Preparation method of high-performance styrene-butadiene-styrene block copolymer (SBS) modified emulsified asphalt

A technology of emulsified asphalt and composite modified asphalt, which is applied in building components, building insulation materials, buildings, etc. , environmental protection, the improvement effect of modified emulsified asphalt is not as good as that of SBS, etc., to achieve good low temperature performance, high temperature performance improvement, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

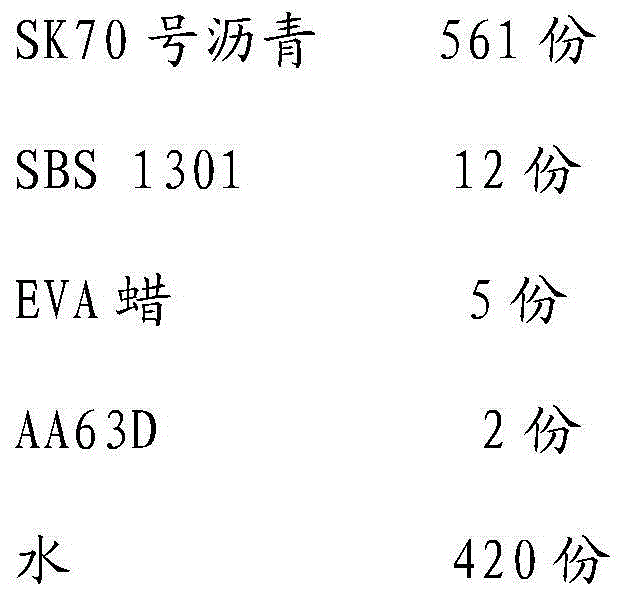

[0030] The SBS modified emulsified asphalt of the present invention is made of the following components in parts by weight:

[0031]

[0032] SK70 asphalt is produced by SK Group of South Korea; SBS1301 is produced by Beijing Yanshan Petrochemical Co., Ltd.; AA63D is produced by MeadWestvaco of the United States; EVA wax is produced by Qingdao Sinoplastic Economic Development Co., Ltd., model EVA-Wax300.

[0033] A kind of preparation method of high-performance SBS modified emulsified asphalt of the present invention, carry out according to the following steps:

[0034] (1) each component is prepared according to the aforementioned weight ratio;

[0035](2) Heat SK70 asphalt to 170°C, add SBS1301 and EVA wax and stir for 30 minutes, then disperse SBS1301 and EVA wax into SK70 asphalt by high-speed shearing for 30 minutes, control the temperature at 180°C, and then stir again After 30min, the SBS composite modified asphalt for emulsification was obtained;

[0036] (3) When...

Embodiment 2

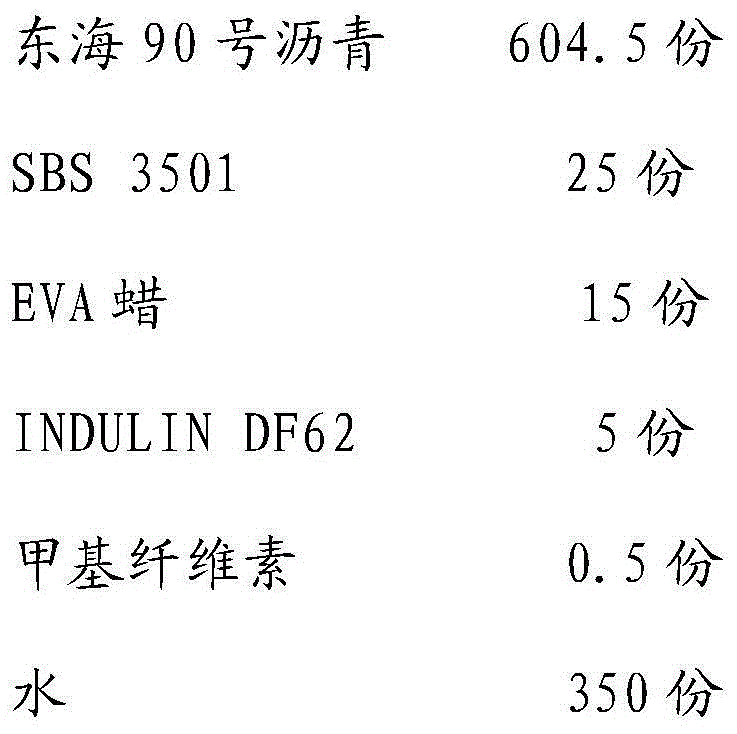

[0040] The SBS modified emulsified asphalt of the present invention is made of the following components in parts by weight:

[0041]

[0042] Donghai No. 90 bitumen is "Donghai Brand" No. 90 bitumen produced by China Petrochemical Corporation; SBS3501 is produced by Li Changrong Chemical Industry Co., Ltd.; INDULIN DF62 is produced by MeadWestvaco of the United States; EVA wax is produced by Qingdao Sinoplastic Economic Development Co., Ltd. , Model EVA-Wax300.

[0043] A kind of preparation method of high-performance SBS modified emulsified asphalt of the present invention, carry out according to the following steps:

[0044] (1) each component is prepared according to the aforementioned weight ratio;

[0045] (2) Heat Donghai No. 90 asphalt to 180°C, add SBS3501 and EVA wax and stir for 30 minutes, then disperse SBS3501 and EVA wax into Donghai No. 90 asphalt through a colloid mill, control the temperature at 170°C, and control the time for 60 minutes, then After stirri...

Embodiment 3

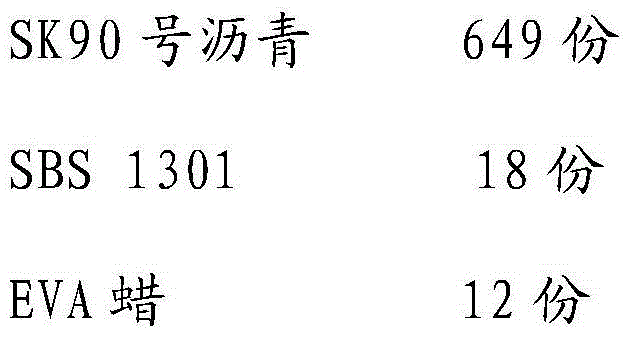

[0050] The SBS modified emulsified asphalt of the present invention is made of the following components in parts by weight:

[0051]

[0052]

[0053] SK90 bitumen is produced by SK Group of South Korea; SBS1301 is produced by Beijing Yanshan Petrochemical Co., Ltd.; MQ3 is produced by MeadWestvaco of the United States; EVA wax is produced by Anhui Yiwei Wax Industry Co., Ltd., model EVA-ZL1.

[0054] A kind of preparation method of high-performance SBS modified emulsified asphalt of the present invention, carry out according to the following steps:

[0055] (1) each component is prepared according to the aforementioned weight ratio;

[0056] (2) Heat SK90 asphalt to 185°C, add SBS1301 and EVA wax and stir for 30 minutes, then disperse SBS1301 and EVA wax into SK90 asphalt through a colloid mill for 90 minutes, control the temperature at 185°C, and then stir for 240 minutes Finally, the SBS composite modified bitumen used for emulsification is obtained;

[0057] (3) Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com