.5-2.5% of a plasticizer, 0-0.3% of organic fibers and 0-1% of an additive. The carbon residue rate of the refractory material is 0.2%-0.7%. The water adding amount is effectively reduced, and moltensteel recarburization is reduced; workers do not need to enter the tundish, construction is convenient, and labor intensity and harm of high-temperature environment construction are avoided; and layered smearing or spraying is avoided, and layered stripping of the working lining in the using process is prevented.

Owner:SHANGHAI LIER REFRACTORY MATERIAL

Preparation process for refractory brick on ladle slag line

The invention discloses a preparation process for a refractory brick on a ladle slag line. The preparation process comprises the following steps of (1) placing waste magnesia bricks, fused magnesia, silicon carbide, zirconia, fused millite and magnesite powder into a mixer to be mixed for about 45-60 minutes; (2) adding graphite powder, asbestos fibers, Suzhou bentonite, zirconium boride, boron nitride and cerium oxide, and mixing for about 120-135 minutes; (3) adding asphalt powder, phenol formaldehyde resin, sodium hexametaphosphate and water, and further mixing for about 150-180 minutes; (4) molding by using a press machine, and drying a green brick at the temperature of 200 DEG C for 24 hours; and (5) calcining at the temperature of about 1800-1840 DEG C, and preserving the heat for about 16-18 hours. The refractory brick prepared by using the preparation method has the following excellent performances: molten steel is recarburized by at most 2.3ppm, the volume density is 3.05-3.15g / cm<3>, the apparent porosity is 1.5-2.5%, the normal-temperature compressive strength is larger than or equal to 45MPa, the 1400-DEG C high-temperature bending strength of buried carbon is larger than or equal to 33Mpa, and the 1400-DEG C linear expansion coefficient is 1.35-1.45%. Through measuring the thermal shock resistance of the refractory brick prepared by using the preparation process disclosed by the invention by using an air quenching method comprising the step of carrying out air cooling once at the temperature 1100 DEG C, the residual strength retention rate is measured to be 74-76%.

Owner:徐州鑫汇耐火材料有限公司

Non-oxide enhanced material for slag line of submersed nozzle

The invention relates to a submersed nozzle for steel making and continuous casting tundish, in particular to a non-oxide enhanced material for a slag line of a submersed nozzle. The material comprises the components in percentage by mass as follows: 5.5%-8% of ZrB2, 75%-78% of m-ZrO2, 6%-8% of graphite, 2%-3% of Al, 5%-6.5% of O'-Sialon, 1.0%-2.0% of Y2O3-PSZ and the balance of impurities; and 8-10% of a modified resin binding agent is additionally added. The non-oxide enhanced material for the slag line of the submersed nozzle has excellent corrosion resistance and plugging resistance, can effectively reduce carbureting of molten steel, and is more suitable for producing low -carbon steel and ultra-low carbon steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Refining method for preventing carbureting of molten steel in LF (ladle furnace) through utilizing argon plasmas

The invention relates to a refining method for preventing carbureting of molten steel in an LF through utilizing argon plasmas, and belongs to the field of refining technologies in steelmaking in the metallurgical industry. A technical scheme is characterized in that a solid graphite electrode of the LF is replaced by a hollow graphite electrode, the center hole of the hollow graphite electrode is used to access argon to form an argon plasma arc, so direct contact of the electrode with air and the molten steel is avoided; and the generated plasma arc is used to heat, so the heating time is shortened, the hollow graphite electrode consumption is reduced, the carbureting of the molten steel in the refining process is mitigated, and the carbureting amount of the molten steel is controlled at below 0.005%. The method has the following positive effects: the argon plasma LF can combine all refining functions of present LF technologies, so it is easy to realize an argon plasma furnace from the LF; the generated argon plasmas have the advantages of high heating efficiency, slugging benefiting and the like; the heating period and the smelting period can be shortened; and electric energy is saved. By controlling the carbureting amount in the LF refining process, a decarburization function of RH or VD can be partially replaced, so the steelmaking operation is reduced, and the production cost is saved.

Owner:HEBEI IRON AND STEEL

Smelting process of ultra-low carbon stainless steel material

InactiveCN107779555AIncrease temperatureShorten cooling timeProcess efficiency improvementGraphite electrodeHigh carbon

The invention discloses a smelting process of an ultra-low carbon stainless steel material, which includes EAF furnace smelting, LF furnace smelting, VOD furnace smelting, LF furnace final component adjustment; LF furnace smelting step includes steps of adding high carbon ferro-chrome, low-carbon ferrochromium, a nickel plate, and ferro-molybdenum in steel fluid, introducing an alloy elements andincreasing the carbon content; the VOD furnace smelting adopts the vacuum oxygen blasting and decarbonizing; the LF furnace final component adjustment includes the step of adjusting the final component of the steel fluid. Through introducing the high carbon alloy to increase the carbon content, the oxygen blowing and decarbonizing in the VOD furnace can fully release, the steel fluid temperature is improved, the Cr oxidization is reduced; the reduction time is shortened, the steel fluid cooling time is shortened, the time and opportunity of the electricity delivery and temperature rise are reduced; thus the steel fluid carbon increasing caused by the graphite electrode electricity delivery and temperature rise is reduced, and the carbon content is reduced.

Owner:KOCEL STEEL

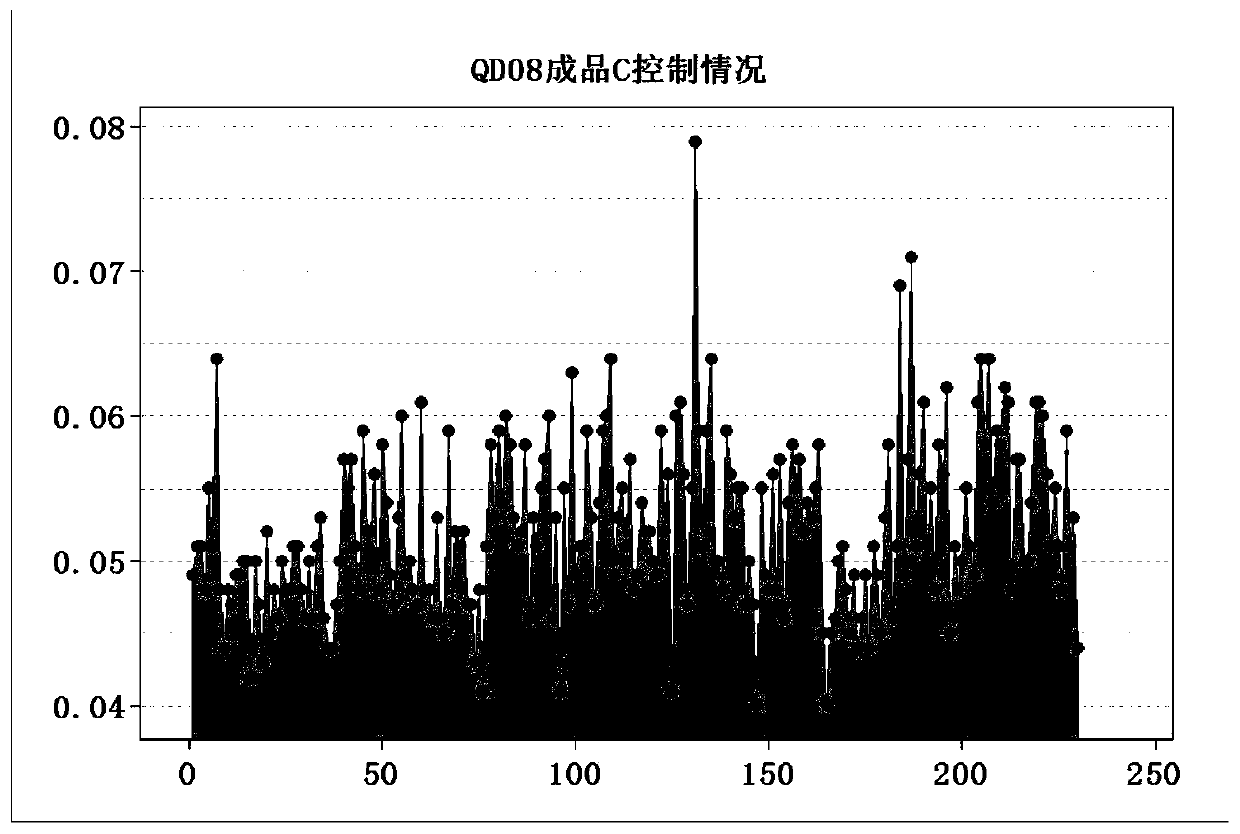

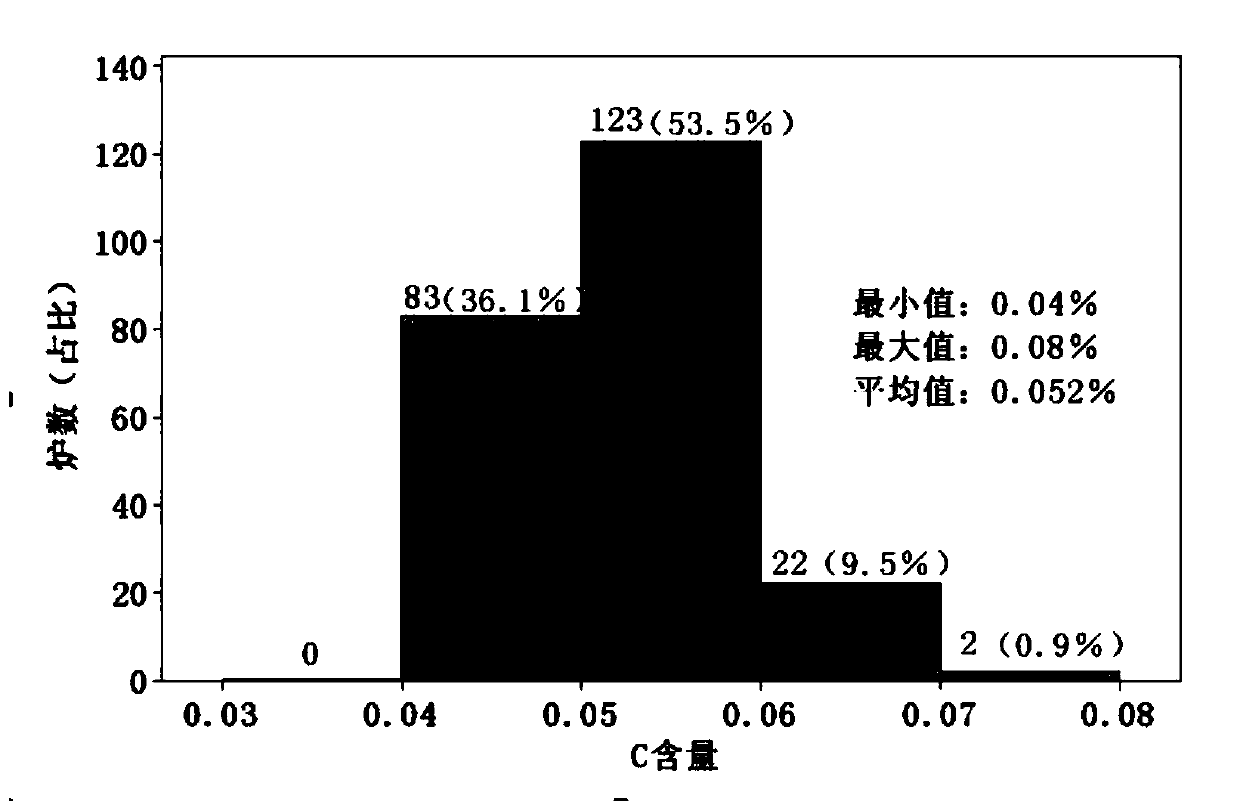

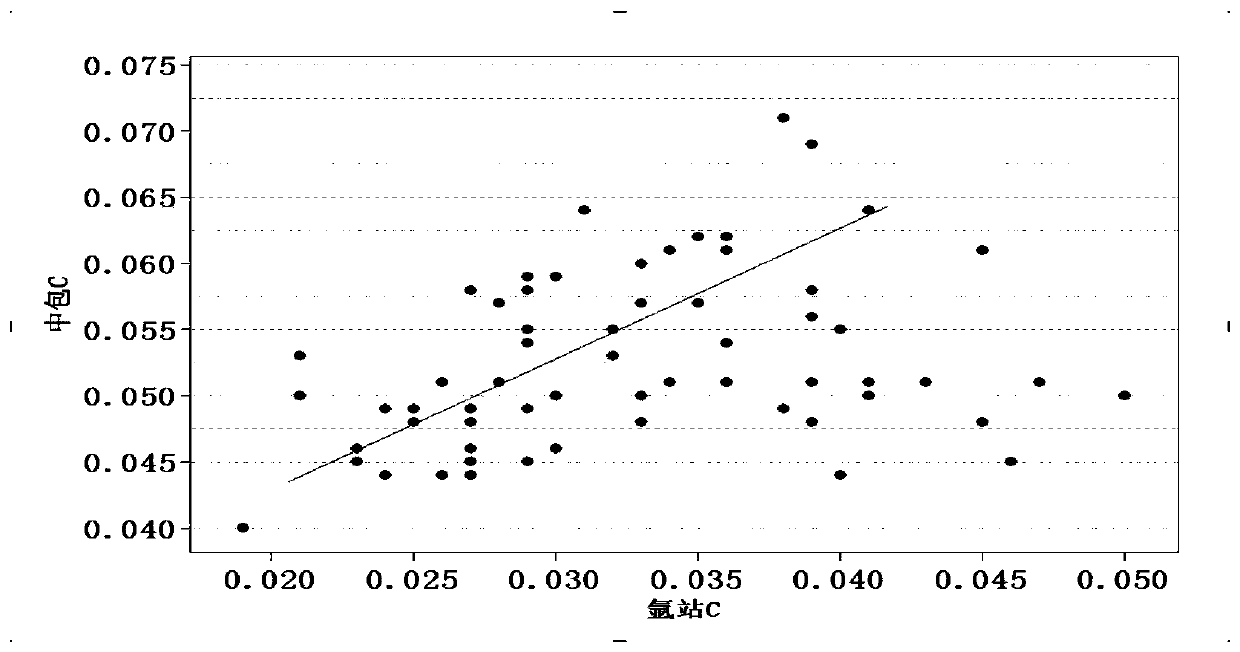

Low-carbon steel carbon content stably-controlled smelting method

ActiveCN110468335AReduce tap carbon contentIncrease tapping temperatureManufacturing convertersSmelting processProcess capability

The invention discloses a low-carbon steel carbon content stably-controlled smelting method. The smelting method includes converter smelting, LF refining and continuous casting. According to the method, by reasonably optimizing process parameters and enhancing process capability control, the carbon content can also be stably controlled within 0.05% without RH vacuum processing, the finished product carbon fluctuation range is small and is controlled at 0.03%-0.05%, the target value hit rate is high, product quality stability is facilitated, and judgement amending or scrapping caused by errantcomponents is reduced. The RH decarburization working procedure is not needed; by means of regulation and cooperation of all step conditions, the carbon steel carbon content is stably controlled at 0.03%-0.05%, and the inclusion content is low; and compared with frequently-used smelting process converter-RH decarburization-LF treatment-continuous casting, operation is easy, the production efficiency is high, and the cost of each ton of steel is effectively reduced.

Owner:ZENITH STEEL GROUP CORP

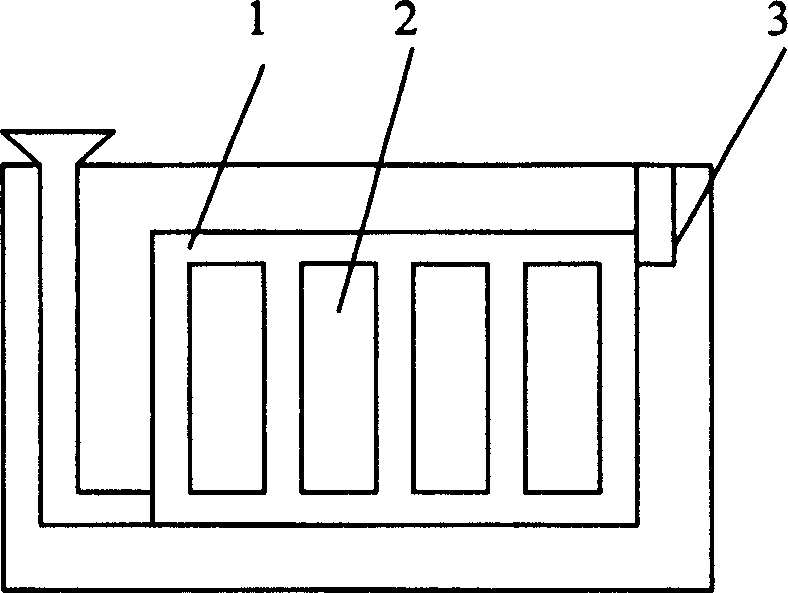

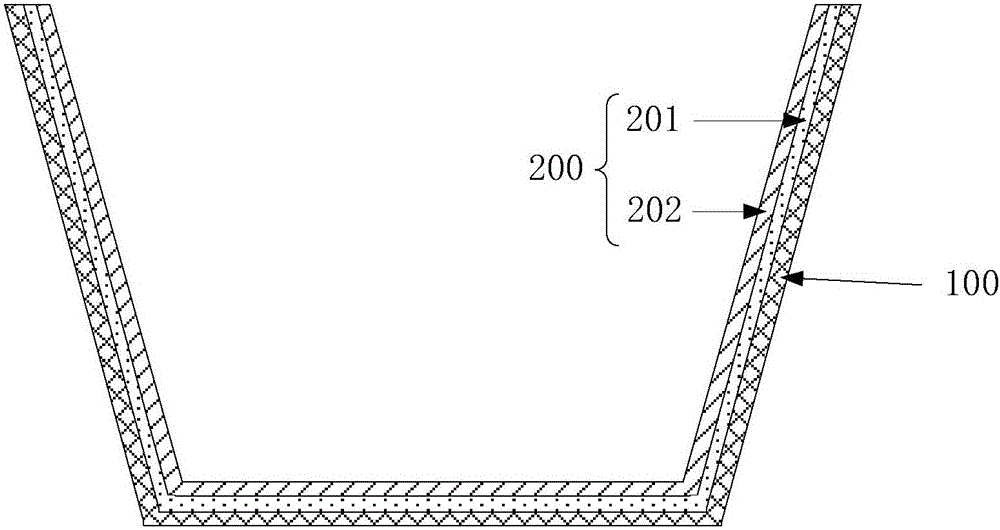

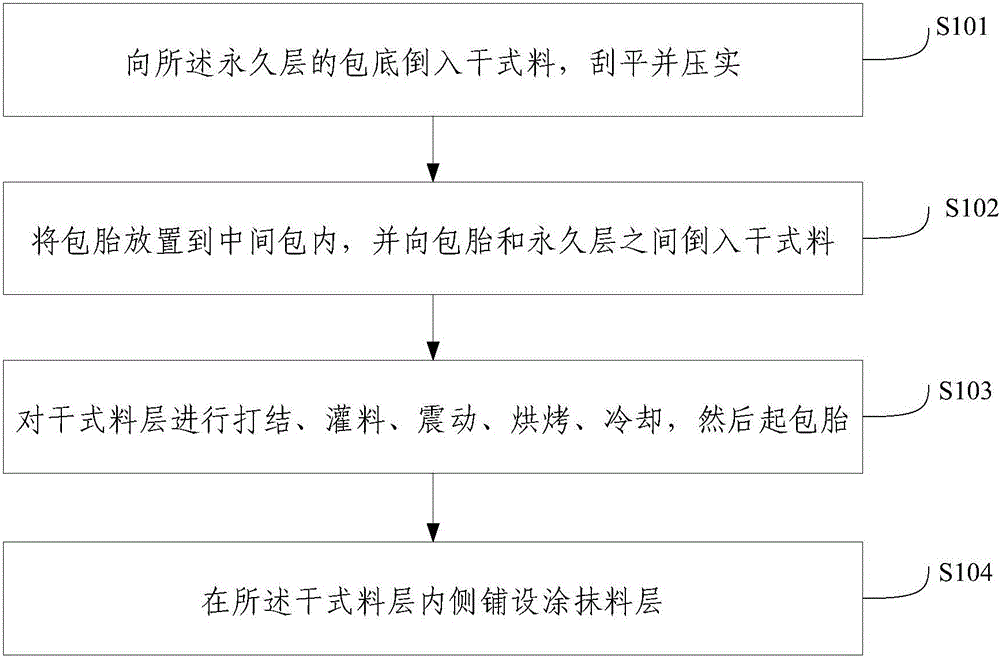

Tundish composite working lining, making method thereof and tundish

The invention provides a tundish composite working lining. The inner layer of the tundish composite working lining is a dry material layer, the outer layer of the composite working lining is a coated layer, and the dry material layer and the coated layer are closely connected and compounded into an integrated structure. The dry material layer and the coated layer are combined into the composite working lining, the advantages of the dry material layer and the coated layer are combined, and the composite working lining has the advantages of convenient construction, difficult sintering, easy tundish tilting and recarburization reduction, etc.

Owner:北京利尔高温材料股份有限公司

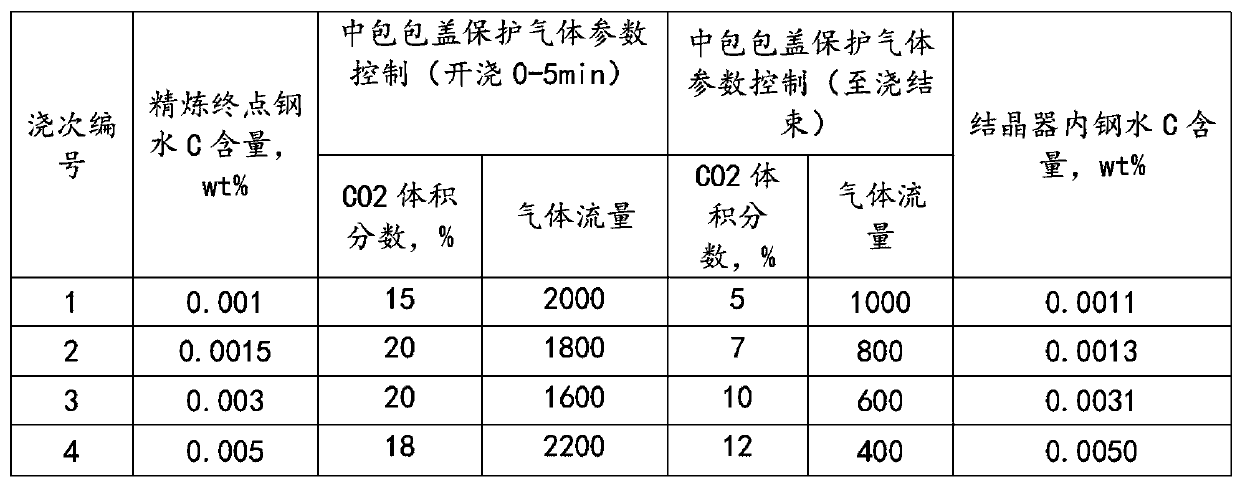

Tundish protection casting method for ultra-low carbon steel

ActiveCN110976787AReduce the difficulty of smeltingReduce carbon removal pressureCarbon steelTundish

The invention discloses a tundish protection casting method for ultra-low carbon steel. The tundish protection casting method comprises the following steps that S1, ultra-low carbon steel is cast, andduring casting, a tundish cover blowing device blows out mixed gas of carbon dioxide and argon; S2, when casting is started for 0-5min, the flow of the carbon dioxide gas in the mixed gas of the carbon dioxide and the argon blown out by the tundish cover blowing device is 1500-2500Nl / min; and S3, after the casting time is 5min, casting is finished, the volume fraction of the carbon dioxide gas is5%-15%, and the gas flow is 200-1500Nl / min. According to the method, the 5%-30% carbon dioxide gas is mixed in the tundish cover protection gas argon, the carbon dioxide gas enters molten steel to react, and carbon monoxide bubbles float up in the molten steel to be discharged. The carbon dioxide gas can consume carbon in the steel under the casting temperature condition, the concentration of thegenerated carbon monoxide gas is extremely low, and the carbon monoxide gas is fully burnt out when escaping out of a tundish, and the safety problem cannot be caused.

Owner:SHOUGANG CORPORATION

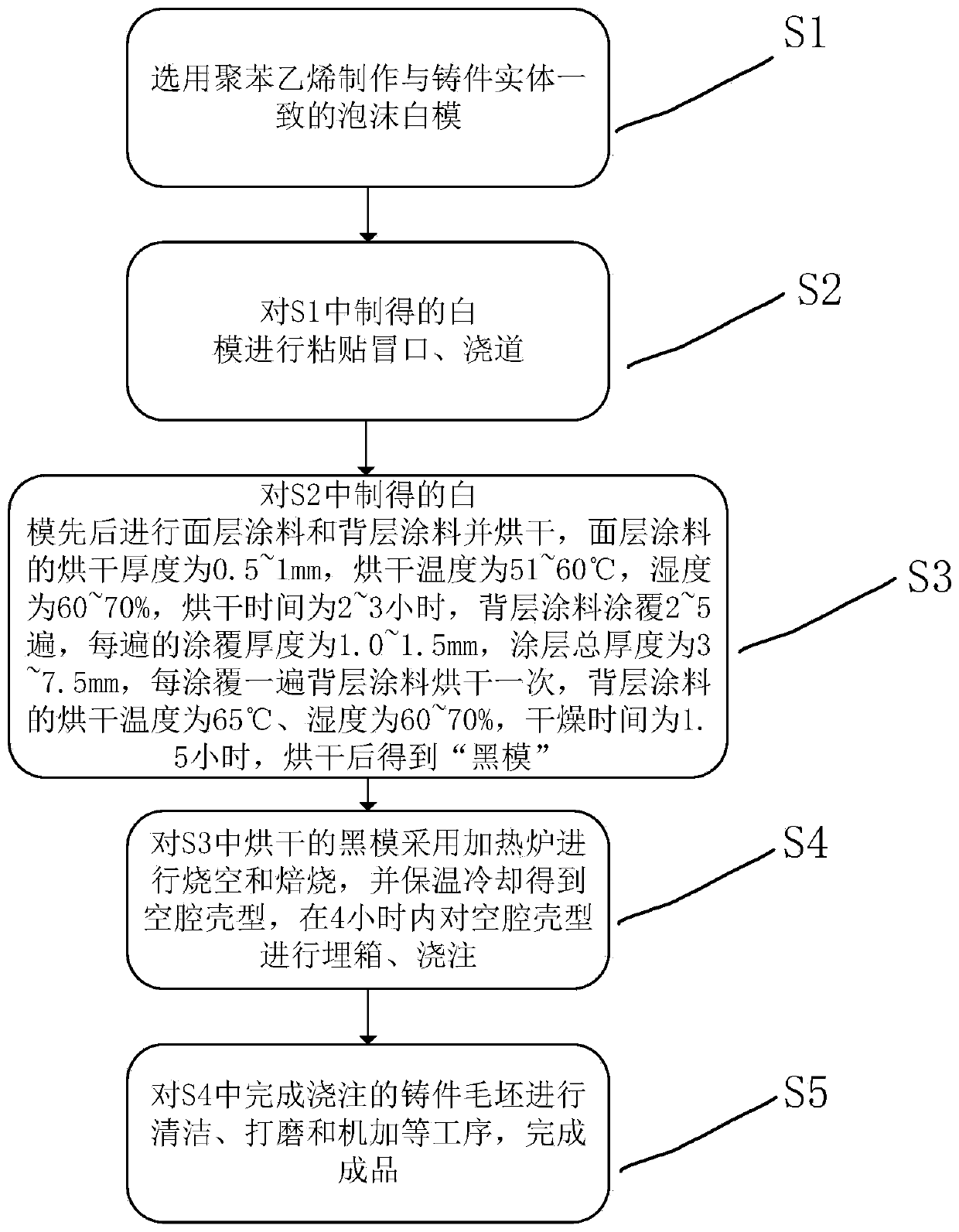

Evaporative pattern casting burned shell type casting process

InactiveCN111421112AReduce subsequent welding repairsReduce grinding workloadFoundry mouldsFoundry coresSurface finishPolishing

The invention relates to the technical field of casting forming and casting, in particular to an evaporative pattern casting burned shell type casting process. The process comprises the primary process flows of molding, riser and pouring gate adhering, coating, drying, burning, box burying, pouring, cleaning, polishing and machining. A casting produced by the casting process has the advantages ofbeing high in surface smoothness, high dimensional precision and the like, and the evaporative pattern casting burned shell type casting process not only can meet the demand on precision of the casting, but also can lower the production cost and reduce the production pollution greatly, can meet the demand on top-grade precise casting of complex structure, and is green and environment-friendly in shell manufacturing process.

Owner:JIANGSU JINGCHENG MASCH MFG CO LTD

A kind of smelting method of low carbon high manganese steel

The invention discloses a smelting method of low-carbon and high-manganese steel. Desulfurated molten iron is added into a converter, the end point carbon content is controlled to be 0.03-0.05%, the oxygen value of tapped steel is 400-500 ppm, and the temperature is controlled to be 1660-1680 DEG C; the temperature when molten steel enters an RH furnace is larger than 1610 DEG C, and decarburization is carried out till the carbon content is below 0.01%; the molten steel processed by the RH furnace is added into the converter, and before the molten steel is added, a mixture of manganese metal and aluminum metal is added into the converter so that alloying of manganese can be conducted; after the molten steel is added, the converter is rocked, a burning torch is put and ignited, steel is discharged after alloy in the converter is wholly molten, and the temperature is controlled to be 1600 DEG C or over; and after the steel enters an LF, if the temperature is lower than 1530 DEG C, the temperature is increased to be over 1530 DEG C firstly, and then alloying of manganese can be carried out, and the temperature when the steel is carried out of the LF is larger than 1500 DEG C. By means of the smelting method, the final manganese content in steel can be controlled to be 15-20% stably, the carbon content is controlled to be below 0.05%, and the problem that the low-carbon and high-manganese steel cannot be produced through conventional converters or refining is solved.

Owner:ANGANG STEEL CO LTD

Low-carbon magnesia carbon brick containing nanometer zinc oxide

A low-carbon magnesia carbon brick containing a nanometer zinc oxide is characterized in that the low-carbon magnesia carbon brick comprises the four following raw materials by weight percentage: 80-94wt% of electric melting magnesia particles, 1-5wt% of crystalline flake graphite, 1-3wt% of metal Al and 1-5wt% of nanometer zinc oxide, and 2-4wt% of a phenol formaldehyde resin with the quantity ofthe weight percentage sum of the four raw materials. The low-carbon magnesia carbon brick utilizes the characteristics of the nanometer zinc oxide powders such as fine granularity, high activity at high temperature, moderate price, and the like to improve the microstructure of the low-carbon magnesia carbon brick, prompts the used metal Al antioxidant to sufficiently play the role and prepares the low-carbon magnesia carbon brick with excellent comprehensive performance and moderate price. The prepared low-carbon magnesia carbon brick can be used for the steel-making furnace, the refining furnace and the lining of the steel ladle in the steel metallurgical industry, reduces the carbon added in the molten steel, reduces the temperature reduction of the molten steel and is beneficial for improving the quality of the steel and saving the energy resource.

Owner:ZHENGZHOU UNIV

Method for preparing low-carbon refractory brick from needle coke

The invention relates to a method for preparing a low-carbon refractory brick from needle coke. The method sequentially comprises the following steps: preparing aggregates; preparing premixed powder; and mixing, molding and drying, so as to produce the low-carbon refractory brick, wherein a material composition of a product is optimized by adding the needle coke in the mixing process; a mesh structure of carbon fibers can be formed in situ in a service environment; and the needle coke has the advantages of high mechanical strength, good oxidation resistance, low energy consumption and the like, and also has the characteristics of high purity, low electrical resistivity, low coefficient of thermal expansion, and high impact resistance of graphite. Due to these unique properties, the mean pore diameter is reduced, and the high-temperature strength is increased even if the amount of the graphite is greatly reduced, or even the graphite is not used; the heat conductivity is reduced; and meanwhile, the product is capable of achieving the same thermal shock resistance, slag resistance and penetration resistance as the traditional high-carbon magnesia carbon brick.

Owner:LIAONING ZHONGMEI HLDG

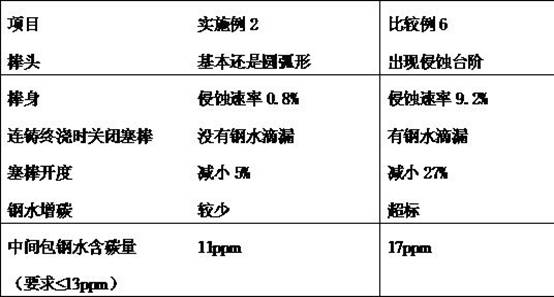

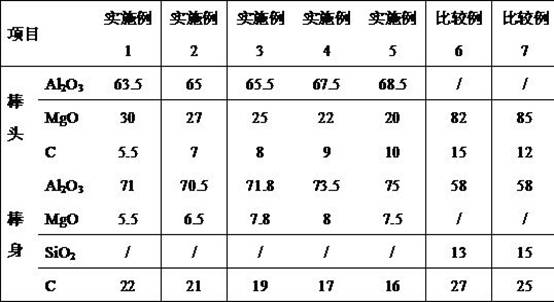

Stopper rod for continuous casting of high-oxygen steel

ActiveCN113526965AGood resistance to molten steel erosionReduce carbon increaseProcess efficiency improvementSlagMolten steel

The invention relates to a stopper rod for continuous casting of high-oxygen steel. The stopper rod comprises a rod head, a rod body and a slag line section, wherein the rod head is made of Spinel-C and comprises the following chemical components in percentage by weight: 60 to 72 percent of Al2O3, 20 to 30 percent of MgO, 5 to 10 percent of C and the balance of trace impurities, and an antioxidant and a phenolic resin binding agent are additionally added; the rod body is made of Al2O3-Spinel-C and comprises the following chemical components in percentage by weight: 70 to 80 percent of Al2O3, 5 to 10 percent of MgO, 15 to 23 percent of C and the balance of trace impurities, and an antioxidant and a phenolic resin binding agent are additionally added; and the slag line segment is made of a MgO-Spinel-C material. According to the invention, when being applied to high-oxygen steel casting, the low-melting-point phase cannot be formed, good corrosion resistance is achieved, recarburization of molten steel is reduced, and the number of continuous casting furnaces is increased.

Owner:BAOSHAN IRON & STEEL CO LTD

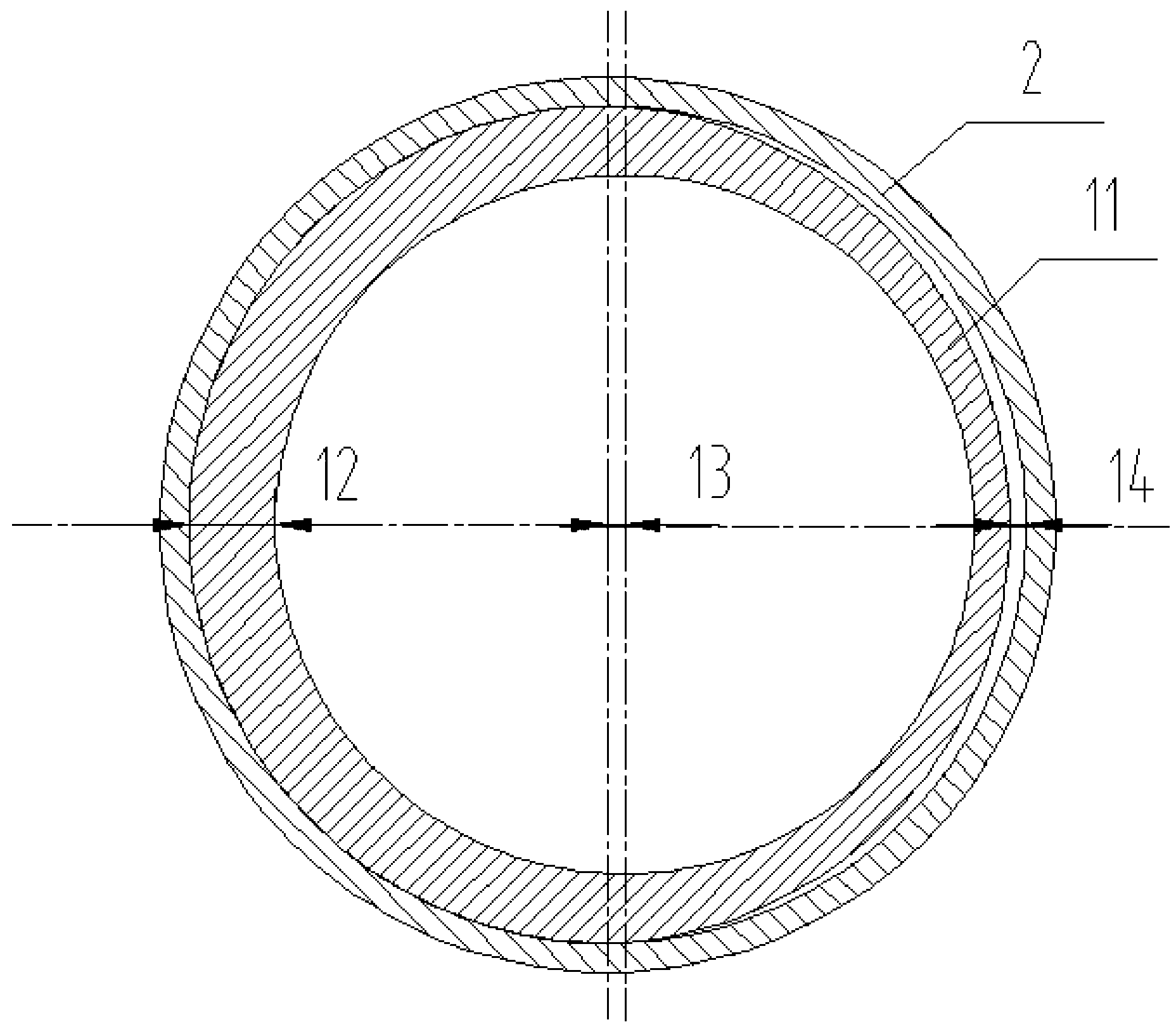

Low carbon magnesia carbon brick and preparation method thereof

The invention relates to the technical field of magnesia carbon brick refractory materials, in particular to a low carbon magnesia carbon brick and a preparation method thereof. The technical proposal comprises the following steps: mixing 58 to 70 weight percent of magnesite grains, 20 to 28 weight percent of magnesite fine powder, 0.5 to 5 weight percent of expansion graphite, 0 to 6 weight percent of crystalline flake graphite, 1 to 5 weight percent of antioxidant, 0.1 to 5 weight percent of metal fibre and 1.5 to 4.5 weight percent of phenolic resin; and molding and drying the mixture to prepare a low carbon magnesia carbon brick of which carbon content is between 2 and 7 percent. The low carbon magnesia carbon brick prepared by the invention has the advantages of low heat expansion rate, good scale resistant performance, good high temperature strengthen, good thermal shock resistant performance, good toughness and corrosion resistance, and the brick is not easy to fracture when using.

Owner:JINAN LUDONG REFRACTORY CO LTD

Phenolic resin containing nano-carbon powder, nano-carbon modified low carbon magnesium carbon brick and production method thereof

The invention relates to a low-carbon MgO-C brick containing modified phenolic resin and nanocarbon which are produced by nano carbon powder and a preparation method thereof. Phenolic resin bonding agent containing nano carbon powder is produced by ohenol, formaldehyde, a dispersant and nano carbon powder; the low-carbon MgO-C brick is produced by adopting fused magnesite, graphite, phenolic resin and an antioxidant as raw materials. The ultrasonic dispersion method adopted by the invention replaces partial graphite with the nano carbon powder and leads the nano carbon powder into the low-carbon MgO-C brick, thus obviously improving the anti-erosion ability and the oxidation resistance of the MgO-C brick. The brick has comparatively low thermal expansion coefficient, low thermal conductivity, low oxidative mass loss and thinner decarburized layer; a slag resistance experiment under conditions of 1600 DEG C, 3h heat preservation and carbon sequestration shows that erosion and osmosis phenomenon of the brick are not obvious, thereby being applicable to sites of converters, electric furnaces and ladle working linings, external scouring of furnaces, key components for continuous castings and refractories for blast furnace ironmaking etc., thus having comparatively large application range.

Owner:ZHENGZHOU UNIV +1

Smelting method for copper-clad steel

ActiveCN106834591ASimplify the smelting processRapid responseManufacturing convertersProcess efficiency improvementSmelting processOxygen

The invention discloses a smelting method for copper-clad steel. A smelting process comprises BOF (Basic Oxygen Furnace) smelting-LF (Ladle Furnace) refining-small square billet continuous casting working procedures in sequence, wherein the BOF smelting controls decarburization strength and tapping temperature, an end point [C] is less than or equal to 0.040%, T is equal to 1620-1680DEG C, and slags are pushed off for tapping; the LF refining controls slag ingredients and static mixing time, (FeO+MnO) is less than or equal to 1.0%, the static mixing time is longer than or equal to 10min, and slag surface deoxidization and calcium feeding processing are carried out; the square billet continuous casting controls pouring temperatures and electromagnetic stirring technologies, T is equal to 1560-1620DEG C, and liquid surface fluctuation and casting speed can be stabilized. Through the smelting method for the copper-clad steel, on the basis of the accurate control on each smelting link, a smelting working procedure of the copper-clad steel is simplified, pre-desulfurization and vacuum processing are omitted, while product quality is kept, production efficiency is improved, cost is lowered, and competitive power is improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

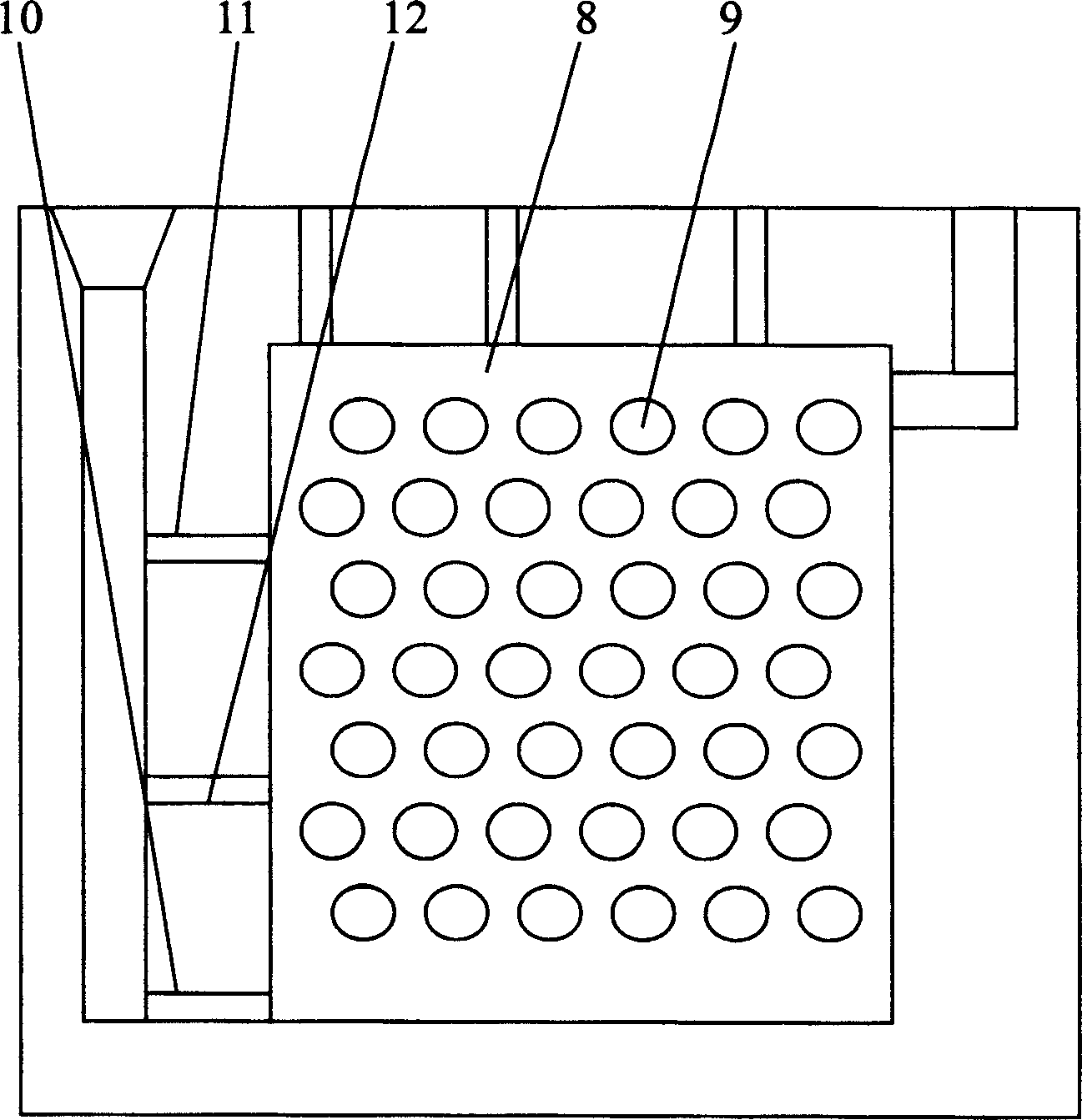

Production process for evaporative pattern centrifugal casting

The invention discloses a production process for evaporative pattern centrifugal casting. The production process comprises the following steps of S1, designing of a pouring gate; S2, designing of a riser; S3, a box loading (manufacturing) process; and S4, a pouring process. Meanwhile, a space with the size reduced due to solidification is filled with molten metal under the action of centrifugal force, and the feeding effect is good; meanwhile, a large number of crystal nuclei are generated through fracture of regrowth dendritic crystals under the action of the centrifugal force and exciting force, crystal grains are refined, and the density of a product is further improved; and the molten metal in the pouring gate and the riser (a slag collecting riser or a feeding riser) moves towards theinterior of a casting model under the action of the centrifugal force, the utilization rate of the molten metal is increased, the yield of centrifugal casting is also increased, and the machining amount of a centrifugal casting machine is reduced.

Owner:洛阳佳会机械科技有限公司

Cast steel coating for vacuum lost foam casting

InactiveCN104550682AReduce carbon increaseReduce defects such as poresFoundry mouldsFoundry coresLost-foam castingMetallurgy

A cast steel coating for vacuum lost foam casting comprises components in percentage by weight as follows: 30-45% of water, 2-5% of sodium bentonite, 1-4% of a suspending agent, 2-4% of an organic binding agent, 50% of emery powder and 0.2-1% of an aid; the performance of the cast steel coating for vacuum lost foam casting depends on composition, a preparation technology, an application technology and a drying technology of the coating. With the adoption of the coating, defects such as recarburization, air holes and the like of cast steel pieces are overcome, the coating is stable in comprehensive coating performance, low in coat and ideal in effect, and the comprehensive product percent of pass of the vacuum lost foam cast steel pieces can be ensured to be higher than 97%.

Owner:ANHUI YONGCHANG CASTING

Metallic composite low carbon magnesium carbon brick for ladle slag wire and manufacture method thereof

The invention discloses a metal complex low-carbon magnesia carbon brick used for ladle slag lines, the weight percentage of the added materials is as following, 50 to 70 percent of magnesia particles, 25 to 35 percent of magnesia powder, and 3 to 6 percent of organic binder, furthermore, the following components are added which are produced by mixing, striating materials, forming and heat-treatment, 0 to 4 percent of flake graphite, 3 to 15 percent of metal powder, and 0.5 to 3 percent of antioxidant containing boron. The antioxidant properties, slag-resistance performance, high temperature strength and the thermal shock resistance of the ladle slag line used metal complex low-carbon magnesia carbon brick are greatly improved, the service life is prolonged, the consumption cost of each ton of refractories is lowered. The preparation method of ladle slag line used metal complex low-carbon magnesia carbon bricks is also disclosed, and the carbon content in the ladle slag line used metal complex low-carbon magnesia carbon bricks produced by the method is less than or equal to 6 percent, little carbon is added so as to reduce the pollution towards liquid steel, and residual strength ratio of the thermal shock resistance is kept at 70 to 80 percent.

Owner:ZHENGZHOU UNIV +1

Refining method for preventing carbureting of molten steel in LF (ladle furnace) through utilizing argon plasmas

The invention relates to a refining method for preventing carbureting of molten steel in an LF through utilizing argon plasmas, and belongs to the field of refining technologies in steelmaking in the metallurgical industry. A technical scheme is characterized in that a solid graphite electrode of the LF is replaced by a hollow graphite electrode, the center hole of the hollow graphite electrode is used to access argon to form an argon plasma arc, so direct contact of the electrode with air and the molten steel is avoided; and the generated plasma arc is used to heat, so the heating time is shortened, the hollow graphite electrode consumption is reduced, the carbureting of the molten steel in the refining process is mitigated, and the carbureting amount of the molten steel is controlled at below 0.005%. The method has the following positive effects: the argon plasma LF can combine all refining functions of present LF technologies, so it is easy to realize an argon plasma furnace from the LF; the generated argon plasmas have the advantages of high heating efficiency, slugging benefiting and the like; the heating period and the smelting period can be shortened; and electric energy is saved. By controlling the carbureting amount in the LF refining process, a decarburization function of RH or VD can be partially replaced, so the steelmaking operation is reduced, and the production cost is saved.

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com