Packaging structure and manufacturing method thereof and display panel

A packaging structure and display panel technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting the sealing performance of the packaging structure, production yield, and structural damage of the sintered part 230, etc., to reduce high temperature and stress , Guarantee airtightness, improve the effect of production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

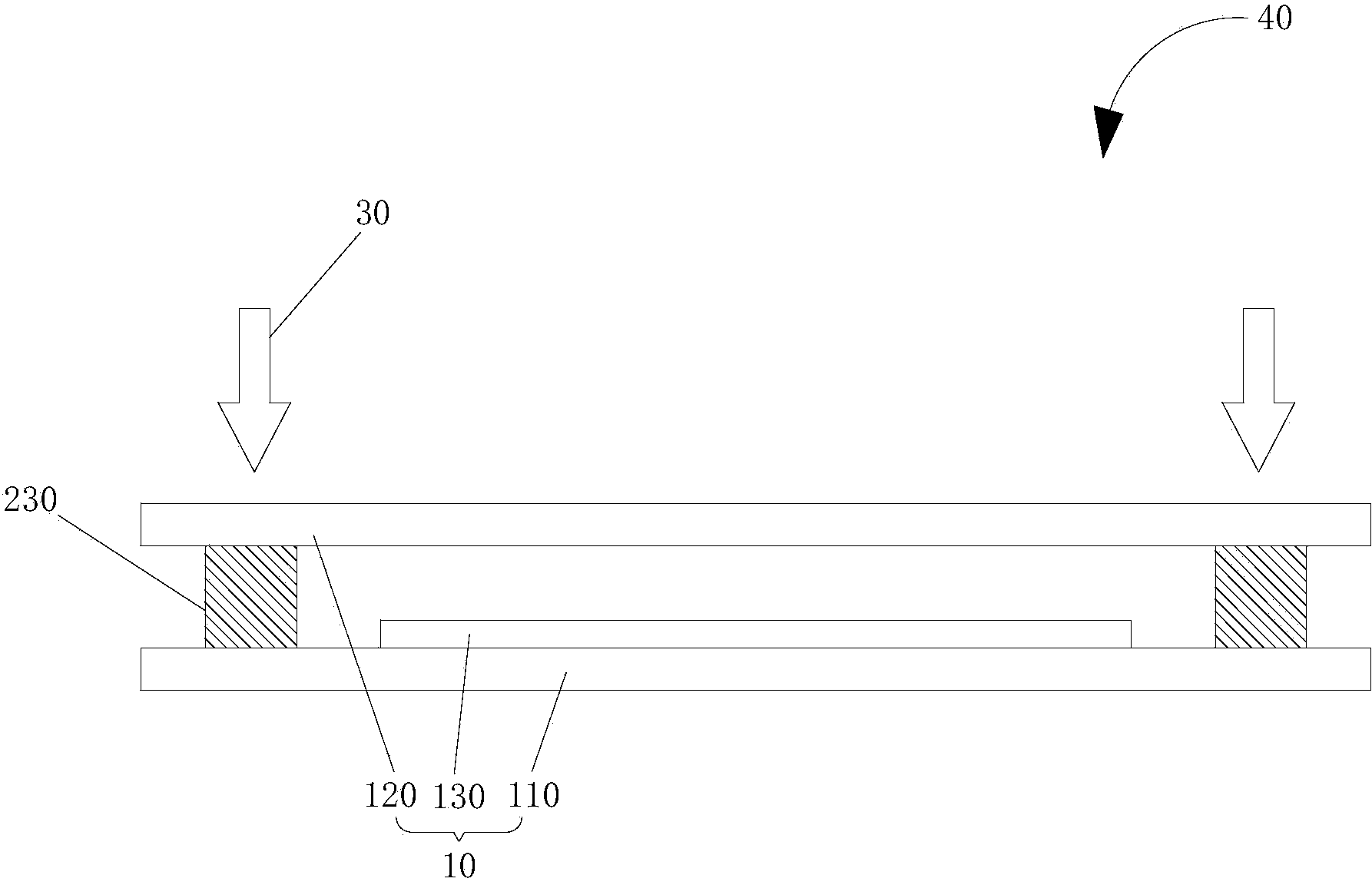

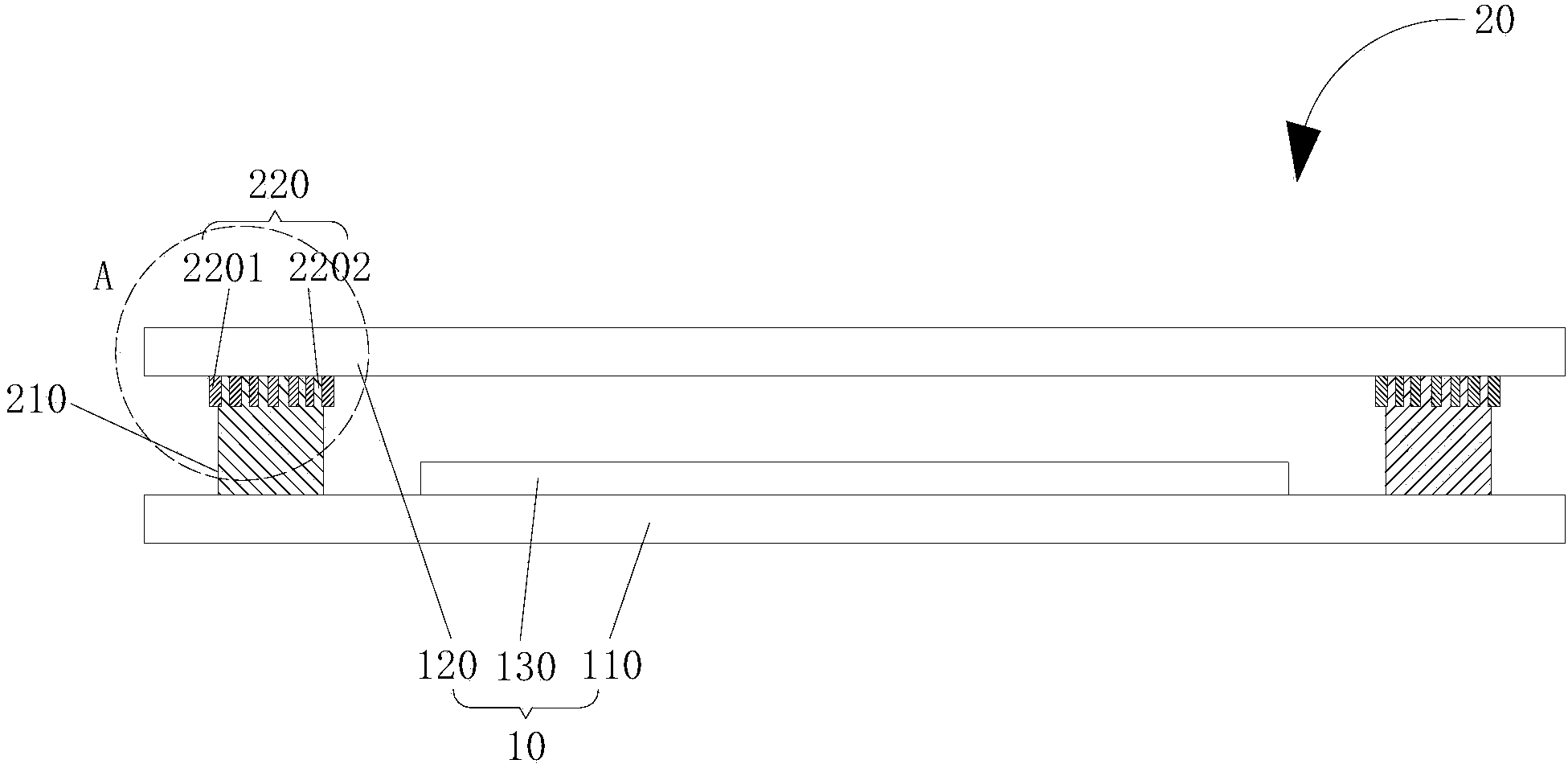

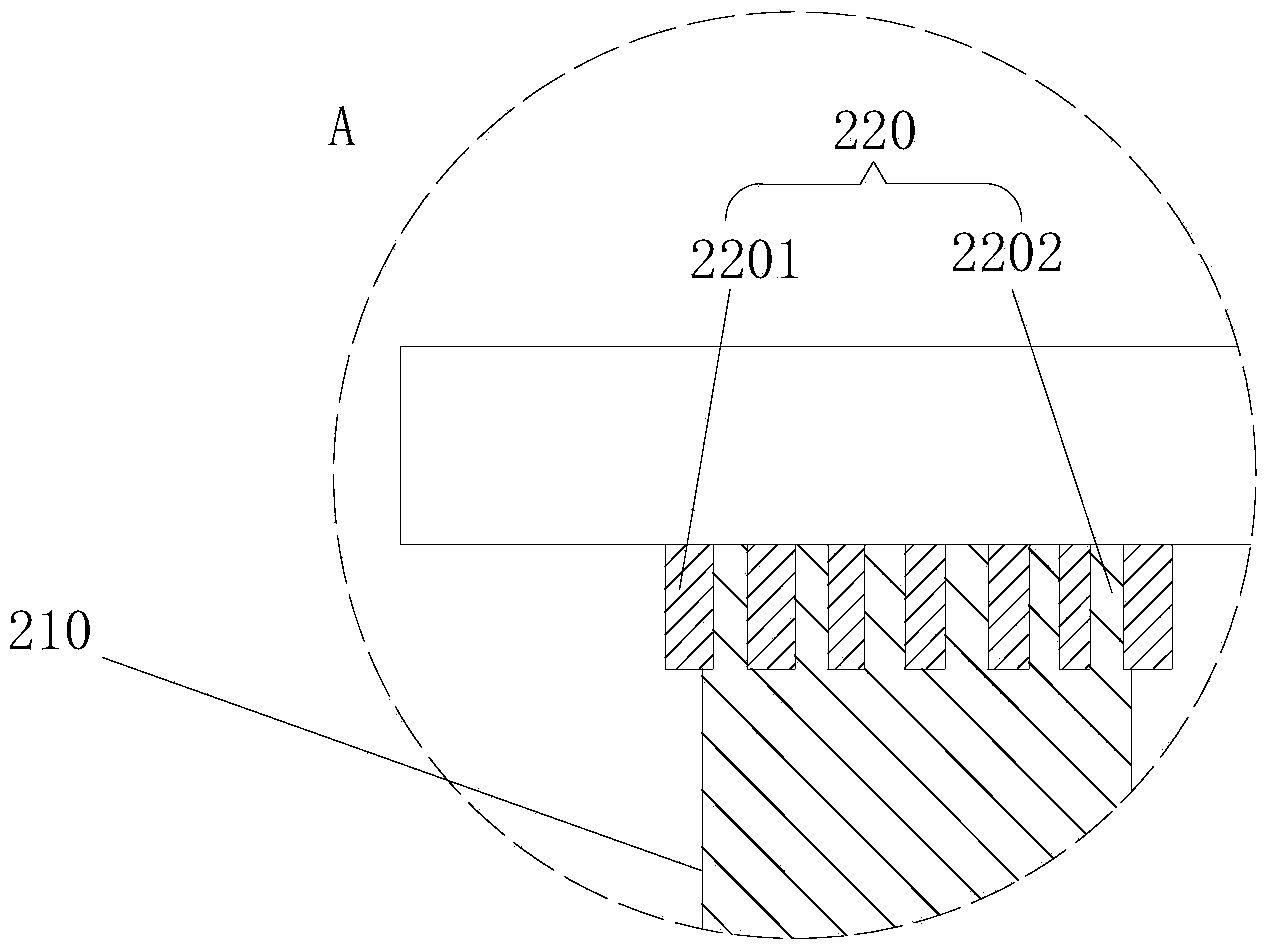

[0060] Such as Figure 2A and 2B As shown, the packaging structure 20 of the present invention is used to seal a display panel 10. The display panel 10 includes a substrate 110, a cover plate 120, and a light-emitting display unit 130 disposed on the surface of the substrate 110. The packaging structure 20 It includes: a sintering part 210, the sintering part 210 is formed between the substrate 110 and the cover plate 120; a protection part 220 is formed between the cover plate 120 and the sintering part 210 and the The sintering part 210 is partially covered, so that the part of the sintering part 210 not covered by the protection part 220 is bonded to the cover plate 120, so as to seal the light-emitting display unit 130 on the substrate 110, the cover plate 120, In a space surrounded by the sintering part 210 and the protection part 220 .

[0061] In the packaging structure 20 of the present invention, a protective portion 220 is additionally provided between the sintered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com