Combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of aluminum electrolysis cell waste cathode carbon block

A technology of aluminum electrolytic cell waste and cathode carbon block, which is applied in the direction of alkali metal fluoride, alumina/aluminum hydroxide, silicon dioxide, etc., can solve the problems of unstable treatment effect and large energy consumption, and achieve the reduction of industrial acid Use of alkali and additives, reduction in consumption, effects of reduction in usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

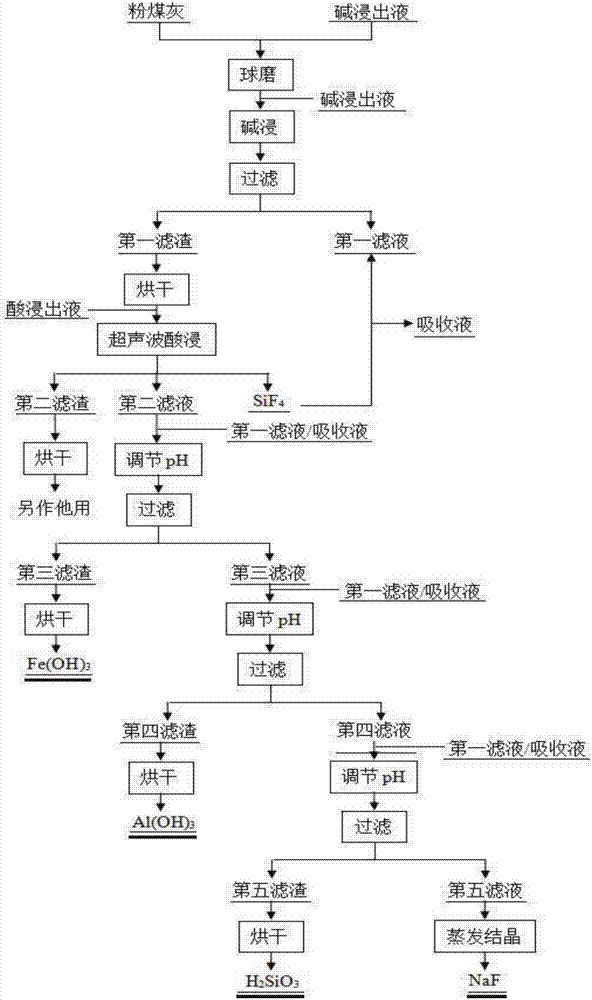

Method used

Image

Examples

Embodiment 1

[0072] Step (1): Mix the alkali leaching solution and the fly ash according to the liquid-solid ratio of 0.5:1, and ball mill to -200 mesh to account for 65%;

[0073] Step (2): The fly ash processed in step (1) is mixed with the alkali leaching solution of the waste cathode carbon block of the aluminum electrolytic cell according to the liquid-solid mass ratio of 5:1, the stirring rate is 180r / min, and the heating temperature is 80 Under the condition of ℃, carry out secondary alkali leaching, react for 120min, filter to obtain the first filtrate and the first filter residue, and dry the first filter residue for use;

[0074] Step (3): The first filter residue obtained in step (2) and the acid leaching solution of the waste cathode carbon block of the aluminum electrolytic cell are carried out according to the liquid-solid mass ratio of 5:1, and the acid leaching is carried out under the condition of an ultrasonic frequency of 30KHz, and the reaction is carried out for 40 minu...

Embodiment 2

[0080] Step (1): mixing the alkali leaching solution and the fly ash according to the liquid-solid ratio mass ratio of 4:1, and ball milling to -200 mesh to account for 65%;

[0081] Step (2): The fly ash processed in step (1) is mixed with the alkali leaching solution of the waste cathode carbon block of the aluminum electrolytic cell according to the liquid-solid mass ratio of 20:1, and the stirring rate is 180r / min, and the heating temperature is 80 Under the condition of ℃, carry out secondary alkali leaching, react for 120min, filter to obtain the first filtrate and the first filter residue, and dry the first filter residue for use;

[0082] Step (3): The first filter residue obtained in step (2) and the acid leaching solution of the waste cathode carbon block of the aluminum electrolytic cell are carried out according to the liquid-solid mass ratio of 15:1, and the acid leaching is carried out under the condition of an ultrasonic frequency of 90KHz, and the reaction is ca...

Embodiment 3

[0088] Step (1): mixing the alkali leaching solution and the fly ash according to the liquid-solid ratio mass ratio of 1:1, and ball milling to -200 mesh to account for 80%;

[0089] Step (2): Mix the fly ash processed in step (1) with the alkali leaching solution of the waste cathode carbon block of the aluminum electrolytic cell according to the liquid-solid mass ratio of 10:1, the stirring rate is 150r / min, and the heating temperature is 70 Under the condition of ℃, carry out secondary alkali leaching, react for 150min, filter to obtain the first filtrate and the first filter residue, and dry the first filter residue for use;

[0090] Step (3): The first filter residue obtained in step (2) and the acid leaching solution of the waste cathode carbon block of the aluminum electrolytic cell are carried out according to the liquid-solid mass ratio of 7:1, and the acid leaching is carried out under the condition of an ultrasonic frequency of 40KHz, and the reaction is carried out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com