Patents

Literature

345results about How to "Reduce high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

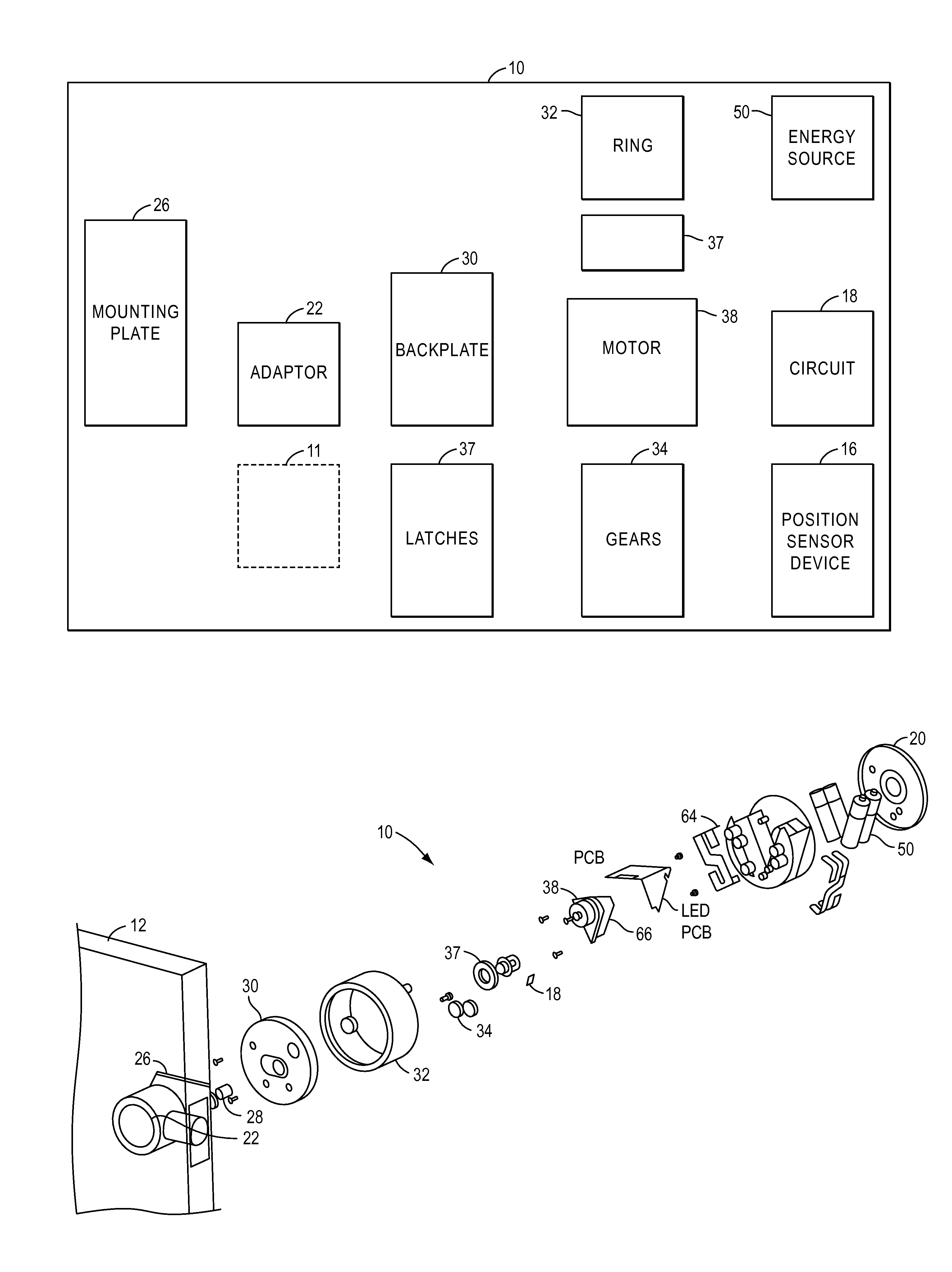

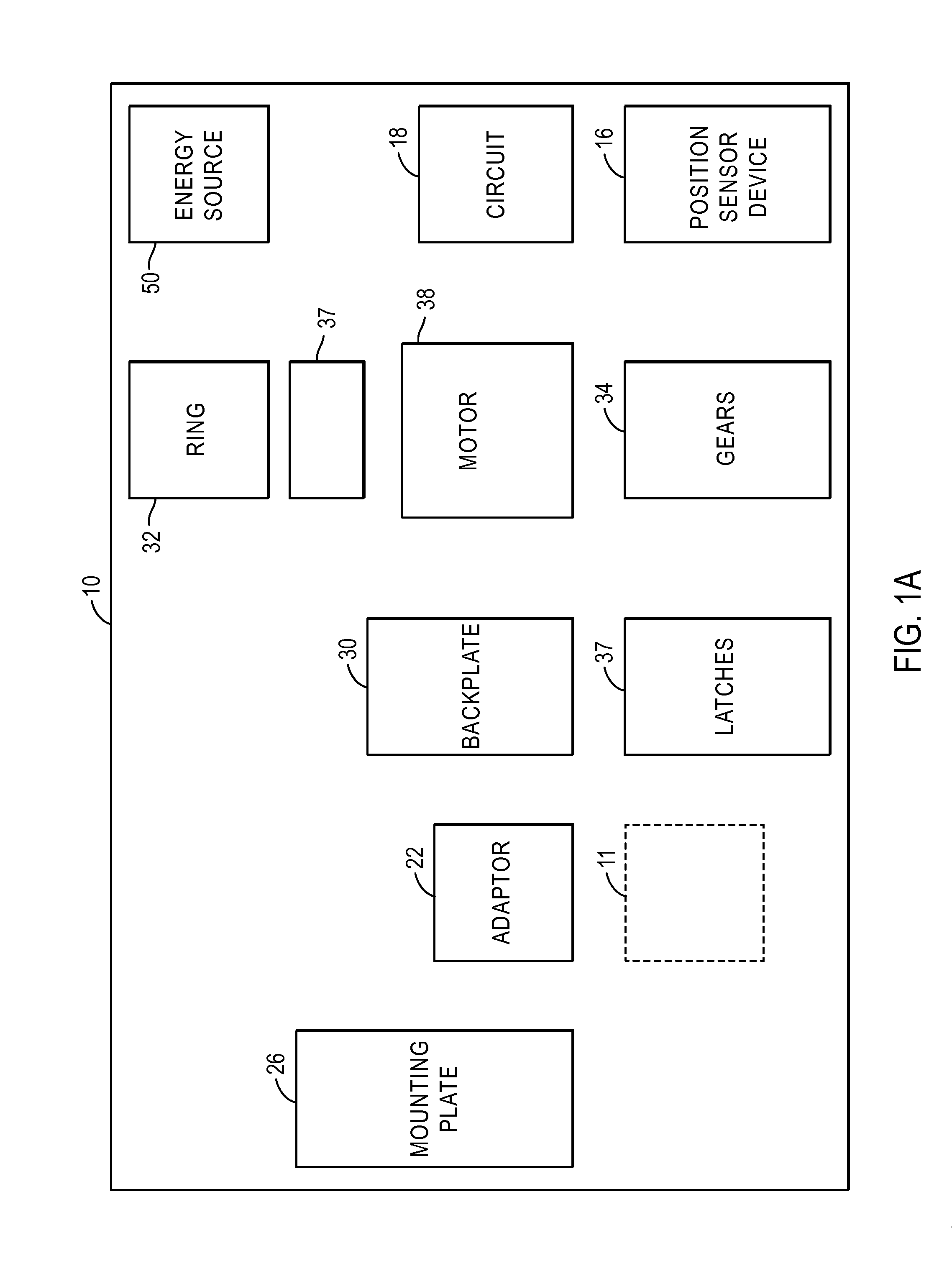

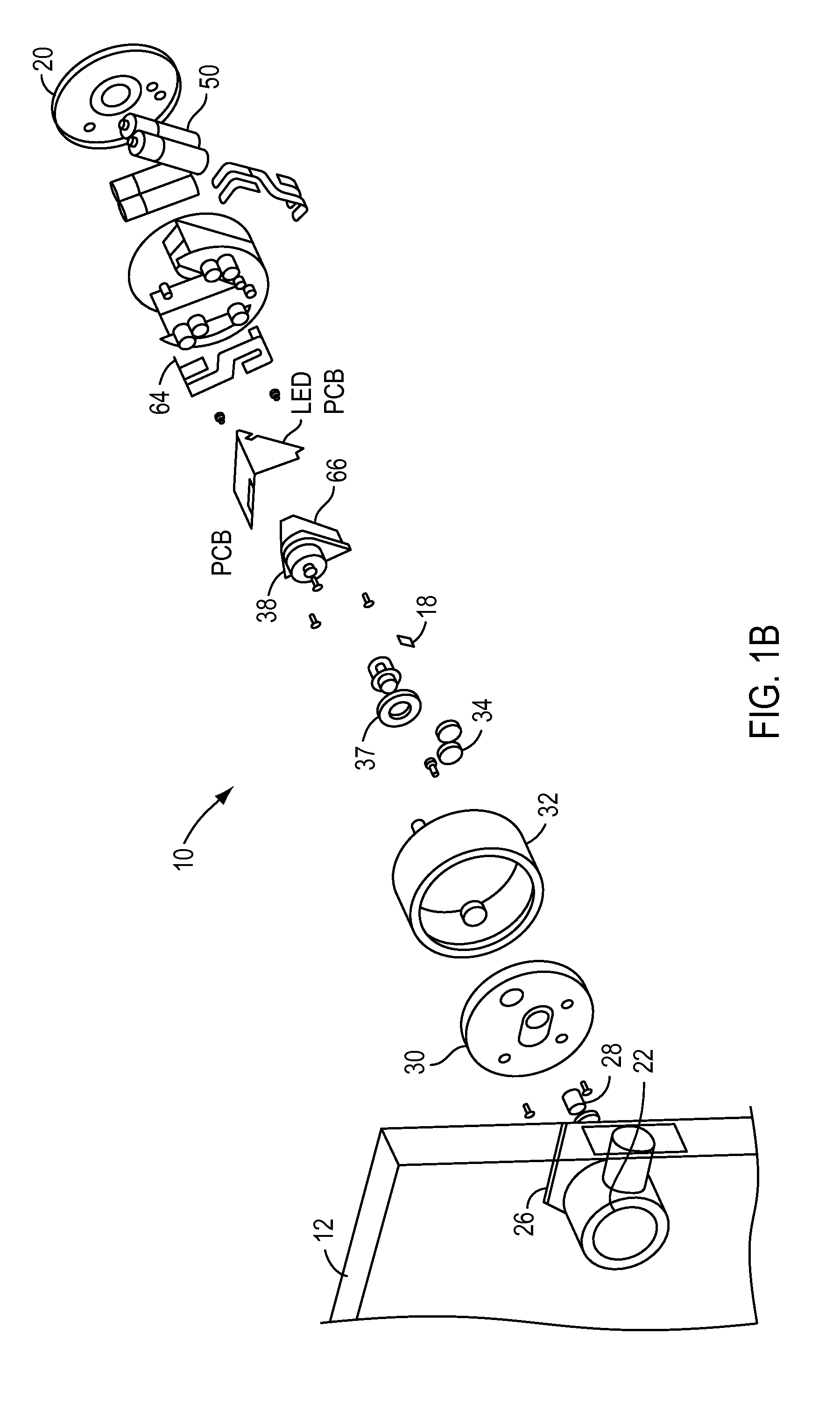

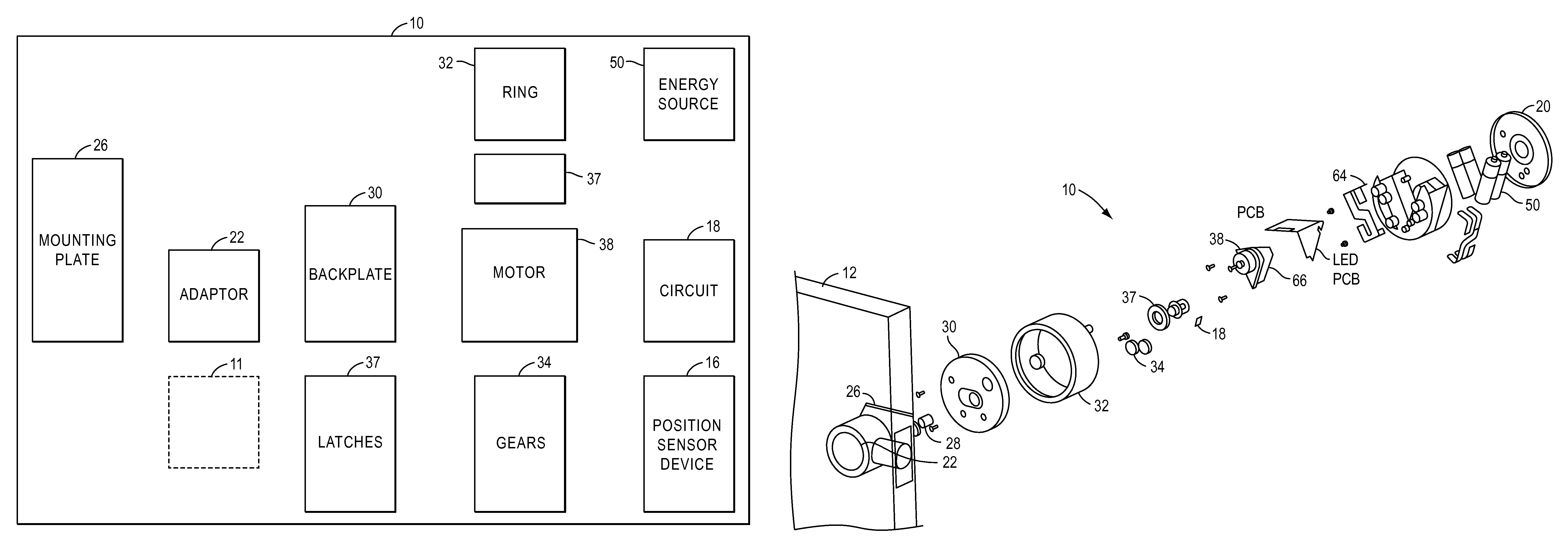

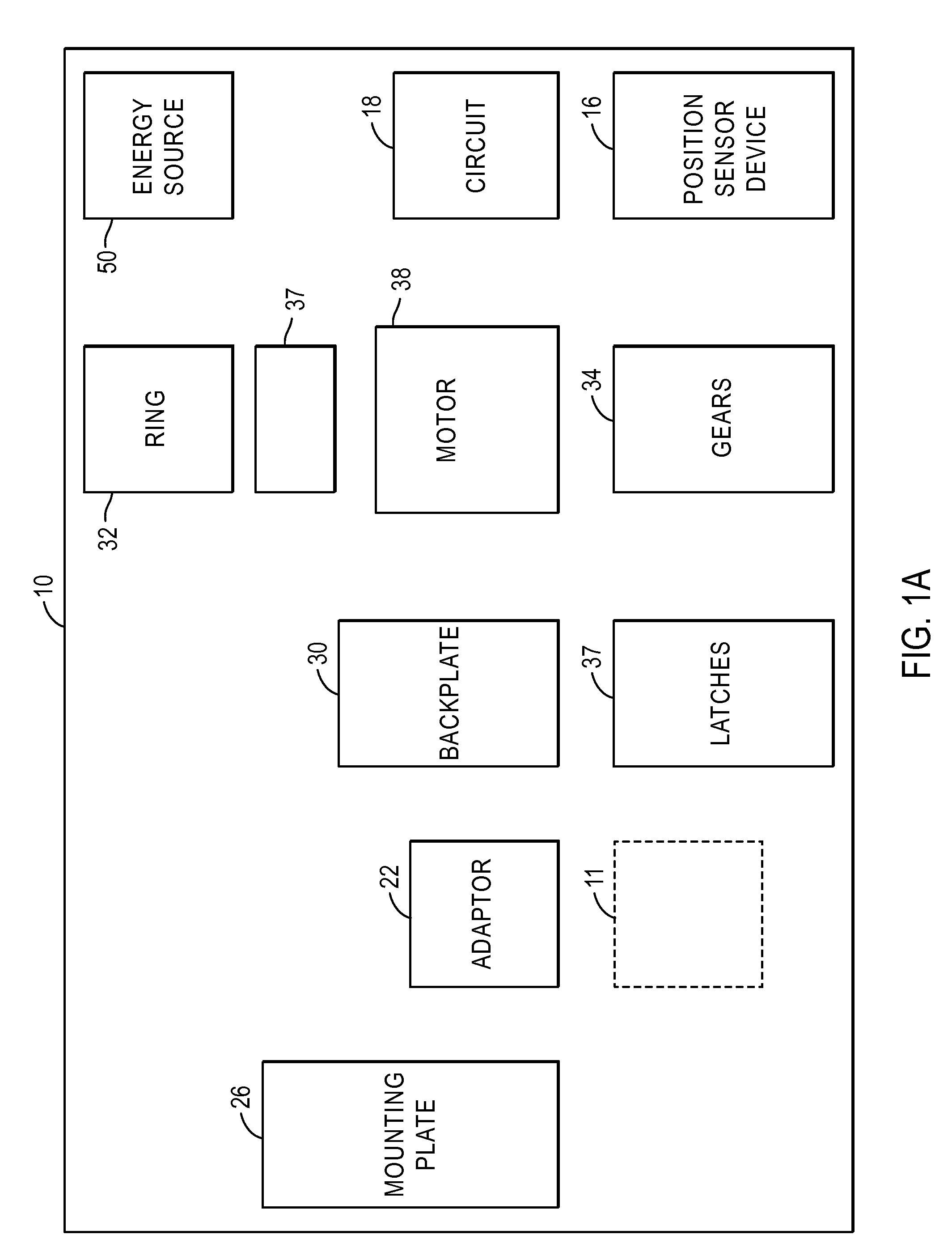

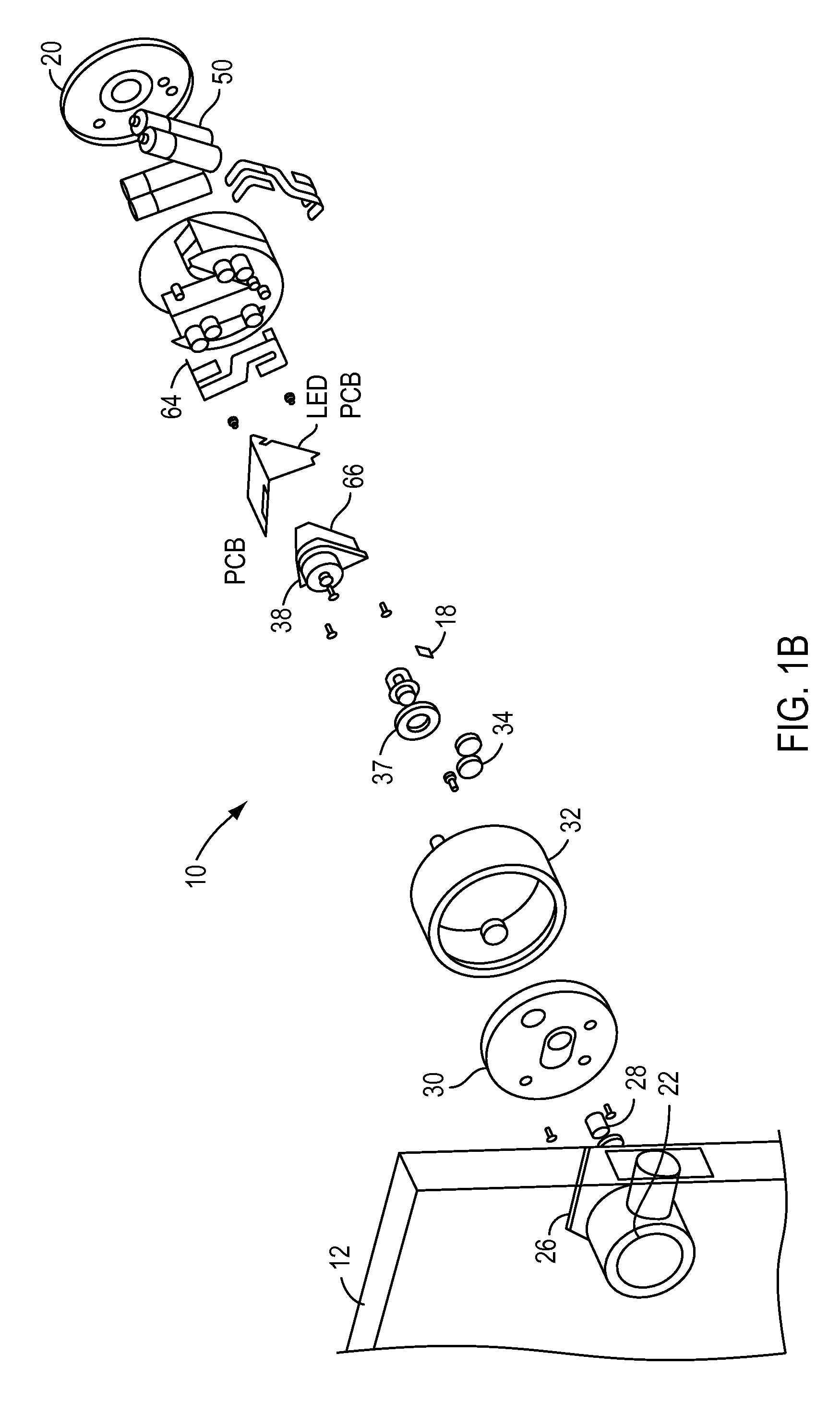

Intelligent Door Lock System that Minimizes Inertia Applied to Components

ActiveUS20150102609A1Wider temperature independenceLow powerWing handlesNon-mechanical controlsDrive shaftMechanical energy

An intelligent door lock system includes components, a drive shaft of a lock device, a processor coupled to a wireless communication device, and an energy source coupled to a circuit. A device that converts energy into mechanical energy is coupled to the circuit and the drive shaft. The device that converts energy is coupled to the energy source to receive energy from the energy source. A ramp-up speed, a steady state speed and a ramp down speed are applied to the device that converts energy into mechanical energy. The ramp-up speed is applied when a first component initially engages with a second component. The steady state speed is applied following the initial engagement and is an operational speed that the device which converts energy uses during a standard operation mode. The ramp down speed is applied as the first and second components begin a state of non-engagement.

Owner:AUGUST HOME

Intelligent door lock system that minimizes inertia applied to components

ActiveUS9574372B2Wider temperature independenceLow powerWing handlesNon-mechanical controlsStable stateDrive shaft

An intelligent door lock system includes components, a drive shaft of a lock device, a processor coupled to a wireless communication device, and an energy source coupled to a circuit. A device that converts energy into mechanical energy is coupled to the circuit and the drive shaft. The device that converts energy is coupled to the energy source to receive energy from the energy source. A ramp-up speed, a steady state speed and a ramp down speed are applied to the device that converts energy into mechanical energy. The ramp-up speed is applied when a first component initially engages with a second component. The steady state speed is applied following the initial engagement and is an operational speed that the device which converts energy uses during a standard operation mode. The ramp down speed is applied as the first and second components begin a state of non-engagement.

Owner:AUGUST HOME

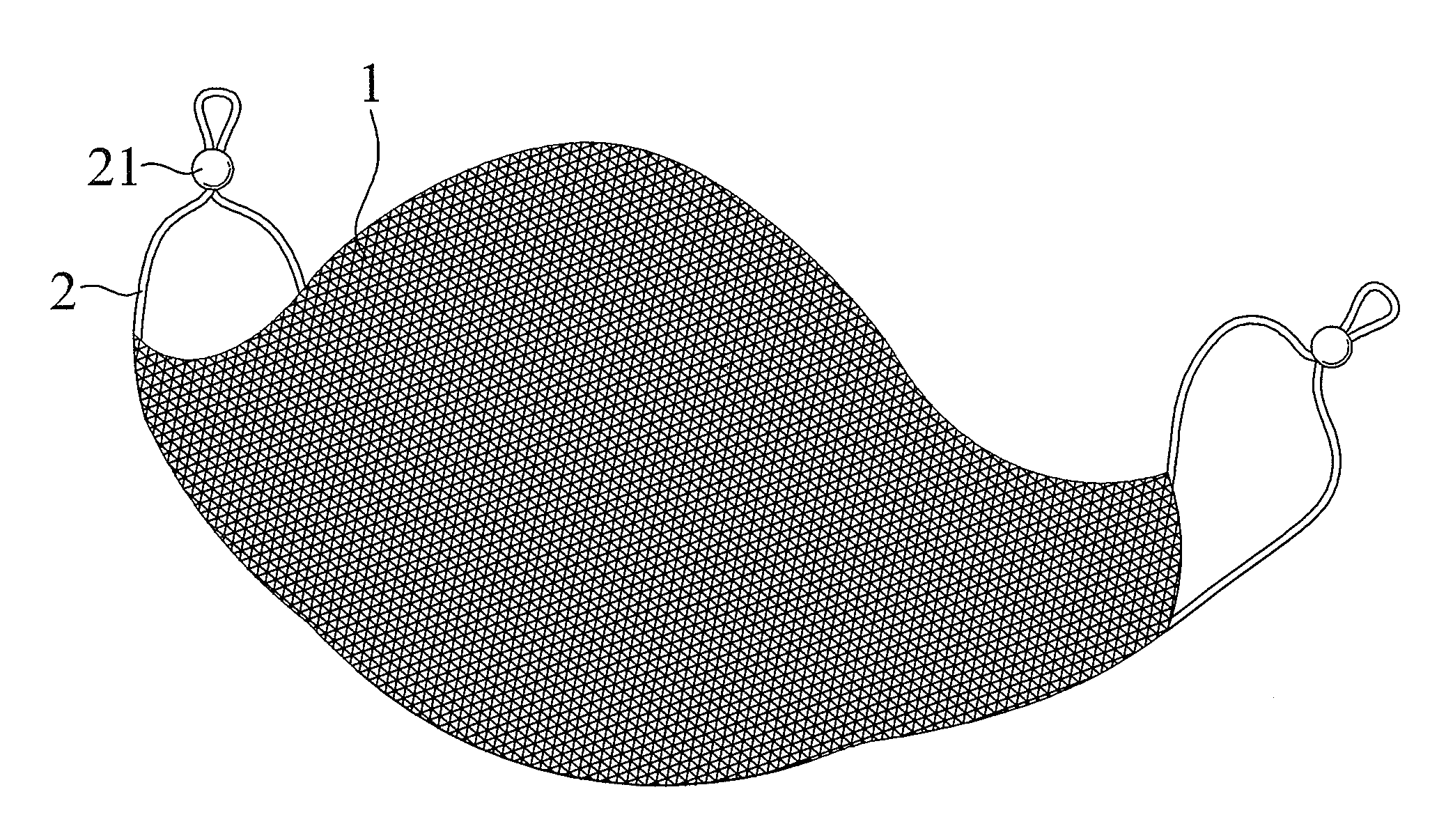

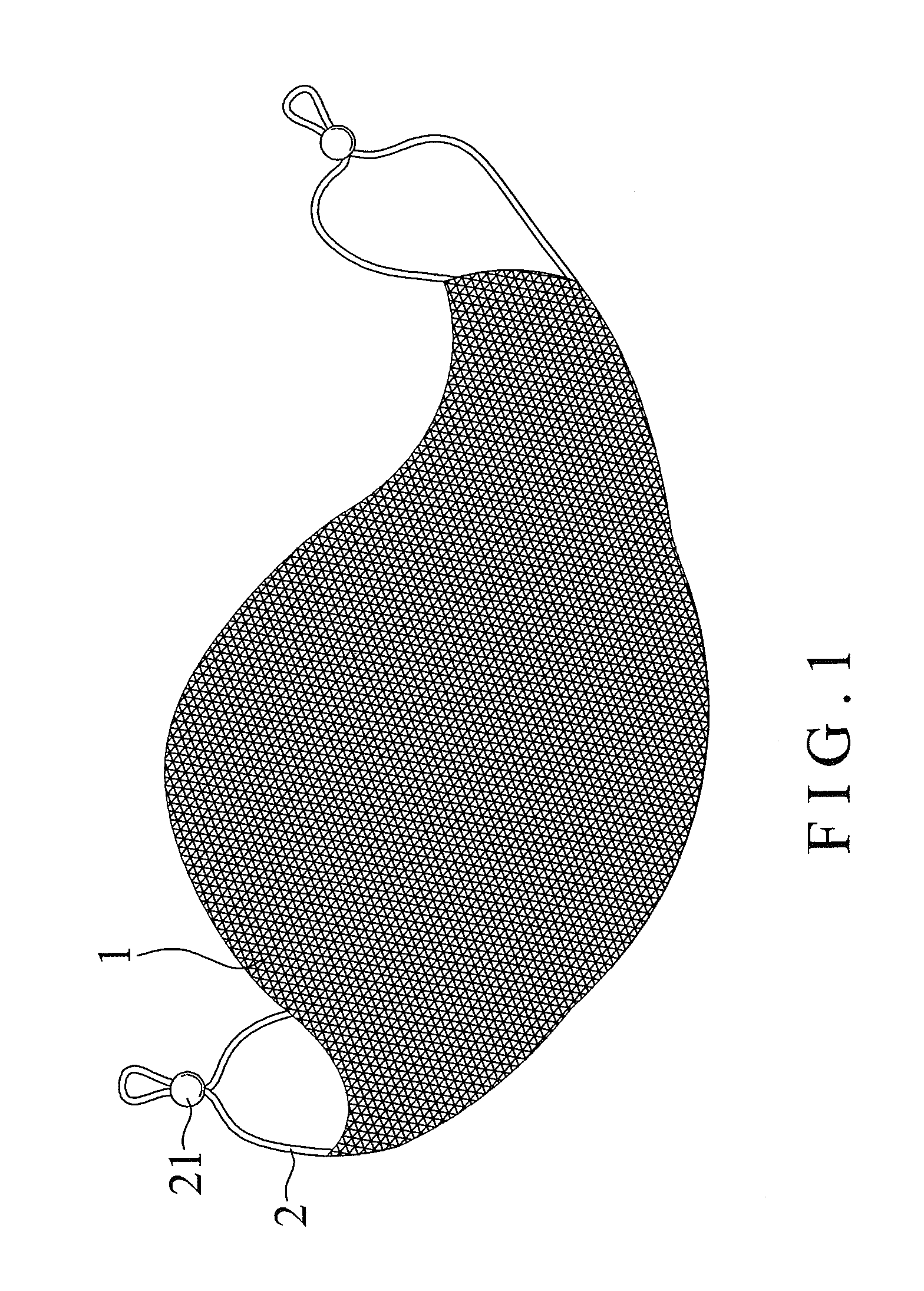

Mask that Provides a Comfortable Sensation to a User

A mask includes a thin film layer having a plurality of net-shaped irregular pores to provide a ventilating effect, two loop-shaped straps mounted on two ends of the thin film layer, and two adjusting rings each movably mounted on a respective one of the straps. The thin film layer is made of soft and tough material, such as e-PTFE, TPE, TPEE, COC or FRP. Each of the pores has a size smaller than that of dust, water molecule, bacterium and virus to isolate and prevent the dust, water molecule, bacterium and virus from entering the thin film layer. When the loop-shaped straps are put on a user's ears, the adjusting rings are moved on the loop-shaped straps to adjust the size of each of the loop-shaped straps so as to fit the user's face.

Owner:CHIA TENG TECH

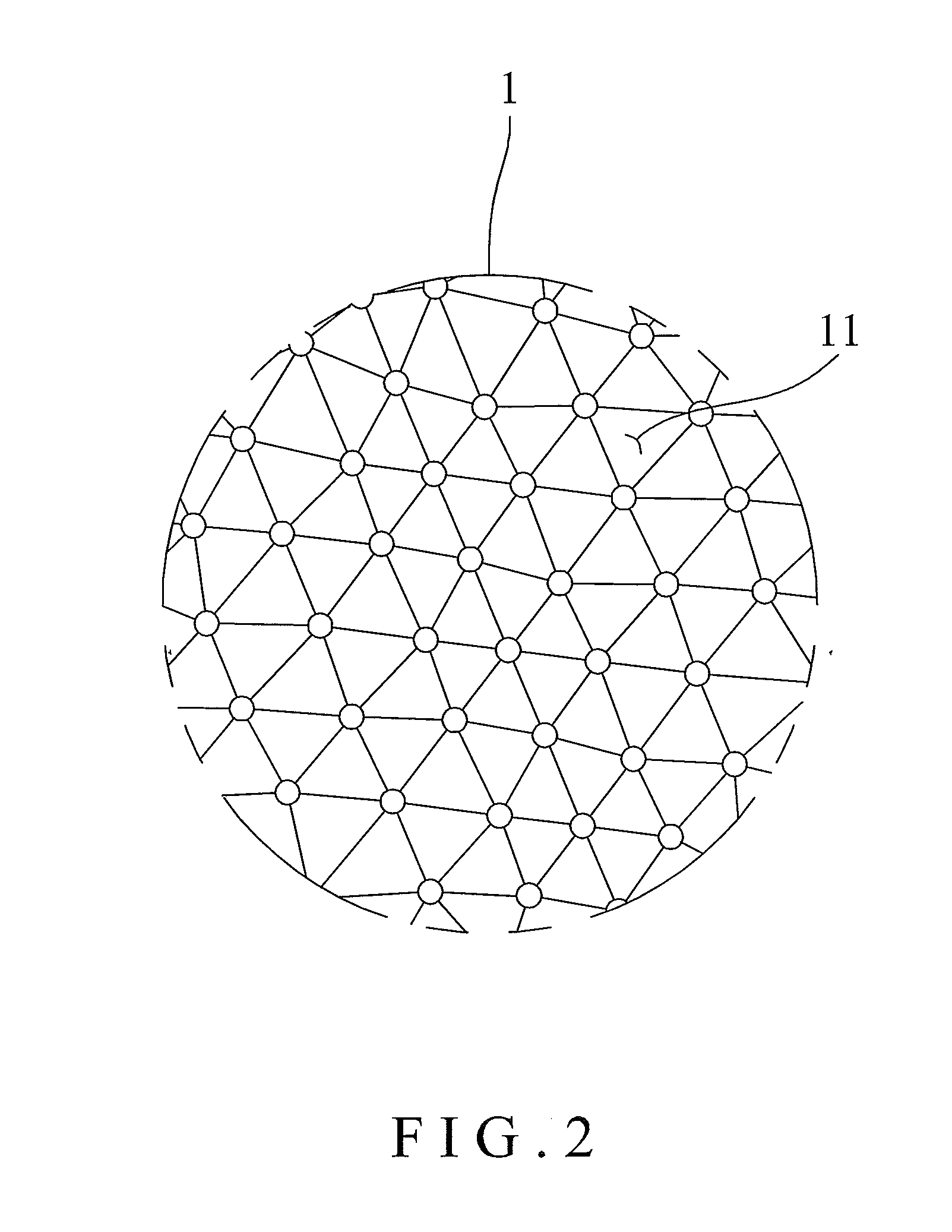

Method to Regulate temperature and Reduce Heat Island Effect

InactiveUS20070113500A1Storage moreReduce air temperatureRoof coveringIn situ pavingsRegulation temperatureEngineering

The present invention relates to a method of regulating and controlling surface temperature of concrete or asphalt structure (the structure) and the like, as well as atmospheric or air temperature around the structure by encapsulating and containing temperature (thermal) control materials (TCMs) or / and water in the structure which constructs or constitutes pavements, roofs, parking lots, walls and the like. Volume ratio of water and one or more TCMs encapsulated and contained in the structure are from 0.01% to 99.99%. Based on simulation analysis, on one hand, the present invention, in summertime, can reduce the highest temperature on surface of the structure by up to 56.5% (reduced by about 46° C.), and reduce the highest temperature of air around the structure by up to 54.4% (reduced by about 48° C.), therefore “heat island” effect in urban areas in summer can significantly be reduced, thus saving cooling energy and benefiting human health. On the other hand, in wintertime, by the invention the surface temperature of the structure can be raised by up to 5.6° C., and the temperature of air around the structure can be raised by up to 5° C., accordingly heating energy demand is reduced.

Owner:ZHAO JOE RU HE

Life-cycle water-free cooling solution

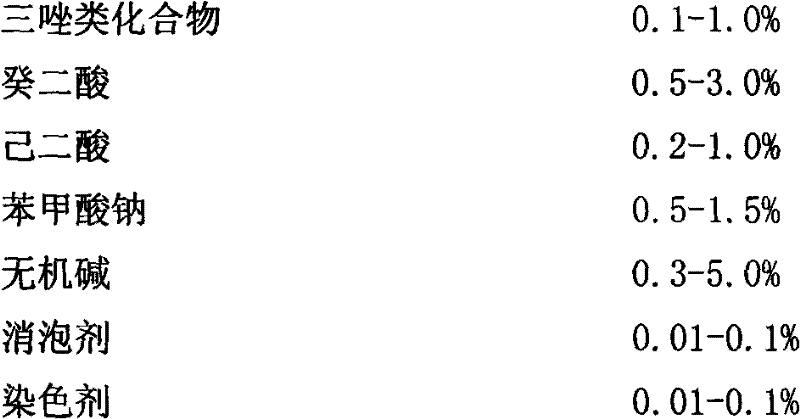

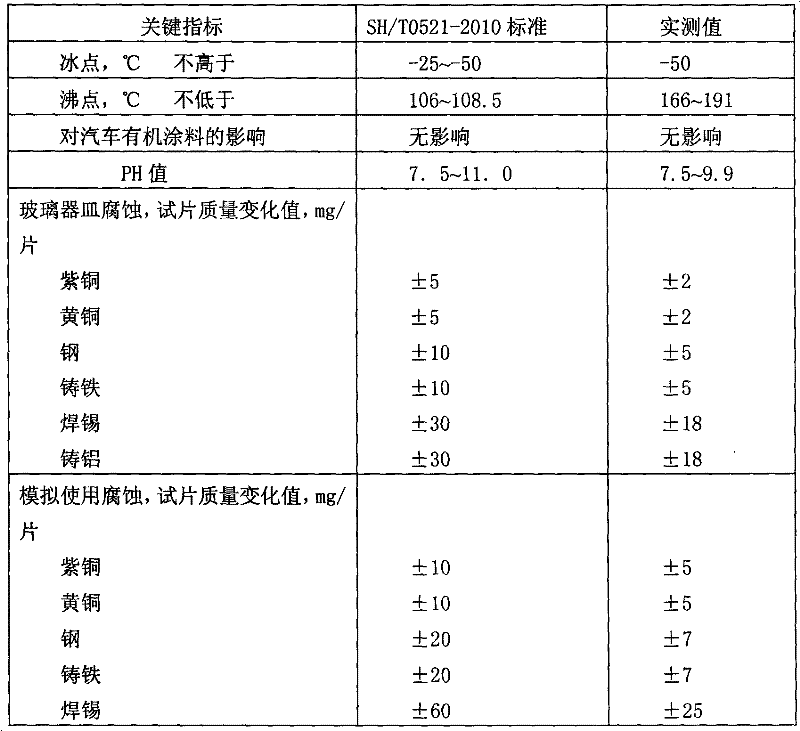

The invention relates to a life-cycle water-free cooling solution which is characterized by comprising the following components in percent by weight: 10-50 percent of propylene glycol, 50-80 percent of ethylene glycol, 0.1-10 percent of triazole compounds, 0.5-3.0 percent of sebacic acid, 0.2-1.0 percent of adipic acid, 0.5-1.5 percent of sodium benzoate, 0.3-5 percent of inorganic base, 0.01-0.1 percent of antifoaming agent and 0.01-0.1 percent of colouring agent. The cooling solution has a freezing point of below -50 DEG C and a boiling point of 166-191 DEG C; and because the cooling solution does not contain water, problems of boiling, gas etching, evaporating, scaling, rusting and the like caused by water existing in the cooling solution are thoroughly eliminated, a steam air resistance layer seriously influencing heat radiation is avoided from generating, power of an engine can be effectively improved and fuel is saved. Because the cooling solution does not contain water and has a reasonable corrosion inhibition system, the problem of corrosion is thoroughly solved; and the cooling solution has a service life of reaching up to 8 hundred thousand kilometers, is added once without replacement, is a life-cycle cooling solution, is especially suitable for military vehicles, high-end vehicles and high-power heavy-loading trucks and passenger cars, and can ensure that the vehicles safely run under extremely hot weather, severe cold weather, and severe environments such as desert, plateau, snowfield and the like.

Owner:JIANGXI CHEPU IND CO LTD

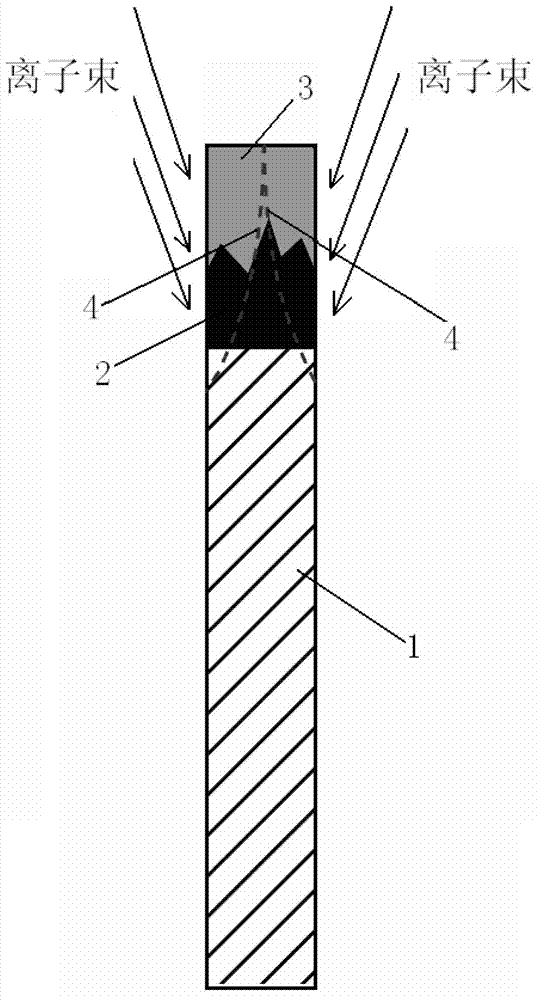

Preparation method of a sample with rust layer for in-situ observation of transmission electron microscope

InactiveCN103196720AEasy to observe in situUnderstanding the Corrosion ProcessPreparing sample for investigationMaterial analysis by measuring secondary emissionConventional transmission electron microscopeCopper

The invention discloses a preparation method of a sample with a rust layer for in-situ observation of a transmission electron microscope. The method comprises the following steps of: (1), integrally packaging an obtained sample with a rust layer by a cold embedding method; 2), cutting the sample according to the sample size facilitating observation of the transmission electron microscope; 3), thinning the sample primarily; 4), forming a thin sample area which can be observed by the transmission electron microscope; and 5), bonding the prepared sample to a phi3mm round copper mesh, so as to obtain the sample with the rust layer for the in-situ observation of the transmission electron microscope. By adopting the preparation method, the initial shape of the rust layer is remained completely, and the method is very suitable for preparing of the sample with the rust layer for observation of the transmission electron microscope; and the prepared sample is representative, can truly indicate the whole characteristics of the analyzed material, and has great significant in the corrosion resistance research of steel and iron materials.

Owner:武汉钢铁有限公司

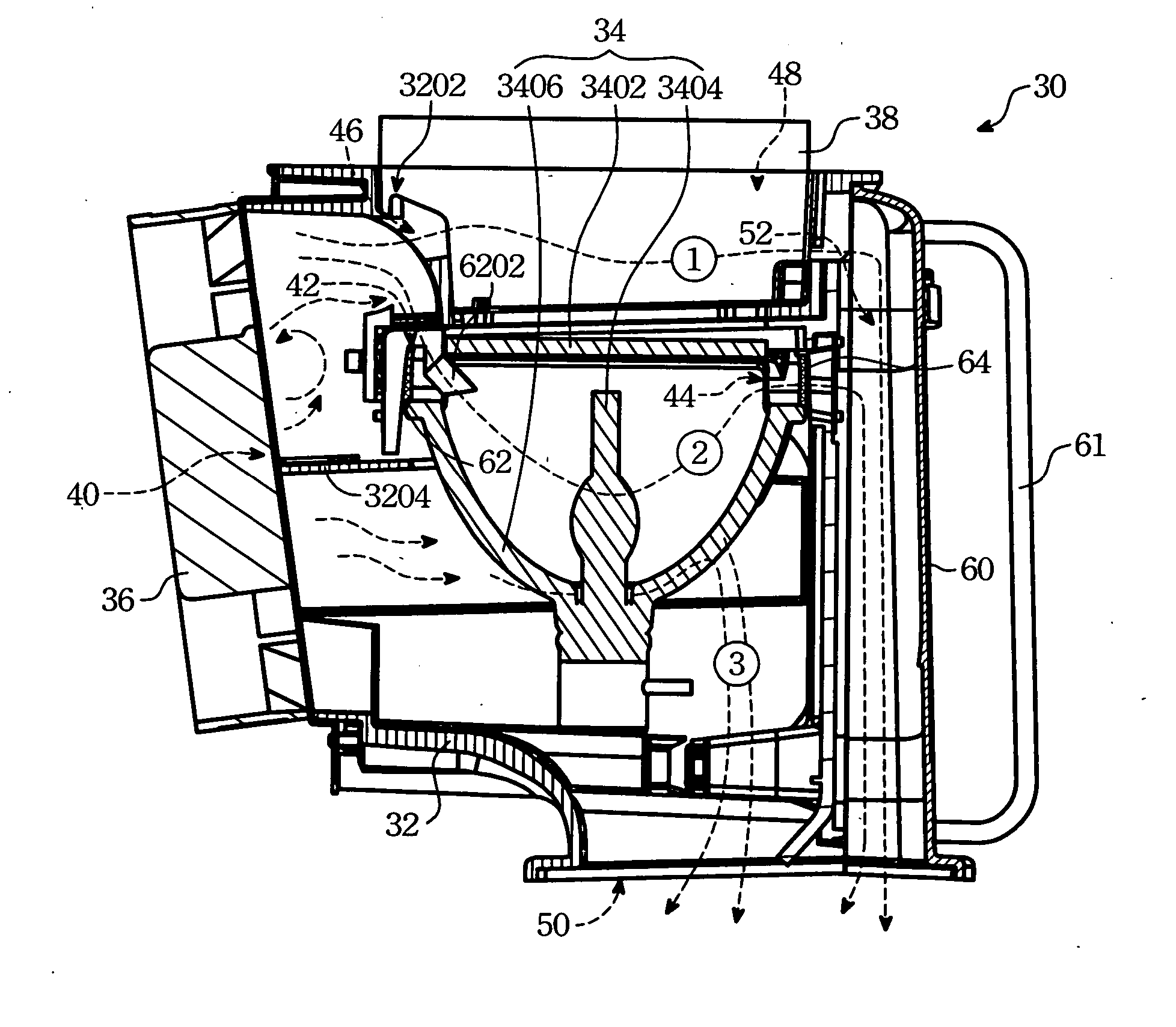

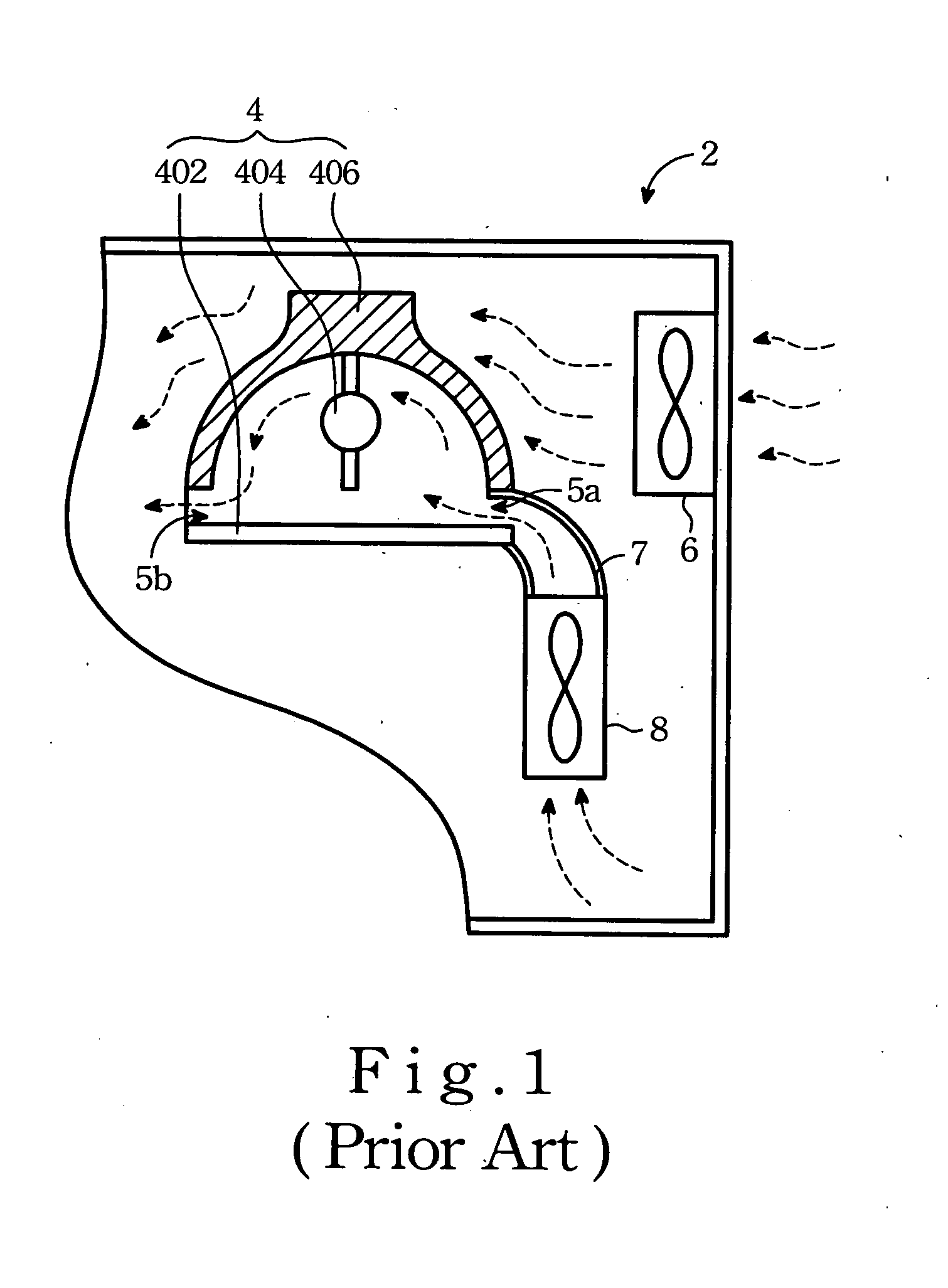

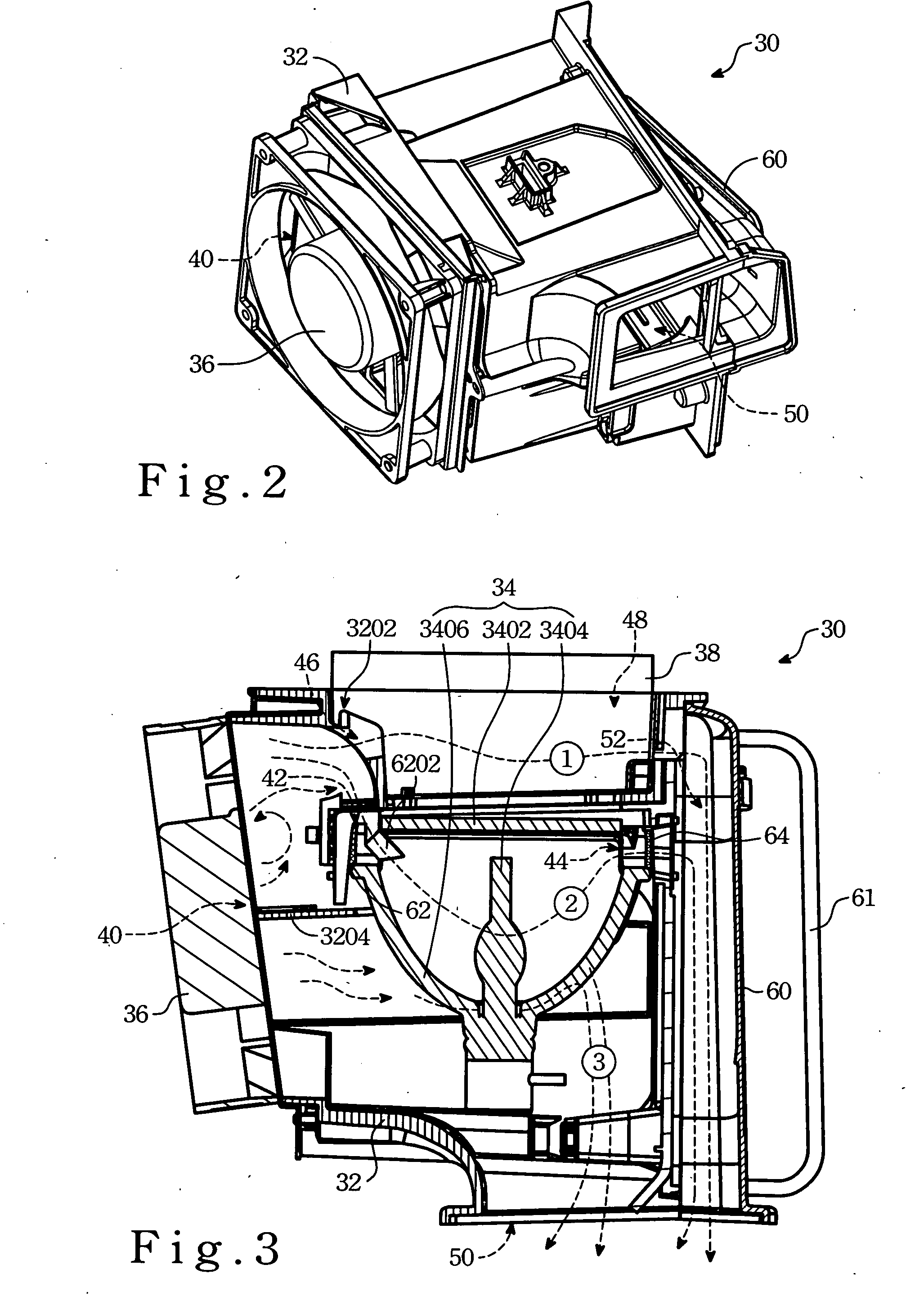

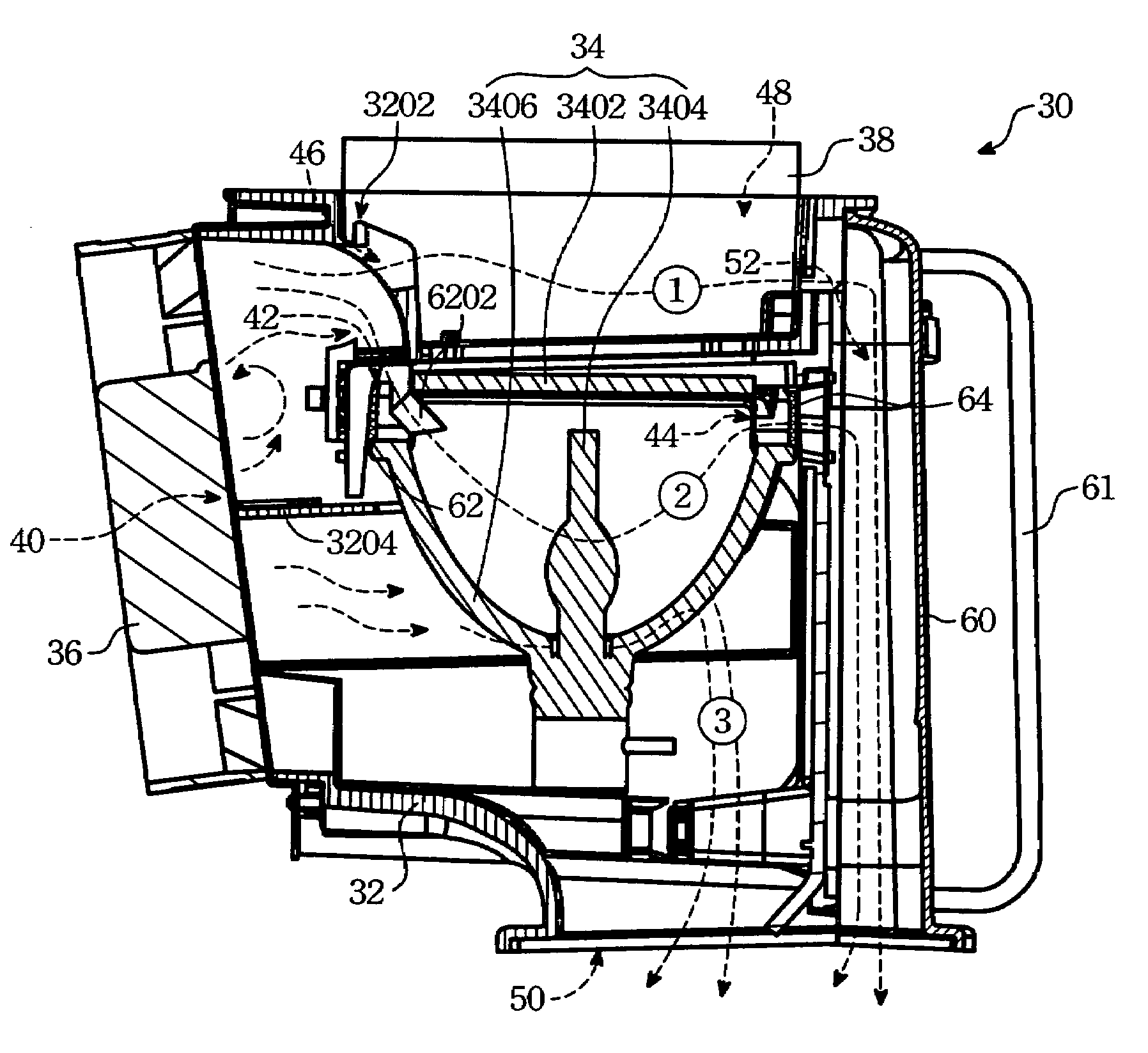

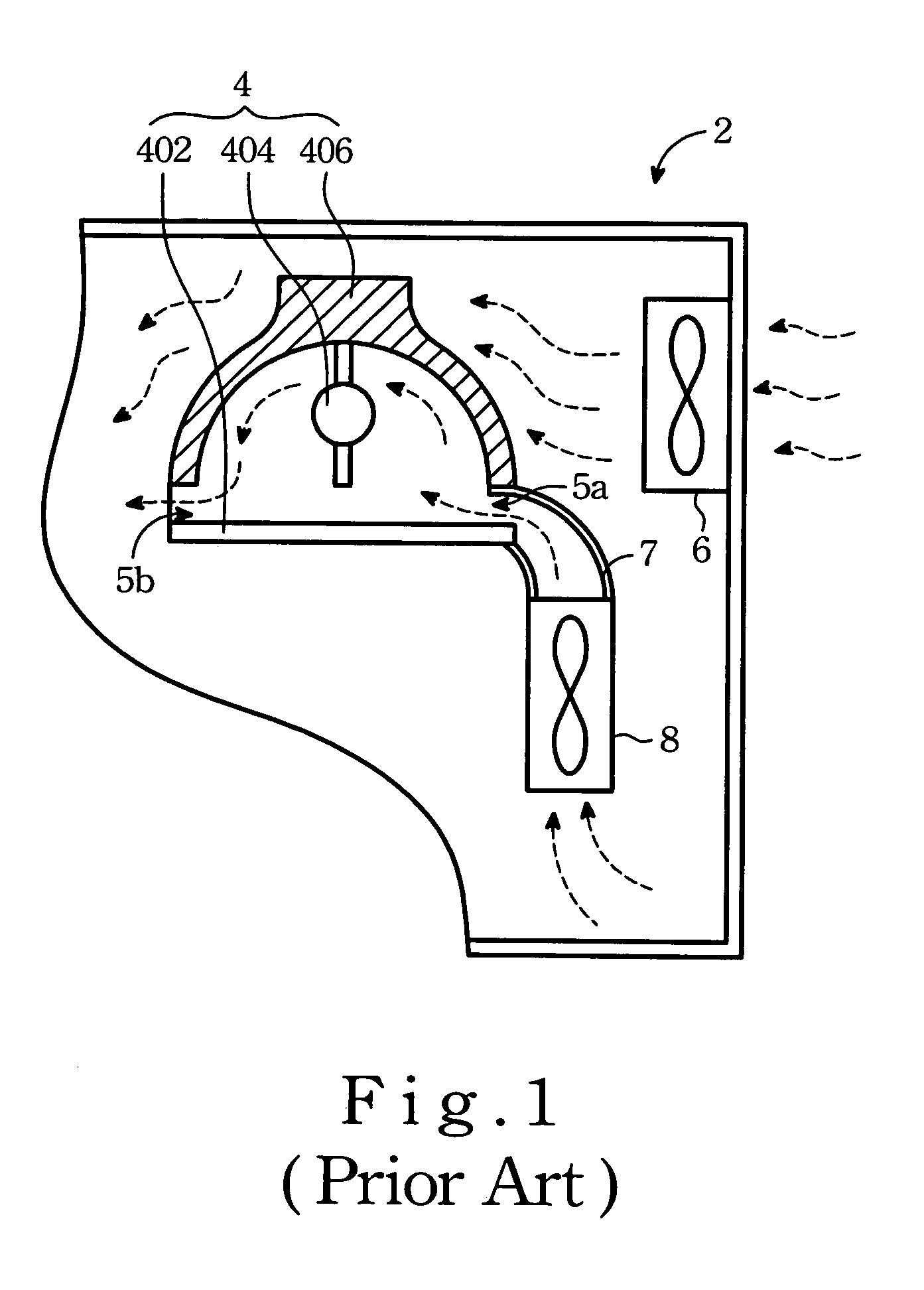

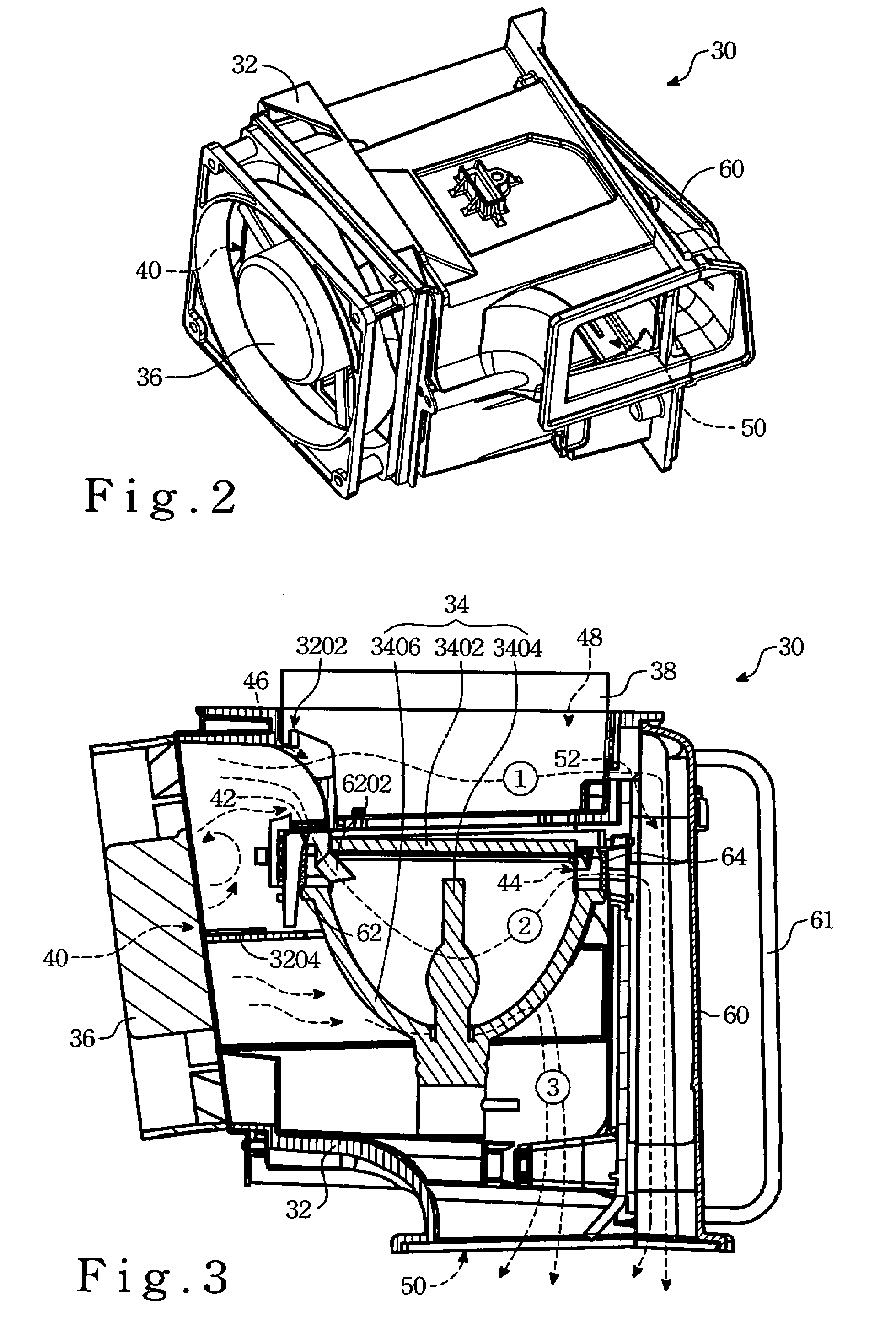

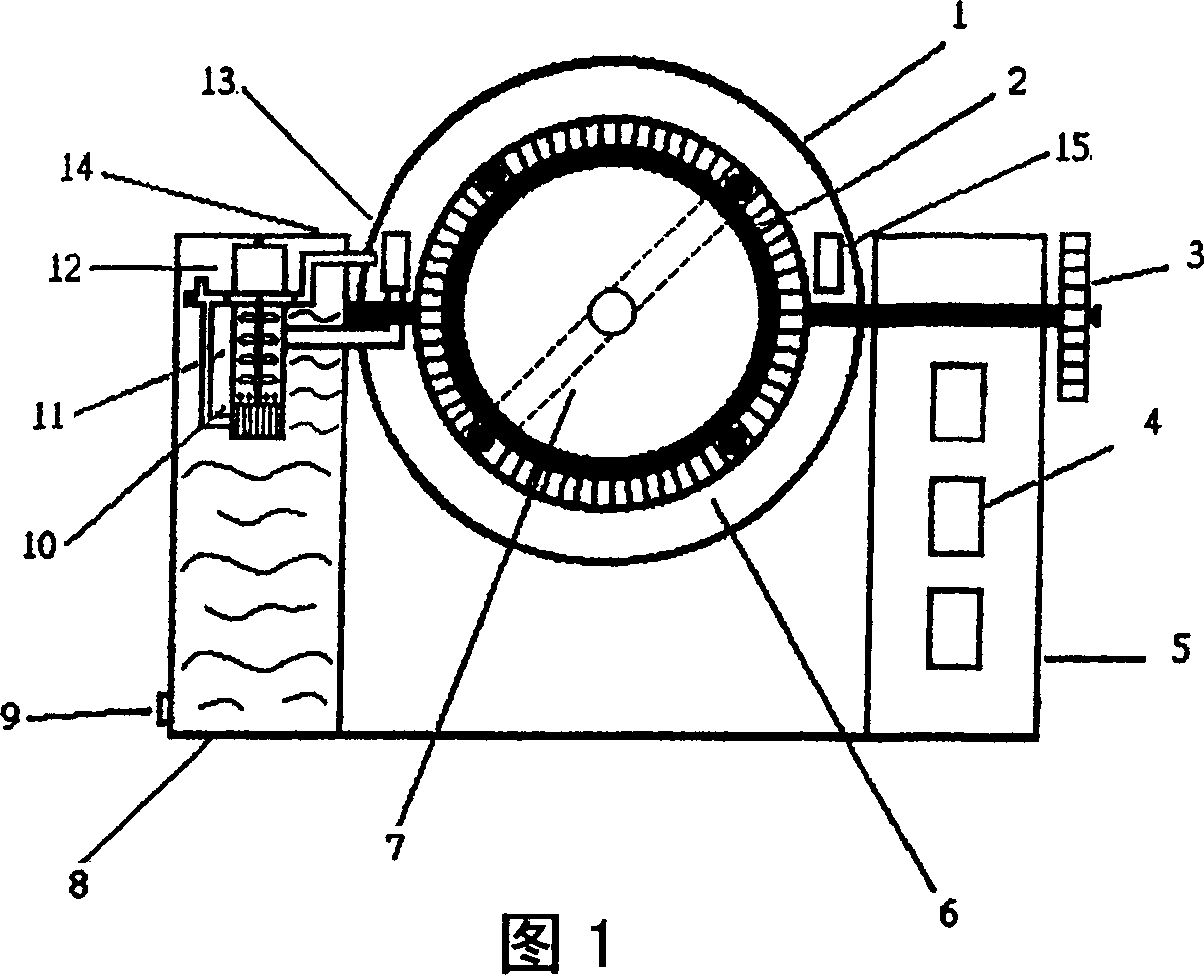

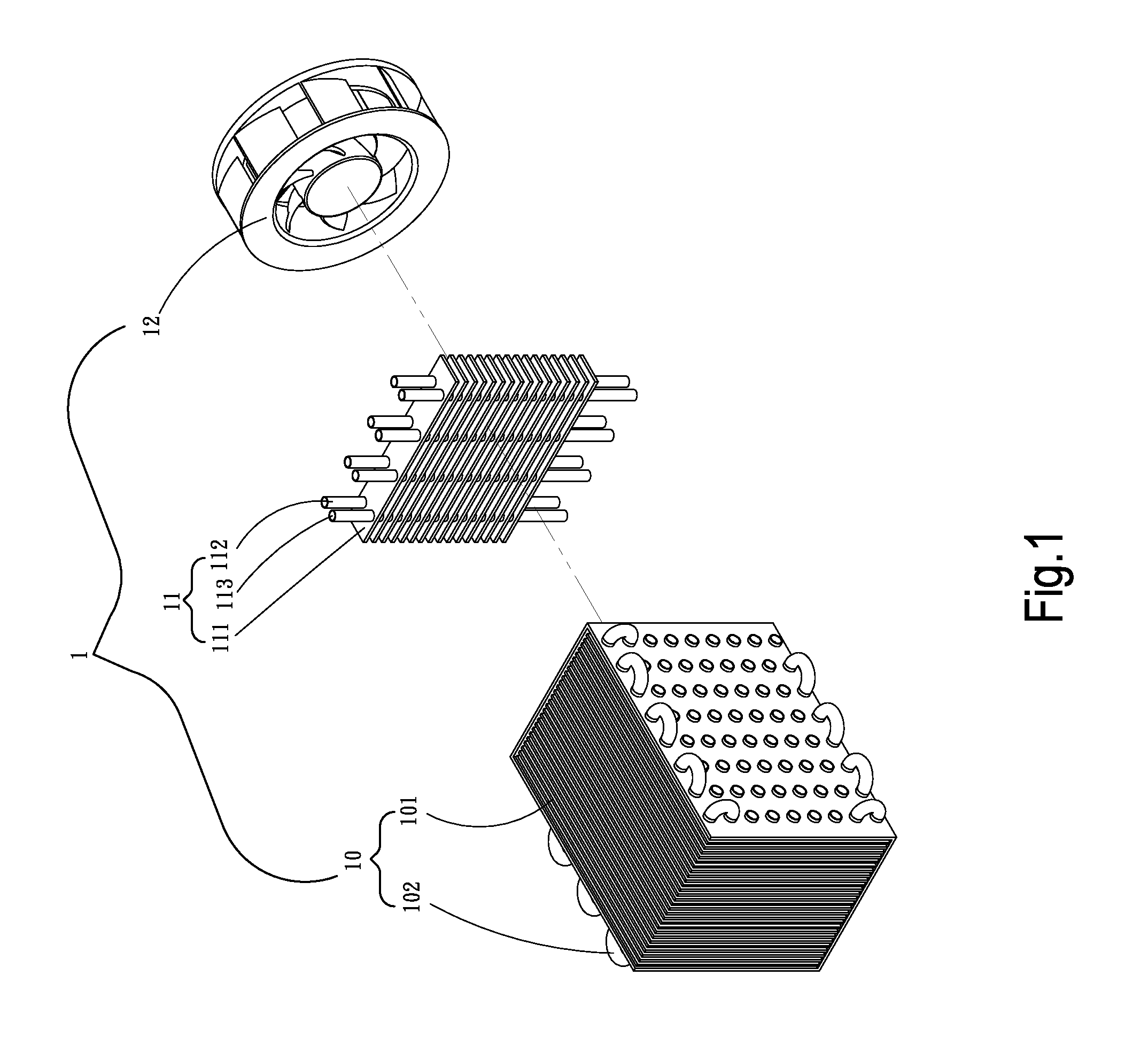

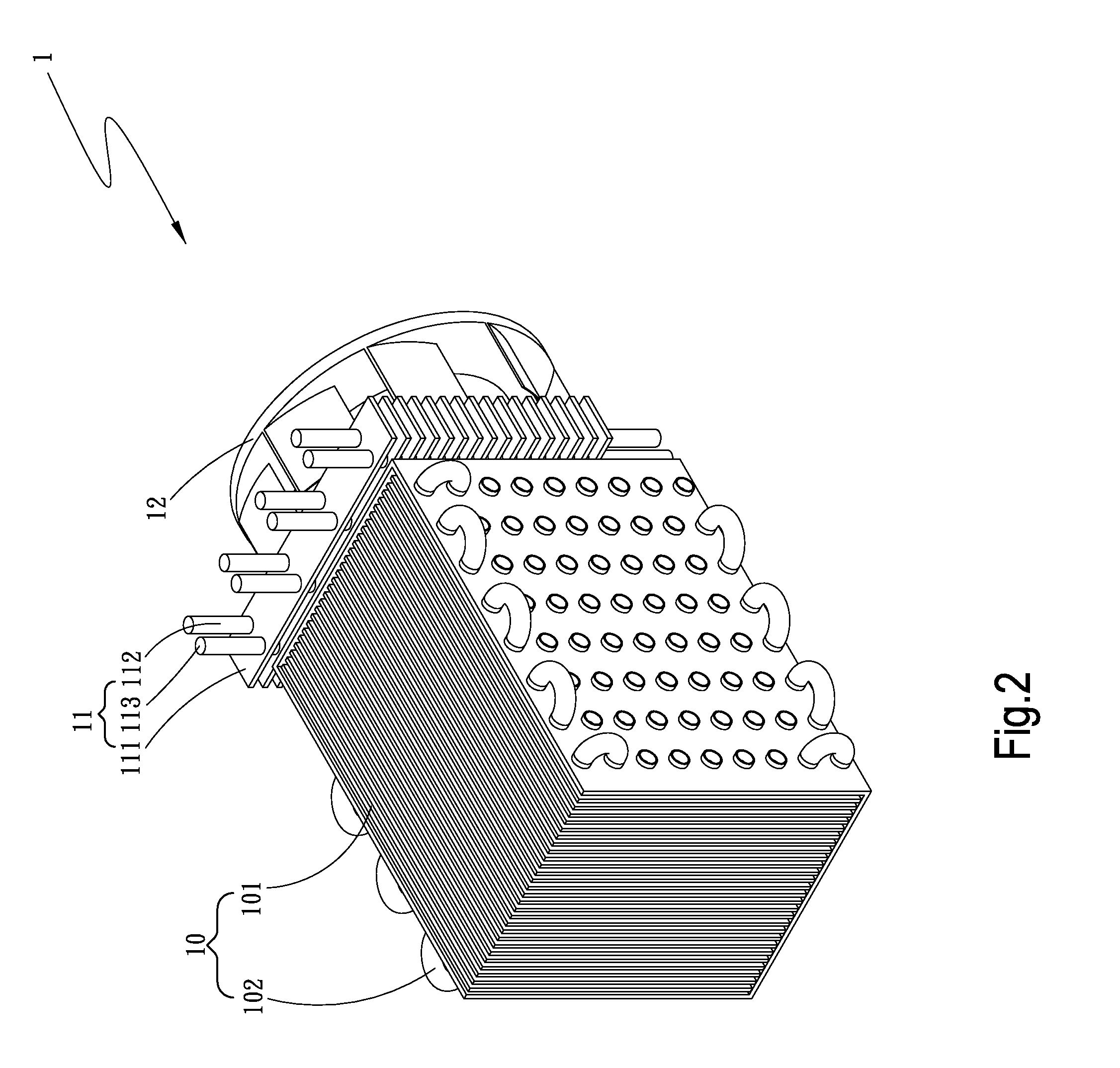

Heat-dissipating device for a projection apparatus

InactiveUS20060256296A1Reduce intensive heatEnhance cool effectLighting heating/cooling arrangementsProjectorsAirflowEngineering

A heat-dissipating device includes a receptacle body having a lateral wall formed with an air vent; a lamp unit including a burner, a reflector covered the burner, a glass plate disposed in front of the reflector, the reflector cooperating with the glass plate to define an air inlet adjacent to the air vent and an air outlet spaced from the air vent; a fan unit mounted on the receptacle body for covering the air vent and for generating airflow to flow into the receptacle body; and a nozzle disposed within the receptacle body between the air vent and the lamp unit for guiding the airflow into the lamp unit.

Owner:YOUNG OPTICS

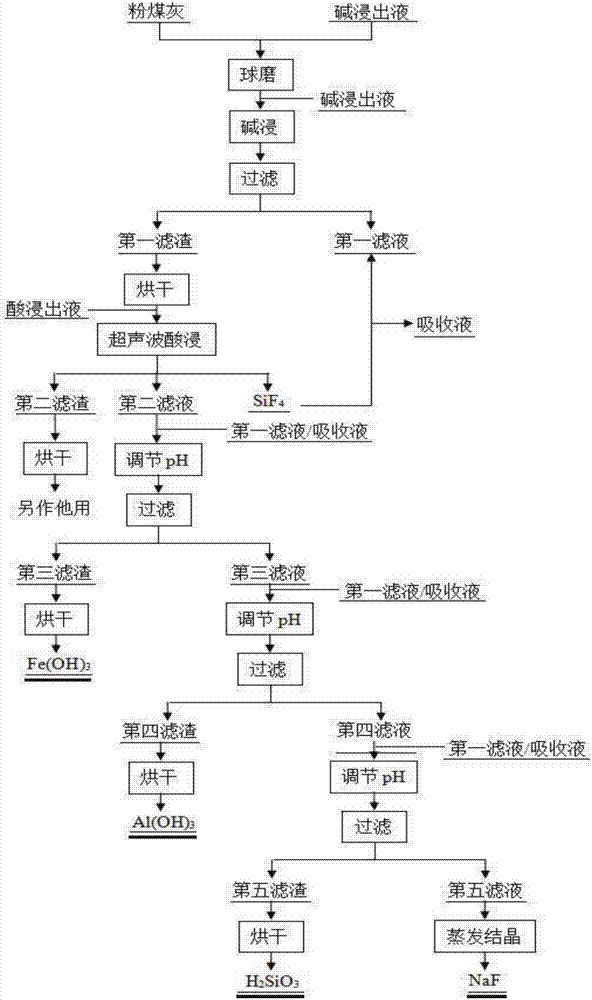

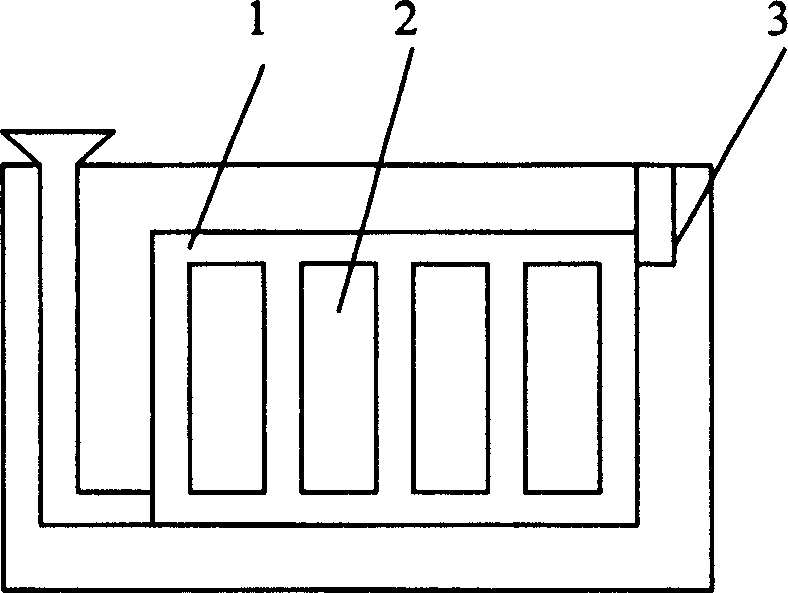

Combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of aluminum electrolysis cell waste cathode carbon block

InactiveCN107162061AEliminate hazardsLow costSilicaIron oxides/hydroxidesPregnant leach solutionElectrolysis

The invention discloses a combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of an aluminum electrolysis cell waste cathode carbon block. The pulverized fuel ash and the alkaline leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed and are subjected to ball milling; primary alkaline leaching is performed; then, the alkaline leaching liquid is replenished; secondary alkaline leaching is performed; solid and liquid separation of a secondary alkaline leaching system is separated to obtain first filter liquid and first filter slag; the first filter slag and the acid leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed; acid leaching is performed under the assistance of ultrasound; then, solid-liquid separation is performed to obtain second filter liquid; the pH of second filter liquid is increased in a gradient way; Fe(OH)3, Al(OH)3 and H2SiO3 are obtained from the second filter liquid through sequential separation; finally, the filter liquid subjected to H2SiO3 separation is concentrated to obtain NaF. The whole treatment method achieves the goals of treating wastes by wastes, reducing the energy consumption, reducing the consumption of industrial raw materials and reducing the equipment loss.

Owner:CENT SOUTH UNIV

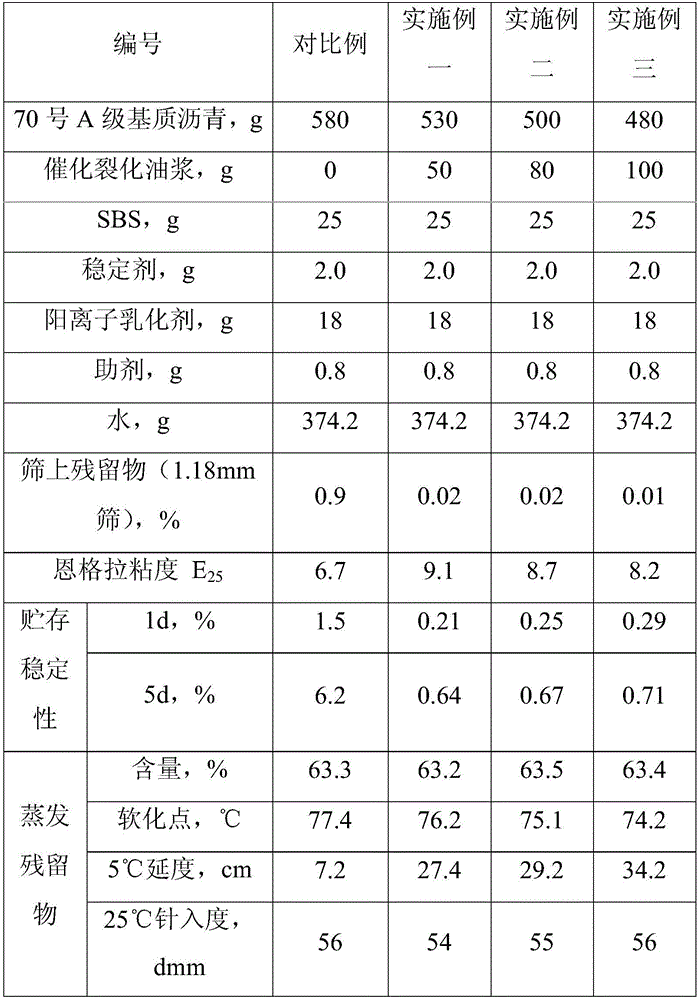

SBS modified emulsified bitumen having a high softening point and a preparing method thereof

InactiveCN106554635AHigh in SBSImprove high temperature performanceBuilding insulationsDuctilityColloid mill

The invention relates to SBS modified emulsified bitumen having a high softening point and a preparing method thereof. The SBS modified emulsified bitumen comprises, by weight, 45.0-60.0% of matrix bitumen, 1.5-3.0% of an SBS modifier, 3-15% of catalytic cracking oil slurry, 0.05-0.5% of a stabilizing agent, 0.8-2.5% of a cation emulsifier, 0-0.2% of an auxiliary agent and 32.0-42.0% of water. During preparation, SBS modified bitumen is firstly prepared, then the cation emulsifier and the auxiliary agent are added into hot water having a temperature of 50-70 DGE C to prepare a soap solution, and finally the SBS modified bitumen and the soap solution are subjected to emulsification together through a colloid mill, pressurization and cooling to obtain the SBS modified emulsified bitumen. The preparing method is simple and steps are easy to operate. The prepared SBS modified emulsified bitumen has a high SBS content, the high softening point, high ductility at 5 DEG C, and excellent high-temperature performance and low-temperature performance. An effective route is provided for high value-added utilization of the catalytic cracking oil slurry.

Owner:CNPC JIANGSU FUEL ASPHALT

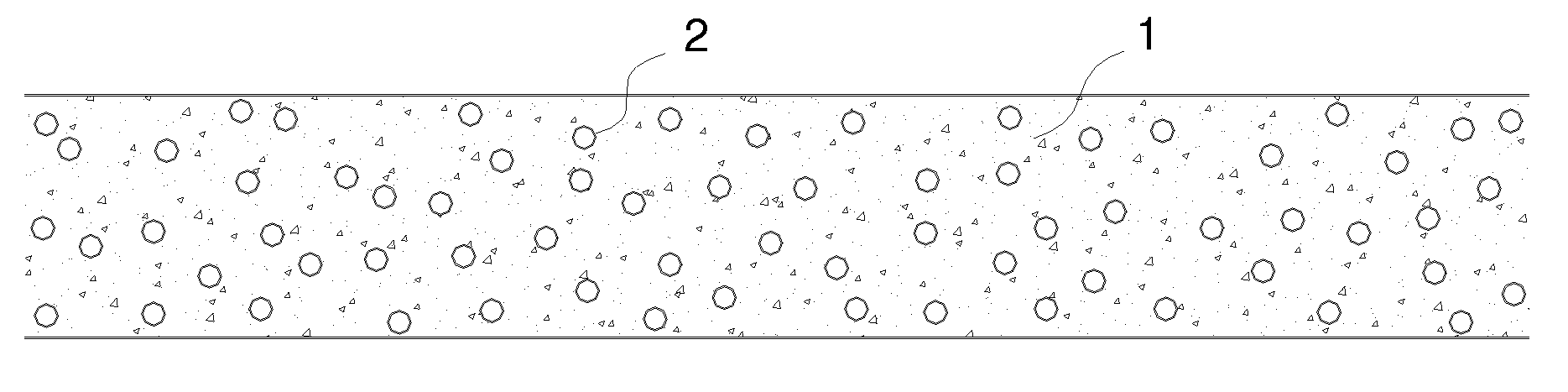

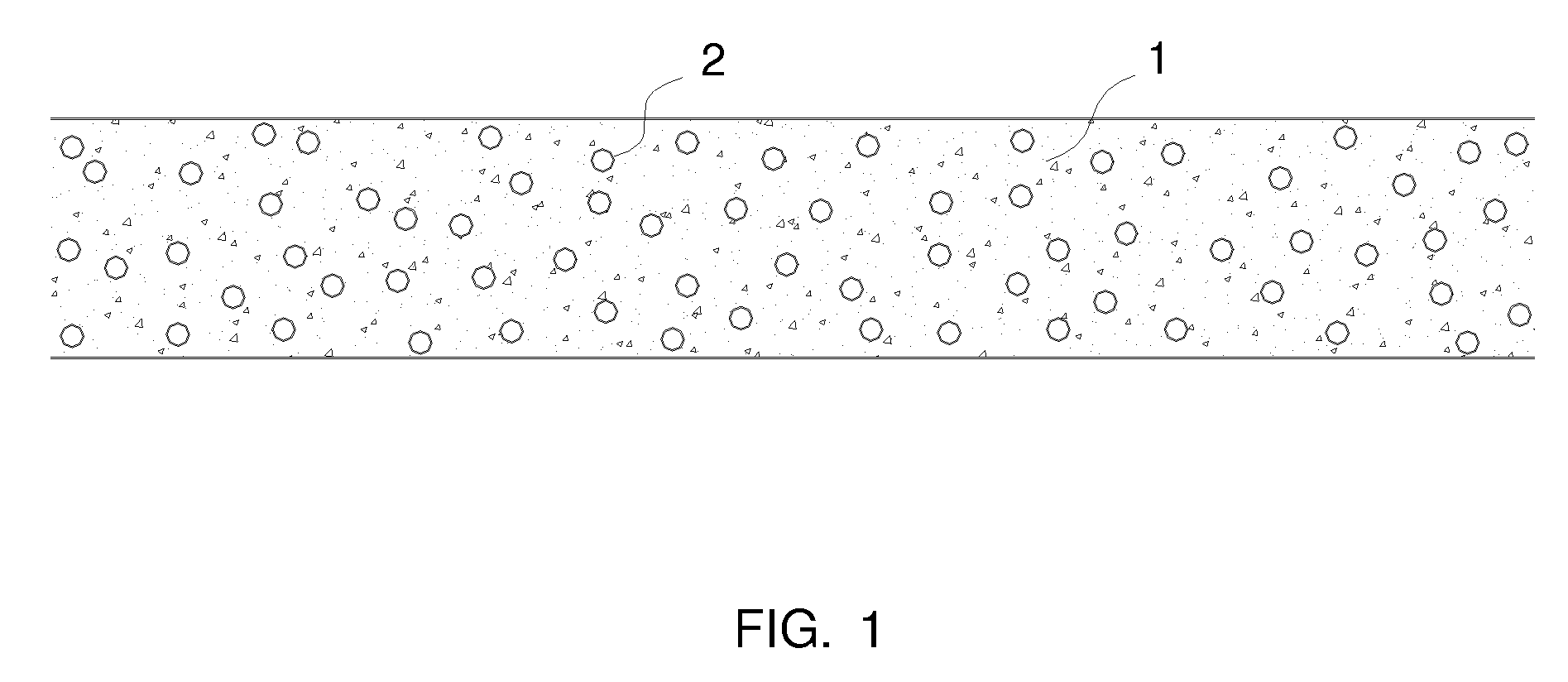

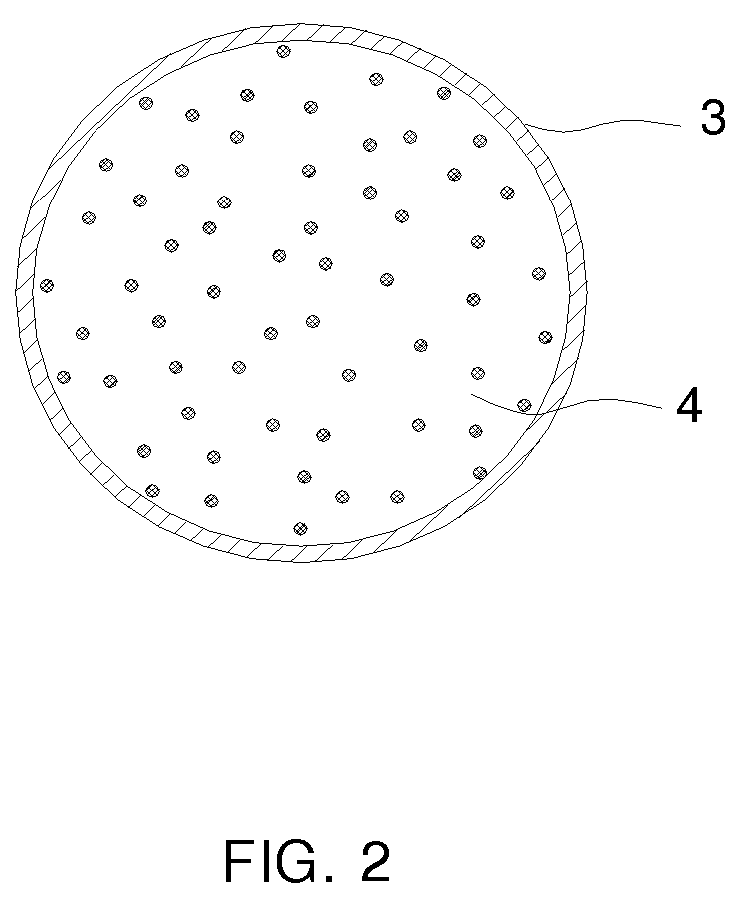

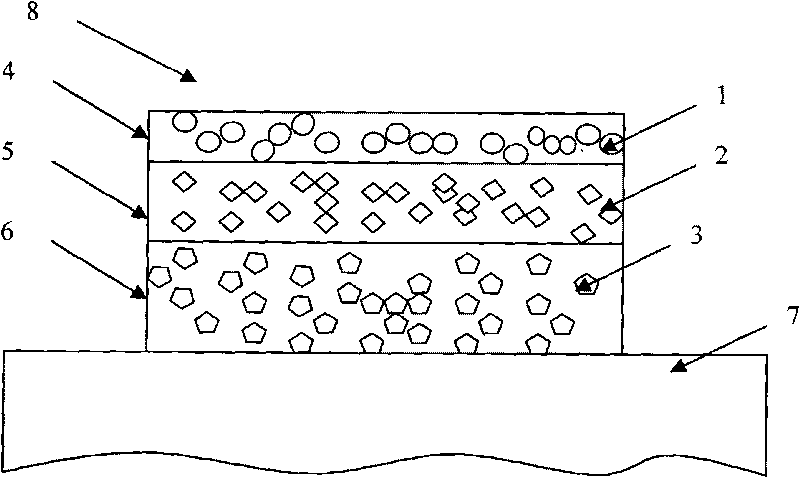

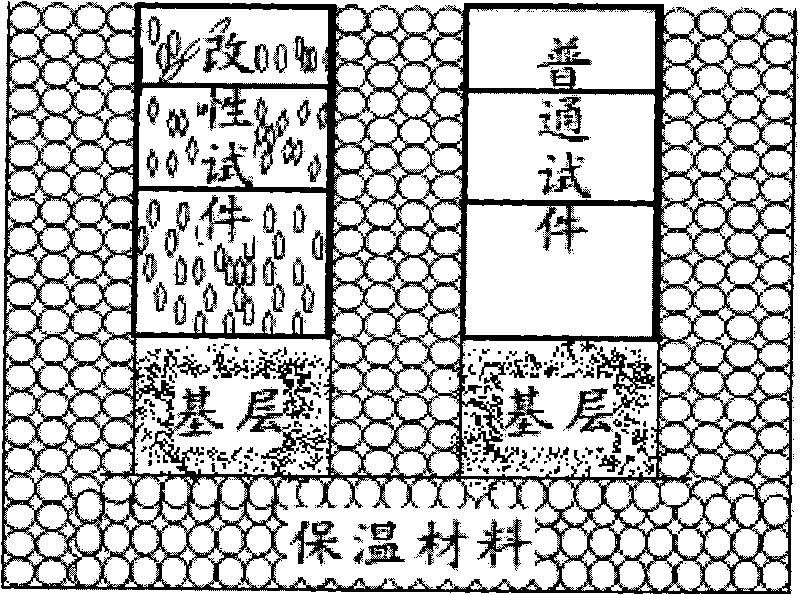

Asphalt pavement structure for alleviating urban heat island effect based on one-way heat conduction

InactiveCN101701443AEasy transferImprove bindingIn situ pavingsClimate change adaptationRoad surfaceEngineering

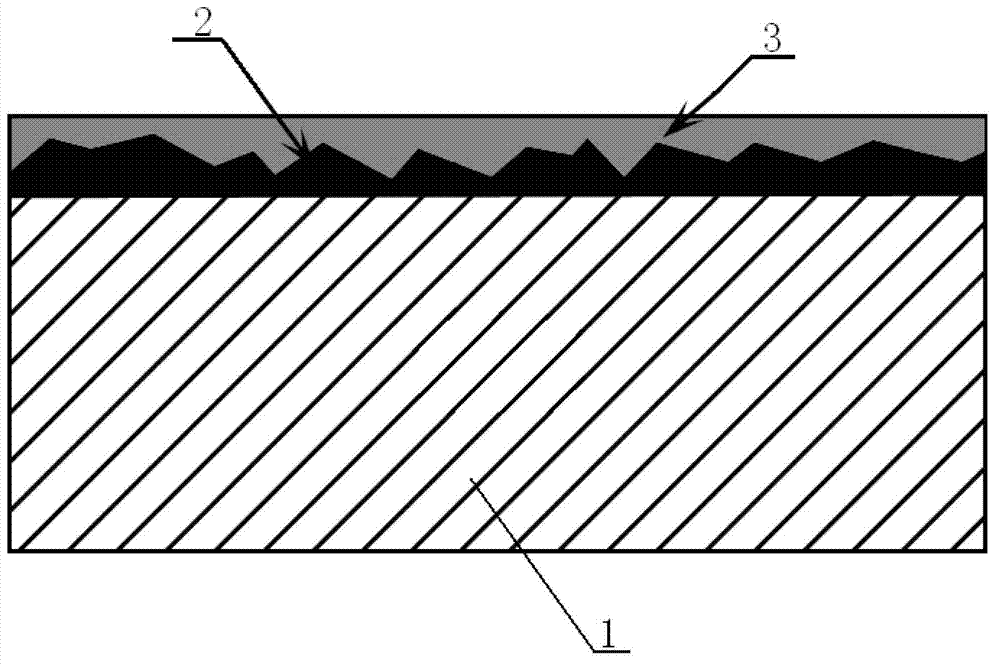

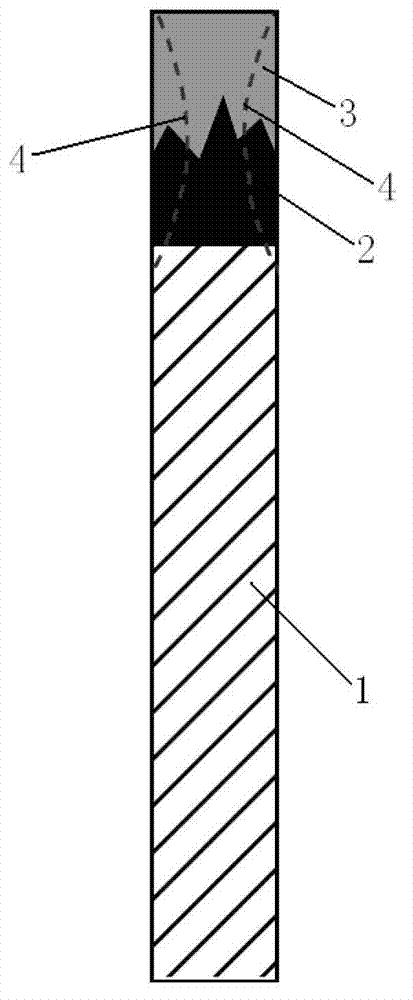

The invention relates to an asphalt pavement structure for alleviating urban heat island effect based on one-way heat conduction, in particular to the asphalt pavement structure which alleviates urban heat island effect by reducing the temperature of urban asphalt pavement. The pavement structure comprises two to multiple layers of structures, and is the pavement layer with a gradient thermal conductivity structure, wherein the thermal conductivity of the external layer is lower than that of the internal layer. The pavement layer has the gradient thermal conductivity structure, comprising an upper layer (4) modified by first micro-nanometer powder (1) with the thermal conductivity of 10 to 30 W / m*k, a middle layer (5) modified by second micro-nanometer powder (2) with the thermal conductivity of 50 to 90 W / m*k, and a lower layer (6) modified by third micro-nanometer powder (3) with the thermal conductivity of 100 to 140 W / m*k. The invention has the advantages of simple structure, convenient construction and low cost, and can be applied to the maintenance and the construction process of urban asphalt pavement to alleviate the urban heat island effect.

Owner:福建省金泉建设集团有限公司

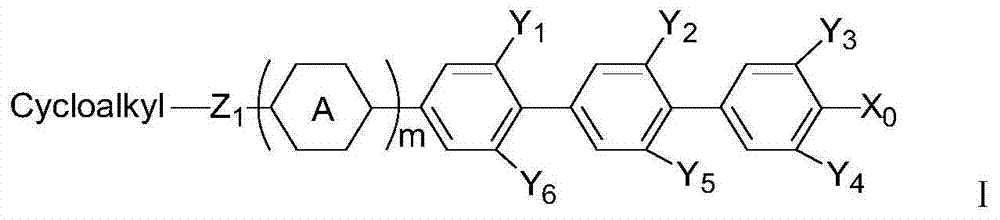

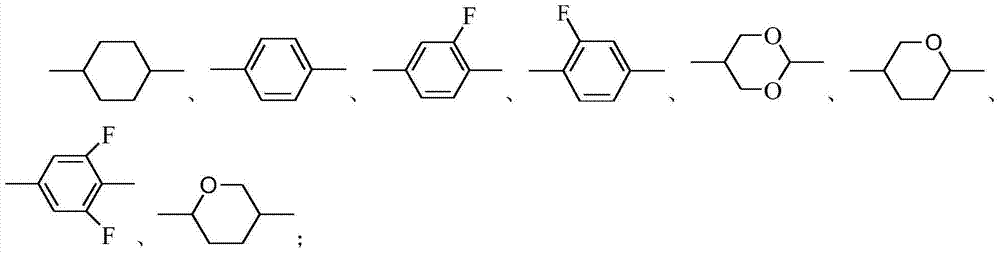

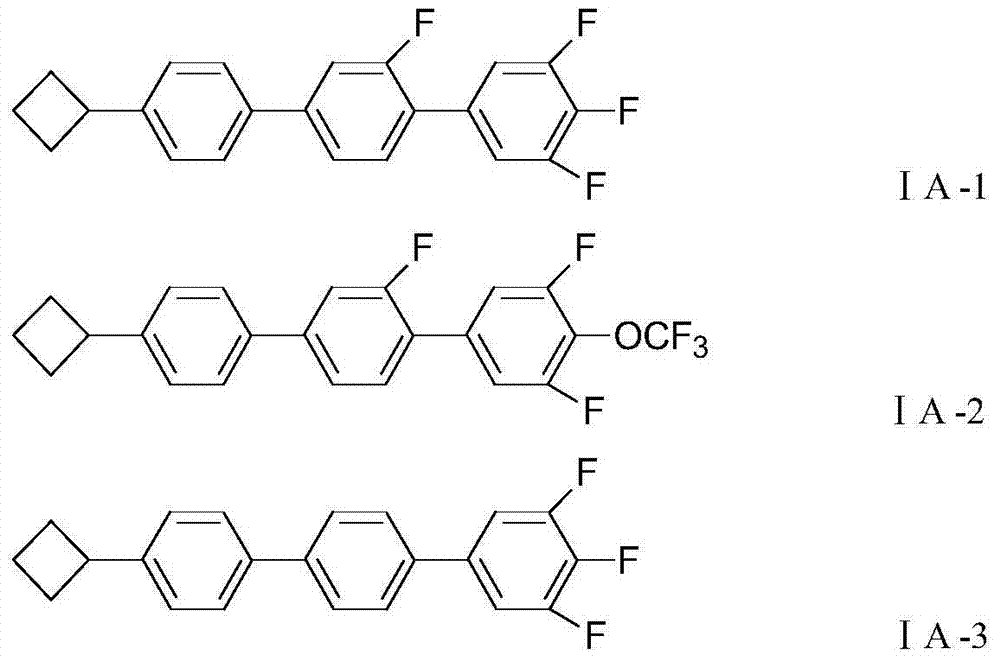

Liquid crystal medium containing triphenyl series compounds and application thereof

InactiveCN104513665AImprove performanceShort response timeLiquid crystal compositionsNon-linear opticsElectricityDielectric anisotropy

The invention relates to a liquid crystal medium containing a terphenyl compound and application thereof, and discloses a liquid crystal medium and application of the liquid crystal medium in liquid crystal display. The liquid crystal medium has positive dielectric anisotropy, and is characterized by containing one or more compounds represented by a structural formula (I) which is shown in the description. The liquid crystal medium provided by the invention is excellent in performance, has wide nematic phase temperature range, high reflective index anisotropy, extremely high electric charge retention rate and low rotary viscosity, can maintain high electric charge retention rate, low power consumption and the like, and has extremely high response speed. The composition disclosed by the invention has wide application prospect and application value in liquid crystal display, and is particularly suitable for manufacturing quick-response active matrix TN-TFT, IPS-TFT, FFS-TFT displays with great refractive index anisotropy.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

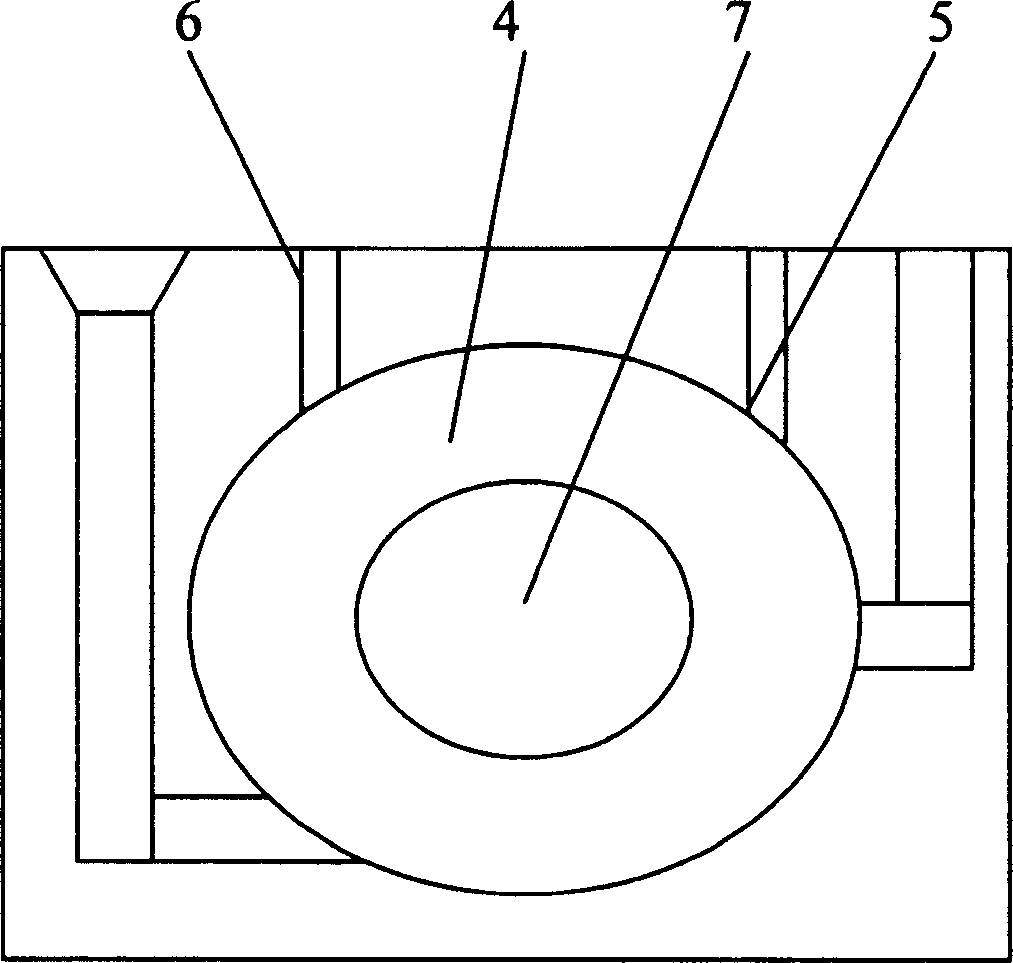

Self-circulation cooling automobile brake drum device

The invention discloses a self-circulation cooling automobile brake drum device, which is provided with a water cooling chamber and a water inlet and outlet channel on a brake drum, an inner ring is connected with the brake drum, the inner ring is sequentially provided with a bearing, a sealing ring, an annular impeller, a sealing ring, an annular impeller and a sealing ring bearing, and is sleeved with an outer ring, wherein the outer ring is provided with the water inlet and outlet channel, the end surfaces of the outer ring and the inner ring are provided with end covers, and the rotation directions of the two annular impellers are opposite. The cooling water of the self-circulation cooling automobile brake drum device can be recycled, and can not pollute the road, so the running safety of the automobile is ensured (i.e. the pollution of sprayed water on the road does not exist), high temperature generated when the automobile brake drum brakes is greatly reduced, and the water supply and drainage circulation of the cooling water in the brake drum is ensured.

Owner:李智

Nutritional breakfast and preparation method beneficial to calcium supplement and stomach nourishing of the elderly

The invention involves a nutritional breakfast beneficial to calcium supplement and stomach nourishing of the elderly. The raw materials include totally 30 food materials in six kinds of grain, beans, fruit, vegetables, nuts and fiber. The specific form is nutrition rice slice and fruit and vegetable particle. The invention also refers to the preparation of the nutritional breakfast beneficial to calcium supplement and stomach nourishing of the elderly. The described nutritional breakfast is of comprehensive nutrition easy to absorb and convenient to carry with and blew. The effect to replenish calcium and strengthen the bone is achieved by adding the rice, soybeans, red beans and red dates which are rich in calcium. The breakfast also has the effect of nourishing stomach, enhancing the heart, reinforcing the vitality and reducing the blood pressure and cholesterol by adding the millet, barley, pumpkin, oats, buckwheat, potato, carrot, lotus seed, banana, grapes, broccoli, pearl barley and gorgon fruit, etc.

Owner:湖南益百年健康科技有限公司

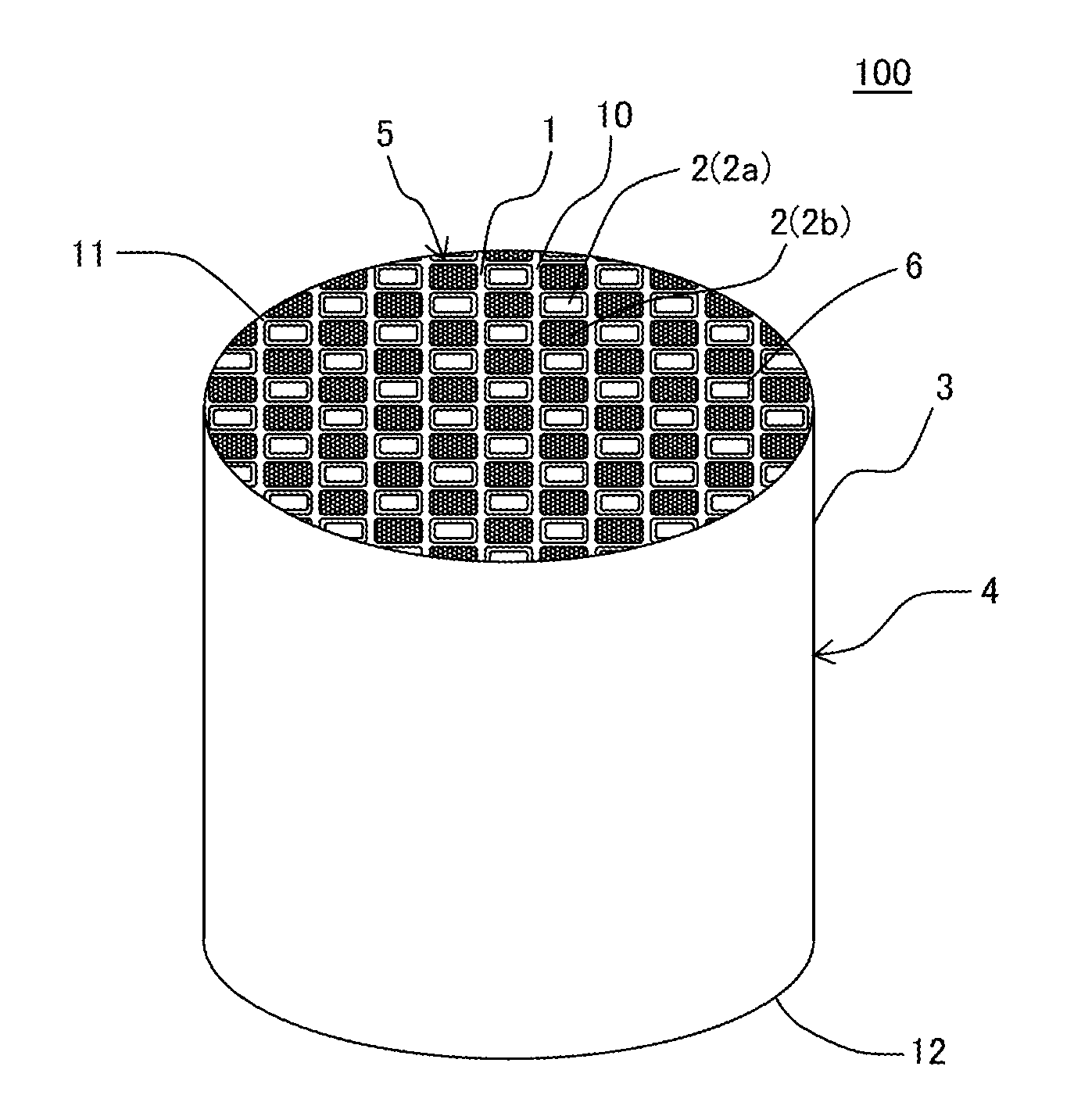

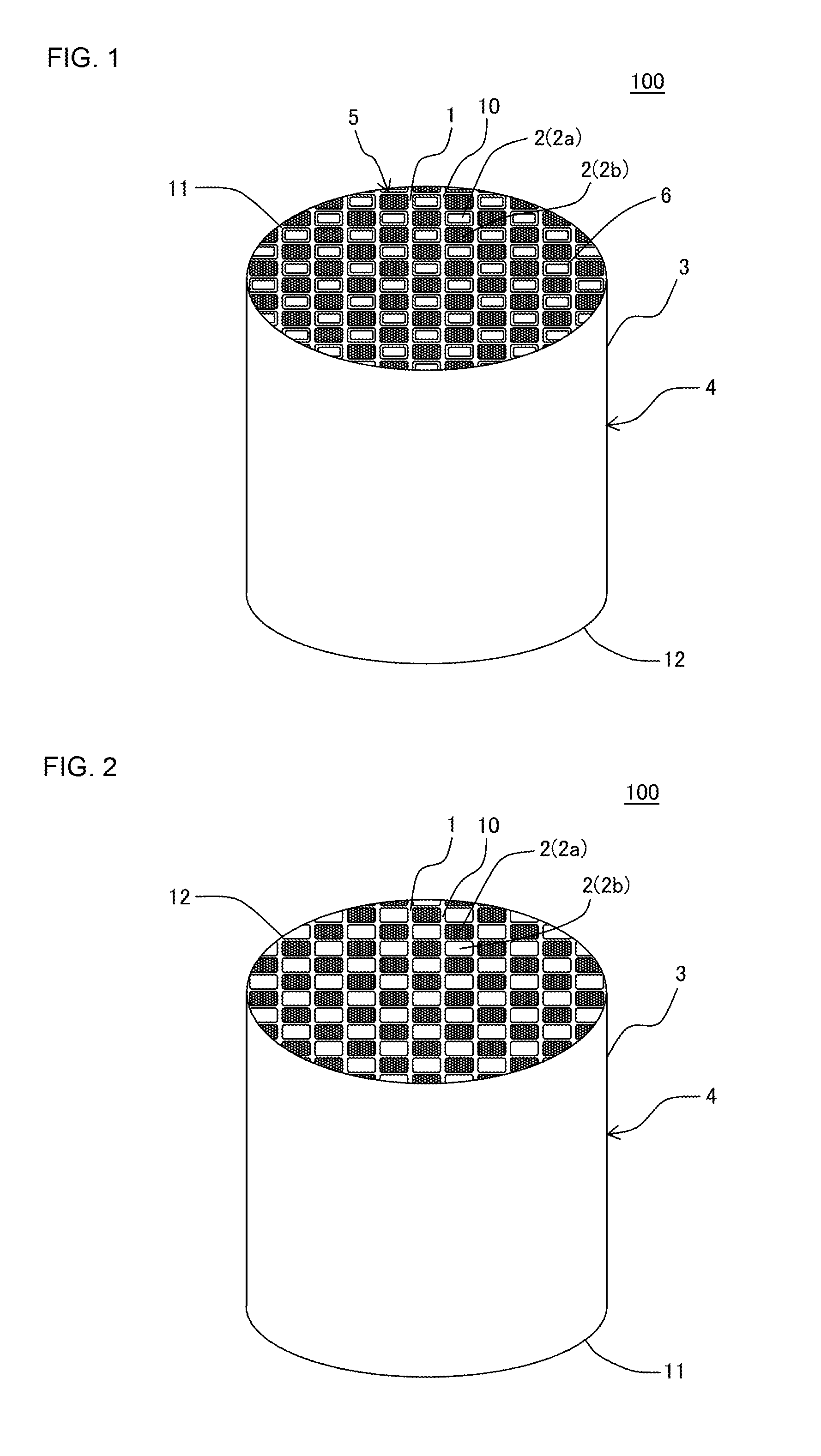

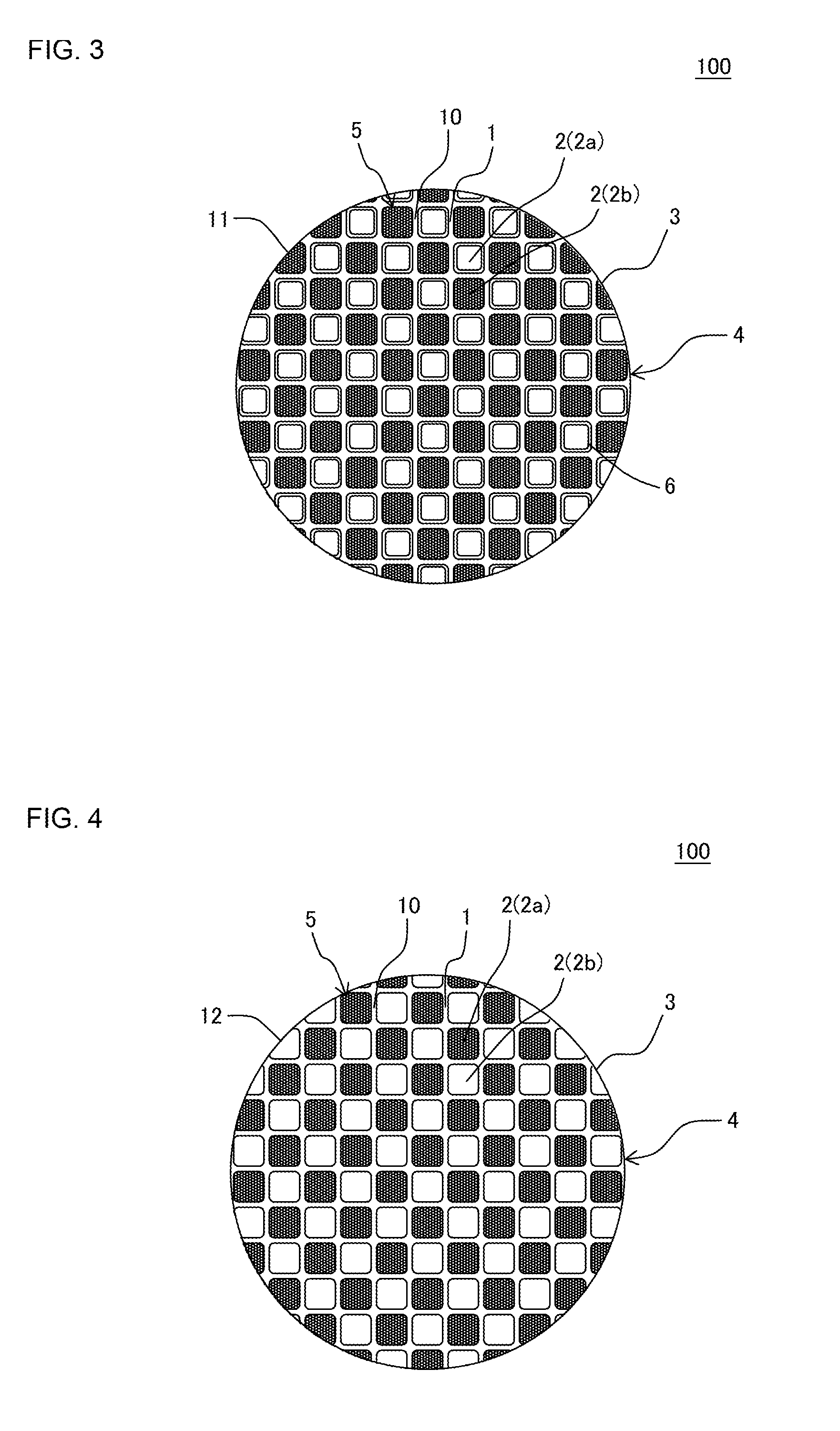

Plugged honeycomb structure and manufacturing method of the same

ActiveUS20150260067A1Increase heating capacityImprove thermal shock resistanceCombination devicesGas treatmentTrappingHoneycomb structure

There is disclosed a plugged honeycomb structure. A plugged honeycomb structure includes a tubular honeycomb structure body having partition walls including a porous partition wall base material defining a plurality of cells which become through channels for a fluid and extend from a first end face to a second end face, and a porous trapping layer disposed on the surface of the partition wall base material; and plugging portions disposed in open ends of predetermined cells in the first end face and open ends of residual cells in the second end face, and the partition wall base material is constituted of a porous body including α-Al2O3 as a main phase and further including aluminum titanate and glass.

Owner:NGK INSULATORS LTD

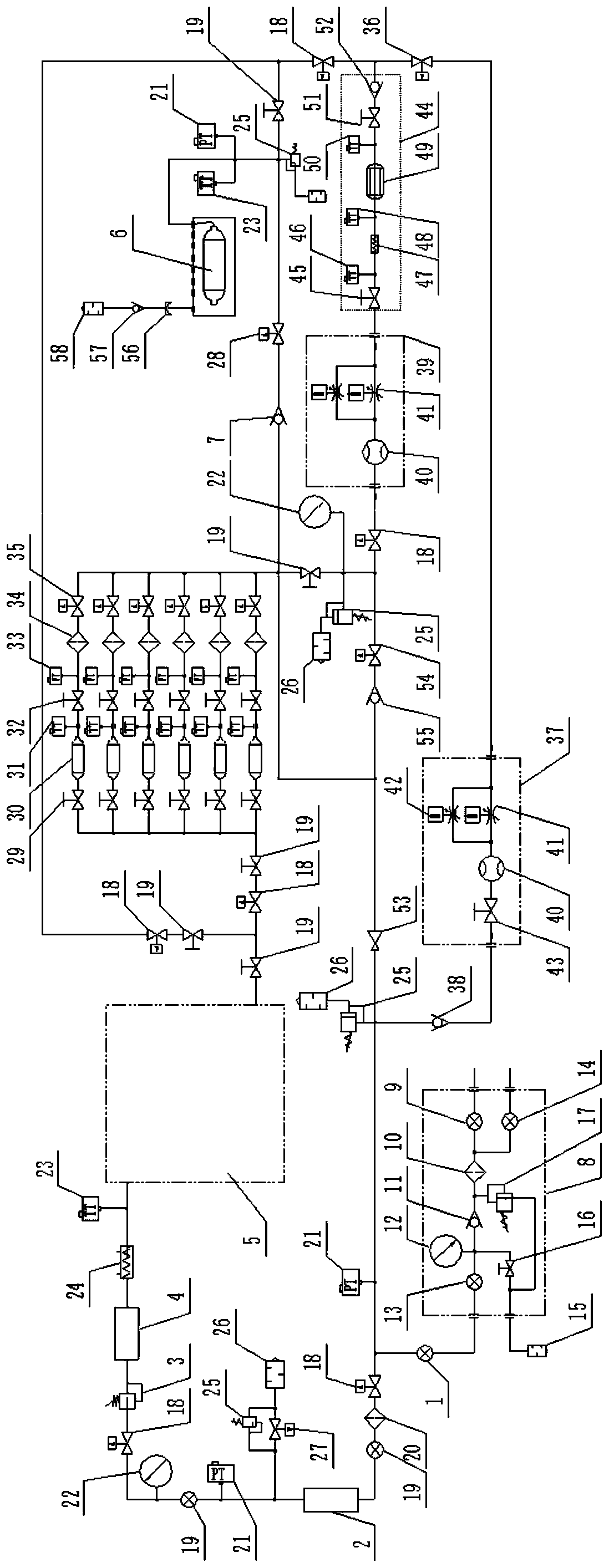

Ultrahigh pressure hydrogen pressure test system

PendingCN110702528AHigh test pressureImprove the efficiency of inflation experimentsMachine part testingMaterial strength using tensile/compressive forcesUltra high pressureGas cylinder

The invention discloses an ultrahigh pressure hydrogen pressure test system. The system comprises a hydrogen input port, wherein the hydrogen input port is connected with a gas inlet of a first gas cylinder group through a first pipeline provided with a first stop valve, a gas outlet of the first gas cylinder group is connected with a gas inlet of a second gas cylinder group through a second pipeline provided with a pressure reducing valve, a gas outlet of the second gas cylinder group is connected with a gas inlet of a 120MPa hydrogen compressor through a third pipeline, a gas outlet of the 120 MPa hydrogen compressor is connected with a gas inlet of a high pressure gas cylinder group through a fourth pipeline, a gas outlet of the high pressure gas cylinder group is connected with a hydrogen inlet and a hydrogen outlet of a test gas cylinder through a fifth pipeline, and the fifth pipeline is also connected with the first pipeline through a sixth pipeline provided with a fifth pneumatic ball valve and a second one-way valve. The ultrahigh pressure hydrogen pressure test system is high in test pressure, and adopts a combined pressurization mode of a diaphragm compressor and a high-pressure liquid-driven oil-free piston machine, and the pressurization pressure can reach 120MPa.

Owner:北京海德利森科技有限公司

Heat-dissipating device for a projection apparatus

InactiveUS7607781B2Reduce high temperatureImprove cooling effectLighting heating/cooling arrangementsProjectorsCombustorEngineering

A heat-dissipating device includes a receptacle body having a lateral wall formed with an air vent; a lamp unit including a burner, a reflector covered the burner, a glass plate disposed in front of the reflector, the reflector cooperating with the glass plate to define an air inlet adjacent to the air vent and an air outlet spaced from the air vent; a fan unit mounted on the receptacle body for covering the air vent and for generating airflow to flow into the receptacle body; and a nozzle disposed within the receptacle body between the air vent and the lamp unit for guiding the airflow into the lamp unit.

Owner:YOUNG OPTICS

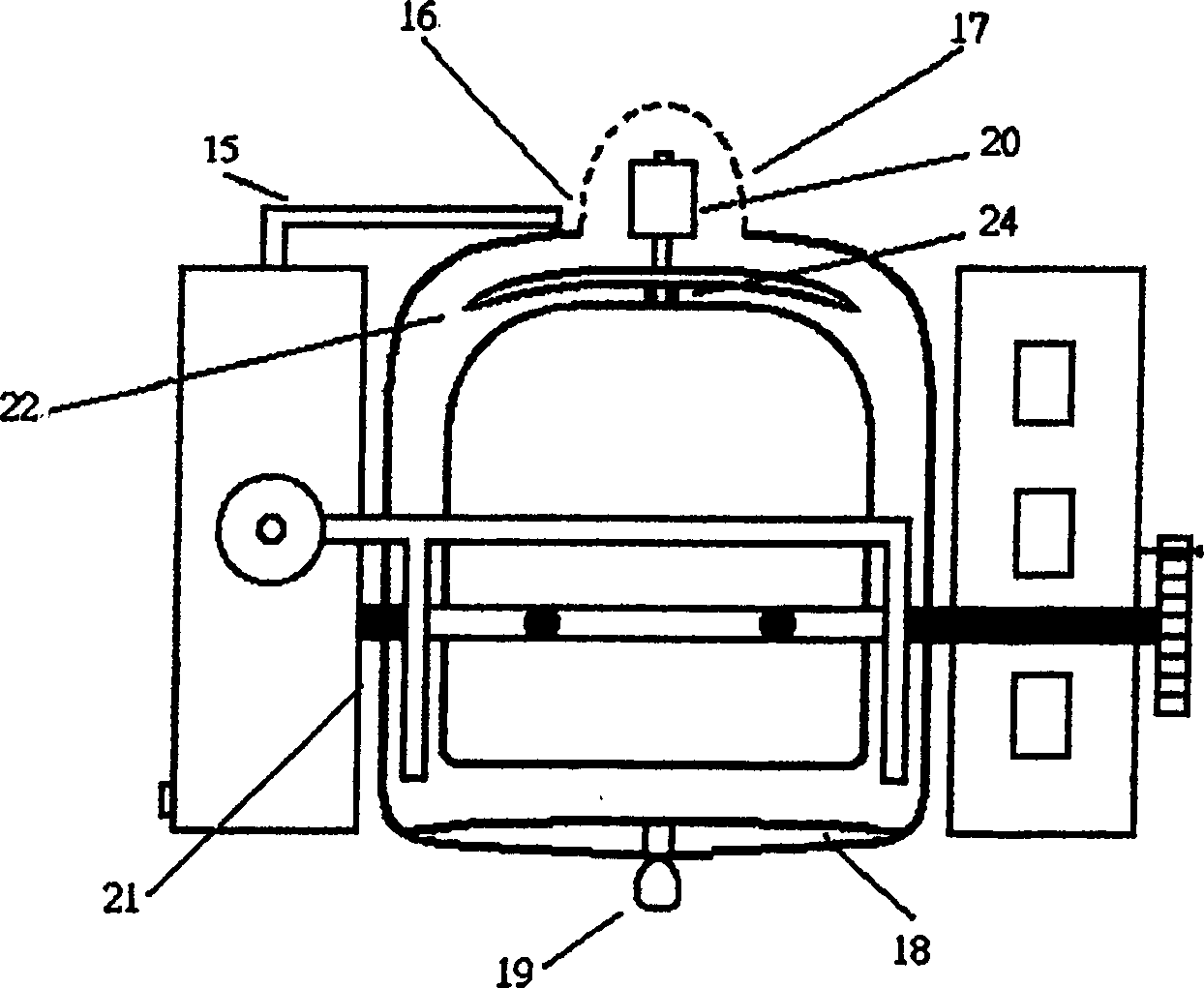

Automatic cooker

InactiveCN1426720AReduce high temperatureTo achieve the purpose of automatic cookingDomestic stoves or rangesLighting and heating apparatusAutomatic controlEngineering

An automatic electric cooker is composed of a semi-spherical hollow pot body able to rotate in both latitudinal and longitudinal directions under drive of a motor, a stirrer in the pot, an electric heater, a casing for containing the pot body and the electric heater, an automatic controller, and a soot exhauster.

Owner:苏福生

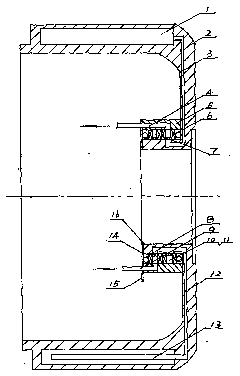

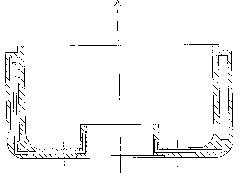

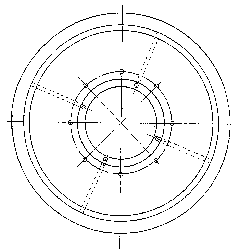

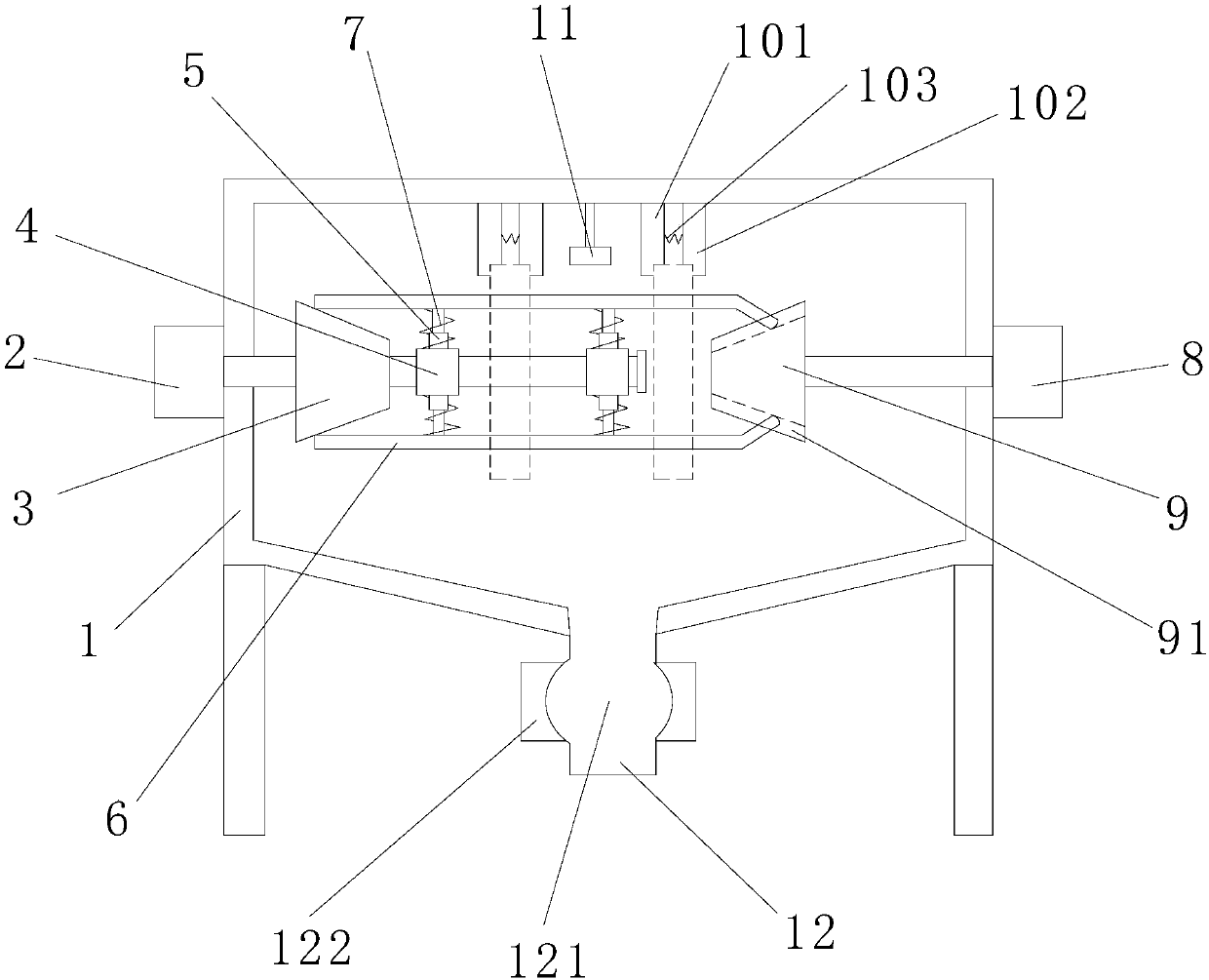

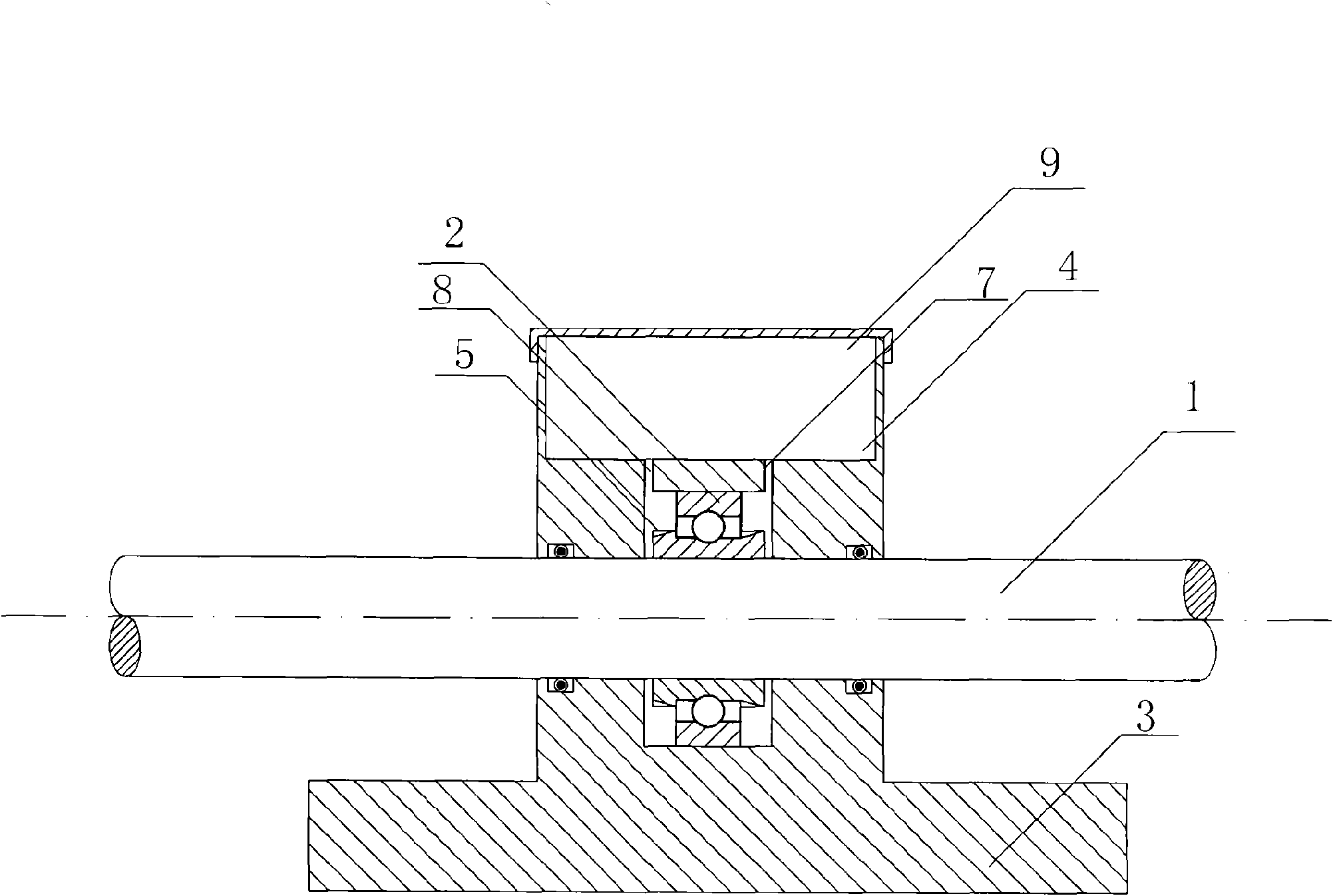

Bearing outer ring grinding equipment

PendingCN108098469AEfficient grindingImprove grinding efficiencyRevolution surface grinding machinesGrinding work supportsEngineeringWater spray

The invention discloses bearing outer ring grinding equipment. The bearing outer ring grinding equipment comprises a hood, a motor, a stop block, shaft sleeves, telescopic rods, supporting rods, springs, an air cylinder, an expanding block, a grinding device, a water spraying sprayer and a water drainage pipe. The motor is fixedly arranged at the left side portion of the hood. A rotation shaft ofthe motor stretches into the hood. The stop block is fixedly arranged on the rotation shaft of the motor. The stop block and the rotation shaft of the motor are coaxially arranged. The part, located on the right side of the stop block, of the rotation shaft of the motor is sleeved with the multiple shaft sleeves in a sliding manner. The multiple telescopic rods arranged in a balanced manner are fixedly arranged on the side face of each shaft sleeve in the radial direction. The multiple supporting rods are arranged around the rotation shaft of the motor. The supporting rods are parallel to therotation shaft of the motor. The side portions of the supporting rods are fixedly connected with the end portions of the telescopic rods. Compared with the prior art, bearing outer rings can be efficiently and rapidly ground, the bearing outer ring grinding efficiency and effect are improved, the high temperature generated in the grinding process is reduced, and scrap iron is effectively preventedfrom polluting the machining environment.

Owner:XINCHANG SANYUAN BEARING CO LTD

Low-temperature propellant storage tank with pressure control device

ActiveCN107726040AImprove heat transfer efficiencyReduce heat leakageContainer filling methodsFluid handledInsulation layerExhaust valve

The invention discloses a low-temperature propellant storage tank with a pressure control device. The low-temperature propellant storage tank comprises a low-temperature propellant storage tank body,a low-temperature circulation pump, a throttling valve, an expansion machine, a double-pipe heat exchanger, an exhaust cooling coil and an exhaust valve. In order to improve the heat exchange efficiency of the heat exchanger, the reverse-flow double-pipe heat exchanger is adopted, and more cooling capacity can be generated. Meanwhile, fluid passing through the throttling valve absorbs heat and becomes saturated gas or superheated gas which is expanded and cooled through the expansion machine after being discharged out of the tank body, the low-temperature gas forms a cold shield through the cooling coil wound in an insulation layer outside the tank body, external leakage is reduced to the greatest extent, and the exhaust cooling capacity is fully used. The low-temperature propellant storage tank is simple in structure and high in heat exchange efficiency, the cooling capacity is fully used, the tank body pressure is effectively controlled, and effective guarantee is provided for long-term storage of a low-temperature propellant and the tank body pressure.

Owner:CHINA UNIV OF MINING & TECH

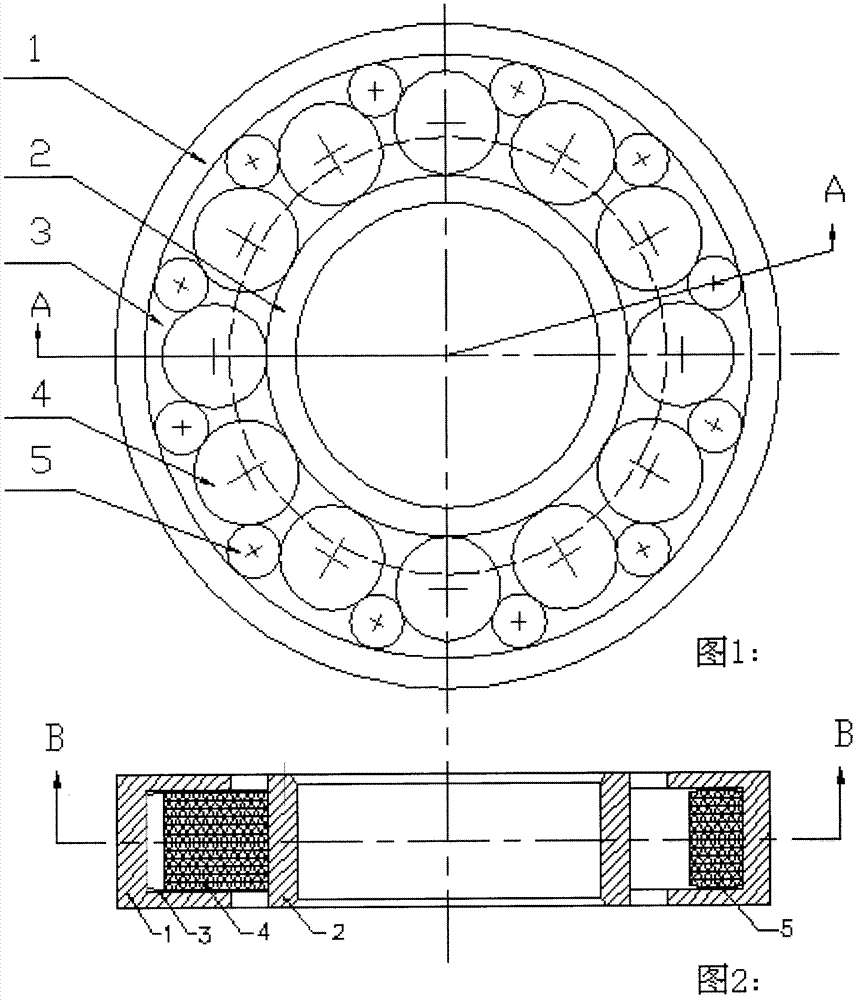

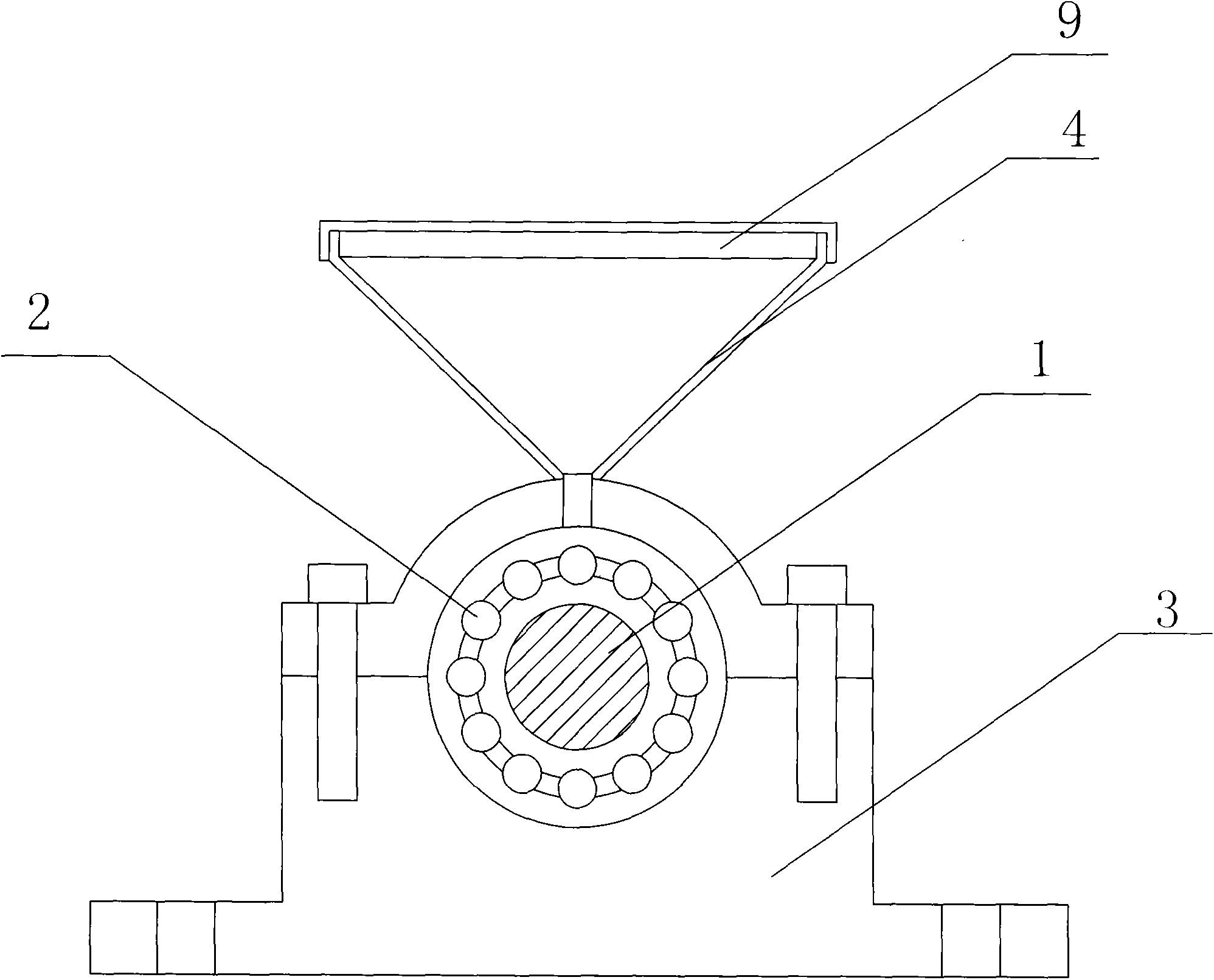

Planetary rolling bearing

InactiveCN103195804AReduce collision frictionReduce high temperatureRolling contact bearingsBearing componentsEngineeringMechanical engineering

Owner:CHANGZHOU DONGFENG BEARING

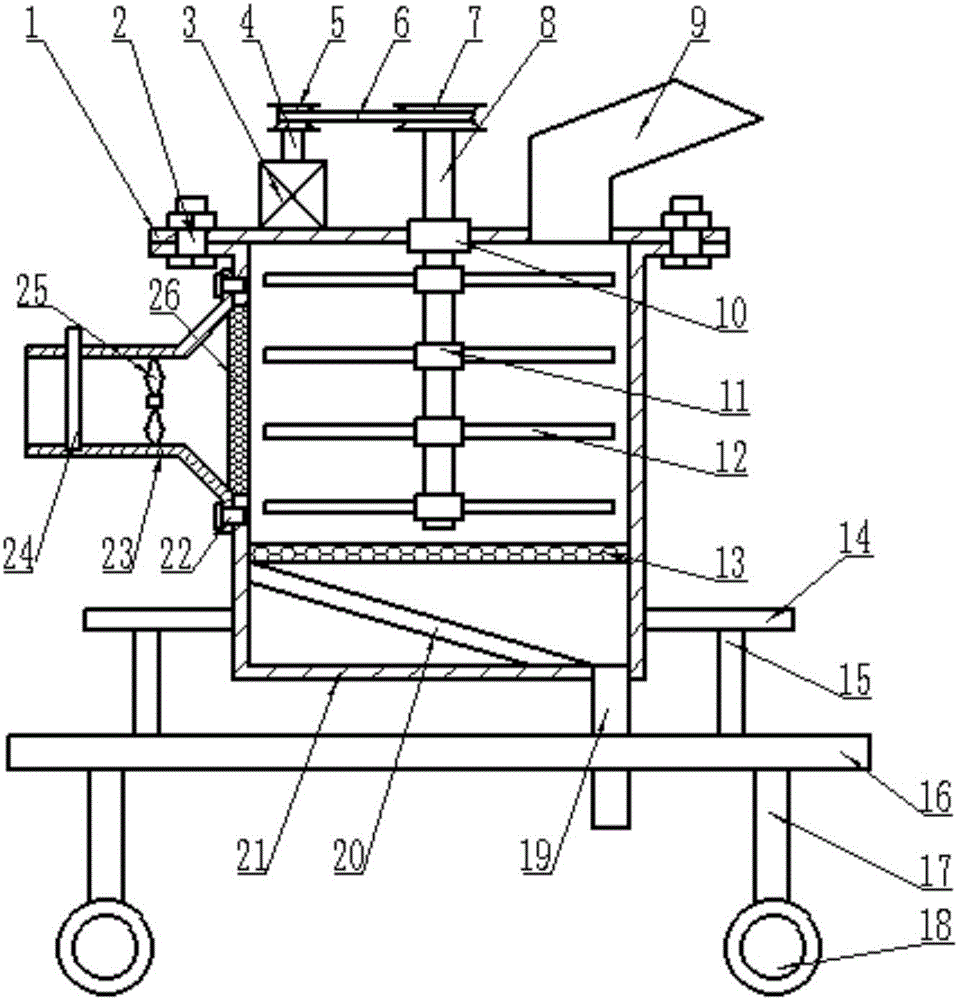

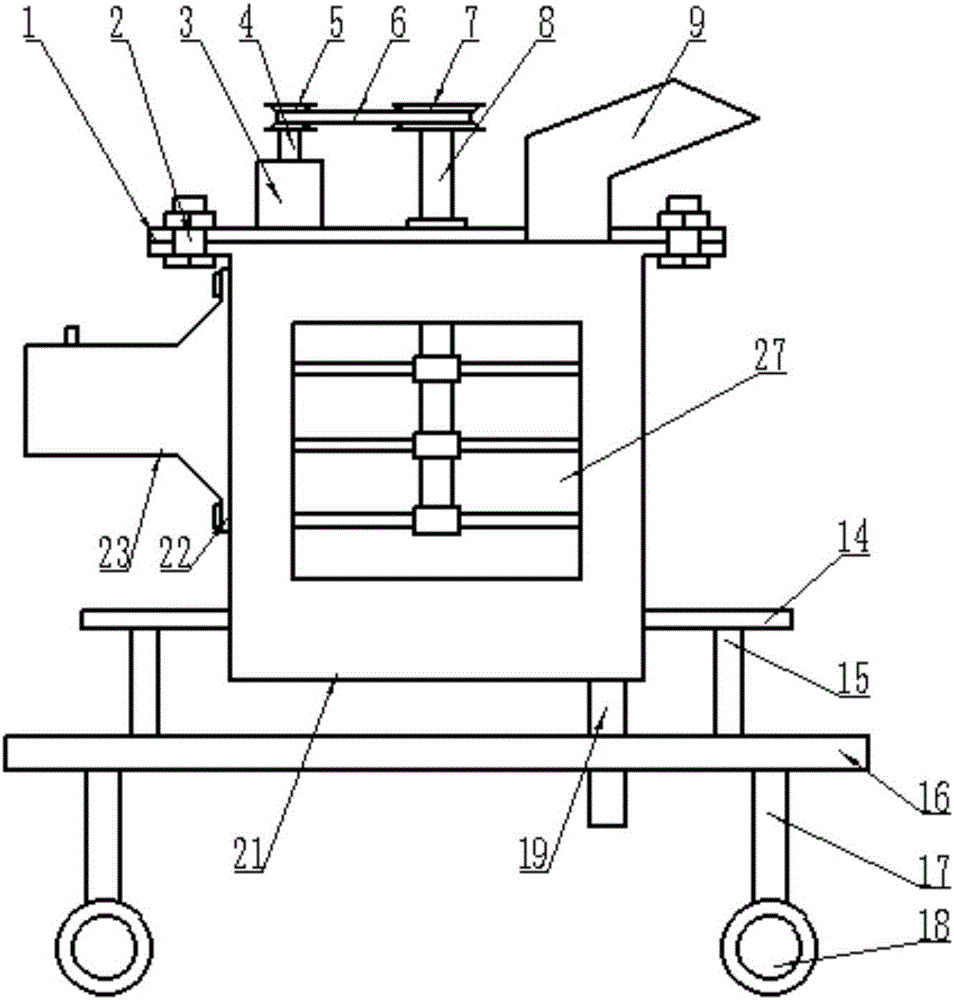

Movable heat-dissipation type medicinal material pulverizing device

InactiveCN106622609AImprove crushing effectReduce high temperatureGrain treatmentsAgricultural engineeringElectric machinery

The invention provides a movable heat-dissipation type medicinal material pulverizing device. The movable heat-dissipation type medicinal material pulverizing device comprises a movable pulverizing and discharging device and a heat-dissipation device, wherein the movable pulverizing and discharging device comprises a motor, pulverizing blades, wheels and a pulverizing box; the wheels are fixedly arranged on wheel supports; the pulverizing box is welded to left and right side surfaces of two fixing plates; the motor is fixedly arranged on the left side of the upper part of a cover plate; the pulverizing blades are fixedly arranged on two sides of each fixing sleeve; the heat-dissipation device comprises a heat-dissipation box, a sponge, a heat-dissipation fan and a net-shaped baffle; the net-shaped baffle is welded to the right side of the heat-dissipation box; the heat-dissipation box is fixedly arranged on the left side surface of the pulverizing box by screws; the heat-dissipation fan is fixedly arranged in the heat-dissipation box; and the sponge is arranged on the left side of the heat-dissipation box. By the device, the medicinal material pulverizing effect is improved, the heat-dissipation performance is good, heat caused by friction between the pulverizing blades and the medicinal materials is avoided, and the property of the medicinal materials is guaranteed. Meanwhile, the movable heat-dissipation type medicinal material pulverizing device moves conveniently.

Owner:HENAN BALING ELECTRONICS TECH CO LTD

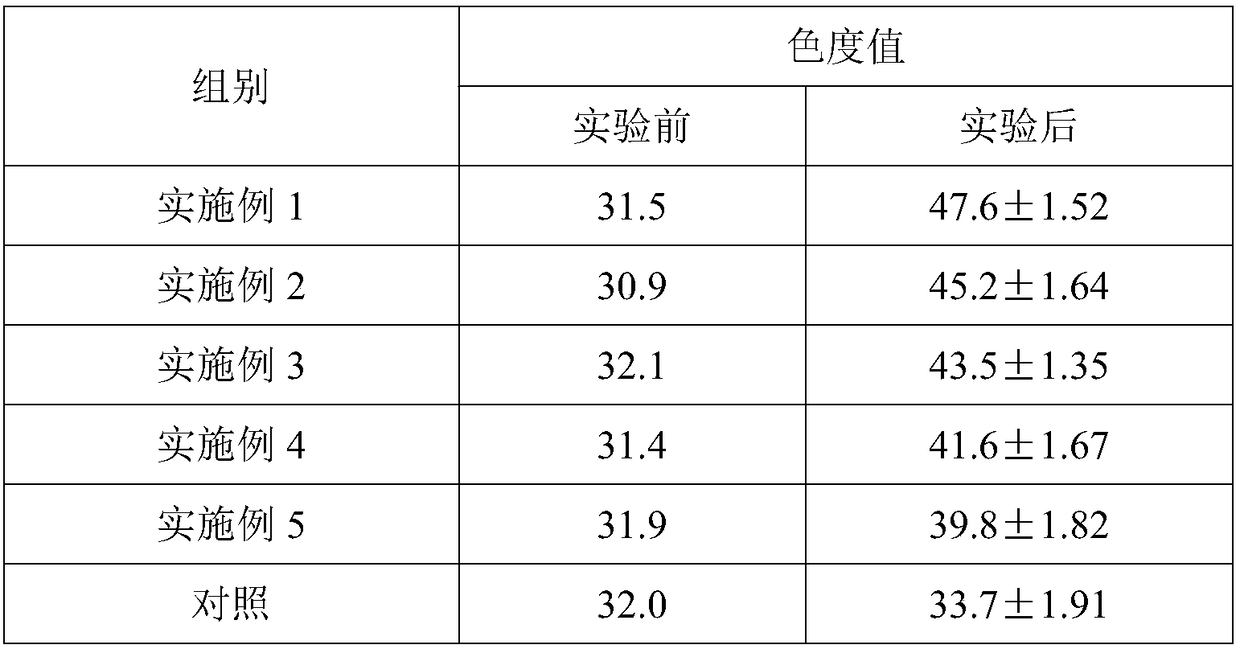

Color enhancing feed for leopard coral groupers, and preparation method of color enhancing feed

ActiveCN108185117AImprove body colorSolve the color is easy to fadeFood processingClimate change adaptationBetaineLeopard

The invention discloses a color enhancing feed for leopard coral groupers, and a preparation method of the color enhancing feed. The feed is prepared from the following components in percentage by mass: 5-30% of natural krill powder, 20-60% of white fish meal, 3-10% of yeast, 10-30% of artemia, 5-15% of turmbicula akamushi, 5-16% of hydrolyzed protein, 10-30% of high gluten flour, 5-20% of squid powder, 5-15% of spirulina, 1-5% of fish oil, 1-3% of lecithin, 1-3% of betaine, 1-2% of a vitamin mixture, 2-4% of a mineral element mixture, 1-5% of a microorganism preparation, 1-3% of a compound immunity reinforcing agent, 1-5% of copepods, 1-3% of casein, 1-3% of EPA, 1-5% of DHA, 1-5% of ARA, and 1-2% of a phagostimulant. The feed disclosed by the invention can effectively improve body color,and the problems that color is gloomy, color enhancement is difficult, and the color is liable to be light and not liable to recover under stress state are solved. Besides, according to the preparation technology, the digestibility and the absorbability of the feed are improved, nutrient elements are not destroyed, and the freshness and the food calling properties of the feed are guaranteed.

Owner:广东越群海洋生物科技股份有限公司

Lubricating device of bearing

InactiveCN101672420AEnsure adequate lubricationReduce high temperatureBearing componentsEngine lubricationOil canFriction reduction

The invention discloses a lubricating device of a bearing which comprises an axle, a bearing, a bearing block and an oil tank, wherein the bearing is arranged on the axle; the lubricating device is characterized in that at least one side of the bearing is provided with an oil suction device along the axle direction; the bearing block is provided with an oil inlet and an oil outlet at one side of the axle provided with a worm gear and at the opposite side respectively; the oil inlet and the oil outlet are respectively connected with the oil tank by an oil pipe; the lubricating device has the advantages that lubricant can be continuously supplied and added again without dismantling an assembled bearing, thus being convenient, saving time, increasing production efficiency and guaranteeing thebearing to be fully lubricated; simultaneously by the rotation of the worm gear, oil can circulate in the whole device, enter the oil tank from an oil inlet pipe and return to the oil tank again froman oil outlet pipe; heat generated by the oil that the oil tank gives off is utilized for reducing high temperature caused by high-speed rotation of the axle, thus reducing friction and prolonging the service life of the axle; moreover the lubricating device has simple structure, convenient operation and is particularly applicable to devices with large bearings.

Owner:海门嘉濠建材贸易有限公司

Method for casting hollow mould

InactiveCN1748901AReduce possessionLow gas productionFoundry mouldsFoundry coresCasting moldCarbon steel

The casting method with hollow mold is an improved solid mold casting method, which has reduced carbon generation, improved carbon exhaust and reduced recarburization of casting by means of one or several measures of improving casting mold, exhausting gas to reduce pressure and setting reasonable casting system.

Owner:蒋斌沅

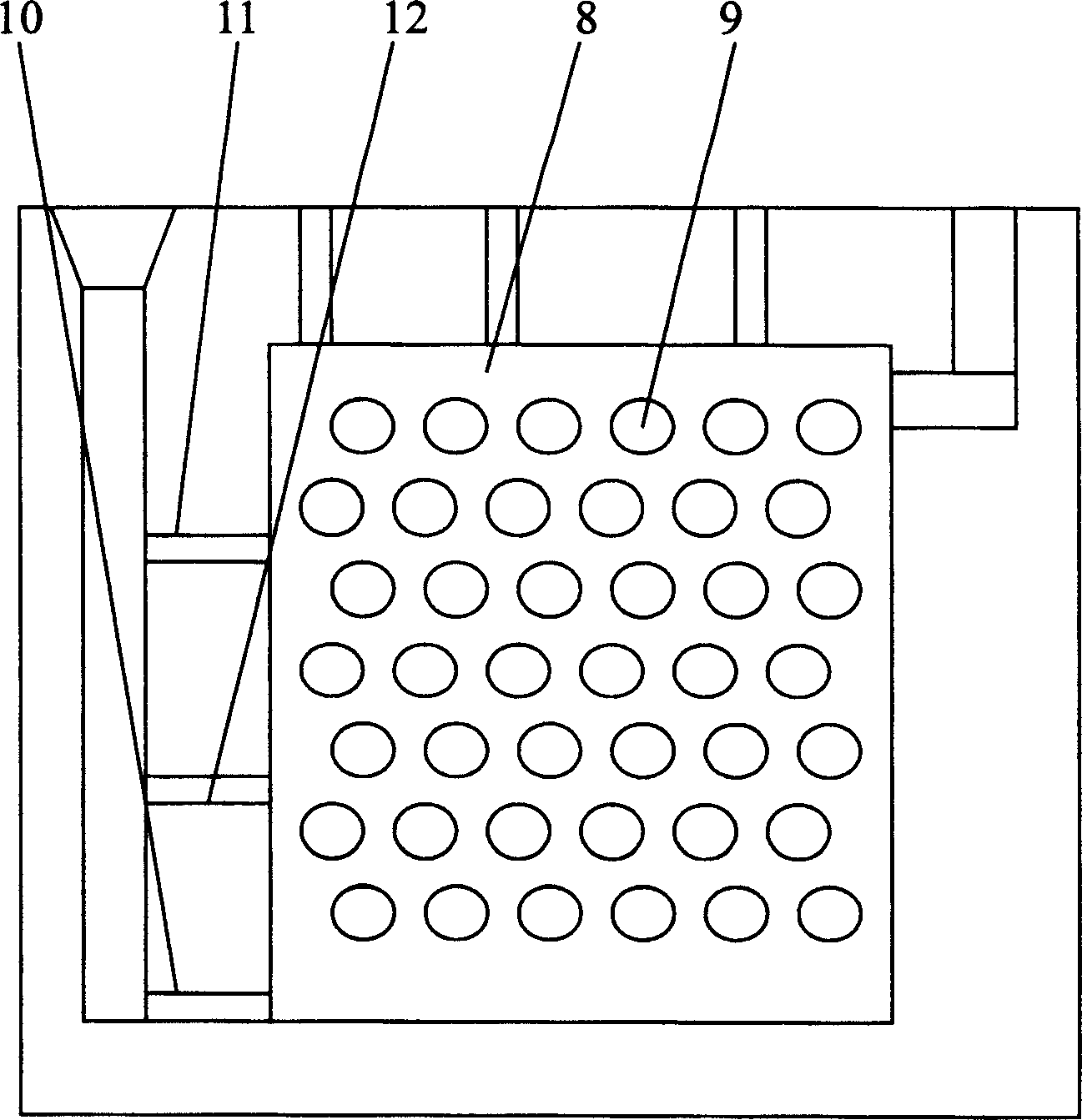

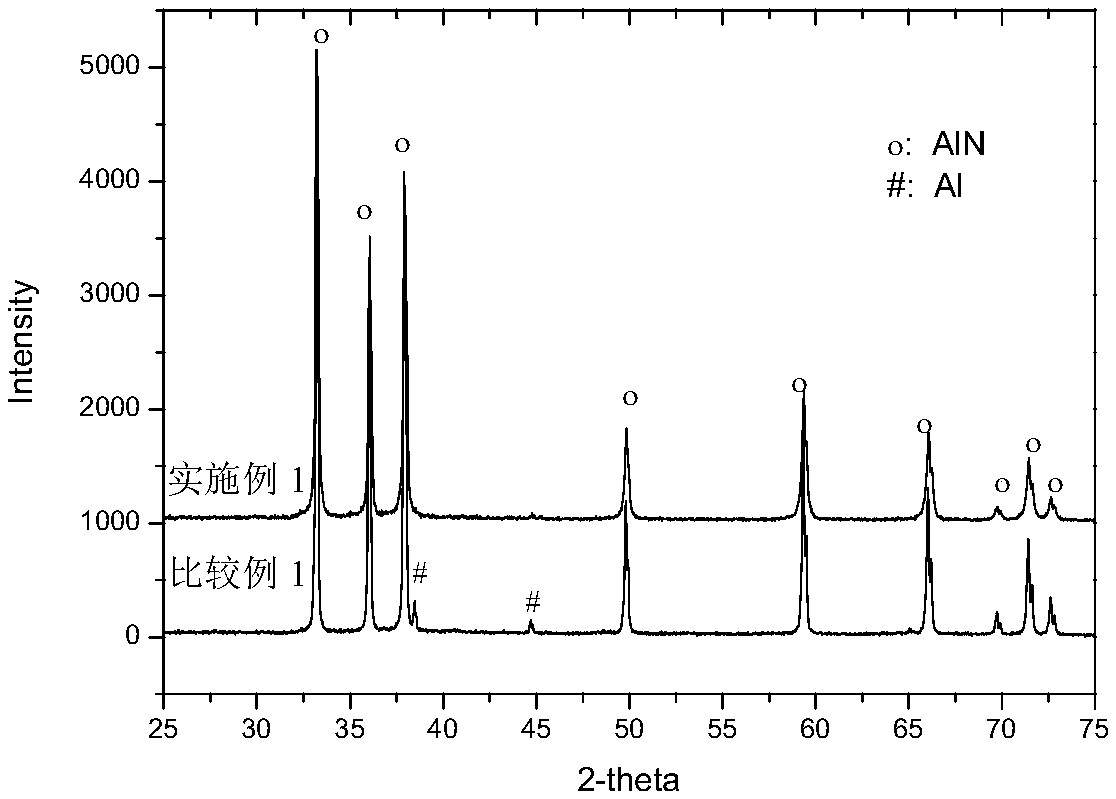

Preparation method for AlN powder

The invention relates to the technical field of powder preparation and particularly relates to a preparation method for homogeneous and high-purity AlN powder. In the process of compounding the AlN powder by nitrifying aluminum powder, less high-purity argon is introduced and the compounding temperature is reduced under the condition of guaranteeing complete nitrification, so that the compounded AlN powder is homogeneous and easy to smash. The AlN powder prepared by the method is capable of shortening the smashing time of the subsequent process and reducing the impurities introduced into the smashing medium, so that the high purity of the milled AlN powder is guaranteed. Compared with a common technology, the preparation method has the advantages that the smashing time is shortened by about 30% under the condition of same grain size and the oxygen content is reduced by about 0.2%.

Owner:SHANGHAI TOYO TANSO

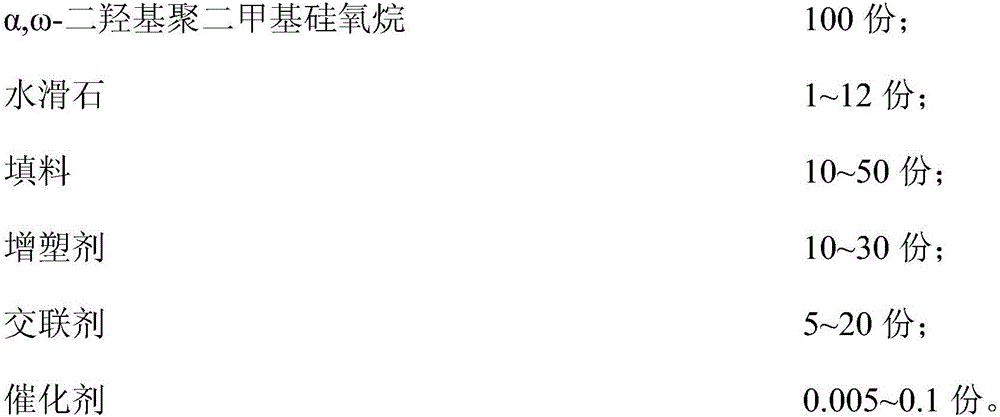

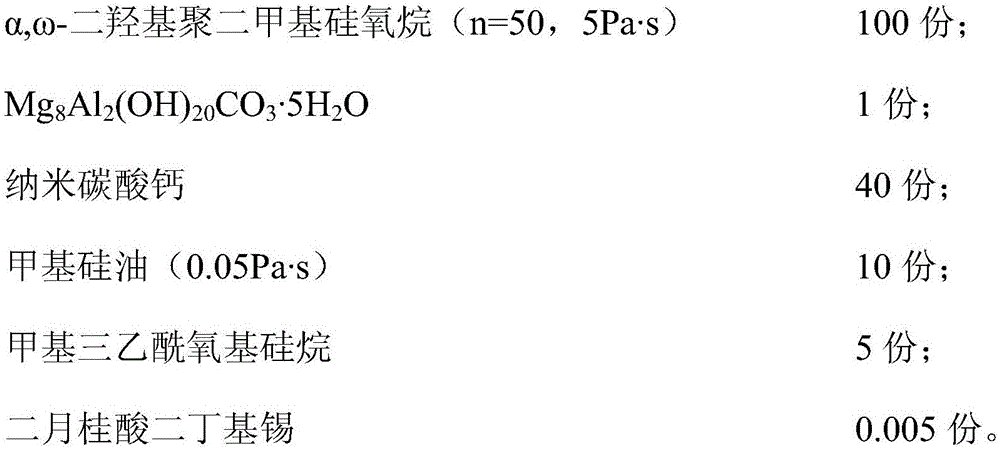

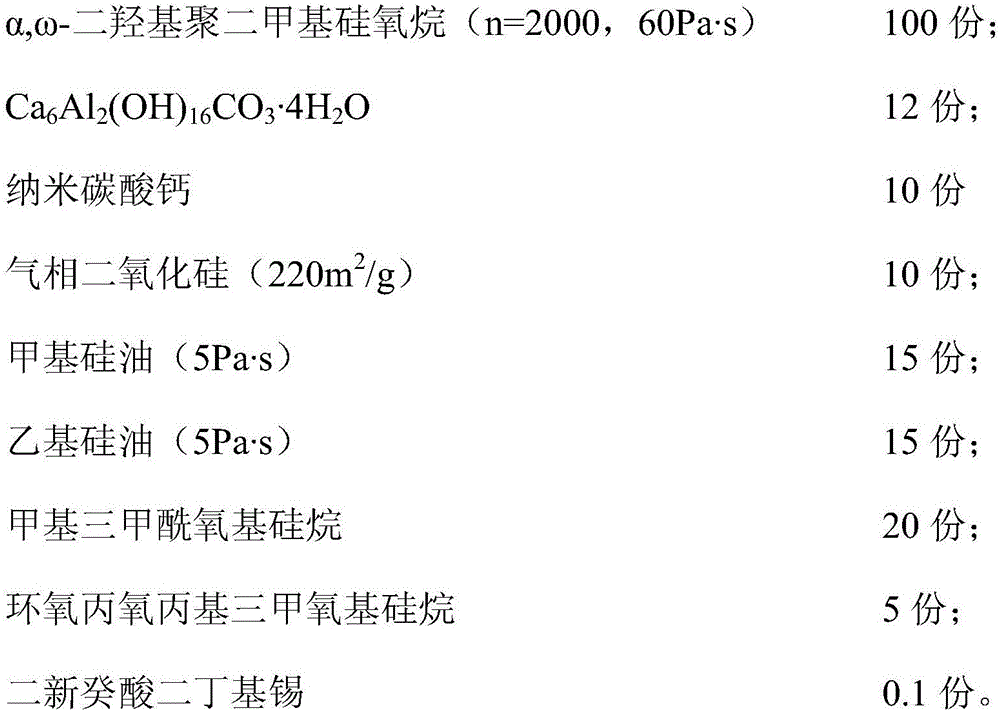

Deacidification type organic silicone adhesive and preparation method thereof

ActiveCN106753203AReduce concentrationBarrier and flame retardantNon-macromolecular adhesive additivesPlasticizerHydrotalcite

The invention relates to a deacidification type organic silicone adhesive and a preparation method thereof. The raw materials of the deacidification type organic silicone adhesive comprise alpha, omega-dihydroxydimethylpolysiloxane, hydrotalcite, filler, a plasticizer, a crosslinking agent and a catalyst, the deacidification type organic silicone adhesive has excellent adhesion and low corrosion to adhered materials, the volatile matters of the used raw materials are few, and meanwhile the deacidification type organic silicone adhesive also has efficient, environmental-friendly, nontoxic and halogen-free flame retardant properties..

Owner:GUANGZHOU BAIYUN CHEM IND

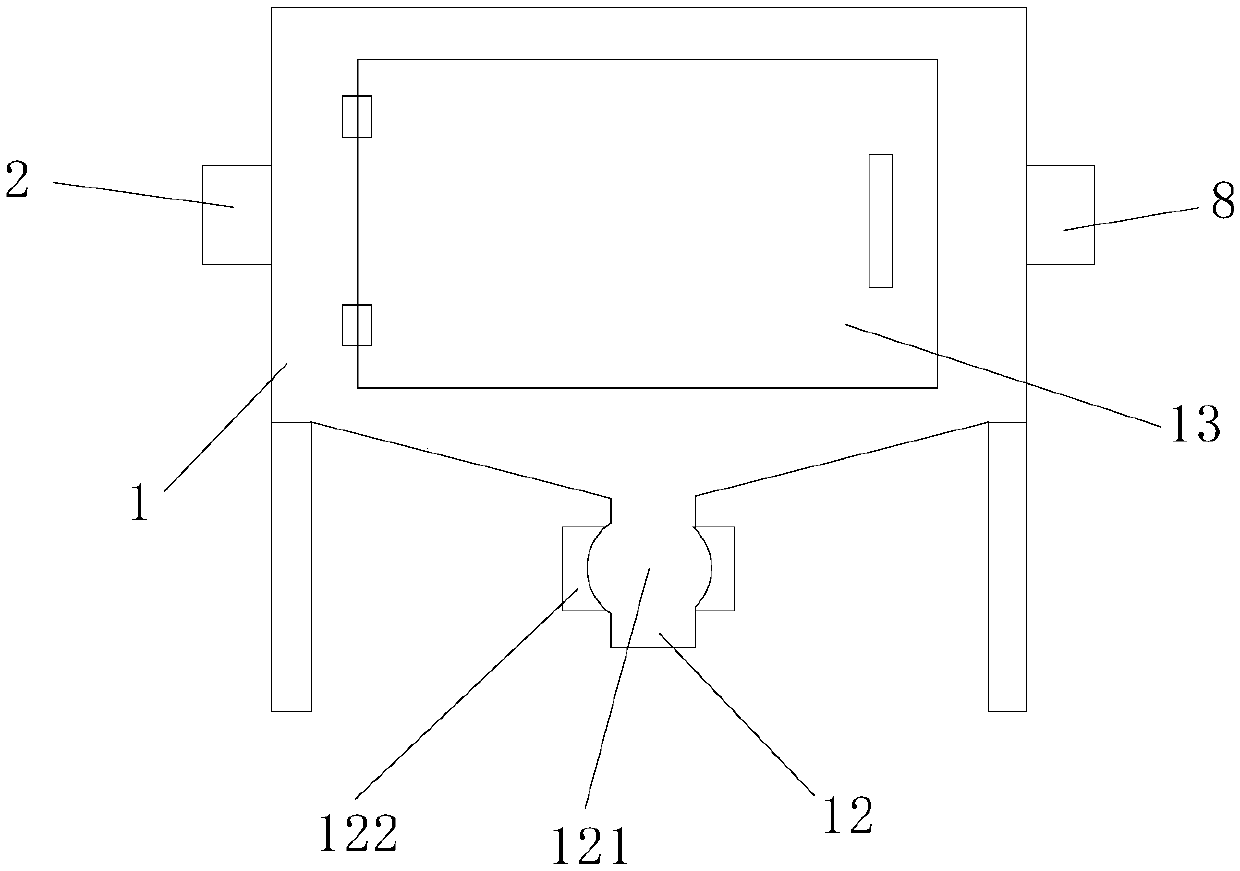

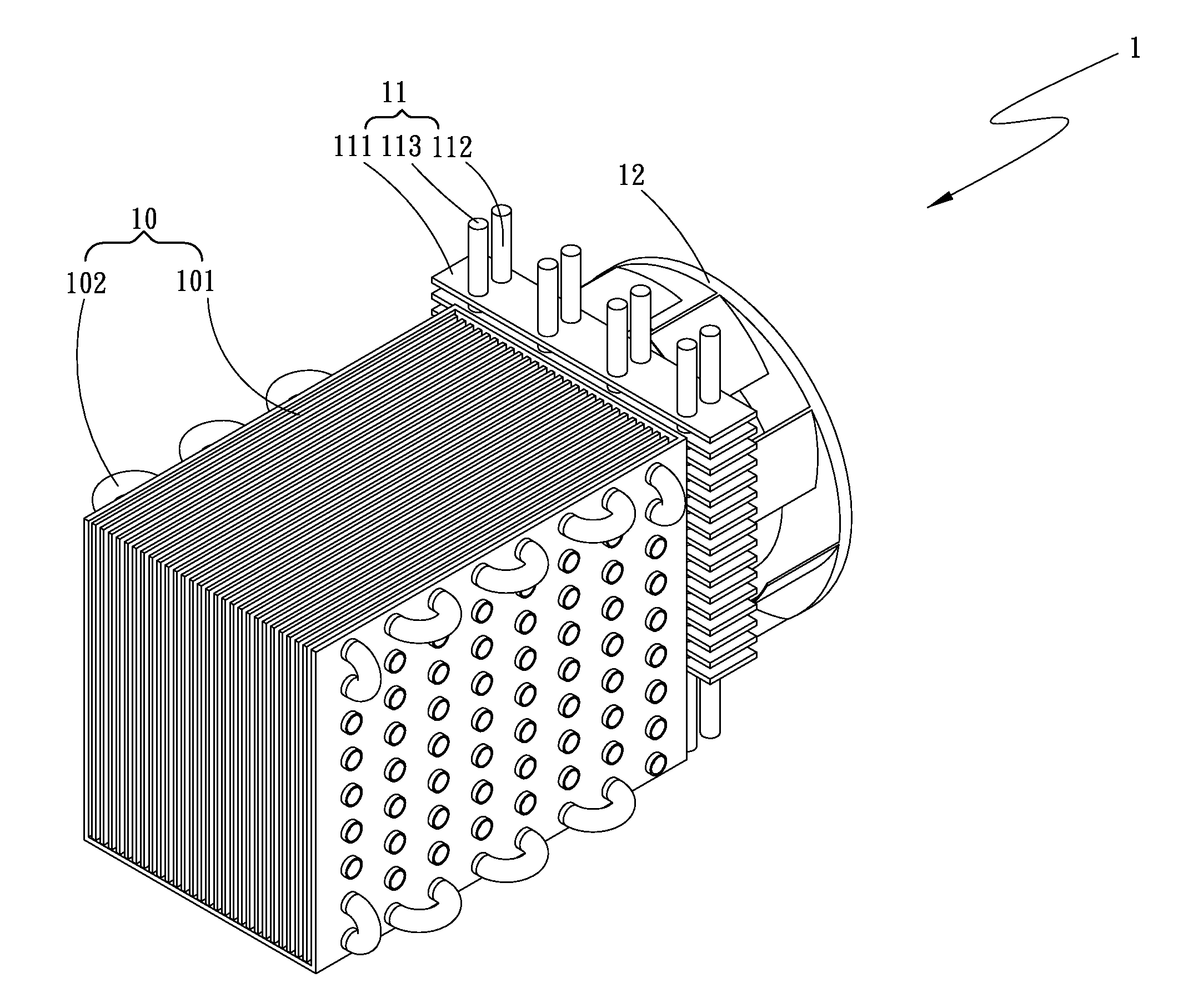

Heating and cooling module for battery

InactiveUS20130078495A1Reduce high temperatureProtect againstCell temperature controlCell component detailsCold airWorking temperature

A heating and cooling module for battery is used with a battery module and includes a heat exchanger unit, a heating element, and an air-guiding element. The heat exchanger unit is arranged in an enclosure of the battery module to face toward a plurality of battery cells of the battery module. The heating element is located to one lateral side of the heat exchanger unit, and the air-guiding element is located at one side of the heating element opposite to the heat exchanger unit. With the heating and cooling module, hot air and cold air can be supplied to heat or cool down the battery module according to actual need, so that the battery module can maintain at its normal working temperature to largely increase its service life and working efficiency.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

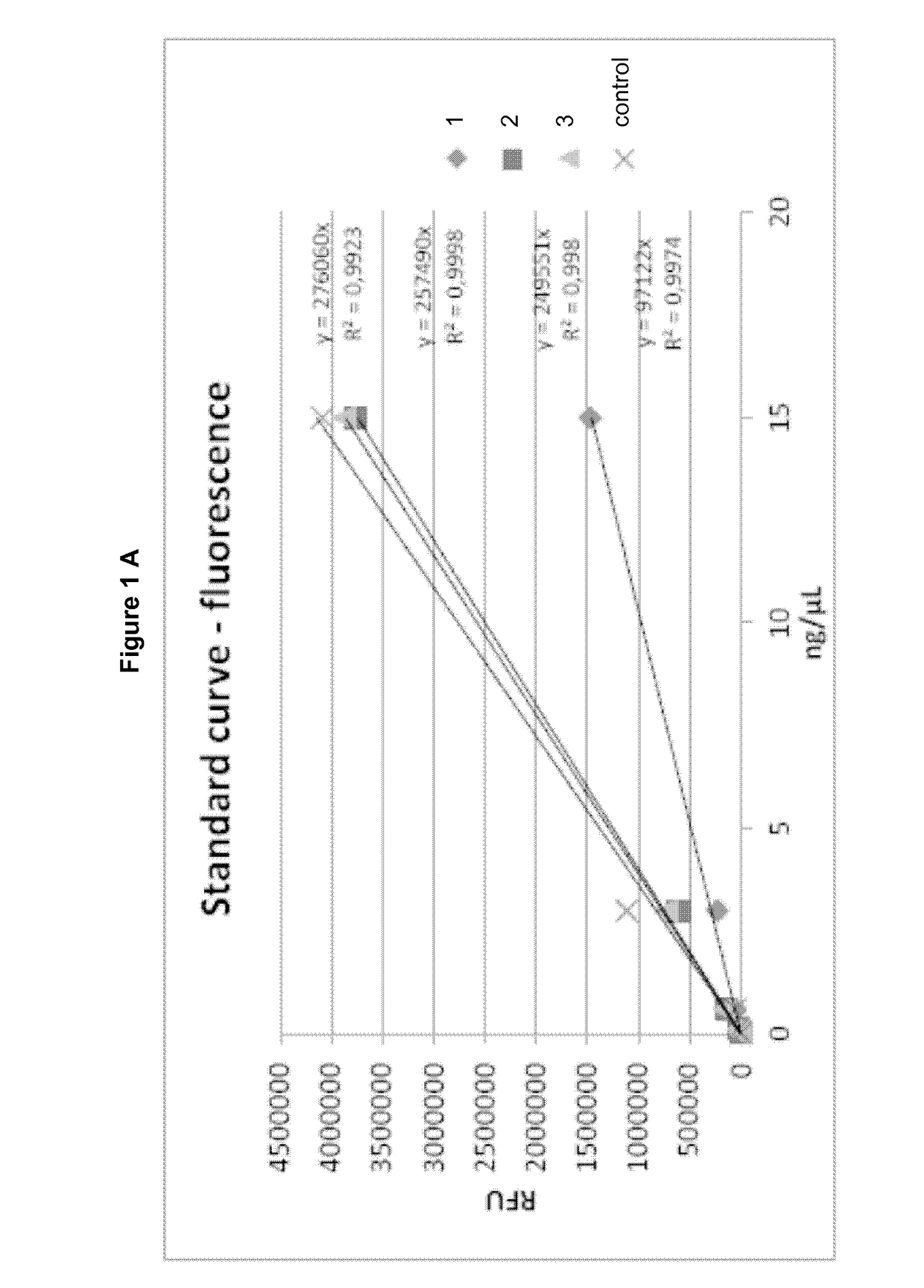

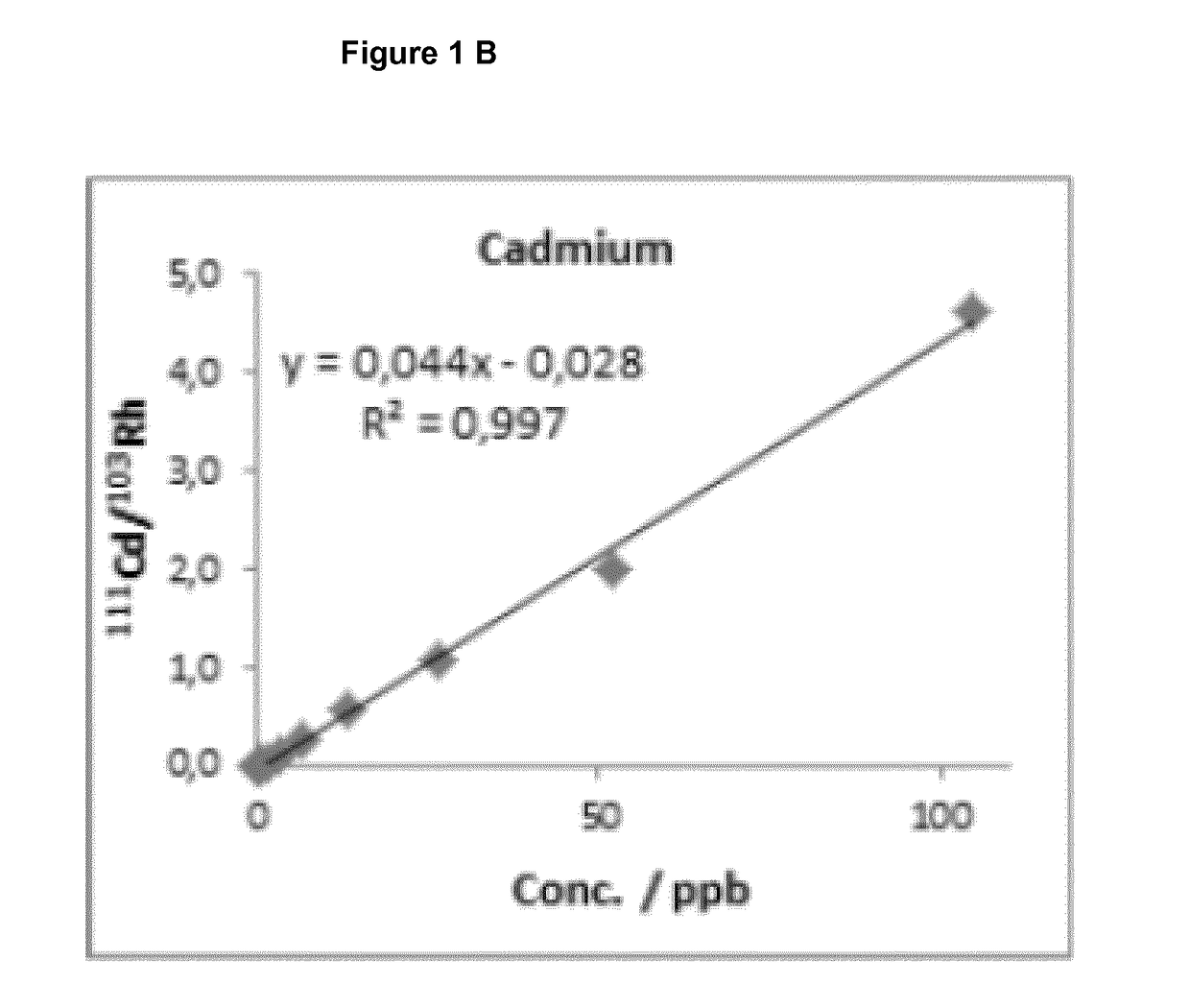

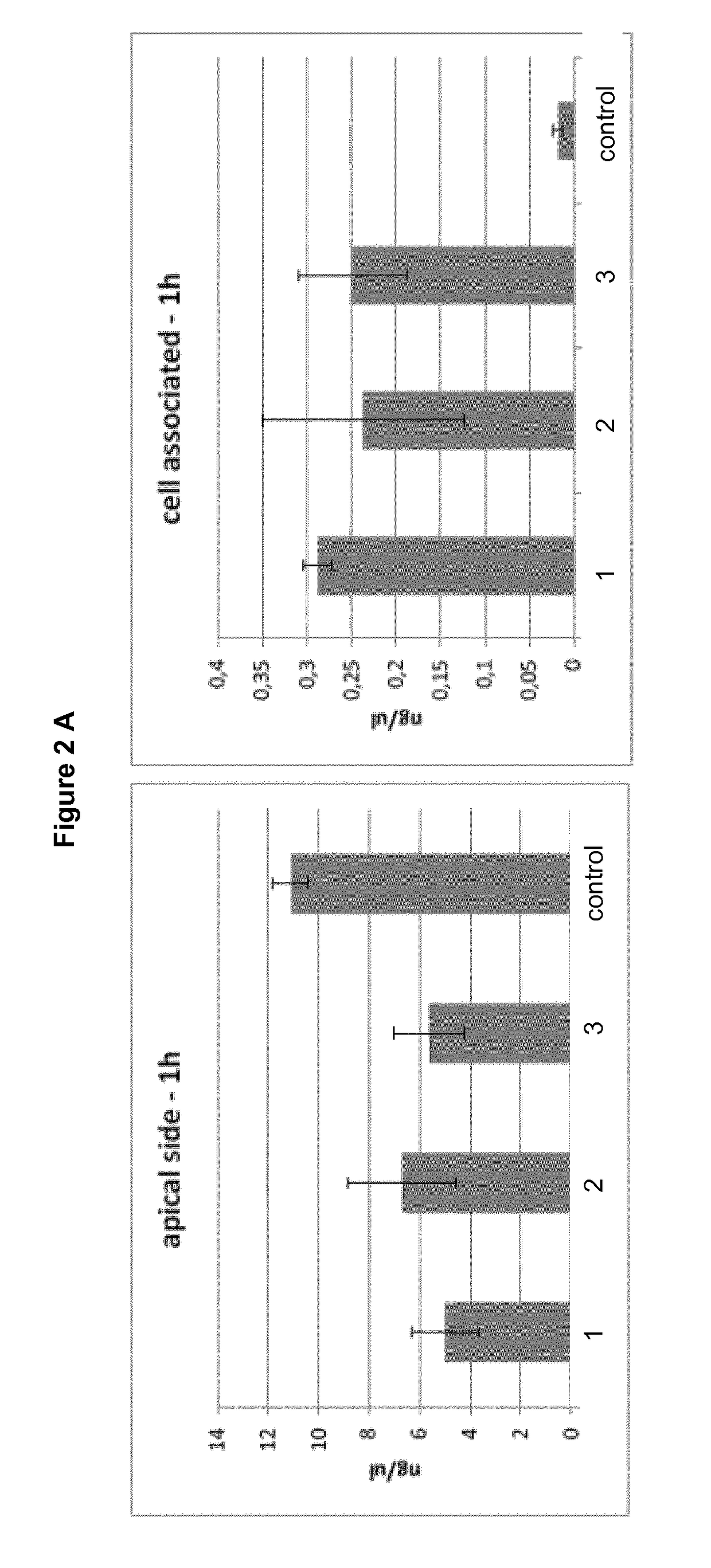

Pharmaceutical formulation having reverse thermal gelation properties for local delivery of nanoparticles

InactiveUS20170340756A1Reduce high temperatureDecreased critical micelle concentrationCompounds screening/testingPowder deliveryEpitopeAqueous buffer

The present invention refers to a pharmaceutical formulation for injection comprising fluorescent nanoparticles as in vivo diagnostics. The present invention relates to an injectable pharmaceutical formulation for human medicine and / or veterinary use, comprising 17% to 20% per weight of poloxamer 407 and 3%-15% per weight of poloxamer 188, 0.10 nM to 10.0 μM fluorescent nanoparticles and water or an aqueous buffer, wherein the pharmaceutical formulation is liquid at 4° C.-32° C. and forms a gel at about 37° C., their use as an in vivo marker and methods of their preparation. The inventive formulation is useful for local control and prevention of spreading / diffusion of nanoparticles, and thus allows full utilization of their quantum physics properties for example as a tool to enable surgical precision of tumor removal; even without tumor specific epitope binding antibodies.

Owner:EXCHANGE IMAGING TECH GMBH

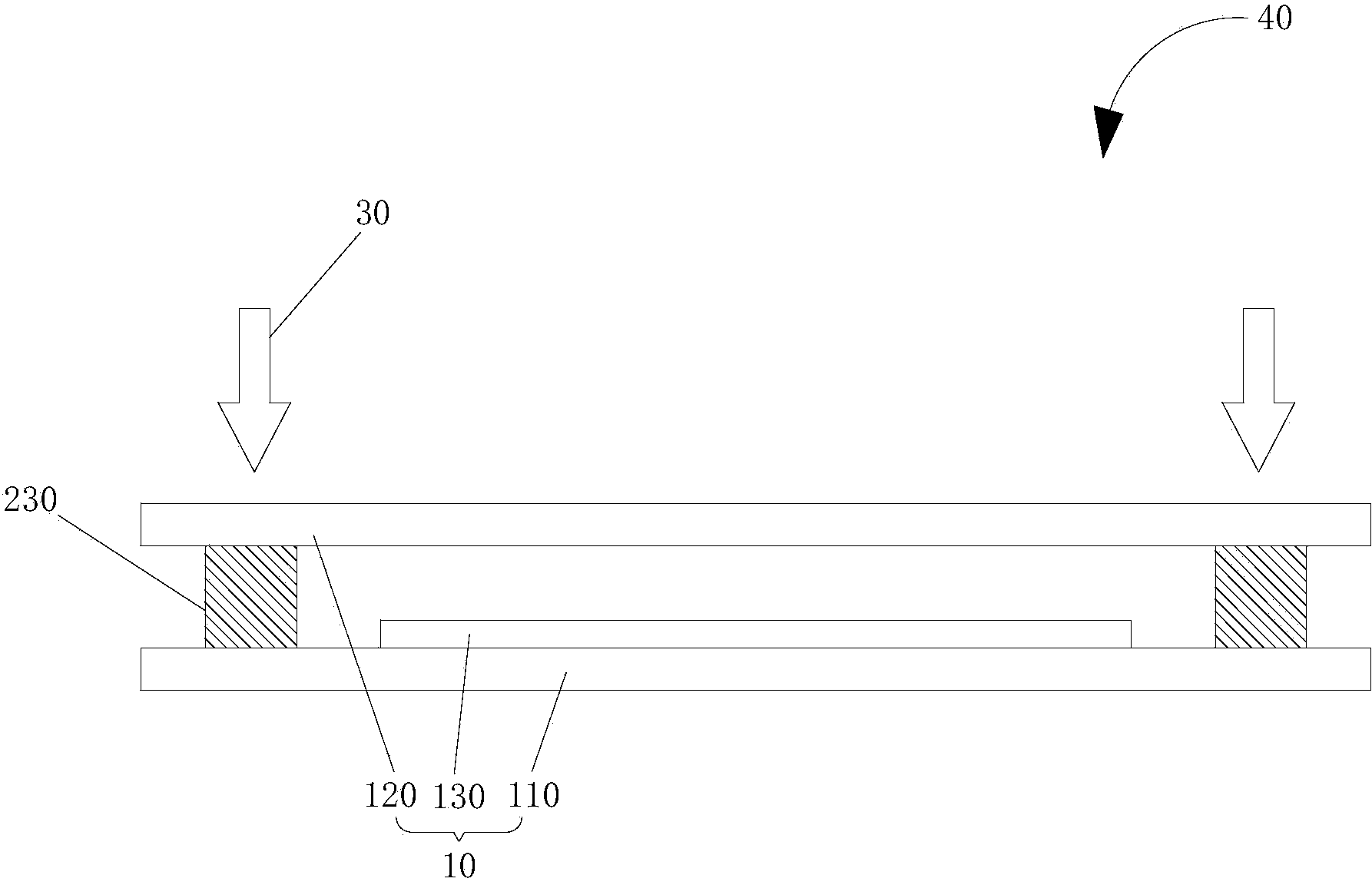

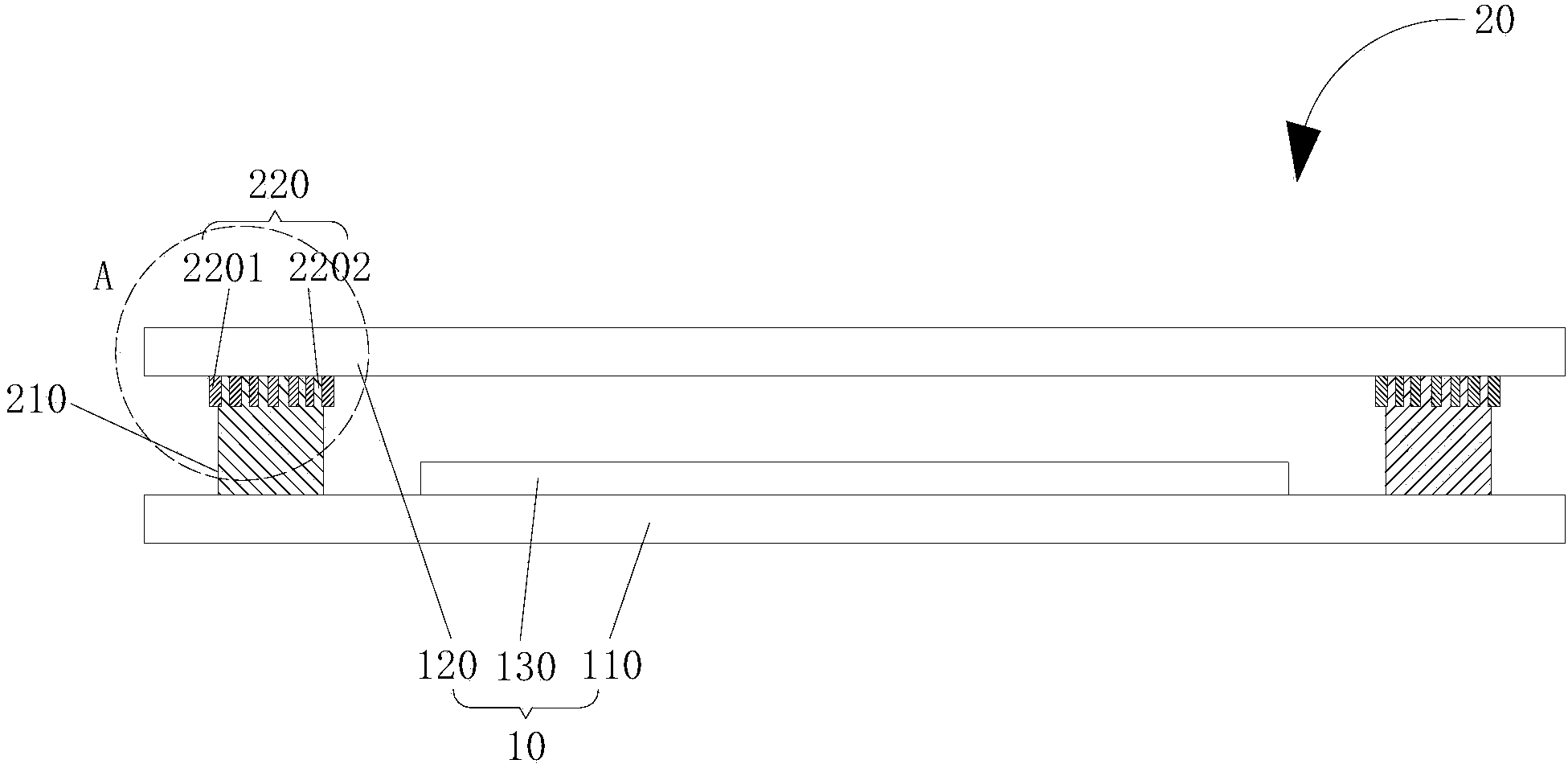

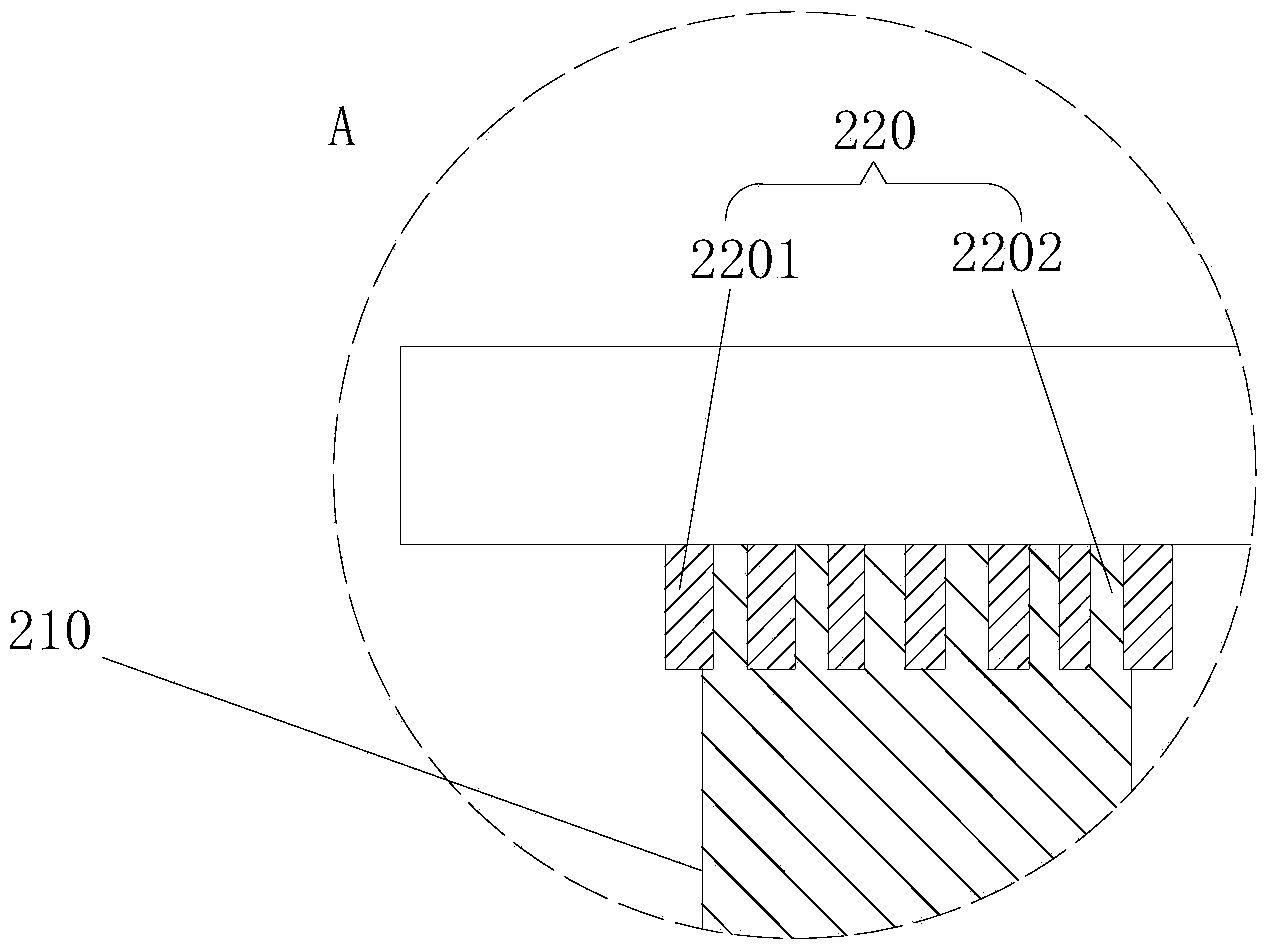

Packaging structure and manufacturing method thereof and display panel

InactiveCN104362256AAvoid destructionGuaranteed tightnessSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsLaser

The invention discloses a packaging structure and a manufacturing method thereof and a display panel. The packaging structure comprises a sintered proportion and a protective portion; the sintered portion is provided between a substrate and a cover plate; the protective portion is provided between the cover plate and the sintered portion and covers part of the sintered portion so that the part, uncovered by the protective portion, of the sintered portion is connected with the cover plate and that a light-emitting display unit is sealed in space formed by the substrate, the cover plate, the sintered portion and the protective portion. The protective portion provided between the sintered portion and the cover plate covers the upper portion of the sintered portion and divides the sintered portion into a non-sintered area and a sintered area, sintering area of the sintered portion under laser radiation is controlled, high temperature and stress occurring in the laser sintering process are reduced, the structure under the sintered portion is protected from damage caused by high temperature, tightness of the packaging structure is guaranteed, and yield is increased.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

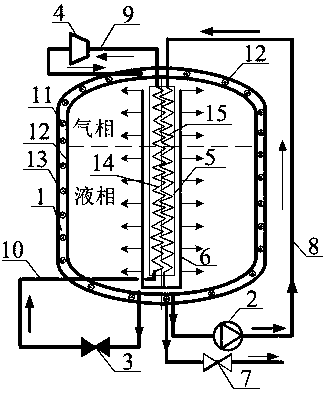

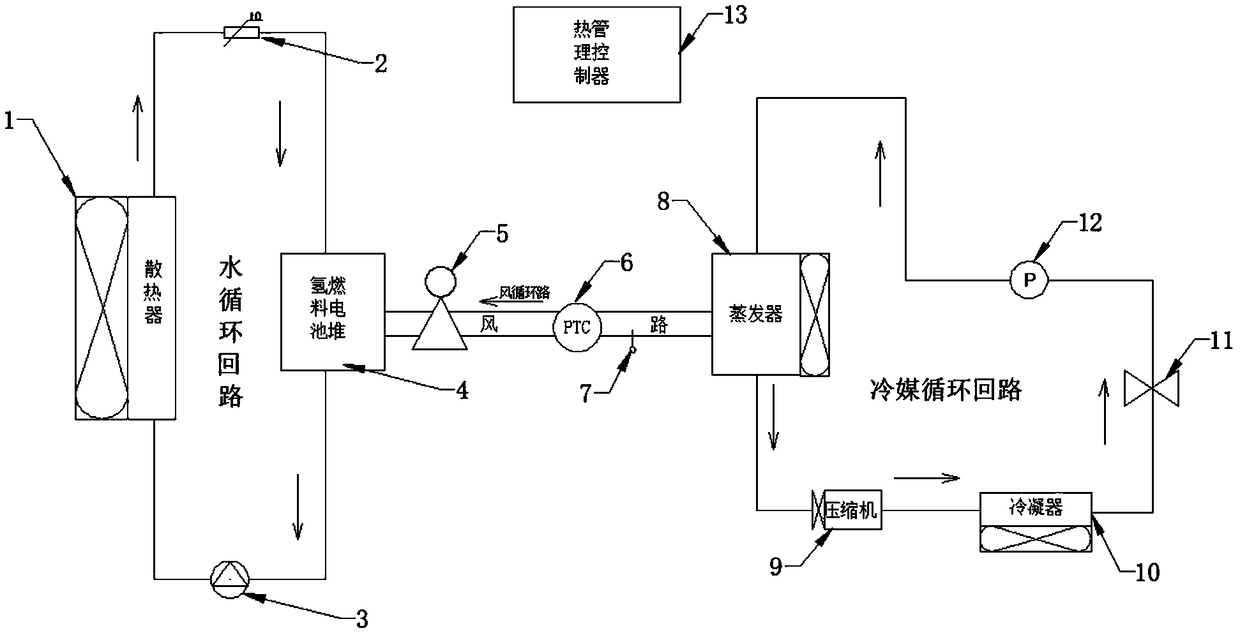

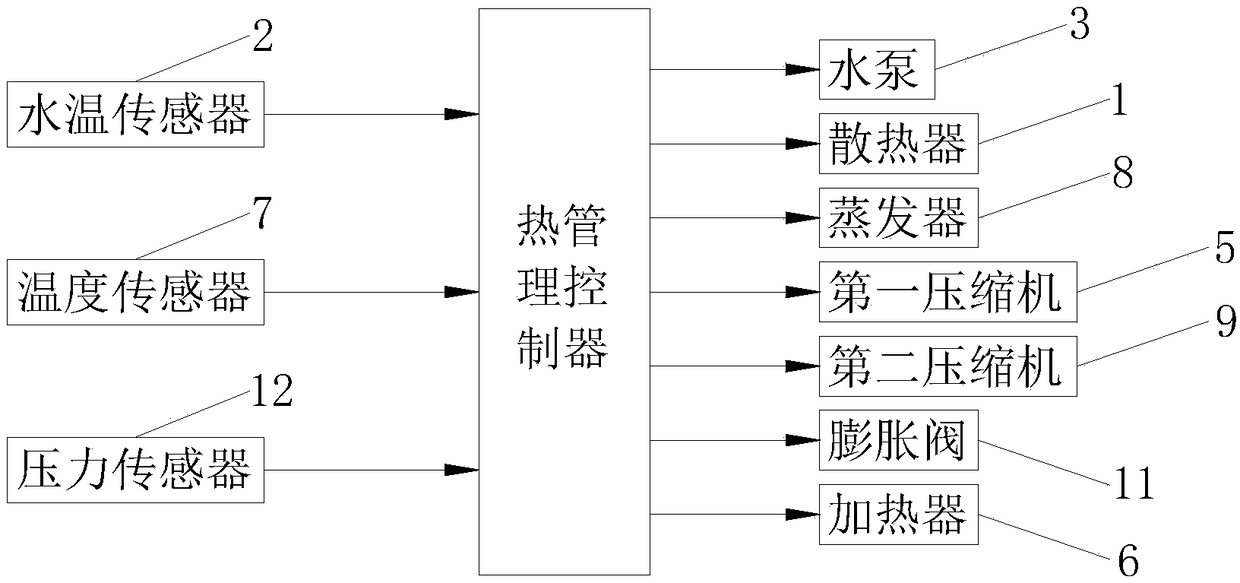

Cooling system of novel hydrogen energy automobile fuel cell stack

PendingCN109461951AReduce high temperatureImprove cooling effectFuel cell heat exchangeHydrogen fuel cellEngineering

The invention relates to a cooling system of a novel hydrogen energy automobile fuel cell stack. The cooling system comprises a hydrogen fuel cell stack, a thermal management controller, a heat sink,a water temperature sensor, a water pump, a temperature sensor, a first compressor, an evaporator, a second compressor, a condenser and an expansion valve, wherein the heat sink, the water temperaturesensor and the water pump form a water-cooling circulation loop by a first pipeline, the evaporator, the second compressor, the condenser and the expansion valve form a refrigerant circulation loop by a third pipeline, a low-temperature condensation liquid required by the evaporator is generated, the first compressor, the evaporator and the hydrogen fuel cell stack form an air-cooling circulationloop by a second pipeline, the thermal management controller is used for receiving signals of the water temperature sensor and the temperature sensor and performing water-cooling or air-cooling processing on the hydrogen fuel cell stack, meanwhile, the heater on the second pipeline can be used for providing hot air for the hydrogen fuel cell stack when the temperature is excessively low, so thatthe temperature is rapidly raised to a normal working temperature, the energy consumption is reduced, and the working efficiency is improved.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com