SBS modified emulsified bitumen having a high softening point and a preparing method thereof

A technology of emulsified asphalt and high softening point, which is applied in building components, building insulation materials, buildings, etc. It can solve the problems of low softening point, low-temperature performance attenuation, and high softening point of modified emulsified asphalt, and achieve high SBS content and excellent high temperature performance and effect of low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

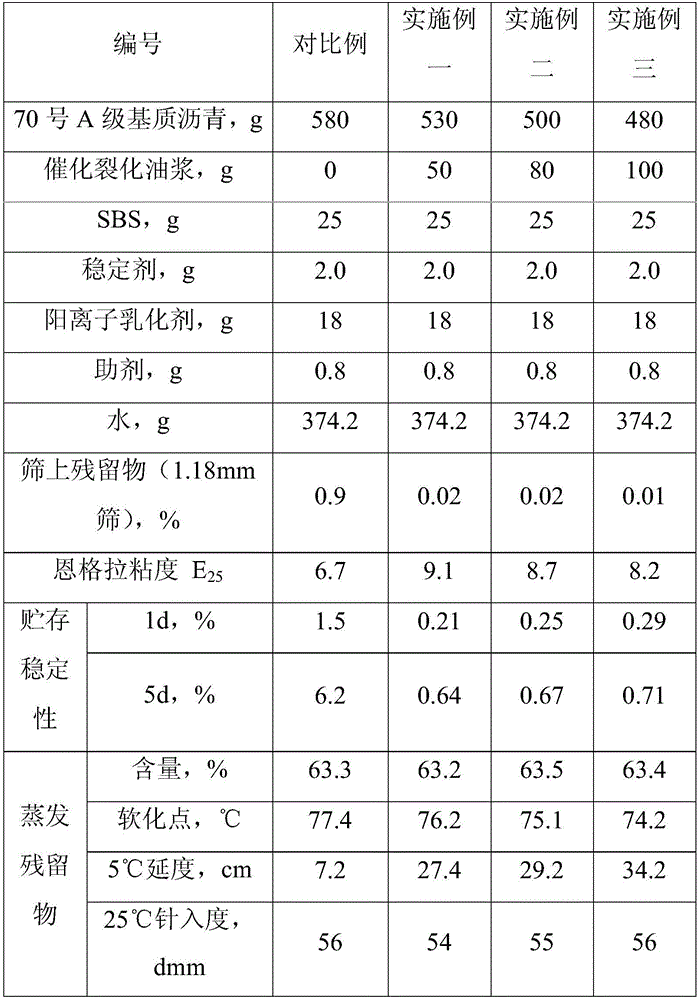

Embodiment 1

[0028] A high softening point SBS modified emulsified asphalt, the content of each component is: 530g of No. 70 A grade base asphalt, 50g of catalytic cracking oil slurry, 25g of SBS modifier, 2.0g of stabilizer, 18g of cationic emulsifier, 0.8 g. Water 374.2g.

[0029] The preparation method of high softening point SBS modified emulsified asphalt comprises the steps:

[0030] (1) Heat 530g of base asphalt to 185°C, add 50g of catalytic cracking oil slurry, add 25g of SBS modifier and 2.0g of stabilizer under high-speed shearing conditions, shear for 45min, and then lower the temperature to 180°C, Stir and develop for 3.5 hours to obtain SBS modified asphalt for emulsification;

[0031] (2) Add 18g of cationic emulsifier MQK-1D and 0.8g of additive HEC into 374.2g of water, heat to 60°C, stir evenly, add hydrochloric acid, and adjust the pH value of the soap to 2;

[0032] (3) Add the SBS modified asphalt prepared in (1) into the asphalt tank of the colloid mill, heat and ke...

Embodiment 2

[0034] A high softening point SBS modified emulsified asphalt, the content of each component is: 500g of No. 70 A grade base asphalt, 80g of catalytic cracking oil slurry, 25g of SBS modifier, 2.0g of stabilizer, 18g of cationic emulsifier, 0.8 g. Water 374.2g.

[0035] The preparation method of high softening point SBS modified emulsified asphalt comprises the steps:

[0036] (1) Heat 500g of base asphalt to 185°C, add 80g of catalytic cracking oil slurry, add 25g of SBS modifier and 2.0g of stabilizer under high-speed shearing conditions, shear for 45min, and then lower the temperature to 180°C, Stir and develop for 3.5 hours to obtain SBS modified asphalt for emulsification;

[0037] (2) Add 18g of cationic emulsifier MQK-1D and 0.8g of additive HEC into 374.2g of water, heat to 60°C, stir evenly, add hydrochloric acid, and adjust the pH value of the soap to 2;

[0038] (3) Add the SBS modified asphalt prepared in (1) into the asphalt tank of the colloid mill, heat and keep...

Embodiment 3

[0040] A high softening point SBS modified emulsified asphalt, the content of each component is: 480g of No. 70 A grade base asphalt, 100g of catalytic cracking oil slurry, 25g of SBS modifier, 2.0g of stabilizer, 18g of cationic emulsifier, 0.8 g, water 374.2g.

[0041] The preparation method of high softening point SBS modified emulsified asphalt comprises the steps:

[0042] (1) Heat 480g of base asphalt to 185°C, add 100g of catalytic cracking oil slurry, add 25g of SBS modifier and 2.0g of stabilizer under high-speed shearing conditions, shear for 45min, and then lower the temperature to 180°C, Stir and develop for 3.5 hours to obtain SBS modified asphalt for emulsification;

[0043] (2) Add 18g of cationic emulsifier MQK-1D and 0.8g of additive HEC into 374.2g of water, heat to 60°C, stir evenly, add hydrochloric acid, and adjust the pH value of the soap to 2;

[0044] (3) Add the SBS modified asphalt prepared in (1) into the asphalt tank of the colloid mill, heat and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com