Method for casting hollow mould

A hollow and solid casting technology, used in casting molding equipment, molds, cores, etc., can solve the problems of carbonization of low-carbon steel castings, carbon defects of iron castings, etc., to reduce the high temperature area of liquid, reduce contact, The effect of reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

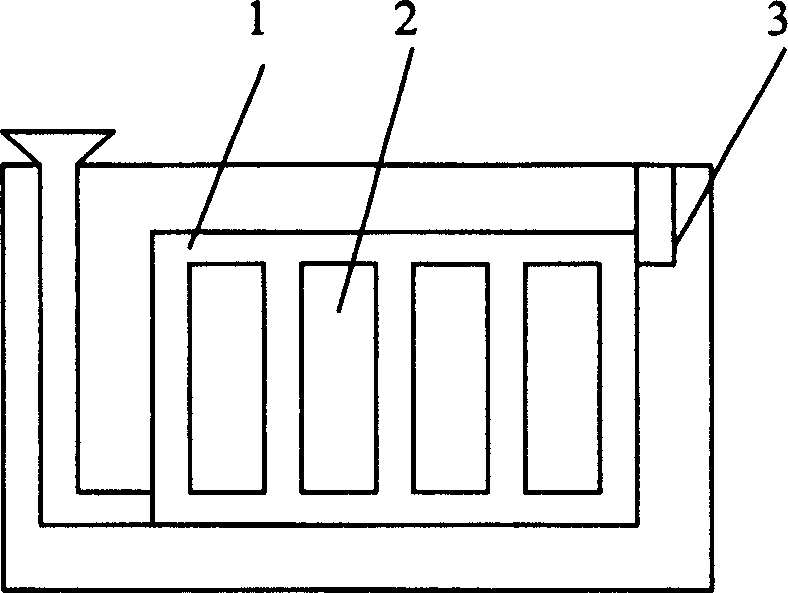

[0027]A full mold casting method, the casting mold 1 is made of polystyrene foam, characterized in that: the casting mold 1 of the full mold casting is hollow, and some holes 2 are added in the body of the casting mold foam part. Due to the existence of these holes, the total amount of foam occupied in this part of the cavity is correspondingly reduced. The form of the hole 2 can take other forms such as fence shape, honeycomb shape to reduce the total amount of foam in the foam mold. Moreover, the material of the casting feeding port 3 is a hollow feeding port made of iron sheet, so that the space of the port can not only store an appropriate amount of gas from the inside of the mold, but also reduce the local pressure of the entire mold by changing the material. Foam occupancy to reduce the amount of foam inside the mold.

[0028] Reduce the total amount of polystyrene foam in the cavity by improving the structure of the foam casting mold, so as to make up for the defects o...

Embodiment 2

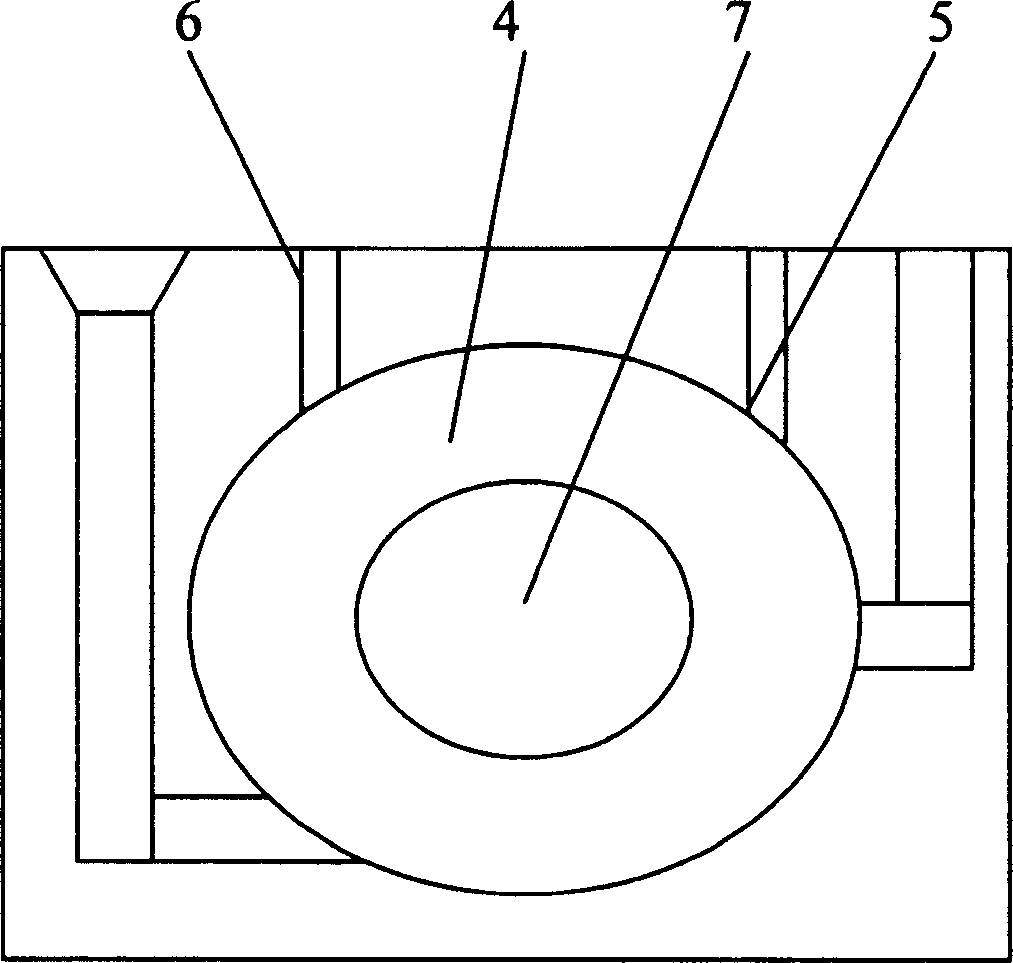

[0031] A method of full mold casting, the casting mold 4 is made of EPS material, characterized in that: the casting mold 4 of the full mold casting is hollow, and a structural inner space 7 is set in the body of the casting mold foam part, and Directly use the exhaust channel set in the mold for exhaust. When the foam casting mold is finished with the last layer of paint or unit type, a certain number of air outlet holes 6 are directly inserted above the mold exhaust holes 5, just like sand molds. Exhaust air is carried out like casting air holes. Because any casting has a filling time when pouring, this filling process also provides a certain time guarantee for the smoke in the cavity to be sucked out. The casting mold is modified to reduce the weight and exhaust, which also reduces the gas pressure inside the cavity due to the foam vaporization industry. The conditions are provided for the compound gas to leave the surface of molten steel. As long as the hydrocarbon gas k...

Embodiment 3

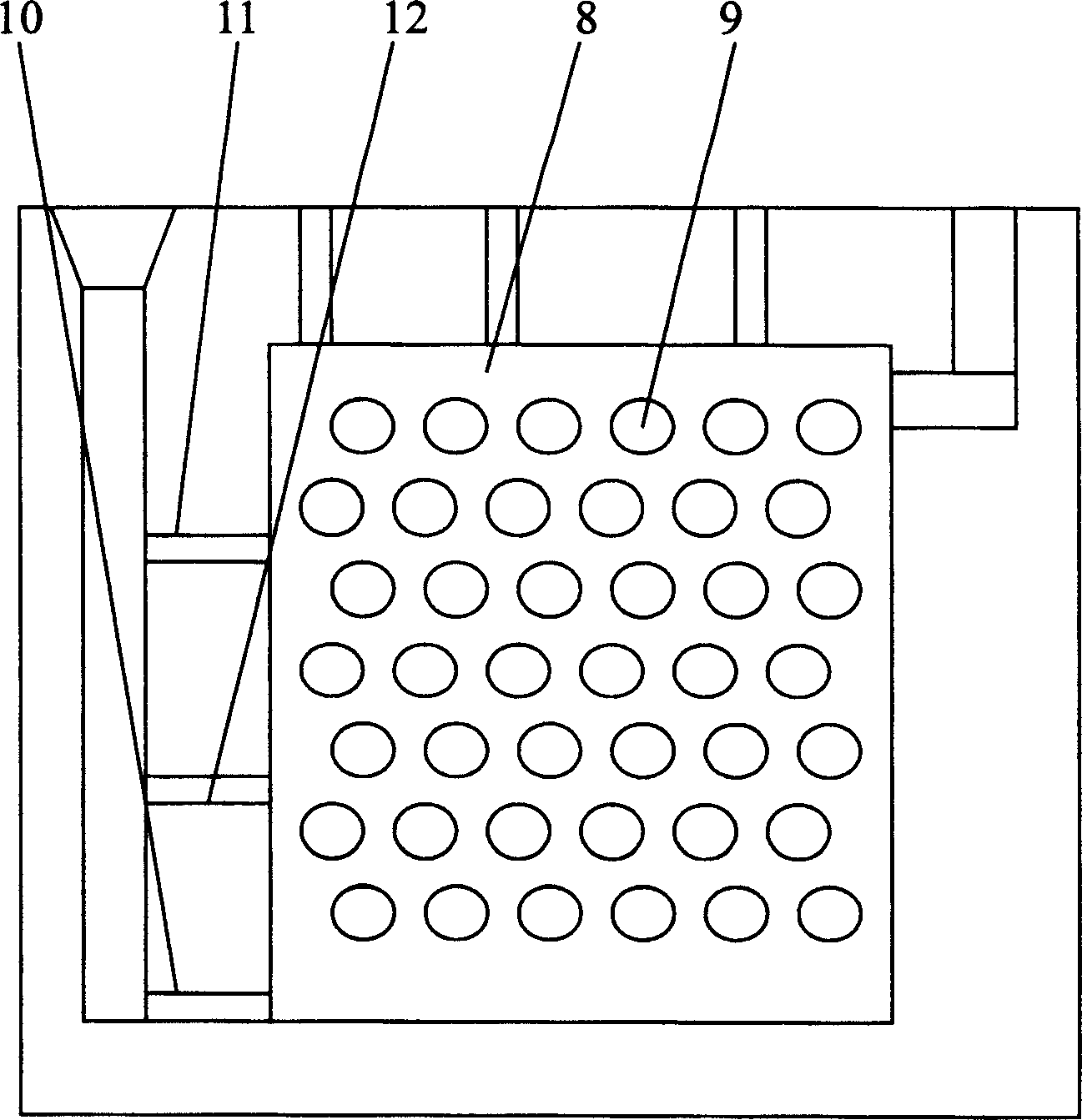

[0033] A full mold casting method, the casting mold 8 is a hollow body made of other foams, and a honeycomb inner hole 9 is set in the body of the casting mold foam part. Due to the existence of polystyrene foam inside the mold cavity, during the pouring process In the process, it is difficult to completely discharge these hydrocarbon gases out of the cavity. This may cause differences in carbon content in the lower, middle and upper parts of the casting body. In order to solve this problem, the cooling speed of the molten steel is fast, and the number and spacing of the gates in the casting are used to reduce the liquid high temperature area in the cavity, reduce the distance of the high temperature molten steel in the cavity, and shorten the existence time of the liquid high temperature, that is, The contact between high temperature molten steel and hydrocarbon gas is reduced. An ingate 12 is added between the two ingates 10 and 11 with a large spacing to form an inner gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com